-

近年来由于食品加工行业的发展,随之产生了大量有机物浓度较高且含盐量较高的废水. 由于高浓度盐分的存在,采用生化处理会造成微生物活性受到严重抑制,最终导致对废水中的有机物降解效率低下[1]. 好氧膜生物反应器(aerobic membrane bioreactor,MBR)技术相较于传统好氧工艺,能很好将污泥截留在系统中,从而提高处理效率. 此外,MBR能将污泥停留时间(sludge retention time, SRT)与水力停留时间(hydraulic retention time, HRT)分开控制,易于管理控制,因此近几年在高盐废水处理中受到普遍关注[2-3]. 然而在采用MBR工艺处理高盐废水过程中面临的主要问题是膜污染问题[4]. 膜污染是指混合液中的污泥絮体、胶体粒子或有机盐和无机盐类,与膜存在物理化学作用而在膜表面沉淀与积累,或由于膜孔的吸附而使膜孔堵塞,过滤性下降,从而导致膜通量与分离特性的不可逆的变化的现象[5]. 膜污染的表观现象是随着MBR的运行,系统拦截的污泥和过滤的水量增多,膜表面会堆积形成滤饼层以及凝胶层,从而造成跨膜压差(trans-membrane pressure,TMP)的增加,导致膜通量越来越低. 当TMP增加到一定值时,膜无法正常使用,需要进行物理和化学清洗,高频次的化学清洗会影响膜的寿命. 因此膜污染是膜生物反应器在运行过程种需要重点控制的对象,它不仅影响膜组件的产水率,还影响膜组件的使用寿命及设备的能耗[6].

目前关于MBR处理高盐废水的膜污染已有较多报道,李津[7]研究发现,MBR工艺处理高盐废水过程中微生物所分泌的大量溶解性微生物产物(soluble microbial products, SMP)和胞外聚合物(bound extracellular polymeric substances, BEPS)是造成膜污染的主要原因,用清水结合次氯酸钠溶液能有效清洗膜. 李彬等[8]针对MBR处理高盐废水时膜面污染物的特性进行了研究,发现随着MBR系统盐度的升高,污泥的性质发生了较大变化,污泥的悬浮性固体(SS)及挥发性悬浮固体(VSS)与SS的比值均发生了下降,SMP的含量略有上升,膜面的有机污染物主要成分为糖类、蛋白和腐殖酸等. 陈启伟[9]研究表明,较小的污泥粒径对膜通量是不利的,较小的粒径会加速浓差极化的形成,从而加速膜污染. 还有报道指出盐度的存在会增加膜表面的结垢倾向,加速膜污染的形成[10].

尽管关于高盐废水处理过程的膜污染问题及影响因素已有相关报道,然而膜污染问题及成因仍然是一个比较复杂的问题,且不同的水质和运行条件对膜污染和污泥性质产生的影响均不同. 因此,本研究针对连云港某营养食品加工企业生产的两种SO42-浓度分别为1.6%和2.6%的废水,采用两套中试规模好氧膜生物反应器(MBR)进行处理,通过对两系统的TMP和污泥性质以及膜阻分布情况进行监测,初步研究对比探讨不同硫酸盐浓度对活性污泥性质和膜污染的影响. 通过对MBR处理高盐废水中膜污染规律和污泥性质的研究,有利于MBR系统在处理高盐废水中的改造和膜清洗方案的选择,且对膜生物反应器的开发及工程化应用有一定的指导意义.

-

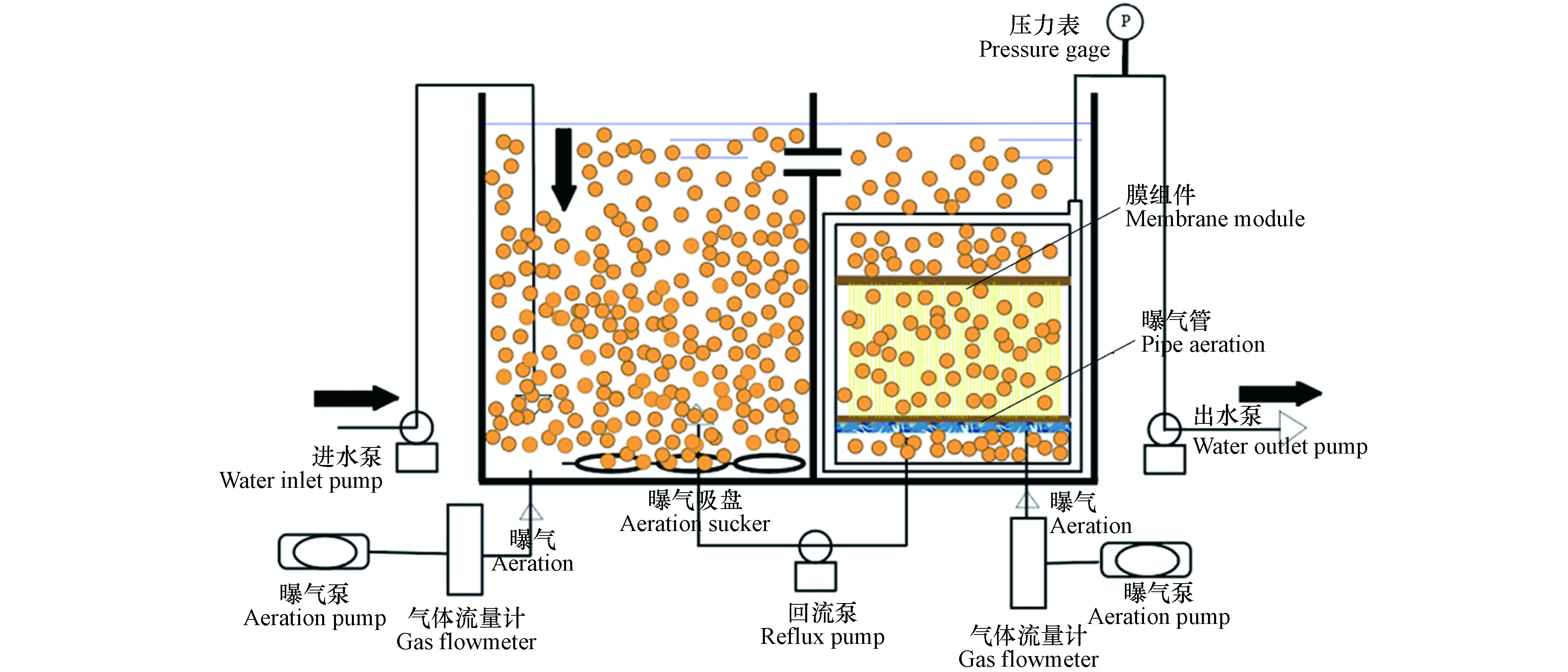

本研究采用MBR工艺,装置如图1所示.

装置主要由硝化池(O池)和MBR池组成,两池的有效容积都为44 L,整套反应器的总有效容积为88 L. 在O池和MBR出的底部装有纳米吸盘曝气装置,曝气装置分别用空气流量计控制,用以保持池内的溶解氧在2—4 mg·L−1,同时可以使池内的污泥混合液充分混合,防止污泥沉底堆积. MBR池的硝化液通过蠕动泵控制回流至O池,以控制两池污泥浓度相同,防止MBR池污泥经浓缩后浓度过高,影响两池的硝化性能. 污泥停留时间(sludge retention time,SRT)为44 d.

实验所用的膜组件为聚偏氟乙烯(PVDF,江苏诺莱智慧水务装备有限公司)的中空纤维膜,有效膜面积为0.43 m2,过滤方式采用负压抽吸. 膜组件底部设有射流曝气装置,在提供溶解氧的同时可以冲刷膜表面,缓解膜污染. 反应器的进出水均采用蠕动泵控制,出水的抽停比为9 min:1 min,跨膜压差(trans-membrane pressuredrop,TMP)采用压力表测定,当TMP超过30 kPa时,对膜组件进行清洗.

-

本实验接种的污泥取自无锡市某餐厨废水处理厂的好氧生化污泥,所用废水为连云港某营养食品加工企业产生的废水,因生产工艺的不同,会产生不同

SO2−4 浓度的废水,故本实验采用两种SO2−4 浓度的废水进行实验研究. 其详细水质如表1和表2所示.两股废水中原水有机物较高,而TN较低,使得C/N过高,在运行了25 d后,

SO2−4 浓度为1.6%的反应器,因有机物降解效率不佳,尝试通过调整进水C/N,控制C/N在25左右. 进水SO2−4 浓度为2.6%的反应器低,在运行了40 d后,添加尿素补充氮源控制C/N同样为25左右. 且其进水SO2−4 在第50 d有所降低,在2.2%—2.3%范围内波动. -

同时运行两组实验MBR装置,一组进水

SO2−4 浓度保持为1.6%,另一组初始进水SO2−4 浓度为2.6%,运行50 d后由于进水水质变化调整为2.3%. 有机负荷根据出水COD值来判断是否提升,若出水COD稳定于200 mg·L−1以下则提升负荷. 进水SO2−4 浓度为1.6%的MBR装置运行时期分两个时期,第一个时期为提盐驯化期(有机负荷为0.5 kg·(m3·d)−1 COD,1—20 d),第二个时期为负荷提升期(21—110 d),其中负荷提升期又分为3个阶段:0.6 kg·(m3·d)−1 COD (21—40 d),0.72 kg·(m3·d)−1 COD (41—80 d),1.0 kg·(m3·d)−1 COD (81—110 d). 因SO2−4 浓度为2.6%的MBR装置出水COD一直高于200 mg·L−1,故此套装置运行阶段分两个时期,分别为提盐驯化期(1—36 d)和负荷稳定期(37—110 d,其有机负荷一直稳定在0.5 kg·(m3·d)−1 COD). 两反应器的运行参数如表3所示. 运行期间室内温度控制在25 ℃左右. -

MLSS、MLVSS采用国家环保总局规定的检测方法[11];溶解性微生物产物(SMP)和结合性胞外聚合物(BEPS)的提取参考陈康等[12]的方法;采用苯酚-硫酸法和Folin-酚法测定SMP和BEPs中的多糖和蛋白质含量,两者的总和即为SMP和BEPS的含量[13]. 采用激光粒径分析仪(BT-2003)测定污泥粒径及粒径分布. 膜阻力分布根据Darcy定律[14]:

式中,Rt时过滤时的总阻力(m−1),Rm是固有阻力(m−1),Rc是外部阻力(m−1),Rf是由不可逆吸附和膜孔堵塞引起的内部阻力(m−1),J是膜通量(L·(m2·h)−1),

Δp 是TMP(Pa),μ 是过滤液的动力黏度(Pa·s). 新膜使用前,采用纯水过滤得到Rm,每个装置第3次清洗前,根据最终的膜通量和TMP计算Rt,采用纯水去除膜面污染物后过滤纯水得到Rm+Rf,根据这些数值利用公式计算出Rt、Rm、Rc和Rf. -

两套实验装置的主要运行数据如表4所示,进水

SO2−4 浓度为1.6%的系统在提盐驯化阶段(最大有机负荷OLR为0.5 kg·(m3·d)−1 COD)后期出水COD值稳定在205—210 mg·L−1,COD的平均去除率为96.2%,氨氮和TN的去除率分别为81.3%和36.7%. 而2.6%系统在提盐驯化阶段(OLR为0.5 kg·(m3·d)−1 COD)末期出水COD值在400—460 mg·L−1波动,平均去除率为94.77%,氨氮和TN的去除率分别为68.2%和35.6%.进入负荷提升/稳定阶段后,对两系统的进水C/N作了调整,通过添加尿素,补充有机氮源,控制C/N在25左右. 随后进水

SO2−4 浓度为1.6%的系统COD值有所下降,在负荷提升阶段Ⅰ(OLR为0.6 kg·(m3·d)−1 COD)和Ⅱ(OLR为0.72 kg·(m3·d)−1 COD)末期出水COD值均稳定在145 mg·L−1以下,COD去除率稳定在97.5%左右. 在负荷提升阶段Ⅲ(OLR为1.0 kg·(m3·d)−1 COD)时,1.6%系统的出水COD值仍稳定在200 mg·L−1以下,平均去除率达97.2%. 而在2.6%系统负荷稳定(OLR为0.5 kg·(m3·d)−1 COD)初期调整C/N后,出水COD仍高于200 mg·L−1,其去除率最终稳定在96.3%. 调整C/N后,1.6%系统的氨氮去除率在负荷提升阶段Ⅰ时,受到影响,下降至57.6%,而后在负荷提升阶段Ⅲ时该系统对氨氮的去除率最终稳定在92.5%,而2.6%系统的氨氮去除率在负荷稳定阶段末期的氨氮去除率为82.6%. 经过稳定运行,两系统对TN均有一定的去除效果,其中1.6%系统最终对TN的去除效率为89.5%,而2.6%系统对TN的去除效率为80.7%. 两种SO2−4 浓度的系统对总磷的去除效率都呈现上升的趋势,最终均达到全部去除的效果. 在本研究中总磷去除率为100%,其原因可能是一体式的膜生物反应器由于膜对微生物的完全截留使得反应器内能维持较高的污泥浓度,会造成氧传递效率降低,形成局部的厌氧环境. 在这种好氧厌氧共存的环境中,一部分的磷通过“厌氧释磷,好氧过量吸磷”的方式去除. 另一方面,BEPS也能储存磷元素,其除磷量也能达到很高,达60%以上. 在本研究中发现,1.6%系统和2.6%系统成熟污泥的BEPS较初始污泥增加了4—5倍. 因此,另一部分磷去除可能是通过BEPS的储存后,再以排泥的方式对水中的磷进行有效去除. 对比发现,运行效能受盐度的影响呈现出明显的差异,相比于2.6%SO2−4 系统,1.6%SO2−4 系统能获得更高的有机负荷,其在较高的有机负荷下,其对COD、氨氮和TN的去除效率均高于2.6%SO2−4 系统.综上,2.6%

SO2−4 系统所能获得的有机负荷和污染物去除效率均不如1.6%SO2−4 系统,这是由于参与污染物处理的大多数微生物都是非耐盐/嗜盐性的微生物,盐度的升高会导致这些微生物逐渐失活[15]. 此外,微生物的生物活性和细菌群落结构随着盐度水平的变化而变化,在较低盐分的环境下,经过长期的驯化有机物去除效率可以得到提高. 然而,当浓度较高时,微生物将面临渗透压力,导致细胞脱水,对生物膜造成不可修复的损害,从而导致系统对污染物的去除效率低下[16]. 因此在本实验室中,较低盐度的1.6%系统相比于2.6%系统能获得较高的有机负荷和污染物去除效率. -

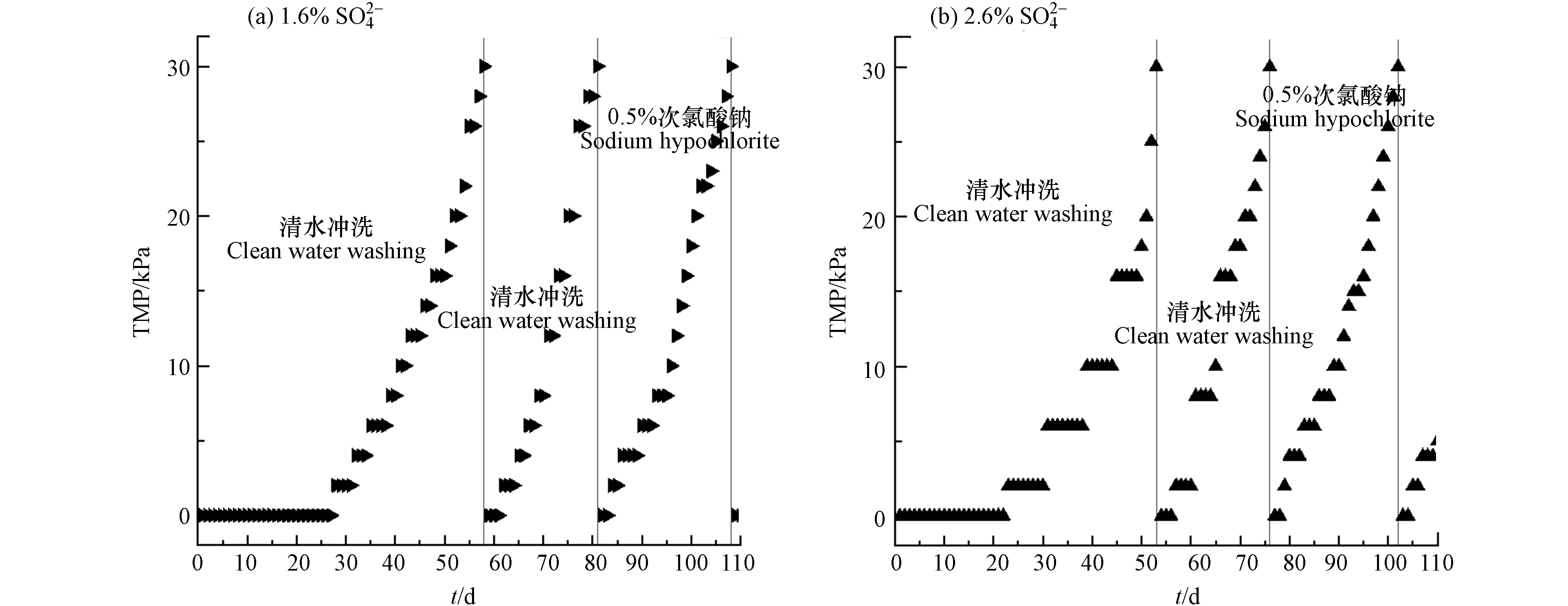

膜污染是衡量膜生物反应器稳定运行最重要的限制因素之一,频繁的膜清洗会减少膜的使用寿命,增加运行成本. 因此,进行膜污染的研究对于了解膜的运行性能至关重要. TMP可以用来表征膜污染的程度,随着反应器的运行,膜组件逐渐受到污染,TMP会随之增加. 图2为MBR在运行期间的TMP变化情况. 在110 d的运行时间里,进水

SO2−4 浓度为1.6%的反应器随着进水量和有机负荷的提升,膜通量作了相应调整. 在0—20 d、21—40 d、41—80 d和80—110 d的4个阶段的膜通量分别控制在0.9 LMH、1.1 LMH、1.3 LMH和12.5 LMH. 而进水SO2−4 浓度为2.6%的反应器由于进水量和有机负荷未增加,膜通量一直控制在0.64 LMH左右.在整个运行过程中,进水

SO2−4 浓度为1.6%和2.6%的反应器TMP均累计3次达到30 kPa. 其中1.6%SO2−4 系统(图2a)分别在第58、81和108 天达到30 kPa,而2.6%SO2−4 系统(图2b)分别是在第53、76和102 天达到30 kPa,分别提早了5、5、6 d. 1.6%和2.6%SO2−4 系统第一次出现TMP读数(2.0 kPa)分别在第28 天和23天,说明SO2−4 浓度为2.6%的反应器膜组件比1.6%的膜污染更快. 有研究表明在更高的盐度下,系统内的微生物会产生更多的SMP和BEPS,加剧膜污染[17]. 在第58 天时对进水SO2−4 浓度为1.6%膜组件进行物理清洗,继续运行时初始TMP为0 kPa,到第81 天第二次TMP达30 kPa,历时23 d. 而进水SO2−4 浓度为2.6%的膜组件在第53 天时进行物理清洗,到第76 天时TMP第二次达30 kPa,历时同样为23 d. 尽管1.6%和2.6%SO2−4 系统TMP到达30 kPa的时间相同,但2.6%SO2−4 系统的膜运行通量较低,说明经过物理清洗后2.6%系统膜污染仍然比1.6%系统更严重. 第二次物理清洗后,两反应器的TMP增加至30 kPa的时间均比第一次少很多,说明两个反应器的膜污染出现了不可逆污染,普通的物理清洗已无法完成有效清洗.随后在第81天用0.5%NaClO对进水

SO2−4 浓度为1.6%的反应器膜组件进行清洗,运行到第108 天,1.6%系统TMP第3次达30 kPa,所需时间为27 d. 同样在第78 天用0.5%NaClO对进水SO2−4 浓度为2.6%的膜组件进行清洗,到102 d,2.6%系统TMP第3次达30 kPa,历时26 d. 说明化学清洗后,尽管2.6%系统的膜运行通量相比1.6%系统较低,但其膜污染速度却更快. 叶芳凝[1]的研究表明,高盐环境下污泥混合液的过滤性会降低,膜污染加剧. -

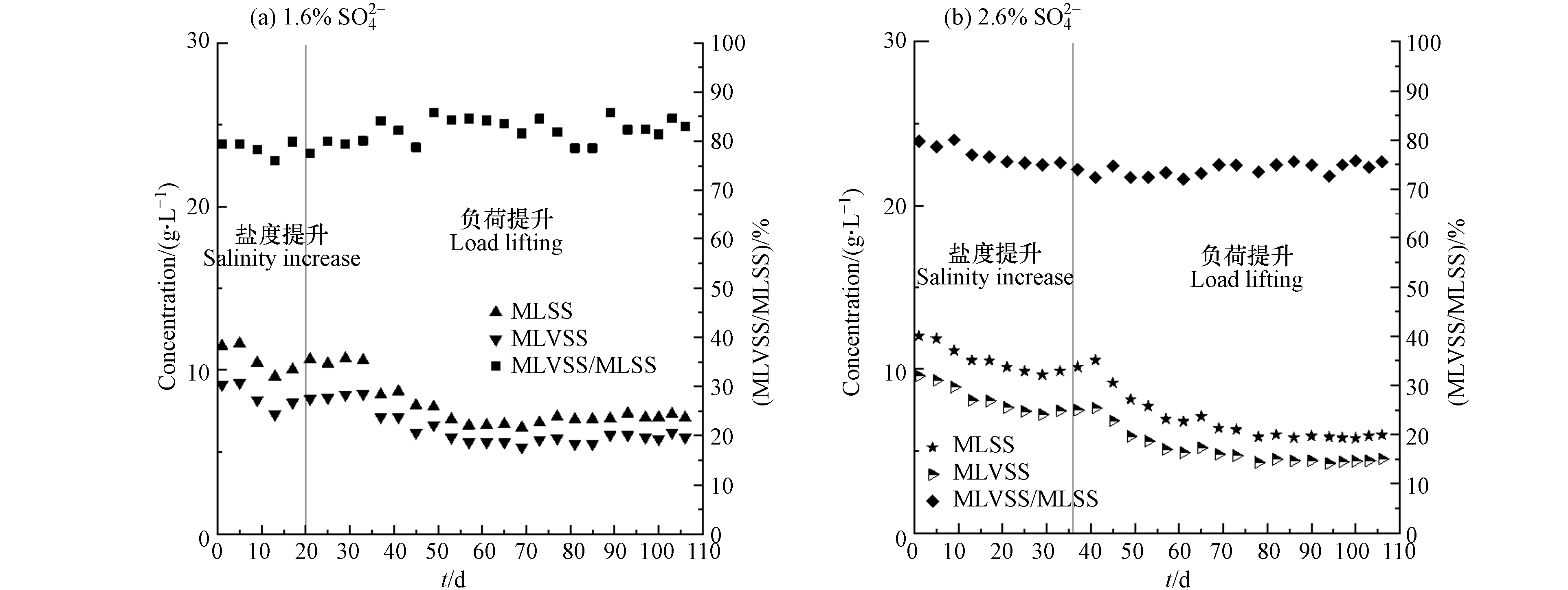

为了解盐度和负荷提升对活性污泥的影响情况,对两反应器MBR池中MLSS、MLVSS以及MLVSS/MLSS的变化情况进行了监测,结果如图3所示. 进水

SO2−4 浓度为1.6%的反应器在提盐驯化期内(1—15 d),系统中的MLSS及MLVSS从11.4 g·L−1和9.3 g·L−1分别下降至9.6 g·L−1和7.3 g·L−1,MLSS/MLVSS从80.2%下降至76%(图3a). 同样进水SO2−4 浓度为2.6%的反应器在提盐驯化期内(1—35 d),MLSS及MLVSS分别从12.0 g·L−1和9.6 g·L−1降低到9.9 g·L−1和7.5 g·L−1,MLVSS/MLSS由接种时的80%降低到了75.4%(图3b).可以看出两系统的MLSS、MLVSS和MLVSS/MLSS在提盐时期均呈现下降趋势,这是由于初始两系统内接种活性污泥盐度较低,随着体系内盐度的逐渐上升,部分活性污泥因为难以适应环境的改变而死亡[18-19],从而导致MLSS、MLVSS以及MLVSS/MLSS的整体下降.

随着活性污泥的逐渐驯化,耐盐微生物开始逐渐增殖,进水

SO2−4 浓度为1.6%的反应器内污泥浓度在负荷提升初期(第26 d)MLSS和MLVSS分别增加至10.4 g·L−1和8.3 g·L−1,MLVSS/MLSS为80.0%. 随后开始排泥2 L以控制SRT为44 d,MLSS和MLVSS逐渐下降最终分别为7.1 g·L−1和5.9 g·L−1,但其MLVSS/MLSS略有上升,最终为83%且高于接种初始值. 进水SO2−4 为2.6%的反应器内污泥浓度在提盐驯化期(1—35 d)结束后缓慢上升,到负荷稳定初期(第40 天),MLSS及MLVSS分别增长到10.5 g·L−1和7.0 g·L−1,而MLVSS/MLSS的值下降到了72.3%. 第40 天开始,2.6%系统开始排泥2 L以控制SRT为44 d,排泥后系统MLSS和MLVSS不断下降至6 g·L−1和4.5 g·L−1左右. MLVSS/MLSS虽略有上升,但始终低于接种初始值,最后稳定在75%左右. 很多研究表明在合适的盐度下,活性污泥经过长期的驯化,MLVSS/MLSS的值会逐渐升高,最终高于接种污泥值. 例如武骁[20]利用好氧污泥处理含盐有机废水时发现,在合适的溶解氧条件下,长期驯化的活性污泥浓度较接种污泥浓度有大幅度提升,接种污泥的MLVSS/MLSS为63%,驯化成熟污泥的值高达78%. 但也有研究表明,在高盐环境下,MLVSS/MLSS的会受到高盐环境的冲击,最终低于接种污泥值. 例如肖小兰等[21]研究发现,在盐度约为3.5%条件下,活性污泥经过长期驯化,负荷提升阶段的MLSS和MLVSS会逐渐增长,但运行结束时,MLVSS/MLSS的值仍是低于接种污泥值. 本研究中发现进水SO2−4 浓度为1.6%的体系内微生物含量(MLVSS/MLSS)经过驯化后逐渐升高,但在更高盐的环境下(SO2−4 浓度为2.6%)微生物受到的影响更加明显,微生物增长较慢,且较高的无机盐也容易在反应器中累积,从而造成MLVSS/MLSS较接种初始值低.目前关于污泥浓度和膜污染关系的研究中,不同学者之间有很大的差别. 研究结果的差异可能来源于不同的反应装置以及不同的污泥性质等,但普遍认为MLSS的变化对膜污染的影响与其范围有很大关系. Le等[22]研究表明,污泥浓度的增加会导致污泥粘度呈现指数形式的增加,从而加剧膜污染;而陆继来[23]在研究污泥浓度对膜污染的影响时,考察了4—10 g·L−1范围内污泥浓度变化对MBR装置TMP变化的影响,发现污泥浓度的升高,有助于保持膜通量,在高污泥浓度下,TMP的升高趋势更加平缓. 陈莉佳等[24]通过中试规模的反应装置,考察了MLSS在4—9 g·L−1和10—14 g·L−1范围内对膜TMP的影响,发现在较低污泥浓度下TMP上升速率很快,膜污染也更加严重,当污泥浓度升高时,TMP上升速率减小. 在本研究中,两套装置在前期接种的污泥浓度均较高,经过盐度驯化以及排泥后,污泥浓度有所降低,TMP增加逐渐加快,而2.6%

SO2−4 系统的膜污染相比于1.6%SO2−4 系统更严重,可能是由于运行稳定后2.6%SO2−4 系统中MLSS值较1.6%SO2−4 系统更低. 此外,MLVSS/MLSS的值对膜污染也有一定影响,在王浩宇[25]的研究表明,同时运行的两套一体化膜生物反应器中,MLVSS/MLSS值更低的装置膜污染情况更严重,在本研究中也能得到相似的结论. -

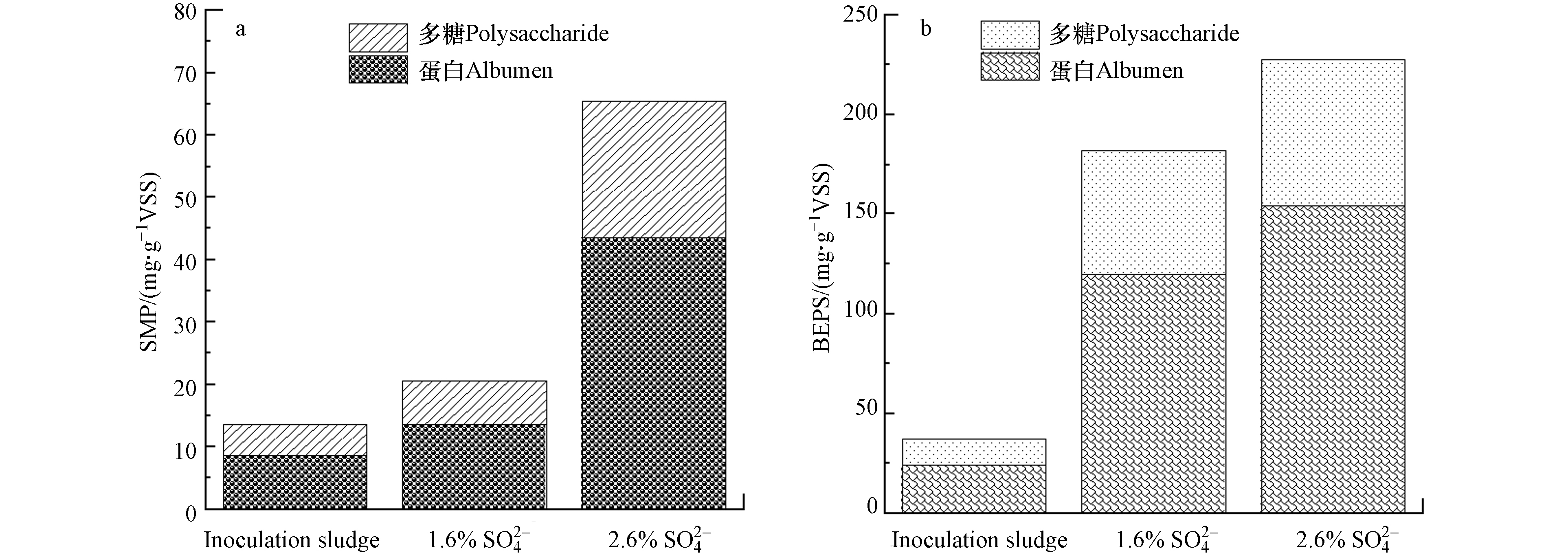

SMP是溶解性的微生物产物,在MBR运行过程中,其会被吸附到膜上或进入到膜孔中造成污染. BEPS是一种结合的细胞外聚合物,它聚集于微生物细胞表面,对微生物具有保护作用,BEPS的存在会使污泥的性质发生改变,从而影响过滤性能. SMP和BEPS主要由蛋白质和多糖构成,在MBR运行结束后,提取两反应器MBR池中成熟污泥的SMP和BEPS,并与接种时污泥的组分进行比较,结果如图4所示. 两反应器接种污泥时其SMP和BEPS浓度分别为13.5 mg·g−1VSS和36.9 mg·g−1VSS (图4a),经过长期的高盐环境驯化后,进水

SO2−4 浓度为1.6%和 2.6%反应器中成熟污泥SMP浓度分别上升到20.4 mg·g−1VSS和65.3 mg·g−1VSS,BEPS浓度分别为181.8 mg·g−1VSS和227.3 mg·g−1VSS (图4b). 可以看出2.6%SO2−4 系统中SMP和BEPS增量比1.6%SO2−4 要高很多. 常规生活污水MBR的处理中,一般SMP处于10—20 mg·g−1VSS,BEPS处于40—80 mg·g−1VSS的范围. 在本研究中,1.6%系统的盐度相对低一些,微生物能有效适应,有机物的降解未受到明显抑制,其含量在20 mg·g−1VSS左右,SMP略高于常规处理体系. 而2.6%系统的有机物降解水平,受到明显抑制,其SMP的含量在65 mg·g−1VSS左右,高于常规的污水MBR处理体系. 此外,两系统的盐度高于常规生活污水的MBR处理体系,微生物需产生更多的BEPS应对因盐度而改变的渗透压力,故两系统的BEPS均是高于常规体系[19, 26]. Luo等[27]和Hong等[28]的研究表明,盐度升高时高浓度的SMP和BEPS可归因于细胞的自溶和细胞分泌的聚合物以及来自有机物质不完全降解的未代谢和/或中间产物的积累.很多研究表明膜污染主要来源于MBR系统中的SMP,其值越高膜污染程度越严重[26, 29-30]. Gao等[31]的报道中指出SMP是MBR中膜面污染物凝胶层的主要成分来源,同时SMP含量的升高会增加混合液的黏度,造成MBR通量下降,膜阻力上升[32]. 而BEPS也是引发膜污染的主要因素,大多数研究都已表明BEPS浓度与膜污染成正相关关系[33-34]. 例如Patsios等[35]发现,生物絮凝体的BEPS含量在MBR长期运行时会影响TMP跳跃期间的不可逆污染的增加率,对膜的过滤性能造成负面的影响. 从2.2节可知,尽管2.6%

SO2−4 系统膜运行通量较小,但其膜污染却比1.6%SO2−4 系统较严重,究其原因很可能是由于2.6%系统中SMP和BEPS含量均高于1.6%系统,导致其膜污染加快. -

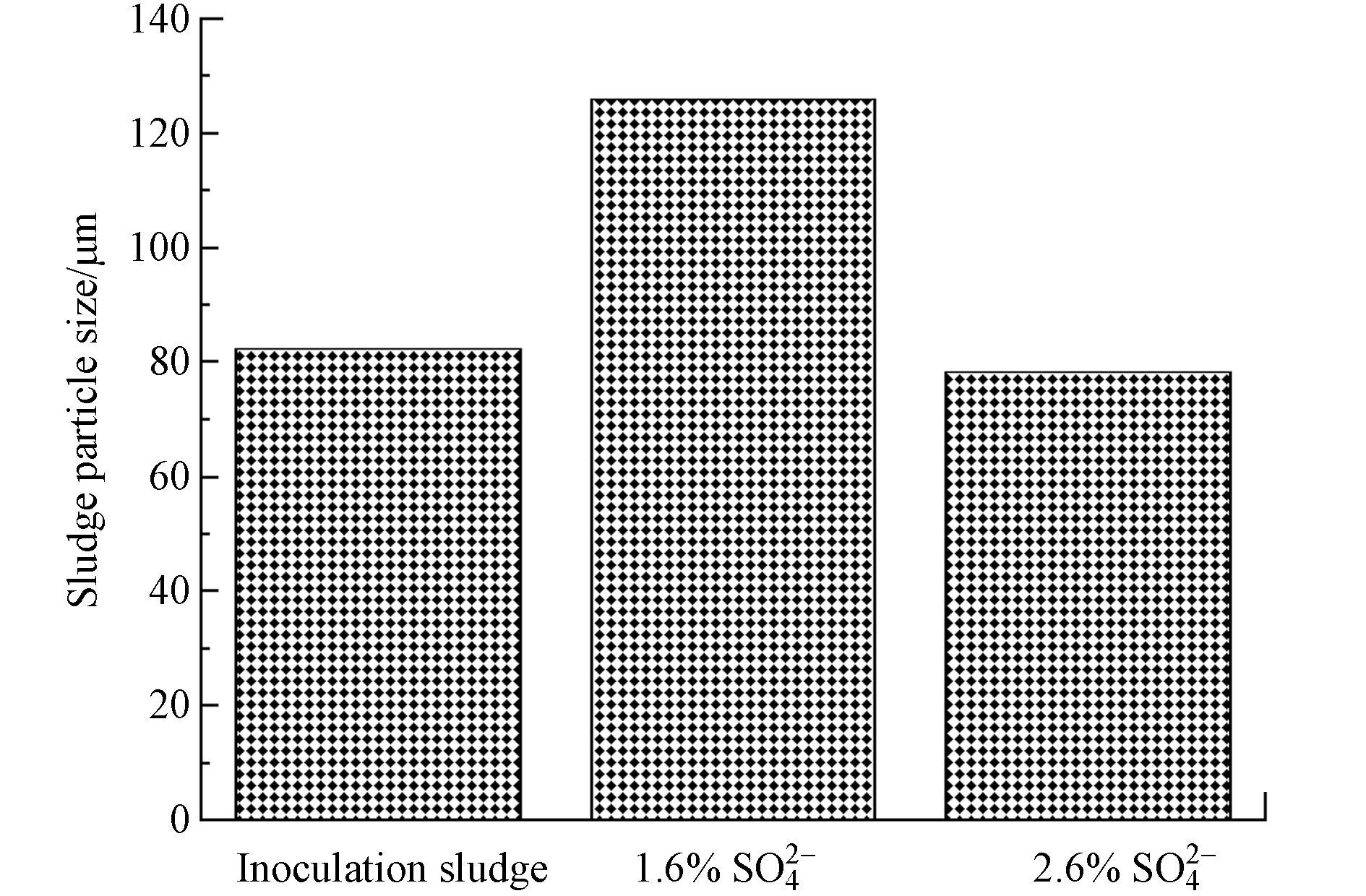

反应器中污泥体积平均粒径的变化如图5所示,两反应器初始接种污泥MBR池的体积平均径为82.3 µm,经过110 d的运行后,进水

SO2−4 浓度为1.6%的反应器中MBR池的污泥粒径增加至125.8 µm. 而进水SO2−4 浓度为2.6%的反应器中污泥驯化成熟后,其MBR池的污泥粒径略有降低至78.2 µm. 目前大部分研究认为盐度会影响污泥的絮凝性能,导致污泥的平均粒径下降. 例如李津[7]研究发现,在盐度为0.35%时,活性污泥颗粒很大,形状为不规则形,絮凝体性能良好;当盐度为1.4%时,活性污泥的结构发生变化,絮凝体变小且紧密度变高. Corsino等[36]研究发现,在3.5%的盐度下,经过115 d的驯化,好氧絮状污泥的粒径平均尺寸略有下降,从152 µm下降至115 µm. 在本研究种发现,在SO2−4 浓度为2.6%的系统中,活性污泥的粒径所有降低,但在SO2−4 浓度为1.6%的系统中,活性污泥经过长期驯化,污泥粒径反而有所增加. 说明适当的盐度可能会刺激微生物产生较多的BEPS使得污泥絮体之间更容易相互聚集,絮体容易变大,粒径增加. 然而在更高盐度下,环境中过高的渗透压力会使微生物细胞脱水,同时丝状菌的生长受到抑制[19],使得2.6%SO2−4 系统污泥絮状物的粒径变小.很多研究表明,膜污染速度和污泥粒径有很大关系,污泥粒径越小,污泥越容易沉积在膜表面,膜污染速率越快[14, 37]. Shen等 [38]研究发现,导致膜污染的泥饼层中粒径较小的污泥絮体的比例更高,也就是说小絮体更容易附着在膜表面,导致膜污染. Lim等[39]研究发现,污泥粒径越小,越容易吸附或沉积在膜表面,甚至堵塞膜内部孔道,形成孔隙率低、密实的膜污染层,造成严重的膜污染. 在本研究中,2.6%

SO2−4 系统中的污泥平均粒径较1.6%SO2−4 更小,其更容易向膜表面迁移,致使膜污染速度也更快. -

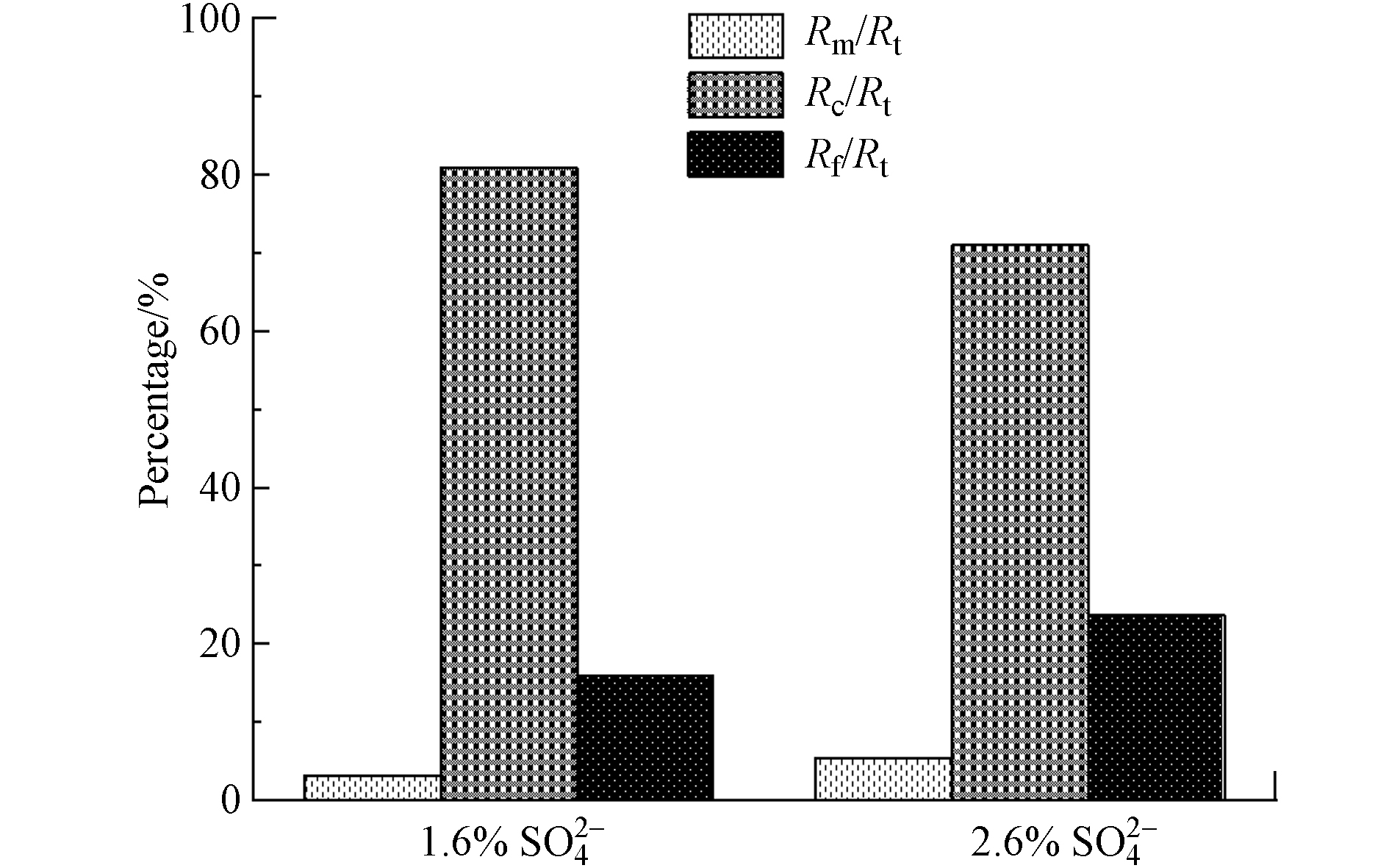

膜阻力主要由三部分组成:膜固有阻力(Rm)、外部阻力(Rc)和不可逆吸附及膜孔堵塞引起的内部阻力(Rf)[12]. 膜固有阻力是指膜未使用之前的自身阻力. 外部阻力主要由泥饼层和凝胶层组成,通过物理清洗可以去除,而内部阻力需要通过化学方法才能去除. 为了探究在不同

SO2−4 浓度下膜阻力的分布差异,对两系统第3次清洗膜时各自的膜阻力分布进行了测定,结果如图6所示.第3次清洗时,进水

SO2−4 浓度为1.6%和2.6%反应器的Rm占比分别为3.2%和5.4%,差异不大. 对比外部阻力和内部阻力发现,1.6%和2.6%SO2−4 系统中膜过滤阻力主要是由外部阻力引起的,分别为80.9%和71%. 此外,系统1.6%SO2−4 系统的内部阻力(Rf)占比为15.9%,而2.6%SO2−4 系统的内部阻力占比为23.6%. 有学者的研究表明,SMP的存在会加剧膜孔堵塞,增加膜的内部阻力. 例如孟凡刚[40]研究发现,MBR中的SMP主要是微生物代谢及细胞破碎等释放的物质,或者称之为溶解性EPS,其分子量分布一般在1000—100000左右,极易堵塞膜孔,增大膜的内部阻力. Tian等[41]的研究表明,SMP通常根据细菌阶段分为两类:与底物吸收和生物量生长相关的生物产物(UAPs),以及与生物量衰减相关的生物产物(BAPs). 这两个阶段的产物均会增加膜孔堵塞的几率,导致膜内部阻力增加. 此外,无机盐的存在也会导致内部阻力的增加. Resosudarmo等[42]研究发现,盐浓度的提高会显著增加腐殖酸等有机质在膜表面的结垢倾向,而结垢层主要是由小尺寸的有机质引起的,这些有机质会堵塞膜孔,增加膜的内部阻力.综上,进水

SO2−4 浓度为2.6%的系统中SMP的含量相比于1.6%系统更高,其中有很多小分子量的SMP,增加了膜孔堵塞的几率;同时较高的无机盐环境,会使得很多小尺寸有机质在膜表面堆积,从而堵塞膜孔增加该系统膜的内部阻力. -

1)经过长期的运行,进水

SO2−4 浓度为1.6%的系统能获得更高的负荷及更好的污染物降解效率.2)在MBR的运行过程中,进水

SO2−4 浓度为2.6%系统相比于1.6%系统的膜污染更严重.3)长期运行下,相比于进水 1.6% 系统,2.6%

SO2−4 中微生物增长较慢且无机盐累积较快,造成MLVSS/ MLSS较接种污泥均有所下降,且比1.6%SO2−4 系统低.4) 1.6%和2.6%

SO2−4 系统中高盐驯化成熟后的污泥较接种污泥的SMP和BEPS均有所增加,其中2.6%SO2−4 系统释放的更多. 此外1.6%SO2−4 系统较接种污泥的粒径有大幅增加,而2.6%系统较接种污泥的粒径有所降低.5)从膜阻力分布来看,两套装置的膜阻力都主要来源于外部阻力,且2.6%

SO2−4 系统的内部阻力相比于1.6%SO2−4 更大.

膜生物反应器(MBR)处理不同浓度高硫酸盐有机废水污泥性质和膜污染研究

Sludge properties and membrane fouling of aerobic membrane bioreactor (MBRs ) in treating organic wastewater with different concentrations of sulfate

-

摘要: 针对食品加工过程中产生的高

SO2−4 的高浓度有机物废水,采用膜生物反应器(MBR)工艺对其进行处理研究,分别考察了1.6%和2.6%SO2−4 浓度下反应器运行性能、污泥性质和膜污染变化情况. 经过110 d的运行时间对比发现,1.6%SO2−4 浓度下MBR获得的最大有机负荷为1.0 kg·(m3·d)−1 COD,其化学需氧量(COD)、氨氮和总氮的去除率分别为97.2%、92.5%和89.5%. 2.6%SO2−4 浓度下微生物受到的抑制更强,其获得的最大有机负荷仅为0.5 kg ·(m3·d)−1 COD,其COD、氨氮和总氮的去除率分别为96.3%、82.6%和80.7%. 此外,SO2−4 浓度为1.6%的反应器在更高的膜运行通量下,膜污染速率反而比2.6%系统更慢. 进一步分析其污泥性质发现SO2−4 浓度为1.6%系统内的混合液悬浮固体浓度(MLSS)和挥发性悬浮固体浓度(MLVSS)稳定在7.1 g·L−1和5.9 g·L−1左右,MLVSS/MLSS值较初始污泥有所提高,从80.2%升高到83%.SO2−4 浓度为2.6%体系内MLSS和MLVSS稳定在6 g·L−1和4.5 g·L−1左右,MLVSS/MLSS较初始污泥有所降低,最终稳定在75%左右. 较低的MLSS和MLVSS/MLSS加速了膜表面滤饼层的形成,导致2.6%SO2−4 系统膜污染更快. 经过长期的高盐环境驯化后,1.6%SO2−4 和2.6%SO2−4 系统成熟污泥的溶解性微生物产物(SMP)和结合性的胞外聚合物(BEPS)均有所上升,SMP从13.5 mg·g−1 VSS上升到20.4 mg·g−1 VSS和65.3 mg·g−1 VSS,BEPS从36.9 mg·g−1 VSS上升到181.8 mg·g−1 VSS和227.3 mg·g−1 VSS. 2.6%SO2−4 系统的SMP和BEPS的值均大于1.6%SO2−4 系统,从而使得2.6%SO2−4 系统的TMP上升加快,膜污染加剧. 1.6%系统MBR中污泥粒径从接种时的82.3 μm增加至125.84 μm,而2.6% SO42-系统中污泥粒径降至78.23 μm. 相较于1.6%SO2−4 系统,2.6%SO2−4 系统的污泥粒径更小,更容易堆积于膜表面,使得滤饼层更加紧致,加速了膜污染的形成. 两套装置的膜阻力都主要来源于外部阻力,但2.6%SO2−4 系统的内部阻力占比较1.6%SO2−4 系统更高. 综上,不同盐度对MBR体系的运行效能、污泥性质及膜污染情况具有显著的影响. 因此本研究可为MBR应用于高盐高浓度有机物废水的处理提供理论基础和实践指导.Abstract: The organic wastewater with highSO2−4 concentration produced in the food processing plant was treated by aerobic membrane bioreactor (MBR) process, and the performance, sludge properties and membrane fouling of the MBR were investigated at differentSO2−4 concentrations of 1.6% and 2.6% respectively. For the operation period of 110 days, it was found that the maximum organic loading rate (OLR) of the MBR at the concentration of 1.6%SO2−4 was 1.0 kg· (m3·d)−1 COD, and the removal efficiencies of chemical oxygen demand(COD), ammonia nitrogen and total nitrogen were 97.2%, 92.5% and 89.5% respectively. However, at the concentration of 2.6%SO2−4 , the maximum OLR was only 0.5 kg·(m3·d)−1 COD, and removal efficiencies of COD, ammonia nitrogen and total nitrogen were 96.3%, 82.6% and 80.7% respectively. In addition, the membrane fouling rate of the reactor with 1.6%SO2−4 concentration was slower than that of the 2.6% system, although the reactor with 1.6%SO2−4 concentration operated at higher membrane flux than the 2.6% system. Further analysis of the sludge properties showed that the MLSS and MLVSS in the system with 1.6%SO2−4 concentration were stable at about 7.1 g·L−1 and 5.9 g·L−1, and the MLVS/MLSS was 83% with higher than that of the initial sludge. The MLSS and MLVSS in the system with 2.6%SO2−4 concentration were stable at 6 g·L−1 and 4.5 g·L−1, and the MLSS/MLVSS was only 75% with lower than that of the initial sludge. Lower MLSS and MLVSS/MLSS accelerated the formation of cake layer on the membrane surface, resulting in a serious membrane fouling of 2.6%SO2−4 system. After long-term acclimation in high-salt environment, SMP and BEPS of mature sludge for 1.6%SO2−4 and 2.6%SO2−4 systems increased. SMP increased from 13.5 mg·g−1VSS to 20.4 mg·g−1VSS and 65.3 mg·g−1VSS, and BEPS increased from 36.9 mg·g−1VSS to 181.8 mg·g−1VSS and 227.3 mg·g−1VSS respectively for 1.6%SO2−4 and 2.6%SO2−4 systems. The SMP and BEPS in 2.6%SO2−4 system were both higher than that of 1.6% SO42- system, thus the TMP of 2.6%SO2−4 system increases rapidly and the fouling aggravated. Compared with inoculated sludge, the particle size of MBR in 1.6% system increased from 82.3 μm to 125.84 μm respectively, while that of 2.6%SO2−4 system decreased from 82.3 μm to 78.23 μm. Compared with 1.6%SO2−4 system, the smaller particle size in 2.6%SO2−4 system was easier to accumulate on the membrane surface, which made the cake layer more compact and accelerated the membrane fouling. The membrane resistances of both the two MBRs mainly composed of the external resistance. However, the internal resistance of 2.6%SO2−4 system was higher than that of 1.6%SO2−4 system. In short, different salinity had significant influence on the operation efficiency, sludge properties and membrane fouling of MBR system. Therefore this study can provide theoretical basis and practical guidance for the application of MBR in the treatment of high-salt and high-concentration organic wastewater. -

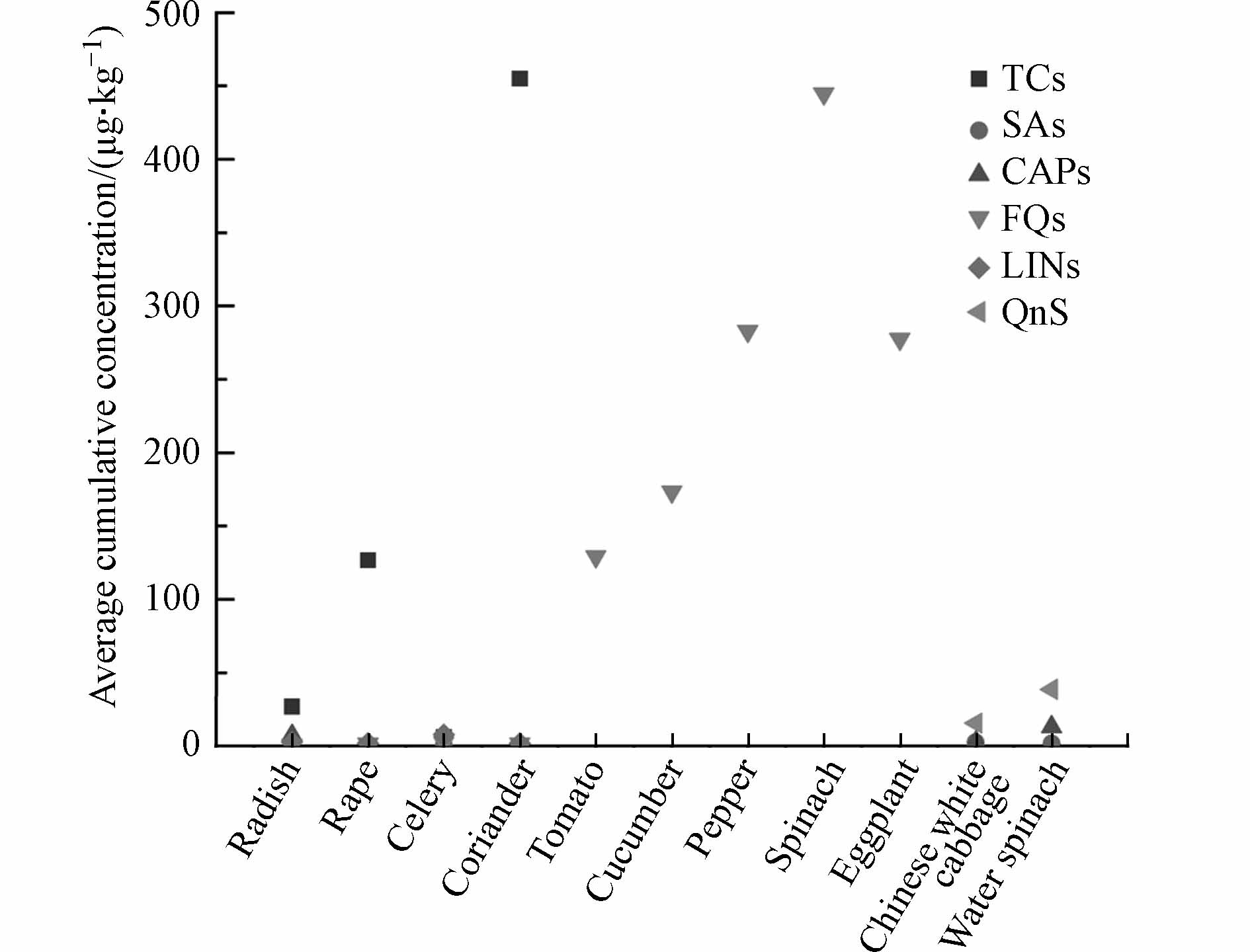

抗生素是一类由微生物(包括细菌、真菌、放线菌属)分泌或化学合成等途径产生的复杂分子,可以抑制微生物活性,提高人和动物的抵抗力,因而在医疗和养殖行业被广泛应用[1]. 滥用现象导致的抗生素耐药性问题,已经使其成为备受关注的一类新型污染物. 抗生素在环境中极为隐蔽、检出难度大、扩散性强且极易被生物积累,对生态系统稳定性和人体健康造成潜在威胁[2].

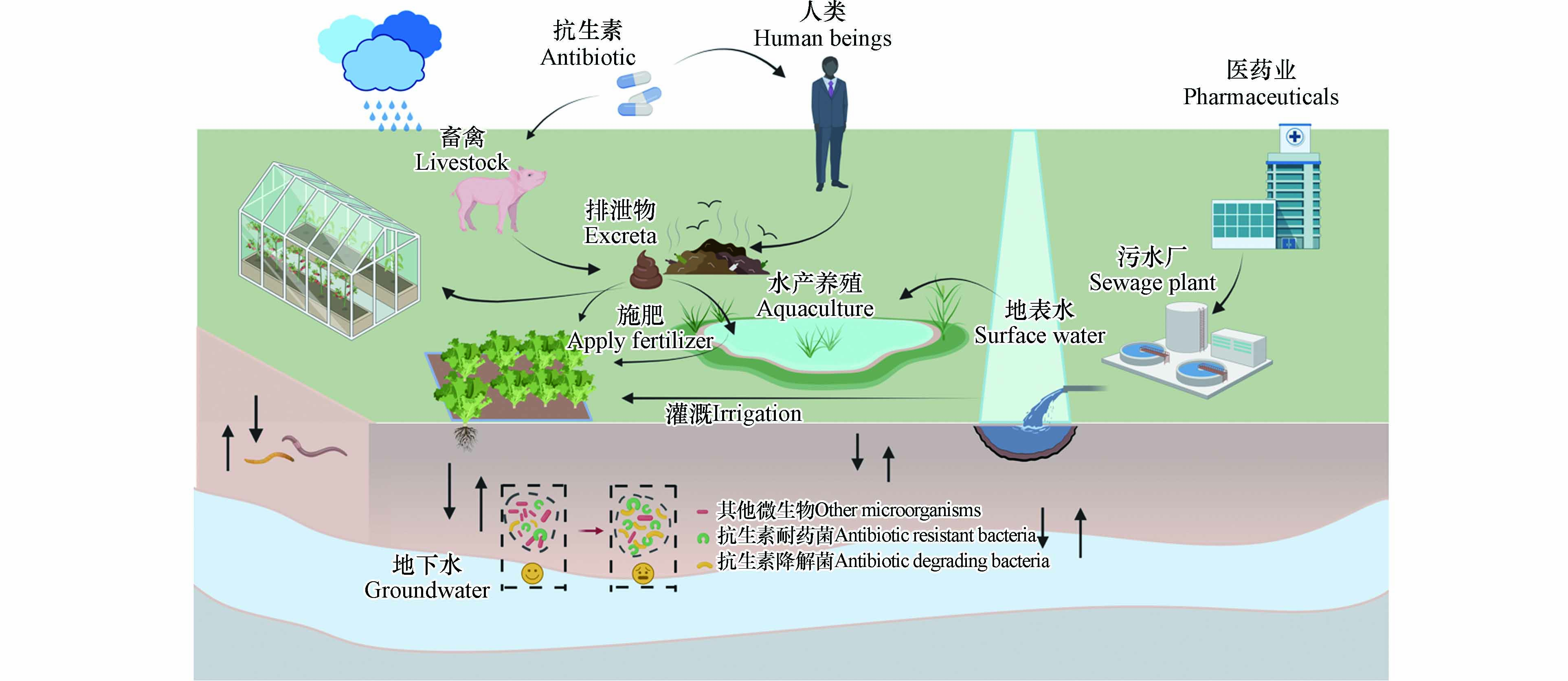

与人类医疗行业使用的抗生素类型不同,四环素类、磺胺类和喹诺酮类药物在畜禽养殖中被广泛使用[3]. 多数兽用抗生素在畜禽体内生物利用率较低,未完全代谢的抗生素极易随动物排泄物进入环境[4]. 因此,畜禽粪便被认为是环境抗生素的主要污染源之一. 进入土壤中的抗生素,一部分在生物因素(如土壤微生物)和非生物因素(如土壤组分)的作用下发生吸附或降解反应,另一部分则会持续对土壤微生物施加选择压力,改变土壤微生物的活性和群落组成,甚至会促进环境中耐药菌的传播和抗生素抗性基因的污染. 此外,抗生素不仅会通过多种途径迁移到动植物体内,还会伴随地表径流以及淋溶作用迁移到地表水和地下水中,扩大污染范围(图1)[5 − 6]. 因此,土壤环境中抗生素的污染现状及其生态风险逐渐成为研究热点.

近年来,作为化肥的替代品,以畜禽粪便为重要来源的有机肥成为了农业生产必不可少的营养来源. 与其他类型的农用地相比,菜地往往因作物生长周期短且经济效益高而轮作频繁,对有机肥的消耗量也远高于其他类型作物[7],因此菜地较粮食作物地更可能受到畜禽粪便污染,也更易出现抗生素残留. 调查显示,相对于常规菜地,施用有机肥的菜地土壤中抗生素残留量更高,部分地区抗生素残留量达到mg·kg−1级别[6, 8]. 尽管学者对抗生素污染的来源、现状和归趋已经有了深入研究成果,但是各类抗生素在菜地系统中的污染现状调查仍然存在技术壁垒等客观限制. 抗生素在环境中具有一定的内在生物活性,能够对生物和人类健康产生毒性作用. 目前关于抗生素的潜在生态危害的相关研究较少,其产生生态毒性效应机制尚不明确. 文章综述了菜地系统中抗生素的污染情况、影响因素和可能造成的生态效应,重点分析了抗生素对土壤生物的毒性作用机制,以期为减轻环境抗生素污染提供理论支撑和实践指导.

1. 菜地土壤抗生素污染特征及其影响因素(Characteristics and influencing factors of antibiotic contamination in vegetable soil)

1.1 土壤中抗生素的空间分布特征

我国菜地土壤受到不同程度抗生素污染,具体污染状况与区域位置密切相关,总体呈现“北高南低,东高西低”的特征(表1). 截至2021年底,我国菜地土壤抗生素的残留量范围在4.59—2101.4 μg·kg−1之间,平均残留量为186.98 μg·kg−1. 其中,西北和华中部分区域的抗生素污染相对严重,平均含量分别高达243.20 μg·kg−1和724.13 μg·kg−1,而东部沿海典型污染带主要分布在黄淮海和长江三角洲地区,该地区抗生素平均总含量达166.32 μg·kg−1. 我国菜地土壤抗生素含量的空间差异可能与当地抗生素的使用情况有关. Zhang等[9]对我国抗生素使用情况调研显示,华东(38800 t)>华北(27900 t)>华中(21100 t)>西南(18300 t)>华南(9030 t)>东北(6070 t)>西北(2360 t). 然而,西北地区抗生素的使用量和土壤抗生素残留量呈现负相关关系,这极可能与区域农户的施肥习惯有关[10]. 此外,研究区域中四环素类抗生素的检出量最高,其次是喹诺酮类和磺胺类抗生素(表1). 可能原因如下:(1)四环素类在畜禽养殖中使用量最大[11]且具有高Koc值[12];(2)喹诺酮类抗生素在土壤中的吸附能力较低,即使畜禽养殖对其消耗量较大,其在土壤中的残留水平仍低于四环素类抗生素[13];(3)磺胺类抗生素较低的pKa值会导致去质子化物种的比例增加进而降低对土壤的吸附[12]. 然而,由于缺少合适的测定方法,复杂基质中的低浓度水平抗生素难以被检出,因此难以全面评估土壤抗生素污染情况. 此外,我国对菜地土壤抗生素污染的研究多集中在人口稠密、经济发达地区,如京津冀、长三角和珠三角地区,对西北地区的关注有限,有关部门理应给予警惕.

表 1 我国菜地表层土壤抗生素检出浓度Table 1. Antibiotic concentrations in the surface soil of vegetable fields in China地理区域Geographic area 省份Provinces 调查地点Investigation sites 抗生素含量/(μg·kg−1)Antibiotic content 参考文献References ∑TCs ∑SAs ∑QNs SUM 华南地区South China 广东省Guangdong Province 珠三角The Pearl River Delta Area 242.6 321.4 1537.4 2101.4 [3] 84.8 9 — 93.8 [32] 佛山市Foshan 4.24 — 17.83 22.07 中山市Zhongshan 14 — — 14 东莞市Dongguan 15.4 0.96 50.23 66.59 广州市Guangzhou 27.48 1.53 55.81 84.82 [33] 37.1 96.2 — 133.3 [34] — — 48.85 48.85 [35] 西南地区Southwest China 云南省Yunnan Province 昆明市Kunming 19.9 0.2 15.2 35.3 [23] 重庆市Chongqing 重庆Chongqing 79.81 — — 79.81 [19] 9.36 2.564 29.83 41.754 [27] 贵州省Guizhou Province 贵阳市Guiyang 5.07 0.62 5.28 10.97 [36] 1.52 0.62 5.28 7.42 [15] 三峡库区the Three Gorges Reservoir 53.3 99.2 75.9 228.4 [37] 华东地区East China 安徽省Anhui Province 安庆市Anqing 31.9 — — 31.9 [38] 合肥市Hefei — 4.59 — 4.59 [39] 上海市Shanghai 上海Shanghai 17.1 7.6 62.5 87.2 [23] 江苏省Jiangsu Province 徐州市Xuzhou 460.8 6.6 54.1 521.5 南京市Nanjing 64.5 10.2 38.5 113.2 黄淮海平原Huang-Huai-Hai Plain 24.01 0.03 16.32 40.36 [40] 浙江省Zhejiang Province 宁波市Ningbo 41.43 0.07 8.97 50.47 [41] 长三角Yangtze River Delta 27.03 3.25 42.67 72.95 [42] 山东省Shandong Province 135.664 32.866 — 168.53 [43] 274 3.91 73.05 350.96 [44] 华中地区Central China 河南省Henan Province 723.42 0.61 0.1 724.13 [45] 华北地区North China 北京Beijing 北京Beijing 103.58 13.41 7.35 124.34 [46] 102 1.1 86 189.1 [47] 河北省Hebei Province 石家庄市Shijiazhuang — — 170.775 170.775 [48] 西北地区Northwest China 宁夏省Ningxia Province 银川市Yinchuan 462.24 — — 462.24 [10] 陕西省Shaanxi Province 杨凌市Yangling 12.77 1.14 51.76 65.67 [49] 甘肃省Gansu Province — 201.676 — 201.676 [50] 东北地区Northeast China 黑龙江省Heilongjiang Province 哈尔滨市Harbin 181.74 — — 181.74 [51] 河北、河南、四川和江苏省Hebei, Henan, Sichuan and Jiangsu Province 82.75 2.61 12.78 98.14 [52] — ,未检测;TCs,四环素类;SAs,磺胺类;QNs,喹诺酮类. — , non-detection; TCs, tetracyclines; SAs, sulfonamides; QNs, quinolones. 1.2 土壤中抗生素污染特征的影响因素

如上所述,我国菜地土壤普遍存在抗生素污染且污染水平在地理空间上差异较大. 土壤作为抗生素富集的一种典型环境载体,其中的抗生素残留量还与很多因素有关,主要包括以下4种.

1.2.1 输入水平

农业生产中灌溉和施肥是大部分土壤中抗生素的主要来源. 污水和粪肥中抗生素含量与土壤抗生素总含量表现显著正相关关系. 厉文辉等[14]对凉水河两岸污灌区和井水灌溉区农田土壤样品进行采集检测,发现污灌区土壤抗生素残留量高于井水灌溉区,这意味着抗生素会从灌溉水转移到农田土壤中. 考虑到不同来源灌溉水污染水平的差异,Pan等[12]比较了用鱼塘水和生活污水灌溉后土壤中抗生素污染情况,发现鱼塘水灌溉的土壤中抗生素污染水平较高,这警示相关部门需要加强对水产养殖业的药品管控. 此外,距灌溉水源越近,土壤中抗生素检出率和残留量越高,反之越低[15]. 在Zhao等[16]的研究中,施用鸡、猪、牛等3类粪肥后土壤抗生素残留水平高低与这3类粪肥中抗生素含量高低一致,说明粪肥施用可显著增加土壤抗生素含量,且土壤抗生素残留水平与输入抗生素量息息相关. 重复性施肥可增加抗生素在土壤中的累积,不过也有学者研究发现,在施用粪肥的前期,土壤中抗生素的浓度会有所降低. 例如徐秋桐等[17]发现,在粪肥施加前期(第8天)施用1%有机肥处理组比未添加有机肥处理组4种抗生素降解率分别高出了12.5%、13.5%、24.8%和12.0%,这与Zhang等[18]的研究结论基本一致. 原因可能是有机肥提高了土壤中某些微生物的活性,从而加速了抗生素的生物降解.

1.2.2 种植条件

种植条件对菜地土壤中抗生素残留水平也存在一定影响. 一般来说,温室菜地中抗生素浓度要高于露天菜地,可能是在温室种植模式下,蔬菜的轮作更加频繁,粪肥的施用频率和总量更高,导致土壤中更多抗生素残留. 但彭秋等[19]和罗凯等[20]的调查发现,大棚菜地土壤抗生素浓度也可能会低于露天菜地. 这可能是该露天菜地靠近污染源,接触了由大气颗粒物携带的抗生素类污染物[21],也可能是露天菜地常以附近地表水作为灌溉水源,而灌溉水源受到了抗生素污染[20]. 其次,相较于露天环境,大棚的高温高湿条件有利于土壤微生物对抗生素的降解[22]. 种植年限与土壤抗生素残留水平存在密切关系. 在Zhang等[23]研究中,四环素类和氟喹诺酮类残留量随种植年限呈(中期)6年至10年<(长期)10年以上<(短期)5年以下的变化趋势,但土壤抗生素残留量的增长率却随种植年限延长而降低,这是由于进入土壤后抗生素的消散速率最初被抑制而后恢复,导致高含量的四环素类和喹诺酮类抗生素出现在短期种植的土壤中. 该现象提醒了今后研究还需关注抗生素代谢产物在土壤中的污染机制. 值得注意的是,磺胺类抗生素呈现出相反的情况. 在长期种植年限的土壤中往往能检测出更高含量的磺胺类[23],Fang等[24]研究也得到类似的结论. 从抗生素本身性质来说,一方面磺胺类抗生素的水溶性较四环素类和氟喹诺酮类更高,因而不易被土壤颗粒吸附. 另一方面,磺胺类抗生素对土壤有机质表现出高亲和力,这减缓了它在土壤中的迁移. 上述结论进一步证实了抗生素在土壤中的动态持久性.

1.2.3 土壤条件

理化性质和颗粒组成等土壤条件制约了抗生素在土壤中的移动. 土壤pH通过改变抗生素的电荷状态间接干扰抗生素的吸附. 多数抗生素(如四环素类和喹诺酮类等)的吸附能力随pH上升呈下降趋势,而磺胺类的吸附能力与pH有强烈的正相关性[25 − 26]. 抗生素进入土壤就会与土壤固相紧密结合,不难推断土壤抗生素含量与土壤有机质呈显著正相关关系[27]. 而有机质多分布在土壤黏粒上,意味着土壤黏粒比重越高土壤抗生素含量越高. 但也出现了不一样的研究结论,即在粘土比例较低的土壤中四环素类抗生素含量反而最高[28],这可能是在多因素的作用下土壤有机质含量下降了[29 − 30]. 因此可以认为土壤性质与抗生素的环境行为密切相关.

1.2.4 其他

关于气候条件对土壤中抗生素分布特征的研究较少. Hu等[6]报道,与夏季相比,冬季菜地土壤抗生素的残留更多,不难推测在一定条件下南方土壤抗生素残留水平要低于北方. 究其原因,适宜的水热条件极大帮助了土壤微生物对抗生素的降解[31],而低温低湿环境不利于抗生素在土壤中的降解和迁移. 此外,蔬菜种类的差异也是影响土壤抗生素含量的重要因素,比如磺胺类抗生素在土壤中表现为根茎类蔬菜土壤(289 μg·kg−1)>瓜果类蔬菜土壤(143 μg·kg−1)>叶菜类蔬菜土壤(98.1 μg·kg−1)[22];四环素类抗生素表现为叶菜类蔬菜土壤(77.4 μg·kg−1)>瓜果类蔬菜土壤(67.8 μg·kg−1)>茄果类蔬菜土壤(54.1 μg·kg−1)>豆类蔬菜土壤(47.7 μg·kg−1)[19],喹诺酮类抗生素总含量表现为果类蔬菜(44.8 μg·kg−1)>根茎类蔬菜(37.0 μg·kg−1)>叶菜类蔬菜(32.1 μg·kg−1)[8].

综上所述,菜地抗生素赋存差异性是多因素共同作用的结果. 其中,输入水平直接决定了土壤中抗生素的污染水平,而抗生素性质、种植条件、土壤条件和气候条件等在一定程度上影响着抗生素在土壤中含量的变化. 如吸附能力强的抗生素更易在土壤中累积,重复的施肥可以增加土壤中抗生素含量,而高温高湿环境有利于抗生素的降解.

2. 蔬菜中抗生素的累积迁移特征(Accumulation and migration characteristics of antibiotics in vegetables)

暴露在受抗生素污染的土壤中时,蔬菜可能会吸收抗生素并在体内不断累积. 某些抗生素甚至能够在较低浓度下被蔬菜吸收并累积,出现蔬菜体内抗生素浓度高于土壤中的现象. 如Hu等[6]发现林可霉素在土壤中的检出量低于在蔬菜中的检出量,Migliore等[53]发现,恩诺沙星在4种果蔬中的含量远高于培养基中的水平. 以上事实均表明,蔬菜对抗生素具有极强的生物累积性,而且实际环境下蔬菜对抗生素的累积系数远低于实验室模拟值,因此可以推断在更严重的污染条件下,该累积系数会增大.

蔬菜对抗生素的吸收按照吸收方式分为主动吸收和被动吸收. 主动吸收主要受蒸腾作用影响,需要消耗能量,而被动运输不需要其他辅助. 有研究比较了田间试验和盆栽试验发现,前者四环素类抗生素含量显著高于后者[54]. 这是由于田间开放条件下的蔬菜蒸腾作用更高,更有利于蔬菜对抗生素的主动吸收. 有研究发现磺胺多辛、土霉素和林可霉素在蔬菜中含量均很高,意味着这些抗生素的理化性质(如水溶性和半衰期)几乎不影响蔬菜对其的吸收,说明了蔬菜对这些抗生素的吸收是被动吸收[6]. 目前认为,蔬菜对有机污染物的吸收以被动吸收为主,并伴有一定程度的主动吸收.

蔬菜对抗生素的吸收和累积受多种因素影响,主要包括蔬菜种类、抗生素性质以及其他环境因子. 不同种类蔬菜中抗生素的残留水平差异很大,一般为叶菜类>果蔬类>块茎类[55],但是Li等[56]调查了蔬菜可食用部分氟喹诺酮的累积情况,发现茄果类>叶菜类. 这可能是不同类型蔬菜对抗生素的吸收能力不同,当然也不能忽略其他影响因素的作用,如土壤性质可以通过控制抗生素的生物可利用度来影响蔬菜对抗生素的吸收[56 − 58]. 抗生素性质似乎是影响抗生素吸收过程的主要因素. 一般认为,强土壤吸附性、高疏水性的四环素类抗生素的生物可利用度较低,而较弱土壤吸附性、较高水溶性的磺胺类和喹诺酮类抗生素生物可利用度较高[59]. 因此可以推测,磺胺类和喹诺酮类更容易被蔬菜吸收并累积. 然而,在某些实际环境中,蔬菜对这3类抗生素的吸收情况不符合上述结论. 如图2所示,前4种蔬菜中四环素类含量显著高于磺胺类和喹诺酮类,这与土壤中不同种类抗生素含量的变化一致[6],说明土壤中抗生素污染水平也是一个重要的影响因素. 此外,抗生素降解、土壤结合和浸出也限制了蔬菜吸收抗生素[2].

表2中抗生素在叶中含量要大于茎和根,但是Migliore等[60]发现,根中抗生素含量高于叶. 这是由于抗生素在蔬菜体内的转运受蒸腾作用驱动,而蒸腾水量的差异最终会影响抗生素在根和叶中含量的差异[61]. 此外,抗生素种类也是影响其在蔬菜组织中分布水平差异的重要因素. 抗生素从植物根部向地上部分的转运能力常用易位因子测定. 大多数四环素类抗生素、喹诺酮类抗生素和林可霉素易位因子>1,但磺胺类抗生素和大环内酯类抗生素易位因子<1[62]. 这就造成了前者在植物体内均能被检出,而后者很难在植物地上部分被检出. 值得注意的是,大环内酯类药物尺寸较大,多数情况下很难在植物中被检测到[63]. 抗生素在蔬菜内的分布随不同生长阶段变化. 如采集收获前15 d蔬菜样品,发现抗生素在叶菜类根部含量高于叶片,而对成熟期采集的蔬菜样品检测得到相反的结论[6].

蔬菜Types of vegetables 抗生素Types of antibiotics 抗生素含量/(μg·kg−1)Antibiotic content 根Root 茎Stem 叶Leaves 萝卜Radish TCs 8.3 22.1 24.4—76.4 SAs 0.1—0.4 0.2—0.5 0.2—0.6 CAPs ND. 1.4—3.4 8—30 QNs ND. 0.5 0.8—1.6 LINs 0.9—3.1 1.5—3.9 1.4—5.4 油菜Rape TCs ND. — 61.1—192.1 SAs 0.1—0.5 — 0.5—1.4 CAPs ND. — 0.7 FQs ND. — 0.7—2.1 LINs 0.5—3.5 — 0.7—3.2 芹菜Celery TCs — 1.0—2.4 15.7 SAs — 0.1—0.3 0.3—0.7 FQs — 0.5—1.9 2.8—4.7 LINs — 1.2—5.1 5—20 香菜Coriander TCs 128.2—690.1 — 133.9—867.6 SAs 0.1—0.5 — 0.5—1.3 FQs ND. — 0.7—3.5 LINs 0.4—2.4 — 0.8—3.8 小白菜Chinese white cabbage TCs ND. — 5.5 QNs 5.9 — 9.6 CAPs ND. — 2.6 SAs 0.8 — ND. 空心菜Water spinach TCs 4.8 — 6.3 QNs 16.9 — 21.8 CAPs 3 — 10.1 SAs 1.7 — ND. —,未检测;ND.,未检测出;TCs,四环素类;SAs,磺胺类;CAPs,氯霉素类;QNs,喹诺酮类;LINs,林可酰胺类;FQs,氟喹诺酮类. —, non-detection; ND., not detected; TCs, tetracyclines; SAs, sulfonamides; CAPs, chloramphenicols; QNs, quinolones; Lins, lincolamide; FQs, fluoroquinolones. 抗生素的理化性质以及蔬菜种类、生长阶段和蒸腾速率是导致其在蔬菜中含量不同的影响因素. 目前已有学者开展了一些蔬菜可食用部分的人体暴露影响的研究,但是仍然缺乏蔬菜摄食途径下抗生素的人体健康风险的全面评估. 因此,需要进一步研究来评估这些抗生素在食物链中的积累,以确定人类使用的安全浓度.

3. 菜地系统中抗生素的生态毒性效应(Ecotoxicity of antibiotics in vegetable field system)

抗生素具有易被生物积累的特性. 大量研究证实,长期的农业生产不仅会促使抗生素在植物间迁移[57, 64 − 65],还会诱导微生物产生抗生素抗性,严重破坏了土壤微生态系统的稳定性[66 − 67],同时,长期暴露在抗生素污染环境中的动物也会表现出诸多不良反应.

3.1 抗生素诱发植物毒性

抗生素对植物生长的影响具有两面性,一方面,抗生素可以帮助植物抵抗病害、提高植物体内Ca、Mg、K、N等营养元素的含量[68 − 69],另一方面,某些条件下,抗生素的存在反而会诱发植物毒性,并持续作用于植物生长发育的不同阶段. 抗生素对蔬菜生长的影响表现为低浓度促进高浓度抑制[68]. 金彩霞等[70]研究发现,低浓度磺胺嘧啶钠(1 mg·kg−1)对大白菜的芽伸长有一定促进作用. 在0、50、100、5000 μg·kg−1恩诺沙星处理的土壤中,黄瓜、菜豆、萝卜和莴苣生长发生变化,低浓度(0—50 μg·kg−1)条件下,根长、下胚轴长、子叶和叶片长度及数量均受到刺激作用,随着恩诺沙星浓度提高,抑制作用逐渐明显[53]. 在种子萌发时期,抗生素的毒性作用影响不大[71],这可能是抗生素难以穿过种皮,因而对胚根生长的抑制作用不大[72]. 从这点来看,为缓解抗生素对种子的毒性作用,未来可以利用现代生物技术培育适宜质地的种皮,以达到减少抗生素渗透的目的[73]. 抗生素对植物的潜在毒性作用常通过干扰蚯蚓和微生物介导的土壤速效养分间接抑制植物生产力[74]. 在抗生素的直接或间接作用下,农业系统可持续性将受到严重威胁.

与其他污染物类似的是,抗生素干预了蔬菜光合作用等许多重要的生理过程. 如四环素类、氟喹诺酮类和大环内酯类等抗生素会影响蔬菜的叶绿体和线粒体蛋白质合成[75 − 76],环丙沙星和头孢菌素会降低气孔导度[77]. 这意味着与光合作用有关的叶绿素和类胡萝卜素的减少和叶片气孔导度的降低,会导致蔬菜光合作用速率降低,从而影响蔬菜的生长[78]. 从根本来看,抗生素的毒性作用机理是破坏遗传物质或限制酶作用途径. 喹诺酮类抗生素能够抑制核酸合成或代谢过程,主要通过改变DNA拓扑异构酶Ⅱ活性、抑制酶的切割和链接,进而对真核DNA复制造成不同程度的影响并抑制了叶绿素的转录,最终影响植物生长[53, 75]. 磺胺类抗生素作用机制是改变能量代谢过程,其具有类似氨基苯甲酸结构,能竞争性作用于叶酸合成途径中的相关酶,阻止叶酸合成,最终干扰根系伸长、木质素和光呼吸作用[79 − 80]. 四环素类和大环内酯类抗生素对植物生长的抑制作用表现在能够显著抑制蛋白质生物合成或诱导染色体变异,而β-内酰胺会影响低等植物的质体分裂[75]. 目前很多有关植物毒性的研究都在实验室环境中进行,其设计的抗生素浓度并不一定会在土壤中出现,因此在实际土壤环境中这些抗生素是否仍会表现出毒性作用有待商榷. 如红扁豆在含较低浓度抗生素营养液中根伸长减缓、植物干重降低,而在相应浓度土壤基质的红扁豆则没有出现植物毒性效应[69].

3.2 抗生素对土壤动物新陈代谢和身体机能的影响

抗生素对土壤动物的毒性作用的相关研究并不多,且各方观点不一. Baguer等[81]发现蚯蚓、线虫和弹尾虫在3000—5000 mg·kg−1土霉素和泰乐菌素胁迫下,其生长并未受到严重影响,说明这两种抗生素不太可能对土壤动物构成直接风险. 然而,一些研究认为,抗生素对动物的毒性具有明显的剂量-效应关系. 如在1.0—2.0 mg·kg−1浓度抗生素胁迫下,蚯蚓的生长和呼吸作用受抑制、繁殖率下降、回避反应增强,且随浓度提高,蚯蚓的反应越明显[82]. 除了蚯蚓,抗生素也在破坏着跳虫和白符䖴的健康机能[83 − 84]. 暴露于10 mg·kg−1诺氟沙星和土霉素中,跳虫出现明显的体重下降[83]. 与对照组相比,当白符䖴暴露在浓度为1000 mg·kg−1的诺氟沙星环境下,其繁殖数和成虫体长分别减少34.4%和9%[84].

抗生素对土壤动物的毒性作用首先表现在对DNA的破坏性. 抗生素代谢产物的自由基和碱基位点等会直接导致土壤动物细胞DNA断裂,造成细胞DNA损伤[85]. DNA损伤程度与抗生素剂量呈显著正相关关系,即使是最低暴露剂量(0.3 mg·kg−1)仍然会造成严重DNA损伤[85]. 其次,抗生素还会引起土壤动物酶活性的变化. 在抗生素的暴露下,动物会出现氧化应激反应,导致其脂质过氧化,最终促进脂质过氧化产物丙二醛的形成并诱导过氧化氢酶、过氧化物酶和超氧化物歧化酶的表达[84]. 如Eisenia foetida蚯蚓在环丙沙星(0—51.2 mg·kg−1)污染土壤中发生了蛋白质羟基化造成的氧化损伤[86]. 为了抵消抗生素产生的负面影响,动物肠道菌群物种组成发生改变,身体机能迅速反应形成一道强硬的防御系统. 动物体内产生的抗氧化酶、抗氧化剂和蛋白水解系统等可以极大缓解细胞的氧化损伤,在一定程度上保护了机体[87]. 此外,动物肠道会将已经发生改变的肠道菌群输送到土壤中,进而引起周边土壤菌群发生改变,形成微生物菌群对抗生素的共代谢模式,最终促成对土壤抗生素的削减. 但是目前关于肠道内生菌对抗生素的降解机制依旧未知.

3.3 抗生素影响土壤微生物群落结构和生态功能

土壤微生物是土壤生态系统的关键组成成分,它们在促进土壤有机物分解、提高土壤肥力和增进作物产量的过程中扮演者重要角色[88]. 而外源输入的抗生素会对土壤生态系统产生一系列的影响[89 − 90],造成土壤微生物群落特征的改变[91],干扰微生物对碳源利用[92],且不利于微生物硝化和反硝化等过程[93].

3.3.1 改变土壤微生物群落特征

多数抗生素为抑菌药物,将其添加到土壤中会显著降低土壤细菌数量、改变群落结构并促使群落演替. Hammesfahr等[94]发现,4 d后暴露在磺胺嘧啶中的细菌/真菌比值从70%减少到57%. 磺胺嘧啶还对土壤氨氧化微生物群落分布和活性有显著影响[95 − 96]. 在磺胺嘧啶处理的土壤中,氨氧化细菌丰度会显著下降,而氨氧化古细菌基本稳定[97],Radl等[98]也得到类似的结论. 但另一项研究得到了不同的结论,在施加粪肥土壤中,具有生物有效性的磺胺嘧啶对全程硝化菌活性的抑制作用最强,其次是氨氧化古细菌,对氨氧化细菌的影响可以忽略不记[99]. 部分抗生素还会对革兰氏阳性菌和革兰氏阴性菌起到选择作用. 如当添加高浓度四环素8 d后,革兰氏阳性菌和革兰氏阴性菌的比例会下降,这可能是环境中耐四环素细菌多为革兰氏阴性菌,而磺胺类抗生素则不受此影响[94,100]. 在添加抗生素的处理中,相较于有益菌群,潜在致病菌群的丰度更高[101],即使是将生物质堆肥处理后仍可能增加土壤中病原菌丰度[102]. 但抗生素对真菌的影响仍然不清楚.

3.3.2 影响碳源利用效率和酶活性

进一步研究表明,抗生素会限制微生物对碳源的正常利用,进而干扰其生长繁殖过程. 有研究检测了施加100 mg·kg−1磺胺甲恶唑水稻土经21 d培育后水稻土中微生物对碳源的利用情况,结果显示,微生物对碳源的利用受到抑制且其Shannon指数降低[103]. 但抗生素也可以作为微生物可利用的碳源,改变其呼吸强度. 有研究显示,最初添加磺胺嘧啶和金霉素处理组的土壤呼吸活性均受到抑制,随抗生素添加频率的增加,土壤呼吸活性逐渐提高[24]. 抗生素对土壤微生物的呼吸作用的影响较复杂,如低浓度的抗生素有促进作用,环境浓度抗生素却无显著作用[104 − 105]. 这些影响一般比较短暂,可能是由于抗生素生物可利用性会随时间推移而降低,最终导致了抗生素对微生物呼吸作用受限[106]. 同样,抗生素的种类和暴露时间也影响了呼吸作用[107]. 在抗生素的胁迫下,土壤微生物的活性出现明显的差异,其活性可能增强也可能受抑制[108 − 109]. 如较低浓度四环素对土壤脱氢酶和磷酸酶活性有明显的抑制效果[110],而微生物在较高浓度土霉素中表现出较低的生物活性[111]. 一个可能的原因是,土壤中的酶一般是由真菌分泌产生,而某些抗生素能够促进真菌繁殖造成土壤酶活性的增加[101]. 反之,酶活性受抑制可能是土壤微生物不能够抵抗抗生素的选择压力,出现了生长停缓或死亡等情况.

3.3.3 干扰硝化反硝化过程

此外,抗生素对微生物的影响还表现在干扰土壤的硝化、反硝化和产甲烷化等过程,最终阻碍了土壤养分循环. 抗生素能够刺激土壤微观世界中氮循环,主要体现在对土壤微生物的硝化和反硝化作用所造成的影响[112]. Ma等[113]观察到高浓度的土霉素(30 mg·kg−1)和磺胺嘧啶(100 mg·kg−1)抑制了土壤微生物的硝化作用. 然而,部分研究发现仅最低浓度的环丙沙星和诺氟沙星(1 mg·kg−1)会刺激土壤微生物的硝化作用[114 − 115]. 低浓度的磺胺甲恶唑、磺胺嘧啶、庆大霉素、甲基盐霉素(500 μg·kg−1)还会抑制反硝化过程,但是更低浓度(<1 μg·kg−1)会促进该过程[116]. 抗生素还被证实可以干扰土壤中铁的转化率和产甲烷化过程. 如超过10 mg·kg−1磺胺甲恶唑和土霉素暴露会强烈抑制三价铁的还原[117],而500 μg·kg−1磺胺甲恶唑可以显著刺激土壤微生物产甲烷化过程[118]. 以上事实证明了抗生素在一定程度上不利于地球化学循环.

4. 结果与展望(Results and perspective)

综上所述,我国菜地系统存在不同程度的抗生素污染,且与输入水平、土壤性质、抗生素种类以及气候条件等息息相关. 抗生素从畜牧业向农业的流动过程不仅对土壤生物产生直接毒性作用,还能干扰土壤速效养分造成植物减产,提高致病菌丰度,并对动、植物生长构成严重威胁. 为维护农业的可持续性,相关领域目前已经开展一系列研究,但仍存在一定局限性,未来研究可以关注以下方向:

(1)抗生素在全国尺度上的长期追踪调查目前还未实现,这不利于全面评估我国土壤抗生素污染现状. 因此,未来可以进一步增加对不同区域的调查研究,尤其是人口密度和经济发展水平较低的西北地区,以期为制定相关政策法规提供科学依据.

(2)学者们已认识到抗生素的分子结构是决定抗生素作用机制的关键因素,抗生素的转化和降解速率很大程度上取决于抗生素的结构. 因此,未来研究可以关注如何利用分子手段等高新技术改造相应的官能团,以保障抗生素本身功效的同时安全高效的实现抗生素降解为研究目标.

(3)为全方面控制农田系统中抗生素污染现状,准确定量土壤中抗生素及其降解产物是极为必要的. 对于复杂环境基质中痕量分析,建议尝试更先进的样品前处理方法以及更高性能的数据采集和分析平台. 吸附、转化和降解是土壤中抗生素主要的环境行为,除抗生素自身性质外,这些过程还受到很多环境因素影响. 因此,未来研究可侧重于土壤性质、水热条件等对抗生素的作用机制. 对于参与土壤中抗生素降解的微生物,其降解能力的遗传效率同样值得研究. 掌握调控微生物降解抗生素的关键功能基因技术,尝试将该基因技术运用到培育具备高降解特性的功能性降解菌,这对未来土壤抗生素污染的修复具有重要意义.

(4)目前对于评估抗生素生态风险的方法并不统一,用于毒性试验的物种仍然局限,抗生素对生态环境造成的风险可能被低估了. SSD和风险熵值法是常见的环境风险评估方法,但易受太多不同因素影响而不可靠. 因此,应进一步扩充多营养级多物种的毒性数据,构建更科学的抗生素生态风险评估体系.

-

表 1 1.6%

SO2−4 Table 1. The influent quality of 1.6%

SO2−4 第1 天—第25天 第26天—第60天 第61天—第110天 pH 3.8—4.2 3.8—4.2 3.8—4.2 硫酸根/(mg·L−1) 16000—17800 17200—17900 17200—17900 COD/(mg·L−1) 5400—5600 5400—5600 7500—8100 TDS/(g·L−1) 27—30 27—30 27—30 电导率/(ms·cm−1) 25—30 28—30 28—30 TN/(mg·L−1) 20—25 180—200 320—350 TP/(mg·L−1) 5—10 8—10 8—10 氨氮/(mg·L−1) 15—20 15—20 15—20 Ca/(mg·L−1) 25—35 25—35 25—35 Mg/(mg·L−1) 5—15 5—15 5—15 Fe/(mg·L−1) 0.1—0.6 0.1—0.6 0.1—0.6 表 2 2.6%

SO2−4 Table 2. The influent quality of 2.6%

SO2−4 第1天—第40天 第41天—第50天 第51天—第110天 pH 3.7—3.9 3.5—4.1 3.6—4.2 硫酸根/(mg·L−1) 26800—28000 26800—28000 22600—23000 COD/(mg·L−1) 8000—8900 7000—7800 7500—8000 TDS/(g·L−1) 42—45 45—55 50—54 电导率/(ms·cm−1) 38—40 38—40 38—40 TN/(mg·L−1) 28—30 320—350 320—350 TP/(mg·L−1) 10—15 10—15 15—20 氨氮/(mg·L−1) 15—20 15—20 15—20 Ca/(mg·L−1) 35—45 35—45 35—45 Mg/(mg·L−1) 10—20 10—20 10—20 Fe/(mg·L−1) 0.2—0.8 0.2—0.8 0.2—0.8 表 3 MBR反应器运行策略

Table 3. Operating strategy of MBR reactor

SO2−4 SO2−4 阶段 Stage 天数/d Days 容积负荷/(kg·(m3·d)−1 COD) VLR HRT /d SRT/d 1.6% 提盐驯化阶 1—20 0.5 10 不排泥 负荷提升阶段Ⅰ 21—40 0.6 8.5 44 负荷提升阶段Ⅱ 41—80 0.72 8.5—10.2 44 负荷提升阶段Ⅲ 81—110 1.0 7 44 2.6% 提盐驯化阶段 1—36 0.5 16 不排泥 负荷稳定阶段 37—110 0.5 16—22 44 注:进水 SO2−4 Note: The reactor with influent of 1.6% SO2−4 表 4 反应器运行数据

Table 4. Reactor Operation Data

SO2−4 SO2−4 阶段Stage 天数/dDays 容积负荷/(kg·(m3·d)−1 COD)VLR 出水COD值/(mg·L−1)COD value of effluent COD去除率/%COD removal rate 氨氮去除率/%Ammonia nitrogen removal rate TN去除率/%TN removal rate TP去除率/%TP removal rate 1.6% 提盐驯化阶 1—20 0.5 205—210 96.2 81.3 36.7 35.2 负荷提升阶段Ⅰ 21—40 0.6 135—145 97.4 57.6 88.4 57.5 负荷提升阶段Ⅱ 41—80 0.7 120—145 97.5 90.8 89.7 99.8 负荷提升阶段Ⅲ 81—110 1.0 180—190 97.2 92.5 89.5 100.0 2.6% 提盐驯化阶段 1—36 0.5 400—460 94.7 68.2 35.6 59.6 负荷稳定阶段 37—110 0.5 280—290 96.3 82.6 80.7 100.0 -

[1] 叶芳凝, 石先阳. 盐度对MBR处理高氨氮废水的运行及微生物群落影响研究 [J]. 膜科学与技术, 2018, 38(5): 77-83. YE F N, SHI X Y. Effect of salinity on operation and microbial community of MBR for treatment of high ammonia nitrogen wastewater [J]. Membrane Science and Technology, 2018, 38(5): 77-83(in Chinese).

[2] 张万友, 张茜新, 张海丰, 等. 膜生物反应器工艺及其在高盐废水处理中的应用 [J]. 硅酸盐通报, 2014, 33(6): 1439-1442. ZHANG W Y, ZHANG X X, ZHANG H F, et al. MBR process and its application to high salinity wastewater [J]. Bulletin of the Chinese Ceramic Society, 2014, 33(6): 1439-1442(in Chinese).

[3] 于得旭. 膜分离技术在水处理工作中的运用分析 [J]. 冶金管理, 2020(11): 83-84. YU D X. Application of membrane separation technology in water treatment [J]. China Steel Focus, 2020(11): 83-84(in Chinese).

[4] 许宝华, 朱桂生, 黄诚. 膜生物反应器处理轻工废水研究进展 [J]. 安徽化工, 2016, 42(6): 12-17. doi: 10.3969/j.issn.1008-553X.2016.06.004 XU B H, ZHU G S, HUANG C. Application of membrane bioreactor in light industrial wastewater treatment [J]. Anhui Chemical Industry, 2016, 42(6): 12-17(in Chinese). doi: 10.3969/j.issn.1008-553X.2016.06.004

[5] 吴金玲, 黄霞. 膜-生物反应器混合液性质对膜污染影响的研究进展 [J]. 环境污染治理技术与设备, 2006(2): 16-24. WU J L, HUANG X. Research progress on effect of mixed liquor characteristics on membrane fouling in membrane reactors [J]. Techniques and Equipment for Environmental Pollution Control, 2006(2): 16-24(in Chinese).

[6] 袁野, 罗玲, 陆柳鲜, 等. MBR膜污染缓解与处理技术 [J]. 应用化工, 2021, 50(10): 2834-2839,2846. doi: 10.3969/j.issn.1671-3206.2021.10.044 YUAN Y, LUO L, LU L X, et al. MBR membrane pollution mitigation and treatment technology [J]. Applied Chemical Industry, 2021, 50(10): 2834-2839,2846(in Chinese). doi: 10.3969/j.issn.1671-3206.2021.10.044

[7] 李津. 膜生物反应器(MBR)处理高盐废水的试验研究[D]. 青岛: 青岛大学, 2008. LI J. Experimental study on treatment of high salinity wastewater by membrane bioreactor (MBR)[D]. Qingdao: Qingdao University, 2008 (in Chinese).

[8] 李彬, 王志伟, 安莹, 等. 膜-生物反应器处理高盐废水膜面污染物特性研究 [J]. 环境科学, 2014, 35(2): 643-650. LI B, WANG Z W, AN Y, et al. Membrane surface fouling properties in MBRs for high-salinity wastewater treatment [J]. Environmental Science, 2014, 35(2): 643-650(in Chinese).

[9] 陈启伟. 浸没式正渗透膜生物反应器通量提高策略研究[D]. 合肥: 合肥工业大学, 2019. CHEN Q W. Study on flux enhancement strategy of submerged osmotic membrane bioreactor[D]. Hefei: Hefei University of Technology, 2019 (in Chinese).

[10] HE Z W, KASEMSET S, KIRSCHNER A Y, et al. The effects of salt concentration and foulant surface charge on hydrocarbon fouling of a poly(vinylidene fluoride) microfiltration membrane [J]. Water Research, 2017, 117: 230-241. doi: 10.1016/j.watres.2017.03.051 [11] 国家环保局本书编委会. 水和废水监测分析方法 [M]. 水和废水监测分析方法, 1989. Editorial Board of the State Environmental Protection Agency. Monitoring and Analysis Methods of Water and Wastewater [M]. Monitoring and Analysis Methods of Water and Wastewater, 1989(in Chinese).

[12] 陈康. 钙离子调配下污泥性质及膜污染行为的识别研究[D]. 无锡: 江南大学, 2012. CHEN K. Identification of sludge properties and membrane fouling in membrane bioreactors with the addition of calcium ion[D]. Wuxi: Jiangnan University, 2012 (in Chinese).

[13] 亓金鹏. AnMBR+AO-MBR组合工艺处理高盐榨菜废水的运行效能及膜污染研究[D]. 无锡: 江南大学, 2021. QI J P. Operation performance and membrane fouling of AnMBR+AO-MBR process for treating high-salt mustard wastewater[D]. Wuxi: Jiangnan University, 2021 (in Chinese).

[14] LEE H S, KIM C G, YOON T I. Comment on Comparison of the filtration characteristics between attached and suspended microorganisms in submerged membrane bioreactor [J]. Water Research, 2002, 36(19): 4938-4939. doi: 10.1016/S0043-1354(02)00039-8 [15] TAN X, ACQUAH I, LIU H Z, et al. A critical review on saline wastewater treatment by membrane bioreactor (MBR) from a microbial perspective [J]. Chemosphere, 2019, 220: 1150-1162. doi: 10.1016/j.chemosphere.2019.01.027 [16] CAO T N D, BUI X T, LE L T, et al. An overview of deploying membrane bioreactors in saline wastewater treatment from perspectives of microbial and treatment performance [J]. Bioresource Technology, 2022, 363: 127831. doi: 10.1016/j.biortech.2022.127831 [17] JANG D, HWANG Y, SHIN H, et al. Effects of salinity on the characteristics of biomass and membrane fouling in membrane bioreactors [J]. Bioresource Technology, 2013, 141: 50-56. doi: 10.1016/j.biortech.2013.02.062 [18] 简陈生. 高盐氨氮废水MBR处理效能及微生物特性研究[D]. 赣州: 江西理工大学, 2016. JIAN C S. Study on MBR treatment efficiency and microbial characteristics of high salinity ammonia nitrogen wastewater[D]. Ganzhou: Jiangxi University of Science and Technology, 2016 (in Chinese).

[19] HE H J, CHEN Y J, LI X, et al. Influence of salinity on microorganisms in activated sludge processes: A review [J]. International Biodeterioration & Biodegradation, 2017, 119: 520-527. [20] 武骁. 好氧颗粒污泥处理含盐有机废水性能及耐盐机理研究[D]. 上海: 华东理工大学, 2020. WU X. Study on performance and salt-tolerance mechanism of aerobic granular sludge treating saline organic wastewater[D]. Shanghai: East China University of Science and Technology, 2020 (in Chinese).

[21] 肖小兰, 亓金鹏, 刘皓, 等. AOA-MBR处理高盐榨菜废水厌氧膜生物反应器出水的效能 [J]. 环境工程学报, 2021, 15(9): 3057-3066. doi: 10.12030/j.cjee.202105095 XIAO X L, QI J P, LIU H, et al. Operation performance of an AOA-MBR treating the effluent from an anaerobic membrane bioreactor dealing with high-salt mustard tuber wastewater [J]. Chinese Journal of Environmental Engineering, 2021, 15(9): 3057-3066(in Chinese). doi: 10.12030/j.cjee.202105095

[22] LE-CLECH P, CHEN V, FANE T A G. Fouling in membrane bioreactors used in wastewater treatment [J]. Journal of Membrane Science, 2006, 284(1/2): 17-53. [23] 陆继来, 刘舒华, 张敏健, 等. 污泥浓度对MBR混合液特性及膜污染的影响 [J]. 中国给水排水, 2014, 30(9): 92-95. doi: 10.19853/j.zgjsps.1000-4602.2014.09.023 LU J L, LIU S H, ZHANG M J, et al. Influence of MLSS on mixed liquor characteristics and membrane fouling in membrane bioreactor [J]. China Water & Wastewater, 2014, 30(9): 92-95(in Chinese). doi: 10.19853/j.zgjsps.1000-4602.2014.09.023

[24] 陈莉佳, 关永年, 庞维海. 平板膜生物反应器用于工业区污水处理厂尾水深度处理中试研究[J]. 给水排水, 2014, 50(S1): 274-277. CHEN L J, GUAN Y N, PANG W H. Pilot study on advanced treatment of tail water of sewage treatment plant in industrial area by flat membrane bioreactor[J]. Water & Wastewater Engineering, 2014, 50(Sup 1): 274-277 (in Chinese).

[25] 王浩宇. 一体式厌氧膜生物反应器在生活污水处理中的应用研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. WANG H Y. The application of submerged anaerobic membrane bioreactor treating domestic wastewater[D]. Harbin: Harbin Institute of Technology, 2014 (in Chinese).

[26] YUAN Y, ZHOU Z, JIANG J, et al. Partial nitrification performance and microbial community evolution in the membrane bioreactor for saline stream treatment [J]. Bioresource Technology, 2021, 320: 124419. doi: 10.1016/j.biortech.2020.124419 [27] LUO W H, HAI F I, KANG J G, et al. Effects of salinity build-up on biomass characteristics and trace organic chemical removal: Implications on the development of high retention membrane bioreactors [J]. Bioresource Technology, 2015, 177: 274-281. doi: 10.1016/j.biortech.2014.11.084 [28] HONG J M, LI W B, LIN B, et al. Deciphering the effect of salinity on the performance of submerged membrane bioreactor for aquaculture of bacterial community [J]. Desalination, 2013, 316: 23-30. doi: 10.1016/j.desal.2013.01.015 [29] Di BELLA G, Di TRAPANI D, TORREGROSSA M, et al. Performance of a MBR pilot plant treating high strength wastewater subject to salinity increase: Analysis of biomass activity and fouling behaviour [J]. Bioresource Technology, 2013, 147: 614-618. doi: 10.1016/j.biortech.2013.08.025 [30] NG K K, LIN C F, LATEEF S K, et al. The effect of soluble microbial products on membrane fouling in a fixed carrier biological system [J]. Separation and Purification Technology, 2010, 72(1): 98-104. doi: 10.1016/j.seppur.2010.01.011 [31] GAO D W, FU Y, REN N Q. Tracing biofouling to the structure of the microbial community and its metabolic products: A study of the three-stage MBR process [J]. Water Research, 2013, 47(17): 6680-6690. doi: 10.1016/j.watres.2013.09.007 [32] WANG X H, CHANG V W C, TANG C Y. Osmotic membrane bioreactor (OMBR) technology for wastewater treatment and reclamation: Advances, challenges, and prospects for the future [J]. Journal of Membrane Science, 2016, 504: 113-132. doi: 10.1016/j.memsci.2016.01.010 [33] TANG J L, PU Y H, ZENG T, et al. Enhanced methane production coupled with livestock wastewater treatment using anaerobic membrane bioreactor: Performance and membrane filtration properties [J]. Bioresource Technology, 2022, 345: 126470. doi: 10.1016/j.biortech.2021.126470 [34] WANG X, ZHANG B, SHEN Z Q, et al. The EPS characteristics of sludge in an aerobic granule membrane bioreactor [J]. Bioresource Technology, 2010, 101(21): 8046-8050. doi: 10.1016/j.biortech.2010.05.074 [35] PATSIOS S I, KARABELAS A J. An investigation of the long-term filtration performance of a membrane bioreactor (MBR): The role of specific organic fractions [J]. Journal of Membrane Science, 2011, 372(1/2): 102-115. [36] CORSINO S F, CAPODICI M, Di PIPPO F, et al. Comparison between kinetics of autochthonous marine bacteria in activated sludge and granular sludge systems at different salinity and SRTs [J]. Water Research, 2019, 148: 425-437. doi: 10.1016/j.watres.2018.10.086 [37] 逄超. 厌氧反应器构型对膜污染的影响及作用机制研究[D]. 合肥: 合肥工业大学, 2019. PANG C. Comparative study of membrane fouling and formation mechanism on different anaerobic reactor configuration[D]. Hefei: Hefei University of Technology, 2019 (in Chinese).

[38] SHEN L G, LEI Q, CHEN J R, et al. Membrane fouling in a submerged membrane bioreactor: Impacts of floc size [J]. Chemical Engineering Journal, 2015, 269: 328-334. doi: 10.1016/j.cej.2015.02.002 [39] LIM A L, BAI R B. Membrane fouling and cleaning in microfiltration of activated sludge wastewater [J]. Journal of Membrane Science, 2003, 216(1/2): 279-290. [40] 孟凡刚. 膜生物反应器膜污染行为的识别与表征[D]. 大连: 大连理工大学, 2007. MENG F G. Identification and characterization of fouling behavior in submerged membrane bioreactors[D]. Dalian: Dalian University of Technology, 2007 (in Chinese).

[41] TIAN Y, CHEN L, ZHANG S, et al. A systematic study of soluble microbial products and their fouling impacts in membrane bioreactors [J]. Chemical Engineering Journal, 2011, 168(3): 1093-1102. doi: 10.1016/j.cej.2011.01.090 [42] RESOSUDARMO A, YE Y, LE-CLECH P, et al. Analysis of UF membrane fouling mechanisms caused by organic interactions in seawater [J]. Water Research, 2013, 47(2): 911-921. doi: 10.1016/j.watres.2012.11.024 -

下载:

下载: