-

村镇承载着我国约40%的人口和农副食品的初级加工[1],厨余垃圾对村镇环境影响较大[2]。由于厨余垃圾易腐败酸化,因此,必须进行及时处理,才能减少厨余垃圾腐败酸化带来的环境影响,这同时也限制了村收集-镇转运-县处理模式的正常运转。基于此,依托农村现有沼气工程[3],就地厌氧处理利用,探索可行有效的技术路线,具有重要现实意义。

厨余渗滤液中易降解COD含量较高,极易导致厨余废水的酸化,从而对厌氧工艺的稳定运行带来较大风险[4],并会进一步影响厌氧微生物的产甲烷和产乙酸过程,导致甲烷产量降低乃至反应器酸化崩溃。已有研究[5]表明,加碱调pH、重新接种和混合厌氧发酵是常用的控制酸化方法,这些方法在村镇应用时存在药剂投加量大、运行维护复杂等缺点,造成运行成本上升15%~37%[6-8],因此,制约了上述方法在村镇处理厨余垃圾渗滤液过程中的推广应用。在酸化崩溃的早期,厌氧体系内CO2大量溢出,不仅使氢营养型产甲烷菌底物浓度下降,限制氢营养型产甲烷途径,还会导致系统中碱度出现损失[9],影响系统运行稳定性。因此,通过沼气循环曝气,促进沼气中CO2在厌氧体系中的再溶解,强化CO2气液传质,提升厌氧系统中CO2浓度,从而促进氢营养型产甲烷反应,可在酸化早期控制过度酸化现象。内循环(IC)厌氧反应器具有二次气液循环系统,通过循环管路增强反应器内气液混合,无需额外加压沼气曝气[10],有利于实现村镇厨余渗滤液废水的就地处理和利用;通过该系统与外置膜系统组合,克服IC反应器出水水质不稳定缺点,有望一步满足工程排放需求,扩大厌氧工艺在处理类似高浓度废水中的应用范围。

本研究针对我国村镇厨余渗滤液处理需求,构建了IC-AnMBR内循环厌氧膜生物反应器,通过反应器构型的设计和过程控制的优化,缓解由VFAs累积造成的酸化抑制,以短流程工艺实现厨余渗滤液的稳定处理,并考察沼气循环曝气对膜污染的缓解效果,以期为AnMBR工艺的高效运行提供参考。

全文HTML

-

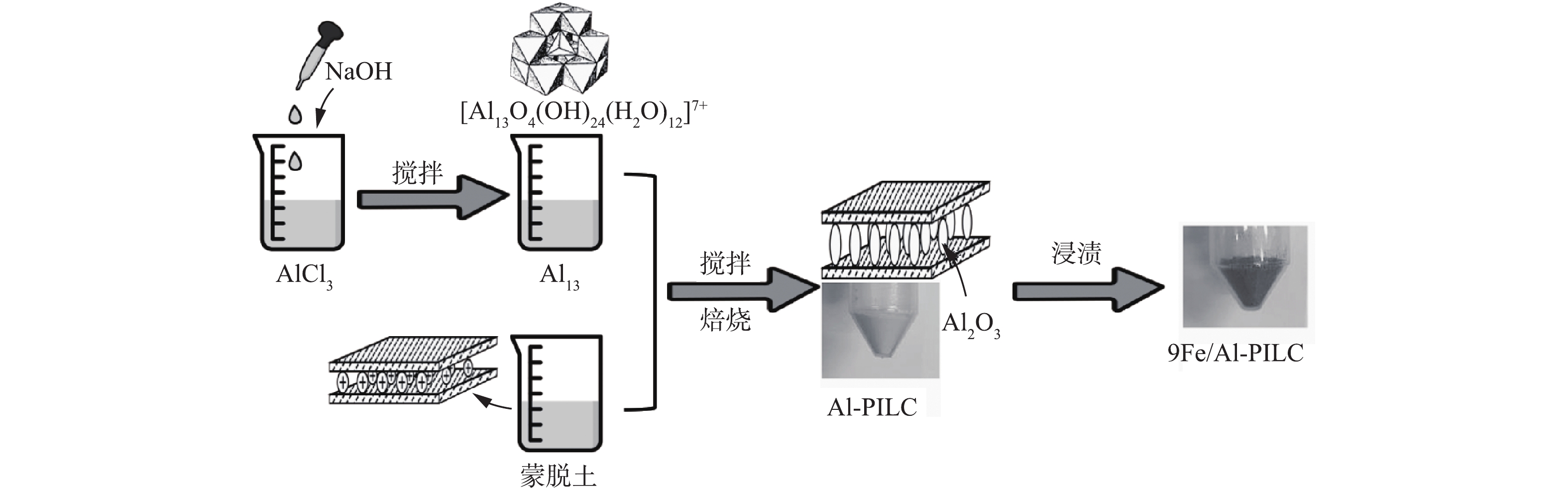

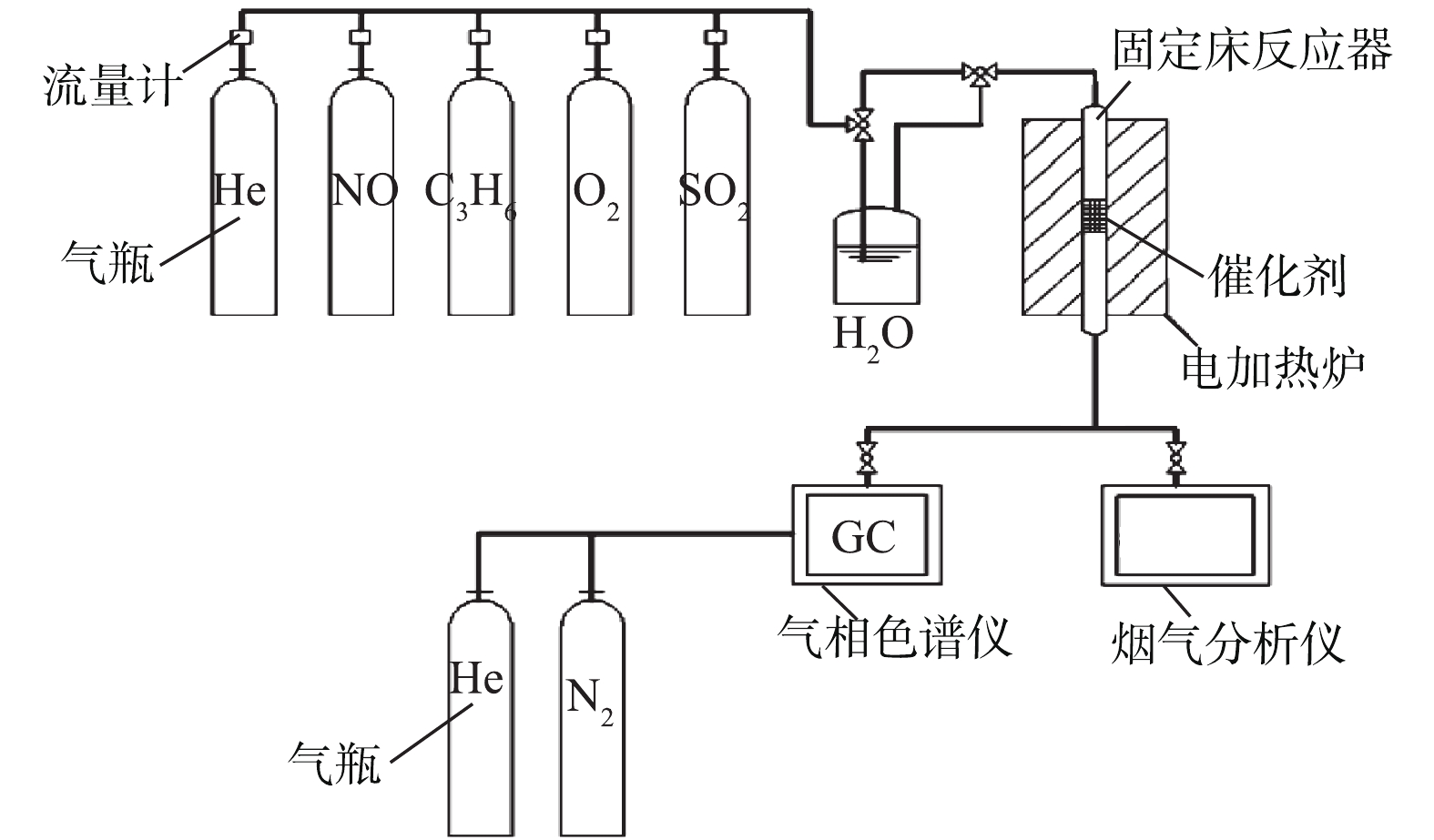

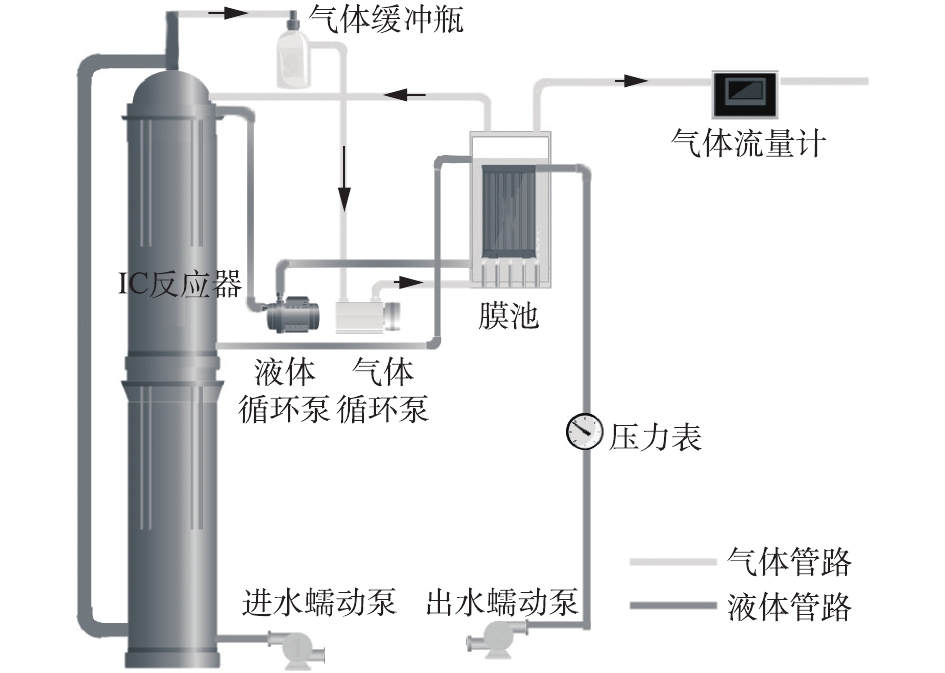

IC-AnMBR实验装置如图1所示。装置主体由IC厌氧反应器与膜池2部分组成。IC反应器容积为27 L,是圆柱形反应器,反应器Φ×H=0.15 m×1.80 m。装置包括第1反应区和第2反应区2部分。外置式膜池工作容积为5 L,是箱式反应器,反应器L×B×H=0.23 m×0.07 m×0.33 m。进出水泵分别采用蠕动泵(YZ1515x,Lab2015,上海SHENCHEN);实验采用平板陶瓷膜(BX-M2,名义孔径为1 μm,江西博鑫),膜面积为0.067 4 m2。反应器和管路材质分别为聚甲基丙烯酸甲酯(PMMA)和硅胶。反应器采用外壁管的方式控制温度稳定在(37±2) ℃,盘管采用循环水浴锅(HH-1,KOY)加热。

-

实验采用模拟村镇厨余废水,其组成成分及质量为蔬菜40 g、谷物30 g、豆制品20 g、肉类9.5 g、鸡蛋壳0.5 g。在IC反应器运行的不同阶段,废水组成与配比不变,通过改变加入水量来控制废水COD。进水水质指标[4-5]如表1所示。反应器内厌氧污泥取自北京市某生猪养殖基地粪污处理UASB反应器,MLSS为13.1 g·L−1、MLVSS为9.9 g·L−1、MLVSS/MLSS为0.75。

-

反应器包括气液循环与进出水2个过程。液体循环路径为IC柱体内混合液从IC顶部溢流堰流出,经液体循环泵(2.5 L·min−1,MP-6R)进入膜池底部,膜池中的混合液一部分经过气体回流管进入IC柱体顶部,再经IC外循环管路进入反应器底部,该回流液体向上推动反应器进行升流循环,强化沼气中CO2溶解;另一部分从膜池中部回流管流入IC二级反应区底部,构成升流循环。通过调节膜池中部回流管开度,能够分配进入IC底部与中部混合液的回流量,从而调整IC反应器一、二级反应区的升流速率。管道的分配比根据清水实验分配比来确定。

IC-AnMBR通过沼气循环曝气,冲刷累积在膜面的滤饼层来缓解膜污染。反应器顶部收集厌氧发酵产生的沼气,通过气体循环泵(5 L·min−1,APN,Iwaki Inc.)进入膜池底部,对膜池中膜组件进行沼气曝气冲刷来抑制膜面滤饼层的形成。沼气从膜池顶部回到IC反应器顶部气液分离区。装置采用微量气体流量计(μFlow,Bioprocess A.B.)实时记录沼气的瞬时流量和累积产气。气体循环泵进气口处设置1个2 L的气体缓冲瓶,调节沼气循环曝气过程中的沼气压力波动。

根据反应器运行负荷控制进水流量,采用恒通量间歇出水,用以缓解膜污染的发展,启停周期为6 min开、2 min停,设计膜通量为6 L·(m2·h)−1。

-

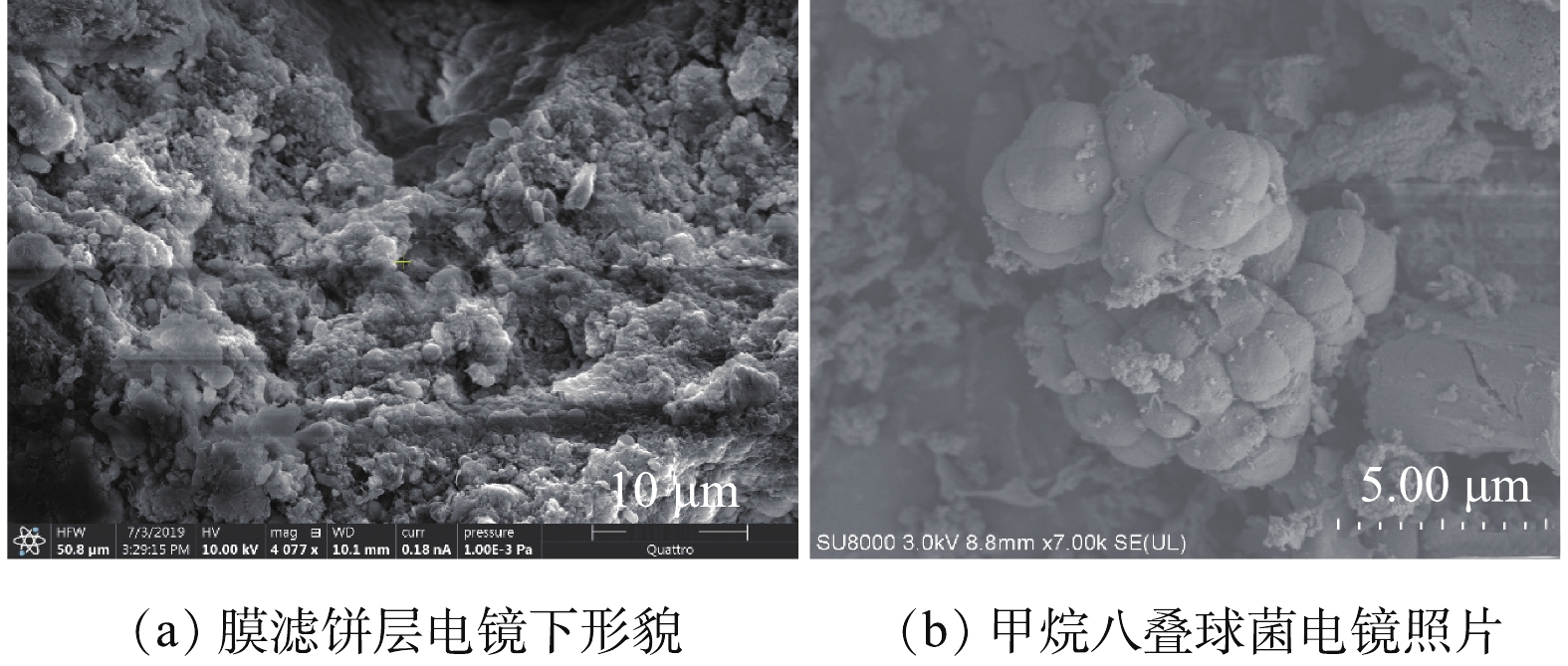

化学需氧量(COD)采用分光光度计(HACH DR2800,USA)测定;污泥浓度(MLSS)和挥发性污泥浓度(MLVSS)采用重量法测定;pH采用METTLER TOLEDO实验室pH计测定;厌氧污泥粒径采用激光衍射粒度仪(MS3000)测定;挥发性脂肪酸(VFAs)通过气相色谱法(GC-2010 Shimadzu, Japan)测定;厌氧颗粒污泥的形态采用电子扫描电镜(SEM)观察;总有机碳(TOC)和总无机碳(TIC)通过岛津TNM-L ROHS总有机碳分析仪[11]测定。

1.1. 实验装置

1.2. 实验材料

1.3. 实验方法

1.4. 分析方法

-

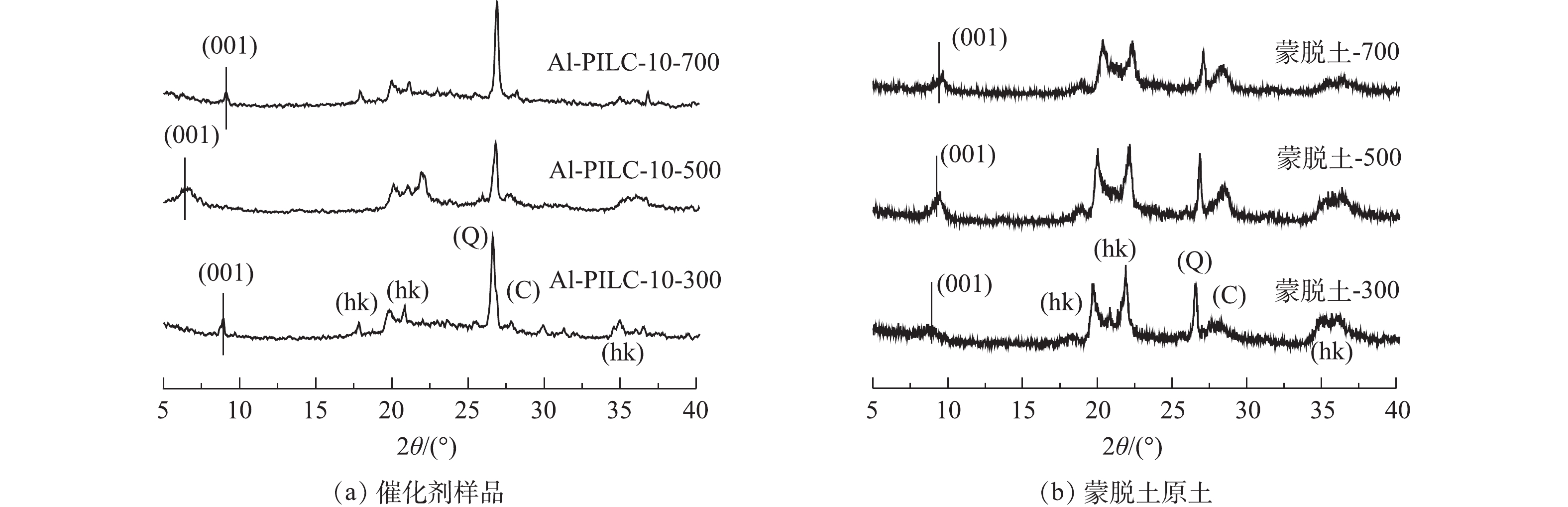

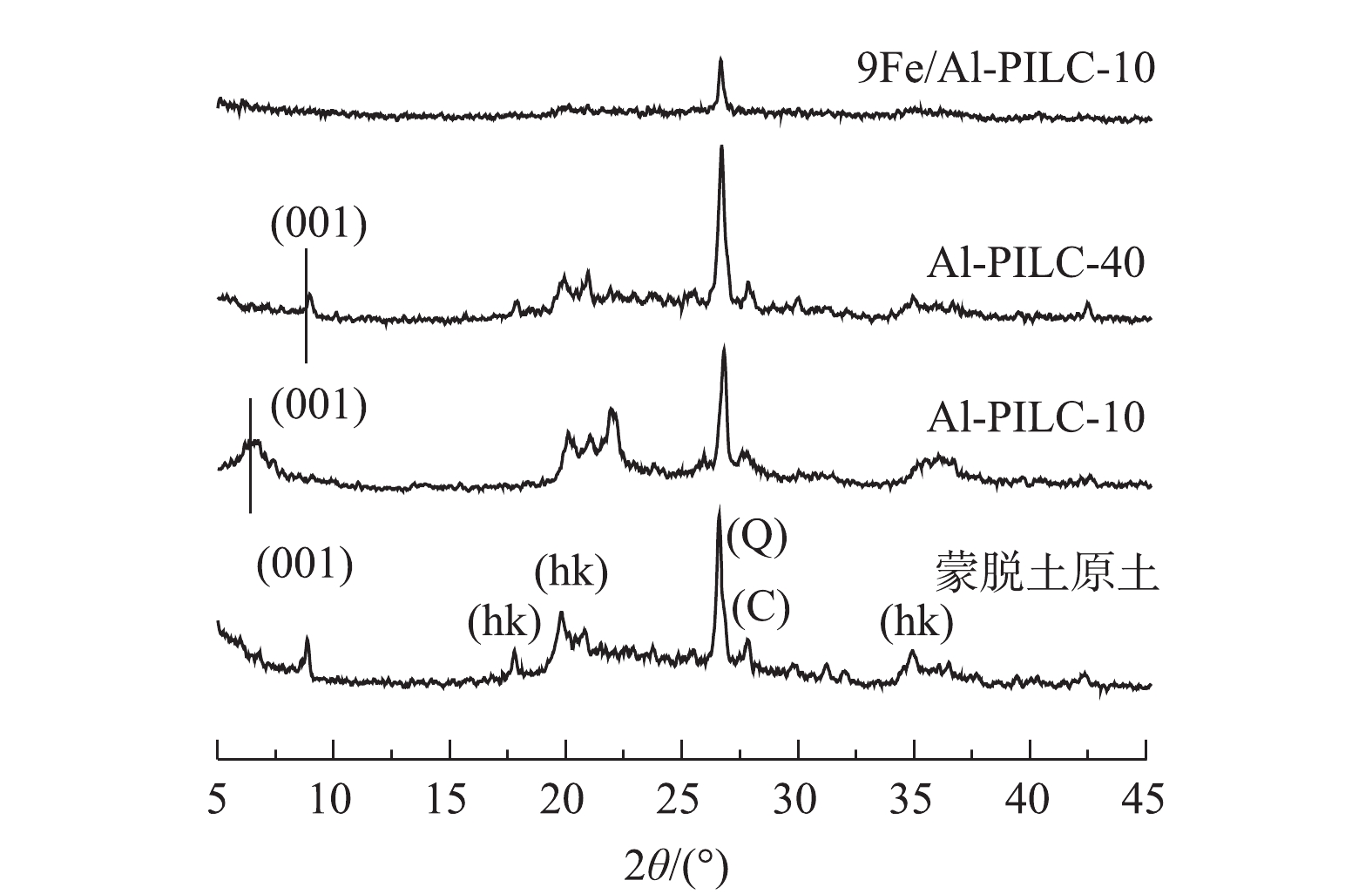

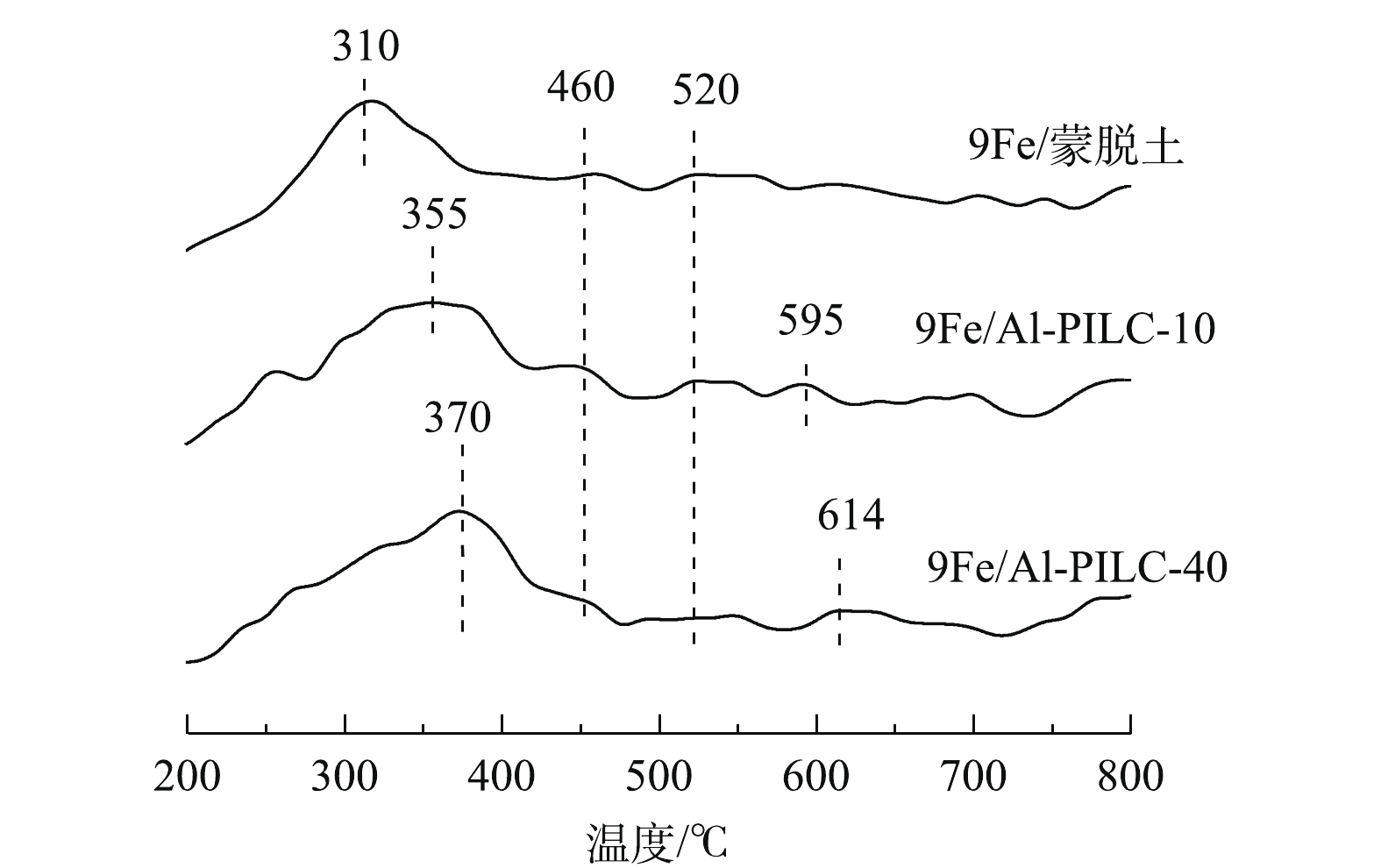

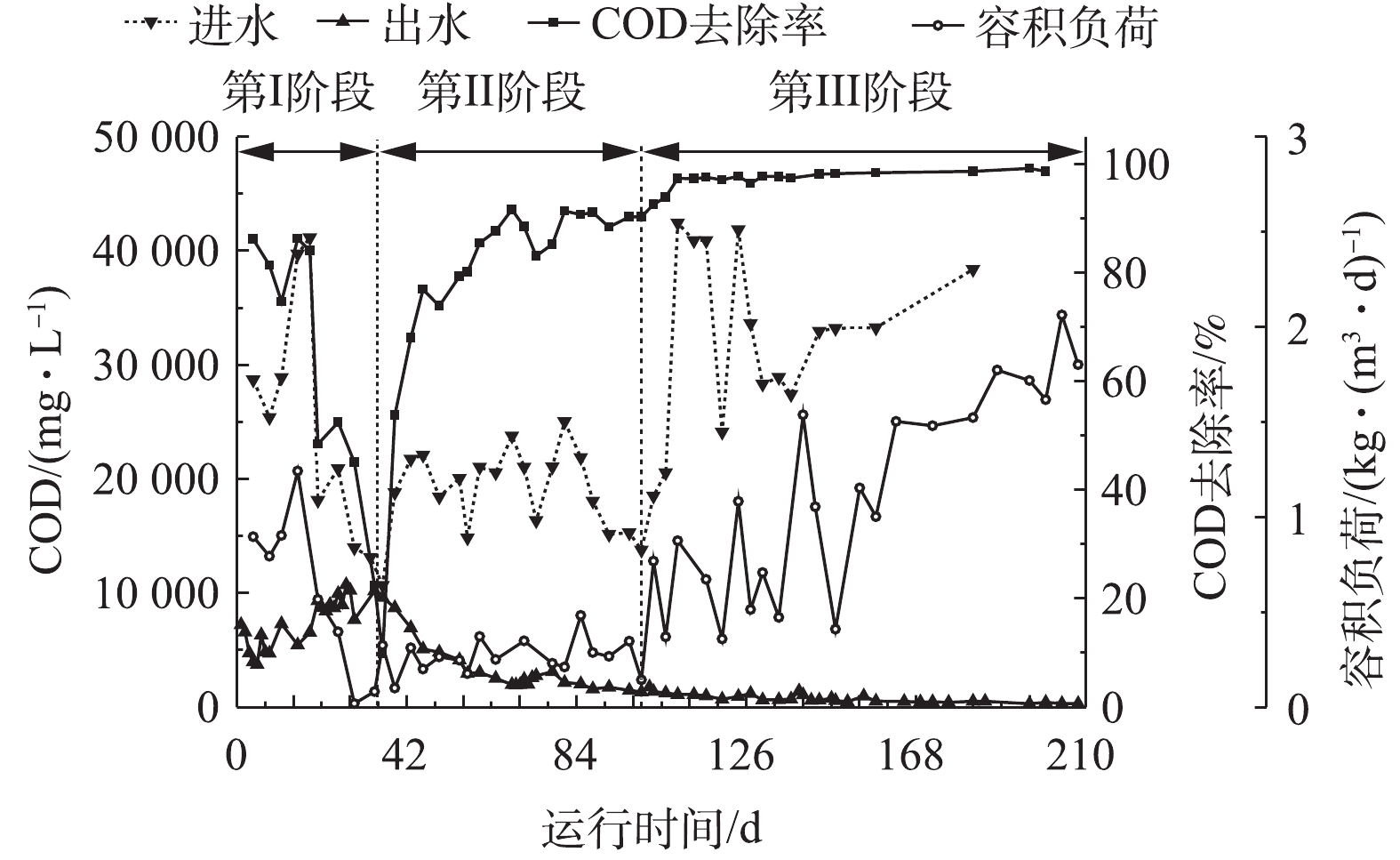

由于村镇厨余垃圾渗滤液污染物浓度高、易酸化,因此,本研究的关键工艺在于优化反应器负荷以达到对COD的稳定去除。为考察反应器负荷对运行效果的影响,将反应器的运行分为3个阶段,如图2所示。反应器运行第Ⅰ阶段处于启动阶段,该阶段运行负荷为(0.61±0.40) kg·(m3·d)−1,反应器出水COD较高,此阶段COD去除率不稳定且处于较低水平。运行至第Ⅱ阶段时,增加水力停留时间至45 d,控制进水COD至(19 414±3 013) mg·L−1,降低反应器容积负荷至(0.30±0.14) kg·(m3·d)−1,将反应器温度稳定在37 ℃。运行至第Ⅱ阶段后期,出水COD明显下降,稳定在3 000 mg·L−1左右,此阶段COD去除率逐步上升,并稳定在84.1%±9.5%。运行至100 d后,提高进水COD至(34 289±6 890) mg·L−1,使得反应器容积负荷达到1.4 kg·(m3·d)−1,此阶段反应器出水COD为(484±35) mg·L−1,COD去除率达到97.7%[12]。运行至140 d后,通过增加出水膜面积解决低膜通量对日处理量的限制,进一步提升了处理负荷,该阶段反应器污泥负荷达到(0.32±0.03) kg·(kg·d)−1。反应器负荷提高后,出水COD稳定在(323.5±0.5) mg·L−1,COD去除率达到98.5%±0.36%。

在反应器运行的3个阶段中,通过逐步提升反应器容积负荷,实现了IC-AnMBR对厨余渗滤液废水的稳定处理。在第Ⅰ阶段,反应器产气较差,负荷较低,厌氧生物系统的酸化风险是该阶段IC-AnMBR系统运行的主要限制因素。在第Ⅱ阶段,厌氧系统稳定后,膜通量逐渐成为提高负荷的限制性因素。在第Ⅲ阶段,实现了厨余渗滤液废水COD的稳定去除,主要通过厌氧处理产甲烷和膜截留2个步骤实现:1)厌氧处理过程针对厨余废水易酸化的特性,将大分子污染物降解为小分子有机酸,并通过产甲烷菌生长代谢,将废水中的有机酸转化为沼气,通过甲烷实现能源回收;2)陶瓷膜强化对混合液中污泥颗粒和大分子难降解有机物的降解,使反应器内保留较高的污泥浓度并维持出水COD的稳定。

-

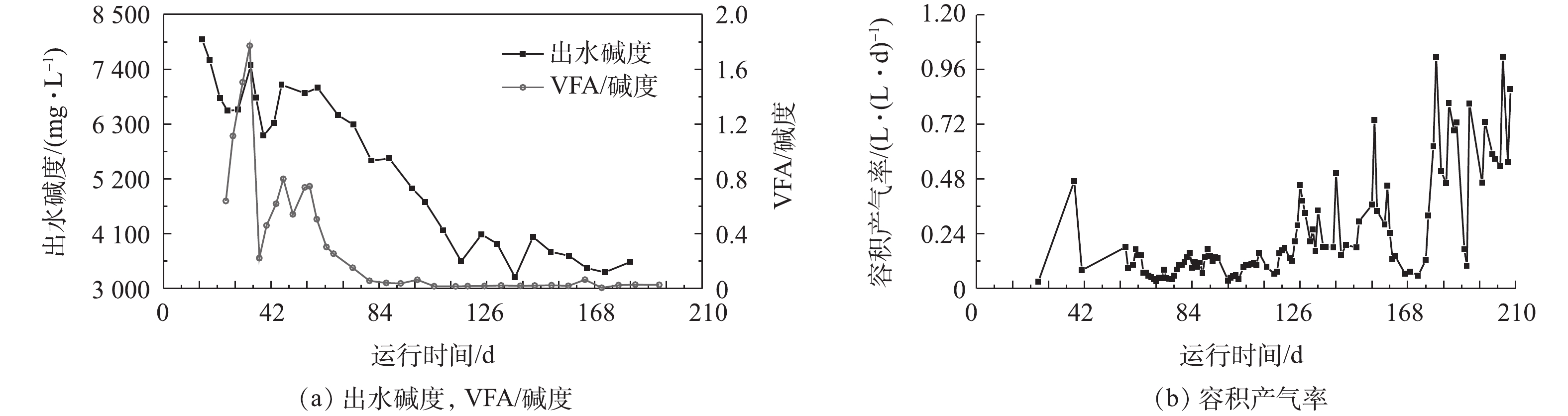

在处理村镇高浓度有机废水过程中,厌氧回收能源的特性具有独特优势。但是,由于影响厌氧产气的因素众多,村镇厌氧工艺在运行中难以实现稳定运行,从而制约了厌氧工艺在村镇的推广。VFAs是厌氧消化中间产物,也是判断产酸菌与产甲烷菌活性的重要指标[13-14]。在反应器运行第Ⅰ阶段,反应器运行负荷控制在(0.61±0.40)kg·(m3·d)−1,此阶段接种厌氧污泥活性差,厨余废水酸化过快,导致累积的VFAs未能够得到及时降解,使得出水COD最高值为10 740 mg·L−1,出水VFAs为6 323 mg·L−1。此时,VFAs/碱度大于0.8[15],反应器内碱度难以缓冲累积的VFAs,从而进一步抑制厌氧污泥活性,结果如图3所示。该阶段丙酸在VFAs中占比呈现上升趋势,产甲烷菌活性受到VFAs的抑制,反应器面临崩溃风险,容积产气率迅速下降,直至产气停止。

在反应器运行的第Ⅱ阶段,通过维持较低的运行负荷,并增强曝气循环以提高CO2的气液传质,从而使反应器逐步恢复稳定运行。在运行至70 d后,VFAs/碱度低于0.2,反应器系统酸化风险解除,容积产气率得到恢复,维持在0.2 L·(L·d)−1,此时反应器有进一步提升负荷的潜能。运行100 d后,反应器经过95 d稀释,碱度逐步下降,并稳定在3 500 mg·L−1左右,厨余废水中有机物充分降解,出水中VFAs浓度低于100 mg·L−1,VFAs/碱度值低至0.02,厌氧系统对低pH废水的冲击耐受程度进一步增强[16]。在反应器运行期间,为提高容积产气率,首先通过低负荷运行与曝气循环,解除反应器酸化风险;再通过提升进水COD来提升运行负荷,将容积产气率提升至0.4 L·(L·d)−1;运行140 d后,增大膜面积至0.628 m2,通过增加进水水量提升反应器容积负荷至(1.75±0.17) kg·(m3·d)−1,使得反应器容积产气率进一步提升,最高达到1.016 L·(L·d)−1。

-

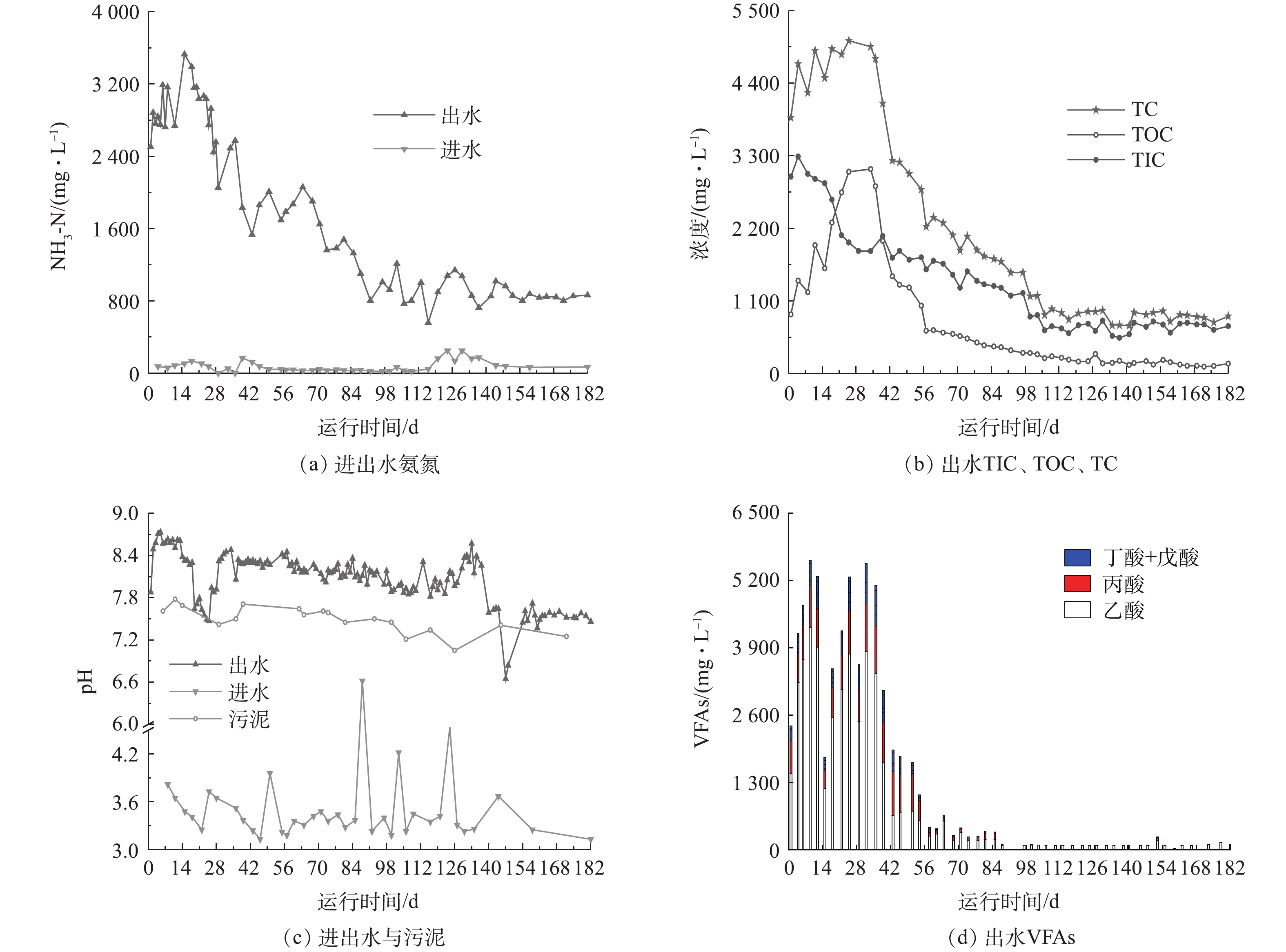

反应器出水指标如表2所示。pH是厌氧工艺高效运行较容易在线监测的重要指标,也是产甲烷的基本工艺参数。H+能够影响种间电子传递,而且对胞内外物质和能量交换有重要作用,同时可通过沼气中CO2的含量来影响甲烷浓度[17]。厨余废水厌氧消化过程中的pH主要由氨氮、VFAs和TIC构成的三元酸碱缓冲体系影响和决定[18]。在第Ⅰ阶段,接种污泥中氨氮浓度为3 500 mg·L−1左右,反应器内厌氧污泥产甲烷过程受到抑制[19],同时因反应器负荷过高[20],厨余废水酸化较快等因素综合作用,因此,在第Ⅰ阶段,没有观测到沼气的产生。在第Ⅱ阶段,通过采取降低负荷、维持温度为37 ℃等措施,使产气逐步得到恢复。在运行60 d后,反应器内VFAs被大幅消耗,酸化风险解除,反应器趋于稳定。在95 d后,由于厨余废水对反应器内氨氮与TIC具有稀释作用,因此,出水氨氮与TIC均低于1 000 mg·L−1,如表2所示。在此阶段,反应器内氨氮与TIC提供的碱度能够对进水过低的pH进行充分缓冲,使反应器污泥的pH稳定在7.6,出水pH稳定在8.17±0.14。可以看出,适宜的环境使得甲烷八叠球菌的活性得到恢复,反应器容积产气率逐步上升[21]。

在反应器运行140 d时,采取提升陶瓷膜面积至0.628 m2的方法,将日处理废水量提升至1.7 L左右,可进一步提升反应器容积负荷至(1.75±0.17) kg·(m3·d)−1。该阶段HRT降至20 d,接种污泥中的原氨氮被稀释,厨余废水中肉类与豆制品所携带氮素经过厌氧消化释放到污泥中,结果如图4所示。可以看出反应器出水氨氮稳定在(880±123) mg·L−1。由于反应器具有稳定的容积负荷,因此,反应器出水pH可维持在7.71±0.37,TC维持在(732.2±74.1) mg·L−1。此时,出水中TOC降至(191.48±31.8) mg·L−1,VFAs降至(89.47±56.63) mg·L−1,可较为完全地去除出水中可降解有机物,提高了出水TIC在TC中的占比。

综上所述,出水COD对厌氧系统运行状态分析有重要指示作用,能够直接指示反应器内污染物的去除和产甲烷情况。通过出水COD及时调整反应器运行负荷,使反应器处于适当的负荷状态。更快速的指标是混合液的pH,其能够反映厨余水解酸化情况以及反应器内VFAs累积情况[22-23]。当pH降低时,表明反应器中VFAs累积过多,此时应适度降低反应器负荷,等待产甲烷菌快速消耗反应器过多VFAs;当pH上升并达到稳定状态时,表明反应器处于底物缺乏状态,提示进水可以开始下一周期的步骤。在反应器运行时,产气速率的变化对底物的消化程度有一定的指示作用和重要的能源回收经济性评价作用。因此,通过pH、出水COD和产气速率等指标,能够判断反应器运行工况并及时调整运行参数,从而实现厌氧处理高浓度有机废水运行参数的稳定及对COD的高效去除。

-

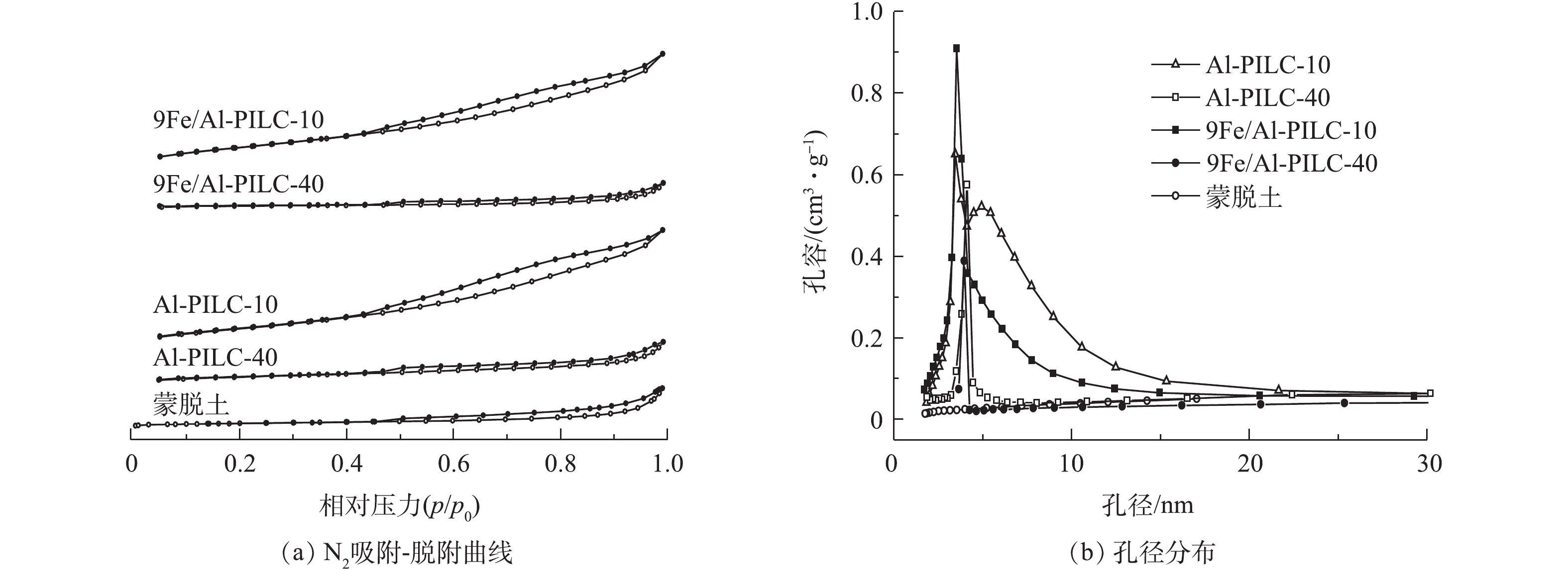

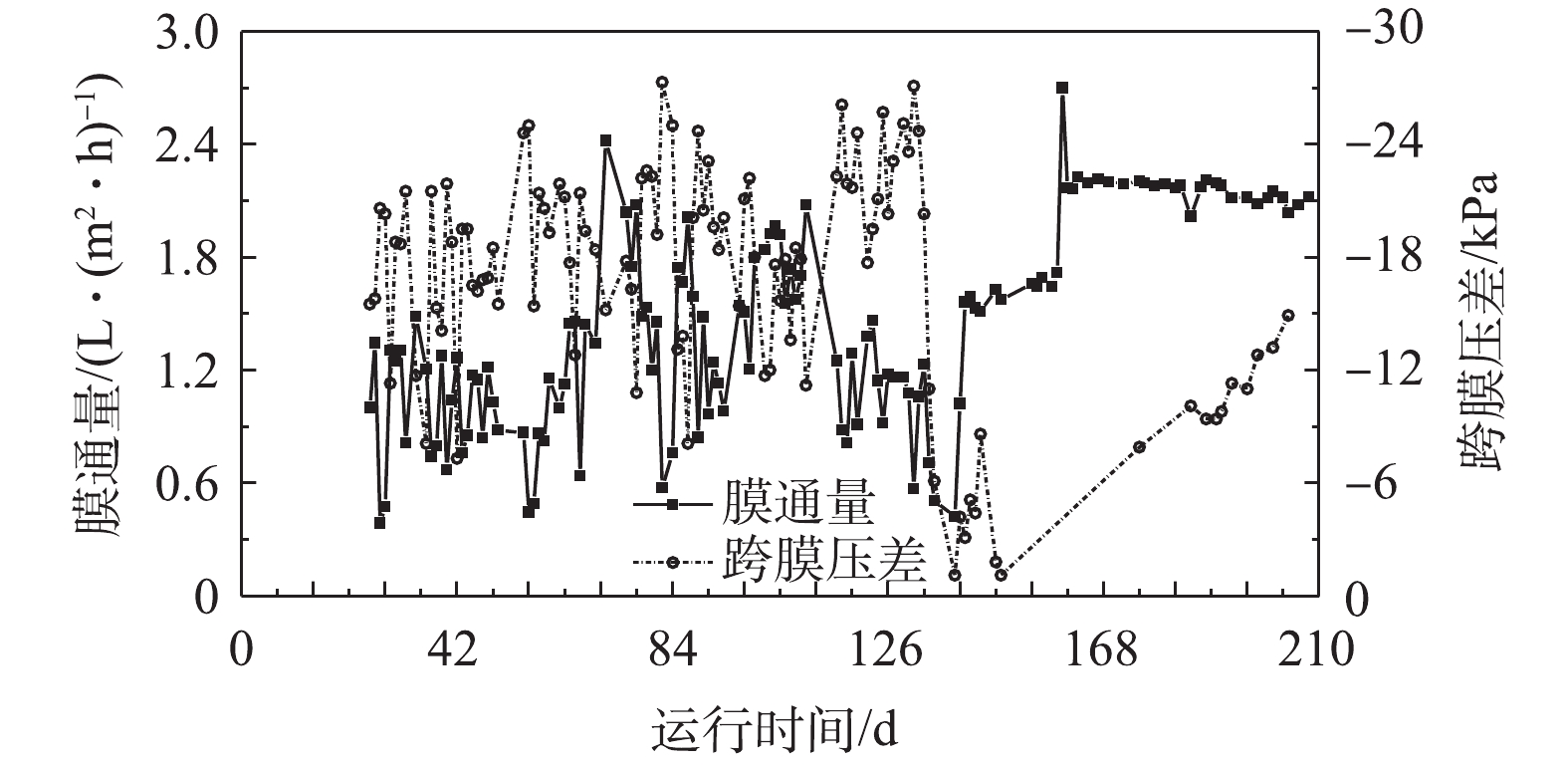

膜污染是MBR工艺发展的重要障碍[24]。在运行前期,膜通量是制约反应器进一步提升负荷的关键,高膜通量是反应器高处理效率的保证。AnMBR工艺在村镇应用时,高膜通量有助于运行成本维持在较低水平。通过对反应器内污泥粒径分布的测量及反应器内细菌形态和膜表面滤饼层的观察,可了解IC-AnMBR在沼气循环条件下的膜污染状况[25]。如图5所示,运行前140 d,膜通量为1.0~2.0 L·(m2·h)−1,跨膜压差为−10~−25 kPa;在运行140 d更换膜池后,反应器的膜通量呈现一种较为稳定的状态,通过提高出水跨膜压差,能够在TMP小于−15 kPa的条件下将膜通量稳定在(2.190±0.019) L·(m2·h)−1。

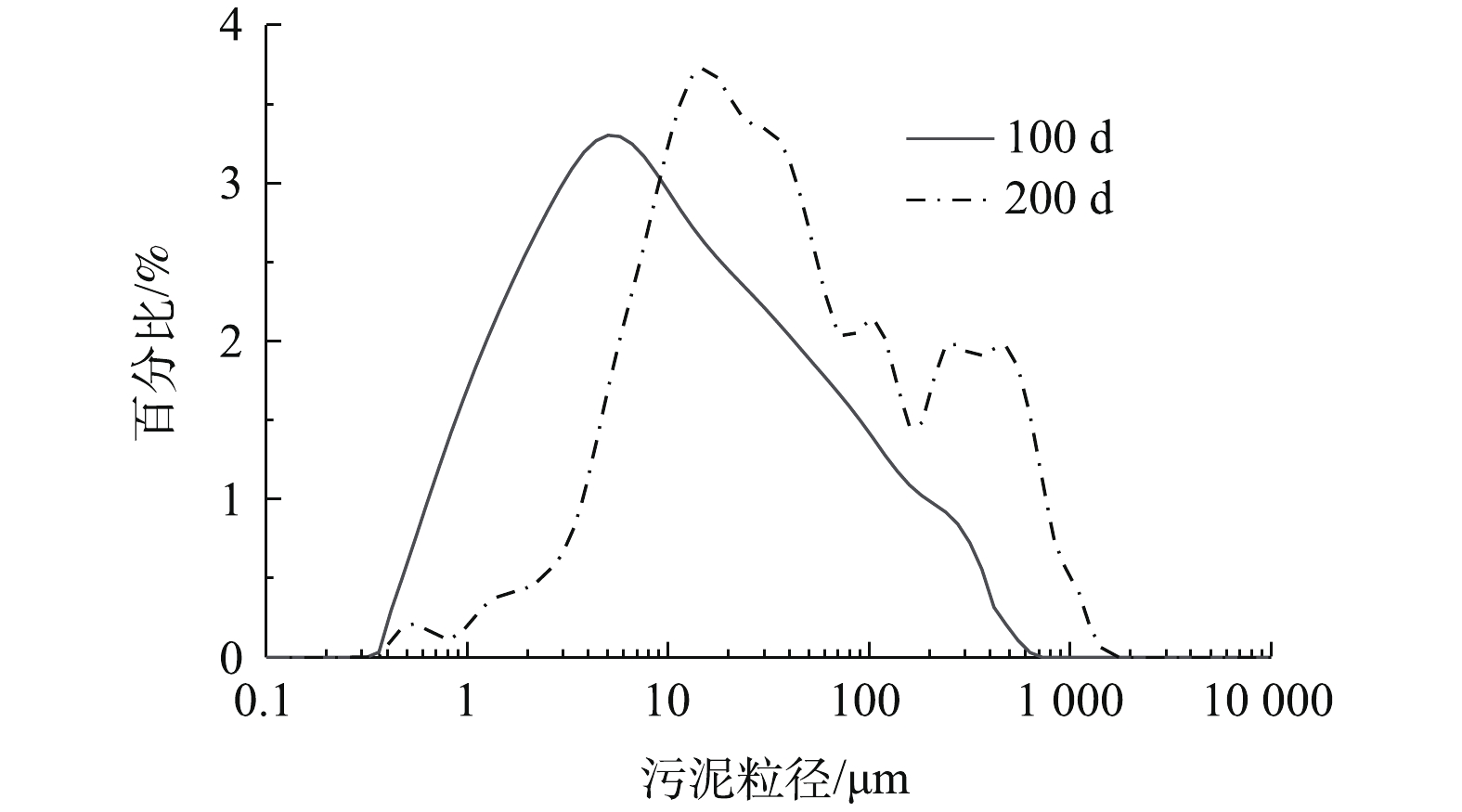

对于MBR工艺而言,目前缺乏高效经济的膜污染控制措施,这给MBR在村镇的应用与推广带来很大障碍。如图6所示,当运行100 d时,反应器内污泥中值粒径为8.0 μm,大于1 μm粒径的污泥是滤饼层形成的主要因素;小于1 μm粒径含量在10%,该范围内粒径在膜孔堵塞造成膜污染形成中起重要作用;当运行200 d时,厌氧污泥中值粒径增大至29.1 μm,表明厌氧颗粒污泥有逐步增长的趋势。沼气曝气冲刷对膜通量有较好的恢复作用。实验表明,持续曝气能够将跨膜压差维持在较低水平。因此,本实验中膜面滤饼层的形成应是膜污染的主要因素。在运行80 d时对陶瓷膜进行更换清洗,在对膜面滤饼层进行电镜分析时,发现膜面滤饼层中EPS有球菌与杆菌黏附其中,厌氧菌分泌的多糖蛋白与代谢产物应是构成膜面滤饼层的主要物质,如图7所示。

2.1. IC-AnMBR对厨余渗滤液废水中COD的去除效果

2.2. IC-AnMBR产气性能及其稳定性

2.3. IC-AnMBR中pH的变化与缓冲性能

2.4. 膜通量与跨膜压差

-

1)本研究所构建的IC-AnMBR经合理调控,能够实现对村镇厨余等高浓度有机废水的有效处理,COD去除率、出水COD分别达到97.7%、(675±283) mg·L−1。

2)通过氨氮与TIC对废水酸化中VFAs的缓冲作用,可减少进水冲击引起的pH剧烈变化,缓解反应器酸化崩溃风险,能够提升反应器负荷,实现反应器稳定运行与高效产气;反应器容积负荷最高能够达到2.1 kg·(m3·d)−1、最佳容积产气率能够到达1.014 L·(L·d)−1。

3)沼气曝气能够强化CO2气液传质,增加系统缓冲能力;抑制膜表面滤饼层的形成,能够使膜通量稳定维持在2.19 L·(m2·h)−1,实现对反应器的高负荷运行及对COD的高效去除。

DownLoad:

DownLoad: