-

工业生产过程中产生的细微颗粒物是造成大气污染的主要原因之一[1- 2]。袋式除尘器是工业领域控制颗粒物尤其是细微颗粒物排放最有效的净化设备之一,滤袋是其核心[3]。不断改进优化纤维滤料可提高其捕集效率,但也会因其阻力不断升高而增加运行成本。因此,需要开发新技术使得滤袋对粉尘捕集效率提高的同时而又不增加其阻力。颗粒物单极预荷电可有效改善滤袋过滤特性[3-5],但是携带大量同性电荷的颗粒物长期堆积在滤袋表面会引起反电晕现象。因此,基于双极荷电凝并行为,一些学者利用预荷电技术使细微颗粒物实现异性电荷中和,进而增大粒径,更易被过滤器捕集脱除。CHANG等[6]已成功应用飞灰颗粒物的凝并行为增强了其在电除尘器中的捕集效率。SOBCZYK 等[7]设计了包含凝并器在内的复合式电除尘器,并证实了其捕集效率远高于传统电除尘器。KOIZUMI等[8]及HUANG等[9]研究了交变电场中双极荷电颗粒物的凝并行为,发现过滤风速及预荷电器施加电压是影响颗粒物凝并最重要的2个因素。以上成果均已证实了双极荷电颗粒物在电场中的电凝并行为。然而,相关研究仍集中于电除尘器领域,对于利用颗粒物双极预荷电凝并技术与传统袋式除尘器相结合的成果还鲜有报道。CIACH等[10]在1996年将预荷电凝并技术与纤维滤料相结合,提高了柴油颗粒物的捕集效率,但并未研究对纤维滤料压差特性的影响。向晓东等 [11-13]对电袋复合除尘器的增效减阻效应进行了实验研究,对于设计优化前置预荷电器结构参数有着重要意义,但其对于后置滤袋的分级数目捕集效率未作研究,仅讨论了其表面粉尘的堆积密度及中位粒径。贾沛等[14]则采用数值模拟研究方法,利用电晕放电模块耦合湍流模块,研究了线-管式双极预荷电中电流体动力学分布规律。黄超等[15]研究了不同预荷电条件下影响颗粒物凝并效果的因素,并得到了包括电压、风速等工况在内的最优凝并条件,但最优条件下颗粒物凝并行为对于滤袋过滤特性的影响未作讨论。综上所述,虽然利用单/双预荷电技术提高袋式除尘器可有效过滤高炉除尘灰,但该技术仍需进一步拓展和完善。

基于此,本课题组设计搭建了由线-板式预荷电器和滤袋集尘装置组成的复合电/袋滤实验平台,对工业实践中影响高炉除尘灰双极荷电凝并的主要因素匹配电压及过滤风速进行了研究。在此基础上,进一步系统对比分析滤袋对未荷电、单极负荷电及双极预荷电高炉除尘灰的分级数目捕集效率和阻力特性,利用扫描电镜观察得到了不同预荷电方式高炉除尘灰在纤维滤袋表面沉积的微观形貌结构,以期为细微颗粒物预荷电技术与传统袋式除尘器的结合与工业应用提供参考。

-

采用纤维滤料为聚苯硫醚 (polyphenylene sulfide,PPS) 针刺毡,测试粉尘取样自建龙集团某钢铁公司炼铁高炉布袋除尘器箱体灰斗内滤袋除尘灰。采用YG(B)141D数字式织物厚度仪、BT224S型分析天平、X射线荧光光谱分析仪及Malvern激光粒度仪对测试粉尘及纤维滤料的相关特性参数进行测量。孔隙率为67.07 %, 厚度为1.41 mm,克重为 0.062 7 g·cm−2,纤维直径为15.25 μm,127 Pa时透气度为7.32 m3·m−2·min−1。表1为测试粉尘的主要成分。图1为高炉除尘灰的粒径分布。其中,d10=1.45 μm,d25=2.40 μm,d50=3.85 μm,d75=6.16 μm,d90=8.68 μm。

-

图2为电/袋滤实验平台示意图。平台主要分为发尘区、预荷电区及集尘区。其中,预荷电区由2个等容线板式预荷电器组成,每个预荷电器由一根铜电晕放电线 (直径0.8 mm,长度200 mm) 及2块接地铜极板 (200 mm×50 mm) 组成,通道容积为50 mm×50 mm×200 mm。测试粉尘通过发尘器及文丘里管被均匀分散后,分别进入2个预荷电器荷电,后被下游滤袋捕集脱除。实验过程中,所有平台设备均接地以减少电场对于亚克力管壁的影响。

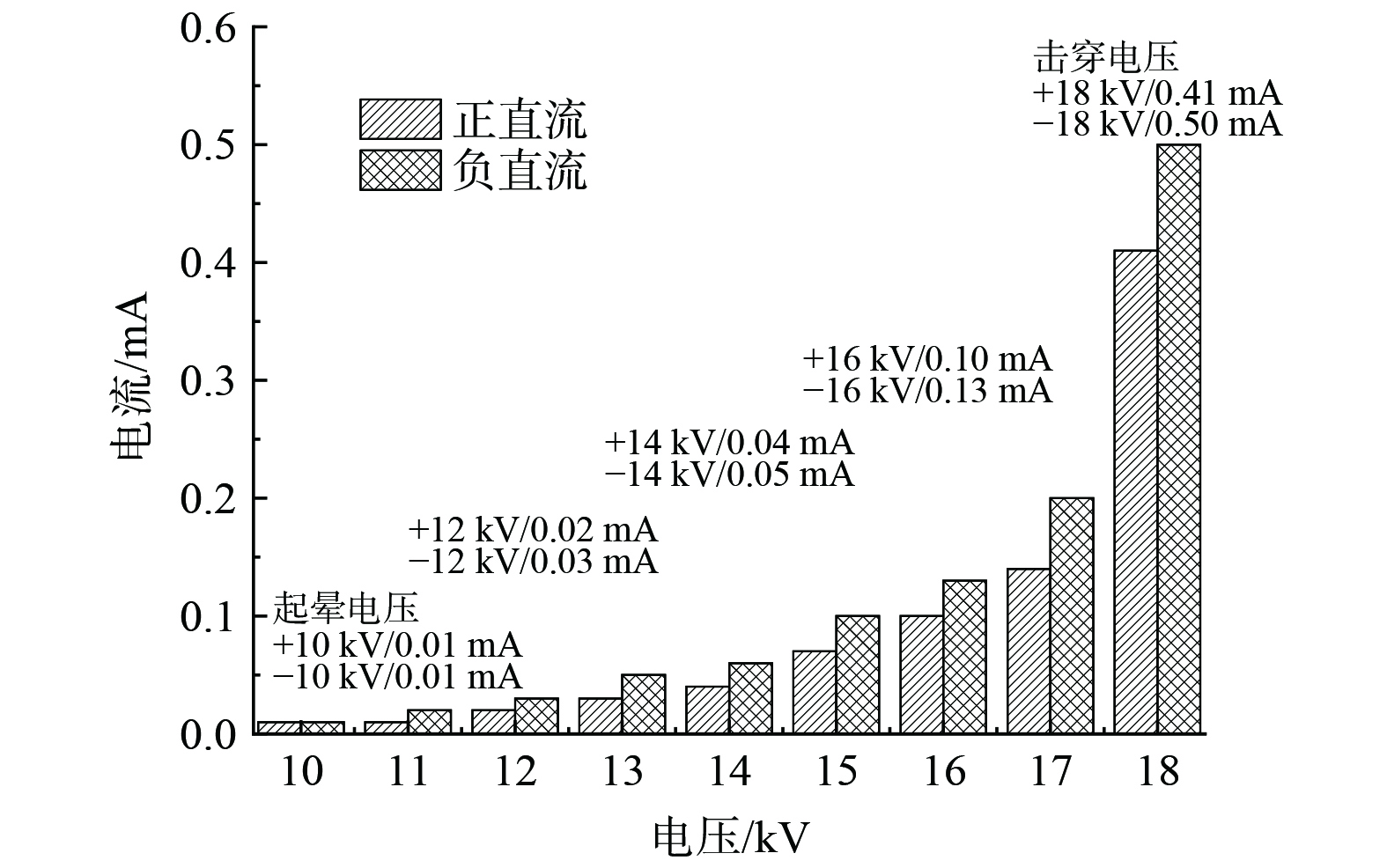

预荷电器伏安特性曲线如图3所示。在相同放电电压条件下,正极性放电电流值低于负极性电流值。这意味着正极性放电的电场强度和离子密度较低。因此,综合考虑颗粒物荷电充足性及设备运行稳定性,将初始电压至击穿电压范围的60 %作为实验区间,即选择正电压 (16 kV/0.10 mA) 作为固定测试电压,负电压调试区间为12~16 kV,用以讨论不同匹配电压下的凝并行为。与此同时,由于负电源放电性能稳定及电晕电流较大等优点,工业应用一般选择高压负直流电源作为供电设备,故本研究选择 (−16 kV,−16 kV) 作为颗粒物单极预荷电实验条件。有关颗粒物单极预荷电 (不同荷电电压/荷电风速/荷电类型) 对纤维滤料过滤特性的影响规律,仅作为参照工况而不再展开阐述,相关详尽研究结果见参考文献[5]。

过滤实验根据“GB/T 38019-2019 工业用过滤布 粉尘过滤性能测试方法”,粉尘质量浓度设定为5 g·m-3。实验环境温度为(10±2) ℃,相对湿度为(20±2)%,粉尘使用前进行80 ℃真空干燥箱预烘干处理10 h。利用空气颗粒计数器 (APC, 型号9306) 测量颗粒数目,压差计 (Testo 512) 测量滤袋压差。为研究颗粒物预荷电对滤袋过滤特性的强化作用,设计以下3种工况条件:1) 颗粒物未荷电;2) 颗粒物单极荷电 (−16 kV,−16 kV) ;3) 颗粒物双极荷电 (双极荷电电压的选择在结果与讨论部分介绍) 。将测定以下5个参数:1) 预荷电器上游 (采样口a) 的颗粒数目Cin;2) 凝并区下游 (采样口b) 的颗粒数目Con和Coff;3) 滤料下游 (采样口c) 的颗粒数目Cout-on和Cout-off。下标on/off分别表示预荷电器的开/关2种状态。通过凝并区下游颗粒数目分数分布

Cion 和Cioff 的变化反映颗粒物双极荷电凝并,滤袋捕集效率计算参考公式 (1) 。式中:f为捕集效率;

Ciin 表示粒径为i的上游颗粒数目;Ciout 表示粒径为i的下游颗粒数目,Cion 以及Cioff 分别表示预荷电器打开和关闭时粒径为i的颗粒数目。另外,由于PM0.5、PM1可能危害人群健康,PM2.5为大气中主要二次污染物,且0.3 μm为袋式除尘器用纤维滤袋最易穿透粒径,故i分别定为如下几类<0.3 μm、0.3~0.5 μm、0.5~1 μm、1~2.5 μm。 -

在预荷电区,电晕线附近区域的电子有足够能量撞击气体分子使其电离,从而产生大量正离子和高能自由电子。对于正直流电场,电子向负电晕线移动,正离子由于库伦斥力扩散到周围,因此,其主要表现为正离子的荷电作用。而对于负直流电场,自由电子由于库仑斥力而远离电晕线区域,其能量急剧下降而大量附着在气体分子上形成了负离子,故以负离子及电子对颗粒物的荷电为主。颗粒物荷电是一个复杂的电流体力学过程,其荷电机制主要分2种[16]:场致荷电qf(式 (2) )和扩散荷电qd (式 (3) ) 。

式中:

ε0 为真空介电常数 (8. 85×10−12 F· m−1) ;ϵ 为颗粒物相对介电常数;a为颗粒物直径,μm;t 为荷电时间,s;τ 为带电时间常数;KB 为玻尔兹曼常数 (1.38×10−23 J·K−1) ;T 为绝对温度,K;e 为电子电荷 (1.6× 10−19 C) ;N0 为离子密度,m−3;c 为离子热运动平均速度 (240 m·s−1) 。ZEBEL[17]和FUCHS [18]给出了无外加电场条件下双极荷电颗粒物库伦凝并系数,其计算公式为式 (4) 。

式中:

fij=αijeαij−1 ,αij=qiqj2πϵ0KT(di+dj) 。对于双极荷电颗粒物,αij 为负值且其绝对值远大于1,故fij≅αij 。kbrij=2π(Di+Dj)(di+dj) 为电中性颗粒凝并系数;Di=KTCi 为扩散系数;ci=3πμdi 为空气阻力系数;μ 为空气粘度,Pa·s−1;qi 和qj 分别表示直径为di 和dj 的颗粒物荷电量,C。因此,库伦凝并系数计算式为式 (5) 。

由于粒径大于0.2 μm的颗粒物以场致荷电为主[19],本研究将细微颗粒物凝并的粒径设定为0.3~10 μm。因此,式 (5) 中颗粒物理论饱和荷电量可由式 (2) 计算得到。而对于工业应用场景,其雷诺数 (>104) 非常大而导致湍流,且其放电产生的离子风也会破坏层流[20]。因此,以上分析均是理论情形,而实验室条件一般会忽略湍流和离子风影响,即电流体的流动被忽略。

-

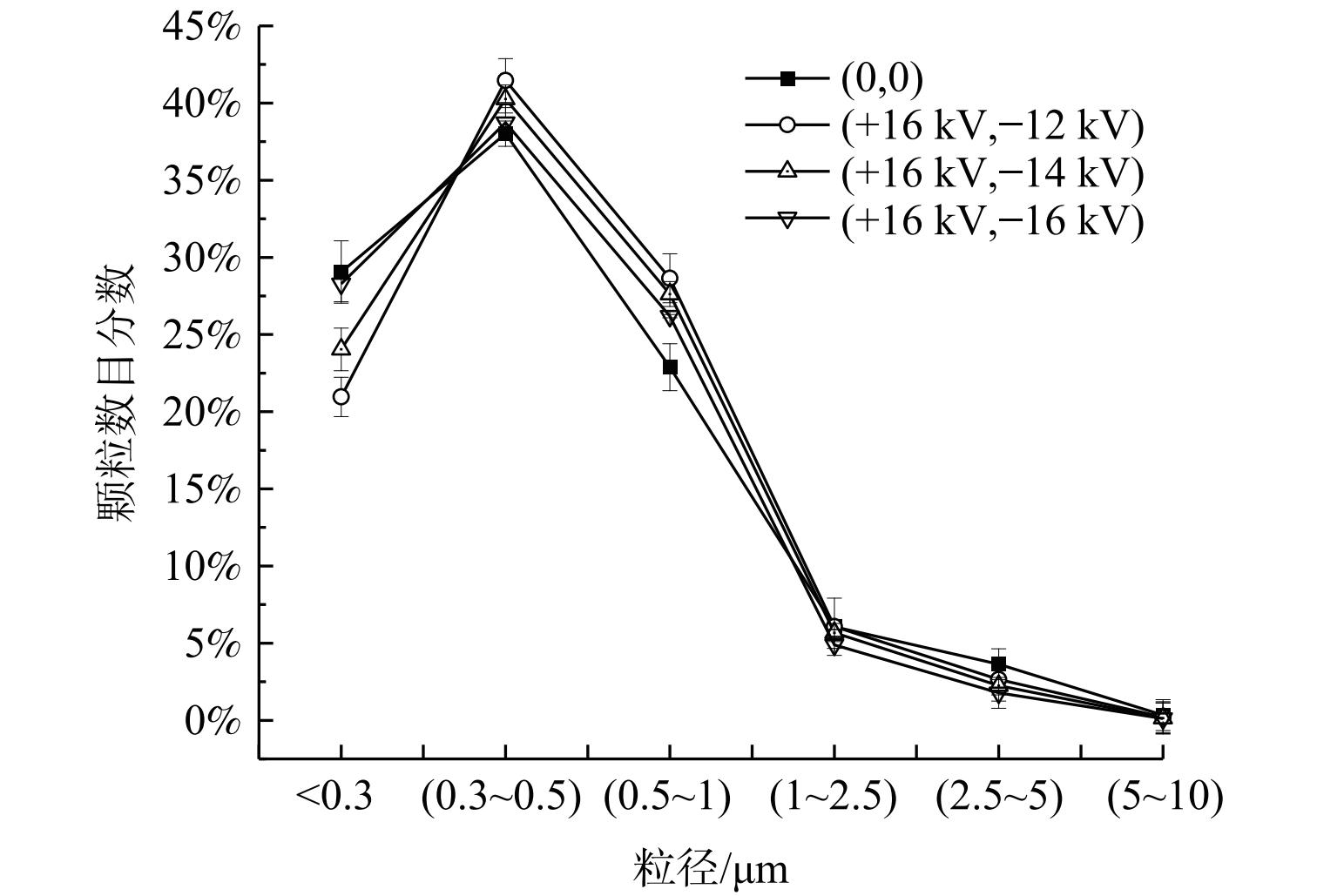

图4为不同匹配电压条件下粒径小于10 μm的颗粒物数目分数变化关系。当负电压从12 kV增至14 kV时,粒径小于0.3 μm的颗粒物数目分数逐渐增加,但仍小于初始数目分数,粒径为0.3~1 μm的数目分数逐渐降低,但仍高于初始数目分数。这主要是由于正离子的荷电效应主要作用于粒径较小的颗粒物,而负离子和电子则主要作用于粒径较大的颗粒物[21]。随着负电压升高,空间内负离子和电子数目增加,正离子数目相对减少。由于扩散荷电机制,其减弱了较小粒径颗粒物的荷电效应。然而,对于粒径为1~10 μm的颗粒物数目分数变化不明显或略微降低,则主要是因为较大粒径颗粒物电荷携带量更大,更容易被预荷电器接地极板吸附。当负电压增至16 kV时,各粒径颗粒物的数目分数与初始数目分数几乎相同。特别地,在本实验条件下,凝并效果随着匹配电压的升高反而降低,其结果与HUANG等[9]的研究结果相悖。其中一个原因可能是,随着负电压的增加,更多的正离子被负离子或电子中和,从而在一定程度上影响颗粒物荷电效应,阻碍了凝并行为;另一个原因则是,由于极化作用,多个中性颗粒会团聚 (或凝并) 在带电颗粒上,当颗粒物饱和荷电后,产生的过量负离子或电子会抑制这种团聚 (或凝并) 效应[22]。本实验条件下,高炉除尘灰颗粒物凝并的最佳匹配电压为 (+16 kV,−12 kV) 。

-

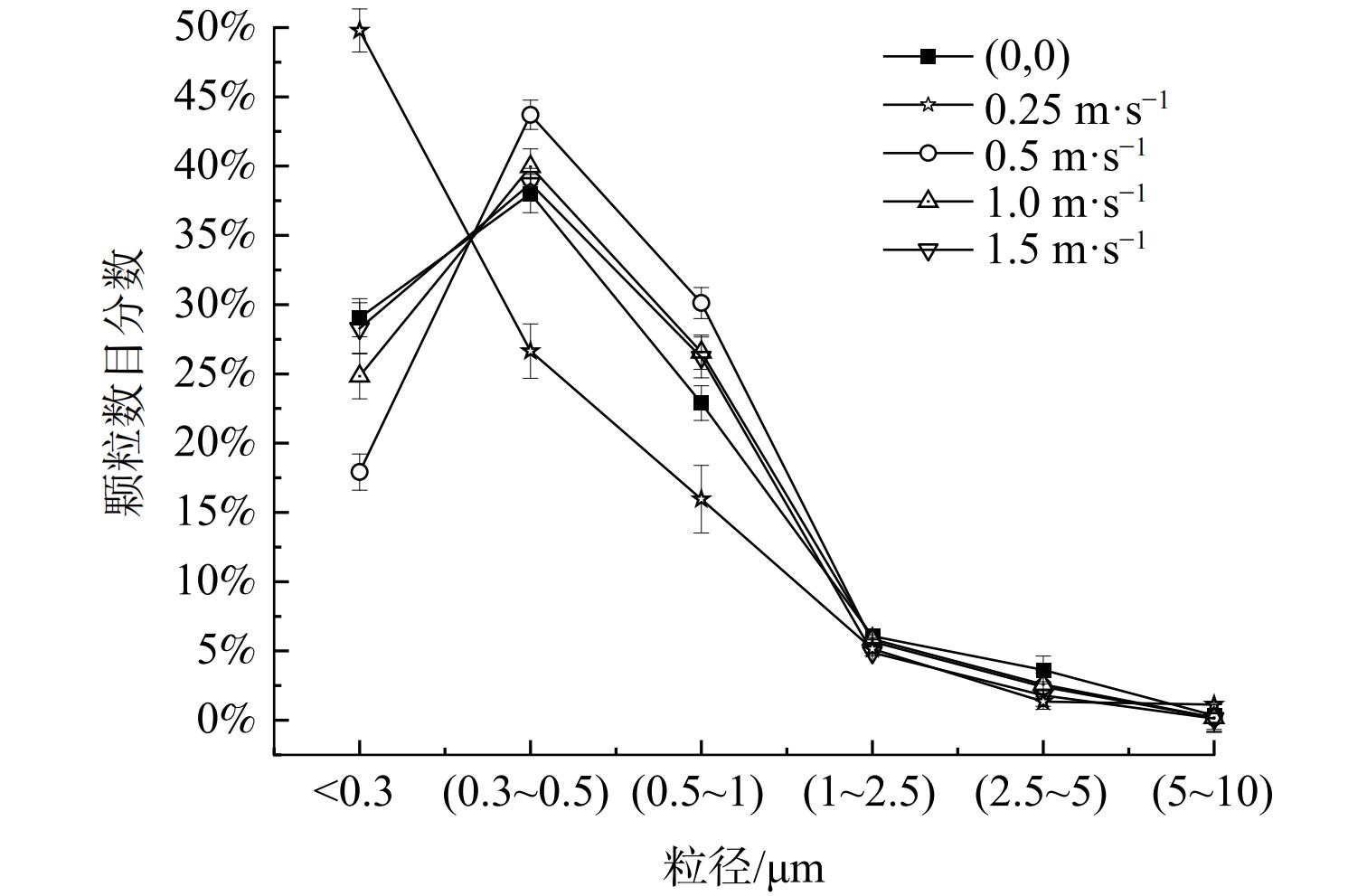

图5为不同风速条件下粒径小于10 μm颗粒物的数目分数变化关系。当流速为0.25 m·s−1时,粒径小于0.3 μm的颗粒数目分数大于初始数目分数,而粒径为0.3~10 μm的数目分数均小于初始数目分数。这主要是由于当过滤风速较小时,颗粒物在预荷电器中停留时间变长,而较大粒径颗粒物荷电量更大,更易被接地极板吸引捕集,使得粒径较小的颗粒物数目分数相对升高。特别地,预荷电器的作用与传统电除尘器类似,但与复合电/袋滤实验平台设计初衷相悖。当流速从0.5 m·s−1增至1 m·s−1时,粒径小于0.3 μm的颗粒数目分数增加,但仍小于初始数目分数;粒径为0.3~1 μm的颗粒数目分数逐渐降低,但仍高于初始数目分数;粒径为1~10 μm的颗粒数目分数几乎不变或略微降低。这是由于随着流速的增加,颗粒物在电场中停留时间缩短,导致其荷电携带量减少[23],故颗粒物电凝并行为减弱。除此之外,过滤风速增大,颗粒物本身动能增加,导致其穿透率增加、效率降低,故滤袋自身能耗也增加。因此,本实验条件下,高炉除尘灰颗粒物凝并的最佳流速为0.5 m·s−1。该结果与文献[22,24]所采用的电除尘器中颗粒物预荷电流速一致。

-

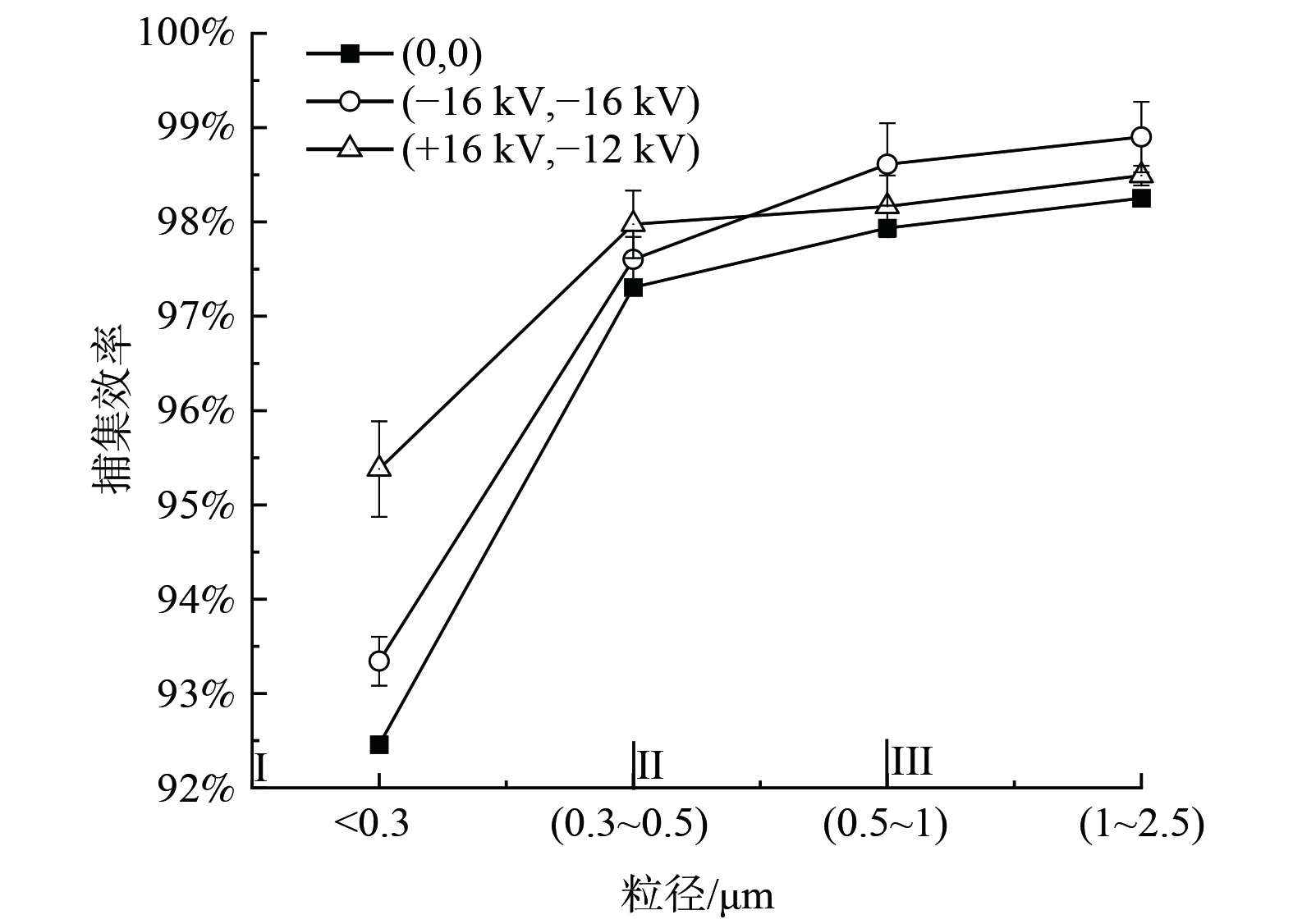

图6为滤袋对于未荷电、单极预荷电以及双极预荷电高炉除尘灰细微颗粒物 (PM2.5) 的分级计数捕集效率。对于粒径小于0.3 μm的颗粒物 (I部分) ,无论单极或双极预荷电,其被捕集效率均显著提高。首先,这是由于当存在外加电场时,颗粒物扩散效应和颗粒迁移率得到加强,尽管小颗粒携带的电荷量较少,但其更大的迁移率将导致更高的捕集效率[25]。其次,荷电颗粒物在滤料表面形成的尘饼具有一定电势,与后续具有同电性颗粒物之间存在库伦阻力,也使得颗粒物更难通过滤袋。双极荷电使得较小粒径颗粒物的被捕集效率高于单极荷电。如对于粒径小于0.3 μm的颗粒,捕集效率由93.34 %提高到95.38 %。根据凝并实验结果,这是因为双极荷电凝并行为使小于0.3 μm的颗粒物数目显著减少。小粒径颗粒物由于凝并行为粒径变大,粒径越大越容易被机械手段捕获,如惯性碰撞和拦截等[26,27]。当颗粒粒径为1~2.5 μm (III部分)时 ,滤袋对单极荷电颗粒物的捕集效率高于双极荷电颗粒物。这是由于单极荷电颗粒物和纤维之间的镜像力有利于颗粒物的捕集[24,28]。另外,当单极荷电颗粒物逐渐沉积在滤袋表面形成尘饼后,使得陆续接近其表面的相同极性带电颗粒物受到库仑斥力的影响,故其在尘饼表面附近速度降低,即更难通过滤袋[22]。粒径越大、电荷量越大,故库仑斥力越大。当颗粒粒径为0.3~1.0 μm (II部分)时,粒径越大,单极荷电对于滤袋过滤性能强化效果更佳。对于双极荷电颗粒物,即使在凝聚区的下游,一些未凝并的单极性颗粒物或发生凝并后的大粒径颗粒物仍可能带正电荷或负电荷。因此,粒径为0.3~1.0 μm为机械过滤-静电增强过滤2种手段相互作用的过渡区域。通过对比未荷电及单极荷电颗粒物捕集实验,双极荷电凝并行为强化滤袋过滤性能的机理是通过增大粒径而强化机械捕集手段的同时,联合静电增强捕集机理 (镜像力及库仑力) 相互作用的结果。综上所述,对于较大粒径颗粒物,单极性带电颗粒物穿透滤袋更为困难,而双极荷电凝并行为对于强化较小粒径颗粒物的过滤效果更加明显。

-

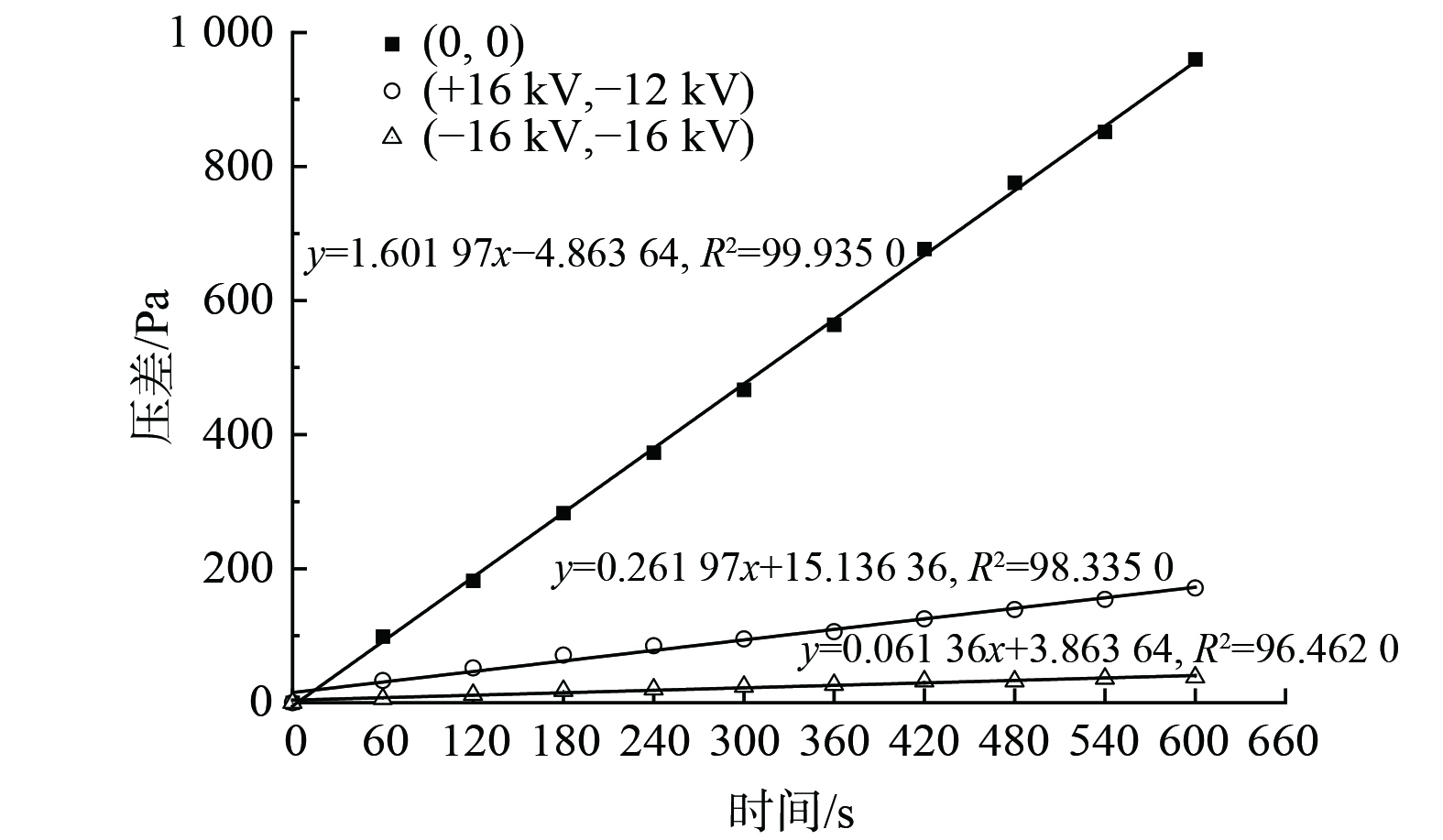

由于不同块滤料初始压差值存在差异,故无法直接比较其压差特性。本研究定义压差增量为过滤中某一时刻纤维滤料上下游压差与其初始压差的差值。图7为滤袋在过滤未荷电、单极预荷电及双极预荷电颗粒物的实验过程中的压差增量曲线。颗粒物带负电荷后,滤料压差增量最小;颗粒物双极预荷电时 (+16 kV,−12 kV),压差增量变大;当预荷电器关闭 (即粉尘不荷电时) ,滤料压差增量最大。这是因为由荷电颗粒物所形成的滤料表面尘饼多呈现多孔 (树枝状) 结构[29-31],此结构有效降低了压差增量,且相同极性的尘饼与颗粒物之间的库仑斥力也使得颗粒不易沉积滤袋表面,从而使得压差增长变缓。其次,双极荷电凝并形成的颗粒物粒径增大,而大粒径粉尘形成的尘饼孔隙率更高[27],而更高的孔隙率则意味着更低的压差增量。

-

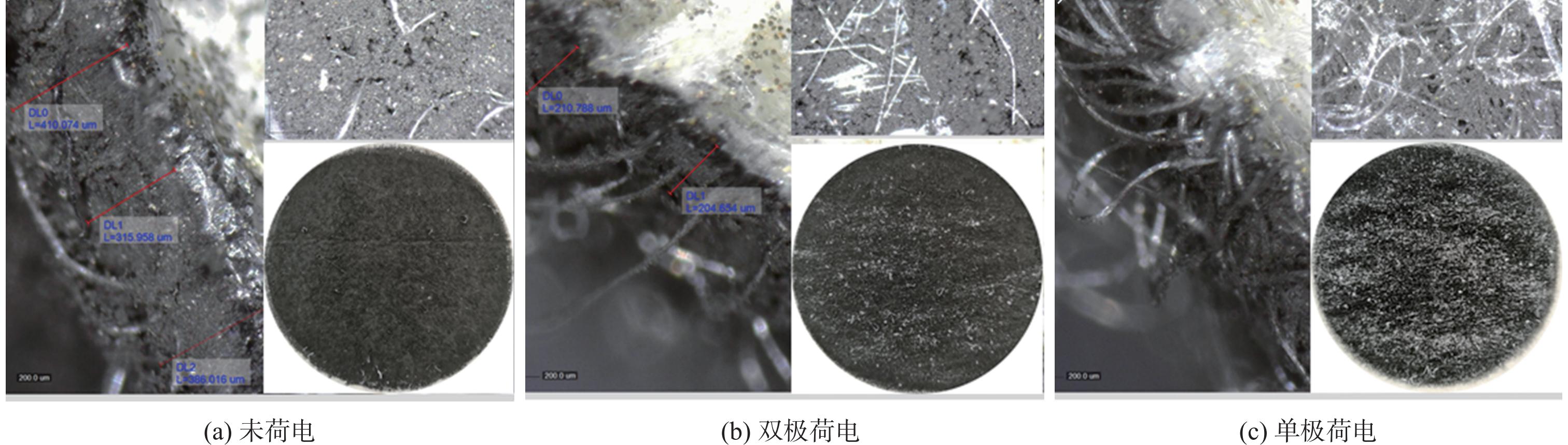

图8为滤袋过滤未荷电 (a) 、双极荷电 (b) 及单极荷负电 (c) 颗粒物后滤袋表面形貌图。在相同测试时间内,滤袋表面尘饼厚度分别为370.68 μm (未荷电) 、197.52 μm (双极荷电) 及未形成明显尘饼 (荷负电) 。这主要是由于负极性放电的电流值高于正极性的电流值,更高的电场强度和离子密度意味着更大的库伦阻力。同时,在相同风速条件下,荷负电颗粒物荷电量大于双极荷电,因此,更容易被预荷电器接地极板部分吸附而导致到达滤料表面颗粒物数目减少。

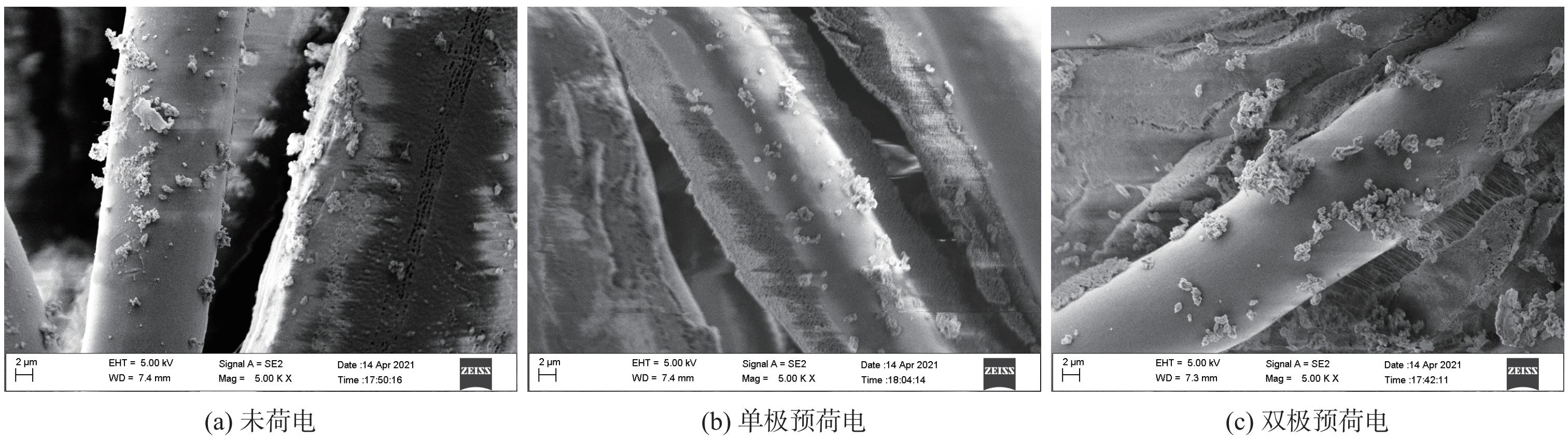

图9为未荷电 (a) 、单极预荷电 (b) 及双极预荷电 (c) 颗粒物沉积在纤维滤料上的5.00 KX微观形貌图。相比未荷电颗粒物,单极荷电颗粒物以更加分散的形态沉积在纤维上,沉积量更少,且多以单一颗粒物形态存在。而由于凝并行为,双极荷电颗粒物的沉积形态以团块状为主。对于滤料表面各类尘饼的形貌分析,更好地解释了关于过滤性能强化的研究。

-

1)正负匹配电压和气体流速 (荷电时间) 会影响高炉除尘灰双极荷电凝并行为。当正电压固定时,随着负电压的升高,颗粒物库伦凝并行为减弱,且流速的过高或过低,均不利于颗粒物的凝并行为。

2)高炉除尘灰单/双极荷电能明显提高滤袋捕集效率。双极预荷电对于捕集粒径小于0.5 μm颗粒物的提升效果好于单极预荷电。而随着颗粒物粒径增加 (0.5~10 μm) ,单极预荷电的提升效果将高于双极预荷电。

3)高炉除尘灰双极荷电凝并行为使得滤袋的压差增量减小,且压差增量的增长速率降低。但其增速降低效果仍低于单极荷电。

4)相比未荷电除尘灰颗粒物,单极荷电除尘灰颗粒物多以更加分散的单一颗粒物形态沉积在纤维上,且沉积量较少,而双极荷电除尘灰颗粒物由于凝并行为,其沉积形态多以团块状为主。

高炉除尘灰细微颗粒物单/双预荷电强化滤袋过滤特性

Unipolar/bipolar pre-charging enhanced the filtration performance of bag filter for fine particulate matter from blast furnace dust

-

摘要: 传统袋式除尘器对于细微颗粒物的捕集效率不甚理想,在袋式除尘器入口前增加预荷电装置是一种切实可行的强化其过滤特性的技术手段。设计搭建线板式直流高压预荷电器,研究了不同正/负匹配电压及风速对于双极预荷电高炉除尘灰电凝并行为的影响规律,对比分析了滤袋对未荷电、单极负荷电以及双极荷电高炉除尘灰细微颗粒物 (PM 2.5) 的捕集效率与压差特性,得到了不同预荷电方式高炉除尘灰细微颗粒物在滤袋表面沉积的微观形貌结构。结果表明:随着过滤风速 (1.5~0.5 m·s−1及匹配负电压 (−16~−12 kV) 的降低,双极荷电颗粒物凝并效率提高;高炉除尘灰细微颗粒物单/双预荷电均能提高滤袋的过滤效率;对于粒径<0.5 μm颗粒,双极预荷电技术对滤袋捕集效率的强化效果好于单极预荷电技术;对粒径为0.5~2.5 μm颗粒,单极预荷电技术的强化效果超过了双极预荷电技术;颗粒物单/双预荷电技术还使得滤袋阻力增量值及其增长速率值降低,且单极预荷电技术对于阻力降低效果更为明显。本研究可为利用单/双预荷电技术提升传统袋式除尘器对高炉除尘灰中细微颗粒物的捕集脱除特性提供参考。Abstract: The collection efficiency of the conventional bag filter for fine particles is still not ideal. Adding a pre- charging device in front of the inlet of the bag filter is a feasible technical mean to improve its filtration performance. The effects of matching voltage and flow velocity on electric agglomeration of bipolarly charged particles were investigated in this paper. The collection efficiency and pressure drop characteristics of bag filter for uncharged, unipolarly and bipolarly charged particles were compared and studied, and the micromorphology and structure of dust cake was also observed. The results showed that the agglomeration efficiency declined with the decrease of flow velocity (1.5~0.5 m·s−1) and matching voltage (-16~ -12 kV). The collection efficiency was significantly improved by the unipolarly and bipolarly charged particle. More specifically, for particles with a particle size smaller than 0.5 μm, the enhancement effect of bipolar pre-charging technology on collection efficiency was higher than that of unipolar pre-charging technology. However, for the particles with a particle size between 0.5 μm and 2.5 μm, the enhancement effect of single-polar precharging technology was higher than that of bipolar precharging technology. The precharging technology also reduced the growth rate and increment of pressure drop of bag filter, and the effect of the single-pole precharging technology on the reduction of resistance was more significant. These findings are very important for the enhanced removal of micron and submicron blast furnace dust by using conventional bag filter.

-

Key words:

- pre-charging /

- blast furnace dust /

- bag filter /

- collection efficiency /

- pressure drop

-

工业生产过程中产生的细微颗粒物是造成大气污染的主要原因之一[1- 2]。袋式除尘器是工业领域控制颗粒物尤其是细微颗粒物排放最有效的净化设备之一,滤袋是其核心[3]。不断改进优化纤维滤料可提高其捕集效率,但也会因其阻力不断升高而增加运行成本。因此,需要开发新技术使得滤袋对粉尘捕集效率提高的同时而又不增加其阻力。颗粒物单极预荷电可有效改善滤袋过滤特性[3-5],但是携带大量同性电荷的颗粒物长期堆积在滤袋表面会引起反电晕现象。因此,基于双极荷电凝并行为,一些学者利用预荷电技术使细微颗粒物实现异性电荷中和,进而增大粒径,更易被过滤器捕集脱除。CHANG等[6]已成功应用飞灰颗粒物的凝并行为增强了其在电除尘器中的捕集效率。SOBCZYK 等[7]设计了包含凝并器在内的复合式电除尘器,并证实了其捕集效率远高于传统电除尘器。KOIZUMI等[8]及HUANG等[9]研究了交变电场中双极荷电颗粒物的凝并行为,发现过滤风速及预荷电器施加电压是影响颗粒物凝并最重要的2个因素。以上成果均已证实了双极荷电颗粒物在电场中的电凝并行为。然而,相关研究仍集中于电除尘器领域,对于利用颗粒物双极预荷电凝并技术与传统袋式除尘器相结合的成果还鲜有报道。CIACH等[10]在1996年将预荷电凝并技术与纤维滤料相结合,提高了柴油颗粒物的捕集效率,但并未研究对纤维滤料压差特性的影响。向晓东等 [11-13]对电袋复合除尘器的增效减阻效应进行了实验研究,对于设计优化前置预荷电器结构参数有着重要意义,但其对于后置滤袋的分级数目捕集效率未作研究,仅讨论了其表面粉尘的堆积密度及中位粒径。贾沛等[14]则采用数值模拟研究方法,利用电晕放电模块耦合湍流模块,研究了线-管式双极预荷电中电流体动力学分布规律。黄超等[15]研究了不同预荷电条件下影响颗粒物凝并效果的因素,并得到了包括电压、风速等工况在内的最优凝并条件,但最优条件下颗粒物凝并行为对于滤袋过滤特性的影响未作讨论。综上所述,虽然利用单/双预荷电技术提高袋式除尘器可有效过滤高炉除尘灰,但该技术仍需进一步拓展和完善。

基于此,本课题组设计搭建了由线-板式预荷电器和滤袋集尘装置组成的复合电/袋滤实验平台,对工业实践中影响高炉除尘灰双极荷电凝并的主要因素匹配电压及过滤风速进行了研究。在此基础上,进一步系统对比分析滤袋对未荷电、单极负荷电及双极预荷电高炉除尘灰的分级数目捕集效率和阻力特性,利用扫描电镜观察得到了不同预荷电方式高炉除尘灰在纤维滤袋表面沉积的微观形貌结构,以期为细微颗粒物预荷电技术与传统袋式除尘器的结合与工业应用提供参考。

1. 材料与方法

1.1 实验材料

采用纤维滤料为聚苯硫醚 (polyphenylene sulfide,PPS) 针刺毡,测试粉尘取样自建龙集团某钢铁公司炼铁高炉布袋除尘器箱体灰斗内滤袋除尘灰。采用YG(B)141D数字式织物厚度仪、BT224S型分析天平、X射线荧光光谱分析仪及Malvern激光粒度仪对测试粉尘及纤维滤料的相关特性参数进行测量。孔隙率为67.07 %, 厚度为1.41 mm,克重为 0.062 7 g·cm−2,纤维直径为15.25 μm,127 Pa时透气度为7.32 m3·m−2·min−1。表1为测试粉尘的主要成分。图1为高炉除尘灰的粒径分布。其中,d10=1.45 μm,d25=2.40 μm,d50=3.85 μm,d75=6.16 μm,d90=8.68 μm。

表 1 测试粉尘主要成分 (质量分数)Table 1. Main constituent of test dustFe2O3 ZnO SiO2 SO3 Al2O3 CaO K2O MgO 31.93% 21.33% 12.89% 9.53% 8.22% 7.40% 2.33% 2.08% 1.2 实验方法

图2为电/袋滤实验平台示意图。平台主要分为发尘区、预荷电区及集尘区。其中,预荷电区由2个等容线板式预荷电器组成,每个预荷电器由一根铜电晕放电线 (直径0.8 mm,长度200 mm) 及2块接地铜极板 (200 mm×50 mm) 组成,通道容积为50 mm×50 mm×200 mm。测试粉尘通过发尘器及文丘里管被均匀分散后,分别进入2个预荷电器荷电,后被下游滤袋捕集脱除。实验过程中,所有平台设备均接地以减少电场对于亚克力管壁的影响。

预荷电器伏安特性曲线如图3所示。在相同放电电压条件下,正极性放电电流值低于负极性电流值。这意味着正极性放电的电场强度和离子密度较低。因此,综合考虑颗粒物荷电充足性及设备运行稳定性,将初始电压至击穿电压范围的60 %作为实验区间,即选择正电压 (16 kV/0.10 mA) 作为固定测试电压,负电压调试区间为12~16 kV,用以讨论不同匹配电压下的凝并行为。与此同时,由于负电源放电性能稳定及电晕电流较大等优点,工业应用一般选择高压负直流电源作为供电设备,故本研究选择 (−16 kV,−16 kV) 作为颗粒物单极预荷电实验条件。有关颗粒物单极预荷电 (不同荷电电压/荷电风速/荷电类型) 对纤维滤料过滤特性的影响规律,仅作为参照工况而不再展开阐述,相关详尽研究结果见参考文献[5]。

过滤实验根据“GB/T 38019-2019 工业用过滤布 粉尘过滤性能测试方法”,粉尘质量浓度设定为5 g·m-3。实验环境温度为(10±2) ℃,相对湿度为(20±2)%,粉尘使用前进行80 ℃真空干燥箱预烘干处理10 h。利用空气颗粒计数器 (APC, 型号9306) 测量颗粒数目,压差计 (Testo 512) 测量滤袋压差。为研究颗粒物预荷电对滤袋过滤特性的强化作用,设计以下3种工况条件:1) 颗粒物未荷电;2) 颗粒物单极荷电 (−16 kV,−16 kV) ;3) 颗粒物双极荷电 (双极荷电电压的选择在结果与讨论部分介绍) 。将测定以下5个参数:1) 预荷电器上游 (采样口a) 的颗粒数目Cin;2) 凝并区下游 (采样口b) 的颗粒数目Con和Coff;3) 滤料下游 (采样口c) 的颗粒数目Cout-on和Cout-off。下标on/off分别表示预荷电器的开/关2种状态。通过凝并区下游颗粒数目分数分布

Cion Cioff f=Ciin−CioutCiin×100% (1) 式中:f为捕集效率;

Ciin Ciout Cion Cioff 2. 结果与讨论

2.1 颗粒物双极预荷电凝并特性理论分析

在预荷电区,电晕线附近区域的电子有足够能量撞击气体分子使其电离,从而产生大量正离子和高能自由电子。对于正直流电场,电子向负电晕线移动,正离子由于库伦斥力扩散到周围,因此,其主要表现为正离子的荷电作用。而对于负直流电场,自由电子由于库仑斥力而远离电晕线区域,其能量急剧下降而大量附着在气体分子上形成了负离子,故以负离子及电子对颗粒物的荷电为主。颗粒物荷电是一个复杂的电流体力学过程,其荷电机制主要分2种[16]:场致荷电qf(式 (2) )和扩散荷电qd (式 (3) ) 。

qf=4πε03εε+2Eatt+τ (2) qd=4πε0aKBTeln(1+acN0e24ε0KBTt) (3) 式中:

ε0 ϵ t τ KB T e × N0 c ZEBEL[17]和FUCHS [18]给出了无外加电场条件下双极荷电颗粒物库伦凝并系数,其计算公式为式 (4) 。

kij=fij×kbrij (4) 式中:

fij=αijeαij−1 αij=qiqj2πϵ0KT(di+dj) αij fij≅αij kbrij=2π(Di+Dj)(di+dj) Di=KTCi ci=3πμdi μ qi qj di dj 因此,库伦凝并系数计算式为式 (5) 。

kij=qiqj(di+dj)3πμϵ0didj (5) 由于粒径大于0.2 μm的颗粒物以场致荷电为主[19],本研究将细微颗粒物凝并的粒径设定为0.3~10 μm。因此,式 (5) 中颗粒物理论饱和荷电量可由式 (2) 计算得到。而对于工业应用场景,其雷诺数 (>104) 非常大而导致湍流,且其放电产生的离子风也会破坏层流[20]。因此,以上分析均是理论情形,而实验室条件一般会忽略湍流和离子风影响,即电流体的流动被忽略。

2.2 颗粒物双极预荷电凝并行为影响因素

2.2.1 匹配电压

图4为不同匹配电压条件下粒径小于10 μm的颗粒物数目分数变化关系。当负电压从12 kV增至14 kV时,粒径小于0.3 μm的颗粒物数目分数逐渐增加,但仍小于初始数目分数,粒径为0.3~1 μm的数目分数逐渐降低,但仍高于初始数目分数。这主要是由于正离子的荷电效应主要作用于粒径较小的颗粒物,而负离子和电子则主要作用于粒径较大的颗粒物[21]。随着负电压升高,空间内负离子和电子数目增加,正离子数目相对减少。由于扩散荷电机制,其减弱了较小粒径颗粒物的荷电效应。然而,对于粒径为1~10 μm的颗粒物数目分数变化不明显或略微降低,则主要是因为较大粒径颗粒物电荷携带量更大,更容易被预荷电器接地极板吸附。当负电压增至16 kV时,各粒径颗粒物的数目分数与初始数目分数几乎相同。特别地,在本实验条件下,凝并效果随着匹配电压的升高反而降低,其结果与HUANG等[9]的研究结果相悖。其中一个原因可能是,随着负电压的增加,更多的正离子被负离子或电子中和,从而在一定程度上影响颗粒物荷电效应,阻碍了凝并行为;另一个原因则是,由于极化作用,多个中性颗粒会团聚 (或凝并) 在带电颗粒上,当颗粒物饱和荷电后,产生的过量负离子或电子会抑制这种团聚 (或凝并) 效应[22]。本实验条件下,高炉除尘灰颗粒物凝并的最佳匹配电压为 (+16 kV,−12 kV) 。

2.2.2 风速

图5为不同风速条件下粒径小于10 μm颗粒物的数目分数变化关系。当流速为0.25 m·s−1时,粒径小于0.3 μm的颗粒数目分数大于初始数目分数,而粒径为0.3~10 μm的数目分数均小于初始数目分数。这主要是由于当过滤风速较小时,颗粒物在预荷电器中停留时间变长,而较大粒径颗粒物荷电量更大,更易被接地极板吸引捕集,使得粒径较小的颗粒物数目分数相对升高。特别地,预荷电器的作用与传统电除尘器类似,但与复合电/袋滤实验平台设计初衷相悖。当流速从0.5 m·s−1增至1 m·s−1时,粒径小于0.3 μm的颗粒数目分数增加,但仍小于初始数目分数;粒径为0.3~1 μm的颗粒数目分数逐渐降低,但仍高于初始数目分数;粒径为1~10 μm的颗粒数目分数几乎不变或略微降低。这是由于随着流速的增加,颗粒物在电场中停留时间缩短,导致其荷电携带量减少[23],故颗粒物电凝并行为减弱。除此之外,过滤风速增大,颗粒物本身动能增加,导致其穿透率增加、效率降低,故滤袋自身能耗也增加。因此,本实验条件下,高炉除尘灰颗粒物凝并的最佳流速为0.5 m·s−1。该结果与文献[22,24]所采用的电除尘器中颗粒物预荷电流速一致。

2.3 过滤特性

2.3.1 捕集效率

图6为滤袋对于未荷电、单极预荷电以及双极预荷电高炉除尘灰细微颗粒物 (PM2.5) 的分级计数捕集效率。对于粒径小于0.3 μm的颗粒物 (I部分) ,无论单极或双极预荷电,其被捕集效率均显著提高。首先,这是由于当存在外加电场时,颗粒物扩散效应和颗粒迁移率得到加强,尽管小颗粒携带的电荷量较少,但其更大的迁移率将导致更高的捕集效率[25]。其次,荷电颗粒物在滤料表面形成的尘饼具有一定电势,与后续具有同电性颗粒物之间存在库伦阻力,也使得颗粒物更难通过滤袋。双极荷电使得较小粒径颗粒物的被捕集效率高于单极荷电。如对于粒径小于0.3 μm的颗粒,捕集效率由93.34 %提高到95.38 %。根据凝并实验结果,这是因为双极荷电凝并行为使小于0.3 μm的颗粒物数目显著减少。小粒径颗粒物由于凝并行为粒径变大,粒径越大越容易被机械手段捕获,如惯性碰撞和拦截等[26,27]。当颗粒粒径为1~2.5 μm (III部分)时 ,滤袋对单极荷电颗粒物的捕集效率高于双极荷电颗粒物。这是由于单极荷电颗粒物和纤维之间的镜像力有利于颗粒物的捕集[24,28]。另外,当单极荷电颗粒物逐渐沉积在滤袋表面形成尘饼后,使得陆续接近其表面的相同极性带电颗粒物受到库仑斥力的影响,故其在尘饼表面附近速度降低,即更难通过滤袋[22]。粒径越大、电荷量越大,故库仑斥力越大。当颗粒粒径为0.3~1.0 μm (II部分)时,粒径越大,单极荷电对于滤袋过滤性能强化效果更佳。对于双极荷电颗粒物,即使在凝聚区的下游,一些未凝并的单极性颗粒物或发生凝并后的大粒径颗粒物仍可能带正电荷或负电荷。因此,粒径为0.3~1.0 μm为机械过滤-静电增强过滤2种手段相互作用的过渡区域。通过对比未荷电及单极荷电颗粒物捕集实验,双极荷电凝并行为强化滤袋过滤性能的机理是通过增大粒径而强化机械捕集手段的同时,联合静电增强捕集机理 (镜像力及库仑力) 相互作用的结果。综上所述,对于较大粒径颗粒物,单极性带电颗粒物穿透滤袋更为困难,而双极荷电凝并行为对于强化较小粒径颗粒物的过滤效果更加明显。

2.3.2 压差特性

由于不同块滤料初始压差值存在差异,故无法直接比较其压差特性。本研究定义压差增量为过滤中某一时刻纤维滤料上下游压差与其初始压差的差值。图7为滤袋在过滤未荷电、单极预荷电及双极预荷电颗粒物的实验过程中的压差增量曲线。颗粒物带负电荷后,滤料压差增量最小;颗粒物双极预荷电时 (+16 kV,−12 kV),压差增量变大;当预荷电器关闭 (即粉尘不荷电时) ,滤料压差增量最大。这是因为由荷电颗粒物所形成的滤料表面尘饼多呈现多孔 (树枝状) 结构[29-31],此结构有效降低了压差增量,且相同极性的尘饼与颗粒物之间的库仑斥力也使得颗粒不易沉积滤袋表面,从而使得压差增长变缓。其次,双极荷电凝并形成的颗粒物粒径增大,而大粒径粉尘形成的尘饼孔隙率更高[27],而更高的孔隙率则意味着更低的压差增量。

2.4 形貌分析

图8为滤袋过滤未荷电 (a) 、双极荷电 (b) 及单极荷负电 (c) 颗粒物后滤袋表面形貌图。在相同测试时间内,滤袋表面尘饼厚度分别为370.68 μm (未荷电) 、197.52 μm (双极荷电) 及未形成明显尘饼 (荷负电) 。这主要是由于负极性放电的电流值高于正极性的电流值,更高的电场强度和离子密度意味着更大的库伦阻力。同时,在相同风速条件下,荷负电颗粒物荷电量大于双极荷电,因此,更容易被预荷电器接地极板部分吸附而导致到达滤料表面颗粒物数目减少。

图9为未荷电 (a) 、单极预荷电 (b) 及双极预荷电 (c) 颗粒物沉积在纤维滤料上的5.00 KX微观形貌图。相比未荷电颗粒物,单极荷电颗粒物以更加分散的形态沉积在纤维上,沉积量更少,且多以单一颗粒物形态存在。而由于凝并行为,双极荷电颗粒物的沉积形态以团块状为主。对于滤料表面各类尘饼的形貌分析,更好地解释了关于过滤性能强化的研究。

3. 结论

1)正负匹配电压和气体流速 (荷电时间) 会影响高炉除尘灰双极荷电凝并行为。当正电压固定时,随着负电压的升高,颗粒物库伦凝并行为减弱,且流速的过高或过低,均不利于颗粒物的凝并行为。

2)高炉除尘灰单/双极荷电能明显提高滤袋捕集效率。双极预荷电对于捕集粒径小于0.5 μm颗粒物的提升效果好于单极预荷电。而随着颗粒物粒径增加 (0.5~10 μm) ,单极预荷电的提升效果将高于双极预荷电。

3)高炉除尘灰双极荷电凝并行为使得滤袋的压差增量减小,且压差增量的增长速率降低。但其增速降低效果仍低于单极荷电。

4)相比未荷电除尘灰颗粒物,单极荷电除尘灰颗粒物多以更加分散的单一颗粒物形态沉积在纤维上,且沉积量较少,而双极荷电除尘灰颗粒物由于凝并行为,其沉积形态多以团块状为主。

-

表 1 测试粉尘主要成分 (质量分数)

Table 1. Main constituent of test dust

Fe2O3 ZnO SiO2 SO3 Al2O3 CaO K2O MgO 31.93% 21.33% 12.89% 9.53% 8.22% 7.40% 2.33% 2.08% -

[1] 荆德吉, 贾鑫, 张天, 等. 落煤过程中涡旋吹吸式除尘技术数值模拟及实验[J]. 中国安全科学学报, 2021, 31(6): 121-127. [2] 张鸽. 基于累积接尘量的尘肺病风险评估方法[J]. 中国安全科学学报, 2022, 32(2): 200-206. [3] 柳静献, 毛宁, 孙熙, 等. 我国除尘滤料历史、现状与发展趋势综述[J]. 中国环保产业, 2020(11): 6. doi: 10.3969/j.issn.1006-5377.2020.11.001 [4] JAWOREK A, SOBCZYKA A, KRUPA A, et al. Hybrid electrostatic filtration systems for fly ash particles emission control. a review[J]. Separation and Purification Technology, 2019, 213: 283-302. doi: 10.1016/j.seppur.2018.12.011 [5] 吕超, 柳静献, 孙熙, 等. 燃煤飞灰单极荷电对纤维滤料过滤性能的强化[J]. 东北大学学报(自然科学版). 2021, 42(9): 1335-1340. [6] CHANG Q, ZHENG C, YANG Z, et al. Electric agglomeration modes of coal-fired fly-ash particles with water droplet humidification[J]. Fuel, 2017, 200: 134-145. doi: 10.1016/j.fuel.2017.03.033 [7] SOBCZYKA A, MARCHEWICZ A, KRUPA A, et al. Enhancement of collection efficiency for fly ash particles PM2.5 by unipolar agglomerator in two-stage electrostatic precipitator[J]. Separation and Purification Technology, 2017, 187(31): 91-101. [8] KOIZUMI Y, KAWAMURA M, TOCHIKUBO F, et al. Estimation of the agglomeration coefficient of bipolar-charged aerosol particles[J]. Journal of Electrostatics, 2000, 48(2): 93-101. doi: 10.1016/S0304-3886(99)00053-4 [9] HUANG C, MA X, SUN Y, at al. Particle agglomeration in bipolar barb agglomerator under AC electric field[J]. Plasma Science and Technology, 2015, 17(4): 317-320. doi: 10.1088/1009-0630/17/4/10 [10] CIACH T, SOSNOWSKI T. removal of soot particles from diesel exhaust[J]. Journal of Aerosol Science, 1996, 27: S705-S706. doi: 10.1016/0021-8502(96)00425-9 [11] 李雪娥, 向晓东, 李梦玲, 等. 双极电袋复合除尘器的增效减阻效应[J]. 环境工程学报, 2019, 13(1): 141-146. doi: 10.12030/j.cjee.201807009 [12] 向晓东, 李雪娥, 贾思扬, 等. 单极与双极电袋复合除尘器增效作用对比实验[J]. 安全与环境学报, 2018, 18(6): 2328-2332. [13] 向晓东, 李梦玲, 贾思扬, 等. 粉尘双极荷电对滤料电荷累积抑制作用[J]. 环境工程学报, 2018, 12(8): 2282-2287. doi: 10.12030/j.cjee.201801209 [14] 贾沛, 常玉锋. 双极预荷电装置凝并特性实验研究[J]. 科学技术与工程, 2021, 21(32): 13998-14005. doi: 10.3969/j.issn.1671-1815.2021.32.053 [15] 黄超, 郝佩瑜, 贺晓杨, 等. 不同预荷电条件下影响颗粒物凝并效果的因素[J]. 安全与环境学报, 2021, 21(5): 2240-2245. doi: 10.13637/j.issn.1009-6094.2020.1085 [16] HINDS W C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles [M]. Canada: John Wiley & Sons, Inc., 1999. [17] ZEBEL G. Zur theorie des verhaltens elektrisch geladener aerosole[J]. Kolloid-Zeitschrift, 1958, 157(1): 37-50. doi: 10.1007/BF01734032 [18] FUCHS N. The mechanics of aerosols [M]. Oxford: Pergamon Press, 1964. [19] HE M, LUO Z, LU M, et al. Effects of acoustic and pulse corona discharge coupling field on agglomeration and removal of coal-fired fine particles[J]. Aerosol Air Quality Research, 2019, 19(11): 2585-2596. doi: 10.4209/aaqr.2018.08.0306 [20] CHANG Q, ZHENG C, GAO X, et al. Systematic approach to optimization of submicron particle agglomeration using ionic-wind-assisted pre-charger[J]. Aerosol Air Quality Research, 2015, 15(7): 2709-2719. doi: 10.4209/aaqr.2015.06.0418 [21] ZHU J, ZHANG X, CHEN W, et al. Electrostatic precipitation of fine particles with a bipolar pre-charger[J]. Journal of Electrostatics, 2010, 68(2): 174-178. doi: 10.1016/j.elstat.2009.12.005 [22] PAR K, YOON K, HWANG J. Removal of submicron particles using a carbon fiber ionizer-assisted medium air filter in a heating, ventilation, and air conditioning (HVAC) system[J]. Building and. Environment, 2011, 46(8): 1699-1708. doi: 10.1016/j.buildenv.2011.02.010 [23] JAWOREK A, MARCHEWICZ A, SOBCZYK A, et al. Two-stage electrostatic precipitator with co- and counter-flow particle Prechargers[J]. Journal of Electrostatics, 2017, 87: 180-194. doi: 10.1016/j.elstat.2017.04.012 [24] CAI R, LU H, ZHANG L. Mechanisms of performance degradation and efficiency improvement of electret filters during neutral particle loading[J]. Powder technology, 2021, 382: 133-143. doi: 10.1016/j.powtec.2020.12.061 [25] WU Z, WALTERS J, THOMAS D. The deposition of particles from an air flow on a single cylindrical fiber in a uniform electrical field[J]. Aerosol Science and Technology, 1999, 30(1): 62-70. doi: 10.1080/027868299304886 [26] BROWN R. Air filtration: An integrated approach to the theory and applications of fibrous filters [M]. Pergamon Press: Oxford, 1993. [27] FENG Z, LONG Z, YU T. Filtration characteristics of fibrous filter following an electrostatic precipitator[J]. Journal of Electrostatics, 2016, 83: 52-62. doi: 10.1016/j.elstat.2016.07.009 [28] CAI R, LI S, ZHANG L, et al. Fabrication and performance of a stable micro/nano composite electret filter for effective PM2.5 capture[J]. Science of the Total Environment, 2020, 725: 138297. doi: 10.1016/j.scitotenv.2020.138297 [29] MEMELSTEIN J, KIM S, SIOUTAS C. Electrostatically enhanced stainless-steel filters: effect of filter structure and pore size on particle removal[J]. Aerosol Science and Technology, 2002, 36(1): 62-75. doi: 10.1080/027868202753339087 [30] WALSH D, STENHOUSE J. The effect of particle size, charge, and composition on the loading characteristics of an electrically active fibrous filter material[J]. Journal of Aerosol Science, 1997, 28(2): 307-321. doi: 10.1016/S0021-8502(96)00434-X [31] LIU W, YOU M, ZHAN M, et al. Cake formation and filtration characteristics of a cyclone-granular bed filter[J]. Powder technology, 2020, 374: 152-159. doi: 10.1016/j.powtec.2020.06.081 -

DownLoad:

DownLoad: