-

活性炭吸附作为一种简单有效的水处理工艺,被广泛运用于废水的处理领域[1]。但是,常规的活性炭吸附工艺用于深度处理仍然存在材料成本高、活性炭利用率偏低以及吸附饱和后需进行再生回收等难题,造成工艺成本的增加[2-3]。因此,针对活性炭吸附工艺,提高活性炭的利用率,减少活性炭的再生频次是工艺优化的重要内容之一。目前,研究大多从炭吸附材料本身性质入手来提高吸附的效果,而有关吸附反应器的设计改良研究则较少[4-5]。

目前,废水活性炭吸附工艺中常采用的设备形式有固定床、流化床[6]和序批式反应器等[7]。固定床又称填充床,活性炭等吸附材料固定填充在装置(如吸附塔)内部,不随水流发生流动,具有设备结构简单、吸附剂磨损小等优势,是活性炭吸附水处理工艺中最常用的方式之一[8]。流化床吸附技术利用固体流态化原理,使水流自下而上通过固体吸附剂颗粒床层使其达到流态化状态,借助吸附剂颗粒和水流的充分接触,使得水流中污染物被活性炭吸附去除[9-15]。与固定床和流化床不同,序批式反应器的进水为非连续进水方式,通过机械搅拌使得吸附剂和废水充分接触,吸附一定时间后进行固液分离和排水。序批式反应器将单一的反应器分解为多个串联的小型反应器,便于机械搅拌强化吸附效果,但需要进行澄清和固液分离操作[16-19]。

为进一步指导工程实践,为活性炭吸附反应器的选择和设计提供科学指导,本研究以双酚A(BPA)为吸附质,活性炭为吸附剂,分别搭建了小型的固定床、流化床、优化流化床以及序批式反应器模拟装置,研究不同吸附反应器中BPA的去除规律,对不同吸附床中的BPA去除效率、穿透时间、活性炭容量利用效率等,进行了综合评估和比较。

-

所用的化学药剂均为分析纯,购自国药化学试剂有限公司。未进行二次纯化处理,实验中所有溶液均以超纯水进行配置。实验使用的椰壳活性炭购自海南星光活性炭有限公司,颗粒粒径均为3~5 mm,按照碘吸附值的大小,分为样品C-1( 碘吸附值 ≥ 1 200 mg/g)、C-2(碘吸附值 ≥ 1 250 mg/g)和C-3(碘吸附值 ≥ 1 100 mg/g)。样品使用前均使用去离子水清洗至中性,并干燥至恒重。根据实验测得,20 ℃条件下,C-1、C-2、C-3炭材料对BPA的饱和吸附量分别为90.09 、104.06、118.06 mg/g。

-

固定床吸附实验。采用的自制空心玻璃填充柱(直径1.6 cm、高度10 cm)进行固定床吸附实验。探究不同流速和填充高度下固定床对BPA的吸附性能。C-1活性炭填充玻璃柱中作为吸附介质。填充高度分别设置为3、4和5 cm。BPA溶液初始浓度为20 mg/L的,以连续流的方式,从填充柱的底端进水(进水流速196、295和396 mL/h),从填充柱的顶端出水。检测出水水样的BPA浓度,当BPA出水浓度达到进水浓度的20 %(即4 mg/L)时,认为固定床反应器穿透(即需要更换活性炭材料)。

流化床吸附实验。采用上端开口的空心玻璃填充柱(内径4.6 cm、高度29.5 cm)进行流化床实验。分别使用C-1、C-2与C-3活性炭作为吸附剂,活性炭投加量为4.96 g,进水BPA浓度为20 mg/L,进水流速为196 mL/h,停留时间设置为1 h,检测出水BPA的浓度。当BPA出水浓度达到4 mg/L时,认为流化床反应器穿透。

序批式反应器吸附实验。采用1、2和5 L烧杯分别进行序批式反应器吸附实验,C-1活性炭的投加量为4.96 g,BPA初始浓度为20 mg/L,模拟废水总体积分别为0.5、1、2 L,使用桨叶机械搅拌器进行搅拌 (搅拌速率为150 r/min),每次吸附时间为2.5、5和10 h(相当于处理量均为200 mL/h),反应结束之后进行采样并检测BPA浓度。

-

BPA样品采用分光光度法进行测试,检测波长为278 nm,水溶液样品先使用0.45 μm滤膜过滤后再进行检测。固定床与流化床为连续进水,在某一段时间内吸附的总污染物质量(U)与吸附剂单位吸附量(qa)计算,见式(1~2):

式中:U为固定床或流化床去除污染物的量,即吸附剂吸附的污染物的量,mg;W1和W2分别为计算时间段的起始时和终止时流经固定床或流化床的溶液体积,L;c0和cw分别为流经床层的吸附质BPA进水浓度与出水浓度,mg/L;qa为吸附剂单位吸附量,mg/g;m为床层填充的吸附剂的量,g。序批式反应器为间歇进水,每批次吸附试验中单位吸附剂吸附污染物的量,见式(3):

式中,V为序批式反应器中的溶液体积,L。各反应器中活性炭对于BPA的去除率计算,见式(4):

反应器活性炭的吸附容量利用效率计算见式(5):

式中:q1为各床层穿透时单位吸附剂吸附污染物的量,mg/g;q0为单位质量吸附剂的饱和吸附量,mg/g。

-

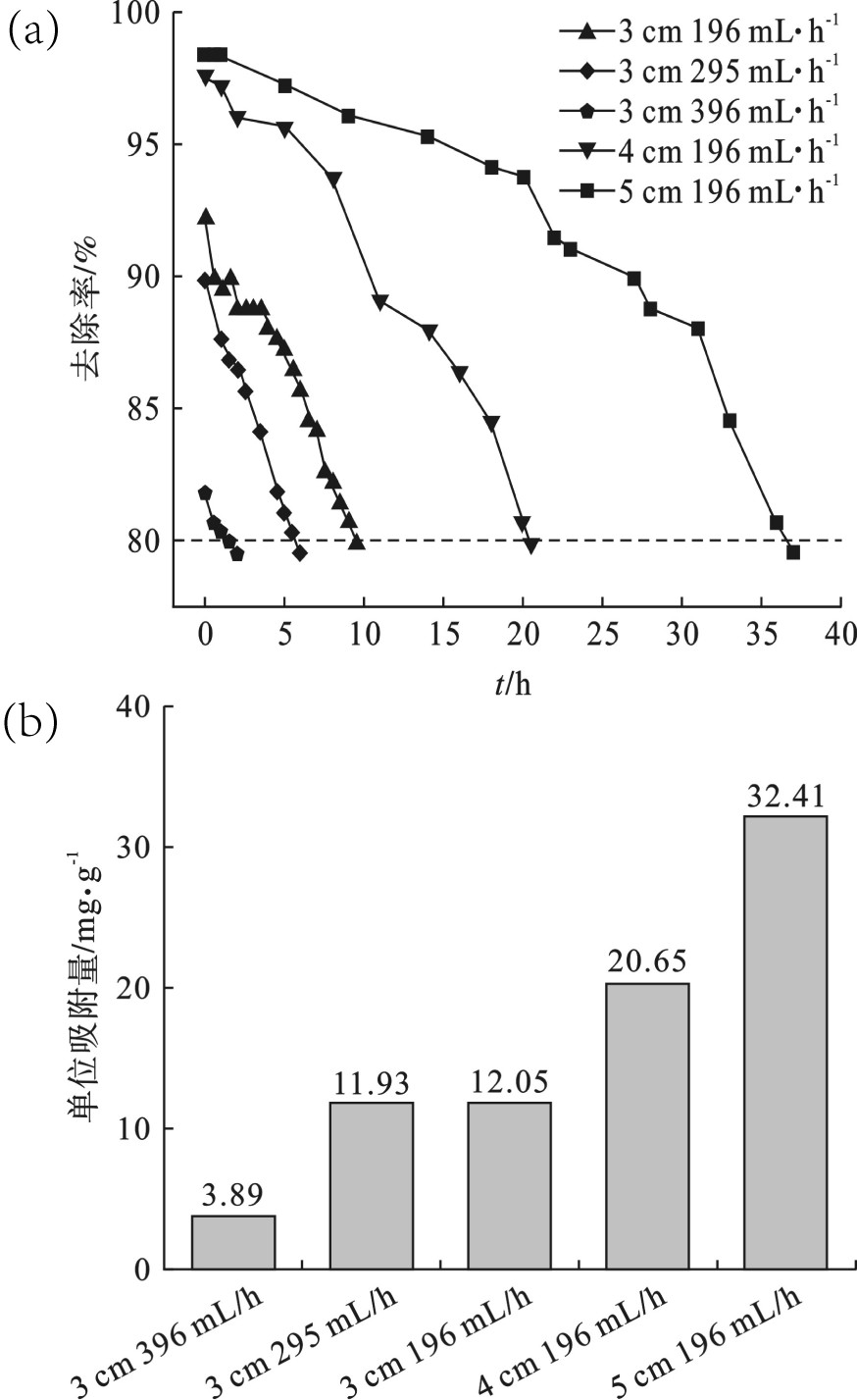

不同进水流速和填充高度下固定床对BPA的去除率及单位吸附量,见图1。

图1可知,当填充高度为3 cm,进水流速为196、295 和396 mL/h时,对应的穿透时间分别为9.5、6和2 h,床层内吸附剂的单位吸附量分别为12.05、11.93和3.89 mg/g。当进水流速增大时,床层达到穿透点的时间缩短,初始去除率也随之减小,固定床中的炭材料利用率逐步减小。当流速增加时,吸附质流经固定床中吸附剂层的时间减少,吸附剂与污染物质接触的时间减少,炭材料的单位吸附量也随之降低。但要指出的是,流速增加会使得单位时间内污染物的处理总量增加,因而在实际的工程中需要综合考虑炭的再生成本和吨水的处理成本。当进水流速为196 mL/h,填充高度分别为3、4和5 cm时,对应的穿透时间分别为6、20.5和37 h。可以发现,吸附床层达到穿透点的时间、同一时期的去除率与活性炭单位吸附量都随填充高度的增加而逐渐增加。

通过对炭材料的单位吸附量和饱和吸附量(90.09 mg/g)进行比较,可以发现,固定床中活性炭的利用率较低,且利用率与床层的高度呈正相关关系,而与进水流速呈负相关关系。当进水流速为196 mL/h,填充高度为5 cm时,活性炭的利用率达到最高,约为36%,说明此时炭材料还有较大的吸附容量未被利用。这是因为,填充高度的增加使得吸附剂与污染物质接触时间相对延长,让溶液中的BPA有更多的时间被充分吸收。同时,吸附传质在固定床中是沿着传质前沿向前移动的,当传质前沿的出水浓度达到穿透点时即意味着床层达到穿透,因此位于传质方向后段的活性炭的利用率会更低。当填充的高度增加时,固定床的前段会有更多的炭材料可以达到或接近吸附饱和,使得固定床内炭材料的平均吸附量增加。但是随着填充高度的增加,也会存在水头损失增大、炭材料消耗过多等问题。因此,在实际应用中,最好通过运行参数试验,并综合考虑工程实际,选取合适的填充高度。

-

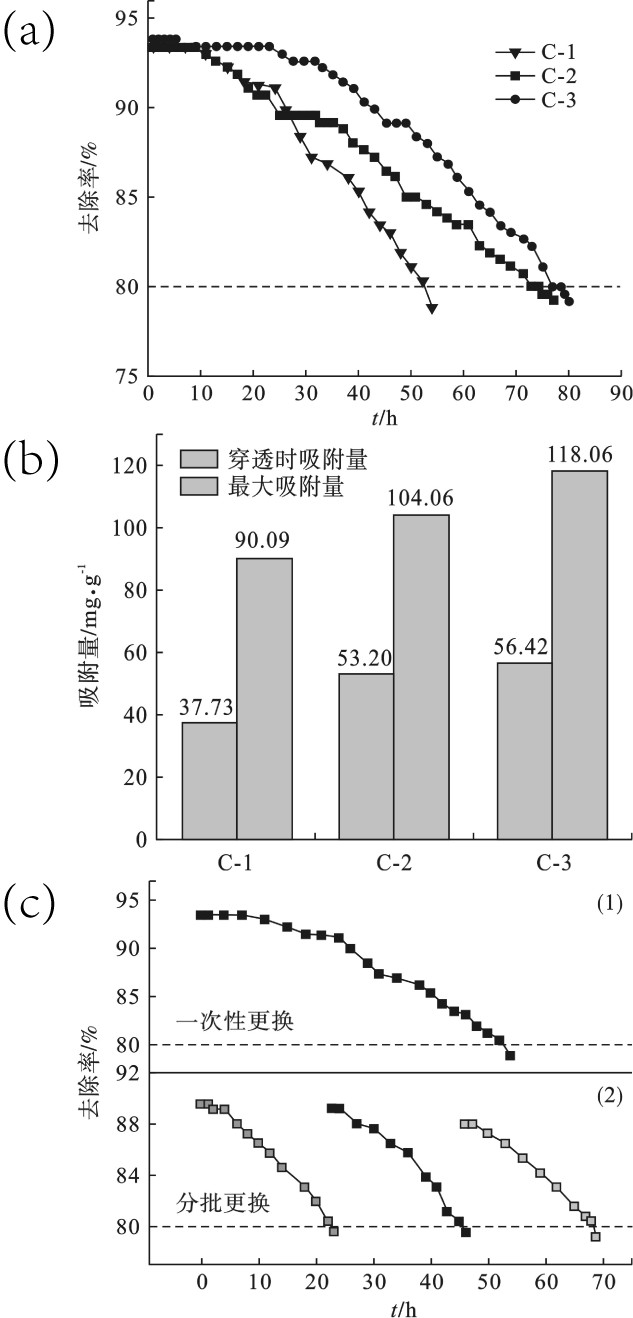

不同炭材料的流化床对BPA的去除率,见图2(a),达到穿透点时的单位吸附量与最大吸附量,见图2(b)。一次性投加与分批投加炭材料的流化床对BPA的去除率比较,见图2(c)。

由出水浓度曲线可以发现,C-3炭材料的处理效果优于C-2和C-1。通过计算达到穿透点时对应的单位吸附量(C-1: 37.73 mg/g;C-2: 52.30 mg/g;C-3:56.42 mg/g),可以发现其吸附容量利用率分别为 41.88 % (C-1)、51.12 % (C-2)和47.79 % (C-3)。随着最大吸附量的增加,床层出水达到穿透点的时间增加,达到穿透点时的单位吸附量也在增加,虽然C-3炭材料的最大吸附量以及穿透时的单位吸附量均大于C-2,但C-2的利用率却高于C-3,这说明炭材料的利用率与最大吸附量并非正关系。观察C-1与C-3的吸附过程,发现二者前期均可以达到较好效果,随后达到某一临界点时,去除率以较快速度减少,即出水浓度快速增加。而对于C-2,其后期出水浓度的增加速率相对缓慢,说明其在活性位点被部分消耗后,仍能保持较好的吸附能力,这可能是因为C-2材料能够在196 mL/h这一进水速率下,能够有效的吸附锁定BPA,而C-1与C-3样品在这一速率下,吸附锁定BPA的能力相对较弱。这也解释了虽然C-3炭材料具有比C-2炭材料更大的饱和吸附量,但达到穿透点时,其利用率却低于C-2。C-2材料的这一特点,很可能与其表面特性有关。

为了进一步增加流化床中炭材料的利用效率,尝试采取分批加入炭材料的方法来优化其吸附容量利用效率。即对C-1炭材料的流化床,将总的活性炭加入量不变,但是分三次加入,即当达到穿透点时,更换1/3量的炭材料,与一次全部加入的情况进行比较。由图2(c)可以发现,采用分批加入方式后,相同总量的炭材料可以处理废水的量更多,计算得到此时的炭材料单位吸附量为46.44 mg/g,相比于普通流化床的37.73 mg/g,活性炭单位吸附量与容量利用率均显著提高。

吸附机理和速率通常可分为3个步骤:吸附质通过溶液边界层到达吸附剂表面的外部扩散,吸附剂孔内或粒子内扩散,吸附质在吸附剂表面活性位点的吸附。在吸附初期,BPA由溶液扩散到吸附剂表面,扩散阻力较小,固液界面浓度差较大,因而吸附速率较高。分批次更换活性炭可以使每次新加入的活性炭都重新处于吸附初期,一定程度上增加了单位活性炭位于吸附初期的时长,使得更多BPA得以进入活性炭内部与活性位点结合固定,因而提高了活性炭的单位吸附量与利用率。因此,对于流化床吸附反应器,在活性炭总量不变的情况下,可以通过分次添加的方式提升炭的容量利用率。

-

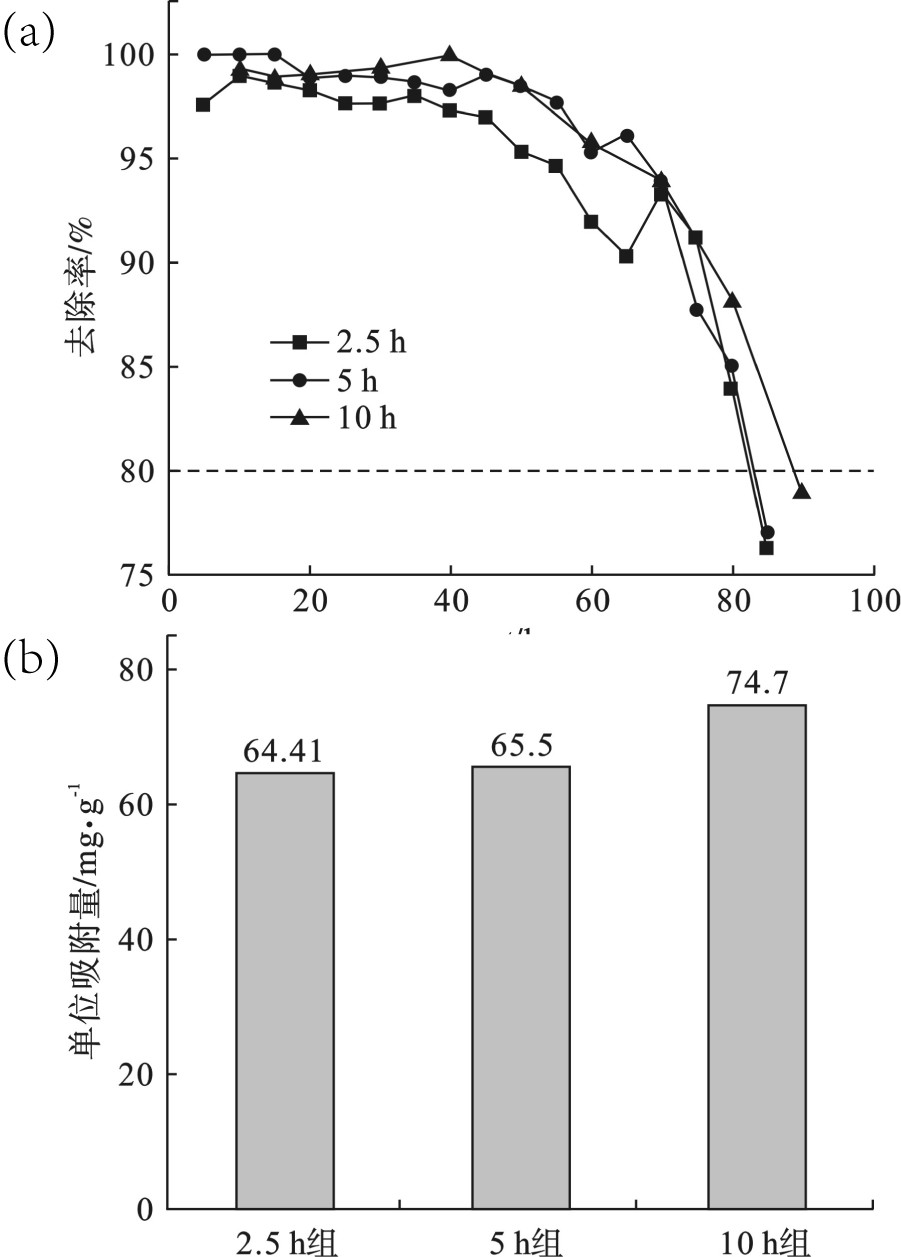

吸附时间分别为2.5、5和10 h的序批式反应器的对BPA的去除率以及达到穿透时的累积单位吸附量,见图3(a)。序批式反应器活性炭单位吸附量,见图3(b)。

图3(a)可知,前几次反应,各组装置均可以在给定时间内保持较高的BPA去除率,使出水的BPA浓度降低到比较低的程度 (< 0.5 mg/L)。当各组活性炭总的吸附时间大约到达50 h时,达到了该系统的一个临界点,之后各组的BPA出水浓度则呈现快速增加趋势,BPA去除率迅速下降。从图3(a)还可以看出,在总吸附时间的同时期,2.5 h组BPA出水浓度相对较高,即BPA去除率相对低一些,这是因为2.5 h组吸附时间较短,BPA的吸附平衡进展程度低。而对于5 h组,吸附平衡的进展程度高,因此与10 h组的差别不大了。图3(b)可知,在达到穿透时,不同吸附时间的序批式反应器的活性炭的单位吸附量均保持在较高的水平,分别为64.41、65.51和74.70 mg/g,对比C-1活性炭的饱和吸附量90.09 mg/g,活性炭的利用效率分别为71.50%、72.72%、82.92%,远大于其他各类吸附反应器。这主要是因为序批反应器的吸附过程有机械搅拌过程,强化了传质,因此活性炭的容量利用效率显著提高。在实际的吸附操作中,采用搅拌的方式来强化传质是比较容易实现的,但机械搅拌是需要耗费能量的。合理的设计机械搅拌的反应器大小,实现活性炭材料吸附容量的高效利用,同时做到能耗相对较小,是序批式反应器设计的重点。

-

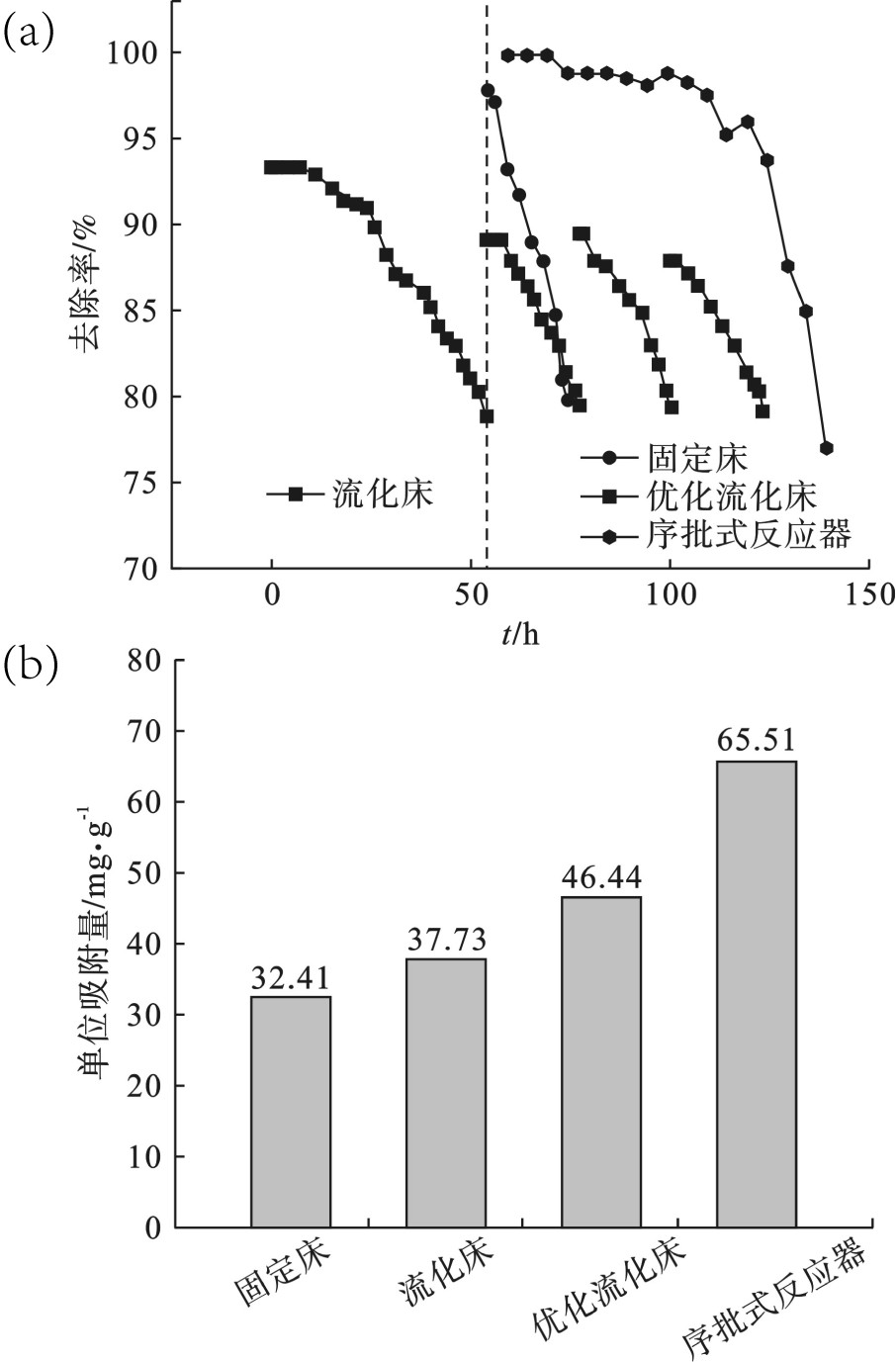

不同类型吸附床对BPA的去除率及达到穿透点时对应的单位吸附量,见图4。

图4可知,对于4种反应器,固定床(填充高度为5 cm、进水流速为196 mL/h)、流化床(以C-1炭材料为吸附质)、分批投加流化床(以下简称优化后流化床)和序批式反应器(吸附时间为5 h),处理相同量的污水时,序批式反应器的炭材料单位吸附量与利用率最高,分批投加活性炭流化床次于序批式反应器,显示这两种吸附反应器在工程中更有利于提高活性炭的容量利用率。序批式反应器容积较大,在实际工程中需要更大的占地面积,而且序批式反应器需要采用机械搅拌,增加了能耗。与其他吸附床相比,分批投加的流化床能够以较小的反应器体积取得较高的容量利用率,但是分批次分离、更换活性炭也增加了工序环节。以上几种吸附反应器的综合效能,特别是运行中的能耗本研究中并没有考虑,还是需要在中试工程中进一步评价。

-

本研究为废水的吸附深度处理工艺的反应器设计提供了参考,形成的主要结论如下。

(1)固定床进水流速越小、填充高度越高时活性炭对双酚A的吸附去除效果更好,活性炭的容量利用率也更高。

(2)在流化床中,吸附穿透时间不仅与流速和炭颗粒浓度有关系,也与炭材料的表面特性有关。在总投加量不变的情况下,采用分批投加的方式,能够显著增加活性炭材料的容量利用效率。

(3)序批式反应器的吸附时间(2.5、5 和10 h)对污染物去除率与活性炭利用效率的影响不显著,主要是由于机械搅拌过程强化了吸附传质,使得BPA被吸附锁定所需的时间减少。

(4)序批式反应器的炭材料吸附容量利用效率最高,最高可以达到82.92%,其次是分批次添加活性炭的流化床反应器,填充床次之,而单次添加炭的流化床的炭容量利用率最低。

(5) 3种吸附反应器各有其特点,在实际的活性炭吸附工艺设计时,应根据工程实际合理选择。在出水水质、炭材料利用率和运行能耗之间找到最佳的技术经济平衡点。

不同反应器中活性炭去除双酚A的吸附容量利用率研究

The utilization of adsorption capacity of granular activated carbon for removal of bisphenol A in different reactors

-

摘要: 实验考察了活性炭在固定床、流化床和序批式反应器中吸附去除双酚A(BPA)的吸附规律和吸附容量利用效率。结果表明,对于固定床来说,进水流速越小、填充高度越高时,活性炭对双酚A的吸附去除效果更好,活性炭的利用率也更高。对于流化床,在总投加量一定的情况下,采用分次添加,可以进一步提高流化床中活性炭的容量利用率。序批式反应器由于有机械搅拌辅助传质,拥有各反应器中最优的活性炭容量利用率。本研究通过不同反应器吸附去除BPA的比较研究,为实际的废水吸附深度处理工艺的设计和设备选型提供了有价值的参考。Abstract: The experiment investigated the adsorption behavior and adsorption capacity utilization efficiency of the activated carbon in different reactors. The results showed that, for the activated carbon in a fixed bed reactor, a lower flow rate and a higher filling height could achieve a better adsorption and a higher removal efficiency on bisphenol A. In the case of the fluidized bed, under a constant total dosage, the utilization efficiency of the activated carbon could be further improved by using incremental additions. The sequencing batch reactor, with a mechanical agitation for enhanced mass transfer, exhibited the highest utilization efficiency of the activated carbon among all the reactors. It provided valuable references for the design and selection of the equipments for the practical wastewater adsorption treatment process.

-

Key words:

- activated carbon /

- adsorption /

- fixed bed /

- fluidized bed /

- sequence batch reaction bed

-

电镀工业是我国经济发达地区的重要加工行业,由于其在工业中适用性高,广泛分布于各个工业部门,电镀生产在耗费大量工艺用水的同时,也产生大量的电镀废水[1]。电镀废水具有重金属含量高、毒性大、污染物杂、环境危害严重等特点[2-4],属于难处理的工业废水。目前电镀废水的处理工艺主要采用物化预处理+生化处理+深度处理的组合工艺,涉及中水回用的主要采用膜分离技术[5],淡水回用于生产漂洗工段.常规的废水深度处理工艺不能彻底将其从水中去除,出水无法稳定达到电镀污染物排放标准(GB 21900-2008)的排放标准,开发高效的深度处理工艺已成为水处理领域的关注点。

臭氧氧化作为一种绿色处理工艺具有易操作、污染物去除效率高、无二次污染等优点已被广泛运用于饮用水和废水深度处理领域[6-9] 。由于臭氧氧化具有一定的选择性[10-11],研究人员开发了多相催化臭氧化技术克服了上述缺点,通过在臭氧氧化过程中加入非均相催化剂,使水中溶解性臭氧在催化剂表面发生链式反应产生羟基自由基(·OH)[12-13],从而提高水中有机物的去除率。

常见的非均相臭氧催化剂有金属氧化物(MnO2、FeOOH、TiO2等)[14-16]、多金属负载催化剂(RuO2/Al2O3、MnO2/Al2O3、TiO2/Al2O3等)[17-19]、矿物(Cu/堇青石、Mn/蜂窝陶瓷[20]等)和活性炭(MnOx/GAC[21]、多壁碳纳米管等)。目前工程项目中应用较广的催化剂多以球形陶瓷颗粒为载体负载多金属氧化物,常装填于固定床形式的反应器[22]内进行进行臭氧催化反应,但其传质效率低,水流易产生局部短流,影响臭氧催化氧化对水中有机物的去除效率。为了开发更为高效、稳定和经济的臭氧催化剂,研究人员除了在催化剂表面负载的活性组进行改进外,对催化剂的结构也进行了研究及优化。

基于陶瓷膜具有优异的化学性能,研究人员就臭氧预氧化+陶瓷膜工艺去除有机物和陶瓷膜改性催化臭氧氧化等开展了相关研究。2003年SCHLICHTER等[23]首次将臭氧氧化和陶瓷膜过滤相结合处理地表水和微污染原水,之后臭氧与陶瓷膜结合的相关研究开始逐渐增多。BYUN等[24]对陶瓷膜进行了改性,将氧化锰或氧化铁负载于陶瓷膜制备成催化膜,发现有机物的去除取决于陶瓷膜被金属氧化物纳米粒子包覆的类型,而且氧化锰膜的性能优于其他测试膜。我国对臭氧/陶瓷膜工艺的研究起步较晚,2011年清华大学的张锡辉课题组首先在国内使用臭氧预氧化/陶瓷膜组合工艺处理水中甲硫醚[25],此后该课题组使用该技术在饮用水处理、微污染水净化等领域的研究。

本研究以陶瓷膜为载体,采用浸渍-焙烧工艺制备了多组分臭氧催化过滤膜,实现了膜分离技术与催化臭氧氧化技术的同步耦合,利用陶瓷过滤膜的微米级孔道过滤废水,可实现污染物的定向移动,有效地促进了扩散传质,同时微米级孔道内部负载的催化剂,增大了催化模块的有效催化比表面积。利用XRD、SEM、DEX等技术对催化过滤膜进行了表征,并以电镀园区物化预处理后的混合废水为研究对象,考察催化过滤膜在常温下臭氧氧化过程中的催化活性。

1. 材料与方法

1.1 实验材料

陶瓷膜,购自江苏久吾高科技股份有限公司;La(NO3)3、Ce(NO3)3,均为分析纯,购自济宁天亿新材料有限公司;Mn(CH3COO)2、氢氧化钠、硝酸、浓硫酸、重铬酸钾,均为分析纯,购自国药集团化学试剂有限公司。

1.2 催化过滤膜的制备及表征

采用浸渍-焙烧法制备催化过滤膜:选用无机陶瓷膜作为催化过滤膜基体,用8%的氢氧化钠溶液浸泡,之后用质量百分比为13%的稀硝酸溶液浸渍1~2 h,再用去离子水洗净至出水中性后烘干备用;选用La(NO3)3、Ce(NO3)3和Mn(CH3COO)2作为催化剂活性组分的前驱物,配置不同质量比(La3+、Ce3+和Mn2+)的浸渍液,将烘干后的陶瓷膜在浸渍液中浸泡24 h后,在105 ℃真空烘4 h, 反复浸渍-烘干步骤5次;置于马弗炉中,在400~950 ℃条件下焙烧2~6 h即得陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜。

通过JEOL JSM-6480LV型扫描电镜(SEM)观察催化过滤膜的表面和断面形貌;催化过滤膜活性层的组成和晶体结构由电子能量色散X射线光谱(EDS)和X射线衍射(XRD, Bruker D8)进行表征,采用Cu Ka(λ=0.154 nm)辐射,扫描范围为10°~80°;利用干湿重量法测定催化过滤膜的孔隙率[26];测定陶瓷膜对不同尺寸聚苯乙烯微球的截留率,确定陶瓷膜的孔径大小[27]。

1.3 臭氧催化氧化化工园区废水的实验

1)目标废水水质。实验所用废水为常州某电镀园区物化预处理后的混合废水,用去离子水稀释4倍后用作实验废水。目前该园区共有28个电镀车间,32条生产线,镀种涉及镀镍、镀铜、镀铬、镀锌、镀银和镀金。稀释后的废水COD为135 mg·L−1,总镍为0.04 mg·L−1,总铬为0.09 mg·L−1,浊度为6 NTU,pH为7.8,废水中有机物主要来源于镀液中添加的稳定剂、络合剂和光亮剂,包含聚乙二醇、柠檬酸、十二烷基磺酸钠和未知名称含氮杂环类物质等。

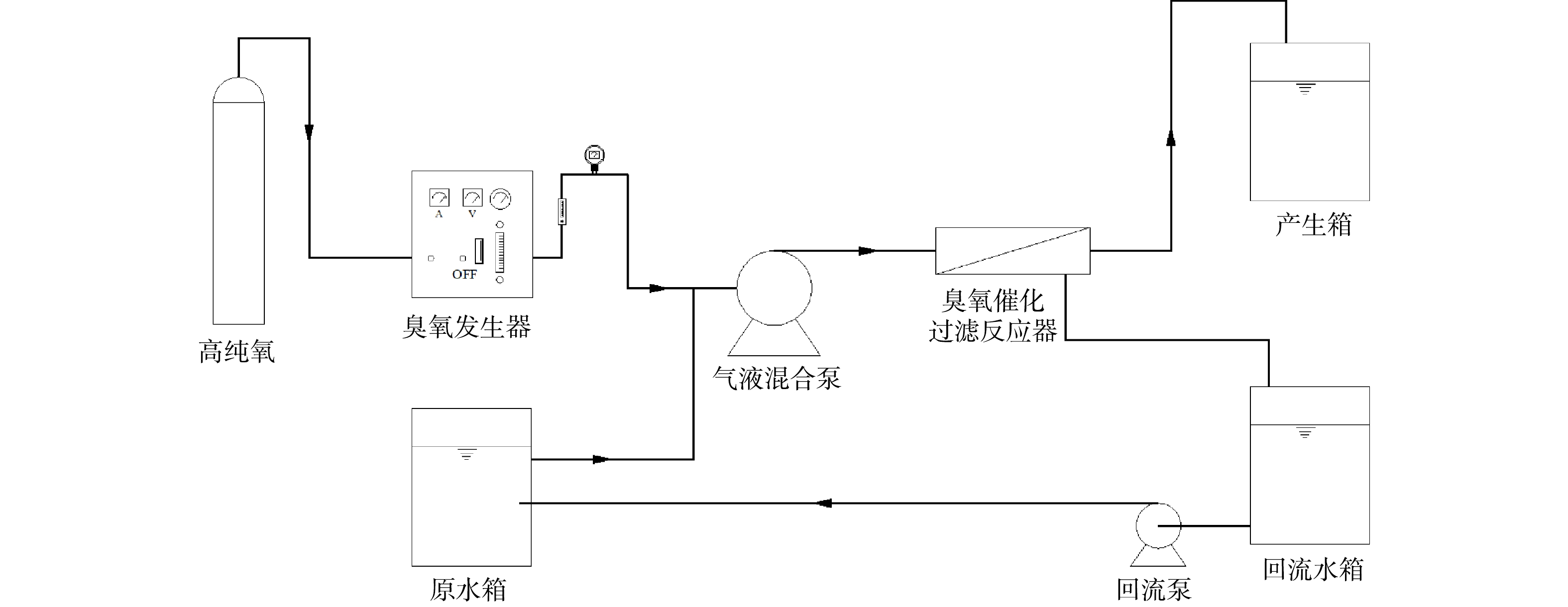

2)实验装置及运行参数。本实验所用装置如图1所示,实验在室温(25±2) °C下进行,实验装置处理规模为200 L·h−1,不锈钢材质。选用最优条件下制备得到的臭氧催化过滤膜处理废水,采用两支臭氧催化过滤膜并联的形式。通过控制臭氧投加量、回流比、跨膜压差、错流速率等反应条件,具体运行参数为:臭氧投加量1~5 mg·L−1;回流比90%;跨膜压差0.15 Mpa;错流速率1.0 m·s−1。观察废水COD降解情况考察催化剂的活性。

1.4 分析测试方法

COD采用重铬酸钾标准方法[28]测定;pH采用酸度计(pHB-2,上海雷磁仪器厂)测定;镍和铬浓度采用焰原子吸收分光光度法测定(GB/T5750.6-2006),所用仪器型号为(TAS-990MFG,北京普析通用仪器厂);浊度采用便携式浊度仪(2100P,HACH)测定。

2. 结果与讨论

2.1 臭氧催化过滤膜制备工艺的优化

臭氧催化过滤膜的制备主要分为浸渍和焙烧2个主要步骤。笔者在前面的研究中发现催化剂的催化活性与浸渍液活性组分的配比、焙烧温度及焙烧时间有关[29]。本实验以电镀园区物化预处理出水进行一定比例稀释后的废水的COD去除率和臭氧催化过滤膜的膜通量为指标,对陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜的制备工艺进行了优化。

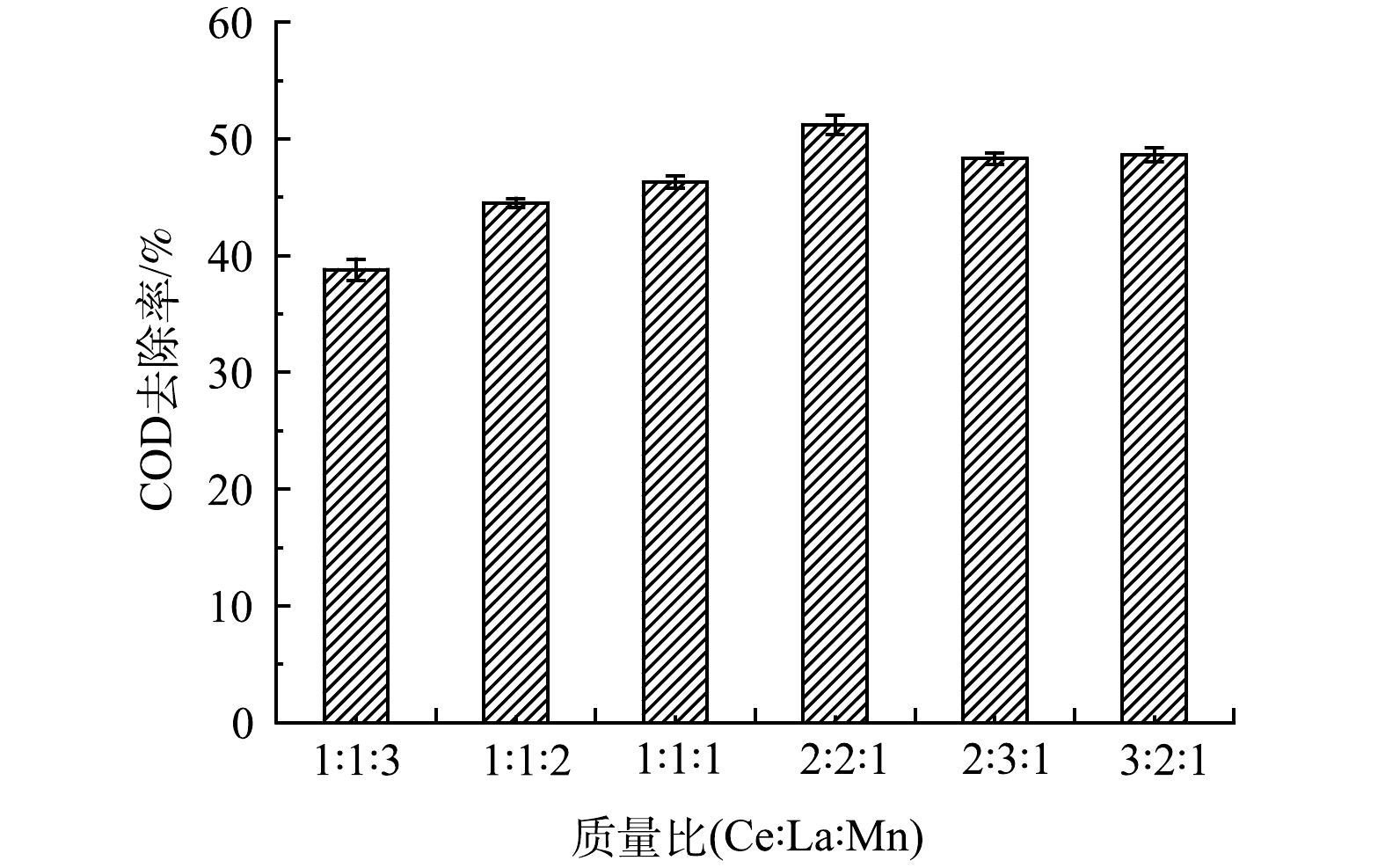

1)活性组分比例的影响。配制以活性组分La3+、Ce3+、Mn2+不同质量比的浸渍液,保持其他条件相同,煅烧温度为700 ℃,煅烧时间 3 h,制备陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜,以一定比例稀释后的电镀园区物化预处理出水为污染物,考察浸渍液中金属离子的质量比与COD去除率的关系,结果如图2所示。可见,随着La3+和Ce3+含量的增加,催化剂的催化活性随之增加,在Ce3+、La3+、Mn2+的质量比到2:2:1,COD的去除率最高。一方面由于随着浸渍液中硝酸铈浓度的增加,煅烧后CeO2的结构更加有规律,晶核更成熟,镧作为同系元素性状与铈类似。另一方面,有研究[30-31]表明,金属氧化物的催化活性由高到低依次为La2O3>CeO2>MnO2。

但当浸渍液中Ce3+和La3+的比例进一步增加时,催化效率反而有所下降,一方面随着浓度的增加,催化活性物质的晶核增大,比表面积减小,不利于增加催化反应活性;另一方面由于尾水中特征有机污染物种类较多,MnO2对部分有机污染物的催化效果明显。因此,将浸渍液中金属离子Ce3+、La3+、Mn2+的质量比确定为2:2:1。

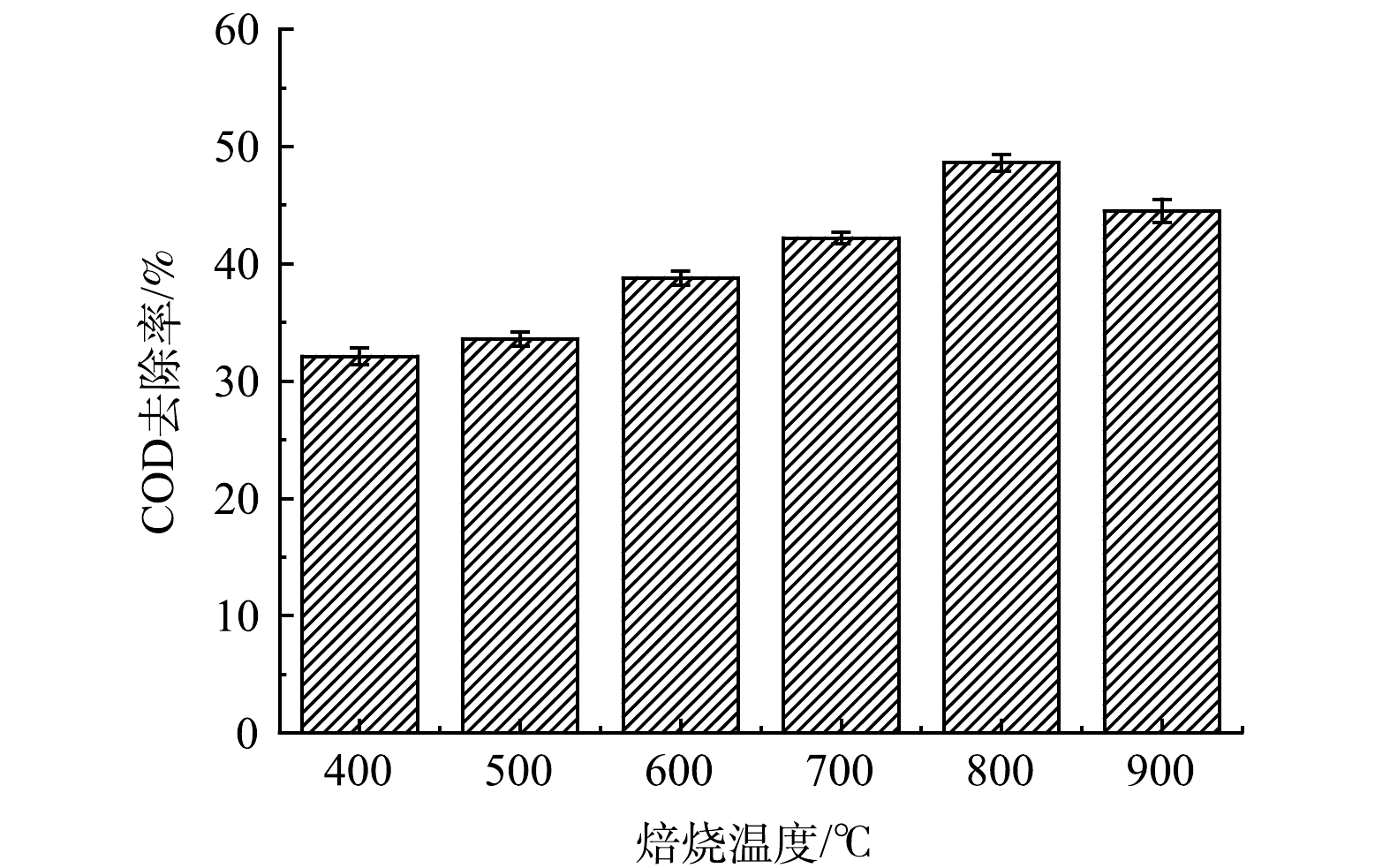

2)焙烧温度的影响。选择适宜的焙烧温度是臭氧催化过滤膜制备中的关键步骤。在浸渍液活性组分Ce3+、La3+、Mn2+的质量比为2:2:1,煅烧时间3 h的条件下,不同焙烧温度下制得的臭氧催化过滤膜在臭氧催化氧化下对废水COD的降解影响如图3所示。由图3可知,随着温度的逐渐升高,催化剂的催化活性先升高后呈现下降趋势。当焙烧温度为800 ℃时,陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜的催化活性最高。这是由于硝酸镧在500 ℃下焙烧得到的产物主要成分为La5O7NO3和La2CO5,在650 ℃下焙烧得到的产物主要是La2O3,还含有少量杂质,当温度达到780 ℃时焙烧产物均是纯度较高的La2O3。当焙烧温度低于500 ℃时,La2O3和CeO2催化剂尚未完全形成,且催化剂的结晶差,颗粒粒径小,催化剂活性低。随着焙烧温度升高,催化剂结晶逐渐变好,颗粒粒径变大,催化效果增强。900 ℃以上高温焙烧时,CeO2催化剂内部结构坍塌,活性位减少,催化剂活性降低。另一方面温度过高也容易导致催化剂烧结,使催化活性组分在载体表面团聚,降低催化剂的比表面和导致活性位点缺失,催化效率降低。因此,本实验中将催化剂的焙烧温度确定为800 ℃。

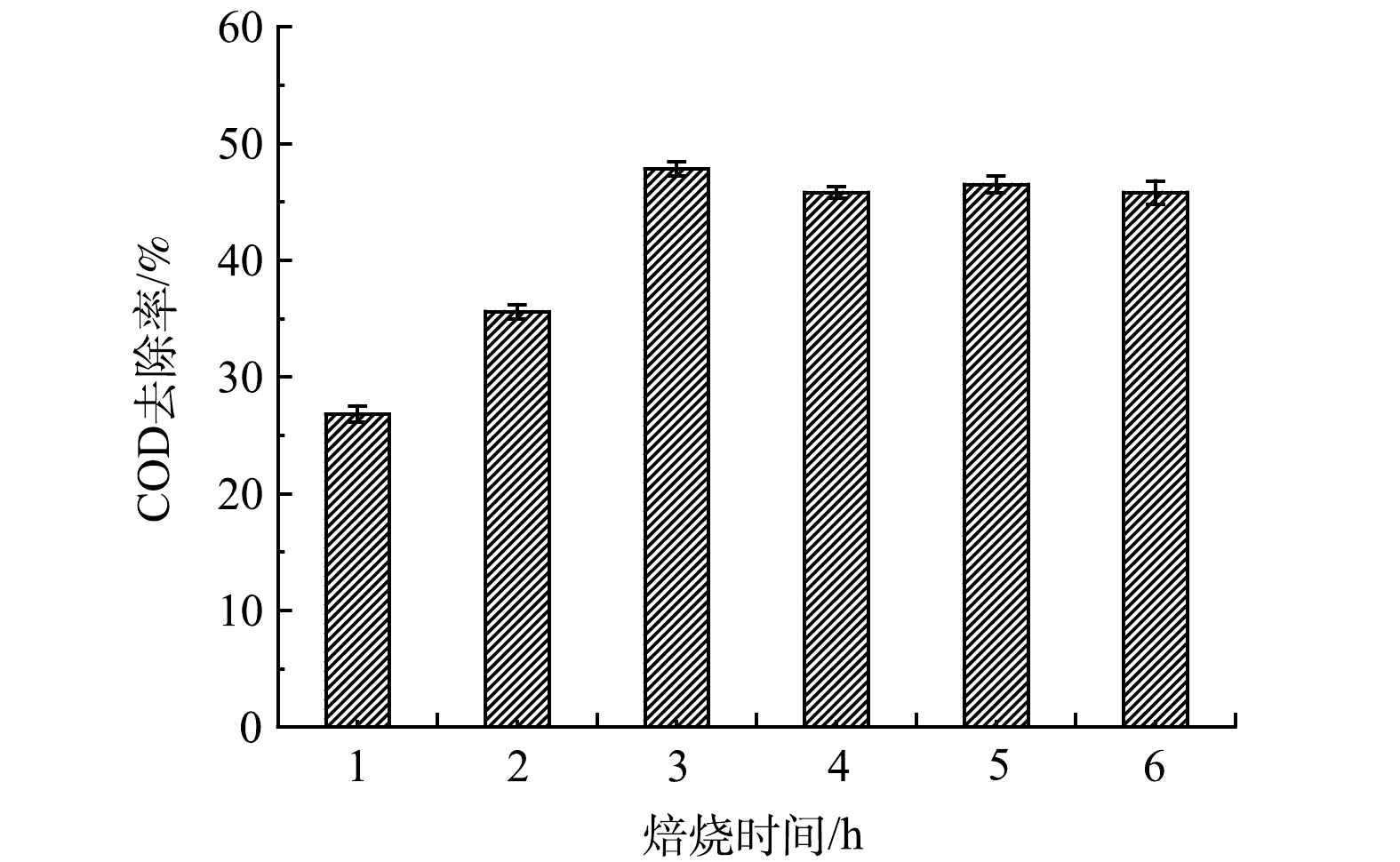

3)焙烧时间的影响。催化剂的焙烧时间对活性组分的前驱体能否转变成活性组分及最终催化剂活性有较大影响. 在浸渍液活性组分Ce3+、La3+、Mn2+的质量比为2:2:1条件下,分别在700 ℃下煅烧0.5、1、2、3、4、6 h制得的臭氧催化过滤膜在臭氧催化氧化下对废水COD的降解影响如图4所示。初始时催化剂的活性随着焙烧时间的延长而增加,当焙烧时间达到3 h时,催化剂的活性趋于稳定,当焙烧时间进一步增加至6 h后,催化效果反而出现小幅下降。因为焙烧时间较短时反应尚未全部完成,催化剂强度达不到要求,无法满足催化剂高温定型的要求,活性组分易出现粉末化;若焙烧时间过长,容易造成已形成的孔道结构塌陷,表面形貌改变,活性组分出现烧结或被掩蔽。因此,本实验中将陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜的最佳焙烧时间定为3 h。

根据以上的研究结果,将陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜的最佳制备条件确定为:将预处理后的无机陶瓷膜浸渍于含有La(NO3)3、Ce(NO3)3和Mn(CH3COO)2的溶液中,其中Ce3+、La3+、Mn2+的质量比为2:2:1。室温下浸渍24 h,然后在105 ℃真空烘4 h,反复浸渍-烘干步骤5次,在马弗炉中800 ℃条件下焙烧3 h,最后得到负载型金属氧化物臭氧催化剂。

2.2 催化过滤膜的表征

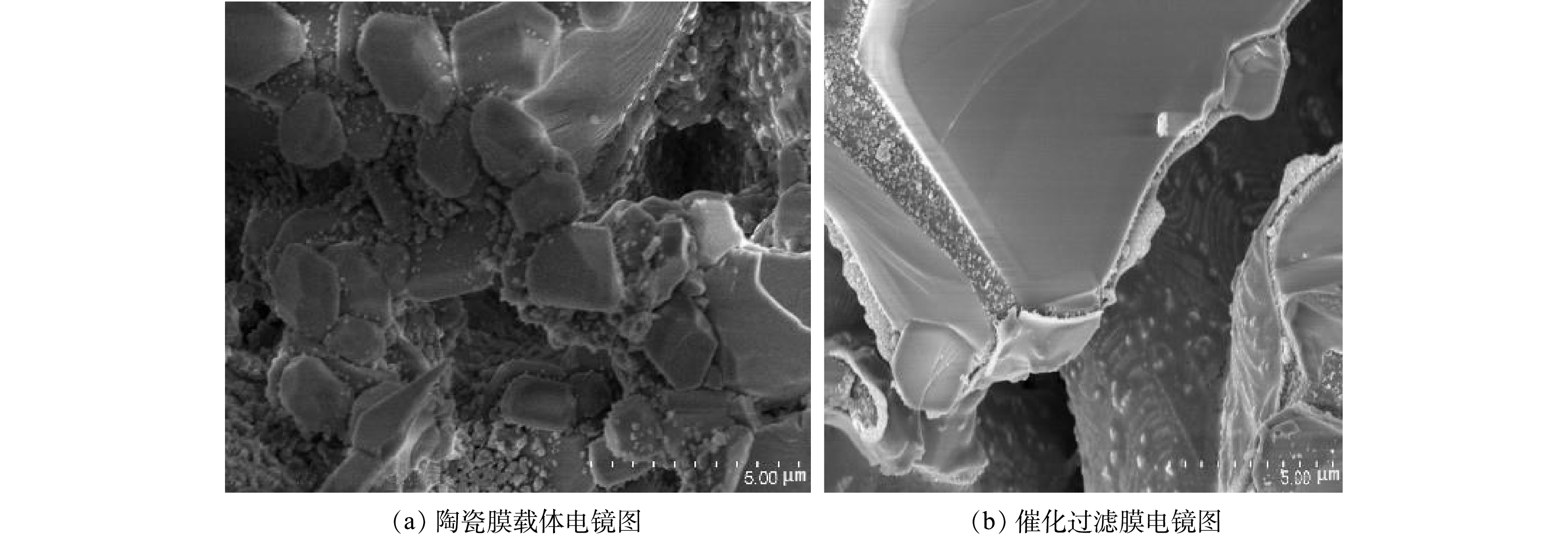

1) SEM和EDS测试结果。图5无机陶瓷膜载体及陶瓷负载型MnO2-CeO2-La2O3臭氧催化过滤膜的SEM图像。由图5(a)可以看出陶瓷膜表面呈疏松多孔结构,孔道彼此交错贯通,具有较大的比表面积孔体积,能提供较多的负载点位。图5(b)呈现了负载后催化过滤膜的形貌,可以明显看出在陶瓷膜表面和孔道内存在大量负载物,活性组分的晶粒大小匀称且分布均匀,未在表面发生团簇现象。

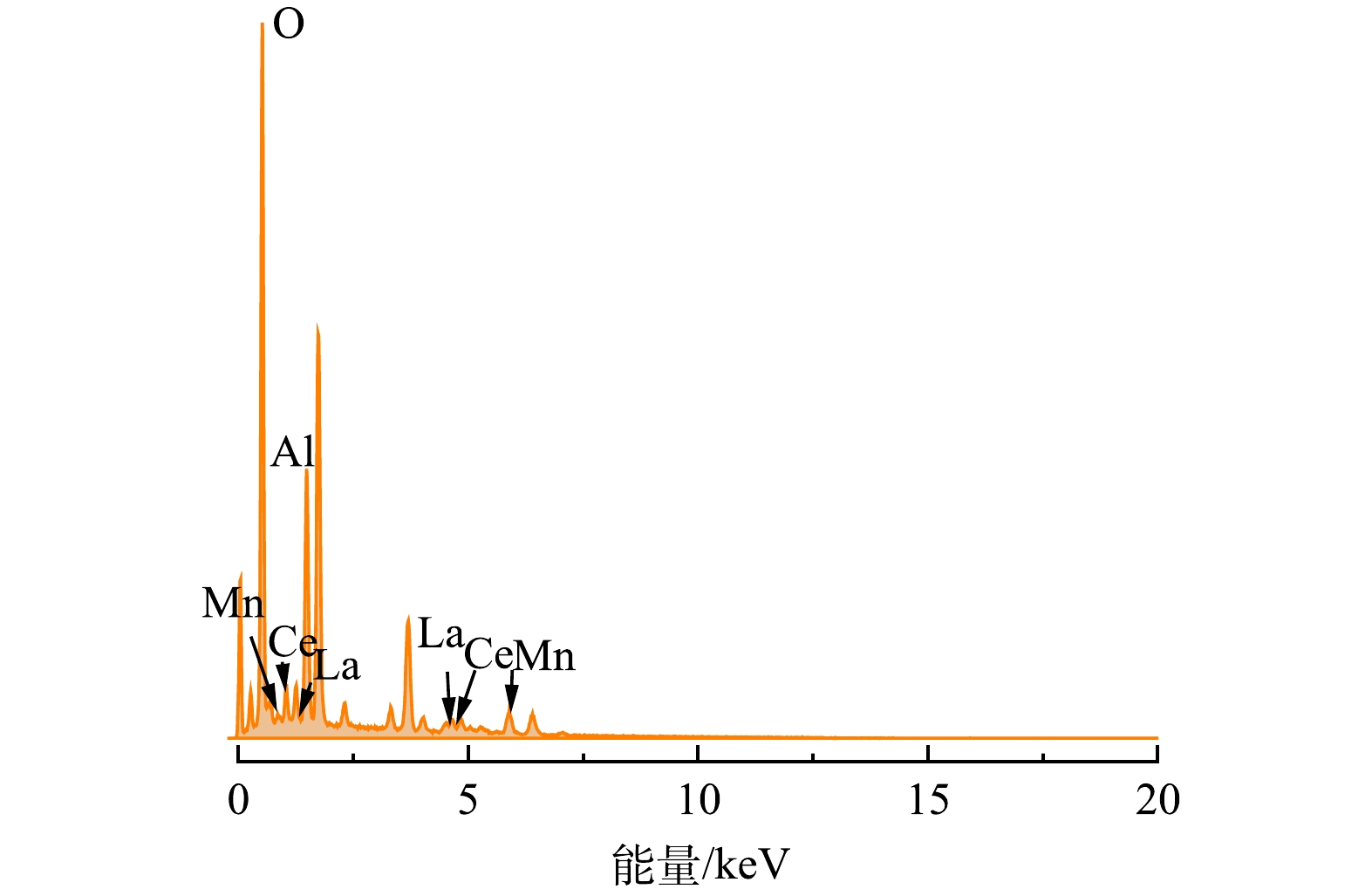

EDS通常被运用于分析物体表面涂层的元素组成。选取浸渍液的金属离子Ce3+、La3+、Mn2+的质量比为2:2:1,焙烧时间3 h,焙烧温度800 ℃的催化剂样品,进行EDS表征,结果如图6所示。由图6可知,陶瓷膜载体主要成分为Al2O3,载体经浸渍、高温煅烧后,催化剂表层的EDS谱图中增加了La、Ce和Mn的特征峰。结合表1可知,表层活性组分金属元素占总质量的11.85%,从而推测在催化剂的表层形成了Ti、Mn和Fe的金属氧化物,且活性组分负载率较高。

表 1 催化过滤膜各活性组分元素含量Table 1. Element content of active components of the catalytic ceramic filtration membranes元素 质量分数/% 原子分数/% O 48.07 65.11 Al 40.08 32.17 Mn 3.65 1.44 La 4.21 0.66 Ce 3.99 0.62 为进一步探究催化活性组分在陶瓷膜载体上孔道内的负载情况,分析了负载后的陶瓷膜截面元素分布情况。对陶瓷膜外部膜层的截面做了元素面分布图(EDS mapping)分析。由图7中可以清晰发现除了陶瓷膜基材元素Al和O外,Mn、La、Ce 3种元素在陶瓷膜孔道内呈现均匀分布。

2)催化过滤膜性能参数与分析。选用孔径为50 nm的陶瓷膜为载体,选取浸渍液的金属离子Ce3+、La3+、Mn2+的质量比为2:2:1,焙烧时间3 h,焙烧温度800 ℃的催化剂样品进行测试。负载前后膜孔径由原来的50 nm变为30 nm(表2),膜通量下降33%。这是因为经负载后,膜孔道被氧化生成的MnO2、CeO2和La2O3活性组分所占居,导致膜孔隙率和膜孔径的减少,从催化剂的SEM表征结果也可以证实这一点,膜通量的下降与孔径的下降有直接关系。负载后陶瓷膜的盐酸可溶率值为0.6%,说明了活性组分与陶瓷膜结合紧密,催化过滤膜稳定性强。

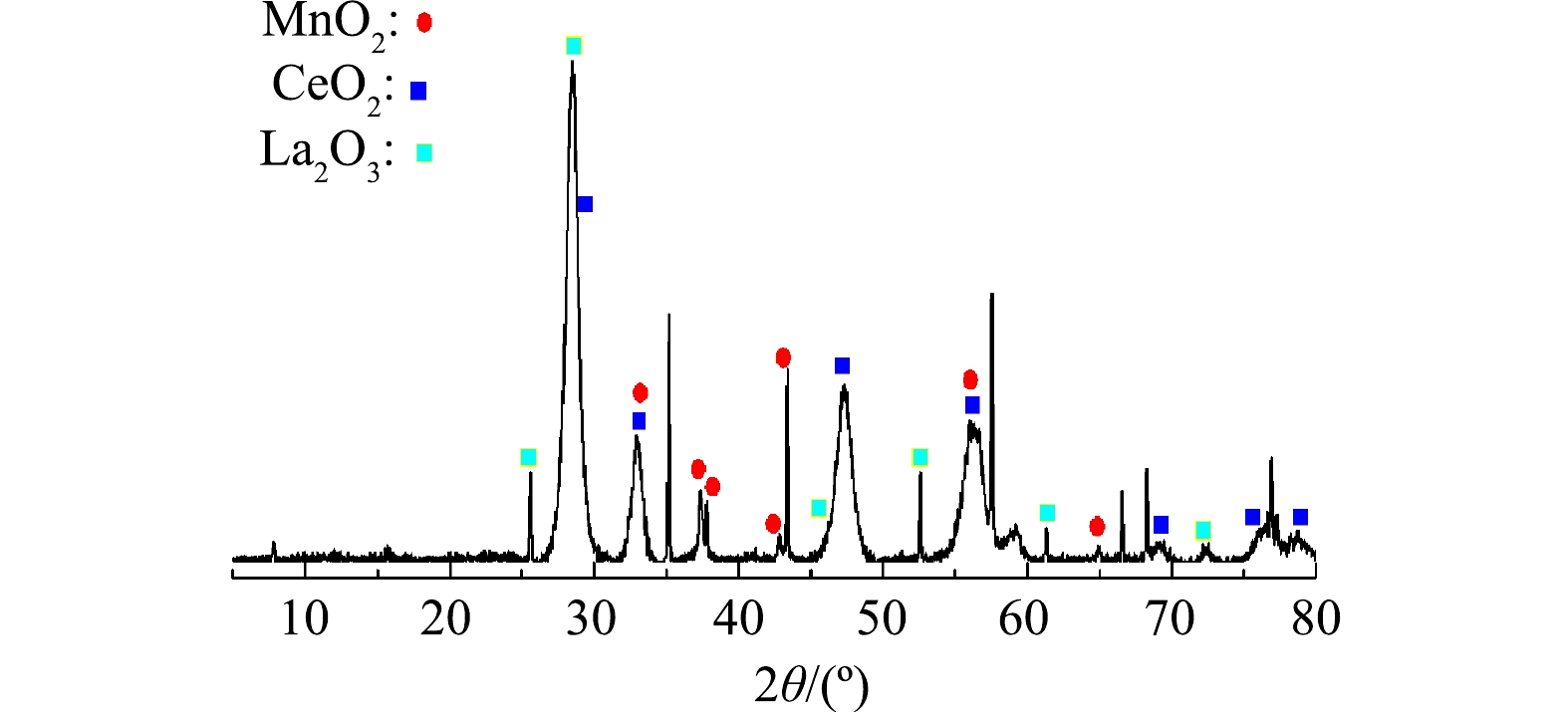

表 2 催化过滤膜的性能参数Table 2. Parameters of the catalytic ceramic filtration membranes陶瓷膜种类 孔隙率/% 孔径/nm 纯水通量/(L·(m2·h·Mpa)−1) 盐酸可溶率/% 陶瓷膜基体 33 50 2 000 — 负载后的陶瓷膜 26 30 1 260 0.6 3) XRD表征结果。将负载后的催化过滤膜表层和孔道内的活性组分刮下进行XRD分析,结果如图8所示。可见,对照JCPDS标准卡,所得物质主相为Al2O3、CeO2、La2O3、MnO2,所得产物粉体为灰色,在2θ=28.8°、33.1°、47.5°、56.8°、69.4°、76.7°、79.1°附近出现的吸收峰属于立方萤石晶相结构的CeO2。在2θ=26.1°、27.9°、46.1°、53.7°、62.2°、73.4°出现的次强峰属于六方晶型La2O3,在2θ=33.3°、36.9°、37.9°、42.8°、44.1°、56.4°、64.8°出现的次强峰属于四方晶系的α-MnO2,未发现其他晶型是由于反应时间延长可使δ-MnO2 向α-MnO2转化。在2θ=35.1°、57.9°、59.1°、66.7°等处出现的一些强峰主要为Al2O3。这是由于Al2O3基体陶瓷膜的主要成分。以上表征结果表明,通过浸渍、焙烧可有效地将CeO2、La2O3、MnO2活性组分负载于陶瓷膜表面及孔道内。

2.3 催化过滤膜的催化性能评估

1)催化过滤膜的催化活性。为了评估臭氧催化过滤膜的催化活性,将其与未负载的普通陶瓷膜进行对比实验,在臭氧投加量为5 mg·L−1,跨膜压差为0.15 MPa,回流比为90%的条件下进行实验,观察其膜通量变化和对水中COD的去除情况。

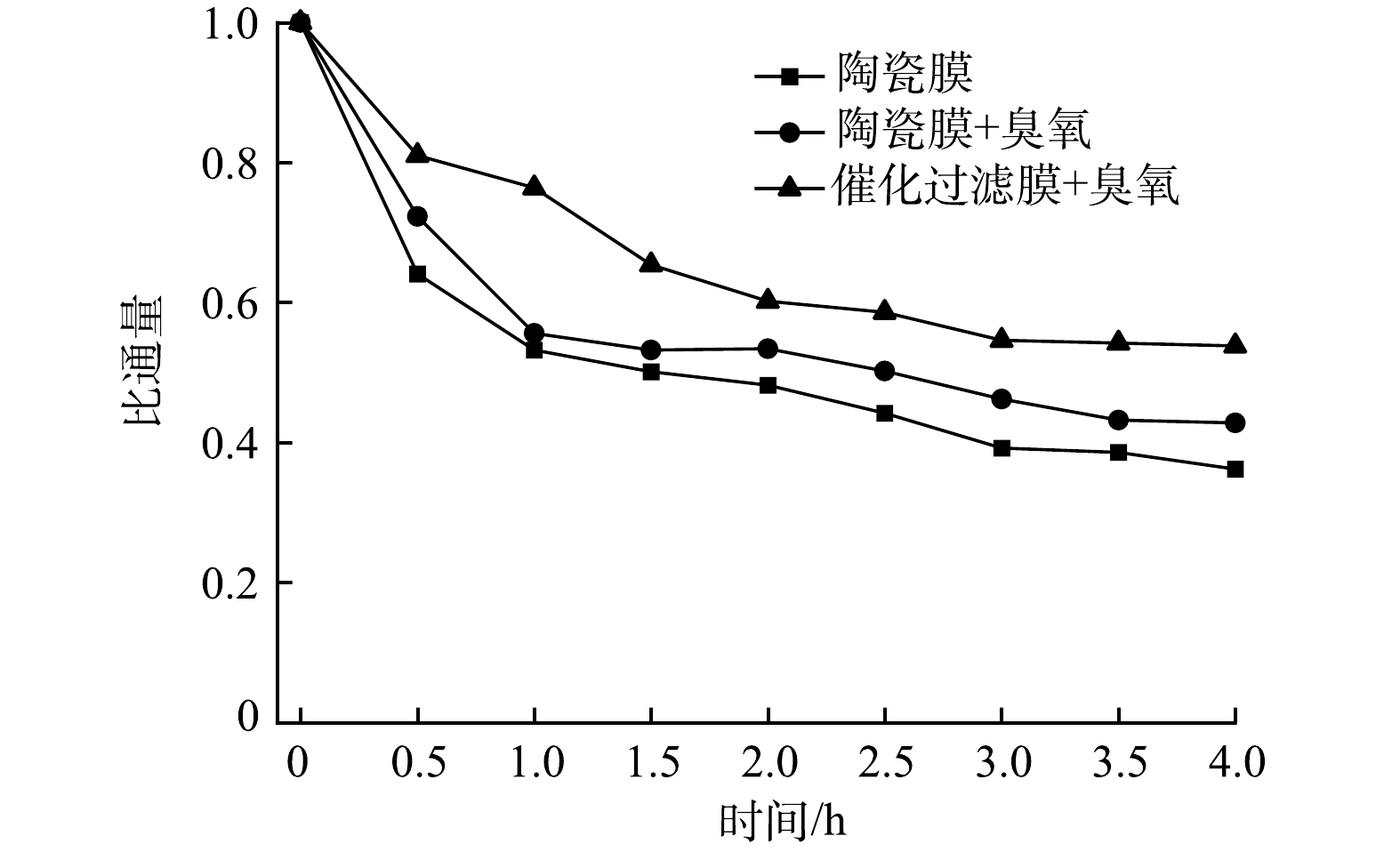

图9为膜通量的变化趋势。由图9可知,随着反应时间的增加,普通陶瓷膜和臭氧催化过滤膜的膜通量呈下降趋势,在臭氧条件下臭氧催化过滤膜的膜通量下降较为缓慢。经过4 h的分离后,在不投加臭氧的情况下,陶瓷膜的膜通量降低了63.8%;在臭氧条件下,普通陶瓷膜和臭氧催化过滤膜的膜通量分别降低了57.2%和46.2%,说明臭氧氧化可以缓解膜污染,同时在催化活性物质的作用下,膜污染的缓解作用更为明显。究其原因是上述反应为过滤和臭氧氧化反应的同步过程,在膜分离的过程中大部分有机物被截止在膜表面和孔道内,臭氧氧化可以降解膜表面的有机物,从而在一定程度上减缓膜污染。臭氧氧化具有一定的选择性[10],因而对膜污染的缓解效果不明显,而催化臭氧氧化产生的活性氧物种[32-33]能够无选择性的氧化有机物,从而更好地缓解膜污染。

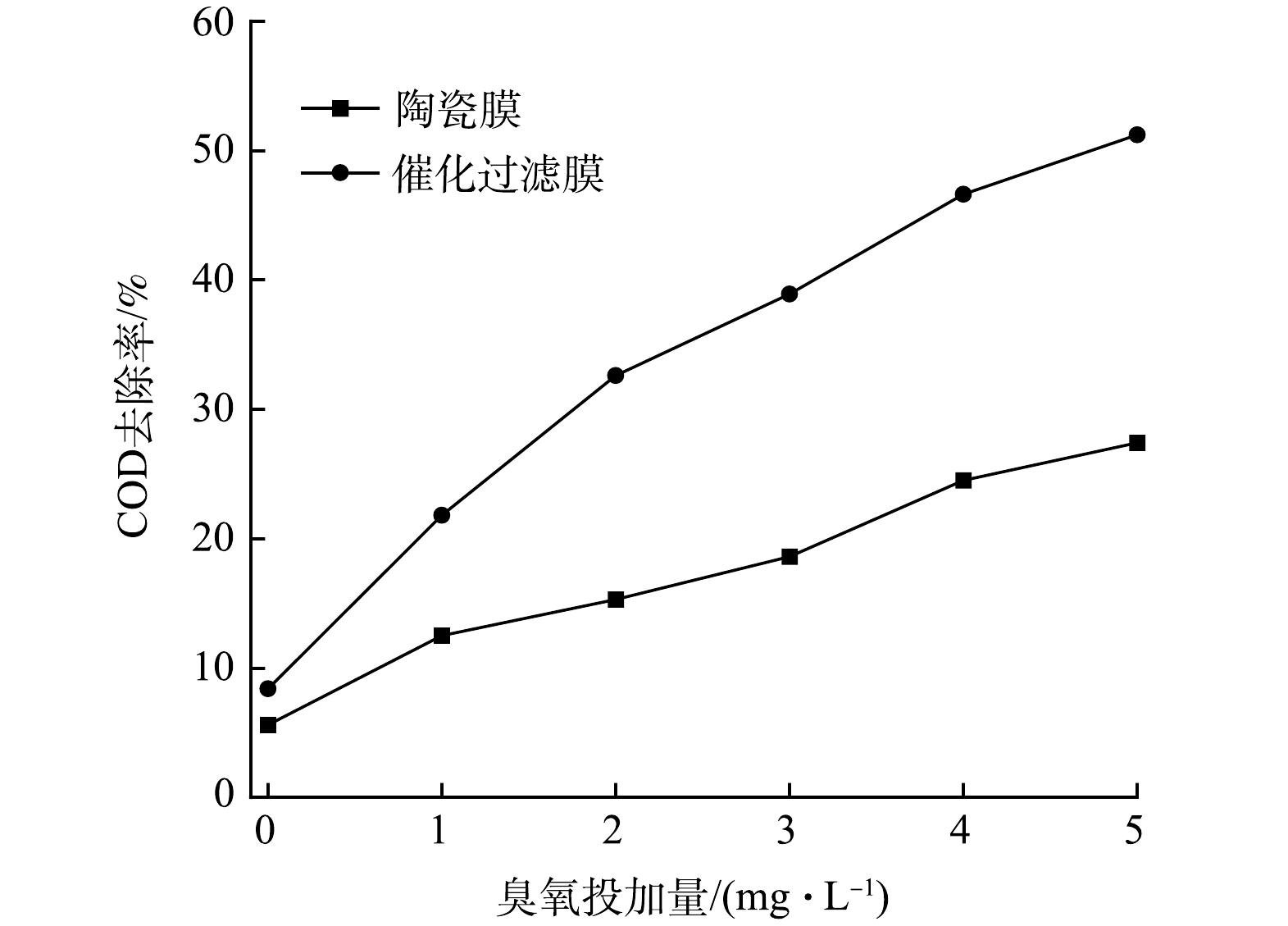

图10反映了当臭氧投加量由0 mg·L−1逐步增加至5 mg·L−1,其余实验参数不变的条件下,水中COD的变化趋势。由图10可知,随着臭氧投加量的增加,催化过滤膜对水中COD的去除率不断升高,当臭氧投加量增加到5 mg·L−1时,污水COD的去除率达到51.2%。采用普通陶瓷过滤膜和催化过滤膜进行对比实验,在不投加臭氧的情况下,2种过滤膜对污水COD的去除率分别为5.6%和8.4%。这是由于在膜表面发生了过滤的物理反应,水中部分大分子有机污染物被截留,催化过滤膜由于负载了活性氧化物导致膜孔径更小,对有机污染物截留效率更高。当臭氧投加量逐步增高,催化过滤膜对水中COD的去除率明显高于普通陶瓷过滤膜;在臭氧投加量为5 mg·L−1时,2种过滤膜对污水COD的去除率分别为27.4%和51.2%,由于催化过滤膜上负载的CeO2、La2O3和MnO2活性组分能够有效地催化臭氧反应生产羟基自由基等活性基团,进而无选择性地氧化降解污水中的有机物污染物。

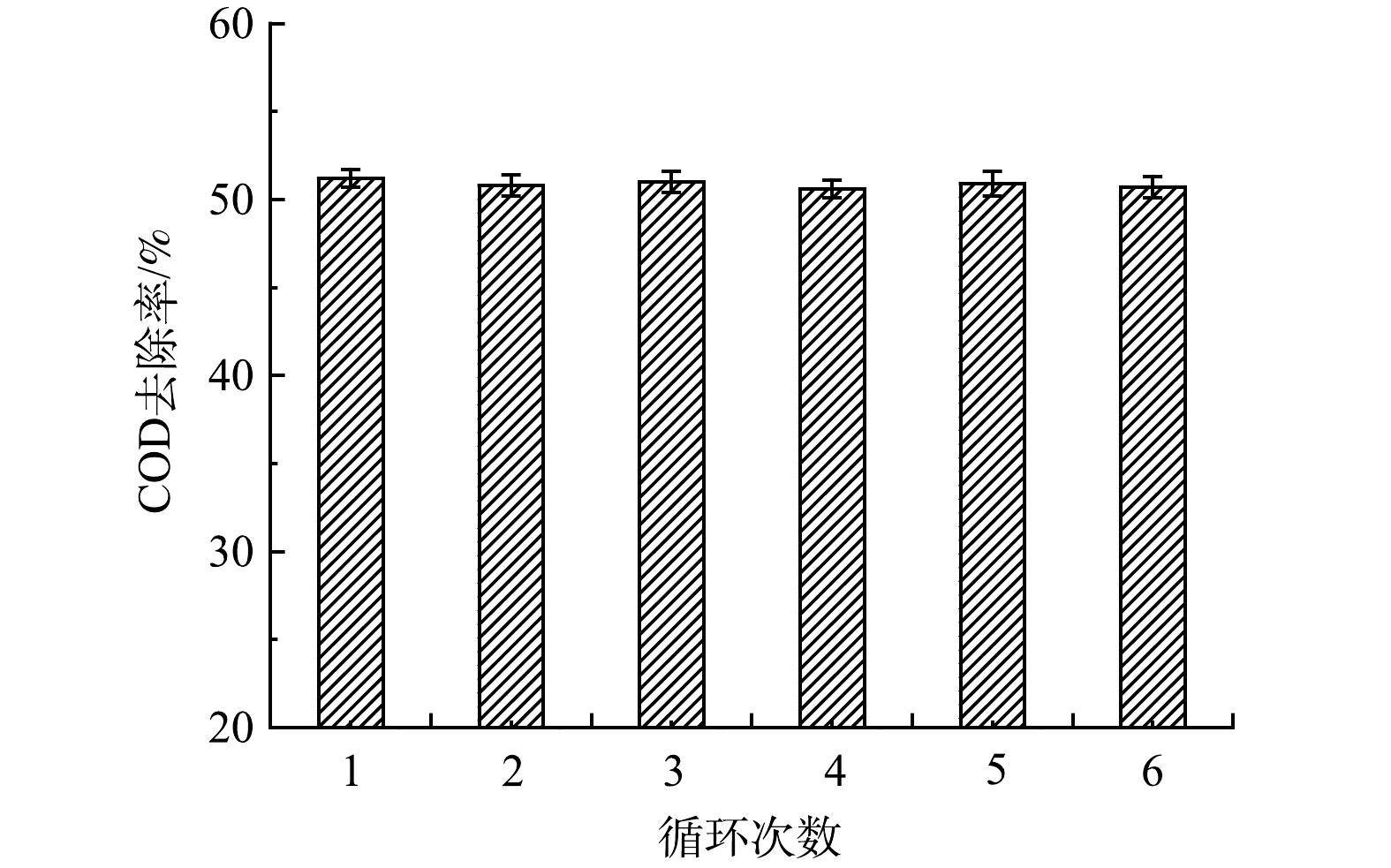

2)催化过滤膜稳定性测试。催化过滤膜的稳定性是评价其性能的一个重要指标,是决定催化剂使用寿命和产业化应用的关键因素。在臭氧投加量为5 mg·L−1,跨膜压差为0.15 MPa,回流比为90%的条件下进行实验,每次反应结束后的催化过滤膜不变,将实验废水更换为初始质量浓度的新鲜实验废水,连续使用5次为1个循环,每次使用1 h。经过6个循环后(每个循环催化剂应用5次),催化过滤膜多次使用对实验废水中COD去除率的影响如图11所示。由图11可知,随着使用次数的增加,催化过滤膜的活性并未有明显减弱,经多次循环后对水中COD的去除率稳定在50%以上,表现出较好的稳定性。对经臭氧催化过滤膜处理后的水样进行多次检测,均未检测出上述负载的金属离子,表明陶瓷膜载体上负载的金属氧化物在此实验条件下不易溶出。

3. 结论

1)以陶瓷膜为载体,La(NO3)3、Ce(NO3)3和Mn(CH3COO)2为催化活性成分的前躯体,采用浸渍-焙烧法制备了MnO2-CeO2-La2O3臭氧催化过滤膜,实现膜分离技术与催化臭氧氧化技术的耦合。浸渍液中Ce3+、La3+、Mn2+的质量比为2:2:1,焙烧时间为3 h,焙烧温度为800 ℃条件下制备出的催化过滤膜在臭氧催化氧化工艺中的催化活性最佳。

2)浸渍后的陶瓷膜经高温煅烧后生成的活性组分均匀地附着在表面及孔道内,陶瓷膜的孔隙率、孔径和通量均有所减小,XRD分析结果表明,催化剂表面形成了活性组分La2O3、CeO2和MnO2,表层活性组分金属元素占总质量的比例达到11.85%。

3)以MnO2-CeO2-La2O3臭氧催化过滤膜为研究对象,在常温和常压下,采用同步臭氧催化和过滤工艺处理电镀园区物化预处理后的混合废水取得了良好的处理效果。在臭氧投加量为5 mg·L−1、跨膜压差为0.15 MPa、回流比为90%的条件下,水中COD的去除率达到51.2%。催化过滤膜经过6次循环后对水中COD的去除率稳定在50%以上,表现出较好的稳定性。

-

图 2 (a)不同种类炭材料的流化床对BPA的去除率;(b)流化床活性炭单位吸附量;(c)一次性投加与分批投加炭材料的流化床对BPA的去除率比较

Figure 2. (a) Removal efficiencies of BPA by fluidized bed with different activated carbon materials; (b) adsorption capacity of activated carbon in different fluidized bed reactors; (c) removal efficiencies of BPA by activated carbon with a one-time and multiple-time dosage mode in a fluidized bed reactor

-

[1] GUO J, LUA A C. Adsorption of sulphur dioxide onto activated carbon prepared from oil-palm shells with and without pre-impregnation[J]. Separation and purification technology, 2003, 30(3): 265 − 273. doi: 10.1016/S1383-5866(02)00166-1 [2] 李栗莹. 活性炭吸附技术在水处理中的应用[J]. 化工管理, 2020(23): 116 − 117. doi: 10.3969/j.issn.1008-4800.2020.23.056 [3] 张晓涛. 木质纤维素/层状硅酸盐纳米复合材料的制备及吸附性能研究[D]. 呼和浩特: 内蒙古农业大学, 2018. [4] NEKOUEI F, NEKOUEI S, TYAGI I, et al. Kinetic thermodynamic and isotherm studies for acid blue 129 removal from liquids using copper oxide nanoparticle-modified activated carbon as a novel adsorbent[J]. Journal of molecular liquids, 2015, 201: 124 − 133. doi: 10.1016/j.molliq.2014.09.027 [5] 左雨欣, 任晓聪. 常用吸附剂及其回收再生技术研究[J]. 当代化工研究, 2021(6): 41 − 42. doi: 10.3969/j.issn.1672-8114.2021.06.018 [6] YE N, CIMETIERE N, HEIM V, et al. Upscaling fixed bed adsorption behaviors towards emerging micropollutants in treated natural waters with aging activated carbon: Model development and validation[J]. Water research, 2019, 148: 30 − 40. doi: 10.1016/j.watres.2018.10.029 [7] 刘剑, 鄢瑛, 张会平. 甲苯在结构化固定床上的吸附性能研究[J]. 材料导报, 2014, 28(14): 44 − 47. [8] 陈天崖, 张世豪, 王亚茹. 活性炭固定床吸附硝基苯废水性能研究[J]. 湖北农业科学, 2019, 58(8): 71 − 73. doi: 10.14088/j.cnki.issn0439-8114.2019.08.016 [9] WANG R C, CHANG S C. Adsorption/desorption of phenols onto granular activated carbon in a liquid-solid fluidized bed[J]. Journal of chemical technology and biotechnology, 1999, 74(7): 647 − 654. doi: 10.1002/(SICI)1097-4660(199907)74:7<647::AID-JCTB95>3.0.CO;2-E [10] 唐思. 流化吸附法去除水中苯酚的材料及工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2012. [11] LANGMUIR I. The Adsorption of Gases on Plane Surfaces of Glass Mica and Platinum[J]. Journal of the american chemical society, 1918, 40: 1361 − 1403. doi: 10.1021/ja02242a004 [12] FREUNDLICH H. Über die Adsorption in Lösungen[J]. Ztschrift physikalische chemie, 1906, 57: 385 − 471. [13] NAJA G, VOLESKY B. Behavior of the mass transfer zone in a biosorption column[J]. Environmental science & technology, 2006, 40(12): 3996 − 4003. [14] DOU B L, CHEN B B, GAO J S, et al. HCl removal and chlorine distribution in the mass transfer zone of a fixed-bed reactor at high temperature[J]. Energy & fuels, 2006, 20(3): 959 − 963. [15] VIEIRA M G A, NETO A F A, GIMENES M L, et al. Removal of nickel on Bofe bentonite calcined clay in porous bed[J]. Journal of hazardous materials, 2010, 176(1-3): 109 − 118. doi: 10.1016/j.jhazmat.2009.10.128 [16] 高宇翔. VOCs在活性炭固定床上的吸附动力学[D]. 广州: 华南理工大学, 2012. [17] 周璇, 张均龙, 马彦涛. 浅谈农村污水处理现状及展望[J]. 农业与技术, 2020, 40(18): 56 − 58. [18] 周兵. 活性炭吸附脱硫实验研究和数学模拟[D]. 上海: 华东理工大学, 2014. [19] Ahmad A A, Hameed B H. Fixed-bed adsorption of reactive azo dye onto granular activated carbon prepared from waste[J]. Journal of hazardous materials, 2010, 175(1-3): 298 − 303. doi: 10.1016/j.jhazmat.2009.10.003 -

下载:

下载: