-

污水再生利用是解决水资源短缺的有效途径,微量污染物在污水处理厂出水中频繁检出,威胁再生水用水安全,需要研发高效的深度处理工艺将其去除[1-2]。常用的深度去除技术主要有生物处理、吸附、膜分离、高级氧化等。其中,吸附和膜分离技术只是对微量污染物进行了相转移,通常需要与高级氧化技术结合以实现污染物降解[3-4]。臭氧催化氧化作为常用的高级氧化技术,通过在反应体系中加入催化剂促进臭氧分解,引发自由基链式反应,具有氧化能力强,反应速率快,适用范围广,去除污染物彻底的特点,但也存在催化剂团聚、回收困难的问题[5-7]。

将臭氧催化氧化与陶瓷膜技术结合,构建的陶瓷催化膜-臭氧工艺,弥补了上述方法的不足,在复杂水体微量污染物处理中有广阔的应用前景。GUO等[8]的研究表明,2-羟基-4-甲氧基二苯甲酮(benzophenone-3, BP-3)的初始质量浓度为0.5 mg·L−1时,陶瓷膜-臭氧工艺对BP-3的去除率约为75%,CuMn2O4改性的陶瓷催化膜-臭氧工艺对BP-3的去除率提高至90%。LEE等[9]的研究表明,在双酚A(bisphenol,BPA)、苯并三唑(benzotriazole,BTA)、氯贝酸(clofibric acid,CA)的初始质量浓度为3 mg·L−1时,与陶瓷膜-臭氧工艺相比,CeOx改性的陶瓷催化膜-臭氧工艺对BPA的去除率由20%增至80%,对BTA去除率由50%增至57%,对CA的去除率由30%增至40%。PARK等[10]的研究表明,在对氯苯甲酸(p-chlorbenzoic acid, p-CBA)的初始质量浓度为5 mg·L−1时,与陶瓷膜-臭氧工艺相比,Fe2O3改性的陶瓷催化膜-臭氧工艺对p-CBA的去除率由28%增至46%。上述关于陶瓷催化膜-臭氧工艺去除微量污染物的研究中,实验进水均为以纯水为背景的自配水,对实际应用的参考价值有限。实际二级出水成分复杂,微量污染物与水中的有机物竞争催化臭氧氧化产生的活性氧物种,需要进一步研究陶瓷催化膜-臭氧工艺处理实际污水中微量污染物的特性。

在催化剂的选择方面,BYUN等[11]比较了铁氧化物、锰氧化物负载的陶瓷催化膜对富营养化湖泊中的有机物的去除效果,发现与铁氧化物相比,锰氧化物负载的陶瓷催化膜对TOC的去除率更高。与锰氧化物相比,锰基双金属氧化物由于双金属氧化物的存在,具有更高的催化性能[12-14]。因此,有必要进一步研究锰基双金属氧化物MnMeOx(Me=Fe、Co、Ce)改性陶瓷催化膜的性能。

本课题组前期研究[15]成功制备了4种基于α-MnO2的锰系陶瓷催化膜,包括单独α-MnO2 的催化膜和基于α-MnO2的MnMe双金属氧化物(Me=Fe、Co、Ce)的陶瓷催化膜(Mn-CM、MnFe-CM、MnCo-CM、MnCe-CM),表征了陶瓷催化膜的物相结构,构建了陶瓷催化膜-臭氧反应器,研究了其在批式运行条件下对阿特拉津的去除特性,与陶瓷膜相比,基于α-MnO2的Mn-CM催化臭氧氧化对阿特拉津的去除率提高了21.15%。与MnCM和MnMe-CM相比,MnCe-CM对阿特拉津的反应速率常数最大(1.62 min−1),去除率最高(99.99%),催化性能最优。进一步的机理分析表明,锰铈催化膜中丰富的微米反应器在臭氧催化氧化微量污染物中的重要作用,首先,电镜结果表明基于抽吸-原位氧化沉淀法制备的锰铈催化膜表面和孔内均存在明显的催化剂沉积;其次,锰铈催化膜-臭氧工艺对阿特拉津的总去除率为79%,其中,膜孔内的催化臭氧反应对阿特拉津的去除率为61%,膜孔催化与过滤对污染物去除的贡献率为77%;根据XPS表征、EPR表征和分子探针实验,MnCe-CM的2组氧化还原对(Ce3+/Ce4+和Mn3+/Mn4+)为锰铈催化膜催化氧化提供更多的氧空位,促进臭氧分解产生大量•OH(9.82 μmol·L−1)和•O2−(1.3 μmol·L−1),自由基氧化是锰铈催化膜催化臭氧氧化微量污染物的主要途径。

本研究基于课题组的前期成果,建立了锰铈催化膜-臭氧工艺(O3/MnCe-CM),并开展了连续运行实验,评估了其在不同臭氧投加量下对实际二级出水中4种典型微量污染物的去除特性,确定了最佳臭氧投加量,并分析了锰铈催化膜-臭氧工艺对实际二级出水中常规污染物的去除特性,目的是为锰铈催化膜-臭氧工艺的实际应用提供参考。

-

本研究使用的陶瓷膜(0.1 μm,中清环境,中国)为平板多通道膜,陶瓷膜的支撑层和膜层均为α-Al2O3,过滤方式为外进内吸,尺寸长10 cm,宽10 cm,高0.5 cm。通过抽吸-煅烧法制备锰铈催化膜,具体制备过程见之前的研究[15]。主要步骤为:将陶瓷膜放入0.03 mol·L−1 Mn(Ac)2和0.01 mol·L−1 Ce(NO3)3·6H2O的混合溶液中,通过蠕动泵过滤,过滤速度为10 mL·min−1,过滤时间为16 h,抽滤完成后,冲洗干燥,去掉多余的溶液。接着将陶瓷膜缓慢放置于0.04 mol·L−1 KMnO4中,通过蠕动泵过滤,过滤速度为200 μL·min−1,过滤时间为16 h。在过滤过程中,KMnO4与金属硝酸盐发生氧化还原反应,原位生成锰铈氧化物,锰铈催化膜记为MnCe-CM。将锰铈催化膜用无机胶封装在膜组件中,室温干燥12 h,待封层牢固即可使用。

实验用水以二级出水为背景,选择了4种在二级出水中频繁检出、臭氧难降解的微量污染物:避蚊胺(

kO3 <10 mol·(L·s) -1)、苯并三唑(kO3 =20 mol·(L·s)−1)、阿特拉津(kO3 =6 mol·(L·s) -1)、西玛津(kO3 =8.7 mol·(L·s)−1),其中kO3 为这些物质与臭氧的反应动力学常数,考虑到微量污染物在实际二级出水中的检出质量浓度,确定投加量为10 μg·L−1[16-19]。二级出水来自北京某再生水厂,工艺流程为粗格栅-细格栅-厌氧/缺氧/好氧池-二沉池-无阀滤池,DOC的质量浓度为3.7~4.3 mg·L−1,UV254的为0.11~0.09 cm−1,多糖的质量浓度为12.6~13.2 mg·L−1,蛋白质的质量浓度为0.037~0.04 mg·L−1。 -

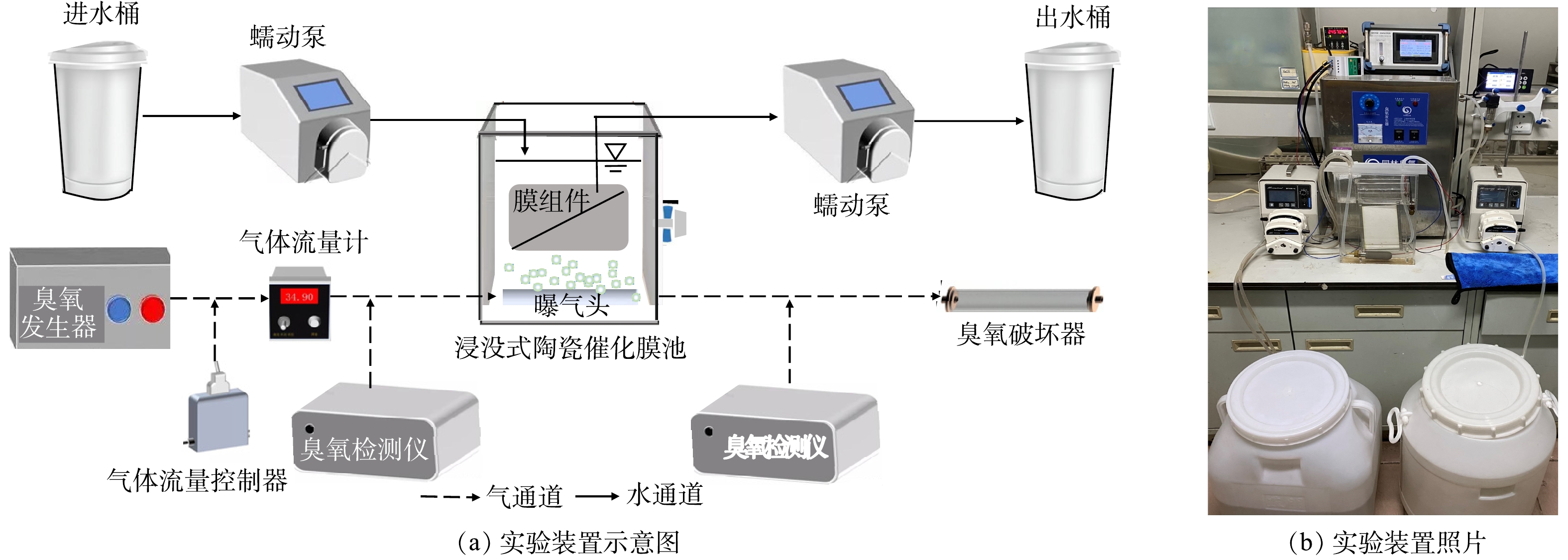

陶瓷催化膜-臭氧工艺的实验装置如图1所示,臭氧由臭氧发生器产生,经过气体流量计和流量控制器,通过曝气头进入膜池。浸没式膜池体积为1 L,配有钛曝气头和膜组件。实验进水通过蠕动泵进入膜池,臭氧曝气与膜过滤同时进行,膜出水通过蠕动泵至出水桶。膜池出口多余的臭氧被臭氧破坏器破坏后排出。系统运行方式为连续运行,过滤方式为死端过滤,臭氧流速为100 mL·min−1,通过调节进气臭氧浓度,控制臭氧投加量分别为2.5 mg·L−1和5 mg·L−1。膜通量为60 L·(m−1·h)−1,膜池停留时间为100 min,过滤时间为180 min,每隔5 min在出水桶中取一次样品。将样品通过0.45 μm聚四氟乙烯滤膜,检测样品微量污染物和常规污染物的质量浓度,评估锰铈催化膜-臭氧工艺在不同臭氧投加量下对污染物的去除效果。采用

CC0 表示微量污染物的去除效果,其中C和C0分别为t时间和污染物的初始浓度,mg·L−1或者μg·L−1。在相同条件下,所有实验重复3次,误差小于10%(保证数据的准确性)。 -

采用总有机碳分析仪(TOC-L,岛津,日本)测定样品中有机物质量浓度;采用紫外分光光度计(DR/5000,哈希,美国)测定样品中有机物在波长254 nm下的吸光度;采用蒽酮-硫酸比色法测定样品中的总糖含量,以葡萄糖为标准溶液,取样品提取液0.4 mL,加入1.6 mL蒽酮试剂,混匀,水浴后冷却至室温,测定样品在620 nm处的吸光度;采用考马斯亮蓝法测定样品中蛋白质的含量,以牛血清白蛋白为标准品,取样品0.1 mL,加入5 mL 考马斯亮蓝G-250,混匀,静置2 min,测定样品在595 nm处的吸光度[20]。

采用液相色谱-质谱联用系统(1290/6460,安捷伦,美国)检测微量污染物的浓度,色谱柱为Acclaim RSLC 120 C18(2.1 mm×100 mm,2.2 μm)。检测时间为10 min,阿特拉津、避蚊胺、苯并三唑、西玛津的出峰时间分别为3.09、4.01、2.58、3.57 min。流动相为甲醇(A)和纯水(B),梯度为:0 min-10%A+90% B;1.5 min-30%A+70%B;3 min-50%A+50%B;4.5 min-70%A+30%B;6 min-90%A+10%B,流速为0.2 mL·min−1,检测模式为ESI正离子模式[15, 21]。

采用荧光分光光度计(F-2500,日立,日本)检测样品中的有机物成分。测试条件为:扫描速度12 000 nm·min−1,激发光波长200~500 nm,发射光波长200~450 nm,步长均为5 nm。根据CHEN等关于荧光数据分区的研究结果[22],将得到的数据分成5个区域,包括腐殖酸类、富里酸类、色氨酸类、酪氨酸类和微生物代谢副产物类。利用Matlab R2018对数据进行批处理积分,得到每个区域的积分面积及占比,从而对样品中有机物含量进行定性及半定量分析。

采用凝胶色谱(Rid-20A,岛津,日本)测定水样的分子质量分布,检测器为示差折光检测器,色谱柱为水相凝胶色谱柱(TSKgelGMPWXL,TOSOH,日本),柱温35 ℃。流动相为0.1 mol·L−1的NaNO3和0.05%的NaN3溶液,流动相流速为0.6 mL·min−1。采用分子质量为903 000、580 000、146 000、44 200、1 000、600 Da的聚乙二醇标样组做标准曲线[23]。

采用微孔板型多功能检测仪(Promega,美国)测定水中发光细菌急性毒性,测试方法参考ISO11348-3[24],用1 mL NaCl溶液将费氏弧菌(NRRLB-11177)冻干粉复苏,将180 μL待测溶液和20 μL菌液加至96孔细胞培养板(Corning,美国)中,在多功能检测仪中测定其发光强度,最后计算费氏弧菌抑制率IR%。

-

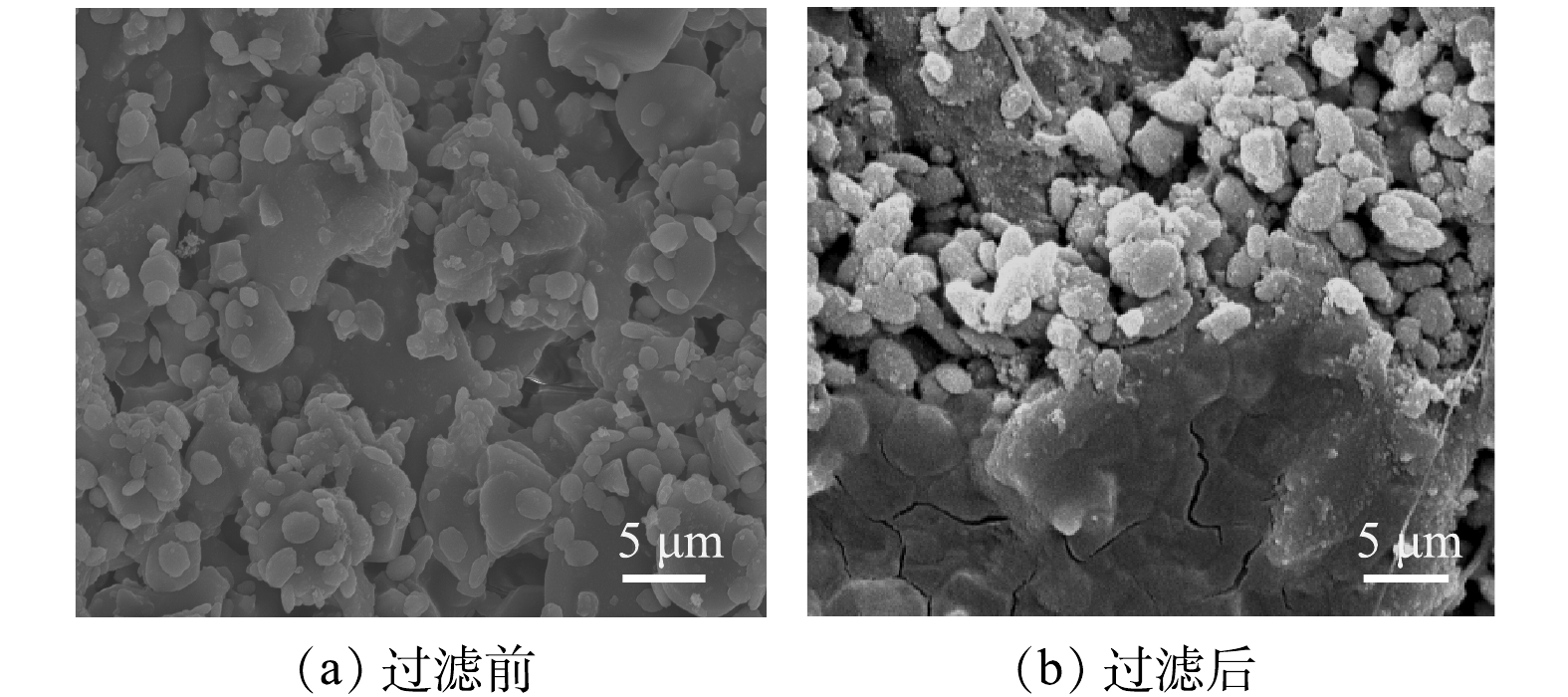

不同臭氧投加量下锰铈催化膜-臭氧工艺对四种典型微量污染物的去除效果如图2所示,阿特拉津、苯并三唑、西玛津、避蚊胺在二级出水中的初始质量浓度为10 μg·L−1。由于二级出水中有机物的存在,膜过滤对微量污染物的去除率随着时间的增加而增加,说明有机物的存在有利于膜对污染物的截留。其中,运行180 min,陶瓷膜过滤阿特拉津、苯并三唑、西玛津、避蚊胺的去除率分别为50%、20%、58%、52%(图2(a))。截留率与4种微量污染物的分子质量有关,陶瓷膜对阿特拉津(分子质量215.68 Da)、西玛津(分子质量201.6 Da)、避蚊胺(分子质量191.27 Da)3种分子质量较大的污染物截留率较高,而对分子质量小的苯并三唑(119 Da)截留率较低。因此,对于膜过滤去除二级出水体系的微量污染物,孔径筛分起主要作用。锰铈催化膜过滤对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率分别为56%、22%、60%、45%,去除趋势与陶瓷膜过滤相似,去除率随着过滤时间的增加而增加(图2(b))。过滤前后锰铈催化膜表面的电镜表征对比如图3所示,与过滤前相比,过滤后锰铈催化膜表面有明显的颗粒物沉积,膜表面孔径减小,进一步证明了孔径筛分在锰铈催化膜过滤去除微量污染物中起重要作用。这与胡尊芳[24]的研究结果一致,二级出水中的SS为微量污染物的去除提供吸附位点,超滤膜表面沉积的有机物有利于截留微量污染物。

臭氧投加量为2.5 mg·L−1时,陶瓷膜-臭氧工艺在180 min对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率分别为23%、28%、65%、56%(图2(c)),锰铈催化膜-臭氧氧化在180 min对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率分别为25%、30%、69%、62%,略高于陶瓷膜(图2(d))。由于二级出水有机物的存在,微量污染物除了彼此竞争羟基自由基外,还需要和水中的有机物竞争。MAILLER等的研究也表明由于实际二级出水中的有机物与微量污染物竞争活性炭的吸附位点,活性炭对微量污染物的吸附量降低,分子质量大的微量污染物对有机物的竞争更敏感[25]。二级出水的大分子有机物被氧化成小分子,消耗了部分臭氧,因此,在复杂水体中去除微量污染物需要更长的反应时间和更高的臭氧投加量。

臭氧投加量5 mg·L−1时,陶瓷膜-臭氧工艺在180 min内对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率分别为40%、72%、78%、55%(图2(e))。如表1所示,伪一级反应动力学常数为0.003~0.009 min−1,约为臭氧投加量2.5 mg·L−1时的1~8倍。锰铈催化膜-臭氧工艺在180 min内对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率分别为80%、94%、96%、92%(图2(f)),伪一级反应动力学常数为0.006~0.016 min−1,约为臭氧投加量2.5 mg·L−1时的2.7~8倍,约为陶瓷膜-臭氧工艺的1.7~3倍。陶瓷膜-臭氧工艺和锰铈催化膜-臭氧工艺对微量污染物的降解效果随着臭氧投加量的增加而增加,锰铈催化膜-臭氧工艺在臭氧投加量5 mg·L−1、运行时间180 min时对4种微量污染物的去除率大于80%。

国家生态环境部《水回用指南 再生水中药品和个人护理品类微量污染物处理技术》(T/CSES 42-2021)中推荐的单位DOC的臭氧投加量为0.35~1.50 mg[26]。针对本研究实验进水的DOC,计算出《指南》推荐臭氧投加量为1.6~7 mg·L−1。本研究建立的锰铈催化膜-臭氧氧化工艺在臭氧投加量5 mg·L−1条件下,对4种微量污染物的去除率大于80%,满足《指南》提出微量污染物去除率大于80%的目标,也满足瑞士对污水处理厂12种指示物去除率高于80%的标准[27]。

通过计算CT值,即氧化剂投加量(C)和作用时间(T)的乘积,比较本研究与前人的研究结果。锰铈催化膜-臭氧工艺的最佳臭氧投加量为5 mg·L−1,水力停留时间为2.5 min,锰铈催化膜-臭氧工艺的CT值为12.5 mg·min·L−1,对4种典型微量污染物的去除率均大于80%,满足国家生态环境部《水回用指南 再生水中药品和个人护理品类微量污染物处理技术》(T/CSES 42-2021)关于微量污染物去除的标准。李先华等[28]研究了臭氧脱色在己内酰胺废水中的应用,结果表明水力停留时间15 min,臭氧投加量30 mg·L−1,CT值为450 mg·min·L−1,COD降低了27%,色度从450倍降至40倍。张云辉等[29]采用臭氧脱色工艺对污水处理厂进行提标改造,结果表明接触时间55 min,臭氧投加量18~25 mg·L−1,CT值990~1375 mg·min·L−1,色度和COD的去除率分别为70%和15%,出水水质符合标准。与上述臭氧脱色工艺的CT值相比,锰铈催化膜-臭氧工艺的CT值远低于臭氧脱色,锰铈催化膜-臭氧工艺能在更低的臭氧投加量和更短的作用时间实现微量污染物的高效去除。

-

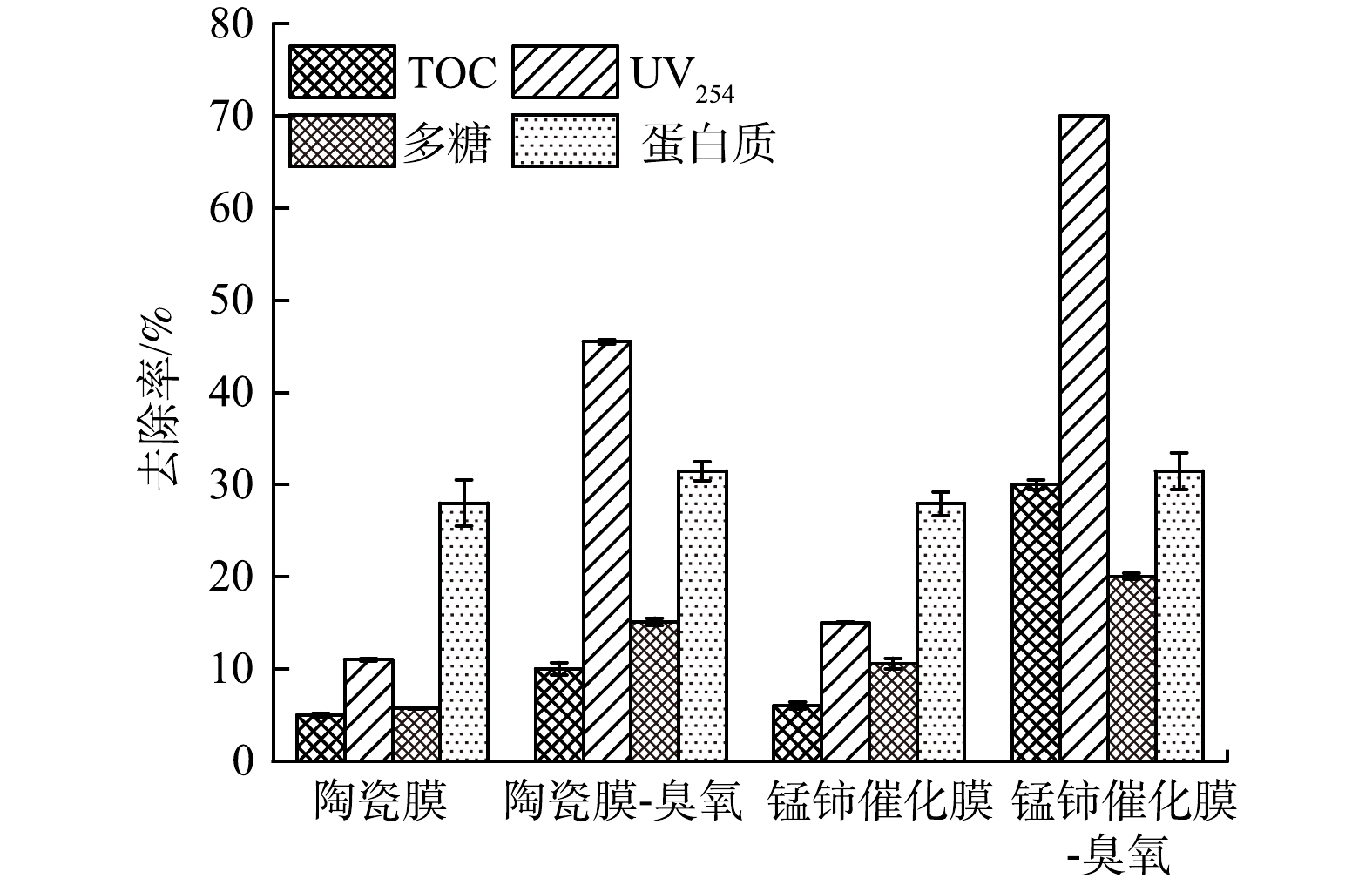

为了深入分析锰铈催化膜-臭氧工艺对二级出水有机物的去除特性,取运行时间30 h的出水,通过分子质量分析、荧光分析的方法表征出水有机物的性质。锰铈催化膜-臭氧工艺对二级出水中TOC、UV254、多糖、蛋白质的去除如图4所示。陶瓷膜过滤对TOC的去除率为5%,锰铈催化膜过滤对TOC的去除率略高于陶瓷膜。锰铈催化膜-臭氧工艺对TOC的去除率为32%,是单独锰铈催化膜过滤的5倍,单独膜过滤对TOC的去除十分有限,耦合臭氧可以提高对TOC的去除。陶瓷膜和锰铈催化膜过滤对UV254的去除率分别为11%和15%,陶瓷膜-臭氧工艺和锰铈催化膜-臭氧工艺对UV254的去除率分别是单独膜过滤的4.1倍和4.4倍,说明臭氧氧化可以提高水中腐殖酸类大分子及芳香族化合物的去除。陶瓷膜-臭氧工艺与锰铈催化膜-臭氧工艺对多糖和蛋白质的去除也表现出相似的规律,其中,锰铈催化膜-臭氧工艺对多糖的去除率比单独膜过滤约提高了10%,对蛋白质的去除率比单独膜过滤约提高了4%。原因是臭氧催化氧化与膜过滤协同作用会产生羟基自由基,提高对水中有机物的去除[15]。

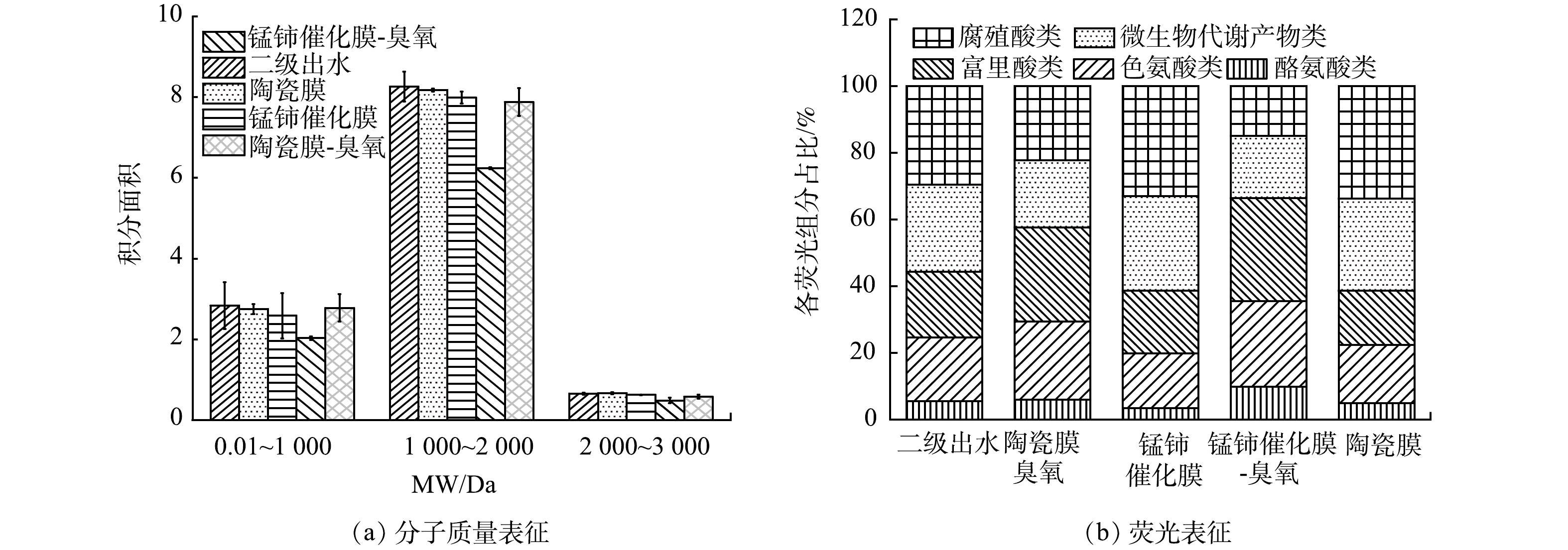

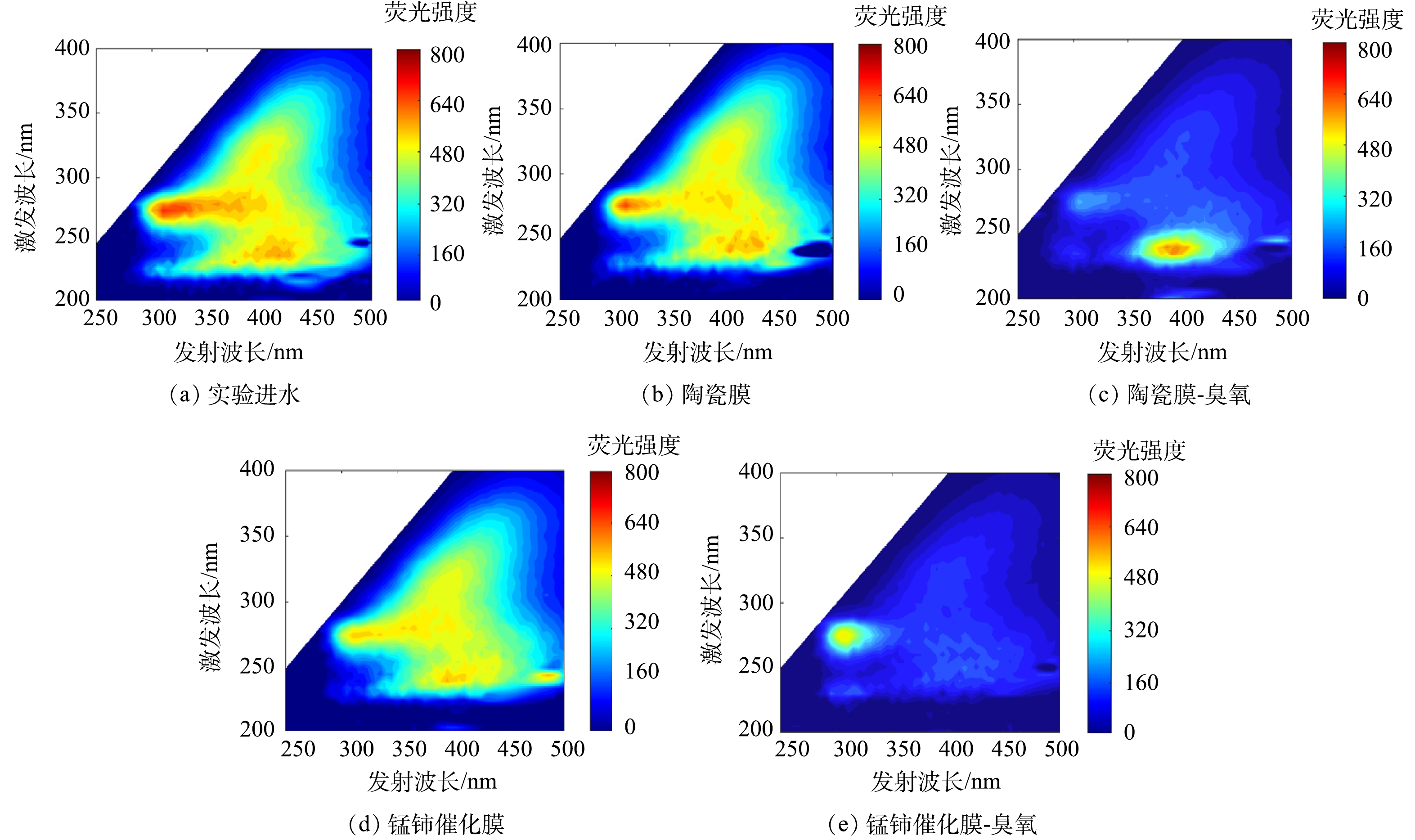

陶瓷膜过滤、陶瓷膜-臭氧工艺、锰铈催化膜过滤、锰铈催化膜-臭氧工艺进出水有机物的分子质量和荧光表征如图5和图6所示,将分子质量分布积分,得到0.01~1 000、1 000~2 000、2 000~3 000 Da的积分面积,实际二级出水的分子质量在684~3 586 Da,主要以腐殖酸类物质为主,锰铈催化膜-臭氧工艺在0.01~1 000、1 000~2 000、2 000~3 000 Da的积分面积均最小。该工艺可以有效矿化水中的有机物,实现对有机物的完全去除,这与工艺对TOC去除率的结果一致。

对荧光光谱进行分区积分,得到陶瓷膜和锰铈催化膜出水中各组分荧光强度占比以及平均荧光强度。二级出水的平均荧光强度为246.38,陶瓷膜过滤对平均荧光强度的去除率为6%,加入臭氧后,平均荧光强度去除率提高至18%,锰铈催化膜过滤对平均荧光强度的去除率为10%,加入臭氧后,平均荧光强度的去除率提高至48%。臭氧的加入可以降低水中荧光物质,锰铈催化膜-臭氧工艺荧光强度去除率的增加证明了臭氧催化氧化与膜过滤协同作用。二级出水中有机物主要以腐殖酸、微生物代谢产物、富里酸、酪氨酸为主,所占比例分别为29%、26%、19%、19%。锰铈催化膜过滤后,富里酸、酪氨酸、色氨酸的去除率分别为18%、22%、20%。耦合臭氧后,陶瓷膜-臭氧工艺和锰铈催化膜-臭氧工艺均对腐殖酸的去除率最高,去除率分别为24%和51%。锰铈催化膜-臭氧工艺对水中腐殖酸类荧光物质的去除率高于陶瓷膜-臭氧工艺,说明臭氧的加入主要通过去除水中的腐殖酸类物质,进而降低水中的荧光强度。锰铈催化膜-臭氧工艺运行180 min,锰离子溶出质量浓度为0.06 μg·L−1,未检测到铈离子溶出,锰离子的溶出质量浓度小于国家《生活饮用水卫生标准》(GB 5749-85)规定值(0.1 mg·L−1)[28],也远低于前人研究CeOx改性的陶瓷催化膜运行60 min,铈的溶出质量浓度为0.61 mg·L−1,MnOx改性的陶瓷催化膜运行60 min,锰离子的溶出质量浓度为5.99 mg·L−1[9]。锰铈催化膜-臭氧工艺进水的费氏弧菌发光强度为3.95×107 cd,平均抑制率为5%,出水的费氏弧菌发光强度平均抑制率为0,表明锰铈催化膜-臭氧工艺出水无生物急性毒性。

-

1)孔径筛分在膜过滤去除二级出水体系中微量污染物起主要作用。锰铈催化膜过滤对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率分别为56%、22%、60%、45%,去除率随着工艺运行时间的增加而增加。

2)与陶瓷膜-臭氧工艺相比,锰铈催化膜-臭氧工艺对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率显著提高,臭氧投加量5 mg·L−1时,锰铈催化膜-臭氧工艺反应动力学常数为陶瓷膜-臭氧工艺的1.7~3倍。

3)锰铈催化膜-臭氧工艺在二级出水体系中最佳臭氧投加量为5 mg·L−1,此时工艺对4种典型微量污染物的去除率均大于80%,满足国家生态环境部《水回用指南 再生水中药品和个人护理品类微量污染物处理技术》(T/CSES 42-2021)关于微量污染物去除的标准。

4)当臭氧投加量5 mg·L−1时,锰铈催化膜-臭氧工艺对二级出水中TOC的去除率为32%,对UV254的去除率为66%,工艺通过降解水中的腐殖酸类荧光物质去除有机物,工艺出水无急性毒性。

锰铈催化膜-臭氧工艺对污水厂二级出水的去除特性

The removal characteristics of pollutants in the secondary effluent by a MnCe-catalytic ceramic membrane-ozonation process

-

摘要: 为深入解析锰铈催化膜-臭氧工艺(O3/MnCe-CM)对二级出水中微量污染物和常规污染物的去除特性,以陶瓷膜-臭氧工艺(O3/CM)为对照,研究了锰铈催化膜-臭氧工艺在单独膜过滤、臭氧投加量2.5~5 mg·L−1时,对二级出水中4种典型微量污染物和常规有机物的去除特性。结果表明,与陶瓷膜-臭氧工艺相比,锰铈催化膜-臭氧工艺对阿特拉津、苯并三唑、避蚊胺和西玛津的去除率显著提高,臭氧投加量5 mg·L−1时,锰铈催化膜-臭氧工艺反应动力学常数为陶瓷膜-臭氧工艺的1.7~3倍。锰铈催化膜-臭氧工艺在二级出水体系中最佳臭氧投加量为5 mg·L−1,此时工艺对微量污染物的去除率均大于80%,满足国家生态环境部《水回用指南 再生水中药品和个人护理品类微量污染物处理技术》(T/CSES 42-2021)关于微量污染物去除的标准。锰铈催化膜-臭氧工艺对二级出水中TOC的去除率为32%,对UV254的去除率为66%,去除的有机物主要是腐殖酸类荧光物质,出水无急性毒性。Abstract: To comprehensively reveal the removal characteristics of micro-pollutants and conventional pollutants in the secondary effluent by the MnCe-catalytic ceramic membrane-ozonation (O3/MnCe-CM) process, the removal performance of O3/MnCe-CM process for four typical micro-pollutants and conventional pollutants was studied at the ozone dosages from 2.5 to 5 mg·L−1 with O3/CM as the control group. Moreover, the removal performance of membrane filtration for MnCe-CM was investigated with CM as the control group. The results show that the removal rates of atrazine, benzotriazole, DEET, and simazine by the O3/MnCe-CM process were significantly improved in comparison to O3/CM process. The kinetic constants of the O3/MnCe-CM process were 1.7-3 times those of the O3/CM process at the ozone dosage of 5 mg·L−1. The optimal ozone dosage of the O3/MnCe-CM process in the secondary effluent system was 5 mg·L−1, the average removal performance of four micropollutants was higher than 80% under this condition, which could meet the standard of 《Guidelines for water reuse—Treatment technologies for pharmaceuticals and personal care products in reclaimed water》(T/CSES 42-2021) of the Ministry of Ecology and Environment. In addition, the removal rates of the O3/MnCe-CM process for TOC and UV254 in the secondary effluent were 32% and 66%, respectively. The removed organic was mainly fluorescent humic acid substances, and no acute toxicity was detected in the effluent of the O3/MnCe-CM process.

-

Key words:

- catalytic ceramic membrane /

- catalytic ozonation /

- membrane fouling /

- secondary effluent

-

表 1 不同臭氧投加量下锰铈催化膜-臭氧工艺和陶瓷膜-臭氧工艺对微量污染物的反应动力学常数

Table 1. The reaction kinetic constants of the O3/CM and O3/MnCe-CM process

臭氧投加量/(mg·L−1) 工艺 反应动力学常数/min−1 阿特拉津 苯并三唑 避蚊胺 西玛津 2.5 陶瓷膜-臭氧 0.002 0.002 0.005 0.005 锰铈催化膜-臭氧 0.002 0.002 0.006 0.004 5 陶瓷膜-臭氧 0.003 0.008 0.009 0.005 锰铈催化膜-臭氧 0.006 0.016 0.016 0.015 -

[1] 王文龙,吴乾元,杜烨,等. 城市污水中新兴微量有机污染物控制目标与再生处理技术[J]. 环境科学研究, 2021, 34(7): 1672-1678. doi: 10.13198/j.issn.1001-6929.2020.09.15 [2] 胡洪营. 聚焦矛盾 精准施策 全面提升污水资源化利用水平[J]. 给水排水, 2021, 57(2): 1-3. [3] 宫飞蓬,李杨,霍健. 超滤+臭氧工艺对再生水厂的应用[J]. 膜科学与技术, 2011, 31(5): 52-57. doi: 10.3969/j.issn.1007-8924.2011.05.010 [4] 张凯. 臭氧/陶瓷膜-活性炭耦合工艺处理再生水协同效能研究[D]. 北京: 清华大学, 2020. [5] MANSAS C,MENDRET J,BROSILLON S,et al. Coupling catalytic ozonation and membrane separation:A review[J]. Separation and Purification Technology, 2020, 236: 116211-116230. [6] PSALTOU S,ZOUBOULIS A. Catalytic ozonation and membrane contactors-a review concerning fouling occurrence and pollutant removal[J]. Water, 2020, 12(11): 2964-2951. doi: 10.3390/w12112964 [7] PRAKASH N,SETHI M. A review of innovative bond instruments for sustainable development in Asia[J]. International Journal of Innovation Science, 2022, 14(3/4): 630-647. doi: 10.1108/IJIS-10-2020-0213 [8] GUO Y,SONG Z,XU B,et al. A novel catalytic ceramic membrane fabricated with CuMn2O4 particles for emerging UV absorbers degradation from aqueous and membrane fouling elimination[J]. Journal of Hazardous Materials, 2018, 344: 1229-1239. doi: 10.1016/j.jhazmat.2017.11.044 [9] LEE W J,BAO Y,HU X,et al. Hybrid catalytic ozonation-membrane filtration process with CeOx and MnOx impregnated catalytic ceramic membranes for micropollutants degradation[J]. Chemical Engineering Journal, 2019, 378: 121670-121682. doi: 10.1016/j.cej.2019.05.031 [10] PARK H,KIM Y,AN B,et al. Characterization of natural organic matter treated by iron oxide nanoparticle incorporated ceramic membrane-ozonation process[J]. Water Research, 2012, 46(18): 5861-5870. doi: 10.1016/j.watres.2012.07.039 [11] BYUN S,DAVIES S H,Alpatova A L,et al. Mn oxide coated catalytic membranes for a hybrid ozonation–membrane filtration:Comparison of Ti,Fe and Mn oxide coated membranes for water quality[J]. Water Research, 2011, 45(1): 163-170. doi: 10.1016/j.watres.2010.08.031 [12] ZHANG J,GUO Q,WU W,et al. Preparation of Fe-MnOX/AC by high gravity method for heterogeneous catalytic ozonation of phenolic wastewater[J]. Chemical Engineering Science, 2022, 255: 117667-117672. doi: 10.1016/j.ces.2022.117667 [13] WANG T,DE W M,DE G J. CoFe2O4-peroxymonosulfate based catalytic UF and NF polymeric membranes for naproxen removal:The role of residence time[J]. Journal of Membrane Science, 2022, 646: 120209-120219. doi: 10.1016/j.memsci.2021.120209 [14] YAN P,CHEN Z,WANG S,et al. Catalytic ozonation of iohexol with α-Fe0.9Mn0.1OOH in water:Efficiency,degradation mechanism and toxicity evaluation[J]. Journal of Hazardous Materials, 2021, 402: 123574-123586. doi: 10.1016/j.jhazmat.2020.123574 [15] HE Y,WANG L,CHEN Z,et al. Novel catalytic ceramic membranes anchored with MnMe oxide and their catalytic ozonation performance towards atrazine degradation[J]. Journal of Membrane Science, 2022, 648: 120362-120375. doi: 10.1016/j.memsci.2022.120362 [16] COSTANZO S D,WATKINSON A J,MURBY E J,et al. Is there a risk associated with the insect repellent DEET (N,N-diethyl-m-toluamide) commonly found in aquatic environments?[J]. Science of the Total Environment, 2007, 384(1-3): 214-220. doi: 10.1016/j.scitotenv.2007.05.036 [17] GAO X,WANG X,LI J,et al. Aquatic life criteria derivation and ecological risk assessment of DEET in China[J]. Ecotoxicology and Environmental Safety, 2020, 188: 109881-109888. doi: 10.1016/j.ecoenv.2019.109881 [18] PILLARD D A,CORNELL J S,DUFRESNE D L,et al. Toxicity of benzotriazole and benzotriazole derivatives to three aquatic species[J]. Water Research, 2001, 35(2): 557-560. doi: 10.1016/S0043-1354(00)00268-2 [19] CHOI Y,LEE J H,KIM K,et al. Identification,quantification,and prioritization of new emerging pollutants in domestic and industrial effluents,Korea:Application of LC-HRMS based suspect and non-target screening[J]. Journal of Hazardous Materials, 2021, 402: 123706-123718. doi: 10.1016/j.jhazmat.2020.123706 [20] TIAN Z,WANG B,LIANG Y,et al. Enhancement on the ammonia oxidation capacity of ammonia-oxidizing archaeon originated from wastewater:utilizing low-density static magnetic field[J]. Frontiers of Environmental Science & Engineering, 2021, 15(5): 81-89. [21] YU H,ANUMOL T,PARK M,et al. On-line sensor monitoring for chemical contaminant attenuation during UV/H2O2 advanced oxidation process[J]. Water Research, 2015, 81: 250-260. doi: 10.1016/j.watres.2015.05.064 [22] CHEN H,PENG C,WANG L,et al. Mechanically tough,healable hydrogels synergistically reinforced by UV-responsive crosslinker and metal coordination interaction for wound healing application[J]. Chemical Engineering Journal, 2021, 403: 126341-126351. doi: 10.1016/j.cej.2020.126341 [23] LI C,SUN W,LU Z,et al. Systematic evaluation of TiO2-GO-modified ceramic membranes for water treatment:Retention properties and fouling mechanisms[J]. Chemical Engineering Journal, 2019, 378: 122138-122150. doi: 10.1016/j.cej.2019.122138 [24] WANG Y,CHEN L,CAO H,et al. Role of oxygen vacancies and Mn sites in hierarchical Mn2O3/LaMnO3-delta perovskite composites for aqueous organic pollutants decontamination[J]. Applied Catalysis B:Environmental, 2019, 245: 546-554. doi: 10.1016/j.apcatb.2019.01.025 [25] MAILLER R,GASPERI J,COQUET Y,et al. Study of a large scale powdered activated carbon pilot:Removals of a wide range of emerging and priority micropollutants from wastewater treatment plant effluents[J]. Water Research, 2015, 72: 315-330. doi: 10.1016/j.watres.2014.10.047 [26] 中国环境科学学会. 水回用指南 再生水中药品和个人护理品类微量污染物处理技术[M]. 北京: 中国环境科学学会, 2021. [27] AGENCY U S E P. Drinking Water Standards and Health Advisories; EPA 822-F-18–001[M]. Office of Water. Washington, DC, USA, USEPA, 2018. [28] 李先华. 己内酰胺废水色度来源分析及臭氧脱色研究[D]. 上海: 华东理工大学, 2014. [29] 张云辉,陆杰,李海宁,等. 臭氧工艺在废水脱色中的应用[J]. 水处理技术, 2012, 38(11): 3-6. doi: 10.16796/j.cnki.1000-3770.2012.11.027 -

下载:

下载: