-

挥发性有机废气(volatile organic compounds,VOCs)是形成次生污染物和光化学烟雾的主要因素[1]。工业排放的VOCs已成为我国雾霾天气产生的重要因素[2-3]。我国高度重视VOCs的治理,国家发展改革委、环境保护部印发的《“十三五”节能减排综合工作方案》将工业涂装列入“十三五”期间全国VOCs减排的重点领域[4]。

目前,各地政府主要推行的涂装废气治理技术有吸附法和直接燃烧法等[5]。活性炭吸附法具有可回收溶剂,可净化低浓度、低温的废气,无需加热的优点;其缺点是需要将漆雾、粉尘、烟等杂质做预处理,处理高温废气前需要冷却,且活性炭需定期更换。直接燃烧法具备操作简单、养护容易,无需预处理,有机物可完全燃烧,有利于净化高浓度废气等优点,燃烧热亦可作为烘干室的热源得以利用;缺点是燃烧过程成本高,存在安全隐患[6-7]。生物法净化VOCs的过程无需额外投加能源,通过微生物新陈代谢作用可使有机物矿化分解,具有工艺简单、操作方便、运行稳定、处理效果好、无二次污染,运行费用低等优点[8-9]。生物净化法在降解低浓度有机废气和恶臭气体方面效果显著,欧洲约有8 000 座废气生物净化装置投入运行,对VOCs的去除率可以达到90%以上[10]。

涂装行业废气量大、组分复杂,是产生VOCs的主要行业之一。汽车轮毂涂装车间的废气主要成分有乙酸乙酯、甲基异丁基酮、甲苯、乙酸丁酯和二甲苯等,涂装生产企业急需成本低、效果好的绿色处理技术。本课题组与浙江某轮毂生产厂家合作开展了生物净化涂装废气现场中试试验,考察绿色低成本的生物技术处理涂装废气的可行性,为实际应用提供参考。

全文HTML

-

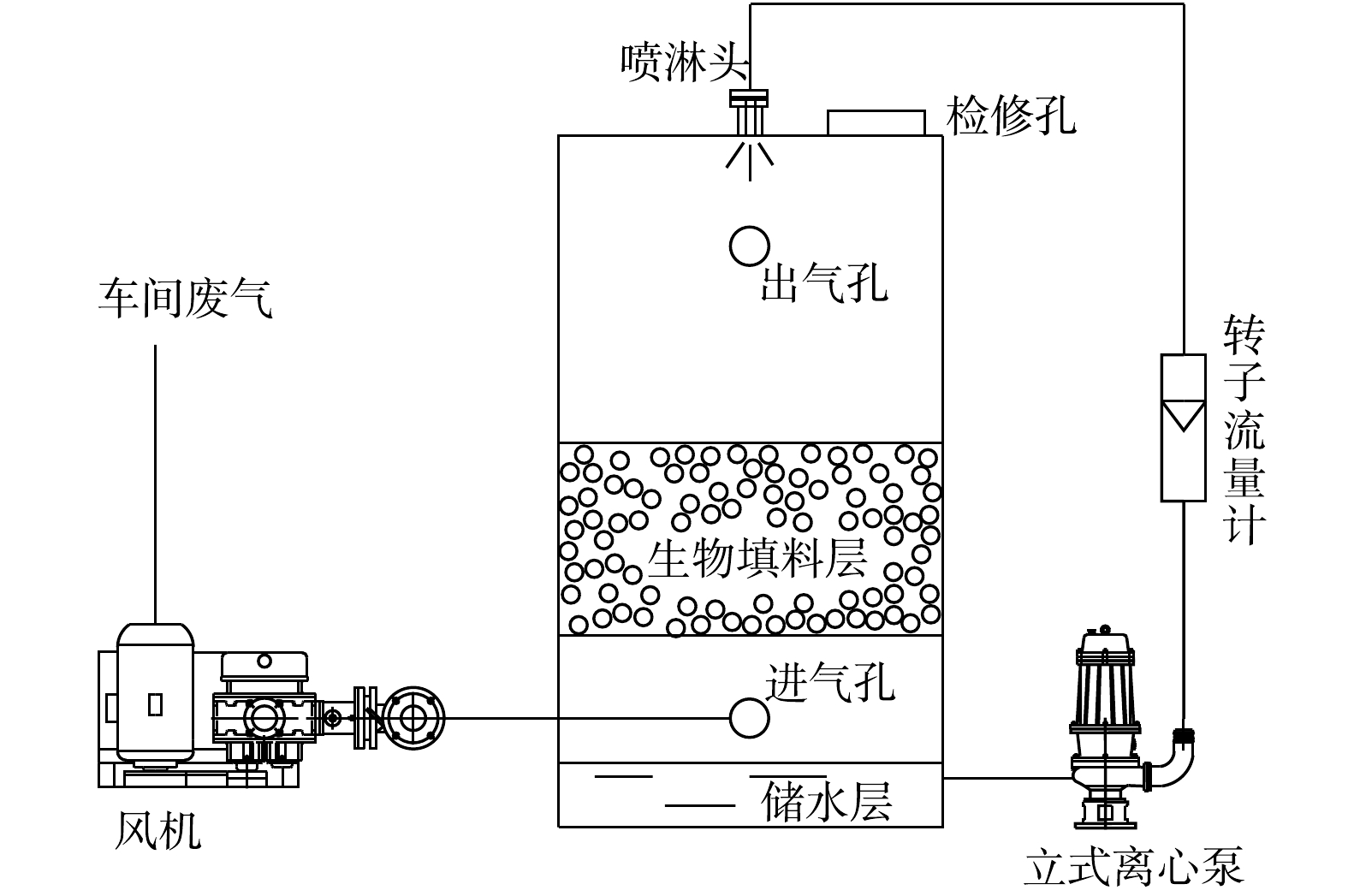

1)实验装置。生物净化设备规格为1.0 m×1.0 m×1.8 m,微生物填料为ϕ10 mm的泡沫小球,填充体积为0.5 m3,循环水泵流量为0.6 m3·h−1。氮磷营养液投加系统1套。风机风量为175~185 m3·h−1,停留时间为10 s,压力降为50~70 Pa。

2)实验方法。用淀粉、氯化铵、磷酸氢二钠配置营养液,按照质量比[BOD5]∶[N]∶[P]=100∶5∶1添加到处理含甲苯废水的活性污泥中,并进行曝气处理,在实验室驯化半个月。驯化期间,每天加入1 g·L−1的二甲苯和乙酸乙酯,按一定比例投加氮、磷营养物质(氮浓度为100 mg·L−1,磷浓度为20 mg·L−1)。启动现场试验,将该驯化污泥用水稀释后接种入净化装置里,开始运行。当生物净化装置对VOCs的去除率达到60%以上时,即挂膜结束。

3)净化工艺。企业车间废气来源包括喷涂房、烘房和流水线。产生废气由引风机送到生物净化设备生物填料下部。设备循环水通过水泵自上向下喷淋,与气体逆流接触。废气在上升过程中被生物填料表面的润湿生物膜捕捉净化,再从顶端排气孔外排。涂装废气生物净化装置如图1所示,净化现场照片见图2。

-

VOCs采用美国华瑞PGM-7320 VOC气体检测仪测定。废气组分分析采用Agilent7890N气质联用仪(GC-MS),色谱柱为DB-5ms石英毛管色谱柱(30 m×0.25 mm×0.25 μm),检测器为氢焰离子检测器。采用程序升温方法:初始温度35 ℃,保持1 min,然后以10 ℃·min−1的速率升至180 ℃,保持5 min,分析时间共20 min。分流进样,分流比为10∶1。载气为氦气,进样口温度230 ℃,FID检测器温度230 ℃。

废水指标测定:TOC采用型号为岛津TNM-L的总有机碳测定仪测定;pH采用pHSJ-4A型精密酸度计进行测定;浊度采用WGZ-B型浊度仪测定。

1.1. 实验装置及净化工艺

1.2. 检测仪器及方法

-

涂装车间制造工艺所使用的原材料主要是有机化学品,产生VOCs主要为芳香烃类、酯类和醇类。在生产过程中,VOCs产生量受原材料、工艺过程、涂装设备等因素影响[11]。喷涂过程使用的油漆组分如表1所示。

-

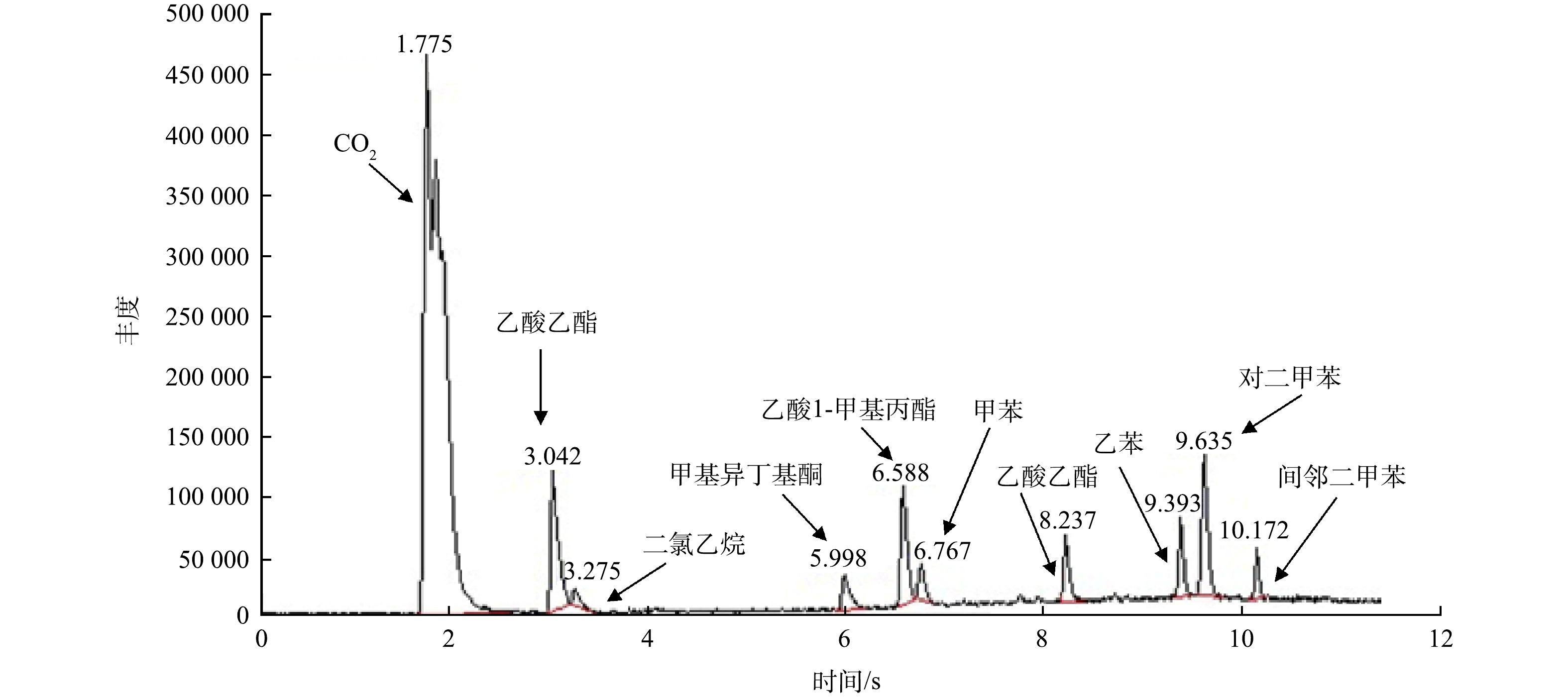

废气组分成分如图3所示。经质谱图检索识别,该车间的废气主要成分为:乙酸乙酯、甲基异丁基酮、乙酸1-甲基丙酯、甲苯、乙酸丁酯、二甲苯等。每日监测发现,不同生产时间段废气组分及浓度波动较大。

-

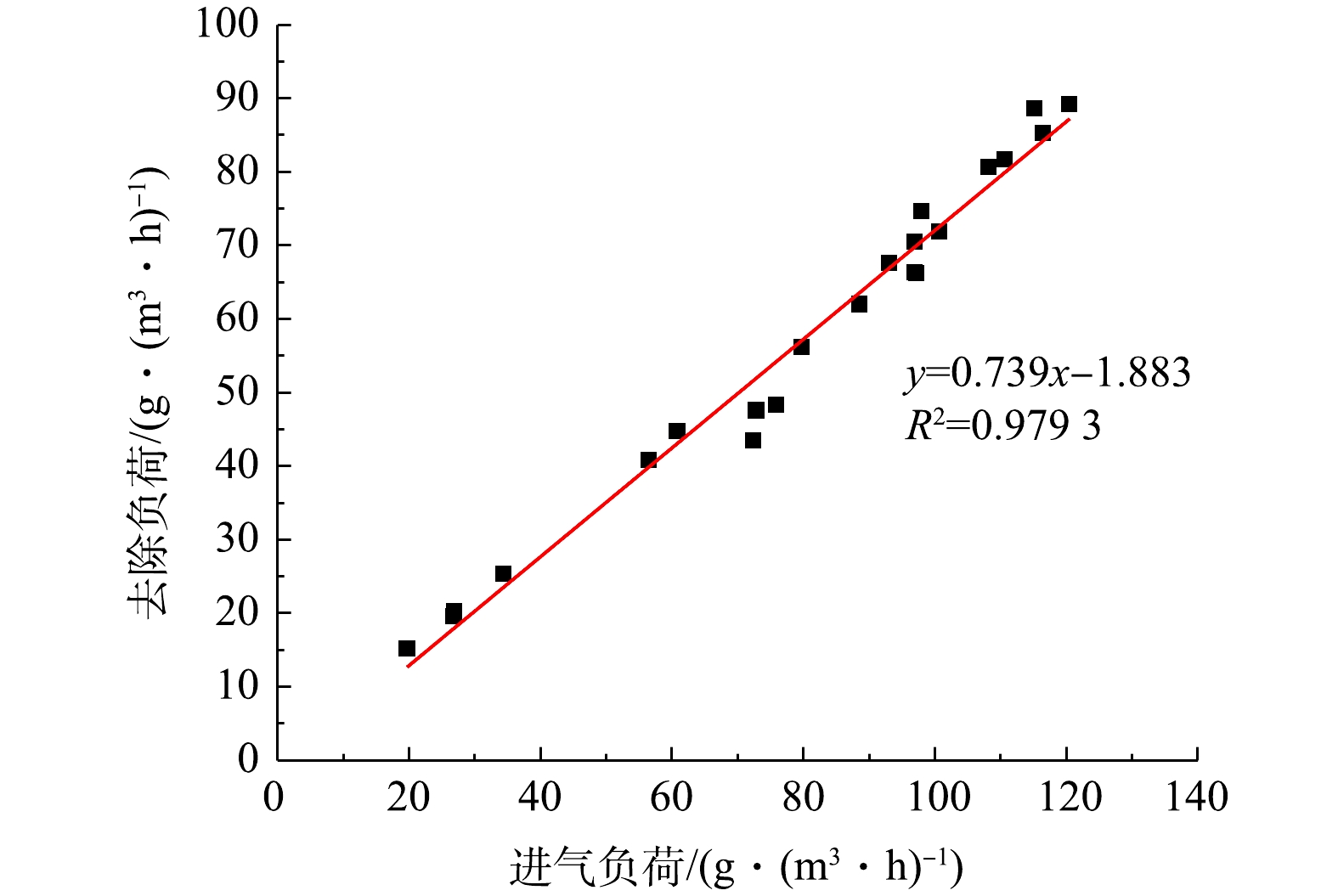

生物装置正式运行后,每日监测进出气中各种污染物浓度,研究进气负荷与废气生物处理效率的关系,结果如图4所示。VOCs的去除负荷与进气负荷基本呈线性关系。随着进气负荷的增加而提高,决定系数R2为0.979 3。在进气VOCs为70~300 mg·m−3时,其去除负荷最高可达89.2 g·(m3·h)−1。

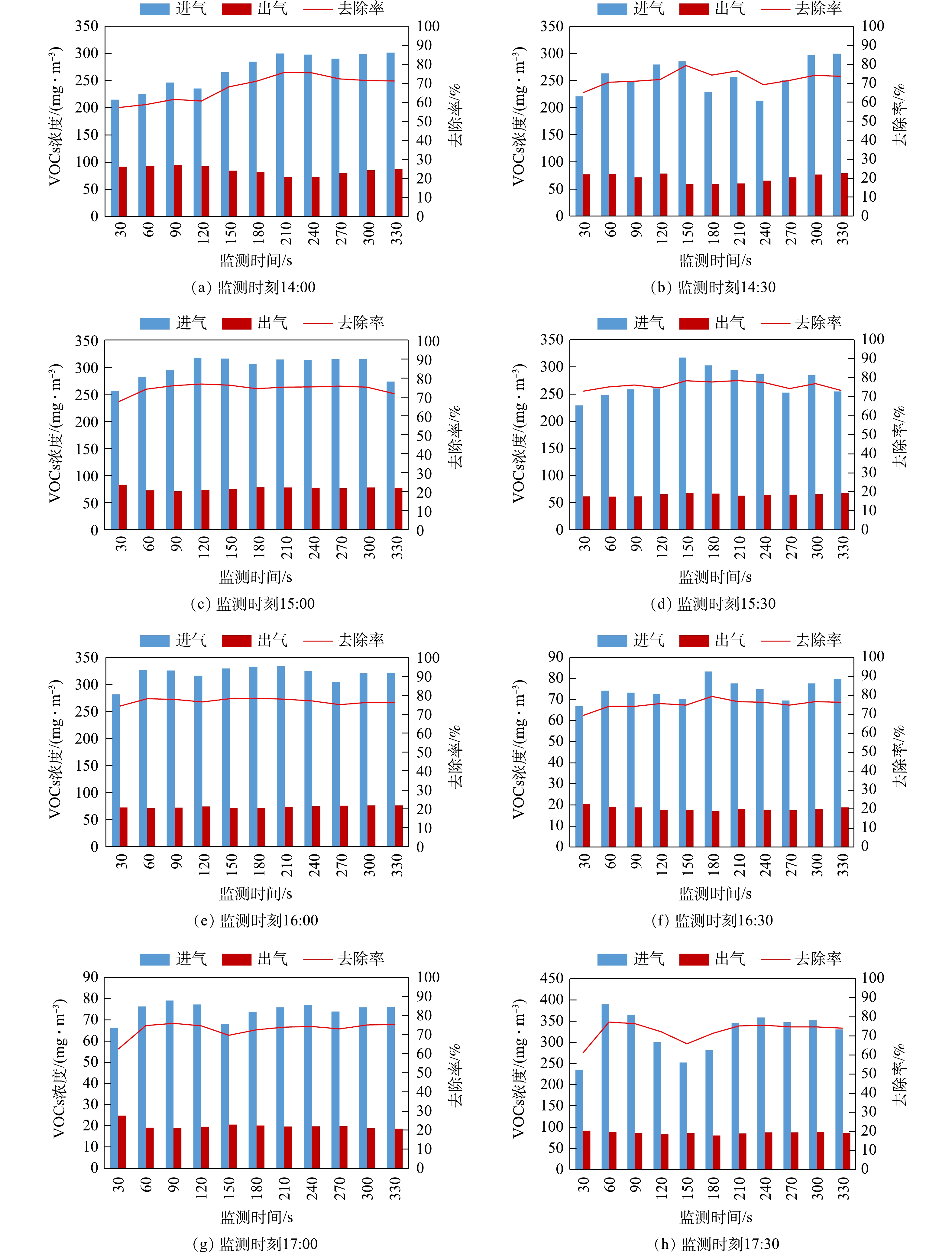

生物净化装置稳定运行1个月后,对VOCs的去除效果做一次4 h的在线监测。废气中VOCs浓度波动很大,但去除率保持平稳,生物净化装置运行效率相对稳定。进气浓度动态变化对于去除效率影响不大,去除率为70%~80%。

-

生物净化装置处理后废气去除效果见表2。图表数据表明,苯系物和酯类是VOCs废气中的主要组分,且均能被有效去除,其中乙酸丁酯去除效果高达90%以上,苯系物去除率为70%~80%。

根据“吸收-生物膜”废气生物净化模型[12-13],废气组分去除率受传质效率和生化降解速率的影响,传质效率对疏水性有机物如苯系物影响很大,生化降解速率对于难生物降解的废气组分如酮类影响很大。而亲水性好且可生化性极好的酯类,去除效果较好。分析其原因,由于苯系物难溶于水且生化性较差,故废气中的甲苯、乙苯、二甲苯等苯系物去除效果一般;乙酸乙酯、乙酸丁酯等羧酸酯类溶剂的可生化性较好,但乙酸丁酯去除率高,而乙酸乙酯去除率一般,这可能与微生物菌群结构有关;同时,浓度低的甲基异丁基酮尽管难生物降解,但也能得到较好去除,可能与进气各组分浓度的影响、微生物群落结构和共代谢机制有关[14]。装置运行过程中,pH维持在4~5.5,适合于真菌生长。现有研究表明,真菌对某些有机物的降解能力强于细菌[15],且真菌具有较大的比表面积和特殊的细胞表面性质,使其能直接捕捉气相污染物[16-17]。

-

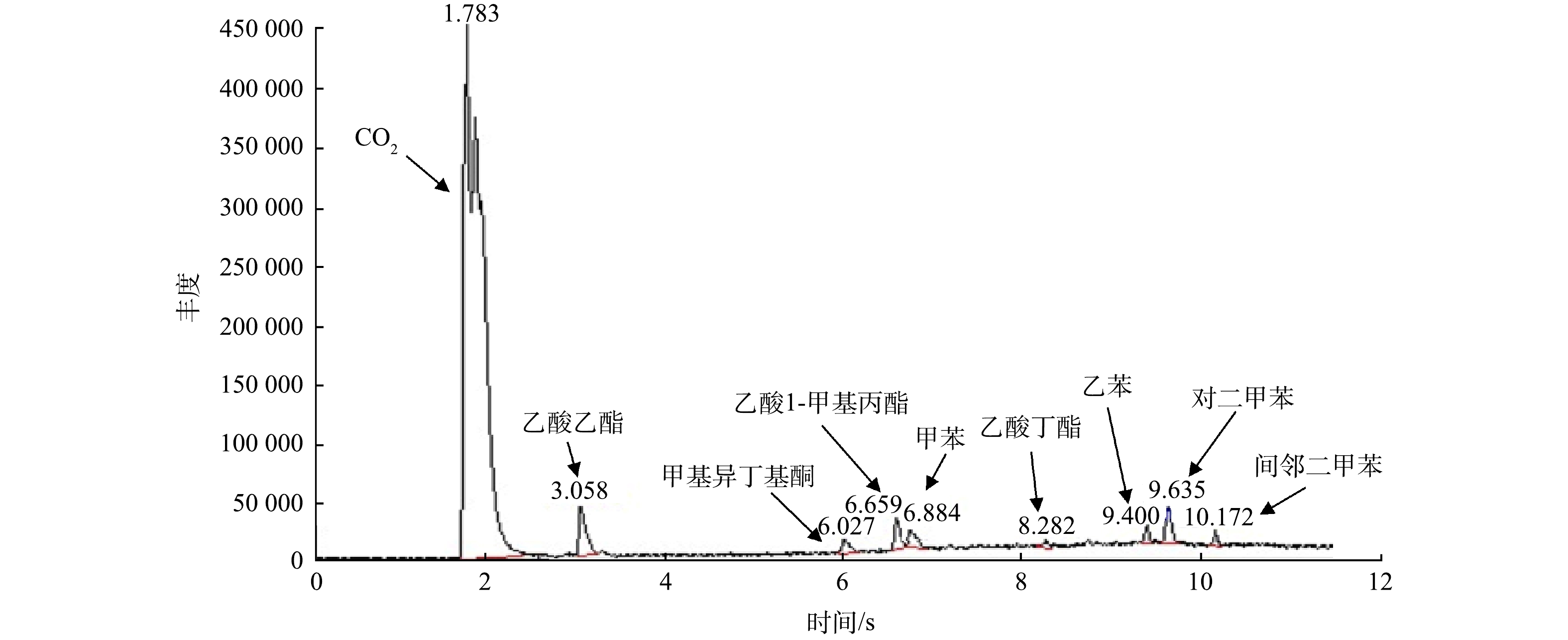

VOCs动态去除效果见图5,生物净化装置处理后废气组分如图6所示。通过GC/MS连续分析发现,净化后的废气中二氧化碳浓度有所上升,说明VOCs通过微生物的新陈代谢作用转化为二氧化碳。进一步监测生物净化装置里的循环液中有机物积累情况表明:在连续运行3 d不更换循环水的条件下,循环液中有机碳(TOC)浓度低于380 mg·L−1,循环液总体积为300 L,循环液里积累的有机物含量为114 g,进气VOCs浓度为70~300 mg·m−3,气体流量Qg为180 m3·h−1;计算得出废气中有机物总量为907~3 888 g,远高于循环液里积累的有机物含量。以上结果表明,废气中各种污染物已大部分被微生物代谢分解去除。

2.1. 涂装油漆组分分析

2.2. 废气组分分析

2.3. 废气生物净化装置的启动与运行

2.4. VOCs中各组分净化效果分析

2.5. VOCs废气生物净化副产物分析

-

1)汽车轮毂涂装废气组分主要为苯系物和酯类。废气中不同组分浓度随生产过程波动较大,各组分的可生物降解性存在很大差异。然而,现场试验表明生物净化装置对涂装废气的降解效率较高,维持在70%~80%。净化装置运行较稳定,表明生物净化装置能有效净化在涂装行业的有机废气。

2)相同停留时间下,装置对苯系物去除率大于70%,对乙酸丁酯去除效果最好,达到90%以上。这与装置中微生物菌群和结构有关。对装置循环液的成分分析表明,废气中各种污染物通过微生物的新陈代谢被分解去除。

3)鉴于涂装废气排放标准对各组分的严格排放要求和生物法对各组分去除率的差异性,可采用多种处理工艺联用,确保各组分在比例波动较大的情况下,能实现稳定去除。生物净化装置在长期运行过程中可能会出现填料堵塞问题,这是接下来需要重点解决的难题。

下载:

下载: