-

传统的污水处理法为了使水质达标,采用“以能消能”的方式去除有机物和营养物质[1],但受到可持续发展观念的影响,能源回收也变成了污水处理的重要目的之一。尽管污水污泥的厌氧消化可以抵消部分能源需求,但考虑到能源回收效率,还是要借助其他工艺来进行更高效的能源回收。有机物的预浓缩对于提高能源回收至关重要,郭超然等[2]在对比了高负荷活性污泥法、絮凝、膜分离等富集技术后,认为絮凝技术可以更高效地富集有机物。絮凝技术的应用要借助絮凝剂,无机絮凝剂应用最为广泛但不仅用量大、会危害环境还不利于磷的回收[3],投加量少、对环境友好的有机高分子絮凝剂[4]是更好的选择,但有机高分子絮凝剂也会增加过程中的物料消耗,因此亟需寻找一种可重复利用的新型絮凝剂。

水热技术是一种可以在相对温和的反应条件下利用湿生物质来生产增值产品的热化学转化技术,水热产物包括被称为水热碳的固体碳质物质、主要成分为二氧化碳的气体以及包含有机物的水热液。目前,水热液的应用主要集中在以下几方面:将水热液中的蛋白质、腐殖质等有机物直接作为再生产品使用[5],进行厌氧消化生产沼气[6],培养藻类生长[7]等。在水热液能源回收的研究中,OLIVEIRA等[8]证明利用水相转化处理水热液可以回收能源;ZHANG等[9]证明可以通过纳滤从水热液中回收羧酸;王灵芝等[3]研究发现污水污泥中的蛋白质、多糖等在水热条件下发生水解、脱水、脱羧、聚合芳香化、美拉德等反应,该重聚与再缩合过程所形成的水溶性有机聚合物 (soluble organic polymers, SOP) 可用来制备聚集介质。因此提出一个工艺设想:将污水污泥经过水热处理得到的SOP,经过改性成为具有吸附功能的聚集介质后再次投入到污水中进行有机物的富集。因为SOP具有类腐殖酸特性[10]、分子量大[5]且具备大量吸附位点可用于接枝共聚,具备可被改性的潜力。

但有关此工艺设想的研究目前尚未见报道,水热条件改变所产生的影响暂不清晰。因此,本研究通过探究在不同水热条件下SOP的生成特性、元素组成、官能团变化以及可能发生的化学反应,得到使SOP产率较高且更适合作为聚集介质前体物的水热制备条件。利用污水污泥为原料制备聚集介质,不仅可以降低成本节约物耗,而且部分有机物可被循环利用,提高能源回收效率。

-

本实验所用的污泥取自苏州市高新区狮山水质净化厂的浓缩池,取回的污泥过筛后低温保存在冰箱内。污泥特性如表1所示。

-

1) 水热反应。在石英内衬中装入100 g浓缩污泥以及10% (w/w污泥干质) 的碱性添加剂,将反应釜 (361 L不锈钢材质,WZA 250型,五洲鼎创有限责任公司,中国) 密封后,用氮气吹扫10 min去除残余空气。搅拌桨以250 r·min−1的速度进行搅拌,待反应釜以4 ℃·min−1的速率达到设定温度 (150、175、200和225 ℃) 后在自体压力 (相应的饱和蒸汽压分别为0、0.5、1.3、2.3 MPa) 下,在设定的反应时间 (0.5、1和1.5 h) 内保持恒温。到达设定时间后,通过自来水的循环将反应釜冷却至室温常压。

2) 水溶性有机聚合物的提取。收集的水热产物经15 min、转速为4 000 r·min−1的离心后,利用真空抽滤分离固液两相。利用1 mol·L−1的HCl将水热液的pH值降到2~3以下,可以观察到水热液呈浑浊状态,再次离心后得到的固相即为SOP。将SOP放入105 ℃的烘箱至恒重后,进行后续的表征以及产率计算。根据水热反应条件不同,将水溶性有机聚合物命名为SOP -X (℃) -X (h) 。

-

SOP表面官能团采用红外光谱仪 (Thermo Scientific Nicolet 6700,美国) 进行分析;采用元素分析仪 (Thermo Scientific Flash 2000,美国) 测定SOP中C、H、N、S元素的含量,O 含量通过差减法计算获得;使用X射线光电子能谱仪 (Thermo Scientific K-Alpha,美国) 分析SOP的C、N、O元素结合态变化,并通过软件Avantage对C 1s、N 1s和O 1s元素进行分峰和拟合。

-

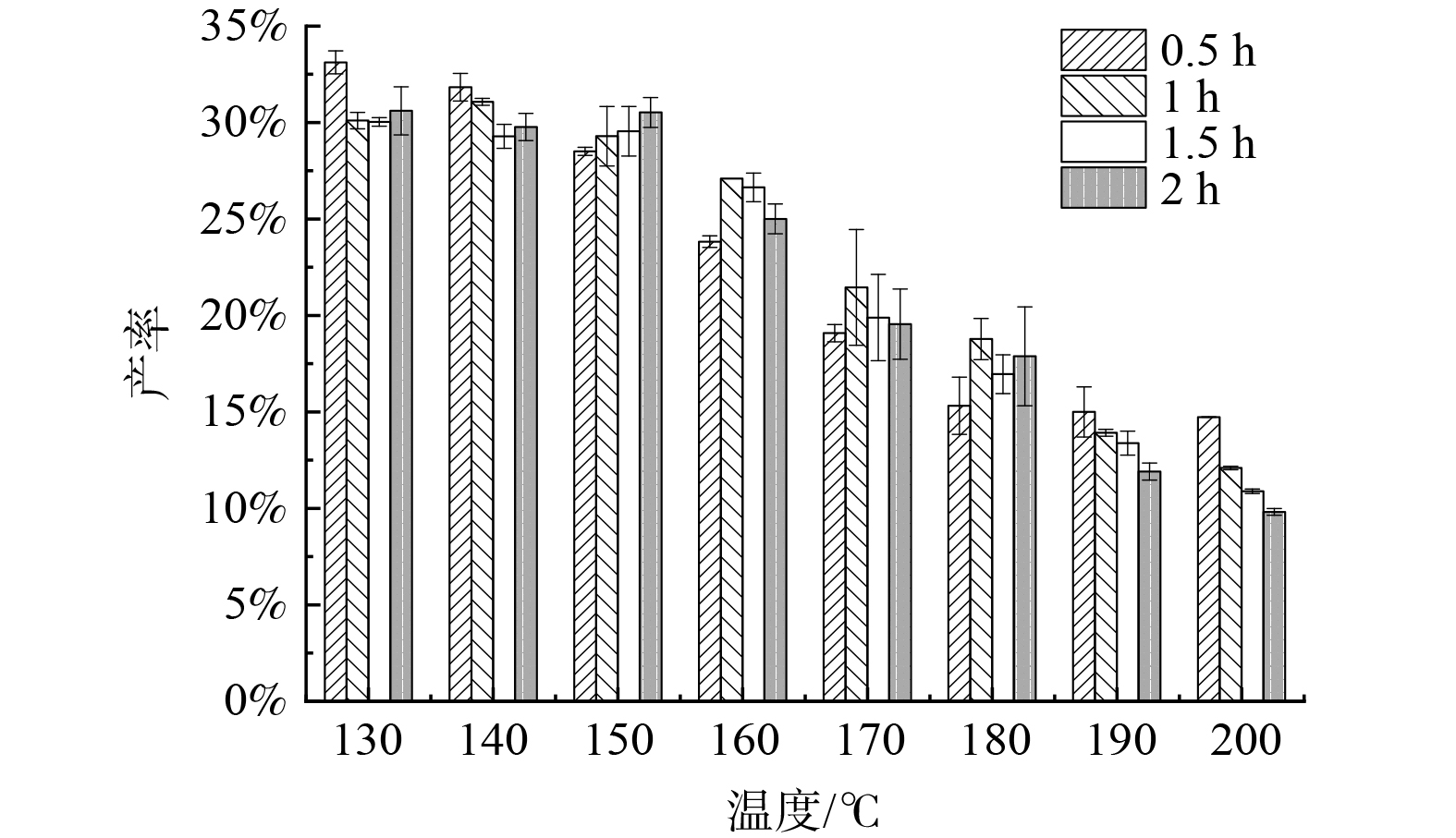

1) 温度和时间的影响。在不同水热温度和时间反应后得到的SOP产率如图1所示。由图1可知,在水热条件为130 ℃、0.5 h时得到最高产率,随着反应温度的上升和时间的延长,SOP的产率整体呈现下降趋势。根据CHEN等[11]研究表明,这可能是由于焦糖化反应的发生,过高的温度不利于类美拉德反应,导致SOP减少。当反应温度在130 ℃到150 ℃之间时,SOP产率相差不大,但当温度超过150 ℃后,产率下降幅度变大。当反应时间为0.5 h时,SOP的产率由150 ℃时的28.5%降到200 ℃的14.73%,降低了13.77%。根据WANG等[12]的研究表明,130 ℃到150 ℃为临界温度范围,可溶生物聚合物的浓度在此温度范围内迅速上升,并且在150 ℃以上受到水热反应的强烈影响。在200 ℃下反应0.5、1、1.5和2 h后,产率分别为14.73%、12.09%、10.89%和9.81%。经过对比可知温度较反应时间对SOP产率的影响更大,ZHANG等[13]的研究也表明温度在确定每个步骤的速率常数方面起着重要作用,高温会加速反应,从而影响SOP的理化性质,进而控制主要反应途径和聚合度。

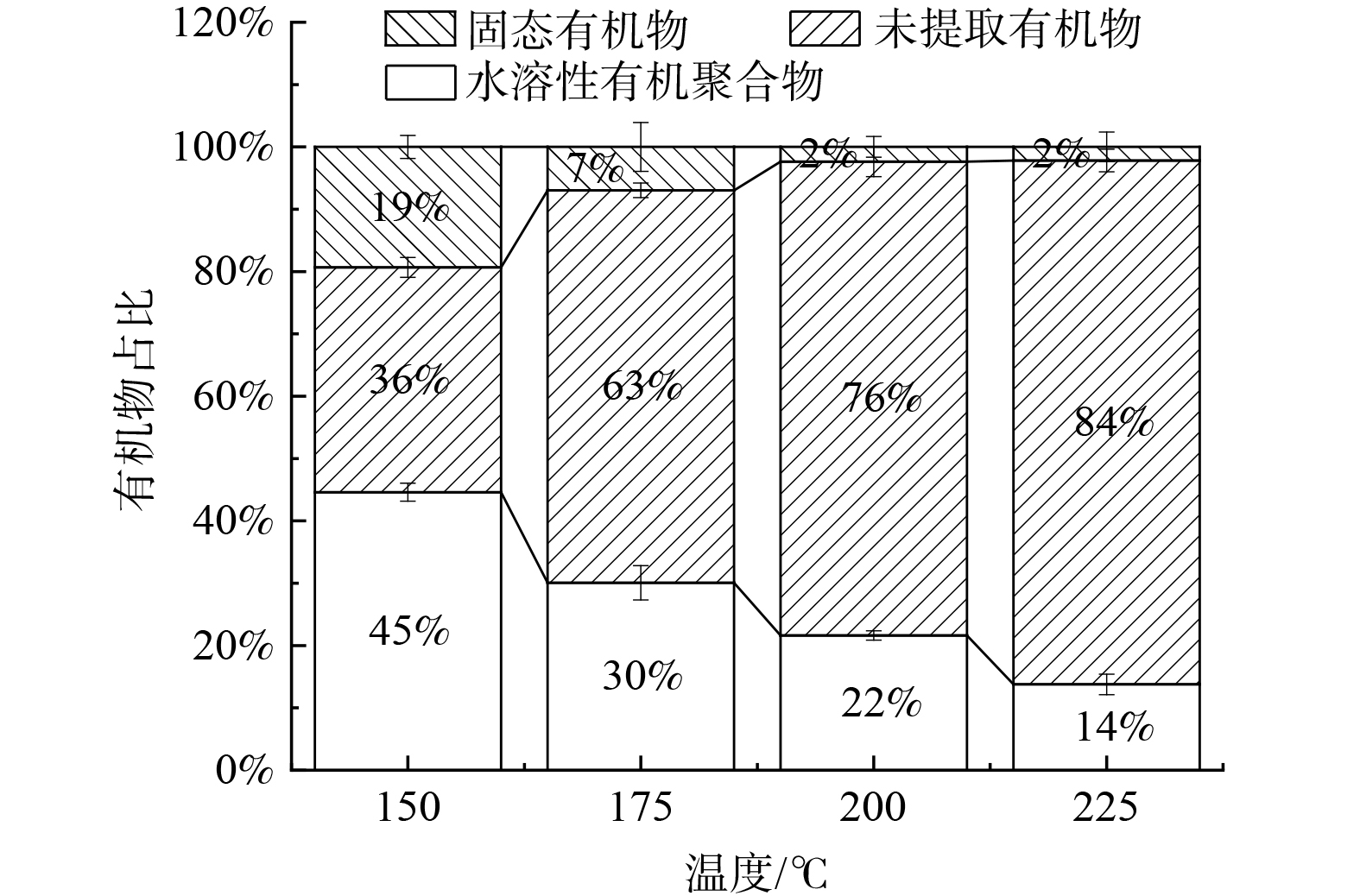

图2列出了在不同水热温度下水热产物中有机物占比分布。通过图2可知,当温度由150 ℃升至225 ℃时,固相中有机物含量由19.32%降至2.18%,说明随着温度的升高,更多的有机物进入到液相。但可提取出来的SOP产量却在减少 (由44.6%降低至13.78%) ,可能是由于原污泥中的固态有机物在水热过程中会经历2种阶段:第一个阶段是固态有机物受温度的影响溶解到水热液中;第二个阶段则是部分大分子有机物例如蛋白质、多糖等分解成小分子溶解进入液相,是无法利用降低pH值提取出来的。因此随着温度的升高,可以通过酸沉降得到的SOP越来越少。

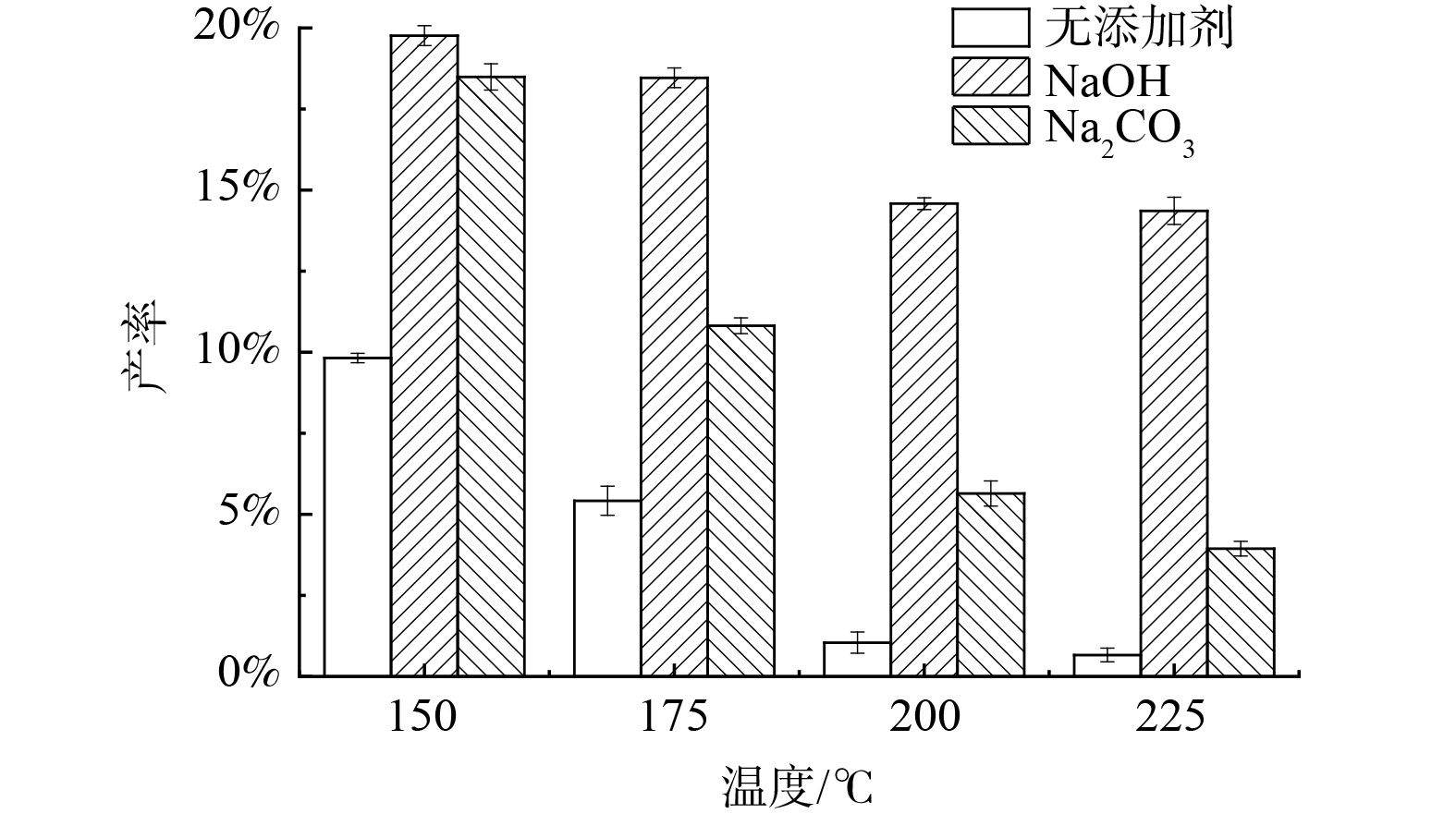

2) 碱性添加剂的影响。不同碱性添加剂对SOP产率的影响见图3。通过图3可知,在反应时间为30 min,水热温度分别为150、175、200和225 ℃时,投加2种碱性添加剂和不投加添加剂的情况下,随着温度的上升,SOP产率均在下降,但投入10% (以污泥干质计)的NaOH和10%的Na2CO3反应后得到的产率明显高于无添加时反应得到的产率。当水热条件为150 ℃、0.5 h时,不投加添加剂时SOP产率是9.82%,而添加了10%的NaOH和Na2CO3之后,分别增长到19.76%和18.49%。这不仅说明碱性添加剂会对SOP的产率产生积极的影响,还说明不同的碱性添加剂对于SOP提取的影响是有差别的。碱的添加可能会协助高温处理,碱性条件会降低有机物的极性[14],通过化学和电离作用使得污泥细胞破裂溶解释放出胞内物质[15],不仅增强了含有羧基、醇和氨基团的有机物从固体向水相的转移还会在较温和的条件下促进含碳基团的水解裂解[14],从而提高了SOP的产率。强碱对于SOP的提取具有更积极的作用,这可能是由于相同剂量的NaOH与Na2CO3在反应中所提供的碱度是不同的,发挥作用的官能团不同导致的。

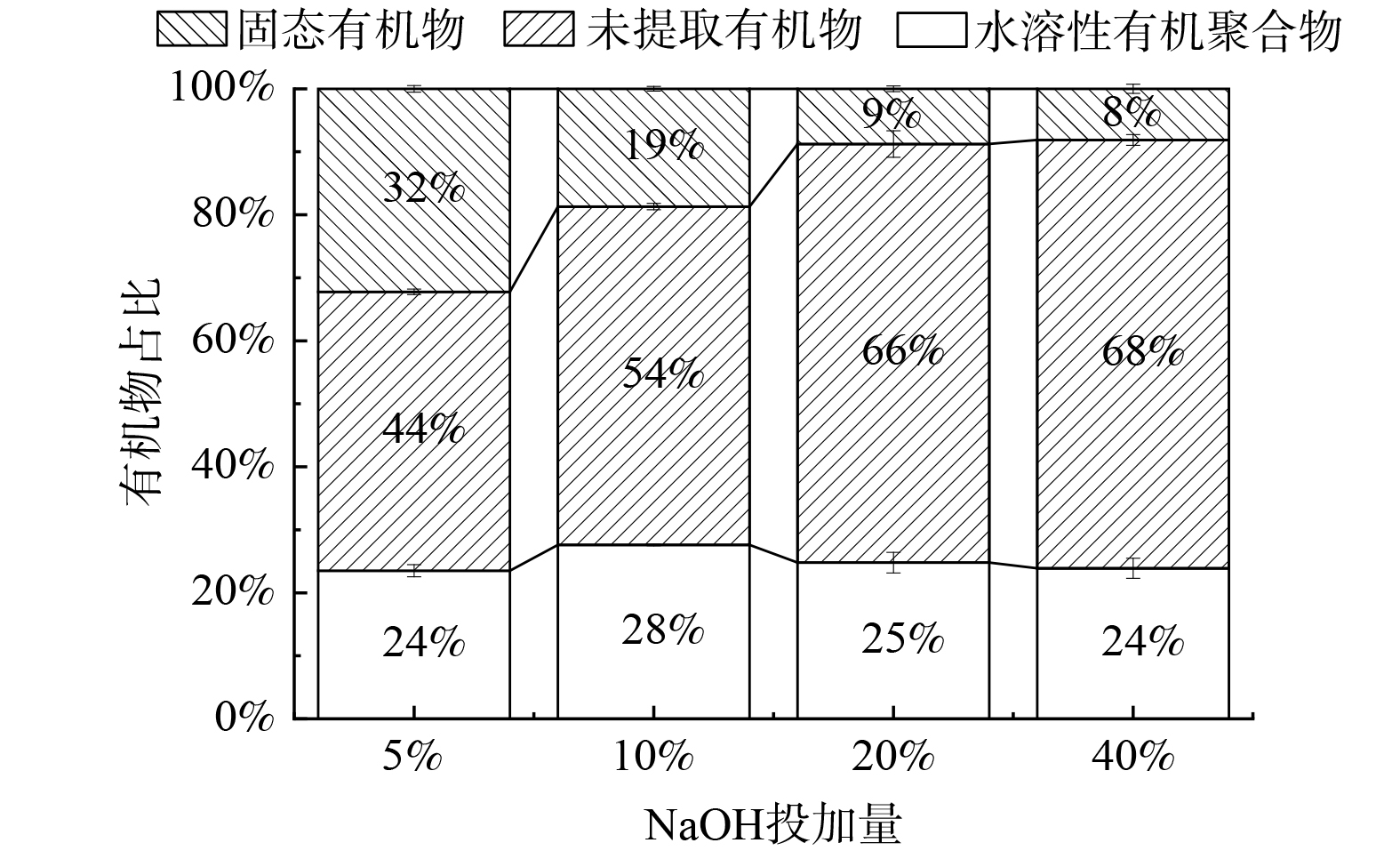

NaOH投加量对有机物分布的影响见图4。通过图4可以看出,不同剂量的NaOH对水热产物中有机物的分布具有一定的影响。在150 ℃、0.5 h的反应条件下,随着NaOH投加量的增加,溶解到液相中不能被酸提取的有机物增多,固态有机物的占比逐渐降低。根据LI等[14]的研究表明,这是由于温度升高会破坏氢键,使水和碱充当溶剂和反应物,并且随着温度的升高,极大地增加了水的离子产物作为溶剂并促进进一步的化学反应,从而促进颗粒聚集和结合水向自由水的转化。SOP在添加了10%NaOH的情况下得到了最高的SOP占比,不论是继续增大投加量还是减少投加量,得到的SOP占比均在24%左右。这与吴鹏等[16]的研究结果一致,随着碱投加量增大下产率升高,但当碱浓度过高时产率反而下降。这可能由于随着NaOH用量的增加,SOP中分子内和分子间电荷的相互作用得到加强,更多的酸性基团暴露在碱性添加剂的攻击之下,因此SOP的提取率得到提高[17],但随着碱性添加剂投加量的升高,多糖会分解成葡萄糖小分子,从而使SOP占比下降。经过上述分析可知投加10%NaOH,不仅会有效地促进污水污泥水解,还会得到最大SOP回收率。

-

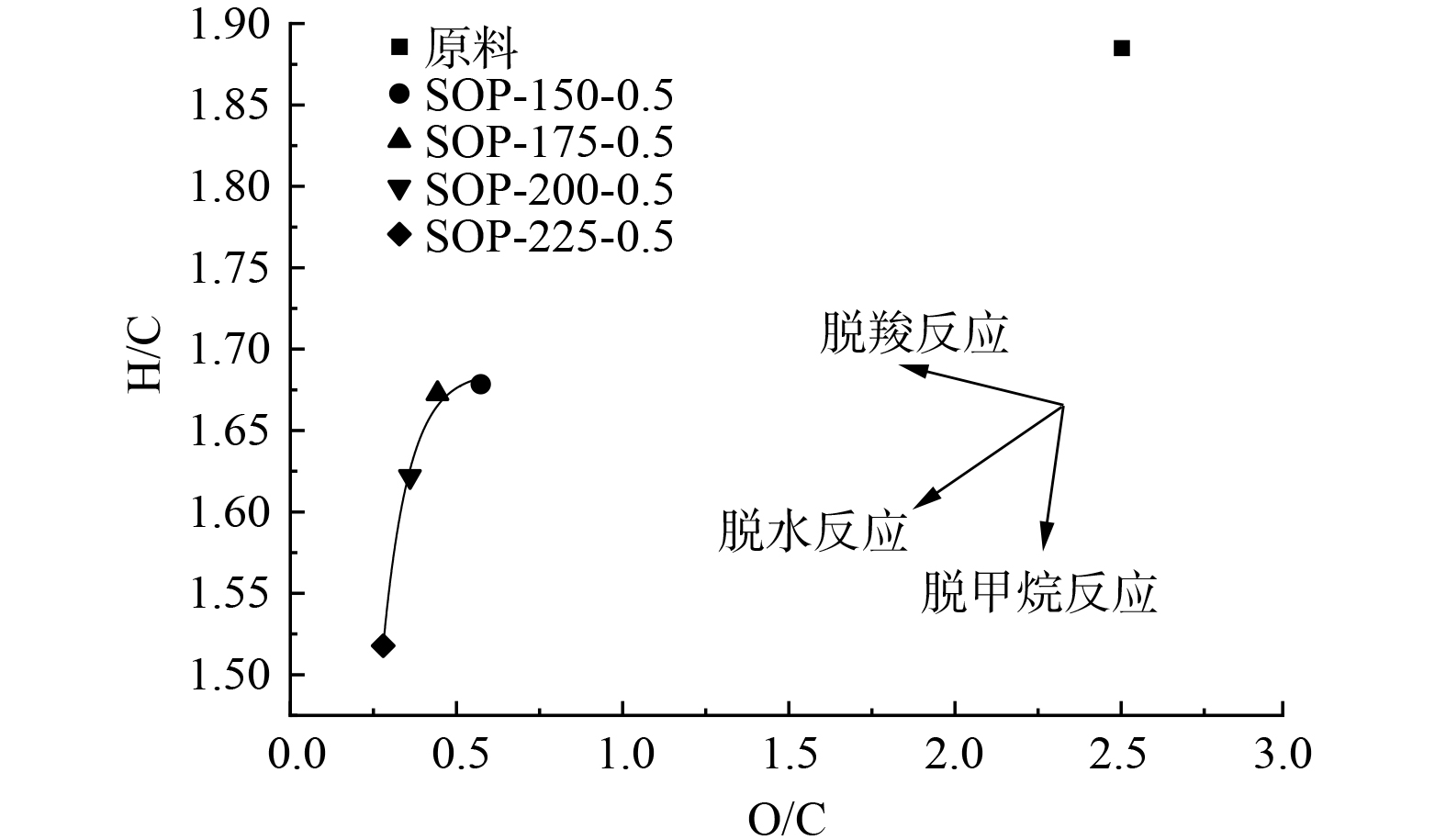

1) 元素分析。表2列出了不同水热温度得到的SOP的元素组成和O/C、H/C原子比。由表2可知,SOP中占比最高的元素是C (占47.38%至62.38%) ,然后分别是O、H、N和S。随着温度的上升,样品中C、H和N含量在上升、O含量在降低,说明样品的腐殖化程度在升高[18]。O/C和H/C原子比的数值变化可用来反映水热处理过程中发生的脱水和脱羧反应程度的变化[19],通过表2和图5发现O/C原子比的下降趋势要大于H/C原子比 (O/C比从0.57降到0.28,H/C从1.68降到1.52) ,说明脱氧反应要比脱羧反应剧烈。但不论温度如何改变,SOP的H/C比值均高于1,这一发现与O/C值的下降一起表明,SOP的化学结构中存在芳香族框架[18]。H/C原子比也可以用来衡量SOP的芳香化情况,与其他条件得到的SOP相比,150 ℃得到的SOP具有相对较高的 H/C原子比,表明脂肪族特征更强,芳香族特征更少[20]。H/C原子比还间接表示SOP的亲水性,温度越低,SOP的亲水性越高,也就越适合后续改性处理。另外,O/C原子比与碳水化合物和羧酸含量有关[21],高O/C比表明样品中含有较高比例的O-烷基和羧酸官能团,表2显示较低温度下得到的SOP的O/C原子比较高,说明较低温度下得到的SOP含有更多的羧酸和呋喃,这与本研究中红外光谱、XPS的分析结果一致。

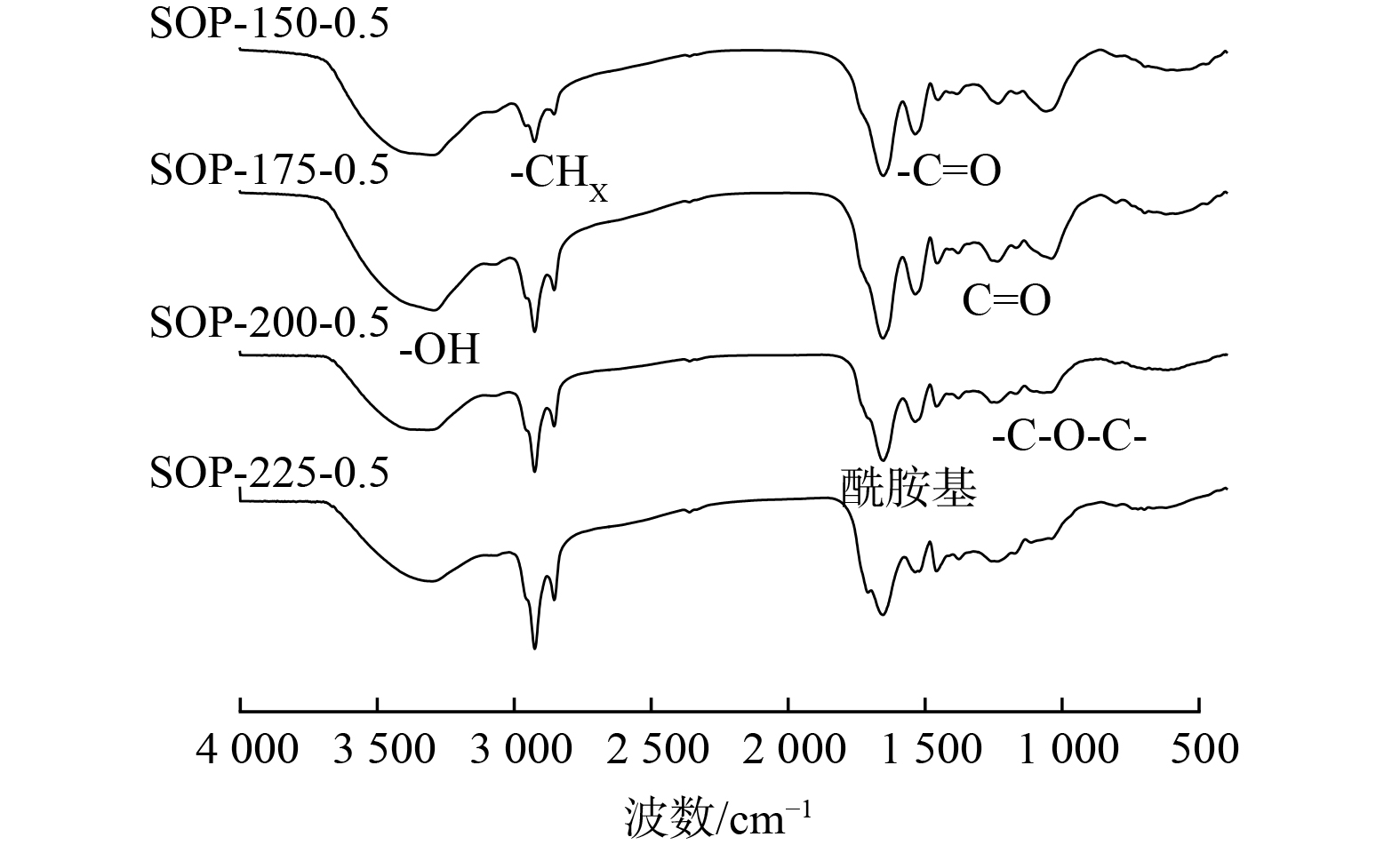

2) 红外光谱。为了揭示反应温度对SOP表面官能团的影响,利用FT-IR对不同水热温度获得的SOP进行了表征,如图6所示。所有SOP在3 500 cm−1~3 300 cm−1都有一个大而强烈的吸收带,是由羟基化集团 (如醇类、酚类和羧酸) 的-OH拉伸振动引起的,但随着温度的升高,此处拉伸的相对强度逐渐减弱,可能是由于水热反应的过程中富含羟基的聚合物 (如多糖) 的缩合反应[22],也可能是由于脱水效果逐渐加强。在2 925和2 850 cm−1处的吸收峰是脂肪族CH3变形振动和-C-H延伸振动引起的,可能是由于聚合物质的断裂导致脂肪族结构的出现[23],此处随着温度升高,吸收带强度逐渐加强,意味着疏水性增强[14]。2 925、2 850和730 cm−1处的吸附峰可以用来估计脂肪族链的长度及其分支程度[11],SOP在730 cm−1处没有峰,表明其线性链少 (结构更稳定) ,但是随着温度的上升,2 925和2 850 cm−1处的吸附峰强度升高,说明SOP中含有的线性链含量增多,结构的不稳定性增强。当温度超过200 ℃,1 705 cm−1处出现了的吸收带,归因于羧酸 (C=O) 、酮类和醛类的伸缩振动,这表明在200 ℃以上获得的SOP有一些羧基和芳香基[11]。1 638 cm−1~1 658 cm−1内的峰值是由酰胺基C=N伸缩振动或肽键振动引起的[24],可能是由于蛋白质结构的破坏暴露了酰胺,当温度超过175 ℃后,酰胺基的强度开始下降,这可能是由于水热过程中发生了美拉德反应,这与元素分析中N含量下降结果一致。1 540 cm−1是羧基中-C=O的不对称伸缩,随着温度的升高,峰值相对强度的逐渐下降说明SOP发生了脱羧反应。1 450~1 465 cm−1区域的吸收带被指定为芳香族化合物的C=C拉伸、脂肪族的-CH2和-CH3拉伸和肽的-NH2弯曲振动。1 200~1 260 cm−1内的峰值可能是酯类、醚类和酚类的C=O拉伸振动。1 040 cm−1处的峰值可以归因C-O-C在脂肪族醚中的不对称拉伸[22]和醇C-O拉伸,也可能是多糖衍生物的特征峰[22],样品中的这一峰值相对强度随着温度的上升出现了下降,可能是由于C-O-C的进一步裂解导致的。

红外光谱的结果表明,SOP含有大量的酚羟基、醇羟基、芳香族和脂肪族化合物,由于其含有芳香族结构和丰富的含氧官能团,因此可以吸附有机和无机 (重金属) 污染物[19]。并且随着温度的升高,羟基、羧基的功能团强度降低,而脂肪族功能团的强度升高,SOP中的含氧官能团被破坏,不利于后续改性。

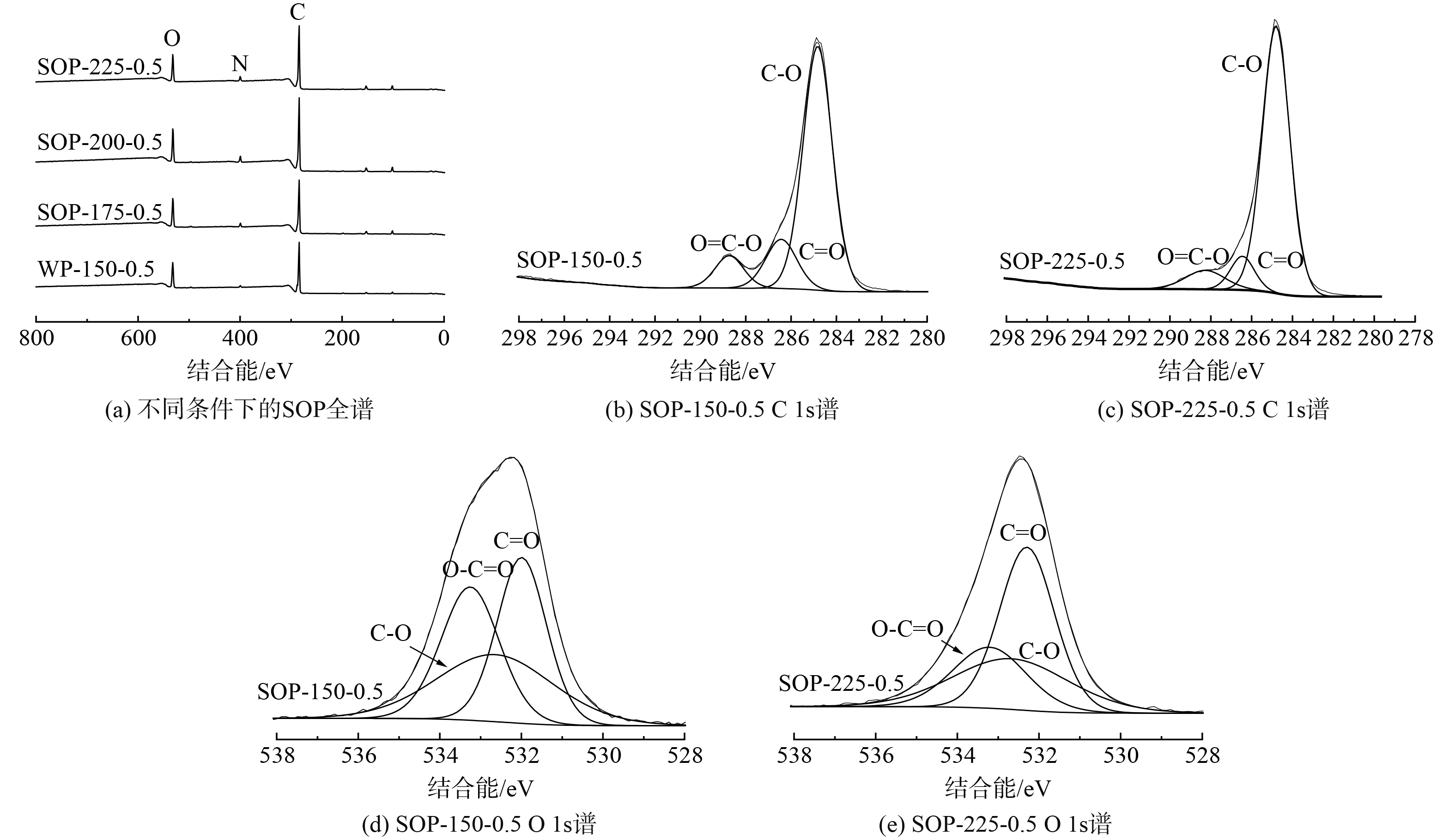

3) XPS光谱。样品的X射线光电子能谱 (XPS) 谱线拟合后如图7所示,从XPS全谱中可以看到在285.09、532.78和400.12 eV左右出现了3个峰,分别对应C 1s、O 1s和N 1s。150 ℃、30 min的反应条件下得到的SOP具有的C 1s峰可分为3个峰,分别位于284.83、286.43和288.73 eV,它们被分配给脂肪族碳(C-O,74.23%)、醚/醇类碳 (C=O,16.05%)和羧酸类碳 (O=C-O,9.72%)。对于O 1s峰,观察到不饱和芳烃中的氧 (C=O,531.99 eV) 、醚/醇基 (C-O,532.64 eV) 和羧基 (O-C=O,533.25 eV) [18]。225 ℃、30 min的反应条件下得到的SOP具有的C 1s峰可分为3个峰,分别位于284.8、286.45和288.27 eV,它们分别对应C-O (82.35%)、C=O (9.25%)和O=C-O (8.4%)。对于O 1s峰,观察到不饱和芳烃中的氧 (C=O,532.29 eV) 、醚/醇基 (C-O, 532.67 eV) 和羧基 (O-C=O,533.21 eV) 。可以看出,温度的上升使脂肪族碳增加,而醚/醇类碳和羧酸类碳的含量下降。就O 1s信号而言,与225 ℃相比,150 ℃得到的SOP的羧基中氧的含量略高,这与C 1s的XPS光谱结果一致。改性利用的反应位点一般是有机物的羟基或氨基等活性基团[3],因此含有越多羟基等活性基团的SOP越适合作为制备聚集介质的前体物质。

-

1) 随着温度和反应时间的增加,尽管进入液相的有机物增多,但水溶性有机聚合物 (SOP) 的产率整体呈现下降趋势。

2) 碱性添加剂的加入大大加速了有机物的溶解速率并且将SOP的产率提高了10%左右。对比加入相同剂量NaOH和Na2CO3后得到的SOP产率,发现NaOH的溶解效率优于Na2CO3。

3) SOP以脂肪族结构和芳香成分为主,含有羟基、羧基等含氧官能团。温度升高导致SOP的线性链含量增多,结构的不稳定性增强;H/C和O/C原子比逐渐降低,SOP脱水脱羧反应强度增加,含氧官能团含量减少,导致后续改性可利用的羧基和羟基含量下降。

4) 综合上述结果表明在150 ℃、0.5 h、10% (以污泥干质计) NaOH的水热条件下获得的SOP更适合作为聚集介质的前体物质,不仅产率较高而且还有更多可被改性的含氧官能团。

不同条件下污泥水热液相产物的生成特性

Character analysis of liquid products from hydrothermal treatment of sludge under different conditions

-

摘要: 将城市污水污泥作为研究对象进行水热处理,目的是得到可以改性成为聚集介质的水溶性有机聚合物 (soluble organic polymers, SOP) 。研究了不同温度 (150、175、200和225 ℃) 、反应时间 (0.5、1和1.5 h) 和碱性添加剂用量等水热条件下SOP的生成特性。结果表明,随着温度和反应时间的增加,SOP产率逐渐下降,由28.5% (150 ℃、0.5 h) 降低至14.73% (200 ℃、0.5 h) 。碱的投加提高了SOP产率,且NaOH的效果优于Na2CO3。元素分析表明,温度升高导致SOP的O/C和H/C下降,腐殖化、芳香化程度均增加。红外光谱和X射线光电子能谱表明,温度的升高导致SOP中改性可利用的含氧基团减少。因而150 ℃、0.5 h、NaOH投加量为污泥干重的10%时,水热反应条件是最适宜的,可以得到更适合作为聚集介质前体物的SOP。本研究结果可为污水污泥资源化利用提供参考。Abstract: Municipal sewage sludge was used as raw substrate for hydrothermal treatment in order to obtain soluble organic polymers (SOP), which can be modified to aggregation media. The characteristics of SOP were investigated under various hydrothermal conditions with different temperatures (150, 175, 200 and 225 ℃), reaction times (0.5, 1 and 1.5 h) and amounts of alkaline additives. The results showed that the SOP yield decreased gradually with increasing temperature and reaction time, from 28.5% (150 ℃-0.5 h) to 14.73% (200 ℃-0.5 h). The alkali addition boosted the SOP yield, besides, NaOH had a better effect than Na2CO3. Elemental analysis demonstrated that the increase of temperature led to the decrease of O/C and H/C of SOP, which meaned the increase of humification and aromatization. Results of infrared spectroscopy and X-ray photoelectron spectroscopy indicated that the increase in temperature led to a decrease in the oxygen-containing functional groups. Thus, the hydrothermal conditions at 150 °C, 0.5 h, and NaOH dosing of 10% (w/w of dry weight ) were optimal to obtain SOP as precursors for aggregation media preparation. This study can provide a reference for the reuse of sewage sludge.

-

Key words:

- reuse of sewage sludge /

- hydrothermal technology /

- soluble organic polymer

-

表 1 浓缩污泥特性

Table 1. Characteristics of thickened sludge

% 含水率 VSS SS C H O N S 97.51±0.46 1.41±0.32 2.50±0.46 21.34±0.05 3.36±0.02 71.38±0.11 3.02±0.01 0.87 表 2 不同温度下的水溶性有机聚合物的元素分析

Table 2. Elemental analysis of SOP at different temperatures

样品 C/% H/% O/% N/% S/% H/C O/C SOP-150-0.5 47.84±0.23 6.69±0.05 36.4±0.29 7.45±0.03 1.47±0.01 1.68 0.57 SOP-175-0.5 53.09±0.18 7.41±0.03 31.14±0.21 6.59±0.01 1.58±0.01 1.67 0.44 SOP-200-0.5 57.42±0.15 7.76±0.01 27.28±0.17 5.9±0.03 1.35±0.01 1.62 0.36 SOP-225-0.5 62.38 7.89±0.02 22.9±0.03 5.3±0.02 1.21 1.52 0.28 -

[1] 刘智晓. 未来污水处理能源自给新途径——碳源捕获及碳源改向[J]. 中国给水排水, 2017, 33(8): 43-52. doi: 10.19853/j.zgjsps.1000-4602.2017.08.008 [2] 郭超然, 黄勇, 朱文娟, 等. 城市污水有机物回收——捕获技术研究进展[J]. 化工进展, 2021, 40(3): 1619-1633. doi: 10.16085/j.issn.1000-6613.2020-0878 [3] 王灵芝, 黄勇, 查晓, 等. 利用污水污泥制备有机物聚集介质的可行性探析[J]. 工业水处理, 2022, 42(10): 22-30. [4] 申娟娟, 刘根起, 宋金月, 等. 有机高分子絮凝剂的研究现状[J]. 材料开发与应用, 2011, 26(2): 96-99. doi: 10.3969/j.issn.1003-1545.2011.02.022 [5] WANG Q, XU Q, DU Z, et al. Mechanistic insights into the effects of biopolymer conversion on macroscopic physical properties of waste activated sludge during hydrothermal treatment: Importance of the Maillard reaction[J]. Science of The Total Environment, 2021, 769: 144798-144798. doi: 10.1016/j.scitotenv.2020.144798 [6] USMAN M, CHEN H, CHEN K, et al. Characterization and utilization of aqueous products from hydrothermal conversion of biomass for bio-oil and hydro-char production: a review[J]. Green Chemistry, 2019, 21(7): 1553-1572. doi: 10.1039/C8GC03957G [7] TSARPALI M, ARORA N, KUHN J N, et al. Beneficial use of the aqueous phase generated during hydrothermal carbonization of algae as nutrient source for algae cultivation[J]. Algal Research, 2021, 60: 102485. doi: 10.1016/j.algal.2021.102485 [8] OLIVEIRA A S, SARRIÓN A, BAEZA J A, et al. Integration of hydrothermal carbonization and aqueous phase reforming for energy recovery from sewage sludge[J]. Chemical Engineering Journal, 2022, 442: 136301. doi: 10.1016/j.cej.2022.136301 [9] ZHANG X, SCOTT J, SHARMA B K, et al. Advanced treatment of hydrothermal liquefaction wastewater with nanofiltration to recover carboxylic acids[J]. Environmental Science:Water Research & Technology, 2018, 4(4): 520-528. [10] DWYER J, STARRENBURG D, TAIT S, et al. Decreasing activated sludge thermal hydrolysis temperature reduces product colour, without decreasing degradability[J]. Water Research, 2008, 42(18): 4699-4709. doi: 10.1016/j.watres.2008.08.019 [11] CHEN P, YANG R, PEI Y, et al. Hydrothermal synthesis of similar mineral-sourced humic acid from food waste and the role of protein[J]. Science of the Total Environment, 2022, 828: 154440. doi: 10.1016/j.scitotenv.2022.154440 [12] WANG L, CHANG Y, LI A. Hydrothermal carbonization for energy-efficient processing of sewage sludge: A review[J]. Renewable and Sustainable Energy Reviews, 2019, 108: 423-440. doi: 10.1016/j.rser.2019.04.011 [13] ZHANG D, FENG Y, HUANG H, et al. Recalcitrant dissolved organic nitrogen formation in thermal hydrolysis pretreatment of municipal sludge[J]. Environment International, 2020, 138: 105629. doi: 10.1016/j.envint.2020.105629 [14] LI X, WANG J, YOU J, et al. Hazardous waste dewatering and dry mass reduction through hydrophobic modification by a facile one-pot, alkali-assisted hydrothermal reaction[J]. Water Research, 2019, 155: 225-232. doi: 10.1016/j.watres.2019.02.050 [15] 盛广宏, 陈蓓蓓, 刘金凤. 热碱处理破解污泥效果研究[J]. 环境科技, 2013, 26(2): 38-42. doi: 10.3969/j.issn.1674-4829.2013.02.010 [16] 吴鹏, 韩宇超, 白佳鑫, 等. 水热法从玉米秸秆中提取腐植酸的工艺条件优化[J]. 安徽农业科学, 2020, 48(11): 190-193. [17] ARANGANATHAN L, RAJASREE S R R, SUMAN T Y, et al. Comparison of molecular characteristics of Type A humic acids derived from fish waste and sugarcane bagasse co-compost influenced by various alkaline extraction protocols[J]. Microchemical Journal, 2019, 149: 104038. doi: 10.1016/j.microc.2019.104038 [18] YANG F, ZHANG S, CHENG K, et al. A hydrothermal process to turn waste biomass into artificial fulvic and humic acids for soil remediation[J]. Science of the Total Environment, 2019, 686: 1140-1151. doi: 10.1016/j.scitotenv.2019.06.045 [19] SHAO Y, BAO M, HUO W, et al. Production of artificial humic acid from biomass residues by a non-catalytic hydrothermal process[J]. Journal of Cleaner Production, 2022, 335: 130302. doi: 10.1016/j.jclepro.2021.130302 [20] RICE J A, MACCARTHY P. Statistical evaluation of the elemental composition of humic substances[J]. Organic Geochemistry, 1991, 17(5): 635-648. doi: 10.1016/0146-6380(91)90006-6 [21] XIAOLI C, SHIMAOKA T, QIANG G, et al. Characterization of humic and fulvic acids extracted from landfill by elemental composition, 13C CP/MAS NMR and TMAH-Py-GC/MS[J]. Waste Management, 2008, 28(5): 896-903. doi: 10.1016/j.wasman.2007.02.004 [22] WANG L, LI A. Hydrothermal treatment coupled with mechanical expression at increased temperature for excess sludge dewatering: The dewatering performance and the characteristics of products[J]. Water Research, 2015, 68: 291-303. doi: 10.1016/j.watres.2014.10.016 [23] LIN Y, WANG D, WANG T. Ethanol production from pulp & paper sludge and monosodium glutamate waste liquor by simultaneous saccharification and fermentation in batch condition[J]. Chemical Engineering Journal, 2012, 191: 31-37. doi: 10.1016/j.cej.2011.09.040 [24] AREEPRASERT C, ZHAO P, MA D, et al. Alternative solid fuel production from paper sludge employing hydrothermal treatment[J]. Energy & Fuels, 2014, 28(2): 1198-1206. -

下载:

下载: