-

近年来,随着城市化进程的加快,工农业快速发展,氨氮废水的污染源数量和排放总量呈现日益增加趋势,由此引起的水体富营养化和水体黑臭严重威胁到水体生态平衡和人类正常的生产生活[1-4]。随着民众对水环境质量要求的提高,氨氮已成为继COD之后我国水体污染第2项约束性控制指标,水体中氨氮的去除刻不容缓[5]。研究开发经济、高效的氨氮去除技术已成为水污染控制工程研究的重点领域之一。

藻类作为水生态环境重要的初级生产者,吸收水中氮、磷及其他无机盐以维持其生长和繁殖,因而被广泛应用于氨氮废水的资源化[6-9]。在使用固定化微藻处理氨氮废水的过程中,反应器内维持较大的藻细胞密度,可增强微藻对高浓度氨氮的耐受性,从而加快了处理速度,提高了处理能力,处理工艺运行稳定可靠且易实现氨氮废水的规模化处理[10-14]。然而,以海藻酸钠为代表的传统固定化载体制备的胶球传质性能较差,限制了微生物与底物的接触[15]。生物炭具有孔隙结构发达、比表面积大和生物相容性好等特点,近年来广泛应用于微生物固定化去除污染物中,提高了固定化胶球的传质性能,有利于发挥生物炭吸附和微生物降解的协同作用,大幅度提高污染物的去除速率[16-18]。

本研究采用柚子皮制备的生物炭与海藻酸钠联合固定小球藻,并将其用于水中氨氮的去除,比较了生物炭-海藻酸钠联合固定化小球藻和游离小球藻对水中氨氮去除性能的差异,并考察了联合固定化小球藻对水中氨氮去除性能的影响因素及其重复利用性能,旨在为生物炭-海藻酸钠联合固定小球藻去除水中氨氮的应用提供参考。

全文HTML

-

实验所用小球藻(Chlorella vulgaris)购自中国科学院水生生物研究所淡水藻种库。微藻培养采用BG11培养基,培养温度为(28±1) ℃,光照强度为1 500 lx,光暗比为12 h∶12 h。

BG11培养基[19]:NaNO3 1.5 g·L−1、K2HPO4 0.04 g·L−1、MgSO4·7H2O 0.075 g·L−1、CaCl2·2H2O 0.036 g·L−1、柠檬酸0.006 g·L−1、FeCl3·6H2O 0.003 15 g·L−1、Na2EDTA·2H2O 0.004 36 g·L−1、Na2CO3 0.02 g·L−1、1 mL A5微量元素。

A5微量元素:H3BO3 2.86 g·L−1、MnCl2·4H2O 1.81 g·L−1、ZnSO4·7H2O 0.222 g·L−1、Na2MoO4·2H2O 0.39 g·L−1、CuSO4·5H2O 0.079 g·L−1、Co(NO3)2·6H2O 0.049 4 g·L−1。

-

将柚子皮洗净烘干后粉碎,置于管式炉中,600 ℃碳化2 h后,将碳化产物与KOH溶液在镍坩埚浸渍2 h,于马弗炉中350 ℃下再活化30 min,以30 ℃·min−1的升温速率加热至800 ℃,活化120 min,待生物炭自然冷却至室温后,用去离子水进行水洗,然后用0.1 mol·L−1的盐酸溶液酸洗至中性,最后再用去离子水水洗2~3次,80 ℃下干燥24 h,冷却后称重并放入自封袋中备用。采用麦克仪器公司ASAP2020M全自动比表面积与孔隙度分析仪测定生物炭比表面积。

-

选择生物炭加入量、海藻酸钠质量分数、胶球中微藻细胞密度以及CaCl2加入量为因素,以氨氮的去除率为考核指标,采用4因素3水平进行正交实验优化联合固定化小球藻胶球的制备条件,正交实验因素水平见表1。生物炭-海藻酸钠固定化藻球固定后,无菌超纯水冲洗3次,制得联合固定化小球藻胶球,胶球的成球性依据胶球交联后的形态及强度确定。

-

将制备好的生物炭-海藻酸钠联合固定化小球藻、生物炭-海藻酸钠空胶球、海藻酸钠单独固定的小球藻以及游离小球藻分别加入到250 mL锥形瓶中,向瓶中加入含120 mg·L−1氨氮的100 mL BG11培养基,置于28 ℃恒温光照培养箱中,定期采用纳氏试剂分光光度法测定溶液中氨氮浓度[20]。

-

分别研究氨氮初始浓度(40、80、120和160 mg·L−1)、胶球投加量(100、300、500和700粒)、胶球粒径(2、5和8 mm)以及胶球循环利用次数对氨氮去除率的影响,每个处理设置3个平行实验。

1.1. 藻种及其培养

1.2. 生物炭的制备及表征

1.3. 生物炭-海藻酸钠联合固定化小球藻胶球的制备

1.4. 生物炭-海藻酸钠联合固定化小球藻去除水中氨氮性能测定

1.5. 生物炭-海藻酸钠联合固定化小球藻去除水中氨氮影响因素实验

-

各实验组制备的生物炭-海藻酸钠联合固定化小球藻胶球8 d氨氮去除率结果如表2所示。由表2可知,最优方案为A1B2C3D1,即胶球中生物炭浓度为0.26 g·L−1、海藻酸钠质量分数为1.8%、藻细胞密度为3.0×106 个·mL−1、CaCl2质量分数为1%;影响胶球制备的各因素对氨氮去除率影响的大小顺序为A>D>C>B,即生物炭浓度>CaCl2质量分数>胶球中藻细胞密度>海藻酸钠质量分数。

-

柚子皮制备的生物炭比表面积为2 018.21 m2·g−1,孔体积大小为0.583 cm3·g−1,作为添加剂制备的海藻酸钠联合固定化胶球比表面积分别为208.18 m2·g−1,而海藻酸钠单独固定化制备的胶球比表面积只有110.01 m2·g−1。

-

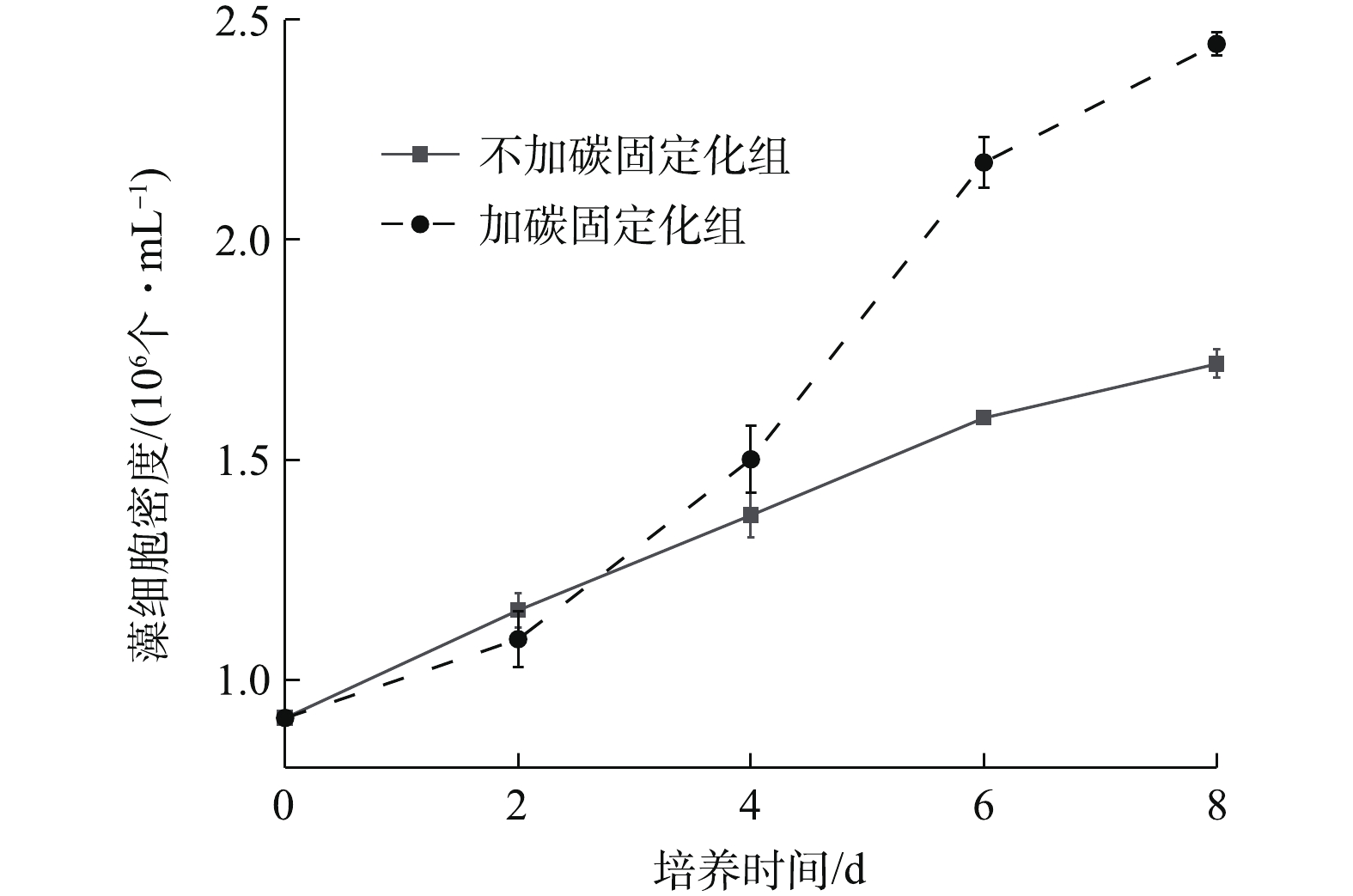

固定化小球藻胶球经50 g·L−1柠檬酸钠溶解后,采用分光光度法结合细胞计数法测定胶球中藻细胞数量,绘制小球藻在生物炭-海藻酸钠联合固定化胶球和海藻酸钠单独固定化胶球中生长曲线(图1)。如图1所示,随着培养时间的延长,小球藻在2种胶球中的藻密度差增大,培养至第8天,生物炭-海藻酸钠联合固定化胶球中小球藻细胞密度达到了2.45×106 个·mL−1,而在海藻酸钠单独固定化胶球中只有1.72×106 个·mL−1。结果表明,生物炭促进了固定化小球藻在海藻酸钠胶球中的生长,可能的原因是,生物炭的加入增加了胶球的比表面积,提高了对营养物的吸附,胶球中的小球藻更容易获得营养物,进而促进其生长[21]。

-

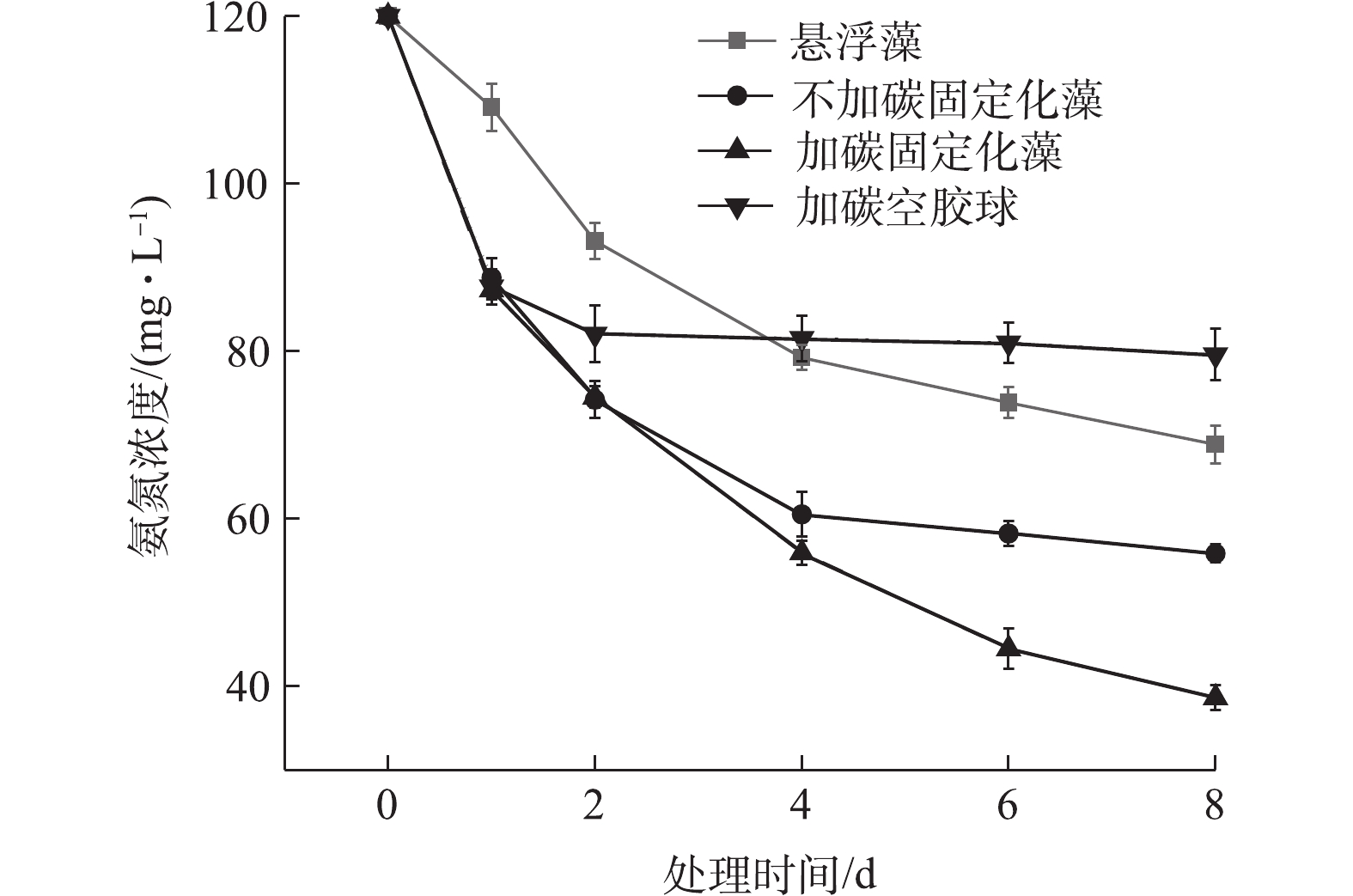

联合固定化小球藻以及3组对照处理(联合固定化空胶球、海藻酸钠固定化小球藻以及游离小球藻)去除水中氨氮结果如图2所示。由图2可知,生物炭-海藻酸钠联合固定化小球藻、海藻酸钠单独固定的小球藻以及生物炭-海藻酸钠联合固定化空胶球3个处理组在第1天时,水中氨氮含量迅速下降,这可能跟胶球对氨氮有较强的吸附有关,联合固定化空胶球由于吸附饱和,水中氨氮浓度变化不大,而海藻酸钠单独固定化小球藻处理组中的氨氮浓度持续降低,但生物炭-海藻酸钠联合固定化小球藻处理组中的氨氮浓度下降最为明显。游离小球藻通过代谢吸收待处理水中的氨氮,溶液中氨氮浓度持续下降,但是氨氮去除速率较慢,处理4 d后,溶液中氨氮的浓度略低于空胶球处理组。赏国锋等[22]采用海藻酸钠将硝化菌固定在稻壳生物炭上,实现了生物炭对水中氨氮的吸附的同时,促进了硝化菌吸收氨氮,从而提高了氨氮的去除率。

-

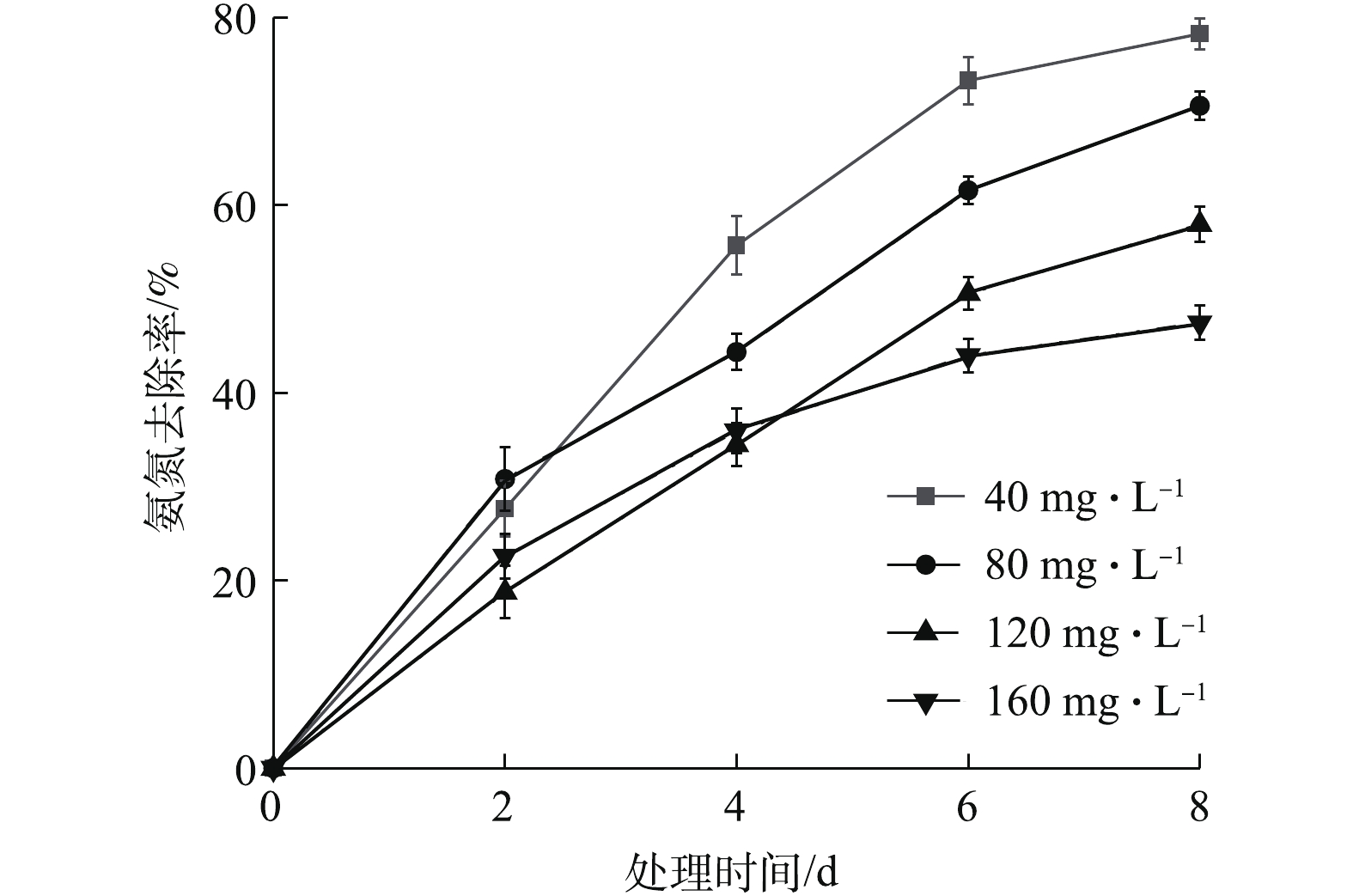

初始氨氮浓度对生物炭-海藻酸钠联合固定化小球藻去除水中氨氮的影响结果如图3所示。由图3可知,随水样中初始氨氮浓度的增加,氨氮的去除率逐渐降低,当初始氨氮的浓度为40、80、120和160 mg·L−1时,处理8 d时的氨氮去除率分别为78.28%、70.59%、57.96%和47.44%。生物炭-海藻酸钠联合固定化小球藻对氨氮的去除率随氨氮初始浓度的升高而降低,这可能是因为氨氮浓度的升高对小球藻的生长产生了抑制作用,影响了小球藻的生理特性,尤其是当氨氮浓度升高到160 mg·L−1时,生物炭-海藻酸钠联合固定化小球藻对水中氨氮去除率达到最低。

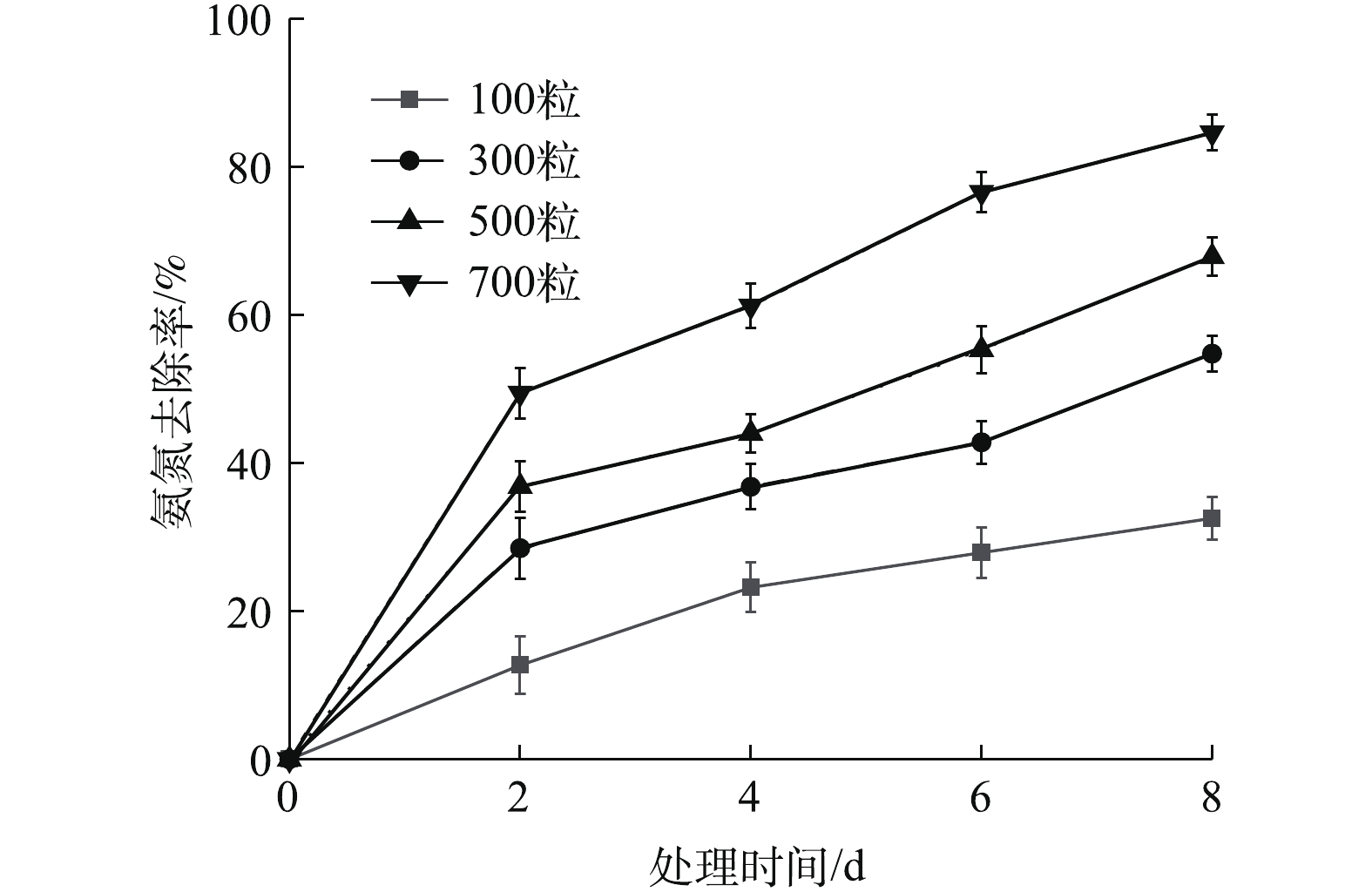

增加联合固定化小球藻胶球投加数量,不仅提高了处理系统中通过代谢去除氨氮的微藻细胞数量,还可增加吸附去除氨氮的生物炭的质量,进而提高了氨氮的去除率。在相同的条件下,制备生物炭-海藻酸钠联合固定化小球藻胶球,考察了胶球加入量对水中氨氮去除的影响,结果如图4所示。由图4可知,在100 mL的待处理氨氮废水(氨氮浓度为120 mg·L−1)中,当生物炭-海藻酸钠联合固定化小球藻胶球加入量从100粒增至700粒时,氨氮去除率可由32.54%提高至84.59%。

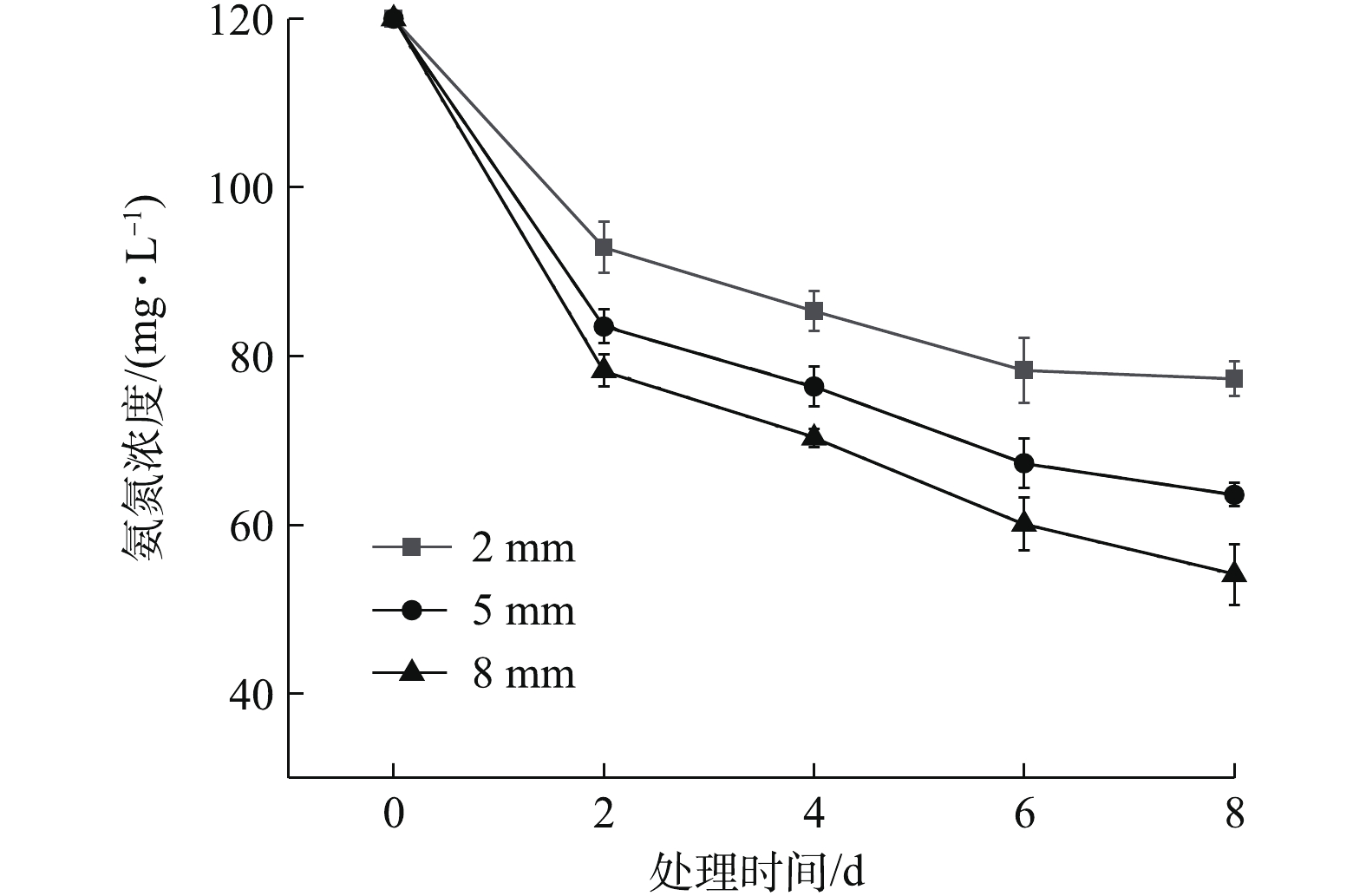

固定化小球藻粒径能够影响固定化胶球的传质性能进而影响其对氨氮的去除性能,为了考察联合固定化小球藻胶球粒径对水中氨氮的去除性能影响,在胶球制备过程中恒定小球藻、生物炭以及海藻酸钠等用量的条件下,分别制备了不同粒径的生物炭-海藻酸钠联合固定化小球藻胶球,胶球粒径对联合固定化小球藻去除水中氨氮效率影响结果如图5所示。由图5可知,粒径为2 mm的胶球在8 d时,其对氨氮的去除率为56.96%,粒径为5 mm的胶球对氨氮的去除率为69.10%,当胶球粒径增加到8 mm时,氨氮去除率可提高到78.82%。

理论上讲,胶球粒径越小,比表面积越大,但是粒径过小,减少了胶球对固定化微藻的保护,加之胶球中的生物炭对溶液中氨氮的吸附,进一步提高了胶球中氨氮浓度,过高浓度的氨氮会影响胶球中微藻的生长,氨氮去除效果反而不好。随着胶球粒径的增加,减少胶球内小球藻的溢出的同时,避免胶球内部的小球藻接触高浓度的氨氮废水,进而使其保持了较好的生理活性,促进了水样中氨氮的去除。随着胶球粒径的进一步增加,胶球传质性能进一步降低,限制了胶球中小球藻与水中氨氮的接触,进而限制了生物炭-海藻酸钠联合固定化小球藻对水中氨氮的去除。

-

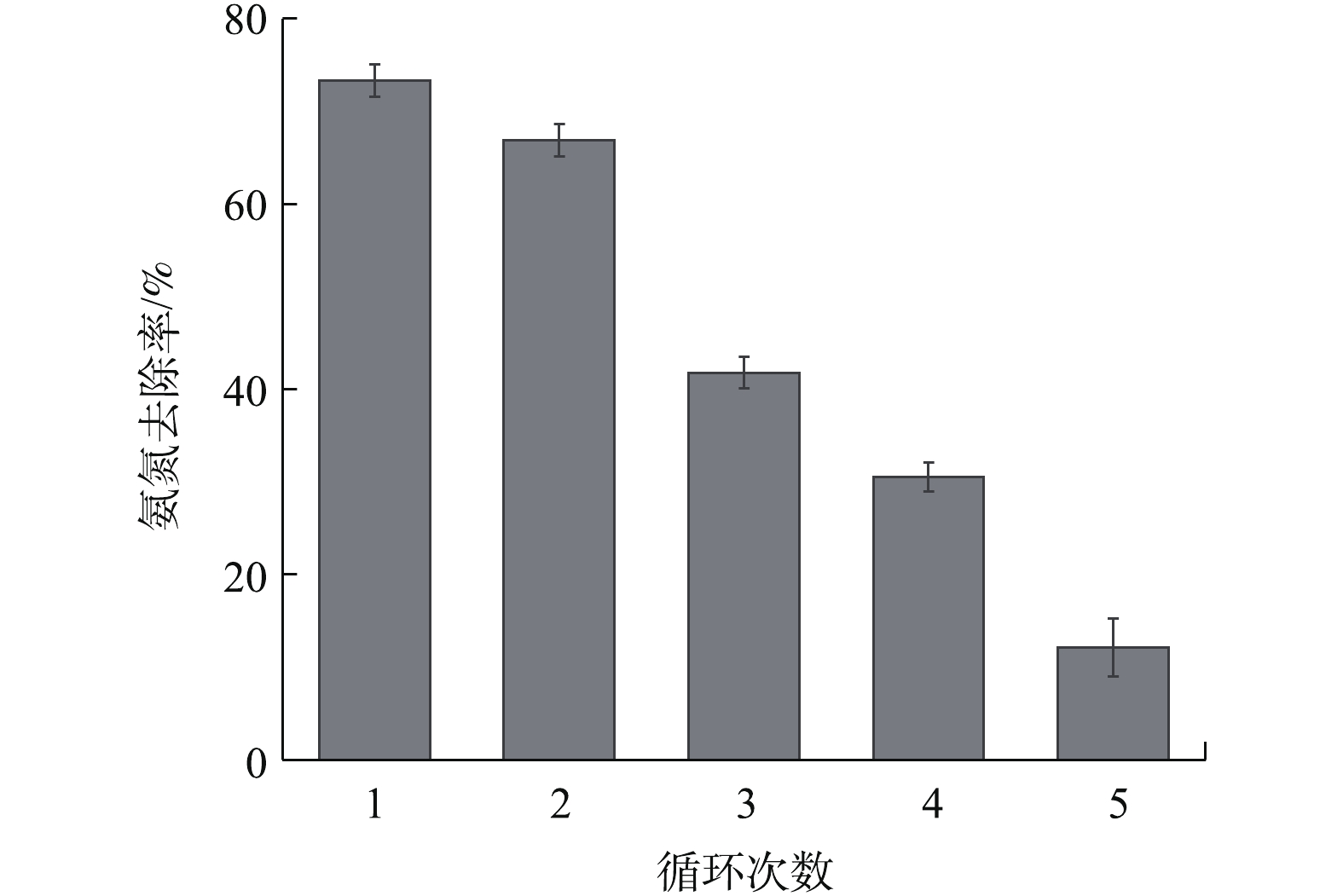

生物炭-海藻酸钠联合固定化胶球的循环使用,可以减少固定化小球藻处理氨氮废水的成本,促进该技术的推广和应用。生物炭-海藻酸钠联合固定化小球藻胶球的重复使用对水中氨氮去除效果见图6。由图6可知,联合固定化小球藻随着循环使用次数的增加,氨氮的去除率出现不同程度地下降。胶球第1次回用氨氮去除率仍达66.87%,但从第3个循环开始,生物炭-海藻酸钠联合固定化小球藻胶球出现膨胀以及部分裂解的现象,氨氮去除率下降到41.78%。

2.1. 生物炭-海藻酸钠联合固定化小球藻胶球的制备条件优化

2.2. 生物炭-海藻酸钠联合固定化胶球比表面积测定

2.3. 生物炭-海藻酸钠联合固定化对小球藻生长的影响

2.4. 生物炭-海藻酸钠联合固定化小球藻对水中氨氮去除性能的测定

2.5. 生物炭-海藻酸钠联合固定化小球藻氨氮去除的影响因素

2.6. 生物炭-海藻酸钠联合固定化小球藻胶球重复使用去氨氮性能评价

-

1) 生物炭-海藻酸钠联合固定化小球藻胶球对水中的氨氮具有较好的去除性能,胶球最佳制备方案为:生物炭浓度0.26 g·L−1、海藻酸钠质量分数1.80%、藻细胞密度3.0×106 个·mL−1、CaCl2质量分数1%。该条件下制得的胶球成球性好,8 d时氨氮的去除率可达到73.30%。

2) 生物炭-海藻酸钠联合固定化小球藻对水中氨氮的去除率随着氨氮初始浓度的增加而降低,而随着胶球数量和粒径的增加而升高。

3)生物炭-海藻酸钠联合固定化小球藻重复使用1次的氨氮去除率仍可达到65%以上,这说明其具有一定的重复使用性。

DownLoad:

DownLoad:

百度学术

百度学术