-

城市卫生填埋场中生活垃圾在卫生填埋过程中,经微生物分解、发酵等反应,产生大量有毒有害的垃圾渗滤液,对填埋场周边生态环境系统构成严重危险[1]。垃圾渗滤液的处置流程通常采用“厌氧-缺氧-好氧”组合生物工艺脱氮并降解有机污染物,但要使垃圾渗滤液达标排放,需进一步结合深度处理工艺。在垃圾渗滤液深度处置工艺中,纳滤技术因其优异的污染物去除效果而备受关注,MAGALHAES等[2]通过纳滤膜能够实现90%以上的COD去除率。但纳滤深度处理工艺会产生处理体积约15%~30%的纳滤浓缩液[3]。相较于垃圾渗滤液,垃圾渗滤液纳滤浓缩液中因含有更高浓度的有机难降解污染物、药物污染物、无机盐等[4],使得生化系统难以对其进一步处置,因此,亟需一种垃圾渗滤液纳滤浓缩液生化预处理工艺以提高其可生化性。

垃圾渗滤液纳滤浓缩液常规处理方法有回灌法、蒸发法和高级氧化法[5]。回灌法直接将浓缩液回流至垃圾填埋场填埋层,具有运行简便,处理成本低的优势,但长期回灌会造成填埋场渗滤液水质严重恶化并影响填埋层稳定性[6]。蒸发法通过加热蒸发的方式,可快速处置垃圾渗滤液纳滤浓缩液,但该方法对处置设备的抗腐蚀要求很高[7]。高级氧化法(advanced oxidation processes, AOPs)主要利用强氧化性的活性自由基(羟基自由基(·OH)、氯自由基、超氧自由基等[8])能高效分解、矿化难降解有机污染物,以提高垃圾渗滤液纳滤浓缩液的可生化性,但AOPs也存在药剂消耗量大和运行成本高等问题[9]。臭氧(O3)氧化法是AOPs中广泛应用于污水处理的一种工艺,O3在水体中可形成O3分子、单线态氧和·OH等一系列强氧化自由基[10]。其中O3分子和单线态氧具有选择氧化性,可选择性降解含有不饱和键的物质[11-12],而·OH则可对绝大多数污染物均有较好的去除效果[13]。ZHAO等[14]通过O3预处理渗滤液纳滤浓缩液,COD去除率可达到25%左右,挥发性脂肪酸质量浓度从18.14 mg·L−1提高至101.70 mg·L−1,其中大分子有机污染物可高效转化为可降解小分子有机物,渗滤液纳滤浓缩液的可生化性得到显著提高。HE等[15]构建的γ-Al2O3/O3体系处理垃圾渗滤液浓缩液,在γ-Al2O3投加量为50 g·L−1,O3投加量为22 mg·min−1,初始pH为7.3,反应温度为30 ℃,处理时间为30 min的最佳条件下,COD去除率可达70%,(BOD5/COD)B/C可从0.01提高到0.2。尽管目前O3氧化在催化剂领域的研究取得了良好进展,但O3催化剂在长期运行中的存在严重的失活问题极大限制其实际应用。HE等[16]在O3催化氧化处理实际废水中发现在O3氧化工艺稳定运行12个月后,O3催化剂的催化处理COD效率由56%回落至14.5%。此外,O3在水中较低的溶解度和传质系数导致其利用率低,也阻碍基于O3的AOPs工艺用于垃圾渗滤液纳滤浓缩液的处理。因此,采用新的O3氧化技术应用于垃圾渗滤液纳滤浓缩液的高效处理已成为未来的着重研究的方向。

臭氧微纳米气泡技术(O3/micro-nanobubbles, O3/MNBs)是将微纳米气泡技术与O3氧化技术高效结合的一种工艺。微纳米气泡技术常采用水力空化,通过改变流体水力条件造成局部压力减小而引发空化效应,产生的微纳米气泡尺寸一般为0.2~50 μm,能够在水中停留数小时[17]。这使得O3可以更有加效的溶于水中,改善了O3溶解度低和传质系数低的问题,提高O3利用率[18]。此外,微纳米气泡较小的直径会导致气泡内部产生较高的压力,进一步加大了O3的溶解度[18]。ZHENG等[19]采用O3/MNBs和常规O3法处理晴纶废水,相同条件下,O3/MNBs可实现42%的COD去除率,B/C从0.04提升到0.13,而常规O3法的COD去除率仅有17%,B/C从0.04提升到0.08。当前O3/MNBs在有机污染物降解方面取得了一定的成果,但该技术的应用仍多停留于模拟废水,在实际废水中的应用鲜有报道。

鉴于此,本研究将采用絮凝-O3/MNBs耦合工艺高效处理垃圾渗滤液纳滤浓缩液,探究耦合工艺中絮凝阶段的絮凝剂投加量、絮凝时间、絮凝转速以及O3/MNBs工艺的进气量、反应时间、反应温度等工艺参数对垃圾渗滤液纳滤浓缩液中污染物去除及可生化性的影响。并深入考察了絮凝-O3/MNBs耦合工艺对双酚A(Bisphenol A, BPA)、磺胺嘧啶(Sulfadiazine, SDZ)、磺胺甲恶唑(Sulfamethoxazole, SMX)和萘普生(Naproxen, NPX)等典型药物物质的去除效能。本研究为絮凝-O3/MNBs耦合在垃圾渗滤液纳滤浓缩液预处理工艺的实际工程运用中提供科学的技术支持。

-

实验中所采用的垃圾渗滤液纳滤浓缩液采集自佛山市高明区苗村白石坳垃圾填埋场一厂,渗滤液纳滤浓缩液的基本水质参数:COD为(4752±140) mg·L−1,BOD5为(427±30) mg·L−1。实验试剂甲醇、乙腈、甲酸等为色谱级,聚合硫酸铁(polymerized ferrous sulfate, PFS)、聚丙烯酰胺(polyacrylamide, PAM)、氢氧化钠、硫酸、BPA、SDZ、SMX和NPX等为分析纯,上述试剂均采购自阿拉丁试剂(中国)。实验仪器包括多功能数控消解仪(昌鸿DIS-36B,中国),微纳米气泡发生器(禹创AD-24030,山东),O3发生器(同林3S-TS10,中国),磁力搅拌器(艾卡C-MAG HS-7,德国)。

-

1)絮凝实验。絮凝实验示意图见图1(a),取1 L垃圾渗滤液纳滤浓缩液于烧杯中。置于磁力搅拌器上,加入适量质量浓度为30%的PFS溶液,以600 r·min−1快速混合60 s,随后在一定范围内调节转速,反应结束后加入适量质量分数(3‰)PAM溶液,200 r·min−1搅拌60 s,随后静置10 min,取上清液。絮凝实验选取絮凝时间(0~60 min)、絮凝剂投加量(0~12 g·L−1)及絮凝转速(0~400 r·min−1)为主要的技术参数进行研究,探究絮凝预处理垃圾渗滤液纳滤浓缩液的最优条件,每批实验重复2次。

2) O3/MNBs实验。絮凝实验完成后,取4 L絮凝处理后的垃圾渗滤液纳滤浓缩液(基本水质参数:COD为(1230±37) mg·L−1,BOD5为(270±15) mg·L−1)于O3/MNBs反应器装置中,O3/MNBs反应器装置如图1(b)所示。该装置高30 cm,内径14 cm,水浴层宽2 cm,有效容积4.6 L。本实验中的O3发生器以纯氧为气源产生O3气体,气体中O3的质量浓度为80 mg·L−1,O3气体进入MNBs发生器与垃圾渗滤液纳滤浓缩液絮凝上清液混合,通过高速旋转和加压溶解作用获得含MNBs的水悬浮液。O3/MNBs反应器装置中未反应的O3通过反应器顶部通气孔进入质量浓度为2%碘化钾(KI)吸收液。O3/MNBs高效氧化处理垃圾渗滤液纳滤浓缩液的实验选取O3进气量(50~500 mL·min−1)、初始pH(3~11)和反应温度(10~50 ℃)等为主要影响因素进行研究,考察其对垃圾渗滤液纳滤浓缩液可生化性的影响,每批实验重复3次。

-

1)水质指标分析。化学需氧量采用COD测定仪(哈希DR1010,美国)测定,pH采用pH计(三信SX 751,上海)测定,5天生化需氧量(BOD5)采用BOD测定仪(赛莱默OxiTop IS12,德国)测定,色度和腐殖质采用紫外分光光度计(岛津UV2700,日本)测定,腐殖质以紫外分光光度计在254 nm波长处的吸光度计,色度计算方法[18]如式(1)所示。

式中:C为色度;A436、A525、A620分别为紫外分光光度计在波长为436、525和620 nm波长处的吸光度。

2)药品和个人护理品污染物分析。本研究中的药品和个人护理品(pharmaceutical and personal care products, PPCPs)污染物检测通过固相萃取法富集浓缩,过膜后装入液相小瓶,浓缩后待测样品4 ℃保存。PPCPs污染物采用高效液相色谱仪(赛默飞Ultimate 3000,美国)进行检测,色谱柱型号为AcclaimTM 120 C18(5 μm,4.6 mm×150 mm),检测方法见表1。

3) 发光细菌急性毒性检测。急性毒性检测采用费氏弧菌(金达清创V.fischeri,北京)作为急性毒性检测的实验菌种,急性毒性检测标准采用硫酸锌作为阳性对照,以质量浓度2%的氯化钠溶液作为空白对照。急性毒性检测时将样品加入培养好的V.fischeri菌液,放入生物发光检测仪内振荡10 s,然后置于空气中暴露15 min后,测定发光值。发光抑制率计算方法见式(2),根据不同的发光抑制率判别水质急性毒性风险等级的标准为:E<30%时,属低毒;30%≤E<50%时,属中毒;50%≤E<70%时,属重毒;70%≤E<100%时,属高毒;E≥100%时,属剧毒[20]。

式中:E为发光抑制率,%;I为样品暴露15 min后的发光值;I0为空白组暴露15 min后的发光值。

-

采用絮凝工艺对垃圾渗滤液纳滤浓缩液进行预处理,能有效去除垃圾渗滤液纳滤浓缩液中的胶体和大分子有机物[21],降低后续O3/MNBs工艺的处理能耗,并提高处理效率,对垃圾渗滤液纳滤浓缩液的高效处理有着重要作用。游丽华[22]采用混凝耦合微气泡O3氧化处理焦化废水生化尾水,可实现83.1%的COD去除率,其中混凝工艺去除效果占比可达到46.1%。

本实验所采用的PFS絮凝剂,水解形成[Fe(H2O)6]3+、[Fe2(H2O)3]3+、[Fe(H2O)2]3+等多核络离子可使垃圾渗滤液纳滤浓缩液中的胶体物质脱稳,形成絮体沉降下来以此去除污染物[23]。本实验通过调整絮凝工艺的时间、PFS投加量和絮凝转速等参数研究污染物的最佳去除条件,结果如图2所示。

在PFS投加量为9 g·L−1,絮凝转速为300 r·min−1的条件下,探究了絮凝时间0~60 min对絮凝工艺的影响,结果见图2(a)。可见,垃圾渗滤液纳滤浓缩液的色度、腐殖质及COD的去除率均随絮凝时间的延长而提高,在0~40 min内色度、腐殖质及COD去除率分别达到62.2%、46.9%和69.9%,B/C由0.09增至0.20。但进一步延长絮凝时间至60 min时,色度、腐殖质和COD的去除率分别为69.8%、52.7%和73.7%,B/C增至0.21。这一结果表明,垃圾渗滤液纳滤浓缩液絮凝工艺在0~40 min时,垃圾渗滤液纳滤浓缩液短时间内可形成大量絮体从而达到较高的去除率,但40 min后随着垃圾渗滤液纳滤浓缩液中的大分子污染物浓度的降低,絮体间的碰撞概率减小,去除效果增长有限。

确定最佳絮凝时间为40 min,选取絮凝转速为300 r·min−1,以此探究PFS投加量在0~12 g·L−1时对絮凝效果的影响,结果如图2(b)所示。当PFS投加量为0~2 g·L−1时,垃圾渗滤液纳滤浓缩液的污染物去除效果较差,色度、腐殖质和COD的去除率仅为1.7%、0.5%和7.4%,B/C从0.09增至0.10;而在PFS投加量为4~10 g·L−1时,垃圾渗滤液纳滤浓缩液处理效果随着PFS投加量的增加而明显提高,当PFS投加量为10 g·L−1时,垃圾渗滤液纳滤浓缩液中色度、腐殖质和COD去除率分别提高至79.8%、59.2%和73.3%,B/C增至0.22。这一结果表明,在垃圾渗滤液纳滤浓缩液的PFS投加量为0~2 g·L−1时,形成的多核络离子较少,凝聚的絮体尺寸小、数量少,难以通过良好的网捕卷扫作用去除污染物[24]。随后增加垃圾渗滤液纳滤浓缩液的PFS投加量为4~10 g·L−1,垃圾渗滤液纳滤浓缩液中多核络离子数量也相应增加,这使得胶体与多核络离子不断碰撞脱稳,脱稳胶体进而被络离子吸附形成长链结构,并促进网捕卷扫作用将小絮体沉淀下来[24]。当PFS投加量进一步增加至12 g·L−1时,絮凝处理效果并无显著提高,这是由于过量的絮凝剂会使得絮体表面电荷发生改变,出现胶体再稳现象,去除率无法提高甚至降低[25]。因此,垃圾渗滤液纳滤浓缩液絮凝处理最佳PFS投加量为10 g·L−1。

在最佳絮凝时间40 min,最佳PFS投加量10 g·L−1的条件下,考察0~400 r·min−1转速对絮凝工艺处理效能的影响,结果如图2(c)所示。当转速为0~300 r·min−1时,絮凝效果随转速的增加而提高,色度、腐殖质及COD去除率分别从0 r·min−1的20.4%、14.2%和13.3%提高至300 r·min−1下的79.8%、59.2%和73.3%,B/C由0.18增至0.22。而当絮凝转速增至400 r·min−1时,相较于300 r·min−1垃圾渗滤液纳滤浓缩液絮凝效果出现下降,色度、腐殖质及COD去除率由79.8%、59.2%和73.3%下降至74.0%、55.3%和69.4%,B/C从0.22降至0.21。上述结果表明,适宜搅拌强度是保证PFS、胶体以及絮体间能够充分接触的必要条件,需要注意的是,在搅拌强度过高时,已经形成的絮体会被水的剪切力破碎从而致使去除率下降[26]。

根据以上实验结果,絮凝时间40 min、PFS投加量10 g·L−1、絮凝转速300 r·min−1为垃圾渗滤液纳滤浓缩液最佳絮凝条件。较GU等[27]用PFS处理渗滤液浓缩液的COD去除效果(44.4%)有较大提高。尽管絮凝去除了大部分污染物,絮凝处理后的垃圾渗滤液纳滤浓缩液可生化性依然较差[28],B/C仅为0.22,仍需进一步处理以提高可生化性。

-

1) O3进气量对O3/MNBs技术处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能影响。垃圾渗滤液纳滤浓缩液经絮凝处理后,尽管COD去除率达到73.3%,但B/C仍较低,无法保证后续生物工艺深度处理效果。因此,本实验采用O3/MNBs高级氧化技术进一步提高垃圾渗滤液纳滤浓缩液的可生化性。O3作为氧化剂直接参与氧化反应,其使用量直接影响整个O3/MNBs处理的效果。实验控制O3气体中O3质量浓度为80 mg·L−1,通过改变O3进气量来探究O3投加量对垃圾渗滤液纳滤浓缩液处理效果的影响。

在初始pH为(5.8±0.2)、反应温度为(25±1) ℃的条件下,研究了O3进气量(50~500 mL·min−1)对O3/MNBs处理垃圾渗滤液纳滤浓缩液效果的影响,结果如图3所示。可见,垃圾渗滤液纳滤浓缩液色度、腐殖质及COD去除率由O3进气量为50 mL·min−1条件下的35.3%、60.8%和10.3%提高至400 mL·min−1的77.6%、75.1%和26.5%。但当进一步提高O3进气量,垃圾渗滤液纳滤浓缩液色度、腐殖质及COD的去除率均无明显增效,这与WU等[29]的研究结果相似。与色度、腐殖质及COD去除率随O3进气量增加而逐步上升的情况不同,O3/MNBs出水B/C在低O3进气量时出现了轻微降低的现象,B/C从垃圾渗滤液纳滤浓缩液絮凝处理后出水时的0.22分别降至50 mL·min−1下的0.14和100 mL·min−1下的0.13。进一步增加O3进气量,O3/MNBs出水B/C出现明显改善,在进气量由200 mL·min−1增至400 mL·min−1的条件下,O3/MNBs出水B/C由0.21增至0.44。但当O3进气量进一步增加至500 mL·min−1时,O3/MNBs出水B/C再次降低。这可能是由于水中O3含量较低时,O3优先与可生物降解污染物进行反应,BOD组分浓度下降;随着O3进气量的提高,O3与难以生物降解的耗氧有机物(以COD计)反应逐步占优,分解大分子难降解有机物并生成小分子有机物,BOD组分浓度上升;O3过量时,多余的O3会与·OH反应[30],导致处理效果不佳,垃圾渗滤液纳滤浓缩液的B/C出现下降。综合考虑,O3/MNBs工艺最佳参数O3进气量为400 mL·min−1。O3投加量是影响O3/MNBs效能的重要因素,但并不是唯一因素,可通过调控其他因素来提高O3/MNBs工艺的处理效果。

2)初始pH对O3/MNBs技术处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能影响。O3氧化方式分为O3分子的直接氧化和·OH的间接氧化,·OH氧化还原电位(2.80 eV)比O3分子的氧化还原电位(2.07 eV)更高,具有更强的氧化性,同时,较O3分子选择性氧化,·OH可以对绝大多数污染物进行降解[31]。并且O3分子与·OH在O3/MNBs反应体系内存在如式(3)~(5)的反应过程,两者均与反应体系的pH密切相关:酸性条件下,体系以O3分子为主;而碱性条件下,体系以·OH为主[32]。O3/MNBs工艺通过改变垃圾渗滤液纳滤浓缩液絮凝处理后的出水初始pH,考察初始pH对O3/MNBs技术处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能影响。

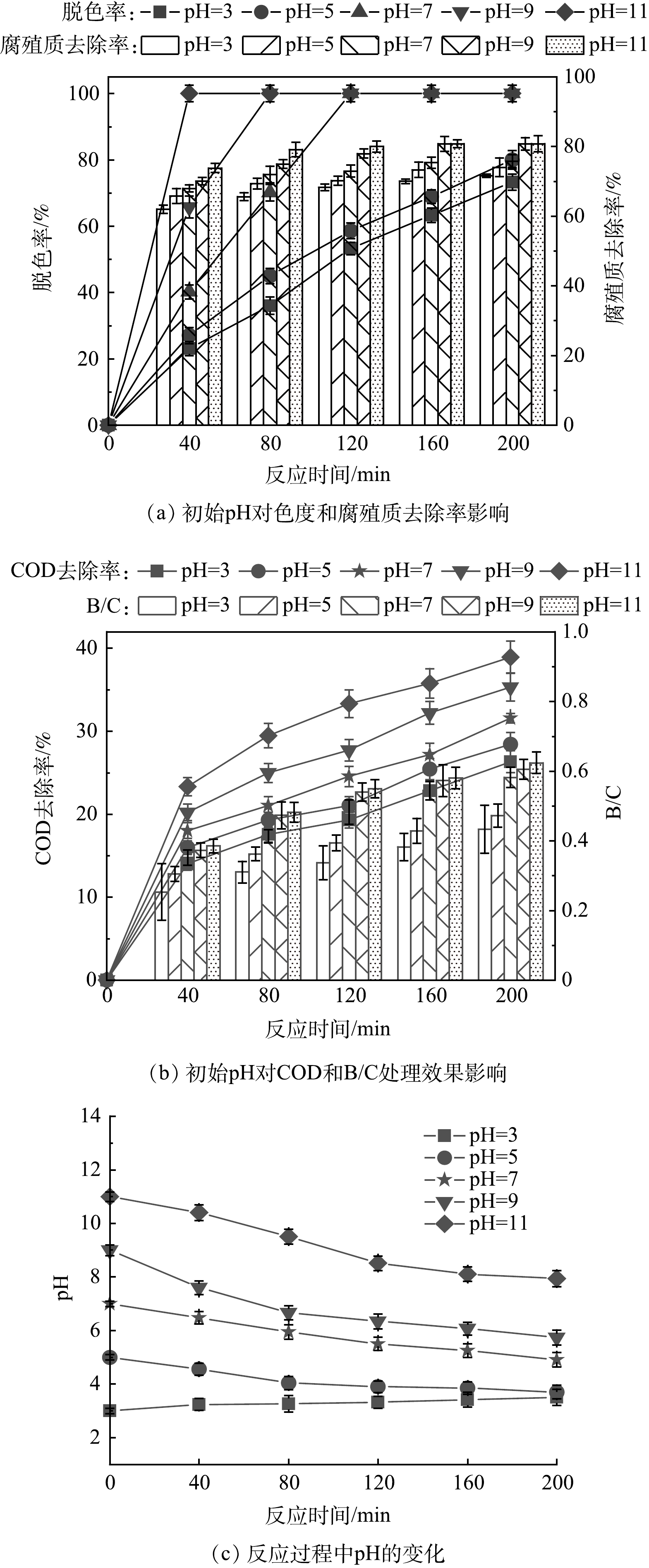

确定最佳O3进气量为400 mL·min−1,在反应温度为(25±1) ℃时,探究初始pH(3、5、7、9、11)对垃圾渗滤液纳滤浓缩液絮凝上清液处理效果的影响,结果如图4所示。由图4(a)可知,当初始pH为3~5时,垃圾渗滤液纳滤浓缩液脱色率随着反应时间一直稳步上升,分别达到了73.3%和80.0%。在pH为7时,色度可完全去除,继续提高初始pH,完全脱色所用时间也越来越短。同时,提高垃圾渗滤液纳滤浓缩液的初始pH对腐殖质去除率也有增益,垃圾渗滤液纳滤浓缩液腐殖质去除率由pH=3时的71.7%增加到pH=11时的80.8%。此外,图4(b)结果显示初始pH对COD去除率和B/C的影响显著,pH=3时,COD去除率为26.3%;pH=11时,COD去除率为38.9%。B/C由pH=3时0.43提高到pH=11时的0.62,垃圾渗滤液纳滤浓缩液的可生化性大幅提升。上述结果表明,提高进水初始pH能够有效提高O3/MNBs体系对垃圾渗滤液纳滤浓缩液絮凝上清液中污染物的去除效果。从反应过程中pH变化(图4(c))可知,在初始pH=3时,反应体系pH从最初的pH=3提高至pH=3.51。这表明O3分子基本未消耗氢氧根离子产生·OH,此时,O3/MNBs反应体系以O3分子氧化为主,使得O3/MNBs体系具有氧化选择性,只能降解含有不饱和键的物质,整体污染物去除率较低[31]。后续提高初始pH,反应过程中pH均成下降趋势,表明O3分子消耗氢氧根离子生成·OH,随着初始pH提高,反应过程中pH下降趋势愈大,这是因为随着氢氧根离子浓度大幅增加,O3分子加速分解为·OH。同时,有研究[33]表明,MNBs表面通常带有负电荷,这意味着阴离子氢氧根将聚集在气-液界面,O3在界面处以更快的速度产生·OH。此外,MNBs的坍缩会产生更多的·OH[34],进一步提高垃圾渗滤液纳滤浓缩液絮凝上清液中的·OH的含量,最终使O3/MNBs工艺进水初始pH=11时,垃圾渗滤液纳滤浓缩液污染物去除率及出水B/C最高。因此,O3/MNBs反应体系处理垃圾渗滤液纳滤浓缩液絮凝上清液的最佳初始pH为11。

3)温度对O3/MNBs技术处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能影响。温度对传统O3氧化的影响较为显著,王新典等[35]研究发现单一O3体系在温度由15 ℃升到65 ℃时,对苯酚溶液的降解率从73.4%提高到89.2%。李玉英等[36]研究了在不同温度条件下,微电解-O3处理水杨酸的效能,水杨酸去除率由15 ℃的78.9%增至30 ℃的96.5%。因此,本实验研究了反应温度对O3/MNBs处理垃圾渗滤液纳滤浓缩液絮凝上清液的影响。

在最佳O3进气量400 mL·min−1,最佳初始pH=11的条件下,考察反应温度10~50 ℃对O3/MNBs处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能影响,结果如图5所示。可见,在反应温度为10 ℃时,色度、腐殖质及COD去除率分别为100.0%、74.7%及33.5%,B/C从0.22增至0.58。反应温度20~50 ℃条件下,垃圾渗滤液纳滤浓缩液的脱色率均在40 min时达到95.0%左右,在80 min可实现色度的完全去除;垃圾渗滤液纳滤浓缩液的腐殖质去除率在80 min时达到80.0%左右,延长反应时间并无明显增效。由图5(b)可见,垃圾渗滤液纳滤浓缩液的COD去除率在20~50 ℃内无显著变化,均随时间逐步提高,最后去除率为37.0%左右;垃圾渗滤液纳滤浓缩液的B/C在20~50 ℃条件下的变化与COD去除率近似,B/C均从0.22增至0.62左右,上述结果表明在反应温度为10 ℃时,O3/MNBs技术处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能会略微降低,这一结果可能是O3分子在水体中存在传质阻力因降温而增大的现象[37],致使O3分子分解缓慢,大量O3分子直接逸散至空气中,参与反应的O3浓度降低。在反应温度20~50 ℃的条件下,O3/MNBs技术处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能均有所提高,这表明升温改善了O3分子传质阻力大的问题。需要注意的是,在反应温度为20~50 ℃时,反应温度从20 ℃增至50 ℃对O3/MNBs处理垃圾渗滤液纳滤浓缩液絮凝上清液的效能无显著影响。这可能是由于随着反应温度的升高,O3的传质效率和反应速率会有所提高,但存在着温度升高O3因分子热运动在垃圾渗滤液纳滤浓缩液中溶解度下降的问题[38]。从反应活化能角度来看,升温会促进溶液中的放热反应,但同时也会抑制存在的吸热反应。垃圾渗滤液纳滤浓缩液含有大量污染物,在O3/MNBs实验中同时发生大量的吸热和放热反应,当垃圾渗滤液纳滤浓缩液中所有放热反应和吸热反应叠加在一起所呈现出来的表观活化能数值比较小时,O3/MNBs体系的反应速率对反应温度的变化就会比较迟钝,体现为反应温度对垃圾渗滤液纳滤浓缩液污染物去除率并无明显影响。这与游丽华[22]研究温度对微气泡O3氧化去除污染物效果得出的结论相似。综合考虑,选择30 ℃为最佳反应温度。综上所述,在O3进气量400 mL·min−1、初始pH=11、反应温度为30 ℃的条件下可以实现O3/MNBs的最佳处理效果。

-

为进一步研究絮凝-O3/MNBs耦合工艺对垃圾渗滤液纳滤浓缩液可生化性的影响,本实验在垃圾渗滤液纳滤浓缩液中选取代表性的PPCPs,如BPA、SDZ、SMX和NPX等药物污染物进行深入研究。有研究表明,现有污水处理厂的活性污泥体系中的微生物无法有效去除大部分PPCPs[39],同时PPCPs会对微生物产生毒害作用[40]。因此,垃圾渗滤液纳滤浓缩液中的高浓度PPCPs的去除对垃圾渗滤液纳滤浓缩液可生化的影响尤为重要。

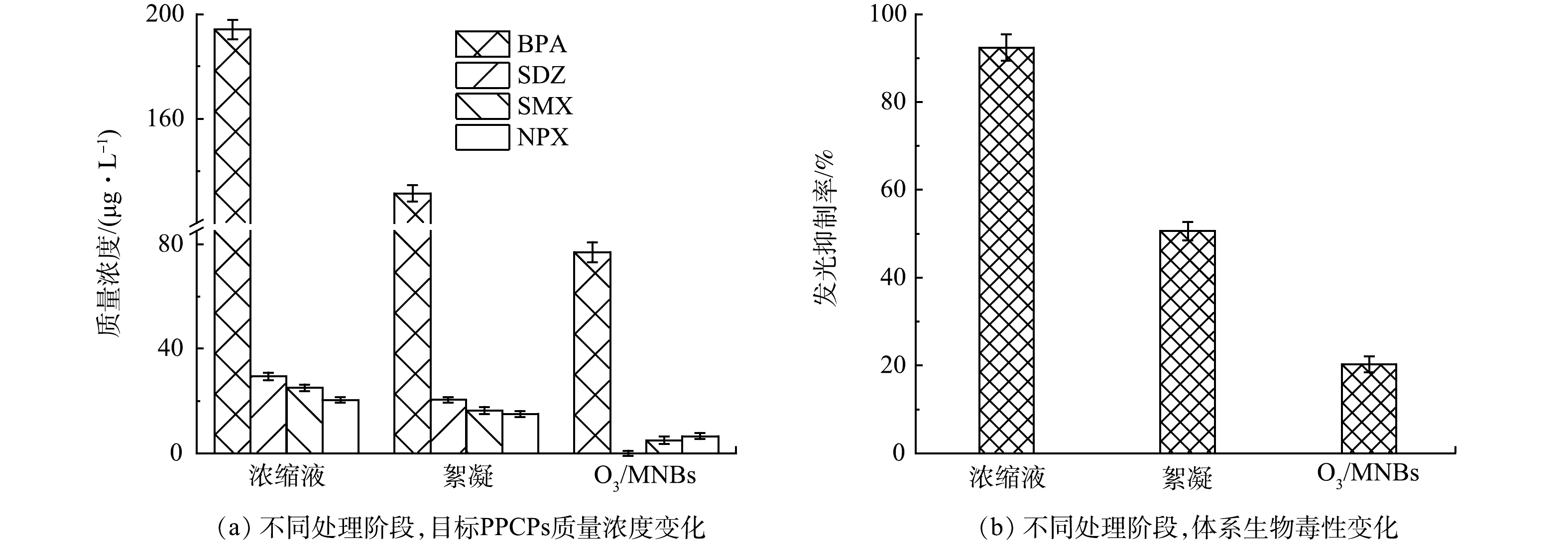

本研究采用的絮凝耦合O3/MNBs工艺对垃圾渗滤液纳滤浓缩液中PPCPs污染物有较高的去除效率,结果如图6(a)所示。最佳条件下的絮凝工艺对垃圾渗滤液纳滤浓缩液中BPA、SDZ、SMX及NPX去除率分别为32.3%、30.8%、34.5%和25.7%,BPA、SDZ、SMX及NPX的质量浓度分别从垃圾渗滤液纳滤浓缩液原液的194.1、29.4、25.0和20.3 μg·L−1降至絮凝工艺出水的131.5、20.3、16.4和15.1 μg·L−1。而在进一步的O3/MNBs处理中,垃圾渗滤液纳滤浓缩液中的BPA、SDZ、SMX和NPX去除率增至60.4%、100.0%、80.4%和67.7%。这一结果表明,垃圾渗滤液纳滤浓缩液通过絮凝工艺去除PPCPs的效能是有限的,絮凝出水进一步通过O3/MNBs工艺处理,才可实现较高的PPCPs去除率。这可能是因为絮凝通过吸附电中和及网捕卷扫作用去除胶体物质,对于非胶体物质,主要通过PFS絮凝剂形成的铁盐氢氧化物网状沉淀裹挟去除[41],PPCPs这类结构尺寸较小的物质可穿过较大孔径的网眼留在垃圾渗滤液纳滤浓缩液絮凝出水中。在进一步的O3/MNBs工艺中,垃圾渗滤液纳滤浓缩液中BPA、SDZ、SMX及NPX等PPCPs通过O3分子和·OH氧化降解[42-45],母体被分解成小分子物质甚至是完全矿化。絮凝-O3/MNBs耦合工艺处理BPA、SDZ、SMX及NPX等难降解物质的过程与垃圾渗滤液纳滤浓缩液中B/C的变化相互验证:絮凝工艺在去除垃圾渗滤液纳滤浓缩液大分子有机物的同时也去除了部分小分子有机物,使得B/C从垃圾渗滤液纳滤浓缩液原液的0.09增至絮凝出水的0.22,可生化性增幅较小,而后的O3/MNBs工艺在降解大分子有机物的同时也生成了小分子有机物,垃圾渗滤液纳滤浓缩液可生化性显著提高,B/C从絮凝出水的0.22增至0.62。

-

垃圾渗滤液纳滤浓缩液因含有高浓度有机物、无机盐和重金属等污染物,具有相当高的生物毒性,本实验采用V.fischeri法检测其生物毒性,并以发光抑制率作为生物毒性的直观体现。垃圾渗滤液纳滤浓缩液原液的发光抑制率高达92.4%,属高毒水体,对于生物工艺的微生物种群有着极高的毒害作用。垃圾渗滤液纳滤浓缩液进行生物处置前,须经预处理工艺降低水质毒性。

在絮凝-O3/MNBs耦合工艺最佳实验条件下,垃圾渗滤液纳滤浓缩液的生物毒性变化如图6(b)所示,絮凝工艺对垃圾渗滤液纳滤浓缩液生物毒性的处理效果非常显著,发光抑制率从垃圾渗滤液纳滤浓缩液原液的92.4%降至垃圾渗滤液纳滤浓缩液絮凝处理出水的50.6%,水质毒性等级从高毒降为重毒,生物毒性大幅降低。而在O3/MNBs中进一步反应,水中的O3分子和·OH通过加成反应、亲电反应、亲核反应和链式反应[13]来使大分子物质发生开环或是断链,有机物分子结构发生变化使得生物毒性降低。此外,O3/MNBs可以对垃圾渗滤液纳滤浓缩液中的重金属络合物进行破络,释放出的部分金属离子水解沉淀,减轻了垃圾渗滤液纳滤浓缩液重金属带来的生物毒性,絮凝处理后的垃圾渗滤液纳滤浓缩液对发光细菌的抑制率从50.6%降至20.3%。水质毒性等级从重毒降为低毒,生物毒性进一步降低。絮凝-O3/MNBs耦合工艺使垃圾渗滤液纳滤浓缩液的生物毒性从92.4%降至20.3%,水质毒性等级从原液的高毒级别降至絮凝-O3/MNBs耦合工艺处理出水的低毒级别,极大减轻了后续生物工艺的负荷,有效提高垃圾渗滤液纳滤浓缩液的可生化性,为垃圾渗滤液纳滤浓缩液进一步生物处置可提供良好的条件。

-

1)在絮凝实验中,在絮凝时间为40 min,PFS投加量为10 g·L−1,絮凝转速为300 r·min−1的最佳条件下,垃圾渗滤液纳滤浓缩液的色度、腐殖质和COD去除率分别达到79.8%、59.2%和73.3%,B/C从0.09增至0.22,垃圾渗滤液纳滤浓缩液的可生化性得到改善,并为后续O3/MNBs工艺的高效处理创造有利条件。

2) O3进气量为400 mL·min−1,初始pH=11,反应温度为30 ℃的条件可以实现O3/MNBs的最佳处理效果,经絮凝处理后的垃圾渗滤液纳滤浓缩液中色度、腐殖质和COD去除率分别为100.0%、80.8%和38.9%,B/C从0.22增至0.62,垃圾渗滤液纳滤浓缩液可生化性得到显著提升。

3)絮凝-O3/MNBs耦合工艺处理垃圾渗滤液纳滤浓缩液的B/C变化及纳滤浓缩液中BPA、SDZ、SMX和NPX等新污染物降解效率的研究一致表明絮凝-O3/MNBs耦合工艺是提升垃圾渗滤液纳滤浓缩液可生化性的有效方法,最佳处置条件下能有效减弱垃圾渗滤液纳滤浓缩液72.1%生物毒性。

絮凝-O3/MNBs耦合工艺高效处理垃圾渗滤液纳滤浓缩液

Efficient treatment of nanofiltration concentrate of landfill leachate through the coupling process of flocculation-O3/MNBs

-

摘要: 针对垃圾渗滤液纳滤浓缩液可生化性极低而无法进行生物处置的问题,本研究采用絮凝-臭氧微纳米气泡(O3/micro-nanobubbles,O3/MNBs)耦合工艺处理垃圾渗滤液纳滤浓缩液以期提高其可生化性。通过改变絮凝工艺的絮凝时间,聚合硫酸铁投加量,絮凝转速以及O3/MNBs工艺的臭氧进气量,初始pH,温度等参数来探究絮凝-O3/MNBs耦合工艺最佳工艺参数。结果表明,在絮凝时间为40 min,聚合硫酸铁投加量为10 g·L−1,絮凝转速为300 r·min−1的最佳絮凝工艺参数下,垃圾渗滤液纳滤浓缩液的色度、腐殖质及COD去除率分别为79.8%、59.2%和73.3%,B/C从0.09增至0.22,生物毒性由92.4%(高毒)降至50.6%(重毒)。垃圾渗滤液纳滤浓缩液絮凝工艺的出水进一步采用O3/MNBs工艺处理,在臭氧进气量为400 mL·min−1,初始pH=11,反应温度为30 ℃的最佳工艺参数下,絮凝出水的色度、腐殖质及COD去除率分别达到100.0%、80.8%和38.9%,B/C由0.22增至0.62,生物毒性由50.6%(重毒)降至20.3%(低毒)。结果表明,絮凝-O3/MNBs耦合工艺是提升垃圾渗滤液纳滤浓缩液可生化性的有效方法。

-

关键词:

- 垃圾渗滤液纳滤浓缩液 /

- 絮凝 /

- 臭氧微纳米气泡 /

- 可生化性

Abstract: Aiming at the problem that nanofiltration concentrate of landfill leachate has the limited bioavailability for biological disposal. In this study, the flocculation-ozone/micro-nanobubbles (O3/MNBs) coupling process was employed to treat nanofiltration concentrate of landfill leachate and improve its bioavailability. The optimal process parameters for the flocculation-O3/MNBs coupling process were explored by adjusting the flocculation time, PFS dosage and flocculation rotation speed in the flocculation process, and O3 inlet volume, initial pH and temperature in the O3/MNBs process. The result showed that at the optimal flocculation process parameters: flocculation time of 40 min, PFS dosage of 10 g·L−1 and flocculation rotation speed of 300 r·min−1, the colorimetry, humus and COD removal rate of nanofiltration concentrate of landfill leachate were 79.8%, 59.2% and 73.3%, respectively, the B/C increased from 0.09 to 0.22, and the biotoxicity decreased from 92.4% (high toxicity) to 50.6% (heavy toxicity). The effluent of flocculation process treating nanofiltration concentrate of landfill leachate was further treated by O3/MNBs process. At the optimal process parameters: O3 inlet volume of 400 mL·min−1, initial pH=11 and reaction temperature of 30°C, the removal rates of chromaticity, humus, and COD of flocculation effluent reached 100.0%, 80.8%, and 38.9%, respectively, and the B/C increased from 0.22 to 0.62, and the biotoxicity was reduced from 50.6% (heavy toxicity) to 20.3% (low toxicity). The results indicated that the flocculation-O3/MNBs coupling process is an effective method to enhance the bioavailability of nanofiltration concentrate of landfill leachate. -

金属镍由于其质地坚硬且具有能够高度磨光、化学稳定性好、耐腐蚀等优点,被广泛应用到金属表面修饰处理中[1]。利用镍进行金属表面修饰处理过程中会产生大量的含镍废水,由于废水中含有的镍离子不能被环境中生物所降解或固化,故存在随着食物链而不断被富集的风险[2]。由于镍是常见的致敏性金属,环境中不断累积的镍将对环境和人类产生严重的危害[3-4]。因此,镍被我国列为典型重金属污染物,属于第一类污染物,在排放前必须进行严格的处理达到国家的排放标准后才能排放。现有的含镍废水常用处理方法有化学沉淀法[5-7]、混凝法[8]、吸附法[9-11]、离子交换法[12-13]、电解法[14-16]和生物法[12-13]等。其中,化学沉淀法由于操作流程简单、运行管理要求低,已被广泛推广到工业应用中。然而,单独的利用化学沉淀处理含镍废水的效果和效率均不能较好的达到生产的要求。

为了提高处理效果,可采用化学沉淀螯合絮凝法来处理含镍废水。生物絮凝剂由于去其具有无毒性可被降解、絮凝效率高等优点,在絮凝处理重金属废水中得到了广泛的关注[17]。已有研究[18]表明,微生物分泌的多糖和蛋白质等具有良好的絮凝能力,脱水污泥中包含有大量的蛋白质和多糖类物质,是制备生物絮凝剂的潜在原料。已有研究人员利用脱水污泥为原料发酵生产生物絮凝剂,然而该方法操作复杂,且耗时较长,培养条件苛刻,制备成本较高。因此,直接提取脱水污泥中的有效絮凝成分成为了降低生物絮凝剂成本的理想方法。

本研究以脱水污泥为原料,提取生物絮凝剂,考察了不同提取方法对脱水污泥中絮凝有效成分的提取影响,确定了最优的脱水污泥提取絮凝剂方法,以期降低生物絮凝剂的生产成本;同时,采用化学沉淀螯合生物絮凝的方法处理含镍废水,考察了不同化学沉淀剂与生物絮凝剂螯合工艺处理含镍废水的能力,并且采用Plackett-Burman设计法结合响应曲面法筛选优化了化学沉淀螯合生物絮凝处理含镍废水的工艺参数。本研究取得的结果可为化学沉淀螯合生物絮凝处理含镍废水的工业应用提供有效的数据参考。

1. 材料与方法

1.1 实验原料

实验过程中使用到的硝酸镍、氢氧化钠、氢氧化钙、氯化钙、高岭土等化学药剂均为分析纯。生物絮凝剂为实验室从脱水污泥提取的生物絮凝剂。脱水污泥取自佛山禅城某生活污水处理厂的污泥脱水机房(污泥含水率为77%,有机质含量为36.78%),该污水处理厂处理工艺采用UNITANK工艺,污泥取回后,按固液比(1:7)的比例加入纯水,充分混匀后静置去除上清液,重复清洗3遍污泥后,清洗后的脱水污泥利用冷冻干燥机进行冷冻干燥成粉末状。

1.2 实验仪器

数显恒温水浴锅(HH-S2,常州万达升实验仪器有限公司);超声波清洗仪(GTSONIC-D20,广东固特超声股份有限公司);冷冻高速离心机(FC-18R,广州市方统生物科技有限公司);台式全温振荡器(ZQTY-70S,上海知楚仪器有限公司);原子吸收分光光度计(200AA,安捷伦科技有限公司);紫外-可见光分光光度计(UV-1800,日本岛津制作所);电子分析天平(AS 220.RS,RADWAG公司);pH计(ST-2100,美国OHAUS公司);恒温磁力搅拌器(HJ-6B,常州朗越仪器制造有限公司);六联混凝实验搅拌机(ZR4-6,常州德图精密仪器有限公司);冷冻干燥机(LGJ-10D,北京四环科学仪器厂有限公司)。

1.3 实验方法

1)生物絮凝剂的制备实验。每次取冻干脱水污泥3 g,分别在不同pH下,以超声(40 kHz)、离心(12 000 r·min−1 )和加热(80 ℃)两两组合的方式进行提取,具体的提取操作如下表1所示。将提取后的生物絮凝剂提取液进行冷冻冻干为粉末,该粉末为生物絮凝剂的成品。

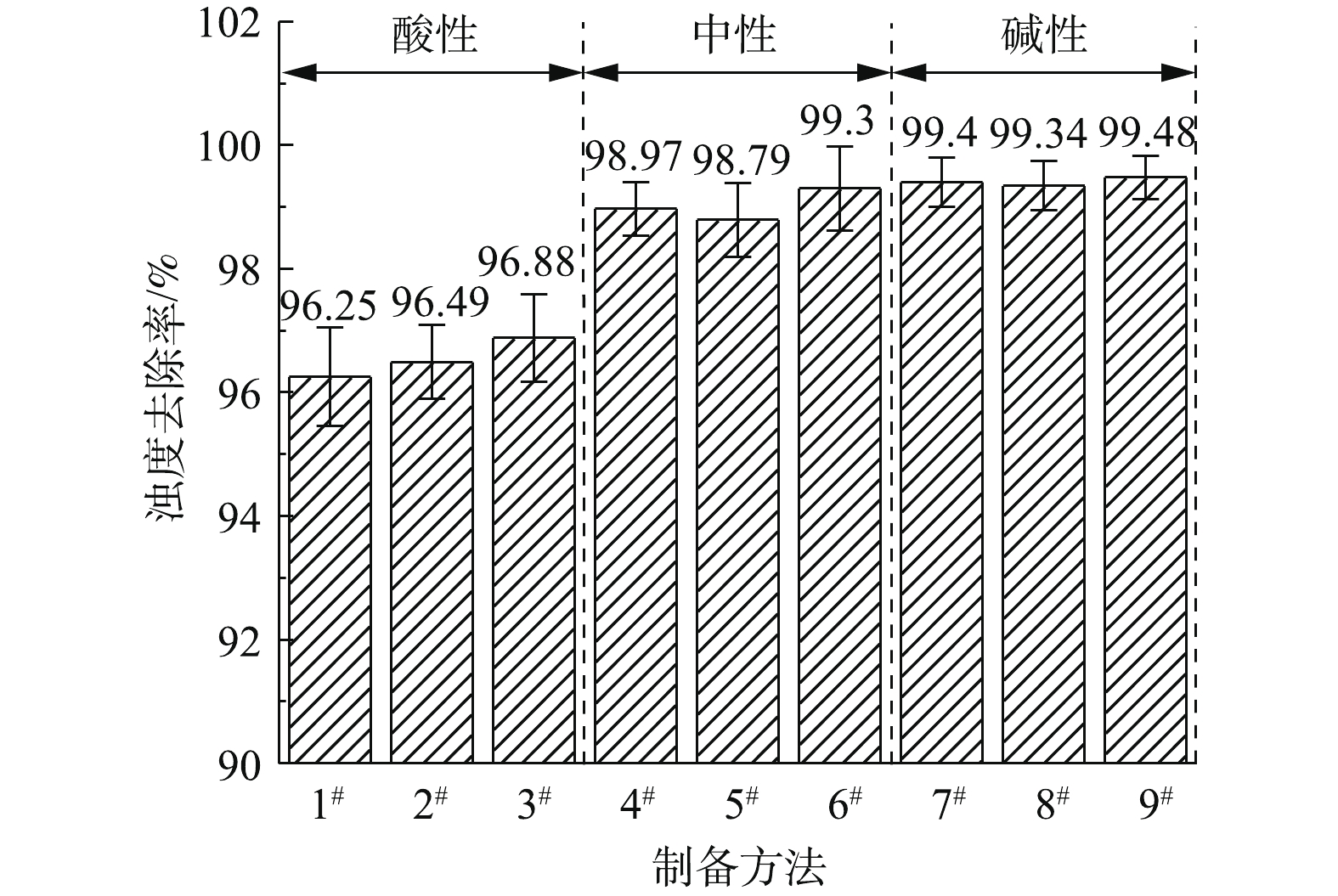

表 1 提取操作参数Table 1. Extraction operation parameters编号 pH 加热/min 超声/min 离心/min 1# 2 − 10 10 2# 2 10 10 − 3# 2 10 − 10 4# 7 − 10 10 5# 7 10 10 − 6# 7 10 − 10 7# 12 − 10 10 8# 12 10 10 − 9# 12 10 − 10 分别称取制备的1#~9#粉末生物絮凝剂100 mg,投加到100 mL的5 g·L−1高岭土悬浮液中,加入100 mg氯化钙后,以160 r·min−1快搅40 s、80 r·min−1 慢搅260 s后,静置15 min。以上清液浊度的去除率作为评价生物絮凝剂的性能指标,浊度的去除率按式(1)计算。每组实验设3个平行样,以3组平行样的平均值为最终实验结果。取浊度去除率最高的制备方法为生物絮凝剂的最终制备方法。

η=Ci−CeCi×100% (1) 式中:η为去除率,%;

Ci 为初始浊度,NTU;Ce 为处理后上清液浊度,NTU。2)重金属沉淀剂的筛选实验。分别考察氢氧化钙、氢氧化钠及其用量对含镍废水中镍离子的沉淀效果,筛选确定重金属沉淀剂的种类和用量。配置50 mg·L−1的模拟含镍废水,分别往100 mL模拟废水中投加氢氧化钙和氢氧化钠,其浓度分别为100、90、80、70、60和50 mg·L−1,以160 r·min−1 快搅2 min后,投加10 mg氯化钙和10 mg生物絮凝剂后,再以160 r·min−1 快搅40 s、80 r·min−1 慢搅260 s后,静置沉淀30 min,取上清液测定溶液中镍离子的含量。每组实验设3个平行样,以3组平行样的平均值为最终实验结果。

3)实验设计优化沉淀螯合生物絮凝处理工艺参数。Plackett-Burman设计法筛选影响沉淀螯合生物絮凝处理工艺的显著因素。根据重金属沉淀剂筛选实验的结果,选择重金属沉淀剂的投量(X1)、氯化钙的投加量(X2)、生物絮凝剂的投加量(X3)、絮凝搅拌强度(X4)、沉淀时间(X5)作为可控因素进行设计,设计7个因子及实验次数12次的Plackett-Burman实验设计,以筛选影响沉淀螯合生物絮凝处理工艺的显著因素,同时预留2个虚拟变量(X6和X7)作为误差分析。每个因素分别取低水平(−1)和高水平(+1) 2个水平,以模拟废水中镍离子的去除率为评价指标,采用Minitab 17进行实验设计、数据分析及模型建立。Plackett-Burman实验设计的设计因素水平及编码见表2。

表 2 Plackett-Burman设计实验设计因素水平及编码Table 2. Levels and factors of Plackett-Burman experiment因素 编码 各水平编码取值 1 −1 重金属沉淀剂投加量/(mg·L-1) X1 50 25 氯化钙投加量/(mg·L-1) X2 50 0 生物絮凝剂的投加量/(mg·L-1) X3 100 50 絮凝搅拌强度/(r·min-1) X4 50 25 沉淀时间/(min) X5 30 10 空项 X6 -1 1 空项 X7 -1 1 4)响应曲面分析法优化沉淀螯合生物絮凝处理工艺的最佳参数。以Plackett-Burman设计法的筛选出的显著因素进行Box-Behnken实验设计,采用Minitab17对实验进行回归分析并且进行误差分析,建立显著因素与响应值之间的函数关系,对沉淀螯合生物絮凝处理工艺的工艺参数进行优化设计,建立预测模型。

5)验证实验。利用Box-Behnken实验设计预测模型预测最优的工艺参数进行3次平行实验,取平均值,与预测的去除率进行比较,从而验证模型的可靠性,进而得出最终优化结果。

2. 结果与讨论

2.1 制备方法对生物絮凝剂的絮凝效果的影响

脱水污泥中包含有大量的蛋白质和多糖类物质,已有研究表明,微生物分泌的多糖和蛋白质等具有良好的絮凝能力。为了提高生物絮凝剂的絮凝性能,首先需要将污泥中的絮凝成分有效提取出来。单一的提取方法效率较低,现采用多种提取方法组合来提高污泥中的絮凝成分的提取效率。采用不同组合提取方法对生物絮凝剂的絮凝效果的影响如图1所示。由图1可以看出,随着提取的环境的pH提高,提取的生物絮凝剂的絮凝效果逐渐提高。由于碱性条件下能破坏微生物的结构,同时改变絮凝有效成分的水溶性,从而使更多的絮凝有效成分得以释放,进而提高了生物絮凝剂的絮凝效果。同时,不同酸碱度的提取环境,可能也改变了提取的生物絮凝剂的表面电荷。碱性条件下提取的生物絮凝剂由于大量的氢氧根的存在,中和了生物絮凝剂表面的氢离子,提高了生物絮凝剂表面的有效吸附位点。同时,通过碱性提取的生物絮凝剂其表面存在与重金属离子相反的电荷,有利于生物絮凝剂与重金属离子及其沉淀物的相互接触,减少生物絮凝剂与重金属离子之间的相互斥力减弱,从而有利于生物絮凝剂与重金属沉淀物之间的桥联作用,促进架桥形成和颗粒沉淀。在碱性条件下,超声+离心(7#)、加热+超声(8#)和加热+离心(9#)的不同组合提取的生物絮凝剂的絮凝效果较为接近,以加热+离心的组合絮凝效果组合最好。因为加热能够有效的破坏污泥的结构,释放更多的有效组分,辅助高速离心,能更有效的将释放的有效组分从污泥中分离出来,提高其提取率[19-21]。因此,生物絮凝剂的最佳提取方法为在碱性条件下,80 ℃加热10 min后再以12000 r·min−1离心10 min。

2.2 重金属沉淀剂的筛选实验

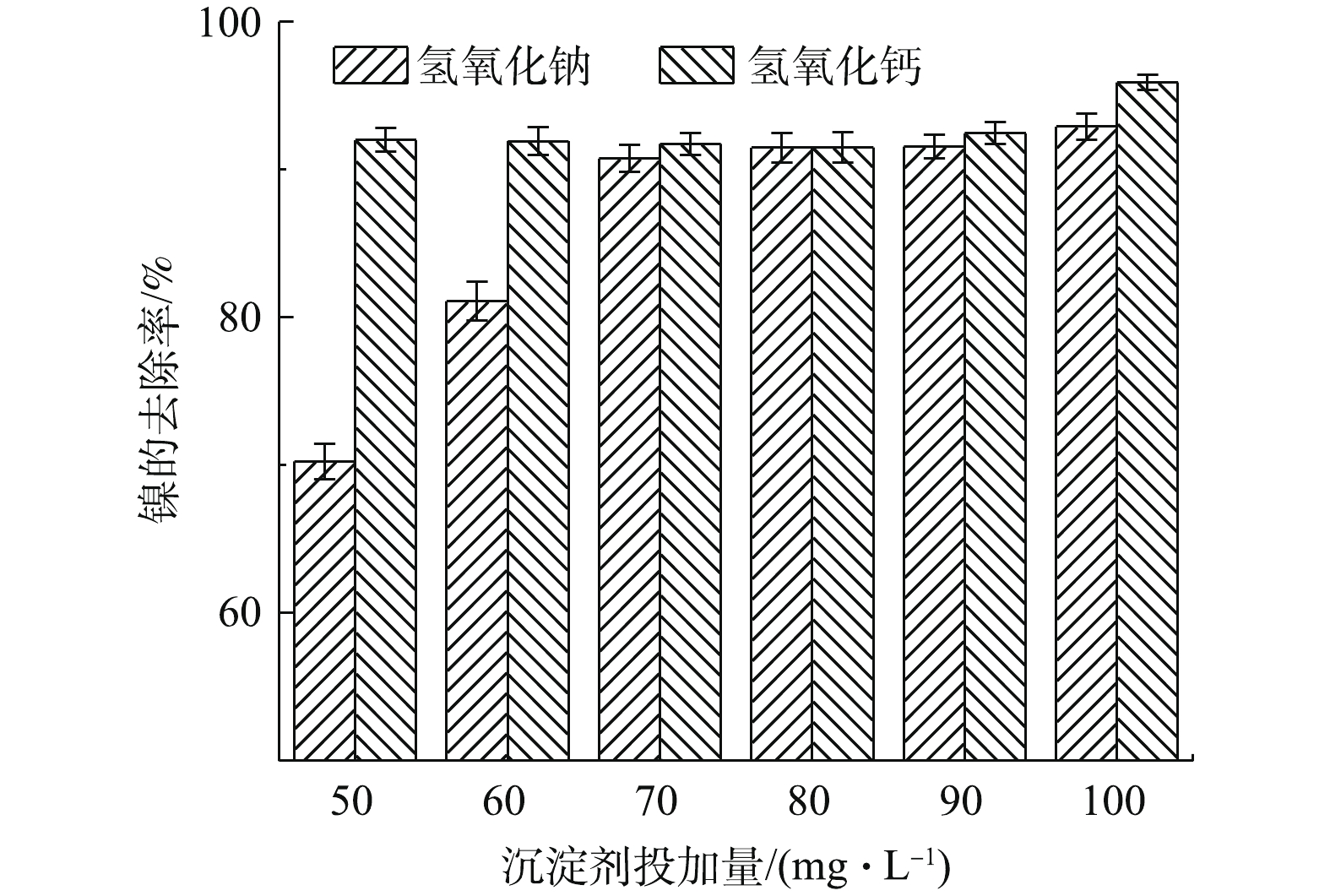

针对重金属镍的处理常将离子态镍转化成氢氧化镍不溶物,再利用混凝沉淀的方法去除。本实验选择氢氧化钠和氢氧化钙作为沉淀剂,考察其与生物絮凝剂协同处理含镍废水。如图2所示,在沉淀剂投加量的大于70 mg·L−1时,氢氧化钠螯合生物絮凝和氢氧化钙螯合生物絮凝处理镍的效果比较接近,镍去除率均超过90%。然而,在沉淀剂投加量小于70 mg·L−1时,氢氧化钠螯合生物絮凝较氢氧化钙螯合生物絮凝处理镍的效果差。钙离子可以加强生物絮凝剂的桥联作用和中和作用,同时可以通过中和作用,增强生物絮凝剂对颗粒物的最初吸附,进而强化微粒间的架桥作用,激发絮凝活性。已有的研究表明,钙离子浓度增加能够有效提高絮凝效果[22]。选用氢氧化钙作为沉淀剂,在同等投加量的情况下,体系的钙离子浓度较氢氧化钠体系的要高,进而较氢氧化钠的处理效果好。因此,确定使用氢氧化钙作为沉淀螯合生物絮凝的重金属沉淀剂。

2.3 沉淀螯合生物絮凝处理含镍废水的显著因素筛选实验

根据表2的影响因素与水平,利用Plackett-Burman设计法进行实验设计,共12组实验,每组实验进行3次,结果取平均值。Plackett-Burman实验设计及结果如表3所示。

表 3 Plackett-Burman实验设计及响应值Table 3. Experimental design and response factors of Plackett-Burman experiment编号 因素 Ni(II)平均去除率/% X1 X2 X3 X4 X5 X6 X7 1 −1 −1 −1 −1 −1 −1 −1 48.31 2 −1 1 −1 −1 −1 1 1 45.68 3 −1 1 1 1 −1 1 1 71.88 4 1 1 1 −1 1 1 −1 99.86 5 1 1 −1 1 −1 −1 −1 95.78 6 −1 1 1 −1 1 −1 −1 69.63 7 1 −1 −1 −1 1 1 1 93.62 8 1 1 −1 1 1 −1 1 94.44 9 1 −1 1 1 −1 1 −1 99.90 10 −1 −1 1 1 1 −1 1 65.25 11 −1 −1 −1 1 1 1 −1 37.74 12 1 −1 1 −1 −1 −1 1 99.48 利用Minitab17对Plackett-Burman设计的各因素水平及响应值进行方差分析评价,评价结果如表4所示。由表4可以看出,实验模型的P为0.001,远远小于0.05,说明实验模型回归方程是显著的,拟合性好[23]。t和P用于检验因素影响的显著性,因素影响约显著,t值越大,P值越小。由表4中各因素水平的t值和P值大小可以看出,沉淀螯合生物絮凝处理含镍废水的操作因素的影响因子依次为X1> X3> X2> X4 >X5。其中絮凝搅拌强度的P值为0.745<0.8,沉淀时间P值为0.997,即絮凝搅拌强度和沉淀时间对于实验结果的影响均小于20%,说明絮凝搅拌强度和沉淀时间对实验结果影响不显著。重金属沉淀剂投加量和生物絮凝剂的投加量的P值均小于0.01,说明重金属沉淀剂投加量和生物絮凝剂的投加量为影响实验结果的显著因素,确定其为Box-Behnken实验的关键因素。同时,考虑到氯化钙的投加量对生物絮凝剂存在一定的促进作用,故将氯化钙投加量也列为Box-Behnken实验的关键因素。

表 4 Plackett-Burman 实验分析结果Table 4. Analytic result of Plackett-Burman experiment因素 t P 显著性排序 X1 10.23 0.000 1 X2 1.38 0.217 3 X3 3.78 0.009 2 X4 0.35 0.737 4 X5 −0.02 0.984 5 模型 0.001 2.4 沉淀螯合生物絮凝处理含镍废水预测模型的建立

运用响应曲面法预测最优工艺条件的优势在于设计的实验次数少、能建立高精度的回归方程、预测准确性高。因此,利用响应曲面优化分析法研究重金属沉淀剂投加量、生物絮凝剂的投加量和氯化钙投加量3个因素,对沉淀螯合生物絮凝处理含镍废水影响的作用,在实验范围内对吸附条件进行优化。本实验采用Box-Behnken响应面优化实验设计分别在低(−1)、中(0)、高(1)的3个水平上对吸附实验进行中心复合设计,设计3因子3水平的响应面分析实验,中心点设置3次重复。同时,由表4的t值可以看出,重金属沉淀剂投加量、生物絮凝剂的投加量和氯化钙投加量的t值均大于0,说明其为正效应,去除率应依次增大,因此确定实验的范围采用Plackett-Burman实验设计的相应水平,实验因子及水平和实验结果如表5和表6所示。

表 5 Box-Behnken自变量因素及其水平Table 5. Factors and levels of Box-Behnken design因素 编码 各水平编码取值 −1 0 1 氢氧化钙投加量/(mg·L−1) X1 25 37.5 50 氯化钙投加量/(mg·L−1) X2 0 25 50 生物絮凝剂的投加量/(mg·L−1) X3 50 75 100 表 6 Box-Behnken实验设计及其响应值Table 6. Experimental design and response factors of Box-Behnken experiment编号 因素 Ni(II)平均去除率/% X1 X2 X3 1 −1 1 0 68.93 2 0 −1 −1 80.18 3 0 −1 1 88.83 4 0 0 0 82.25 5 0 0 0 87.76 6 −1 0 −1 57.53 7 −1 0 1 69.77 8 0 1 −1 76.39 9 0 1 1 88.85 10 −1 −1 0 62.95 11 1 1 0 95.46 12 1 0 1 98.90 13 1 −1 0 99.86 14 0 0 0 83.48 15 1 0 −1 93.08 利用Minitab 17对Box-Behnken设计的各因素水平及响应值进行回归拟合分析,回归方程如式(2)所示。

Y=−0.382+0.3439X1+0.0134X2+0.0679X3−0.02115X12+0.00070X22−0.00219X32−0.00774X1X2−0.00513X1X3+0.00152X2X3 (2) 同时,进行了显著性和方差分析评价,回归模型的R2=0.990 1,这表明改模型拟合程度良好,仅有0.99%的变异不能由该模型解释,说明实验设计可靠。显著性和方差分析分析结果如表7所示。由表7可见,回归模型P=0.000<0.05,这说明拟合的回归模型是显著的,预测模型能很好地解释实验数据的变异性;模型的失拟项P为0.859,表明模型失拟不显著,说明预测模型较为稳定,可以与实验数据进行较好地拟合。同时,由线性P值可以看出,模型线性影响是显著的,而平方影响和交互作用影响的P值均大于0.05,说明其影响是不显著的,实验因子对响应值的影响为线性关系。

表 7 Box-Behnken实验结果方差分析Table 7. Analysis of variance (ANOVA) test for Box-Behnken experiment result来源 自由度 F P 回归模型 9 55.84 0.000 线性 3 161.39 0.000 X1 1 442.31 0.000 X2 1 0.06 0.815 X3 1 41.81 0.001 平方 3 3.43 0.109 交互作用 3 2.71 0.155 误差 5 失拟 3 0.25 0.859 纯误差 2 合计 14 2.5 验证和优化

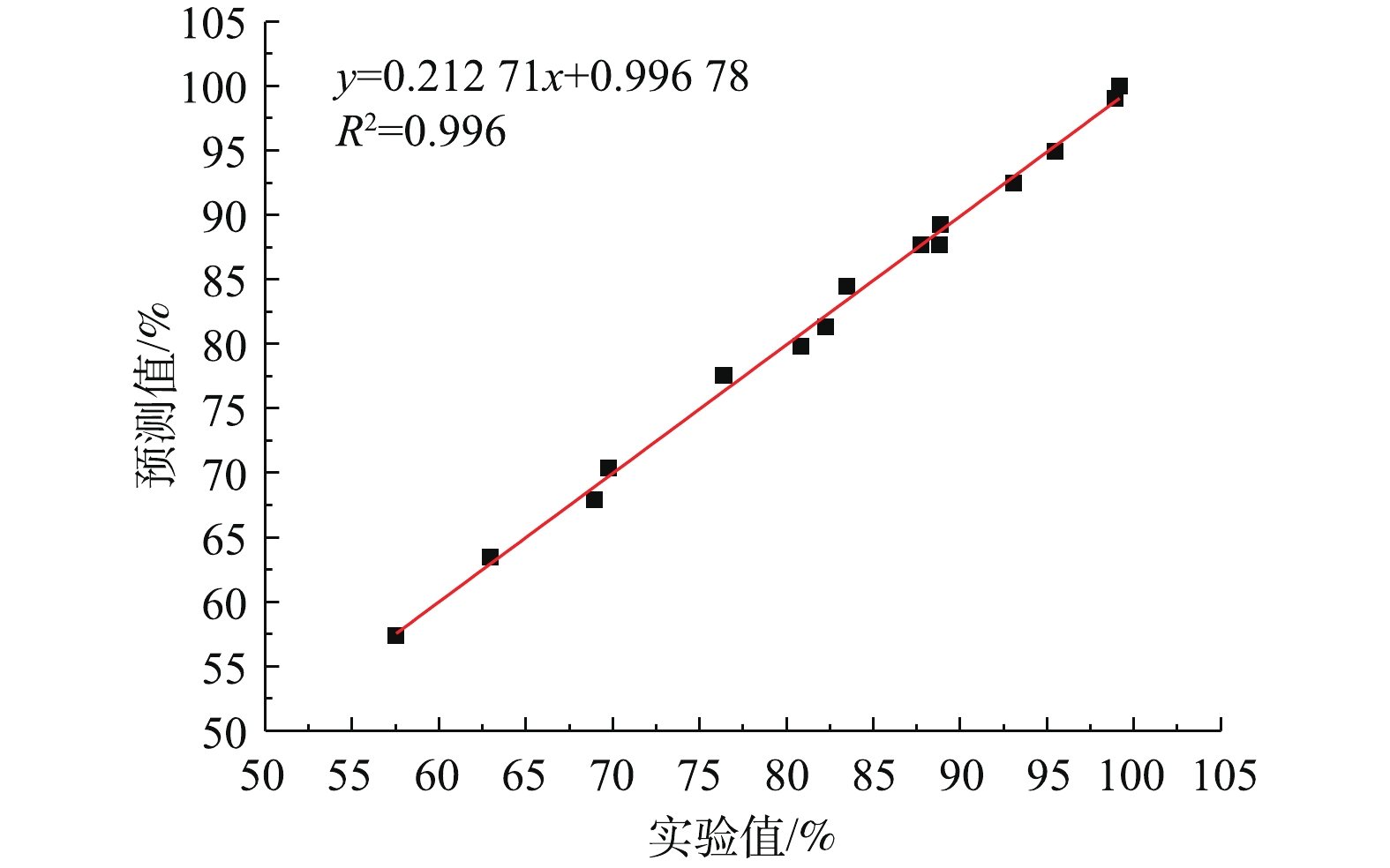

根据模型预测的Ni(Ⅱ)去除率与实验值进行拟合,拟合结果如图3所示。由图3可知,预测值与实验值的线性拟合R2为0.996,说明模型预测的结果能够很好的跟实际实验结果吻合,说明该模型能够用于氢氧化钙耦合生物絮凝剂处理含Ni(Ⅱ)的废水中。在Ni(Ⅱ)初始浓度50 mg·L−1的条件下,根据软件预测最大的去除率为100%时,工艺参数优化条件为:氢氧化钙投加量为50 mg·L−1,氯化钙投加量为0 mg·L−1,生物絮凝剂投加量为73.35 mg·L−1。根据该条件,在实验室所能达到的精度线,对回归分析结果进行了实验验证,3次重复实验结果分别为99.35%、99.16%和99.2%,实验结果均与预测结果基本吻合,表明优化结果与拟合方程合理,能够较准确反映氢氧化钙投加量、氯化钙投加量和生物絮凝剂投加量对沉淀螯合生物絮凝处理含Ni(Ⅱ)废水的影响情况。

3. 结论

1)碱性条件有利于脱水污泥中絮凝有效成分的提取,生物絮凝剂的提取方法为在碱性条件下、80 ℃加热10 min后,再以12 000 r·min−1离心10 min。

2)氢氧化钙作为沉淀剂能够有效提高沉淀螯合生物絮凝剂处理含镍废水的处理效果。

3)沉淀螯合生物处理含镍废水中镍的影响因素的显著性为重金属沉淀剂投加量>生物絮凝剂的投加量>氯化钙投加量>絮凝搅拌强度>沉淀时间,其中,重金属沉淀剂投加量(P=0)和生物絮凝剂的投加量(P=0.009)为主要的控制因素。

4) Box-Behnken响应面优化拟合模型能有效吻合实际处理效果(R2=0.990 1),根据模型预测,处理50 mg·L−1含镍废水的最优处理工艺参数为:氢氧化钙投加量为50 mg·L−1,生物絮凝剂投加量为73.35 mg·L−1,在此条件下,Ni(Ⅱ)的去除率可达99%以上。

-

表 1 PPCPs污染物检测条件

Table 1. Detection conditions for PPCPs contaminants

污染物 流动相比例 流速/(mL·min−1) 检测波长/nm 温度/℃ 双酚A 甲醇∶超纯水=70∶30 1.0 225 30 萘普生 甲醇∶0.1%甲酸水=70∶30 1.0 254 30 磺胺嘧啶 甲醇∶0.1%甲酸水=35∶65 1.0 269 30 磺胺甲恶唑 甲醇∶0.1%甲酸水=35∶65 1.0 275 30 -

[1] ABDEL-SHAFY H I, IBRAHIM A M, AL-SULAIMAN A M, et al. Landfill leachate: sources, nature, organic composition, and treatment: An environmental overview[J]. Ain Shams Engineering Journal, 2024, 15(1): 102293. doi: 10.1016/j.asej.2023.102293 [2] AMARAL M C S, MORAVIA W G, LANGE L C, et al. Nanofiltration as post-treatment of MBR treating landfill leachate[J]. Desalination and Water Treatment, 2015, 53(6): 1482-1491. doi: 10.1080/19443994.2014.943061 [3] VAN DER BRUGGEN B, LEJON L, VANDECASTEELE C. Reuse, treatment, and discharge of the concentrate of pressure-driven membrane processes[J]. Environmental Science & Technology, 2003, 37(17): 3733-3738. [4] KEYIKOGLU R, KARATAS O, REZANIA H, et al. A review on treatment of membrane concentrates generated from landfill leachate treatment processes[J]. Separation and Purification Technology, 2021, 259: 118182. doi: 10.1016/j.seppur.2020.118182 [5] 杨亚新. 紫外催化湿式氧化处理垃圾渗滤液纳滤浓缩液的实验研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. [6] 蒋宝军, 李俊生, 杨威, 等. 垃圾渗滤液反渗透浓缩液回灌处理中试研究[J]. 哈尔滨商业大学学报(自然科学版), 2006, 22(6): 36-40. [7] 岳东北, 许玉东, 何亮, 等. 浸没燃烧蒸发工艺处理浓缩渗滤液[J]. 中国给水排水, 2005(7): 71-73. [8] 王磊. 超重力高级氧化法降解水中双酚A的研究[D]. 北京: 北京化工大学, 2022. [9] 何硕, 黄祯晶, 李柏瑛, 等. 高级氧化法处理废水的赤泥综合利用研究进展[J]. 中国资源综合利用, 2023, 41(7): 112-117. [10] 敖蒙蒙, 刘利, 魏健, 等. β-内酰胺类抗生素臭氧氧化机理与降解途径[J]. 土木与环境工程学报(中英文), 2021, 43(6): 187-196. [11] JAE-WUK K, JUWON L, SOOK-HYUN N, et al. Evaluation of the prediction of micropollutant elimination during bromide ion-containing industrial wastewater ozonation using the ROH, O3 value[J]. Chemosphere, 2023, 338: 139450. doi: 10.1016/j.chemosphere.2023.139450 [12] KASHYAP A, RAMASAMY E, RAMALINGAM V, et al. Supramolecular control of singlet oxygen generation[J]. Molecules, 2021, 26(9): 2673. doi: 10.3390/molecules26092673 [13] 邝江濛. 两种典型PPCPs的臭氧氧化降解及机理研究[D]. 北京: 清华大学, 2013. [14] HAORAN Z, LIANPEI Z, MENGTING J, et al. Ozone pretreatment combined with partial denitrification-anammox process for efficient nitrogen removal from nanofiltration concentrate of landfill leachate[J]. Chemical Engineering Journal, 2023, 471: 144641. doi: 10.1016/j.cej.2023.144641 [15] HE Y, ZHANG H, LI J, et al. Treatment of landfill leachate reverse osmosis concentrate from by catalytic ozonation with γ-Al2O3[J]. Environmental Engineering Science, 2017, 35(5): 501-511. [16] HE C, WANG J, WANG C, et al. Catalytic ozonation of bio-treated coking wastewater in continuous pilot- and full-scale system: Efficiency, catalyst deactivation and in-situ regeneration[J]. Water Research, 2020, 183: 116090. doi: 10.1016/j.watres.2020.116090 [17] 张志强, 常娜, 王社平, 等. 微纳米气泡物化特性及其水处理应用研究进展[J]. 中国给水排水, 2023, 39(4): 24-30. [18] HU L, CHEN B, MA J. Micro-/nano- bubbles ozonation for effective industrial wastewater remediation: from lab to pilot-scale application[J]. Journal of Environmental Chemical Engineering, 2023, 11(5): 110807. doi: 10.1016/j.jece.2023.110807 [19] ZHENG T, WANG Q, ZHANG T, et al. Microbubble enhanced ozonation process for advanced treatment of wastewater produced in acrylic fiber manufacturing industry[J]. Journal of Hazardous Materials, 2015, 287: 412-420. doi: 10.1016/j.jhazmat.2015.01.069 [20] 那广水, 张月梅, 陈彤, 等. 发光细菌法评价排污口污水中总有机污染物毒性[J]. 中国环境监测, 2010, 26(5): 61-64. [21] 潘碌亭, 吴锦峰. 聚合硫酸铁制备技术的研究与进展[J]. 工业水处理, 2009, 29(9): 1-5. doi: 10.11894/1005-829x.2009.29(9).1 [22] 游丽华. 混凝和微气泡臭氧氧化组合处理焦化废水生化尾水[D]. 武汉: 华中科技大学, 2020. [23] 高鹏, 任更波, 李本行, 等. 絮凝耦合过硫酸钠氧化处理实际含糖废水[J]. 环境工程学报, 2023, 17(4): 1206-1215. doi: 10.12030/j.cjee.202301016 [24] WU X, GE X, WANG D, et al. Distinct coagulation mechanism and model between alum and high Al13-PACl[J]. Colloids & Surfaces A Physicochemical & Engineering Aspects, 2007, 305(1-3): 89-96. [25] 陈金垒, 龚佳昕, 苏善煜, 等. 聚合硫酸铁对水中聚乙烯微塑料的混凝效果与机理研究[J]. 安全与环境学报, 2024, 24(02): 695-702. [26] CAO S, CHEN L, ZHAO M, et al. Advanced treatment of phosphorus pesticide wastewater using an integrated process of coagulation and ozone catalytic oxidation[J]. Catalysts, 2022, 12(1): 103. doi: 10.3390/catal12010103 [27] GU Z, CHEN W, HE C, et al. Molecular insights into the transformation of refractory organic matter in landfill leachate nanofiltration concentrates during a flocculation and O3/H2O2 treatment[J]. Journal of Hazardous Materials, 2022, 435: 128973. doi: 10.1016/j.jhazmat.2022.128973 [28] AL-MOMANI F, TOURAUD E, DEGORCE-DUMAS J R, et al. Biodegradability enhancement of textile dyes and textile wastewater by VUV photolysis[J]. Journal of Photochemistry and Photobiology A:Chemistry, 2002, 153(1): 191-197. [29] WU C, ZHOU Y, SUN X, et al. The recent development of advanced wastewater treatment by ozone and biological aerated filter[J]. Environmental Science and Pollution Research, 2018, 25(12): 1-15. [30] WEI S, XU H, LI G, et al. Coagulation and ozonation treatment of biologically treated wastewater from recycled paper pulping industry: Effect on the change of organic compounds[J]. Environmental Science and Pollution Research, 2023, 30(40): 92482-92494. doi: 10.1007/s11356-023-28803-3 [31] 郑广宏, 于蕾, 夏邦天, 等. 臭氧技术处理印染废水研究进展[J]. 工业用水与废水, 2009, 40(2): 6-10. [32] 钟理, 张浩, 陈英, 等. 臭氧在水中的自分解动力学及反应机理[J]. 华南理工大学学报(自然科学版), 2002(2): 83-86. [33] LIU Y, WANG S, SHI L, et al. Enhanced degradation of atrazine by microbubble ozonation[J]. Environmental Science:Water Research & Technology, 2020, 6(6): 1681-1687. [34] TAKAHASHI M, CHIBA K, LI P. Free-radical generation from collapsing microbubbles in the absence of a dynamic stimulus[J]. The Journal of Physical Chemistry B, 2007, 111(6): 1343-1347. doi: 10.1021/jp0669254 [35] 王新典, 王韶峰, 匡佳, 等. 臭氧—过氧化氢体系处理含苯酚废水的探究[J]. 云南化工, 2023, 50(8): 72-75. [36] 李玉英, 苏琪, 王海燕, 等. 微电解-臭氧化协同降解水杨酸的动力学及毒性研究[J]. 工业水处理, 2019, 39(1): 60-64. [37] 王帅, 况欣怡, 赵紫琴, 等. 高浓度羟基自由基水对室内生物气溶胶消杀的实验研究[J/OL]. 化学工业与工程, 1-7. [2024-02-05].https://doi.org/10.13353/j.issn.1004.9533.20220834. [38] OUEDERNI A, MORA J C, BES R S. Ozone absorption in water: mass transfer and solubility[J]. Ozone:Science & Engineering, 1987, 9(1): 1-12. [39] 贺德春, 郑密密, 黄伟, 等. 污水处理过程中典型PPCPs的污染特征及降解转化研究进展[J/OL]. 环境科学, 1-20. [2024-02-05].https://doi.org/10.13227/j.hjkx.202305189. [40] PRANGYA R R, TIAN C Z, PUSPENDU B, et al. Treatment technologies for emerging contaminants in wastewater treatment plants: A review[J]. Science of the Total Environment, 2021, 753: 141990. doi: 10.1016/j.scitotenv.2020.141990 [41] PACKHAM R F. Some studies of the coagulation of dispersed clays with hydrolyzing salts[J]. Journal of Colloid Science, 1965, 20(1): 81-92. doi: 10.1016/0095-8522(65)90094-2 [42] 王培良, 钱锋, 宋永会, 等. 臭氧氧化降解水中磺胺嘧啶的机理研究[J]. 环境工程技术学报, 2017, 7(4): 451-456. [43] 徐超, 毛晶璘, 冯继勤. 臭氧氧化萘普生的机理及其动力学研究[J]. 浙江工业大学学报, 2014, 42(1): 31-36. [44] 陈娇玉, 孟冠华, 魏旺, 等. 臭氧氧化双酚A的性能及机理[J]. 过程工程学报, 2020, 20(2): 230-236. [45] 金昊, 马富媛, 柴柳英, 等. 臭氧对8种磺胺类抗生素降解效果研究[J]. 生物化工, 2019, 5(2): 57-59. -

DownLoad:

DownLoad: