-

赤泥 (red mud,RM) 是铝土矿精炼氧化铝时产生的废弃物,据统计平均每吨氧化铝生产过程中就会产生1~1.8 t RM[1],我国为氧化铝生产大国,2021年RM产量约为1.12×108 t。拜耳法生产氧化铝流程下产生的RM主要成分是Fe2O3[2] ,呈强碱性。以往RM的处理方式主要为露天堆放,不仅占用大量的土地资源,还会造成土壤和水体的污染。目前RM资源化利用的方向包括回收有价金属、制备混凝剂及吸附剂和作为建筑材料进行利用,然而目前其综合利用率很低 (约8%) ,因此亟需开发其新的资源利用方式。近年来RM作为催化剂的潜力受到了众多研究者的关注,RM由于富含氧化铁,常作为廉价的Fe基催化剂使用。据报道,RM作为催化剂有促进焦油裂解的效果[3-6],在降酸升级生物油中具有取代HZSM-5的潜力[6-7]。特别是有研究提出RM有定向催化能力,例如有文献提出RM可以酮化热解产物中油/气产物,增强酮和醛的选择性生产[8-10],而另一些文献提出RM催化生物质热解可以有效生产芳烃[11-16]。造成这样不同的定向催化效果可能和选用的RM中Na、Ca等原有成分差异或后续负载的不同元素有关[17-18],另外还需要考虑煅烧等活化前处理中造成RM中主要活性组分Fe基价态发生的变化对催化效果的影响。

人造板是利用木材在加工过程中产生的边角废料,添加胶粘剂制作的板材。2021年我国人造板总产量约为3.37×108 m3,按照10%的报废率,年产废弃人造板十分可观。传统的处理方式 (填埋或燃烧) 由于人造板中3%~15%粘合剂的限制会造成环境污染与资源浪费,例如填埋会占用大量土地资源,且板材里的粘合剂难以降解导致人造板降解时间长。而燃烧可以通过提升原料颗粒温度[19]、促进氮中间体破裂等途径提高人造板中杂原子 (氮、氯等) 向小分子气体的转化率[20-21],造成环境污染。人造板热解相对于燃烧可以减少或调节氮释放[19, 22]以促进其清洁利用,还可以回收高附加值的生物油。因此,本研究提出一种利用RM催化热解人造板以实现以废治废的策略,为RM和人造板的消纳提供了新的途径。由于人造板既包含生物质,又包含作为粘合剂等使用的聚合物,导致其产物和热解机理相对单纯生物质或聚合物更加复杂。AHMED等[23]研究了低密度聚乙烯和松木的共热解,发现二者存在协同效应,协同反应增强了油产率且导致油中脂肪族C-C含量增加,而添加RM催化共热解后消除了生物质与塑料中间体之间的协同作用,从而提高了气体产率。RYU等[24]研究了木质素和聚丙烯在RM催化下的共热解,发现RM进一步提高了裂解效率,且增强了含氧中间体 (例如呋喃) 和烯烃之间的Diels-Alder反应,产生大量芳烃。目前关于RM催化热解生物质与聚合物混合原料方面的研究十分有限,热解过程中生物质和聚合物之间的协同作用和催化机理仍需要深入研究。另外,关于RM催化人造板热解实现协同处理的相关文献十分欠缺。此外,RM在前处理活化 (煅烧) 、热解过程以及循环利用中,主要催化物质Fe基会发生晶相、价态变化。而鲜少有研究者关注RM的成分变化对其催化效果的影响,这对确定RM前处理活化参数、循环利用次数以及通过焙烧还原后进行Fe回收的理论基础十分重要,亟需进一步的研究。

本研究通过热重、TG-FTIR-MS、GC-MS多种手段对RM催化等温和非等温热解进行研究。研究了RM催化热解人造板的机理,并调查了RM添加比例以及RM热解时铁氧化物成分变化对催化效果的影响,并在固定床上研究了RM与炭的复合材料的催化效果以探索RM作为添加剂循环利用的可能性。

-

人造板为某废弃木质碎屑压型加工而成的,其粉碎至180 μm以下,样品工业分析和元素分析见表1。可以看到人造板的挥发分高达73%,固定碳含量低,易着火,好燃尽。同时元素分析表明,其氮,硫含量较高,可能是由于人造板中含有部分胶粘剂的原因。拜尔法RM的元素分析见表2,可以看到RM中还含有6.49%的碱及碱土金属,在热解过程中具有促进气化,协同催化的作用[11, 18]。拜尔法RM含有44.06%的Fe2O3,因此RM可以作为廉价易得的铁基添加剂使用。为使RM与人造板粉末混合均匀,采用湿浸渍法处理混合的RM和人造板 (即加入去离子水后在45 ℃下振荡3 h,并在110 ℃下烘干6 h) 。将RM和人造板粉末分别单独放置在坩埚中,在500 ℃下还原性气氛下热处理2 h和4 h,得到的改性RM (modified red mud) 样品分别称为MRM2*和MRM4*。

-

拜尔法RM利用X射线荧光光谱仪 (XRF) Bruker S8 Tiger进行分析,原始拜耳法RM、经过改性后的MRM2*和MRM4*通过X射线衍射仪 (XRD) Bruker D8 ADVANC进行分析,使用Jade软件对XRD谱图进行分析。热重实验中采用的热重分析仪为热重分析仪 (耐驰STA449F5) ,TG-FTIR-MS联用实验中采用热分析红外气质联用 (STA8000-Spectrum 3-Clarus690 SQ8C) 。管式炉实验装置主要由通气装置、高温管式炉装置 (KJ-T1 700,郑州科佳电炉有限公司,最大功率为5 kW,最高调节温度为1 500 ℃,升温速率为10 ℃·min−1,刚玉管内径60 mm,刚玉瓷舟大小为100 mm×40 mm×22 mm) 组成。收集的焦油用气相色谱仪GC-MS (Shinadzu GC-2010)进行分析测试。

-

1) 热重实验。在室温至1 000 ℃间对人造板以及人造板混合不同比例的RM以5、10、20 ℃·min−1进行热分析。RM与人造板通过浸渍法混合,具体为RM和人造板的混合粉末加入去离子水后在45 ℃下振荡3 h,并在110 ℃下烘干6 h。人造板简称为R,人造板与10%的RM混合后制成的样品成为0.1RMR,RM以20%、30%比例混合人造板时制成的样品以此类推,分别为0.2RMR、0.3RMR。

2) TG-FTIR-MS联用。分别将RM、MRM4*以8%的比例与人造板通过浸渍法混合。得到的混合物RMR,MRM4*R以及人造板R分别在40 mL·min−1的氦气下以20 mL·min−1的速率进行加热。FTIR用于对热解过程中产生的气体进行分析,MS用于确定热解过程中主要产生的常见气体进行分析,典型热解气体产品包括H2 (m/z=2) 、CH4 (m/z=16) 、CO (m/z=28) 、CO2 (m/z=44) 。

3) 恒温管式炉实验。在管式炉上进行了RM原位催化人造板的热解实验,载气为100 mL·min−1的氮气,取1 g样品在500 ℃进行热解实验,热解时间为30 min,出气口末端接有焦油冷却装置,用二氯甲烷冲洗冷却管壁上的残留焦油以及稀释混合收集到的焦油溶液,充分稀释后的溶液在GC-MS上进行分析。

-

由于RM作为添加剂的存在,0.1RMR、0.2RMR、0.3RMR的热重曲线并不能反映人造板粉末真实失重,故对RM在相同工况下进行测试作为空白组对照,人造板的真实热重曲线及转化率α见式(1)、(2)。本研究中所有热重曲线均采用该处理方式。

式中:mR,t为添加RM后人造板的t时刻的真实失重,质量分数%;mt为热重实验t时刻的失重,质量分数%;MRM,t为RM空白组热重t时刻的失重,质量分数%;λ为RM添加比例,质量分数%;m0为初始时刻失重,质量分数%;m∞为终止时刻时候失重,质量分数%;。

热重曲线利用DAEM (Distributed Activation Energy Model) 模型进行处理,DAEM模型广泛应用于分析复杂的化学反应,例如生物质或煤的热解。DAEM模型假定分解反应由大量平行、独立一级反应组成,这些反应具有不同的活化能,使整体分解反应的活化能以一定函数形式f (E) 连续分布。DAEM方程求解十分复杂,MIURA等[25]提出了无分布方法,该方法不需要预先规定活化能分布,大大化简了方程的求解。Miura简化式见式(3)。

式中:β为加热速率,以In(β/T2)与1/T为纵横坐标拟合曲线,通过斜率和截距可求得样品的表观活化能和频率因子。

-

RM热处理过程中,铁基化合物的晶相和成分都可能变化[26],RM、MRM2*和MRM4*的晶相分析见图1。可以看到RM中Fe基主相为α-Fe2O3,改性煅烧2 h后出现磁赤铁矿γ-Fe2O3晶相,这是部分α-Fe2O3转化而来的。同时,热解初期氧化铝中结晶水释放,有利于改善RM的孔隙结构[27-28]。改性煅烧4 h后,铁基物质主相变为Fe3O4。这是由于Fe2O3在还原性气氛中失氧,进一步向磁铁矿和铁单质转化。且热解4 h后部分Fe和Ti相互融合形成新的矿物,RM部分失活活性。该过程如式(4)所示。

因此RM作为添加剂使用前可以在还原性气氛中进行煅烧前处理,煅烧时间应小于4 h,推荐煅烧时间为2 h左右。据报道[29],γ-Fe2O3相对于α-Fe2O3具有更丰富的酸位点,因此导致更高的催化活性;而Fe2O3相对于Fe3O4具有更强的还原能力,因此具有更强的促进焦炭裂解的能力[30],因此Fe2O3向Fe3O4的转化可能导致催化活性的减弱或者不同的催化产物。有关对比Fe2+和Fe3+催化能力的相关文献较少,需要进一步分析。因此选取主相分别为α-Fe2O3和Fe3O4的RM和MRM4*的催化机理在下文TG-FTIR-MS中进行分析。

-

如图2所示,可以看到,加入RM后人造板热解过程中经历3个失重峰,第一个失重峰发生在50~150 ℃,主要是由于脱水和少量挥发分析出;第二个失重峰发生在170-470 ℃,主要是由于大量挥发分的释放;由图2中不同加热速率下DTG可以发现,在600-700 ℃下有1个很小的失重峰,可能与炭化阶段脱芳重组有关;第四个失重峰仅在RM催化人造板热解曲线中700-900 ℃下出现,且由于热解在惰性气氛氦气中进行,该失重峰可能是由于RM影响了焦炭的芳香性并促进了焦炭的二次裂解,而非通过Boudouard反应焦炭气化。由图2中各加热速率下的TG曲线可知,添加RM后人造板的整体失重增加,特别是650 ℃以后的持续失重,且大体上呈现总失重率随RM添加量增加而增加的趋势。加入RM后人造板的最大失重峰不仅“加深”了,其失重速率所在温度Tmax也有所提前,且发现低升温速率(≤10 ℃/min)下Tmax随RM添加比例增加呈现先减小,后在添加比例≥30%后缓慢增加的趋势,如表3所示。需要说明的是,此时认为RM对人造板传热传质的影响很小,一是因为热重实验中样品量很小,RM的密度又远高于人造板粉末,因此实验中分散在人造板粉末中的RM粉末量认为很少,对传热传质的影响可以忽略。二是如果RM对传热传质的影响会显著影响热重曲线,那么该影响在更高的升温速率和RM添加比例下会更显著,且均会促进4个失重峰峰值温度的提前。如表3所示,各失重峰峰值所在温度随RM添加比例增加的变化趋势并不一致且非单向减少,Tmax也未随RM添加比例或加热速率增加时呈现越来越明显的下降趋势。

利用DAEM模型对各RM添加比例下人造板的TG曲线进行活化能的计算,结果如图3所示。由于当转化率≥0.8时,计算得到的活化能开始大幅上升,可能由于此时生物质处于炭化阶段,此时芳构化反应和缩聚反应需要较高的活化能,且此时计算结果误差变大,故图中仅显示转化率在0.1~0.7间的活化能计算结果,计算的R2≥0.9。如图,人造板热解的活化能随转化率由0.1增至0.2间先显著降低,后缓慢增加。初始人造板的热解活化能较高可能是因为人造板中的胶合剂存在,使得人造板中生物质升温速率缓慢,且热解产物难以逸散。随RM添加比例增加,初始活化能 (转化率≤0.2) 和整体活化能先降低后增加。这说明过量的RM可能不利于人造板的热解,因此建议添加比例应≤30%。

-

1) 热质联用的热重结果。如图4所示,对比RM和MRM4*的催化效果时,可以看到RMR和MRM4*R失重曲线大致相同,说明MRM4*仍能有效地催化人造板,其对人造板失重的效果和RM相似。由微分失重曲线中可以发现,RM对于第一失重峰促进效果更明显,说明RM有效促进了人造板的脱水,而MRM4*R第二峰和第四峰的失重速率略高于RMR,说明MRM4*对挥发分释放阶段和炭化阶段挥发分的析出有更显著的促进作用。这说明RM中铁氧化物成分变化会影响RM在不同热解阶段的催化效果。

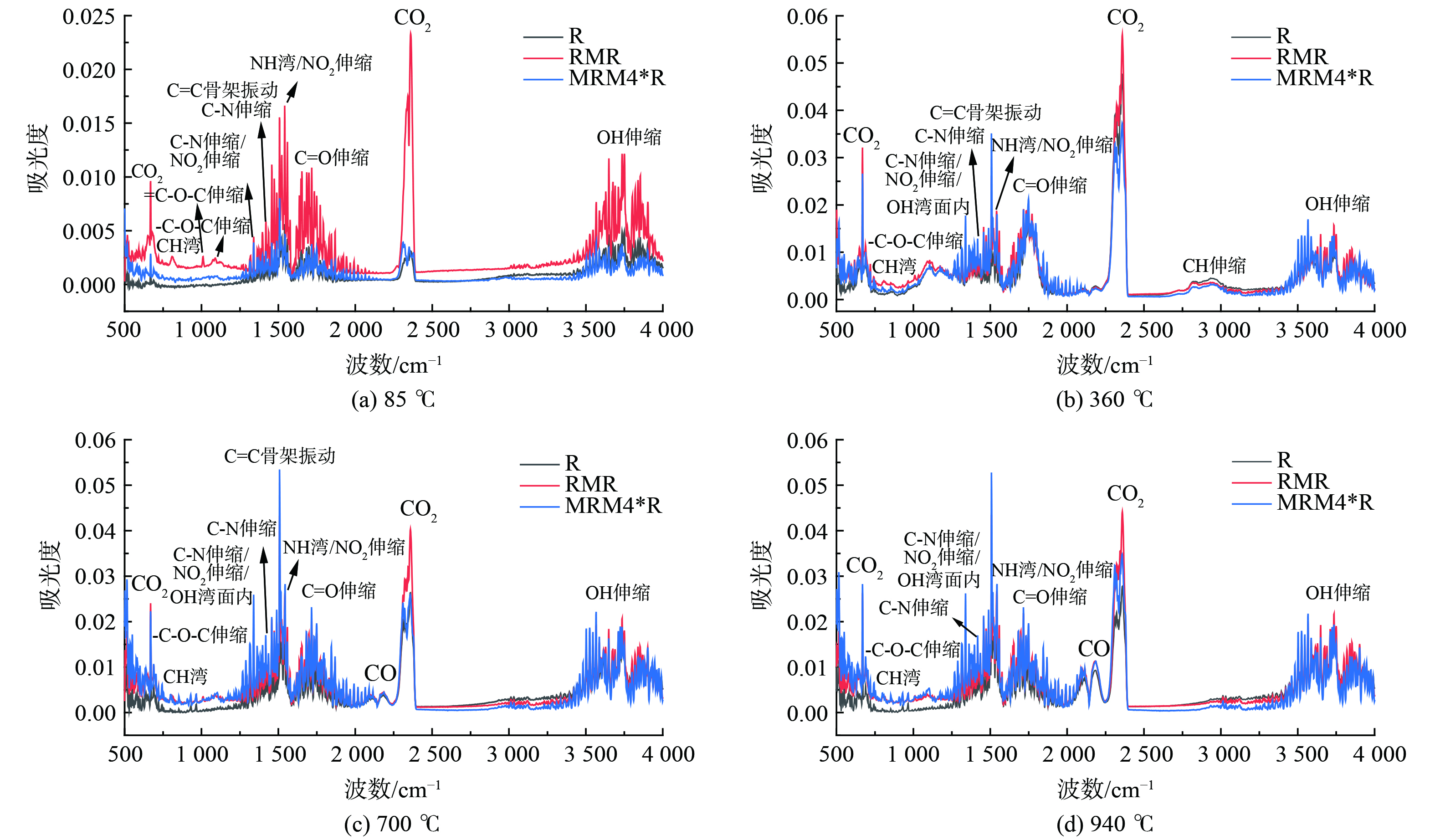

2) 热质联用的红外结果。图5为R、RMR以及MRM4*R在热解过程中挥发性产物的红外谱图,如图所示3个样品的红外谱图相似,部分区域仅在特定温度下出现或显著增强。如图在250~400 ℃温度区间内,位于2 780~3 000 cm−1、2 216~2 400 cm−1、1 720~1 810 cm−1、927~1 311 cm−1以及617~742 cm−1区域内的红外特征峰强度明显加强,400 ℃后强度显著下降。上述特征峰分别代表烷烃的C-H键、CO2的C=O键、酰卤/酸酐/酯/酸/饱和脂肪醛的C=O键、酰卤的C-C键或酸酐/醇/醚/酯的C-O键以及C-Cl/ C-Br键的红外吸收峰强度。说明在250~400 ℃阶段产生的挥发分产物主要包括烷烃、CO2、酰卤、酸酐以及酯等。其中,250~325 ℃温度区间位于930和966 cm−1代表NH3的红外吸收峰出现,280~400 ℃温度区间位于2 780~3 000 cm−1代表烷烃的红外吸收峰出现。3 015 cm−1处代表CH4的红外特征峰在400 ℃后出现且随温度增加而增强,但600 ℃后该特征峰强度显著下降。700 ℃后1 508 cm−1、2 216~2 400 cm−1、2 020~2 250 cm−1区域分别代表C=C骨架振动、CO2、CO的红外吸收峰强度增强,说明此时可能焦炭发生了二次裂解,产生了大量芳香化合物,其中芳环侧链的含氧基团断裂产生小分子气体CO2、CO。

对比R、RMR以及MRM4*R在4个失重峰的最大失重速率所在温度的挥发分产物的红外谱图。由图6(a)可以看到,RMR的红外吸收峰强度显著高于R和MRM4*R,说明RM显著的提高了废弃人造板的低温下的反应性。1 600~1 875 cm−1、1 540~1 580 cm−1、1 340~1 460 cm−1区域分别代表酸或酰胺的C=O伸缩振动,胺或酰胺的NH弯曲振动或硝基取代芳环的NO2伸缩振动,胺或酰胺的CN伸缩振动。上述峰显著高于其他两样品,说明RM促进人造板第一失重峰的最大失重速率所在温度降低,并且第一失重峰的最大失重速率增加可能是通过促进了人造板的胶合剂中含氮化合物例如酰胺或硝基取代化合物提前分解和断裂。同时,RMR在85 ℃处CO2的红外特征峰强度显著高于R和MRM4*R,可能是由于RM显著促进酰胺断裂后C=O键转化而来。3 300~4 000 cm−1区域对应游离羟基或分子内氢键的OH伸缩振动,RMR红外谱图中这部分红外吸收峰强度显著增加,可能来源于热解过程中RM受热后AlO(OH)中结晶水的脱除。MRM4*R的各红外吸收峰均低于RMR,但MRM4*R在1 340、1 508 cm−1处的红外吸收峰仍高于R,说明MRM4*R在反应初始阶段也有一定促进人造板中酰胺分解的作用,但其作用相对于RM已大大削弱。

如图6(b),在大量挥发分释放的阶段,发现MRM4*和RM的催化效果有所不同。对比RMR和R可以发现RM显著的促进了代表酮、酸的C=O伸缩键,代表醚的-C-O-C伸缩键以及CO2的红外吸收峰,另外代表苯环的C=C骨架振动的红外吸收峰也有所增强,说明RM显著的促进了人造板中芳香化合物的释放和芳环侧链的裂解。对比MRM4*R和R,MRM4*R谱图中代表芳环中C=C骨架振动的红外吸收峰的增加十分显著,而代表CO2的红外吸收峰强度下降。说明MRM4*主要促进挥发分中芳香化合物的产生,对芳环侧链含氧基团进一步裂解为小分子的促进作用相对于RM减弱。另外,代表芳酸、芳酮中C=O伸缩键的1 539~1 699 cm−1区域的红外吸收峰强度下降,代表环酸酐的C=O伸缩键和C-O伸缩键的1 750~1 870 cm−1区域以及1 200~1 300 cm−1区域增红外吸收峰强度增加。说明MRM4*催化的人造板热解中CO2释放减少很可能是因为芳环侧链的羰基、羧基发生了环化缩合生成了环酸酐,使得羰基、羧基断裂的活化能增高,更难以破裂。另外,处于3 461~3 587 cm−1和1 268~1 434 cm−1区域,代表芳香胺的NH伸缩键和C-N伸缩键的吸收峰强度相比于R和RMR增强,说明MRM4*可能促进了芳香胺的生成。另外发现700 ℃以上温度下MRM4*R的CO2红外吸收峰的强度强于R,可能是MRM4*促进了环酸酐在高温中破裂,产生了CO2。

3) 热质联用的质谱结果。由于FTIR只能分析官能团,因此对主要合成气CO (m/z=28) 、CO2 (m/z=44) 、CH4 (m/z=16) 、H2 (m/z=2) 进行质谱检测,如图7所示。可以发现RM和MRM4*显著的促进了合成气的产生,同时发现RM和MRM4*对合成气催化效果有所不同,CO2和CO的质谱结果中RMR样品的离子强度最高,说明相对于MRM4*,RM对人造板中脱羰基、羧基等碳氧基团反应的促进程度更强,MRM4*的CO2和CO的离子强度在750 ℃以上开始显著提高,说明MRM4*对脱碳氧基团反应在高温下的促进作用更显著,这也符合之前红外谱图的结果。另外,发现CH4和H2的质谱结果中MRM4*样品的离子强度最高,说明MRM4*对脱甲基/亚甲基、脱氢反应具有更强的促进作用。

-

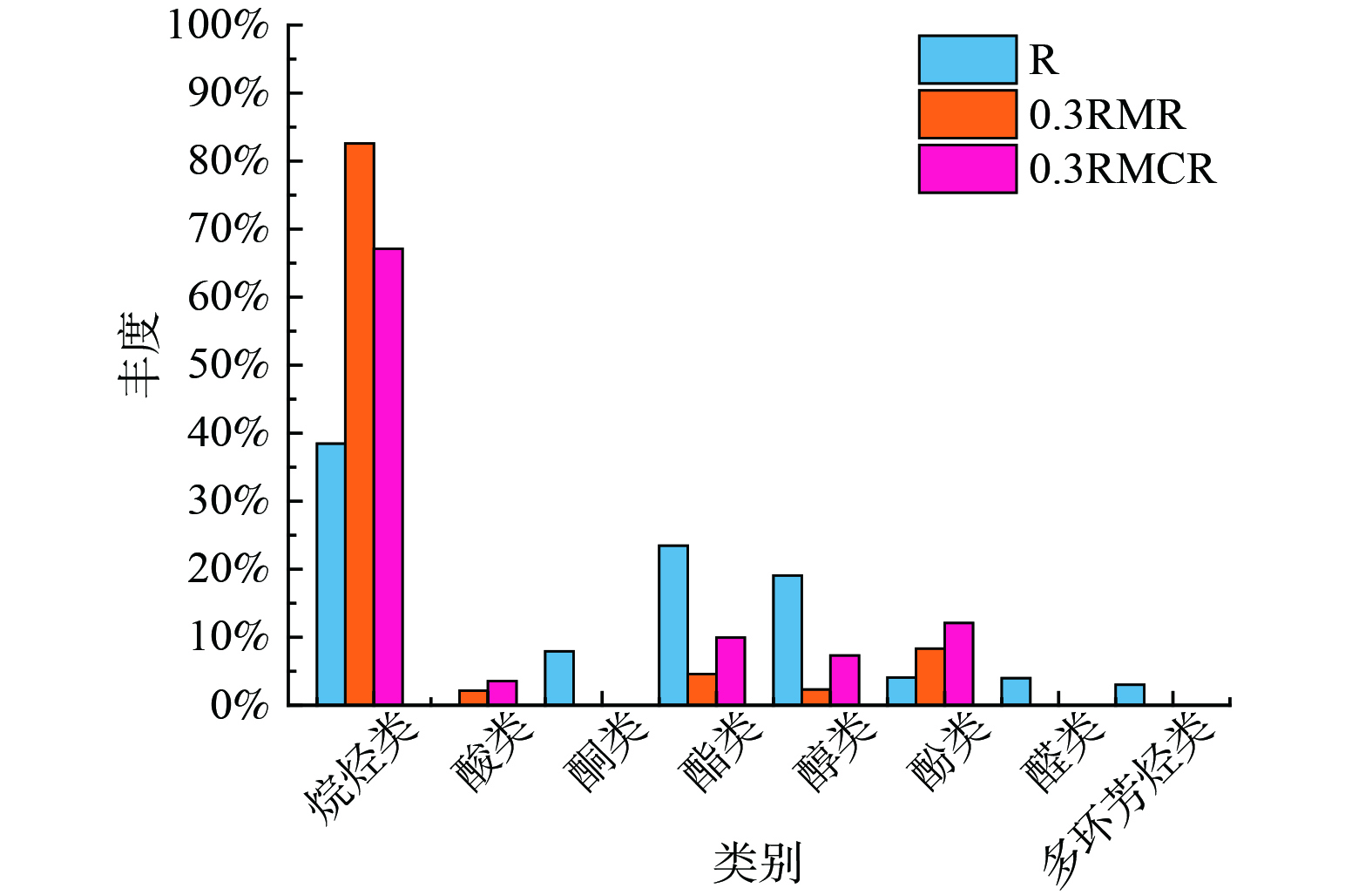

RM作为人造板热解添加剂使用后,焦油和合成气可以回收,但是RM和热解后的焦炭混合均匀,难以分离,混合物称为赤泥炭 (RMC) 。另外,经过共热解后RMC中赤泥也与原始RM的晶相有所不同,于是在管式炉上探索了RMC作为添加剂循环使用的潜力。由前文图1可知,当RM还原性气氛下热解,Fe2O3会逐渐向Fe转化,当多次循环热解后,可以利用Fe基物质磁性的差异,在热解后固体产品中回收Fe。以往文献显示Fe在活性炭中作为“锚点”在配位上是不饱和的,因此能够进一步与客体相互作用[31-32],例如和生物炭中的SiO2和炭结构形成稳定的化学键,防止活性物质流失[33-34]。同时由于Fe原子分散在具有良好孔隙结构的载体上,不仅能够最大限度地提高金属原子的效率,而且有利于防止烧结和焦化造成的失活。因此RMC有作为添加剂循环催化热解的潜力,本节在恒温管式炉上调查了复合材料RMC的催化效果,30%的RMC作为添加剂重新与人造板混合,制得的样品成为0.3RMCR。需要说明的是,添加30%的RMC作为添加剂时中RM的质量比实际小于30%,根据之前热重结果推测此时还存在少量残留焦炭,其作为载体均匀负载经历共热解后的RM。结果如图8所示。0.3RMCR热解后收集的焦油烷烃类浓度高于R但低于0.3RMR,而酯类、醇类浓度低于R但高于0.3RMR,说明RMC有促进人造板焦油脱氧提质,促进脂肪族C-C键的生成,且0.3RMCR的催化效果弱于RM。同时,注意到焦油中酚类含量0.3RMCR高于RM,这可能是因为RMC复合材料中含有生物质炭,其中部分木质素在循环热解中裂解产量生了酚类。另外,注意到500 ℃下人造板热解产生的焦油含有多环芳烃,而RM以及RMC均有效地抑制了多环芳烃和醛类的形成。

-

1) 随RM添加比例由0%增加至40%,人造板的整体失重增加,最大失重峰以及炭化阶段失重峰的最大失重速率所在温度提前。当RM比例≤20%时,人造板热解的活化能有效降低,尤其是转化率在0.1—0.2时的活化能。RM添加比例过高,人造板热解活化能反而增加,因此推荐RM添加比例≤30%。

2) 人造板热解挥发分释放阶段产物主要包括烷烃、CO2、酰卤、酸酐以及酯等。700 ℃后焦炭发生了二次裂解,产生了大量芳香化合物以及小分子气体CO2、CO。

3) RM热解过程中经历“αFe2O3→γFe2O3→Fe3O4→Fe”的过程,导致对人造板热解过程的催化效果不同。RM主要铁氧化合物为Fe2O3,促进了人造板的胶合剂中含氮化合物例如酰胺或硝基取代化合物提前分解和断裂,并且相对于MRM4*对人造板中脱羰基、羧基等碳氧基团反应的促进程度更强。MRM4*主要铁氧化合物为Fe3O4,主要促进挥发分中芳香化合物的产生,750 ℃以上显著地促进了CO2、CO的释放。

4) RMC对焦油脱氧提质的催化效果弱于RM,但仍然有效地提高了焦油中烷烃含量,是人造板无催化热解烷烃含量的1.8倍。RM以及RMC均有效地抑制了焦油中多环芳烃的形成。

拜耳法赤泥催化热解废弃人造板的产物特性分析

Product characteristics analysis of Bayer red mud catalytic pyrolysis of waste wood-based panel

-

摘要: 针对拜耳法赤泥年产量巨大亟需资源化回收、以及由于人造板包含3%~15%聚合物的特性导致传统处理方式污染较大的问题,提出一种利用赤泥原位低温催化热解废弃人造板的处理方式,实现废弃赤泥和人造板的有效消纳。首先在热重反应器上比较了不同添加比例的赤泥对人造板热解的影响,并采用DAEM (distributed activation energy model) 模型计算了传统热解和赤泥催化热解的活化能。热重结果表明:随赤泥添加比例增加,人造板的整体失重增加,而热解平均活化能呈先增加后降低的趋势,推荐赤泥添加比例≤30%。然后通过TG-FTIR-MS联用探究了拜尔法赤泥原位催化人造板的机理,并且关注了热解过程中铁基成分变化对催化机理的影响,结果表明:赤泥中铁氧化合物主相分别为Fe2O3和Fe3O4时,对人造板热解过程的催化效果显著不同,Fe2O3促进了酰胺的提前分解和断裂,且对脱羰基、羧基反应的促进作用更强;Fe3O4能够更显著地促进挥发分中芳香化合物的产生以及高温下CO2、CO的释放。最后在固定床上研究了赤泥焦炭复合材料的催化效果以探索其循环利用的潜力,结果表明,赤泥炭催化效果弱于赤泥,但仍能有效实现脱酸提质焦油,焦油中可燃脂肪烃的含量增加1.8倍。Abstract: In view of the huge annual generation of Bayer red mud to be recovered, as well as the risk of pollutants emission for traditional treatment methods dealing wood-based panel due to its 3%~15% polymer component, a strategy was proposed to utilize low temperature in-situ red mud catalytic pyrolysis of wood-based panel, to realize effective consume of wasted red mud and wood-based panel. Firstly, the effects of different addition ratios of red mud on pyrolysis of wood-based panel were compared on the thermogravimetric reactor, and the activation energies of traditional pyrolysis and catalytic pyrolysis of red mud were calculated using DAEM mode (distributed activation energy model). The TG results showed that with the increasing proportion of red mud, the overall weight loss of wood-based panel increased, while the average activation energy of pyrolysis increased first and then decreased. The recommended proportion of red mud was below 30%. TG-FTIR-MS was used to investigate the in-situ catalytic mechanism of Bayer red mud during the pyrolysis process. And the influence of component change of iron-based on pyrolysis mechanism was especially focused. Results indicated that when the main phases of iron oxides were Fe2O3 and Fe3O4 respectively, their catalytic effects on the pyrolysis of wood-based panel were significantly different. Fe2O3 promoted the early decomposition and cleavage of amides, and had a stronger promoting effect on decarbonylation and decarboxylation reactions. Fe3O4 could significantly promote the production of aromatic compound in volatile matter and the release of CO2 and CO at high temperature. Finally, the catalytic effect of red mud char composite materials was studied on a fixed bed to explore the possibility of cyclic utilization. The results showed that the catalytic effect of red mud char was weaker than red mud, but it still achieved an effective deacidification and upgrading of tar, and the content of combustible aliphatic hydrocarbons in tar increased 1.8 times.

-

Key words:

- red mud /

- catalytic pyrolysis /

- wood-based panel /

- TG-FTIR /

- dynamics

-

南水北调中线工程作为世界上最大的调水措施,旨在缓解华北地区的水资源短缺问题。中线干渠水源来自多条河流,含有大量的营养物质如氮、磷等,且水流速度较慢,容易形成静水区域,使得藻类容易生长繁殖。水流通过干渠断面的过程中由于流速减慢,水中携带的泥沙、沉积物等物质会逐渐沉淀,形成堆积在干渠底部的底泥[1]。藻类的释放是丹江口水库溶解性有机物(dissolved organic matter, DOM)的重要来源,直接关系到南水北调水源地的水质安全[2]。而作为污染物、养分和有机物的汇,底泥中的DOM可以提供比其上覆水更多的物质循环信息[3]。总干渠水质应达到《地表水环境质量标准》(GB3838-2002)的Ⅰ-Ⅱ类水标准。近年来主河道输水至北京和天津时DOM浓度有上升趋势,导致水质的重要有机污染指标化学需氧量(chemical oxygen demand, COD)上升,对京津两地的饮用水供应安全构成威胁[4]。

地表水中的DOM是由多糖、蛋白质和木质素等各种活性物质组成的复杂和非均相混合物[5]。在输送溶解性有机碳(dissolved organic carbon, DOC)的过程中,DOM会受到阳光照射而发生转化和降解,是从地表水中除去DOC的重要途径之一[6]。MORAN等[7-8]研究了地表水DOM在紫外辐射下的光漂白和光矿化作用,包括紫外吸光度和荧光强度的损失及DOC浓度的降低。但关于比较分析不同来源DOM光反应行为的研究较少。考虑到水环境中DOM来源的复杂性及其生态重要性,需要更全面地了解控制其转化的行为。

北京段清河位于中线的末端,来水已经流经了中线所有的区域,可以提供水质累积影响的有价值的信息。本文以南水北调终点清河段的水、底泥中DOM及微囊藻衍生的I-DOM和E-DOM为研究对象,利用三维荧光光谱和紫外可见吸收光谱技术比较了不同来源DOM光学性质和光降解行为的差异性,对控制输水过程DOM的积累具有重要价值。

1. 材料与方法

1.1 样品准备与预处理

地表水和底泥采集自南水北调北京段清河(40°0′43.73″N, 116°16′27.55″E),样品分别简写为W-DOM和S-DOM。采集的底泥与Milli-Q水充分混合后在4 000 r·min−1转速下离心10 min,上清液为底泥DOM [9]。对干渠中相对丰度最高的常见藻类——微囊藻(Microcystis sp.)进行纯藻种培养,培养箱温度设置为(25±1) ℃,光照和黑暗循环时长均为12 h,光照强度2 000 lux,模拟藻类的生长环境[10]。培养结束后分别采用离心和冻融法提取胞内和胞外DOM [11],样品分别简写为I-DOM和E-DOM。

1.2 光化学降解实验

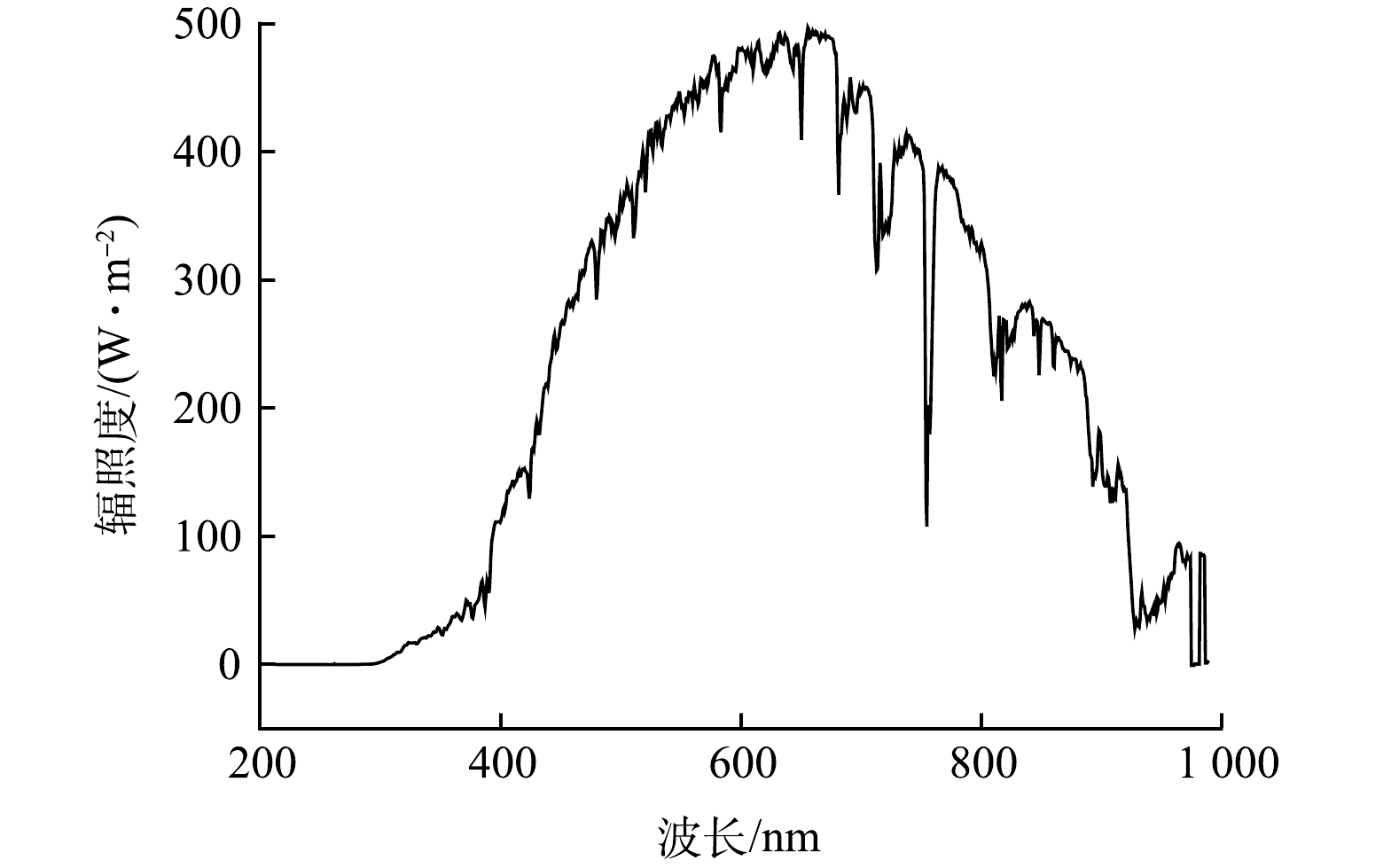

实验前所有DOM样品用0.22 μm的纤维素酯膜过滤。光降解实验在装有1 000W氙灯的太阳光模拟器(Sol 2A ABA,美国Newport公司)中进行,采用持续光照模式。氙灯光谱如图1所示,其在紫外波段的辐照度与实际太阳光的辐照度相近。采用恒温装置将反应器中的温度保持在约25 ℃。在光照第0、1、2、3、5、7 d取平行样品分析。

1.3 分析方法

用Lambda 850型分光光度计(Perkinelmer,美国)检测波长范围在200~600 nm的紫外-可见吸收光谱,测得的吸光度(A)用式(1)转换为波长λ处的吸收系数(aλ)[12]。

aλ=2.303Aλ/r (1) 式中:aλ为波长λ处的吸收系数,m−1;r为比色皿厚度,m。

由于原始光谱在光照过程中信号变化较微弱,所以参考DRYER等[13]对光谱的处理方法:分别将测得的原始光谱与光照前的原始光谱做差,即为吸收损失光谱。用320 nm处的吸收系数(a320)近似表示CDOM浓度[14]。特征紫外吸光度(SUVA254)通过254 nm处的吸收系数除以DOC浓度计算,代表样品的芳香性碳含量[15]。通过非线性拟合得到275~295 nm和350~400 nm的光谱斜率S275~295和S350~400,计算出斜率比(SR),其与DOM的分子质量成反比[16]。

使用F-4500型荧光光谱仪(Hitachi,日本)测量荧光激发-发射矩阵(EEM)光谱,并以5 nm的增量在200~450 nm改变激发波长(Ex),随后以5 nm的增量在270~600 nm扫描发射波长(Em)。荧光光谱分为5个峰:类腐殖质峰A(Ex/Em=260 nm/400~460 nm)、峰M(Ex/Em=290~310 nm/370~410 nm)和峰C(Ex/Em=320~360 nm/420~460 nm)、类蛋白质峰B(Ex/Em=225nm/340nm)和峰T(Ex/Em=275 nm/340 nm),并利用荧光区域积分法计算各个荧光峰强度。采用性质相似的类腐殖质荧光组分之和Ch(即A+M+C)和类蛋白质荧光组分之和Cp(即B+T)代替单一组分分析降解规律。荧光指数(fluorescence index, FI)可以表示DOM的来源,FI<1.4时;DOM主要为陆生植物及土壤有机质等外源物质输入,FI>1.9时,DOM主要为微生物活动等内源过程产生[17]。腐殖化指数(humification index, HIX)可以衡量DOM的腐殖化程度,HIX越大,说明分子组成越复杂,腐殖质的含量越高。自生源指数(biological index, BIX)主要反映DOM的生物可利用性,BIX越高,说明DOM的降解程度越高,内源碳产物越容易生成[18]。

2. 结果与讨论

2.1 DOM光学性质差异

DOM样品的三维荧光光谱、荧光组分含量和荧光参数分别如图2和表1所示。不同来源DOM样品在荧光峰的分布和强度上表现出明显的异质性。W-DOM中峰A、峰M和峰C的强度较高,其主要荧光组分是类腐殖质。S-DOM中峰B和峰T的强度较高,其主要荧光组分是类蛋白质和类色氨酸[19]。微囊藻衍生的DOM中5种峰的强度都较高,其中I-DOM中强度最高的是峰T,E-DOM中强度最高的是峰A。

表 1 DOM样品荧光组分的含量和荧光光谱参数Table 1. Content of fluorescent components and fluorescence spectra parameters of DOM samples样品名称 荧光峰强度 FI HIX BIX B T A M C W-DOM 67.23 99.68 187.04 155.82 158.82 2.18 0.80 1.01 S-DOM 138.53 116.99 53.24 221.10 60.69 2.45 0.48 3.62 I-DOM 239.13 542.06 240.33 193.62 126.29 2.79 0.53 0.70 E-DOM 103.90 239.01 441.23 151.60 212.18 2.16 0.82 1.07 所有样品的FI均大于2.0,说明清河DOM基本为内源过程产生。W-DOM和E-DOM的腐殖化程度较高,而S-DOM和I-DOM的腐殖化程度较低。除S-DOM的生物可利用性较高外,其余样品都较低。本研究中I-DOM的BIX值与KIM等[20]对Miho河中藻类DOM的研究结果(BIX=0.67)接近,其认为荧光参数会受生物地球化学过程影响而发生变化,从而导致高估或低估DOM源的相对贡献率。因此,荧光光谱参数只提供定性分析,FI和BIX之间没有必然的联系和相关性。W-DOM和E-DOM的荧光特征具有一定的相似性;S-DOM和I-DOM的荧光特征具有一定的相似性,这可能与不同的生物地球化学过程有关。藻类代谢产生的E-DOM不断释放到水体中,是河道DOM的主要来源之一。藻类死亡后会在河流底部沉降积累,成为沉积物的一部分。因此,藻细胞破裂后释放的I-DOM是S-DOM的重要组成部分。

2.2 光漂白对DOM紫外可见吸收性质的影响

样品的吸收损失光谱如图3所示。可以看出所有样品在UV-B波段(280~320 nm)的吸光度损失率大于UV-A波段(320~400 nm),说明CDOM的光漂白效率与光子的能量密切相关[21]。CDOM在可见光波段的吸光度损失很小,说明光照主要影响其在紫外区的吸光度损失。值得注意的是,在光照中期的某些时间点I-DOM的吸光度反而略微增加,这个现象被认为与DOM中含有更高分子质量、更高度芳香结构物质的生成有关。CHEN等[22]发现了低分子质量芳烃,如来自单宁分解的多酚或通过从生物质中浸出的低分子质量DOM的光腐殖化反应可以增强吸光度信号。

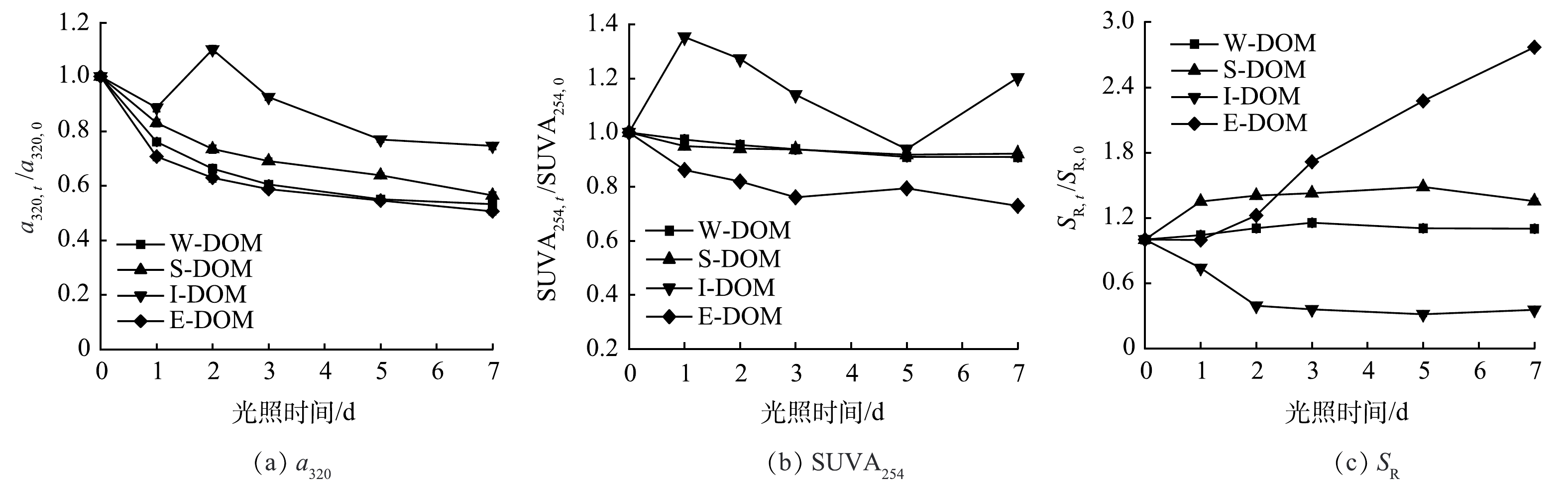

将a320、SUVA254和SR分别以第0 天为基准归一化处理后得到3种指标随光照时间的变化如图4所示。光照后所有样品的a320均显著降低,其中I-DOM降低幅度最小,约为25%,其他样品的降解比例大体相同,约为40%~50%。这表明CDOM具有很强的吸光能力,当受到光照时其吸收能力会发生变化,通过自由基反应导致化学结构和分子大小发生变化,从而降低其吸收光谱的强度。光照显著降低了E-DOM中芳香性碳含量,这是因为光照激发了水中的氧,产生一系列活性物质,如羟基自由基(·OH)和超氧自由基(O2·-),可以与芳香碳发生氧化反应,使其分解成更小的分子[23]。光照对S-DOM和W-DOM中芳香性碳含量的影响很小,而I-DOM中芳香性碳的含量波动较大,这也表明可能发生了光腐殖化作用。除I-DOM外,其他样品的SR均有增加趋势,表明光照能够将大分子DOM分解为小分子DOM。I-DOM的SR下降的确切原因尚不清楚,但先前的报道称浮游生物衍生的DOM的存在会干扰S275~295的值,因为蛋白质的典型的宽吸收带集中在280 nm[24]。

进一步分析表明,除I-DOM外,其余3个样品CDOM降解率随光照时间的增加而指数减少,最终逐渐稳定。为了定量评估光降解过程,选择指数模型进行拟合,拟合公式如式(2)所示[25]。

Y=R0+RP⋅exp(−Kx) (2) 式中:x为光照时间,d;Y为以第0 天为基准归一化的a320;R0为耐光性组分所占百分比,%;Rp为光不稳定组分所占百分比,%;K为光降解速率常数,d−1。

拟合结果如表2所示。可以看出3个DOM样品拟合的相关系数都是0.99,拟合结果较好。结果表明E-DOM中的CDOM光降解速率最高,其次是W-DOM,S-DOM最低。

表 2 CDOM的光降解动力学拟合结果Table 2. Fitting results of photodegradation kinetics of CDOM样品名称 拟合方程 R2 光降解速率常数/d−1 W-DOM Y=0.46exp(−0.66x)+0.53 0.99 0.66 S-DOM Y=0.43exp(−0.44x)+0.57 0.99 0.44 E-DOM Y=0.46exp(−0.84x)+0.53 0.99 0.84 2.3 光漂白对DOM荧光性质的影响

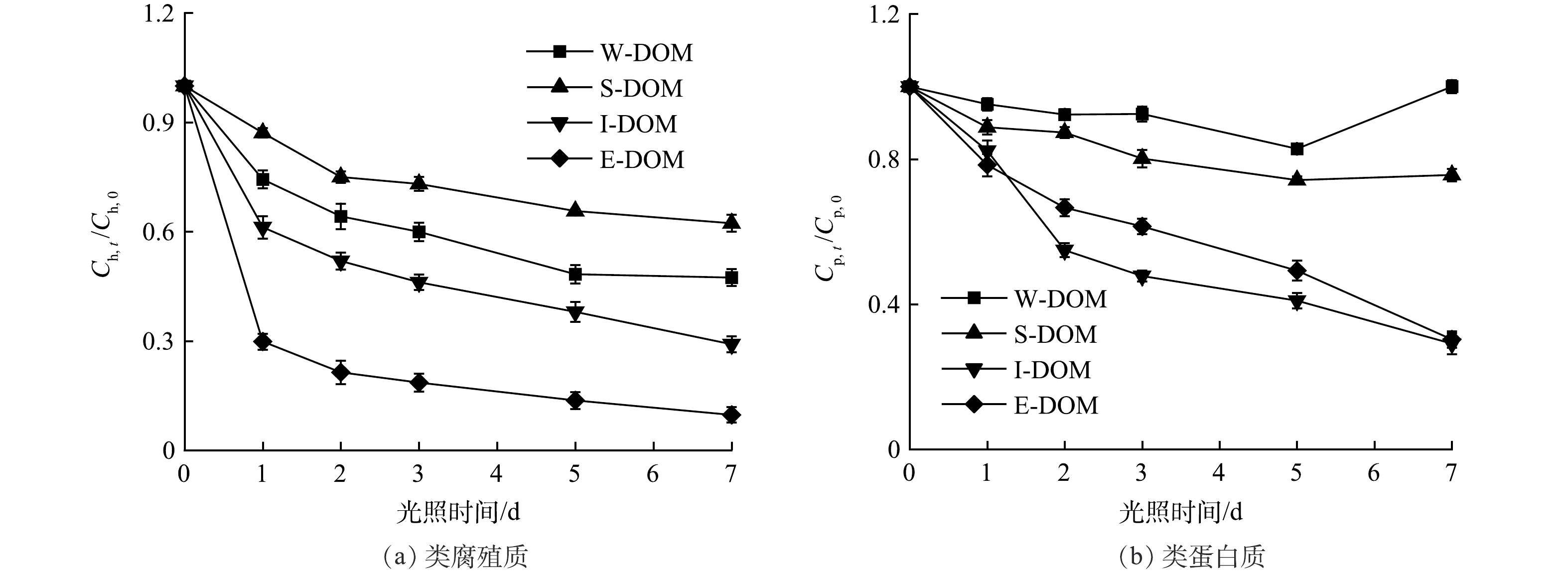

类腐殖质荧光组分Ch和类蛋白质荧光组分Cp分别以第0 d为基准归一化处理后得到其随光照时间的变化如图5所示。从图5(a)中可以看出光照过程中所有样品的类腐殖质的含量均有降低趋势,但降解比例各不相同。E-DOM的降解比例最大,超过90%;其次是I-DOM和W-DOM,分别约70%和50%;S-DOM的降解比例最低,不到40%。由图5(b)中可以看出,W-DOM的类蛋白质的含量在光照过程中小幅波动,光照后没有明显的降低;S-DOM降解了约25%;藻衍生的DOM降解比例最高,约70%。综合以上结果,类腐殖质的光降解比例普遍大于类蛋白质,表明其光活性更强。

归一化的荧光光谱参数FI、HIX和BIX随光照时间的变化如图6所示。所有样品的FI和HIX均有下降趋势,表明荧光组分的降解程度不断增加,结构复杂的腐殖质类物质容易受到破坏,可被光降解为结构简单的物质。I-DOM与W-DOM样品的BIX明显升高,其余样品变化不明显。结果表明光照可以在一定程度上将难以被微生物利用的DOM转化为更具生物利用性的低分子量光产物,这取决于DOM的来源。BERTILSSON等[26]已经发现腐殖质湖中羧酸在光照中大量生成,并利用同位素示踪证明了羧酸是浮游生物利用的主要底物。

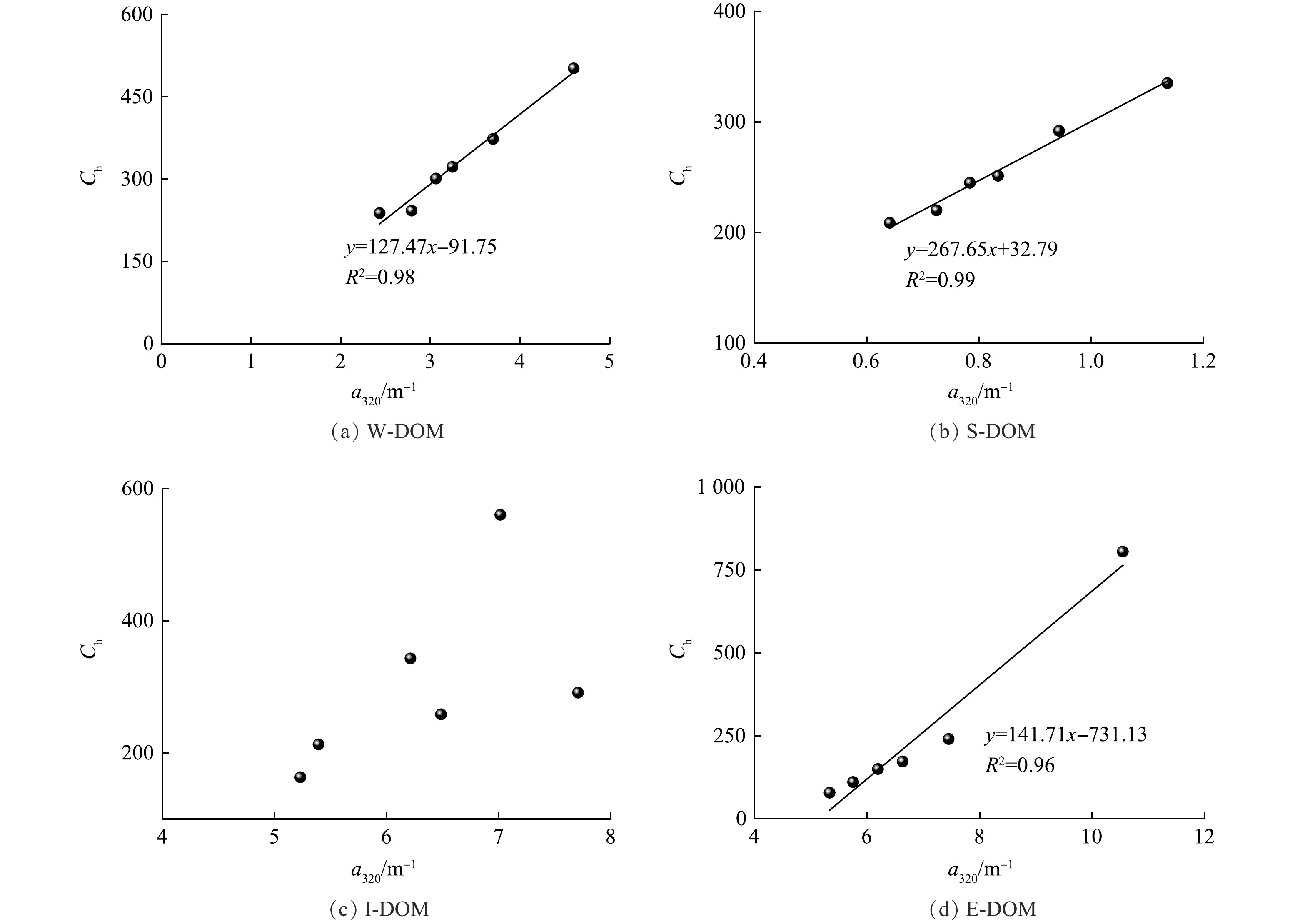

2.4 光漂白过程荧光组分与CDOM含量变化相关性

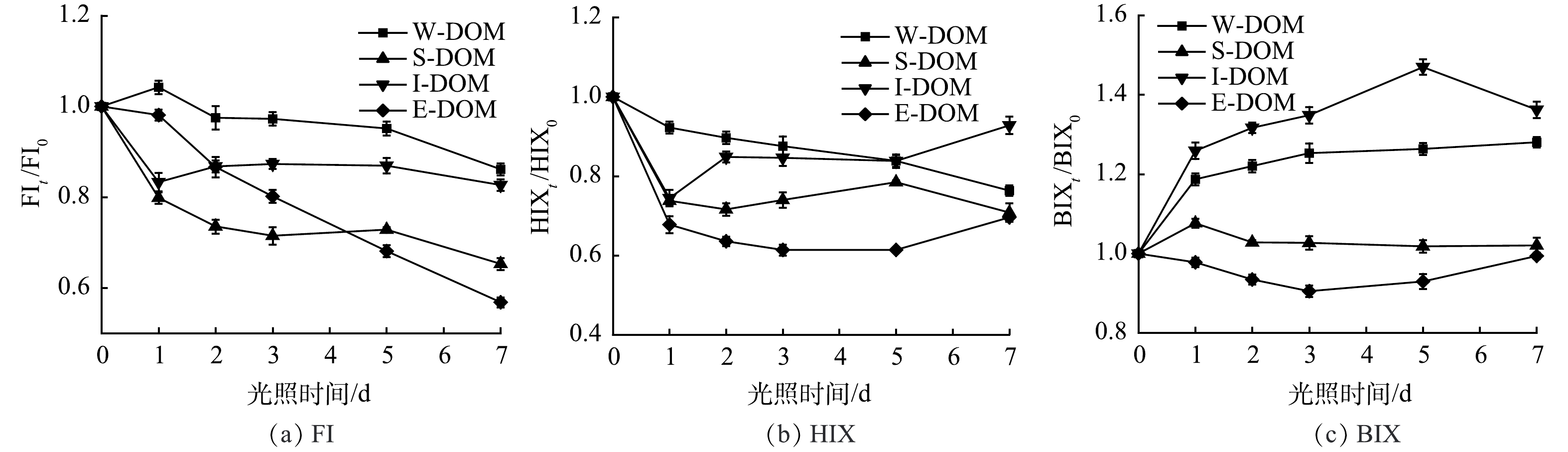

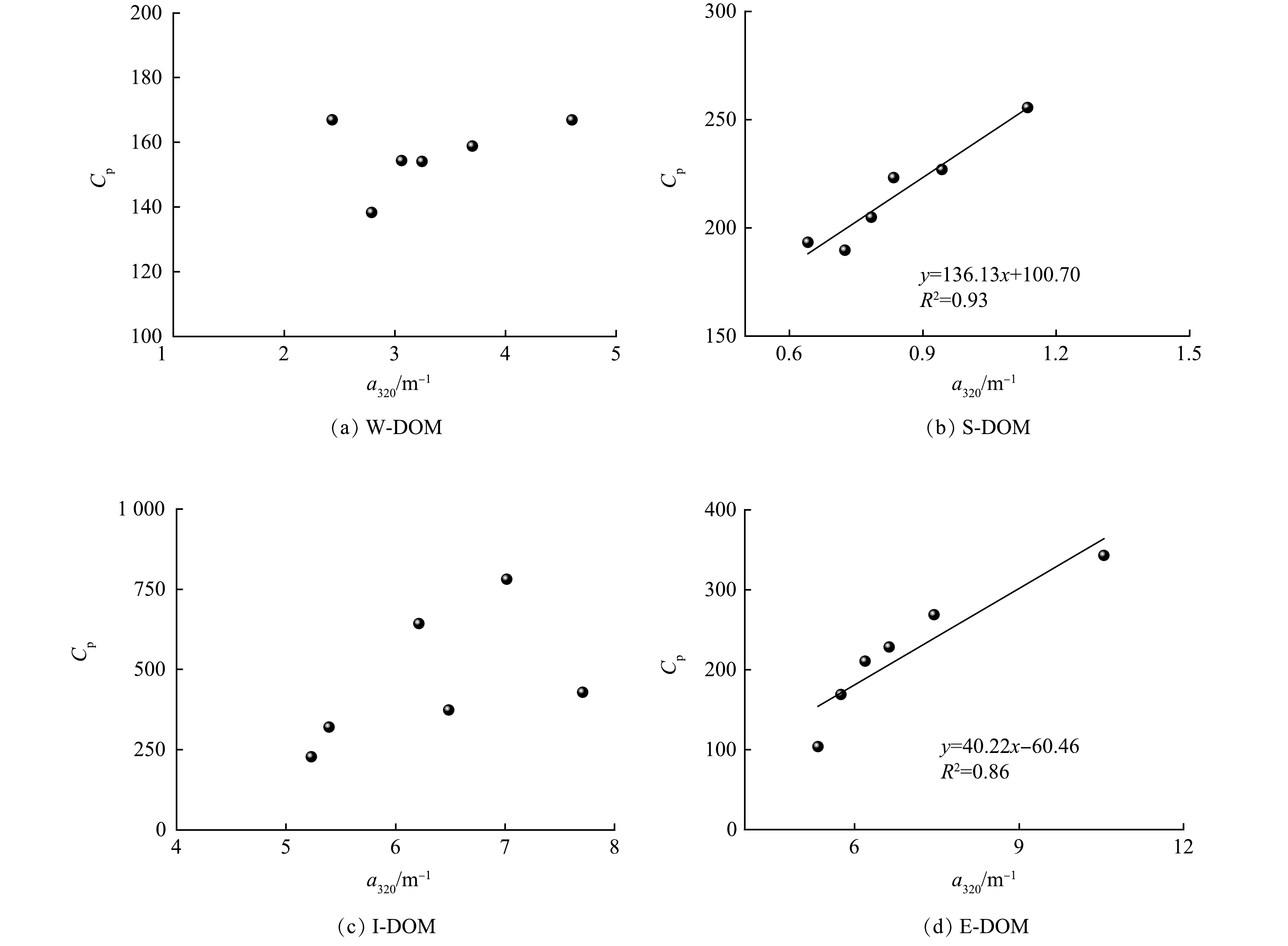

对DOM样品在7 d光漂白过程中类腐殖质含量与a320进行相关性分析,结果如图7所示。结果表明,在W-DOM、S-DOM和E-DOM中类腐殖质含量与a320变化趋势呈显著正相关,说明这些样品中CDOM的光降解速率与类腐殖质的光降解速率在相同时间下基本保持一致。

对DOM样品在7 d光漂白过程中类蛋白质含量与a320进行相关性分析,结果如图8所示。结果表明,在S-DOM和E-DOM中类蛋白质含量与a320变化趋势呈显著正相关,说明这些样品中CDOM的光降解速率与类蛋白质的光降解速率在相同时间下基本保持一致。在I-DOM中类腐殖质、类蛋白质含量与a320变化趋势均无显著相关,说明I-DOM中CDOM与类腐殖质、类蛋白质的光降解速率在相同时间下均不一致。

3. 结论

1)清河水和底泥中DOM在荧光特征上分别与微囊藻衍生的胞外和胞内DOM具有较高相似性,说明清河中的DOM主要形成于内源的微生物过程。

2)DOM的光漂白主要发生在紫外区,且UV-B波段的光漂白效率大于UV-A波段。清河水、底泥和微囊藻胞外DOM中CDOM的降解率为40%~50%,光照可以将其中复杂的大分子物质分解成结构简单的小分子物质;I-DOM中CDOM降解率相对较低,约为25%。

3)CDOM中类腐殖质的光降解率比类蛋白质更高,清河水、底泥和微囊藻胞外DOM中CDOM与类腐殖质的光降解速率在相同时间下基本保持一致;清河底泥和微囊藻胞外DOM中CDOM与类蛋白质的光降解速率在相同时间下基本保持一致。

-

表 1 人造板的工业和元素分析

Table 1. Proximate and ultimate analysis of wood-based panel

% (质量分数) 工业分析 (空气干燥基) 元素分析 水分M 灰分A 挥发分V 固定碳FC C H O N S 9.50 1.73 73.03 15.74 44.86 5.99 43.87 5.18 0.10 表 2 拜尔RM的XRF元素分析结果

Table 2. XRF elemental analysis result of Bayer RM

% (质量分数) Fe2O3 Al2O3 CaO SiO2 TiO2 Na2O 其他 44.06 18.04 2.39 15.07 4.79 4.10 11.56 表 3 热重曲线图的相关参数

Table 3. Relevant parameters of thermogravimetric curve

升温速率/ ( ℃·min−1) 样品 最大失重峰峰值所在温度/ ℃ 最大失重速率/ (10−2·%· ℃−1) 总失重/% 1 2 3 4 1 2 3 4 5 R 67.17 325.57 639.17 — 3.40 89.86 1.99 0.00 18.11 0.1RMR 62.65 318.65 649.85 794.65 5.10 96.18 2.29 2.95 13.19 0.2RMR 60.95 318.55 654.55 824.15 5.48 89.88 2.57 4.69 11.32 0.3RMR 59.92 319.12 656.72 816.72 4.27 96.72 3.01 5.54 6.26 0.4RMR 80.03 320.83 636.83 760.03 9.64 111.73 2.19 6.29 1.21 10 R 68.81 336.01 659.21 — 3.62 88.77 1.75 0.00 18.93 0.1RMR 66.83 331.63 668.43 806.03 4.48 91.52 2.13 2.28 18.47 0.2RMR 69.54 331.14 675.14 805.54 4.60 96.90 2.53 3.70 11.15 0.3RMR 65.93 326.73 665.93 799.53 4.85 104.92 2.47 4.14 1.43 0.4RMR 87.76 329.36 660.56 777.36 8.24 100.94 2.41 6.25 4.56 20 R 78.83 346.03 680.43 — 3.90 85.71 1.96 0.00 21.05 0.1RMR 73.07 339.47 685.07 792.27 4.72 88.61 2.15 2.20 18.71 0.2RMR 76.99 341.79 686.59 831.39 4.50 86.48 3.10 5.20 8.34 0.3RMR 73.65 341.65 684.85 807.25 4.40 103.79 2.64 4.50 4.83 0.4RMR 87.52 340.32 674.72 784.32 13.00 106.80 2.29 5.13 0.33 -

[1] 李彬, 张宝华, 宁平, 等. 赤泥资源化利用和安全处理现状与展望[J]. 化工进展, 2018, 37(2): 714-723. doi: 10.16085/j.issn.1000-6613.2017-0843 [2] 刘昌俊, 李文成, 周晓燕, 等. 烧结法赤泥基本特性的研究[J]. 环境工程学报, 2009, 3(4): 739-742. [3] YAN X Y, LI Y J, SUN C Y, et al. Enhanced H2 production from steam gasification of biomass by red mud-doped Ca-Al-Ce bi-functional material[J]. Applied Energy, 2022, 312: 118737. doi: 10.1016/j.apenergy.2022.118737 [4] ZHAO A M, LV J W, CHEN Q L, et al. Spirit-based distillers’ grains and red mud synergistically catalyse the steam gasification of anthracite to produce hydrogen-rich synthesis gas[J]. International Journal of Hydrogen Energy, 2021, 46(1): 314-323. doi: 10.1016/j.ijhydene.2020.10.027 [5] WANG Y M, LI Y, WANG G J, et al. Effect of Fe components in red mud on catalytic pyrolysis of low rank coal[J]. Journal of the Energy Institute, 2022, 100: 1-9. doi: 10.1016/j.joei.2021.10.005 [6] DUAN J Y, WU Y K, ZHENG J, et al. Enhancing catalytic performance of red mud for palmitic acid hydrodeoxygenation by acid pretreatment-induced structural modification[J]. Fuel Processing Technology, 2023, 248: 107839. doi: 10.1016/j.fuproc.2023.107839 [7] LY H V, PARK J W, KIM S S, et al. Catalytic pyrolysis of bamboo in a bubbling fluidized-bed reactor with two different catalysts: HZSM-5 and red mud for upgrading bio-oil[J]. Renewable Energy, 2020, 149: 1434-1445. doi: 10.1016/j.renene.2019.10.141 [8] SHAO S S, ZHANG P F, XIANG X L, et al. Promoted ketonization of bagasse pyrolysis gas over red mud-based oxides[J]. Renewable Energy, 2022, 190: 11-18. doi: 10.1016/j.renene.2022.02.105 [9] WEBER J, THOMPSON A, WILMOTH J, et al. Effect of metal oxide redox state in red mud catalysts on ketonization of fast pyrolysis oil derived oxygenates[J]. Applied Catalysis B:Environmental, 2019, 241: 430-441. doi: 10.1016/j.apcatb.2018.08.061 [10] SHAO S S, CAO Y, YE Z A, et al. Enhanced selective production of aldehydes and ketones by catalytic upgrading of pyrolysis vapor from holocellulose over red mud-based composite catalysts[J]. Fuel, 2024, 355: 129367. doi: 10.1016/j.fuel.2023.129367 [11] WANG J X, ZHANG S P, XU D, et al. Catalytic activity evaluation and deactivation progress of red mud/carbonaceous catalyst for efficient biomass gasification tar cracking[J]. Fuel, 2022, 323: 124278. doi: 10.1016/j.fuel.2022.124278 [12] VESES A. , AZNAR M. , LOPEZ J. M. , et al. Production of upgraded bio-oils by biomass catalytic pyrolysis in an auger reactor using low cost materials[J]. Fuel, 2015, 141: 17-22. [13] WANG S Q, LI Z H, BAI X Y, et al. Catalytic pyrolysis of lignin in a cascade dual-catalyst system of modified red mud and HZSM-5 for aromatic hydrocarbon production[J]. Bioresource Technology, 2019, 278: 66-72. doi: 10.1016/j.biortech.2019.01.037 [14] WANG L H, YI W M, ZHANG A D, et al. Catalytic Fast Pyrolysis of Corn Stalk for Phenols Production With Solid Catalysts[J]. Frontiers in Energy Research, 2019, 7:86. [15] LI X H, SUN J Y, ZHANG H C, et al. Enhanced production of monocyclic aromatic hydrocarbons by catalytic pyrolysis of rape straw in a cascade dual-catalyst system of modified red mud and HZSM-5[J]. Fuel Processing Technology, 2022, 236: 107381. doi: 10.1016/j.fuproc.2022.107381 [16] LI X H, HUANG Z H, SHAO S S, et al. Catalytic pyrolysis of biomass to produce aromatic hydrocarbons in a cascade dual-catalyst system: Design of red mud based catalyst assisted by the analysis of variance[J]. Journal of Cleaner Production, 2023, 404: 136849. doi: 10.1016/j.jclepro.2023.136849 [17] YANG X Y, ZHANG J P, ZHENG J, et al. In-situ and ex-situ catalytic pyrolysis of cellulose to produce furans over red mud-supported transition metal catalysts[J]. Journal of Analytical and Applied Pyrolysis, 2023, 169: 105830. doi: 10.1016/j.jaap.2022.105830 [18] WANG L H, SI B C, HAN X, et al. Study on the effect of red mud and its component oxides on the composition of bio-oil derived from corn stover catalytic pyrolysis[J]. Industrial Crops and Products, 2022, 184: 114973. doi: 10.1016/j.indcrop.2022.114973 [19] LEI M, ZHANG Y C, HONG D K, et al. Characterization of nitrogen and sulfur migration during pressurized coal pyrolysis and oxy-fuel combustion[J]. Fuel, 2022, 317: 123484. doi: 10.1016/j.fuel.2022.123484 [20] CHEN G Y, LI J T, LI K, et al. Nitrogen, sulfur, chlorine containing pollutants releasing characteristics during pyrolysis and combustion of oily sludge[J]. Fuel, 2020, 273: 117772. doi: 10.1016/j.fuel.2020.117772 [21] CHEN H Y, SHAN R, ZHAO F X, et al. A review on the NOx precursors release during biomass pyrolysis[J]. Chemical Engineering Journal, 2023, 451: 138979. doi: 10.1016/j.cej.2022.138979 [22] ZHAN H, ZHUANG X Z, SONG Y P, et al. A review on evolution of nitrogen-containing species during selective pyrolysis of waste wood-based panels[J]. Fuel, 2019, 253: 1214-1228. doi: 10.1016/j.fuel.2019.05.122 [23] AHMED M, BATALHA N, QIU T F, et al. Red-mud based porous nanocatalysts for valorisation of municipal solid waste[J]. Journal of Hazardous Materials, 2020, 396: 122711. doi: 10.1016/j.jhazmat.2020.122711 [24] RYU S M, LEE H W, KIM Y M, et al. Catalytic fast co-pyrolysis of organosolv lignin and polypropylene over in-situ red mud and ex-situ HZSM-5 in two-step catalytic micro reactor[J]. Applied Surface Science, 2020, 511: 145521. doi: 10.1016/j.apsusc.2020.145521 [25] LIU X G, LI B Q, MIURA K. Analysis of pyrolysis and gasification reactions of hydrothermally and supercritically upgraded low-rank coal by using a new distributed activation energy model[J]. Fuel Processing Technology, 2001, 69(1): 1-12. doi: 10.1016/S0378-3820(00)00113-2 [26] 张吉元, 柳丹丹, 郭晓方, 等. 赤泥-煤矸石协同还原焙烧回收Fe、 Al有价元素[J]. 环境工程学报, 2021(10): 3306-3315. [27] CAO J L, YAN Z L, DENG Q F, et al. Mesoporous modified-red-mud supported Ni catalysts for ammonia decomposition to hydrogen[J]. International Journal of Hydrogen Energy, 2014, 39(11): 5747-5755. doi: 10.1016/j.ijhydene.2014.01.169 [28] WANG S Q, LI Z H, BAI X Y, et al. Catalytic pyrolysis of lignin with red mud derived hierarchical porous catalyst for alkyl-phenols and hydrocarbons production[J]. Journal of Analytical and Applied Pyrolysis, 2018, 136: 8-17. doi: 10.1016/j.jaap.2018.10.024 [29] LI X Y, CHEN J, LU C M, et al. Performance of Mo modified γ-Fe2O3 catalyst for selective catalytic reduction of NOx with ammonia: Presence of arsenic in flue gas[J]. Fuel, 2021, 294: 120552. doi: 10.1016/j.fuel.2021.120552 [30] XU R S, DAI B W, WANG W, et al. Effect of iron ore type on the thermal behaviour and kinetics of coal-iron ore briquettes during coking[J]. Fuel Processing Technology, 2018, 173: 11-20. doi: 10.1016/j.fuproc.2018.01.006 [31] ZHAO C X, LI B Q, LIU J N, et al. Intrinsic Electrocatalytic Activity Regulation of M–N–C Single-Atom Catalysts for the Oxygen Reduction Reaction[J]. Angewandte Chemie International Edition, 2021, 60(9): 4448-4463. doi: 10.1002/anie.202003917 [32] 何立平, 杨迎春, 徐成华, 等. Fe/活性炭多相类Fenton法湿式氧化罗丹明B废水的研究[J]. 环境工程学报, 2009, 3(8): 1433-1437. [33] Wang S. , Zhao C. , Shan R. , et al. A novel peat biochar supported catalyst for the transesterification reaction[J]. Energy Conversion and Management, 2017, 139: 89-96. [34] ZENG Y X, ALMATRAFI E, XIA W, et al. Nitrogen-doped carbon-based single-atom Fe catalysts: Synthesis, properties, and applications in advanced oxidation processes[J]. Coordination Chemistry Reviews, 2023, 475: 214874. doi: 10.1016/j.ccr.2022.214874 -

下载:

下载: