-

二恶英(dioxins)是一类具有相似结构和性质的氯代芳香烃族杂环化合物的统称,包括多氯代二苯并-对-二恶英(polychlorinated dibenzo-p-dioxins,PCDDs)和多氯代二苯并呋喃(polychlorinated dibenzofurans,PCDFs),共有210个同族体. PCDD/Fs作为典型的非故意产生的持久性有机污染物(UP-POPs),其来源包括自然源和人为源两大类,前者包括火山爆发、森林火灾等一些自然过程,后者包括固体废弃物焚烧、钢铁生产、有色金属生产、含氯化学品生产和纸浆漂白等工业过程. 由于环境中的PCDD/Fs主要来源于人类活动,自然排放的PCDD/Fs极少,故针对PCDD/Fs的研究主要围绕人为源展开[1-2].

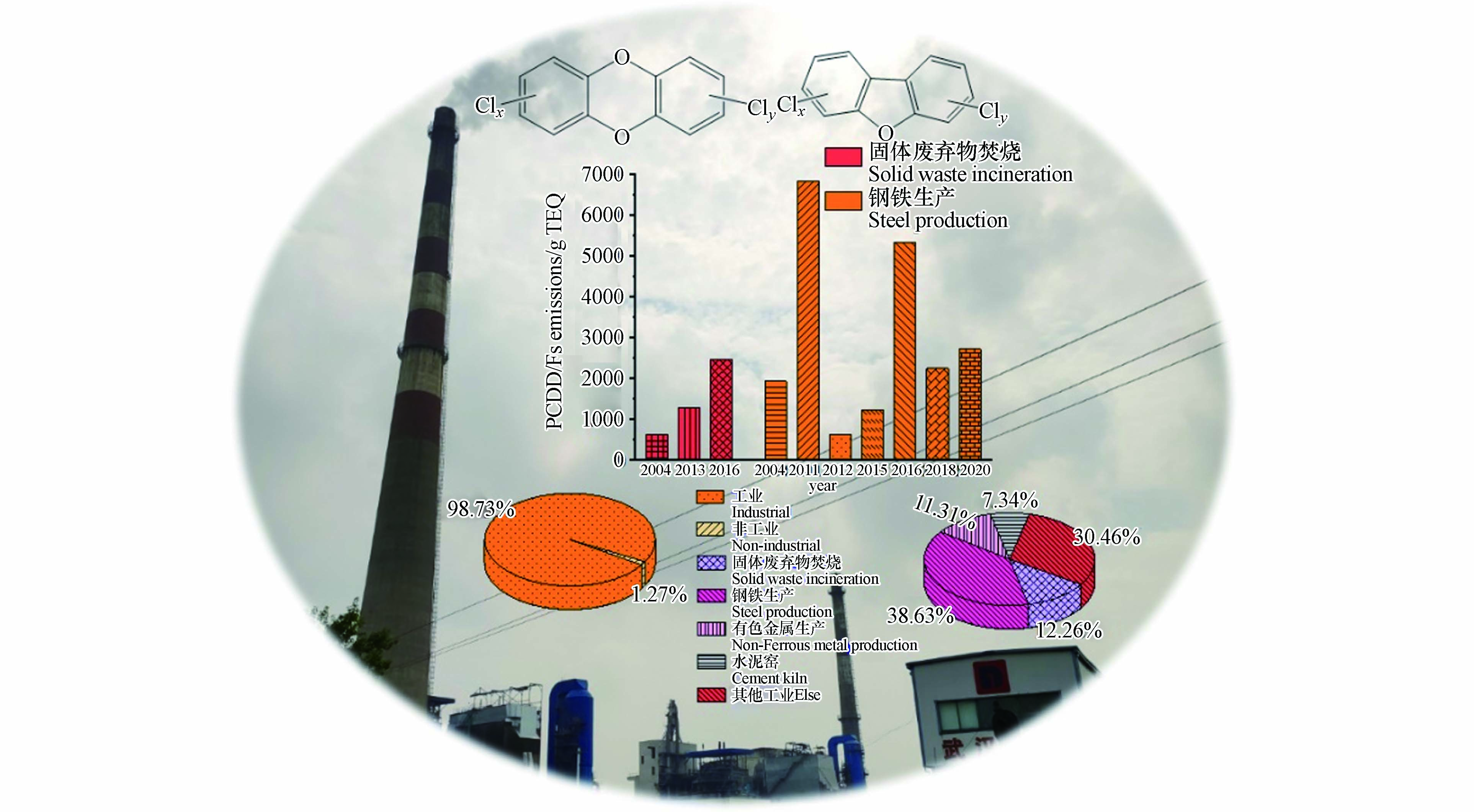

研究显示,2004年我国PCDD/Fs大气排放量为5042 g毒性当量(TEQ),之后一段时间未见官方统计数据,但有研究指出2016年我国PCDD/Fs大气排放量为10366 g TEQ[3-4],尽管不同研究中对排放因子和生产强度的选择差异较大,导致PCDD/Fs大气排放量的计算存在一定差异[5],但金属生产、固体废弃物焚烧等工业污染源导致的PCDD/Fs排放量占大气总排放量的90%以上[4]. 因此积极削减工业源排放的PCDD/Fs是其污染防治的关键,也是我国履行《关于持久性有机污染物的斯德哥尔摩公约》,推动国内经济高质量发展和生态文明建设的必然选择.

2010年我国加强大气污染物防治,工业废气治理投资快速增长,并于2014年达到峰值[6]. 但截止2018年,我国除固体废弃物焚烧行业外的其他行业专门针对UP-POPs控制的措施十分有限,且相关工作多停留在实验室研究阶段[7],与2010年的研究状况几近相似[8]. 减少工业污染源UP-POPs的排放仍然是我国POPs污染控制面临的最大挑战[7].

尽管目前对PCDD/Fs的工业排放源已有大量研究报道,但对于不同工业的PCDD/Fs排放特征、污染控制措施及其成效评估的文献综述仍然相对较少,且近年来随着工业的发展,不同工业PCDD/Fs排放特征和排放量也发生了一定的变化,因此,有必要进一步对比以前和近年来PCDD/Fs排放特征、控制措施变化. 根据联合国环境规划署(UNEP)在2013年提出的《鉴别及量化PCDD/Fs类排放标准工具包》以及其他研究对不同行业PCDD/Fs的排放因子及排放量的核算结果[9-12],本文选取固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置固体废弃物这四类排放因子较大、生产强度较高的行业为主要研究对象,系统总结了固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置四类重要工业源PCDD/Fs排放的相关研究进展,阐述了不同行业PCDD/Fs排放特征及及其变化趋势,比较分析了这四类重要行业针对PCDD/Fs排放采取的控制技术及其效果,在此基础上对工业生产过程中PCDD/Fs污染控制技术的发展方向进行了展望. 本文可为更加深入了解工业排放PCDD/Fs的研究现状及其污染控制技术提供参考.

-

焚烧等工业热过程中的PCDD/Fs生成机理包括高温气相合成、低温异相催化前驱体反应和低温异相催化从头合成等. 异相反应被认为是热过程PCDD/Fs的主要生成机理,可通过分析样品中PCDFs/PCDDs比值是否大于1来判断某排放源的PCDD/Fs生成途径是从头合成还是前驱体反应占主导地位[13].

-

固体废弃物焚烧主要指生活垃圾、危险废物、医疗废弃物等固体废弃物的焚烧[3, 7]. 焚烧能减少70%—80%的质量以及90%的体积[14],且焚烧产生的热能不仅能有效杀灭病原体,还可以用来发电[15-16],因此焚烧逐渐成为固体废弃物集中处置的首选方法[17-18]. 2010—2020年,我国城市生活垃圾焚烧处理量从2317万t增长到14608万t(年增长率为53.0%),处理量和增长率均超过传统的填埋处理(9598万t下降为7772万t,年增长率为-19.0%);危险废物产生量从1587万t增长到7282万t,年增长率为35.9%[6, 19].

从PCDD/Fs指纹分布看,大部分固体废弃物焚烧产生的烟气中PCDD/Fs以7—8氯代同族体为主,少部分以4—5氯代同族体为主,且PCDFs/PCDDs比值通常显著大于1,其生成机理主要为从头合成[7, 20-22]. 从PCDD/Fs排放量,2004年我国固体废物焚烧大气PCDD/Fs排放量为610 g TEQ(占大气PCDD/Fs排放量12.1%),2016年为2469 g TEQ(占大气PCDD/Fs排放量23.8%)[3-4],同2004年相比,2016年我国固体废弃物焚烧PCDD/Fs排放量增加1859 g TEQ(304.8%),排放占比升高11.7%. 在焚烧量相同的情况下,焚烧医疗废弃物和危险废弃物产生的PCDD/Fs要远高于生活垃圾焚烧的排放量[23].

固体废弃物焚烧厂因规模、工艺和操作控制等差异较大,PCDD/Fs的排放水平有很大差别(0.5—3500 μg·t−1 TEQ)[11]. Ni等[24]在2009年的研究中指出,我国生活垃圾焚烧过程中PCDD/Fs的平均排放因子为1728 ng·t−1 TEQ,这与2013年UNEP提供的排放因子参考范围相一致[11],2018年Zhu等[25]的研究结果显示排放因子有所下降(27—225 ng·t−1 I-TEQ),其均值为170 ng·t−1 I-TEQ,这可能与后来的焚烧厂采取更加完善的控制措施有关. 若以2020年我国生活垃圾焚烧量14608万 t[6]和Zhu等的排放因子[25]进行推测,我国2020年生活垃圾焚烧PCDD/Fs排放量达3.9—36.7 g TEQ. 对于医疗废弃物,Cao等[26]2009年的研究指出我国此类焚烧炉烟气中PCDD/Fs排放因子为0.78—474 μg·t−1 I-TEQ,据此估算的当年医疗废弃物焚烧产生的PCDD/Fs为4.87 g TEQ;若以2019年我国医疗废弃物产量(226万 t)[27]进行推测,PCDD/Fs年排放量可达1.76—1071 g I-TEQ.

总体相比于2004年,2016年我国固体废弃物焚烧行业大气PCDD/Fs总排放量增加1859 g TEQ(304.8%),排放占比升高11.7%[3-4]. 同时,由于焚烧技术的推广,新冠疫情后医疗废弃物的产量急剧增加(增幅可达24.7%)[28],危险废弃物处置量于2020年首次超过产生量[6, 19],这可能直接导致固体废弃物焚烧PCDD/Fs排放量的增加,然而相关研究报道比较欠缺,相关工作有待进一步开展.

-

钢铁生产流程可分为长流程和短流程两种,其中长流程是指以铁矿石为原料,以烧结、球团、炼焦、高炉炼铁、转炉炼钢和轧钢等工序为整套流程的生产工艺;短流程则是以废钢和直接还原铁为原料,直接从电炉炼钢开始的生产工艺[29]. 我国长流程炼钢约占90%左右[30],但因电炉炼钢过程中废钢原料中的塑料和油漆等有机物对该过程PCDD/Fs的产生有重要影响[31],故本文中的钢铁生产主要是指长流程生产工艺和电炉炼钢.

炼焦、烧结、电弧炉炼钢等钢铁生产过程中生成的PCDD/Fs均以7-8氯代同族体为主,且PCDFs/PCDDs比值大于1,其主要生成途径为从头合成[11, 32-34]. 从排放量来看,2004年我国钢铁行业大气PCDD/Fs排放量为1923 g TEQ,而针对2016年的研究则估算为5333 g TEQ,同2004年相比PCDD/Fs排放量增加177.3%[3-4]. 我国钢铁生产行业大气PCDD/Fs排放的90%以上集中在3个环节:铁矿石烧结(60%以上)、电弧炉炼钢(20%—30%)和炼焦(5%—10%)[35-36],因此后续研究控制应重点关注这些主要过程.

汤铃等[30]对我国966家钢铁企业(占我国粗钢产量96.4%)进行研究表明,2018年我国钢铁行业烧结和电炉工序的PCDD/Fs排放因子分别为1583、1246 ng I-TEQ·t−1,而炼焦等其它工序的排放因子小于300 ng I-TEQ·t−1;关于烧结和电炉排放PCDD/Fs的研究结果与Wang等[37-38]的结果基本一致(1330—7610 ng·t−1 I-TEQ和177—869 ng·t−1 I-TEQ),但远高于2020年杨艳艳等[36]的研究结果((180±220)ng·t−1 I-TEQ和(270±230 ng·t−1 )I-TEQ),这可能与后者所涉及的研究企业数量较少、生产工艺和污染控制措施较为先进等因素有关. 根据汤铃[30]等获得的排放因子和高炉炼铁物料平衡关系(每 t生铁需要1.6 t铁矿石和0.4 t焦炭)[39-41],结合我国2020年生铁和粗钢产量(分别为88898、106477万 t)[6],2020年我国烧结和电弧炉炼钢大气PCDD/Fs排放量分别为2252 g I-TEQ和133 g I-TEQ(焦炭和转炉炼钢分别为57 g I-TEQ、266 g I-TEQ),明显高于固体废弃物焚烧的PCDD/Fs估算值.

总体来看,相比于2004年,2016年我国钢铁行业大气PCDD/Fs排放量增加3410 g TEQ(117.3%),排放占比升高13.3%[3-4];同时结合现有数据对我国钢铁行业大气PCDD/Fs的排放进行计算,结果表明目前钢铁行业仍具有较高的大气PCDD/Fs排放水平,因此,针对该行业PCDD/Fs排放及其控制的研究仍需持续加强.

-

有色金属生产包括有色金属生产和再生有色金属生产,其中再生有色金属生产因原料中含废弃导线、电子部件和废旧塑料等,为PCDD/Fs的产生提供了丰富的氯源,经物料中的铜、铁等金属的催化后可生成大量PCDD/Fs(与有色金属生产相比可增加1—3个数量级)[37, 42-43]. 有色金属种类丰富,原料和生产工艺的不同对PCDD/Fs的排放特征和排放量有较大影响,但多数研究表明有色金属行业排放的PCDD/Fs主要源于铝、铜、铅生产过程[42, 44].

从指纹分布来看,铜生产过程中产生的PCDD/Fs多以7—8氯代同族体为主,且高氯代单体比例同原料中废铜含量成正比;而铝、铅、镁生产过程中多以4—7氯代同族体为主,主要生成途径为从头合成[45-48]. 从排放量来看,2004年我国有色金属行业大气PCDD/Fs排放量为563 g I-TEQ[3];近年来关于有色金属行业PCDD/Fs排放的研究数据较少,文献报道2013年再生铝生产过程中PCDD/Fs排放量为609 g I-TEQ[42],高于2004年有色金属行业的总排放量,由此推测2004至2013年有色金属生产行业PCDD/Fs排放量可能呈现出一定的增加趋势.

聂志强[49]对铜、镁冶炼以及废旧导线焚烧回收过程的研究表明,PCDD/Fs排放因子范围为38.5—5569 ng·t−1 TEQ;这与Yu等[38, 50]的研究结果基本一致(14.2—24451 ng·t−1 I-TEQ),但远低于Zou等[37]的研究结果(0.24—1.7 g·t−1 I-TEQ,其中二次铅生产的排放因子为4297 ng·t−1 I-TEQ). 排放因子范围变化较大的原因可能与有色金属类型、生产原料、生产工艺和控制措施等有关. 目前有色金属产量以精炼铜、电解铝以及十种有色金属总产量来核算,因此难以对有色金属行业排放的PCDD/Fs进行相对精细的计算,但2004至2020年我国十类有色金属总产量从1430万t增加到6188万t[6, 51],相关生产过程排放的PCDD/Fs总量可能出现相应增加.

-

因固体废弃物中含有水泥生产所需的部分原料,同时水泥窑的工作温度较高(1600 ℃以上)、物料停留时间长(30 min以上),因此水泥窑常被开发用于固体废弃物的协同处置[52-53]. 但固体废弃物中的大量氯源和金属催化剂在高温过程中可能导致PCDD/Fs的产生[3],因此水泥窑协同处置也是PCDD/Fs的排放源. 水泥窑协同处置过程中废弃物的类型、添加量、处理工艺等均会影响PCDD/Fs的排放特征和排放量[54].

从指纹分布特征看,除少数样品中PCDD/Fs以7—8氯代同族体为主外,大部分水泥窑协同处置过程产生的PCDD/Fs以4—6氯代同族体为主[53-56],主要生成途径为从头合成. 从排放量看,2004年我国水泥生产过程PCDD/Fs排放量为365.3 g TEQ[3]. 张婧等[57]研究指出,不同炉型的水泥窑PCDD/Fs排放因子差别可达100倍,而我国主要采用的水泥立窑生产工艺,PCDD/Fs排放因子为5.0 μg·t−1 TEQ,远高于干法旋窑. Aykan[58]对协同处置危险废物和医疗废弃物的水泥窑进行研究,结果表明烟气中PCDD/Fs排放量为每年0.02 g. 2018年Zou等[55]研究指出,我国水泥窑协同处置过程PCDD/Fs排放因子为0.01—1.35 mg·t−1 I-TEQ. 尽管2020年我国水泥生产高达339736万 t[6],但其中协同处置固体废弃物生产的水泥比例并不清晰,无法对该过程PCDD/Fs排放量进行计算[59]. 以水泥工业计划中提出的2015年建成10%的协同处置水泥厂的目标来推算[59],水泥窑PCDD/Fs排放量将达到2397 g I-TEQ,这与钢铁生产行业的排放量几乎相当. 由于我国水泥窑协同处置固体废弃物的生产线投产较晚,相关研究的基础数据仍然较少,因此加强水泥窑协调处置固体废弃物过程中PCDD/Fs的排放监测研究十分必要,可为准确评估该行业PCDD/Fs排放量提供重要科学依据.

-

基于以上排放特征分析,固体废弃物焚烧、钢铁生产和铜生产排放的PCDD/Fs多以7—8氯代同族体为主,而水泥窑协同处置和铅、铝等有色金属生产过程中多以4—6/7氯代同族体为主;尽管不同行业的PCDD/Fs指纹分布特征有所不同,但均以呋喃类为主要同族体,表明其来源主要为从头合成机理[20, 34, 45, 54].

从排放量分析(表1,图1),PCDD/Fs排放量依次为钢铁生产>固体废弃物焚烧>有色金属生产>水泥窑协同处置;依据现有文献数据进行估算,2020年PCDD/Fs排放量依次为钢铁生产>水泥窑协同处置>有色金属色生产>固体废弃物焚烧,但水泥窑协同处置的排放量存在较大不确定性,仍需要更多的研究结果进行支撑.

-

相比于发达国家,我国PCDD/Fs污染控制工作起步较晚[67]. 根据PCDD/Fs的生成机理及其来源,PCDD/Fs的控制主要针对生成前、生成中和生成后三个过程开展相关工作[44]. 原料中的PCDD/Fs大多在高温下可直接分解,因此高温再生成是PCDD/Fs排放量的主要来源,故PCDD/Fs的控制减排主要通过控制运行的工作参数、添加抑制剂或增加末端空气污染控制装置(APCDs)等措施[68](详见表2),本文主要针对工业烟气末端处理装置及其控制效果进行综述介绍.

由于不同行业烟气中PCDD/Fs的排放特征和浓度有所差别,烟气温度、烟气量、烟气中粉尘和氮氧化物等常规污染物的种类和数量相差较大,因此不同行业APCDs存在一定差异,而PCDD/Fs多以协同净化为主[81],且不同行业排放控制标准不尽相同(见表3),因此本文针对不同行业的措施效果分别进行综述.

-

固体废弃物焚烧作为PCDD/Fs主要的排放源,相关控制技术比较完善[7]. Wei等[89]研究发现,经过垃圾发酵等预处理措施和焚烧参数控制后,采用半干洗涤器(SDS)+干洗涤器(DS)+活性炭喷射(AC)+袋式除尘器(BF)+选择性催化还原(SCR)技术组成的APCDs对烟气中PCDD/Fs进行脱除,最终的排放水平可达0.0028 ng·m−3I-TEQ,远低于0.1 ng·m−3 I-TEQ的控制标准;许多研究也表明,通过良好的过程和末端控制,固体废弃物焚烧厂烟气中PCDD/Fs的排放基本都能满足相关标准要求[25, 90-91]. 值得注意的是,一些研究也报道了焚烧厂由于控制技术不达标或不稳定,造成存在PCDD/Fs超标排放的现象(排放水平最高可达8.12 ng·m−3 I-TEQ,均值为0.423 ng·m−3 I-TEQ)[20, 24-26, 92-95]. 基于已有文献报道(表4),目前固体废弃物焚烧行业的PCDD/Fs末端控制技术基本以AC+BF为主,配以SDS、DS、WS、SCR、SCNR等不同技术组成APCDs,可有效降低烟气中PCDD/Fs浓度[96-98].

-

钢铁生产流程较长,不同工序烟气理化性质差异较大,其中烧结因烟气温度高、含尘量大等原因不适合使用BF,而静电除尘器(ESP)使用较为普遍[99]. 2018年,我国烧结和炼钢的PCDD/Fs达标率仅为33.3%和66.7%[100-101]. 近期研究表明[36, 102],截止2021年,我国钢铁行业排放烟气中PCDD/Fs的浓度范围为0.05—2.93 ng·m−3 I-TEQ,均值为0.42 ng·m−3 I-TEQ,同2005—2019年相比下降1—2个数量级,能够满足0.5 ng·m−3 I-TEQ的排放要求. 钢铁生产行业的PCDD/Fs末端控制技术以ESP或BF为主,配备SCR、湿法脱硫等脱硫脱硝技术组成的APCDs(表4),可对PCDD/Fs等污染物进行协同控制. 尽管排放烟气中PCDD/Fs的浓度能够达到0.5 ng·m−3 I-TEQ的排放要求,但其排放浓度仍普遍高于固体废弃物焚烧行业. 因此钢铁行业尤其是烧结、电炉炼钢等工序的PCDD/Fs排放形势仍较为严峻,相关污染控制研究工作需进一步加强.

-

有色金属生产通常采用的烟气PCDD/Fs控制技术见表4. 目前我国对再生有色金属生产行业烟气PCDD/Fs的排放限值为0.5 ng·m−3 TEQ [87]. 研究表明[47, 103],有色金属生产厂采用以BF或ESP为主要控制技术时,烟气中PCDD/Fs排放水平为0.009—0.13 ng·m−3 I-TEQ,能够持续满足0.5 ng·m−3 TEQ的限值要求. 但部分工厂排放PCDD/Fs的水平接近甚至超过限值要求(表4),且有色金属生产厂PCDD/Fs排放超标率可达22.2%[101]. 这表明能否有效利用现有控制技术(如BF或ESP为主的烟气污染控制系统)对有色金属行业的PCDD/Fs污染控制具有重要影响.

-

水泥窑协同处置行业针对烟气污染采取的控制技术和手段见表4. 水泥工业本身对排放的烟气中PCDD/Fs浓度水平并无明确限值,目前协同处置固体废物的水泥窑烟气中PCDD/Fs排放限值为0.1 ng·m−3 TEQ [88, 104]. 尽管水泥窑协同处置固体废物时原料中PCDD/Fs浓度较高,但经过高温分解处理后,烟气采用BF、BF+SNCR(选择性非还原催化)或ESP为主的APCDs进行净化,PCDD/Fs排放水平可达0.011—0.076 ng·m−3 I-TEQ[55, 103, 105-106],均可使PCDD/Fs以较低浓度排放.

-

从表4中可以看出,目前固体废弃物焚烧行业多以BF或AC+BF为主要技术,配备SDS、DS等非ESP技术组成的APCDs对烟气进行深度净化;钢铁生产、有色金属生产、水泥窑协同处置行业则以BF或ESP为主要技术,配备SDS、脱硫脱硝等技术组成的APCDs对烟气进行处理. 当过程控制和末端控制均能得到有效保障时,烟气中PCDD/Fs的排放水多处于较低水平,但钢铁生产和有色金属生产的PCDD/Fs排放强度仍然明显高于其他行业.

-

本文系统的总结了固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置等四类主要行业烟气中PCDD/Fs排放特征及污染控制的研究进展. 从排放特征来看,水泥窑协同处置行业排放的PCDD/Fs以4—6/7氯代同族体为主要单体,而固体废弃物焚烧、钢铁生产、有色金属生产等行业排放的PCDD/Fs以7—8氯代同族体为主,四类工业源的主要生成机理均为从头合成;从现有排放量数据来看,2004—2016年我国大气PCDD/Fs总排放量上升明显,PCDD/Fs排放量依次为:钢铁生产>固体废弃物焚烧>有色金属生产>水泥窑协同处置;依据现有文献数据进行估算,2020年PCDD/Fs排放量依次为钢铁生产>水泥窑协同处置>有色金属色生产>固体废弃物焚烧,但水泥窑协同处置固体废弃物产生PCDD/Fs的研究仍比较有限,相关工作亟需加强.

从烟气中PCDD/Fs的控制技术来看,在传统污染控制装置基础上增加活性炭吸附、催化剂、抑制剂等可以有效降低PCDD/Fs的大气排放[117-119]. 但目前各类工业源的PCDD/Fs末端控制多以除尘器结合吸附脱除装置为主,并未实现PCDD/Fs的总量削减;此外由于记忆效应导致的PCDD/Fs排放水平变化以及飞灰中高浓度PCDD/Fs带来的固废处置问题也给现有技术升级带来较大难度[46, 89, 120-123],因此,如何有效控制PCDD/Fs的排放总量仍然面临极大挑战. 末端控制技术方面,AC+BF吸附技术存在活性炭使用量大、价格高、活性炭吸附效率低、存在记忆效应、产生高毒性粉煤灰等缺点[108, 124-127],近年来,生物质制备活性炭、活性炭改性处理、双袋式除尘器、喷射聚丙烯胺、协同处置粉煤灰、热等离子体、紫外光降解等技术逐渐得到开发,能够有效改善或避免吸附法存在的问题[76-80, 128-136],然而诸多新技术尚停留在实验室阶段,且PCDD/Fs降解技术还存在反应时间长、去除效率不稳定等问题[137-140]. 因此尚无法在企业层面上推广应用.

一些针对工业过程中PCDD/Fs生成的研究发现,传统硫脲、硫酸铵等含N或含S的抑制剂存在氨溢出、额外成本等问题,研发使用无氨溢出风险的氧化钙,或采用含N或P的污泥等作为抑制剂可降低污染控制成本,且具有良好的抑制PCDD/Fs生成的控制效果[141-145],可能是未来控制某些工业过程中PCDD/Fs排放的重要技术手段.

基于以上研究现状,本文对典型工业过程中PCDD/Fs排放特征及其污染控制研究做以下两方面展望:

(1) 工业过程是PCDD/Fs人为排放的主要来源,尽管我国已经制定了相关行业的排放标准,排放总量也有所下降,但是部分行业仍然存在PCDD/Fs排放量增加的趋势,因此及时更新典型行业PCDD/Fs排放因子并完善排放清单,对于我国履行《斯德哥尔摩公约》和降低PCDD/Fs暴露风险具有重要意义.

(2) 对工业排放PCDD/Fs的控制应遵循“源头-过程-末端”的全过程控制原则. 开发新技术新材料,通过对原料预处理等措施从源头上弱化PCDD/Fs生成条件;通过添加抑制剂等措施从过程中减少PCDD/Fs的生成;积极研发PCDD/Fs的催化降解技术,结合活性炭吸附等末端控制技术可实现PCDD/Fs排放总量的有效削减.

工业过程二恶英的排放特征及其控制技术

Dioxin emission characteristics and control technologies in industrial processes

-

摘要: 工业排放是环境中二恶英(PCDD/Fs)最主要的人为排放源. 2010年我国九部委联合发布PCDD/Fs污染防治指导意见,之后出台多项政策要求对主要行业持久性有机污染物(POPs)开展污染防治. 在一系列防治措施下,PCDD/Fs的工业排放水平有所下降,整体取得良好成效. 本文针对固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置四类主要行业的PCDD/Fs排放研究进展进行综述,阐述了不同行业PCDD/Fs排放量、排放特征及其变化趋势,比较分析了目前四类主要行业针对PCDD/Fs排放的控制技术及其效果,并对烟气中PCDD/Fs污染控制技术的发展方向进行了展望. 本文可为更加深入地了解工业排放PCDD/Fs的研究现状以及污染控制技术提供参考.Abstract: Industrial emissions are the main sources of anthropogenic polychlorinated dibenzo-p-dioxin and dibenzofurans (PCDD/Fs) in the environment. In 2010, nine ministries and commissions of China jointly issued the Guidance on the Strengthening of Dioxin Pollution Prevention, and then issued many policy documents for pollution prevention and control of persistent organic pollutants (POPs) in major industries. Under a series of control measures, the industrial emission of PCDD/Fs has been reduced in recent years. In this review, we summarized the research progress on PCDD/Fs emission in solid waste incineration, iron and steel smelting, non-ferrous metal smelting and coordinated disposal of cement kiln. The emission levels , emission characteristics and temporal trend of PCDD/Fs from these different industries were discussed, the control technologies and their effects to PCDD/Fs emission in four major industries were also evaluated. The development about PCDD/Fs control measures in flue gas was finally prospected. This review may enhance understanding the industrial emissions of PCDD/Fs and their control effects.

-

Key words:

- industrial emissions /

- dioxins /

- emission characteristics /

- control technology.

-

二恶英(dioxins)是一类具有相似结构和性质的氯代芳香烃族杂环化合物的统称,包括多氯代二苯并-对-二恶英(polychlorinated dibenzo-p-dioxins,PCDDs)和多氯代二苯并呋喃(polychlorinated dibenzofurans,PCDFs),共有210个同族体. PCDD/Fs作为典型的非故意产生的持久性有机污染物(UP-POPs),其来源包括自然源和人为源两大类,前者包括火山爆发、森林火灾等一些自然过程,后者包括固体废弃物焚烧、钢铁生产、有色金属生产、含氯化学品生产和纸浆漂白等工业过程. 由于环境中的PCDD/Fs主要来源于人类活动,自然排放的PCDD/Fs极少,故针对PCDD/Fs的研究主要围绕人为源展开[1-2].

研究显示,2004年我国PCDD/Fs大气排放量为5042 g毒性当量(TEQ),之后一段时间未见官方统计数据,但有研究指出2016年我国PCDD/Fs大气排放量为10366 g TEQ[3-4],尽管不同研究中对排放因子和生产强度的选择差异较大,导致PCDD/Fs大气排放量的计算存在一定差异[5],但金属生产、固体废弃物焚烧等工业污染源导致的PCDD/Fs排放量占大气总排放量的90%以上[4]. 因此积极削减工业源排放的PCDD/Fs是其污染防治的关键,也是我国履行《关于持久性有机污染物的斯德哥尔摩公约》,推动国内经济高质量发展和生态文明建设的必然选择.

2010年我国加强大气污染物防治,工业废气治理投资快速增长,并于2014年达到峰值[6]. 但截止2018年,我国除固体废弃物焚烧行业外的其他行业专门针对UP-POPs控制的措施十分有限,且相关工作多停留在实验室研究阶段[7],与2010年的研究状况几近相似[8]. 减少工业污染源UP-POPs的排放仍然是我国POPs污染控制面临的最大挑战[7].

尽管目前对PCDD/Fs的工业排放源已有大量研究报道,但对于不同工业的PCDD/Fs排放特征、污染控制措施及其成效评估的文献综述仍然相对较少,且近年来随着工业的发展,不同工业PCDD/Fs排放特征和排放量也发生了一定的变化,因此,有必要进一步对比以前和近年来PCDD/Fs排放特征、控制措施变化. 根据联合国环境规划署(UNEP)在2013年提出的《鉴别及量化PCDD/Fs类排放标准工具包》以及其他研究对不同行业PCDD/Fs的排放因子及排放量的核算结果[9-12],本文选取固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置固体废弃物这四类排放因子较大、生产强度较高的行业为主要研究对象,系统总结了固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置四类重要工业源PCDD/Fs排放的相关研究进展,阐述了不同行业PCDD/Fs排放特征及及其变化趋势,比较分析了这四类重要行业针对PCDD/Fs排放采取的控制技术及其效果,在此基础上对工业生产过程中PCDD/Fs污染控制技术的发展方向进行了展望. 本文可为更加深入了解工业排放PCDD/Fs的研究现状及其污染控制技术提供参考.

1. 不同工业烟气中PCDD/Fs排放特征(Emission characteristics of PCDD/Fs in flue gas of different industries)

焚烧等工业热过程中的PCDD/Fs生成机理包括高温气相合成、低温异相催化前驱体反应和低温异相催化从头合成等. 异相反应被认为是热过程PCDD/Fs的主要生成机理,可通过分析样品中PCDFs/PCDDs比值是否大于1来判断某排放源的PCDD/Fs生成途径是从头合成还是前驱体反应占主导地位[13].

1.1 固体废弃物焚烧

固体废弃物焚烧主要指生活垃圾、危险废物、医疗废弃物等固体废弃物的焚烧[3, 7]. 焚烧能减少70%—80%的质量以及90%的体积[14],且焚烧产生的热能不仅能有效杀灭病原体,还可以用来发电[15-16],因此焚烧逐渐成为固体废弃物集中处置的首选方法[17-18]. 2010—2020年,我国城市生活垃圾焚烧处理量从2317万t增长到14608万t(年增长率为53.0%),处理量和增长率均超过传统的填埋处理(9598万t下降为7772万t,年增长率为-19.0%);危险废物产生量从1587万t增长到7282万t,年增长率为35.9%[6, 19].

从PCDD/Fs指纹分布看,大部分固体废弃物焚烧产生的烟气中PCDD/Fs以7—8氯代同族体为主,少部分以4—5氯代同族体为主,且PCDFs/PCDDs比值通常显著大于1,其生成机理主要为从头合成[7, 20-22]. 从PCDD/Fs排放量,2004年我国固体废物焚烧大气PCDD/Fs排放量为610 g TEQ(占大气PCDD/Fs排放量12.1%),2016年为2469 g TEQ(占大气PCDD/Fs排放量23.8%)[3-4],同2004年相比,2016年我国固体废弃物焚烧PCDD/Fs排放量增加1859 g TEQ(304.8%),排放占比升高11.7%. 在焚烧量相同的情况下,焚烧医疗废弃物和危险废弃物产生的PCDD/Fs要远高于生活垃圾焚烧的排放量[23].

固体废弃物焚烧厂因规模、工艺和操作控制等差异较大,PCDD/Fs的排放水平有很大差别(0.5—3500 μg·t−1 TEQ)[11]. Ni等[24]在2009年的研究中指出,我国生活垃圾焚烧过程中PCDD/Fs的平均排放因子为1728 ng·t−1 TEQ,这与2013年UNEP提供的排放因子参考范围相一致[11],2018年Zhu等[25]的研究结果显示排放因子有所下降(27—225 ng·t−1 I-TEQ),其均值为170 ng·t−1 I-TEQ,这可能与后来的焚烧厂采取更加完善的控制措施有关. 若以2020年我国生活垃圾焚烧量14608万 t[6]和Zhu等的排放因子[25]进行推测,我国2020年生活垃圾焚烧PCDD/Fs排放量达3.9—36.7 g TEQ. 对于医疗废弃物,Cao等[26]2009年的研究指出我国此类焚烧炉烟气中PCDD/Fs排放因子为0.78—474 μg·t−1 I-TEQ,据此估算的当年医疗废弃物焚烧产生的PCDD/Fs为4.87 g TEQ;若以2019年我国医疗废弃物产量(226万 t)[27]进行推测,PCDD/Fs年排放量可达1.76—1071 g I-TEQ.

总体相比于2004年,2016年我国固体废弃物焚烧行业大气PCDD/Fs总排放量增加1859 g TEQ(304.8%),排放占比升高11.7%[3-4]. 同时,由于焚烧技术的推广,新冠疫情后医疗废弃物的产量急剧增加(增幅可达24.7%)[28],危险废弃物处置量于2020年首次超过产生量[6, 19],这可能直接导致固体废弃物焚烧PCDD/Fs排放量的增加,然而相关研究报道比较欠缺,相关工作有待进一步开展.

1.2 钢铁生产

钢铁生产流程可分为长流程和短流程两种,其中长流程是指以铁矿石为原料,以烧结、球团、炼焦、高炉炼铁、转炉炼钢和轧钢等工序为整套流程的生产工艺;短流程则是以废钢和直接还原铁为原料,直接从电炉炼钢开始的生产工艺[29]. 我国长流程炼钢约占90%左右[30],但因电炉炼钢过程中废钢原料中的塑料和油漆等有机物对该过程PCDD/Fs的产生有重要影响[31],故本文中的钢铁生产主要是指长流程生产工艺和电炉炼钢.

炼焦、烧结、电弧炉炼钢等钢铁生产过程中生成的PCDD/Fs均以7-8氯代同族体为主,且PCDFs/PCDDs比值大于1,其主要生成途径为从头合成[11, 32-34]. 从排放量来看,2004年我国钢铁行业大气PCDD/Fs排放量为1923 g TEQ,而针对2016年的研究则估算为5333 g TEQ,同2004年相比PCDD/Fs排放量增加177.3%[3-4]. 我国钢铁生产行业大气PCDD/Fs排放的90%以上集中在3个环节:铁矿石烧结(60%以上)、电弧炉炼钢(20%—30%)和炼焦(5%—10%)[35-36],因此后续研究控制应重点关注这些主要过程.

汤铃等[30]对我国966家钢铁企业(占我国粗钢产量96.4%)进行研究表明,2018年我国钢铁行业烧结和电炉工序的PCDD/Fs排放因子分别为1583、1246 ng I-TEQ·t−1,而炼焦等其它工序的排放因子小于300 ng I-TEQ·t−1;关于烧结和电炉排放PCDD/Fs的研究结果与Wang等[37-38]的结果基本一致(1330—7610 ng·t−1 I-TEQ和177—869 ng·t−1 I-TEQ),但远高于2020年杨艳艳等[36]的研究结果((180±220)ng·t−1 I-TEQ和(270±230 ng·t−1 )I-TEQ),这可能与后者所涉及的研究企业数量较少、生产工艺和污染控制措施较为先进等因素有关. 根据汤铃[30]等获得的排放因子和高炉炼铁物料平衡关系(每 t生铁需要1.6 t铁矿石和0.4 t焦炭)[39-41],结合我国2020年生铁和粗钢产量(分别为88898、106477万 t)[6],2020年我国烧结和电弧炉炼钢大气PCDD/Fs排放量分别为2252 g I-TEQ和133 g I-TEQ(焦炭和转炉炼钢分别为57 g I-TEQ、266 g I-TEQ),明显高于固体废弃物焚烧的PCDD/Fs估算值.

总体来看,相比于2004年,2016年我国钢铁行业大气PCDD/Fs排放量增加3410 g TEQ(117.3%),排放占比升高13.3%[3-4];同时结合现有数据对我国钢铁行业大气PCDD/Fs的排放进行计算,结果表明目前钢铁行业仍具有较高的大气PCDD/Fs排放水平,因此,针对该行业PCDD/Fs排放及其控制的研究仍需持续加强.

1.3 有色金属生产

有色金属生产包括有色金属生产和再生有色金属生产,其中再生有色金属生产因原料中含废弃导线、电子部件和废旧塑料等,为PCDD/Fs的产生提供了丰富的氯源,经物料中的铜、铁等金属的催化后可生成大量PCDD/Fs(与有色金属生产相比可增加1—3个数量级)[37, 42-43]. 有色金属种类丰富,原料和生产工艺的不同对PCDD/Fs的排放特征和排放量有较大影响,但多数研究表明有色金属行业排放的PCDD/Fs主要源于铝、铜、铅生产过程[42, 44].

从指纹分布来看,铜生产过程中产生的PCDD/Fs多以7—8氯代同族体为主,且高氯代单体比例同原料中废铜含量成正比;而铝、铅、镁生产过程中多以4—7氯代同族体为主,主要生成途径为从头合成[45-48]. 从排放量来看,2004年我国有色金属行业大气PCDD/Fs排放量为563 g I-TEQ[3];近年来关于有色金属行业PCDD/Fs排放的研究数据较少,文献报道2013年再生铝生产过程中PCDD/Fs排放量为609 g I-TEQ[42],高于2004年有色金属行业的总排放量,由此推测2004至2013年有色金属生产行业PCDD/Fs排放量可能呈现出一定的增加趋势.

聂志强[49]对铜、镁冶炼以及废旧导线焚烧回收过程的研究表明,PCDD/Fs排放因子范围为38.5—5569 ng·t−1 TEQ;这与Yu等[38, 50]的研究结果基本一致(14.2—24451 ng·t−1 I-TEQ),但远低于Zou等[37]的研究结果(0.24—1.7 g·t−1 I-TEQ,其中二次铅生产的排放因子为4297 ng·t−1 I-TEQ). 排放因子范围变化较大的原因可能与有色金属类型、生产原料、生产工艺和控制措施等有关. 目前有色金属产量以精炼铜、电解铝以及十种有色金属总产量来核算,因此难以对有色金属行业排放的PCDD/Fs进行相对精细的计算,但2004至2020年我国十类有色金属总产量从1430万t增加到6188万t[6, 51],相关生产过程排放的PCDD/Fs总量可能出现相应增加.

1.4 水泥窑协同处置

因固体废弃物中含有水泥生产所需的部分原料,同时水泥窑的工作温度较高(1600 ℃以上)、物料停留时间长(30 min以上),因此水泥窑常被开发用于固体废弃物的协同处置[52-53]. 但固体废弃物中的大量氯源和金属催化剂在高温过程中可能导致PCDD/Fs的产生[3],因此水泥窑协同处置也是PCDD/Fs的排放源. 水泥窑协同处置过程中废弃物的类型、添加量、处理工艺等均会影响PCDD/Fs的排放特征和排放量[54].

从指纹分布特征看,除少数样品中PCDD/Fs以7—8氯代同族体为主外,大部分水泥窑协同处置过程产生的PCDD/Fs以4—6氯代同族体为主[53-56],主要生成途径为从头合成. 从排放量看,2004年我国水泥生产过程PCDD/Fs排放量为365.3 g TEQ[3]. 张婧等[57]研究指出,不同炉型的水泥窑PCDD/Fs排放因子差别可达100倍,而我国主要采用的水泥立窑生产工艺,PCDD/Fs排放因子为5.0 μg·t−1 TEQ,远高于干法旋窑. Aykan[58]对协同处置危险废物和医疗废弃物的水泥窑进行研究,结果表明烟气中PCDD/Fs排放量为每年0.02 g. 2018年Zou等[55]研究指出,我国水泥窑协同处置过程PCDD/Fs排放因子为0.01—1.35 mg·t−1 I-TEQ. 尽管2020年我国水泥生产高达339736万 t[6],但其中协同处置固体废弃物生产的水泥比例并不清晰,无法对该过程PCDD/Fs排放量进行计算[59]. 以水泥工业计划中提出的2015年建成10%的协同处置水泥厂的目标来推算[59],水泥窑PCDD/Fs排放量将达到2397 g I-TEQ,这与钢铁生产行业的排放量几乎相当. 由于我国水泥窑协同处置固体废弃物的生产线投产较晚,相关研究的基础数据仍然较少,因此加强水泥窑协调处置固体废弃物过程中PCDD/Fs的排放监测研究十分必要,可为准确评估该行业PCDD/Fs排放量提供重要科学依据.

1.5 不同工业过程PCDD/Fs排放特征比较

基于以上排放特征分析,固体废弃物焚烧、钢铁生产和铜生产排放的PCDD/Fs多以7—8氯代同族体为主,而水泥窑协同处置和铅、铝等有色金属生产过程中多以4—6/7氯代同族体为主;尽管不同行业的PCDD/Fs指纹分布特征有所不同,但均以呋喃类为主要同族体,表明其来源主要为从头合成机理[20, 34, 45, 54].

从排放量分析(表1,图1),PCDD/Fs排放量依次为钢铁生产>固体废弃物焚烧>有色金属生产>水泥窑协同处置;依据现有文献数据进行估算,2020年PCDD/Fs排放量依次为钢铁生产>水泥窑协同处置>有色金属色生产>固体废弃物焚烧,但水泥窑协同处置的排放量存在较大不确定性,仍需要更多的研究结果进行支撑.

表 1 我国PCDD/Fs的主要排放源及其排放量Table 1. Main emission sources of dioxins and their emissions in China排放源Emission source 排放因子/(ng·t−1 I-TEQ)Emission factor 年排放量/(g TEQ)Annual emission 参考文献References 大气Atmosphere 总量Total 固体废弃物焚烧 生活垃圾 — 125.8 338 [3] 危险废物 — 57.27 243.27 医疗废物 — 427.4 1176.3 总计(2004) — 610.47 1757.57 生活垃圾 1728 — — [24] 27—225 — — [25] 12200 217 — [23] 56—607 — — [60] 危险废物 70—3270 — — [60] 工业废物 302500 103 — [23] 医疗废物 97800 272 — [23] 780—473930 — — [26] 1923.6 0.466 — [20] 总计(2013) — 1280 — [61] 总计(2016) — 2469 — [4] 钢铁生产 铁矿石烧结 — 1522.5 1523.4 [3] 钢铁冶炼 — 150.9 1125.4 铸铁生产 — 10.7 97 炼焦 239.2 252.6 总计(2004) — 1923.31 2998.4 铁矿石烧结 1582.95 — — [30] 772.2—827.9 — — [37] 1330—7610 [38] 180±220 [36] 电弧炉 1245.85 — — [30] 270±23 [36] 3160 — — [37] 177—869 — — [38] 炼焦 160.09 — — [30] 28.9(WHO) — — [62] 总计(2011) — 6817 — [63] 总计(2012) — 618 — [64] 总计(2015) — 1216.83 — [35] 总计(2016) — 5333 — [4] 总计(2018) — 2240 — [30] 有色金属生产 铜生产 — 403 1133.8 [3] 铝生产 — 133.5 365.5 铅生产 — 13.4 17.4 其他 — 12.99 51.85 总计(2004) — 562.89 1568.55 铜生产 38.5、651(WHO) — — [49] 14.2 — — [50] 铝生产 1240.2 — — 铅生产 3140.0 — — 锌生产 166.0 — — 再生铜 241719—1707200 — — [37] 14802 37.5 — [65-66] 24451.3 — — [50] 再生铝 147819—434840 — — [37] 84.8—2720 — — [38] 再生铅 4297 — — [37] 镁生产 412(WHO) — — [49] 废旧导线回收 5569(WHO) — — [49] 水泥窑协同处置 水泥窑(2004) — 365.3 365.3 [3] 水泥窑 5000 0.02g — [57-58] 水泥窑 0.01—1.35 mg — — [55] 上述四类总计(2004) — 3461.97 6437.22 [3] 所有污染源总计(2004) — 5042.4 10236.8 [3] 注:“—”:表示未提及;其他:包锌、黄铜和青铜、镁等未提及的有色金属生产; 2. 不同工业烟气PCDD/Fs污染控制技术(Control technology of PCDD/Fs in different industrial processes)

相比于发达国家,我国PCDD/Fs污染控制工作起步较晚[67]. 根据PCDD/Fs的生成机理及其来源,PCDD/Fs的控制主要针对生成前、生成中和生成后三个过程开展相关工作[44]. 原料中的PCDD/Fs大多在高温下可直接分解,因此高温再生成是PCDD/Fs排放量的主要来源,故PCDD/Fs的控制减排主要通过控制运行的工作参数、添加抑制剂或增加末端空气污染控制装置(APCDs)等措施[68](详见表2),本文主要针对工业烟气末端处理装置及其控制效果进行综述介绍.

表 2 PCDD/Fs的全过程控制方法Table 2. Whole process control method of PCDD/Fs由于不同行业烟气中PCDD/Fs的排放特征和浓度有所差别,烟气温度、烟气量、烟气中粉尘和氮氧化物等常规污染物的种类和数量相差较大,因此不同行业APCDs存在一定差异,而PCDD/Fs多以协同净化为主[81],且不同行业排放控制标准不尽相同(见表3),因此本文针对不同行业的措施效果分别进行综述.

表 3 不同行业烟气PCDD/Fs排放控制标准Table 3. PCDD/Fs emission control standard for different industries2.1 固体废弃物焚烧

固体废弃物焚烧作为PCDD/Fs主要的排放源,相关控制技术比较完善[7]. Wei等[89]研究发现,经过垃圾发酵等预处理措施和焚烧参数控制后,采用半干洗涤器(SDS)+干洗涤器(DS)+活性炭喷射(AC)+袋式除尘器(BF)+选择性催化还原(SCR)技术组成的APCDs对烟气中PCDD/Fs进行脱除,最终的排放水平可达0.0028 ng·m−3I-TEQ,远低于0.1 ng·m−3 I-TEQ的控制标准;许多研究也表明,通过良好的过程和末端控制,固体废弃物焚烧厂烟气中PCDD/Fs的排放基本都能满足相关标准要求[25, 90-91]. 值得注意的是,一些研究也报道了焚烧厂由于控制技术不达标或不稳定,造成存在PCDD/Fs超标排放的现象(排放水平最高可达8.12 ng·m−3 I-TEQ,均值为0.423 ng·m−3 I-TEQ)[20, 24-26, 92-95]. 基于已有文献报道(表4),目前固体废弃物焚烧行业的PCDD/Fs末端控制技术基本以AC+BF为主,配以SDS、DS、WS、SCR、SCNR等不同技术组成APCDs,可有效降低烟气中PCDD/Fs浓度[96-98].

表 4 工业烟气PCDD/Fs控制技术Table 4. Collaborative dioxin control technology for industrial flue gas工业类型Industrial Type 空气污染控制装置Air pollution control devices(APCDs) 进口Before 出口After 效率Efficiency 参考文献Reference 固体废弃物焚烧 生活垃圾焚烧 SDS+DS+AC+BF+SCR 0.2253 0.0028 98.76% [89] SNCR+SDS+AC+BF — 0.0365 — [98] — 0.076—0.153 — [107] — 0.007—0.095 — [25] SDS+AC+BF+SCR — 0.41 — [108] — 0.06 — [108] 热交换+SDS+AC+BF 2.58 0.0246 99% [109] 急冷+SDS+AC+BF — 0.45 — [94] SDS+AC+BF — 0.078 — [110] — 0.008—0.12 91.7%—99.3% [93] — 0.026 — [94] — 0.099 — [98] DS+AC+BF — 0.0844 — [38] WDS+AC+BF — 0.082 — [98] AC+BF — 0.239 — [38] CY+SDS+BF — 0.54 — [111] WDS+BF — 0.50 — [94] SDS+BF — 1.33 — [94] CY+ESP 16.137 0.946 94.14% [112] CY+ESP+BF 0.23 1.948 -747% [112] 0.436 5.018 -1051% [112] 危险废物焚烧 VS+CY+AC+BF 113 0.054(WHO) 99.95% [90] SDS+AC+BF — 0.01—11.91 — [92] AC+BF — 0.225 — [38] 医疗废弃物焚烧 SDS+AC+BF+WDS 5.32 0.07 98.68% [91] DS+AC+BF — 1.64 — [38] SDS+AC+BF — 0.07—12.21 — [92] SDS+BF — 0.07 — 钢铁生产 电弧炉炼钢 BF — 0.17 — [113] — 0.148—0.757 — [38] — 0.34 — [37] ESP+脱硫 — 0.003—0.557 — [36] 烧结 ESP+WFGD 2.3±0.56 0.99±0.53 — [99] ESP+SFGD 0.32—0.69 0.022—0.2 — [99] WFGD+WESP — 0.15 — [103] 钢铁生产 烧结 ESP+SCR — 0.137—0.657 — [38] ESP — 0.233 — [38] — 0.005—0.48 — [37] BF — 0.006—0.057 — [36] 炼焦 BF — (4.9—89.3)×10−3 (WHO) — [33] — 0.00870 — [38] — (0.0039—0.03)×10−3 — [114] 有色金属生产 再生铜 BF — 0.310 — [38] — 0.84 — [115] — 0.004—0.37 — [46] — 0.009—1.29 — [47] 再生锌 GS或ESP+BF — 0.48 — [103, 115] 再生铅 BFESP+GS+BF — 0.05 — BF+WDS+DS — 0.037 — [37] 再生铝 AC+BF — 0.1 — [45] BF — (5.68—44)×10−3 — [38] — 2.05 — [37] WDS — 0.88 — [37] 水泥窑 水泥窑协同处置 ESP — 5.9×10−3 — [115,103] — (9.3—49.3)×10−3 — [116] — 0.01—0.19 — [55] BF — 0.076 — [106] — (17.8—90.8) ×10−3 — [116] — 0.01—0.46 — [55] WDS — 0.04 — [55] 单位:ng·m−3 I-TEQ:“—”:未提及;WDS:湿法除尘器;CY:旋风除尘器;VS:文丘里洗涤器;WFGD:湿法脱硫;SFGD:半干法脱硫;WESP:湿法静电除尘;GS:重力沉降 unit:ng·m−3 I-TEQ;“—”:Not Reported;WDS:Wet dust collector;CY:Cyclone dust collector;VS:Venturi scrubber;WFGD:Wet flue gas desulfurization;SFGD:Semi-dry desulphurization;WESP:Wet electrostatic precipitator;GS:Gravity settling 2.2 钢铁生产

钢铁生产流程较长,不同工序烟气理化性质差异较大,其中烧结因烟气温度高、含尘量大等原因不适合使用BF,而静电除尘器(ESP)使用较为普遍[99]. 2018年,我国烧结和炼钢的PCDD/Fs达标率仅为33.3%和66.7%[100-101]. 近期研究表明[36, 102],截止2021年,我国钢铁行业排放烟气中PCDD/Fs的浓度范围为0.05—2.93 ng·m−3 I-TEQ,均值为0.42 ng·m−3 I-TEQ,同2005—2019年相比下降1—2个数量级,能够满足0.5 ng·m−3 I-TEQ的排放要求. 钢铁生产行业的PCDD/Fs末端控制技术以ESP或BF为主,配备SCR、湿法脱硫等脱硫脱硝技术组成的APCDs(表4),可对PCDD/Fs等污染物进行协同控制. 尽管排放烟气中PCDD/Fs的浓度能够达到0.5 ng·m−3 I-TEQ的排放要求,但其排放浓度仍普遍高于固体废弃物焚烧行业. 因此钢铁行业尤其是烧结、电炉炼钢等工序的PCDD/Fs排放形势仍较为严峻,相关污染控制研究工作需进一步加强.

2.3 有色金属生产

有色金属生产通常采用的烟气PCDD/Fs控制技术见表4. 目前我国对再生有色金属生产行业烟气PCDD/Fs的排放限值为0.5 ng·m−3 TEQ [87]. 研究表明[47, 103],有色金属生产厂采用以BF或ESP为主要控制技术时,烟气中PCDD/Fs排放水平为0.009—0.13 ng·m−3 I-TEQ,能够持续满足0.5 ng·m−3 TEQ的限值要求. 但部分工厂排放PCDD/Fs的水平接近甚至超过限值要求(表4),且有色金属生产厂PCDD/Fs排放超标率可达22.2%[101]. 这表明能否有效利用现有控制技术(如BF或ESP为主的烟气污染控制系统)对有色金属行业的PCDD/Fs污染控制具有重要影响.

2.4 水泥窑协同处置

水泥窑协同处置行业针对烟气污染采取的控制技术和手段见表4. 水泥工业本身对排放的烟气中PCDD/Fs浓度水平并无明确限值,目前协同处置固体废物的水泥窑烟气中PCDD/Fs排放限值为0.1 ng·m−3 TEQ [88, 104]. 尽管水泥窑协同处置固体废物时原料中PCDD/Fs浓度较高,但经过高温分解处理后,烟气采用BF、BF+SNCR(选择性非还原催化)或ESP为主的APCDs进行净化,PCDD/Fs排放水平可达0.011—0.076 ng·m−3 I-TEQ[55, 103, 105-106],均可使PCDD/Fs以较低浓度排放.

2.5 不同工业过程PCDD/Fs污染控制效果比较

从表4中可以看出,目前固体废弃物焚烧行业多以BF或AC+BF为主要技术,配备SDS、DS等非ESP技术组成的APCDs对烟气进行深度净化;钢铁生产、有色金属生产、水泥窑协同处置行业则以BF或ESP为主要技术,配备SDS、脱硫脱硝等技术组成的APCDs对烟气进行处理. 当过程控制和末端控制均能得到有效保障时,烟气中PCDD/Fs的排放水多处于较低水平,但钢铁生产和有色金属生产的PCDD/Fs排放强度仍然明显高于其他行业.

3. 结果与展望(Results and perspectives)

本文系统的总结了固体废弃物焚烧、钢铁生产、有色金属生产和水泥窑协同处置等四类主要行业烟气中PCDD/Fs排放特征及污染控制的研究进展. 从排放特征来看,水泥窑协同处置行业排放的PCDD/Fs以4—6/7氯代同族体为主要单体,而固体废弃物焚烧、钢铁生产、有色金属生产等行业排放的PCDD/Fs以7—8氯代同族体为主,四类工业源的主要生成机理均为从头合成;从现有排放量数据来看,2004—2016年我国大气PCDD/Fs总排放量上升明显,PCDD/Fs排放量依次为:钢铁生产>固体废弃物焚烧>有色金属生产>水泥窑协同处置;依据现有文献数据进行估算,2020年PCDD/Fs排放量依次为钢铁生产>水泥窑协同处置>有色金属色生产>固体废弃物焚烧,但水泥窑协同处置固体废弃物产生PCDD/Fs的研究仍比较有限,相关工作亟需加强.

从烟气中PCDD/Fs的控制技术来看,在传统污染控制装置基础上增加活性炭吸附、催化剂、抑制剂等可以有效降低PCDD/Fs的大气排放[117-119]. 但目前各类工业源的PCDD/Fs末端控制多以除尘器结合吸附脱除装置为主,并未实现PCDD/Fs的总量削减;此外由于记忆效应导致的PCDD/Fs排放水平变化以及飞灰中高浓度PCDD/Fs带来的固废处置问题也给现有技术升级带来较大难度[46, 89, 120-123],因此,如何有效控制PCDD/Fs的排放总量仍然面临极大挑战. 末端控制技术方面,AC+BF吸附技术存在活性炭使用量大、价格高、活性炭吸附效率低、存在记忆效应、产生高毒性粉煤灰等缺点[108, 124-127],近年来,生物质制备活性炭、活性炭改性处理、双袋式除尘器、喷射聚丙烯胺、协同处置粉煤灰、热等离子体、紫外光降解等技术逐渐得到开发,能够有效改善或避免吸附法存在的问题[76-80, 128-136],然而诸多新技术尚停留在实验室阶段,且PCDD/Fs降解技术还存在反应时间长、去除效率不稳定等问题[137-140]. 因此尚无法在企业层面上推广应用.

一些针对工业过程中PCDD/Fs生成的研究发现,传统硫脲、硫酸铵等含N或含S的抑制剂存在氨溢出、额外成本等问题,研发使用无氨溢出风险的氧化钙,或采用含N或P的污泥等作为抑制剂可降低污染控制成本,且具有良好的抑制PCDD/Fs生成的控制效果[141-145],可能是未来控制某些工业过程中PCDD/Fs排放的重要技术手段.

基于以上研究现状,本文对典型工业过程中PCDD/Fs排放特征及其污染控制研究做以下两方面展望:

(1) 工业过程是PCDD/Fs人为排放的主要来源,尽管我国已经制定了相关行业的排放标准,排放总量也有所下降,但是部分行业仍然存在PCDD/Fs排放量增加的趋势,因此及时更新典型行业PCDD/Fs排放因子并完善排放清单,对于我国履行《斯德哥尔摩公约》和降低PCDD/Fs暴露风险具有重要意义.

(2) 对工业排放PCDD/Fs的控制应遵循“源头-过程-末端”的全过程控制原则. 开发新技术新材料,通过对原料预处理等措施从源头上弱化PCDD/Fs生成条件;通过添加抑制剂等措施从过程中减少PCDD/Fs的生成;积极研发PCDD/Fs的催化降解技术,结合活性炭吸附等末端控制技术可实现PCDD/Fs排放总量的有效削减.

-

表 1 我国PCDD/Fs的主要排放源及其排放量

Table 1. Main emission sources of dioxins and their emissions in China

排放源Emission source 排放因子/(ng·t−1 I-TEQ)Emission factor 年排放量/(g TEQ)Annual emission 参考文献References 大气Atmosphere 总量Total 固体废弃物焚烧 生活垃圾 — 125.8 338 [3] 危险废物 — 57.27 243.27 医疗废物 — 427.4 1176.3 总计(2004) — 610.47 1757.57 生活垃圾 1728 — — [24] 27—225 — — [25] 12200 217 — [23] 56—607 — — [60] 危险废物 70—3270 — — [60] 工业废物 302500 103 — [23] 医疗废物 97800 272 — [23] 780—473930 — — [26] 1923.6 0.466 — [20] 总计(2013) — 1280 — [61] 总计(2016) — 2469 — [4] 钢铁生产 铁矿石烧结 — 1522.5 1523.4 [3] 钢铁冶炼 — 150.9 1125.4 铸铁生产 — 10.7 97 炼焦 239.2 252.6 总计(2004) — 1923.31 2998.4 铁矿石烧结 1582.95 — — [30] 772.2—827.9 — — [37] 1330—7610 [38] 180±220 [36] 电弧炉 1245.85 — — [30] 270±23 [36] 3160 — — [37] 177—869 — — [38] 炼焦 160.09 — — [30] 28.9(WHO) — — [62] 总计(2011) — 6817 — [63] 总计(2012) — 618 — [64] 总计(2015) — 1216.83 — [35] 总计(2016) — 5333 — [4] 总计(2018) — 2240 — [30] 有色金属生产 铜生产 — 403 1133.8 [3] 铝生产 — 133.5 365.5 铅生产 — 13.4 17.4 其他 — 12.99 51.85 总计(2004) — 562.89 1568.55 铜生产 38.5、651(WHO) — — [49] 14.2 — — [50] 铝生产 1240.2 — — 铅生产 3140.0 — — 锌生产 166.0 — — 再生铜 241719—1707200 — — [37] 14802 37.5 — [65-66] 24451.3 — — [50] 再生铝 147819—434840 — — [37] 84.8—2720 — — [38] 再生铅 4297 — — [37] 镁生产 412(WHO) — — [49] 废旧导线回收 5569(WHO) — — [49] 水泥窑协同处置 水泥窑(2004) — 365.3 365.3 [3] 水泥窑 5000 0.02g — [57-58] 水泥窑 0.01—1.35 mg — — [55] 上述四类总计(2004) — 3461.97 6437.22 [3] 所有污染源总计(2004) — 5042.4 10236.8 [3] 注:“—”:表示未提及;其他:包锌、黄铜和青铜、镁等未提及的有色金属生产; 表 2 PCDD/Fs的全过程控制方法

Table 2. Whole process control method of PCDD/Fs

表 3 不同行业烟气PCDD/Fs排放控制标准

Table 3. PCDD/Fs emission control standard for different industries

表 4 工业烟气PCDD/Fs控制技术

Table 4. Collaborative dioxin control technology for industrial flue gas

工业类型Industrial Type 空气污染控制装置Air pollution control devices(APCDs) 进口Before 出口After 效率Efficiency 参考文献Reference 固体废弃物焚烧 生活垃圾焚烧 SDS+DS+AC+BF+SCR 0.2253 0.0028 98.76% [89] SNCR+SDS+AC+BF — 0.0365 — [98] — 0.076—0.153 — [107] — 0.007—0.095 — [25] SDS+AC+BF+SCR — 0.41 — [108] — 0.06 — [108] 热交换+SDS+AC+BF 2.58 0.0246 99% [109] 急冷+SDS+AC+BF — 0.45 — [94] SDS+AC+BF — 0.078 — [110] — 0.008—0.12 91.7%—99.3% [93] — 0.026 — [94] — 0.099 — [98] DS+AC+BF — 0.0844 — [38] WDS+AC+BF — 0.082 — [98] AC+BF — 0.239 — [38] CY+SDS+BF — 0.54 — [111] WDS+BF — 0.50 — [94] SDS+BF — 1.33 — [94] CY+ESP 16.137 0.946 94.14% [112] CY+ESP+BF 0.23 1.948 -747% [112] 0.436 5.018 -1051% [112] 危险废物焚烧 VS+CY+AC+BF 113 0.054(WHO) 99.95% [90] SDS+AC+BF — 0.01—11.91 — [92] AC+BF — 0.225 — [38] 医疗废弃物焚烧 SDS+AC+BF+WDS 5.32 0.07 98.68% [91] DS+AC+BF — 1.64 — [38] SDS+AC+BF — 0.07—12.21 — [92] SDS+BF — 0.07 — 钢铁生产 电弧炉炼钢 BF — 0.17 — [113] — 0.148—0.757 — [38] — 0.34 — [37] ESP+脱硫 — 0.003—0.557 — [36] 烧结 ESP+WFGD 2.3±0.56 0.99±0.53 — [99] ESP+SFGD 0.32—0.69 0.022—0.2 — [99] WFGD+WESP — 0.15 — [103] 钢铁生产 烧结 ESP+SCR — 0.137—0.657 — [38] ESP — 0.233 — [38] — 0.005—0.48 — [37] BF — 0.006—0.057 — [36] 炼焦 BF — (4.9—89.3)×10−3 (WHO) — [33] — 0.00870 — [38] — (0.0039—0.03)×10−3 — [114] 有色金属生产 再生铜 BF — 0.310 — [38] — 0.84 — [115] — 0.004—0.37 — [46] — 0.009—1.29 — [47] 再生锌 GS或ESP+BF — 0.48 — [103, 115] 再生铅 BFESP+GS+BF — 0.05 — BF+WDS+DS — 0.037 — [37] 再生铝 AC+BF — 0.1 — [45] BF — (5.68—44)×10−3 — [38] — 2.05 — [37] WDS — 0.88 — [37] 水泥窑 水泥窑协同处置 ESP — 5.9×10−3 — [115,103] — (9.3—49.3)×10−3 — [116] — 0.01—0.19 — [55] BF — 0.076 — [106] — (17.8—90.8) ×10−3 — [116] — 0.01—0.46 — [55] WDS — 0.04 — [55] 单位:ng·m−3 I-TEQ:“—”:未提及;WDS:湿法除尘器;CY:旋风除尘器;VS:文丘里洗涤器;WFGD:湿法脱硫;SFGD:半干法脱硫;WESP:湿法静电除尘;GS:重力沉降 unit:ng·m−3 I-TEQ;“—”:Not Reported;WDS:Wet dust collector;CY:Cyclone dust collector;VS:Venturi scrubber;WFGD:Wet flue gas desulfurization;SFGD:Semi-dry desulphurization;WESP:Wet electrostatic precipitator;GS:Gravity settling -

[1] FIEDLER H. Sources of PCDD/PCDF and impact on the environment [J]. Chemosphere, 1996, 32(1): 55-64. doi: 10.1016/0045-6535(95)00228-6 [2] GUL N, KHAN B, KHAN H, et al. Levels of polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs) in municipal waste dumping site, incinerator and brick kiln residues: evaluation for potential risk assessment [J]. Arabian Journal of Geosciences, 2021, 14(9): 1-10. [3] 郑明辉, 孙阳昭, 刘文彬. 中国二噁英类持久性有机污染物排放清单研究[M]. 北京: 中国环境科学出版社, 2008:9-30. ZHENG M H, SUN Y Z, LIU W B. Mission inventory of dioxin persistent organic pollutants in China[M]. Beijing: China Environmental Science Press, 2008:9-30(in Chinese).

[4] 陈露露, 黄韬, 陈凯杰, 等. 我国PCDD/Fs网格化大气排放清单[J]. 环境科学, 2020, 41(2): 510-519. CHEN L L, HUANG T, CHEN K J, et al. Gridded atmospheric emission inventory of PCDD/Fs in China(in Chinese).

[5] HUANG Y, CHEN Y, LI Y, et al. Atmospheric emissions of PCDDs and PCDFs in China from 1960 to 2014[J]. Journal of Hazardous Materials, 2022, 424(Pt A): 127320. [6] 中华人民共和国国家统计局. 中国统计年鉴-2021[M]. 北京: 中国统计出版社, 2021. National Bureau of Statistics, PRC. China Statistical Yearbook, 2021[M]. Beijing: China Statistics Press, 2021(in Chinese).

[7] 刘国瑞, 郑明辉, 孙轶斐, 等. 工业过程中持久性有机污染物排放特征[M]. 北京: 科学出版社, 2018:1. LIU G R, ZHENG M H, SUN Y F, et al. Emission characteristics of persistent organic pollutants from industrial processes[M]. Beijing: Science press, 2018:1(in Chinese).

[8] TIAN B, HUANG J, WANG B, et al. Emission characterization of unintentionally produced persistent organic pollutants from iron ore sintering process in China [J]. Chemosphere, 2012, 89(4): 409-415. doi: 10.1016/j.chemosphere.2012.05.069 [9] YANG L L, ZHAO Y Y, SHI M W, et al. Brominated dioxins and furans in a cement kiln co-processing municipal solid waste [J]. Journal of Environmental Sciences, 2019, 79: 339-345. doi: 10.1016/j.jes.2018.12.009 [10] YANG Y P, YANG L L, WANG M X, et al. Concentrations and profiles of persistent organic pollutants unintentionally produced by secondary nonferrous metal smelters: Updated emission factors and diagnostic ratios for identifying sources [J]. Chemosphere, 2020, 255: 126958. doi: 10.1016/j.chemosphere.2020.126958 [11] UNEP. The Stockholm Convention on Persistent Organic Pollutants. Geneva, Switzerland[M]. United Nations Environmental Programme, 2013. [12] XHROUET C, de PAUW E. Formation of PCDD/Fs in the sintering process: Influence of the raw materials [J]. Environmental Science & Technology, 2004, 38(15): 4222-4226. [13] HUANG H, BUEKENS A. On the mechanisms of dioxin formation in combustion processes [J]. Chemosphere, 1995, 31(9): 4099-4117. doi: 10.1016/0045-6535(95)80011-9 [14] LI H M, ZHANG N, GUO X, et al. Summary of flue gas purification and treatment technology for domestic waste incineration [J]. IOP Conference Series:Earth and Environmental Science, 2020, 508(1): 012016. doi: 10.1088/1755-1315/508/1/012016 [15] MAGUHN J, KARG E, KETTRUP A, et al. On-line analysis of the size distribution of fine and ultrafine aerosol particles in flue and stack gas of a municipal waste incineration plant: Effects of dynamic process control measures and emission reduction devices [J]. Environmental Science & Technology, 2003, 37(20): 4761-4770. [16] NIU Y Q, WEN L P, GUO X, et al. Co-disposal and reutilization of municipal solid waste and its hazardous incineration fly ash [J]. Environment International, 2022, 166: 107346. doi: 10.1016/j.envint.2022.107346 [17] HAN Y, LIU W B, LI H F, et al. Gas-particle partitioning of polychlorinated dibenzo-p-dioxins, dibenzofurans, and biphenyls in flue gases from municipal solid waste incinerators [J]. Aerosol and Air Quality Research, 2017, 17(11): 2847-2857. doi: 10.4209/aaqr.2017.09.0308 [18] 竹涛, 种旭阳, 王若男, 等. 生活垃圾焚烧飞灰处理技术研究进展 [J]. 洁净煤技术, 2022, 28(7): 189-201. doi: 10.13226/j.issn.1006-6772.21080202 ZHU T, CHONG X Y, WANG R N, et al. Research progress on the treatment technology of municipal solid waste incineration fly ash [J]. Clean Coal Technology, 2022, 28(7): 189-201(in Chinese). doi: 10.13226/j.issn.1006-6772.21080202

[19] 中华人民共和国国家统计局. 中国统计年鉴-2011[M]. 北京: 中国统计出版社, 2011. National Bureau of Statistics, PRC. China Statistical Yearbook, 2011[M]. Beijing: China Statistics Press, 2011(in Chinese).

[20] LI J F, LV Z W, DU L, et al. Emission characteristic of polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans (PCDD/Fs) from medical waste incinerators (MWIs) in China in 2016: A comparison between higher emission levels of MWIs and lower emission levels of MWIs [J]. Environmental Pollution, 2017, 221: 437-444. doi: 10.1016/j.envpol.2016.12.009 [21] WANG L, LEE W, LEE W, et al. Effect of chlorine content in feeding wastes of incineration on the emission of polychlorinated dibenzo-p-dioxinsydibenzofurans [J]. The Science of the Total Environment, 2003, 302: 185-198. doi: 10.1016/S0048-9697(02)00306-6 [22] ZHU J X, HIRAI Y, YU G, et al. Levels of polychlorinated dibenzo-p-dioxins and dibenzofurans in China and chemometric analysis of potential emission sources [J]. Chemosphere, 2008, 70(4): 703-711. doi: 10.1016/j.chemosphere.2007.06.053 [23] LI C, YANG L L, LIU X Y, et al. Bridging the energy benefit and POPs emission risk from waste incineration [J]. The Innovation, 2021, 2(1): 100075. doi: 10.1016/j.xinn.2020.100075 [24] NI Y W, ZHANG H J, FAN S, et al. Emissions of PCDD/Fs from municipal solid waste incinerators in China [J]. Chemosphere, 2009, 75(9): 1153-1158. doi: 10.1016/j.chemosphere.2009.02.051 [25] ZHU F, LI X F, LU J W, et al. Emission characteristics of PCDD/Fs in stack gas from municipal solid waste incineration plants in Northern China [J]. Chemosphere, 2018, 200: 23-29. doi: 10.1016/j.chemosphere.2018.02.092 [26] GAO H C, NI Y W, ZHANG H J, et al. Stack gas emissions of PCDD/Fs from hospital waste incinerators in China [J]. Chemosphere, 2009, 77(5): 634-639. doi: 10.1016/j.chemosphere.2009.08.017 [27] 李凡. 我国医疗废物管理法律制度探析[D]. 兰州: 西北民族大学, 2022:2. LI F. On the legal system of medical waste management in China[D]. Lanzhou: Northwest Minzu University, 2022:2(in Chinese).

[28] 王艳, 张俊林, 周丽. 新冠肺炎疫情环境下医疗废物的信息化储运策略 [J]. 环境工程, 2021, 39(4): 134-139. doi: 10.13205/j.hjgc.202104021 WANG Y, ZHANG J L, ZHOU L. Strategy of information storage and transportation of medical waste in epidemic situation [J]. Environmental Engineering, 2021, 39(4): 134-139(in Chinese). doi: 10.13205/j.hjgc.202104021

[29] 孙文强. 钢铁制造流程中物质流与能量流优化及其协同运行基础研究[D]. 沈阳: 东北大学, 2013:1. SUN W Q. Fundamental research on optimization and synergy of material flow and energy flow in steel manufacturing process[D]. Shenyang: Northeastern University, 2013:1(in Chinese).

[30] 汤铃, 贾敏, 伯鑫, 等. 中国钢铁行业排放清单及大气环境影响研究 [J]. 中国环境科学, 2020, 40(4): 1493-1506. doi: 10.3969/j.issn.1000-6923.2020.04.014 TANG L, JIA M, BO X, et al. High resolution emission inventory and atmospheric environmental impact research in Chinese iron and steel industry [J]. China Environmental Science, 2020, 40(4): 1493-1506(in Chinese). doi: 10.3969/j.issn.1000-6923.2020.04.014

[31] SHEN J, YANG L L, LIU G R, et al. Occurrence, profiles, and control of unintentional POPs in the steelmaking industry: A review [J]. Science of the Total Environment, 2021, 773: 145692. doi: 10.1016/j.scitotenv.2021.145692 [32] 杨秋婷. 电弧炉炼钢过程中氯代和溴代二恶英的排放特征研究[D]. 北京: 钢铁研究总院, 2021:4. YANG Q T. Study on emission profile of PCDD/fs and PBDD/fs in the electric arc furnace steelmaking process[D]. Beijing: General Iron and Steel Research Institute, 2021:4(in Chinese).

[33] LIU G R, ZHENG M H, LIU W B, et al. Atmospheric emission of PCDD/Fs, PCBs, hexachlorobenzene, and pentachlorobenzene from the coking industry [J]. Environmental Science & Technology, 2009, 43(24): 9196-9201. [34] YANG Q T, YANG L L, SHEN X J, et al. Organic pollutants from electric arc furnaces in steelmaking: A review [J]. Environmental Chemistry Letters, 2021, 19(2): 1509-1523. doi: 10.1007/s10311-020-01128-0 [35] GAO C K, GAO W G, SONG K H, et al. Spatial and temporal dynamics of air-pollutant emission inventory of steel industry in China: A bottom-up approach [J]. Resources, Conservation and Recycling, 2019, 143: 184-200. doi: 10.1016/j.resconrec.2018.12.032 [36] 杨艳艳, 谢丹平, 付建平, 等. 钢铁生产行业二噁污染特征变化及其排放因子 [J]. 环境科学, 2022, 43(8): 3990-3997. YANG Y Y, XIE D P, FU J P, et al. Pollution characteristics and emission factors of PCDD/fs from iron and steel industry [J]. Environmental Science, 2022, 43(8): 3990-3997(in Chinese).

[37] ZOU C, HAN J L, FU H Q. Emissions of PCDD/Fs from steel and secondary nonferrous productions [J]. Procedia Environmental Sciences, 2012, 16: 279-288. doi: 10.1016/j.proenv.2012.10.039 [38] WANG J B, HUNG C H, HUNG C H, et al. Polychlorinated dibenzo-p-dioxin and dibenzofuran emissions from an industrial park clustered with metallurgical industries [J]. Journal of Hazardous Materials, 2009, 161(2/3): 800-807. [39] 阿不力克木·亚森. 八钢高炉入炉原料的冶金性能及配料优化研究[D]. 西安: 西安建筑科技大学, 2004:1-26. Yasen A. Research on metallurgical performance of blast furnace burden in bayi iron and steel company[D]. Xi'an: Xi'an University of Architecture and Technology, 2004:1-26(in Chinese).

[40] 朱苗勇. 现代冶金工艺学-钢铁冶金卷[M]. 2版. 北京: 冶金工业出版社, 2016:108. ZHU M Y. Modern Metallurgical Technology -- Iron and Steel Metallurgy Volume (2nd edition)[M]. Beijing: Metallurgical Industry Press, 2016:108(in Chinese).

[41] 李小克. 铁矿粉价铁比与铁水成本的统计关系 [J]. 金属材料与冶金工程, 2013, 41(5): 31-34. doi: 10.3969/j.issn.1005-6084.2013.05.007 LI X K. The statistic relationship between the price-iron ratios of iron ore powder and the molten iron cost [J]. Metal Materials and Metallurgy Engineering, 2013, 41(5): 31-34(in Chinese). doi: 10.3969/j.issn.1005-6084.2013.05.007

[42] LI H F, LIU W B, TANG C, et al. Emissions of 2, 3, 7, 8-substituted and non-2, 3, 7, 8-substituted polychlorinated dibenzo-p-dioxins and dibenzofurans from secondary aluminum smelters [J]. Chemosphere, 2019, 215: 92-100. doi: 10.1016/j.chemosphere.2018.10.004 [43] 孟聪, 岳波, 孟棒棒, 等. 进口再生铜冶炼烟气中二噁英的生成特性 [J]. 环境化学, 2021, 40(8): 2462-2472. doi: 10.7524/j.issn.0254-6108.2020122502 MENG C, YUE B, MENG B B, et al. Formation characteristics of PCDD/Fs in imported secondary copper smelting flue gas [J]. Environmental Chemistry, 2021, 40(8): 2462-2472(in Chinese). doi: 10.7524/j.issn.0254-6108.2020122502

[44] 李家玲, 张正洁. 再生铝生产过程中二噁英成因及全过程污染控制技术 [J]. 环境保护科学, 2013, 39(2): 42-46. doi: 10.3969/j.issn.1004-6216.2013.02.011 LI J L, ZHANG Z J. Causes of dioxin generation during secondary aluminum production process and the whole process pollution control technology [J]. Environmental Protection Science, 2013, 39(2): 42-46(in Chinese). doi: 10.3969/j.issn.1004-6216.2013.02.011

[45] COLLINA E, BORTOLAMI M, FRANZONI F, et al. PCDD/F and dioxin-like PCB minimization: A 13-year experimental study along the flue gas cleaning system of a secondary aluminium refining plant [J]. Chemosphere, 2017, 181: 409-417. doi: 10.1016/j.chemosphere.2017.04.097 [46] LI H F, LIU W B, TANG C, et al. Emission profiles and formation pathways of 2, 3, 7, 8-substituted and non-2, 3, 7, 8-substituted polychlorinated dibenzo-p-dioxins and dibenzofurans in secondary copper smelters [J]. The Science of the Total Environment, 2019, 649: 473-481. doi: 10.1016/j.scitotenv.2018.08.279 [47] HU J C, ZHENG M H, NIE Z Q, et al. Polychlorinated dibenzo-p-dioxin and dibenzofuran and polychlorinated biphenyl emissions from different smelting stages in secondary copper metallurgy [J]. Chemosphere, 2013, 90(1): 89-94. doi: 10.1016/j.chemosphere.2012.08.003 [48] NIE Z Q, ZHENG M H, LIU W B, et al. Estimation and characterization of PCDD/Fs, dl-PCBs, PCNs, HxCBz and PeCBz emissions from magnesium metallurgy facilities in China [J]. Chemosphere, 2011, 85(11): 1707-1712. doi: 10.1016/j.chemosphere.2011.09.016 [49] 聂志强. 有色金属冶炼过程中UP-POPs的生成与排放研究[D]. 北京: 中国科学院大学, 2012:91.NIE Z Q.Formation and emission of UP-POPS during smelting processes in nonferrous metallurgical facilites[D].Beijing:Chinese academy of sciences,2012:91(in Chinese). [50] YU B W, JIN G Z, MOON Y H, et al. Emission of PCDD/Fs and dioxin-like PCBs from metallurgy industries in S. Korea [J]. Chemosphere, 2006, 62(3): 494-501. doi: 10.1016/j.chemosphere.2005.04.031 [51] 中华人民共和国国家统计局. 中国统计年鉴-2005[M]. 北京: 中国统计出版社, 2005. National Bureau of Statistics, PRC. China Statistical Yearbook, 2005[M]. Beijing: China Statistics Press, 2005(in Chinese).

[52] 嵇鹰, 蒲奋飞, 刘博鑫, 等. 水泥窑协同处置含锌粉尘对水泥熟料性能及环境安全性的影响 [J]. 环境工程学报, 2022, 16(3): 946-953. JI Y, PU F F, LIU B X, et al. Effect of cement kiln co-processing of Zinc-containing powders on clinker performance and leaching [J]. Chinese Journal of Environmental Engineering, 2022, 16(3): 946-953(in Chinese).

[53] LIU G R, ZHAN J Y, ZHENG M H, et al. Field pilot study on emissions, formations and distributions of PCDD/Fs from cement kiln co-processing fly ash from municipal solid waste incinerations [J]. Journal of Hazardous Materials, 2015, 299: 471-478. doi: 10.1016/j.jhazmat.2015.07.052 [54] YE W W, CAI P T, ZHAN M X, et al. Dioxin emission and distribution from cement kiln co-processing of hazardous solid waste [J]. Environmental Science and Pollution Research International, 2022, 29(35): 53755-53767. doi: 10.1007/s11356-022-19675-0 [55] ZOU L L, NI Y W, GAO Y, et al. Spatial variation of PCDD/F and PCB emissions and their composition profiles in stack flue gas from the typical cement plants in China [J]. Chemosphere, 2018, 195: 491-497. doi: 10.1016/j.chemosphere.2017.12.114 [56] ZHAO Y Y, ZHAN J Y, LIU G R, et al. Evaluation of dioxins and dioxin-like compounds from a cement plant using carbide slag from chlor-alkali industry as the major raw material [J]. Journal of Hazardous Materials, 2017, 330: 135-141. doi: 10.1016/j.jhazmat.2017.02.018 [57] 张婧, 倪余文, 张海军, 等. 水泥窑除尘器捕集灰中PCDD/Fs、PCBs和PCNs的分布特征 [J]. 环境科学, 2009, 30(2): 568-573. doi: 10.3321/j.issn:0250-3301.2009.02.043 ZHANG J, NI Y W, ZHANG H J, et al. Patterns of PCDD/Fs, PCBs and PCNs homologues in fly ash from cement kilns [J]. Environmental Science, 2009, 30(2): 568-573(in Chinese). doi: 10.3321/j.issn:0250-3301.2009.02.043

[58] KARADEMIR A. Health risk assessment of PCDD/F emissions from a hazardous and medical waste incinerator in Turkey [J]. Environment International, 2004, 30(8): 1027-1038. doi: 10.1016/j.envint.2004.05.008 [59] 王昕, 刘晨, 颜碧兰, 等. 国内外水泥窑协同处置城市固体废弃物现状与应用 [J]. 硅酸盐通报, 2014, 33(8): 1989-1995. doi: 10.16552/j.cnki.issn1001-1625.2014.08.028 WANG X, LIU C, YAN B L, et al. Statue and application of abroad and home co-processing of municipal solid waste by cement kiln [J]. Bulletin of the Chinese Ceramic Society, 2014, 33(8): 1989-1995(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2014.08.028

[60] QIU J, TANG M H, PENG Y Q, et al. Characteristics of PCDD/Fs in flue gas from MSWIs and HWIs: Emission levels, profiles and environmental influence [J]. Aerosol and Air Quality Research, 2020, 20(10): 2085-2097. doi: 10.4209/aaqr.2019.11.0610 [61] 王梦京. 铁矿石烧结行业脱硫工艺对多种UP-POPs协同减排研究[D]. 上海: 上海应用技术大学, 2016:54. WANG M J. UP-POPs emissions from sintering plants synergistically controlled by the desulfurization process[D]. Shanghai: Shanghai Institute of Technology, 2016:54(in Chinese).

[62] 刘国瑞. 炼焦过程中典型UP-POPs的生成和排放研究[D]. 北京: 中国科学院大学, 2010:76. LIU G R. Formation and Emission of Selected UP-POPs during Coking Processes[D]. Beijing: University of Chinese Academy of Sciences, 2010:76(in Chinese).

[63] WANG K, TIAN H Z, HUA S B, et al. A comprehensive emission inventory of multiple air pollutants from iron and steel industry in China: Temporal trends and spatial variation characteristics [J]. The Science of the Total Environment, 2016, 559: 7-14. doi: 10.1016/j.scitotenv.2016.03.125 [64] WU X C, ZHAO L J, ZHANG Y X, et al. Primary air pollutant emissions and future prediction of iron and steel industry in China [J]. Aerosol and Air Quality Research, 2015, 15(4): 1422-1432. doi: 10.4209/aaqr.2015.01.0029 [65] BA T, ZHENG M H, ZHANG B, et al. Estimation and congener-specific characterization of polychlorinated naphthalene emissions from secondary nonferrous metallurgical facilities in China [J]. Environmental Science & Technology, 2010, 44(7): 2441-2446. [66] BA T, ZHENG M H, ZHANG B, et al. Estimation and characterization of PCDD/Fs and dioxin-like PCBs from secondary copper and aluminum metallurgies in China [J]. Chemosphere, 2009, 75(9): 1173-1178. doi: 10.1016/j.chemosphere.2009.02.052 [67] ZHAO B, ZHENG M H, JIANG B. Dioxin emissions and human exposure in China: A brief history of policy and research [J]. Environmental Health Perspectives, 2011, 119(3): a112-a113. [68] FU J Y, CAI P T, ZHAN M X, et al. Formation and control of dioxins during thermal desorption remediation of chlorine and non-chlorine organic contaminated soil [J]. Journal of Hazardous Materials, 2022, 436: 129124. doi: 10.1016/j.jhazmat.2022.129124 [69] 陈彤. 城市生活垃圾焚烧过程中二噁英的形成机理及控制技术研究[D]. 杭州: 浙江大学, 2006:134. CHEN T. Mechanism and exPerimental study on PCDD/Fs fonrration and control during munieiPal solid wastes incineration[D]. Hangzhou: Zhejiang University, 2006:134(in Chinese).

[70] 龙红明, 丁龙, 钱立新, 等. 烧结烟气中NOx和二噁的减排现状及发展趋势 [J]. 化工进展, 2022, 41(7): 3865-3876. LONG H M, DING L, QIAN L X, et al. Current situation and development trend of NOx and dioxins emission reduction in sintering flue gas [J]. Chemical Industry and Engineering Progress, 2022, 41(7): 3865-3876(in Chinese).

[71] HE H, GUO X H, JIN L Z, et al. The effect of adjusting sinter raw mix on dioxins from iron ore co-sintering with municipal solid waste incineration fly ash [J]. Energies, 2022, 15(3): 1136. doi: 10.3390/en15031136 [72] JI Z Y, HUANG B B, GAN M, et al. Dioxins control as co-processing water-washed municipal solid waste incineration fly ash in iron ore sintering process[J]. Journal of Hazardous Materials, 2022, 423(Pt B): 127138. [73] NEUER-ETSCHEIDT K, NORDSIECK H O, LIU Y B, et al. PCDD/F and other micropollutants in MSWI crude gas and ashes during plant start-up and shut-down processes [J]. Environmental Science & Technology, 2006, 40(1): 342-349. [74] XIONG S J, PENG Y Q, LU S Y, et al. PCDD/Fs from a large-scale municipal solid waste incinerator under transient operations: Insight formation pathways and optimal reduction strategies [J]. Journal of Environmental Management, 2022, 314: 114878. doi: 10.1016/j.jenvman.2022.114878 [75] ADELODUN A A. Influence of operation conditions on the performance of non-thermal plasma technology for VOC pollution control [J]. Journal of Industrial and Engineering Chemistry, 2020, 92: 41-55. doi: 10.1016/j.jiec.2020.08.026 [76] QIN Y, GU J, CAI W T, et al. Catalytic oxidation of chlorobenzene and PCDD/Fs over V2O5-WO3/TiO2: Insights into the component effect and reaction mechanism [J]. Environmental Science and Pollution Research International, 2022, 29(28): 42809-42821. doi: 10.1007/s11356-022-18768-0 [77] TANG M H, YE Q L, DU C C, et al. PCDD/F removal at low temperatures over vanadium-based catalyst: Insight into the superiority of mechanochemical method [J]. Environmental Science and Pollution Research International, 2022, 29(5): 7042-7052. doi: 10.1007/s11356-021-15477-y [78] MA Y F, LAI J W, LI X D, et al. Field study on PCDD/F decomposition over VOx/TiO2 catalyst under low-temperature: Mechanism and kinetics analysis [J]. Chemical Engineering Journal, 2022, 429: 132222. doi: 10.1016/j.cej.2021.132222 [79] TRINH M M, CHANG M B. Transformation of mono- to octa- chlorinated dibenzo-p-dioxins and dibenzofurans in MWI fly ash during catalytic pyrolysis process [J]. Chemical Engineering Journal, 2022, 427: 130907. doi: 10.1016/j.cej.2021.130907 [80] ALVARADO R, RAMOS-BERDULLAS N, MANDADO M. On the adsorption affinity of graphene and white graphene sheets by dioxin-like pollutants [J]. International Journal of Quantum Chemistry, 2021, 121(9): e26591. [81] LONG Y P, SU Y T, XUE Y H, et al. V2O5-WO3/TiO2 catalyst for efficient synergistic control of NOx and chlorinated organics: Insights into the arsenic effect [J]. Environmental Science & Technology, 2021, 55(13): 9317-9325. [82] 环境保护部、国家质量监督检验检疫总局. 生活垃圾焚烧污染物控制标准: GB18485—2014[S]. 北京: 中国环境科学出版社, 2014. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Standard for pollution control on the municipal solid waste incineration: GB18485-2014[S]. Beijing: China Environmental Science Press, 2014(in Chinese).

[83] 国家环境保护总局、国家质量监督检验检疫总局. 危险废物焚烧污染控制标准: GB 18484—2001[S]. 北京: 中国环境科学出版社, 2001. State Environmental Protection Administration, General Administration of Quality Supervision, Inspection and Quarantine of PPC. Pollution control standard for hazardous waste incineration: GB 18484—2001[S]. Beijing: China Environmental Science Press, 2001 (in Chinese).

[84] 环境保护部、国家质量监督检验检疫总局. 火葬场大气污染物排放标准: GB 13801-2015[S]. 北京: 中国环境科学出版社, 2015. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Emission standard of air pollutants for crematory : GB13801-2015[S]. Beijing: China Environmental Science Press, 2015(in Chinese).

[85] 环境保护部、国家质量监督检验检疫总局. 炼钢工业大气污染物排放标准: GB 28664—2012[S]. 北京: 中国环境科学出版社, 2012. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Emission standard of air pollutants for steel smelt industry: GB 28664—2012[S]. Beijing: China Environmental Science Press, 2012(in Chinese).

[86] 环境保护部、国家质量监督检验检疫总局. 钢铁烧结、球团工业大气污染物排放标准: GB 28662—2012[S]. 北京: 中国环境科学出版社, 2012. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Emission standard of air pollutants for sintering and pelletizing of iron and steel industry: GB 28662—2012[S]. Beijing: China Environmental Science Press, 2012(in Chinese).

[87] 环境保护部、国家质量监督检验检疫总局. 再生铜、铝、铅、锌工业污染物排放标准: GB 31574—2015[S]. 北京: 中国环境科学出版社, 2015. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Emission standards of pollutants for secondary copper, aluminum, lead and Zink industry: GB 31574—2015[S]. Beijing: China Environmental Science Press, 2015(in Chinese).

[88] 环境保护部、国家质量监督检验检疫总局. 水泥窑协同处置固体废物污染控制标准: GB 30485—2013[S]. 北京: 中国环境科学出版社, 2013. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Standard for pollution control on co-processing of solid wastes in cement kiln: GB30485-2013[S]. Beijing: China Environmental Science Press, 2014(in Chinese).

[89] WEI J X, LI H, LIU J G. Phase distribution of PCDD/Fs in flue gas from municipal solid waste incinerator with ultra-low emission control in China [J]. Chemosphere, 2021, 276: 130166. doi: 10.1016/j.chemosphere.2021.130166 [90] LIN S L, WU J L, CHEN W H, et al. Ultra-low PCDD/F emissions and their particle size and mass distribution in a hazardous waste treatment system[J]. Journal of Hazardous Materials, 2022, 423(Pt A) : 127032. [91] MA Y F, LIN X Q, CHEN T, et al. Field study on the emission characteristics of micro/trace pollutants and their correlations from medical waste incineration [J]. Energy & Fuels, 2020, 34(12): 16381-16388. [92] 陈佳, 陈彤, 王奇, 等. 中国危险废物和医疗废物焚烧处置行业二噁英排放水平研究 [J]. 环境科学学报, 2014, 34(4): 973-979. doi: 10.13671/j.hjkxxb.2014.0158 CHEN J, CHEN T, WANG Q, et al. PCDD/Fs emission levels of hazardous and medical waste incineration in China [J]. Acta Scientiae Circumstantiae, 2014, 34(4): 973-979(in Chinese). doi: 10.13671/j.hjkxxb.2014.0158

[93] LI Y C, YANG Y, YU G, et al. Emission of unintentionally produced persistent organic pollutants (UPOPs) from municipal waste incinerators in China [J]. Chemosphere, 2016, 158: 17-23. doi: 10.1016/j.chemosphere.2016.05.037 [94] LIU W B, TIAN Z Y, LI H F, et al. Mono- to Octa-chlorinated PCDD/Fs in stack gas from typical waste incinerators and their implications on emission [J]. Environmental Science & Technology, 2013, 47(17): 9774-9780. [95] TIAN H H, OUYANG N. Preliminary investigation on dioxins emission from MWS incinerators [J]. Environmental Chemistry, 2003, 22(3): 255-258. [96] YING Y X, XU L, LIN X Q, et al. Influence of different kinds of incinerators on PCDD/Fs: a case study of emission and formation pathway [J]. Environmental Science and Pollution Research, 2023,30: 5903-5916. [97] 雷鸣. 小型农村生活垃圾热处理炉二噁英及重金属的排放特性及控制研究[D]. 广州: 华南理工大学, 2017:110. LEI M. Emission characteristics and control of PCDD/Fs and heavy metals from small-scale thermal treatment furnace for disposing rural domestic solid waste [D]. Guangzhou: South China University of Technology, 2017:110(in Chinese).

[98] 俞明锋, 付建英, 詹明秀, 等. 生活废弃物焚烧处置烟气中二噁英排放特性研究 [J]. 环境科学学报, 2018, 38(5): 1983-1988. YU M F, FU J Y, ZHAN M X, et al. The research of PCDD/Fs emission characteristics in flue gas from municipal solid waste incinerations [J]. Acta Scientiae Circumstantiae, 2018, 38(5): 1983-1988(in Chinese).

[99] WANG M J, LIU W B, HOU M F, et al. Mono- to octachlorinated polychlorinated dibenzo-p-dioxin and dibenzofuran emissions from sintering plants synergistically controlled by the desulfurization process [J]. Environmental Science & Technology, 2016, 50(10): 5207-5215. [100] 王凤炜, 付建英, 林晓青, 等. 钢铁冶炼行业二噁英排放特性和厂区内大气中二噁英分布规律 [J]. 环境科学学报, 2018, 38(4): 1404-1409. doi: 10.13671/j.hjkxxb.2017.0461 WANG F W, FU J Y, LIN X Q, et al. The emission characteristics of dioxins from steel industry and distribution of dioxins in the atmosphere of plant [J]. Acta Scientiae Circumstantiae, 2018, 38(4): 1404-1409(in Chinese). doi: 10.13671/j.hjkxxb.2017.0461

[101] 唐娜, 李馥琪, 罗伟铿, 等. 废物焚烧及工业金属冶炼烟气中二噁英的排放水平及同系物分布 [J]. 安全与环境学报, 2018, 18(4): 1496-1502. TANG N, LI F Q, LUO W K, et al. Concentrations and congener distributions of PCDD/Fs in the flue gas from combustion and metallurgical processing [J]. Journal of Safety and Environment, 2018, 18(4): 1496-1502(in Chinese).

[102] ZHAN M X, MA Y F, CHEN T, et al. PCDD/Fs characteristics in flue gas and surrounding environment of iron and steel smelting industry [J]. Environmental Science and Pollution Research International, 2021, 28(11): 14092-14104. doi: 10.1007/s11356-020-11650-x [103] SONG S, ZHOU X, GUO C Q, et al. Emission characteristics of polychlorinated, polybrominated and mixed polybrominated/chlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs, PBDD/Fs, and PBCDD/Fs) from waste incineration and metallurgical processes in China [J]. Ecotoxicology and Environmental Safety, 2019, 184: 109608. doi: 10.1016/j.ecoenv.2019.109608 [104] 环境保护部、国家质量监督检验检疫总局. 水泥工业大气污染物排放标准: GB 4915—2013[S]. 北京: 中国环境科学出版社, 2014. Ministry of Environmental Protection of PRC, General Administration of Quality Supervision, Inspection and Quarantine of PRC. Emission standard of air pollutants for cement industry: GB 4915—2013[S]. Beijing: China Environmental Science Press, 2014(in Chinese).

[105] 肖海平, 茹宇, 李丽, 等. 水泥窑协同处置生活垃圾焚烧飞灰过程中二噁英的迁移和降解特性 [J]. 环境科学研究, 2017, 30(2): 291-297. XIAO H P, RU Y, LI L, et al. Migration and degradation characteristics of dioxins during the process of cement kiln co-processing of municipal solid waste incineration fly ash [J]. Research of Environmental Sciences, 2017, 30(2): 291-297(in Chinese).

[106] CHEN T, ZHAN M X, LIN X Q, et al. Emission and distribution of PCDD/Fs and CBzs from two co-processing RDF cement plants in China [J]. Environmental Science and Pollution Research International, 2016, 23(12): 11845-11854. doi: 10.1007/s11356-016-6403-0 [107] HUANG Y Q, LU J W, XIE Y S, et al. Process tracing of PCDD/Fs from economizer to APCDs during solid waste incineration: re-formation and transformation mechanisms [J]. Waste Management, 2021, 120: 839-847. doi: 10.1016/j.wasman.2020.11.007 [108] MA Y F, LIN X Q, CHEN Z L, et al. Influence factors and mass balance of memory effect on PCDD/F emissions from the full-scale municipal solid waste incineration in China [J]. Chemosphere, 2020, 239: 124614. doi: 10.1016/j.chemosphere.2019.124614 [109] 张漫雯, 冯桂贤, 黄蓉, 等. 国产活性炭喷射去除大型城市生活垃圾焚烧发电厂烟气中的二恶英 [J]. 环境工程学报, 2015, 9(11): 5531-5536. doi: 10.12030/j.cjee.20151164 ZHANG M W, FENG G X, HUANG R, et al. Removal of dioxin in flue gas from a large-scale MSWI by domestic activated carbon injection [J]. Chinese Journal of Environmental Engineering, 2015, 9(11): 5531-5536(in Chinese). doi: 10.12030/j.cjee.20151164

[110] ZHANG G, HAI J, CHENG J. Characterization and mass balance of dioxin from a large-scale municipal solid waste incinerator in China [J]. Waste Management, 2012, 32(6): 1156-1162. doi: 10.1016/j.wasman.2012.01.024 [111] 孙立, 张晓东. 生物质热解气化原理与技术[M]. 北京: 化学工业出版社, 2013. SUN L, ZHANG X D. Principle and technology of biomass pyrolysis and gasification[M]. Beijing: Chemical Industry Press, 2013(in Chinese).

[112] CHOI K I, LEE D H, OSAKO M, et al. The prediction of PCDD/DF levels in wet scrubbers associated with waste incinerators [J]. Chemosphere, 2007, 66(6): 1131-1137. doi: 10.1016/j.chemosphere.2006.06.019 [113] 陆勇, 田洪海, 周志广, 等. 电弧炉炼钢过程中二噁英类的排放浓度和同类物分布 [J]. 环境科学研究, 2009, 22(3): 304-308. LU Y, TIAN H H, ZHOU Z G, et al. Concentrations and congener profiles of dioxins in stack gas and fly ash samples from an electric arc furnace [J]. Research of Environmental Sciences, 2009, 22(3): 304-308(in Chinese).

[114] 孙鹏程, 李晓璐, 成钢, 等. 焦炉烟气中二噁英类物质排放水平研究 [J]. 环境科学, 2014, 35(7): 2515-2519. doi: 10.13227/j.hjkx.2014.07.012 SUN P C, LI X L, CHENG G, et al. Preliminary investigation on emission of PCDD/Fs and DL-PCBs through flue gas from coke plants in China [J]. Environmental Science, 2014, 35(7): 2515-2519(in Chinese). doi: 10.13227/j.hjkx.2014.07.012

[115] YANG Y P, WU G L, JIANG C, et al. Variations of PCDD/Fs emissions from secondary nonferrous smelting plants and towards to their source emission reduction [J]. Environmental Pollution, 2020, 260: 113946. doi: 10.1016/j.envpol.2020.113946 [116] CHEN T, GUO Y, LI X D, et al. Emissions behavior and distribution of polychlorinated dibenzo-p-dioxins and furans (PCDD/Fs) from cement kilns in China [J]. Environmental Science and Pollution Research International, 2014, 21(6): 4245-4253. doi: 10.1007/s11356-013-2356-8 [117] ZHAO C, DONG Y, FENG Y P, et al. Thermal desorption for remediation of contaminated soil: A review [J]. Chemosphere, 2019, 221: 841-855. doi: 10.1016/j.chemosphere.2019.01.079 [118] LEE Y, CUI M, CHOI J, et al. Treatment of polychlorinated dibenzo-p-dioxins and dibenzofurans contaminated soil using S2O82− with ferrous ion and heat as activating methods [J]. Chemical Engineering Journal, 2020, 384: 123299. doi: 10.1016/j.cej.2019.123299 [119] PENG Y Q, LU S Y, LI X D, et al. Formation, measurement, and control of dioxins from the incineration of municipal solid wastes: Recent advances and perspectives [J]. Energy & Fuels, 2020, 34(11): 13247-13267. [120] WANG M J, LI Q Q, LIU W B, et al. Monochlorinated to octachlorinated polychlorinated dibenzo-p-dioxin and dibenzofuran emissions in sintering fly ash from multiple-field electrostatic precipitators [J]. Environmental Science & Technology, 2018, 52(4): 1871-1879. [121] WANG M J, LI Q Q, LIU W B. Effects of desulfurization processes on polybrominated dibenzop-dioxin and dibenzofuran emissions from iron ore sintering [J]. Environmental Science & Technology, 2018, 52(10): 5764-5770. [122] DENG D Y, QIAO J Q, LIU M Q, et al. Detoxification of municipal solid waste incinerator (MSWI) fly ash by single-mode microwave (MW) irradiation: Addition of urea on the degradation of Dioxin and mechanism [J]. Journal of Hazardous Materials, 2019, 369: 279-289. doi: 10.1016/j.jhazmat.2019.01.001 [123] ZIMMERMANN R, BLUMENSTOCK M, HEGER H J, et al. Emission of nonchlorinated and chlorinated aromatics in the flue gas of incineration plants during and after transient disturbances of combustion conditions: Delayed emission effects [J]. Environmental Science & Technology, 2001, 35(6): 1019-1030. [124] CHEN T L, CHEN L H, CHEN Y H, et al. A systematic approach to evaluating environmental-economic benefits of high-gravity technology for flue gas purification and municipal solid waste incineration fly ash utilization [J]. Journal of Environmental Chemical Engineering, 2021, 9(6): 106438. doi: 10.1016/j.jece.2021.106438 [125] WANG P J, YAN F, CAI J J, et al. Emission levels and phase distributions of PCDD/Fs in a full-scale municipal solid waste incinerator: The impact of wet scrubber system [J]. Journal of Cleaner Production, 2022, 337: 130468. doi: 10.1016/j.jclepro.2022.130468 [126] dal POZZO A, MURATORI G, ANTONIONI G, et al. Economic and environmental benefits by improved process control strategies in HCl removal from waste-to-energy flue gas [J]. Waste Management, 2021, 125: 303-315. doi: 10.1016/j.wasman.2021.02.059 [127] XUE Y, LIU X M. Detoxification, solidification and recycling of municipal solid waste incineration fly ash: A review [J]. Chemical Engineering Journal, 2021, 420: 130349. doi: 10.1016/j.cej.2021.130349 [128] ZHAN M X, LIU Y W, YE W W, et al. Modification of activated carbon using urea to enhance the adsorption of dioxins[J]. Environmental Research, 2022, 204(Pt B): 112035. [129] HSU Y C, CHANG S H, CHANG M B. Emissions of PAHs, PCDD/Fs, dl-PCBs, chlorophenols and chlorobenzenes from municipal waste incinerator cofiring industrial waste [J]. Chemosphere, 2021, 280: 130645. doi: 10.1016/j.chemosphere.2021.130645 [130] WEI X N, LI T T. Wooden activated carbon production for dioxin removal via a two-step process of carbonization coupled with steam activation from biomass wastes [J]. ACS Omega, 2021, 6(8): 5607-5618. doi: 10.1021/acsomega.0c06032 [131] GAN M, WONG G, FAN X H, et al. Enhancing the degradation of dioxins during the process of iron ore sintering co-disposing municipal solid waste incineration fly ash [J]. Journal of Cleaner Production, 2021, 291: 125286. doi: 10.1016/j.jclepro.2020.125286 [132] LI H F, LIU W B, LU A X, et al. PCDD/Fs emissions from secondary copper production synergistically controlled by fabric filters and desulfurization [J]. Environmental Pollution, 2021, 270: 116065. doi: 10.1016/j.envpol.2020.116065 [133] LIN X Q, MA Y F, CHEN Z L, et al. Effect of different air pollution control devices on the gas/solid-phase distribution of PCDD/F in a full-scale municipal solid waste incinerator[J]. Environmental Pollution, 2020, 265(Pt B): 114888. [134] LUO G P, ZHANG K, PENG Y Q, et al. Pilot study on removal characteristics of multiple pollutants by the dual baghouse filter system [J]. Energies, 2022, 15(10): 3728. doi: 10.3390/en15103728 [135] LV Z Y, YU Y, REN M H, et al. Spraying polyacrylamide solution to improve the removal of particle-phase dioxins by bag filter in a full-scale municipal solid waste incineration system [J]. Chemosphere, 2021, 285: 131392. doi: 10.1016/j.chemosphere.2021.131392 [136] GUO Y Y, LUO L, ZHENG Y, et al. Low-medium temperature application of selective catalytic reduction denitration in cement flue gas through a pilot plant [J]. Chemosphere, 2021, 276: 130182. doi: 10.1016/j.chemosphere.2021.130182 [137] CAI X W, DU C M. Thermal plasma treatment of medical waste [J]. Plasma Chemistry and Plasma Processing, 2021, 41(1): 1-46. doi: 10.1007/s11090-020-10119-6 [138] ORTIZ ALMIRALL X, SOLÀ YAGÜE N, GONZALEZ-OLMOS R, et al. Photochemical degradation of persistent organic pollutants (PCDD/FS, PCBS, PBDES, DDTS and HCB) in hexane and fish oil [J]. Chemosphere, 2022, 301: 134587. doi: 10.1016/j.chemosphere.2022.134587 [139] ZHANG H J, ZHANG Y N, ZHONG Y C, et al. Novel strategies for 2, 8-dichlorodibenzo-p-dioxin degradation using ternary Au-modified iron doped TiO2 catalysts under UV-vis light illumination[J]. Chemosphere, 2022, 291(Pt 2): 132826. [140] DING X X, YANG Y T, ZENG Z Q, et al. Insight into the transformation behaviors of dioxins from sintering flue gas in the cyclic thermal regeneration by the V2O5/AC catalyst-sorbent [J]. Environmental Science & Technology, 2022, 56(9): 5786-5795. [141] LU S Y, XIANG Y F, CHEN Z L, et al. Development of phosphorus-based inhibitors for PCDD/Fs suppression [J]. Waste Management, 2021, 119: 82-90. doi: 10.1016/j.wasman.2020.09.019 [142] CHEN Z L, LIN X Q, LU S Y, et al. Suppressing formation pathway of PCDD/Fs by S-N-containing compound in full-scale municipal solid waste incinerators [J]. Chemical Engineering Journal, 2019, 359: 1391-1399. doi: 10.1016/j.cej.2018.11.039 [143] WIELGOSIŃSKI G, CZERWIŃSKA J, SZYMAŃSKA O, et al. Simultaneous NOx and dioxin removal in the SNCR process [J]. Sustainability, 2020, 12(14): 5766. doi: 10.3390/su12145766 [144] WANG X X, MA Y F, LIN X Q, et al. Inhibition on de novo synthesis of PCDD/Fs by an N-P-containing compound: Carbon gasification and kinetics [J]. Chemosphere, 2022, 292: 133457. doi: 10.1016/j.chemosphere.2021.133457 [145] CONESA J A. Sewage sludge as inhibitor of the formation of persistent organic pollutants during incineration [J]. Sustainability, 2021, 13(19): 10935. doi: 10.3390/su131910935 期刊类型引用(3)

1. 阳陈,张欢燕,杨文武. 雾霾天气下泰州市环境空气中二噁英类物质浓度研究. 环境科学与管理. 2024(02): 116-120 .  百度学术

百度学术

2. 林炳丞,王枭,王健,金蓉,马云峰,刘国瑞,郑明辉. 工业热过程中无意生成持久性有机污染物的自由基转化机制. 环境化学. 2024(11): 3665-3677 .  本站查看

本站查看

3. 晋好城. 工业排放污染治理工程在大气环境保护中的作用与挑战. 皮革制作与环保科技. 2024(23): 142-144 .  百度学术

百度学术

其他类型引用(0)

-

DownLoad:

DownLoad: