-

菜籽饼是油菜籽经压榨制油后得到的副产物,含有丰富的蛋白质、氨基酸以及其他营养物质,是一种可资源化利用的农业固废[1-2]。我国作为世界上油菜种植面积最大的国家,菜籽饼产量巨大,近年来每年产量均在500×104 t以上[3]。若不对其进行充分利用,不仅会造成资源浪费,还会增加固废物处置压力。随着油菜产业的快速发展,菜籽饼的资源化利用尤为重要。与此同时,据不完全统计,我国每年畜禽粪污的产量在38×108 t以上,但有效利用率却不到50%;大量粪便的随意堆放和低效处理,亦给环境造成了较大污染[4]。现阶段,在农业废弃物资源化利用方法中,厌氧发酵产沼气是一条清洁高效的途径,不仅可以实现废弃物的资源化利用、减轻环境污染,还可作为农村生活用能;同时,还能产出有机肥,从而促进生态农业发展[5-6]。

目前,对菜籽饼的利用主要集中在作为动物饲料添加剂[7-9]和肥料[10-11]等的研究上,而将其作为原料进行厌氧发酵的研究鲜见报道。菜籽饼富含蛋白质等有机物质(粗蛋白含量30%~38%),是较理想的产沼气原料。近年来,高含固率(≥10%)厌氧发酵因能有效解决低含固率(<10%)发酵存在的需水量大、沼液排放量大及耗能大等问题,已成为该领域中试实验及大规模推广研究的热点[12-14]。有研究表明,在作物废弃物类原料中添加牲畜粪便进行共发酵具有诸多优点,不仅能平衡发酵原料的营养成分、改善单一原料发酵消化效率不高的问题、提高沼气产量;还可以促进种、养殖业的协调发展和生物质资源的循环利用,对实现农业可持续发展具有重要意义[15-17]。但目前还未见高含固率菜籽饼与牲畜粪便不同配比混合厌氧发酵的报道。因此,本研究以农用沼气池为发酵装置,分析高含固率菜籽饼和牛粪-羊粪不同配比混合厌氧发酵产沼气的特性;并采用修正的Gompertz模型对各处理沼气产生过程进行动力学分析,以期为菜籽饼等农业废弃物资源的再利用及高含固率厌氧发酵技术的推广和使用提供参考。

全文HTML

-

菜籽饼取自青海省湟中县多巴镇农贸市场,粉碎至30 mm以下粒度备用。牛粪和羊粪来自青海省贵南县过马营牧场。接种物取自青海省某以羊粪为原料发酵的农用沼气池。发酵原料和接种物的特性见表1。

-

本实验采用青海省某公司的农用沼气池(36°3′11″N、101°19′36″E)为发酵装置。所有沼气池构造统一,为地下水压式球形沼气池,容积8 m3,装料量5 m3左右。每个沼气池外接沼气流量表,记录沼气产气情况;每个沼气池外接RC-4温度记录仪,设置每2 h自动记录1次发酵温度数据。

-

将菜籽饼、羊粪和牛粪共做10个配比处理(以干物质计):纯菜籽饼(T1)、纯羊粪(T2)、纯牛粪(T3)、菜籽饼与羊粪1∶1(T4)、菜籽饼与羊粪1∶2(T5)、菜籽饼与羊粪1∶3(T6)、菜籽饼与羊粪1∶4(T7)、菜籽饼与羊粪2∶1(T8)、菜籽饼与牛粪1∶3(T9)及菜籽饼与羊牛粪1∶1.5∶1.5(T10)。设定每组的总干物质相同,含固率调节至16%,每组实验设置2个平行。各处理分别将不同原料用一定量的沼液(调节含水率为70%)搅拌均匀后,覆盖塑料薄膜堆沤5 d,堆沤过程中每天搅拌;并用1 500 kg接种物(接种量为30%)混匀后填入沼气池,再分别补充沼液添加到5 m3。各处理原料具体添加量见表2。自填入沼气池第2天起,每天定时记录沼气流量,同时每3 d用自制的取样器从沼气池水压间采集1次发酵液,用于理化性质测定。前期研究表明,青海农用沼气池8月上中旬到9月中旬发酵温度最高,为15 ℃左右;此时沼气产量最大,且该时期发酵温度的前后温差不超1.5 ℃[18]。本实验自2020年8月3日开始,9月11日结束,共计40 d;各处理组发酵温度范围为15.2~17.8 ℃,自稳定后发酵前后温差为0.9~1.3 ℃,基本保证了沼气池发酵温度的恒定。

-

总固体(TS)和挥发性固体(VS)采用烘干法,其中,总固体于烘箱105 ℃烘24 h,挥发性固体于马弗炉550 ℃灼烧3 h[19];氨氮含量测定采用苯酚次氯酸钠比色法[20];挥发性脂肪酸(VFA)浓度测定采用分光光度法[21];pH用pH计(pHS-2F)检测;碱度含量用电位滴定仪(ZDJ-4A)测定;总碳和总氮含量用元素分析仪检测[22];木质素、纤维素和半纤维素含量检测采用木质纤维素仪测定[23];粗蛋白用凯氏定氮法[24]测定。

-

对菜籽饼与羊-牛粪混合发酵产沼气过程进行动力学分析,采用目前被认为最适于描述产沼气潜力的动力学模型修正的Gompertz方程(式(1))对累积产沼气量进行拟合[25]。

式中:P为t时刻对应的累积VS产沼气量,m3·t−1;Pm为最大VS产沼气量,m3·t−1;Rm为最大VS产气速率,m3·(t·d)−1;λ为产气滞留时间,d。t为发酵时间,d;e为exp(1)=2.7183。根据模型拟合结果推算发酵过程中最大VS产气速率Rm和产气滞留时间λ。

1.1. 实验原料

1.2. 实验装置

1.3. 实验方法

1.4. 分析方法

1.5. 动力学分析

-

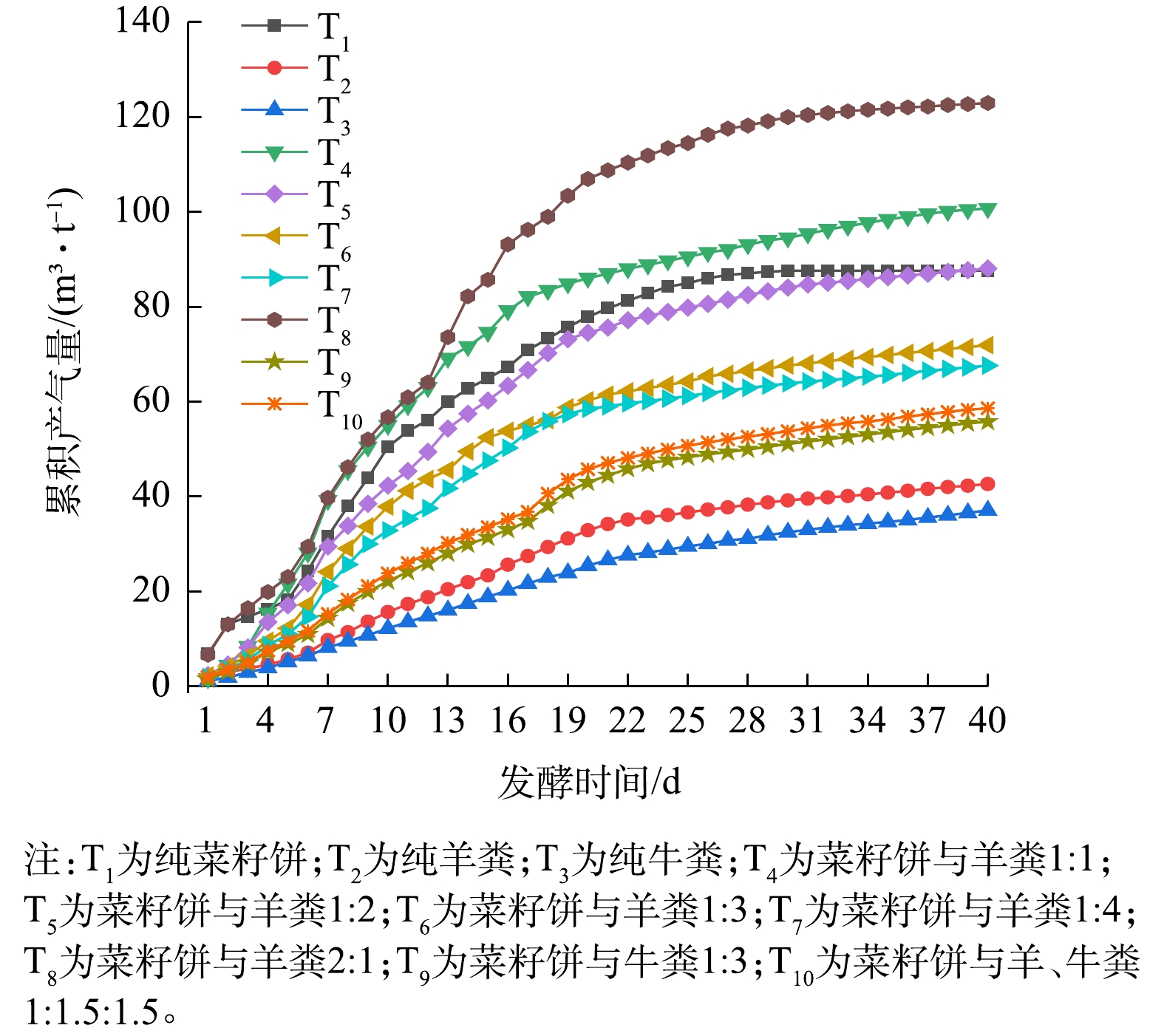

不同处理组日产气量及累积产气量变化情况见图1。由图1可知,40 d内各处理组日产沼气量出现2~3个高峰,集中在7~20 d;前20 d维持在较高水平,随后逐渐下降。混合发酵各处理组在第7天出现最大峰值,且均高于纯羊粪和纯牛粪发酵。其中,菜籽饼与羊粪2∶1组与菜籽饼与羊粪1∶1组最高,分别达到了6.897和7.193 m3。第7天后,各处理波动较大,纯菜籽饼组、菜籽饼与羊粪1∶1组和菜籽饼与羊粪2∶1组均出现了第2和第3个产气高峰,高于其他处理组,最高日产气量分别为4.6、4.01和5.74 m3。纯菜籽饼组发酵在30 d内完成消化过程。

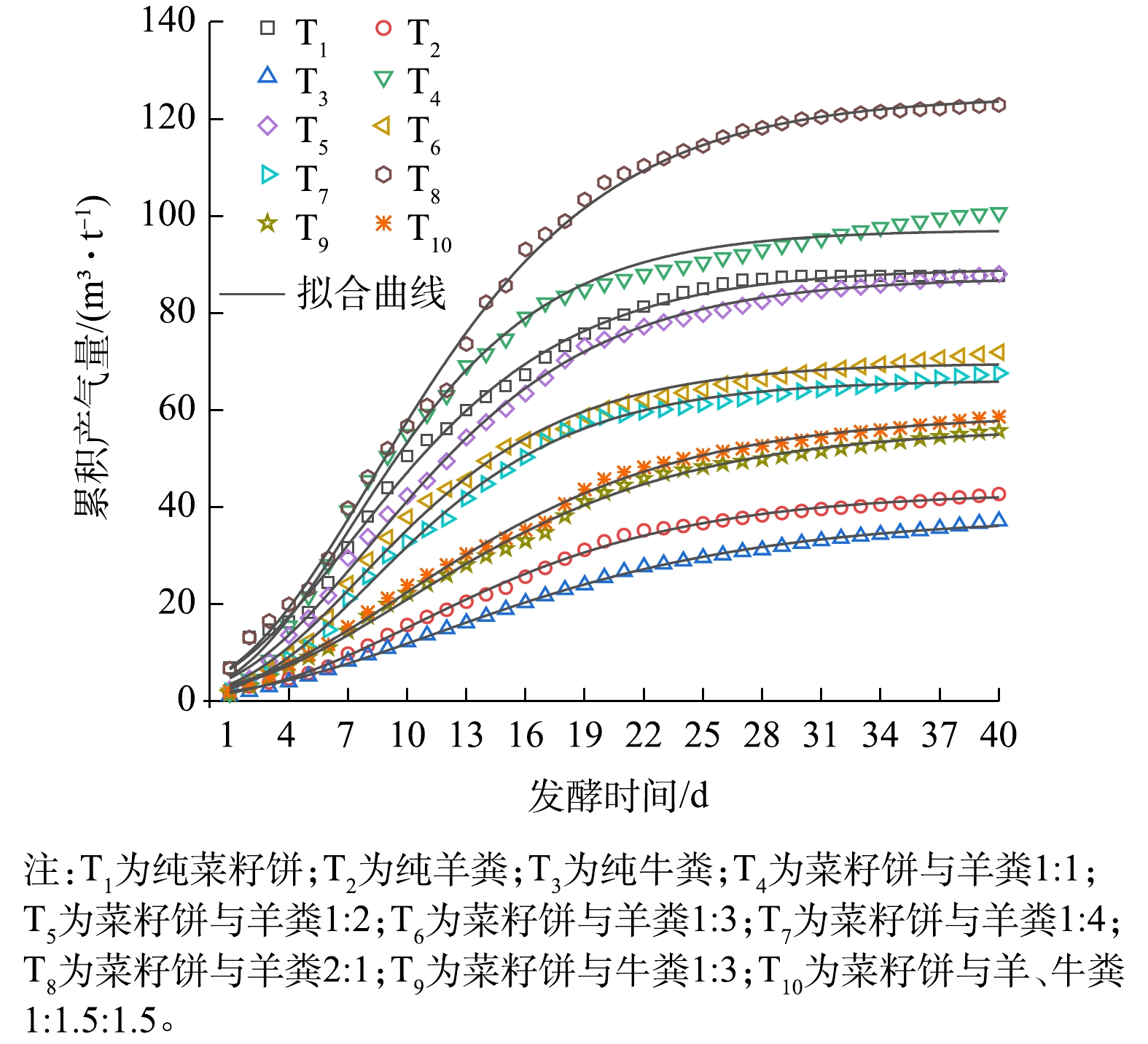

由图2可知,除纯菜籽饼组发酵外的9个处理组的累积产气量在前20 d均呈明显上升趋势,之后上升趋势逐渐变缓。在40 d内,纯菜籽饼组发酵积累产气量较大,为87.58 m3·t−1,且最早完成消化过程。菜籽饼与羊粪1∶1组和菜籽饼与羊粪2∶1组积累产气量更大。其中,菜籽饼与羊粪2∶1组最大,达到了122.92 m3·t−1;40 d内纯羊粪组、纯牛粪组及菜籽饼与牛粪1∶3组积累产气量较低,分别为42.66、37.12和55.76 m3·t−1;菜籽饼与羊粪2∶1组分别是3个较低配比的2.88、3.31和2.2倍。各混合处理组中,积累产气量随着菜籽饼添加量的增加而逐渐增加,当菜籽饼与羊粪干物质质量配比为2∶1时,发酵物料具有较高的潜力,相比其他处理更适宜。这说明,相较于单一原料发酵组,菜籽饼与羊粪混合发酵的组合产气效果更好,产气持续时间更长。该结果与文献报道的研究结果一致[26-27]。另外,菜籽饼与羊粪混合发酵的产气效果要优于菜籽饼与牛粪混合。这可能是因为,菜籽饼与羊粪混合发酵后,更易于被微生物分解利用[28]。

-

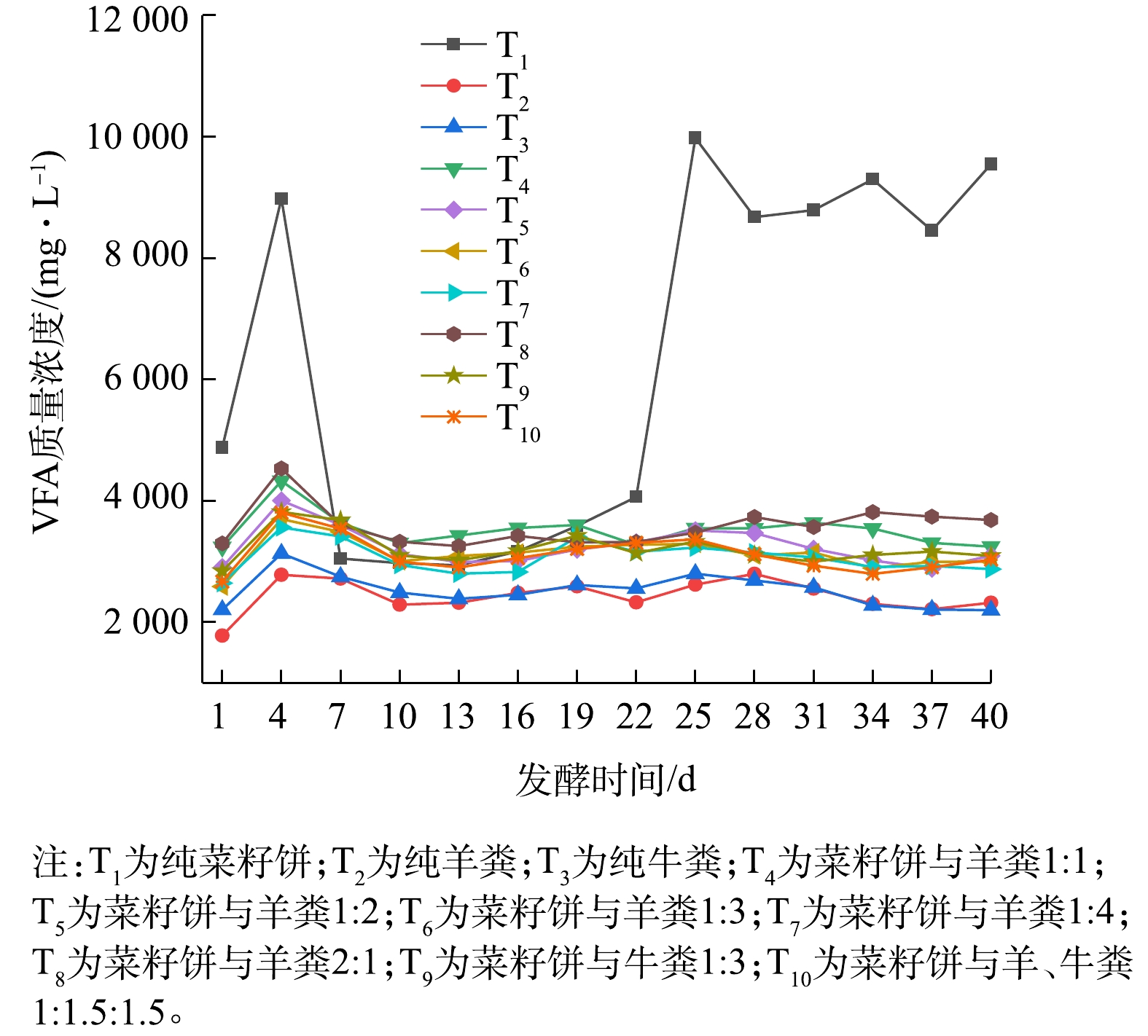

VFA、碱度、氨氮及pH是评价厌氧发酵效果的重要指标,能够反映发酵系统的稳定性和厌氧消化的运行效果。一般来说,VFA过度累积、碱度过低、氨氮质量浓度过高和pH过低等均可能导致发酵系统的崩溃[29-30]。

VFA是有机质经过水解和酸化形成的主要产物,是影响厌氧消化的主要因素之一[31-33]。当厌氧发酵酸化阶段产生的VFA含量大于4 500 mg·L−1时,会造成系统中pH的降低,形成的酸性环境会抑制产甲烷菌的活性,最终容易造成反应过程的崩溃[34]。由图3可见,在第1~4天,各处理VFA质量浓度都呈上升趋势,并在第4天达到峰值。这说明,产酸菌能够在前4 d迅速启动。在40 d内,纯菜籽饼组发酵VFA含量波动较大,前4 d均高于其他处理组,且VFA质量浓度大于4 500 mg·L−1。这说明,该时段体系内的产酸菌的产酸速率高于产甲烷菌利用酸的速率,从而导致VFA的大量累积。第4天后,纯菜籽饼发酵VFA质量浓度迅速下降,7~22 d趋于平稳。这说明,此时段菜籽饼发酵体系内产甲烷菌活性较高,能正常利用体系产生的酸。22 d后,纯菜籽饼发酵的VFA质量浓度急剧上升并一直维持在较高水平。这说明,该时期菜籽饼正在逐渐完成厌氧消化过程,而产酸菌还在正常代谢,导致VFA的过度累积。对于其他9个处理组,纯粪便发酵的VFA质量浓度40 d内相对较低,而各混合处理整个过程变化较为平稳,且均小于4 500 mg·L−1,说明这9个处理体系内的产酸和耗酸趋于平衡,未造成酸抑制。

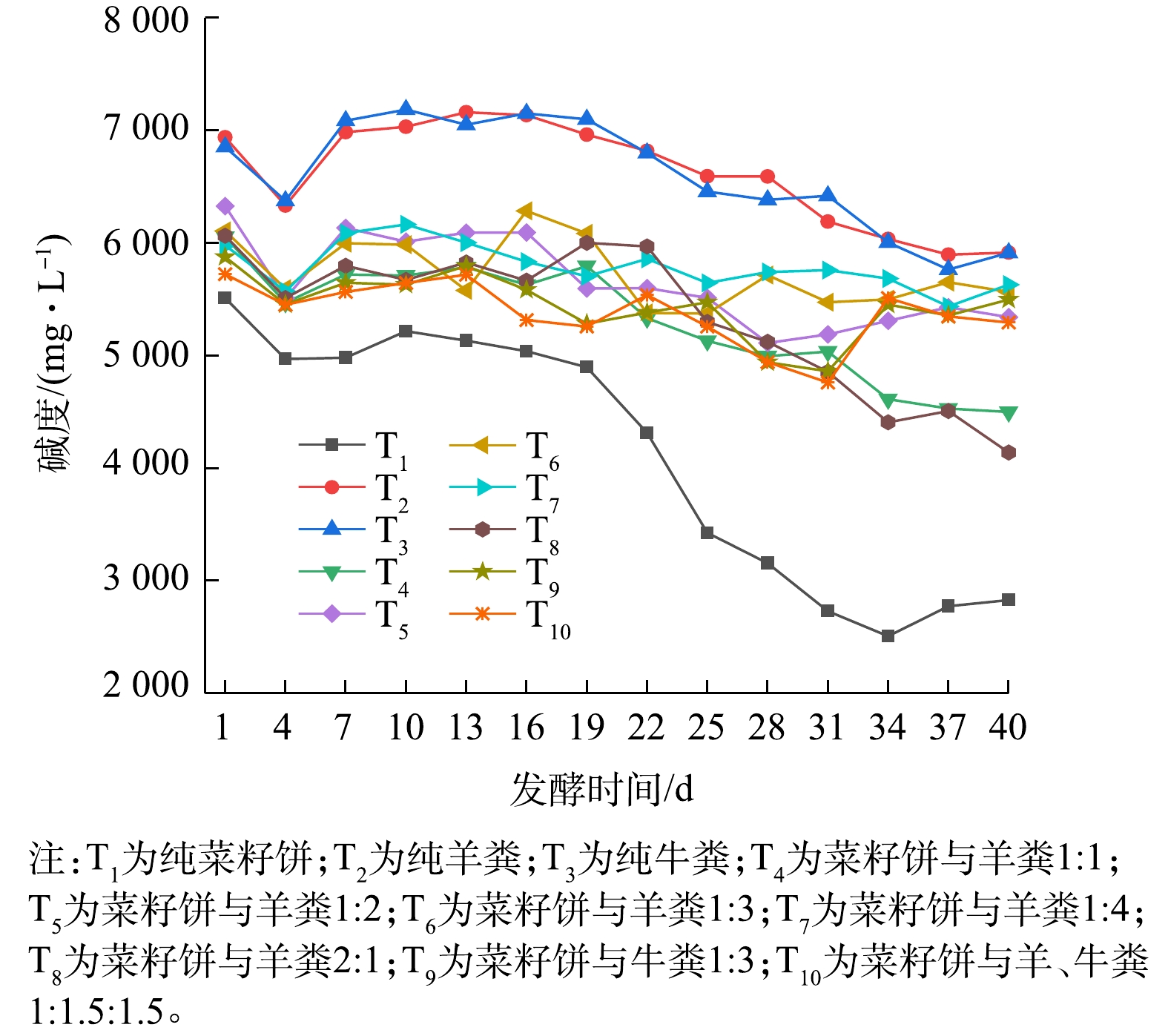

碱度是判断厌氧发酵系统缓冲能力的重要指标[35]。VFA与碱度的比值可以反映厌氧发酵系统的稳定性,若比值高于0.8,厌氧消化过程可能会受到抑制[36-38]。由图4可知,发酵40 d内,10个处理组的碱度整体均呈下降趋势。其中,纯菜籽饼组发酵碱度最小,整体下降较大,且多数时期内其VFA与碱度比值均高于0.8。这说明,菜籽饼单独发酵时系统并不稳定。其余9个处理组40 d内VFA与碱度比值均低于0.8,说明纯粪便发酵组和各混合处理组厌氧发酵进程良好。

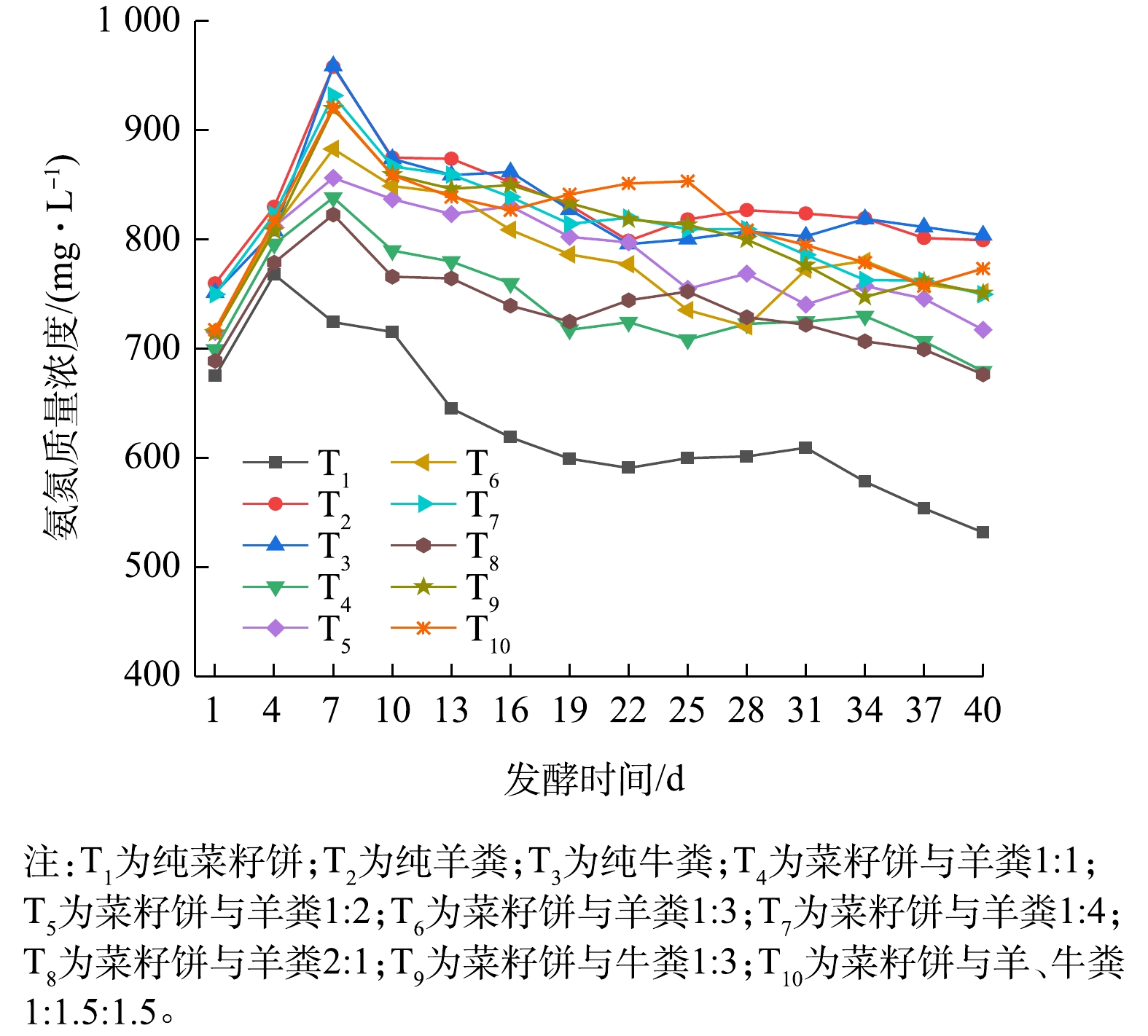

氨氮是厌氧微生物生长必要的营养物质之一,适量的氨氮质量浓度有助于提高产甲烷菌的活性[39];当氨氮质量浓度高于800 mg·L−1时,厌氧发酵系统可能会受到抑制[40]。由图5可知,40 d内各处理组发酵液中的氨氮质量浓度均呈先升高后降低的变化趋势。其中,纯粪便发酵组在整个过程中的氨氮质量浓度均高于其他处理,最高值可达到959 mg·L−1,因此,在发酵过程中容易出现氨抑制现象;纯菜籽饼组、菜籽饼与羊粪1∶1组和菜籽饼与羊粪2∶1组这3个处理组40 d内氨氮质量浓度均低于800 mg·L−1,未形成氨抑制。其余5个混合处理组均在发酵前中、期高于800 mg·L−1;但随着发酵的进行,氨氮质量浓度逐渐降低,发酵体系基本不受氨氮干扰。

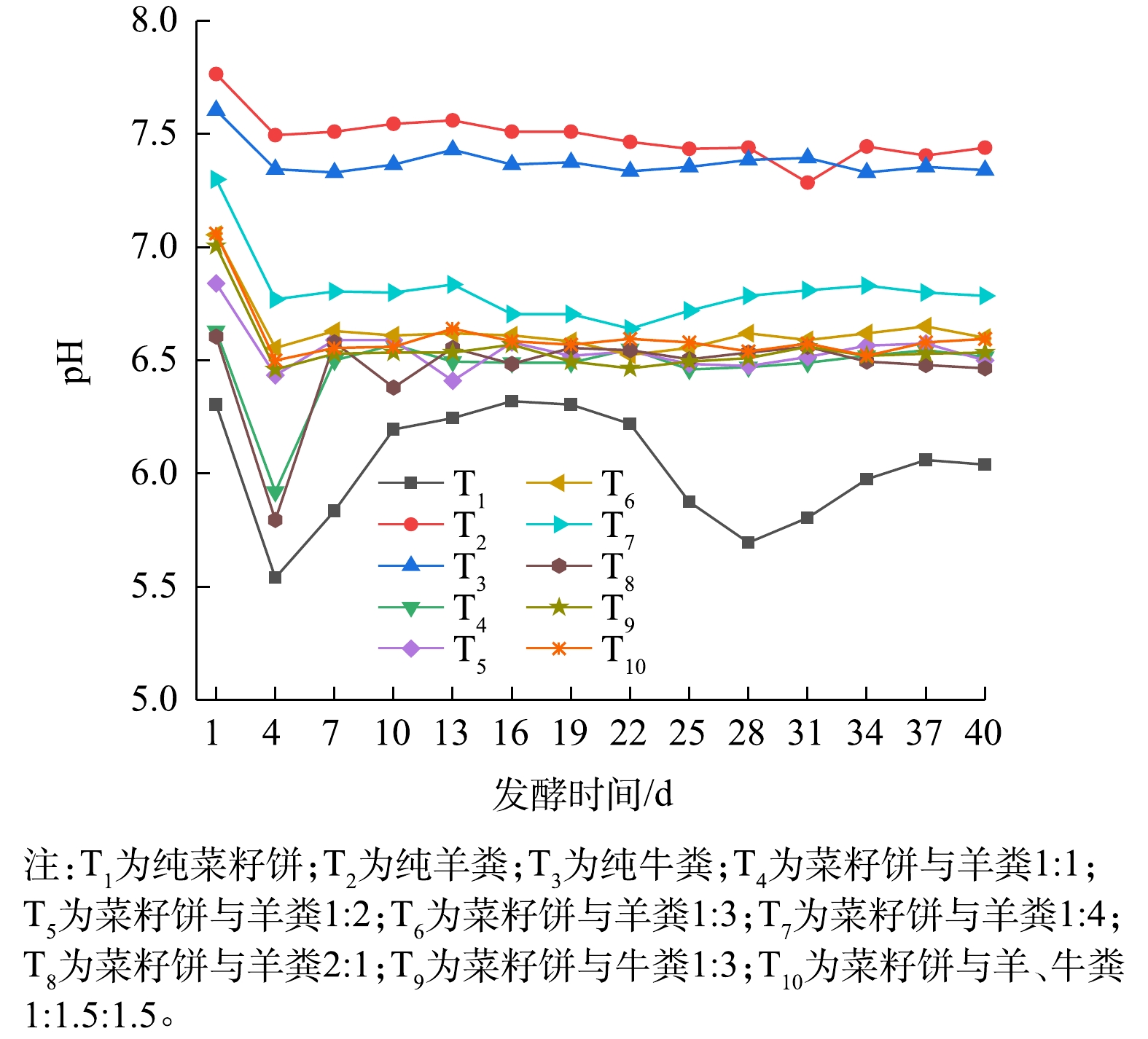

pH是影响厌氧消化进程的主要因素之一。产甲烷菌在pH为6.0~8.0均可生长,其产气的最佳pH为6.5~7.5[41];如果pH过低可能导致发酵系统的崩溃[42]。如图6所示,在40 d内,纯菜籽饼组发酵的pH总体偏低,为5.5~6.3;纯粪便发酵组pH相对较高,为7.3~7.8;而混合发酵组介于二者间,为6.5~7.3。经榨油后形成的菜籽饼仍含有部分油脂,其在发酵过程中会降解,从而造成中间代谢产物长链脂肪酸的积累,最终导致pH降低[43-44]。但是,当菜籽饼与粪便混合后,营养元素得到了平衡,使得发酵液中pH和脂肪酸都趋于合理。同时,脂类物质仍具有较高的产甲烷潜能[45-47],从而导致纯菜籽饼组发酵的累积产气量较高。

综合以上结果分析可知,厌氧发酵是蛋白质、脂类物质和木质纤维素间相互协调、相互制约的代谢过程;原料的种类和数量对厌氧发酵的有机质降解过程、原料利用效率和沼气产率都起着决定性作用。一般来说,蛋白质和脂类等物质含量越高,产气潜力越大;灰分和木质纤维素类物质含量越高,产气潜力越小[48]。菜籽饼蛋白质含量高,并含有一定量的油脂,而且其灰分和木质纤维素含量较低,故其作为沼气发酵原料的优势较为明显。在本实验中,纯菜籽饼发酵比同干物质量纯粪便发酵的累积产气量大,但系统会存在pH偏低和后期VFA累积的现象;但当菜籽饼与牛羊粪混合后,发酵液的各项指标趋于正常,发酵系统较为稳定。

-

不同配比原料发酵累积产气量与修正的Gompertz方程拟合曲线如图7所示。表3显示了拟合得到的最大产沼气量、最大产气速率、产气滞留时间和决定系数等关键参数。由表3可知,各处理均能较好地拟合发酵产沼气过程。其中,菜籽饼与羊粪2∶1配比处理组的最大产沼气量和最大产气速率最大,分别为124.741 m3·t−1和6.766 m3·(t·d)−1。各处理组的最大产沼气量和最大产气速率随菜籽饼添加量的增加而增大。这说明,混合发酵能增加产沼气的协同作用,有助于提高物料的产气速率,最终提高沼气的产量。同时,各处理组产气滞留时间随菜籽饼添加量的增加而降低。这说明,菜籽饼容易降解,且混合发酵之后反应更迅速,体系也更稳定。

2.1. 不同处理组日产气量及累积产气量的变化

2.2. 发酵过程中VFA、碱度、氨氮及pH的变化

2.3. 产沼气过程的动力学分析

-

1)在菜籽饼和牛粪-羊粪的10个不同配比组中,各混合处理组40 d内发酵过程运行良好,由此可知混合发酵可以提高厌氧消化运行效果;菜籽饼与羊粪2∶1配比组的积累产气量最大,达到了122.92 m3·t−1;而且,菜籽饼与羊粪混合发酵的产气效果要优于菜籽饼与与牛粪混合的效果。

2)修正的Gompertz模型能够较好地拟合产沼气过程。菜籽饼与羊粪2∶1配比组的Pm和Rm值最大,分别为124.741 m3·t−1和6.766 m3·(t·d)−1;Pm和Rm随菜籽饼添加量的增加而增大,λ则相反。

DownLoad:

DownLoad: