-

沉淀池是一种常见的固液分离装置,广泛应用于污水处理。沉淀池的固液分离效率与沉淀距离和面积直接密切相关,因此斜管沉淀池被认为是首选的高效沉淀池[1-3],显著提高了絮体沉降的时空效率。但因池体几何构型、流动特征和污泥回流等多种因素的限制,导致斜管沉淀池的分离效率低于理论值[4-5]。例如,在较高的污泥浓度和表面负荷下,上清液-污泥絮体之间的相互作用决定了分离效率,成为表面负荷的首要影响因素[6-7]。已有研究表明,单个逆流斜管沉淀的理想沉淀模型中,混合液的速度矢量、浓度、倾角等流动条件,会在叠加作用下降低污泥沉降分离[8-9],导致流动引起的干扰作用通常导致污泥絮体的沉积通量低于理论值[10-11]。从而,混合液在斜管之间的均匀分布制约着每个在斜管上所能获得的对应流速和沉速,均匀分布有助于提高斜管的总体分离效率,因此,流场均匀性是影响斜管沉淀池表面负荷稳定提高的重要因素。

有研究[12-13]表明,不同地区、温度、季节的水体混合液、上清液或污泥絮体(较大或较小,密实或疏松)之间的相互作用区别较大,上清液-污泥絮体之间的相互作用会影响泥水分离效果。所以,探究污泥混合液的流变性和流动本构有助于提升二沉池的分离性能。计算流体力学(computation fluid dynamic, CFD)是反应器设计过程的高效辅助工具,可用来分析污泥混合液的流动特性和沉淀池的流场特征,包括如流速、流量、污泥分布和累积(相分布)等[14],进而据此优化沉淀池构型。商业CFD软件包含的流动模型通常已获得可靠性验证,但在实际工程模拟中仍需与实际流体性质、反应器构型相结合,对反应器的保留时间分布(retention time distribution, RTD)进行比较和验证,据此选择适宜的流动模式才能使沉淀池模拟优化结果能够较好地贴合其实际应用效果[15]。高效沉淀池中污泥需经历从自由沉淀到压缩沉淀等4个沉淀阶段,污泥浓度、絮体尺寸和流动性质变化很大,是沉淀池流动模型建模的难点。基于此,本研究以工程规模的高效沉淀池为研究对象,以提高其表面负荷为目标,结合现有工程操作运行条件和典型污泥混合液的物料特性,建立标准化的计算流体力学模拟方法,模拟絮凝出水在上升区和下降区的不同流速条件下的流态特征,并根据流态模拟效果给出不同情景的优化结果及池体改进的策略,以期为高效沉淀池的升级改造提供参考,亦可为污水处理厂的减污降碳协同增效提供系统优化工具及案例参考。

-

该高效沉淀池位于山东某污水处理厂,具体构型如图1(a)和图1(b)所示。其进水平均流量5×104 m3·d−1,整体结构的长、宽、高为26.4 m×18.9 m×6.5 m,图1包括进水混合区A、絮凝出水上升区B、水泵扰动区、絮凝出水下降区C(沉降区)以及斜管区D、E、F,其中絮凝出水上升区尺寸为11.5 m×1.4 m×6.5 m,絮凝出水下降区尺寸为11.5 m×2.05 m×6.5 m,沉淀池(含絮凝出水下降区C)直径和高度为11.5 m×6 m,高效沉淀池的絮凝出水上升区B流速V1 =64.7 m·h−1,絮凝出水下降区C流速V2=44.2m·h−1,斜管区D上升流速V3=12 m·h−1。

-

1)样品采集与分析。在上述高效沉淀池进水区至斜管区的A-F区域(图1),对北京、山东等不同高效沉淀池进行多次采样,分别采集了进出水、排泥和污泥层等,其基本性质如表1所示。

对采集水样的水质指标、流动特性等进行了检测分析,其中COD、氨氮、浊度、pH和电导率等常规指标按照国标方法进行测定[16-17]。溶解性有机碳(total organic carbon, TOC)和粒径分布(particle size distribution, PSD)的测定分别采用总有机碳分析仪(TOC-LC, Shimadu Inc.,Japan)测量、激光粒度分析仪(Mastersizer 2000, Marvin Panakow Inc., England)[18]。

2)污泥混合液流变性测试。采用旋转流变仪(Anton Paar MCR301, Anton Paar GmbH., Australia),选用同轴平板转子(半径R=35mm,板厚D=1mm)测定混合液流变性[19]。使用帕尔帖(Peltier)加热系统将温度保持在(20±0.1) °C。流动条件下分析污泥的流变特性设计测序如下:首先,为消除非牛顿流体本身的记忆性,将污泥以200 s−1的剪切速率预剪切5 min,静置5 min,其次,运行测量程序设定,剪切速率由10 s−1线性增加至1 000 s−1(向上曲线,历时3 min),稳定运行1 000 s−1(历时30 s),剪切速率从1 000 s − 1线性下降至10 s−1(下降曲线,历时3 min)。此外,测试数据结果通过Herschel-Bulkley等模型进行流变性拟合,从而表征污泥的流变性特征[20]。

-

1)边界条件。通过高效沉淀池的优化策略和流体特性分析结果,对模拟情景进行设置,模拟絮凝出水上升区不同流速、絮凝出水下降区不同流速,其中情景设置如表2所示。据此剖分了结构化网格,并对部分网格应用了ANSYS Fluent® 高级网络技术更好的保持了计算精度和重现性,并进一步加速提高计算收敛速度与稳定性[21],从而可以在700~1000计算步内达到收敛,有效提高计算效率。

2)流动模型。根据文献调研结果,沉淀池湍流模型[22]采用k-omega模型比k-epsilon模型更符合实验观测结果[14] ,同时测试了两相欧拉[23]和混合物模型[24-25],据此选用两相k-omega模型[26]。

基于初始高效沉淀池池体的几何构型,根据现场调研结果确定物料性质和进出口条件,采用计算流体力学方法,模拟高效沉淀池的流速、污泥浓度等空间分布特征,比较不同情景下的流场分布均匀性、污泥层情况,从而得到优化的高效沉淀池几何构型。

-

沉淀池在不同高度上污泥经历了自由沉淀、絮凝沉淀、成层沉淀、压缩沉淀等过程,污泥的流动特性存在一定区别,影响着沉淀池的表面负荷,采集不同批次样品进行密度、粘度等性质检测分析。如图2(a)所示,在高效沉淀池固液分离过程中,混合液密度变化较为复杂,对物料性质的影响程度高。在密度测量结果中,取平均结果1 005 kg·m−3作为模拟的混合液密度。如图2(b)所示,沉淀池中混合液的剪切应力不断增强,流体的流动性能也不断提高,混合液流变性虽然可以通过自由沉淀、絮凝沉淀、成层沉淀、压缩沉淀阶段的上清液-污泥絮体交互作用来描述,但在实际上仍然是一种工程化的概化模型。限制了沉淀池水力表面负荷提升,一般为3.0~4.0 m·h−1[27]。如图2(c)所示,絮凝区在化学品的作用下明显提高了水体的表面负荷,远高于常规类型沉淀池水力表面负荷的1.0~1.5 m·h−1,提高了进水中污泥的沉降效率,但仍需进一步对不同来源进水的季节温度、水化学特性、有机物成分等或添加外源药剂策略下进水的密度变化规律进行系统性分析[27-28]。如图2(d)所示,污泥中的总碳(total carbon, TC)在整个沉淀池的区域中仍处于上升趋势。这可能是导致样品中的流变性变化相对较小,低于对应高效沉淀池的历史测量数据和其他研究结果的原因之一[29],也可能是由于季节性较低的污泥含水率、有机物浓度等因素造成的。添加絮凝剂后,胶体物质的沉淀性是影响流变性的另一个重要因素。通常,现有的混合液流变性研究结果多来源于曝气池等,对加药混凝沉淀后的沉淀池污泥流变性还尚不明确[30-31]。

-

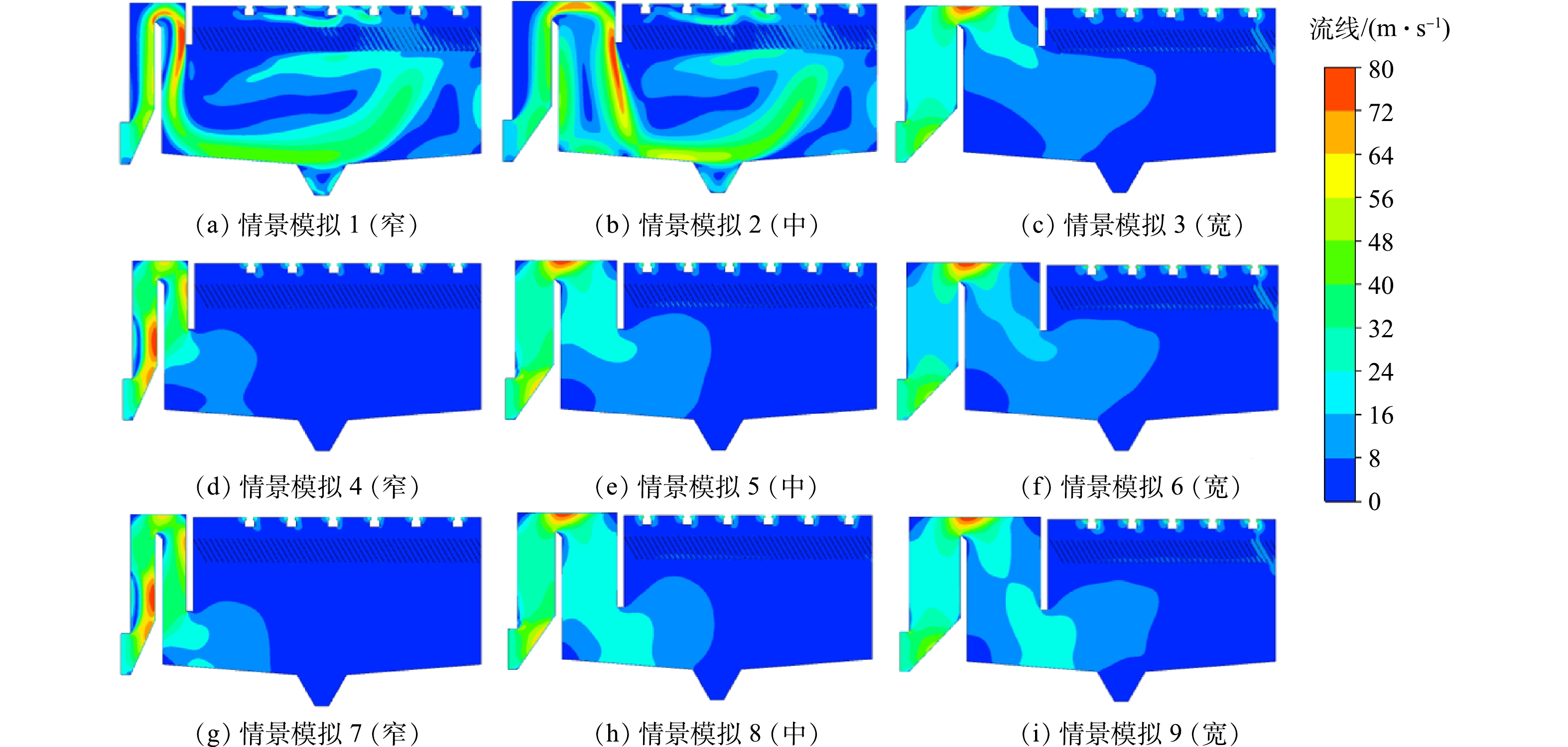

流场模拟结果如图3所示。其中,沉淀池内部不同上升区宽度的横向和纵向比较结果表明,短隔墙不利于沉淀区的流场均匀,其中情景模拟1和情景模拟2形成了强烈的湍流区,对底部产生的吹扫冲刷也较为强烈。较长的隔墙减弱了局部湍流,反应器的内流场均匀性逐步提高,能够在沉淀区形成较为均匀的流场。在不同长度隔墙中,随着流道宽度的变化,高效沉淀池内的速度梯度均呈现升高趋势,较长的隔墙中能够给流体提供较长的时间进行缓冲,也能使污泥流动足够均匀,提升高效沉淀池内流态稳定性及均匀性,减少死区范围和翻泥风险。

流速空间分布(图4)比较表明,情景9出水堰上的流速分布均匀,从而出水过程中相对不易产生流量和污泥集中流失的问题,污泥流失风险较小。情景3、5、6的流线在池体中的分布也较为均匀,表明流体较为均匀地通过了高效沉淀池的池体内部。短挡墙的流线和流量更多在右侧,表明短隔墙使得池体内部流体更加偏向于远端流动。模拟结果表面,高效沉淀池的数值模拟能提供较准确的模拟结果和预测高效沉淀池池体中的实际流场,具有较高的可靠性,可为高效沉淀池的流场流动提供优化策略,为该类型池体模拟变化提供了理论参考,降低了工程应用投资。

-

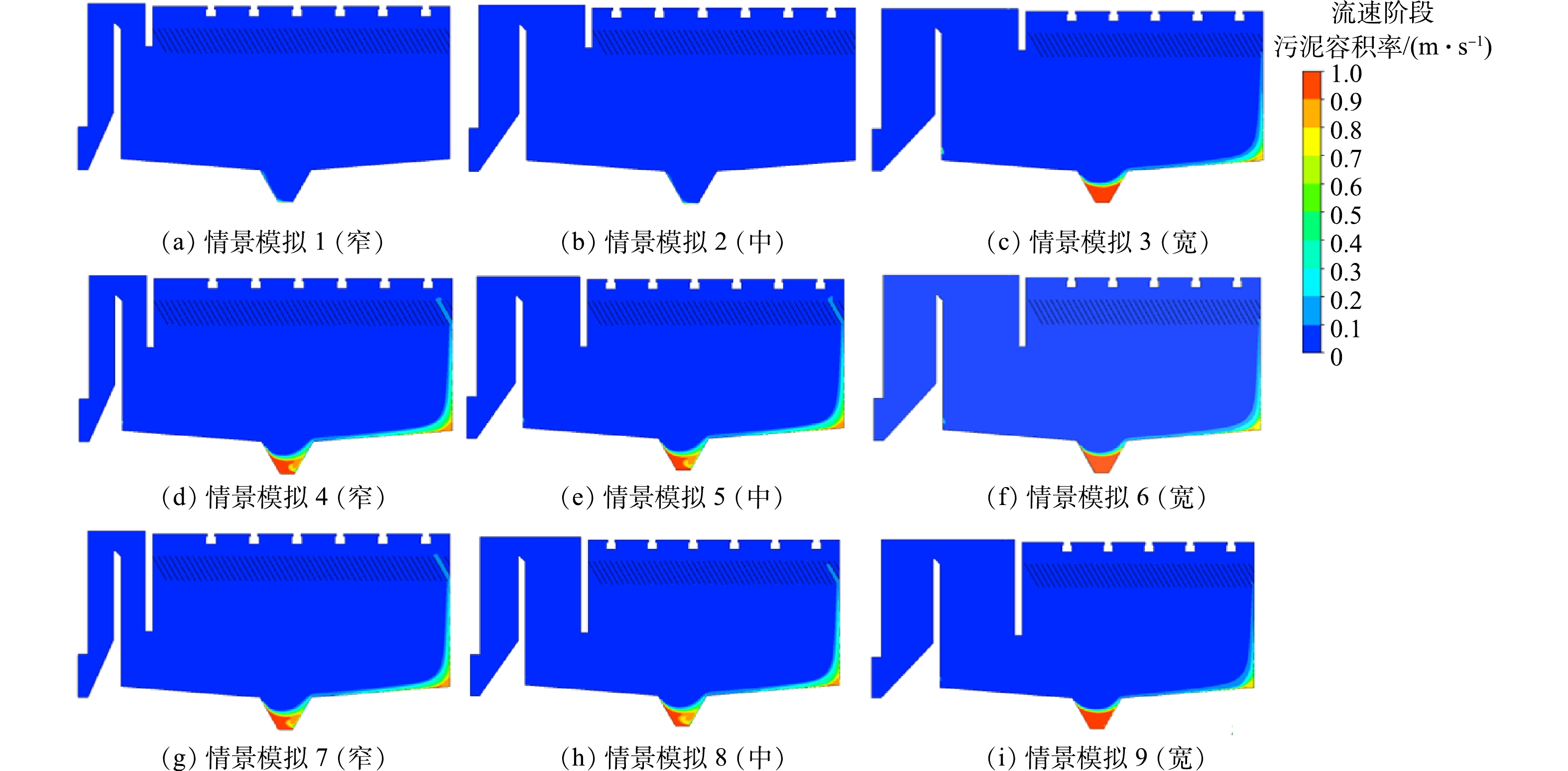

污泥的相分布图模拟结果比较如图5所示,结果基本与流速空间分布较为一致。情景1、2中,沉淀池底部没有形成有效的污泥沉积区域;情景3、6、9在污泥斗中都形成了较为密实的集泥区,情景4、5、7、8可能存在末端污泥流失的风险,并且底部的集泥区也受到不同程度的扰动,但不稳定风险程度和影响因素仍需进一步明确。综合流速与污泥相分布的模拟结果表明,情景模拟9较理想,情景模拟5、6比较均匀,而情景模拟3基本均匀,明显趋向于中等长度的挡墙更加容易实现较为均匀的流场,情景模拟9流场分布均匀,污泥流失及不稳定情况较少,底部污泥较为密实,因此长挡墙、宽流道的设计对高效沉淀池的流场分布存在较大的优化潜力。

-

如图6所示,密度体积渲染模拟结果综合了相分布和流量分布的结果,与物料特性和流场场强耦合,模拟结果表征最右侧出水堰在多种条件下存在末端泥质缺失的不稳定因素,仍需提高操作(抬高、左移等)以优化最后一个出水堰[32]。最左侧挡墙高度引发形成了一个速度快、湍流强的区域,极具扰动效率的作用结果表明该区域可以进一步作为优化区。高效沉淀池混合液的流动特性在混凝沉淀过程中发生了明显的变化,产生了较复杂的对应空间结构,因混合液流动特性改变了产生的流态,使其在沉淀池空间构型受到了阻碍,从而限制了流动速度的提高,明显存在较大的可提升空间。模拟过程中的高效沉淀池目标表面负荷为15m·h−1(25 cm·min−1),超过或接近污泥体积指数(sludge volume index,SVI)测试中的污泥静态沉降速度。因此,高效沉淀池的构型设计仍需耦合混凝动力学和流体力学,将大部分池容保持在密集沉淀过程,以达到目标沉降速度[33]。本研究中模拟设计的优点在于可能将优化后的表面负荷维持在等同于污泥静态沉降中的密集沉淀阶段达到最大沉淀速度,从而形成并维持稳定、清晰的泥水界面,实现高速高效泥水分离。

-

采用流变性和k-omega 模型结合模拟优化高效沉淀池构效关系是可行的。基于计算流体力学形成了高效沉淀池标准化的模拟方法,识别了沉淀池的关键特性是密度(1 005 kg·m−3)和流变性。流变性能够描述沉淀过程中污泥流动性质变化,提高了模拟的准确度。流道构型决定沉淀区流场分布的均匀性,影响高效沉淀池内密度分布,导致污泥絮体沉淀或漂浮,从而对表面负荷起着至关重要的作用。模拟优化的上升区流速、下降区流速、表面负荷分别可达44.70、32.90、12 m·h−1。长挡墙、宽流道利于高效沉淀池工程形成均匀的流场,从而维持较高的表面负荷。宽流道降低了沉淀池内流速和电耗,高表面负荷可节约沉淀池占地,可实现减污降碳协同增效的目标。

规模化城市污水处理厂沉淀池模拟优化

Digital optimization of sedimentation tank in a full-scale municipal wastewater treatment plant

-

摘要: 高效沉淀池广泛应用于市政污水处理厂,其表面负荷是沉淀效率的关键指标。为将实际工程表面负荷稳定提升到12 m·h−1,采用计算流体力学方法,模拟优化了高效沉淀池的负荷。结果表明,污泥特性和几何构型的协同关系是提高沉淀池表面负荷的关键。宽下降区、长挡墙有利于提升流场的均匀性,但远端出水堰的污泥流失风险限制了表面负荷提升。优化的挡墙长度、上升区/下降区(1/2.65)之比等几何构型特征,能够减少积泥斗污泥扰动,改善总体流场均匀性,从而将表面负荷提高到11~12 m·h−1。污泥沉淀过程中的流变特性和流动本构认识不足,限制了表面负荷的进一步提升。上述结果提升了高效沉淀池工程负荷,深化了对高效沉淀池流态的认识,亦为污水处理系统的减污降碳协同增效提供运行优化工具及案例参考。Abstract: Highly efficient sedimentation tank is widely used in municipal wastewater treatment plant, its surface loading rate dominates the settling efficiency. In order to increase the loading rate of real sedimentation tank to12 m·h−1 in a full-scale municipal wastewater treatment plant, it was digitally optimized with computational fluid dynamics methodology. Results demonstrated that the loading rate was dominated by interaction between sludge characteristics and geometry configuration of sedimentation tank. Wider descending-zone and longer baffle-wall were conducive to form a more homogeneous velocity field, while the loading rate was still restrained by the risk of sludge lost from the distal effluent weir. Optimizing geometry configuration, i.e., baffle-wall and ascending-zone/descending-zone ratio (1/2.65), could stabilize sludge blanket in bucket and equalize flow field, therefore the loading rate could increase to 11~12 m·h−1. The further increase of loading rate was limited by insufficient understanding of sludge rheological characteristics and constitutive relationship. These results promoted the loading rate of sedimentation tank and deepened understanding of flow characteristics of concentrated sludge in highly efficient sedimentation tank.

-

沉淀池是一种常见的固液分离装置,广泛应用于污水处理。沉淀池的固液分离效率与沉淀距离和面积直接密切相关,因此斜管沉淀池被认为是首选的高效沉淀池[1-3],显著提高了絮体沉降的时空效率。但因池体几何构型、流动特征和污泥回流等多种因素的限制,导致斜管沉淀池的分离效率低于理论值[4-5]。例如,在较高的污泥浓度和表面负荷下,上清液-污泥絮体之间的相互作用决定了分离效率,成为表面负荷的首要影响因素[6-7]。已有研究表明,单个逆流斜管沉淀的理想沉淀模型中,混合液的速度矢量、浓度、倾角等流动条件,会在叠加作用下降低污泥沉降分离[8-9],导致流动引起的干扰作用通常导致污泥絮体的沉积通量低于理论值[10-11]。从而,混合液在斜管之间的均匀分布制约着每个在斜管上所能获得的对应流速和沉速,均匀分布有助于提高斜管的总体分离效率,因此,流场均匀性是影响斜管沉淀池表面负荷稳定提高的重要因素。

有研究[12-13]表明,不同地区、温度、季节的水体混合液、上清液或污泥絮体(较大或较小,密实或疏松)之间的相互作用区别较大,上清液-污泥絮体之间的相互作用会影响泥水分离效果。所以,探究污泥混合液的流变性和流动本构有助于提升二沉池的分离性能。计算流体力学(computation fluid dynamic, CFD)是反应器设计过程的高效辅助工具,可用来分析污泥混合液的流动特性和沉淀池的流场特征,包括如流速、流量、污泥分布和累积(相分布)等[14],进而据此优化沉淀池构型。商业CFD软件包含的流动模型通常已获得可靠性验证,但在实际工程模拟中仍需与实际流体性质、反应器构型相结合,对反应器的保留时间分布(retention time distribution, RTD)进行比较和验证,据此选择适宜的流动模式才能使沉淀池模拟优化结果能够较好地贴合其实际应用效果[15]。高效沉淀池中污泥需经历从自由沉淀到压缩沉淀等4个沉淀阶段,污泥浓度、絮体尺寸和流动性质变化很大,是沉淀池流动模型建模的难点。基于此,本研究以工程规模的高效沉淀池为研究对象,以提高其表面负荷为目标,结合现有工程操作运行条件和典型污泥混合液的物料特性,建立标准化的计算流体力学模拟方法,模拟絮凝出水在上升区和下降区的不同流速条件下的流态特征,并根据流态模拟效果给出不同情景的优化结果及池体改进的策略,以期为高效沉淀池的升级改造提供参考,亦可为污水处理厂的减污降碳协同增效提供系统优化工具及案例参考。

1. 材料与方法

1.1 高效沉淀池几何构型

该高效沉淀池位于山东某污水处理厂,具体构型如图1(a)和图1(b)所示。其进水平均流量5×104 m3·d−1,整体结构的长、宽、高为26.4 m×18.9 m×6.5 m,图1包括进水混合区A、絮凝出水上升区B、水泵扰动区、絮凝出水下降区C(沉降区)以及斜管区D、E、F,其中絮凝出水上升区尺寸为11.5 m×1.4 m×6.5 m,絮凝出水下降区尺寸为11.5 m×2.05 m×6.5 m,沉淀池(含絮凝出水下降区C)直径和高度为11.5 m×6 m,高效沉淀池的絮凝出水上升区B流速V1 =64.7 m·h−1,絮凝出水下降区C流速V2=44.2m·h−1,斜管区D上升流速V3=12 m·h−1。

1.2 混合液特性测定

1)样品采集与分析。在上述高效沉淀池进水区至斜管区的A-F区域(图1),对北京、山东等不同高效沉淀池进行多次采样,分别采集了进出水、排泥和污泥层等,其基本性质如表1所示。

表 1 某厂高效沉淀池混合液物性特征平均值Table 1. Average physical properties of mixed liquid in a highly efficient sedimentation tank项目 粒径/μm 密度/(kg·L−1) 污泥浓度/(g·L−1) COD/(mg·L−1) 氨氮/(mg·L−1) TC/(mg·L−1) TOC/(mg·L−1) D10 D50 D90 进水 7.913 20.814 49.486 1.001 0.80 20.3 0.35 67.0 2.26 排泥 12.23 30.18 63.426 1.005 10.00 — — — — 出水 — — — — — 18.1 0.15 66.2 2.14 对采集水样的水质指标、流动特性等进行了检测分析,其中COD、氨氮、浊度、pH和电导率等常规指标按照国标方法进行测定[16-17]。溶解性有机碳(total organic carbon, TOC)和粒径分布(particle size distribution, PSD)的测定分别采用总有机碳分析仪(TOC-LC, Shimadu Inc.,Japan)测量、激光粒度分析仪(Mastersizer 2000, Marvin Panakow Inc., England)[18]。

2)污泥混合液流变性测试。采用旋转流变仪(Anton Paar MCR301, Anton Paar GmbH., Australia),选用同轴平板转子(半径R=35mm,板厚D=1mm)测定混合液流变性[19]。使用帕尔帖(Peltier)加热系统将温度保持在(20±0.1) °C。流动条件下分析污泥的流变特性设计测序如下:首先,为消除非牛顿流体本身的记忆性,将污泥以200 s−1的剪切速率预剪切5 min,静置5 min,其次,运行测量程序设定,剪切速率由10 s−1线性增加至1 000 s−1(向上曲线,历时3 min),稳定运行1 000 s−1(历时30 s),剪切速率从1 000 s − 1线性下降至10 s−1(下降曲线,历时3 min)。此外,测试数据结果通过Herschel-Bulkley等模型进行流变性拟合,从而表征污泥的流变性特征[20]。

1.3 CFD模型与数值方法

1)边界条件。通过高效沉淀池的优化策略和流体特性分析结果,对模拟情景进行设置,模拟絮凝出水上升区不同流速、絮凝出水下降区不同流速,其中情景设置如表2所示。据此剖分了结构化网格,并对部分网格应用了ANSYS Fluent® 高级网络技术更好的保持了计算精度和重现性,并进一步加速提高计算收敛速度与稳定性[21],从而可以在700~1000计算步内达到收敛,有效提高计算效率。

表 2 模拟优化的几何构型及其对应的网格要求、进出口条件Table 2. Simulation scenario and related boundary conditions情景编号 出水上区流速/(m·h−1) 上升区宽度/m 出水下区流速/(m·h−1) 下降区宽度/m 高度/m 进水量/(kg·s−1) 出泥量/(kg·s−1) 出水量/(kg·s−1) 情景1(窄) 100.70 0.90 106.60 0.85 1.50 289.35 1.16 288.19 情景2(中) 64.70 1.40 44.20 2.05 1.50 289.35 1.16 288.19 情景3(宽) 44.70 1.90 32.90 2.75 1.50 289.35 1.16 288.19 情景4(窄) 100.70 0.90 106.60 0.85 2.50 289.35 1.16 288.19 情景5(中) 64.70 1.40 44.20 2.05 2.50 289.35 1.16 288.19 情景6(宽) 44.70 1.90 32.90 2.75 2.50 289.35 1.16 288.19 情景7(窄) 100.70 0.90 106.60 0.85 3.50 289.35 1.16 288.19 情景8(中) 64.70 1.40 44.20 2.05 3.50 289.35 1.16 288.19 情景9(宽) 44.70 1.90 32.90 2.75 3.50 289.35 1.16 288.19 2)流动模型。根据文献调研结果,沉淀池湍流模型[22]采用k-omega模型比k-epsilon模型更符合实验观测结果[14] ,同时测试了两相欧拉[23]和混合物模型[24-25],据此选用两相k-omega模型[26]。

基于初始高效沉淀池池体的几何构型,根据现场调研结果确定物料性质和进出口条件,采用计算流体力学方法,模拟高效沉淀池的流速、污泥浓度等空间分布特征,比较不同情景下的流场分布均匀性、污泥层情况,从而得到优化的高效沉淀池几何构型。

2. 结果与讨论

2.1 混合液特性

沉淀池在不同高度上污泥经历了自由沉淀、絮凝沉淀、成层沉淀、压缩沉淀等过程,污泥的流动特性存在一定区别,影响着沉淀池的表面负荷,采集不同批次样品进行密度、粘度等性质检测分析。如图2(a)所示,在高效沉淀池固液分离过程中,混合液密度变化较为复杂,对物料性质的影响程度高。在密度测量结果中,取平均结果1 005 kg·m−3作为模拟的混合液密度。如图2(b)所示,沉淀池中混合液的剪切应力不断增强,流体的流动性能也不断提高,混合液流变性虽然可以通过自由沉淀、絮凝沉淀、成层沉淀、压缩沉淀阶段的上清液-污泥絮体交互作用来描述,但在实际上仍然是一种工程化的概化模型。限制了沉淀池水力表面负荷提升,一般为3.0~4.0 m·h−1[27]。如图2(c)所示,絮凝区在化学品的作用下明显提高了水体的表面负荷,远高于常规类型沉淀池水力表面负荷的1.0~1.5 m·h−1,提高了进水中污泥的沉降效率,但仍需进一步对不同来源进水的季节温度、水化学特性、有机物成分等或添加外源药剂策略下进水的密度变化规律进行系统性分析[27-28]。如图2(d)所示,污泥中的总碳(total carbon, TC)在整个沉淀池的区域中仍处于上升趋势。这可能是导致样品中的流变性变化相对较小,低于对应高效沉淀池的历史测量数据和其他研究结果的原因之一[29],也可能是由于季节性较低的污泥含水率、有机物浓度等因素造成的。添加絮凝剂后,胶体物质的沉淀性是影响流变性的另一个重要因素。通常,现有的混合液流变性研究结果多来源于曝气池等,对加药混凝沉淀后的沉淀池污泥流变性还尚不明确[30-31]。

2.2 流场模拟结果

流场模拟结果如图3所示。其中,沉淀池内部不同上升区宽度的横向和纵向比较结果表明,短隔墙不利于沉淀区的流场均匀,其中情景模拟1和情景模拟2形成了强烈的湍流区,对底部产生的吹扫冲刷也较为强烈。较长的隔墙减弱了局部湍流,反应器的内流场均匀性逐步提高,能够在沉淀区形成较为均匀的流场。在不同长度隔墙中,随着流道宽度的变化,高效沉淀池内的速度梯度均呈现升高趋势,较长的隔墙中能够给流体提供较长的时间进行缓冲,也能使污泥流动足够均匀,提升高效沉淀池内流态稳定性及均匀性,减少死区范围和翻泥风险。

流速空间分布(图4)比较表明,情景9出水堰上的流速分布均匀,从而出水过程中相对不易产生流量和污泥集中流失的问题,污泥流失风险较小。情景3、5、6的流线在池体中的分布也较为均匀,表明流体较为均匀地通过了高效沉淀池的池体内部。短挡墙的流线和流量更多在右侧,表明短隔墙使得池体内部流体更加偏向于远端流动。模拟结果表面,高效沉淀池的数值模拟能提供较准确的模拟结果和预测高效沉淀池池体中的实际流场,具有较高的可靠性,可为高效沉淀池的流场流动提供优化策略,为该类型池体模拟变化提供了理论参考,降低了工程应用投资。

2.3 污泥分布模拟结果

污泥的相分布图模拟结果比较如图5所示,结果基本与流速空间分布较为一致。情景1、2中,沉淀池底部没有形成有效的污泥沉积区域;情景3、6、9在污泥斗中都形成了较为密实的集泥区,情景4、5、7、8可能存在末端污泥流失的风险,并且底部的集泥区也受到不同程度的扰动,但不稳定风险程度和影响因素仍需进一步明确。综合流速与污泥相分布的模拟结果表明,情景模拟9较理想,情景模拟5、6比较均匀,而情景模拟3基本均匀,明显趋向于中等长度的挡墙更加容易实现较为均匀的流场,情景模拟9流场分布均匀,污泥流失及不稳定情况较少,底部污泥较为密实,因此长挡墙、宽流道的设计对高效沉淀池的流场分布存在较大的优化潜力。

2.4 密度空间分布

如图6所示,密度体积渲染模拟结果综合了相分布和流量分布的结果,与物料特性和流场场强耦合,模拟结果表征最右侧出水堰在多种条件下存在末端泥质缺失的不稳定因素,仍需提高操作(抬高、左移等)以优化最后一个出水堰[32]。最左侧挡墙高度引发形成了一个速度快、湍流强的区域,极具扰动效率的作用结果表明该区域可以进一步作为优化区。高效沉淀池混合液的流动特性在混凝沉淀过程中发生了明显的变化,产生了较复杂的对应空间结构,因混合液流动特性改变了产生的流态,使其在沉淀池空间构型受到了阻碍,从而限制了流动速度的提高,明显存在较大的可提升空间。模拟过程中的高效沉淀池目标表面负荷为15m·h−1(25 cm·min−1),超过或接近污泥体积指数(sludge volume index,SVI)测试中的污泥静态沉降速度。因此,高效沉淀池的构型设计仍需耦合混凝动力学和流体力学,将大部分池容保持在密集沉淀过程,以达到目标沉降速度[33]。本研究中模拟设计的优点在于可能将优化后的表面负荷维持在等同于污泥静态沉降中的密集沉淀阶段达到最大沉淀速度,从而形成并维持稳定、清晰的泥水界面,实现高速高效泥水分离。

3. 结论

采用流变性和k-omega 模型结合模拟优化高效沉淀池构效关系是可行的。基于计算流体力学形成了高效沉淀池标准化的模拟方法,识别了沉淀池的关键特性是密度(1 005 kg·m−3)和流变性。流变性能够描述沉淀过程中污泥流动性质变化,提高了模拟的准确度。流道构型决定沉淀区流场分布的均匀性,影响高效沉淀池内密度分布,导致污泥絮体沉淀或漂浮,从而对表面负荷起着至关重要的作用。模拟优化的上升区流速、下降区流速、表面负荷分别可达44.70、32.90、12 m·h−1。长挡墙、宽流道利于高效沉淀池工程形成均匀的流场,从而维持较高的表面负荷。宽流道降低了沉淀池内流速和电耗,高表面负荷可节约沉淀池占地,可实现减污降碳协同增效的目标。

-

表 1 某厂高效沉淀池混合液物性特征平均值

Table 1. Average physical properties of mixed liquid in a highly efficient sedimentation tank

项目 粒径/μm 密度/(kg·L−1) 污泥浓度/(g·L−1) COD/(mg·L−1) 氨氮/(mg·L−1) TC/(mg·L−1) TOC/(mg·L−1) D10 D50 D90 进水 7.913 20.814 49.486 1.001 0.80 20.3 0.35 67.0 2.26 排泥 12.23 30.18 63.426 1.005 10.00 — — — — 出水 — — — — — 18.1 0.15 66.2 2.14 表 2 模拟优化的几何构型及其对应的网格要求、进出口条件

Table 2. Simulation scenario and related boundary conditions

情景编号 出水上区流速/(m·h−1) 上升区宽度/m 出水下区流速/(m·h−1) 下降区宽度/m 高度/m 进水量/(kg·s−1) 出泥量/(kg·s−1) 出水量/(kg·s−1) 情景1(窄) 100.70 0.90 106.60 0.85 1.50 289.35 1.16 288.19 情景2(中) 64.70 1.40 44.20 2.05 1.50 289.35 1.16 288.19 情景3(宽) 44.70 1.90 32.90 2.75 1.50 289.35 1.16 288.19 情景4(窄) 100.70 0.90 106.60 0.85 2.50 289.35 1.16 288.19 情景5(中) 64.70 1.40 44.20 2.05 2.50 289.35 1.16 288.19 情景6(宽) 44.70 1.90 32.90 2.75 2.50 289.35 1.16 288.19 情景7(窄) 100.70 0.90 106.60 0.85 3.50 289.35 1.16 288.19 情景8(中) 64.70 1.40 44.20 2.05 3.50 289.35 1.16 288.19 情景9(宽) 44.70 1.90 32.90 2.75 3.50 289.35 1.16 288.19 -

[1] 梁炎伦. 应用于二沉池的斜管沉淀池数学模型建立研究[D]. 广州: 广州大学, 2020. [2] 刘天顺, 杨淑霞, 魏迅, 等. 高效沉淀池+浅层高效滤池用于污水厂深度处理[J]. 中国给水排水, 2021, 37(24): 82-86. doi: 10.19853/j.zgjsps.1000-4602.2021.24.015 [3] 梁翡珏, 林显增, 肖丹, 等. 沉淀池工艺及排泥设备优化改造及应用[J]. 城镇供水, 2021(6): 24-27. doi: 10.3969/j.issn.1002-8420.2021.06.009 [4] 丰桂珍, 童祯恭, 唐朝春. 斜管沉淀技术优化研究进展[J]. 华东交通大学学报, 2011, 28(6): 28-32. doi: 10.3969/j.issn.1005-0523.2011.06.006 [5] 王伟强, 李星, 杨艳玲, 等. 污泥回流比对絮体破碎再絮凝及沉后水水质的影响[J]. 中国给水排水, 2014, 30(17): 70-72,76. doi: 10.19853/j.zgjsps.1000-4602.2014.17.019 [6] 吴志超, 黄友谊, 陈和谦, 等. 沸石颗粒在污泥絮体中的形态及其对污泥泥水分离的影响[J]. 环境污染与防治, 2005(3): 177-180. doi: 10.3969/j.issn.1001-3865.2005.03.006 [7] 何志江, 张源凯, 王洪臣, 等. 活性污泥絮凝沉降速率计算方法研究[J]. 环境污染与防治, 2015, 37(12): 35-40. doi: 10.15985/j.cnki.1001-3865.2015.12.007 [8] 倪玲英. 斜板沉降器内油粒运动规律分析[J]. 化工机械, 2010, 37(4): 457-460. doi: 10.3969/j.issn.0254-6094.2010.04.017 [9] BEHIN J, AGHAJARI M. Influence of water level on oil–water separation by residence time distribution curves investigations[J]. Separation and Purification Technology, 2008, 64(1): 48-55. doi: 10.1016/j.seppur.2008.08.009 [10] OKOTH G, CENTIKAYA S, BRUGGEMANN J, et al. On hydrodynamic optimisation of multi-channel counter-flow lamella settlers and separation efficiency of cohesive particles[J]. Chemical Engineering and Processing:Process Intensification, 2008, 47(1): 90-100. doi: 10.1016/j.cep.2007.08.003 [11] 赵一德, 周振, 麦穗海, 等. 活性污泥沉降速率模型的研究进展[J]. 净水技术, 2008(5): 14-17. doi: 10.3969/j.issn.1009-0177.2008.05.004 [12] 朱哲, 李涛, 王东升, 等. 不同泥龄下活性污泥絮体性状的研究[J]. 环境化学, 2009, 28(1): 10-15. doi: 10.3321/j.issn:0254-6108.2009.01.002 [13] 柯水洲, 涂家勇, 朱佳, 等. 不同混凝剂对污泥回流效果和絮体特性影响研究[J]. 水处理技术, 2016, 42(2): 19-22. doi: 10.16796/j.cnki.1000-3770.2016.02.005 [14] SALEM A I, OKOTH G, THOMING J. An approach to improve the separation of solid–liquid suspensions in inclined plate settlers: CFD simulation and experimental validation[J]. Water Research, 2011, 45(11): 3541-3549. doi: 10.1016/j.watres.2011.04.019 [15] SAM K Y, LEE S H, BAN Z H. Computational fluid dynamics (CFD) modelling on effect of fume extraction[J]. Journal of Chemical Health and Safety, 2019, 26(6): 20-31. doi: 10.1016/j.jchas.2019.04.004 [16] 穆瑞, 乐高杨, 杨慧中. 基于O3/UV法在线COD检测的气体溶解量估计方法[J]. 化工学报, 2019, 70(2): 730-735. [17] 牛雨彤, 刘吉宝, 马爽, 等. 零价铁和微波预处理组合强化污泥厌氧消化[J]. 环境科学, 2019, 40(3): 1431-1438. doi: 10.13227/j.hjkx.201806079 [18] GUIMARAES A A, KLEIN T S, MEDRONHO R D A. Fish-hook effect in granulometric efficiency curves of hydrocyclones: A misuse of laser diffraction particle size analysers[J]. Powder Technology, 2020, 374: 185-189. doi: 10.1016/j.powtec.2020.06.091 [19] ANGLE C W, CLARKE B, DABROS T. Dewatering kinetics and viscoelastic properties of kaolin as tailings model under compressive pressures[J]. Chemical Engineering Research and Design, 2017, 118: 286-293. doi: 10.1016/j.cherd.2016.10.029 [20] LIU J, YU D, ZHANG J, et al. Rheological properties of sewage sludge during enhanced anaerobic digestion with microwave-H2O2 pretreatment[J]. Water Research, 2016, 98: 98-108. doi: 10.1016/j.watres.2016.03.073 [21] ELTAYEB A, TAN S, ALA A A, et al. The study of the influence of slug density on the mixing performance in the reactor vessel, using PLIF experiment and FLUENT simulation[J]. Progress in Nuclear Energy, 2021, 131: 103558. doi: 10.1016/j.pnucene.2020.103558 [22] AGGUL M, LABOVSKY A E, SCHWIEBERT K J. NS-ω model for fluid–fluid interaction problems at high Reynolds numbers[J]. Computer Methods in Applied Mechanics and Engineering, 2022, 395: 115052. doi: 10.1016/j.cma.2022.115052 [23] NARTU M S K K, DASARI S, SHARMA A, et al. Omega versus alpha precipitation mediated by process parameters in additively manufactured high strength Ti–1Al–8V–5Fe alloy and its impact on mechanical properties[J]. Materials Science and Engineering:A, 2021, 821: 141627. doi: 10.1016/j.msea.2021.141627 [24] ZHAO R, LIU S, LIU J, et al. Generalizability evaluation of k-ε models calibrated by using ensemble Kalman filtering for urban airflow and airborne contaminant dispersion[J]. Building and Environment, 2022, 212: 108823. doi: 10.1016/j.buildenv.2022.108823 [25] LI J, ZENG F, CHEN S, et al. Bayesian model evaluation of three k–ω turbulence models for hypersonic shock wave–boundary layer interaction flows[J]. Acta Astronautica, 2021, 189: 143-157. doi: 10.1016/j.actaastro.2021.08.050 [26] CHENG X, TAK N. Investigation on turbulent heat transfer to lead–bismuth eutectic flows in circular tubes for nuclear applications[J]. Nuclear Engineering and Design, 2006, 236(4): 385-393. doi: 10.1016/j.nucengdes.2005.09.006 [27] SRINRVASAN S, VANDEN AKKER H E A, SHARDT O. Inclusion of DLVO forces in simulations of non-Brownian solid suspensions: Rheology and structure[J]. International Journal of Multiphase Flow, 2022, 149: 103929. doi: 10.1016/j.ijmultiphaseflow.2021.103929 [28] WILKINSON D, WALIDE B, MOHAMAD NOR M I, et al. Baffle plate configurations to enhance separation in horizontal primary separators[J]. Chemical Engineering Journal, 2000, 77(3): 221-226. doi: 10.1016/S1385-8947(99)00170-9 [29] ALVARADO A, VEDANTAM S, GOETHALS P, et al. A compartmental model to describe hydraulics in a full-scale waste stabilization pond[J]. Water Research, 2012, 46(2): 521-530. doi: 10.1016/j.watres.2011.11.038 [30] 王伟. 废水预处理混凝沉淀实验分析[J]. 中国环保产业, 2021(7): 56-58. doi: 10.3969/j.issn.1006-5377.2021.07.015 [31] 戴林明, 彭玉玲. Ca(OH)2-FeSO4混凝沉淀法脱除钨冶炼废水中氟、磷、砷的研究[J]. 中国钨业, 2021, 36(2): 48-52. doi: 10.3969/j.issn.1009-0622.2021.02.008 [32] AUBIN J, PRAT L, XUEREB C, et al. Effect of microchannel aspect ratio on residence time distributions and the axial dispersion coefficient[J]. Chemical Engineering and Processing:Process Intensification, 2009, 48(1): 554-559. doi: 10.1016/j.cep.2008.08.004 [33] HAN H, WU X, GE L, et al. A sludge volume index (SVI) model based on the multivariate local quadratic polynomial regression method[J]. Chinese Journal of Chemical Engineering, 2018, 26(5): 1071-1077. doi: 10.1016/j.cjche.2017.08.007 期刊类型引用(2)

1. 郑炳德. 污水处理厂建设监理工作要点分析. 中国建筑金属结构. 2024(06): 172-174 .  百度学术

百度学术

2. 吴艳涛. 城镇工业园区给水厂工艺设计研究. 价值工程. 2023(36): 63-65 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: