-

随着我国城市化水平的不断推进和基础设施的不断完善,城市污水处理能力逐渐提升,而污泥作为污水处理的副产物其产量也不断增加。污泥组成成分十分复杂,是一种由高度分散的絮凝体组成的稳定复杂胶体结构[1],特别是污泥细胞和EPS具有高度亲水性使污泥含水率高 (二沉池污泥的含水率可高达98%以上[2]) ,因此实现其有效的处理、处置及资源化利用,如填埋或焚烧,则必须建立在高效的污泥脱水基础之上。

传统的污泥脱水技术,如板框脱水法,需预先将湿污泥与化学调理剂 (如氯化铁、氧化钙等) 混合,通过试剂与胞外聚合物相互作用,实现污泥细胞的溶解及絮体颗粒的沉降,经这种方法调理后的污泥饼含水率仍高达75%~85%[3-4]。近些年,基于电化学原理而形成的污泥调理方法被认为是一种更清洁和高效的污泥脱水技术[1,5-6]。在电场作用下,污泥絮体不仅可以通过电极放电被直接破坏和分解,由电场作用形成的电势差更可以极化每一个污泥粒子而促使细胞的电渗析脱水[7-8]。为进一步改善污泥絮体的凝聚作用,强化污泥絮体的孔道结构与脱水功能,以铁、铝等作为可牺牲性阳极材料的电絮凝技术进一步提高了电化学法在调理污泥、强化污泥脱水过程中的作用。

电絮凝作为一种新型的电化学污泥预处理方法,虽然可以在一定程度上改变污泥粒子的稳态结构并增强其团聚性,使污泥颗粒粒径增加、流变性降低、脱水孔道结构增强[9],但由于有限的污泥极板接触面积和较弱的电极催化活性[10],电絮凝对絮体颗粒和细胞的破解效果仍然有限。目前,已经有学者通过将电絮凝与氧化法耦合以增强污泥絮体的破解、EPS的降解和细胞水的释放,如利用双阳极电极 (可牺牲性阳极和DSA电极) 的电絮凝耦合直接氧化法和利用向体系中投加H2O2的电絮凝耦合间接氧化法[11-12],均取得了令人满意的污泥调理效果。然而,由于2种氧化方法的作用机制存在较大差异,在电极上的直接氧化和基于溶液相中形成强氧化性中间体对污泥絮体的分解,尤其是不同EPS结构中蛋白和多糖的降解与结合水的释放等均存在显著的差异,而影响其预处理的最佳条件,目前还尚未有较系统性的报道。

因此,本研究比较了电絮凝耦合DSA电极和电絮凝耦合H2O2对调理污泥强化污泥脱水的影响。以CST和泥饼MC为指标对2种耦合技术的操作参数进行对比和优化,拟得到2种耦合法的最优预处理条件;以絮体改变和溶胞程度方面探究2种耦合技术对污泥的预处理机制;以各层级水中EPS的成分改变、污泥颗粒粒径等指标的变化以及自由基猝灭实验揭示2种耦合工艺的各自作用机理;最后,通过对沉淀过程中的铁形态分析,结合脱水泥饼的扫描电子显微镜 (SEM) 观察,解释2种耦合工艺在电絮凝过程中的差异。

-

1) 实验污泥。本研究中的污泥样品来自上海松申水环境净化有限公司的二沉池污泥,收集的污泥储存在聚丙烯容器中并于4 ℃下保存,以尽量减少微生物的活性。原污泥的含水率、pH、CST和MC分别为98%±0.2%、6.35±0.05、(61.2±0.05) s和88%±0.15%,本研究涉及污泥的实验在3 d内全部完成,且使用的污泥为同一批次的污泥。

2) 主要试剂。硫酸钠 (Na2SO4) 、氢氧化钠 (NaOH) 、盐酸 (HCl,36%) 、硫酸 (H2SO4,98%) 、考马斯亮蓝 (Coomassie brilliant blue G-250) 均为分析纯,所有原液制备和实验均使用去离子水。

-

1) 电化学实验。电化学实验在1 000 mL的有机玻璃矩形槽内进行,使用 Mer sanDC (0~30 V) 作为稳压直流电源,每次实验的污泥样品为0.5 L。电絮凝耦合DSA电极方法采用Fe板和Ti/PbO2以并联方式组装为第一阳极和第二阳极,阴极为Al板;电絮凝耦合H2O2工艺采用Fe板和Al板分别作为阳极、阴极,极板间距为4 cm,在反应器中一次性滴加H2O2 (0~2.5 mL·L−1) 并利用恒速搅拌器于100 r·min−1充分混合。每块极板的几何尺寸为10 cm×10 cm×0.1 cm,所有电化学实验均进行3次以降低实验误差。

2) 极板预处理。实验前将电极板浸泡在10%的盐酸溶液中20 min,随后用砂纸打磨极板表面,然后再将极板放置于5%的盐酸溶液中浸泡10 min去除其表面的氧化物,最后用去离子水清洗干净即可使用。

-

1) 基本参数。污泥过滤性能由毛细吸水时间 (CST) 评估,在配备不锈钢管 (10 mm) 和色谱级滤纸的CST仪器 (304 M, Triton, UK) 中进行测量,pH值pH计 (PB10,瑞士Mettler Toledo) 测定。采用哈希消化仪 (DRB 200, US) 和分光光度计 (Hach® DR3900, US) 测定污泥上清液的可溶性化学需氧量 (SCOD,Soluble Chemical Oxygen Demand) ,探讨污泥的溶胞效率。

2) 泥饼MC的测定。用标准布克纳漏斗在0.095 MPa的压力下过滤,通过泥饼MC的变化来评价污泥的脱水能力。将洗净后的坩埚放入105 ℃的烘箱烘干2 h后放至干燥器中冷却;然后用电子天平称坩埚的重量,记为m1;取50 mL污泥置于标准布克纳漏斗,在0.095 MPa的压力下过滤30 min,将过滤后的滤饼于105 ℃干燥箱中烘干至恒重放入坩埚中,称重m2;将泥饼与坩埚一并放入105 ℃烘箱中,泥饼完全干化后,取出放置在干燥器中冷却,记为m3。根据公式计算污泥泥饼含水率MC (%) 。

3) EPS的提取与测定。污泥样品的EPS组分采用三步热提取法获得[13]。首先将原污泥样品离心,收集含S-EPS的上清液;然后在离心管中加入相当于原上清体积的0.05% (w/w) NaCl溶液于50 ℃下混合,重悬固体,再次离心,收集含有LB-EPS的上清液。在60 ℃下再次悬液,然后离心收集含有TB-EPS的上清液。DOC采用TOC-VCPH分析仪 (VCPH,日本岛津) 测定;蛋白质含量采用考马斯亮蓝法测定,以牛血清蛋白为标准物质[14];多糖含量采用苯酚-硫酸法测定,以葡萄糖为标准物质[15]。采用荧光分光光度计 (RF6 000,日本岛津制作所) 测量EPS的三维荧光激发-发射光谱。

4) SCOD增长动力学分析方法。采用动力学模型 (2) 和 (3) 对2种耦合工艺处理下SCOD的增长特征的动力学变化分析[16]。

式中:K表示溶解速率常数;b为截距;以-ln (Ct/C0) 与t分别为横坐标和纵坐标绘制直线即可得到斜率,即SCOD增长的表观速率常数。

5) 自由基猝灭实验。在2种耦合工艺分别加入碘化钾 (KI) 、异丙醇 (i-PrOH) 、叔丁醇 (TBA) 分别作为表面结合的·OH (·OHads) 、游离态·OH (·OHfree) 、·OHfree和·OHads的清除剂[17],以SCOD为指标确定自由基种类在2种耦合工艺下的作用。

6) 能耗分析。根据式 (3) 计算湿污泥电化学调控能耗[18]。

式中:U为施加的电压,V;I是电流,A;t是预处理时间,min;Vs是处理的污泥体积,L。

7) 其他分析。污泥颗粒的中位直径由粒度分析仪 (BT-9 300Z,上海,中国) 检测。用激光衍射仪 (Omni, Brookhaven, US) 测量污泥上清液的Zeta电位。用傅里叶红外光谱仪 (FT-IR, Nicolet/iS 10,美国赛默飞世尔仪器公司) 对污泥EPS和蛋白质二级结构进行分析。采用X射线光电子能谱仪 (XPS, Thermo Fischer, ESCALAB 250Xi, USA) 对泥饼表面铁元素的价态进行测试和分析。利用扫描电子显微镜 (SEM, Sigma500, ZEISS,德国) 表征了电解前后污泥絮凝体结构的变化,并采用Ferron逐时比色法对沉淀过程中的铁形态做了研究[19]。

-

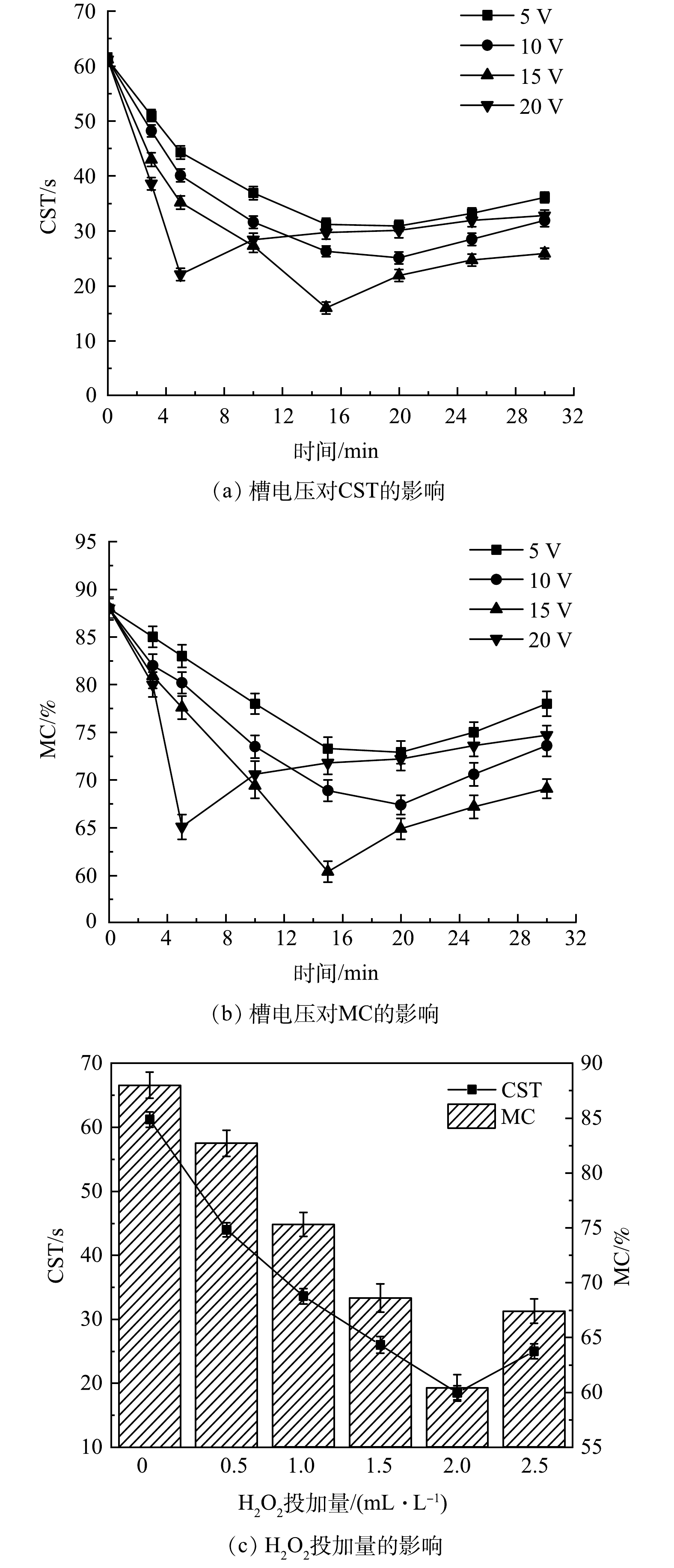

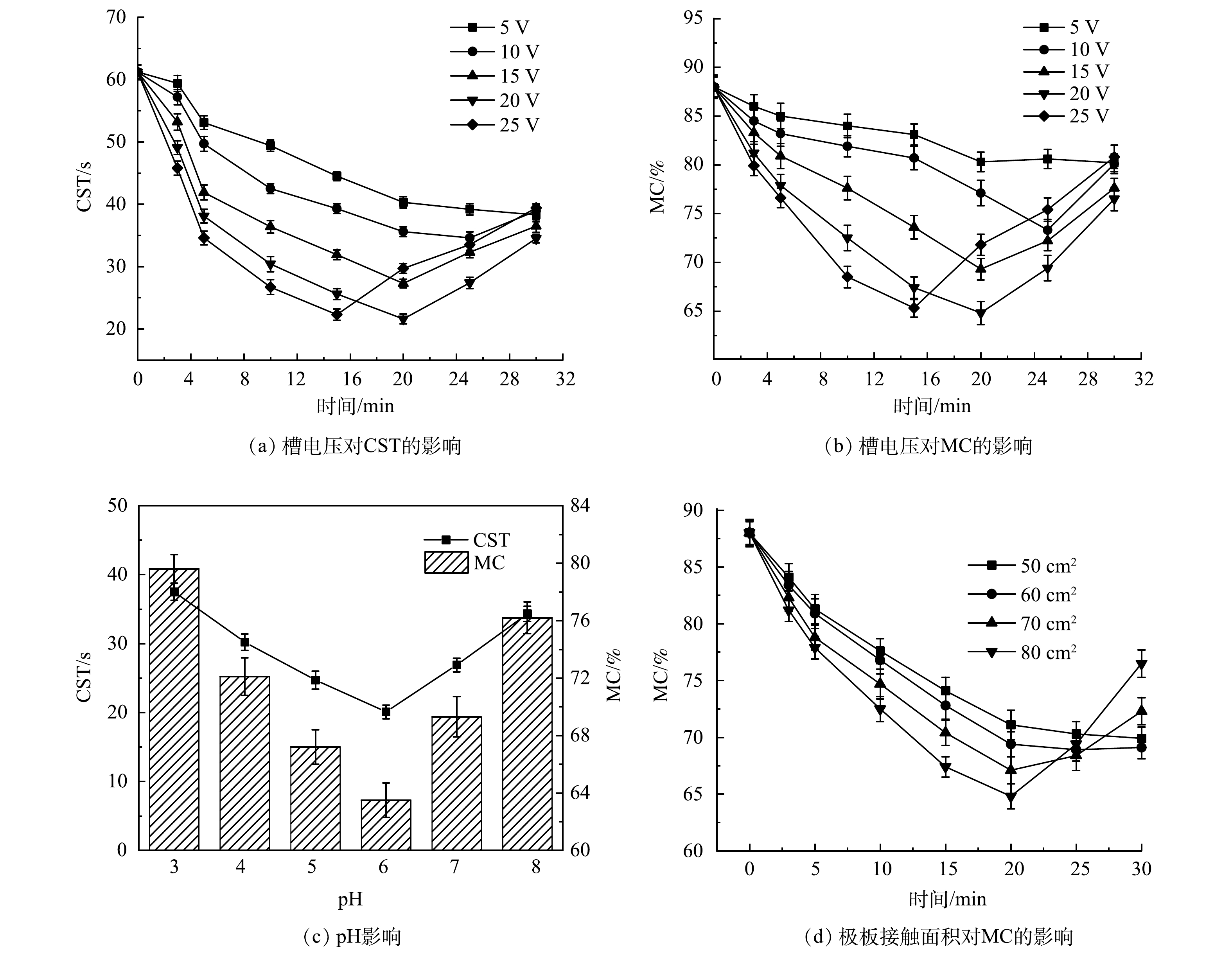

1) 电絮凝耦合DSA电极。图1(a)、图1(b)显示的是电絮凝耦合DSA电极中不同电解电压和电解时间对污泥CST和泥饼MC的影响。可以看到,增加电压和电解时间会导致CST和泥饼MC下降。当电压增加至20 V,电场作用显著加强,污泥絮体受到破坏,细胞发生裂解,污泥中间隙水和内部结合水得到释放[1];同时,Fe阳极中Fe2+的不断溶出及Fe3+的累积 (式 (5)~式 (6) ) 产生较强的絮凝作用使污泥絮体发生沉降,电解时间20 min污泥的CST和泥饼MC降至最低,分别为21.6 s和64.8%。继续增大电压至25 V时,此时受阳极氧化和电场作用,污泥细胞被破坏、胞内和胞外物质的释放增加了污泥的粘度[1],形成的更多细小污泥颗粒阻塞了滤纸,造成污泥的过滤性能下降[20]。初始pH会影响电化学强化污泥脱水的效果[11]。在电压为20 V、电解时间为20 min时,发现在pH < 6时,污泥CST和泥饼MC随着pH的增加而降低 (图1(c)) 。因为在酸性条件下,H+可以中和污泥表面的负电荷使污泥絮体脱稳凝聚,促进污泥的絮凝和脱水[21]。但过量的H+将会使阳极的铁离子溶出过程受限,导致电凝的效果下降。而在中性条件下,铁离子电中和的能力被削弱,导致絮凝效果变差[22]。对于电絮凝耦合DSA电极设计不同极板接触面积对污泥脱水的影响,详见图1(d)。从图中可以看出,随着有效极板面积的增加,污泥的脱水性能有所改善,于极板接触面积为80 cm2时达到最低。基于本实验的设计框架,该接触面积为最大接触面积,但是其对污泥脱水性能的改善效果有限。阳极极板面积影响铁离子的溶出,污泥的脱水性能与铁离子的溶出量有关,而Fe2+析出量又由电解时间与电流密度影响[23]。而随着电解时间的增加,电解污泥在极板表面形成氧化膜,使极板钝化且催化活性降低,导致电化学的电解效率降低[24]。一般情况下,在电化学体系中,极板面积往往受限于反应池容积、水力停留时间和工程造价等因素,因此实验室前期通过引入接触面积更高的三维粒子电极等方法则可以有效解决面积限制[18]。综合污泥脱水效果和成本,电压20 V、电解时间20 min、不调节pH、极板接触面积为80 cm2为后续电絮凝耦合DSA体系试验的操作条件。

2) 电絮凝耦合H2O2。图2显示的是电絮凝耦合H2O2过程参数 (电压、电解时间和H2O2投加量) 对污泥CST和泥饼MC的影响。如图2(a)、图2(b)所示,15 min时,污泥CST值和泥饼MC随着电压的增加呈先降低后升高趋势。当电压为15 V时,污泥CST和泥饼MC值达到最低,分别为16 s和60.8%。进一步增加电压污泥的脱水性能恶化。电压为15 V时,随着电解的进行 (< 15 min) 体系内铁阳极溶出的Fe2+ (式 (5) ) 会与H2O2芬顿反应体系 (式 (7) ),产生具有强氧化性的·OH以破解污泥絮体及细胞结构并释放结合水,使污泥CST和泥饼MC值下降,污泥脱水性能得以改善;而当进一步增加电解时间或操作电压时,由于阳极释放的过量铁离子会反过来消耗体系内产生的自由基,而导致副反应加剧 (式 (8)~式 (9) ) ,氧化效率降低[1]。此外,电解时间或操作电压的增加导致胞内和胞外物质的过度释放,污泥中细颗粒的数量和污泥粘度增加,恶化了污泥的脱水性能[12]。

H2O2是体系内·OH的主要来源[25]。H2O2投加量对污泥的过滤性能的影响如图2(c)所示。当H2O2投加量增加至2.0 mL·L−1时,污泥的CST和MC相较于原污泥分别下降了73.9%和31.4%;继续增加至2.5 mL·L−1时,污泥CST和泥饼MC缓慢上升,污泥的脱水性能变差。这说明,在一定范围 (0~2 mL·L−1) 内向体系内投加H2O2,可以一定程度上改善污泥的过滤性能。但是过量的H2O2会与·OH反应生成氧化性相对较低OH2· (式 (10) ) ,而OH2·会进一步消耗·OH产生O2 (式 (11) ) ,降低了H2O2的利用率,无法达到进一步改善污泥脱水性能的效果[25]。综合考虑污泥脱水效果和成本,选择电压15 V、电解时间15 min、H2O2投加量2.0 mL·L−1为后续电絮凝耦合H2O2体系试验的操作条件。

-

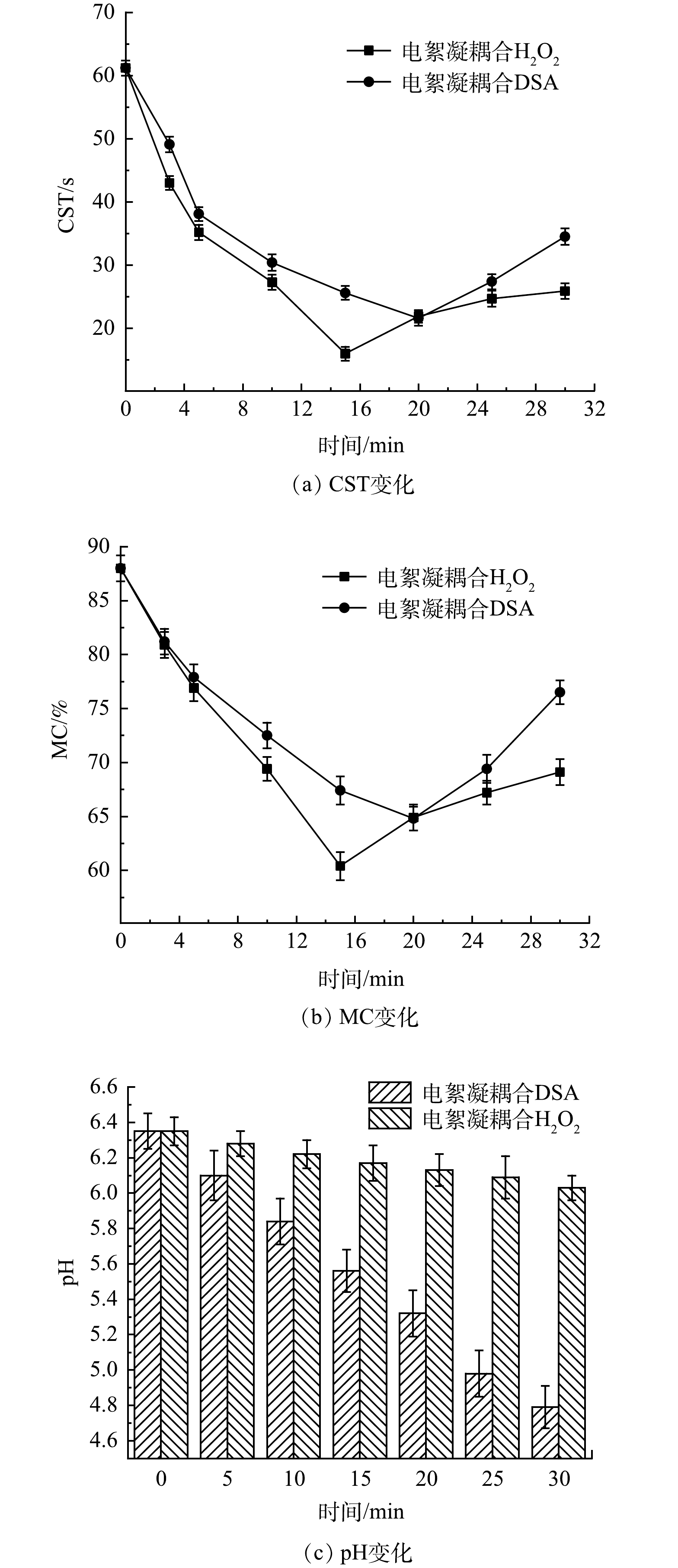

1) pH、CST和泥饼MC变化。污泥分别经电絮凝耦合DSA直接电氧化和电絮凝耦合H2O2间接电氧化后,其体系的pH、CST和泥饼MC随预处理时间的变化如图3所示。图3(a)~图3(b),电絮凝耦合直接电氧化在电解前期 (< 20 min) 污泥的过滤性能随着电解时间的延长不断提升。极板的直接氧化使污泥絮体裂解并破坏污泥细胞,释放部分间隙水和胞内水,随着电解的进行,体系中产生的铁离子形成的水解产物可以使破碎的污泥细颗粒重新聚集,减少了脱水孔道的阻塞,提高了污泥的过滤性能[26]。该体系在20 min时的CST和泥饼MC会达到最低,对比原污泥时分别下降了64.9%和26.4%。电絮凝耦合H2O2间接电氧化法中,污泥在15 min时其CST和泥饼MC便可下降了73.9%和31.4%。这说明,间接氧化形成的溶液相·OH,能够更加无选择性地接触并攻击污泥絮体、降解EPS,释放更多的间隙水和结合水[13]。

体系的pH会影响铁离子的存在形式和对污泥粒子的絮凝效果[11]。低pH下,铁离子的水解受到了抑制,而中性pH左右时,铁离子的水解产物为聚铁物质,有助于污泥沉降脱水[27]。从图3(c)可以看出,2种体系的pH随时间的变化均存在显著差异。由于DSA阳极的析氧作用 (式12) ,电絮凝耦合DSA体系的pH值随电解过程会逐渐降低;而电絮凝耦合H2O2体系中当加入氧化剂加入后,体系pH值略微下降 (< 5%) [28],这有利于Fe3+在体系中的积累和网捕微粒的形成 (式 (7-8) ) ,促进破碎后污泥絮凝体的重聚及沉降。

2) 絮体破解程度。高亲水性的胞外聚合物EPS通常以带负电荷的胶体形式存在,具有高的胶体稳定性和粘度,本节分别测定了经2种工艺预处理后污泥各层EPS中DOC含量,结果如表1所示。可以看到,经2种工艺在最佳条件下预处理后得到的LB-EPS和TB-EPS中的DOC含量均降低,说明污泥的脱水性能得到了提升[29]。电絮凝耦合DSA体系中,极板的直接氧化作用会破裂污泥絮体,降解EPS,其中LB-EPS的下降较为明显,与原污泥相比降低了34.18%;而电絮凝耦合H2O2则能同时降低LB-EPS和TB-EPS,DOC的去除率分别为56.81%和49.05%。TB-EPS层是离微生物最近的部分,因此TB-EPS的降解表明污泥絮体的破解程度得到进一步加强。由于细菌表面带有负电荷,铁阳极产生的Fe2+与带有负电荷的胶体颗粒吸引形成表面铁离子,促发原位Fenton反应,因此使得TB-EPS在耦合间接电氧化的体系中得到了更有效的降解。

3) 溶胞效应。污泥上清液SCOD含量作为污泥预处理过程中的一个关键性能指标,可反映出污泥释放出有机质的含量[30]。2种预处理工艺对污泥SCOD含量变化随时间的影响如图4所示。可以看出,电絮凝耦合DSA中,电解时间为20 min时,SCOD含量由原泥的104 mg·L−1增加到153 mg·L−1,增加了47.12%; 20 min后,SCOD的增长速率开始变缓,这可能与极板钝化有关[24]。电絮凝耦合H2O2中,SCOD值快速升高随后缓慢降低,说明间接氧化形成的溶液相·OH提升了体系的氧化性,释放污泥细胞内的蛋白质、多糖等高分子可溶性物质。20 min时,相对于原泥 (104 mg·L−1) ,污泥SCOD浓度增加了68.27%。而进一步延长电解时间,体系中·OH会继续降解可溶性物质,使SCOD值略微下降。

为分析2种工艺的溶胞速率差异,采用动力学一级模型分别对0~20 min (即快速溶胞阶段) 和20~30 min (即平稳阶段) 中污泥上清液SCOD浓度变化进行分析,结果如图4(b)和表2所示,发现电絮凝耦合间接电氧化的溶胞速率在第一阶段明显高于电絮凝耦合直接电氧化法,2体系的对应的溶胞速率常数分别为−34.71×10−3 min−1和-23.9×10−3 min−1,表明体系中生成的羟基自由基对污泥絮体破坏和细胞分解的能力高于电极直接氧化和电场作用力。阶段二中,间接电氧化体系中SCOD的变化趋于负值,说明此阶段更有利于自由基对污泥上清液中溶解性有机物的降解,而直接氧化体系则表现出稳定而持续的溶胞效应。

-

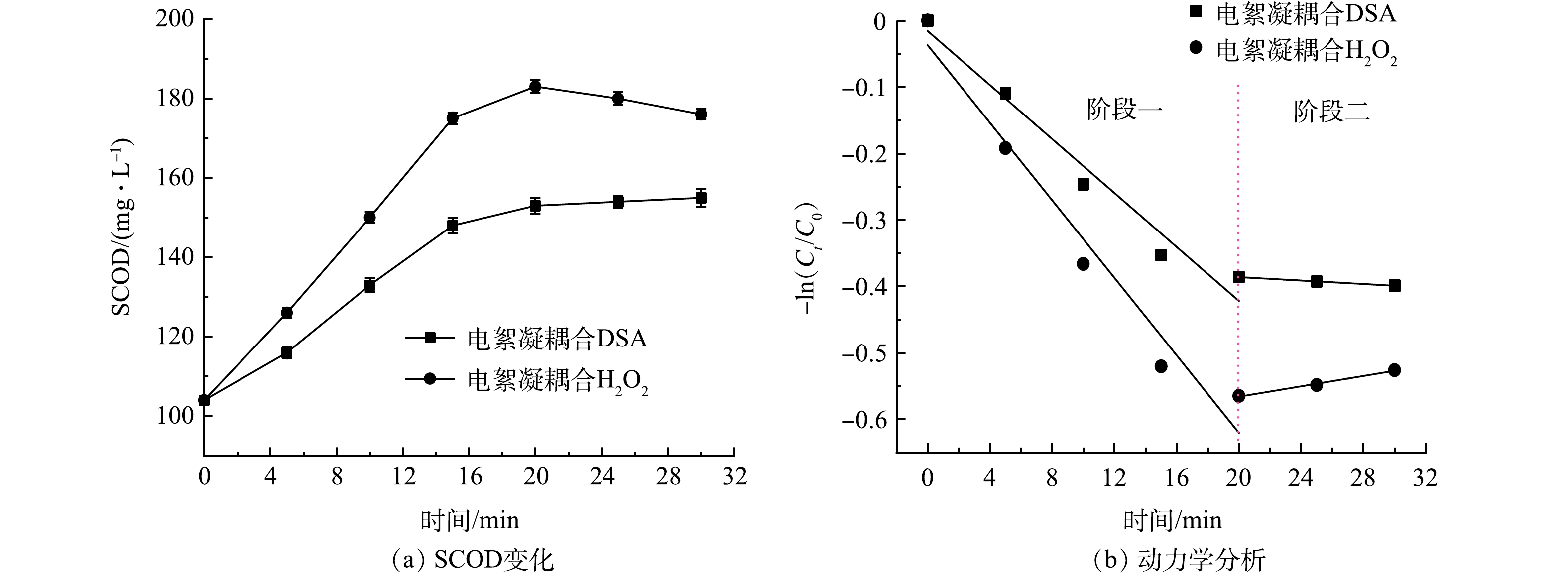

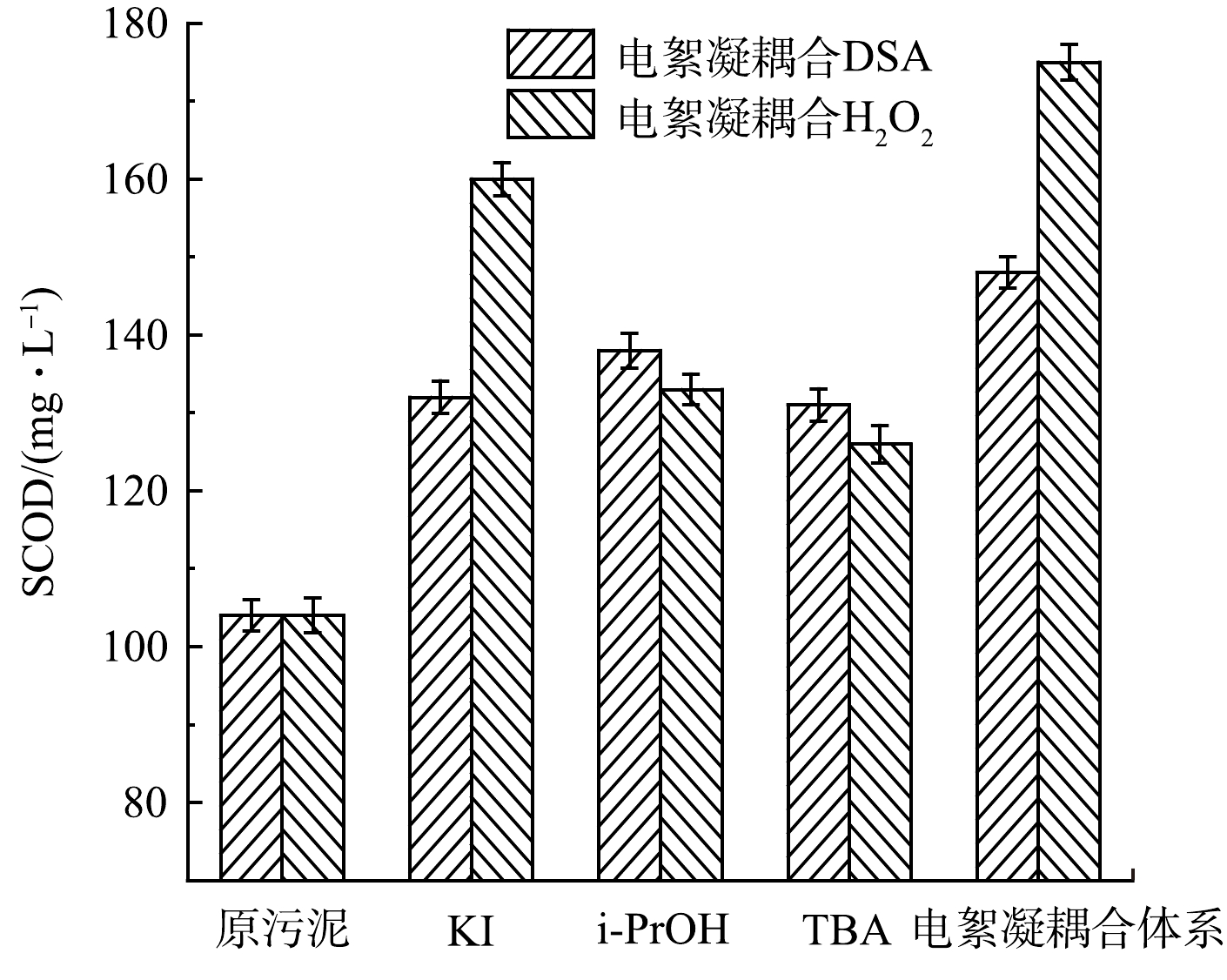

1) 自由基抑制试验。在体系中分别加入碘化钾 (KI) 、异丙醇 (i-PrOH) 、叔丁醇 (TBA) 作为表面结合的·OH (·OHads) 、游离态·OH (·OHfree) 、·OHfree和·OHads的清除剂,以判断自由基类别在电化学污泥调理过程中对污泥的作用机制,结果如图5所示。电絮凝耦合DSA体系中分别投加KI、i-PrOH和TBA,相比于直接电絮凝耦合DSA调理,污泥SCOD值相对应地降低了36.36%、22.73%和38.64%,表明DSA电极表面上通过H2O在酸性条件下的氧化产生了少量的·OHads[31],有限的破解了被吸附在电极表面的污泥絮体,此外,随着电解的进行电极涂层和Ti基体之间形成TiO2氧化物层导致电极失活[32],使体系的氧化性下降,主体料液中的污泥絮体未被深度破坏,后期絮凝效果差;而电絮凝耦合H2O2中,抑制剂对污泥SCOD的变化影响较大,分别投加KI、i-PrOH和TBA较未加时的SCOD分别下降了21.13%、59.15%和69.01%,说明电解槽中形成的·OHfree对污泥絮体的分解以及细胞溶解的作用更加明显。已有的报道指出,·OHfree能够全方位地、无选择性地破坏污泥絮体结构和微生物细胞结构,释放胞内物质并同时降解EPS,释放间隙水和内部结合水,提升污泥脱水性能[13]。

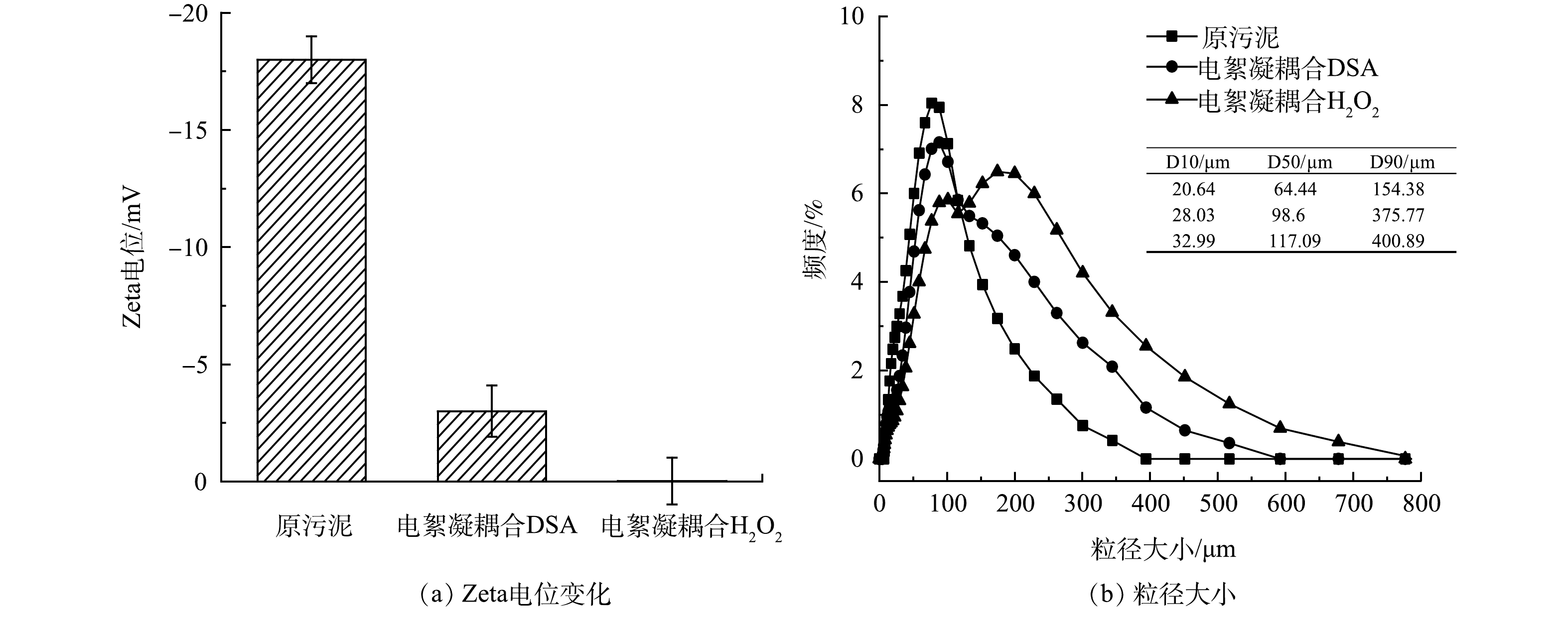

2) Zeta电位与粒径分布。Zeta电位是反映污泥稳定性的关键参数[33]。污泥的Zeta电位越高,污泥颗粒之间的斥力越大,说明污泥絮体的稳定性越高,越不利于污泥的脱水[34]。如图6(a)所示,原污泥的Zeta电位为-18 mV,污泥絮体之间的静电斥力较大,不利于污泥脱水。电絮凝耦合DSA电极预处理后,水分子在DSA阳极发生电离或者离子吸附作用,则DSA电极表面带正电。通常情况下,表面负电荷的污泥颗粒向阳极移动[34]。此时,受阳极表面的直接氧化和电场作用,污泥颗粒表面的羟基、羧基等负电荷官能团被破坏[35],同时由于铁阳极不断释放的阳离子的电中和作用,Zeta电位绝对值降至3 mV,污泥中位粒径 (D50) 经脱稳凝聚后增至98.61 μm (原泥为64.44 μm,图6(b)) 。DSA电极由于受极板面积和阳极钝化的影响,污泥与极板的接触机会较低,表现出有限的絮体破解与EPS降解能力。在电絮凝耦合H2O2体系中,污泥Zeta电位绝对值降低至0.02 mV,接近于0,污泥颗粒间斥力大幅下降。Zeta电位绝对值的降低可能与体系中产生的·OH对EPS中的阴离子官能团和带负电的生物聚合物的降解所致[25];同时,快速由于类Fenton作用生成的Fe3+水解多核铁羟基化合物作为絮凝剂可以重聚被释放的污泥细颗粒和EPS片段,进一步压缩了颗粒的Zeta电位[36],同时使污泥颗粒聚集,中位粒径显著增加至117.09 μm[12,28]。

3) 脱水过程中EPS变化

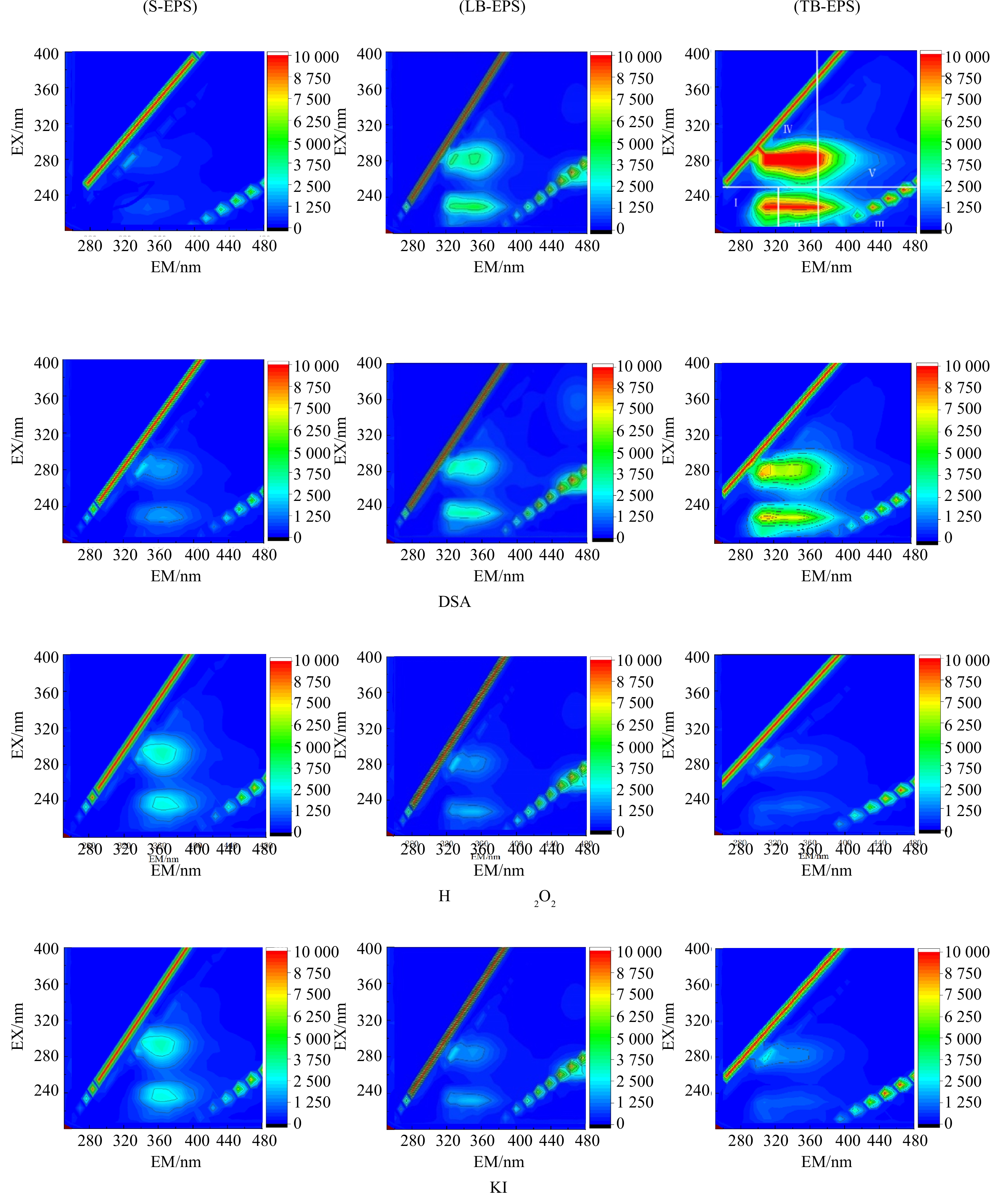

1) 三维荧光光谱分析。采用三维EEM荧光光谱法 (3D-EEM) 对不同污泥样品滤液中的有机化合物进行表征,如图7所示。各EPS层均有4个荧光峰[37],分别为色氨酸类蛋白 (TPN, λex/λem = 280 nm/335 nm) 、芳香蛋白 (APN, λex/λem = 225 nm/340 nm) 、腐殖酸 (HA, λex/λem = 330 nm/410 nm) 和黄腐酸类物质 (FA, λex/λem = 275 nm/ 425 nm) 。

先前研究表明,电化学处理对LB-EPS的去除具有显著效果[38];本研究中电絮凝耦合工艺调理污泥对LB-EPS、TB-EPS的去除均有显著影响,如图7所示。电絮凝耦合DSA体系预处理后,LB-EPS的荧光强度下降明显,这可能与荧光团结构中羧基、羟基和氨基的释放有关[39]。而经过电絮凝耦合H2O2的间接氧化体系处理后,LB-EPS和TB-EPS的荧光强度进一步下降,其中,TB-EPS中色氨酸类蛋白 (TPN) 和芳香蛋白物质 (APN) 的下降尤为明显 (表3) 。这是由于该体系下催化产生·OHfree能以非选择性的方式与大分子物质发生反应,包括氢原子抽离、电子转移和亲电加成等[40-41];同时,体系内不断累积的Fe3+与H2O2循环生成·OH和HO2·,将可溶性物质以及蛋白物质矿化[42]。随着铁离子溶解速率的加快,体系内产生更多的Fe2+、Fe3+,经过水解产生的能够以有机-金属络合物形式与蛋白质、腐殖质等反应[43],有助于骨架脱水。

在电絮凝耦合H2O2体系中,加入KI后,污泥三层EPS的荧光强度变化较小,表明体系中·OHads的作用微弱;加入i-PrOH,样品TB-EPS中TPN、APN、FA荧光强度的增加 (表3) ,证实了·OHfree对EPS的降解作用。此外,TBA的加入产生的效果与i-PrOH相似,验证了·OHfree而不是·OHads对不同EPS组分的降解和破坏作用。

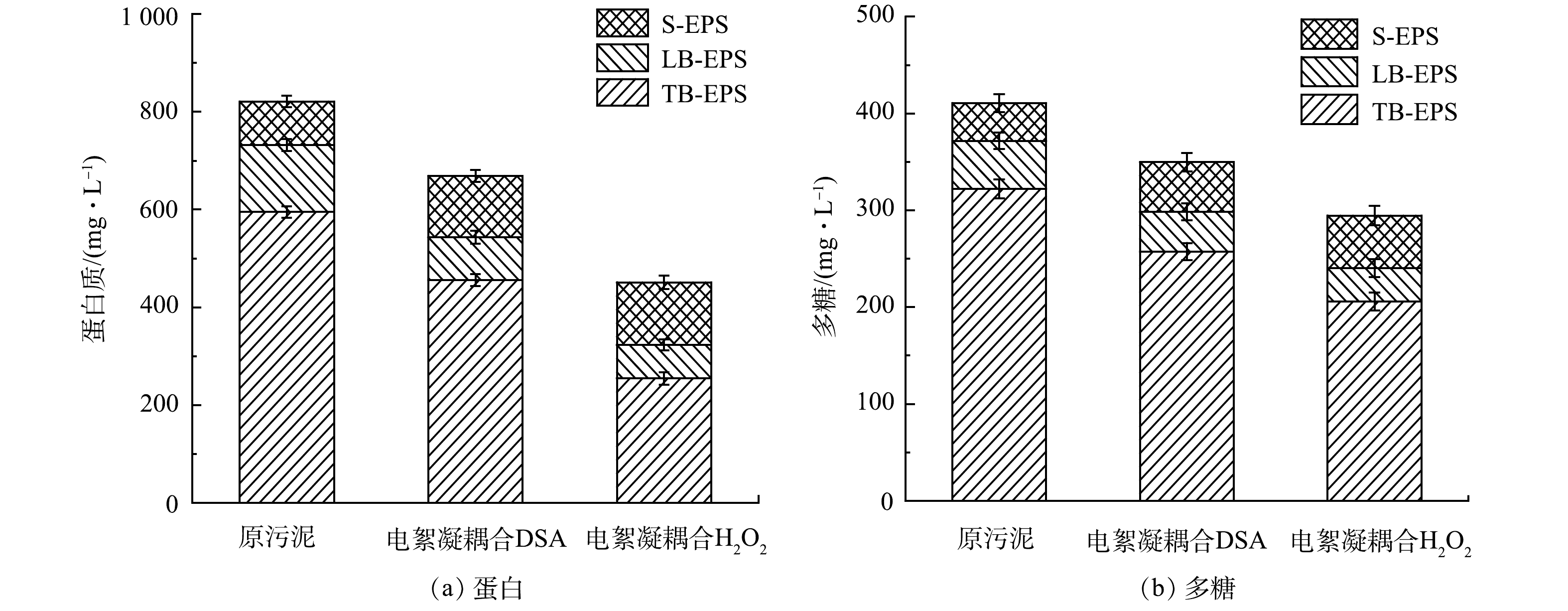

(2) PN、PS含量。如图8所示,蛋白质和多糖主要分布在TB-EPS组分中,LB-EPS和S-EPS组分中较少 [44-45]。原污泥中三层EPS的蛋白质和多糖含量分别为88.7、137.3、595.1 mg·L−1和322.2、49.5、38.9 mg·L−1。电絮凝耦合DSA电极预处理后,LB-EPS和TB-EPS中蛋白质的含量分别降低了29.2%和20.1%,而S-EPS中蛋白质含量增长了32.2% (图8(a)) 。电絮凝耦合DSA电极一方面通过极板的直接氧化作用破坏污泥絮体、裂解污泥细胞,促使污泥胞内和胞外 (主要是LB-EPS) 蛋白、多糖等有机物质的释放[1];另一方面,铁阳极产生的Fe3+可以络合蛋白质和电中和多糖阴离子官能团,降低蛋白质和多糖含量,但2者含量只是轻微下降[12]。而电絮凝耦合H2O2体系中,间接氧化形成的·OH可以氧化降解EPS并与蛋白质、脂质和DNA发生反应[46],进一步降低了LB-EPS和TB-EPS中蛋白、多糖的含量,且蛋白质含量的下降程度远大于多糖。这表明,蛋白质比多糖更容易受自由基攻击而被氧化[13]。此外,TB-EPS中蛋白、多糖含量下降的更为明显,这与表1中3层EPS浓度的变化一致。TB-EPS是最接近微生物的一层,发生在污泥微生物附近的Fenton使TB-EPS得到有效降解,与原污泥比TB-EPS的蛋白、多糖明显降低[28]。

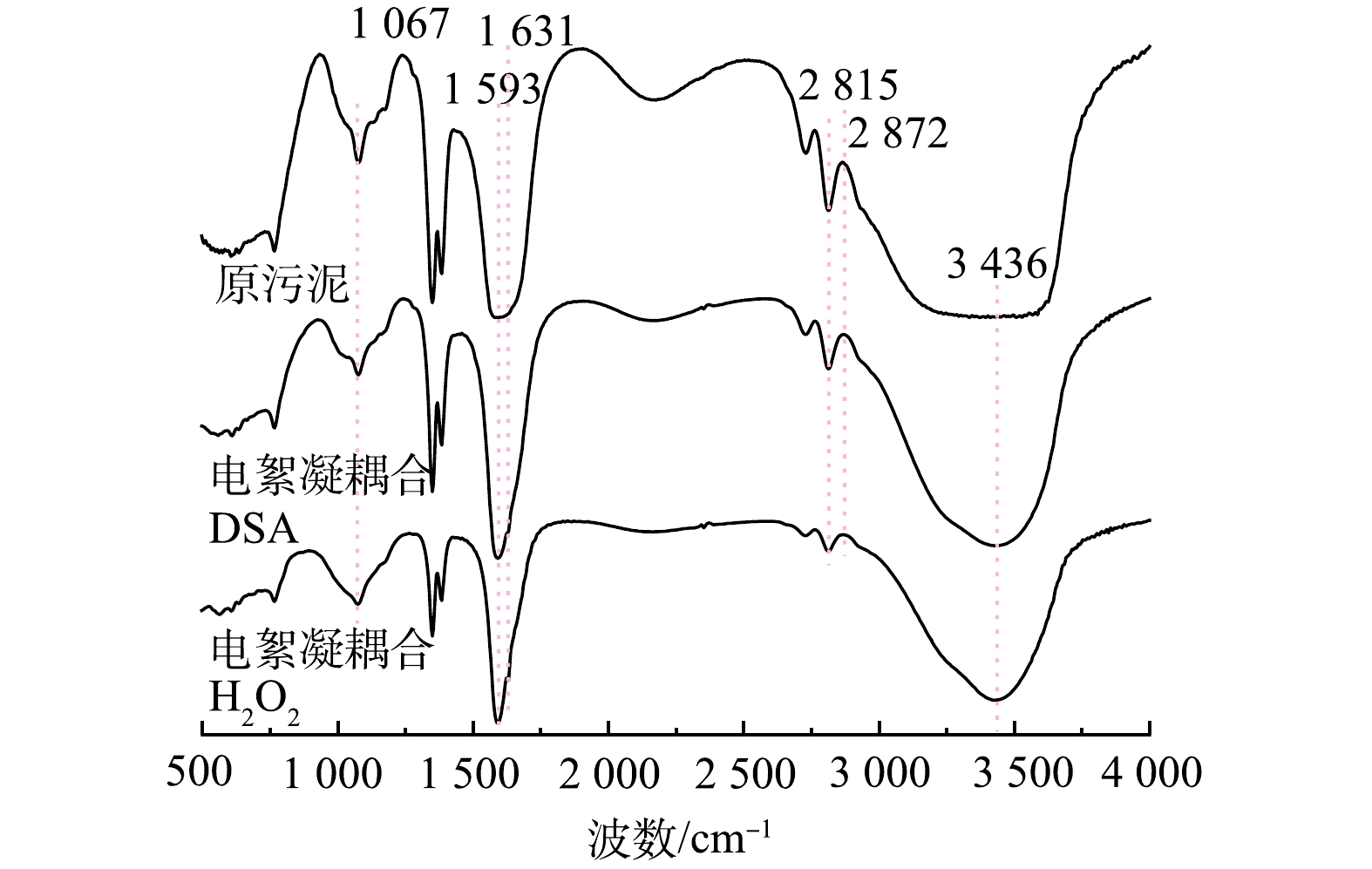

(3) 红外分析。利用FTIR光谱分析确定处理前后污泥表面官能团和蛋白二级结构的变化,如图9所示。在3 200~3 600 cm−1范围的特征峰显示羟基官能团中O-H键存在伸缩振动[47];在2 816和2 872 cm−1处出现的谱带C-H拉伸引起的[48];1 631和1 593 cm−1左右的峰值与C-O和C-N键的变形和拉伸振动有关,伴随蛋白质的N-N和N-H键 (分别为酰胺I区和酰胺II区) [49];在1 067 cm−1处的峰值证实了多糖和核酸的存在,这与C-OH振动和C-O-C的环振动有关[50]。蛋白质多糖的光谱变化强度进一步说明蛋白质比多糖更容易被氧化。电絮凝耦合DSA电极预处理后,上述特征官能团的强度有所减弱,验证了电絮凝耦合DSA电极预处理一定程度降解了蛋白、多糖物质;当采用电絮凝耦合H2O2预处理时,特征官能团的强度显著减弱,特别是峰3 436和1 631 cm−1的减弱,表明自由基可以有效破坏蛋白质结构,进一步消除蛋白质与水的亲和力并释放结合水。这与3D-EEM荧光光谱结果一致。·OH的非选择性攻击导致官能团断裂或芳香环羟基化,最终导致EPS降解。

除EPS含量对污泥脱水性能有显著影响外,EPS空间结构对污泥脱水性能也有显著影响[51]。为进一步分析提取的EPS蛋白二级结构,对EPS 1 700~1 600 cm−1的酰胺Ⅰ区进分析[52]。从表4可以看到,原污泥的α-螺旋为18.64%。电絮凝耦合DSA电极处理后,α-螺旋下降至14.08%;而电絮凝耦合H2O2处理后,α-螺旋降低至6.01%,表明电絮凝耦合的间接氧化体系对α-螺旋结构的降解能力更强,这可能与自由基的强吸电子作用破坏了α-螺旋结构的中酰胺氢和羰基氧之间的氢键而造成的[53]。α-螺旋结构中的氢键的破坏会导致PN分子松散,从而暴露出PN中的疏水位点或基团[54]。此外,α-螺旋/ (β-折叠+无规卷曲) 的值与污泥的疏水性有关。值越小,疏水性越高。电絮凝耦合H2O2处理的污泥α-螺旋/ (β-折叠+无规卷曲) 的值最低,为17.41%,疏水性最高,有助于污泥脱水。

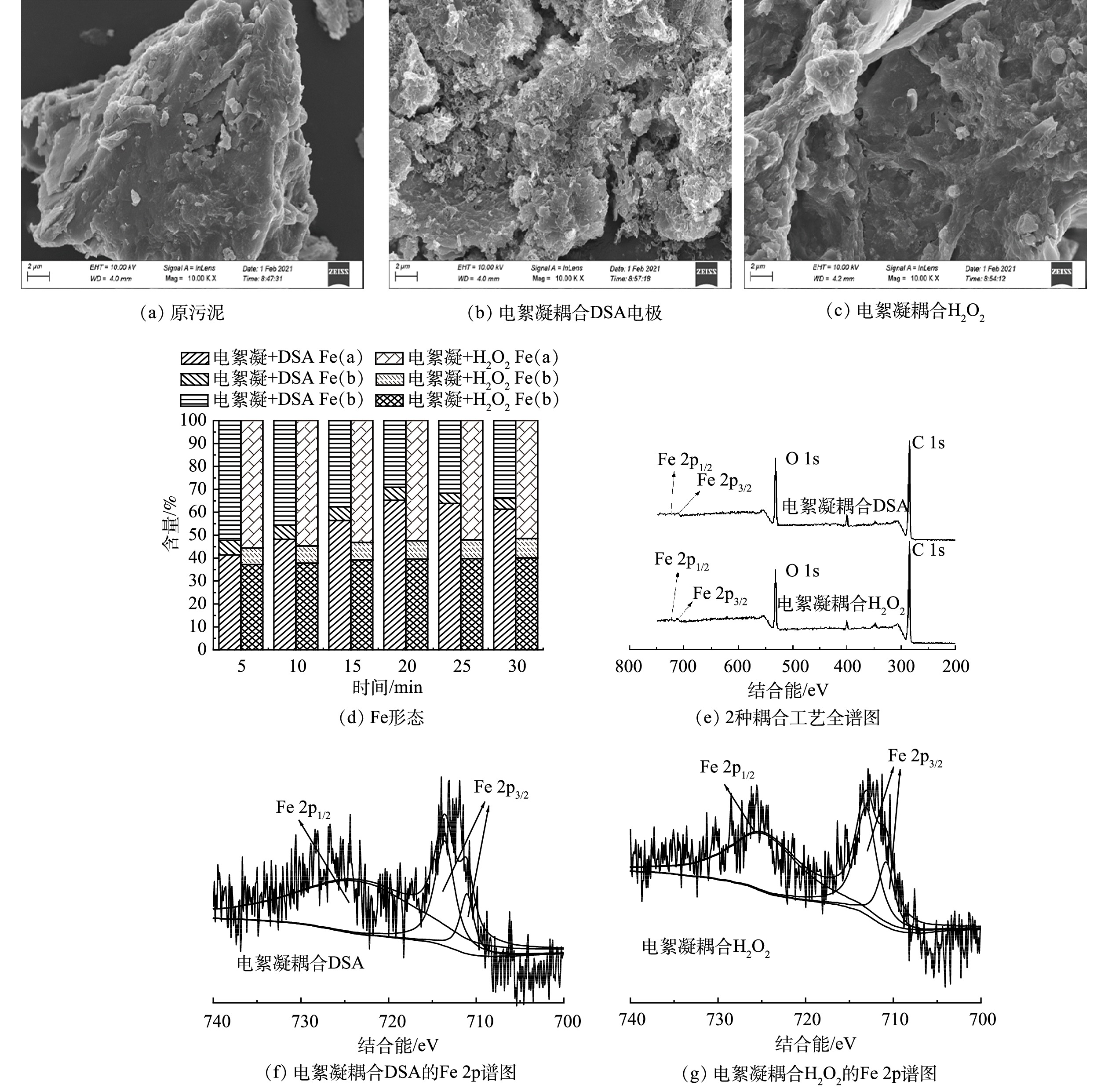

(4) 脱水泥饼的微观形态及铁形态分析。通过扫描电镜 (SEM) 对预处理前后脱水污泥饼的表面形貌进行了表征。由图10所示,原污泥 (图10(a)) 絮体表现为表面致密的块状结构,较多不规则的小颗粒吸附在污泥表面。由于大量的水分和有机质被包裹在絮体内部,表面呈致密状态,用于水分迁移转化的孔隙较少,不利于污泥脱水行为。电絮凝耦合DSA电极预处理后,极板的直接氧化和电场作用使污泥絮体破碎、粒径变小 (图10(b)) ,但电絮凝效果不佳。而电絮凝耦合H2O2预处理后,污泥絮体呈现出多孔的状态,表明电絮凝耦合间接电氧化可以深度破坏污泥絮体结构,更有利于体系中Fe3+的累积和网捕作用,使破碎的微粒的重聚及沉降 (图10(c)) 。

根据Ferron逐时络合比色法将体系中的Fe3+分为3类:Fe (a) 、Fe (b) 和Fe (c) 。Fe (a) 主要是铁单体络合物,絮凝效果较差;Fe (b) 是低聚态的聚铁物质,是絮凝剂中最富活性的有效成分;Fe (c) 代表较为稳定的高聚物,有利于提高絮凝剂的电中和、压缩双电层以及吸附架桥作用[55]。pH是影响Fe3+水解形态的主要因素之一,当体系pH小于5时,主要以Fe (a) 的形态,即[Fe(H2O)6]3+[56],而中性、弱碱性条件下,Fe3+的水解产物主要以聚合络合物为主[27]。电絮凝耦合直接氧化中,由于DSA电极的析氧作用使体系的pH不断下降 (图3(c)) ,此时体系中的Fe3+主要以Fe (a) 形态存在 (图10(d)) ,絮凝效果不佳;而间接氧化体系中由于H2O2的加入使体系的pH变化微弱且促进了Fe3+的生成,快速积累的Fe3+水解产生的聚合物 (Fe (b) 和Fe (c) ) 占3种铁形态的60%以上,具有较强的絮凝效果,破解的污泥絮体得以重聚和沉降。此外,Fe3+与有机物形成有机-金属络合物还可以作为脱水孔道的刚性支撑,提高污泥的脱水性能。

用XPS法测定了2种耦合工艺预处理后的污泥滤饼进一步鉴定铁的价态,如图10(e)~图10(g)) 所示。全谱图结果说明2种耦合工艺调理后的污泥表面含有一定的铁氧化物[57]。Fe 2p1/2在结合能为724.1 eV处存在谱峰,Fe 2p3/2在结合能为711.2 eV处存在谱峰,表明污泥表面含有Fe2+和Fe3+,证明在电化学过程中牺牲性阳极形成的混凝剂在污泥调理过程中发挥了网捕及团聚沉降的作用。

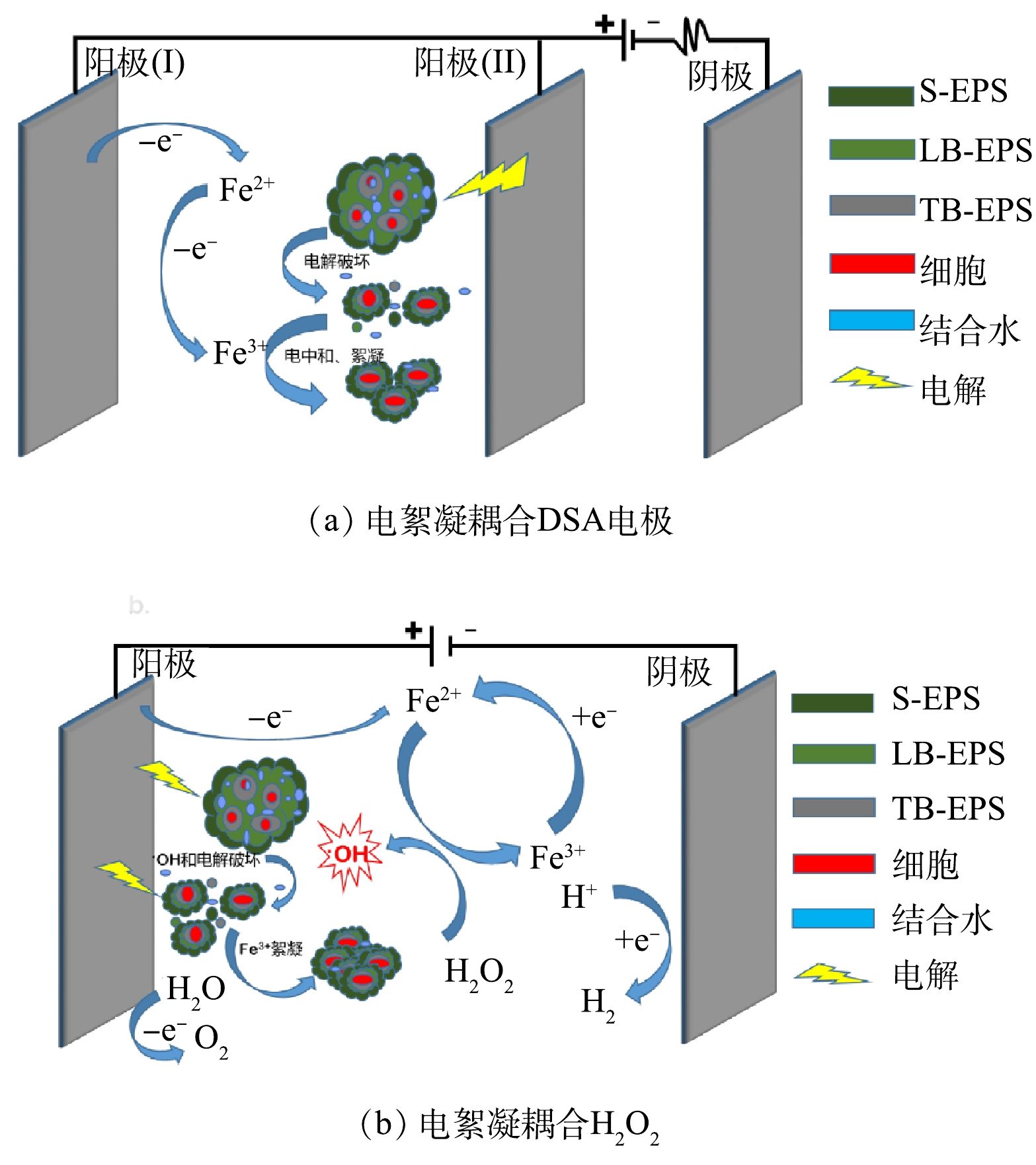

4) 脱水机制及成本估算。图11提出了2种电絮凝耦合方法预处理污泥的作用机制图。如图11(a)所示,电絮凝耦合DSA电极体系中,在电场的作用下带负电的污泥向两阳极移动并在极板表面通过电子转移发生部分氧化,使絮体破碎,释放间隙水和部分结合水,污泥脱水性能得到改善。但受限于极板面积、极板快速钝化以及与污泥的接触时间,污泥絮体的破解程度有限,且能耗高 (表5) 。而电絮凝耦合间接电氧化中 (图11(b)) ,H2O2的加入增强了氧化剂在体系的传质作用。一方面,铁阳极释放的铁离子与H2O2形成芬顿反应产而生强氧化性的·OH,能无选择性地破坏污泥絮体结构并同时氧化降解疏松层和紧密层中的EPS,导致蛋白和多糖分解,水分子与亲水基团间的作用力减弱,结合水向自由水转变,污泥脱水性能增强;另一方面,催化氧化产生的Fe3+在适宜的pH范围内水解产生铁聚物并通过电中和、网捕、吸附架桥等作用使破碎的细小颗粒重聚并沉淀,且沉淀形成的金属-有机络合物可以作为污泥絮体支撑,形成脱水孔道,促进水分的转移,增强污泥的过滤性能。

从环境成本和经济角度看,根据公式 (4) 计算了电化学调理湿污泥的比能耗 (式4) 。电价为0.5 ¥· (kWh) −1,在比能耗为0.002 2 kWh·L−1的情况下,电絮凝耦合H2O2调理污泥的电耗成本为62.51 ¥·t−1 DS。综合成本来看,电絮凝耦合H2O2的成本为90.11 ¥·t−1 DS,明显少于电絮凝耦合DSA调理,说明电絮凝耦合H2O2可以降低脱水成本 (表5) ,在工程实际中有一定的参考价值。本研究系统性的比较了电絮凝耦合直接电氧化和间接电氧化调理污泥强化污泥脱水的效果及其作用机制,发现电絮凝耦合DSA电极由于受极板面积和界面接触时间的影响,污泥絮体破解效果差,溶胞作用有限,Zeta电位和颗粒粒径绝对值下降不明显,电絮凝效果不佳。

-

1) 系统性的比较了电絮凝耦合直接电氧化和间接电氧化调理污泥强化污泥脱水的效果及其作用机制,发现电絮凝耦合DSA电极由于受极板面积和界面接触时间的影响,污泥絮体破解效果差,溶胞作用有限,Zeta电位和颗粒粒径绝对值下降不明显,电絮凝效果不佳。在最佳条件下的CST和泥饼MC分别只下降了64.9%和26.4%。

2) 电絮凝耦合H2O2形成的间接氧化体系中,由于类Fenton作用产生的·OH在溶液相中能无选择性地破坏污泥絮体、破解细胞结构并降解EPS,从而使阳极释放的Fe3+迅速生成聚铁物质并通过吸附架桥、网捕等作用使絮体碎片和EPS片段重聚并沉淀。得力于有机-金属络合物沉淀形成的脱水孔道具有较强的刚性支撑,水分子在沉淀中能够迅速迁移,使得15 min内CST和泥饼MC分别下降了73.9%和31.4%。

3) 间接氧化体系可以同时降解LB-EPS和TB-EPS,改善了传统电化学法主要降解LB-EPS的不足,实现了提高电化学方法在同步污泥破解与沉淀脱水方面的双重效能。

参 考 文 献

电絮凝耦合DSA或过氧化氢强化污泥脱水性能的比较与机理分析

Comparison and mechanism of electric flocculation coupled with DSA or hydrogen peroxide to enhance sludge dewatering performance

-

摘要: 为解决电絮凝法调理污泥期间电场无法有效破解污泥絮体、改善污泥脱水问题,分别将电絮凝与尺寸稳定阳极 (DSA,Dimensionally-stable anodes) 电极、H2O2进行耦合,比较和分析2种耦合工艺对污泥过滤性能、絮体破解程度、胞外聚合物 (EPS) 组分改变和污泥脱水性能的差异。结果表明,电絮凝耦合H2O2形成的间接氧化体系中,由于电致·OH在非均相体系中能无选择性地破坏污泥絮体、破解污泥细胞并降解胞外聚合物 (EPS),从而促使阳极释放的铁离子通过吸附架桥、网捕等作用与絮体碎片和EPS片段重聚并沉淀,使15 min内污泥毛细吸水时间 (CST) 和污泥含水率 (MC) 分别下降了73.9%和31.4%;然而电絮凝耦合DSA直接氧化法同期的污泥CST和MC仅分别下降了64.9%和26.4%。此外,间接氧化法可以同时降解松散结合层 (LB-EPS) 和紧密结合层 (TB-EPS) ,破坏EPS蛋白质亲水基团与水的作用力,并改善传统电化学法主要降解LB-EPS的不足,实现了提高电化学方法在同步污泥破解与沉降脱水方面的双重效能。本研究结果可为电化学预处理改善污泥脱水提供参考。Abstract: Abstract Aiming to solve the problems that traditional electric field cannot effectively crack the sludge flocs and improve the sludge dewatering during sludge conditioning by electric flocculation, coupling electric flocculation with DSA (Dimensionally Stable Anodes) electrode and H2O2 was used and their effects were compared. The differences was evaluated in terms of sludge filtration performance, floc breaking degree, changes in the composition of extracellular polymers (EPS). Results showed that in indirect oxidation systems (electro-coagulation with H2O2), the electro-generated ·OH could selectively destroy the sludge flocs, break sludge cells and degrade the extracellular polymer (EPS), causing the dissolution and degradation of EPS. The system could also promote the quick release of ferric ions and generate polyferric substance, enhancing the reunion and sediment of EPS fragments. In this circumstance, the CST and MC of sewage sludge could be decreased by 73.9% and 31.4% respectively within 15 min. However, the sludge CST and MC with DSA coupled direct oxidation just realized 64.9% and 26.4% reduction. The indirect oxidation could degrade both loosely bound layer (LB-EPS) and tightly bound (TB-EPS), destroying the interactions between hydrophilic groups of EPS protein and water and thus improving the drawbacks of direct oxidation. The results of this study would provide a reference for electrochemical pretreatment to improve sludge dewatering.

-

随着我国城市化水平的不断推进和基础设施的不断完善,城市污水处理能力逐渐提升,而污泥作为污水处理的副产物其产量也不断增加。污泥组成成分十分复杂,是一种由高度分散的絮凝体组成的稳定复杂胶体结构[1],特别是污泥细胞和EPS具有高度亲水性使污泥含水率高 (二沉池污泥的含水率可高达98%以上[2]) ,因此实现其有效的处理、处置及资源化利用,如填埋或焚烧,则必须建立在高效的污泥脱水基础之上。

传统的污泥脱水技术,如板框脱水法,需预先将湿污泥与化学调理剂 (如氯化铁、氧化钙等) 混合,通过试剂与胞外聚合物相互作用,实现污泥细胞的溶解及絮体颗粒的沉降,经这种方法调理后的污泥饼含水率仍高达75%~85%[3-4]。近些年,基于电化学原理而形成的污泥调理方法被认为是一种更清洁和高效的污泥脱水技术[1,5-6]。在电场作用下,污泥絮体不仅可以通过电极放电被直接破坏和分解,由电场作用形成的电势差更可以极化每一个污泥粒子而促使细胞的电渗析脱水[7-8]。为进一步改善污泥絮体的凝聚作用,强化污泥絮体的孔道结构与脱水功能,以铁、铝等作为可牺牲性阳极材料的电絮凝技术进一步提高了电化学法在调理污泥、强化污泥脱水过程中的作用。

电絮凝作为一种新型的电化学污泥预处理方法,虽然可以在一定程度上改变污泥粒子的稳态结构并增强其团聚性,使污泥颗粒粒径增加、流变性降低、脱水孔道结构增强[9],但由于有限的污泥极板接触面积和较弱的电极催化活性[10],电絮凝对絮体颗粒和细胞的破解效果仍然有限。目前,已经有学者通过将电絮凝与氧化法耦合以增强污泥絮体的破解、EPS的降解和细胞水的释放,如利用双阳极电极 (可牺牲性阳极和DSA电极) 的电絮凝耦合直接氧化法和利用向体系中投加H2O2的电絮凝耦合间接氧化法[11-12],均取得了令人满意的污泥调理效果。然而,由于2种氧化方法的作用机制存在较大差异,在电极上的直接氧化和基于溶液相中形成强氧化性中间体对污泥絮体的分解,尤其是不同EPS结构中蛋白和多糖的降解与结合水的释放等均存在显著的差异,而影响其预处理的最佳条件,目前还尚未有较系统性的报道。

因此,本研究比较了电絮凝耦合DSA电极和电絮凝耦合H2O2对调理污泥强化污泥脱水的影响。以CST和泥饼MC为指标对2种耦合技术的操作参数进行对比和优化,拟得到2种耦合法的最优预处理条件;以絮体改变和溶胞程度方面探究2种耦合技术对污泥的预处理机制;以各层级水中EPS的成分改变、污泥颗粒粒径等指标的变化以及自由基猝灭实验揭示2种耦合工艺的各自作用机理;最后,通过对沉淀过程中的铁形态分析,结合脱水泥饼的扫描电子显微镜 (SEM) 观察,解释2种耦合工艺在电絮凝过程中的差异。

1. 材料与方法

1.1 实验材料

1) 实验污泥。本研究中的污泥样品来自上海松申水环境净化有限公司的二沉池污泥,收集的污泥储存在聚丙烯容器中并于4 ℃下保存,以尽量减少微生物的活性。原污泥的含水率、pH、CST和MC分别为98%±0.2%、6.35±0.05、(61.2±0.05) s和88%±0.15%,本研究涉及污泥的实验在3 d内全部完成,且使用的污泥为同一批次的污泥。

2) 主要试剂。硫酸钠 (Na2SO4) 、氢氧化钠 (NaOH) 、盐酸 (HCl,36%) 、硫酸 (H2SO4,98%) 、考马斯亮蓝 (Coomassie brilliant blue G-250) 均为分析纯,所有原液制备和实验均使用去离子水。

1.2 实验方法

1) 电化学实验。电化学实验在1 000 mL的有机玻璃矩形槽内进行,使用 Mer sanDC (0~30 V) 作为稳压直流电源,每次实验的污泥样品为0.5 L。电絮凝耦合DSA电极方法采用Fe板和Ti/PbO2以并联方式组装为第一阳极和第二阳极,阴极为Al板;电絮凝耦合H2O2工艺采用Fe板和Al板分别作为阳极、阴极,极板间距为4 cm,在反应器中一次性滴加H2O2 (0~2.5 mL·L−1) 并利用恒速搅拌器于100 r·min−1充分混合。每块极板的几何尺寸为10 cm×10 cm×0.1 cm,所有电化学实验均进行3次以降低实验误差。

2) 极板预处理。实验前将电极板浸泡在10%的盐酸溶液中20 min,随后用砂纸打磨极板表面,然后再将极板放置于5%的盐酸溶液中浸泡10 min去除其表面的氧化物,最后用去离子水清洗干净即可使用。

1.3 分析方法

1) 基本参数。污泥过滤性能由毛细吸水时间 (CST) 评估,在配备不锈钢管 (10 mm) 和色谱级滤纸的CST仪器 (304 M, Triton, UK) 中进行测量,pH值pH计 (PB10,瑞士Mettler Toledo) 测定。采用哈希消化仪 (DRB 200, US) 和分光光度计 (Hach® DR3900, US) 测定污泥上清液的可溶性化学需氧量 (SCOD,Soluble Chemical Oxygen Demand) ,探讨污泥的溶胞效率。

2) 泥饼MC的测定。用标准布克纳漏斗在0.095 MPa的压力下过滤,通过泥饼MC的变化来评价污泥的脱水能力。将洗净后的坩埚放入105 ℃的烘箱烘干2 h后放至干燥器中冷却;然后用电子天平称坩埚的重量,记为m1;取50 mL污泥置于标准布克纳漏斗,在0.095 MPa的压力下过滤30 min,将过滤后的滤饼于105 ℃干燥箱中烘干至恒重放入坩埚中,称重m2;将泥饼与坩埚一并放入105 ℃烘箱中,泥饼完全干化后,取出放置在干燥器中冷却,记为m3。根据公式计算污泥泥饼含水率MC (%) 。

MC=m3−m1m2−m1×100% (1) 3) EPS的提取与测定。污泥样品的EPS组分采用三步热提取法获得[13]。首先将原污泥样品离心,收集含S-EPS的上清液;然后在离心管中加入相当于原上清体积的0.05% (w/w) NaCl溶液于50 ℃下混合,重悬固体,再次离心,收集含有LB-EPS的上清液。在60 ℃下再次悬液,然后离心收集含有TB-EPS的上清液。DOC采用TOC-VCPH分析仪 (VCPH,日本岛津) 测定;蛋白质含量采用考马斯亮蓝法测定,以牛血清蛋白为标准物质[14];多糖含量采用苯酚-硫酸法测定,以葡萄糖为标准物质[15]。采用荧光分光光度计 (RF6 000,日本岛津制作所) 测量EPS的三维荧光激发-发射光谱。

4) SCOD增长动力学分析方法。采用动力学模型 (2) 和 (3) 对2种耦合工艺处理下SCOD的增长特征的动力学变化分析[16]。

−dxdt=K×x (2) lnx=K×t+b (3) 式中:K表示溶解速率常数;b为截距;以-ln (Ct/C0) 与t分别为横坐标和纵坐标绘制直线即可得到斜率,即SCOD增长的表观速率常数。

5) 自由基猝灭实验。在2种耦合工艺分别加入碘化钾 (KI) 、异丙醇 (i-PrOH) 、叔丁醇 (TBA) 分别作为表面结合的·OH (·OHads) 、游离态·OH (·OHfree) 、·OHfree和·OHads的清除剂[17],以SCOD为指标确定自由基种类在2种耦合工艺下的作用。

6) 能耗分析。根据式 (3) 计算湿污泥电化学调控能耗[18]。

Energyconsumption(kWh⋅L−1)=∑tt=0UI×t/601000Vs\hspace{0.25em} (4) 式中:U为施加的电压,V;I是电流,A;t是预处理时间,min;Vs是处理的污泥体积,L。

7) 其他分析。污泥颗粒的中位直径由粒度分析仪 (BT-9 300Z,上海,中国) 检测。用激光衍射仪 (Omni, Brookhaven, US) 测量污泥上清液的Zeta电位。用傅里叶红外光谱仪 (FT-IR, Nicolet/iS 10,美国赛默飞世尔仪器公司) 对污泥EPS和蛋白质二级结构进行分析。采用X射线光电子能谱仪 (XPS, Thermo Fischer, ESCALAB 250Xi, USA) 对泥饼表面铁元素的价态进行测试和分析。利用扫描电子显微镜 (SEM, Sigma500, ZEISS,德国) 表征了电解前后污泥絮凝体结构的变化,并采用Ferron逐时比色法对沉淀过程中的铁形态做了研究[19]。

2. 结果与讨论

2.1 2种耦合工艺最佳条件比较

1) 电絮凝耦合DSA电极。图1(a)、图1(b)显示的是电絮凝耦合DSA电极中不同电解电压和电解时间对污泥CST和泥饼MC的影响。可以看到,增加电压和电解时间会导致CST和泥饼MC下降。当电压增加至20 V,电场作用显著加强,污泥絮体受到破坏,细胞发生裂解,污泥中间隙水和内部结合水得到释放[1];同时,Fe阳极中Fe2+的不断溶出及Fe3+的累积 (式 (5)~式 (6) ) 产生较强的絮凝作用使污泥絮体发生沉降,电解时间20 min污泥的CST和泥饼MC降至最低,分别为21.6 s和64.8%。继续增大电压至25 V时,此时受阳极氧化和电场作用,污泥细胞被破坏、胞内和胞外物质的释放增加了污泥的粘度[1],形成的更多细小污泥颗粒阻塞了滤纸,造成污泥的过滤性能下降[20]。初始pH会影响电化学强化污泥脱水的效果[11]。在电压为20 V、电解时间为20 min时,发现在pH < 6时,污泥CST和泥饼MC随着pH的增加而降低 (图1(c)) 。因为在酸性条件下,H+可以中和污泥表面的负电荷使污泥絮体脱稳凝聚,促进污泥的絮凝和脱水[21]。但过量的H+将会使阳极的铁离子溶出过程受限,导致电凝的效果下降。而在中性条件下,铁离子电中和的能力被削弱,导致絮凝效果变差[22]。对于电絮凝耦合DSA电极设计不同极板接触面积对污泥脱水的影响,详见图1(d)。从图中可以看出,随着有效极板面积的增加,污泥的脱水性能有所改善,于极板接触面积为80 cm2时达到最低。基于本实验的设计框架,该接触面积为最大接触面积,但是其对污泥脱水性能的改善效果有限。阳极极板面积影响铁离子的溶出,污泥的脱水性能与铁离子的溶出量有关,而Fe2+析出量又由电解时间与电流密度影响[23]。而随着电解时间的增加,电解污泥在极板表面形成氧化膜,使极板钝化且催化活性降低,导致电化学的电解效率降低[24]。一般情况下,在电化学体系中,极板面积往往受限于反应池容积、水力停留时间和工程造价等因素,因此实验室前期通过引入接触面积更高的三维粒子电极等方法则可以有效解决面积限制[18]。综合污泥脱水效果和成本,电压20 V、电解时间20 min、不调节pH、极板接触面积为80 cm2为后续电絮凝耦合DSA体系试验的操作条件。

Fe−2e−→Fe2+ (5) Fe2+−e−→Fe3+ (6) 2) 电絮凝耦合H2O2。图2显示的是电絮凝耦合H2O2过程参数 (电压、电解时间和H2O2投加量) 对污泥CST和泥饼MC的影响。如图2(a)、图2(b)所示,15 min时,污泥CST值和泥饼MC随着电压的增加呈先降低后升高趋势。当电压为15 V时,污泥CST和泥饼MC值达到最低,分别为16 s和60.8%。进一步增加电压污泥的脱水性能恶化。电压为15 V时,随着电解的进行 (< 15 min) 体系内铁阳极溶出的Fe2+ (式 (5) ) 会与H2O2芬顿反应体系 (式 (7) ),产生具有强氧化性的·OH以破解污泥絮体及细胞结构并释放结合水,使污泥CST和泥饼MC值下降,污泥脱水性能得以改善;而当进一步增加电解时间或操作电压时,由于阳极释放的过量铁离子会反过来消耗体系内产生的自由基,而导致副反应加剧 (式 (8)~式 (9) ) ,氧化效率降低[1]。此外,电解时间或操作电压的增加导致胞内和胞外物质的过度释放,污泥中细颗粒的数量和污泥粘度增加,恶化了污泥的脱水性能[12]。

H2O2是体系内·OH的主要来源[25]。H2O2投加量对污泥的过滤性能的影响如图2(c)所示。当H2O2投加量增加至2.0 mL·L−1时,污泥的CST和MC相较于原污泥分别下降了73.9%和31.4%;继续增加至2.5 mL·L−1时,污泥CST和泥饼MC缓慢上升,污泥的脱水性能变差。这说明,在一定范围 (0~2 mL·L−1) 内向体系内投加H2O2,可以一定程度上改善污泥的过滤性能。但是过量的H2O2会与·OH反应生成氧化性相对较低OH2· (式 (10) ) ,而OH2·会进一步消耗·OH产生O2 (式 (11) ) ,降低了H2O2的利用率,无法达到进一步改善污泥脱水性能的效果[25]。综合考虑污泥脱水效果和成本,选择电压15 V、电解时间15 min、H2O2投加量2.0 mL·L−1为后续电絮凝耦合H2O2体系试验的操作条件。

H2O2+Fe2+→Fe3++·OH+OH− (7) Fe2++·OH→Fe3++OH− (8) Fe3++H2O2→Fe2++HO2·+H+ (9) H2O2+·OH→HO2·+OH− (10) HO2·+·OH→O2+H2O (11) 2.2 电絮凝耦合2种工艺预处理效果比较

1) pH、CST和泥饼MC变化。污泥分别经电絮凝耦合DSA直接电氧化和电絮凝耦合H2O2间接电氧化后,其体系的pH、CST和泥饼MC随预处理时间的变化如图3所示。图3(a)~图3(b),电絮凝耦合直接电氧化在电解前期 (< 20 min) 污泥的过滤性能随着电解时间的延长不断提升。极板的直接氧化使污泥絮体裂解并破坏污泥细胞,释放部分间隙水和胞内水,随着电解的进行,体系中产生的铁离子形成的水解产物可以使破碎的污泥细颗粒重新聚集,减少了脱水孔道的阻塞,提高了污泥的过滤性能[26]。该体系在20 min时的CST和泥饼MC会达到最低,对比原污泥时分别下降了64.9%和26.4%。电絮凝耦合H2O2间接电氧化法中,污泥在15 min时其CST和泥饼MC便可下降了73.9%和31.4%。这说明,间接氧化形成的溶液相·OH,能够更加无选择性地接触并攻击污泥絮体、降解EPS,释放更多的间隙水和结合水[13]。

体系的pH会影响铁离子的存在形式和对污泥粒子的絮凝效果[11]。低pH下,铁离子的水解受到了抑制,而中性pH左右时,铁离子的水解产物为聚铁物质,有助于污泥沉降脱水[27]。从图3(c)可以看出,2种体系的pH随时间的变化均存在显著差异。由于DSA阳极的析氧作用 (式12) ,电絮凝耦合DSA体系的pH值随电解过程会逐渐降低;而电絮凝耦合H2O2体系中当加入氧化剂加入后,体系pH值略微下降 (< 5%) [28],这有利于Fe3+在体系中的积累和网捕微粒的形成 (式 (7-8) ) ,促进破碎后污泥絮凝体的重聚及沉降。

H2O-4e−→O2+4H+ (12) 2) 絮体破解程度。高亲水性的胞外聚合物EPS通常以带负电荷的胶体形式存在,具有高的胶体稳定性和粘度,本节分别测定了经2种工艺预处理后污泥各层EPS中DOC含量,结果如表1所示。可以看到,经2种工艺在最佳条件下预处理后得到的LB-EPS和TB-EPS中的DOC含量均降低,说明污泥的脱水性能得到了提升[29]。电絮凝耦合DSA体系中,极板的直接氧化作用会破裂污泥絮体,降解EPS,其中LB-EPS的下降较为明显,与原污泥相比降低了34.18%;而电絮凝耦合H2O2则能同时降低LB-EPS和TB-EPS,DOC的去除率分别为56.81%和49.05%。TB-EPS层是离微生物最近的部分,因此TB-EPS的降解表明污泥絮体的破解程度得到进一步加强。由于细菌表面带有负电荷,铁阳极产生的Fe2+与带有负电荷的胶体颗粒吸引形成表面铁离子,促发原位Fenton反应,因此使得TB-EPS在耦合间接电氧化的体系中得到了更有效的降解。

表 1 污泥中EPS含量和组成Table 1. EPS content and composition in sludgemg·L-1 污泥样品 S-EPS LB-EPS TB-EPS 原污泥 124.01 148.90 864.01 电絮凝耦合DSA 278.14 98.00 609.80 电絮凝耦合H2O2 302.40 64.30 440.24 3) 溶胞效应。污泥上清液SCOD含量作为污泥预处理过程中的一个关键性能指标,可反映出污泥释放出有机质的含量[30]。2种预处理工艺对污泥SCOD含量变化随时间的影响如图4所示。可以看出,电絮凝耦合DSA中,电解时间为20 min时,SCOD含量由原泥的104 mg·L−1增加到153 mg·L−1,增加了47.12%; 20 min后,SCOD的增长速率开始变缓,这可能与极板钝化有关[24]。电絮凝耦合H2O2中,SCOD值快速升高随后缓慢降低,说明间接氧化形成的溶液相·OH提升了体系的氧化性,释放污泥细胞内的蛋白质、多糖等高分子可溶性物质。20 min时,相对于原泥 (104 mg·L−1) ,污泥SCOD浓度增加了68.27%。而进一步延长电解时间,体系中·OH会继续降解可溶性物质,使SCOD值略微下降。

为分析2种工艺的溶胞速率差异,采用动力学一级模型分别对0~20 min (即快速溶胞阶段) 和20~30 min (即平稳阶段) 中污泥上清液SCOD浓度变化进行分析,结果如图4(b)和表2所示,发现电絮凝耦合间接电氧化的溶胞速率在第一阶段明显高于电絮凝耦合直接电氧化法,2体系的对应的溶胞速率常数分别为−34.71×10−3 min−1和-23.9×10−3 min−1,表明体系中生成的羟基自由基对污泥絮体破坏和细胞分解的能力高于电极直接氧化和电场作用力。阶段二中,间接电氧化体系中SCOD的变化趋于负值,说明此阶段更有利于自由基对污泥上清液中溶解性有机物的降解,而直接氧化体系则表现出稳定而持续的溶胞效应。

表 2 不同耦合工艺处理污泥SCOD增长的动力学分析Table 2. Table 2 Kinetic analysis of SCOD growth of sludge treated by different coupled processes10−3 min−1 耦合工艺类型 阶段一 阶段二 表观速率常数 表观速率常数 电絮凝耦合DSA电极 −23.9 −1.3 电絮凝耦合H2O2 −34.71 3.9 2.3 2种体系对污泥的作用机制研究

1) 自由基抑制试验。在体系中分别加入碘化钾 (KI) 、异丙醇 (i-PrOH) 、叔丁醇 (TBA) 作为表面结合的·OH (·OHads) 、游离态·OH (·OHfree) 、·OHfree和·OHads的清除剂,以判断自由基类别在电化学污泥调理过程中对污泥的作用机制,结果如图5所示。电絮凝耦合DSA体系中分别投加KI、i-PrOH和TBA,相比于直接电絮凝耦合DSA调理,污泥SCOD值相对应地降低了36.36%、22.73%和38.64%,表明DSA电极表面上通过H2O在酸性条件下的氧化产生了少量的·OHads[31],有限的破解了被吸附在电极表面的污泥絮体,此外,随着电解的进行电极涂层和Ti基体之间形成TiO2氧化物层导致电极失活[32],使体系的氧化性下降,主体料液中的污泥絮体未被深度破坏,后期絮凝效果差;而电絮凝耦合H2O2中,抑制剂对污泥SCOD的变化影响较大,分别投加KI、i-PrOH和TBA较未加时的SCOD分别下降了21.13%、59.15%和69.01%,说明电解槽中形成的·OHfree对污泥絮体的分解以及细胞溶解的作用更加明显。已有的报道指出,·OHfree能够全方位地、无选择性地破坏污泥絮体结构和微生物细胞结构,释放胞内物质并同时降解EPS,释放间隙水和内部结合水,提升污泥脱水性能[13]。

2) Zeta电位与粒径分布。Zeta电位是反映污泥稳定性的关键参数[33]。污泥的Zeta电位越高,污泥颗粒之间的斥力越大,说明污泥絮体的稳定性越高,越不利于污泥的脱水[34]。如图6(a)所示,原污泥的Zeta电位为-18 mV,污泥絮体之间的静电斥力较大,不利于污泥脱水。电絮凝耦合DSA电极预处理后,水分子在DSA阳极发生电离或者离子吸附作用,则DSA电极表面带正电。通常情况下,表面负电荷的污泥颗粒向阳极移动[34]。此时,受阳极表面的直接氧化和电场作用,污泥颗粒表面的羟基、羧基等负电荷官能团被破坏[35],同时由于铁阳极不断释放的阳离子的电中和作用,Zeta电位绝对值降至3 mV,污泥中位粒径 (D50) 经脱稳凝聚后增至98.61 μm (原泥为64.44 μm,图6(b)) 。DSA电极由于受极板面积和阳极钝化的影响,污泥与极板的接触机会较低,表现出有限的絮体破解与EPS降解能力。在电絮凝耦合H2O2体系中,污泥Zeta电位绝对值降低至0.02 mV,接近于0,污泥颗粒间斥力大幅下降。Zeta电位绝对值的降低可能与体系中产生的·OH对EPS中的阴离子官能团和带负电的生物聚合物的降解所致[25];同时,快速由于类Fenton作用生成的Fe3+水解多核铁羟基化合物作为絮凝剂可以重聚被释放的污泥细颗粒和EPS片段,进一步压缩了颗粒的Zeta电位[36],同时使污泥颗粒聚集,中位粒径显著增加至117.09 μm[12,28]。

3) 脱水过程中EPS变化

1) 三维荧光光谱分析。采用三维EEM荧光光谱法 (3D-EEM) 对不同污泥样品滤液中的有机化合物进行表征,如图7所示。各EPS层均有4个荧光峰[37],分别为色氨酸类蛋白 (TPN, λex/λem = 280 nm/335 nm) 、芳香蛋白 (APN, λex/λem = 225 nm/340 nm) 、腐殖酸 (HA, λex/λem = 330 nm/410 nm) 和黄腐酸类物质 (FA, λex/λem = 275 nm/ 425 nm) 。

先前研究表明,电化学处理对LB-EPS的去除具有显著效果[38];本研究中电絮凝耦合工艺调理污泥对LB-EPS、TB-EPS的去除均有显著影响,如图7所示。电絮凝耦合DSA体系预处理后,LB-EPS的荧光强度下降明显,这可能与荧光团结构中羧基、羟基和氨基的释放有关[39]。而经过电絮凝耦合H2O2的间接氧化体系处理后,LB-EPS和TB-EPS的荧光强度进一步下降,其中,TB-EPS中色氨酸类蛋白 (TPN) 和芳香蛋白物质 (APN) 的下降尤为明显 (表3) 。这是由于该体系下催化产生·OHfree能以非选择性的方式与大分子物质发生反应,包括氢原子抽离、电子转移和亲电加成等[40-41];同时,体系内不断累积的Fe3+与H2O2循环生成·OH和HO2·,将可溶性物质以及蛋白物质矿化[42]。随着铁离子溶解速率的加快,体系内产生更多的Fe2+、Fe3+,经过水解产生的能够以有机-金属络合物形式与蛋白质、腐殖质等反应[43],有助于骨架脱水。

表 3 不同处理下活性污泥样品S-EPS、LB-EPS和TB-EPS的EEM荧光强度Table 3. EEM fluorescence intensities of S-EPS, LB-EPS and TB-EPS of sludge sample under different treatment systems调理方法 S-EPS LB-EPS TB-EPS TPN APN HA FA TPN APN HA FA TPN APN HA FA 原污泥 972 965 107 112 4 284 3 569 223 429 9 999 7 326 361 1 343 电絮凝耦合DSA 1 442 1 167 125 379 3 876 3 358 201 397 8 680 7 216 342 1 273 电絮凝耦合H2O2 1 775 1 547 565 531 3 536 2 876 142 245 3 771 2 963 198 437 KI 1 765 1 503 567 528 3 514 2 873 140 243 3 759 2 961 199 433 i-PrOH 1 583 1 391 364 415 3 678 3 043 171 302 6 425 5 712 256 934 TBA 1 507 1 344 332 391 3 699 3 147 165 311 6 501 5 796 263 1 008 在电絮凝耦合H2O2体系中,加入KI后,污泥三层EPS的荧光强度变化较小,表明体系中·OHads的作用微弱;加入i-PrOH,样品TB-EPS中TPN、APN、FA荧光强度的增加 (表3) ,证实了·OHfree对EPS的降解作用。此外,TBA的加入产生的效果与i-PrOH相似,验证了·OHfree而不是·OHads对不同EPS组分的降解和破坏作用。

(2) PN、PS含量。如图8所示,蛋白质和多糖主要分布在TB-EPS组分中,LB-EPS和S-EPS组分中较少 [44-45]。原污泥中三层EPS的蛋白质和多糖含量分别为88.7、137.3、595.1 mg·L−1和322.2、49.5、38.9 mg·L−1。电絮凝耦合DSA电极预处理后,LB-EPS和TB-EPS中蛋白质的含量分别降低了29.2%和20.1%,而S-EPS中蛋白质含量增长了32.2% (图8(a)) 。电絮凝耦合DSA电极一方面通过极板的直接氧化作用破坏污泥絮体、裂解污泥细胞,促使污泥胞内和胞外 (主要是LB-EPS) 蛋白、多糖等有机物质的释放[1];另一方面,铁阳极产生的Fe3+可以络合蛋白质和电中和多糖阴离子官能团,降低蛋白质和多糖含量,但2者含量只是轻微下降[12]。而电絮凝耦合H2O2体系中,间接氧化形成的·OH可以氧化降解EPS并与蛋白质、脂质和DNA发生反应[46],进一步降低了LB-EPS和TB-EPS中蛋白、多糖的含量,且蛋白质含量的下降程度远大于多糖。这表明,蛋白质比多糖更容易受自由基攻击而被氧化[13]。此外,TB-EPS中蛋白、多糖含量下降的更为明显,这与表1中3层EPS浓度的变化一致。TB-EPS是最接近微生物的一层,发生在污泥微生物附近的Fenton使TB-EPS得到有效降解,与原污泥比TB-EPS的蛋白、多糖明显降低[28]。

(3) 红外分析。利用FTIR光谱分析确定处理前后污泥表面官能团和蛋白二级结构的变化,如图9所示。在3 200~3 600 cm−1范围的特征峰显示羟基官能团中O-H键存在伸缩振动[47];在2 816和2 872 cm−1处出现的谱带C-H拉伸引起的[48];1 631和1 593 cm−1左右的峰值与C-O和C-N键的变形和拉伸振动有关,伴随蛋白质的N-N和N-H键 (分别为酰胺I区和酰胺II区) [49];在1 067 cm−1处的峰值证实了多糖和核酸的存在,这与C-OH振动和C-O-C的环振动有关[50]。蛋白质多糖的光谱变化强度进一步说明蛋白质比多糖更容易被氧化。电絮凝耦合DSA电极预处理后,上述特征官能团的强度有所减弱,验证了电絮凝耦合DSA电极预处理一定程度降解了蛋白、多糖物质;当采用电絮凝耦合H2O2预处理时,特征官能团的强度显著减弱,特别是峰3 436和1 631 cm−1的减弱,表明自由基可以有效破坏蛋白质结构,进一步消除蛋白质与水的亲和力并释放结合水。这与3D-EEM荧光光谱结果一致。·OH的非选择性攻击导致官能团断裂或芳香环羟基化,最终导致EPS降解。

除EPS含量对污泥脱水性能有显著影响外,EPS空间结构对污泥脱水性能也有显著影响[51]。为进一步分析提取的EPS蛋白二级结构,对EPS 1 700~1 600 cm−1的酰胺Ⅰ区进分析[52]。从表4可以看到,原污泥的α-螺旋为18.64%。电絮凝耦合DSA电极处理后,α-螺旋下降至14.08%;而电絮凝耦合H2O2处理后,α-螺旋降低至6.01%,表明电絮凝耦合的间接氧化体系对α-螺旋结构的降解能力更强,这可能与自由基的强吸电子作用破坏了α-螺旋结构的中酰胺氢和羰基氧之间的氢键而造成的[53]。α-螺旋结构中的氢键的破坏会导致PN分子松散,从而暴露出PN中的疏水位点或基团[54]。此外,α-螺旋/ (β-折叠+无规卷曲) 的值与污泥的疏水性有关。值越小,疏水性越高。电絮凝耦合H2O2处理的污泥α-螺旋/ (β-折叠+无规卷曲) 的值最低,为17.41%,疏水性最高,有助于污泥脱水。

表 4 不同污泥EPS样品蛋白质二级结构比例Table 4. Protein secondary structure ratio of different sludge EPS samples% 调理方法 不同二级结构的分数比例 β-折叠 无规卷曲 α-螺旋 β-转角 α-螺旋/(β-折叠+无规卷曲) 原污泥 59.85 12.82 18.64 8.69 25.65 电絮凝耦合DSA 69.89 9.23 14.08 6.80 17.80 电絮凝耦合H2O2 30.46 4.05 6.01 2.88 17.41 (4) 脱水泥饼的微观形态及铁形态分析。通过扫描电镜 (SEM) 对预处理前后脱水污泥饼的表面形貌进行了表征。由图10所示,原污泥 (图10(a)) 絮体表现为表面致密的块状结构,较多不规则的小颗粒吸附在污泥表面。由于大量的水分和有机质被包裹在絮体内部,表面呈致密状态,用于水分迁移转化的孔隙较少,不利于污泥脱水行为。电絮凝耦合DSA电极预处理后,极板的直接氧化和电场作用使污泥絮体破碎、粒径变小 (图10(b)) ,但电絮凝效果不佳。而电絮凝耦合H2O2预处理后,污泥絮体呈现出多孔的状态,表明电絮凝耦合间接电氧化可以深度破坏污泥絮体结构,更有利于体系中Fe3+的累积和网捕作用,使破碎的微粒的重聚及沉降 (图10(c)) 。

根据Ferron逐时络合比色法将体系中的Fe3+分为3类:Fe (a) 、Fe (b) 和Fe (c) 。Fe (a) 主要是铁单体络合物,絮凝效果较差;Fe (b) 是低聚态的聚铁物质,是絮凝剂中最富活性的有效成分;Fe (c) 代表较为稳定的高聚物,有利于提高絮凝剂的电中和、压缩双电层以及吸附架桥作用[55]。pH是影响Fe3+水解形态的主要因素之一,当体系pH小于5时,主要以Fe (a) 的形态,即[Fe(H2O)6]3+[56],而中性、弱碱性条件下,Fe3+的水解产物主要以聚合络合物为主[27]。电絮凝耦合直接氧化中,由于DSA电极的析氧作用使体系的pH不断下降 (图3(c)) ,此时体系中的Fe3+主要以Fe (a) 形态存在 (图10(d)) ,絮凝效果不佳;而间接氧化体系中由于H2O2的加入使体系的pH变化微弱且促进了Fe3+的生成,快速积累的Fe3+水解产生的聚合物 (Fe (b) 和Fe (c) ) 占3种铁形态的60%以上,具有较强的絮凝效果,破解的污泥絮体得以重聚和沉降。此外,Fe3+与有机物形成有机-金属络合物还可以作为脱水孔道的刚性支撑,提高污泥的脱水性能。

用XPS法测定了2种耦合工艺预处理后的污泥滤饼进一步鉴定铁的价态,如图10(e)~图10(g)) 所示。全谱图结果说明2种耦合工艺调理后的污泥表面含有一定的铁氧化物[57]。Fe 2p1/2在结合能为724.1 eV处存在谱峰,Fe 2p3/2在结合能为711.2 eV处存在谱峰,表明污泥表面含有Fe2+和Fe3+,证明在电化学过程中牺牲性阳极形成的混凝剂在污泥调理过程中发挥了网捕及团聚沉降的作用。

4) 脱水机制及成本估算。图11提出了2种电絮凝耦合方法预处理污泥的作用机制图。如图11(a)所示,电絮凝耦合DSA电极体系中,在电场的作用下带负电的污泥向两阳极移动并在极板表面通过电子转移发生部分氧化,使絮体破碎,释放间隙水和部分结合水,污泥脱水性能得到改善。但受限于极板面积、极板快速钝化以及与污泥的接触时间,污泥絮体的破解程度有限,且能耗高 (表5) 。而电絮凝耦合间接电氧化中 (图11(b)) ,H2O2的加入增强了氧化剂在体系的传质作用。一方面,铁阳极释放的铁离子与H2O2形成芬顿反应产而生强氧化性的·OH,能无选择性地破坏污泥絮体结构并同时氧化降解疏松层和紧密层中的EPS,导致蛋白和多糖分解,水分子与亲水基团间的作用力减弱,结合水向自由水转变,污泥脱水性能增强;另一方面,催化氧化产生的Fe3+在适宜的pH范围内水解产生铁聚物并通过电中和、网捕、吸附架桥等作用使破碎的细小颗粒重聚并沉淀,且沉淀形成的金属-有机络合物可以作为污泥絮体支撑,形成脱水孔道,促进水分的转移,增强污泥的过滤性能。

表 5 不同调理污泥方法的经济能耗对比Table 5. Comparison of economic energy consumption of different sludge conditioning methods不同的方法调理污泥 单位能耗/ (kWh·L−1) 电耗成本 数据来源 成本估算/ (¥·t −1 DS) EZP(电解/电凝和零价铁活化过硫酸盐氧化) 0.015 0 318.255 ¥·t −1 DS [58] — E+Fe (电氧化+Fe2+) 0.018 0 630.78 ¥·t −1 DS [59] — 电化学与处理 0.005 0 5 kWh·m−3 [60] — 电化学与处理 0.009 2 7 ¥·m−3 [61] — ECP-EF (电化学过氧化-电Fenton) 0.065 2 0.23 ¥·L−1×29% [11] — 电絮凝耦合DSA调理 0.003 6 105.15 ¥·t −1 DS 本研究 105.15 电絮凝耦合H2O2 0.002 2 62.51 ¥·t −1 DS 本研究 90.11 从环境成本和经济角度看,根据公式 (4) 计算了电化学调理湿污泥的比能耗 (式4) 。电价为0.5 ¥· (kWh) −1,在比能耗为0.002 2 kWh·L−1的情况下,电絮凝耦合H2O2调理污泥的电耗成本为62.51 ¥·t−1 DS。综合成本来看,电絮凝耦合H2O2的成本为90.11 ¥·t−1 DS,明显少于电絮凝耦合DSA调理,说明电絮凝耦合H2O2可以降低脱水成本 (表5) ,在工程实际中有一定的参考价值。本研究系统性的比较了电絮凝耦合直接电氧化和间接电氧化调理污泥强化污泥脱水的效果及其作用机制,发现电絮凝耦合DSA电极由于受极板面积和界面接触时间的影响,污泥絮体破解效果差,溶胞作用有限,Zeta电位和颗粒粒径绝对值下降不明显,电絮凝效果不佳。

3. 结论

1) 系统性的比较了电絮凝耦合直接电氧化和间接电氧化调理污泥强化污泥脱水的效果及其作用机制,发现电絮凝耦合DSA电极由于受极板面积和界面接触时间的影响,污泥絮体破解效果差,溶胞作用有限,Zeta电位和颗粒粒径绝对值下降不明显,电絮凝效果不佳。在最佳条件下的CST和泥饼MC分别只下降了64.9%和26.4%。

2) 电絮凝耦合H2O2形成的间接氧化体系中,由于类Fenton作用产生的·OH在溶液相中能无选择性地破坏污泥絮体、破解细胞结构并降解EPS,从而使阳极释放的Fe3+迅速生成聚铁物质并通过吸附架桥、网捕等作用使絮体碎片和EPS片段重聚并沉淀。得力于有机-金属络合物沉淀形成的脱水孔道具有较强的刚性支撑,水分子在沉淀中能够迅速迁移,使得15 min内CST和泥饼MC分别下降了73.9%和31.4%。

3) 间接氧化体系可以同时降解LB-EPS和TB-EPS,改善了传统电化学法主要降解LB-EPS的不足,实现了提高电化学方法在同步污泥破解与沉淀脱水方面的双重效能。

参 考 文 献

-

表 1 污泥中EPS含量和组成

Table 1. EPS content and composition in sludge

mg·L-1 污泥样品 S-EPS LB-EPS TB-EPS 原污泥 124.01 148.90 864.01 电絮凝耦合DSA 278.14 98.00 609.80 电絮凝耦合H2O2 302.40 64.30 440.24 表 2 不同耦合工艺处理污泥SCOD增长的动力学分析

Table 2. Table 2 Kinetic analysis of SCOD growth of sludge treated by different coupled processes

10−3 min−1 耦合工艺类型 阶段一 阶段二 表观速率常数 表观速率常数 电絮凝耦合DSA电极 −23.9 −1.3 电絮凝耦合H2O2 −34.71 3.9 表 3 不同处理下活性污泥样品S-EPS、LB-EPS和TB-EPS的EEM荧光强度

Table 3. EEM fluorescence intensities of S-EPS, LB-EPS and TB-EPS of sludge sample under different treatment systems

调理方法 S-EPS LB-EPS TB-EPS TPN APN HA FA TPN APN HA FA TPN APN HA FA 原污泥 972 965 107 112 4 284 3 569 223 429 9 999 7 326 361 1 343 电絮凝耦合DSA 1 442 1 167 125 379 3 876 3 358 201 397 8 680 7 216 342 1 273 电絮凝耦合H2O2 1 775 1 547 565 531 3 536 2 876 142 245 3 771 2 963 198 437 KI 1 765 1 503 567 528 3 514 2 873 140 243 3 759 2 961 199 433 i-PrOH 1 583 1 391 364 415 3 678 3 043 171 302 6 425 5 712 256 934 TBA 1 507 1 344 332 391 3 699 3 147 165 311 6 501 5 796 263 1 008 表 4 不同污泥EPS样品蛋白质二级结构比例

Table 4. Protein secondary structure ratio of different sludge EPS samples

% 调理方法 不同二级结构的分数比例 β-折叠 无规卷曲 α-螺旋 β-转角 α-螺旋/(β-折叠+无规卷曲) 原污泥 59.85 12.82 18.64 8.69 25.65 电絮凝耦合DSA 69.89 9.23 14.08 6.80 17.80 电絮凝耦合H2O2 30.46 4.05 6.01 2.88 17.41 表 5 不同调理污泥方法的经济能耗对比

Table 5. Comparison of economic energy consumption of different sludge conditioning methods

不同的方法调理污泥 单位能耗/ (kWh·L−1) 电耗成本 数据来源 成本估算/ (¥·t −1 DS) EZP(电解/电凝和零价铁活化过硫酸盐氧化) 0.015 0 318.255 ¥·t −1 DS [58] — E+Fe (电氧化+Fe2+) 0.018 0 630.78 ¥·t −1 DS [59] — 电化学与处理 0.005 0 5 kWh·m−3 [60] — 电化学与处理 0.009 2 7 ¥·m−3 [61] — ECP-EF (电化学过氧化-电Fenton) 0.065 2 0.23 ¥·L−1×29% [11] — 电絮凝耦合DSA调理 0.003 6 105.15 ¥·t −1 DS 本研究 105.15 电絮凝耦合H2O2 0.002 2 62.51 ¥·t −1 DS 本研究 90.11 -

[1] YUAN H P, YAN X F, YANG C F, et al. Enhancement of waste activated sludge dewaterability by electro-chemical pretreatment[J]. Journal of Hazardous Materials, 2011, 187(1): 82-88. [2] 甄广印, 吴太朴, 陆雪琴, 等. 高级氧化污泥深度脱水技术研究进展[J]. 环境污染与防治, 2019, 41(9): 1108-1113+1119. doi: 10.15985/j.cnki.1001-3865.2019.09.020 [3] LIANG J, GU H, ZHANG S, et al. Novel insight into sludge dewaterability mechanism using polymeric aluminium ferric chloride and anaerobic mesophilic digestion treatment under ultrahigh pressure condition[J]. Separation and Purification Technology, 2020, 234: 116137. [4] 徐慧敏, 何国富, 熊南安, 等. 双频超声波促进剩余污泥的破解[J]. 环境工程学报, 2017, 11(4): 2452-2456. doi: 10.12030/j.cjee.201510194 [5] WU B, DAI X, CHAI X. Critical review on dewatering of sewage sludge: Influential mechanism, conditioning technologies and implications to sludge re-utilizations[J]. Water Research, 2020, 180: 115912. [6] LV H, LIU D, ZHANG Y, et al. Effects of temperature variation on wastewater sludge electro-dewatering[J]. Journal of Cleaner Production, 2019, 214: 873-880. [7] DONG Y, YUAN H, GE D, et al. A novel conditioning approach for amelioration of sludge dewaterability using activated carbon strengthening electrochemical oxidation and realized mechanism[J]. Water Research, 2022, 220: 118704. [8] XIAO J, YUAN H, HUANG X, et al. Improvement of the sludge dewaterability conditioned by biological treatment coupling with electrochemical pretreatment[J]. Journal of the Taiwan Institute of Chemical Engineers, 2019, 96: 453-462. [9] 施钦, 刘宇川, 谭学才, 等. 电絮凝法调理剩余污泥CST的影响因素分析[J]. 化工技术与开发, 2021, 50(11): 45-48. doi: 10.3969/j.issn.1671-9905.2021.11.013 [10] 陆香玉, 俞海祥, 陈亚, 等. 化学絮凝与电絮凝调理污泥脱水性能影响作用的对比研究[J]. 环境科学学报, 2022, 42(03): 257-267. doi: 10.13671/j.hjkxxb.2021.0441 [11] OLVERA-VARGAS H, ZHENG X, GARCIA-RODRIGUEZ O, et al. Sequential “electrochemical peroxidation – Electro-Fenton” process for anaerobic sludge treatment[J]. Water Research, 2019, 154: 277-286. [12] GHARIBI H, SOWLAT M H, MAHVI A H, et al. Performance evaluation of a bipolar electrolysis/electrocoagulation (EL/EC) reactor to enhance the sludge dewaterability[J]. Chemosphere, 2013, 90(4): 1487-1494. [13] CAI M, WANG Q, WELLS G, et al. Improving dewaterability and filterability of waste activated sludge by electrochemical Fenton pretreatment[J]. Chemical Engineering Journal, 2019, 362: 525-536. [14] FR/OLUND B, GRIEBE T, NIELSEN P H. Enzymatic activity in the activated-sludge floc matrix[J]. Applied Microbiology and Biotechnology, 1995, 43(4): 755-761. [15] DUBOIS M, GILLES K A, HAMILTON J K, et al. Colorimetric Method for Determination of Sugars and Related Substances[J]. Analytical Chemistry, 1956, 28(3): 350-356. [16] 李洁. 电解强化剩余污泥脱水及机理研究[D]. 南京: 南京大学, 2018. [17] CHEN Y, LU A, LI Y, et al. Naturally Occurring Sphalerite As a Novel Cost-Effective Photocatalyst for Bacterial Disinfection under Visible Light[J]. Environmental Science & Technology, 2011, 45(13): 5689-5695. [18] YU H, GU L, ZHANG D, et al. Enhancement of sludge dewaterability by three-dimensional electrolysis with sludge-based particle electrodes[J]. Separation and Purification Technology, 2022, 287: 120599. [19] 董红钰. 铁盐混凝剂中铁形态对混凝—超滤联用工艺的影响[D]. 济南: 山东大学, 2015. [20] HU S, ZHAO W, HU J, et al. Integration of electrochemical and calcium hypochlorite oxidation for simultaneous sludge deep dewatering, stabilization and phosphorus fixation[J]. Science of The Total Environment, 2021, 750: 141408. [21] GE D, YUAN H, XIAO J, et al. Insight into the enhanced sludge dewaterability by tannic acid conditioning and pH regulation[J]. Science of The Total Environment, 2019, 679: 298-306. [22] PENG H, ZHONG S, XIANG J, et al. Characterization and secondary sludge dewatering performance of a novel combined aluminum-ferrous-starch flocculant (CAFS)[J]. Chemical Engineering Science, 2017, 173: 335-345. [23] 谭鑫. 电化学沉淀磷酸铵镁-电氧化一体化对高氮磷废水脱氮除磷研究[D]. 2020. [24] 黄雪琪, 靖波, 陈文娟, 等. 电絮凝过程中倒极消除极板钝化[J]. 环境工程学报, 2019, 13(11): 2661-2667. doi: 10.12030/j.cjee.201901028 [25] 王丽苹. Fe0/H2O2类芬顿法对污泥脱水性能的改善及机理分析[D]. 广州: 华南理工大学, 2018. [26] 戴常超, 陈大宏, 刘峻峰, 等. 强化电絮凝技术的基础、现状和未来展望[J]. 工业水处理, 2022, 42(01): 1-14. doi: 10.19965/j.cnki.iwt.2020-1164 [27] 谢琦莹. 无机铁盐及铁基MOFs去除富营养化水体中磷的应用基础研究[D]. 昆明: 云南大学, 2018. [28] MASIHI H, BADALIANS GHOLIKANDI G. Employing Electrochemical-Fenton process for conditioning and dewatering of anaerobically digested sludge: A novel approach[J]. Water Research, 2018, 144: 373-382. [29] BADALIANS GHOLIKANDI G, ZAKIZADEH N, MASIHI H. Application of peroxymonosulfate-ozone advanced oxidation process for simultaneous waste-activated sludge stabilization and dewatering purposes: A comparative study[J]. Journal of Environmental Management, 2018, 206: 523-531. [30] SARI ERKAN H, ONKAL ENGIN G. A comparative study of waste activated sludge disintegration by electrochemical pretreatment process combined with hydroxyl and sulfate radical based oxidants[J]. Journal of Environmental Chemical Engineering, 2020, 8(4): 103918. [31] ZENG Q, HAO T, YUAN Z, et al. Dewaterability enhancement and sulfide mitigation of CEPT sludge by electrochemical pretreatment[J]. Water Research, 2020, 176: 115727. [32] 王璠, 李建新, 崔帅, 等. 钛基金属氧化物电极的失活机制及改进方法的研究进展[J]. 山东化工, 2021, 50(12): 52-54+57. [33] GUAN B, YU J, FU H, et al. Improvement of activated sludge dewaterability by mild thermal treatment in CaCl2 solution[J]. Water Research, 2012, 46(2): 425-432. [34] MAHMOUD A, OLIVIER J, VAXELAIRE J, et al. Electrical field: A historical review of its application and contributions in wastewater sludge dewatering[J]. Water Research, 2010, 44(8): 2381-2407. [35] 赵学雷, 霍志保, 蔡俊. 污泥电化学脱水研究进展[J]. 化工设计通讯, 2020, 46(12): 185-188. [36] 秦雅鑫. Fe(Ⅲ)/H2O2类Fenton体系中Fe(Ⅲ)/Fe(Ⅱ)循环调控及其降解除草剂甲草胺性能的研究[D]. 武汉: 华中师范大学, 2016. [37] CAO B, WANG R, ZHANG W, et al. Carbon-based materials reinforced waste activated sludge electro-dewatering for synchronous fuel treatment[J]. Water Research, 2019, 149: 533-542. [38] RUIZ-HERNANDO M, MARTíN-DíAZ J, LABANDA J, et al. Effect of ultrasound, low-temperature thermal and alkali pre-treatments on waste activated sludge rheology, hygienization and methane potential[J]. Water Research, 2014, 61: 119-129. [39] BAZRAFSHAN E, MOHAMMADI L, ANSARI-MOGHADDAM A, et al. Heavy metals removal from aqueous environments by electrocoagulation process– a systematic review[J]. Journal of Environmental Health Science and Engineering, 2015, 13(1): 74. [40] BRILLAS E, SIRéS I, OTURAN M A. Electro-Fenton Process and Related Electrochemical Technologies Based on Fenton's Reaction Chemistry[J]. Chemical Reviews, 2009, 109(12): 6570-6631. [41] ÖZCAN A, ŞAHIN Y, OTURAN M A. Complete removal of the insecticide azinphos-methyl from water by the electro-Fenton method – A kinetic and mechanistic study[J]. Water Research, 2013, 47(3): 1470-1479. [42] 罗玮. 铁系化合物活化H2O2/O2在分析和有机污染物降解中的应用[D]. 武汉: 华中科技大学, 2010. [43] KIM T, KIM T-K, ZOH K-D. Removal mechanism of heavy metal (Cu, Ni, Zn, and Cr) in the presence of cyanide during electrocoagulation using Fe and Al electrodes[J]. Journal of Water Process Engineering, 2020, 33: 101109. [44] SHAO L, HE P, YU G, et al. Effect of proteins, polysaccharides, and particle sizes on sludge dewaterability[J]. Journal of Environmental Sciences, 2009, 21(1): 83-88. [45] NIU T, ZHOU Z, REN W, et al. Effects of potassium peroxymonosulfate on disintegration of waste sludge and properties of extracellular polymeric substances[J]. International Biodeterioration & Biodegradation, 2016, 106: 170-177. [46] TAO N, HU L, FANG D, et al. Supplementation of tea polyphenols in sludge Fenton oxidation improves sludge dewaterability and reduces chemicals consumption[J]. Water Research, 2022, 218: 118512. [47] GAO S, WANG Y, ZHANG D, et al. Insight to peroxone-Fe(III) joint conditioning-horizontal electro-dewatering process on water reduction in activated sludge: Performance and mechanisms[J]. Journal of Hazardous Materials, 2021, 402: 123441. [48] LIU X, ZHAI Y, LIU G, et al. Mechanistic insights into enhanced waste activated sludge dewaterability with Cu(II) and Cu(II)/H2O2 treatment: Radical and non-radical pathway[J]. Chemosphere, 2022, 288: 132549. [49] DONG Y, YUAN H, BAI L, et al. A comprehensive study on simultaneous enhancement of sludge dewaterability and elimination of polycyclic aromatic hydrocarbons by Fe2+ catalyzing O3 process[J]. Science of The Total Environment, 2022, 819: 152015. [50] ZHANG W, DAI X, DONG B, et al. New insights into the effect of sludge proteins on the hydrophilic/hydrophobic properties that improve sludge dewaterability during anaerobic digestion[J]. Water Research, 2020, 173: 115503. [51] LIANG J, ZHANG L, YAN W, et al. Mechanistic insights into a novel nitrilotriacetic acid-Fe0 and CaO2 process for efficient anaerobic digestion sludge dewatering at near-neutral pH[J]. Water Research, 2020, 184: 116149. [52] DING A, LIN W, CHEN R, et al. Improvement of sludge dewaterability by energy uncoupling combined with chemical re-flocculation: Reconstruction of floc, distribution of extracellular polymeric substances, and structure change of proteins[J]. Science of The Total Environment, 2022, 816: 151646. [53] LI Y, PAN L, ZHU Y, et al. How does zero valent iron activating peroxydisulfate improve the dewatering of anaerobically digested sludge?[J]. Water Research, 2019, 163: 114912. [54] LI Y, XU Q, LIU X, et al. Peroxide/Zero-valent iron (Fe0) pretreatment for promoting dewaterability of anaerobically digested sludge: A mechanistic study[J]. Journal of Hazardous Materials, 2020, 400: 123112. [55] 田宝珍, 汤鸿霄. Ferron逐时络合比色法测定Fe(Ⅲ)溶液聚合物的形态[J]. 环境化学, 1989, 8(4): 27-34. [56] 高乔枫. 外加静电场强化三氯化铁絮凝效能关键技术研究[D]. 秦皇岛: 燕山大学, 2021. [57] 崔蒙蒙. 水铁矿对含磷废水的吸附性能及机理分析[D]. 苏州: 苏州科技大学, 2017. [58] LI Y, YUAN X, WU Z, et al. Enhancing the sludge dewaterability by electrolysis/electrocoagulation combined with zero-valent iron activated persulfate process[J]. Chemical Engineering Journal, 2016, 303: 636-645. [59] HU S, HU J, LIU B, et al. In situ generation of zero valent iron for enhanced hydroxyl radical oxidation in an electrooxidation system for sewage sludge dewatering[J]. Water Research, 2018, 145: 162-171. [60] SONG L-J, ZHU N-W, YUAN H-P, et al. Enhancement of waste activated sludge aerobic digestion by electrochemical pre-treatment[J]. Water Research, 2010, 44(15): 4371-4378. [61] ZENG Q, ZAN F, HAO T, et al. Electrochemical pretreatment for stabilization of waste activated sludge: Simultaneously enhancing dewaterability, inactivating pathogens and mitigating hydrogen sulfide[J]. Water Research, 2019, 166: 115035. -

下载:

下载: