-

随着环保形势的日益严峻,污染物排放标准愈加严格,尤其是导致水体富营养化的氮元素,如北京市最新标准《北京地方水污染排放标准》(DB 11/307-2013)规定,污水厂出水TN不得高于15 mg·L−1。污水生物处理过程中氮元素的去除是在硝化和反硝化反应共同作用下实现的,但由于我国城镇污水厂进水碳源普遍不足导致反硝化效率低下,使得碳源不足成为制约出水TN达标的重要因素[1]。为解决这一问题,在水厂运行过程中,一般通过投加甲醇等补充碳源的方式提高脱氮效率[2]。然而投加补充碳源不仅增加了运行成本,也会增加剩余污泥的产量[3]。与此同时,在生物处理过程中,微生物将有机物同化为自身细胞物质,以剩余污泥的形式被排出系统。这不仅增加后续污泥处理的成本,还造成了其所含丰富碳源的浪费[4]。在此背景下,研究者们提出多种剩余污泥破解方法并将其作为碳源回用。QIANG等[5]采用臭氧污泥破解液回流至A2/O系统,除磷效果得到明显改善。LIU等[6]研究了污泥水力破解后作为碳源对反硝化速率的影响,发现反硝化速率增加,TN去除率增加。LIU等[7]将碱解发酵污泥破解液作为A2/O系统的反硝化补充碳源,脱氮除磷率均得到明显的提高,并且与传统工艺相比有巨大的经济优势;KONDO等[8]进一步研究了剩余污泥破解回流比对强化反硝化脱氮的影响,发现当污泥破解量为总污泥量9.40%时,剩余污泥排放量减少50%,反硝化效果提高。

高铁酸盐作为一种氧化性强、绿色、多功能的新型氧化剂,在污泥处理领域已得到了广泛研究和应用,相关研究[9-11]证实了高铁酸盐具有良好的污泥溶胞性能,能有效地破坏污泥细胞,溶出胞内物质。在氧化破解污泥的过程中,Fe6+可被还原为Fe3+,Fe3+可以改善污泥的沉降性能和脱水性能[12-14]。为实现高铁酸盐的工艺利用,本研究采用复合高铁酸盐溶液(composite ferrate solution,CFS)破解污泥,将破解液回流至A/O系统强化反硝化脱氮,即高铁酸盐氧化-A/O工艺(ferrate oxidation-A/O,FO-A/O),详细考察了不同剩余污泥回流比(25%、50% 和100%)对污泥浓度、污泥活性(SOUR)、污泥沉降性能(SVI)及系统出水水质的影响,重点考察了污泥减量效果和脱氮效果,为实现污泥减量及强化脱氮提供参考。

-

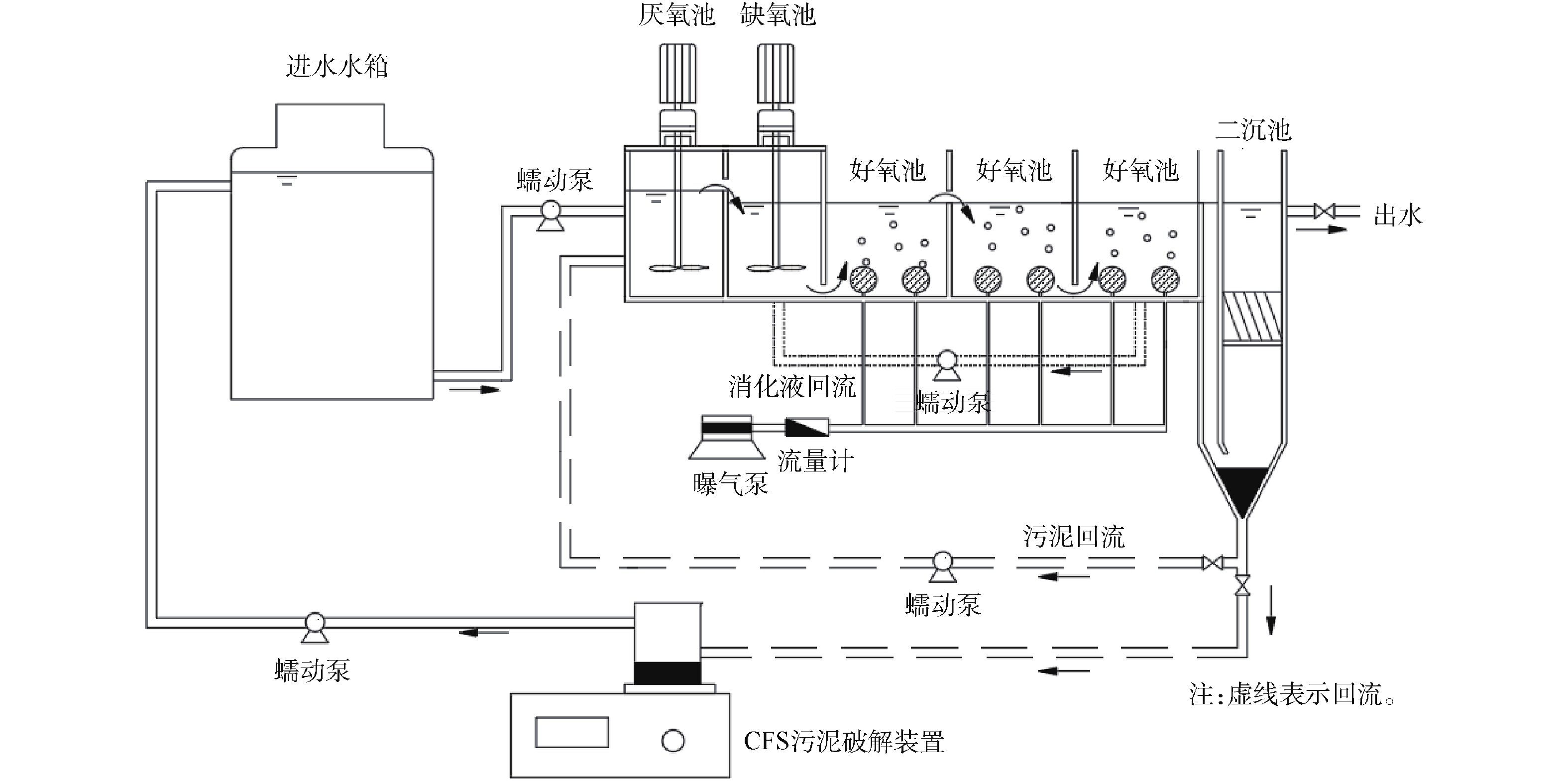

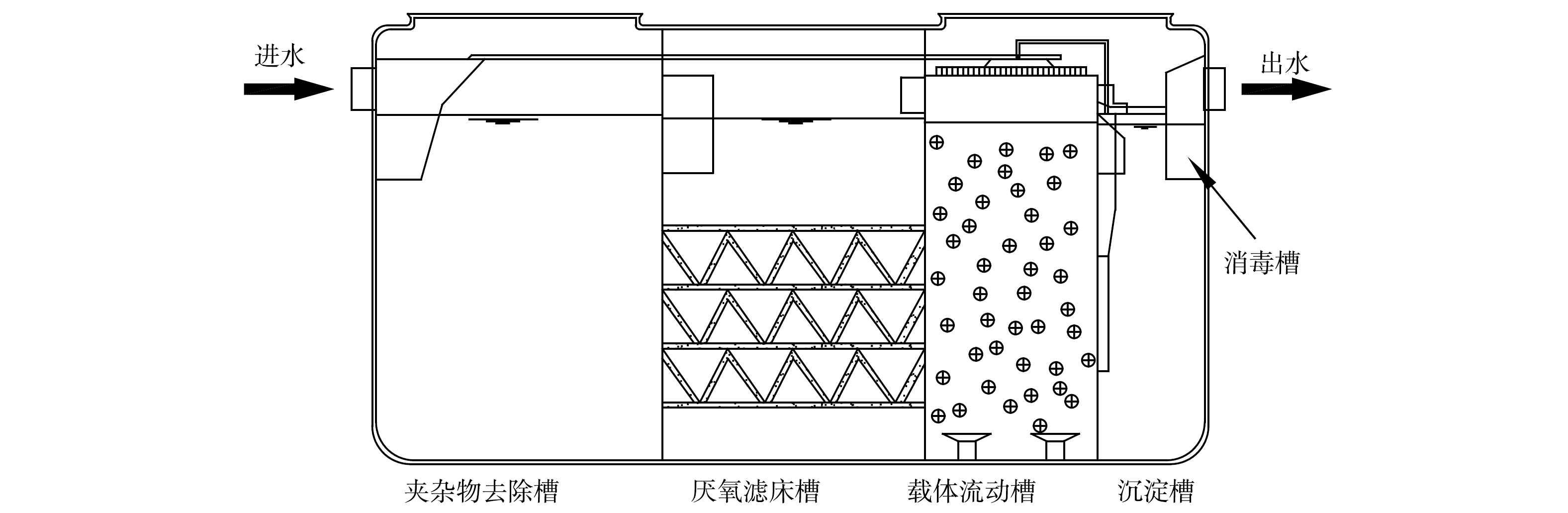

实验装置由A/O工艺模型和FO污泥破解装置2部分组成(见图1)。在A/O模型中,缺氧池、好氧池和二沉池有效容积分别为4.3、16.4和11.7 L,缺氧池设搅拌器,以确保泥水均匀混合,好氧池底部设置曝气砂头。FO污泥破解装置同时具备污泥破解和沉淀2个功能,沉淀完成后,调节上清液pH,上清液经蠕动泵进入进水箱,与污水混合后一同进入A/O工艺模型。

-

实验所用污泥取自天津市北辰区某污水厂,该厂采用A2/O工艺处理生活污水且运行效果良好。工艺进水为模拟生活污水,模拟生活污水由自来水添加葡萄糖、氯化铵、磷酸二氢钾及微量元素[5]配制而成,其水质指标为:COD=223.33 mg·L−1,BOD5=126.90 mg·L−1,TN=30.04 mg·L−1,

NH+4 -N=29.17 mg·L−1,NO−3 -N=0.18 mg·L−1,NO−2 -N=0.09 mg·L−1,TP=3.31 mg·L−1,pH=6.0~7.5。 -

CFS为实验室自制,其中

FeO2−4 浓度为30.91 g·L−1,ClO−浓度为38.63 g·L−1,OH−浓度为90.27 g·L−1,其他所用化学药品均为国产分析纯。 -

将活性污泥接种至A/O工艺模型启动装置,待出水C、N达到一级A标准后调试完成,A/O模型运行参数为进水流量48 L·d−1、好氧区水力停留时间8.3 h、缺氧区水力停留时间2.1 h,污泥龄15 d、污泥回流比70%、消化液回流比200%、硝化液回流比200%、好氧池溶解氧3.5~7.0 mg·L−1、缺氧池溶解氧0.2~0.5 mg·L−1。

实验装置的运行分为A/O阶段(对照组)和FO-A/O阶段,FO-A/O阶段又分为3种工况,3种工况下剩余污泥破解回流比(r)分别为25%、50%、100%,其中剩余污泥破解回流比指每日被CFS破解的剩余污泥与系统排出剩余污泥干重之比。破解剩余污泥时CFS投加量按50 mg·g−1(以Fe6+计)投加,反应时间为24 h。

本研究采用污泥产率系数(YOBS)表征系统运行过程中污泥产率的变化,采用比好氧速率(SOUR)表征污泥活性的变化,二者的计算如式(1)和式(2)所示。

式中:YOBS为污泥产率系数,g·g−1;QW为剩余污泥量,L·d−1;Q为进水量,L·d−1;XW为剩余污泥浓度,mg·L−1;Xe为出水悬浮物浓度,mg·L−1;S0为进水SCOD浓度,mg·L−1;Se为出水SCOD浓度,mg·L−1;U0为污泥比耗氧速率,mg·(g·h)−1;ΔmDO为DO减少量,mg·L−1;X为混合液SS浓度,g·L−1;t为测试时间,h。

-

MLSS、MLVSS、SVI、SS均采用重量法测定,COD采用快速消解法、

NH+4 -N、TP、TN、NO−3 、NO−2 均采用分光光度法[15]测定,水质指标测定前使用0.45 μm微孔滤膜过滤;SOUR采用膜电极法[16]测定。 -

实验研究了在污泥破解回流比r分别为25%、50%和100%时的FO-A/O工艺的污泥产率系数,分析了污泥破解回流比对污泥减量效果的影响,结果如图2所示。可以看出,污泥产率系数YOBS随着r的增加而明显降低。r=100%时,YOBS=0.04 g·g−1,与A/O对照组(YOBS=0.09 g·g−1)相比减少了55.56%。这是由于在FO-A/O运行过程中产生的部分剩余污泥被CFS溶胞破解,CFS中所含

FeO2−4 、ClO−以及OH−通过氧化[17-18]、皂化[19]的方式破坏污泥细胞,释放出胞内物质,并将难溶的大分子有机物转为容易被微生物所摄取利用的小分子有机物,最终作为碳源被重新利用,从而导致YOBS的降低。当r=50%时,YOBS=0.048 g·g−1,污泥产量较A/O工艺减量46%,该工艺的污泥产率系数低于臭氧+A2/O工艺(YOBS=0.1 g·g−1)和K2FeO4+A2/O工艺(YOBS=0.21 g·g−1)。 -

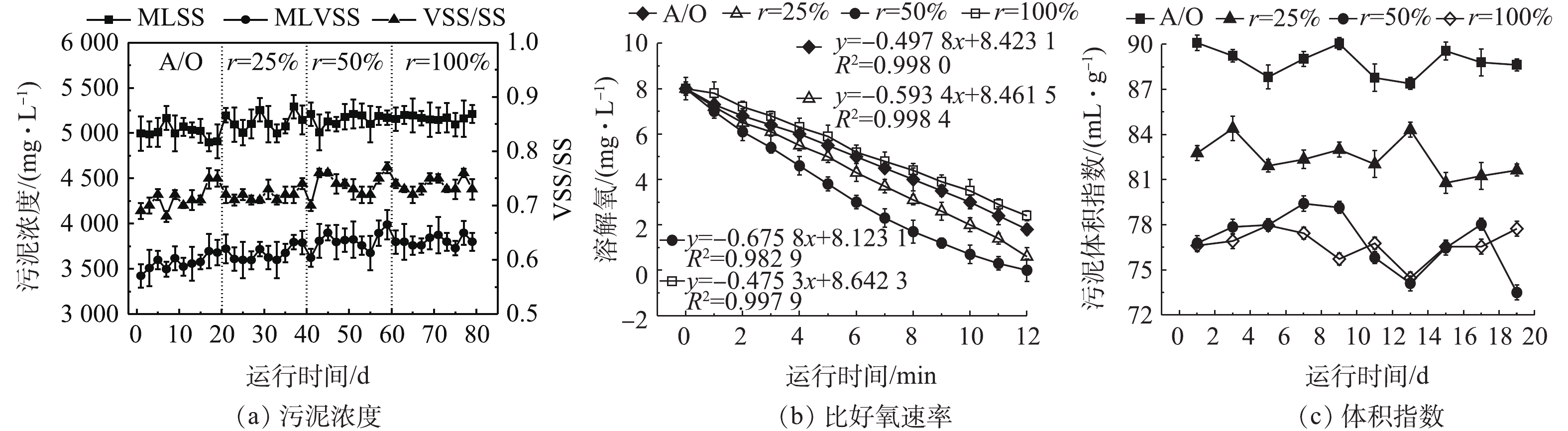

污泥破解液回流至A/O系统引入Fe3+,可能会对污泥性能产生影响,因此,本研究探讨了不同剩余污泥破解回流比对A/O工艺中污泥浓度、污泥活性和污泥沉降性能的影响,结果见图3。由图3(a)可知:随着r的升高,污泥浓度逐渐升高,这是由于污泥破解液中含有易降解有机物;随着r的增加,易降解有机物增加,导致微生物数量增加,从而使得污泥浓度有所增加。另外,工艺运行过程中,VSS/SS变化幅度不大,维持在0.74左右,表明破解液回流不会造成系统内惰性物质的积累。

实验进一步研究了污泥破解液对污泥活性的影响,结果见图3(b),SOUR的计算方法见式(2)。由图3(b)可知,当r为25%和50%时,SOUR分别为7.21 mg·(g·h)−1和7.77 mg·(g·h)−1,均较对照组(6.2 mg·(g·h)−1)有所提高;当r增加至100%,SOUR有所下降。分析其原因是:一方面,由于在r为25%和50%时,适量的Fe3+进入A/O系统,好氧条件下,Fe3+可以作为氧化细胞色素的电子受体,也可以用于多种酶的合成,但过高浓度的Fe3+会对某些酶的活性产生抑制作用[20];另一方面,破解液中含有腐殖酸等难被微生物降解利用的物质,微生物对此类物质降解速率慢,降解速率决定微生物对水中DO的摄取量,随着此类物质的增加,对DO的摄取量减少,SOUR降低。回流的Fe3+除对SOUR产生影响外,还有助于污泥沉降性能的提高,结果见图3(c)。从图3(c)可以看出,随着r的增加,SVI逐渐减小,这源于破解液中Fe3+的絮凝作用,其改变了污泥絮体的大小和结构,强化了污泥密度与水密度之间的差异,使MLSS增大,进而导致SVI减小,改善污泥沉降性能,从而有利于后续污泥脱水处理。但当r=100%时,污泥沉降性能较r=50%时变化不大,这可能是由于此时污泥活性降低所致。

-

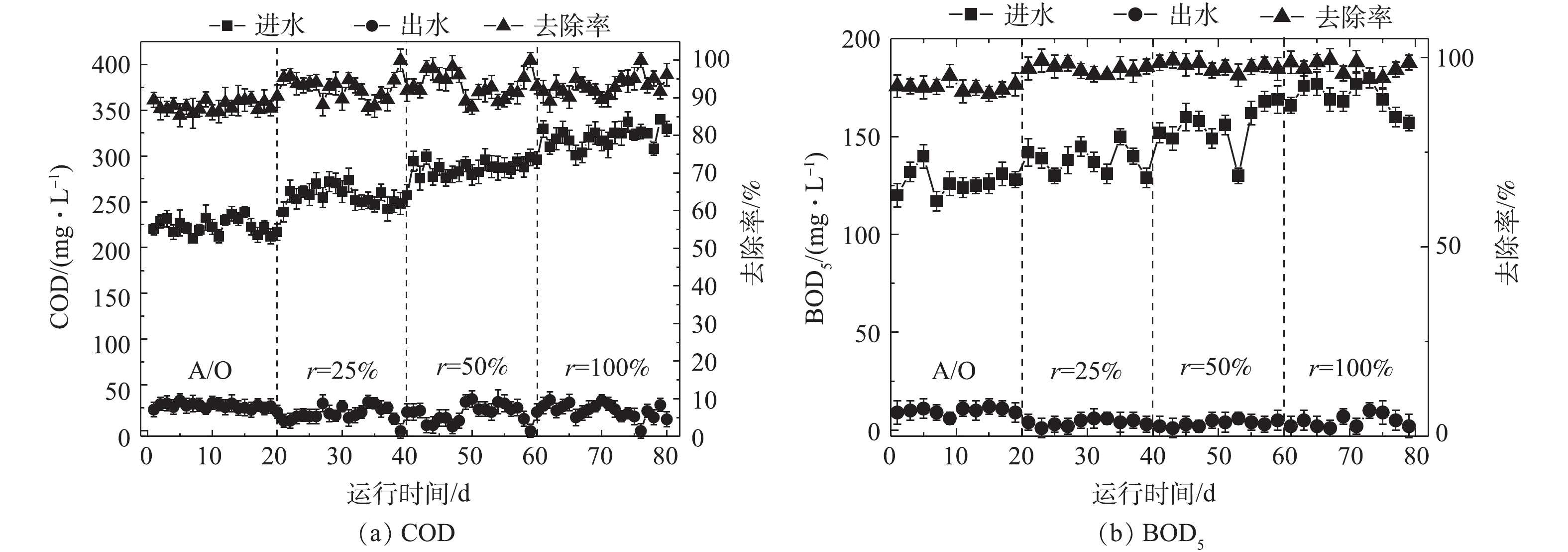

1)对有机物的去除效果。COD与BOD5为常用的有机污染参数,实验通过测量进出水COD与BOD5的变化来研究有机物的去除效果,结果如图4所示。可以看出,尽管进水COD、BOD5随着r的提高有所增加,但出水COD与BOD5浓度与A/O对照组相比基本保持恒定,均能达到《城镇污水处理场污染物排放标准》一级A标准排放要求。这表明污泥破解液具有良好的可生化性,微生物能够较好地适应并降解破解液回流引入的有机物。此外,在A/O对照组和FO-A/O工艺运行过程中,污泥负荷(F/M)均低于0.15 kg·(kg·d)−1,处于低负荷状态运行,低负荷状态下微生物对COD和BOD5的去除率较高。

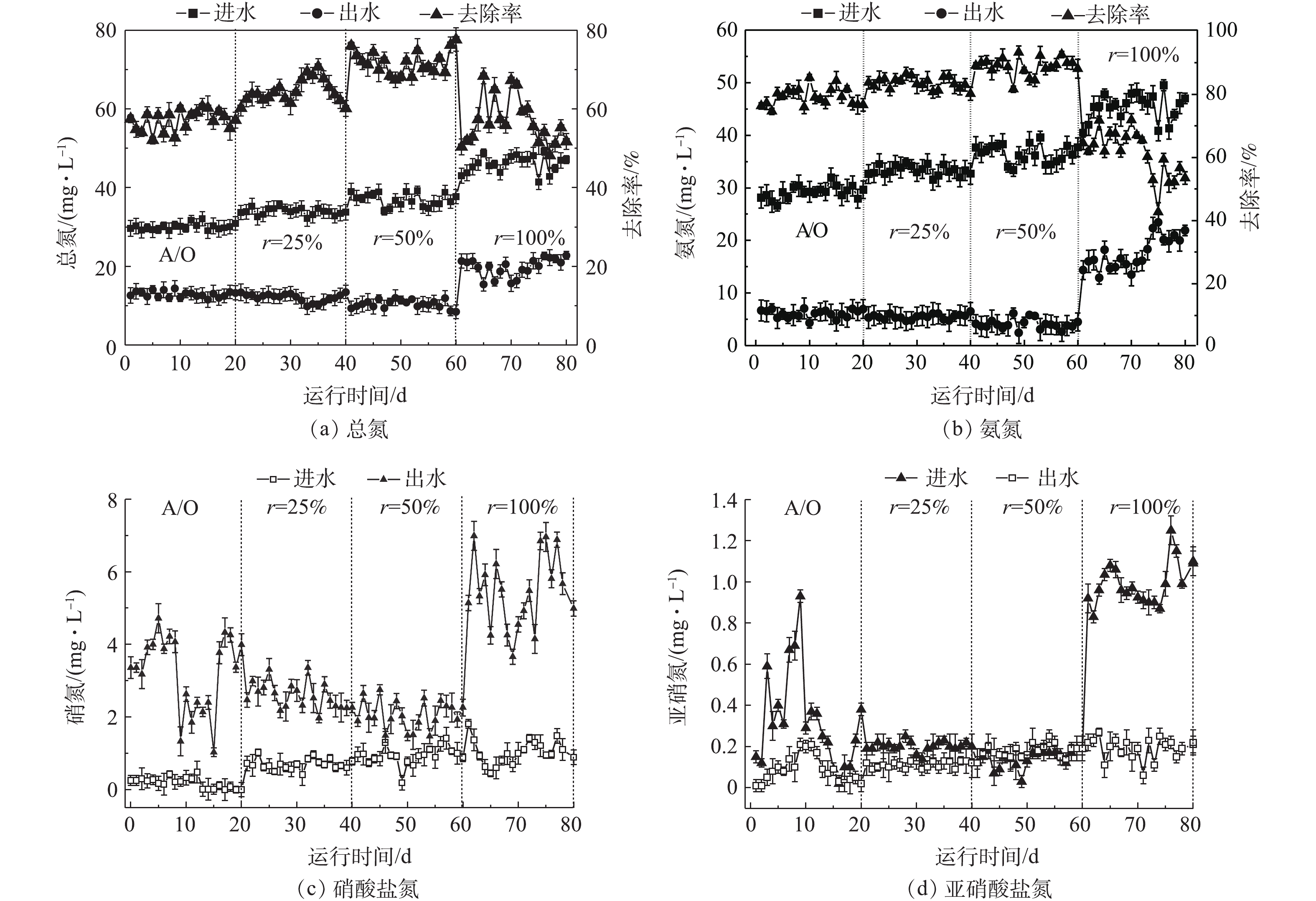

2) FO-A/O工艺的脱氮效果。氮是导致水体富营养化的主要元素,也是污水厂深度处理的主要目标物,实验详细研究了污泥破解液作为碳源时FO-A/O工艺对不同形态氮的去除效果,结果见图5。由图5(a)~(d)可见,随着r的提高,破解液中大量氮元素进入A/O系统,导致系统氮负荷增加。但在r=25%和50%工况时,FO-A/O系统对TN、

NH+4 -N的脱除效果均优于A/O对照组,由图5(c)和图5(d)可见,出水NO3-N、NO2-N相比A/O对照组也有所降低,这表明在r为25%和50%时,硝化反硝化效率均有所提高。一方面,这是由于破解液回流改善了系统的C/N比,A/O对照组、r=25%和r=50%时的C/N分别为7.44、7.56和7.79,碳氮比增加为反硝化反应提供了更多的碳源;另一方面,Fe3+作为一种酶促反应激活剂,提高了微生物体内酶的反应效率[21],对硝化和反硝化反应均有一定促进作用。继续增加r至100%时,氮负荷进一步增大,C/N降低,脱氮效果较A/O对照组下降。从FO-A/O工艺运行监测结果可以看出,r的取值对脱氮效果有明显影响,r=50%时,TN的去除率为68.36%~77.59%。该结果优于臭氧+A2/O工艺和K2FeO4+A2/O工艺,与碱解发酵+A2/O和机械法+SBR工艺效果基本相当。由此可见,确定合理的剩余污泥破解回流比是实现污泥减量同步强化脱氮的关键。为了进一步证实不同剩余污泥破解回流比下破解液作为补充碳源对反硝化脱氮的强化作用,对进出系统的碳、氮进行物料衡算,其中剩余污泥中的COD、TN含量按0.80 g·g−1和0.07 g·g−1[22]计算,衡算的结果如表1所示。可以看出,随着r的增加,碳矿化率逐渐提高,r=100%时,矿化率为93.13%;对氮而言,在A/O对照组及r=25%、r=50%时,随着r的增加,矿化率增大,r=50%时,氮矿化率为71.07%,继续增大r至100%,矿化率虽有所降低,但仍高于对照组。另外,由于剩余污泥的破解回流,随剩余污泥排出系统的碳和氮减少。以上计算结果表明,氮矿化率的提高与碳的矿化率相关,证实了污泥破解液回流引入的有机物被反硝化菌利用,起到强化系统脱氮的作用。

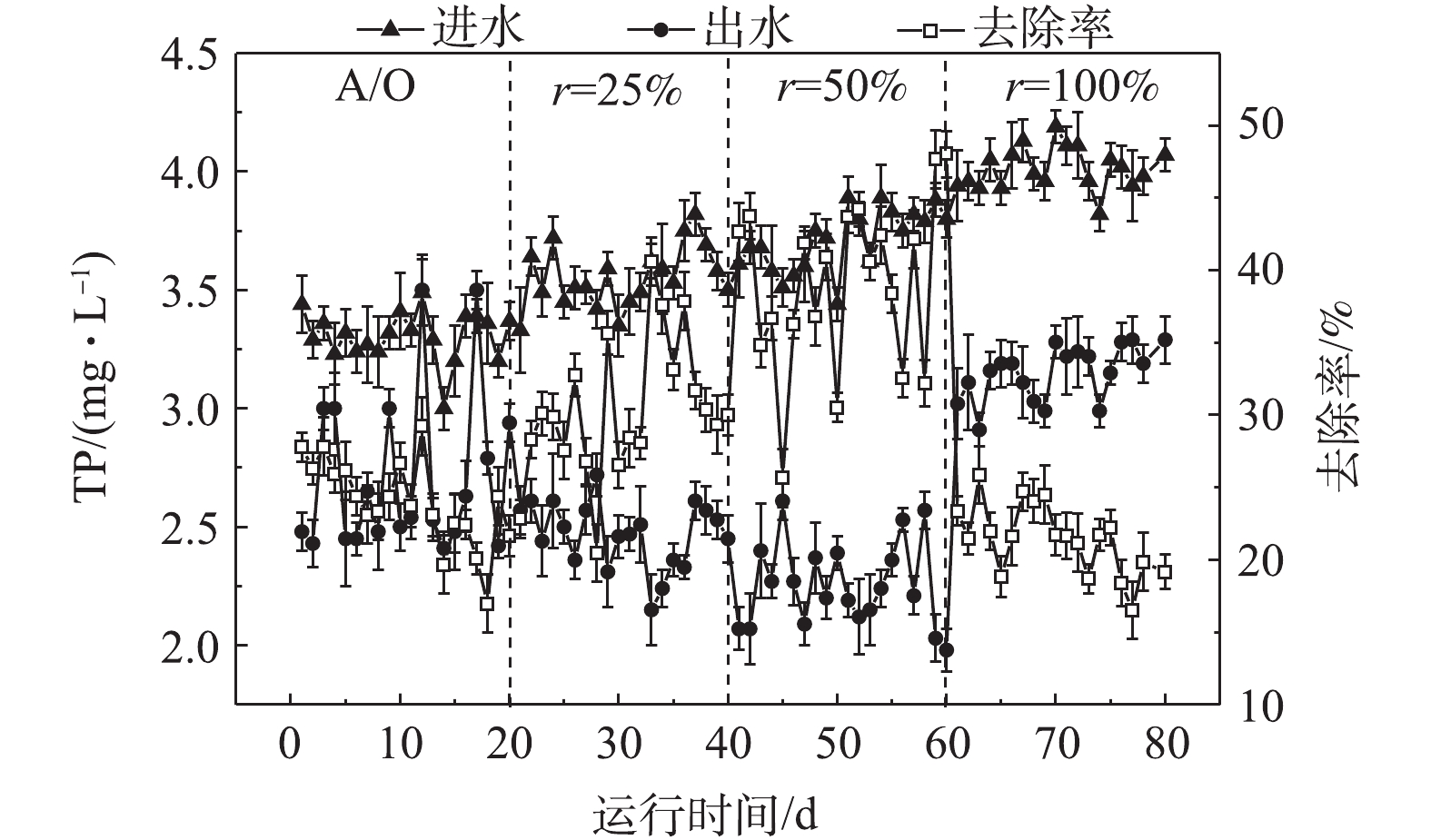

3)进出水TP浓度变化。由于CFS含有大量Fe6+,Fe6+在破解污泥过程中被还原为Fe3+,而Fe3+可以通过混凝、沉淀等方式去除水中的磷[23-24],为了明确这部分Fe3+对TP的影响,在实验中监测了进出水TP的变化规律,如图6所示。可以看出,r为25%和50%工况时,进水TP负荷稍有提高,但污泥破解液回流增加了进水碳源,使得污泥活性提高(图3(b)结果),同时引入Fe3+,2种作用同时作用使得TP去除率上升。而当r=100%时,系统对磷的去除效果急剧恶化,出水TP浓度高于A/O对照组。这是由于r=100%时,全部剩余污泥被溶胞破解回流,系统进水TP负荷升高,同时污泥活性大幅度降低(图3(b)),使得磷在系统中累积[25],从而使得出水TP浓度升高,出水水质恶化。在最佳回流比条件下,对TP的平均去除率为39.09%,高于K2FeO4+A2/O工艺的32%。

-

运行维修费用在工艺处理系统中占有重要地位,包括药剂费、人工费、电费、维修费及污泥处理费用。本研究在A/O工艺的基础上增加了CFS的费用,1 t污泥需要投加Fe6+ 0.40 kg,其药剂成本约为169元·t−1,相同药剂投加量下市售固体K2FeO4的药剂成本为9 900元·t−1(市售1 400元·kg−1,纯度约20%),同时由于污泥减量46%,因此,减少了后续46%的污泥处理费用(污泥填埋费用约为200元·t−1,污泥焚烧约为100~300元·t−1,污泥堆肥为90~150元·t−1),由此可见,此方法有一定的应用前景。

-

1)在传统A/O工艺基础上,增加FO污泥减量装置可以取得良好的污泥减量效果,在r=50%时,YOBS=0.048 g·g−1,相比A/O工艺,污泥减量了46%,此时出水COD、TN、

NH+4 -N分别为18.83、10.43和4.05 mg·L−1,达到《城镇污水处理场污染物排放标准》一级A标准排放要求。该工艺中药剂制备成本低于固体K2FeO4,且减少了后续污泥处置量,具有一定的应用前景。2)破解液污泥回流增加了进水SCOD值,导致微生物量增加,污泥浓度提高,但不会造成系统内惰性物质积累。回流引入的Fe3+可改善污泥沉降性,且适量的Fe3+可作为电子受体,也可用于细胞内多种酶的合成,促进污泥活性,但过多Fe3+则会产生毒害作用,导致污泥活性降低。

3)污泥破解液回流可提高系统C/N比,且C、N物料衡算结果表明,污泥碳源可被反硝化菌有效利用,起到强化脱氮的效果,且回流的Fe3+对硝化、反硝化反应和除磷均有一定的促进作用,但r=100%回流会导致C/N比降低,脱氮、除磷效果降低。

高铁酸盐氧化-A/O工艺污泥减量及强化脱氮

Sludge reduction and enhanced nitrogen removal in ferrate oxidation-A/O process

-

摘要: 为了减少传统生物处理工艺剩余污泥排放量及强化脱氮效果,设计了高铁酸盐氧化-A/O工艺。以模拟生活污水为处理对象,研究对比了破解后不同回流比对高铁酸盐氧化-A/O工艺的污泥减量和强化脱氮效果的影响,并对出水水质和污泥性能进行了综合评价。实验结果表明:剩余污泥破解回流比r为50%时,污泥产率系数YOBS为0.05 g·g−1,剩余污泥量减少最多,为46%;高铁酸盐氧化-A/O工艺对TN和

NH+4 -N去除率分别达到71.7%和88.8%,CFS污泥破解液具有较好的可生化性,可被反硝化菌有效利用,脱氮效果明显提高;该运行工况下,污泥浓度、污泥活性均有所提高,污泥沉降性得到改善。此外,污泥破解液引入系统的Fe3+可在一定程度上提高了TP的去除率。高铁酸盐氧化-A/O工艺能够提高污染物去除率,实现污泥减量同步强化脱氮的目的。-

关键词:

- 反硝化碳源 /

- 污泥减量 /

- 脱氮 /

- 高铁酸盐氧化-A/O工艺

Abstract: The A/O process coupled with composite ferrate oxidation (i.e. FO-A/O process) was designed to reduce waste activated sludge (WAS) and enhance nitrogen removal. The experiments were conducted for the simulated domestic sewage treatment. The effects of the reflux ratios of disintegrated sludge on sludge reduction and denitrification enhancement in FO-A/O process were investigated and compared. Meanwhile, a comprehensive assessment on the effluent quality and sludge properties was performed. The results showed that sludge yield coefficient (YOBS) was 0.05 g·g−1, the most reduction for WAS occurred with a value of 46% at the disintegrated sludge reflux ratio of 50%, and the removal rates of TN andNH+4 -N reached 71.7% and 88.8%, respectively. The disintegrated sludge supernatant had good biodegradability, which could be effectively utilized as carbon source by denitrifying bacteria and improve the rate of nitrogen removal. Under this operation condition, the sludge concentration (MLSS and MLVSS) and sludge activity (SOUR) increased, and the sludge settleability was ameliorated as well. In addition, the iron induced by WAS disintegrated supernatant improved TP removal to some degree. In summary, the FO-A/O process could effectively improve the removal rate of pollutants and realize the purpose of simultaneous intensified denitrification and sludge reduction. -

已有研究[1-2]表明,生活污水中包含一定量的潜在致病微生物(大肠埃希氏菌、沙门氏菌、志贺氏菌等)。因此,在污水处理系统末端需增加消毒,处理达标之后方可排放。近2年,随着新冠疫情的全球肆虐,不同层面的生物安全问题受到了广泛关注。我国于2021年4月15日起全面实施《生物安全法》,标志着我国生物安全问题进入了依法治理的新阶段[3]。目前,我国现行城市污水生物处理过程中已全部覆盖消毒工艺。但是,对于卫生设施相对薄弱的农村地区,污水中潜在致病微生物的分布、相应污水处理设施的消毒效果等仍存在认识不清、运维不稳等问题,从而对农村地区居民身体健康及区域生态安全造成了极大的潜在风险。

截至2020年,全国共有约5.1亿农村人口,占全国总人口的36%,生活污水排放量很大,而目前针对已有农村污水处理设施的监测重点仍然为COD、NH3-N、TP等基础水质排放控制指标[4-5]。农村生活污水主要来源于厨房污水、生活洗涤污水和冲厕水等,其具有分散性强、水质水量变化大等特点;同时,我国农村区域相对城市而言,经济水平比较低。因此,成本低廉、高度集成、占地面积较小、施工工程量小、运行维护简便的小型化、装备化污水处理设施在农村地区得到广泛应用,净化槽即是其中一种[6-10]。基于其在单户或联用处理中的优势,目前净化槽已经在上海、江苏、云南、山东、黑龙江等地多数农村投入实际使用[11]。调研发现,目前市场上销售的净化槽在工艺单元是配有消毒设施的。但在实际运用中,由于消毒工艺投入成本高,投入的化学消毒试剂如次氯酸钠等在维护不当时可能会造成泄露而引起二次污染,因此,大部分农村地区一体化污水处理设备的消毒设施处于闲置状态,农村污水处理后,未经消毒就直接排放[10]。基于以上研究现状,本研究选取江苏省常熟市虞山街道(N 120°40′48″,E 31°40′48″)处理量为1 m3·d−1的一体化污水处理设施,解析不同工段潜在致病微生物的分布特征,为后续村镇小型污水处理设施运行过程中的健康风险评估研究提供参考。

1. 材料与方法

1.1 设备简介

本研究选择江苏省常熟市虞山街道(N 120°4′48″,E 31°40′48″)处理量为1 m3·d−1的一体化污水净化槽(HJA-10,江苏中车环保设备有限公司;长×宽×高=2 190 mm×1 120 mm×1 550 mm)进行研究。净化槽采用A/O处理工艺,主要由夹杂物去除槽-厌氧滤床槽-载体流动槽-沉淀槽-消毒槽处理单元组成(图1)。其中厌氧滤床槽采用PE滤料,载体流动槽即为加有曝气设施和圆球状填料的生物处理单元,消毒槽设定为添加三氯异氰尿酸消毒剂消毒。该村现有农户370多户,共计1 500余人,其中青年人(非假期外出务工、上学等)和老年人(长期在当地居住)的占比分别为60%和40%。净化槽主要收集处理村民家中排放的生活污水(厨房洗涤废水、洗漱用水、马桶废水等),实际运行时,槽中污水依次经过夹杂物去除槽、厌氧滤床槽、载体流动槽和沉淀槽,载体流动槽出水处设有回流管,向夹杂物去除槽回流。

1.2 样品采集

样品按照《水质采样技术指导》( HJ 494-2009 ) 和《水质采样样品的保存和管理技术规定》( HJ 493-2009 ) 要求[12-13],分别从净化槽进水口(A1)、夹杂物去除槽(A2)、厌氧滤床槽(A3)、载体流动槽(A4)、沉淀槽(A5)、出水口处(A6)、出水受纳水体(A7),各采集1 L水样。采样容器材质为聚乙烯,容器采样前均进行灭菌处理,以满足采样需要。水样分别采集于夹杂物去除槽液面下0.8 m,厌氧滤床槽、载体流动槽、沉淀槽液面下0.3 m。各处理单元所采样品分成2份:1份于4 ℃保存,用于理化指标测定;另1份存于−20 ℃,用于微生物多样性分析。

1.3 理化指标测定

采用重铬酸钾法(HJ 828-2017)测定COD值[14];采用纳氏试剂分光光度法(HJ 535-2009)测定NH3-N浓度[15];采用哈希法测定TN浓度;采用重量法(GB 11901-1989)测定SS浓度[16]。

1.4 16S rDNA高通量测序

利用引物338F(5'-ACTCCTACGGGAGGCAGCAG-3')和806R(5'-GGACTACHVGGGTWTCTAAT-3')对 16S rRNA基因V3~V4 可变区进行 PCR 扩增[17-18],产物纯化定量后通过Illumina Miseq平台进行测序。使用UPARSE软件,根据97%的相似度对序列进行聚类并剔除嵌合体,然后利用RDP classifier对每条序列进行物种分类注释,比对数据库,设置比对阈值为70%,最终生成操作分类单元(operational taxonomic unit,OTU) [19-21]。利用mothur进行微生物群落的α多样性分析,计算参数分别为Ace、Chao1、Shannon和Simpson指数。Ace和Chao1指数反映微生物种群丰度,其值越高表明微生物丰度越高;Shannon和Simpson指数反映微生物种群多样性,高Shannon指数和低Simpson指数代表高多样性,其数值受样品群落中丰度和物种均匀度的影响[22]。多样性指数根据式(1)~式(3)计算[23]。

SChao1=Sobs+n1(n1−1)2(n2+1) (1) 式中:SChao1表示估计的OTU数;Sobs表示实际测得OTU数;n1表示只含1条序列的OTU数;n2表示只含2条序列的OTU数。

DSimpson=Sobs∑i=1ni(ni−1)N(N−1) (2) 式中:Sobs表示实际测得OTU数;ni表示第i个OTU所含序列数;N表示所有序列数。

HShannon=−Sobs∑i=1niNlnniN (3) 式中:Sobs表示实际测得OTU数;ni表示第i个OTU所含序列数;N表示所有序列数。

2. 结果与讨论

2.1 一体化污水净化槽运行效果

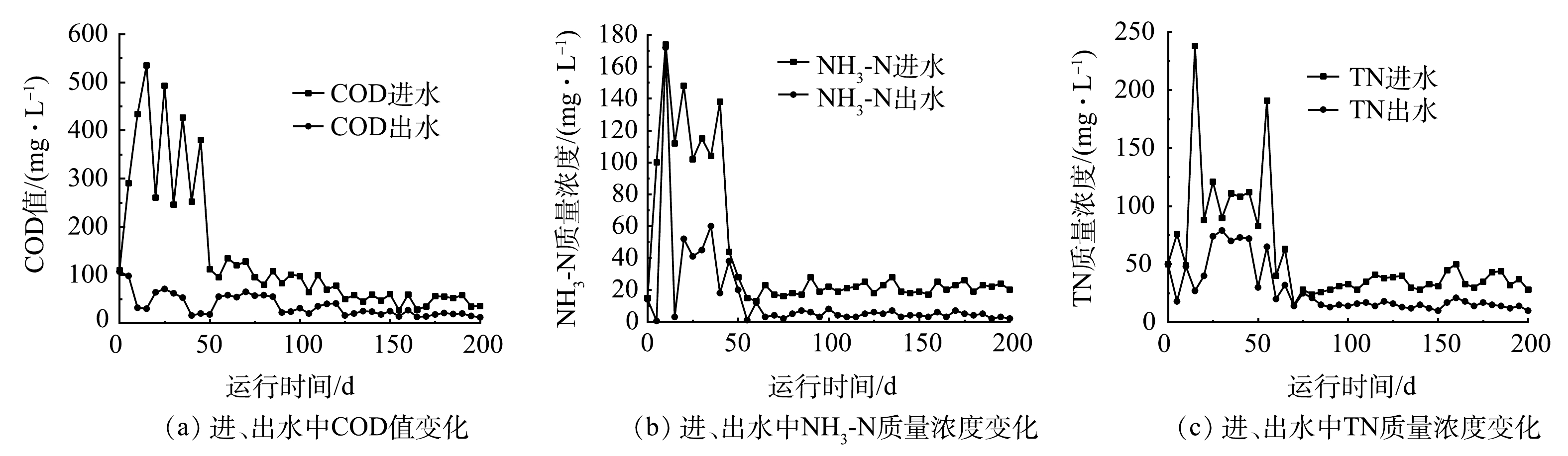

对首次投入使用的一体化污水净化槽进行长期连续进出水水质监测,时间为200 d。结果如图2所示。运行期内,设备进水中COD值为27~537 mg·L−1,NH3-N和TN的质量浓度分别为13~174 mg·L−1和15~238 mg·L−1。50 d内,设备运行处于启动状态,COD去除效果较好, NH3-N和TN去除波动较大。随着设备的运行,在50 d后,其出水COD值稳定在(35.5±22.5) mg·L−1,NH3-N和TN的质量浓度稳定在(5±3) mg·L−1和(22±10) mg·L−1,表明该设备出水水质达到了《农村生活污水处理设施水污染物排放标准》(DB 32/ 3462-2020)[24]。

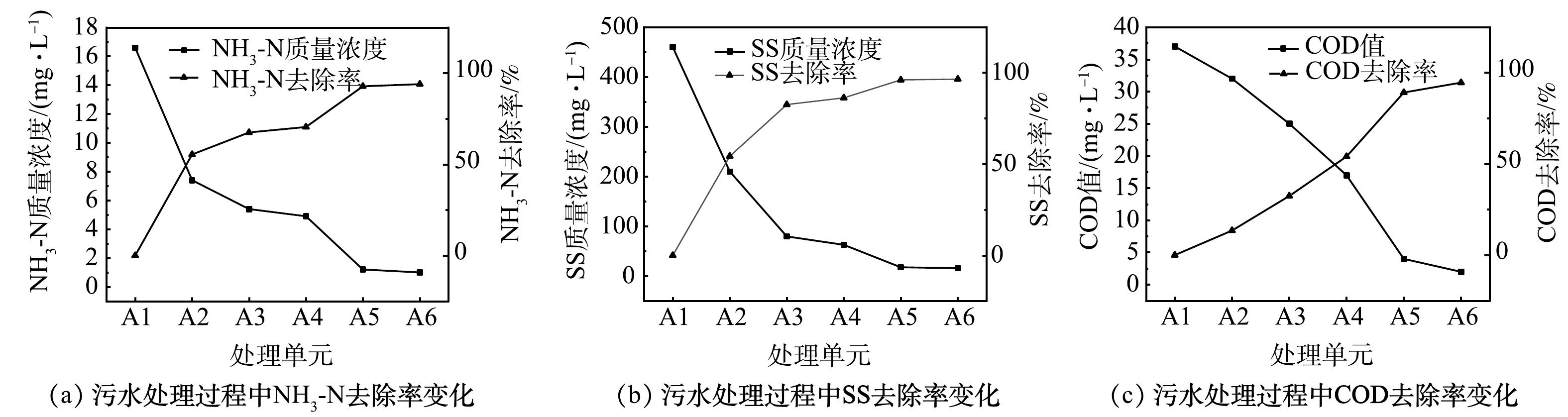

在装置运行约100 d后,考察不同工段污水中NH3-N、SS质量浓度和COD值的沿程变化,结果如图3所示。沿设备运行工段流程,NH3-N、SS质量浓度和COD值均呈逐步下降趋势,NH3-N在A2、A3、A4、A5、A6单元的去除率分别为55.42%、67.47%、70.48%、92.77%、93.98%;SS在A2、A3、A4、A5、A6单元的去除率分别为54.35%、82.61%、86.30%、96.09%、96.52%;COD在A2、A3、A4、A5、A6单元的去除率分别为13.50%、32.43%、54.46%、89.19%、94.59%。以上结果表明,该设备处于长期稳定运行状态,并且不同处理单元对污染物的去除率有所不同。

2.2 一体化污水净化槽各处理单元中微生物群落多样性

采用高通量测序分别对不同处理单元中样本进行了细菌多样性分析,其中Ace和Chao1指数用来表征不同处理单元微生物种群丰度,Shannon和Simpson指数用来表征微生物种群多样性,具体结果如表1所示。由表1可以看出,A3单元Chao1和Ace值最高,分别为2 404.32和2 396.72;Shannon指数最高、Simpson指数最低,分别为5.49和0.01。在该设备中,A3单元中细菌不仅丰度最高,而且多样性也是最高的。这可能与本设备中污水的流程有密切的关系,污水经夹杂物去除槽后,首先进入厌氧滤床槽。因此,该单元有机物更为丰富,异养微生物快速繁殖,从而导致该单元细菌种类及丰度均相对较高。这一结果与前人研究结果存在一定的差异。黄潇等[22]发现,当采用多级A/O工艺处理城市污水时,最高的Shannon和Simpson指数出现在第2好氧区,这可能与工艺流程和污水来源的差异有关。

表 1 不同处理单元微生物群落丰度和多样性Table 1. Microbial community abundance and diversity in different treatment units处理单元 Ace Chao1 覆盖率/% Shannon Simpson A1 1 252.21 1 025.01 99.30 2.25 0.26 A2 1 986.92 1 965.48 98.93 4.13 0.15 A3 2 396.72 2 404.32 98.75 5.49 0.01 A4 2 260.19 2 221.75 98.95 5.01 0.02 A5 1 910.35 1 841.82 99.16 4.92 0.02 A6 2 029.49 1 981.27 98.68 5.06 0.03 2.3 一体化污水净化槽各处理单元中的种群结构

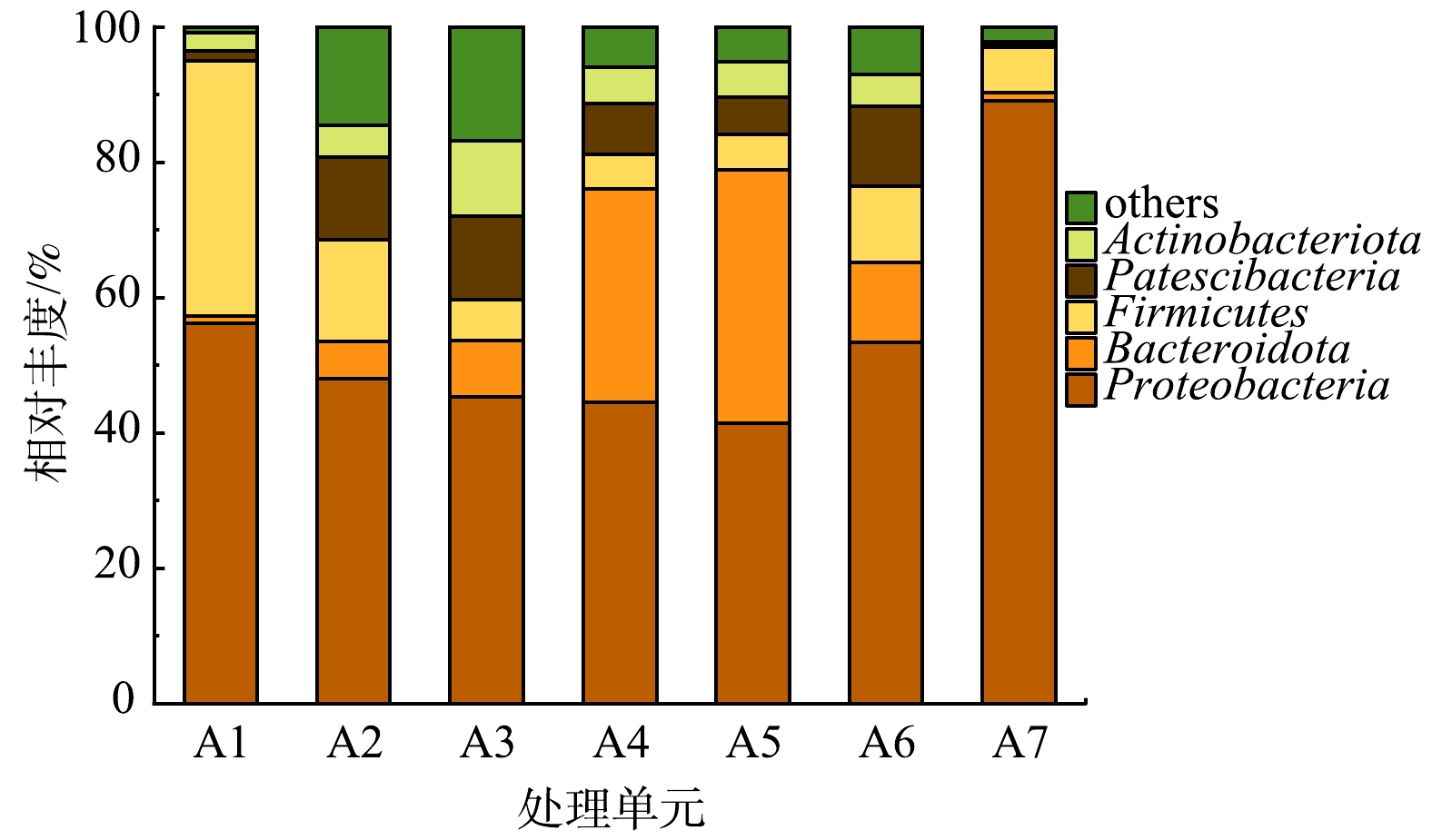

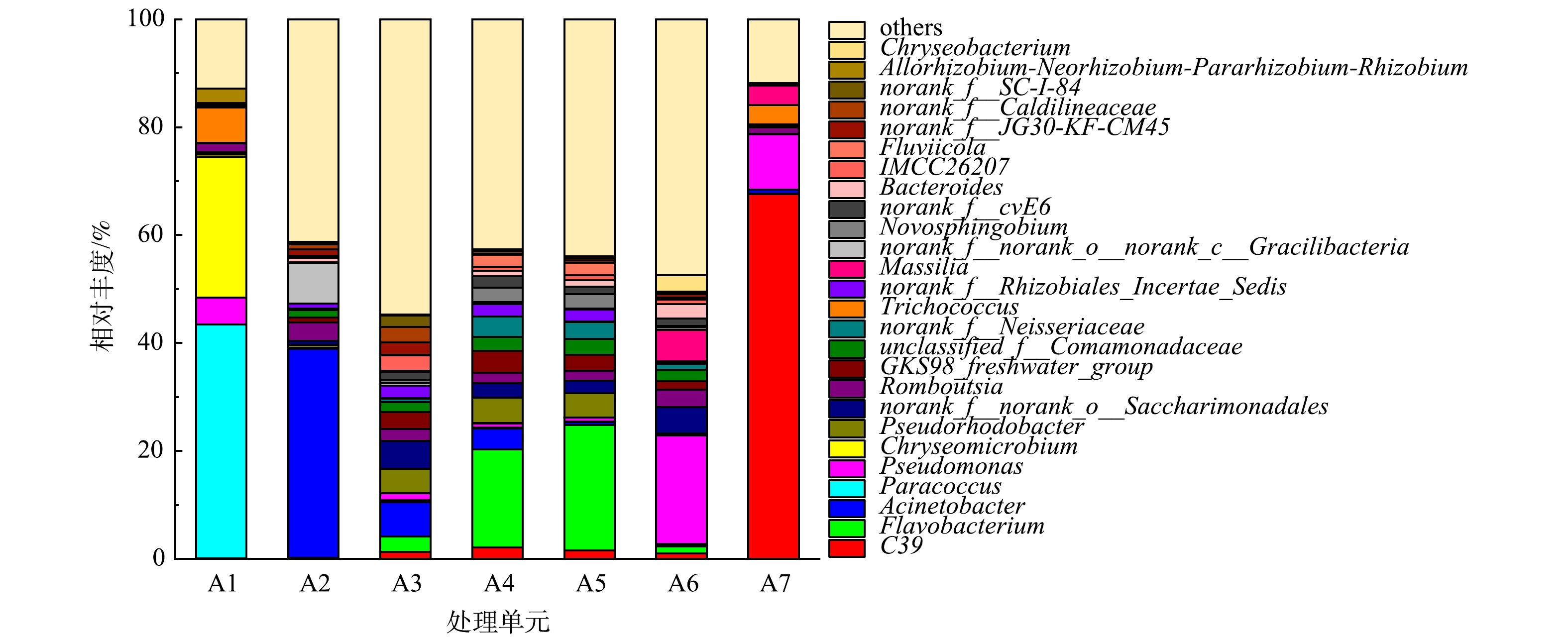

进一步分析受纳水体和设备运行稳定状态下不同单元中细菌种群结构特征,其差异如图4所示。在门水平上,进水中Proteobacteria和Firmicutes是优势菌门,其相对丰度分别为56.21%和37.65%。随着污水流经各处理单元,这2个菌门虽然仍然处于优势地位,但其相对丰度却逐步下降。由图4可见,由A2到A5,Proteobacteria相对丰度分别为48.00%、45.33%、44.58%和41.47%。Proteobacteria在各单元中检测片段数基本不变,在A2~A5单元相对丰度降低是由于各单元其他菌门种类和丰度的增加。由A2到A5,Firmicutes相对丰度分别为15.04%、6.14%、5.21%和5.27%。A2单元Firmicutes相对丰度下降主要是由其门下Chryseomicrobium属相对丰度急降所导致;在A3~A5单元,Firmicutes所测片段数基本不变,其相对丰度变小是由各单元其他菌门种类和丰度的增加所导致。在出水中,检测到的细菌总片段变少,导致Proteobacteria相对丰度增高,此时Firmicutes门下梭菌纲丰度上升是导致Firmicutes相对丰度上升的主要原因,梭菌纲适合在氧气浓度相对较低的出水中繁殖。同时,图4中的结果也表明,进水中Bacteroidota相对丰度较低,为1.08%,但在各单元中Bacteroidota相对丰度呈现逐步升高趋势,尤其是在A4和A5单元,其相对丰度分别可达31.43%和37.42%,这与已有研究结果基本一致 [25-26]。Bacteroidota相对丰度变化主要由其门下Flavobacterium属相对丰度变化引起,Flavobacterium是一种好氧反硝化细菌,适合在含氮物质和氧气含量充足的环境中生存。 本研究中,净化槽消毒单元处于关闭状态,因此,出水中检出的细菌多样性也较高,Proteobacteria仍是优势菌门,其相对丰度为53.41%,Firmicutes、Bacteroidota、Patescibacteria、Actinobacteriota的相对丰度也分别达到了11.31%、11.73%、11.86%、4.68%。与净化槽出水相似,排水口处受纳水体中Proteobacteria也是优势菌门,相对丰度为89.09%,且Patescibacteria、Actinobacteriota相对丰度则显著降低,这可能是由受纳水体中微生物相互作用导致的。

为了更加准确地反映净化槽不同单元和受纳水体中细菌的组成,对所选样本中细菌种群特征进行了属水平上的分析。结果如图5所示,进水中细菌种群相对简单,其中优势菌属为Paracoccus(43.31%)、Chryseomicrobium(26.00%)、Trichococcus(6.60%)和Pseudomonas(5.00%)。同样在有夹杂物的去除槽内,其细菌种群相对也较为简单,不同之处在于其优势菌属发生了明显变化,分别为Acinetobacter(38.70%)、norank_f__norank_o__norank_c__Gracilibacteria(7.54%)和Romboutsia(3.48%)。其原因可能是,在物理去除污水中较大颗粒物的同时,附着在颗粒物上的细菌也一并被去除,从而导致其优势菌属种类发生了变化。与其形成明显对比的是,A3、A4、A5单元中细菌菌属多样性明显增加,并且该3个单元中细菌相似性明显升高。除无法鉴定种类的others之外,A3单元中主要细菌菌属分别为Acinetobacter(6.38%)、norank_f__norank_o__Saccharimonadales(5.11%)、Pseudorhodobacter(4.52%)、Flavobacterium(2.85%)、Pseudomonas(1.29%)等。在A4、A5单元里,这些细菌菌属种类并未发生明显变化,但其相对丰度呈现一定差异。在A3、A4、A5单元中,Flavobacterium相对丰度呈现逐步上升趋势,分别为2.85%、18.12%、23.19%。Flavobacterium是活性污泥工艺的常见的好氧反硝化菌[27],适合在含氮物质和氧气含量充足的A4、A5单元中生存,A3单元的厌氧环境并不适合其生存。在A3、A4、A5单元中,Acinetobacter相对丰度呈现逐步下降趋势,分别为6.38%、3.95%、0.57%。Acinetobacter是水处理过程中常见的异养硝化-好氧反硝化细菌[28],所以在有机物质量浓度相对较低的A4、A5单元中并不利于其生长,导致其相对丰度下降。在A3、A4、A5单元中,Pseudomonas相对丰度呈现逐步下降趋势,分别为1.29%、0.83%、0.72%。有研究[29]表明,在人工湿地等脱氮除磷工艺中发现了参与有机物去除的Pseudomonas,因此,对于有机物质量浓度相对较低的A4、A5单元,Pseudomonas相对丰度可能会有所下降。与出水相比,受纳水体细菌组成出现显著变化,其中C39和Pseudomonas为主要的优势菌属,相对丰度分别为67.61%、10.21%,二者总相对丰度超过75%。

2.4 一体化污水净化槽各处理单元中潜在致病细菌种群特征

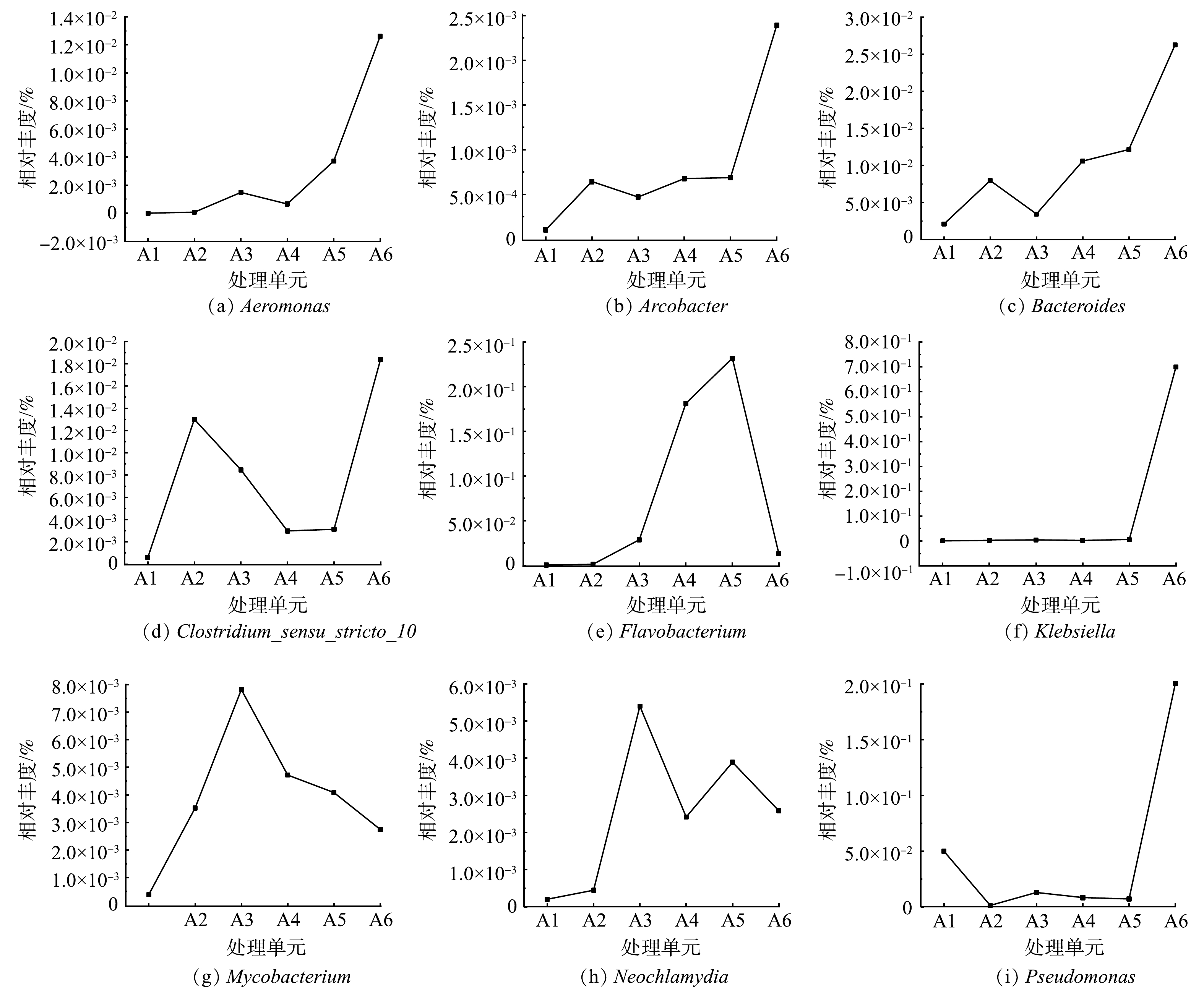

进一步深入分析本研究中一体化污水净化槽各处理单元的细菌特征,结果发现,其检出的潜在人致病性细菌种类丰富,并且各个单元的种类及含量也存在一定差异。进水中共检测到16种潜在致病细菌属, 而出水中则检出了20种潜在致病细菌属。有研究[30-39]表明,出水中检出的相对丰度较高的Klebsiella、Aeromonas、Arcobacter、Neochlamydia、Clostridium_sensu_stricto_10、Mycobacterium、Pseudomonas、Bacteroides、Acinetobacter和Flavobacterium均对人体存在潜在危害。Aeromonas hydrophila普遍存在于淡水、污水、淤泥、土壤和人类粪便中,可引起多种水产动物的败血症和人类腹泻[30];Klebsiella pneumoniae是人类呼吸道和肠道的常居菌,可引起下呼吸道、血液、泌尿道、消化道、手术切口、颅内、皮肤软组织等多个部位感染[31];Arcobacter skirrowii与人类和动物的腹泻、菌血症等疾病密切相关[32];属于易引起疾病衣原体目的Neochlamydia,对人体健康也存在潜在威胁[33];Mycobacterium tuberculosis可引起人体结核病,一种传染性疾病,主要是通过呼吸道传播,以肺结核为最多见[34];Pseudomonas aeruginosa为假单胞菌属中最为常见的一种机会致病菌,常可引起尿路感染、烧伤创面及褥疮感染、败血症和肺部感染等[35];Bacteroides fragilis系革兰阴性厌氧菌,由于其具有黏附性、血细胞凝集素、多糖胶囊、菌毛等多种毒力因素,在拟杆菌属中致病性最强,其可引起腹腔感染、术后伤口感染、糖尿病足感染、菌血症等[36];Acinetobacter bamnannii是我国医院感染最主要的致病菌之一,该菌最常引起的感染为下呼吸道感染,尤其为呼吸机相关性肺炎,其次为血流感染[37];Clostridium perfringens广泛存在于自然界及人和动物的肠道中,是近年来我国家畜“猝死症”的主要病因,可引起气性坏疽和食物中毒的主要病原菌坏死性肠炎[38];Flavobacterium可引起肺炎,也可招致脑膜炎、败血症等感染,该菌会在机体免疫力下降时引起感染[39]。以上结果表明,当污水生物处理设施末端出水不经消毒处理时,其出水中潜在致病微生物的危害可能存在升高趋势。本研究选取了9种对人体危害性较大的致病细菌,对其在不同单元中的相对丰度变化进行了分析,结果如图6所示。不同致病细菌的变化趋势各有差异,总体可分为以下3类。

第1种为进水中相对丰度较低,但在设备不同单元随着污水流向相对丰度逐步呈升高趋势。Aeromonas和 Klebsiella在进水中几乎未检出,但在A2、A3、A4、A5、A6的相对丰度则分别升高至0.007 4%和0.002 5%、0.15%和0.004 5%、0.066%和0.001 9%、0.37%和0.005 9%、1.26%和0.70%。Arcobacter (0.01%)和Bacteroides(0.21%)在进水中有少量检出,但在不同单元中也均呈现上升趋势,A2、A3、A4、A5、A6的相对丰度分别为0.064%和0.80%、0.047%和0.34%、0.068%和1.06%、0.069%和1.22%、0.24%和2.63%。这可能是因为Aeromonas、Klebsiella、Arcobacter、Bacteroides、Pseudomonas等菌属细菌是活性污泥中大量存在且具有降解有机污染物功能的菌属[24,29,40]。因此,相对进水而言,后续各处理单元中这些细菌的相对丰度呈现出上升趋势。

第2种为进水中相对丰度较低,但在整个水处理过程中其相对丰度呈现先上升后下降趋势。Mycobacterium(0.04%)和Neochlamydia(0.02%)在A2、A3、A4、A5、A6的相对丰度分别为0.35%和0.045%、0.78%和0.54%、0.47%和0.24%、0.41%和0.39%、0.27%和0.26%。这2种致病细菌丰度的最大值均在A3单元,可能是由于这2种细菌均属于厌氧菌,当溶解氧浓度较高时会抑制其活性,甚至会影响其生存。同样,Flavobacterium (0.04%)在A2、A3、A4、A5、A6的相对丰度也呈现出先上升后下降趋势,分别为0.10%、2.85%、18.12%、23.18%、1.32%,但下降点在A5单元,这可能因为Flavobacterium同时是一种好氧反硝化细菌[24],在氮物质、有机物含量相对较低环境中会影响其繁殖,导致其相对丰度下降。

第3种为进水中相对丰度较低,但在整个水处理过程中呈现先上升后下降再上升趋势。Clostridium_sensu_stricto_10在进水中的相对丰度为0.06%,而在设备其他处理单元的相对丰度分别为A2(1.30%)、A3(0.85%)、A4(0.30%)、A5(0.31%)、A6(1.84%),其相对丰度的峰值分别在A2和A6中。高通量测序结果显示,各单元检测总片段分别为38 979、40 364、44 672、51 735、50 945、36 408。分析高通量测序结果表明,A1、A2、A3、A4、A5和A6单元中Clostridium_sensu_stricto_10的核酸检出片段量分别为23、525、378、154、159、669。造成这种现象的原因可能是:在功能单元中功能菌种类和相对含量增大,而Clostridium_sensu_stricto_10较功能菌对营养物质的竞争力较小,导致相对丰度下降,但具体原因需要进一步开展研究。以上分析结果表明,无论那种类型变化趋势,其设备出水中均包含一定量的潜在致病性细菌。

3. 结论

1)所研究的一体化污水净化槽设施处理农村生活污水时,不同处理单元细菌中群结构呈现一定差异,尤其是进水、夹杂物去除槽和后续生化处理单元之间。出水中也包含多样性丰富的细菌。

2)本研究在一体化污水净化槽中共检出21种潜在致病细菌,以Flavobacterium、Pseudomonas等为主。值得注意的是,在其出水中存在20种潜在致病细菌,并且有9种优势潜在致病细菌的相对丰度较进水存在明显升高现象。

-

表 1 C和N物料衡算

Table 1. Overall mass balances of C and N elements

运行工况 C的质量/g N的质量/g 进水 矿化 出水 剩余污泥 进水 矿化 出水 剩余污泥 A/O 214.39 181.73 25.96 6.70 28.84 15.98 12.39 0.47 r=25% 246.31 222.96 18.05 5.30 32.59 20.62 11.60 0.37 r=50% 275.79 253.71 18.18 3.90 35.50 25.23 10.00 0.27 r=100% 308.08 284.43 21.15 2.50 44.16 24.96 19.03 0.17 -

[1] WANG X X, WANG S Y, XUE T L, et al. Treating low carbon/nitrogen (C/N) wastewater in simultaneous nitrification-endogenous denitrification and phosphorous removal (SNDPR)systems by strengthening anaerobic intracellular carbon storage[J]. Water Research, 2015, 77(15): 191-200. [2] LI Y Y, HU Y Y, WANG G H, et al. Screening pretreatment methods for sludge disintegration to selectively reclaim carbon source from surplus activated sludge[J]. Chemical Engineering Journal, 2014, 255: 365-371. doi: 10.1016/j.cej.2014.06.034 [3] SUN H H, WU Q, YU P, et al. Denitrification using excess activated sludge as carbon source: performance and the microbial community dynamics[J]. Bioresource Technology, 2017, 238: 624-632. doi: 10.1016/j.biortech.2017.04.105 [4] 徐强. 污泥处理处置技术及装置[M]. 北京: 化学工业出版社, 2003. [5] QIANG Z M, WANG L, DONG H Y, et al. Operation performance of an A/A/O process coupled with excess sludge ozonation and phosphorus recovery: A pilot-scale study[J]. Chemical Engineering Journal, 2015, 268: 162-169. doi: 10.1016/j.cej.2015.01.054 [6] LIU Y, WANG H L, XU Y X, et al. Sludge disintegration using a hydrocyclone to improve biological nutrient removal and reduce excess sludge[J]. Separation & Purification Technology, 2016, 177: 192-199. [7] LIU H, HAN P, LIU H B, et al. Full-scale production of VFAs from sewage sludge by anaerobic alkaline fermentation to improve biological nutrients removal in domestic wastewater[J]. Bioresource Technology, 2018, 260: 105-114. doi: 10.1016/j.biortech.2018.03.105 [8] KONDO T, TSUNEDA S, EBIE Y, et al. Improvement of nutrient removal and phosphorus recovery in the anaerobic/oxic/anoxic process combined with sludge ozonation and phosphorus adsorption[J]. Journal of Water & Environment Technology, 2009, 7(7): 135-142. [9] YE F X, LIU X W, YING L. Effects of potassium ferrate on extracellular polymeric substances (EPS) and physicochemical properties of excess activated sludge[J]. Journal of Hazardous Materials, 2012, 199(2): 158-163. [10] AN Y, ZHOU Z, YAO J, et al. Sludge reduction and microbial community structure in an anaerobic/anoxic/oxic process coupled with potassium ferrate disintegration[J]. Bioresource Technology, 2017, 245: 954-961. doi: 10.1016/j.biortech.2017.09.023 [11] 张彦平, 李芬, 樊伟, 等. 高铁酸盐溶液破解剩余污泥效能研究[J]. 环境科学与技术, 2016, 39(6): 65-69. [12] MING X A, FENG Y F, WU J J, et al. Effect of K2FeO4/US treatment on textile dyeing sludge disintegration and dewaterability[J]. Journal of Environmental Management, 2015, 162: 81-86. [13] ZHANG Y P, HU R Q, TIAN J Y, et al. Disintegration of waste activated sludge with composite ferrate solution: Sludge reduction and settleability[J]. Bioresource Technology, 2018, 267: 126-132. doi: 10.1016/j.biortech.2018.07.027 [14] ZHANG X H, LEI H Y, CHEN K, et al. Effect of potassium ferrate (K2FeO4) on sludge dewaterability under different pH conditions[J]. Chemical Engineering Journal, 2012, 210: 467-474. doi: 10.1016/j.cej.2012.09.013 [15] 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境科学出版社, 2002. [16] 尹军, 王雪峰, 王建辉, 等. SBR工艺活性污泥比耗氧速率与控制参数的关系[J]. 环境污染与防治, 2007, 29(7): 481-483. doi: 10.3969/j.issn.1001-3865.2007.07.001 [17] WAITE T, GILBERT M. Oxidative destruction of phenol and other organic matter by iron(VI) ferrate[J]. Water Pollution Control Federation, 1978, 50(3): 543-551. [18] 张智瑞. 小城镇自来水厂消毒技术的研究与选择[D]. 重庆: 重庆大学, 2006. [19] 于子淇. 剩余污泥二级碱解及厌氧消化的研究[D]. 广州: 华南理工大学, 2013. [20] 李慧, 刘健, 左悦. 聚合氯化铝铁对活性污泥系统的影响[J]. 中国给水排水, 2018, 34(7): 103-105. [21] HENZE M, GUJER W, MATSUO T, et al. Activated sludge model No.2D, ASM2D[J]. Water Science & Technology, 1999, 39(1): 165-182. [22] 孟顺龙, 裘丽萍, 陈家长, 等. 污水化学沉淀法除磷研究进展[J]. 中国农学通报, 2012, 28(35): 264-268. doi: 10.3969/j.issn.1000-6850.2012.35.049 [23] 胡猛, 曹军, 张艳, 等. 化学除磷辅助A2/O工艺处理城市污水脱氮除磷研究[J]. 环境工程, 2014, 32(3): 29-33. doi: 10.11835/j.issn.1000-582X.2014.03.005 [24] MAGER T R, LANDES J D, MOON D M, et al. Effect of low frequencies on the fatigue crack growth characteristics of A533 grade B class 1 plate in an environment of high-temperature primary grade nuclear reactor water. Heavy section steel technology technical report No.35[J]. Journal of Environmental Chemical Engineering, 2017, 5(2): 1828-1842. doi: 10.1016/j.jece.2017.03.025 [25] ZUBROWSKA-SUDOL M, WALCZAK J. Enhancing combined biological nitrogen and phosphorus removal from wastewater by applying mechanically disintegrated excess sludge[J]. Water Research, 2015, 76: 10-18. doi: 10.1016/j.watres.2015.02.041 期刊类型引用(4)

1. 唐建,张宿义,敖宗华,唐恒军. 高铁酸盐耦合过硫酸盐对污泥减量化研究进展. 资源节约与环保. 2023(03): 5-7+11 .  百度学术

百度学术

2. 张绪婷. 污泥处理处置技术的应用研究. 科学技术创新. 2020(02): 166-167 .  百度学术

百度学术

3. 赵凯亮,刘安迪,南彦斌,梁利民,王云霞,陈永志. HRT对改良式A~2/O-BAF反硝化除磷脱氮的影响. 环境科学. 2020(06): 2771-2778 .  百度学术

百度学术

4. 张天歌,刘永红,王宁. 废水处理过程中污泥减量技术及机理研究进展. 水处理技术. 2020(08): 6-12 .  百度学术

百度学术

其他类型引用(2)

-

下载:

下载: