-

2018年,我国城市生活垃圾焚烧处理量已达1.02×108 t。垃圾焚烧会带来污染物形态的转移。其中,NOx是垃圾焚烧过程中产生的最主要气体污染物之一,会引起酸雨、光化学烟雾等环境问题[1-2]。目前,垃圾焚烧烟气的脱硝手段包括选择性催化还原(selective catalytic reduction,SCR)和选择性非催化还原(selective non-catalytic reduction,SNCR)2种。SCR催化剂在垃圾焚烧烟气中变性失活严重且工艺运行成本过高,故其应用相对较少;SNCR技术具有设备投资低、适应性强及经济性较好等优势,故在垃圾焚烧处理中得到广泛应用[3-4]。然而,受化学反应动力学限制,SNCR脱硝技术存在温度窗口。在理想情况下,将反应温度控制在窗口(875~1 050 ℃)内可达到60%~80%的脱硝效率[5],而当反应温度偏离此脱硝温度窗口时,脱硝效率将大幅降低[6]。由于垃圾焚烧烟气温度较低,且烟气中含有的O2、H2O及飞灰等成分均会影响SNCR脱硝效率,因此,在实际工程中,常规SNCR脱硝技术仅有约30%~50%的脱硝效率,无法满足我国日趋严苛的NOx排放标准[7-8]。因此,拓宽垃圾焚烧烟气SNCR的温度窗口、强化SNCR脱硝是垃圾焚烧行业亟待解决的问题。

近年来,研究者主要通过加入各种添加剂来改善SNCR脱硝特性,以提升其脱硝效率。所采用的添加剂包括小分子气体、碱金属化合物、有机含氧化合物及其他新型添加剂。在气体添加剂方面,张彦文等[9-10]通过对添加甲烷的SNCR脱硝实验研究及CHEMKIN模拟研究,证明了添加CH4能提高低温时的脱硝效率,并可拓宽温度窗口。这是由于CH4的氧化反应使得反应氛围中的OH和HO2等基元含量增加,促进了NH3反应形成NH2,从而促进脱硝过程。HAO等[5]发现,Na/K添加剂在850~1 150 ℃都能起到明显提升SNCR脱硝效率的作用,促进效果Na2CO3 > KCl > NaCl。ROTA等[11]通过实验研究证明了添加醇、酯、酚、羧酸、醛及醚等6类典型含氧化合物后,SNCR脱硝温度窗口均不同程度地拓宽至原来的1.5~2倍,且促进作用的强弱与含氧化合物的种类没有必然联系。在150 kW中试实验台上,JAVED等[12]研究了添加H2O2、C2H5OH、C2H4(OH)2和C3H5(OH)3对SNCR脱硝的影响,发现4种添加剂都能使最佳脱硝温度大幅度向低温区移动。其中,[C3H5(OH)3]/[NO]为2.0时,最佳脱硝温度降低了330 ℃。

不同添加剂均可不同程度地影响SNCR温度窗口和脱硝特性,但碱金属化合物的引入则可能带来烟气颗粒物浓度提升及换热器结焦问题[13-14]。气体添加剂因其在工艺实际中的存储问题等限制了其应用,而有机含氧化合物可被直接喷入炉膛SNCR反应区域,在高温烟气中会被分解氧化成无害气体排出,故可行性较好。截至目前,已有大量研究者认为,添加单一组分有机含氧化合物能拓宽SNCR温度窗口[11-12, 15]。生物油作为一种生物质热利用过程中的副产品,其成本低廉且含有丰富有机含氧化合物,但将其作为SNCR添加剂的研究相对较少。张波[16]将生物油作为循环流化床燃煤锅炉SNCR脱硝添加剂,结果表明,添加1%质量比例谷壳油会使SNCR脱硝窗口向低温方向移动约50 ℃,并拓宽了窗口宽度。

本研究针对垃圾焚烧烟气的SNCR脱硝,利用高温管式炉研究了生物油添加比例(β)、氨氮比(NSR)与氧浓度对生物油强化垃圾焚烧烟气SNCR脱硝特性及CO排放的影响,并分析了其作用机理,旨在为以生物油作为添加剂的SNCR技术的工业化应用提供参考。

-

本研究中所使用的生物油取自湖北某热解多联产示范基地,由农林废弃物白杨木屑和竹屑经烘焙1 h,在600 ℃移动床热解后经空冷和水冷后得到[17]。考虑到木焦油富含酚类有机物,可能带来二次污染,故本研究仅添加生物质热解油的上清液(后简称“生物油”,bio-oil,BO)来进行研究。生物油的pH为2~3,其成分由气相色谱-质谱联用(GC-MS,Aligent,7890A/5975C)分析。分析结果表明,该生物油由有机酸(乙酸38.56%、丙酸3%)、糠醛3.1%、酚类(苯酚4.45%、2-甲氧基苯酚3.74%)及少量醇、酮类等组成。

-

实验台架装置主要由模拟烟气发生系统、高温管式炉、尿素及生物油喷射系统与烟气在线分析系统组成(见图1)。模拟烟气采用NO、O2、CO2和N2标准钢瓶气配制,通过质量流量计精确控制各气体流量。所有气体经过混气瓶混合均匀后,送入反应器内进行脱硝反应。在高温电加热管式炉内,配置内径50 mm、长900 mm的圆柱形刚玉反应器。实验时,通过程序控温保证炉内温度在700~1 200 ℃,实验前采用标准K型热电偶对反应区域温度进行标定。尿素及生物油的混合液采用微量注射泵匀速注入毛细石英管初步预热分解后,进入反应器恒温段并发生SNCR脱硝反应。模拟烟气与尿素混合液对冲设计,目的是强化烟气与还原剂之间的混合,促进脱硝反应的发生。出口烟气中NO及CO气体浓度由Testo350烟气分析仪在线测量,取反应稳定后5 min内目标气体浓度的平均值作为最终稳定的浓度值。

实验模拟烟气总流量为2 L·min−1,成分参考实际垃圾焚烧炉烟气,O2体积分数为4%~12%、CO2体积分数为15%、NO初始体积浓度为CNO, in= 600 μL·L−1,N2为平衡气。尿素与生物油混合液以0.4 mL·min−1速率匀速喷射,保证反应区域水蒸气体积分数约为15%。通过改变尿素溶液的浓度控制NSR,生物油按照指定比例,在尿素溶液定容前添加至尿素溶液中。反应器中恒温段长度约为450 mm。在设计烟气流量下,反应气体在恒温段停留时间为2.0 s以上。

在生物油热分解特性实验中,由微量注射泵精确控制,使生物油以0.2 mL·min−1速率匀速注入反应器,并在反应器中恒温区进行热分解,同时通入流量为1.5 L·min−1的N2作为吹扫气体。分解过程中,采用Testo350烟气分析仪在线监测CO等气体体积浓度,待反应稳定后由气袋收集尾气并通过气相色谱(Panna A91 GC)进行成分分析。

反应过程中SNCR脱硝效率通过式(1)进行计算。

式中:CNO, in和CNO, out分别为反应前NO体积浓度和反应稳定后的出口NO体积浓度,μL·L−1;ηNO为SNCR的脱硝效率。

定义温度窗口宽度(Tw)为脱硝效率达到本工况下最佳脱硝效率80%以上的温度区间长度[11]。为比较低温条件下生物油对SNCR脱硝效率的提升效果,定义低温范围脱硝效率提升平均值(ηpro)为700~900 ℃时脱硝效率相比空白实验提升的平均值。

-

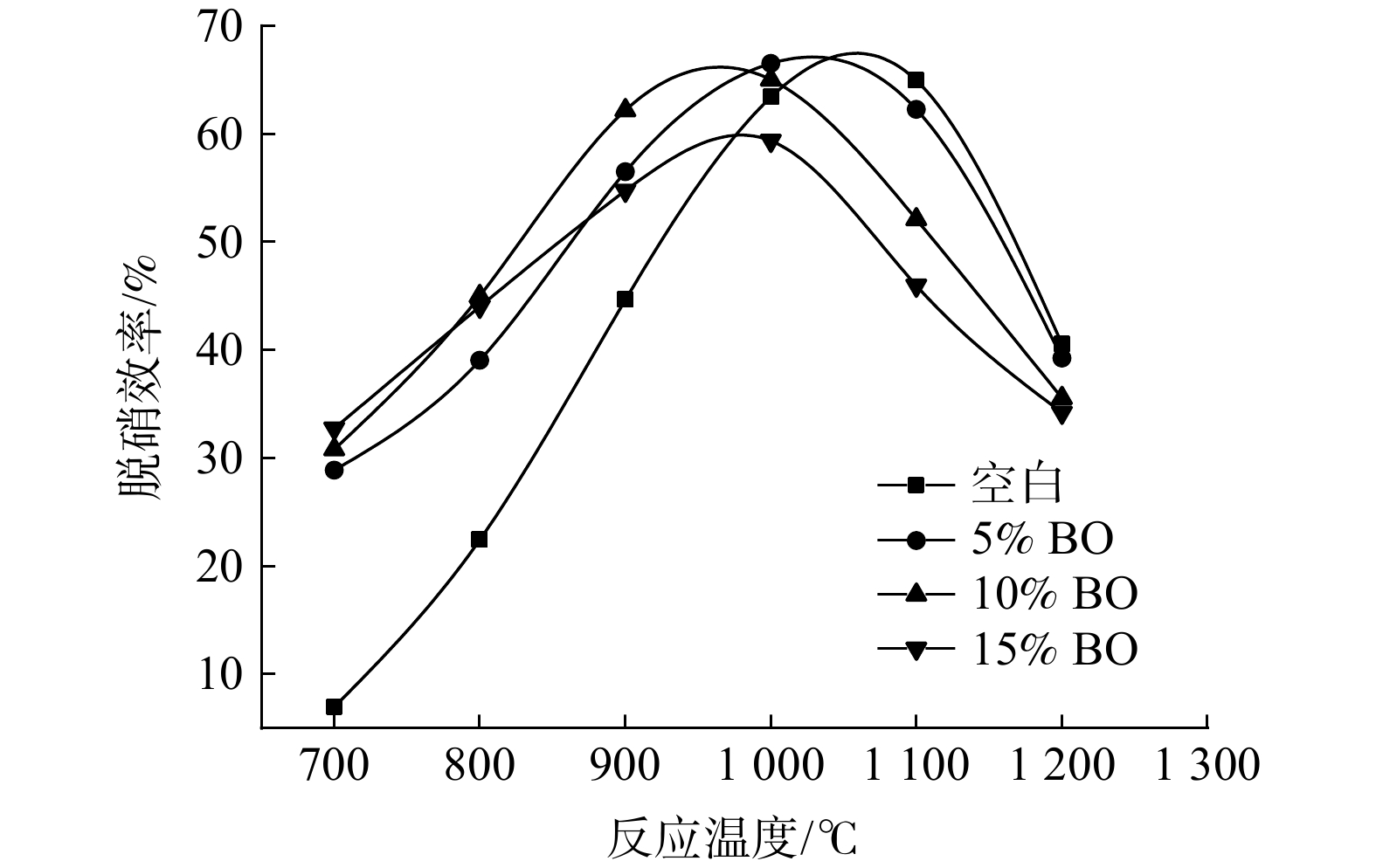

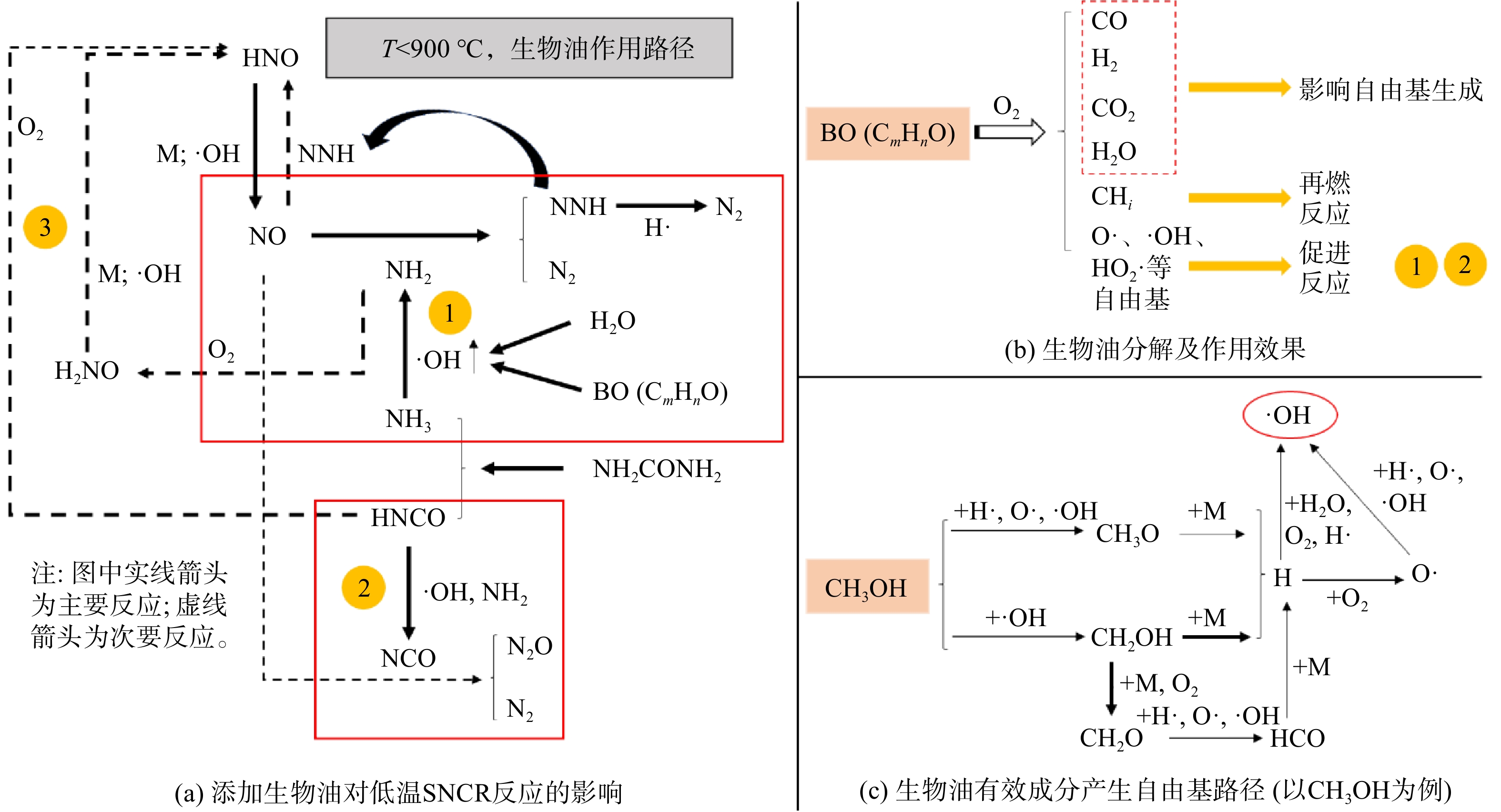

在氧气体积分数为6%,NSR为1.5的条件下,分别进行了空白及不同生物油添加比例下的SNCR脱硝实验。脱硝效率随温度变化情况如图2所示。图2表明,所有脱硝效率曲线均呈倒“V”型。其中,不添加生物油时最佳脱硝效率为67.7%,700 ℃时脱硝效率基本为0,与文献[12, 18]实验结果一致。添加生物油后,最佳脱硝温度明显向低温移动,生物油按质量分数5%、10%和15%添加时,Topt从1 061 ℃分别降低为1 027、963和969 ℃。900 ℃以下时,脱硝效率明显提高,而在1 000 ℃以上时,脱硝效率却有所降低。这是由于:在SNCR过程中,还原NOx的核心反应(式(3)、式(4))的发生严重依赖于·OH的质量浓度。在无任何添加剂的情况下,·OH主要通过系统中H2O分解产生(式(2))。在温度较低(< 900 ℃)时,O2分解产生O原子的反应受限,反应氛围中·OH质量浓度极低[19]。因此,NH2来源(式(3))受限,系统中NO无法得到充分还原(式(4)、(5))[20-21],故脱硝效率较低。而添加的生物油会在较低温度下迅速分解,产生较多的O·、·OH及CHi·等自由基,·OH促进了NH2的生成来将大量NO还原,CHi同时也能还原部分NO(式(6)~(8))[15],从而使得低温段脱硝效率明显提升。

在较高温度(>1 000 ℃)下,生物油和H2O分解生成·OH,使其浓度迅速增加。系统生成的NH2(式(3))会与NH3竞争部分·OH生成NH·(式(9))。NH·在高温下会被氧化成NO(式(10)~(12))[12]。然而,随着温度升高,氧化反应逐渐增强。因此,在温度较高时,脱硝效率反而下降。整体来看,添加生物油强化了温度在900 ℃以下的脱硝反应,而温度在1 000 ℃以上又会促进NH3的氧化,因此,脱硝效率曲线与Topt往低温移动。

在不同生物油添加比例下,ηopt、Tw及ηpro的变化如图3所示。由图3可知,添加5%和10%生物油时,ηopt都略微降低。这是由于最佳脱硝温度往低温移动后,NH2还原NO的反应速率有所降低[12]。而添加比例为15%时,ηopt降低约12%。这可能是由于生物油添加比例过高,导致·OH过量,促进了NH2氧化生成NO。在3种添加比例下,Tw分别从210 ℃拓宽到262、254和256 ℃。这表明添加生物油对SNCR脱硝效率在低温下的提升效果大于高温下的降低效果,对整体脱硝特性是优化提升的。另外,在700~900 ℃时,ηpro分别为16.78%、21.30%和19.14%。因此,对于相对较低的垃圾焚烧烟气温度而言,通过在900 ℃及以下区域适当添加生物油来提升SNCR脱硝效率是可行的。

-

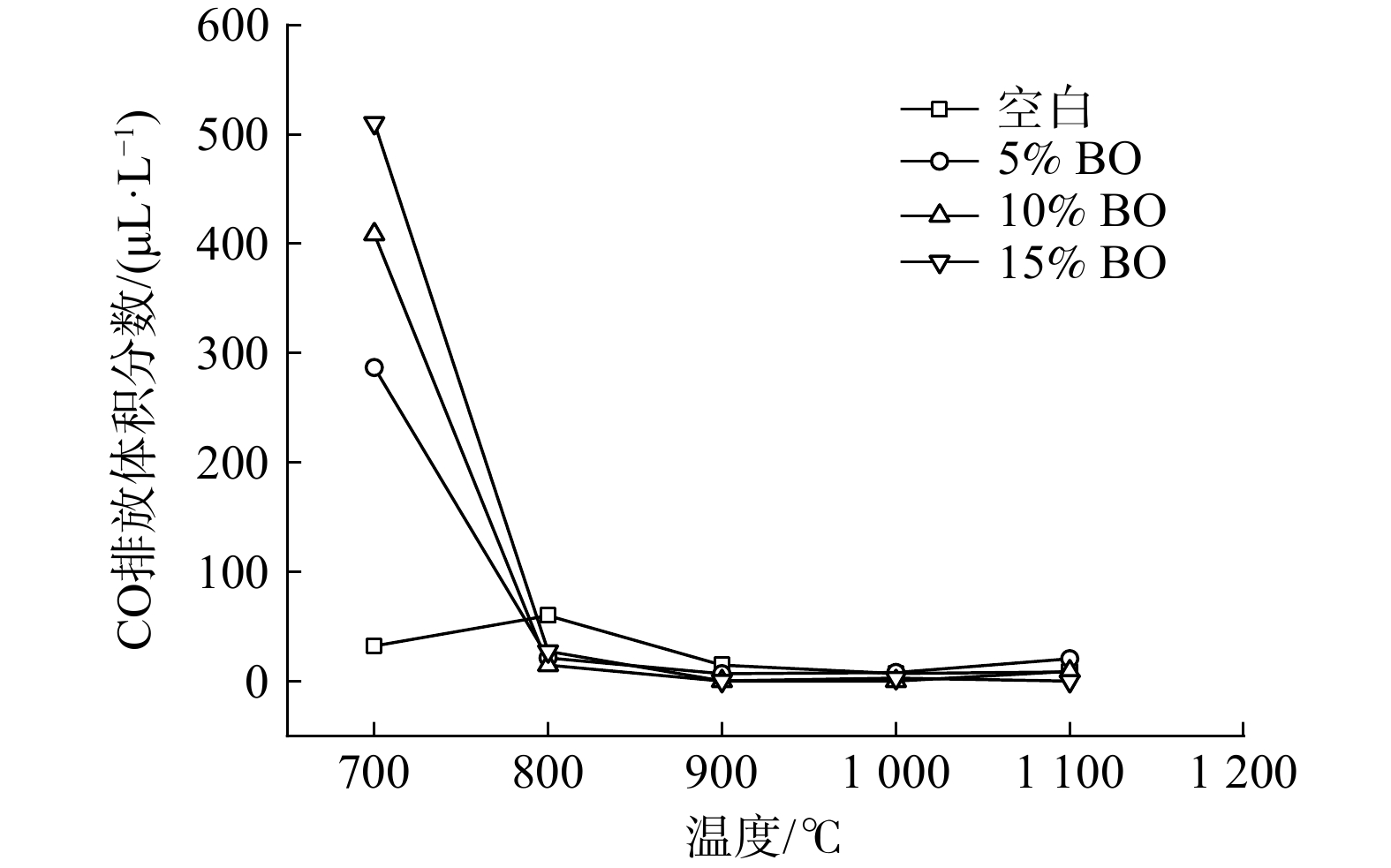

SNCR反应过程中NCO还原NO及其氧化过程(式(13)和式(14))会生成二次污染物CO[21]。图4显示了当

ϕO2 ϕO2 -

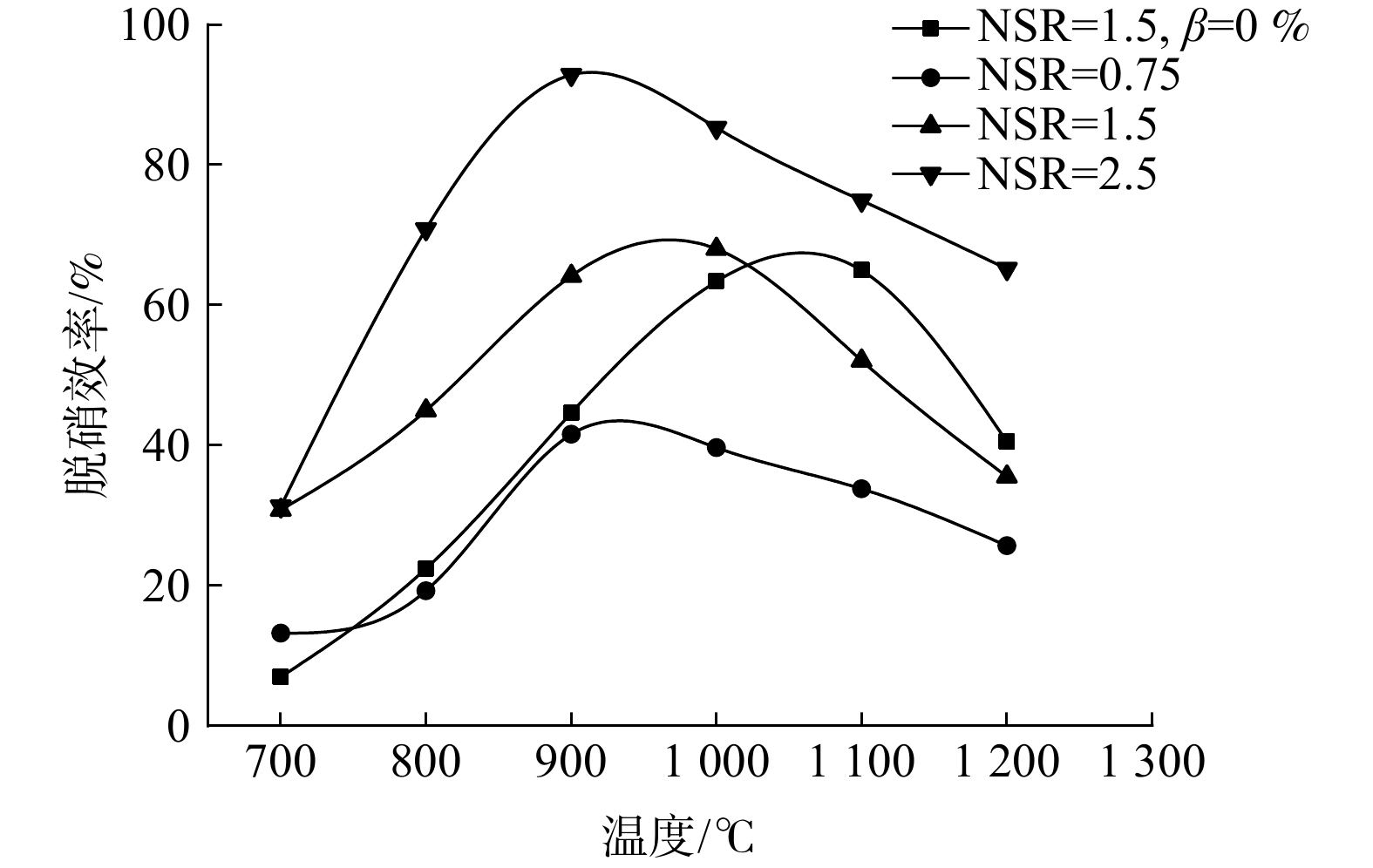

图5为添加10%生物油时,脱硝效率随NSR的变化情况。图5表明,在700~1 200 ℃时,脱硝效率均随NSR的增加而明显增加。在温度T为900 ℃,NSR为2.5的条件下,ηopt为92.84%,最佳脱硝温度及温度窗口均不同程度地往低温移动。对比NSR为0.75和空白样可知,NSR为0.75时,添加10%生物油,在900 ℃以下可将脱硝效率提升到与NSR为1.5时的空白相当,在700 ℃时甚至还要高些。这表明,当温度低于900 ℃时,可通过添加少量生物油来代替提高NSR实现的脱硝效率提升效果。同时,添加生物油不会出现高NSR时的氨逃逸问题[24-25]。另外,从高温段脱硝效率曲线来看,当NSR为0.75、1.5和2.5时,脱硝效率曲线下降均变得相对平缓。这是由于,加入的生物油在高温下所产生的大量CHi会与NH2竞争·OH,而CHi还原能力强于NH2[10],因此弱化了NH2向NH的转化(式(9)),减少了NH3的氧化,在高温下缓冲了脱硝效率的下降,故导致温度窗口向高温拓展。

-

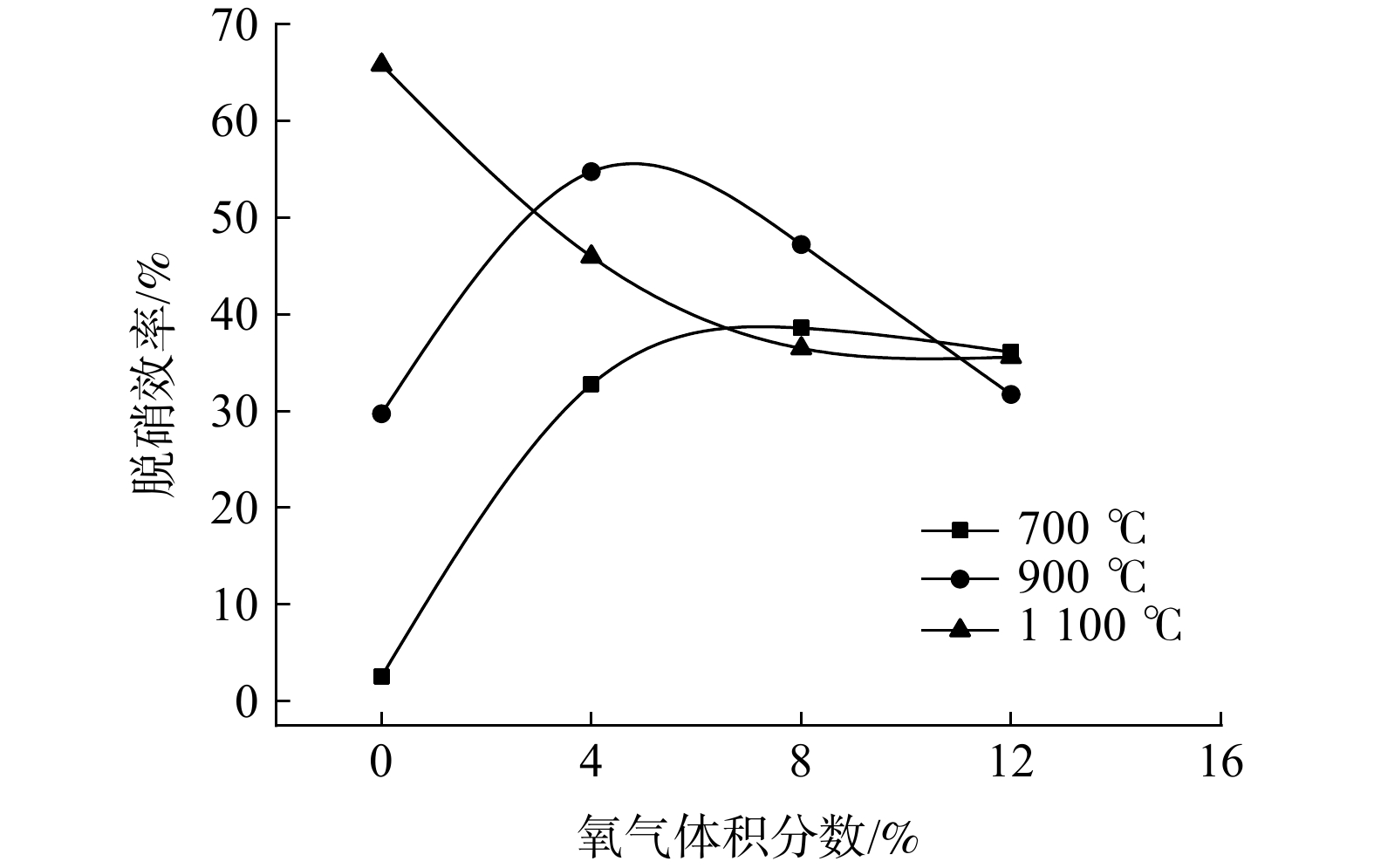

图6反映了氧浓度对生物油强化SNCR脱硝效率的影响。由图6可知,

ϕO2 图6还表明,在β 为 15%、

ϕO2 -

生物油中的有机成分在高温下分解成小分子气体后,会被烟气中的O2氧化,故氧气体积分数对于烟气中的CO排放起到关键影响作用。图7为不同氧气体积分数下,添加15%生物油的SNCR脱硝反应过程中CO的排放情况。由图7可知,氧气体积分数的升高会降低CO排放。温度为700 ℃时,受化学反应动力学限制,在氧气体积分数为12%时,CO仍无法完全被氧化;而在温度为900 ℃和1 100 ℃时,氧气体积分数为4%即可将CO基本氧化完全。因此,在垃圾焚烧烟气中,氧气体积分数为6%~12%时[28],将生物油作为添加剂时,不应从温度700 ℃及低于700 ℃的区域加入。

-

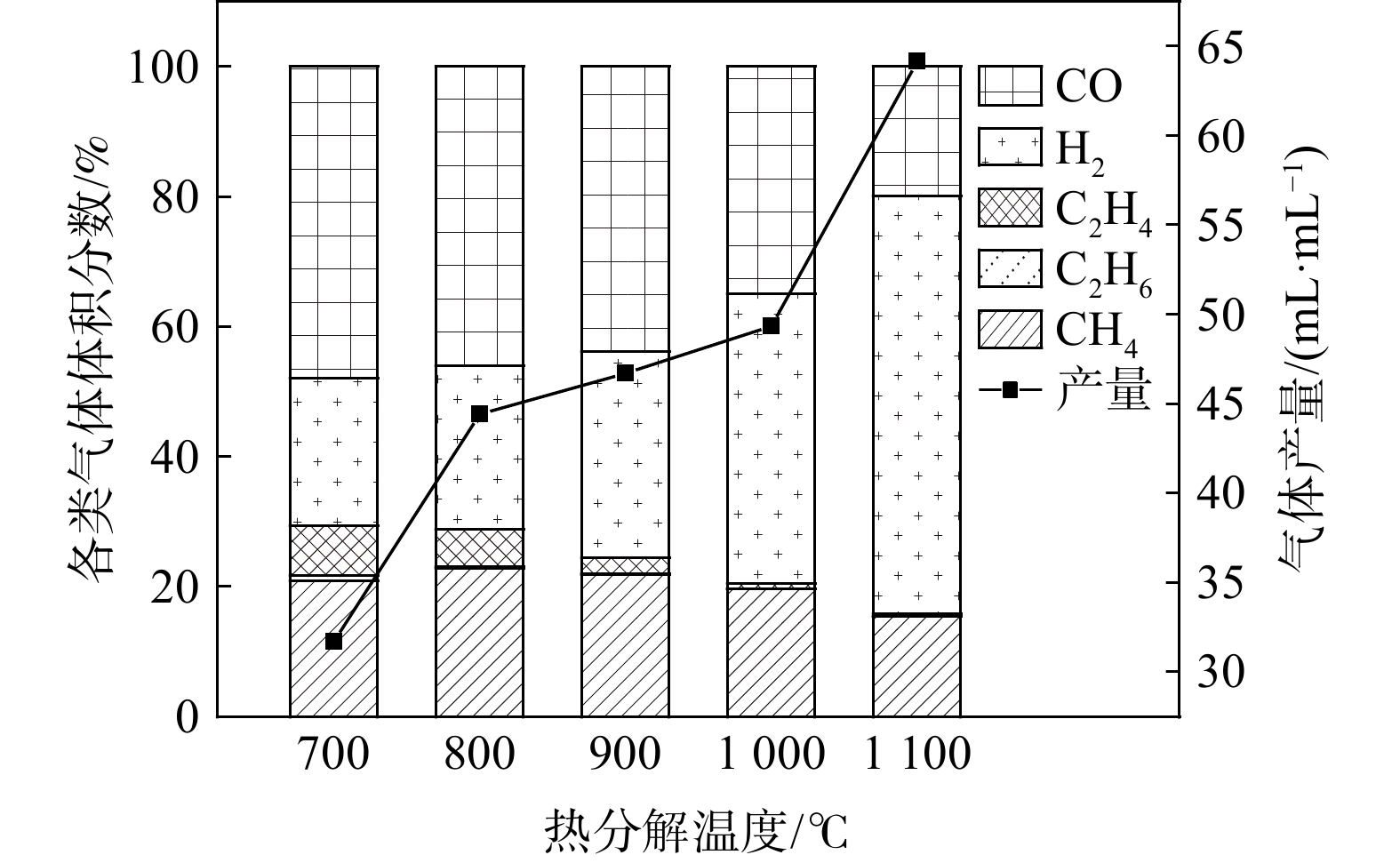

在温度为700~1 100 ℃时,进行了生物油热分解实验。图8为生物油在各温度下分解产生的气体产物图。由图8可知,生物油分解产生的气体产物主要是CO、H2及CH4、C2H4等低碳烃类。这与张谋等[29]的研究相吻合,即富钙生物油温度高于320 ℃时会分解产生大量有机气体CHi,且随着温度的升高,总气体产量增加。这是由于高温促进了生物油中有机大分子化合物化学键的断裂,造成小分子气体产量增加。生物油易受热分解,生成小分子气体的同时使反应氛围中H·、O·、·OH及CHi·等自由基的浓度上升。另外,添加H2、CO及CH4等对于SNCR脱硝影响的研究亦表明,CO、H2和CH4的添加会不同程度拓宽SNCR脱硝温度窗口,降低最佳脱硝温度,并在较低温度时提升脱硝特性[30-32]。因此,添加生物油强化低温段脱硝作用主要是通过促进O·、·OH等自由基的生成和产生小分子气体来实现的,其机理如图9所示。

-

1)对于垃圾焚烧烟气而言,将生物油作为添加剂,能拓宽SNCR脱硝反应的温度窗口,可促使最佳脱硝温度往低温移动30~100 ℃。生物油添加比例在10%以下时,最大脱硝效率基本保持不变;添加比例为10%时,在温度低于900 ℃时,SNCR脱硝效率平均提升21%。

2)低温段可通过添加适量生物油来代替提升NSR带来的脱硝效率的提升。在较高NSR下,生物油分解产生的CHi会与NH2竞争·OH,约束了NH3的氧化路径,缓冲了高温段脱硝效率的下降。

3)生物油会分解产生高浓度CO,但当温度在800 ℃以上、氧气体积分数在4%以上时,CO能被完全氧化,不会带来CO二次污染。生物油在温度高于700 ℃时会分解生成H2、CO及CH4等气体,同时使反应氛围中H·、O·、·OH等自由基浓度增加,从而促进低温下的SNCR脱硝反应。

下载:

下载: