-

排水管道是排水系统的重要组成部分,具有收集和输送污废水和雨水的功能,在保障居民生活卫生、控制水环境污染、降低洪涝灾害等方面发挥了重要作用[1]。在自身结构特征和外界环境因素的影响下,排水管道在长期运行过程中容易发生堵塞[2-3],堵塞造成的管道溢流风险将对周边居民正常生活和环境质量造成严重威胁[4-5],且疏通堵塞的运维费用消耗巨大[6]。为解决排水管道堵塞问题,行业内已开展大量研究,对排水管道的堵塞成因、发展机制和控制方法进行了广泛探索[7]。

脂肪、油和油脂 (fat, oil and grease,FOG) 沉积物的形成和发展是造成排水管道堵塞的关键因素之一[8],由FOG沉积物造成的排水管道堵塞占所有排水管道堵塞的40%~50%[9-10]。为解决排水管道堵塞问题,亟需开展针对排水管道内FOG沉积物的研究,解析其理化特征、形成机制和控制方法。目前,已有研究解析了FOG沉积物的物质组成、发展过程、控制方法等[11],然而研究对象和研究目标相对分散,亟待梳理关键参数并提出下一步的治理建议。

基于此,本研究系统调研现有排水管道FOG沉积物研究,总结排水管道内FOG沉积物的理化特征及形成机制,探讨排水管道FOG沉积物的控制方法并提出研究建议,以期为排水管道堵塞领域的进一步研究提供参考,并助推相关技术的研发和应用。

-

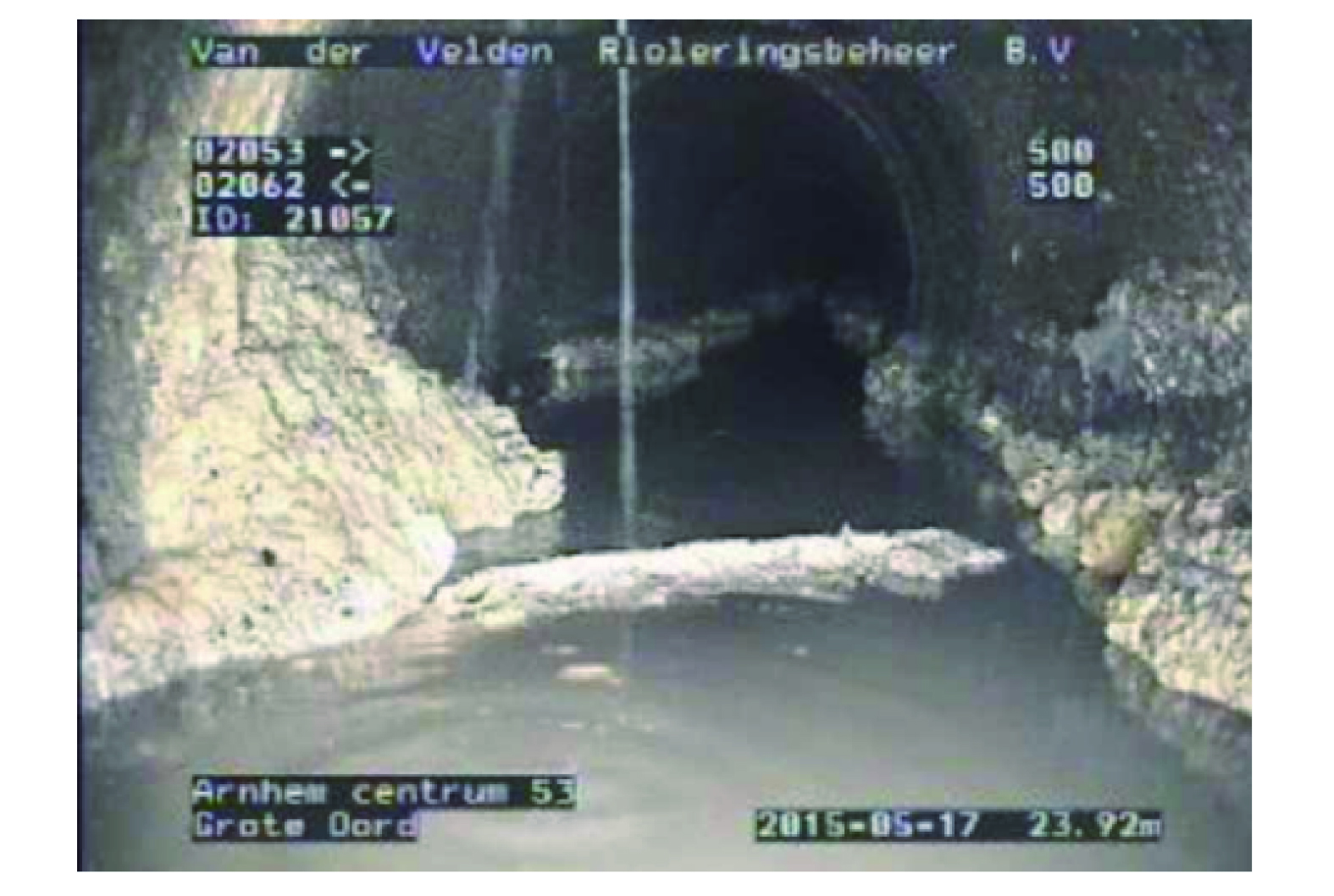

在实验室状态下,FOG沉积物为浅棕色或白色、无臭、密度小于水且不溶于水[6,12],但可溶于有机溶剂 (如正己烷、乙醚和氯仿) 的固体[13]。在下水管道内,FOG沉积物呈黄褐色并散发恶臭[11,14] (图1) 。FOG沉积物具有含水率高 (最高95%) 、挥发性高[6]、密度低 (0.66~1.23 g·cm−3) 、屈服强度高 (最大34.24 kPa) 和熔点宽泛 (15~300 ℃) 等特点[15-16]。

-

FOG沉积物主要由游离脂肪酸 (free fatty acid,FFA) 和金属离子组成,其中金属离子包括铝、钙、镁、钠、铜、锌、铁、钾等[17]。钙是FOG沉积物中含量较高的金属[18],占总固体质量的0.01%~19.8%,铁、镁和铝的含量相对较少[16]。实验生成的皂化固体总脂肪酸 (fatty acid,FA) 含量为80.4%~98.9%,而在现场FOG沉积物的含量为78.5%~91.4%[15]。FOG沉积物主要呈弱酸性到强碱性,其中弱酸性主要归因于厨房废水中的有机化合物和隔油池微生物活动引起的酸化[19-20]。弱碱性到强碱性的变化主要归因于碱性洗涤剂用量的变化。除此之外,FOG通常是中性的[21]。

-

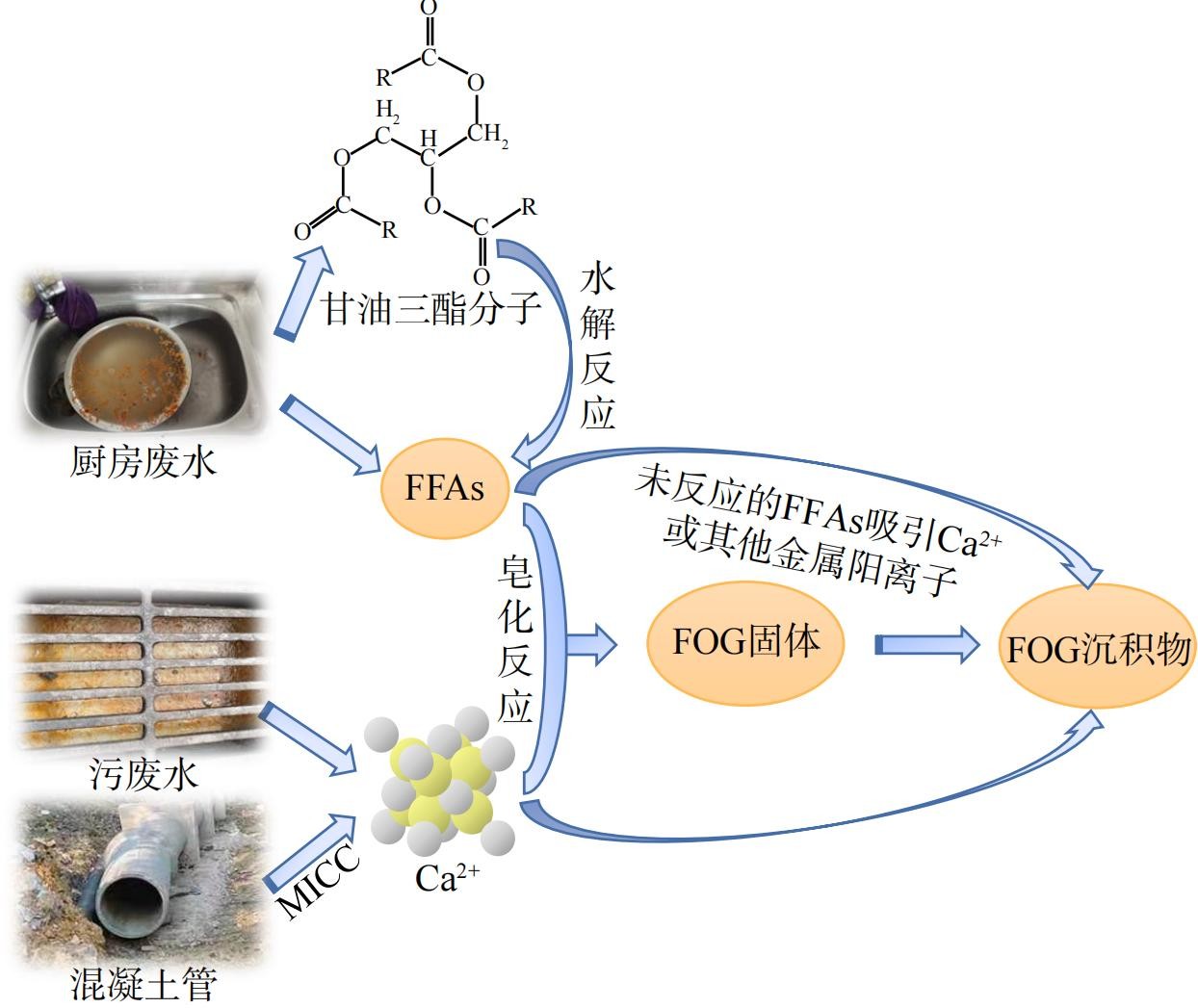

含有大量甘油三酯的废水被排放到下水道中,甘油三酯分子通过水解反应被分解为FA和甘油[22]。其中,一些FFA与下水道管道中的Ca2+和Na+发生皂化反应,形成皂化固体。皂化固体粘附沉积在管道内壁,形成FOG沉积物[23]。具体而言,FOG沉积物的形成机制可概括为3个过程。1) 污水中含有的或排水管道释放的金属离子 (比如Ca2+) 聚集压缩FFA胶体颗粒双电层,增大FFA发生皂化反应的几率[24];2) FFA和Ca2+等金属离子之间发生皂化反应,产生皂化固体,凝固并积聚在排水管道管壁上和管道中的固体物质上[23];3) 附着在排水管道管壁上的皂化沉积物,吸引废水中未反应的FFA。然后,在范德华力和静电力的共同作用下,这些未反应的FFA吸引Ca2+或其他金属阳离子[25],通过皂化反应形成沉积固体,粘附在先前形成的脂肪酸钙盐上,导致FOG沉积物在下水管道内壁上积聚,并造成管道堵塞[26]。FOG沉积物的形成过程如图2所示。

-

FOG沉积物的形成受金属离子类型和质量浓度、FFA类型和质量浓度、pH、温度、流速、管道结构和根系入侵等因素的影响[8,27]。FOG沉积物的物理特性如熔点和硬度的变化可归因于Ca2+。Ca是FOG沉积物中最常见的金属,其次是Na、Fe、Al和Mg[6]。形成FOG沉积物所需要的Ca2+一部分来自于自然存在于废水中,另一部分是由微生物引起的混凝土腐蚀 (microbially induced concrete corrosion,MICC) 溶解混凝土中的钙化合物产生的Ca2+释放。污水pH和温度分别影响混凝土管道的Ca2+释放量和管道废水中Ca2+的溶解度[23],从而影响FOG沉积物中的Ca2+浓度。当Ca2+浓度增大时,FOG沉积物的熔点和硬度会相对变高,其内聚力也会变大[24],同时反应中Ca2+也明显增加了沉积物的质量[15,28]。

污水中FFA的类型和浓度是决定沉积物强度的主要因素[14,29]。FFA的浓度是FOG沉积物体积、质量和状态差异的原因,含有过量FFA的FOG沉积物重量较大、粘度较高[30]。含有不同FFA的FOG沉积物表现出不同的物理性质。比如含有大量饱和脂肪酸 (saturated fatty acids,SFAs) 的FOG沉积物结构强度较大,而不饱和脂肪酸 (unsaturated fatty acids,UFAs) 产生的沉积物结构强度相对较小[31]。同时,不同的FFA参与反应时的皂化程度不同,油酸、棕榈酸和硬脂酸比例较高的脂肪和油皂化程度更高,亚油酸和月桂酸只产生少量的皂化固体[30]。在参与皂化反应常见的FFA中,棕榈酸是最普遍的饱和脂肪酸,其浓度对皂化和固体形成的速度有很大影响[32]。建议在烹饪中更多地使用UFAs,同时避免大量SFAs进入下水管道,这会降低FOG沉积物的强度,并减少下水道溢流现象的发生[15]。

FOG沉积物的形成还受到温度的影响[33]。低温条件使皂化速度降低,沉积物的形成随之减缓[25]。高温条件则会加速废水中固态油脂的融化并水解为FFA,从而促进皂化反应,更快速地形成FOG沉积物[27]。FOG沉积物的形成是一个连续积累的过程,这个过程随着排水管道的水力特征、管件配置和空间结构的变化而变化[34]。排水管道内水体流速是影响沉积物沉积的重要因素之一,在管道下陷等影响排水流速的区域,较低水流速度对管道的冲刷力较小,使FOG沉积物的形成速率加快。同时,FOG更易吸附在表面粗糙度较大的管道或管件上,形成沉积物[34]。树根的入侵也被认为是造成FOG沉积物形成的一个重要影响因素[35]。排水管道的损坏和裂缝可能会导致树根的入侵,入侵的树根为下水道管道内的FOG沉积物的形成提供更大的表面积,加速了FOG沉积物的进一步积累[36-37]。

-

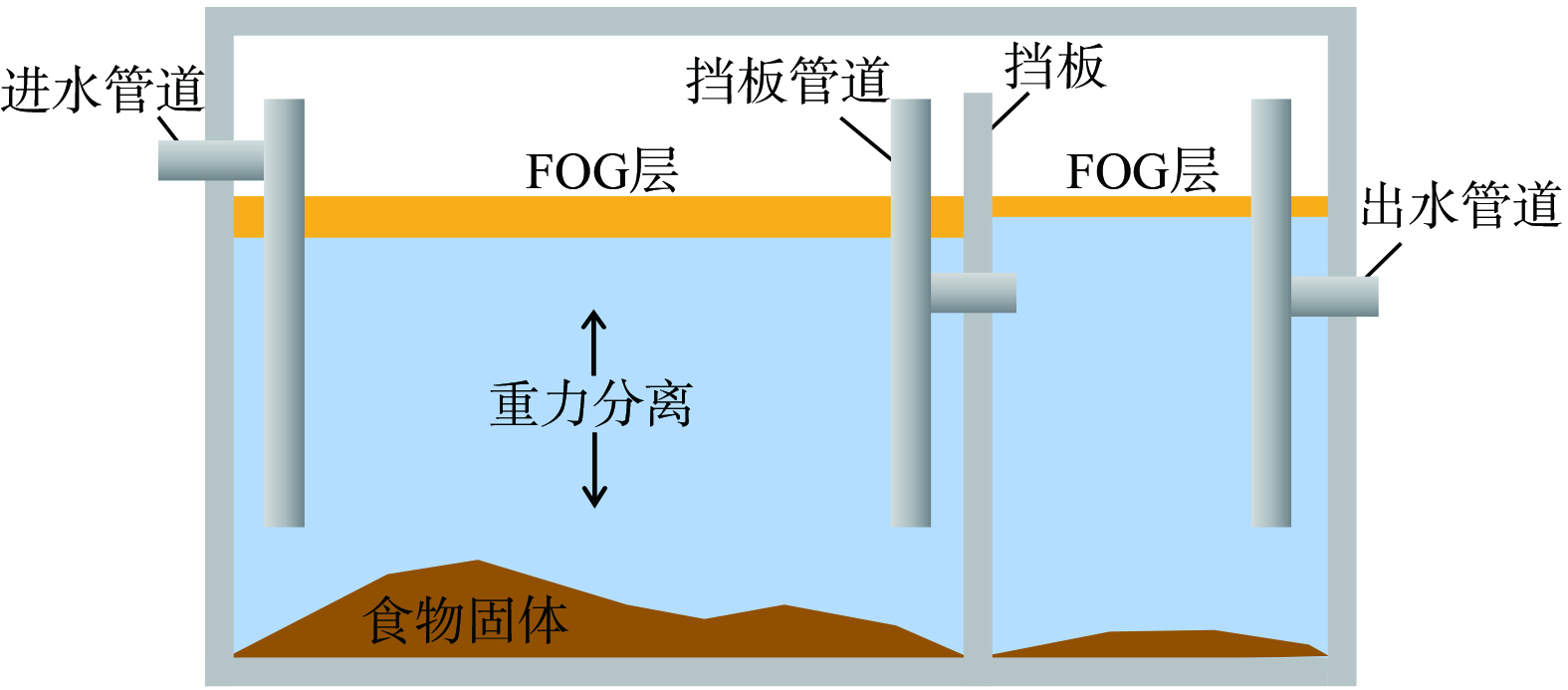

1) 隔油池预处理法。隔油池是利用油滴与水的密度差产生上浮作用来去除含油废水中可浮性油类物质的一种废水预处理构筑物。标准隔油池是一个带有水下进水管道和出口管道的两室水箱 (图3),其中第一个水箱占据了隔油池总体积的约70%[38],隔油池能在源头处理进入排水管道之前的废水,去除水中粒径大于150 μm的油滴[21],其中FOG和上浮污泥在水面堆积,密度较大的FOG固体颗粒物由于重力作用沉淀于装置底部,以达到去除水体FOG的效果[33]。

标准隔油池在20 min的水力停留时间 (hydraulic retention time,HRT) 下FOG的理论去除率约为78%,但现场实际使用的隔油池最大处理效率约为30%[38]。在缺少运维的情况下,分离固体颗粒物的过程可能无法正常进行,影响隔油池的处理效果,但通过调整标准隔油池的进水特征可适当提高处理效率[39]。适当降低进水温度有助于提高FOG去除效率。比如当进水温度从21 ℃增至38 ℃时,标准隔油池的去除效率下降了10%[40]。适当延长HRT可提高FOG去除效率,如当HRT从20 min增至1 h时,去除效率从78%增至90%[38]。FOG在隔油池中的乳化强度也会影响隔油池的去除效果。在弱乳化强度下,隔油池对FOG的去除率较高,随着乳化强度的增加,去除性能随之下降[40]。因此,可对标准隔油池的温度、HRT、废水乳化强度进行优化从而达到最高的FOG控制能力[40]。

此外,对标准隔油池进行内部结构改造也可提高FOG的控制能力。如使用扩口管道或分流式入口管道与分流式挡板管道的组合或者缩短隔油池入口管道并且取消中间挡板,通过提升水动力条件可有效提高FOG去除效率[38]。在隔油池中安装斜管沉淀器且HRT为30 min时,可最大限度提高FOG的去除效率。由于斜管沉淀器在很大程度上增加了油滴凝聚的有效表面积,从而加强油滴凝聚力,实现FOG的分离,且维护工作简单容易[41]。过用筛网、一级和二级沉淀池、FOG分离室和毛发过滤器组成的多隔间来改进隔油池的重力分离过程,通过提高水动力条件同时在流速为8.27 L·min−1条件下,系统可达到FOG的最佳去除效率,这种方法过程简单且处理效果好[42]。对隔油池的多种改进措施进行了对比,如表1所示。

2) 生物处理法。生物处理法是将选定的微生物菌株或混合培养物添加到废水中,以分解代谢废水中的有机物,达到提高污染物去除效率、缩短去除时间和削减成本等效果[43]。通过在隔油池中添加微生物菌株或混合培养物这一预处理过程,可减少FOG水解产生的游离脂肪酸并降低皂化率,从而降低隔油池污水中的FOG含量[44]。

由于芽孢杆菌具有生长速度快、分布广、易于培养并耐受多种不良条件的特点[45-46],通常被用作处理含油废水的生物降解剂[47-48]。嗜热芽孢杆菌菌株“IHI-91”能产生大量高浓度的热活性脂肪酶和酯酶,使其在很宽的温度范围内降解多种脂类,且该细菌在65 ℃和pH为6.0的条件下生长最佳,故该菌株通常被用作处理含油废水的理想菌株[49]。一种新分离的菌株铜绿假单胞菌D2D3可去除废水中大量FOG,当进水质量浓度≥5 000 mg·L−1时,FOG的去除率稳定且最高去除率超过97%[50-51]。单一属的芽孢杆菌能降解橄榄油的脂肪,却不能降解黄油的脂肪[52]。在单一属的芽孢杆菌内加入假单胞菌菌株CP1后对橄榄油和黄油的去除率分别为94%和97%[52]。多菌种添加剂“F69” (包含芽孢杆菌属、假单胞菌属、乳酸杆菌属、孢子菌和微球菌) 也具有降解各种脂肪和油的能力,其多菌种的特点能将几种脂肪酸的降解率提高37%~62%,而所有的单菌种实验均未达到这种效果[53-54]。

当隔油池中FOG含量过高时,在其中添加生物降解剂能有效降解废水中的FOG[55],这项技术可被广泛使用。不同生物降解剂对FOG去除效率的对比如表2所示。

3) 电絮凝法和气浮法。电絮凝 (electrocoagulatio,EC) 是一种利用电荷产生絮状物的电化学过程,是处理含FOG废水的一种可行工艺,其特点是去除废水中含量较高的FOG及不同浓度的悬浮固体和BOD5[56]。EC工艺可调节废水pH,对餐饮废水中油脂、SS、COD和BOD5的整体去除效率分别为94.4%~99.9%、84.1%~99.0%、68.0%~94.5%和59.3%~93.4%[57];对清洗汽车污水的油脂去除率为92.5%[58]。EC工艺在FOG控制方面具有污染物去除率高、设备尺寸紧凑、操作简单、综合费用较低的优势[59],但在处理废水方面的实际应用有限,这是由于实际现场样品中大量溶解性有机化合物会降低EC去除FOG的可靠性[57]。

气浮法是通过压缩空气的方式从隔油池底部安装的微孔扩散板的板面产生小气泡[60],利用高度分散的微小气泡作为载体粘附于废水中的油滴表面上,使其浮力大于重力和上浮阻力,从而使油滴上浮至水面,用刮刀去除表面颗粒,实现FOG与水的分离[61]。在聚合氯化铝 (PAC) 的帮助下应用气浮技术,可实现98.8%的FOG去除率[62]。使用气浮法处理含油废水会产生污泥,这些污泥可进一步转化为肥料或生物燃料[63]。气浮法的主要缺点是占用空间较大,在许多小型餐饮设施排水上难以利用[63]。

通过结合电絮凝和气浮来提高FOG处理效率,在这个过程中,电絮凝用来稳定和聚集细小颗粒,而气浮有助于形成漂浮的絮凝体[64],从而实现在较短HRT条件下高效去除油和油脂,其FOG去除效率可达到约95%[64]。

-

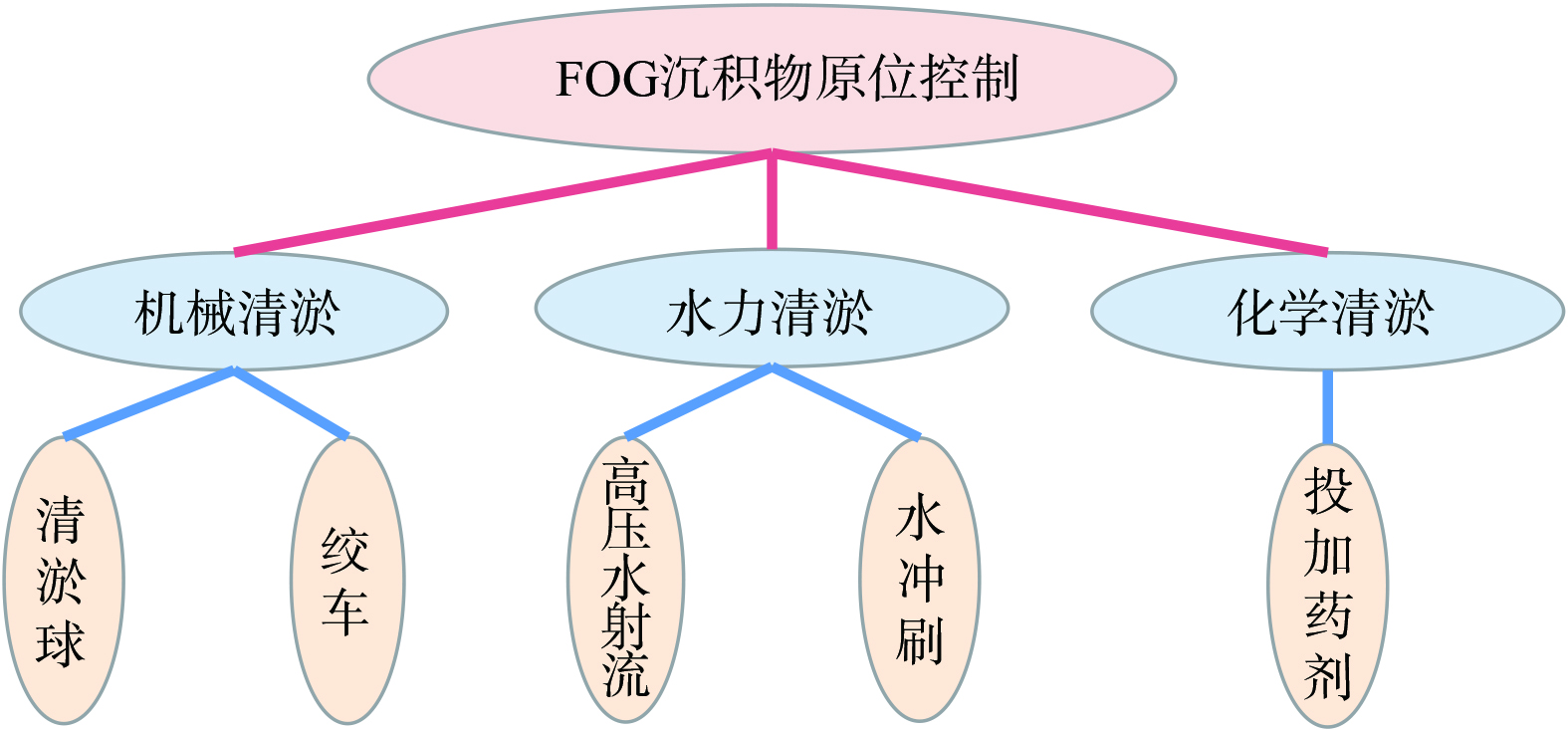

排水管道FOG沉积物的原位控制方法包括机械清淤、水力清淤和化学清淤3大类[65]。其中,机械清淤包括清淤球、绞车清淤等方法;水力清淤包括高压水射流清淤、水冲刷清淤等方法;化学清淤通过向排水管道中添加药剂去除FOG沉积物[66],FOG原位控制方法如图4所示。

清淤球清淤法是防止管道内发生FOG沉积的一种预防性方法[67],指将直径明显小于排水管道直径的清淤球在上游检查井放入到排水管道中,利用排水管道内的水流将清淤球推向下游检查井,并在下游检查井被回收[67]。球体在管道内运动的过程中球上带冲水孔的薄板使清淤球在管道中滚动,并迫使周围的污水快速搅动,从而将FOG沉积物搅起,并利用水流将其冲走[68]。该方法虽操作简便,但是一种预防性的清淤方法,管道淤积到一定程度后便不能适用[66]。

绞车清除FOG沉积物是目前国内普遍采用的方法[69],其工作原理是先用竹片穿过需要清通的管道,然后利用管道两端检查井上的绞车绞动钢丝绳,从而使FOG沉积物被清通工具刮至下游检查井中。这种方法可适用各种直径管道中FOG沉积较严重、粘结较密实的淤积清理[70]。

高压水射流清淤法是目前国内外广泛应用的一种管道水力清淤法,其工作原理是由喷射车引擎驱动高压水泵,将水加压后送入射水喷头,靠喷头射水产生的反作用力使喷头和胶管一起向前行进,清除排水管道中的FOG沉积物[69]。当喷头到达下游检查井时,机动卷扬机将软管卷回,卷回的过程中喷头继续喷射高速水流,将管道内残余的FOG沉积物冲到下游检查井内,最后由吸泥车将其吸走[67]。高压水射流清淤法的工作压力为70~150 MPa,且只限于清洗管径小于1.3 m的管道[71]。与机械清淤和化学清淤方法相比,高压水射流清洗有清洗效率高、清洗成本低、易于机械化、操作方便和安全可靠等优点[71]。

水冲刷清淤法是将清淤装置放到管道某一位置,利用装置将管道中的污水阻挡在装置的上游,当水位达到一定高度后便放水,利用上游蓄水形成的水流来冲走管道内的沉积物。每冲刷一次清淤装置就向下游移动一段距离,并再次进行集水清淤。该方法需要管道本身必须有一定流量,管道FOG沉积物不宜过多(约20%),且上游污水不能从其他支管流走[72]。

多种化学物质可用于去除或控制FOG沉积物的沉积,如酶、氢氧化物、腐蚀剂、杀菌剂和中和剂[73]。化学法清除管道中的FOG沉积物费用较高且有可能造成新的环境风险,故在实际应用中应用较少[66]。

-

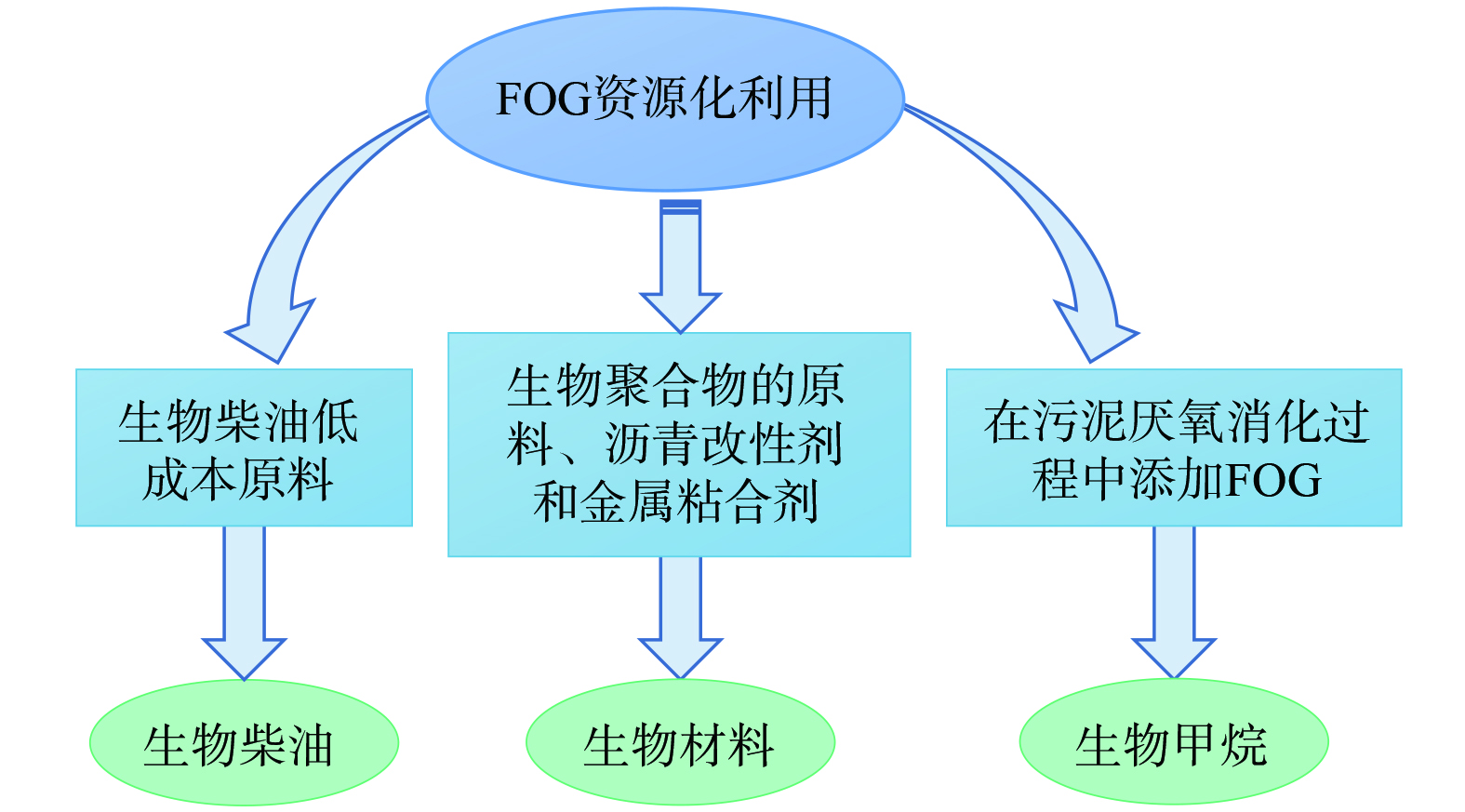

FOG可转化为多种形式的可再生能源或资源,如生物柴油和生物材料[74]。此外,FOG可作为额外的碳源,用于废水处理的污泥厌氧消化过程,以提高甲烷产量[75-76],资源化利用的方向和主要措施如图5所示。

FOG可作为生产生物柴油的低成本原料[77-78],其生产工艺首先使用正乙烷等有机溶剂萃取获得可用于酯化过程的原料[79],再采用两阶段工艺生产生物柴油,通过酯化或甘油分解工艺将FFA转化为烷基酯或甘油酯[80],然后采用均相催化剂、异相催化剂或酶催化剂将剩余的甘油酯转酯化为脂肪酸酯[80-82]。该技术的生物柴油产量高 (99%) 且FFA转化率高 (96%) [83],生产出的生物柴油具有良好的环境效益和经济可行性[84-86]。FOG也可帮助生产高价值环保生物聚合物和生物材料[87]。由FOG产生的生物油可被用作沥青改性剂和金属粘合剂等[88]。

此外,FOG含有挥发性脂肪酸 (VFA) ,由于其高生物降解性,有利于生物甲烷的产生[17]。在污泥厌氧消化器中添加FOG可以显著提高生物甲烷产量 (109%~197%) ,并可使污水处理厂通过现场发电满足50%以上的电力需求[89-90]。因此,FOG可作为生产沼气的原料,以提升污水处理的经济效益[91-92]。

-

1) 加强FOG沉积物的形成机制及影响因素研究。采用力学、材料学、微生物学等研究手段破解FOG沉积物的微观机制,解析FOG沉积物的时空分布特征和变化规律,量化构建FOG沉积物的数学模型。

2) 深化FOG沉积物的控制方法及管控策略探索。联合物理、化学、生物和管理多种手段开发新的FOG沉积物控制技术,采用生命周期评价方法评估不同技术的综合效益,针对不同情景提出成套的FOG沉积物控制方案。

3) 推动FOG资源化利用的研究和应用。以机理解析和控制方案研究结果为基础,研发相应的FOG采集、输送、资源化处置、末端处置相关配套技术及装备,推动FOG的安全、经济、高效资源化。

排水管道中脂肪、油和油脂 (FOG) 沉积物的理化特征、形成机制及控制方法

Physicochemical characteristics, formation mechanism and control methods of fat, oil and grease (FOG) deposits in drainage pipes

-

摘要: 脂肪、油和油脂 (FOG) 沉积物是排水管道堵塞的重要成因,对其开展机制研究并开发控制技术对于提高排水管道运行安全性和稳定性具有重要意义。在统筹分析既有FOG研究的基础上,系统论述FOG沉积物的物理化学特征及其在排水管道内的形成机制,并对FOG沉积物的影响因素和控制方法进行深入探讨,重点解析排水管道进水FOG控制、FOG沉积物原位控制以及FOG资源化利用的研究成果,从而提出针对排水管道FOG沉积物的研究建议,为排水管道FOG沉积物控制提供参考。Abstract: Fat, oil and grease (FOG) deposits are important causes of drainage pipe clogging, it is of great significance to study the mechanism and develop the control technology for improving the safety and stability of drainage pipe operation. Based on the comprehensive analysis of existing FOG research, the physicochemical characteristics of FOG deposits and their formation mechanism in drainage pipes were systematically discussed, and the influencing factors and control methods of FOG deposits were thoroughly explored. The research results of drainage pipe inlet FOG control, in-situ FOG deposit control and FOG resource utilization, were analyzed, so as to propose research recommendations for drainage pipe FOG deposits and provide reference for drainage pipe FOG deposit control.

-

Key words:

- fat, oil and grease(FOG) deposits /

- drainage pipes /

- formation mechanism /

- blockage /

- treatment

-

表 1 隔油池改进措施的对比

Table 1. Comparison of improvement measures of grease trap

改造方式 改造措施 去除效果 参考文献 优化进水特征 进水温度从21 ℃增加到38 ℃ FOG去除率下降10% [40] HRT从20 min增加到1 h时 FOG最大去除率90% [37] 乳化强度降低 FOG最大去除率为82% [40] 进水流速增加 FOG去除效率提高 [40] 改造内部结构 缩短入口管道且取消中间挡板 FOG最大去除率85% [37] 使用扩口管道 FOG最大去除率83% 分流式入口管道和挡板管道 FOG最大去除率87% 安装斜管沉淀器 HRT≤30 min,FOG去除率提高10% [41] HRT≥30 min,FOG最大去除率87% 增加筛网、一级和二级沉淀池、FOG分离室和毛发过滤器隔间 FOG最大去除率93% [42] 表 2 不同生物降解剂对FOG去除效率的对比

Table 2. Comparison of FOG removal efficiency of different biodegraders

生物降解剂 菌种名称 菌株个数 适应水体 处理效率 参考文献 IHI-91 嗜热芽孢杆菌 1 温度范围较宽的水体 三烯酸 (存在于橄榄油中) 去除率93% [49] D2D3 铜绿假单胞菌 1 环境变化较大的水体 FOG最高去除率97%~99% [50] 芽孢杆菌和假单胞菌CP1的混合体 芽孢杆菌 1 橄榄油和黄油含量较多的水体 橄榄油去除率94%黄油的去除率97% [52] 假单胞菌 1 多菌种:F69 枯草杆菌 13 脂肪含量复杂的水体 FOG降解率提高37%~67% [54] 巨大芽孢杆菌 4 苏云金芽孢杆菌 6 嗜热脂肪杆菌 3 地衣芽孢杆菌 5 多粘芽孢杆菌 4 枯草芽孢杆菌 2 芽孢乳酸杆菌 2 芽孢杆菌 5 酵母菌 2 荧光假单胞菌 5 施氏假单胞菌 3 潮湿纤维单胞菌 1 微球菌 1 新型硫杆菌 1 -

[1] 周玉文, 赵洪宾. 排水管网理论与计算[M]. 北京: 中国建筑工业出版社, 2000. [2] 张伟, 余健, 李葳, 等. 广州市排水管道沉积现状研究分析[J]. 给水排水, 2012, 38(7): 147-150. doi: 10.3969/j.issn.1002-8471.2012.07.035 [3] METCALF L, EDDY H P, TCHOBANOGLOUS G. Wastewater engineering: treatment, disposal, and reuse [M]. New York: McGraw-Hill , 1991. [4] BRIDGES O. Double trouble: Health risks of accidental sewage release[J]. Chemosphere, 2003, 52(9): 1373-1379. doi: 10.1016/S0045-6535(03)00472-7 [5] ASHLEY R M, FRASER A, BURROWS R, et al. The management of sediment in combined sewers[J]. Urban Water, 2000, 2(4): 263-275. doi: 10.1016/S1462-0758(01)00010-3 [6] WILLIAMS J, CLARKSON C, MANT C, et al. Fat, oil and grease deposits in sewers: Characterisation of deposits and formation mechanisms[J]. Water Research, 2012, 46(19): 6319-6128. doi: 10.1016/j.watres.2012.09.002 [7] HUSAIN I A F, ALKHATIB M A F, JAMMI M S, et al. Problems, control, and treatment of fat, oil, and grease (FOG): A review[J]. Journal of Oleo Science, 2014, 63(8): 747-752. doi: 10.5650/jos.ess13182 [8] MARLOW D R, BOULAIRE F, BEALE D J, et al. Sewer performance reporting: Factors that influence blockages[J]. Journal of Infrastructure Systems, 2011, 17(1): 42-51. doi: 10.1061/(ASCE)IS.1943-555X.0000041 [9] SOUTHERLAND R. Sewer fitness: Cutting the fat[J]. American City and County, 2002, 117(15): 27-27. [10] YOUSEFELAHIYEH R, DOMINIC C C S, DUCOSTE J. Modeling fats, oil and grease deposit formation and accumulation in sewer collection systems[J]. Journal of Hydroinformatics, 2017, 19(3): 443-455. doi: 10.2166/hydro.2017.016 [11] WALLACE T, GIBBONS D, O'DWYER M, et al. International evolution of fat, oil and grease (FOG) waste management-A review[J]. Journal of Environmental Management, 2017, 187: 424-435. [12] COLLIN T, CUNNINGHAM R, JEFFERSON B, et al. Characterisation and energy assessment of fats, oils and greases (FOG) waste at catchment level[J]. Waste Management, 2020, 103: 399-406. doi: 10.1016/j.wasman.2019.12.040 [13] SINCERO A P, SINCERO G A. Physical-chemical treatment of water and wastewater[M]. CRC press, 2002: 59-63. [14] NIEUWENHUIS E, LANGEVELD J, CLEMENS F O. The relationship between fat, oil and grease (FOG) deposits in building drainage systems and FOG disposal patterns; proceedings of the Iwa/iahr International Conference on Urban Drainage, F, 2018[C [15] GROSS M A, JENSEN J L, GRACZ H S, et al. Evaluation of physical and chemical properties and their interactions in fat, oil, and grease (FOG) deposits[J]. Water Research, 2017, 123: 173-182. doi: 10.1016/j.watres.2017.06.072 [16] KEENER K M, DUCOSTE J J, HOLT L M. Properties influencing fat, oil, and grease deposit formation[J]. Water Environment Research, 2008, 80(12): 2241-2246. doi: 10.2175/193864708X267441 [17] SHIN H, HAN S, HWANG H. Analysis of the characteristics of fat, oil, and grease (FOG) deposits in sewerage systems in the case of Korea[J]. Desalination and Water Treatment, 2015, 54(4/5): 1318-1326. [18] KUSUM S A, POUR-GHAZ M, DUCOSTE J J. Reducing fat, oil, and grease (FOG) deposits formation and adhesion on sewer collection system structures through the use of fly ash replace d cement-base materials[J]. Water Research, 2020, 186: 116304. doi: 10.1016/j.watres.2020.116304 [19] BARTON P. Enhancing separation of fats, oils and greases (FOGs) from catering establishment wastewater[D]. Cranfield: Cranfield University, 2012. [20] MOHAMED R, CHAN C M, GHANI H, et al. Application of peat filter media in treating kitchen wastewater[J]. International Journal of Zero Waste Generation, 2013, 1(1): 11-16. [21] GURD C, JEFFERSON B, VILLA R. Characterisation of food service establishment wastewater and its implication for treatment[J]. Journal of Environmental Management, 2019, 252: 109657. doi: 10.1016/j.jenvman.2019.109657 [22] BRUICE P Y. Organic Chemistry[M]. London: Pearson, 2017. [23] HE X, LEMING M L, DEAN L O, et al. Mechanisms of fat, oil and grease (FOG) deposit formation in sewer lines[J]. Water Research, 2013, 47(13): 4451-4459. doi: 10.1016/j.watres.2013.05.002 [24] 王越. 污水管道中油脂沉积物的形成机理及控制方法的研究进展[J]. 当代化工研究, 2018(3): 104-107. [25] HE X, DE LOS REYES III F L, DUCOSTE J J. A critical review of fat, oil, and grease (FOG) in sewer collection systems: Challenges and control[J]. Critical Reviews in Environmental Science and Technology, 2017, 47(13): 1191-1217. doi: 10.1080/10643389.2017.1382282 [26] HE X, IASMIN M, DEAN L O, et al. Evidence for fat, oil, and grease (FOG) deposit formation mechanisms in sewer lines[J]. Environmental Science & Technology, 2011, 45(10): 4385-4391. [27] IASMIN M, DEAN L O, LAPPI S E, et al. Factors that influence properties of FOG deposits and their formation in sewer collection systems[J]. Water Research, 2014, 49: 92-102. doi: 10.1016/j.watres.2013.11.012 [28] GUTIéRREZ-PADILLA M G D, BIELEFELDT A, OVTCHINNIKOV S, et al. Biogenic sulfuric acid attack on different types of commercially produced concrete sewer pipes[J]. Cement and Concrete Research, 2010, 40(2): 293-301. doi: 10.1016/j.cemconres.2009.10.002 [29] OAKES K. Rise of the fatbergs[J]. New Scientist, 2019, 241(3214): 22-23. doi: 10.1016/S0262-4079(19)30159-9 [30] DEL MUNDO D M N, SUTHEERAWATTANANONDA M. Influence of fat and oil type on the yield, physico-chemical properties, and microstructure of fat, oil, and grease (FOG) deposits[J]. Water Research, 2017, 124: 308-319. doi: 10.1016/j.watres.2017.07.047 [31] FIRESTONE D. Physical and chemical characteristics of oils, fats, and waxes[M]. AOCS press, 2006: 123-126. [32] IASMIN M, DEAN L O, DUCOSTE J J. Quantifying fat, oil, and grease deposit formation kinetics[J]. Water Research, 2016, 88: 786-795. doi: 10.1016/j.watres.2015.11.009 [33] SULTANA N, RODDICK F, GAO L, et al. Understanding the properties of fat, oil, and grease and their removal using grease interceptors[J]. Water Research, 2022, 225. [34] DOMINIC C C S, SZAKASITS M, DEAN L O, et al. Understanding the spatial formation and accumulation of fats, oils and grease deposits in the sewer collection system[J]. Water Science and Technology, 2013, 68(8): 1830-1836. doi: 10.2166/wst.2013.428 [35] DUCOSTE J J, KEENER K M, GRONINGER J W, et al. Assessment of grease interceptor performance[J]. Water Environment Research Foundation: Alexandria, Virginia, 2008. [36] DUCOSTE J J, KEENER K M, GRONINGER J W, et al. Fats, roots, oils, and grease (FROG) in centralized and decentralized systems[M]. IWA Publishing, 2009. [37] OSTBERG J, MARTINSSON M, STAL O, et al. Risk of root intrusion by tree and shrub species into sewer pipes in Swedish urban areas[J]. Urban Forestry & Urban Greening, 2012, 11(1): 65-71. [38] AZIZ T N, HOLT L M, KEENER K M, et al. Performance of grease abatement devices for removal of fat, oil, and grease[J]. Journal of Environmental Engineering-Asce, 2011, 137(1): 84-92. doi: 10.1061/(ASCE)EE.1943-7870.0000295 [39] MOORE G, DANG H. An experimental investigation of wastewater treatment in a grease interceptor trap[J]. Water Practice and Technology, 2009, 4(2). [40] GALLIMORE E, AZIZ T N, MOVAHED Z, et al. Assessment of internal and external grease interceptor performance for removal of food-based fats, oil, and grease from food service establishments[J]. Water Environment Research, 2011, 83(9): 882-892. doi: 10.2175/106143011X12989211840972 [41] CHU W, NG F L. Upgrading the conventional grease trap using a tube settler[J]. Environment International, 2000, 26(1-2): 17-22. doi: 10.1016/S0160-4120(00)00073-8 [42] AL-GHEETHI A. Establish in-house: A pre-treatment method of fat, oil and grease (FOG) in kitchen wastewater for safe disposal[J]. International Journal of Integrated Engineering, 2019, 11(2). [43] HERRERO M, STUCKEY D C. Bioaugmentation and its application in wastewater treatment: A review[J]. Chemosphere, 2015, 140: 119-128. doi: 10.1016/j.chemosphere.2014.10.033 [44] HE X, OSBORNE J, DE LOS REYES F L, III. Physico-chemical characterization of grease interceptors with and without biological product addition[J]. Water Environment Research, 2012, 84(3): 195-201. doi: 10.2175/106143012X13280358613345 [45] ROETS-DLAMINI Y, LALLOO R, MOONSAMY G, et al. Development of Bacillus spp. consortium for one-step “Aerobic Nitrification-Denitrification” in a fluidized-bed reactor[J]. Bioresource Technology Reports, 2022, 17: 100922. doi: 10.1016/j.biteb.2021.100922 [46] BORAH D, YADAV R. Bioremediation of petroleum based contaminants with biosurfactant produced by a newly isolated petroleum oil degrading bacterial strain[J]. Egyptian Journal of Petroleum, 2017, 26(1): 181-188. doi: 10.1016/j.ejpe.2016.02.005 [47] YANG Y, XIE L, TAO X, et al. Municipal wastewater treatment by the bioaugmentation of Bacillus sp. K5 within a sequencing batch reactor[J]. PLoS One, 2017, 12(6): e0178837. doi: 10.1371/journal.pone.0178837 [48] OGBONNA D N, NRIOR R R, EZINWO F E. Bioremediation efficiency of Bacillus amyloliquefaciens and Pseudomonas aeruginosa with the nutrient amendment on crude oil polluted the soil[J]. Microbiology Research Journal International, 2019, 29(5): 1-13. [49] MARKOSSIAN S, BECKER P, MARKL H, et al. Isolation and characterization of lipid-degrading Bacillus thermoleovorans IHI-91 from an icelandic hot spring[J]. Extremophiles, 2000, 4(6): 365-371. doi: 10.1007/s007920070006 [50] NISOLA G M, CHO E S, SHON H K, et al. Cell immobilized fog-trap system for fat, oil, and grease removal from restaurant wastewater[J]. Journal of Environmental Engineering, 2009, 135(9): 876-884. doi: 10.1061/(ASCE)0733-9372(2009)135:9(876) [51] LAUPRASERT P, CHANSIRIRATTANA J, PAENGJAN J. Effect of selected bacteria as bioremediation on the degradation of fats oils and greases in wastewater from cafeteria grease traps[J]. European Journal of Sustainable Development, 2017, 6. [52] TZIRITA M, PAPANIKOLAOU S, QUILTY B. Enhanced fat degradation following the addition of a Pseudomonas species to a bioaugmentation product used in grease traps[J]. Journal of Environmental Sciences, 2019, 77: 174-188. doi: 10.1016/j.jes.2018.07.008 [53] WAKELIN N G, FORSTER C F. An investigation into microbial removal of fats, oils and greases[J]. Bioresource Technology, 1997, 59(1): 37-43. doi: 10.1016/S0960-8524(96)00134-4 [54] BROOKSBANK A M, LATCHFORD J W, MUDGE S M. Degradation and modification of fats, oils and grease by commercial microbial supplements[J]. World Journal of Microbiology & Biotechnology, 2007, 23(7): 977-985. [55] TANG H L, XIE Y F, CHEN Y-C. Use of Bio-Amp, a commercial bio-additive for the treatment of grease trap wastewater containing fat, oil, and grease[J]. Bioresource Technology, 2012, 124: 52-58. doi: 10.1016/j.biortech.2012.08.012 [56] TAHREEN A, JAMI M S, ALI F. Role of electrocoagulation in wastewater treatment: A developmental review[J]. Journal of Water Process Engineering, 2020, 37: 101440. doi: 10.1016/j.jwpe.2020.101440 [57] CHEN X M, CHEN G H, YUE P L. Separation of pollutants from restaurant wastewater by electrocoagulation[J]. Separation and Purification Technology, 2000, 19(1/2): 65-76. [58] PRIYA M, JEYANTHI J. Removal of COD, oil and grease from automobile wash water effluent using electrocoagulation technique[J]. Microchemical Journal, 2019, 150: 104070. doi: 10.1016/j.microc.2019.104070 [59] AHMAD I, ABDULLAH N, KOJI I, et al. The role of restaurant wastewater for producing bioenergy towards a circular bioeconomy: A review on compositions, environmental impacts, and sustainable integrated management[J]. Environmental Research, 2022: 113854. [60] CHAN H. Separation of pollutants from restaurant effluents as animal feed, fertilizer and renewable energy to produce high water quality in a compact area[J]. Water Resources and Industry, 2013, 3: 35-47. doi: 10.1016/j.wri.2013.09.001 [61] WANG L, ZHOU Q, CHUA H. Evaluation of a novel integrated bioreactor - AOS system for treating oil-containing restaurant wastewater on site in Hong Kong[J]. Journal of Environmental Science and Health Part a-Toxic/Hazardous Substances & Environmental Engineering, 2005, 40(1): 227-243. [62] ZHENG T, WANG Q, SHI Z, et al. Separation of pollutants from oil-containing restaurant wastewater by novel microbubble air flotation and traditional dissolved air flotation[J]. Separation Science and Technology, 2015, 50(16): 2568-2577. [63] CHAN H. Removal and recycling of pollutants from Hong Kong restaurant wastewaters[J]. Bioresource Technology, 2010, 101(17): 6859-6867. doi: 10.1016/j.biortech.2010.03.104 [64] JI M, JIANG X, WANG F. A mechanistic approach and response surface optimization of the removal of oil and grease from restaurant wastewater by electrocoagulation and electroflotation[J]. Desalination and Water Treatment, 2015, 55(8): 2044-2052. doi: 10.1080/19443994.2014.929034 [65] ROBERTS R L. Pipeline Cleaning [M]. Oil and Gas Pipelines, 2015. [66] SIRINGI D O, HOME P G, KOEHN E. Cleaning Methods for Pipeline Renewals[J]. International Journal of Engineering and Technical Research (IJETR), 2014, 2(9): 44-47. [67] 李华飞. 大管径排水管道水力清淤技术研究[D]. 重庆: 重庆大学, 2012. [68] 孙勇, 杨向东, 孙建宇, 等. 排水管道清淤方法及开发新设备的构想[J]. 给水排水, 1996, 22(8): 52-54. [69] 边艳玲, 董巍. 排水管道中的清淤方法[J]. 黑龙江水利科技, 2003, 31(3): 1. [70] 李婧琳, 缑变彩, 杨志远. 市政排水管道清淤技术浅谈[J]. 山西建筑, 2017, 43(27): 2. doi: 10.3969/j.issn.1009-6825.2017.27.057 [71] ZHU Y, MENG Z, LV H. Application of high pressure water in pipeline cleaning[J]. IOP Conference Series Earth and Environmental Science, 2019, 300: 022032. doi: 10.1088/1755-1315/300/2/022032 [72] 王健, 刘嘉, 宋鸽. 城市排水管道沉积物新型清除方法[J]. 水科学与工程技术, 2009(6): 46-48. doi: 10.3969/j.issn.1672-9900.2009.06.020 [73] KAMALI M, PIROUZ M, GHOBADIAN M, et al. Investigation of Capabilities and Limitations of Different Cleaning Methods for Sewer Lines[J]. Journal of Water and Sustainable Development, 2017, 3(2): 43-54. [74] FOSTER W, AZIMOV U, GAUTHIER-MARADEI P, et al. Waste-to-energy conversion technologies in the UK: Processes and barriers - A review[J]. Renewable & Sustainable Energy Reviews, 2021, 135. [75] POH P, GOUWANDA D, MOHAN Y, et al. Optimization of wastewater anaerobic digestion using mechanistic and meta-heuristic methods: current limitations and future opportunities[J]. Water Conservation Science and Engineering, 2016, 1: 1-20. doi: 10.1007/s41101-016-0001-3 [76] LONG J H, AZIZ T N, III F L D L R, et al. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations[J]. Process Safety and Environmental Protection, 2012, 90(3): 231-245. doi: 10.1016/j.psep.2011.10.001 [77] RINZEMA A, BOONE M, VANKNIPPENBERG K, et al. Bactericidal effect of long-chain fatty-acids in anaerobic-digestion[J]. Water Environment Research, 1994, 66(1): 40-49. doi: 10.2175/WER.66.1.7 [78] YAU Y-H, RUDOLPH V, LO C C-M, et al. Restaurant oil and grease management in Hong Kong[J]. Environmental Science and Pollution Research, 2021, 28(30): 40735-40745. doi: 10.1007/s11356-018-2474-4 [79] TU Q, WANG J, LU M, et al. A solvent-free approach to extract the lipid fraction from sewer grease for biodiesel production[J]. Waste Management, 2016, 54(aug.): 126-130. [80] KARNASUTA S, PUNSUVON V, CHIMCHAISRI C, et al. Optimization of biodiesel production from trap grease via two-step catalyzed process[J]. Energy Environment, 2007, 8: 145-168. [81] NIJU S, MEERA S B, K. M. , ANANTHARAMAN N. Modification of egg shell and its application in biodiesel production[J]. Journal of Saudi Chemical Society, 2014, 18(5): 702-706. [82] B N N T A, C M E G, A S L, et al. Enzymatic pretreatment of recycled grease trap waste in batch and continuous-flow reactors for biodiesel production[J]. Chemical Engineering Journal, 2021, 426: 131703. doi: 10.1016/j.cej.2021.131703 [83] TRAN N N, TISMA M, BUDZAKI S, et al. Production of biodiesel from recycled grease trap waste: A review[J]. Industrial & Engineering Chemistry Research, 2021(46): 60. [84] LEUNG K K, YAU Y H. The utilization of leftover as acid catalyst to catalyse the transesterification and esterification reactions; proceedings of the 3rd International Conference on Water Resource and Environment (WRE), Qingdao, PEOPLES R CHINA, F 2017Jun 26-29, 2017[C]. 2017. [85] CANAKCI M. The potential of restaurant waste lipids as biodiesel feedstocks[J]. Bioresource Technology, 2007, 98(1): 183-190. doi: 10.1016/j.biortech.2005.11.022 [86] GHERGHEL A, TEODOSIU C, DE GISI S. A review on wastewater sludge valorisation and its challenges in the context of circular economy[J]. Journal of Cleaner Production, 2019, 228(AUG.10): 244-263. [87] CARUS M, CARREZ D, KAEB H, et al. Level playing field for biobased chemistry and materials[J]. Nova Institute, 2011: 4-18. [88] SUN Z, YI J, HUANG Y, et al. Properties of asphalt binder modified by bio-oil derived from waste cooking oil[J]. Construction and Building Materials, 2016, 102: 496-504. doi: 10.1016/j.conbuildmat.2015.10.173 [89] DAVIDSSON A, LOVSTEDT C, LA COUR JANSEN J, et al. Co-digestion of grease trap sludge and sewage sludge[J]. Waste Management, 2008, 28(6): 986-992. doi: 10.1016/j.wasman.2007.03.024 [90] KABOURIS J C, TEZEL U, PAVLOSTATHIS S G, et al. The anaerobic biodegradability of municipal sludge and fat, oil, and grease at mesophilic conditions[J]. Water Environment Research, 2008, 80(3): 212-221. doi: 10.2175/106143007X220699 [91] GROSSER A, NECZAJ E. Enhancement of biogas production from sewage sludge by addition of grease trap sludge[J]. Energy Conversion And Management, 2016, 125: 301-308. doi: 10.1016/j.enconman.2016.05.089 [92] HAO J, HE X. Fat, oil, and grease (FOG) deposits yield higher methane than FOG in anaerobic co-digestion with waste activated sludge[J]. Journal of Environmental Management, 2020, 268: 110708. doi: 10.1016/j.jenvman.2020.110708 -

下载:

下载: