-

聚偏氟乙烯(polyvinylidene difluoride,PVDF)广泛应用于水处理当中,PVDF属于结晶聚合物,具有高机械强度、良好耐化学性和热稳定性等特点,且在制备平板、中空纤维或管状膜时显示出良好的加工性能[1]。然而,PVDF的强疏水性易导致疏水污染物在膜表面的吸附和沉积,进而造成结垢现象,将显著降低抗污性能,并增加运行成本,限制其在水处理方面的应用[2]。通常,PVDF亲水性的增加会提高其抗污性能,可以防止疏水性污染物在膜表面的吸附和沉积[3]。目前,研究者已尝试多种方法用于增强PVDF膜的表面亲水性,如亲水聚合物表面涂层、表面接枝聚合、与亲水聚合物共混及无机材料的杂化复合等。近年来,将无机材料与有机高分子化合物添加到铸膜液中制备PVDF有机/无机复合膜已成为分离膜领域的研究热点[4-6],然而对于复合膜的抗菌效果研究较为欠缺,以及使用寿命未知。

选择性催化还原(selective catalytic reduction, SCR)法常用在大气脱硝过程中治理废气,通过氨水或尿素与氮氧化物(NOx)反应生成氮气(N2)和水(H2O),使得中高浓度的NOx污染物转化为可氧化的无害产品[7]。在SCR系统运行过程中,催化剂由灰分堵塞、活性组分的损失等情况而丧失部分功能。商业化的催化剂再生程序可以通过洗涤、吹灰等过程重新恢复其活性。但是,经过反复再生后会造成催化剂内部结构的损伤,损坏的SCR催化剂不能再生使用[8-9]。由于废旧SCR催化剂(waste selective catalytic reduction,WSCR)中含有大量的二氧化钛(TiO2)、二氧化硅(SiO2)、氧化钨(WO3)等金属元素,随意丢弃会造成大量的资源浪费。另外,具有亲水性的TiO2纳米粒子同时还具备抗菌的功能,是制备抗菌水处理膜的良好材料[10]。

离子液体(ionic liquid,IL)是常温常压下的熔融有机盐,无污染、无气味、可回收,是良好的环保友好型试剂[11]。离子液体在许多化学反应过程中具有取代传统有机溶剂的潜力,由于其独特的物理化学性质,如蒸气压可忽略不计,不易燃和高离子电导率等,对环境、设备及人体健康损害较小[12-14]。此外,一些IL具有良好得抗微生物和抗真菌性能,将IL与膜相结合实现真正的反复回收利用和可持续发展[15-16]。

因此,本研究针对PVDF膜水通量低、易污染和细菌附着繁殖等问题,通过在PVDF膜中添加WSCR和季铵盐类IL,用相转换的方法制备共混超滤膜,本研究选用的IL为双癸基二甲基氯化铵,制备出来的共混膜对污染物具有优异的截留效果,对大肠杆菌具有高抗性能,这不仅符合绿色发展理念,也在膜污染和抗菌方面有较高的潜力。

-

实验所用的主要化学试剂如表1所示。所用药品在购买后均未做进一步提纯或其他处理,实验所用水均为去离子水,WSCR由废气处理厂家提供。

-

首先将PVDF粉末在60 ℃下干燥24 h以上,WSCR进行清洗研磨,过400目筛网后烘干备用。将不同质量比的WSCR在紫外照射条件下通过超声分散在的30.0 g DMAc溶剂中,再将5.0 g PVDF和1.0 g PVP-k30均匀混合进溶剂中,最后加入不同质量比的双癸基二甲基氯化铵在室温下搅拌12 h,随后在真空条件下静置脱泡24 h得到铸膜液(不同配比的铸膜液见表2)。将铸膜液均匀倒在干净的玻璃板上,用厚度为400 μm的刮膜刀在匀速地条件下进行制膜,在空气中静置30 s左右,将制成的膜连同玻璃板一同放入凝固浴(超纯水)中。在凝固浴中,玻璃板上的铸膜液发生传质交换,而PVDF在界面处迅速析出,使膜与水相分离,形成分离膜。

-

利用扫描电子显微镜(scanning electron microscope,SEM,美国Thermo Scientific Phenom Pharos)观察膜截面形貌特征,以及元素分布情况。用接触角测量仪(承德鼎盛JY-82C视频接触角测定仪)测量超滤膜表面接触角,进一步分析膜表面的润湿性能。采用广角X射线衍射仪(X-ray diffractometer,XRD,Bruker D8 Advanced)以及X射线光电子能谱仪(X-ray photoelectron spectrometer,XPS,美国Thermo Scientific K-Alpha)分析评估WSCR和膜内元素组成。使用原子力显微镜(atomic force microscope,AFM,德国Bruker Dimension Icon)观察膜表面粗糙程度,以及使用傅里叶变换红外(fourier transform infrared spectroscopy,FTIR,美国PE)进行分析。

-

在一定的压力以及温度条件下,纯水通量一定程度上反映了膜的致密程度,是指单位时间内通过单位面积的纯水体积。

在小于0.1 MPa的压力下,先将纯水预压0.5 h使之稳定后,记录在相同的一定时间内纯水通过错流过滤装置的体积,并按式(1)计算超滤膜的纯水通量。

式中:Q为膜的纯水通量,L·(m2·h)−1;V为透过液体积,L;A为膜有效面积,m2;t为测试时间,h

本实验以BSA为污染物测试膜水通量恢复率。在小于0.1 MPa的压力下,先将500 mg·L−1的BAS溶液预压0.5 h使之稳定后再开始展开抗污染实验,持续过滤BSA溶液1 h时,测定各组超滤膜在过滤BSA溶液前后的纯水通量,并按式(2)计算水通量恢复率。

式中:R为膜的水通量恢复率(FRR),%;J1为滤后水通量,L·(m2·h)−1;J0为初始水通量,L·(m2·h)−1

-

用干湿膜重量法测量膜的孔隙率(ε),具体测试过程如下。首先,剪取2 cm×2 cm的复合膜样品,将其表面的纯水擦干,称其质量(保留至小数点后4位),记录为w1。随后将称量后的复合膜置于25 ℃真空干燥箱中恒温干燥至恒重,并用同一个电子天平称取干燥后的复合膜质量,记录为w2,最后通过式(3)计算其孔隙率。

式中:w1为膜被完全浸湿的质量,g;w2为膜在25 ℃真空烘干后的质量,g;ρ为纯水的密度(0.998 g·cm−3);A为膜样品面积,m2;l为膜样品厚度,m

本实验采用滤速法测试膜的平均孔径(rm)。采用错流过滤评价装置测试复合膜的水通量,在0.1 MPa压力下计算出复合膜的水通量,并代入到Guerout-Elford-Ferry 公式中,计算出复合膜的平均孔径,具体计算如式(4)所示。

式中:ε为膜的孔隙率,%;

η 为水的粘度(8.9×10−4 Pa s);l为膜的厚度,m;Q为纯水通量,L·(m2·h)−1;ΔP为错流过滤实验的操作压力,Pa;A为膜样品面积,m2 -

使用纳米粒度仪观察滤液中油滴的粒径分布。分离测试在真空过滤装置中进行,选用二氯甲烷和SDS制备乳液,以 1:100 的体积比加入油类物质和纯水,并加入 0.2 mg·mL−1 的SDS后高速搅拌6 h形成稳定的水包油型乳液,经过抽滤后用DLS进行测试。

本研究选择大肠杆菌为指示菌株进行抗菌性能的测试。在无菌超净工作台上从试管斜面培养的大肠杆菌菌种中取一接种环细菌,接种于50 mL LB营养肉汤(lennox)中,(37±1) ℃摇床内以220 r·min−1振荡培养12 h,作为菌悬液。将膜用蒸馏水洗净烘干,剪成碎片,在254 nm紫外灯下灭菌30 min。准备若干个装有100 mL LB营养肉汤的锥形瓶,经高温高压灭菌后各加入菌悬液0.1 mL,准确称取灭菌后的膜100 mg 加入瓶中作为抗菌试样悬浮液。每种膜样品做3组平行实验以消除偶然误差的影响,不加膜样品的培养液做空白对照。将抗菌试样悬浮液置于(37士1) ℃摇床中以200 r·min−1振荡培养12 h后测定其OD值。

-

通过SEM观察WSCR,其内部结构主要由棒状结构和块状结构组成,如图1(a)所示,棒状粉末直径大小大约在5~7 μm,块状粉末直径大小大约在5~40 μm,其微观结构比较规整。由图1(c)~(d)能够看出,棒状结构上有多种无机颗粒附着在表层,而图1(e)~(f)所显示的块状结构是由多种物质团聚而成。由图1(b) 对应的FTIR图谱可见羟基基团的存在,这为后续的亲水性能奠定了良好的基础。

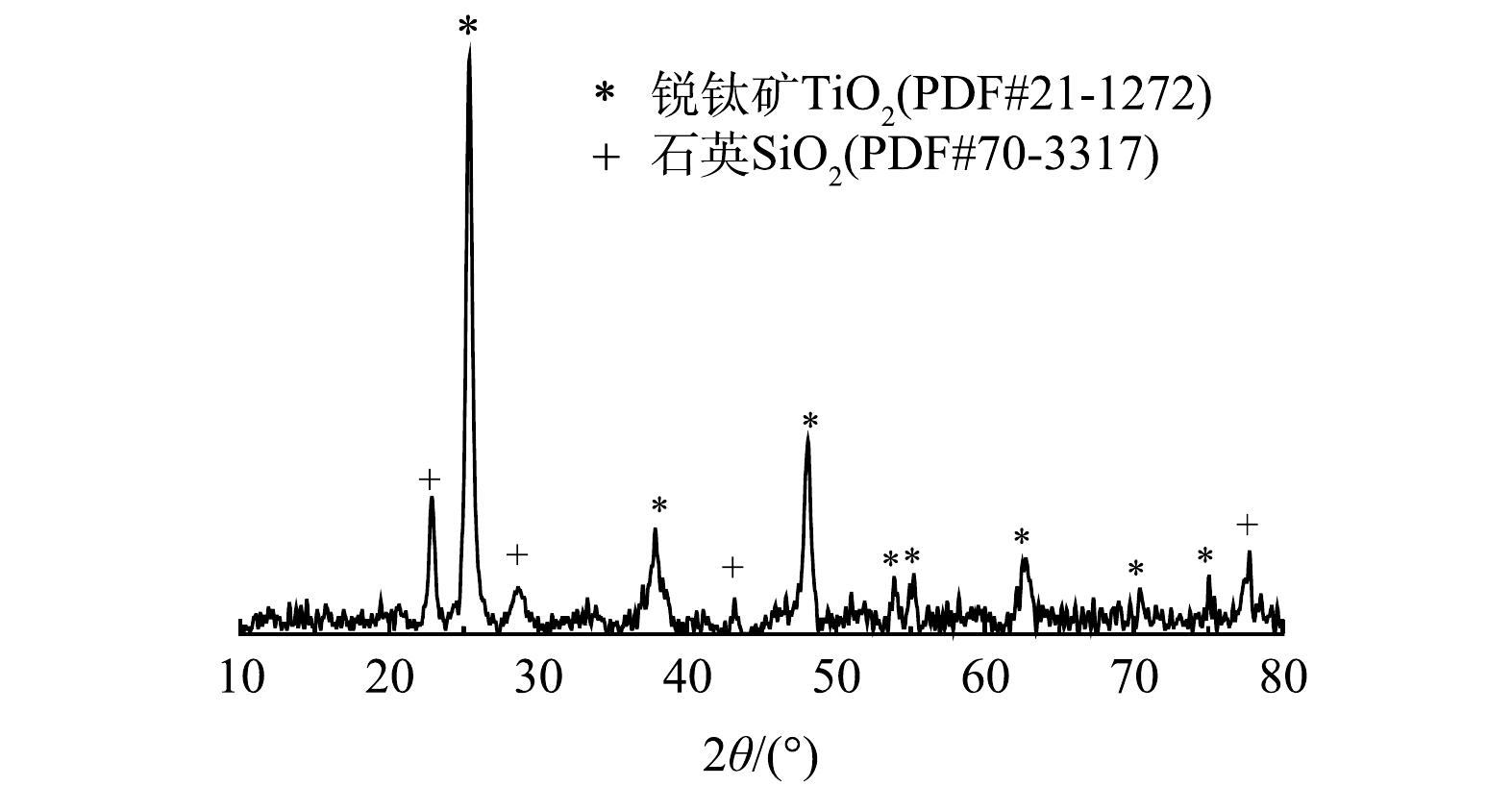

再次通过SEM对WSCR的棒状结构如图1(c)~(d)和块状结构如图1(e)~(f)进行全元素分析,WSCR所含元素十分丰富,其中表3显示棒状含量较多的元素为O、Si、Ca、Al,还含有少量的Mo,块状结构所含元素相对复杂,其中较多为O、Ti(C元素作为电镜扫描基底可能为干扰)等。通过扫描结果可以看出,该催化剂的元素比较复杂,金属元素较多,由于TiO2、氧化铝(Al2O3)等表面含有大量的羟基基团和羧基基团,具有很强的亲水性能,而且一些金属元素具有一定的抗菌效果,能够有效杀死细菌,所以与PVDF膜结合可以改善PVDF膜的亲水性、抗污性和抗菌性能[17-20]。由图2的XRD测试结果也可见,WSCR内含有大量的TiO2、SiO2等多种亲水物质和抗菌粒子。

-

先对原膜和WSCR&IL-PVDF膜的表面化学成分进行FTIR分析,结果如图3所示。由图3可以看出,M0膜在1 405 cm−1处存在吸收峰,这是PVDF中与C—F键相连的变形振动吸收峰;1 179 cm−1为PVDF中C—F键的伸缩振动吸收峰;841 cm−1为膜的无定形相的特征吸收峰,在762 cm−1处观察到α相的振动吸收峰;1 288 cm−1为β相的振动吸收峰[21]。

对比M0和各复合膜的图谱发现,添加了WSCR和IL之后复合膜的FTIR图谱与纯PVDF膜类似,特征峰的峰强有所不同。这说明WSCR和IL的物理掺杂并不会影响PVDF原本的结晶结构。由图3中还可以看出,添加WSCR之后,1 181 cm−1和762 cm−1附近的吸收峰带略微变宽,峰强增强。这是因为添加的无机材料与聚合物网络发生了键合。由于IL与CF2键之间的强静电相互作用,显著促进了β相在PVDF分子链中晶体的形成,这种强烈的静电相互作用可以促进聚合物朝着有利于电活性晶型形成的方向发展[22-23]。

与此同时,和M0相比,M2和M5都出现了轻微的红移现象,这是由于WSCR随着粒径的减小,颗粒内部的内应力会增加,这种内应力的增加会导致能带结构的变化,电子波函数重叠加大,结果带隙、能级间距变窄,这就导致电子由低能级向高能级及半导体电子由价带到导带跃迁引起的光吸收带和吸收边发生红移。在加入IL后,制膜过程中由于结构内部亲疏水性不同和DMAc的强极性非质子化特性,使M5出现红移现象[24]。

-

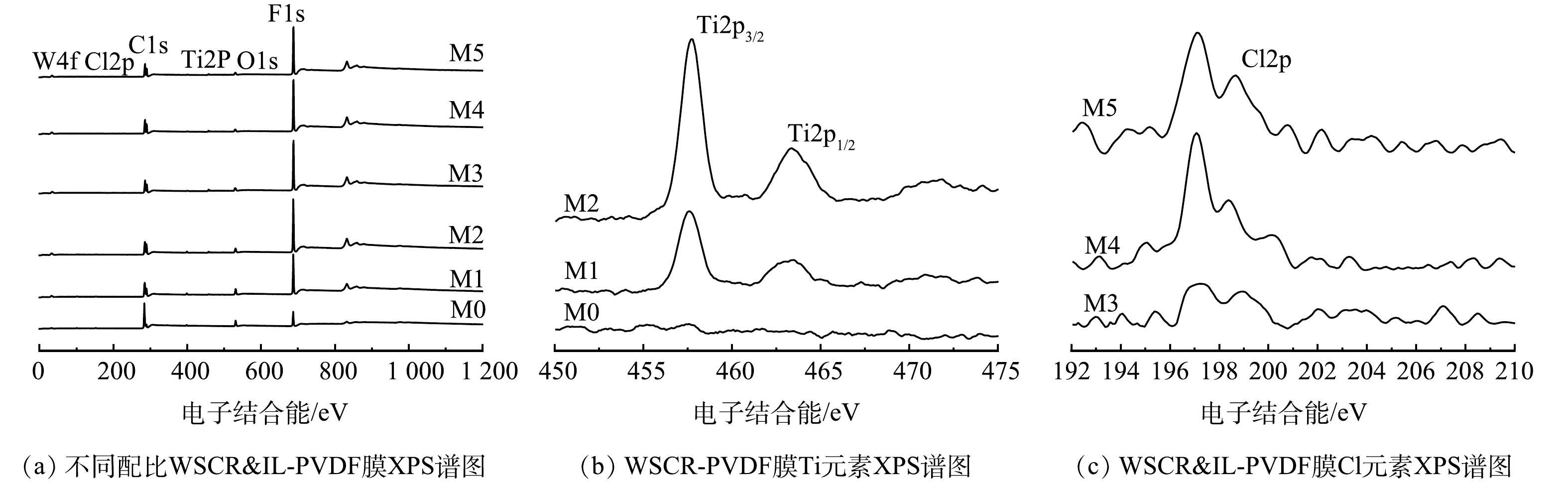

随后对各组膜进行XPS元素分析。对于WSCR&IL-PVDF膜,在289.2 eV和686.3 eV检测到C、F元素。与M0相比,在XPS光谱上,M1、M2表面存在Ti (Ti2p1/2, 464.3 eV; Ti2p3/2,458.6 eV)元素信号,这些XPS结果表明了WSCR成功掺杂进PVDF膜内,并随着WSCR的增加,膜内的Ti元素也随之增加[25]。由图4可知,M3、M4、M5膜内存在Cl(Cl2p,198.7 eV),随着IL的添加,膜内的Cl元素随之增加,这也说明了离子液体已经成功掺杂在PVDF膜内。

-

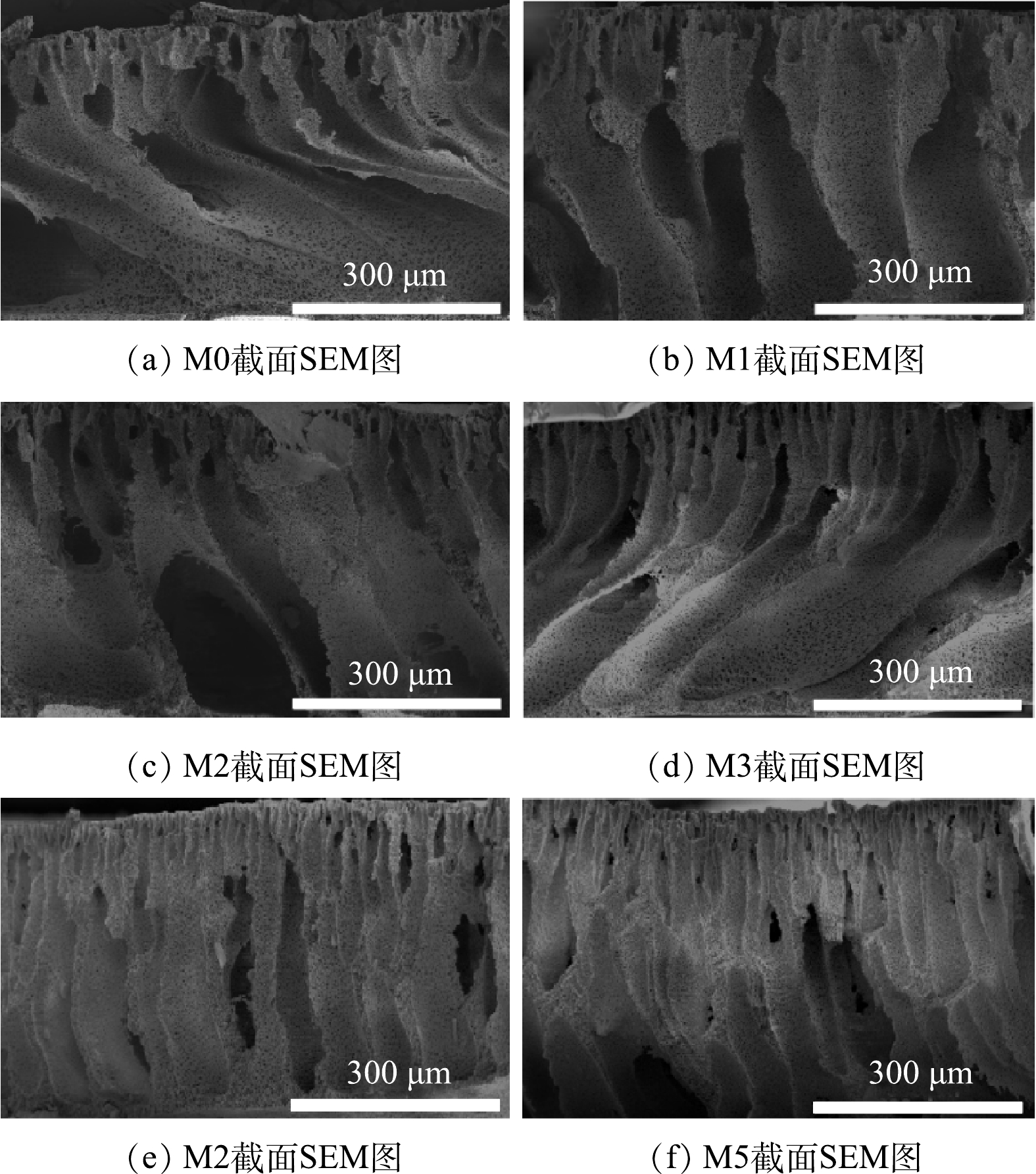

纯膜和复合膜横截面的SEM扫描结果如图5所示。可见,膜的断面形态为膜典型的非对称结构, 由致密皮层和指状孔亚层共同组成。外壁附近出现指状结构,中间出现海绵状结构,这可能是在平板涂膜时聚合物和溶剂的析出差异造成的。在实际应用过程中,致密皮层主要影响污染物截留率,指状孔亚层主要起到支撑性和水通道的作用。这种主要是膜在形成的过程中,由于凝固浴(纯水)和DMAc有机溶剂之间的相互扩散性高而形成的,随着WSCR质量百分比的增加,上皮层越来越密集,这有利于截留率的提高,指状孔亚层逐渐变宽,更加有利于液体的传输,这也是因为WSCR表面含有亲水官能团羟基的存在,会提高相分离过程中各组分间的交换速率,加速它们之间相互扩散分离效率,从而产生更多的大孔。与M2相比,M3、M4、M5在添加IL后,膜截面的指状孔结构更为整齐,并且随着IL重量百分比的提高,整齐度不断上升,而且孔的数量也同步增加。

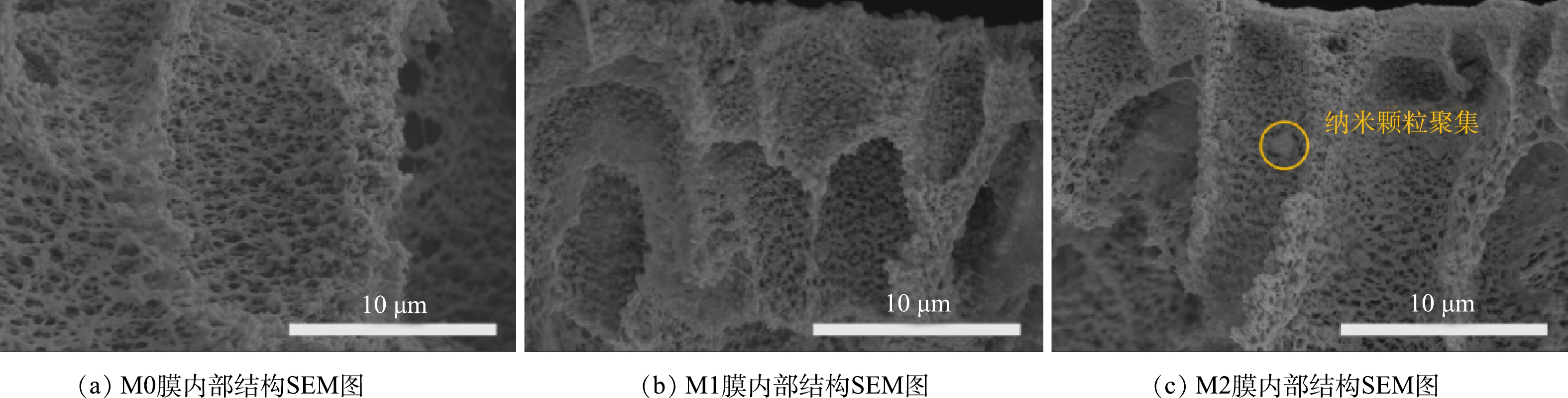

由图6可以看出,膜内部由球型晶体相互连接,并且随着WSCR的添加,球型结构分布更加均匀。但由M2可见,加入过量的WSCR反而导致内部分布不均匀,球型晶体数量减少,而且存在纳米颗粒物的团聚[26]。这可能是由于过量的WSCR内存在众多无机颗粒,在制膜过程中不能均匀分散在铸膜液内从而聚集,抑制了球型结构的均匀生长。

-

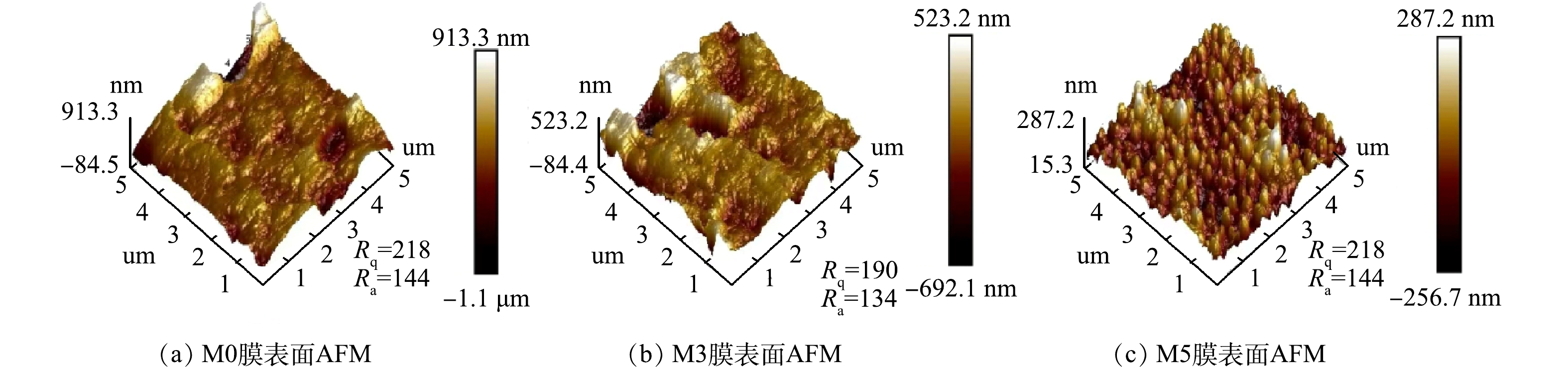

膜表面的粗糙度影响了膜的亲疏水性能和抗污效果,粗糙度的降低能够减少污染颗粒附着的面积,同时可以削弱污染物与膜表面的作用力,有效降低膜表面污染物的积累,提高膜的防污性能。采用AFM技术,测量膜表面的粗糙程度。由图7可以看出原膜M0的表面粗糙度较高,蛋白分子等污染物质会积聚在膜表面的山谷中,不易被清洗掉,增加膜的受污染程度。当加入WSCR后,膜表面的一些大峰谷被小峰谷取代,逐渐形成比较光滑的表面,这是由于WSCR里一些亲水无机颗粒的存在,降低了膜表面的粗糙度。IL的存在使表面粗糙度进一步降低,由于其对称的结构和适中的碳链长度,能够填补大峰谷,从而提升表面光滑性[27-28]。

-

接触角的大小能够评估膜的抗污性能,接触角的减小能够提升膜的亲水性能,抗污性能与膜的亲疏水性有关,从而提供了更好的防污性能。由图8可知,复合膜的表面润湿性随着膜结构中WSCR质量百分比的增加而减少,M0~M3依次为110.28 °、104.98 °、95.41 °, 这是因为 WSCR内亲水性颗粒TiO2等粒子的作用,有效地增加膜的亲水性[29]。结合图8和表4发现,接触角随着WSCR的增加而减小,膜的平均孔径大概在10 nm左右。随着WSCR的添加,膜的孔隙率也在增加,这也同时应证了接触角与孔隙率之间也存在一定的关系。但在添加IL后,接触角反而上升且孔隙率下降,这可能是由于在添加IL后,填充了一部分膜的孔隙,导致孔隙率下降,一部分WSCR内的亲水颗粒被IL包覆,降低了其亲水性能。总体来说,亲水性和孔隙率由于添加量的不同,有些差别,但整体波动不大。

-

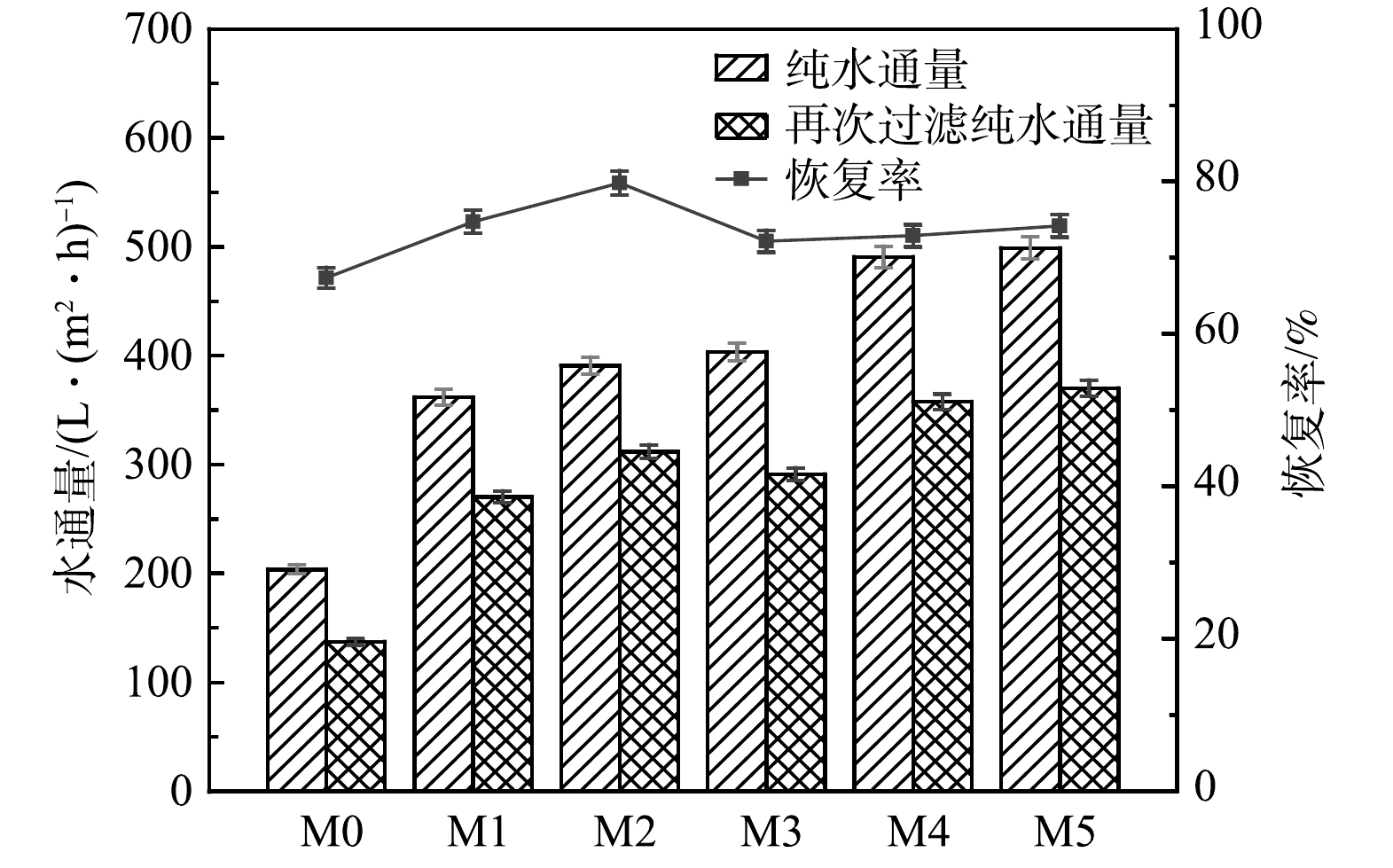

采用错流过滤装置,分别用纯水和 500 mg/L的BSA溶液作为进料液,测试 WSCR&IL对 PVDF膜纯水通量影响以及抗污效果。随着WSCR在铸膜液中含量的增加,纯水通量明显增加,如图9所示,添加WSCR后,M2膜的纯水通量提升为原膜M0的1.5倍,达到 390.85 L·(m2·h)−1,复合膜纯水通量的提高与表面亲水性的增强、膜孔隙率的增大有关。加入IL后,膜的纯水通量随着添加量的增加而逐渐提升,M3、M4、M5水通量分别为403.33、490.64、498.96 L·(m2·h)−1,均是原膜的2倍多,同时也说明了在膜内部IL和WSCR两者均能够共同提高膜性能。IL的引入改变了膜的整体结构,平均孔径增加,而在膜的内部减少宏观大孔洞的出现,使孔更均匀,水通量进一步优化[30]。

用BSA过滤0.5 h后,再次测试膜的纯水通量,考察其抗污性能。由图9中可以看出,再次过滤后膜的纯水通量均有所下降,这是由于BSA是高分子质量的蛋白质,在过滤BSA时会堵塞在膜的孔隙中,从而阻碍纯水的通过。但可明显地发现,所有复合膜的通量均比原膜M0在相同操作条件下的通量高,M1、M2、M3、M4、M5恢复率分别为67.35%、74.71%、79.79%、72.16%、72.88%、74.17%,除了原膜M0,其余膜的恢复率都在70%以上,从而说明加入WSCR和IL后能有效提升膜的抗污性能。

-

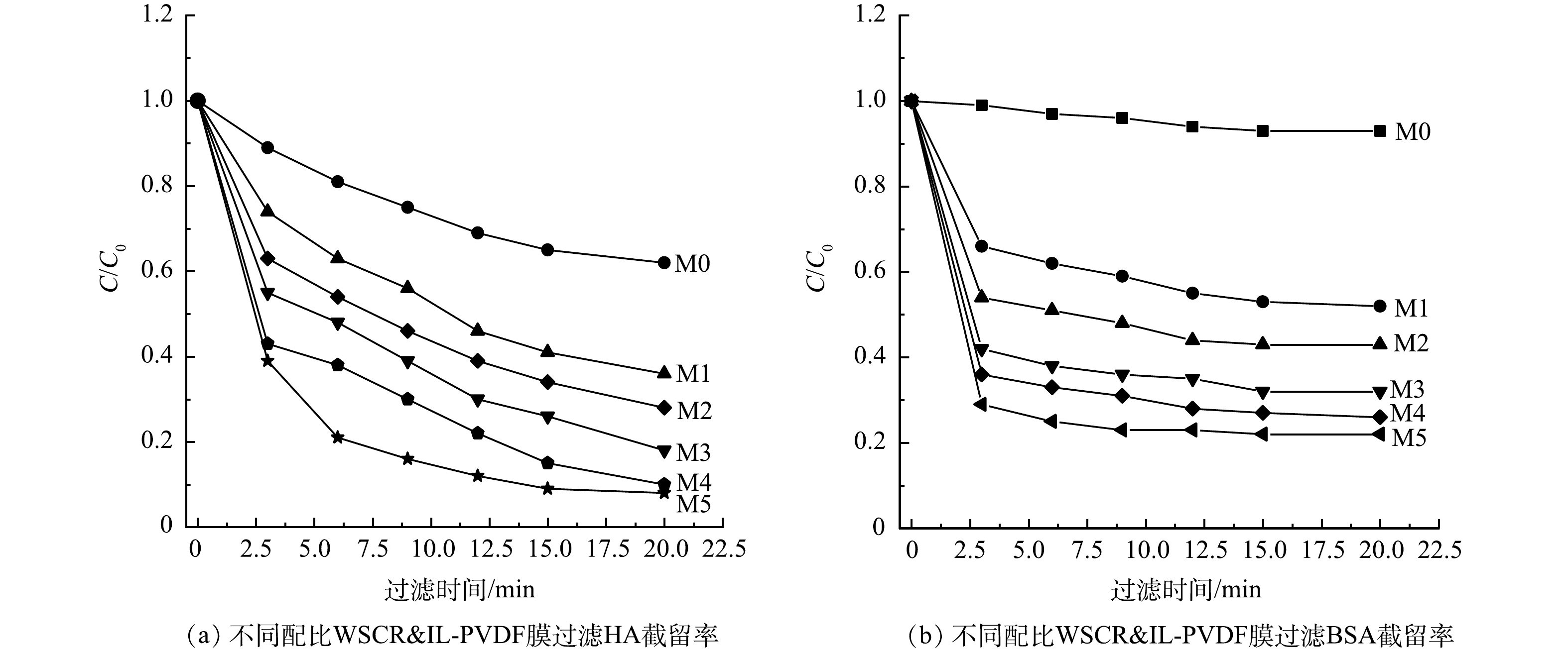

过程中采用HA(10 mg·L−1)和BSA(1.2 g·L−1)测试膜的截留率R。HA的截留率结果如图10(a)所示。可见,空白膜M0在截留 HA 过程中,20 min内 HA 的截留率为38%,从M1和M2可以看出膜的截留率随着WSCR含量的增加而显著提高。当WSCR为5.0%时,最终截留率达到72%,这也证明了WSCR的加入能够提高膜的截流效果。M3、M4、M5的去除率分别为82%、90%、92%,这是因为在PVDF膜中引入的IL,改变了膜的部分结构,表层孔洞变大,膜的内部空洞较小, 孔更均匀,增加了海绵状结构的支撑体,这大大提升了膜的截留性能。对于BSA的结果如图10(b)所示,空白膜M0在20 min内的截留率为6%,M1、M2、M3、M4、M5膜截留率依次为48%、57%、68%、74%、78%,同时也验证了上述的规律,对比发现所有膜对HA的截留效果优于对BSA的效果。

-

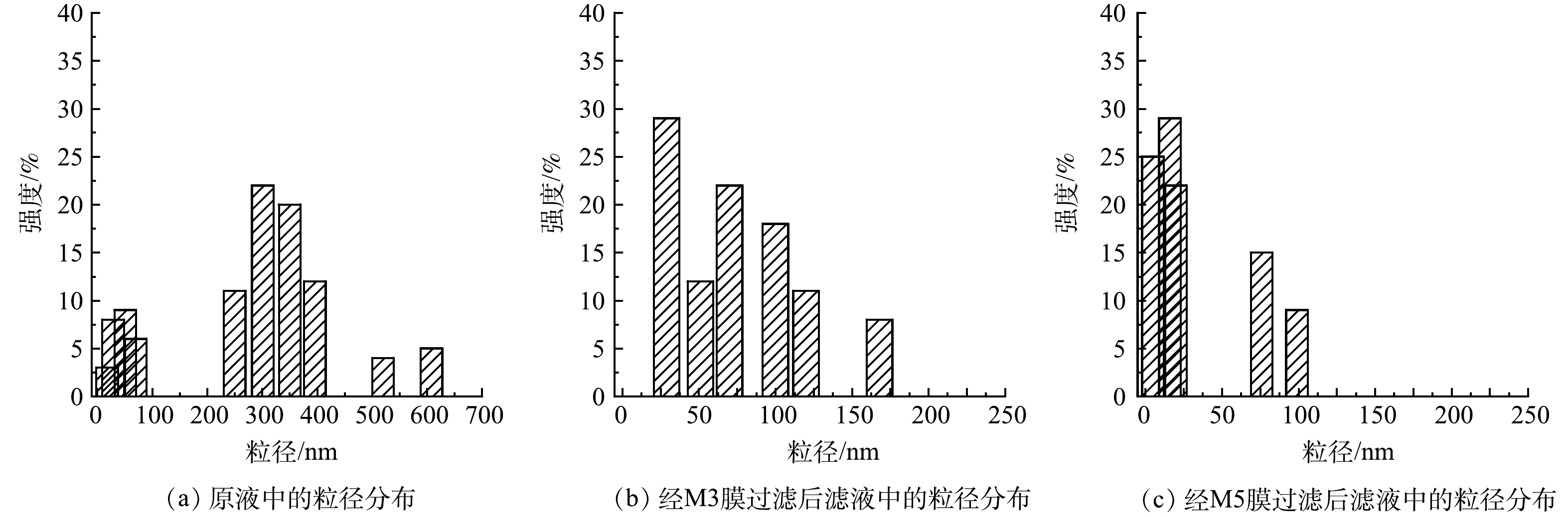

通过 DLS 测定了过滤前后油滴的粒径分布,结果如图11所示。过滤前,图11(a)显示出原液中油滴粒径分布范围较广,其中的纳米级油滴主要集中在10~608 nm。图11(b)~(c)显示,经过过滤后,粒径分布范围变窄,由于在孔径筛分原理的作用下,料液中原本的大粒径油滴难以通过孔,经M3过滤后的滤液粒径分布在29~168 nm,经M5过滤后的滤液粒径分布均小于99 nm,基本集中在5~25 nm。

-

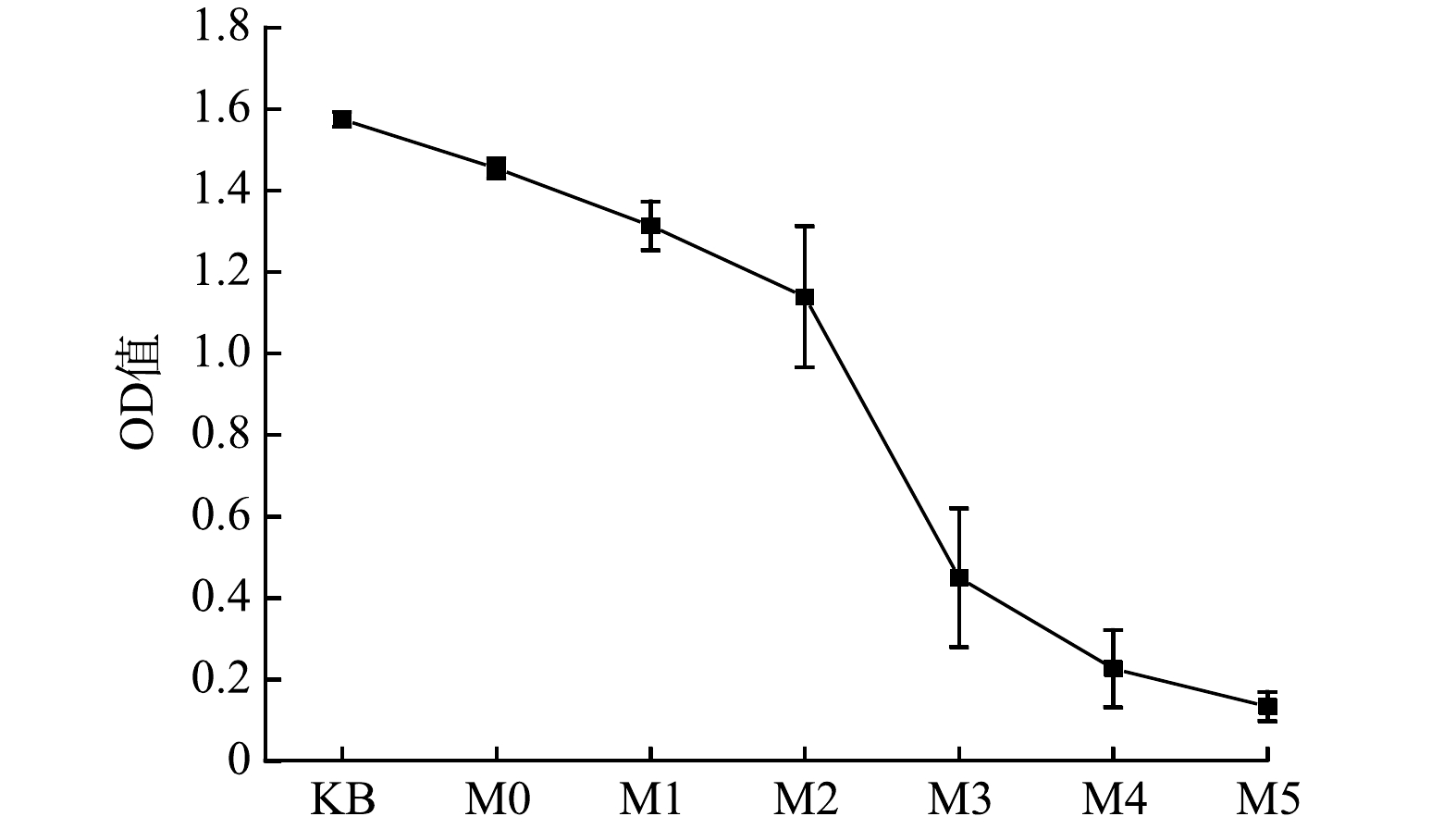

由于WSCR内含有TiO2和众多抗菌性的金属离子,所以能够有效的杀死细菌,另外离子液体双癸基二甲基氯化铵具有长碳链,有研究表明,季铵盐类的物质碳链长度为C8-C16时具有较强的抗菌效果[31-32]。将两者掺入膜中从而赋予材料抗菌性能。根据《生活饮用水卫生标准》(GB 5749-2022),本研究以大肠杆菌为实验对象,对其抑菌活性进行了测试。与无膜的空白样对比,图12中原膜M0的OD平均值减少了0.120,有细微的抗菌效果,当加入WSCR时,M1、M2的OD平均值相对减少, 能够减小到1.139,说明WSCR的加入能够提高膜的抗菌效果,但抗菌强度不是很高,这可能由于在制膜阶段纳米颗粒中的TiO2尚未完全被紫外所激发,或者能量不够。当加入IL后OD平均值降至0.134,抗菌率达到91.5%,说明掺杂之后的膜具有优异的抗菌性能,这是因为带正电的季铵盐基团通过破坏细菌外膜、细胞壁和细胞质膜来杀死细菌,从而达到抗菌的效果,所以说M5能够达到更高效的抗菌效果。

-

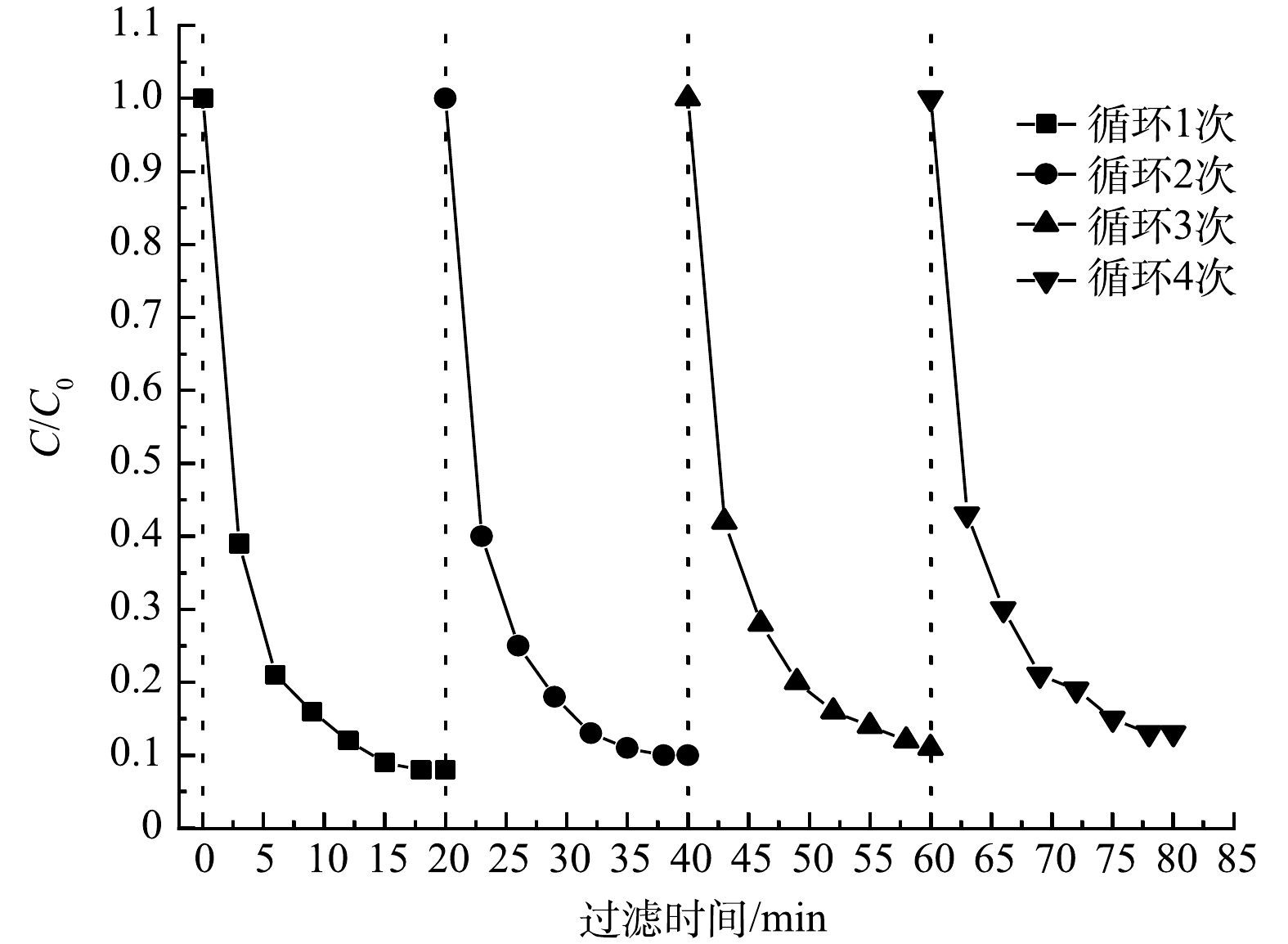

结合上述各项性能测试,选取效果最优的M5进行重复过滤测试,将复合膜回收重复使用4次后,WSCR&IL-PVDF复合膜具有良好的重复使用性。由图13可以看出,经过前2次依次过滤20 min 后,HA的去除率分别为92%和90%。反复实验后HA的去除率为87%,去除效果仍然较好。

-

1) XPS表征结果表明WSCR和IL成功掺杂进膜内,WSCR和IL的加入可影响PVDF膜的形貌、孔隙率和孔径分布,加入WSCR后亲水性明显提高,接触角最多高降低了14.87 °。

2)当WSCR添加量为5.0%,IL添加量为8.0%时,膜水通量最大,为498.96 L·(m2·h)−1;改性膜对HA的截留率可达92.0%;改性膜BSA通量恢复率均在70%以上,防污性能优于未改性的PVDF膜。改性膜对大肠杆菌的抑制率可达91.5%。所以结合以上数据,我们选取的最优膜为M5,且具有优异的重复使用性。

WSCR&IL-PVDF有机-无机超滤膜的制备及性能

Preparation and properties of WSCR&IL-PVDF organic-inorganic ultrafiltration membrane

-

摘要: 选择性催化还原法脱硝催化剂在使用过程中会吸附有害物质,这些有害物质随废催化剂排出,也会对周围环境造成污染,环保部在2014年将其列为危险废物,并在2016年将其纳入危险废物名录。该研究从大气处理企业回收废旧选择性催化还原法脱硝催化剂,将之与离子液体结合得到高效抗菌剂,随后利用相转化的方法将抗菌剂与聚偏氟乙烯共混制备得到高水通量的有机-无机超滤膜。通过表面接触角的测定、扫描电子显微镜、原子力显微镜、低压过滤实验研究了膜的亲疏水性、表面形貌和水通量大小,并对其抗污和抗菌性能进行了表征,最优配比膜M5的水通量为498.96 L·(m2·h)−1,抗菌率达到91.5%,水通量恢复率提高至74.17%,抗污性能进而提高。将废旧选择性催化还原法脱硝催化剂与膜相结合,提高膜性能的同时能够资源再利用,践行绿色发展理念。

-

关键词:

- 超滤膜 /

- 抗菌 /

- 离子液体 /

- 选择性催化还原法脱硝催化剂 /

- 聚偏氟乙烯

Abstract: The selective catalytic reduction denitrification catalyst(SCR catalyst) will adsorb harmful substances during its operation, which will be discharged along with the waste catalyst and contaminate the surrounding environment. In 2014, the Ministry of Environmental Protection classified this SCR catalyst as hazardous waste, and included it in the list of hazardous waste in 2016. In this study, the waste SCR catalyst was recovered from an air treatment enterprise. Then it was combined with an ionic liquid to obtain a highly efficient antibacterial agent. Subsequently, the phase conversion method was used to prepare the organic-inorganic ultrafiltration membrane with high water flux by blending the antibacterial agent with polyvinylidene fluoride. The hydrophilicity, surface morphology, and water flux of the membranes were investigated through measurements of surface contact angle, scanning electron microscopy (SEM), atomic force microscopy (AFM), and low-pressure filtration experiments. Furthermore, their anti-fouling and antibacterial properties were characterized. The maximum water flux was 498.96 L·(m2·h)−1 with a high antibacterial rate of 91.5%. Additionally, the water flux recovery rate increased to 79.79%, and the anti-fouling performance was further enhanced. The waste SCR catalyst is integrated with the membrane, thereby enhancing membrane performance and promoting resource recycling, aligning with the principles of green development.-

Key words:

- ultrafiltration membrane /

- antibiosis /

- ionic liquid /

- SCR catalyst /

- PVDF

-

燃煤烟气脱硫工艺分为湿法脱硫、干法脱硫和半干法脱硫3种[1-3]。其中,湿法脱硫工艺应用最广泛,SO2脱除率达95%以上。然而,该工艺存在设备腐蚀严重、易造成石膏雨,并产生大量废水等问题[4-6]。干法脱硫为气固反应,其工艺流程及装置较为简单,且具有能耗低、二次污染少等优点,但其脱硫效果较差、脱硫剂利用率较低,且系统运行可靠性不高[7]。半干法脱硫工艺为气、液、固三相反应,利用烟气显热可将湿浆料中的水分或喷入的增湿水加热蒸发以实现烟气增湿,其产物呈干燥态[8-9]。半干法脱硫工艺结合了湿法脱硫工艺和干法脱硫工艺的优势,且SO2脱除率可达90%以上[10-11],故备受关注。

半干法脱硫工艺采用Ca(OH)2为脱硫剂。在干燥条件下,Ca(OH)2几乎不与SO2反应,而在有水或水蒸气存在的条件下,Ca(OH)2与SO2具有很高的反应活性[12-15]。因此,探究水及其他因素对半干法脱硫效果的影响,对于其工况的选取及工艺的改进具有重要意义。式(1)、式(2)为有水及水蒸气存在的条件下Ca(OH)2与SO2的主要脱硫反应方程式。

Ca(OH)2+SO2+H2O→CaSO3⋅2H2O (1) CaSO3⋅2H2O+1/2O2→CaSO4⋅2H2O (2) 本研究利用固定床反应器,以Ca(OH)2作为脱硫剂,考察反应温度、脱硫剂颗粒粒径、反应空速、模拟烟气中水蒸气含量对半干法脱硫反应的影响;同时,以脉冲增湿方法改善半干法工艺的脱硫效果,以期为钙基半干法脱硫工艺的改进提供参考。

1. 实验材料和方法

1.1 实验材料

所使用的二氧化硫气体(SO2,浓度1%,氮平衡)、空气(Air,21%O2/N2)、氮气(N2,纯度99.999%)均购自北京环宇京辉京城气体科技有限公司;氢氧化钙(Ca(OH)2,AR,≥95.0%)购自天津百伦斯生物技术有限公司;无水氯化钙(CaCl2,AR,≥96.0%)购自国药集团化学试剂有限公司。

1.2 实验装置和方法

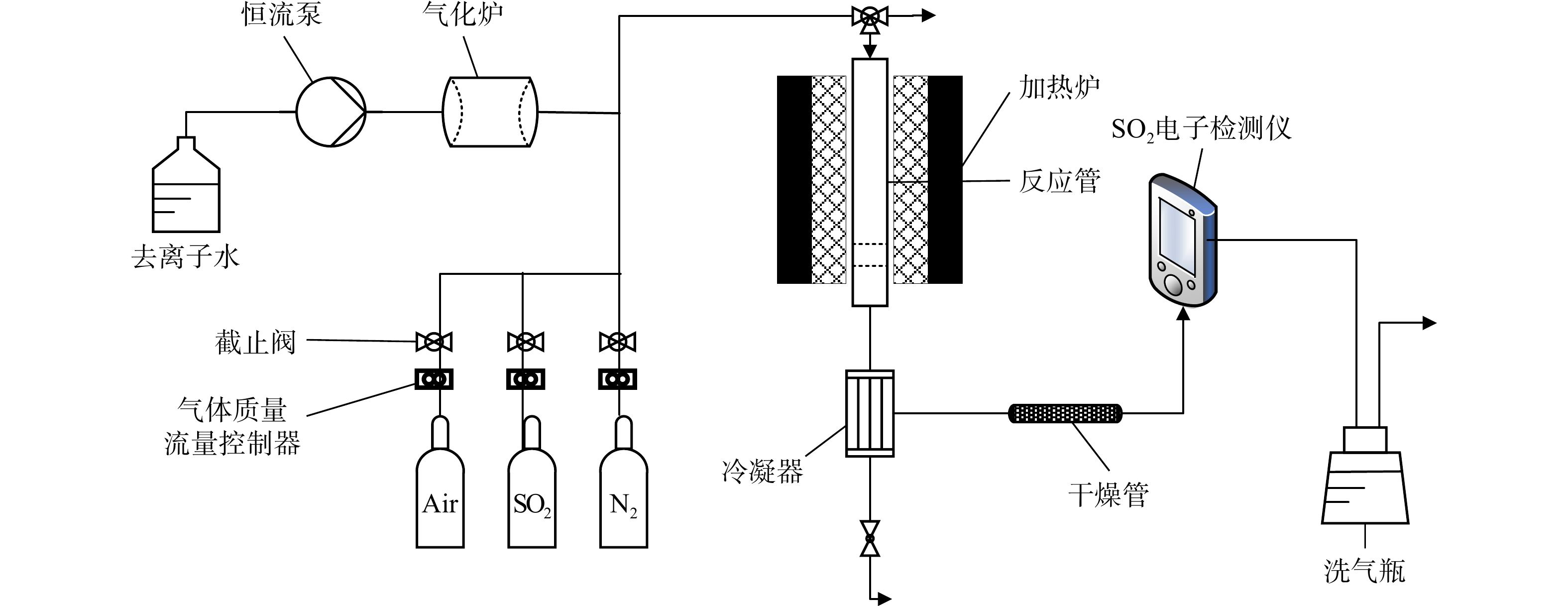

实验装置由配气系统、反应系统、出口气体检测系统、尾气处理系统4部分组成(见图1)。配气系统主要装置有恒流泵、气化炉、气瓶(SO2、N2、Air);反应系统主要有加热炉和管式固定床反应器;出口气体检测系统由冷凝器、干燥管、SO2检测仪组成;尾气处理系统为盛有NaOH水溶液的洗气瓶。

模拟烟气的SO2、N2及空气流量由质量流量控制器设定。SO2质量浓度为2 285.7 mg·Nm−3。去离子水经连接管路流入气化炉,其流量由恒流泵控制,在气化炉中产生水蒸气后再与反应气混合并通入固定床反应器中进行脱硫反应。

将200目的Ca(OH)2粉末加去离子水制浆后造粒,在120 ℃下干燥,再破碎、筛分,得到不同粒径的Ca(OH)2颗粒备用。固定床下部填充直径2 mm的刚玉球作为支撑,并在刚玉球上方装填Ca(OH)2颗粒。

反应管出口气体经过冷凝器、干燥管除水后,进入SO2检测仪进行分析,之后进入尾气处理系统经充分净化后外排至环境中。

1.3 参数定义

采用SO2检测仪分析进出口SO2质量浓度。我国火电厂燃煤烟气中SO2的质量浓度排放标准为35 mg·Nm−3[16]。本研究将该质量浓度定义为SO2穿透浓度,将SO2出口质量浓度达到穿透浓度时的反应时间定义为穿透时间。

脱硫率(η)的计算方法式为式(3)。Ca(OH)2利用率(Ue)是评价脱硫效果及脱硫反应经济性的重要指标,其计算式为式(4)。Ca/S,即Ca(OH)2的使用量与SO2穿透时的SO2脱除量之比,其计算式为式(5)。

η(%)=Cin−CoutCin×100 (3) Ue=Vt1∫0(Cin−Cout)dt2285.7Vt2 (4) Ca/S=NCa(OH)2NSO2 (5) 式中:Cin为反应气体中SO2进口质量浓度,mg·Nm−3;Cout为SO2出口质量浓度,mg·Nm−3;V为反应气体体积流量,mL·min−1;t1为脱硫反应的穿透时间,min;t2为脱硫反应的理论反应时间,min;

NCaOH2 NSO2 2. 结果和讨论

2.1 反应温度对脱硫效果的影响

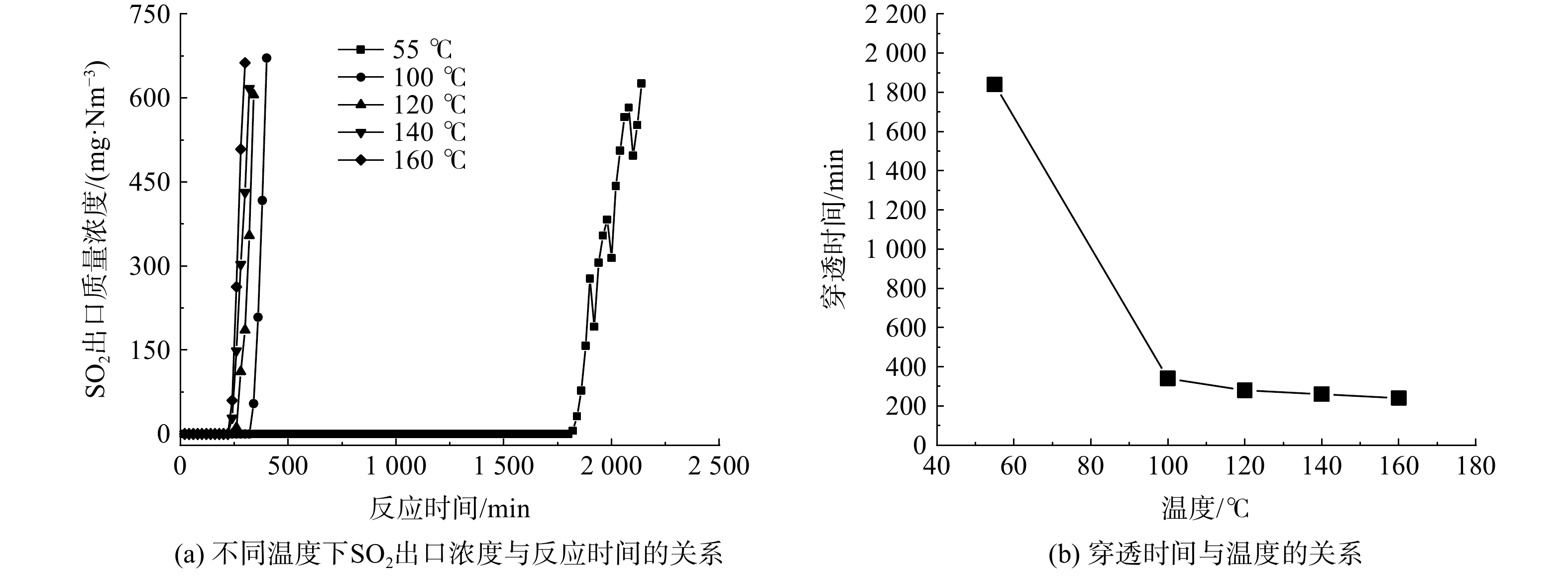

温度对Ca(OH)2与SO2的脱硫反应有一定影响。在55~160 ℃下,采用平均粒径0.58 mm的Ca(OH)2颗粒,在空速2 500 h−1、含硫气体中水蒸气体积分数5%的条件下进行脱硫实验,SO2出口质量浓度随反应时间的变化如图2(a)所示,穿透时间与反应温度的关系如图2(b)所示。穿透时间随温度的升高而降低,当温度由55 ℃逐渐升至160 ℃时,穿透时间由1 840 min降至240 min。此结果表明,在55~160 ℃下,Ca(OH)2的脱硫效果会随着反应温度的升高而下降,这与文献[17-18]的结论相吻合。

2.2 Ca(OH)2颗粒的粒径对脱硫效果的影响

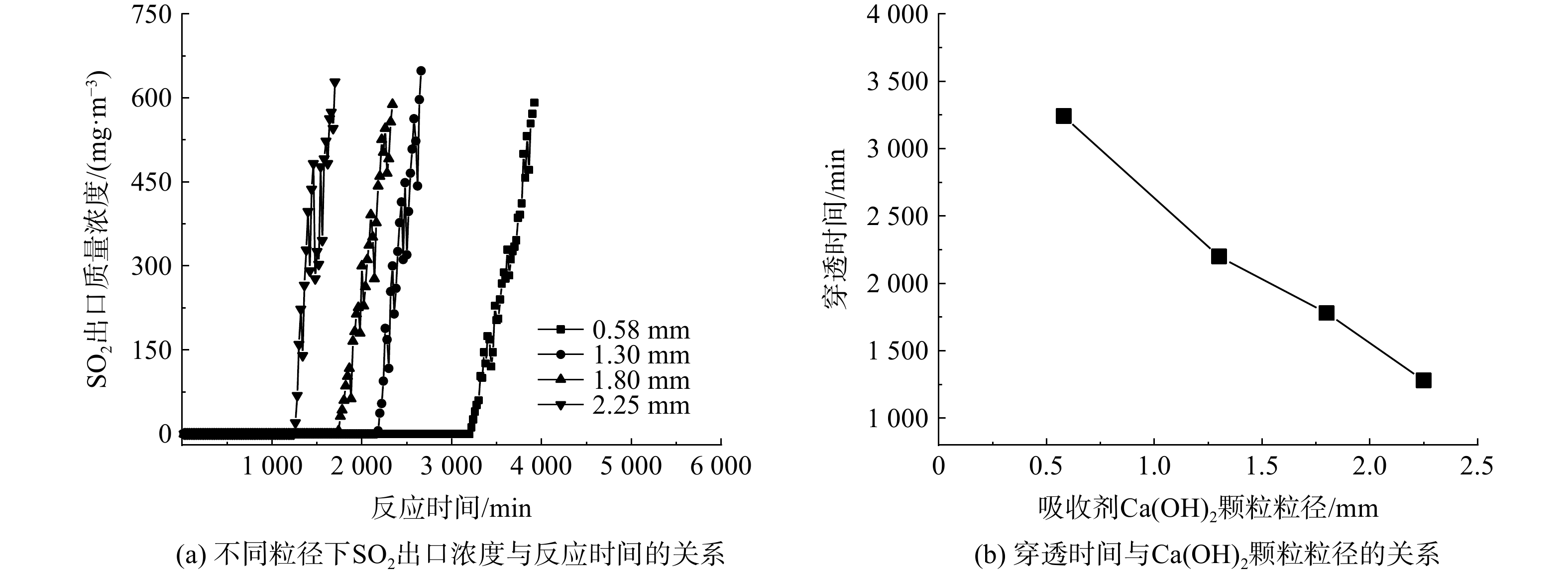

固定床反应器内填充的Ca(OH)2颗粒粒径越大,床层空隙率则越高。为避免空隙率过高影响实验结果,采用了40 mm直径的反应管。较大的管径比可有效减小壁面附近空隙增大时带来的壁面效应影响[19]。同时,Ca(OH)2颗粒粒径的增大还会造成SO2的内扩散阻力增大,不利于进行脱硫反应。图3反映了半干法脱硫在不同Ca(OH)2颗粒粒径条件下的实验结果,在55 ℃、2 500 h−1及水蒸气体积分数为12%的条件下,随着Ca(OH)2颗粒粒径的增大,脱硫反应的穿透时间不断缩短。

图4分别反映了Ca/S及Ca(OH)2利用率与Ca(OH)2颗粒粒径的变化关系。在Ca(OH)2颗粒的平均粒径为0.58 mm、反应温度为55 ℃、空速为2 500 h−1、水蒸气体积分数为12%的条件下,当出口SO2达到穿透浓度时,可获得本实验的最佳脱硫效果。根据式(4)和(5)计算出该条件下的Ca(OH)2利用率为71.3%、Ca/S为1.4。Ca/S随Ca(OH)2粒径的增加而不断增大,而Ca(OH)2利用率则不断降低。当Ca(OH)2颗粒的平均粒径由0.58 mm增至2.25 mm时,Ca/S由1.4增至3.6,Ca(OH)2的利用率则从71.3%降至27.8%。可见,Ca(OH)2颗粒的平均粒径增大不利于半干法脱硫效果的提升。这是由于:Ca(OH)2颗粒的粒径增大会造成颗粒的比表面积减小及SO2内扩散阻力的增加,导致颗粒内部大量Ca(OH)2未能与SO2发生反应,最终使得Ca(OH)2利用率降低,穿透时间随之缩短。

2.3 空速对脱硫效果的影响

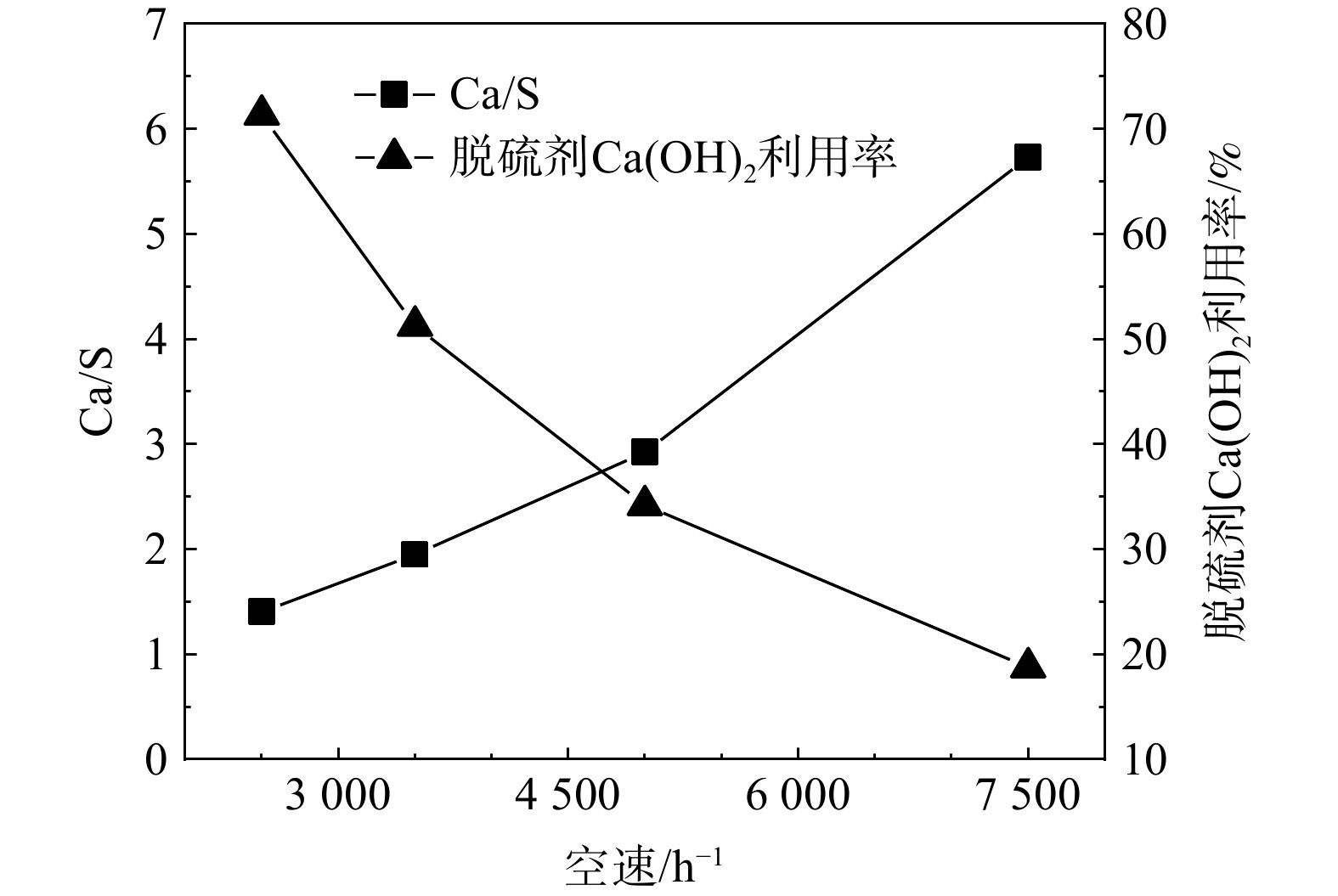

空速对脱硫效果的影响如图5所示。空速的提高使得脱硫反应的穿透时间缩短,在Ca(OH)2颗粒平均粒径为0.58 mm、水蒸气体积分数为12%、温度为55 ℃的条件下,当空速由2 500 h−1升至7 500 h−1时,穿透时间由3 240 min大幅降至260 min。

不同空速对Ca/S及脱硫剂Ca(OH)2利用率的影响如图6所示。随着反应空速的增大,Ca/S随之增大而Ca(OH)2利用率则随之降低。保持其他条件不变,当反应空速由2500 h−1增加到7500 h−1时,Ca/S由1.4提高为5.7,Ca(OH)2的利用率则由71.3%降低到18.8%。可见,空速的增大会导致脱硫效果急剧下降。在较高的空速下,烟气在床层的停留时间会缩短,脱硫反应速率则大幅提高。反应中会快速生成大量脱硫产物并覆盖至脱硫剂颗粒表面,所形成的致密产物层可阻止SO2与颗粒内部的Ca(OH)2继续反应,使得脱硫反应快速穿透。

2.4 反应气体中水蒸气含量对脱硫效果的影响

在半干法脱硫工艺中,烟气中的水蒸气含量对脱硫效果影响显著[20-21]。图7反映了水蒸气体积分数对脱硫效果的影响规律。穿透时间随着反应气体中水蒸气含量的增加而增大,在Ca(OH)2颗粒平均粒径为0.58 mm、空速为2 500 h−1、温度为55 ℃的条件下,当水蒸气的体积分数由5%升至12%时,脱硫反应的穿透时间由1 840 min大幅增至3 240 min。

水蒸气体积分数对Ca/S及脱硫剂Ca(OH)2利用率的影响如图8所示。随着水蒸气含量的增加,Ca/S相应不断降低,Ca(OH)2利用率则不断提高。水蒸气的体积分数由5%增至12%时,Ca/S由2.5降至1.4,Ca(OH)2的利用率由40.9%增至71.3%。这表明水蒸气含量的增大有利于半干法脱硫反应的进行。实际上,烟气中水蒸气的体积分数越大,反应中Ca(OH)2颗粒的表面越容易润湿从而形成液膜,这使得Ca(OH)2可游离出部分OH−,进而与烟气中的SO2进行快速、充分的离子反应[22-23]。反之,当烟气中水蒸气含量太低时,水蒸气不足以使得Ca(OH)2颗粒表面润湿,SO2与Ca(OH)2的离子反应便难以进行。当烟气为不含水蒸气的极端干燥状态时,SO2与干燥的Ca(OH)2几乎不发生反应[24]。

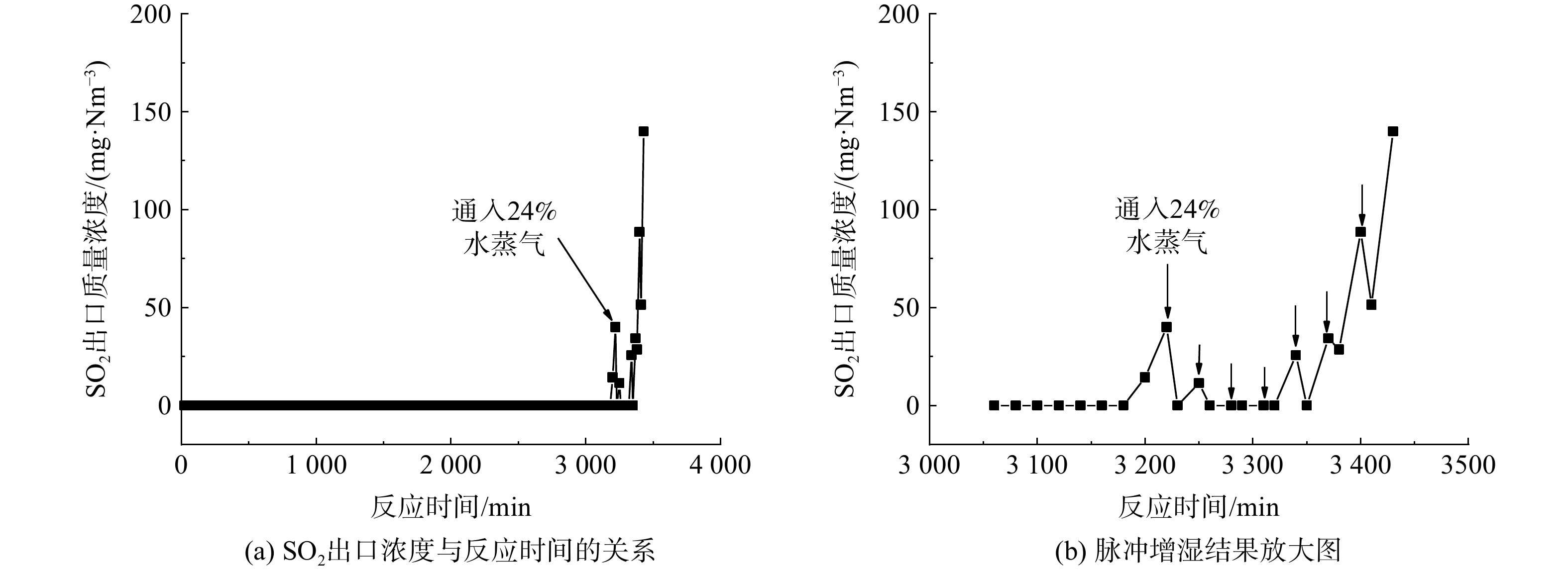

本研究提出了以脉冲式增湿方法对半干法脱硫工艺进行改进,故对水蒸气含量对半干法脱硫反应的影响进行了研究。当出口SO2质量浓度首次达到穿透浓度时,通过恒流泵调节水的流量,使反应气体中的水蒸气体积分数由12%增至24%并保持10 min。之后,将水蒸气体积分数调回原来的12%。20 min之后,再将反应气体中的水蒸气体积分数由12%增至24%并保持10 min。如此循环往复进行脉冲式的增湿,直至脱硫反应出口SO2质量浓度再次达到35 mg·Nm−3这一穿透浓度,结果如图9所示。图9(b)中的箭头为反应气体中的水蒸气体积分数由12%增至24%的时间节点。在反应3 220 min时,出口SO2质量浓度达到40 mg·Nm−3,即在水蒸气体积分数为12%条件下,脱硫反应首次穿透。而首次脉冲增湿后,出口SO2质量浓度降至0,接着水蒸气体积分数调回原先的12%并保持20 min。之后出口SO2质量浓度逐渐增至11 mg·Nm−3。这表明水蒸气含量的增加促进了脱硫,即使在反应穿透后,通过增加水蒸气含量仍可增加脱硫剂颗粒表面的润湿程度,使得SO2与颗粒内部未反应的Ca(OH)2得以继续反应。如此循环往复,直至第7次脉冲增湿时还有明显效果。在前6次脉冲增湿期间,出口SO2质量浓度一直保持低于穿透浓度。通过脉冲增湿,反应穿透时间延长了约160 min,Ca(OH)2利用率提高了4.4%,Ca/S由1.43降至1.36。

又研究了Ca(OH)2颗粒的平均粒径为2.25 mm时的脱硫反应当出口SO2浓度首次达到穿透浓度时脉冲增湿方法对脱硫效果的影响。实验结果如图10所示。结果表明,脉冲增湿使得该条件下的脱硫反应的穿透时间延长了约720 min,计算得到的Ca(OH)2利用率提高了15.6%,Ca/S由3.6降低到了2.3。2.25 mm的Ca(OH)2颗粒粒径条件下的脉冲增湿结果虽然仍与本实验最佳脱硫效果有较大差距,但脉冲增湿对脱硫效果的改善幅度较0.58 mm Ca(OH)2颗粒粒径的条件下有了较大提升。

分析脉冲式增湿方法对半干法脱硫效果的促进原因可发现,由于水蒸气体积分数为24%时,反应气体处于过饱和状态,在进入反应管后易凝结成为液态水并覆盖在Ca(OH)2颗粒表面形成液膜,使得脱硫剂表面及内部未反应的Ca(OH)2得以继续游离出部分OH−并与SO2发生反应,最终导致出口SO2质量浓度降低,穿透时间也相应延长。然而,长时间通入24%体积分数的水蒸气会发生Ca(OH)2颗粒团聚和床层板结,而以2:1的时长比循环通入水蒸气体积分数为12%和24%的脉冲增湿方法,则可保证在脱硫效果改善的同时有效避免上述不利情形发生。因此,采用脉冲增湿方法可优化半干法脱硫技术。

3. 结论

1)较低的反应温度、Ca(OH)2颗粒粒径的减小、反应空速的降低、烟气中水蒸气含量的提高均有利于半干法脱硫效果的提升,即有利于穿透时间的增加、脱硫剂利用率的提高及Ca/S的降低。当反应温度为55 ℃、Ca(OH)2颗粒平均粒径为0.58 mm、反应空速2 500 h−1、烟气中水蒸气体积分数12%时,可获得最佳脱硫效果。在SO2质量浓度为穿透浓度(35 mg·Nm−3)时,Ca(OH)2利用率达可到71.3%,Ca/S为1.4。

2)脉冲增湿方法可促进半干法脱硫工艺的脱硫效果。在上述最佳条件下,当反应器出口SO2达到穿透浓度时,通过实施脉冲增湿,即间歇提高反应气体中水蒸气体积分数可使穿透时间延长160 min,达到3 380 min,此时Ca(OH)2利用率提高了4.4%。采用脉冲增湿方法可优化半干法脱硫工艺。

-

表 1 实验所用主要化学试剂

Table 1. Main chemical reagents used in the experiment

试剂名称 英文全称及简写 纯度/规格 生产厂家 聚偏氟乙烯 polyvinylidene difluoride(PVDF) 分析纯 麦克林试剂有限公司 N,N—二甲基乙酰胺 N,N—dimethylacetamide(DMAc) 分析纯 阿拉丁生化试剂有限公司 聚乙烯吡咯烷酮 polyvinylpyrrolidone k30(PVP-k30) 分析纯 阿拉丁生化试剂有限公司 双癸基二甲基氯化铵 didecyl dimethyl ammonium chloride 分析纯 上海皓鸿生物医药科技有限公司 牛血清蛋白 bovine albumin(BSA) 分析纯 阿拉丁生化试剂有限公司 腐殖酸 humic acid(HA) 分析纯 国药集团化学试剂有限公司 十二烷基硫酸钠 sodium dodecyl sulfate(SDS) 分析纯 国药集团化学试剂有限公司 表 2 不同配比的铸膜液

Table 2. Casting liquid with different proportions

膜编号 WSCR(质量百分比)/% IL(质量百分比)/% M0 0 0 M1 3.0 0 M2 5.0 0 M3 5.0 2.0 M4 5.0 6.0 M5 5.0 8.0 表 3 WSCR棒状结构和块状结构所含元素

Table 3. Elements contained in rod-like structure and block-like structure of WSCR catalyst

棒状结构 块状结构 元素 含量占比/% 元素 含量占比/% O 49.2 O 46.9 Si 25.4 Ti 32.1 Ca 15.7 C 11.9 Al 8.0 Ce 3.6 Ti 1.6 La 2.1 Mo 0.1 Si 1.2 V 0 Al 0.8 Mo 0.4 Fe 0.3 V 0.3 Mg 0.3 表 4 WSCR&IL-PVDF膜孔隙率以及平均孔径

Table 4. WSCR&IL-PVDF membrane porosity and average pore size

膜样品 厚度/μm 孔隙率/% 平均孔径/nm M0 400 50.38±2.52 8.80±0.44 M1 400 77.38±3.87 8.28±0.41 M2 400 81.13±4.06 8.23±0.41 M3 400 74.50±3.73 9.06±0.45 M4 400 76.08±3.80 9.80±0.49 M5 400 79.81±3.99 9.45±0.47 -

[1] LANG W Z, XUAN Z, SHEN J P, et al. The contrastive study of chemical treatment on the properties of pvdf/pfsa and pvdf/pvp ultrafiltration membranes[J]. Desalination, 2014, 341: 72-82. doi: 10.1016/j.desal.2014.02.027 [2] YAN L, WANG J. Development of a new polymer membrane-pvb/pvdf blended membrane[J]. Desalination, 2011, 281: 455-461. doi: 10.1016/j.desal.2011.08.024 [3] YU H, SHANGGUAN S, YANG H, et al. Chemical cleaning and membrane aging of poly(vinylidene fluoride) (PVDF) membranes fabricated via non-solvent induced phase separation (NIPS) and thermally induced phase separation (TIPS)[J]. Separation and Purification Technology, 2023, 313: 123488. doi: 10.1016/j.seppur.2023.123488 [4] ZOU D, XIA L, LUO P, et al. Fabrication of hydrophobic bi-layer fiber-aligned pvdf/pvdf-psf membranes using green solvent for membrane distillation[J]. Desalination, 2023, 565: 116810. doi: 10.1016/j.desal.2023.116810 [5] DAI J, XIAO K, DONG H, et al. Preparation of Al2O3/pu/pvdf composite membrane and performance comparison with pvdf membrane, pu/pvdf blending membrane, and Al2O3/pvdf hybrid membrane[J]. Desalination and Water Treatment, 2016, 57(2): 487-494. doi: 10.1080/19443994.2014.967308 [6] GRASSO G, GALIANO F, YOO M J, et al. Development of graphene-pvdf composite membranes for membrane distillation[J]. Journal of Membrane Science, 2020, 604: 118017. doi: 10.1016/j.memsci.2020.118017 [7] TANG X, WU P, WANG Y, et al. Recent advances in heavy metal poisoning mechanism and regeneration methods of selective catalytic reduction (SCR) denitration catalyst[J]. Fuel, 2024, 355: 1-20. [8] WU P, TANG X, HE Z, et al. Alkali metal poisoning and regeneration of selective catalytic reduction denitration catalysts: Recent advances and future perspectives[J]. Energy & Fuels, 2022, 36(11): 5622-5646. [9] ZHANG Z, ZHAO Z, TAN D, et al. Overview of mechanisms of promotion and inhibition by H2O for selective catalytic reduction denitrification[J]. Fuel Processing Technology, 2023, 252: 107956. doi: 10.1016/j.fuproc.2023.107956 [10] LIU J, WANG C, WANG X, et al. Iron removal and titanium dioxide support recovery from spent V2O5-WO3/TiO2 catalyst[J]. Separation and Purification Technology, 2022, 301: 121934. doi: 10.1016/j.seppur.2022.121934 [11] KAWAI K, KANEKO K, YONEZAWA T. Hydrophilic quaternary ammonium type ionic liquids. systematic study of the relationship among molecular structures, osmotic pressures, and water-solubility[J]. Langmuir, 2011, 27(12): 7353-7356. doi: 10.1021/la201070n [12] HASSAN R, ASGHAR M A, IQBAL M, et al. A comparative evaluation of antibacterial activities of imidazolium, pyridinium, and phosphonium-based ionic liquids containing octyl side chains[J]. Heliyon, 2022, 8(5): e09533. doi: 10.1016/j.heliyon.2022.e09533 [13] PATIL V, MAHAJAN S, KULKARNI M, et al. Synthesis of silver nanoparticles colloids in imidazolium halide ionic liquids and their antibacterial activities for gram-positive and gram-negative bacteria[J]. Chemosphere, 2020, 243: 125302. doi: 10.1016/j.chemosphere.2019.125302 [14] ZUNITA M, HASTUTI R, ALAMSYAH A, et al. Polyionic liquid membrane: Recent development and perspective[J]. Journal of Industrial and Engineering Chemistry, 2022, 113: 96-123. doi: 10.1016/j.jiec.2022.06.027 [15] CYBULSKI J, WISNIEWSKA A, KULIG-ADAMIAK A, et al. Long-alkyl-chain quaternary ammonium lactate based ionic liquids[J]. Chemistry-A European Journal, 2008, 14(30): 9305-9311. doi: 10.1002/chem.200800973 [16] WALKIEWICZ F, MATERNA K, KROPACZ A, et al. Multifunctional long-alkyl-chain quaternary ammonium azolate based ionic liquids[J]. New Journal of Chemistry, 2010, 34(10): 2281-2289. doi: 10.1039/c0nj00228c [17] ALAYANDE A B, KANG Y, JANG J, et al. Antiviral nanomaterials for designing mixed matrix membranes[J]. Membranes, 2021, 11(7): 458. doi: 10.3390/membranes11070458 [18] LI Y, GAO S, ZHANG B, et al. Electrospun Ag-doped SnO2 hollow nanofibers with high antibacterial activity[J]. Electronic Materials Letters, 2020, 16(3): 195-206. doi: 10.1007/s13391-020-00203-6 [19] AKHTAR S, SHAHZAD K, MUSHTAQ S, et al. Antibacterial and antiviral potential of colloidal Titanium dioxide (TiO2) nanoparticles suitable for biological applications[J]. Materials Research Express, 2019, 6(10): 105409. doi: 10.1088/2053-1591/ab3b27 [20] ZHOU L, SHI C, XU X, et al. Robust nanoporous Cu/TiO2 ceramic filter membrane with promoted bactericidal function[J]. Science China-Technological Sciences, 2022, 65(11): 2687-2694. doi: 10.1007/s11431-022-2151-0 [21] BORMASHENKO Y, POGREB R, STANEVSKY O, et al. Vibrational spectrum of pvdf and its interpretation[J]. Polymer Testing, 2004, 23(7): 791-796. doi: 10.1016/j.polymertesting.2004.04.001 [22] LIU L, FU W, WANG L, et al. Dopamine-coated nano-SiO2-modified pvdf piezoelectric composite film[J]. New Journal of Chemistry, 2021, 45(26): 11544-11551. doi: 10.1039/D1NJ01153G [23] SAGAR R, GAUR M S, ILKOVIC S. Effect of 105 MeV gold ion irradiation on dielectric properties of pvc/pvdf@BaZrO3 nanohybrid thin film[J]. Radiation Effects and Defects in Solids, 2024, 179: 501-513. doi: 10.1080/10420150.2023.2294032 [24] 何文玉. 反蛋白石结构聚偏氟乙烯滤膜的制备及性能研究[D]. 杭州: 浙江理工大学, 2023. [25] SHI F, MA Y, MA J, et al. Preparation and characterization of pvdf/TiO2 hybrid membranes with ionic liquid modified nano-TiO2 particles[J]. Journal of Membrane Science, 2013, 427: 259-269. doi: 10.1016/j.memsci.2012.10.007 [26] WANG X, LI X, YUE J, et al. Fabrication of poly(vinylidene fluoride) membrane via thermally induced phase separation using ionic liquid as green diluent[J]. Chinese Journal of Chemical Engineering, 2020, 28(5): 1415-1423. doi: 10.1016/j.cjche.2020.01.011 [27] QIAN W, SUN S, JOHNSON T J, et al. Integrated analysis of chain orientation induced anisotropy in nanoimprinted pvdf based copolymers[J]. Polymer, 2022, 239: 124435. doi: 10.1016/j.polymer.2021.124435 [28] TADIC A P, BLAGOJEVIC V A, STOJANOVIC D, et al. Nanomechanical properties of pvdf-ZnO polymer nanocomposite[J]. Materials Science and Engineering B: Advanced Functional Solid-State Materials, 2023, 287: 116126. [29] YAN L, YANG X, ZENG H, et al. Nanocomposite hydrogel engineered hierarchical membranes for efficient oil/water separation and heavy metal removal[J]. Journal of Membrane Science, 2023, 668: 121243. doi: 10.1016/j.memsci.2022.121243 [30] MUKHERJEE M, BANDYOPADHYAYA R. Engineered polyethersulfone membrane for well-dispersed silver nanoparticle impregnation at high loading: High water permeate flux and biofouling prevention[J]. Water Science and Technology, 2021, 84(1): 27-42. doi: 10.2166/wst.2021.218 [31] LIANG X, DAI R, MA H, et al. Synergistic antibacterial properties of ZnO-SnO2 composite under both light and dark conditions[J]. Ceramics International, 2022, 48(21): 32089-32103. doi: 10.1016/j.ceramint.2022.07.148 [32] MISHRA J R, SAMAL S K, MOHANTY S, et al. Polyvinylidene fluoride (PVDF)/Ag@TiO2 nanocomposite membrane with enhanced fouling resistance and antibacterial performance[J]. Materials Chemistry and Physics, 2021, 268: 124723. doi: 10.1016/j.matchemphys.2021.124723 -

下载:

下载: