-

金属加工液广泛应用于金属材料的加工、切割、研磨、钻孔和锻造等制造过程。除了冷却和润滑功能外,金属加工液还能起到减少摩擦、控制传热、防止腐蚀和提高加工效率[1]的作用,有助于提高加工工具的使用寿命和功能,成本约为加工费用的15%[2]。据统计,金属加工液的全球使用量超过1×107 t·a−1[3]。在金属加工液的使用过程中需要加水稀释,故实际废水排放量是加工液使用量的十倍以上。由于专利问题及加工工艺存在的差异,金属加工液废水不仅组成复杂,而且不同厂家排放的废水成分差异很大,因此,金属加工液废水的处理及其资源化是工业废水处理中的难点。

切削液是一种金属加工液,通常由油、表面活性剂和各种添加剂组成。切削液废水包含大量乳化油、金属屑、有机物等,其COD、总有机碳(TOC)和油浓度都很高[4]。若未经处理的切削液废水排入自然水体,会在水面形成油膜,导致水体缺氧,威胁水中生物的生长。此外,切削液废水中的油脂具有较强的渗透能力,还会透过土壤进入地下水层,进而污染地下水源。废水中的添加剂和金属屑进入水循环后,会通过食物链进入人体,引发患癌风险,危害人类健康[5-10]。2016年,我国发布《国家危险废物名录》,将切削液废水列入HW09废液的一种[11]。因此,以切削液为代表的废乳化液的处理是机械和装备制造领域亟待解决的问题。

由于切削液废水具有成分复杂、浓度高及危害性强的特点,所以需要针对不同行业产生的切削液废水个性化地研发有效的水处理单元或组合工艺。气浮、混凝、过滤、氧化和生物处理等技术已应用于废切削液处理。废水组成的复杂性使得单一处理单元都存在局限性,而组合工艺能够更好地实现废切削液的有效处理,如混凝与过滤联用、氧化与生物法联用等。本文综述了近年来切削液废水处理技术的研究进展,介绍了切削液废水处理过程的难点和新的发展方向,并提出了相关建议,以期为切削液废水的处理提供参考。

全文HTML

-

切削液可分为油基切削液和水基切削液。油基切削液是将基础油与含有乳化剂的水混合得到的水包油乳化液,呈乳白色,基础油体积分数(浓度)为1%~10%,常被称为“水溶性油”。传统油基切削液的基础油通常为矿物油。矿物油是石油等化石燃料精炼得到的液态烃混合物,会带来环境污染问题。近年来,已有学者开始研究环保型植物油基切削液。水基切削液可分为合成型和半合成型。合成型切削液是包含乳化剂、防腐剂或消泡剂等水溶性化合物的混合物,与水混合会形成透明或半透明的溶液;这类切削液不含基础油,故具有较好的冷却性能。半合成型切削液是水包油乳化液与合成液的组合,兼具油基和水基切削液的特性[2,12-14]。

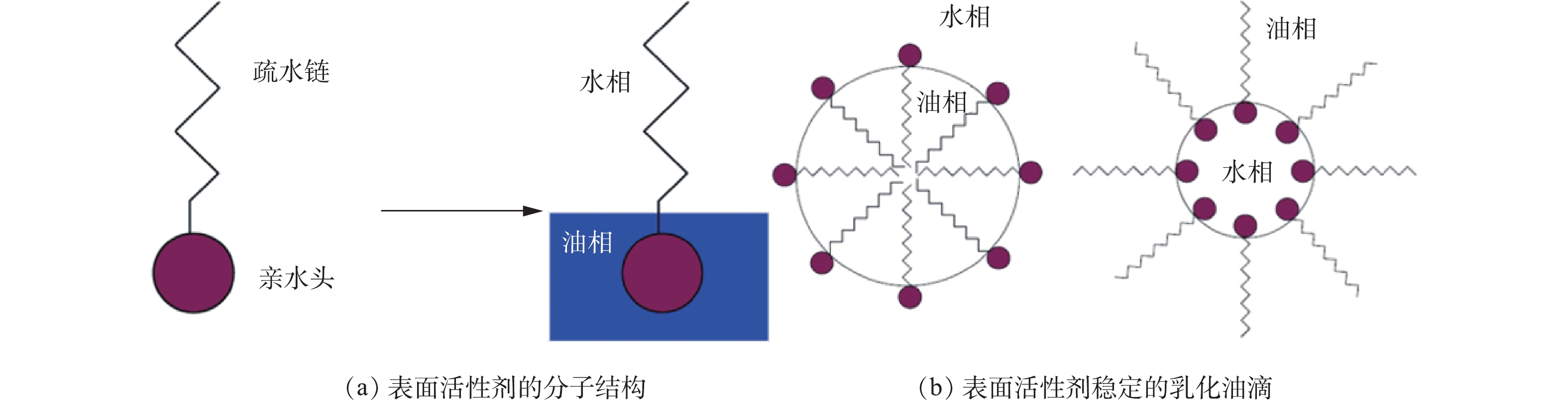

切削液废水中的油按形态可分为:浮油(>150 μm)、分散油(20~150 μm)、乳化油(<20 μm)及溶解油(<5 μm)[15]。浮油粒径较大时,可通过简单的物理分离法将其去除;分散油粒通常带电,可通过引入反离子中和小油滴的电性使其聚集成大油珠而去除;而由于表面活性剂的稳定作用,乳化油的水相和油相分离则更加复杂和困难[16]。从热力学角度分析,乳化油是不稳定体系,但加入表面活性剂后,其稳定性得以增强。表面活性剂的结构为包含亲水基团和疏水碳氢长链的有机分子[2](见图1)。表面活性剂的亲水基团是离子性或强极性的,在极性溶剂中具有增溶作用;疏水部分则为线性或支化烃,表现出弱的溶质-溶剂相互作用。表面活性剂可以包覆微小油滴,降低总表面能,减少油滴的碰撞聚合概率,进而形成稳定的乳化油体系[2,17]。

-

切削液废水的处置,一方面可将处理工作直接交由商业废物处理公司负责,另一方面则可对不同企业针对性开发高效废水现场处理工艺。从企业的长期发展来看,废切削液的现场处置则更具有效益和环保优势。事实上,随着环境问题的日益突出和相关法律制度的完善,监管机构要求厂家对废物承担更多的处置责任。在处置成本及法律监管压力下,现场废液处理工艺的开发已成为一个值得关注的问题[16]。

切削液废水处理大致分为化学、物理和生物法3大类。不同的处理方法都有都各自的优缺点。具体到实际处理中时,由于不同工业、工段产生的切削液废水水质差异很大,处理方案还需根据实际情况制定。含油废水处理主要采用气浮、混凝、膜过滤、生物氧化、化学氧化等方法[18-21]。其中,重力分离、气浮、混凝等传统处理方法对于浮油和分散油有一定处理效果,但对表面活性剂稳定的乳化油体系处理效果较差。另外,切削液废水可生化性差,单独的生物处理单元难有好的处理效果,还需要与其他工艺单元进行组合。膜过滤技术可有效去除粒径小于10 μm的乳化油滴[22],可应用于含油废水处理。微滤和超滤处理乳化油废水已有大量研究。制约膜技术应用的主要问题是由膜污染导致的通量下降,以及渗透性(溶质穿过膜的速度)与选择性(溶质与溶剂分离的程度)间的平衡问题[15, 23]。总结以上含油废水处理方法的优缺点[15-16]并进行对比,具体结果见表1。

1.1. 切削液废水的组成和特点

1.2. 切削液废水的处理技术

-

切削液废水是一个成分复杂的乳化油体系,而乳化油废水的处理关键在于破乳[24]。目前,较为有效的破乳方法有化学破乳、超声破乳、磁场破乳、微生物破乳等[21,24-26]。下面将重点梳理物理法、化学法、生物法等方法进行破乳的技术。

-

1)气浮法除油技术。气浮法是将微小气泡注入水中,利用气泡黏附水中油滴,形成密度小于水的絮体,并在浮力作用下漂浮到水面形成浮油层,最终通过刮去浮油层达到油水分离的过程[27]。气浮法具有处理效率高、易操作等优点[28]。常用的气浮工艺有溶解气浮(dissolved air flotation,DAF)、电气浮(electro-flotation,EF)、散气气浮(dispersed (induced) air flotation,IAF)、离心气浮(centrifugal flotation,CF)等[29]。

MOFRAD等[30]进行了DAF与非均相光催化(UV/H2O2/ZnO)联用降解金属加工废液的研究。该废液COD为35 000 mg·L−1,总石油烃(total petroleum hydrocarbons,TPH)为3 200 mg·L−1,油含量为15 500 mg·L−1,pH为9。经DAF处理后,COD去除率为98.5%,TPH去除率为70%,油去除率为99.8%。进一步提高溶液碱性,并进行非均相催化反应后,可实现COD、TPH和油的进一步去除。最终去除率分别达到99.9%、97.9%、99.9%,出水COD为45.54 mg·L−1,含油量为6.1 mg·L−1。因此,气浮工艺可去除废水中大部分的COD和油,为深度去除污染物,还应增加如混凝、氧化等额外的处理单元。

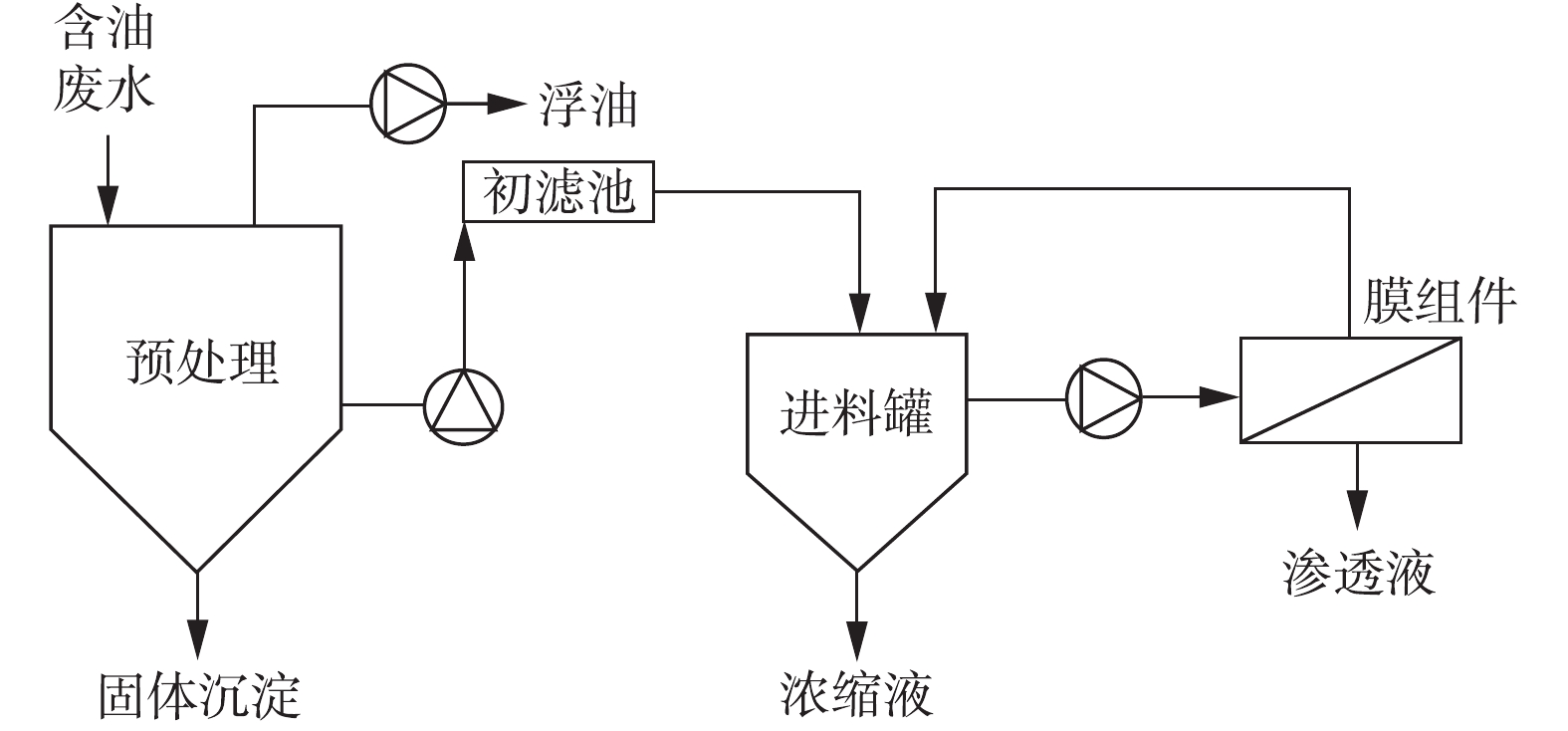

2)膜分离法除油技术。膜分离技术具有除油效率高、出水水质稳定、能耗低、占地面积小、无二次污染等优点,是一种绿色高效的废水处理方法。切削液废水中的乳化油粒径小于10 μm,可通过超滤(ultrafiltration,UF)和微滤(micro-filtration,MF)得以有效去除;而纳滤(nano-filtration,NF)、反渗透(reverse osmosis,RO)和正渗透(forward osmosis,FO)的应用还较少。对于O/W型乳化液,超滤膜能够有效截留5 μm的乳化油滴;而微滤膜尽管水通量更高,但油滴穿透的风险也更大。因此,常采用超滤膜处理含油废水,以确保稳定的渗透水质[16]。典型的超滤法含油废水处理工艺流程[16]如图2所示。处理含油废水的常用膜材料主要有聚合物膜和陶瓷膜。聚合物膜包括聚偏氟乙烯(polyvinylidene fluorides,PVDF)、聚砜(polysulfone,PS)、聚醚砜(polyethersulfone,PES)、聚丙烯腈(polyacrylonitrile,PAN)和再生纤维(regenerated cellulose,RC)、纳米纤维膜等;陶瓷膜有Al2O3、ZrO2、SiO2等[31-36]。杨振生等[37]采用PED/TiO2改性超滤膜处理切削液废水。原水COD为96 873 mg·L−1。在聚醚砜微孔膜表面经PED/TiO2杂化处理得到超滤尺度滤膜,截留分子质量为3 000 Da。在压力为0.4 MPa、流速为1.0 m·s−1的条件下,该滤膜可将切削液废水中的大部分油污过滤去除。其中,COD去除率为89.7%,膜通量为69 L·(m2·h)−1。

在膜分离过程中,浓差极化和膜污染会导致膜通量显著下降,是制约膜分离效率的2个关键因素[38],且浓差极化往往导致更严重的膜污染。

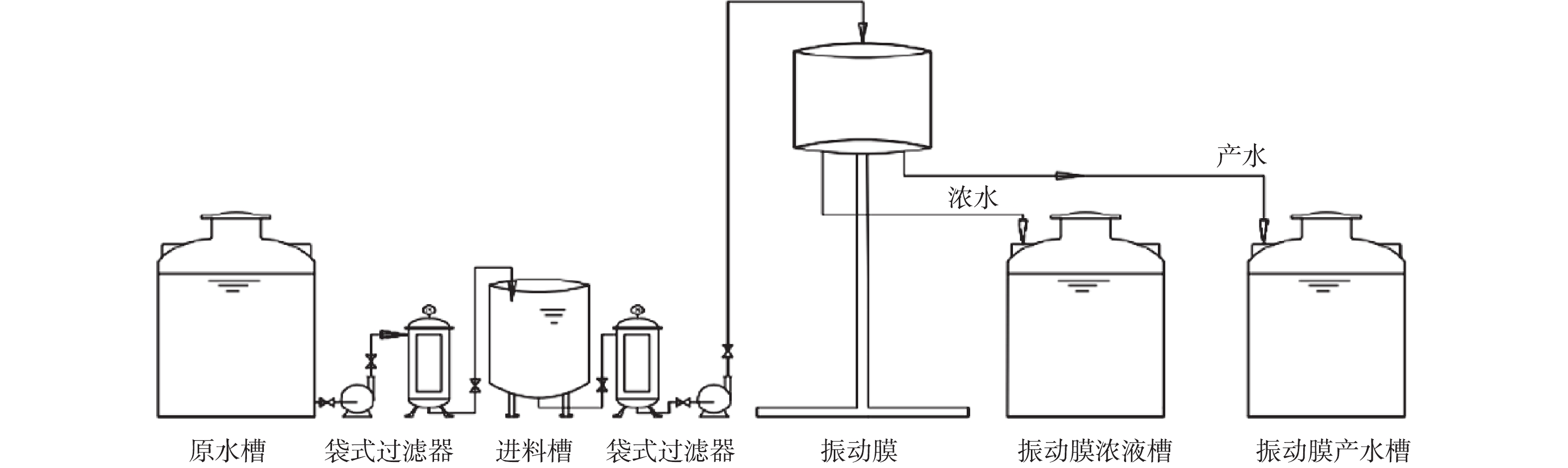

提高错流速度(cross-flow velocity,CFV)是降低膜表面浓差极化的有效措施之一。通过提高CFV可增强膜表面的剪切力,从而减小膜表面与料液本底的污染物浓度梯度。近年来,有研究者通过引入湍流促进器,如振动膜、纽带等方式来提高膜表面的流体剪切力[39-40]。郑帅飞等[39]采用振动膜技术处理切削液废水(图3),通过在膜表面的震动达到提高剪切力的目的。在原水COD为156 200 mg·L−1、矿物油为8 616 mg·L−1、SS为2 688 mg·L−1、压力为0.5 MPa、温度为60 ℃的条件下,回收率可达85%,最终COD去除率为81%、除油率为95%,SS可100%被去除。POPOVIĆ等[40]通过在错流过滤装置内添加纽带的方式提高进料液湍流以减小浓差极化的影响。纽带为一根固定在膜反应器内的螺旋状杆。由于螺旋状表面的作用,水相流过杆表面时会产生更强的湍流。纽带的主要控制参数OTP为节长度Le与直径DTP的比值。纽带作用使膜通量明显增加,OTP对处理效果有正向影响。当OTP 为1.55、油的体积分数(浓度)为2%时,过滤装置可获得最大通量(201 L·(m2·h)−1)及最小能量消耗(1.34 kWh·m−3)。因此,与简单地增加错流速率相比,增加纽带可更高效地减缓浓差极化和膜污染,并获得更高通量。

膜污染是油滴在膜表面和膜孔内沉积导致膜通量下降的复杂过程,是由于污染物在膜表面的吸附、膜孔内污染物的堵塞及污染物在膜表面附着形成滤饼层[33]而造成。膜污染通常分为可逆污染和不可逆污染。膜污染导致膜通量迅速下降后,需要频繁清洗来恢复其通量。而不可逆污染需要采用化学清洗来缓解,这也缩短膜材料的使用寿命。膜污染与表面化学性质、膜孔径、表面结构、表面活性剂、盐含量、操作条件等[41]因素相关。近年来,研究者们通过改善工艺条件、新型膜材料开发、膜材料改性,以及与其他技术联用的方法来减缓膜污染、提高膜分离效率。

实际处理过程中,优化工艺参数对于缓解膜污染具有重要作用。其中,跨膜压差(trans-membrane pressure,TMP)对膜通量和膜污染有重要影响。当进料液浓度较低时,通量随TMP增加而呈线性增加。而当处理高浓度废水时,TMP过高会在膜表面形成致密污染层,导致严重的膜污染和通量的快速下降。若在膜过滤前进行预处理,可有效地减缓膜污染。MILIĆ等[42]使用电混凝(electric coagulation,EC)预处理与MF联用处理废切削液。当使用MF直接过滤体积分数为0.1%的切削油时,膜通量下降65%,说明这是由小粒径油滴堵塞膜孔所造成的不可逆污染。当采用EC预处理后,乳化油的粒径快速增大,MF效能明显提升,EC预处理5 min即可有效缓解不可逆污染。这时,膜通量下降原因则是由于浓差极化引起的可逆污染,而污染物在膜表面形成的具有疏松结构的多孔滤饼层还可有效提高膜的水渗透性。

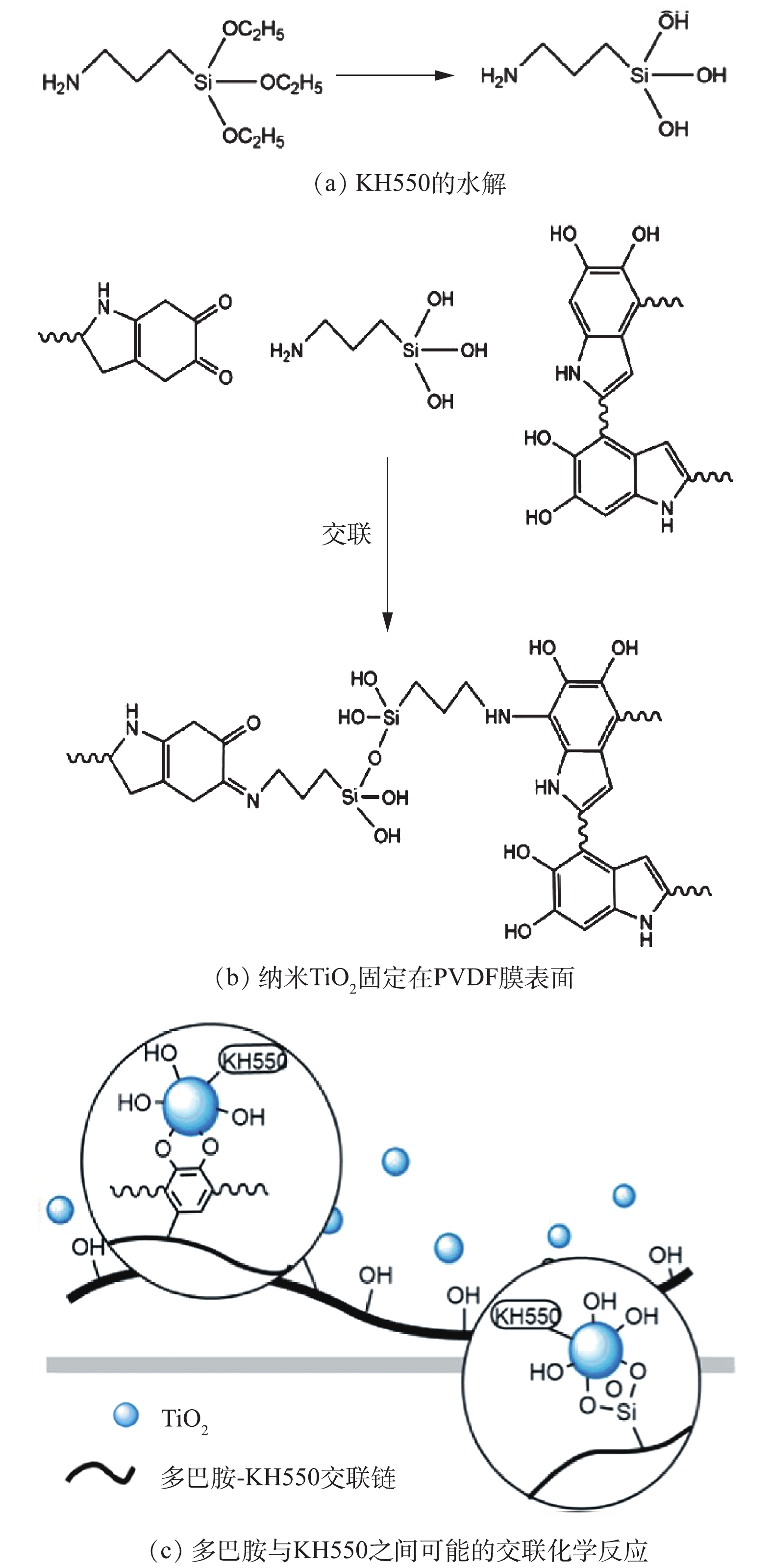

控制膜污染的另一个途径是提高膜表面的亲水性能。油滴与膜表面的亲和力是影响膜污染的重要因素。与膜表面亲和力大的油滴会优先吸附并进入膜孔,造成膜污染。增强材料的亲水性可在膜表面形成水合层,在处理O/W型废水时,可减少油滴的附着,减缓膜污染的发生,从而有效减少膜通量的下降[43-45]。现有研究主要通过共混、表面接枝或涂覆的方法在膜基质或膜表面引入亲水性材料(如无机物、聚乙二醇、低聚糖基团、两性离子聚合物、纳米颗粒等),制备混合基质、纳米颗粒掺杂或表面官能团修饰膜材料,以实现膜材料的亲水化改性[46-49]。GAO等[50]通过热致相分离(thermally induced phase separation,TIPS)技术制备了聚苯硫醚(polyphenylene sulfide,PPS)微孔膜,然后在不同温度下用硝酸(HNO3)对膜进行后处理。HNO3可使PPS膜表面形成大量的亲水性基团(—SO=、—SO2—、C=O、—NH2和—NO2)。经50 ℃的HNO3溶液处理的PPS膜具有超亲水性(接触角为0)。在过滤氯苯/水乳化油时,水通量为155 L·(m2·h)−1,分离效率为99%。SHI等[47]在PVDF表面涂覆纳米TiO2获得亲水膜,并进一步引入硅烷偶联剂KH550将亲水膜改性为超亲水膜。采用硅烷偶联剂KH550与多巴胺共聚,通过一步浸渍法直接将TiO2纳米颗粒接枝到PVDF膜表面,可使PVDF膜具有水下超疏油性(过程[47]如图4 所示)。KH550通过氨基与多巴胺衍生物结合,在膜表面产生丰富的羟基和氨基,改善了膜的亲水性。改性超亲水膜的水通量最高可达785 L·(m2·h)−1,对O/W型乳化液的分离效率为99%。

开发抗污染膜是膜法应用于切削液废水处理领域的解决思路。有机膜存在不可逆污染严重、化学清洗频繁、处理效果较差等问题[51]。陶瓷膜具有化学性质稳定、耐有机溶剂、pH适用范围宽、适宜苛刻环境工作等优点,已在含油废水处理领域得到快速发展[52-53]。常用的陶瓷膜基底和改性材料有Al2O3、ZrO2、SiO2、TiO2等。由于无机氧化物颗粒表面羟基的存在,陶瓷膜通常表现较好的亲水性[43,45,53]。MILIĆ等[54]比较了陶瓷膜(Al2O3/ZrO2)和聚合物膜(polyvinyl chloride,PVC)过滤金属加工液的性能,研究发现陶瓷膜比聚合物膜具有更高的通量和污染物去除效率。陶瓷膜的优势在于:1)机械强度高,可在较高的压力和流速下运行;2)较强的耐酸碱和氧化能力,pH变化对其影响较小;3)亲水性更好,膜表面主要发生可逆污染,简单冲洗后即可明显恢复其通量。因此,陶瓷膜对切削液废水具有较好的处理效果及应用潜力。受到金属有机框架(metal-organic frameworks,MOF)材料在气体分离和储存等领域应用的启发,近年来,液体分离领域的学者也开展了关于MOF材料的研究,已有多种相关纳米材料应用于水处理领域[55-57]。MOF由金属簇与有机配体通过配位键构成,可在基质上生长成连续膜,或用作填充剂制备MMM。MOF的有机配体可促进与聚合物的相互作用,从而实现良好的相容性。但传统的MOF由于配体较少,水热稳定性较差,难以用于水处理。表面亲水性的构建和良好的稳定性是MOF膜发展所面临的主要问题[58]。目前,已开发出一些基于MOF的膜分离材料,如ZIF系列(Zn2+/Co2+与亚咪唑酸酯连接剂一起构建的稳定晶体)、UiO-66(基于锆金属簇的有机金属骨架,Zr-MOF)等。基于MOF的膜材料具有优异的通量、抗污性,有很大应用潜力。相关研究尚处于实验阶段,还未应用到切削液废水处理的实际工程中。

-

1)酸析破乳法。切削液废水多数呈碱性。表面活性剂使废水中油珠带电。由于ζ电位和双电层的存在,乳化油颗粒之间无法接触聚集。通过加酸,增加体系中的H+,可中和乳化油油滴表面的负电荷,从而降低ζ电位实现破乳。吴文珍等[59]使用硫酸酸化处理某机械加工废水,原水COD为8 763 mg·L−1,pH为8.5,当调节废水pH为2.5时,COD去除率为48%;当使用酸析-混凝联用工艺时,COD去除率可达71%。酸析破乳的主要问题是出水呈酸性,易腐蚀设备,需要额外投加碱来中和pH,且出水悬浮物较多,单独的酸析处理单元难以达到排放标准。

2)混凝法除油。混凝是水处理领域广泛使用的技术之一,已在乳化油废水处理中得到应用。切削液废水中的乳化油主要通过油滴间的静电排斥作用,以及大分子有机物或无机颗粒的吸附作用而稳定存在[60]。通过投加混凝剂,可以改变乳化油油珠表面电荷,使油珠相互吸附聚集,完成破乳过程。然而,由于不同工业、工段产生的切削液废水成分有差异,需要对处理对象进行大量实验来筛选混凝剂[61]。单独的混凝工艺一般不能直接使切削液废水达到排放标准,但可作为预处理去除大部分COD[62]。韩卓然等[63]使用聚合氯化铝(polyaluminum chloride,PAC)与聚合硫酸铁(polyferric sulfate,PFS)处理某机械制造厂铝加工过程产生的切削液废水(COD为40 377 mg·L−1),PAC和PFS的最佳投量均为9 g·L−1;PAC对切削液废水中大分子有机物的去除效果好于PFS,而对小分子有机物的去除效果均相对较差,应增加后续单元对废水进行深度处理。

对传统混凝剂进行改性可以提高混凝效率。CHEN等[64]使用丙烯酰胺、丙烯酰氧基乙基三甲基氯化铵(acryloyloxyethyl trimethylammonium chloride,DAC)和椰子二乙醇酰胺(coconut diethanolamide,CDEA)为单体,通过短波紫外线(short-wave ultraviolet,UVC)引发聚合,获得改性阳离子聚丙烯酰胺絮凝剂,并用于切削液废水的处理中。原水COD为1 488 mg·L−1,油浓度为241 mg·L−1。在最佳条件下,最终达到COD去除率为75%、油去除率为92%,且改性絮凝剂具有耐酸性。该絮凝反应的主要机理是电荷中和,而絮凝剂分子中包含的低润湿性疏水嵌段是其除油效率高的原因。

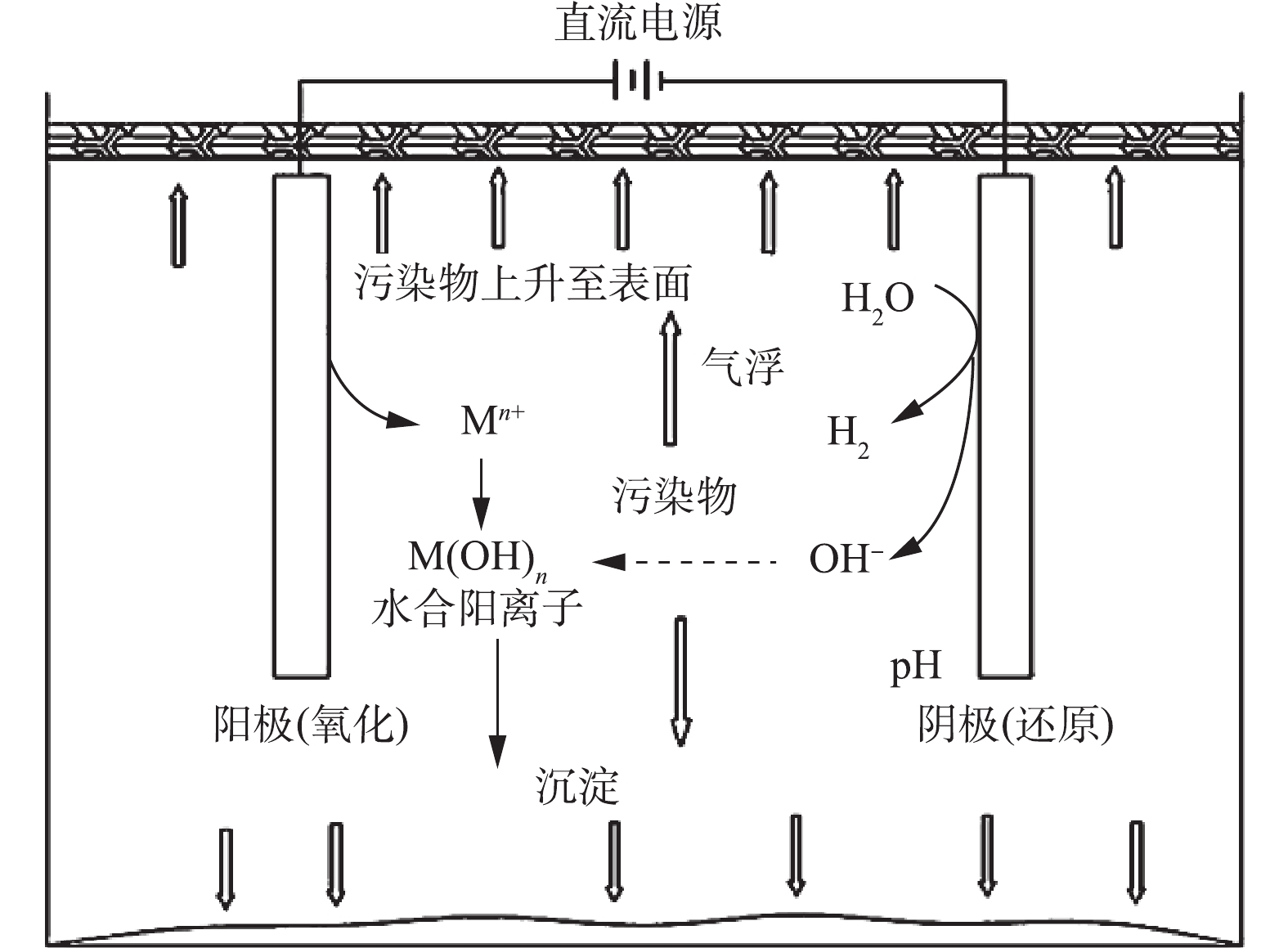

电化学混凝(EC)技术具有操作设计简单、无需添加额外化学药剂、对污染物去除能力强等特点。作为一种绿色混凝工艺,EC已被应用于切削液废水处理领域。EC通过牺牲阳极释放金属离子(通常为Al3+或Fe2+,反应见式(1)~式(3)),发生电解反应,从而在阴极处生成气体[65](通常为H2,反应见式(4))。与化学混凝相比,EC技术产生的污泥量少且稳定,其反应过程包括3个方面:1)电极氧化;2)产生气泡;3)絮凝沉淀。EC反应的机制[66]如图5所示。阳极释放的金属离子作为絮凝剂,阴极产生气泡,絮凝剂与水中的污染物结合形成大絮体,然后通过沉淀或气浮去除[67]。

AVANCINI等[68]使用电混凝反应器处理金属加工液,通过电极打孔、调节流速及增加电极间距等方式,使最终除油率可达到90%,且电极质量没有明显损失。KOBYA等[69]通过连续电混凝工艺(continuous electrocoagulation process,CEP)处理金属加工废水,并比较了Al电极和Fe电极的去除效率。原水COD为17 312 mg·L−1、TOC为3 155 mg·L−1、浊度为15 350 NTU,最终Fe电极的COD、TOC和浊度的去除率分别为98%、95%、99.9%,优于Al电极体系的去除率,且去除率与电流强度呈正比,与流速呈反比。GUVENC等[70]的研究同样证明了Fe电极比Al电极更适合处理金属加工液。CANIZARES等[71]发现,混凝与电混凝的处理效果与pH密切相关,pH对Al2O3沉淀物的表面电荷有影响,进而影响到絮凝物的形成种类和形成过程。较高的pH可提高传统混凝的效率,而电混凝需要在中性或低pH下进行。在优化混凝工艺时也应考虑废水pH这一因素,针对具体的切削液废水,最佳的pH条件需要现场测定。

3)高级氧化法处理含油废水。高级氧化法通过化学反应产生具有强氧化性的自由基或非自由基等活性氧组分,进而氧化有机物使其矿化为简单的无机物,是切削液废水处理领域的新兴技术。高级氧化法的主要优点是能将大部分有机物矿化为无害的无机物,无二次污染。然而,高级氧化法的活性氧利用效率较低,对高浓度有机废水的处理成本高,难以作为单独的处理工艺来降解切削液废水。若将其作为预处理方法,可显著提高废水的可生化性。

Fenton氧化法是指在酸性条件下,利用H2O2和Fe(Ⅱ)反应生成具有强氧化性的羟基自由基(·OH)来氧化降解有机物的方法。边艳勇等[72]用Fenton反应处理汽车配件加工切削液,当pH 为3.5、质量比FeSO4/30% H2O2 为1∶3.5、温度为50 ℃时,COD去除率可达95%。pH过低会抑制Fe3+还原为Fe2+,最佳pH为2.8~5[73]。此外,还可通过与光、电、超声、磁联用等多种途径提高Fenton反应的效率[73]。Photo-Fenton(ph-F)是指在Fenton反应基础上引入紫外光UV或可见光,通过光的照射促进过氧化氢分解为·OH,使[Fe(OH)]2+发生光解生成·OH[74]。AMIN等[75]对经溶解气浮(DAF)处理后的金属加工废水进行ph-F处理,该废水COD为35 000 mg·L−1,油含量为15 500 mg·L−1,pH 为 9。经DAF处理后,在pH 为3,FeSO4投加量为100 mg·L−1,H2O2(30%)投加量为17 g·L−1的条件下,COD和油去除率均可达到约99%。

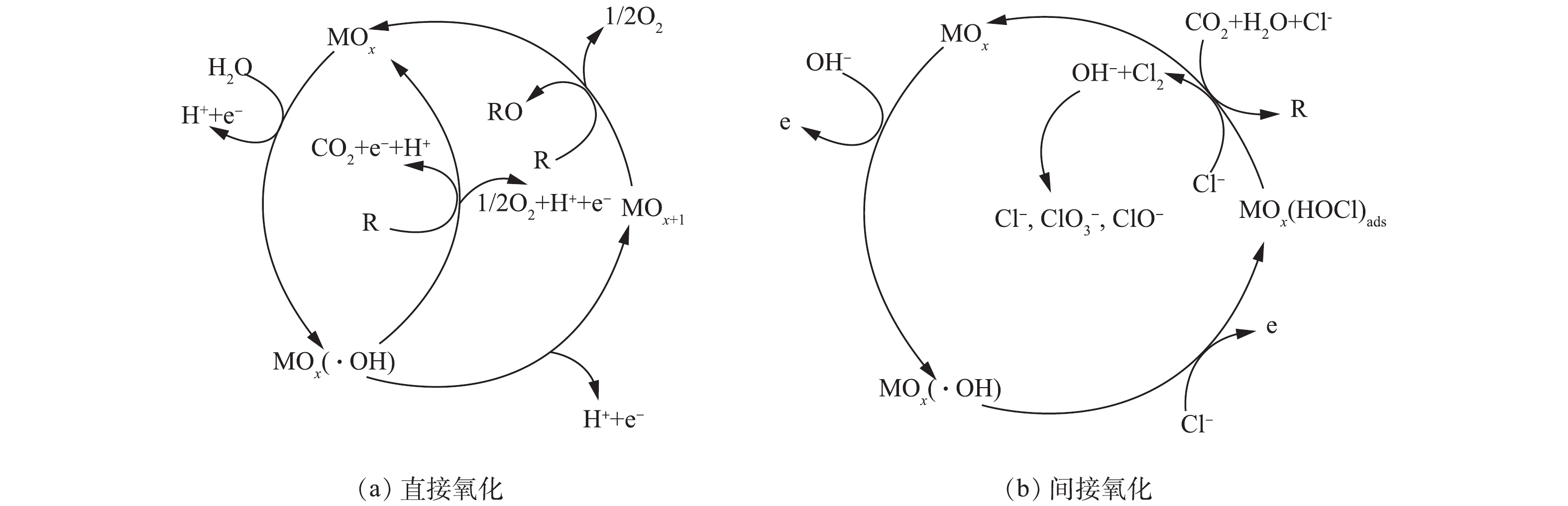

电化学氧化法(electrochemical oxidation,EO)是指通过电化学方式产生氧化剂,从而氧化降解水中污染物的方法。EO可以通过直接氧化和间接氧化这2种机制降解污染物。直接氧化可通过在阳极物理吸附的“活性氧”(·OH)或化学吸附的“活性氧”(MOx+1)直接降解污染物。·OH对有机物的氧化没有选择性,而MOx+1可参与特定氧化产物的形成。此外,过氧化物、Fenton试剂、Cl2、次氯酸盐、过二硫酸盐和臭氧也可以通过电化学方法生成氧化剂。这些氧化剂与有机底物发生氧化反应,这一过程为间接氧化。间接氧化最常用的氧化剂是氯[76]。直接氧化和基于活性氯的间接氧化过程[77]如图6所示。若废水中氯含量较低,则需添加大量盐以提高处理效率[78]。

KAUR等[79]采用Ti/RuO2阳极电氧化法处理切削液废水。废水含油量为8 775 mg·L−1,以批序和连续方式提升该方法的处理效果。在批序式操作条件下可达到除油率99%,COD去除率94%,能耗2.8 kWh·m−3。连续式操作条件下的除油率为93%,COD去除率为91%,能耗20 kWh·m−3。最佳pH为中性,表明·OH介导的直接氧化起主要作用[76]。·OH的氧化还原电位很高(2.8 V),可以抑制含氯化合物的产生[80]。YANG等[81]采用Ti/IrO2电极处理某工厂的切割和研磨冷却废液,原水pH为10,COD为125 000 mg·L−1,溶解油体积分数为5%。在电流密度为100 A·m−2的条件下,反应60 min时COD去除率为78%。

-

生物处理是指微生物以废水中的污染物作为营养,维持生命活动,并将污染物降解为无害物质的过程。根据微生物的需氧程度,可将生物处理分为好氧生物处理和厌氧生物处理。与物化法相比,废水的生物处理法具有低成本、环境友好、高效等优点。然而,微生物对环境条件需求苛刻,需要适宜的生存环境,故生物法很难直接处理可生化性低的特种有机废水。CHENG等[12]综述了生物处理法对金属切削液的研究工作。这些处理技术仅能部分去除可生物降解的有机物,出水中仍含有大量残余有机物[82]。这些有机物一般是不可生物降解或难以降解的有机物,需要采用其他方法来处理。TELI等[83]使用浸没式厌氧膜生物反应器(submerged anaerobic membrane bioreactor,SAMBR)来处理废金属加工液。反应器的COD去除率为64%,但甲烷产量很低,即该过程主要通过物化作用去除污染物,微生物的作用只是辅助。

氧化预处理可有效提高废水的可生化性[84-86]。ZHANG等[87]研究了膜生物反应器(membrane bio-reactor,MBR)与Fenton反应联用处理废切削液。在最佳条件下,COD去除率可达到97%。JAGADEVAN等[85]采用生物法结合Fenton氧化降解金属加工液。废液pH为7.4,COD为11 500 mg·L−1,TOC为2 100 mg·L−1。在Fenton反应条件下,COD和TOC的去除率分别为65%和55%;出水毒性降低了91%,;BOD5/COD从0.160增加到0.538,说明废水的可生化性显著提高,可进行生物处理。VYRIDES等[88]通过分析金属加工液中菌株的COD去除和产甲烷情况,从废金属加工液中分离出特定菌株以用于COD去除并产生甲烷。研究结果证明,从切削液或金属加工液中分离特定的菌株来处理原废水是可行的,但仍需克服苛刻的生物处理条件。

2.1. 物理法处理技术

2.2. 化学法含油废水处理技术

2.3. 生物法含油废水处理技术

-

在废切削液处理过程中,将多种工艺进行有序组合是有效、有前景的策略。在组合系统中,针对不同的水质情况采用不同的物理、化学和生物法进行联动处理,可以切削液废水达到排放要求。

陈益成[89]采用预处理加生化处理的工艺组合处理切削液废水;预处理由机械格栅+pH调节+隔油池+气浮组成;生化处理由厌氧+缺氧+好氧+MBR工艺组成。原水pH 为 10.4,BOD5为26 000 mg·L−1,SS为477 mg·L−1,最终出水pH 为 7.8,BOD5小于10 mg·L−1,SS小于100 mg·L−1。赵露霞等[90]用混凝-热活化过硫酸盐氧化处理金属切削液废水,先通过混凝去除大部分有机物,再通过过硫酸盐氧化技术产生硫酸根自由基(

SO−⋅4 )进攻残余有机污染物。原水COD为43 000 mg·L−1。混凝过程中,COD去除率为76%,再经过硫酸盐氧化。在最佳条件下,又进一步去除了81%的COD,最终出水COD为1 463 mg·L−1。尽管出水尚未达到排放标准,但已具备了生物处理的条件。黄腾蛟等[91]采用混凝和Fenton工艺联用处理切削液废水。原水pH 为6.4,COD为9 950 mg·L−1。当PFS投加量为6 g·L−1时,COD去除率为55.5%,再通过Fenton处理,COD的最终去除率为80%。Fenton反应前增加混凝预处理可以先去除大部分COD,以减少Fenton反应的药剂用量。JAGADEVAN等[92]采用纳米零价铁nZVI与微生物联合处理金属加工液。废水COD为12 650 mg·L−1。当pH为3时,COD去除率为76%。这主要是由于溶液在酸性条件下会产生·OH,经nZVI处理的切削液毒性降低了85%,BOD5/COD从0.154上升至0.512。进一步生物降解后,出水COD为570 mg·L−1。这表明使用nZVI处理实际工业废水可降低其毒性并提高可生物降解性。在实际处理过程中,对较成熟的工艺进行组合能够达到各工艺单元互补的效果,可有效处理实际废切削液。然而,多个工艺单元也会导致成本的增加,故需根据废水的实际水质设计合理、经济的组合技术,在保证达到外排或回用标准的前提下尽可能节省投资成本。

-

切削液是机械加工和制造业中的重要物料,其广泛应用产生的大量切削液废水成分复杂,含有大量乳化油、添加剂(表面活性剂、缓蚀剂、消泡剂),以及废油、粉尘和金属屑等杂质,且存在不同行业的差异性,排放前需经过严格的处理。

由于膜分离技术具有效率高、占地小、无二次污染等优点,因此,在切削液废水的处理中有很大的发展潜力。制约膜技术应用的主要问题是浓差极化和膜污染,故应当从工艺和材料2个角度来解决当前问题。工艺上,通过化学混凝去除大部分悬浮物,过滤阶段可采用纽带、填料、搅拌等方式促进液相湍流,来减轻浓差极化的影响。材料上,增强膜表面的亲水性以及开发混合基质膜、陶瓷膜是有效的解决方案,如通过共混、表面接枝或涂覆的方法在膜基质或膜表面引入亲水性材料(如无机物、聚乙二醇、低聚糖基团、两性离子聚合物、纳米颗粒等),制备混合基质、纳米颗粒掺杂或表面官能团修饰膜材料,以实现膜材料的亲水化改性,从而开发具有化学性质稳定、耐有机溶剂、pH适用范围宽等有点的陶瓷膜,以及具有金属有机框架的纳米材料等。

切削液的毒性使直接生物法处理较难实施,但当通过氧化法提高废水的可生化性,再进行成本低廉的生物处理的组合处理方案仍具有实际应用价值。鉴于切削液废水的复杂特性,其处理技术的改进还依赖于新材料的研发、传统工艺的创新,以及多重工艺的组合应用。

下载:

下载: