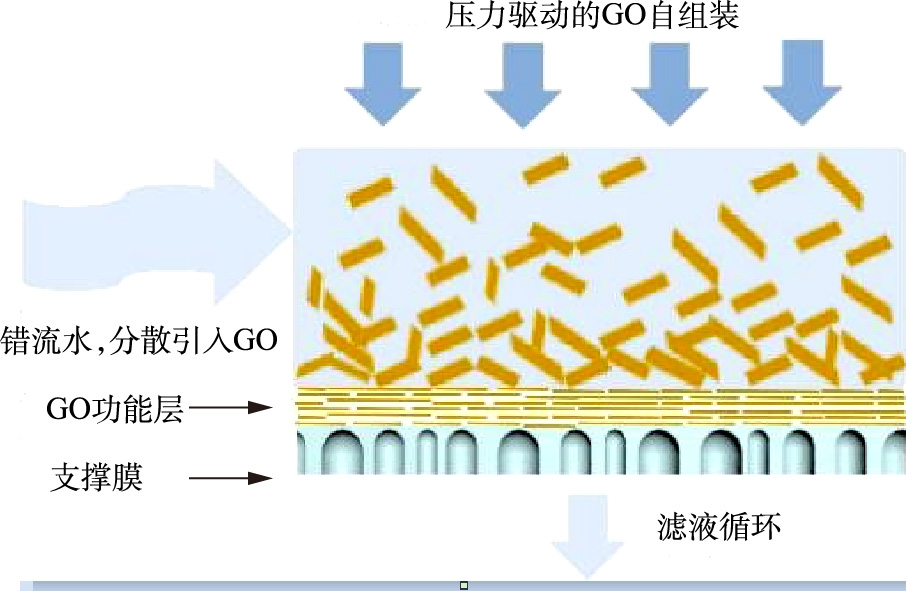

-

随着人类社会的飞速发展,水资源的利用程度日益提升,水资源短缺问题受到了人们的广泛关注[1]。工业生产过程会消耗大量的洁净水,并相应排出大量难降解废水,出于经济方面的考虑,这些废水的处理方法仍以生物处理为主[2-10]。然而,生物处理出水中会残余一定量的有机物[9,11-14]。出水有机物(enflluent organic matter,EfOM)中包括有难降解物质、降解残余物、中间产物、终产物、复杂的有机物,以及溶解性微生物代谢产物(soluble microbial products,SMP)。生物处理二级出水中EfOM或SMP的存在及其特点对于生物处理的出水水质及深度处理的效率会有较大的影响。同时这些有机物中的一部分在后续氯化消毒过程中可被转化为消毒副产物[15],与其他难降解的毒性组分一起排放到环境中,会带来水污染及其他水环境问题[16]。因此工业废水深度净化与资源化对于提升我国水环境质量、缓解我国水资源短缺具有重要意义。

膜过滤技术是一种污水处理及深度净化回用技术,具有出水水质好、能耗低、占地小、副产物少、易于升级改造等诸多优点,已逐渐成为该领域的主导技术[17-18]。然而,实际应用中,膜过滤技术存在浓水处理与资源化困难、膜污染严重、对进水水质要求严苛等诸多问题。这些问题加大了运行管理难度,提高了整体工艺的复杂性,拉升了投资及运行成本,限制了膜过滤技术在工业废水深度处理与回用中的进一步推广应用[19]。其中,膜污染问题及膜过滤浓水资源化问题被认为是膜过滤技术的核心问题。膜污染会导致膜通量和膜分离能力下降,使膜处理后水量及水质低于设计要求。为恢复通量,生产过程中通常会进行频繁的化学清洗,导致膜的使用寿命缩短[20]。而现有的聚酰胺膜材料因其耐氧化能力差等原因,限制了氧化法膜污染控制方法的使用,导致控制膜污染变得困难,也增加了预处理的成本。目前,浓水处理的主要技术有蒸发分盐、酸碱再生等。然而,由于难降解工业废水膜过滤浓水往往是有机物、无机盐的混合浓水,其中残留的有机物会在进一步的浓缩、蒸发及资源化过程中使无机盐或再生酸碱的纯度受到影响,最终降低了资源化的品味。同时,有机物的存在也会导致二次母液的排放,进一步提高浓水处理成本。目前,浓水分盐或酸碱回用带来的高昂成本给企业发展带来了较大负担。从水的循环利用角度出发,不必将氯化钠、硫酸钠等视为重要污染物。但若要实现浓水或杂盐的排海等自然消纳过程,浓水中毒性或风险性有机物需要实现深度净化。这也成为膜过滤技术发展过程中的新需求及难点。

基于以上背景,国内外研究者针对工业废水深度净化与回用的特点,持续对膜过滤技术进行改进或者开发新的膜过滤技术与范式,力求进一步降低膜过滤技术的技术壁垒和运行成本。由于目前工业废水处理中所使用的有机膜及无机陶瓷等材质或多或少存在着一定的不足,限制了膜过滤技术的进一步推广应用。因此,寻找具备更好的耐氧化性、亲水性、抗污染性,化学稳定性及更高的水通量的膜材料来制备纳滤膜,可为解决现有的膜存在的问题提供新的思路及方法。氧化石墨烯具有较好的化学稳定性、亲水性以及较低的制备成本。通过过滤自组装、精准刻蚀、逐层自组装、表面接枝、过滤、聚合物共混等方式制备成的氧化石墨烯滤膜具有优异的有机物分离性能、较低的无机盐截留特点,以及良好的抗氧化(氯氧化、自由基氧化)能力、机械性能、较高的渗透性能和抗污性能[20-21]。这些优势有望为解决传统有机膜存在的膜污染、有机物无机盐混合浓水等问题提供新途径,使膜技术更为广泛地应用于工业废水的深度净化与回用中。

本研究从工业废水深度净化的需求出发,综述氧化石墨烯膜制备、性能特点及应用中面临的问题,从膜污染控制等方面总结氧化石墨烯膜的研究现状,以期为氧化石墨烯膜在工业废水中的深度净化与回用技术中的进一步优化提供参考。

全文HTML

-

2012年,COHEN-TANUGI等[22]通过模拟计算预测具有10%孔隙率的纳米多孔石墨烯膜可以在保持有效的盐离子排斥率下,使膜的过水通量比传统反渗透膜高出2~3个数量级,达到10~100 L·(cm2·d·MPa)−1。该发现展示了石墨烯膜远超出普通滤膜的优异性能,引起了全球范围内关于石墨烯膜的研究热潮。石墨烯是已知的、强度最高最薄的材料之一[23],具有很好的韧性、导热性、比表面积、可弯曲等特性。由于这些优势,研究者们采取了化学气相沉积、化学还原、机械剥离、热剥离等多种方法,试图制备出厚度更薄、通量更大、稳定性更高、价格更为低廉的水处理用膜。其中,通过离子轰击和选择性刻蚀可形成亚纳米孔,从而制备出石墨烯膜,但这种方法成本较高,无法达到工业应用的程度,且纳米孔的精确制备尚存在困难。在一定的支撑膜表面,采用化学气相沉积或原子层沉积过程,直接精准造纳米孔有可能成为解决问题的新方案,但具体实施步骤尚待进一步探索。

基于成本、制备及应用中的问题,研究者们将目光投向了更易成规模制备的氧化石墨烯膜。氧化石墨烯是一种具有较多含氧官能团的石墨烯衍生物。HUMMERS等[24]于1958年成功制备出了氧化石墨烯,但受限于当时科研界对二维材料的认识及硬件条件,并未将这种氧化石墨烯鉴定出来。氧化石墨烯具有优异的水渗透性、筛分性能、化学稳定性、亲水性和抗菌性,也具有良好的平整度及原子级厚度,且可以石墨为原料进行大规模工业化生产。此外,氧化石墨烯表面含有丰富的含氧官能团,便于将氧化石墨烯进行交联化以制备成稳定的膜,也便于膜表面的改性。

氧化石墨烯的主要制备方法有BRODIE法、STAUDENMAIER法和HUMMERS法[25]。其中,HUMMERS法的产率和安全性相对较好,且具有环境友好性,是应用最广泛的一种制备氧化石墨烯的方法。该方法用浓硫酸中的高锰酸钾与鳞片状石墨反应,经氧化、插层之后,得到边缘有衍生羧基及表面有酚羟基和环氧基团的棕色氧化石墨片,最后将氧化石墨片层经超声或高剪切剧烈搅拌剥离成为氧化石墨烯,成品在水中形成稳定、棕黄色的寡层氧化石墨烯胶体。

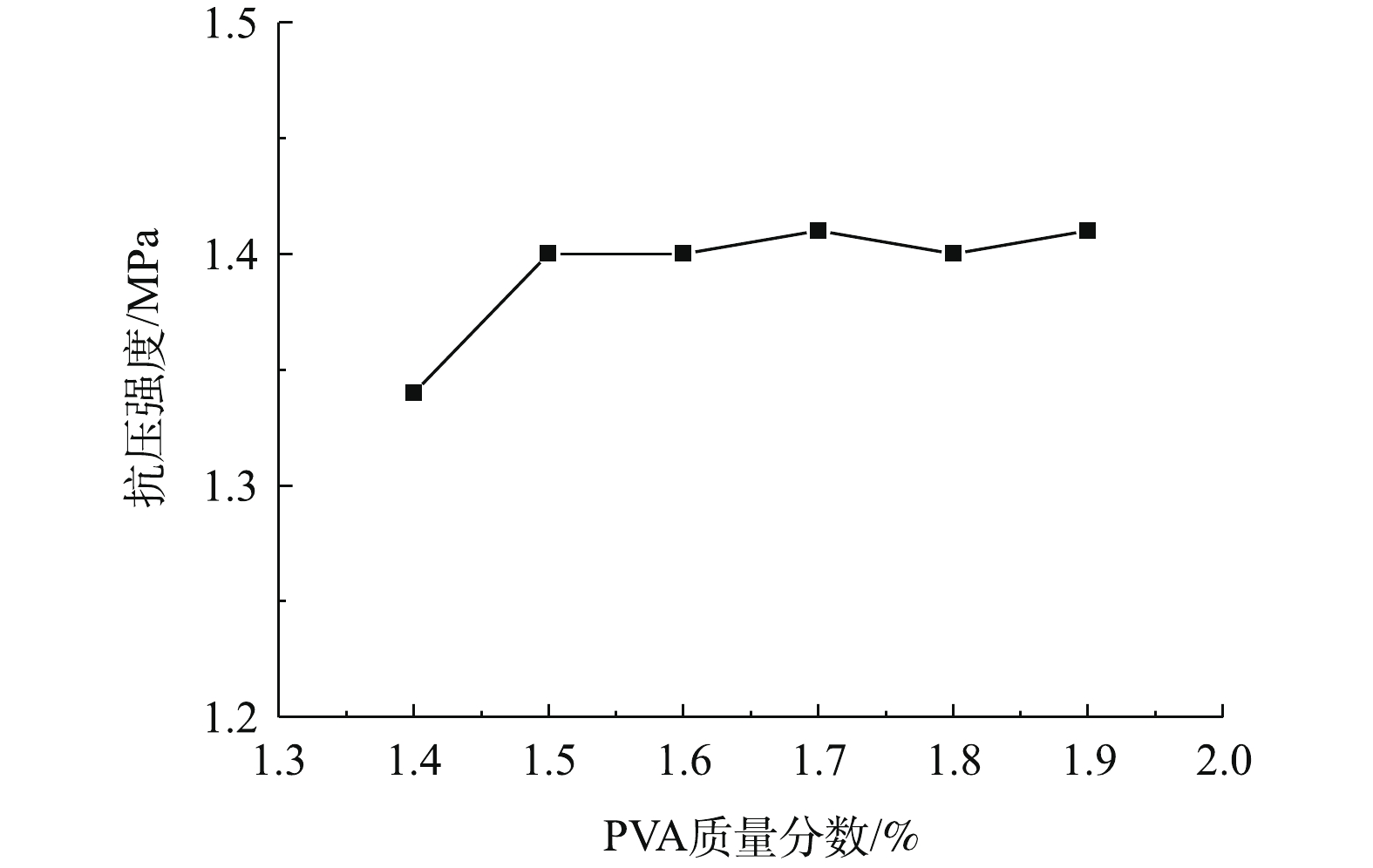

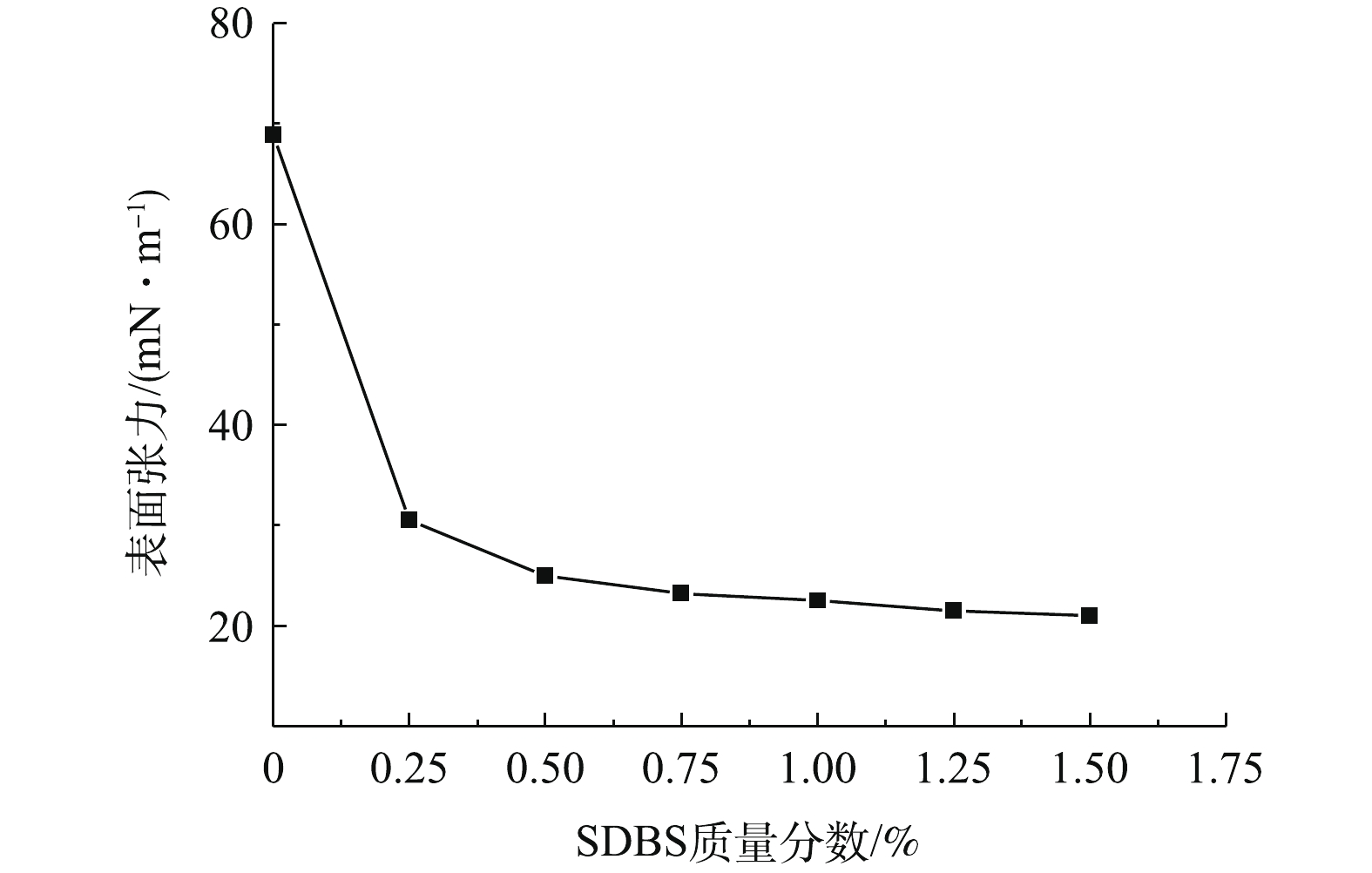

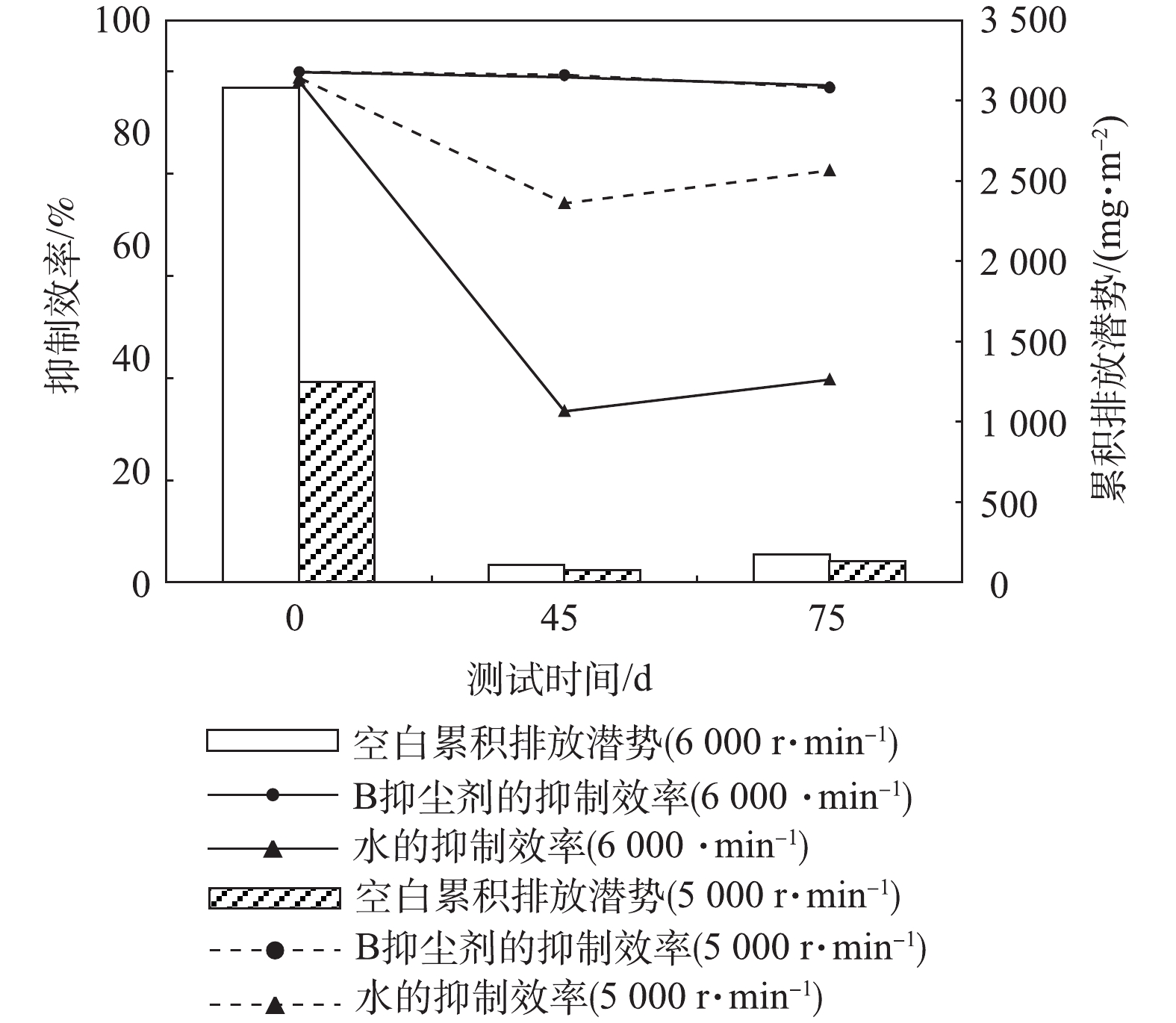

氧化石墨烯膜的制备方法有聚合物共混、表面接枝和过滤自组装等[26-28]。聚合物共混法是一种广泛应用的制膜方法。由于聚偏氟乙烯(polyvinylidene fluoride,PVDF)、聚四氟乙烯(poly tetra fluoro ethylene,PTFE)等有机膜具有疏水性,会导致有机膜在脱盐过程中受到污染,增加膜脱盐过程的操作成本,同时较强的疏水性也会降低膜的渗透性能。为增强膜表面的亲水性能,通常将有机膜与聚乙二醇、聚乙烯醇、聚吡咯烷酮、碳纳米管、氧化石墨烯等两亲性物质混合,由此制得的氧化石墨烯具有高比表面积,具有环氧基、羟基、羧基等丰富的含氧官能团和高亲水性能。将原子级厚度的氧化石墨烯片与聚合物基体结合时,仅需较低的掺杂量就可以改善主体聚合物的物理、化学性能。在膜基质中掺入氧化石墨烯可增加亲水位点,改善膜的亲水性。在相转变过程中,掺杂氧化石墨烯增加了膜孔隙,膜的水通量也随之升高。图1显示了氧化石墨烯聚合物共混膜中氧化石墨烯的行为[26]。GANESH等[26]选择使用具有高比表面积、亲水性、pH敏感性、优异的力学性能,以及可诱发膜表面负电荷的氧化石墨烯作为基质膜的改性材料,通过将氧化石墨烯混合到聚砜基质中制备出聚砜/氧化石墨烯混合基质膜。该研究成果证实了氧化石墨烯的掺杂有效地增强了膜的亲水性、增大了水通量。

虽然使用聚合物共混法制备氧化石墨烯膜可能会提高有机膜的性能,但这种制备方法会导致大多数氧化石墨烯嵌在膜基体中而难于与过滤介质相互作用,使该方法制备的膜难于发挥出氧化石墨烯抗污染的特性。另外,聚合物共混法需要的氧化石墨烯用量,常高于表面接枝和自组装法,这会提高实际氧化石墨烯膜的制备成本。因此,研究者们更倾向于用表面接枝及自组装的方法来制备氧化石墨烯膜。

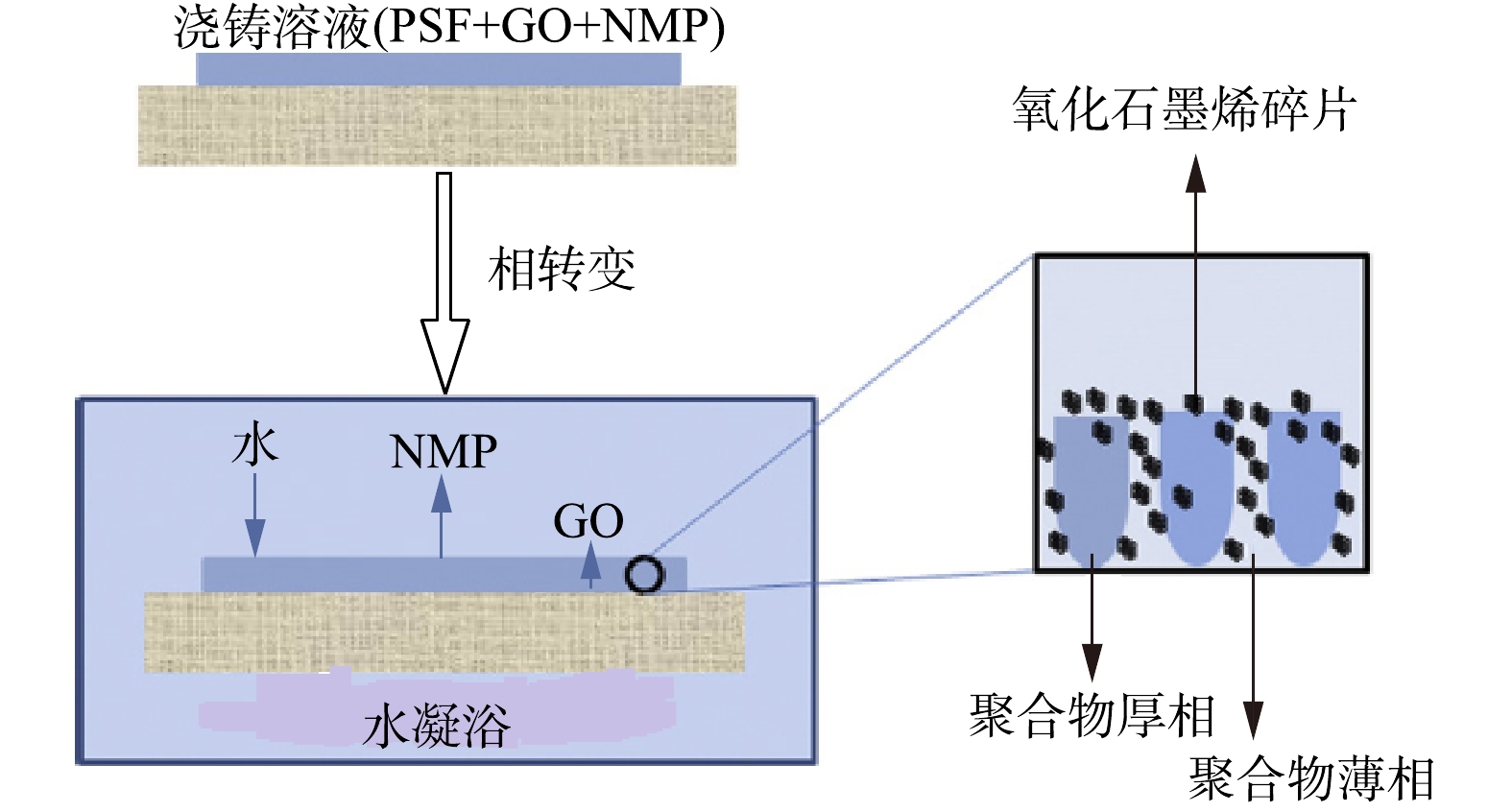

表面接枝法可以通过化学反应在膜表面引入改性基团,依靠在膜表面形成亲水性基团和接枝亲水性分子来提高膜表面亲水性和抗污染性能。同时,相比于聚合物共混法制备的氧化石墨烯膜,表面接枝法可以将氧化石墨烯纳米片通过化学键共价结合于有机膜的活性层表面,利用氧化石墨烯纳米片具有的杀菌性达到灭活细菌的目的,并提高氧化石墨烯膜抗生物污染的能力。图2显示了氧化石墨烯纳米片与有机膜活性层共价结合的反应过程[27]。表面接枝法制备出的氧化石墨烯膜具有一定的抗菌特性,可减少膜在实际应用中受到生物污染的影响,膜表面的亲水性也得到提升,但使用表面接枝法制膜无法提升膜的渗透通量。这是因为水的传输主要是由有机膜活性层的溶液扩散控制,而在氧化石墨烯纳米片与有机膜活性层共价结合的反应过程中,有机膜活性层基本没有改变,故无法提高膜的水通量。PERREAULT等[27]成功将氧化石墨烯纳米片覆盖上了聚酰胺膜,使氧化石墨烯纳米片可以与细菌细胞直接接触,并证明了制备的氧化石墨烯膜具备了较好的抗菌性能,但该方法无法提升膜的水通量和选择性。

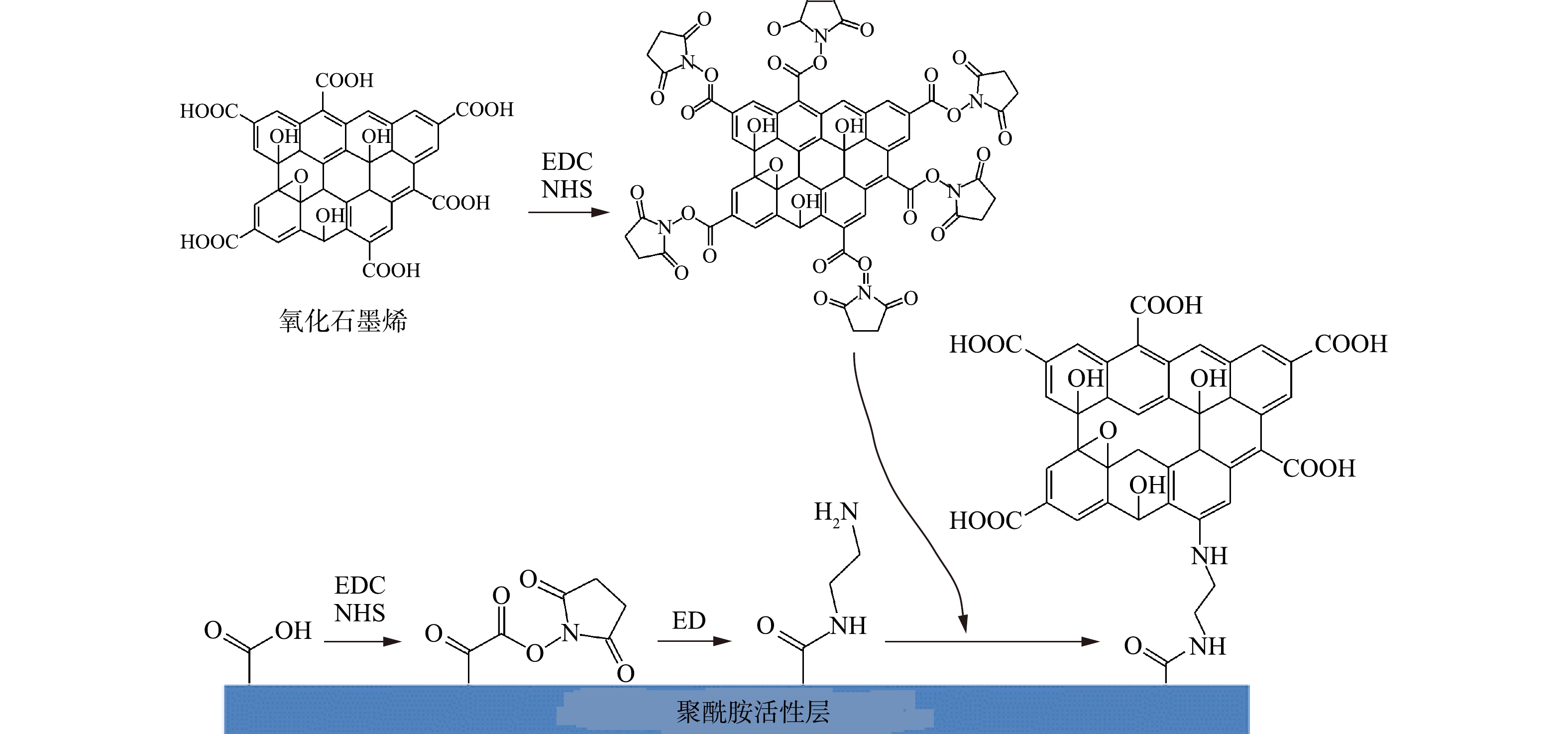

表面接枝法制备出的氧化石墨烯膜除了性能得以提升,还缩减其商业化制造成本和相关的环境影响。然而,表面接枝法尚面临成本较高、接枝率不理想、接枝层长期使用稳定性待检验等问题。过滤自组装法制备氧化石墨烯膜利用了氧化石墨烯纳米片具有单原子级厚度、水中良好的分散性能、较高的横向尺寸和层与层之间较强的相互作用等特点。通过将氧化石墨烯溶液在基质膜上过滤,使氧化石墨烯纳米片自由堆叠,形成的氧化石墨烯膜呈现有序的层状结构。水流可以通过氧化石墨烯纳米片间形成的相互连接的纳米通道,沿着疏水性非氧化表面,而不是亲水性氧化区域的曲折路径流动[28];没有摩擦的非氧化石墨烯区域也促进了水流的流动。另外,氧化石墨烯膜表面含有制备、超声过程中造成的破碎微孔缺陷,使氧化石墨烯膜形成了丰富的多孔结构[29]。这些特性都使得自组装法制备的氧化石墨烯膜比聚合物共混法和表面接枝法制备的氧化石墨烯膜具有更高的水通量。而堆叠于有机膜表面的氧化石墨烯纳米片所具有的尖锐边缘可对细胞膜造成物理损伤。这种接触灭活细菌的特性也使其具备了一定的抗菌性[30-31],并保持了氧化石墨烯层良好的抗氧化能力。图3为氧化石墨烯膜过滤自组装的过程[32]。

HU等[28]通过逐层沉积的方法在聚多巴胺包覆的聚砜载体上接枝氧化石墨烯纳米片,再将氧化石墨烯纳米片通过1,3,5-三氯苯甲酰基交联以提升纳米片层之间的稳定性和间距。由于氧化石墨烯纳米通道独特的水运输特性,氧化石墨烯膜的水通量可达到普通纳滤膜的4~10倍,并且对单价及二价盐具有较低的排斥效率(6%~46%)。这种特性使其可能应用于工业废水中有机无机混合浓水的处理中。GOGOI等[33]采用叠层制备法,通过选择合适的空隙偏移距离和氧化石墨烯纳米片横向尺寸,制备了3种不同的氧化石墨烯膜。该研究表明氧化石墨烯膜的渗透性会随着叠层制备中选用纳米片横向尺寸的增大而减小;随着选择性增大,空隙偏移距离的增大还会导致水分子和离子的绕流距离增大。因此,GOGOI等[33]认为可按照对于渗透性及盐排斥率的需求,来选择不同的氧化石墨烯纳米片叠层以制备氧化石墨烯膜,而不需要在膜中加入其它的纳米材料。

相比于通过聚合物共混法,使用自组装技术制备的氧化石墨烯膜具备了良好的抗菌性、渗透性和对无机盐的选择性。同时,每平米膜的氧化石墨烯用量可低至14.4 mg·m−2 (约10 层氧化石墨烯),适合商业化规模生产。然而,由于氧化石墨烯纳米薄片较强的亲水性,通过溶液过滤制成的氧化石墨烯薄膜在水中长期使用会存在脱落的风险。这可能会阻碍过滤自组装技术制备的氧化石墨烯膜在水处理中的实际应用。为解决这个问题,必须稳定地交联氧化石墨烯纳米片,以防止其在水中分散。

以石墨为原料通过化学氧化的方法批量生产氧化石墨烯可大大降低材料成本,促进膜工艺规模化。相比于聚合物共混法和表面接枝法,过滤自组装制备成的氧化石墨烯膜更适合商业化的应用于工业废水处理中,但利用氧化石墨烯制备的氧化石墨烯膜的应用尚待实际生产检验。

-

膜过滤过程中,不能透过膜的有机物和无机盐被膜截留后形成浓水[34]。这一现象限制了纳滤膜在工业废水处理中的进一步应用。浓水无法直接排放到环境中,需要对其进行资源化处理。通过蒸发结晶或酸碱再生可实现浓水中无机盐的资源化。但由于工业污水膜过滤浓水中含有的有机物使无机盐或再生酸碱的纯度变低[35],最终得到的低品位无机盐应用范围较窄。另外,有机物的存在造成蒸发器污堵、影响传质,导致蒸发浓缩处理浓水过程的成本进一步提高。因此,如果可以在浓盐水蒸发前对工业废水中的有机物及无机盐进行选择性分离,将有利于提高后续结晶处理得到的无机盐纯度,以实现各组分高品位的资源化利用,减少由于无法有效将蒸出物纯化导致的二次母液排放等问题。

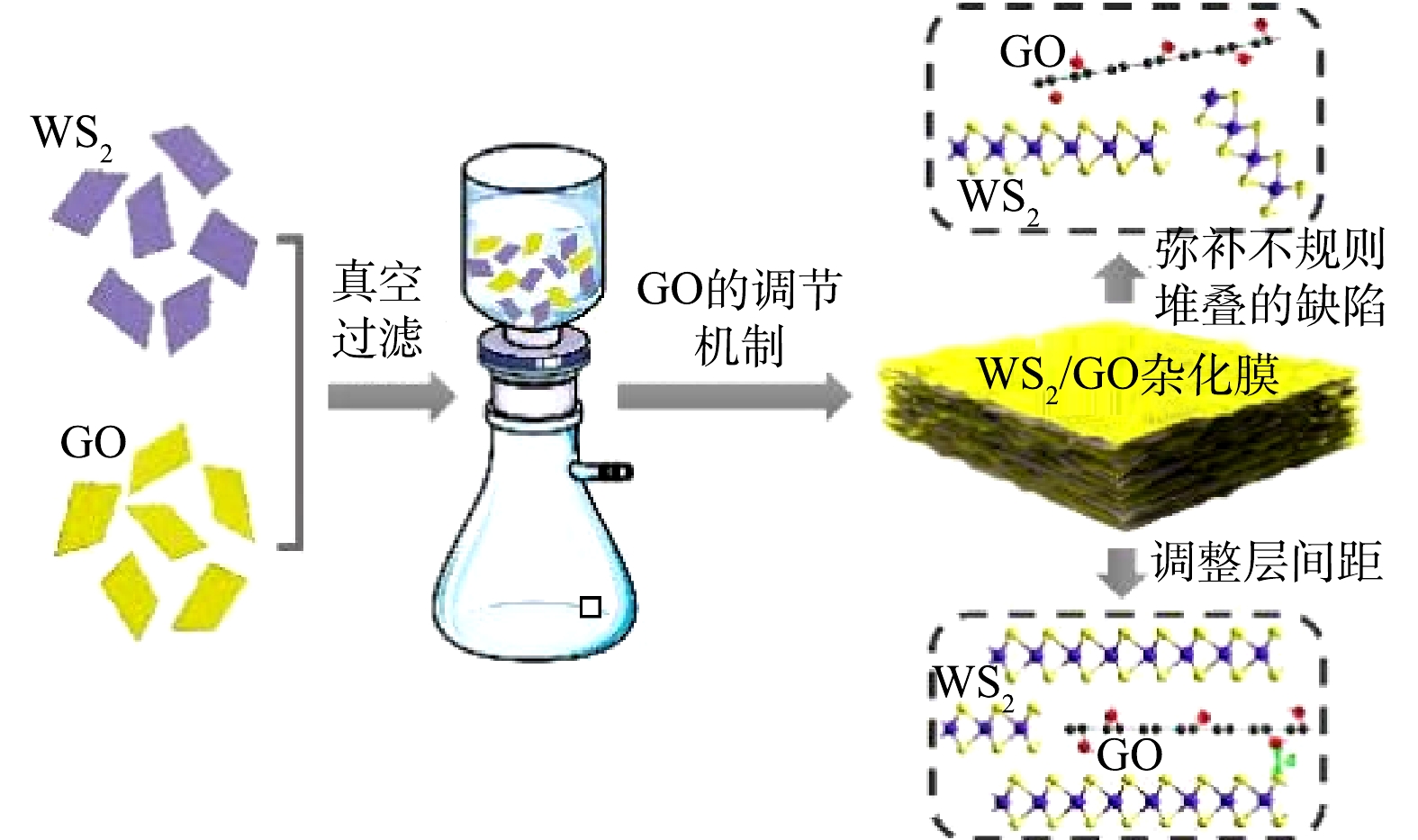

氧化石墨烯通过堆叠纳米片形成层状结构,为小分子通过提供路径。尺寸排阻、电荷排斥等是氧化石墨烯膜对水合离子的主要筛分机制。尺寸小于氧化石墨烯纳米通道的离子在氧化石墨烯膜中渗透速度比简单扩散快。水合半径大的离子则被石墨烯层与层之间的通道阻断[29]。因此,通过控制氧化石墨烯纳米片间的层间距,可实现对工业废水中水合离子的精确筛分。CHENG等[36]报道了一种可实现精确分子筛功能的WS2/GO膜,将氧化石墨烯引入到WS2膜中。通过真空过滤将氧化石墨烯纳米片覆盖到WS2膜表面上,抑制制备过程的缺陷和针孔、形成规则的纳米通道,并调节复合膜的层间距,实现精确的分子筛筛分功能。相较于单独的WS2膜,WS2/GO膜对染料和水合半径大于4.9 nm的离子的截留率超过90%,而对于水合半径小于4.9 nm的离子则具有较低的截留率,如氯化钠和硫酸钠等。改性后的WS2/GO膜具备的优异分离性能使其有望成为一种理想的工业水处理膜。图4为WS2/GO复合膜的制备工艺及其调控机理[36]。

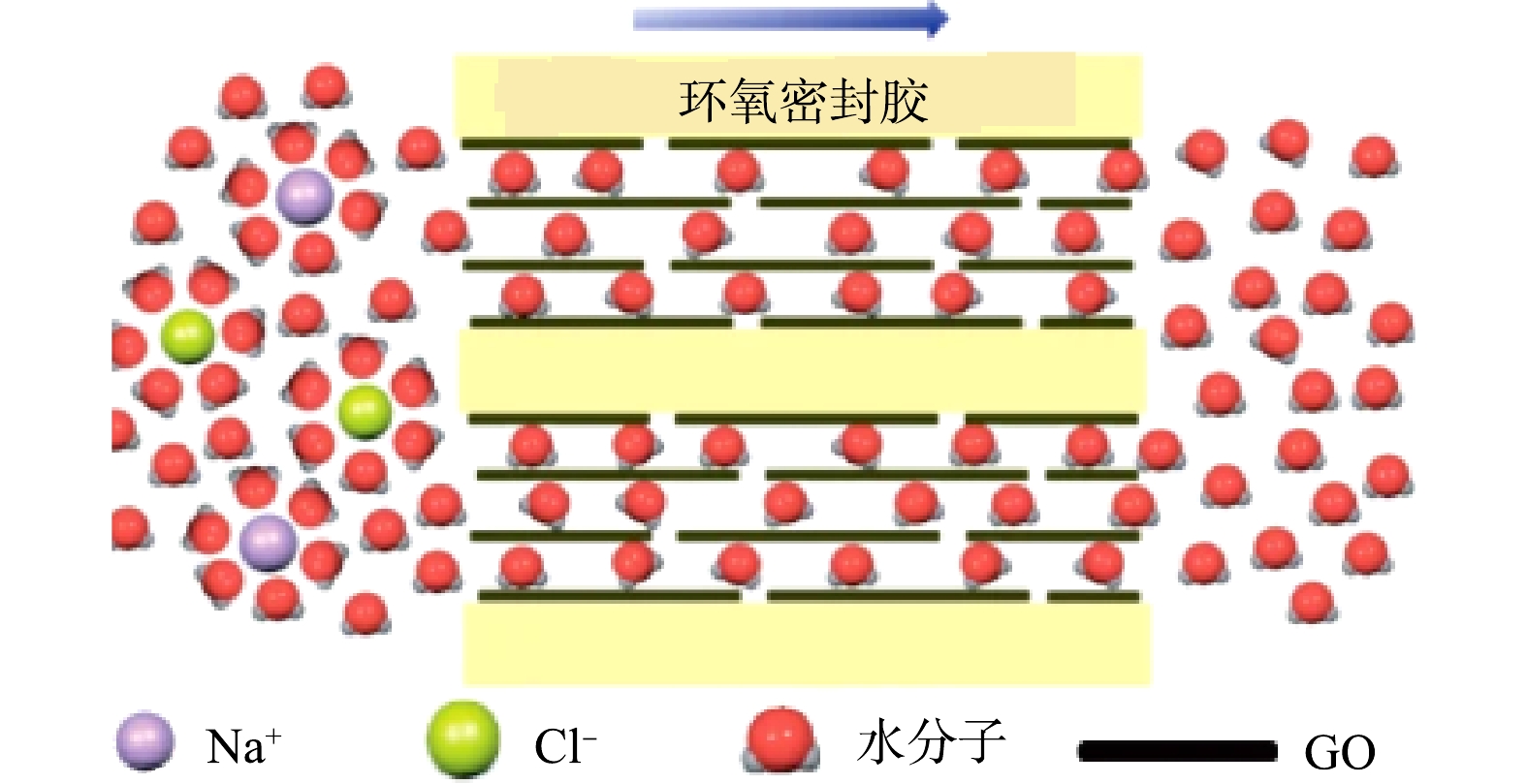

由于氧化石墨烯在水中容易吸水溶胀,导致氧化石墨烯纳米片层之间距离大于水合离子直径这一特性,ABRAHAM等[37]通过环氧树脂物理约束控制层间距制备出具有优异的分子渗透性、精确可调离子筛分功能的氧化石墨烯膜,筛孔筛分尺寸降低到比水合离子直径小的程度,并成功截留了溶液中97%的氯化钠,同时发现该膜可应用于海水淡化中。图5表现出控制层间距后水合离子和水分子沿石墨烯层的渗透方式[37]。

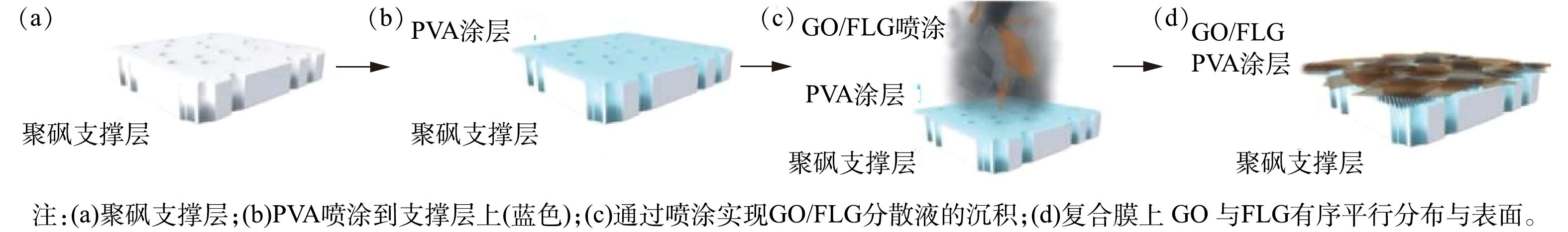

GOMEZ等[38]制备了具有良好渗透性及较高强度的复合膜,可承受120 h的强错流剪切。图6为该复合膜的制备过程[38]。这种氧化石墨烯/多层石墨烯/聚乙烯醇复合膜具有良好的耐氯性,对阴离子和氯化钠的截留率高达85%和96%,其强大的脱盐性能、抗剪切和耐氯性能使其在实际水处理应用中具有广阔前景。

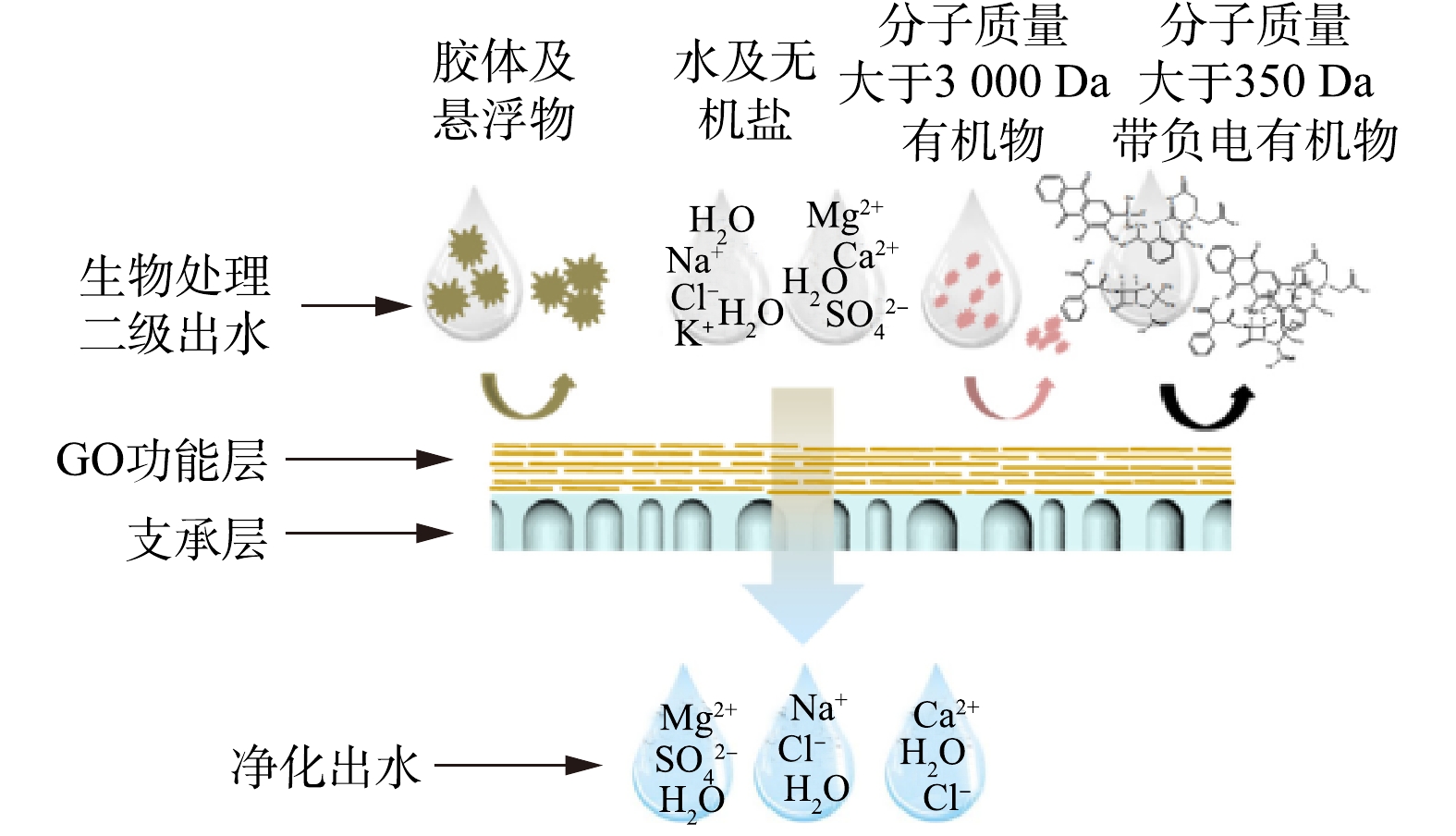

由于膜表面上羧基官能团的解离及对溶液中离子的吸附,氧化石墨烯膜一般具有较强的负电性[39],使得氧化石墨烯膜可以通过静电排斥作用截留工业废水中的负电性有机物,并允许无机盐离子通过,可能会避免有机/无机混合浓水的产生。HAN等[32]通过对氧化石墨烯活性层层数、支撑层材质和孔径、外加自组装压力等条件的优化,制备了可有效分离工业废水二级出水中有机物和无机盐的氧化石墨烯膜。经过优化制备的膜可达10层,并获得更好的截留率和通量。选取以0.1 μm更具备抗氧化能力的聚偏氟乙烯微滤膜做为支撑层,并选取了较高的自组装压力(1 MPa),以获得更小的层间距、粗糙度和更强的层间作用力。这种具有较强电负性的氧化石墨烯膜可有效地截留负电性有机物,而对氯化钠和硫酸镁均保持较低的截留效率,从而可以避免有机/无机混合浓水的产生,具体技术原理[32]见图7。

1.1. 氧化石墨烯膜的制备

1.2. 氧化石墨烯膜的性能特点

-

通过过滤自组装制备的氧化石墨烯膜具有良好的规整结构、无摩擦表面、高拉伸强度、选择性及水渗透量大等特点,其层流结构和层间距可实现工业废水中的有机物和无机盐离子的精确分离。然而,氧化石墨烯的层间具有氢键作用、π-π相互作用,以及表面亲水官能团对水分子的吸附引起的层间溶胀等多种作用[39],使得氧化石墨烯的层间距对所处环境较为敏感。干燥时,氧化石墨烯层间紧密贴合只有水蒸气分子可以通过;处于水溶液中时,水分子嵌入氧化石墨烯纳米片中使得层间的氢键作用和π-π相互作用力减弱。层间作用力急剧降低使得氧化石墨烯层在水中的层间距比干燥环境下大许多,分离性能也有所降低[40]。同时,在长期的错流过滤中,由于吸水溶胀可能导致氧化石墨烯活性层的膨胀及脱落,使氧化石墨烯层存在解体风险。因此,若要提高氧化石墨烯层间相互作用,实现有效交联、并减小层间距,需要对氧化石墨烯纳米片层间进行部分还原或共价交联。交联过程中,氧化石墨烯膜的层间距也可通过加入不同尺寸和结合位置的交联剂来调节。常用的交联剂包括小分子交联剂、高分子交联剂、纳米颗粒等[41-43]。小分子交联剂具有体积小,可有效固定层间距离的特点,但交联效率较低,通常需要使用过量的交联剂来弥补;高分子交联剂具有较好的柔性和较高的桥联效率,但这种柔性也降低了膜的选择性;常用的纳米交联剂具有固定的层间距,且不易受溶液环境影响,但存在纳米颗粒容易聚集在氧化石墨烯纳米片中间的问题。不同物质官能团可与氧化石墨烯表面官能团进行层间交联的相互作用,如酰氯基与羧基、羟基之间的酯键交联,氨基与环氧基之间的反应交联,以及金属离子与羟基、环氧基之间的配位键交联等[44-45]。表1总结了部分氧化石墨烯膜的层间交联方式。

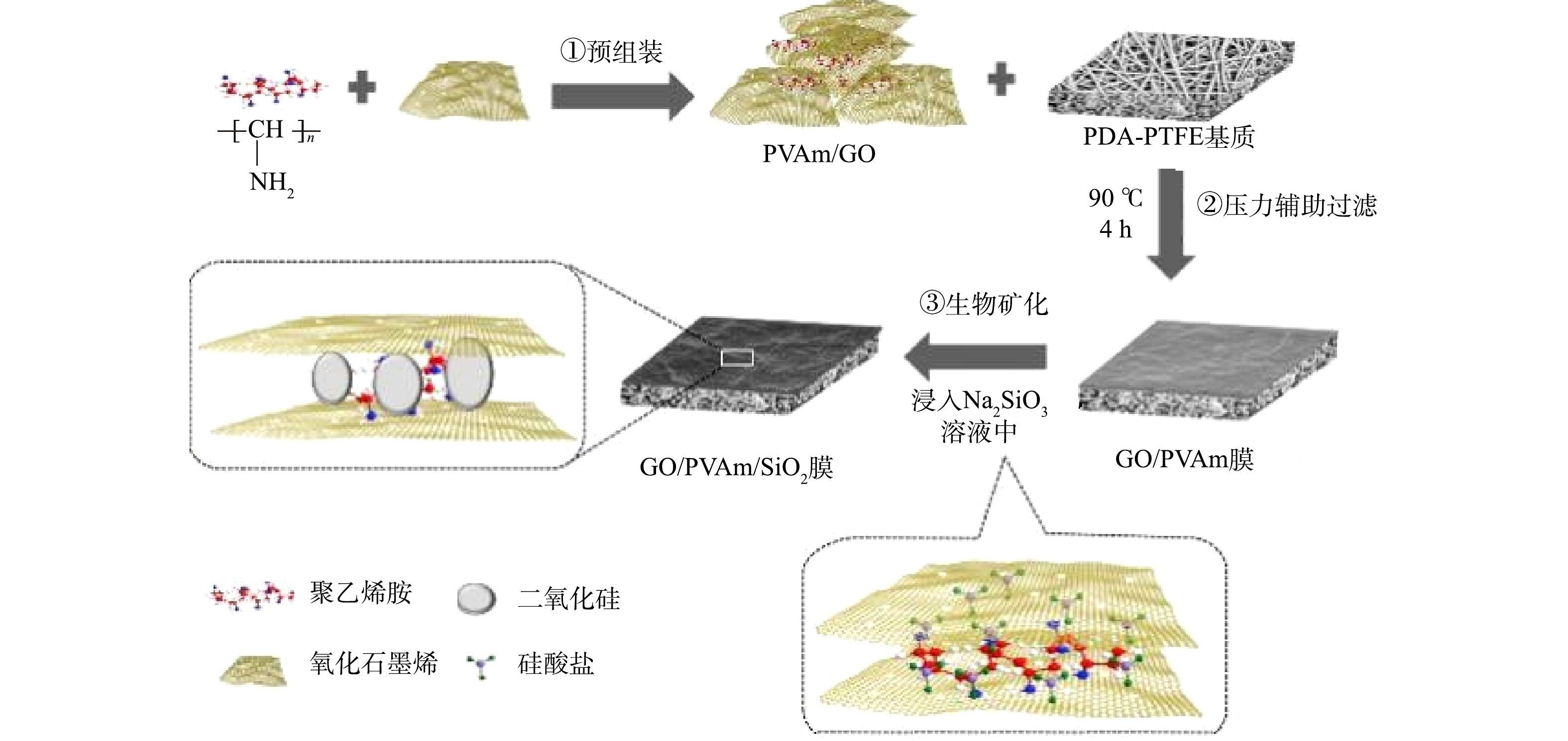

为提高氧化石墨烯膜的水相分离能力和长期稳定性,解决溶胀问题,LIN等[46]利用乙二胺作为交联剂,通过乙二胺的氨基和氧化石墨烯的环氧基反应进行交联,交联后的氧化石墨烯膜解决了膜的机械强度弱和在水中易溶胀的问题,并在不同环境的溶液中均具有良好的稳定性和分离效率。PAN等[40]使用双交联剂制备了一种具有固定二维通道尺寸的氧化石墨烯膜,具有高度有序的二维层状结构、清晰的形态和精确调整的层间距,并具备较高水通量、良好分离性能和长期的稳定性等优点。图8为氧化石墨烯/聚乙烯胺/二氧化硅膜的制备过程[40]。

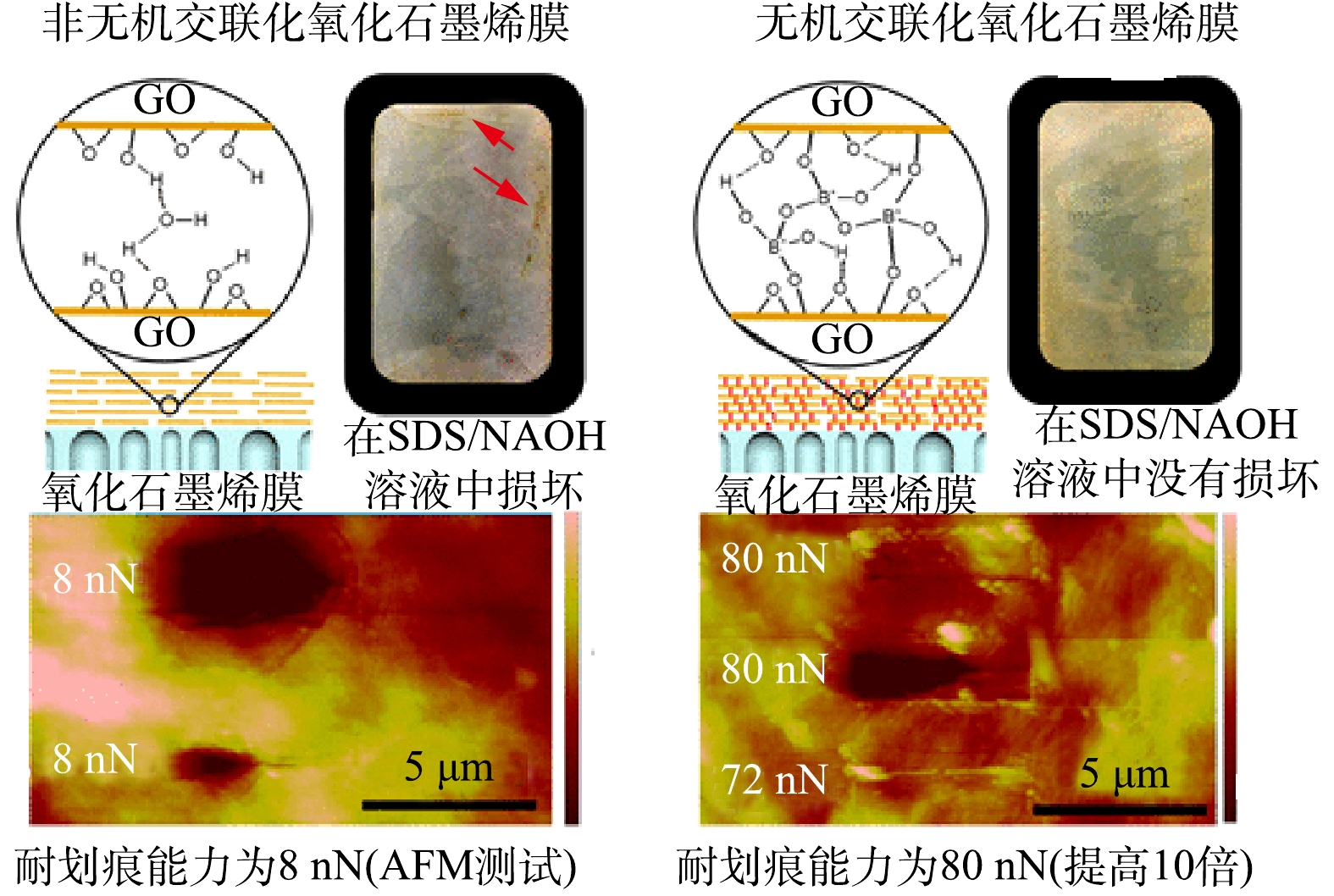

尽管交联可解决膜在水中吸水溶胀的问题,但使用的有机交联剂抗氧化能力较弱,会导致交联后的氧化石墨烯活性层耐氧化能力下降;在投加氧化剂进行膜表面清洗或膜污染控制时,容易出现氧化石墨烯活性层解体的现象。为解决这个问题,HAN等[55]使用抗氧化的无机交联剂四硼酸钠,经过90 ℃的热干燥制备出无机交联化的氧化石墨烯膜。这种膜出现了—C—O—B—O—交联峰,活性层更加致密,并且截留率升高。原子力显微镜划痕评价显示,抗划痕能力提高了10倍,并且在应对SDS/NAOH破坏性清洗的测试中通量、截留率和膜的形貌特征均无明显变化。这些特性使其在工业废水处理中不易发生吸水溶胀现象,在长期错流过滤中也不会存在解体危险。另外,其耐氧化能力的提高为引入氧化剂控制膜污染提供了可能,使氧化石墨烯膜可以应对实际工业废水处理中存在的各种复杂情况。相关的技术原理[55]如图9所示。

-

对于氧化石墨烯膜来说,由于氧化石墨烯具有巨大的比表面积、丰富的π键、大量的含氧官能团而且未氧化区域有较强的疏水性,可能会通过疏水作用、π-π作用和静电作用吸附有机污染物形成致密的凝胶层[56-57]。有机污染的持续累积可能会堵塞氧化石墨烯膜的水渗透通道,从而引起水通量的下降。工业废水中除了含有大量有机物外,通常含有一定浓度的二价或高价的金属离子。这些金属离子可通过静电相互作用或者配位架桥作用与膜表面的官能团及其它有机污染物的羧基官能团相结合,引起有机/金属离子的复合污染[57]。随着膜表面金属离子浓度的提高,表面架桥作用会增强,并吸附更多的有机污染物。此外,虽然氧化石墨烯被证实具有较强的抗菌性[31],但由于膜污染初始阶段以有机污染为主。这导致了膜表面形成了一层凝胶污染层,使细菌不能与氧化石墨烯直接接触,从而使细菌得以生长造成生物污染。因此,最理想控制策略是在保持原有渗透性和截留率的同时,有效解决上述膜污染问题,使氧化石墨烯膜能经济、高效且稳定地应用于工业废水的深度净化与回用。

常规的有机膜膜表面改性污染控制方法需要以牺牲通量、分离能力为代价增强防污性能,以及长期使用稳定性不理想的问题,限制了有机膜在水处理中的实际应用。因此,氧化石墨烯膜的膜污染控制要以维持高通量、分离效率为前提。理论分析可知,引起膜污染的有机物在膜表面受到错流水流的侧向剪切力,跨膜压差带来的进水压力,以及有机物与膜表面官能团或已有的污染物之间的氢键、离子键、范德华力等相互作用,堆积在膜表面。因此,若能减少有机物在膜表面的吸附,增加侧向剪切力,可以减缓膜污染的发生。然而,增加侧向剪切力意味着需要增加错流速率,运行上并不经济。减少有机物吸附沉积的最佳方法是增强膜对水分子的吸附,形成水分子的防护层,防止引起膜污染的有机物的累积[58]。与此同时,可能还需要降低引起膜污染的有机物的聚合作用,减少其聚集成凝胶层的倾向。增强膜表面亲水性和平整度就是通过减少膜-污染物之间的相互作用,来达到减少甚至实现无污染的膜过滤过程[59]。作为新一代膜材料,氧化石墨烯具有大量的环氧基、羧基、羟基等含氧基团,表面具备高亲水性、电负性且光滑平整,对微量羟基自由基耐受能力较好,利用氧化石墨烯的这些特性可实现膜污染的控制。

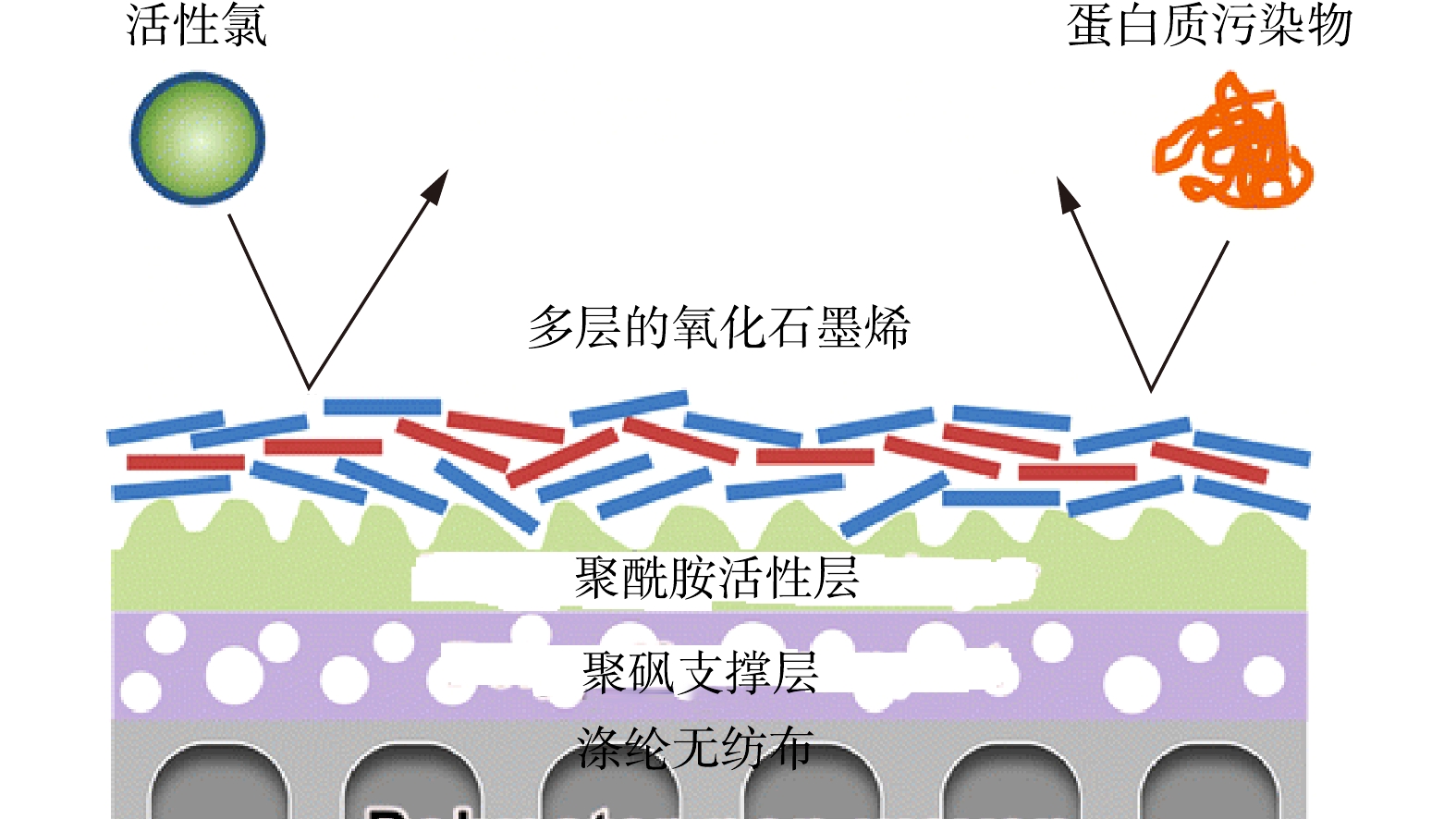

从降低膜-污染物之间的相互作用出发,氧化石墨烯膜表面性能的提高可有效降低水中有机污染物与膜界面之间的氢键作用和范德华力相互作用,实现污染物在膜面沉降累积的缓减;从增强膜-污染物之间的排斥出发,由于工业废水中的有机污染物通常带有负电荷,故带负电的氧化石墨烯纳米片沉积后在膜表面可有效增强膜-污染物之间的静电排斥作用,进而削弱污染物对膜表面的亲和势能。但是,增强膜表面负电性的方法在应对多价金属离子(Ca2+、Mg2+和Fe3+)与含羧基等官能团的有机物复合污染时,则不能起到良好的效果。CHOI等[21]将氧化石墨烯纳米片通过层间沉积的方式涂覆在聚酰胺膜的表面,来提高聚酰胺膜的抗污染能力。在12 h过滤时间内,膜通量下降从34%减少到15%,膜污染现象得到缓解。同时,由于氧化石墨烯纳米片之间独特的水传输机制,使用氧化石墨烯改性后膜的渗透性并没有像传统有机膜改性一样出现下降现象。图10展示了氧化石墨烯纳米片膜污染控制的原理[21]。KARKOOTI等[60]通过非溶剂诱导相分离法将不同形状和氧化态的氧化石墨烯加入到聚醚砜(PES)基质中制备出聚醚砜/氧化石墨烯复合膜。氧化石墨烯对膜的改性提高了膜表面性能,可抑制膜表面污垢的形成。通量回收率的实验证实了改性后氧化石墨烯膜的防污性能比未改性聚醚砜膜提高了30%。

虽然上述的氧化石墨烯膜的膜污染控制方法可有效减少膜污染现象,但膜污染现象仍然存在。由于污染物-污染物之间的作用力控制着稳定运行期的膜污染行为,故仍吸附在膜表面的污染物可以继续与水中的其他污染物相作用。另外,由于氧化石墨烯具有良好的吸附特性,在实际的废水处理过程中,有机物仍可能快速地被膜吸附并累积。因此,如何基于氧化石墨烯膜本身的特点,实现其在工业废水深度净化中长久的零污染过滤过程是膜过滤净化过程的进一步追求。

氧化石墨烯与有机物污染物相互作用的官能团主要有环氧基、羟基及疏水区间的π键,而氧化石墨烯膜表面的含氧官能团以环氧基、羟基为主。这2种官能团在实际的水溶液中由于电子云密度的不同与水分子、有机物和金属离子的成键能力也有很大的差别。其中,羟基与水分子具有更强的氢键相互作用,而环氧基更容易与金属离子和有机物相互作用。因此,如果可以调控膜表面的含氧官能团,将以环氧基为主的氧化石墨烯膜表面转变为以羟基为主,便有望增强水分子与膜之间的氢键相互作用,并在膜表面形成相对致密的水分子保护层,从而减弱有机污染物在膜表面的吸附。由于初始的污染层是膜污染形成的重要一步,没有前驱层,后续的污染物-污染物相互作用也无法发生,故在膜污染发生前实现对膜污染的控制,就有望实现零污染的膜过滤净化过程。

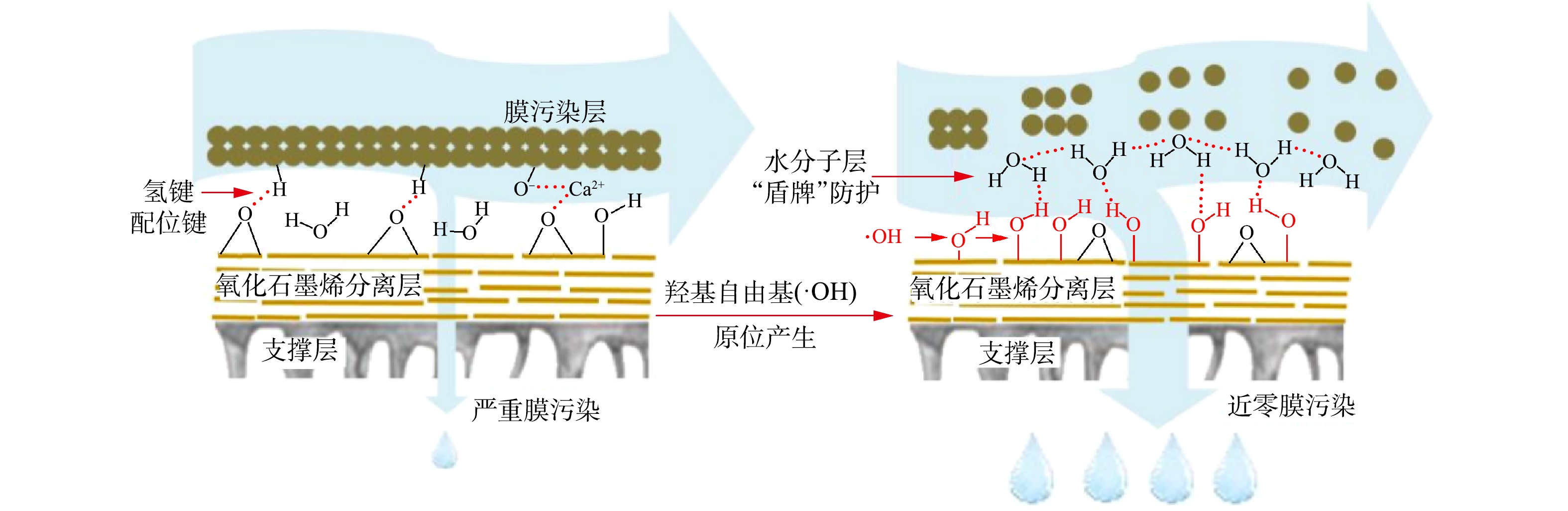

HAN 等[61]发现由于氧化石墨烯膜比传统有机膜具有更强的抗氧化能力,故可在过滤过程中引入微量的羟基自由基,调谐氧化石墨烯膜表面的官能团,将以环氧基为主的膜表面变为以羟基为主的状态。羟基通过氢键作用在膜表面形成水分子防护层,可减少膜-污染物之间的黏附力。有机污染物很难在膜表面上积累,后续的污染物-污染物的作用也难以发生。另外,羟基自由基的氧化性可进一步阻止污染物在膜表面自聚合形成凝胶层,防止膜污染发生。羟基自由基在膜表面产生后,会吸附到未氧化部分形成暂稳态羟基,增加与水分子之间的吸附能,同时减弱与有机污染物之间的吸附能,从而使膜与有机污染物之间的粘附力从0.36 mN·m−1下降至接近于0。具体的技术原理[61]见图11。

常规的膜污染控制思路即通过改善膜面的化学特性和膜表面的物理结构性来减少膜与污染物之间的作用力,以维持膜的高通量和分离效率,从而减少膜污染。引入微量的羟基自由基,可提高氧化石墨烯表面的羟基含量,并配合自由基的氧化过程实现膜污染控制。该方法可实现近乎零污染的膜过滤净化过程。同时,这种方法也可进一步降低进水水质调节、膜组件优化、膜表面高错流速率以及膜表面清洗等过程带来的额外费用。微量羟基自由基的引入也能控制生物污染的发生。表2总结了部分氧化石墨烯膜的膜污染控制情况。

-

考虑到氧化石墨烯膜的性能特点及不同工业废水的处理及回用需求,将氧化石墨烯膜与生物处理装置联用以实现工业废水的深度处理与回用,可能是氧化石墨烯膜的应用方向。

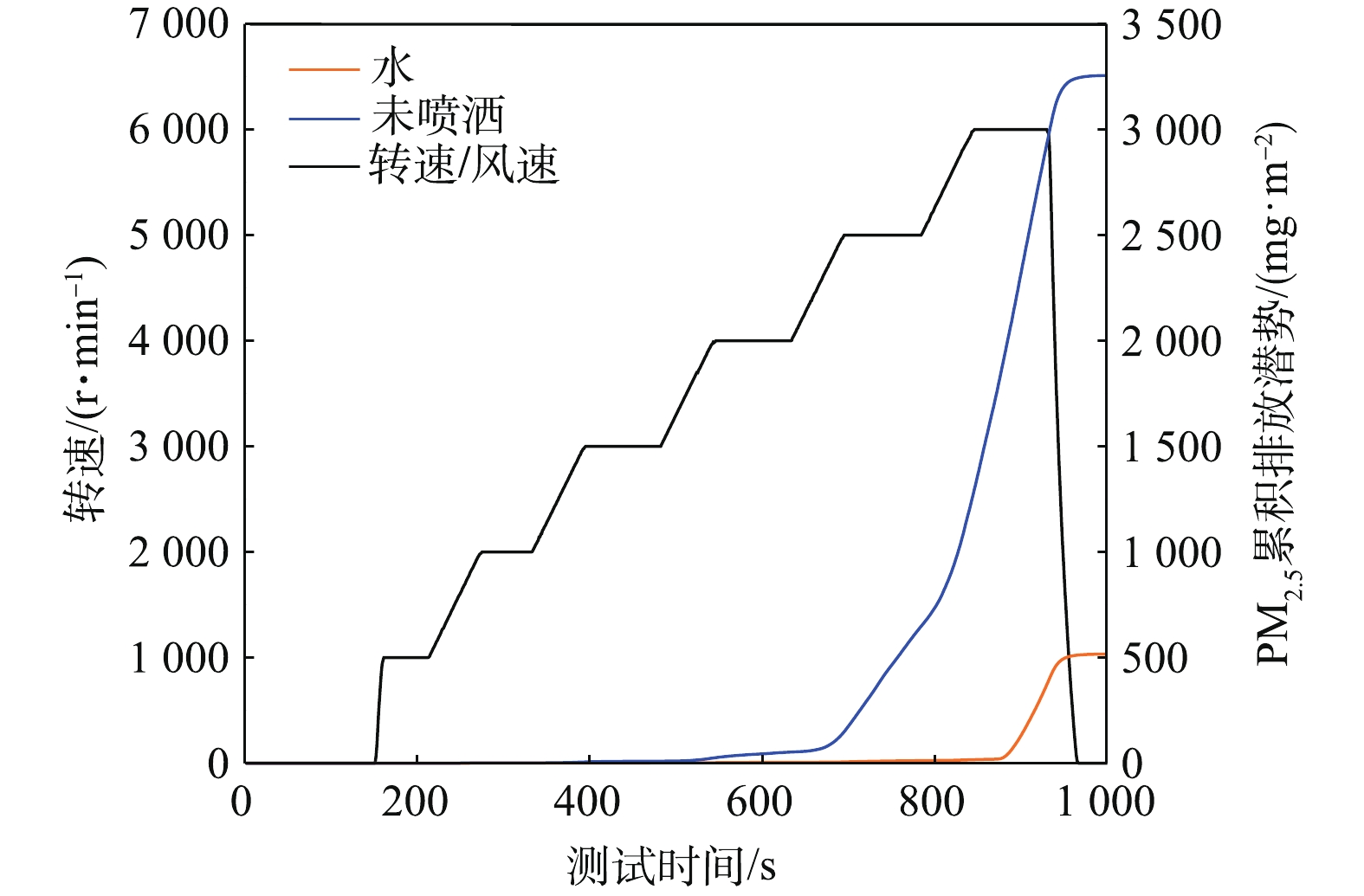

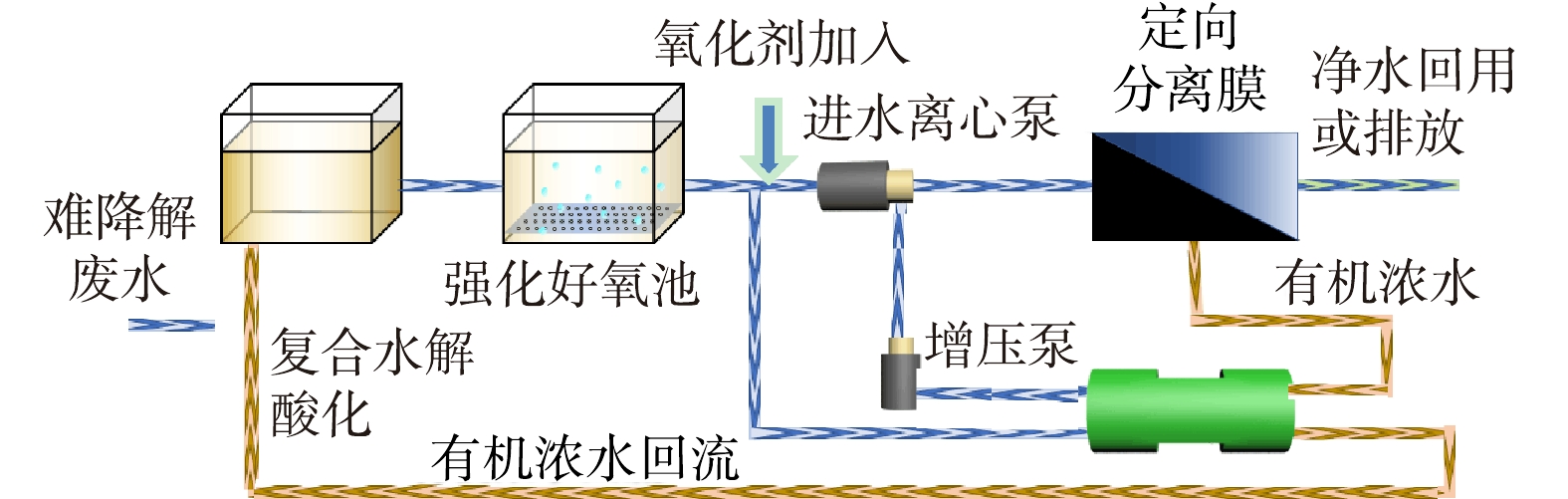

为发挥生物处理的核心作用,受MBR工艺启发,笔者将具有选择性作用的膜分离工艺与生物处理反应器联用[32](见图12)。这是一种生物反应器-膜分离系统的耦合工艺。该工艺可将经过厌氧/好氧处理废水中的有机污染物通过氧化石墨烯膜截留形成有机浓水,截留得到的有机浓水再回流到生化处理段。通过厌氧/好氧的多次交替来延长有机物在生化段的停留时间。由于有机物在系统中的停留时间要远高于水力停留时间,所以长期的厌氧/好氧交替处理过程使有机物得到了微生物的充分矿化降解,化工废水中含有的无机盐成分可在膜分离纯化后进行资源化利用,不会回流到生化段造成盐度积累。而关于膜污染问题,则可使用氧化石墨烯膜的原位膜污染控制方法。通过加入氧化剂产生微量的羟基自由基以调谐氧化石墨烯膜表面的官能团,增强膜表面对水分子的吸附,从而在膜表面形成牢固的水分子层来阻挡有机污染物的粘附,并避免凝胶层形成,最终有效控制了膜污染的出现。生化-氧化石墨烯膜耦合工艺有望为氧化石墨烯膜在工业废水深度净化中的应用提供技术支持,并进一步推动难降解工业废水的达标排放及回用技术的发展。

2.1. 氧化石墨烯膜的层间交联问题

2.2. 氧化石墨烯膜污染控制

2.3. 氧化石墨烯膜在工业废水深度净化中的应用方式

-

氧化石墨烯具有抗氧化性良好、制备成本低廉、过滤及截留性能优异、膜污染控制相对方便等诸多优异的性能。基于这些特性,氧化石墨烯膜有望在工业废水的深度处理与回用中得到应用。然而,在实际应用中,还需在以下方面开展进一步研究:氧化石墨烯层长期使用的稳定性;膜污染控制手段在实际进水条件下的长期有效性;在近零污染膜过滤过程中、与生化法耦合的技术,以期通过该材料增加水和有价资源的回用率,实现近“零排放”。目前,氧化石墨烯膜制备及膜污染控制方面的基础研究已趋于成熟。随着应用放大研究的进一步推进,氧化石墨烯膜有望在不久的将来应用于废水的深度净化中,为工业及园区污水的深度净化及资源化提供新路径。

下载:

下载: