-

为缓解NOx引起的雾霾、光化学烟雾、酸雨等环境问题,中国于2015年发布《全面实施燃煤电厂超低排放和节能改造工作方案》[1-2]。作为主要人为NOx排放源,燃煤电厂普遍采用选择性催化还原(selective catalytic reduction,SCR)技术进行烟气脱硝,以满足NOx排放质量浓度低于50 mg· (m3) −1的标准[3-6]。在“双碳”能源结构转型背景下,脱硝效率和氨逃逸率作为评估燃煤电厂SCR脱硝性能的关键指标[7],容易受燃煤机组调峰运行引起的喷氨量、NOx质量浓度、烟气流量、烟气温度等波动带来的影响[8-9]。

由于实验手段难以全面评估脱硝性能变化的内在机理,数值模拟凭借方便和准确等优点被广泛应用[9]。基于数值模拟,众多学者对脱硝性能开展了大量研究。为优化烟气流场分布,凌忠钱等[7]和邹红果等[10]利用FLUENT分析了喷氨格栅和导流板布置对SCR反应器内流场分布均匀性影响,发现速度与NH3体积分数分布不均会严重影响脱硝性能,并对喷氨格栅和导流板设计进行优化,使系统流场与氨氮摩尔比(NSR)分布更加均匀。为探讨有关因素对脱硝性能的影响机理,较多学者利用FLUENT建立SCR催化剂单孔道三维模型进行了模拟研究。其中,ZHENG等[11]采用SIMPLE算法求解控制方程,系统研究了NO在单通道中轴向和径向浓度分布梯度,发现SCR反应仅发生在催化剂壁表面约0.2 mm的薄层内;LEI等[12]使用相同方法,单因素分析了入口速度、NSR和反应温度对脱硝效率的影响,发现入口速度降低、烟气温度和NSR增加均有利于提升脱硝效率;赵大周等[13]探究了不同NSR和空速下脱硝效率随温度的变化规律,以及NSR与温度对氨逃逸率的共同作用,发现NSR增加在提升脱硝效率的同时还会加剧氨逃逸,空速增大会显著降低脱硝效率;杜云贵等[14]联立烟气停留时间与NSR对脱硝效率进行了分析,并探讨了NSR与氨逃逸率间的关系;李晗天等[15]则更为细致地耦合空速与NSR模拟了出口NO与NH3的分布情况。此外,张迪等[16]和沈伯雄等[17]建立SCR催化剂单孔道一维模型,采用MATLAB进行数值仿真,重点研究了不同温度下NSR和烟气流速对脱硝效率的影响,发现NSR超1.05时氨逃逸率显著上升,后者还讨论了入口NO质量浓度及催化剂孔几何特性与脱硝效率间的紧密联系,发现蜂窝式催化剂脱硝效率最高。

以上研究表明,反应器入口参数(NSR、入口NO浓度、入口速度)和反应温度均为脱硝性能的重要影响因素。然而,目前研究考虑二者间耦合效应不够全面,多关注脱硝效率,氨逃逸也多局限于NSR影响,缺少相同耦合条件下脱硝效率与氨逃逸率的横向对比。基于此,本课题组针对各入口参数同反应温度对脱硝效率及氨逃逸率的交互作用进行系统分析,并在此基础上探究调峰运行负荷下脱硝效率及氨逃逸率随温度的变化规律,以期为燃煤电厂SCR脱硝性能的整体优化提供参考。

-

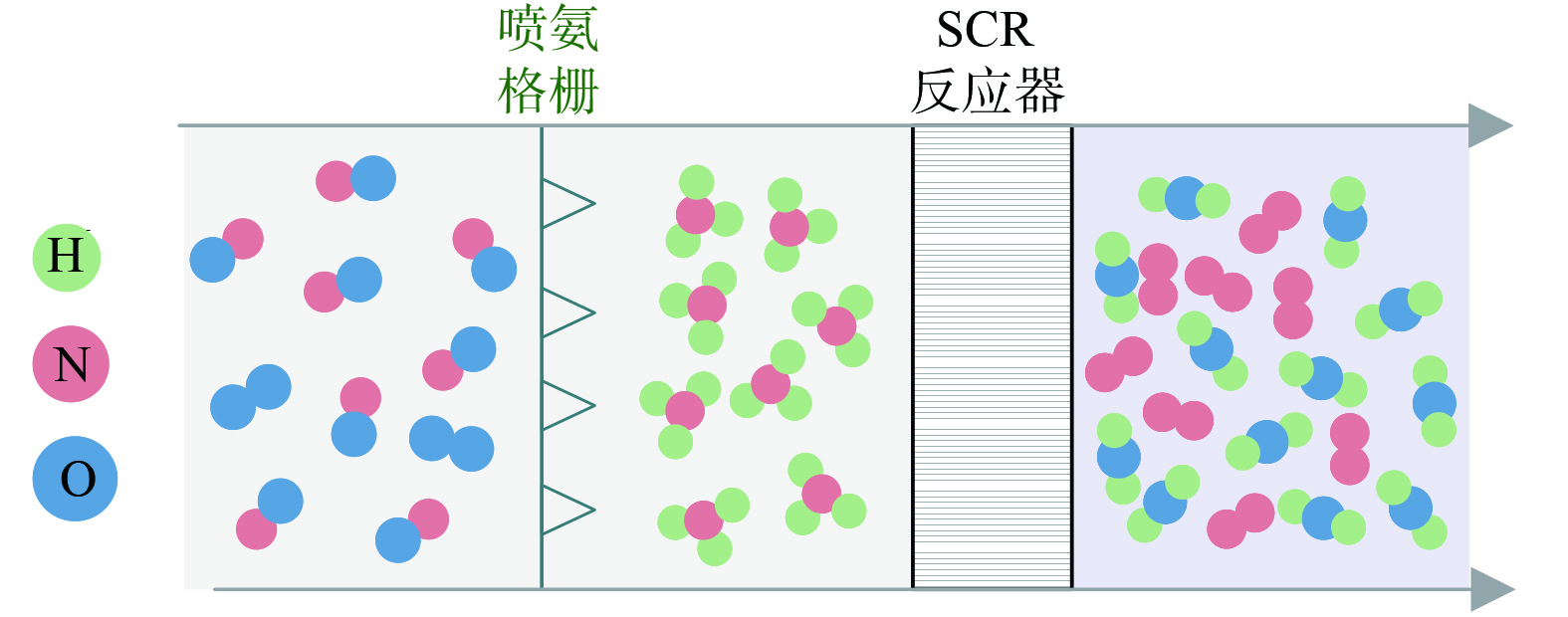

SCR脱硝反应是指烟气中的NOx与NH3的混合气体流经SCR催化剂发生氧化还原反应,选择性地将NOx转化为N2和H2O的过程。进入SCR反应器的燃煤电厂尾部烟气中NOx主成分为NO和NO2,其中NO占比为95%,NO2占比为5%,忽略NO2对整体脱硝性能影响不大[18],故本文仅考虑NO的脱除。SCR脱硝反应过程见图1。

燃煤电厂SCR脱硝反应遵循Eley-Rideal (E-R)机理[19],即NH3先吸附于催化剂表面,再与NO分子反应。该过程涉及的主要化学反应如式(1)和(2)所示。式(1)为脱硝主反应,式(2)为脱硝过程中发生的副反应。NO的化学反应速率和NH3的总化学反应速率可分别由化学反应动力学模型式(3)和(4)确定。

式中:

rNO 为NO反应速率,mg·(Nm3·s)−1;rNH3 为NH3的反应速率,mg·(Nm3·s)−1;K0 为吸附反应的反应速率常数,s−1;K1 为脱硝反应的反应速率常数,s−1;K2 为氨气氧化反应的反应速率常数,s−1;cNO 为NO的摩尔浓度,mg·Nm−3;cNH3 为NH3的摩尔浓度,mg·Nm−3。 -

蜂窝状催化剂由多个相同且孤立的孔道构成。单通道作为其基本组成单元,能真实反映烟气在其中的流动、传质和反应过程,可作为对象进行SCR脱硝性能研究,所得结果(脱硝效率和氨逃逸率)在入口参数均匀分布的条件下同样适用于整个催化反应器。基于此,本课题组以贵州某660 MW超临界机组W型火焰锅炉SCR脱硝系统为模拟对象,建立催化剂单通道一维模型,讨论脱硝性能影响因素间的交互作用。催化剂单通道几何结构参数如表1所示。

SCR反应器系统布局及单通道几何模型详见图2。其中,SCR反应器位于省煤器和空气预热器之间,由3层V2O5-WO3/TiO2催化剂组成,模型主要考虑了轴向对流、气固外部传输、催化剂壁内扩散和催化剂表面反应。

-

以SCR催化剂单通道为对象建立数学模型,模型只考虑主反应(1)和副反应(2),基于以下简化和假设[20]:1)反应器与外界无热交换,系统绝热;2)单通道中气体流动与反应过程为稳态;3)烟气流动为一维柱塞流;4)反应物浓度仅沿轴向变化,径向均匀分布;5)整体入口速度、温度和NO浓度分布均匀。

通过分析NO和NH3在孔道中的浓度分布,结合化学反应动力学模型式(3)和式(4),得到两气体组分对流扩散方程为式(5)和(6)。

-

大规模并网的可再生能源在生产中表现出强烈的间歇性和波动性特征[21],为确保稳定的电能输出,燃煤电厂在能源供应系统中承担了大部分可再生能源电网调峰任务,导致运行条件频繁变化,通常在非高峰时段以低负荷水平运行[22]。本研究对象的额定负荷为660 MW,SCR脱硝系统在330 MW(50%负荷)、350 MW(53%负荷)、400 MW(61%负荷)、450 MW(68%负荷)、500 MW(76%负荷)和550 MW(83%负荷)运行工况下的入口速度及入口NO质量浓度变化如图3所示。图3表明,入口速度与调峰运行负荷近线性变化,烟气入口NO质量浓度虽然波动幅度较大,但总体上与调峰运行负荷呈正相关。鉴于该图仅涵盖50%~83%负荷运行数据,在对脱硝性能进行研究时,入口烟气的流速和NO质量浓度还需留存一定裕度,以满足深度调峰与负荷极端变化。

-

入口速度、入口NO质量浓度、氨氮摩尔比和反应温度作为数值模拟的入口边界,需合理限定其数值。模拟参考电厂调峰实际运行数据,结合现有SCR催化剂研究[14,23-24],设定上述入口参数范围如表2所示。

-

建立的数学模型可利用四阶Runge-Kutta,以1 mm作为步长,通过MATLAB软件编程展开数值求解。化学反应动力学模型遵循E-R机理求解化学反应速率,化学反应速率常数由Arrhenius公式[25]确定,详见式(7)。Arrhenius公式中涉及的各化学反应动力学参数取值[17]如表3所示。

式中:

A0 为氨气吸附指前因子,s−1;A1 为脱硝反应指前因子,s−1;A2 为氨气氧化反应指前因子,s−1;E0 为氨气吸附活化能,J·mol−1;E1 为脱硝反应活化能,J·mol−1;E2 为氨气氧化反应活化能,J·mol−1;R 为气体常数,8.314 J·(mol·K)−1;T 为反应温度,K。结合NO还原和NH3氧化的反应速率,以及烟气流经SCR催化剂的时间,可基于式(8)和(9)获得不同入口参数下的脱硝效率及氨逃逸率[26]。

式中:

ηNO 为脱硝效率;ηNH3 为氨逃逸率;CNO,in 为NO入口质量浓度,mg·Nm−3;CNO,out 为NO出口质量浓度,mg·Nm−3;CNH3,in 为NH3入口质量浓度,mg·Nm−3;CNH3,out 为NH3出口质量浓度,mg·Nm−3。 -

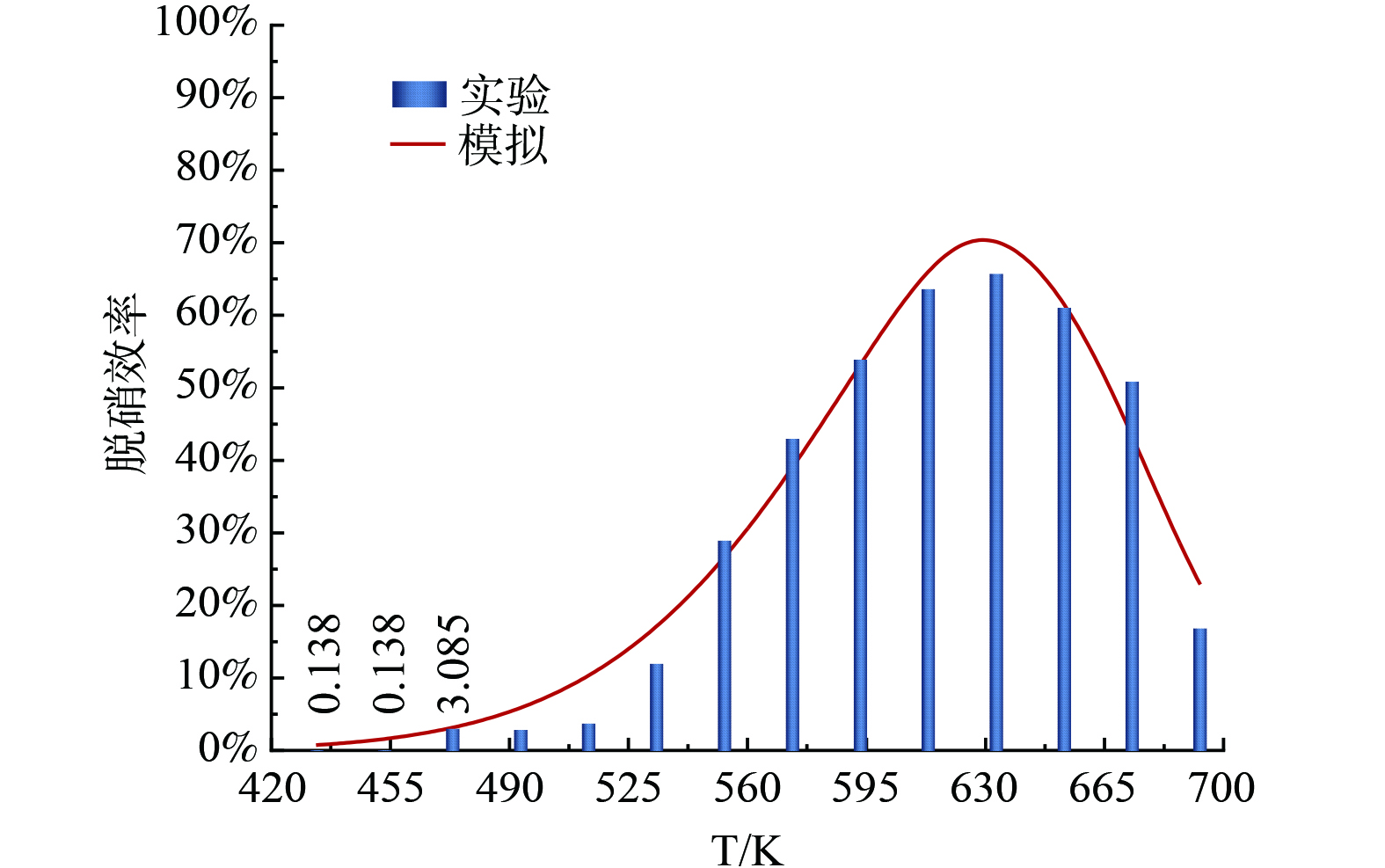

为验证模型准确性,通过建立的模型模拟了不同温度下的脱硝效率,并将相同参数条件下的模拟预测值与运行数据进行对比,如图4所示。对比结果发现,预测值与实验数据吻合良好,变化趋势一致,且预测值和实验值平均误差为5.3%,在工程要求的允许误差范围内[27]。这表明建立的SCR催化剂单通道模型能反映因子与响应值的关系,预测精度较高,可用于SCR脱硝性能预测。

-

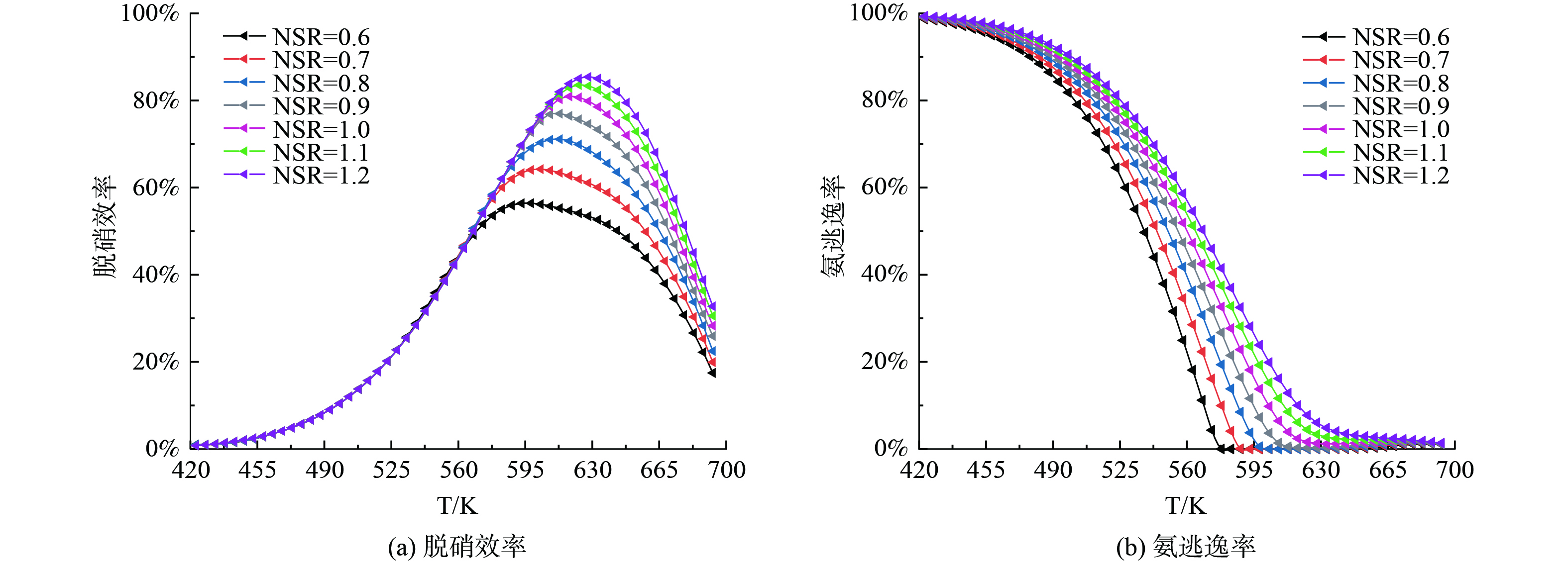

氨氮摩尔比(NSR)为还原剂中NH3摩尔数与SCR反应器入口烟气中NOx摩尔数的比值[28]。为研究NSR与反应温度对脱硝性能的交互作用,使NSR以公差为0.1在0.6~1.2的限度中变动,在入口NO质量浓度为600 mg·Nm−3,入口速度为4 m·s−1的边界条件下,得到脱硝效率及氨逃逸率随温度变化趋势如图5所示。当温度一定时,NSR越大,对应脱硝效率越高。这是由于NSR变大使得烟气中的NH3质量浓度增加,促进了其在催化剂中的扩散与吸附,加快了式(1)反应速率,进而提升了催化剂脱硝效率。此外,增加NSR还会导致最佳反应温度升高。氨逃逸率变化规律与脱硝效率一致,从高到低依次为:NSR(1.2)>NSR(1.1)>NSR(1.0)>NSR(0.9)>NSR(0.8)>NSR(0.7)>NSR(0.6)。在所选温度区间,相同NSR对应的脱硝效率均呈先升后降趋势。这是由于催化剂在较高反应温度域中会产生更多的反应活性位点和吸收位点,而温度过高以后催化剂活性出现一定程度的下降。当NSR<1时,脱硝效率和氨逃逸率随NSR变化波动较大,主要原因是NSR较低时,影响脱硝效率的关键因素是反应物NH3量,NSR增加会使催化剂表面NH3吸附量增加,有利于式(1)反应的进行。当NSR=1.0时,脱硝效率可达85.39%,继续增加NSR脱硝效率增幅不大。这表明NH3在催化剂活性中心上接近吸附饱和,再增加NSR会使NH3质量浓度过大,无法吸附在催化剂上反应而直接逸散的NH3量加多,最终导致氨逃逸率上升。在低反应温度范围(573 K)内,NSR对脱硝效率影响较小,却对氨逃逸率影响显著,而在较高的反应温度范围内,NSR对脱硝效率影响更大,NSR对氨逃逸率的影响主要集中在最佳反应温度附近,偏离最佳反应温度越大,其影响程度越弱。不同NSR的氨逃逸率在573 K时差值最大,为41.60%,主要原因为NSR=0.6在该温度下脱硝效率接近最佳,氨逃逸率较低,而该温度距离NSR=1.2的最佳温度较远,使得其氨逃逸率偏高。继续升温,脱硝效率开始下降,NSR<1的氨逃逸率曲线由低谷出现一定反弹,这可归因于温度上升导致NH3吸附能力降低,未参与反应直接逸出的NH3质量浓度上升。

-

NO与NH3的化学反应为一级反应[29],入口NO质量浓度(

CNO,in )变化会影响其化学反应速率。为研究CNO,in 与反应温度对脱硝性能的交互作用,在NSR为1.0,入口速度为4 m·s−1的边界条件下,使CNO,in 以150 mg·Nm−3的间距在150~1 050 mg·Nm−3中变动,得到脱硝效率及氨逃逸率随温度变化规律如图6所示。在温度达到588 K前,脱硝效率及氨逃逸率随入口NO质量浓度变化波动不大,但对温度变化较为敏感。随着温度升高,式(1)反应速率加快,脱硝效率上升显著,氨逃逸率下降加快。继续升温,式(2)竞争反应物中的NH3量加剧,削弱了式(1)的反应进行程度,导致脱硝效率上升趋势变缓。随着温度进一步升高,式(2)作用更为显著,同时催化剂活性也有所降低,脱硝效率开始下降,但由于式(2)同样消耗NH3,因此当温度抵达最佳反应温度后,氨逃逸率随温度变化不大,氨逃逸率下降曲线趋于平缓。随着入口质量NO浓度增加,最佳反应温度向右偏移,脱硝效率有所提升,入口NO质量浓度由150 mg·Nm−3逐渐增至1 050 mg·Nm−3,最佳脱硝效率增幅分别为4.781%、2.283%、1.272%、0.824%、0.581%及0.434%。在反应温度达到600 K之后,较高入口NO质量浓度会轻微降低氨逃逸率,当CNO,in 为1 050 mg·Nm−3时,脱硝效率可达82.42%,氨逃逸率低至0.33%。这是由于在固定的NSR下,入口NO质量浓度与氨质量浓度同幅增长,有助于烟气和氨在催化剂上反应。 -

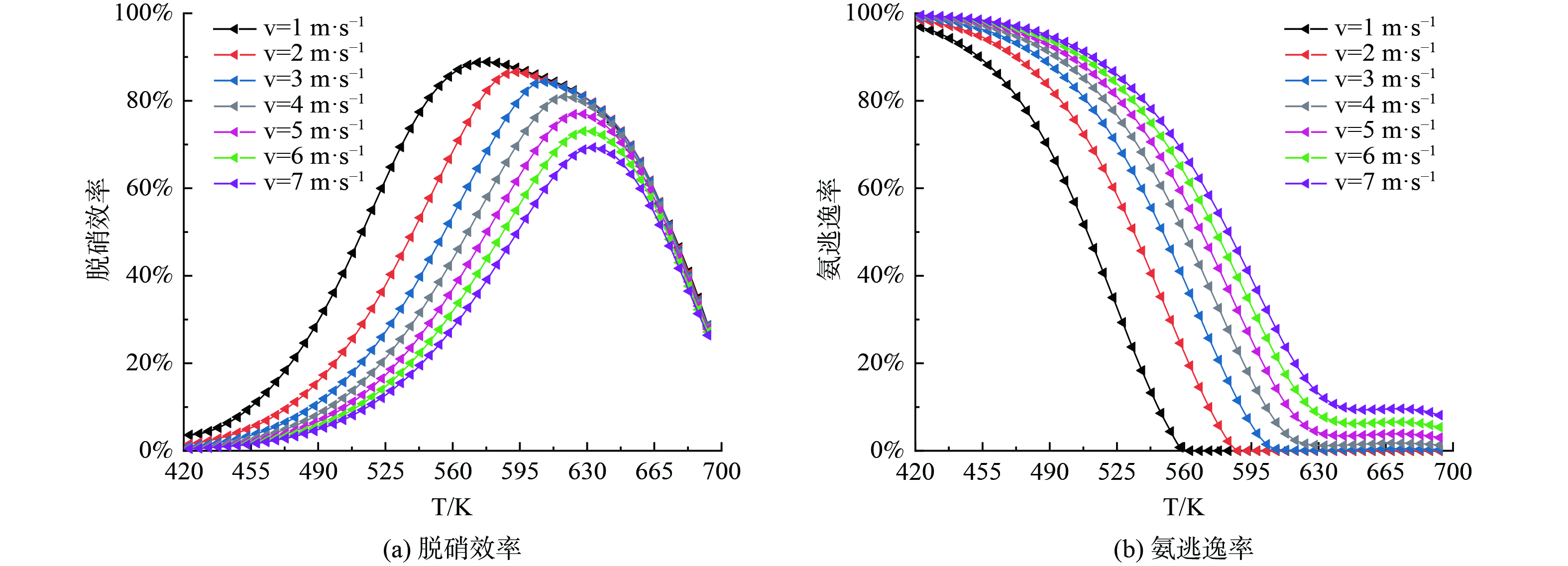

为研究入口速度与反应温度对脱硝性能的交互作用,固定氨氮摩尔比为1.0,

CNO,in 为600 mg·Nm−3,控制入口速度为1~7 m·s−1,并以1 m·s−1递增,得到脱硝效率及氨逃逸率随温度变化情况如图7所示。所有入口速度条件下脱硝性能随温度的变化趋势大致类似。当入口速度一定时,脱硝效率随温度增加急剧上升,到达最佳反应温度后下降趋势加快,而氨逃逸率在最佳反应温度前随温度增加急剧下降,抵达最佳反应温度后下降速率变缓。此外,随入口速度增加,整个反应温度区间脱硝效率与氨逃逸率分别呈逐渐下降和逐步上升趋势。在低温区域(T<633 K),入口速度变化对脱硝效率及氨逃逸率影响较大,而在高温区域(T>633 K),入口速度变化对脱硝效率影响较小。随着入口速度增大,烟气在催化剂表面停留时间减少。为保证反应完全,最佳反应温度向右偏移,催化剂活性受到一定影响,高活性温度窗口收缩。入口速度对脱硝性能影响显著,当入口速度从1 m·s−1升至7 m·s−1时,最佳脱硝效率由89.17%下降到69.32%,最低氨逃逸率由趋近于0上升到8.11%。这是由于较高的入口速度会使催化剂微孔接触的反应物停留时间更短,停留时间缩短不利于反应物在催化剂孔隙中的扩散和吸附,导致反应速率降低,最终表现为脱硝效率降低和氨逃逸加剧。随着入口速度减小,温度对脱硝性能的影响变得更为明显,但提高温度并不一定能增加脱硝效率。这种现象在最佳反应温度之后更加明显,可解释为高温下扩散增加导致反应物在活性层中的停留时间减少及催化剂活性降低。达到最佳活性点后,入口速度相近的2条曲线,脱硝效率下降趋势随入口速度增加而相对减缓。这是因为入口速度增加导致扰流增强,在某种程度上促进了式(1)的反应。在v=1~5 m·s−1的两相邻曲线间,脱硝效率与氨逃逸率差异都很明显,最高脱硝效率和最低氨逃逸率均发生在最低入口速度曲线 (v=1 m·s−1) 上。这说明当v<5 m·s−1时,降低入口速度可显著提升脱硝效率,同时还能大幅降低氨逃逸率。 -

双碳背景下燃煤电厂承担了灵活的调峰任务,机组调峰运行负荷频繁变化总是伴随烟气流量与NO质量浓度的波动[8],两者对脱硝性能的影响皆不可忽略。参考电厂实际运行工况,设置对应的入口速度与入口NO质量浓度。在NSR=1的条件下,得到不同调峰运行负荷下脱硝效率及氨逃逸率如图8所示。调峰运行负荷上升会增大入口NO质量浓度与反应温度,理论上可提升整体脱硝性能。随着调峰运行负荷上升,脱硝效率并未明显增加,反而出现了轻微下降趋势,氨逃逸率也略有上升,脱硝性能整体恶化。这与周智健等[30]和刘景龙等[31]的研究结果一致。当调峰运行负荷从50%负荷升至83%负荷,脱硝效率峰值由85.20%降至81.44%,氨逃逸率最大差值为18.20%。这是由于调峰运行负荷增加导致入口速度、入口NO质量浓度与烟气温度同向升高,而此时影响催化还原反应的主要因素为反应时间[32],83%负荷下SCR反应器平均入口烟气流速是50%负荷下的1.56倍,即83%负荷下SCR反应器的脱硝反应时间仅为50%负荷下的0.64倍,较短的停留时间使得反应不够彻底,脱硝效率降低。同时,由于负荷增加导致烟气平均流速加快,致使更多的NH3分子来不及吸附在催化剂上,加剧了氨逃逸。氨逃逸率升高和脱硝效率降低共同作用的结果表现为燃煤电厂调峰运行负荷增加导致脱硝性能整体下降。

-

1)在不同入口参数下,脱硝效率随温度升至峰值后均呈抛物线快速下落,氨逃逸率随温度增加以先快后慢的趋势下降,入口参数对最佳反应温度影响较大。2)当T<570 K时,氨氮摩尔比(NSR)对脱硝效率无影响,NSR对氨逃逸率的影响主要集中在最佳反应温度附近,偏离最佳反应温度越多,影响程度越弱。NSR>1后,脱硝效率与氨逃逸率随其变化波动不大。3)当T>600 K后,入口NO质量浓度增大在提升脱硝效率的同时会轻微改善氨逃逸。入口NO质量浓度为1 050 mg·Nm−3时,脱硝效率可达82.42%,氨逃逸率低至0.33%。4)入口速度与反应温度对脱性能的交互作用最大。降低入口速度可拓宽催化剂高活性温度窗口,显著改善脱硝性能,速度由7 m·s−1降至1 m·s−1,最佳脱硝效率由69.32%上升到89.17%,最低氨逃逸率由8.11%趋近于0。5)调峰运行负荷上升会加快烟气平均流速,进而导致脱硝效率下降和氨逃逸加剧。

SCR反应器入口参数与反应温度对脱硝性能的交互作用

Interaction effect of inlet parameters and reaction temperature on denitration performance of SCR reactor

-

摘要: 为系统研究选择性催化还原(SCR)反应器入口参数与反应温度对脱硝性能的交互作用,基于E-R机理,通过建立SCR脱硝反应一维模型,结合燃煤电厂调峰实际运行数据设定入口参数界限,利用MATLAB数值仿真,分别对反应温度同氨氮摩尔比(NSR)、入口NO质量浓度和入口速度对脱硝效率及氨逃逸率的耦合效应进行了重点分析。结果表明:入口参数对最佳反应温度影响较大;偏离最佳反应温度越多,NSR对氨逃逸率影响程度越低,NSR>1时,脱硝性能对NSR敏感性降低;增大入口NO质量浓度可改善整体脱硝性能,当入口质量NO浓度为1 050 mg·Nm−3时 ,脱硝效率可达82.42%,氨逃逸率低至0.33%;入口速度与反应温度的交互作用最大,降低入口速度可拓宽催化剂高活性温度窗口,显著提升脱硝性能,将入口速度由7 m·s−1降至1 m·s−1,最佳脱硝效率由69.32%升至89.17%,最低氨逃逸率由8.11%趋近于0;燃煤电厂调峰运行负荷上升会导致脱硝效率下降和氨逃逸加剧。该研究结果可为燃煤电厂SCR脱硝性能的整体优化提供参考。Abstract: In order to systematically study the interaction effects between inlet parameters and reaction temperature of selective catalytic reduction (SCR) reactor on denitration performance, a one-dimensional model of SCR denitration reaction was established based on the E-R mechanism, the inlet parameter boundaries were set by combining actual coal-fired power plant operation data of different loads in peak shaving. The coupling effects of reaction temperature with molar ratio of NH3 to NOx (NSR), inlet NO concentration, inlet velocity on denitration efficiency and ammonia escape rate were examined separately by numerical simulation in MATLAB. The results showed that all the inlet parameters had great influence on the optimum reaction temperature, and the impact of NSR on ammonia escape rate dampened with the increase of deviation from the ideal reaction temperature. When NSR>1, the denitration performance was less sensitive to NSR. By raising the inlet NO concentration, denitration performance could be made better generally. When the concentration of NO was 1 050 mg·Nm−3, the denitration efficiency reached 82.42% and the ammonia escape rate was as low as 0.33%. The interaction between the inlet velocity and reaction temperature was the largest, reducing the inlet velocity could broaden the high activity temperature window of the catalyst and significantly improve the denitration performance. When the inlet velocity was reduced from 7 m·s−1 to 1 m·s−1, the optimal denitration efficiency increased from 69.32% to 89.17%, and the lowest ammonia escape rate approached to 0 from 8.11%. The increase of peak load in coal-fired power plants would lead to the decrease of denitration efficiency and the intensification of ammonia escape. The results of this study can provide a reference for the overall optimization of SCR denitration performance in coal-fired power plants.

-

表 1 催化剂几何结构参数

Table 1. Geometric structure parameters of catalyst

参数 (符号) 单位 数值 孔径(d) mm 6.5 节距(p) mm 7.4 长度(L) mm 985 内壁厚(δin) mm 0.9 外壁厚(δout) mm 1.45 表 2 入口参数范围

Table 2. Value range of inlet parameters

参数 (符号) 单位 数值 入口速度(v) m·s−1 1~7 氨氮比(NSR) — 0.6~1.2 温度(T) K 423~693 入口浓度(CNO,in) mg·Nm−3 150~1 050 表 3 化学反应动力学参数

Table 3. Kinetic parameters of chemical reaction

参数 单位 数值 A0 s−1 2.68·10−17 A1 s−1 1.00·106 A2 s−1 6.80·107 E0 J·mol−1 −2.43·105 E1 J·mol−1 6.00·104 E2 J·mol−1 8.50·104 -

[1] CHEN J, GUAN B, LIU Z, et al. Review on advances in structure–activity relationship, reaction & deactivation mechanism and rational improving design of selective catalytic reduction deNOx catalysts: Challenges and opportunities[J]. Fuel, 2023, 343: 127924. doi: 10.1016/j.fuel.2023.127924 [2] YAO X, ZHANG M, KONG H, et al. Investigation and control technology on excessive ammonia-slipping in coal-fired plants[J]. Energies, 2020, 13(16): 4249. doi: 10.3390/en13164249 [3] 武洁, 张志勇, 刘显丽. 燃煤电厂机组负荷变化与SCR系统参数的相关性分析[J]. 环境工程, 2021, 39(8): 131-135. doi: 10.13205/j.hjgc.202108018 [4] LI Z, LEE Y S, CHEN J, et al. Developing variable moving window PLS models: Using case of NO x emission prediction of coal-fired power plants[J]. Fuel, 2021, 296: 120441. doi: 10.1016/j.fuel.2021.120441 [5] YIN J, LIU M, WU Q, et al. Optimized fluegas denitrification control strategy to enhance SCR performance during load-cycling transient processes in coal-fired power plants[J]. Fuel, 2023, 344: 127837. doi: 10.1016/j.fuel.2023.127837 [6] 冯前伟, 张杨, 王丰吉, 等. 燃煤机组SCR脱硝超低排放改造前后性能对比分析[J]. 中国电机工程学报, 2020, 40(20): 6644-6653. [7] 凌忠钱, 曾宪阳, 胡善涛, 等. 电站锅炉SCR烟气脱硝系统优化数值模拟[J]. 动力工程学报, 2014, 34(1): 50-56. [8] ZHENG C, LI X, LI J, et al. Investigation on the ammonia emission characteristics in coal-fired power plants of China[J]. Fuel, 2022, 314: 123046. doi: 10.1016/j.fuel.2021.123046 [9] HU B, CHEN C, JIANG S, et al. Investigating the optimization design of internal flow fields using a selective catalytic reduction device and computational fluid dynamics[J]. Energies, 2022, 15(4): 1451. doi: 10.3390/en15041451 [10] 邹红果, 啜广毅, 张丽丽, 等. CFD模拟对SCR系统流场及性能的优化[J]. 环境工程, 2019, 37(12): 149-152. [11] ZHENG C, XIAO L, QU R, et al. Numerical simulation of selective catalytic reduction of NO and SO2 oxidation in monolith catalyst[J]. Chemical Engineering Journal, 2019, 361: 874-884. doi: 10.1016/j.cej.2018.12.150 [12] LEI Z, LIU X, JIA M. Modeling of selective catalytic reduction (SCR) for NO removal using monolithic honeycomb catalyst[J]. Energy & Fuels, 2009, 23(12): 6146-6151. [13] 赵大周, 何胜, 司风琪, 等. 选择性催化还原单孔催化剂数值模拟[J]. 热力发电, 2016, 45(4): 100-105. [14] 杜云贵, 吴其荣, 邓佳佳, 等. SCR烟气脱硝催化剂的化学动力学模拟研究[J]. 热力发电, 2010, 39(2): 52-55. [15] 李晗天, 宋蔷, 姚强. SCR反应器入口速度与氨分布不均匀性对脱硝性能的影响[J]. 中国电机工程学报, 2017, 37(9): 2599-2607. [16] 张迪, 王勇强, 周月桂. 低尘SCR系统单孔催化剂模拟研究[J]. 锅炉技术, 2018, 49(5): 1-6. [17] 沈伯雄, 赵宁, 刘亭. 烟气脱硝选择性催化还原催化剂反应模拟研究[J]. 中国电机工程学报, 2011, 31(8): 31-37. [18] 叶蒙双, 冯晓露, 张政江. 先进预测控制在SCR控制系统中的运用[J]. 科学技术与工程, 2016, 16(10): 155-158. doi: 10.3969/j.issn.1671-1815.2016.10.031 [19] ZHANG K, FANGMING X, ZHIQIANG W, et al. Research on prediction model of formation temperature of ammonium bisulfate in air preheater of coal-fired power plant[J]. Chinese Journal of Chemical Engineering, 2022, 48: 202-210. doi: 10.1016/j.cjche.2021.09.018 [20] SCHAUB G, UNRUH D, WANG J, et al. Kinetic analysis of selective catalytic NOx reduction (SCR) in a catalytic filter[J]. Chemical Engineering and Processing:Process Intensification, 2003, 42(5): 365-371. doi: 10.1016/S0255-2701(02)00056-9 [21] ZHU S, HUI J, LYU Q, et al. Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: Preheating characteristics for peak shaving[J]. Fuel, 2022, 324: 124684. doi: 10.1016/j.fuel.2022.124684 [22] LIN L, XU B, XIA S. Multi-angle economic analysis of coal-fired units with plasma ignition and oil injection during deep peak shaving in China[J]. Applied Sciences, 2019, 9(24): 5399. doi: 10.3390/app9245399 [23] SZYMASZEK A, SAMOJEDEN B, MOTAK M. The deactivation of industrial SCR catalysts—A short review[J]. Energies, 2020, 13(15): 3870. doi: 10.3390/en13153870 [24] SHANG D, LI B, LIU Z. Large eddy simulation of transient turbulent flow and mixing process in an SCR denitration system[J]. Chemical Engineering Research and Design, 2019, 141: 279-289. doi: 10.1016/j.cherd.2018.11.006 [25] XIN Q, HUA Z, FU Y, et al. Investigation on optimal active layer thickness and pore size in dual-layer NH3-SCR monolith for low SO2 oxidation by numerical simulation[J]. Fuel, 2020, 279: 118420. doi: 10.1016/j.fuel.2020.118420 [26] CHEN L, LIAO Y, XIN S, et al. Simultaneous removal of NO and volatile organic compounds (VOCs) by Ce/Mo doping-modified selective catalytic reduction (SCR) catalysts in denitrification zone of coal-fired flue gas[J]. Fuel, 2020, 262: 116485. doi: 10.1016/j.fuel.2019.116485 [27] ZHOU Z, CHANG J, WANG X. Large eddy simulation of hydrodynamics and deNO x process in a coal-fired power plant SCR system[J]. Journal of Environmental Management, 2022, 320: 115800. doi: 10.1016/j.jenvman.2022.115800 [28] 金森旺, 吴芳, 孙献斌, 等. 床温及SNCR脱硝对CFB锅炉NO x 和N2O排放影响的试验研究[J]. 热力发电, 2020, 49(5): 104-110. [29] LIU L, ZHANG L, ZHANG Q, et al. Catalytic performance and kinetics of Wire-mesh honeycomb catalyst for reduction of NO with NH3[J]. Journal of Nanoscience and Nanotechnology, 2014, 14(9): 7199-7203. doi: 10.1166/jnn.2014.8972 [30] 周智健, 王信, 常剑, 等. 660MW燃煤电厂SCR脱硝系统CFD模拟优化研究[J]. 中国电机工程学报, 2021, 41(19): 6688-6699. doi: 10.13334/j.0258-8013.pcsee.202015 [31] 刘景龙, 张利孟, 赵中华, 等. 1000MW燃煤机组SCR脱硝系统变负荷特性试验研究[J]. 山东电力技术, 2022, 49(10): 66-73. [32] 欧阳朔. 电站锅炉尾部烟道流场数值模拟分析及优化[D]. 北京: 华北电力大学(北京), 2022. -

下载:

下载: