-

煤矸石是煤炭开采过程中的大宗工业固废,目前处置方式以堆存为主,存在占用土地、生态破坏、地下水污染等问题。煤矿瓦斯在经燃烧利用所产中低温烟气余热未得到有效利用,造成能源的大量浪费。

煤矸石在矿物组成上与土壤具有高度的相似性,但因其粒径粗大、保水性能差等原因,煤矸石大规模生态化利用受限。魏忠义和王秋兵[1]研究认为微粒含量上升即持水率提高是煤矸石复垦的先决条件,胡振琪等[2]认为矿区复垦重点在于土壤性能综合提升。煤矸石颗粒粉化可提升基质持水能力,实现基质成土的初期演替。自然环境中,煤矸石等岩石颗粒的风化粉化主要由温度和水分驱动,但自然扰动强度小、频率低,煤矸石风化进程缓慢。蔡毅等[3]对淮南矿区煤矸石进行采样分析,结果表明风化2~12年的煤矸石持水率才具有较为明显的提升。张清峰等[4]研究表明煤矸石经36个月风化后含水率趋于稳定并超过10%。针对煤矸石风化粉化,梁冰等[5]利用木霉菌对煤矸石进行分解改良,作用30 d后,0.5 mm以下微粒上升了5%左右,时间成本较高;尚志等[6]、ZHANG等[7]采用冻融循环提高煤矸石黏粒细砂含量,研究表明冻融对土壤矿物化学性能改变不大,但对其粒径粉化效果显著,但冻融循环受环境制约难以大规模推广。张素等[8]认为干湿/冷热扰动有利于基质微粒含量的快速提升。通过瓦斯烟气余热利用对煤矸石进行强化风化处理,增强环境扰动的强度和频率,有望实现煤矸石的快速粉化及矿物转化,均衡其土壤学要素,达到综合性能的提升,开辟煤矸石原位风化成土的新途径。所以将煤矸石与瓦斯烟气余热进行协同处理处置,实现资源与能源的高效利用,是煤炭企业绿色可持续发展的重要课题。

针对煤矸石粒径粗大、持水能力薄弱的问题,本研究利用瓦斯烟气余热,强化煤矸石干湿/冷热的交替循环,加速煤矸石结构风化粉化,促进煤矸石的矿物分解与重构,提升风化产物的透气保墒性能,并通过植物生长考核其风化产物的生态化应用效果,以实现煤矸石与瓦斯烟气余热的资源能源的高效利用。

-

实验所用煤矸石来自云南恩洪煤矿,岩性以页岩、砂岩、泥岩为主,矿物成分主要为钙长石、伊利石、方解石等,以及少量黄铁矿。实验设置3组样品,初始持水率为6.3%±0.5%,每组样品重量为1 kg,样品粒径分布如表1所示。

-

1) 干湿交替实验。对煤矸石进行高频干湿/冷热交替的扰动模拟,将煤矸石用滤布包裹后放入直径15 cm的PVC反应器,向容器中注入1 000 mL超纯水对煤矸石浸泡30 min并记录容器总重;提起滤布取出样品,沥干30 min,然后在45~50 ℃下烘干8 h,此为1个循环。样品分别经历10、20、30次循环,样品命名为CG1、CG2、CG3,干湿交替过程中堆浸液循环使用,每次浸泡时补充超纯水至初始记录总重,堆浸液命名为R1、R2、R3。反应完成后底部煤矸石微粒采用真空抽滤进行分离。

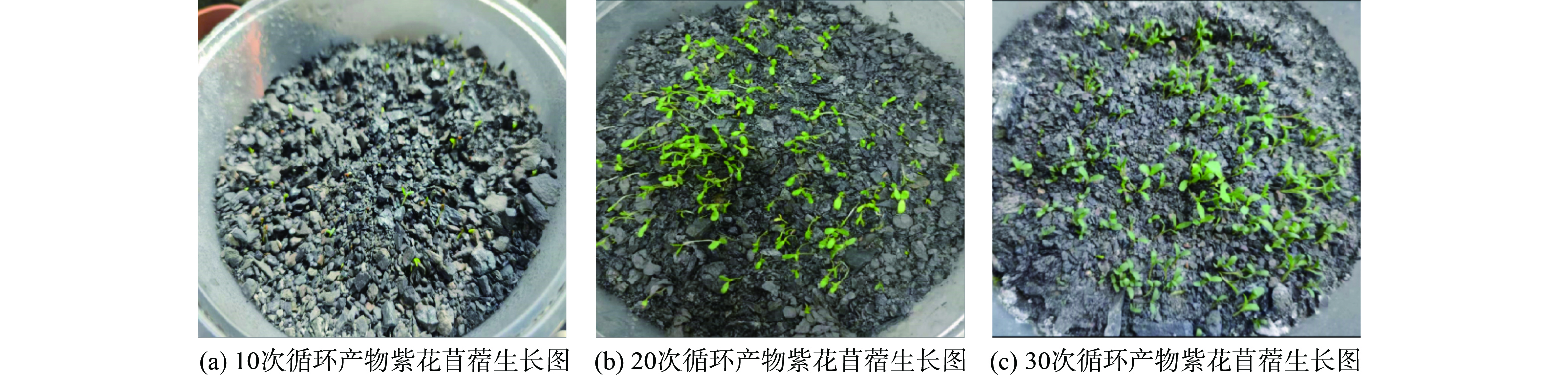

2) 紫花苜蓿生长试验。处理后的样品各取80 g,混匀后放入种植盆,每盆播种20颗紫花苜蓿种子,观察紫花苜蓿发芽及生长状况。每组样品设计3组平行样。

-

1) 堆浸液。堆浸液静置沉淀30 min,样品过0.45 μm滤膜,使用电导率仪 (上海雷磁,DDS-11A) 检测其电导率,为减小实验误差,相邻2次电导率取平均值作图。样品分别循环处理完成后,30次循环的堆浸液上清液过0.45 μm滤膜烘干得到堆浸液盐分结晶,测定浸出液盐分的元素种类。样品粒径检测采用干筛法,筛分时间t (

m样品50g×20 s) ,过5、2、1 mm筛后分别记录筛下物质量,质量所占总重比例即为其粒径分布指标;持水率、孔隙度采取室内环刀法测定及计算。2) 风化产物。利用XRD (日本 Rigaku Ultima IV) 检测颗粒矿物种类;将干湿交替循环结束的样品经105 ℃干燥,利用体式显微镜 (江西凤凰 XTL-165-VB) 表征循环处理风化产物表面形貌,用XRF (美国 Thermo Scientific™ Niton™ XL3t 600) 表征结晶盐元素含量,使用SEM-EDS (捷克 TESCAN MIRA LMS) 表征20次循环颗粒表面结晶盐形貌及元素种类;紫花苜蓿发芽后记录发芽时间,待其继续生长7 d后测定其发芽率、用直尺测量茎长。

-

如图1所示,干湿/冷热交替过程中,R1、R2、R3堆浸液电导率呈现上升、下降、再次上升的趋势,将0~6次循环划分为干湿交替初期。将7~22次循环划分为干湿交替中期,将22次以后的循环划分为后期。溶液电导率与其离子质量浓度呈正比,说明干湿交替初期煤矸石盐分快速溶出,造成堆浸液电导率上升,中期时堆浸液内盐分下降,而后煤矸石颗粒再次发生溶出。

干湿/冷热交替初期盐分大量溶出,电导率持续上升说明除颗粒表面游离盐分外,煤矸石可溶性组分也不断溶解。干湿交替过程提高了水分的迁移速率,增加了与可溶性组分的接触面积,对其进行溶解,而后在干燥的条件下水分受热蒸发,向颗粒表面移动,盐分随着水流一起向外转移,并进入溶液。这与SHEILA[9]、ZHANG等[10]研究结果相符,干湿交替促进水分不断侵入新区域,还萌生、连接了微裂隙,提高了岩石颗粒孔隙度。可溶组分的持续溶解和溶出通道的形成加速了干湿交替初期煤矸石所含盐分向溶液转移的过程,导致盐分质量浓度的显著上升。

干湿/冷热交替中期堆浸液电导率下降可能的原因是煤矸石颗粒经历了初期的快速溶出,颗粒表面活性组分含量下降,盐分溶出作用受限。而溶液中盐分在干燥作用下发生重结晶,不但堵塞盐分溶出通道还粘附在容器上,从溶液中脱除;除重结晶作用,盐分还被煤矸石中微粒吸附、固定,当盐分脱除速度高于盐分的溶出速度时,溶液盐分质量浓度下降。ZHAO等[11]对砂岩的研究结果表明,随着干湿交替进行,颗粒中低溶性组分相对含量增加,盐分溶出速率下降。HAYNES等[12]、曹勇等[13]认为非晶铝硅酸盐、页硅酸盐以及采矿伴生的黏土对溶液离子有较强吸附作用。本试验初期的盐分溶出使矿物向非晶格形式或次生黏土矿物转变,溶液中离子的吸附固定作用增强,总体而言,溶液盐分含量变化受溶出作用与多方面的固定作用影响,盐分的固定作用强于溶出作用时,溶液盐分质量浓度下降。

干湿/冷热交替后期溶液电导率上升说明颗粒表面可溶组分再次增加,其可能的原因是煤矸石颗粒形成了大量的活性界面,水的溶出作用会降低表面活性,所以这部分活性界面的形成应来源于干湿交替过程中颗粒的物理性损伤。ZHU等[14]研究煤矸石粉改良膨润土裂隙发育的机理,结果表明干湿交替过程中颗粒内部会形成不与外界相连的裂隙,随着循环次数的增加,裂隙不断发育、连接,最终形成宏观裂隙或断面,与外界联系。HUANG等[15]的研究结果也表示风化导致煤矸石中粗孔、大裂隙发育明显,提升了煤矸石元素的溶出速率。MA等[16]研究了干湿交替对固废再生絮凝膏体的破坏作用,发现样品宏观裂隙是逐渐发育的过程,颗粒受到周期性损伤,在中途的4~5个循环时变质程度显著加大。随着干湿/冷热交替的不断进行,煤矸石内微裂隙逐渐发育,形成宏观断面,暴露出新鲜界面,使后期溶液盐分质量浓度再次上升。

-

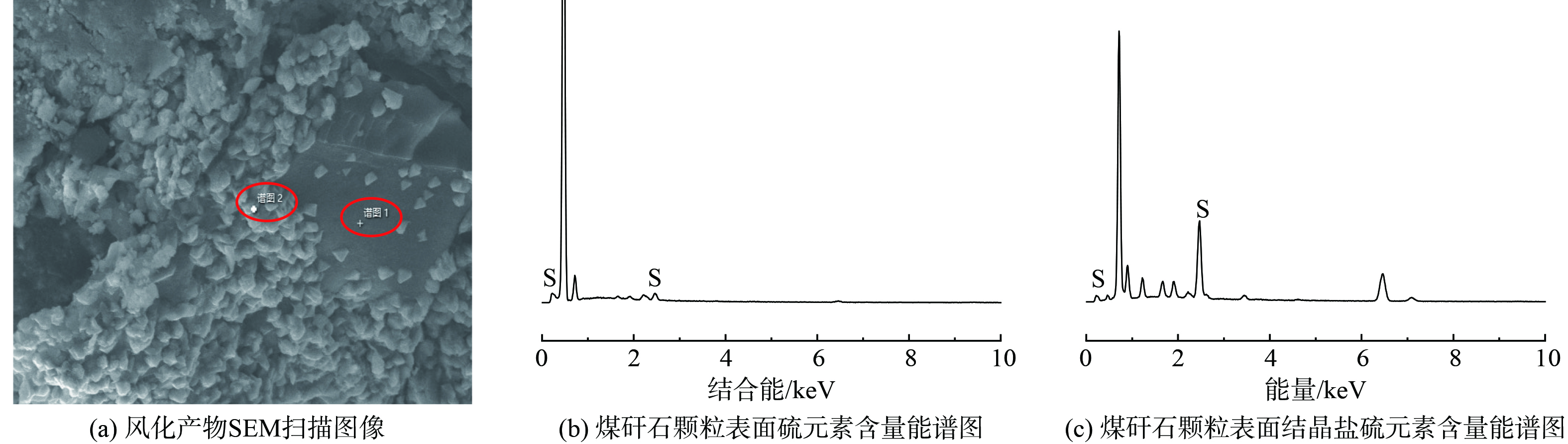

如图2所示,煤矸石颗粒表面出现盐分重结晶,能谱表征显示其为硫酸盐,结果表明干湿/冷热交替过程中煤矸石发生了涉硫组分的溶出与重构。煤矸石中涉硫组分以黄铁矿为主,占总硫组分90%以上,所以认为颗粒表面硫酸盐的来源是黄铁矿氧化溶解。硫酸盐随水分向颗粒表面转移,而后水分蒸发,盐分再结晶并附在颗粒表面。黄铁矿氧化过程如式(1)所示。黄铁矿在氧气和水分作用下氧化,干湿交替增大了煤矸石的孔隙度,从而加速氧气与水分的扩散,提高了黄铁矿的氧化速度。

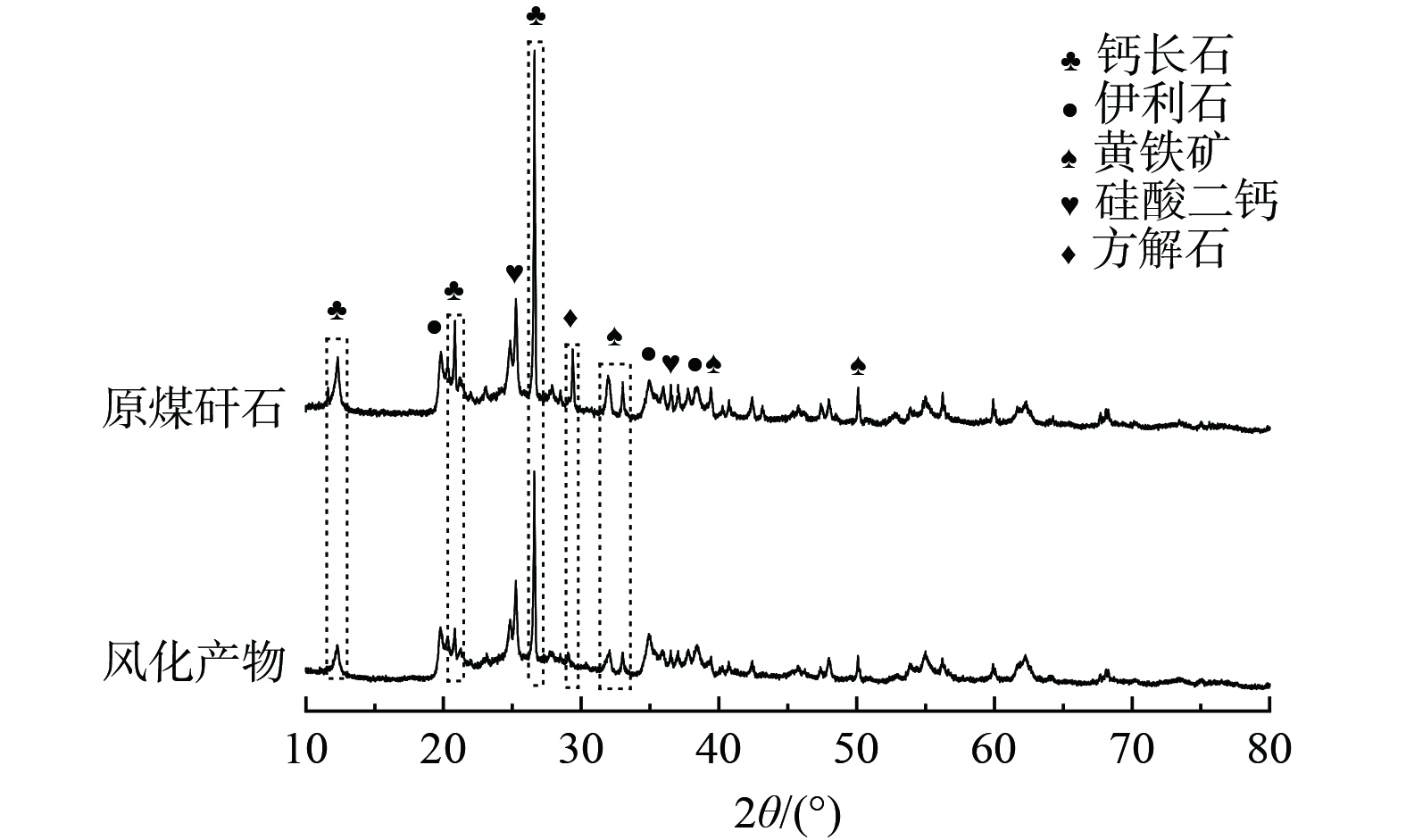

干湿/冷热交替处理30次的风化产物进行XRD表征,其结果与原煤矸石结果对比如图3所示。处理后煤矸石所含黄铁矿、钙长石、方解石等衍射强度显著降低,黄铁矿峰趋于消失。但煤矸石为复杂矿物混合物,杂峰较多,且本试验未外加溶蚀药剂对矸石浸出,所以图3显示的前后样品结果变化幅度较小,难以直接说明煤矸石矿物溶出重构过程。CHETTY[17]认为矿渣脉石矿物所含长石、伊利石在表面溶蚀作用下向高岭石转变,YUAN等[18]认为中性条件下,长石向高岭石转变并生成正硅酸。基于图3显示的煤矸石黄铁矿、钙长石、方解石发生溶出,在H+存在及中性条件下的条件下,对含钾含钙矿物进行热力学分析,反应如式(2)~(7)所示。

公式(2)~(7)说明钙长石、伊利石等含钾含钙矿物在H+存在时具有自发反应趋势,而在无H+时反应难度较大。煤矸石中含有的黄铁矿在干湿/冷热交替下氧化溶解速率提升,H+产率上升,从而加快长石等硅酸盐矿物溶解速率。NORDSTROM等[19]研究认为硅酸盐矿物、碳酸盐矿物在高浓度酸性矿山废水中起到显著的中和作用,说明黄铁矿的大量氧化形成的H+可与伴生矿物快速反应并导致钾、钙组分的溶出。

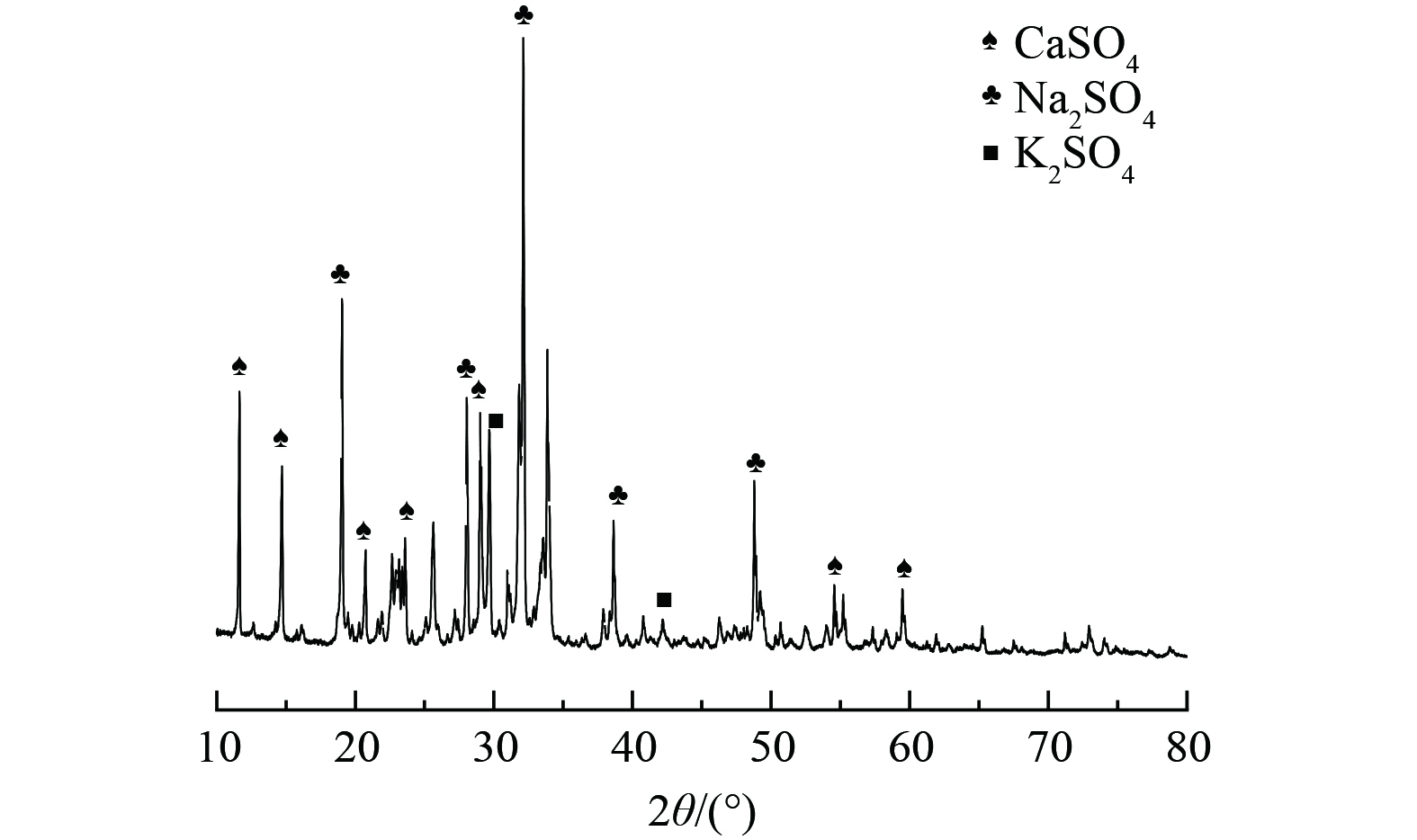

样品处理完成后,将30次处理的浸出液烘干得到盐结晶,进行XRD表征,结果如图4所示。堆浸液结晶盐主要成分为硫酸钙、硫酸钠、硫酸钾,说明溶出的盐分中SO42−、K+、Ca2+、Na+含量最高。其中SO42−、K+、Ca2+来源于矿物的溶出,Na+在原煤矸石XRD表征中没有对应的晶型含钠矿物,所以认为钠元素为煤矸石自身所含的可溶性组分,在处理过程中直接溶解在水中,在水分蒸发后与溶液中硫酸根结合,形成硫酸钠。

使用XRF测定堆浸液烘干后的盐结晶,结果如表2所示。除硅酸盐矿物组分外,Fe含量也较高,根据前文结果,认为这部分Fe来自黄铁矿的氧化溶出。干湿/冷热交替过程导致岩石矿物碎裂,进而生成大量高反应活性界面,热力学不平衡也会导致矿物化学键的减弱,所以也存在含钾含钙矿物直接与表面水膜发生物质交换的可能。

-

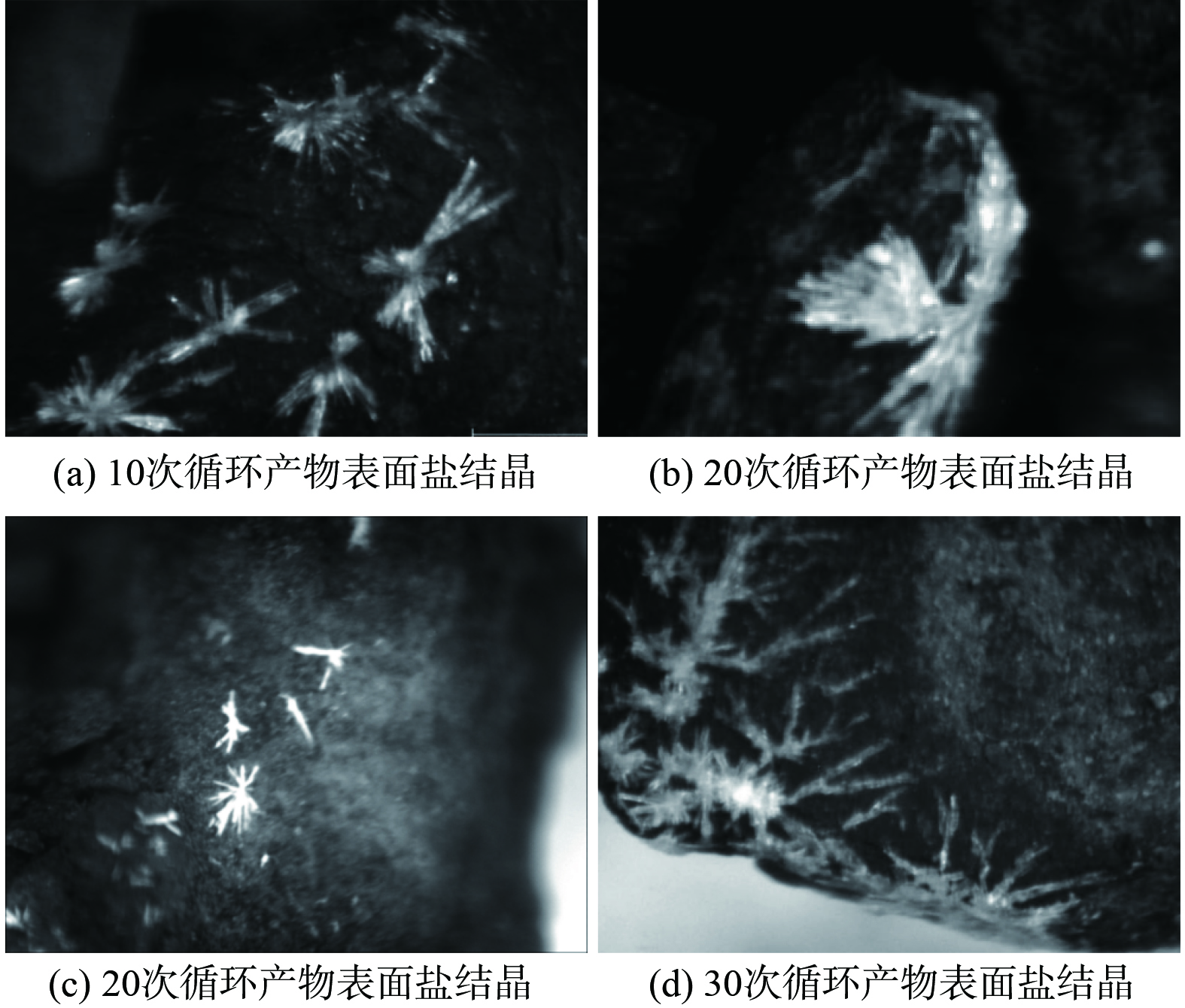

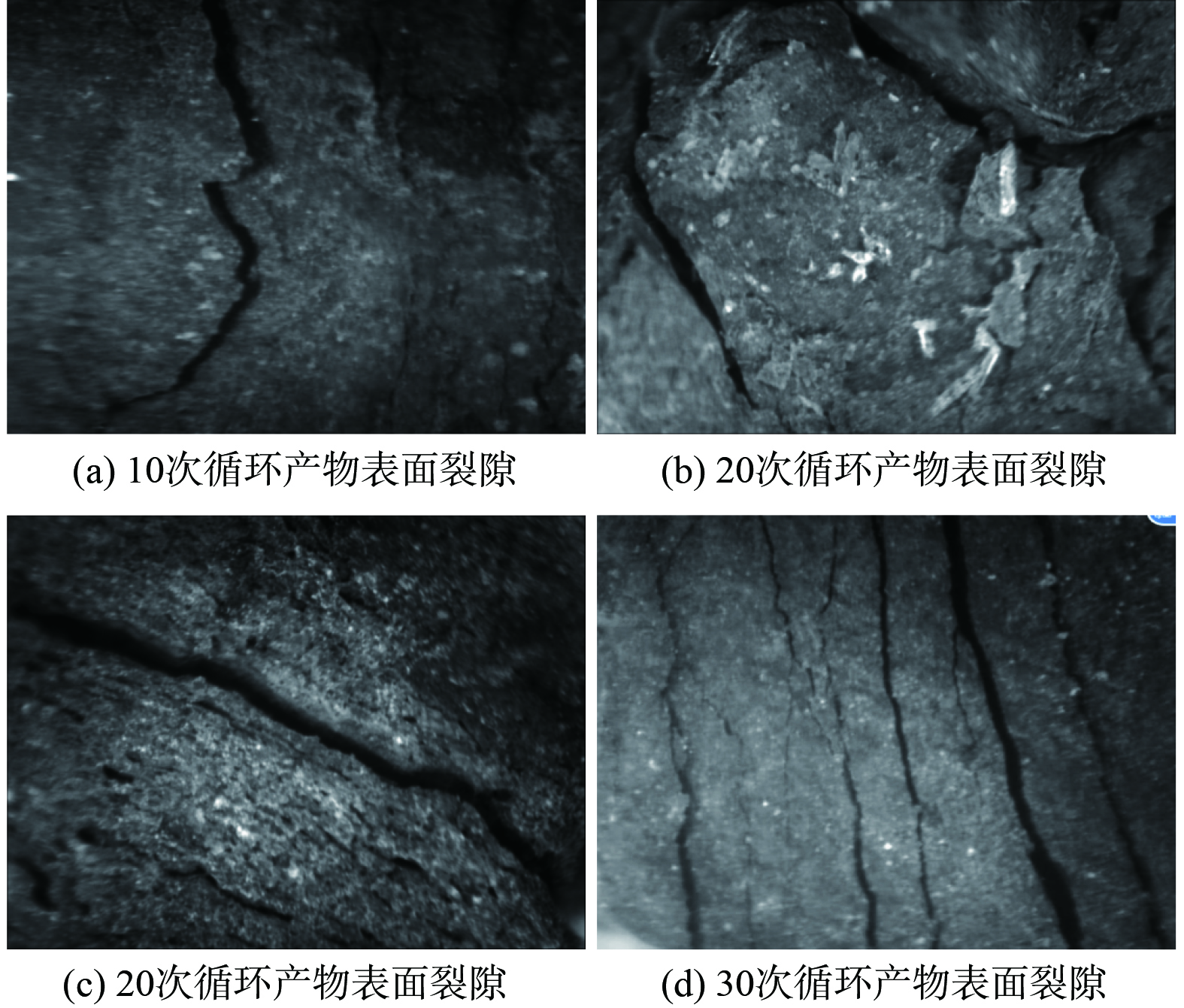

如图5所示,干湿/冷热交替处理完成后观察20次处理的颗粒表面形貌,图(a)、(b)、(c)、(d)表明10~30次处理后产物颗粒都出现盐分重结晶现象。所以煤矸石颗粒的粉化除2.2所述可溶矿物的溶解外,还受盐分结晶的挤压作用。高润东等[20]研究认为干湿交替使含硫混凝土盐分溶出,随着蒸发进行,盐分发生重结晶,而结晶作用可对颗粒产生挤压应力,促使裂隙的进一步发育。CELIK和SERT[21]对安山岩进行冻融、热冲击和盐结晶处理,试验表明空隙的重结晶作用有助于裂隙和孔洞的扩大。AN等[22]对长石砂岩进行干湿交替处理,试验发现盐的结晶作用对砂岩的劣化效果最为显著。干湿/冷热交替加速颗粒组分的结晶频率,从而促使颗粒裂隙发育,侵蚀离子、水分子进入颗粒内部,与新鲜活化界面反应、溶出,使煤矸石粉化反应不断进行。

如图6所示,图(a)、(b)、(c)、(d)表明10~30次处理后煤矸石颗粒都受到损伤,出现裂隙,根据煤矸石颗粒岩性,认为这部分裂隙除盐结晶作用外,还可能是黏土矿物不均匀性膨胀、收缩造成的。煤矸石中伊利石、长石等具有不同的膨胀性能,梁冰等[23]对弱崩解泥岩开展干湿循环试验,结果表明含伊利石、高岭石较多的泥岩在干湿交替过程中,界面结合处发生力学破坏能,加速促进裂隙、微裂隙的扩展。YANG等 [24]对泥岩进行干湿交替处理,发现水的侵入导致黏土矿物膨胀,并产生拉伸应力,失水导致的收缩使裂隙不断发展,进而有利于下一次水分的侵入,展示了混合矿物颗粒裂隙发育原理。因此,煤矸石在干湿交替过程中会发生物理性损伤而粉化。

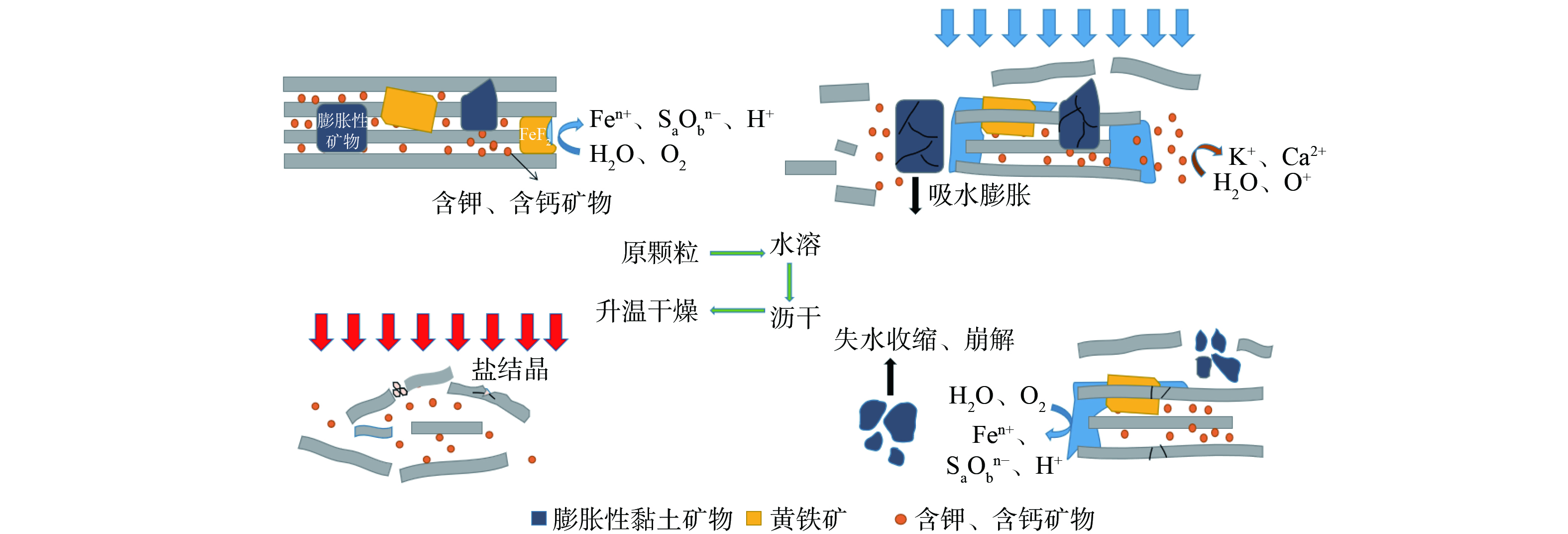

煤矸石颗粒在干湿/冷热交替过程中发生盐分溶解作用、盐结晶挤压作用、黏土矿物崩解作用,3类作用促使煤矸石颗粒不断粉化,形成微粒,过程如图7所示。

-

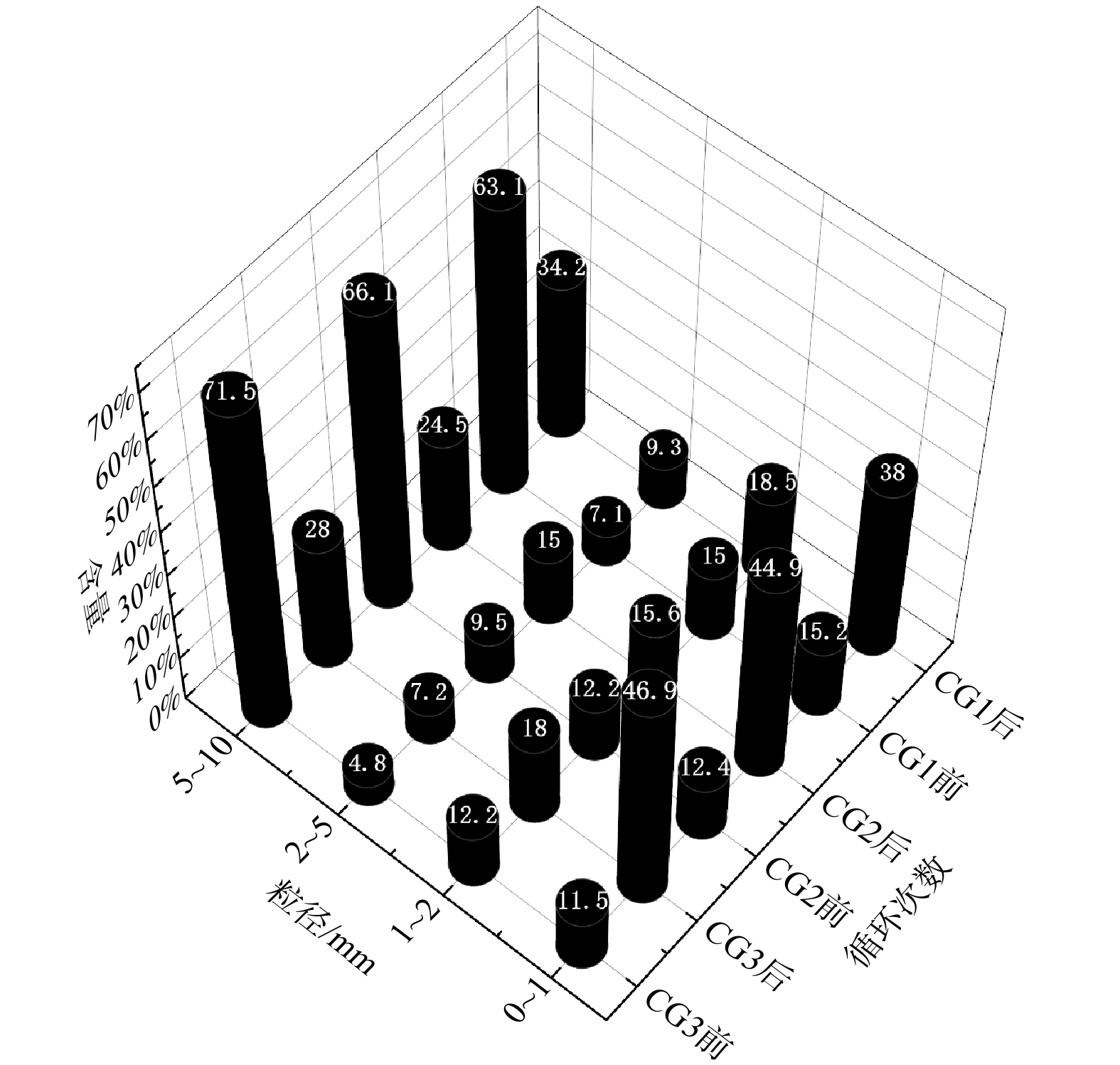

干湿/冷热交替处理后检测煤矸石粉化效果,测定各粒径范围内煤矸石颗粒的含量变化,结果如表3、图8所示。干湿交替对煤矸石颗粒粉化具有显著效果,3组样品中,5~10 mm颗粒显著下降,1 mm以下微粒显著上升,20和30次循环后1 mm以下细砂含量上升30%以上,可达35.4%,较低扰动强度 (10次循环) 对1 mm以下微粒提升也有较好的效果。ZHANG等[25]实验表明干湿交替处理过程中,10次循环时,岩石颗粒微观结构已发生较大变化,20~30个循环后,颗粒劣化速度趋于稳定。1~5 mm颗粒含量略微上升,说明在此粒径范围内集中的主要是结构较为稳定的矿物或岩石颗粒,粉化作用较5~10 mm颗粒弱。

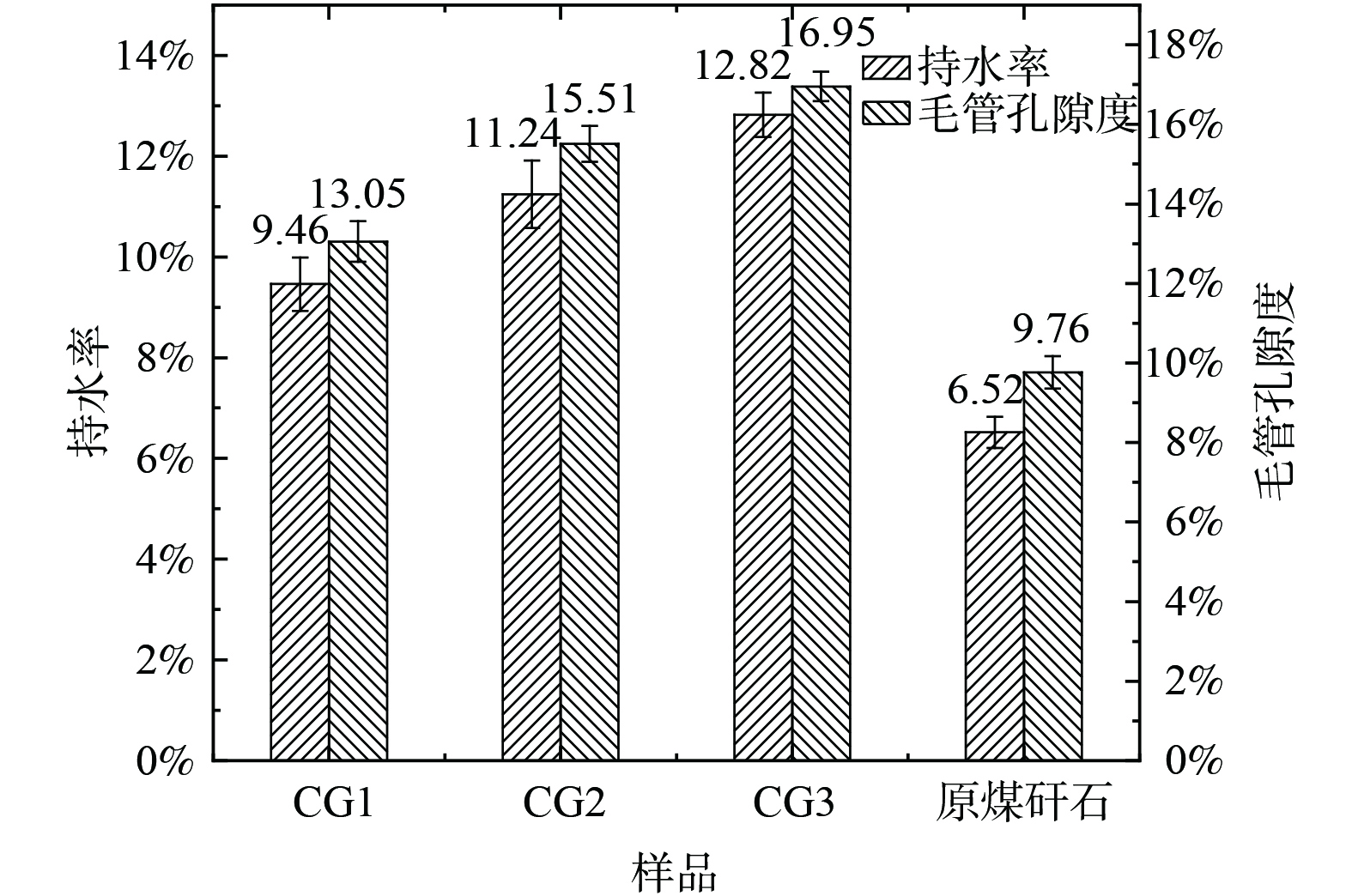

煤矸石经历干湿/冷热交替后,其粒度显著下降,风化产物的持水率与孔隙度上升,与循环次数呈正比,如图9所示。持水率和空隙度是土壤物理性质的重要指标,两者的提高有利于风化基质的生态化利用。风化产物持水率在30次循环后最大,达到12.82%,该指标满足砂土持水标准。毛管空隙度上升可提高风化产物透气性能,未经处理的煤矸石粒径粗大,颗粒间缝隙大,因此宏观上较为透气,但颗粒本身致密,无法满足土壤基质缓冲、透气的要求。本试验中煤矸石毛管孔隙度随循环次数增加而不断上升,与DEHESTANI等[26]研究结果一致,即岩石颗粒的有效孔隙度与干湿循环次数呈正比。

20与30次循环后,煤矸石1 mm以下微粒增长量相似,但30次循环后风化基质毛管孔隙度提升较多,说明30次循环后样品含有较多的微裂隙或小孔,此结果与前文所述煤矸石电导率变化情况相符合,证明煤矸石颗粒的崩解存在一个缓慢发育的周期,由微裂隙/微孔逐渐扩大,最终形成断面,微粒含量提高。

紫花苜蓿是常见的牧草,是牧业种植的重要经济作物。风化产物进行紫花苜蓿种植,其考核结果如表4所示,经过干湿交替处理的煤矸石基质发芽率、同生长时间茎长等均优于未处理的对照组,图10为3组样品经干湿交替后种植效果展示。

-

1) 干湿/冷热交替可显著降低煤矸石的结构强度,加速煤矸石的风化粉化,风化产物中0~1 mm微粒含量上升30%以上,风化产物粒度级配得到优化,显著提升了煤矸石风化产物的透气保墒性能。

2) 干湿/冷热交替促进煤矸石发生矿物分解与重构,加速盐分的溶出与重结晶,产生挤压应力加速煤矸石碎裂及矿物稳定化;硫化矿物发生氧化溶出,并轰击硅酸盐矿物,导致K、Ca、S、Si等元素的溶出,提升煤矸石风化产物的肥力性能。

3) 紫花苜蓿种植结果表明,基于余热利用的干湿循环可显著加速煤矸石风化成土过程,显著提升风化产物的土壤学性能,有效促进苜蓿等绿肥植物的生长,进而为煤矸石的大规模生态化利用提供可靠路径。

基于瓦斯燃烧余热利用的煤矸石快速风化成土

Rapid weathering and pulverization of coal gangue based on gas waste heat utilization

-

摘要: 基于瓦斯燃烧的余热利用,对煤矸石进行高频率的干湿/冷热交替处理,加速煤矸石结构风化粉化,提升风化产物的保墒-透气-蓄肥等土壤学性能。结果表明煤矸石在50 ℃下经30次干湿/冷热交替后粒径显著下降,粗砂 (5~10 mm) 比例下降43%,细砂 (<1 mm) 含量上升35%,持水率可达12.78%,达到砂土持水标准,持水率、微粒含量、毛管孔隙度与循环次数呈正比;颗粒粉化主要受矿物溶出产生溶蚀裂隙、矿物重构并干燥产生盐结晶强化裂隙涨裂,以及黏土矿物的不均匀性膨胀/收缩的影响;风化产物种植紫花苜蓿,发芽率在80%以上,发芽时间、茎长等优于低扰动样品。本研究结果可为瓦斯与煤矸石的能源化、资源化协同利用提供参考。Abstract: Utilizing waste heat generated from gas combustion, this study explored the rapid weathering and pulverization of coal gangue through high-frequency dry/wet/cool/hot alternating treatments. The objective was to enhance the soil properties of the weathered products, including moisture retention, ventilation, and fertilizer storage. Experimental results demonstrated that after 30 cycles of dry/wet/hot/cold alternating treatment at 50 ℃, the particle size of coal gangue significantly decreases, with a corresponding 43% reduction in coarse sand (5~10 mm) content and a 35% increase in fine sand (<1 mm) content. The water holding rate reached 12.78%, meeting the standards for moisture retention in sandy soil. Moreover, the water holding rate, particle content, and capillary porosity exhibited a proportional relationship with and number of cycles. Particle pulverization primarily resulted from mineral dissolution, which generated etching cracks, mineral restructuring under dry conditions leading to salt crystallization-induced crack strengthening, and clay minerals' uneven expansion/contraction. Planting alfalfa using the weathered products yielded a germination rate of over 80%, surpassing that of low-disturbance samples in terms of germination time and stem length. This research provides valuable insights for the collaborative utilization of gas and coal gangue, aiming to facilitate their energy and resource co-utilization.

-

煤矸石是煤炭开采过程中的大宗工业固废,目前处置方式以堆存为主,存在占用土地、生态破坏、地下水污染等问题。煤矿瓦斯在经燃烧利用所产中低温烟气余热未得到有效利用,造成能源的大量浪费。

煤矸石在矿物组成上与土壤具有高度的相似性,但因其粒径粗大、保水性能差等原因,煤矸石大规模生态化利用受限。魏忠义和王秋兵[1]研究认为微粒含量上升即持水率提高是煤矸石复垦的先决条件,胡振琪等[2]认为矿区复垦重点在于土壤性能综合提升。煤矸石颗粒粉化可提升基质持水能力,实现基质成土的初期演替。自然环境中,煤矸石等岩石颗粒的风化粉化主要由温度和水分驱动,但自然扰动强度小、频率低,煤矸石风化进程缓慢。蔡毅等[3]对淮南矿区煤矸石进行采样分析,结果表明风化2~12年的煤矸石持水率才具有较为明显的提升。张清峰等[4]研究表明煤矸石经36个月风化后含水率趋于稳定并超过10%。针对煤矸石风化粉化,梁冰等[5]利用木霉菌对煤矸石进行分解改良,作用30 d后,0.5 mm以下微粒上升了5%左右,时间成本较高;尚志等[6]、ZHANG等[7]采用冻融循环提高煤矸石黏粒细砂含量,研究表明冻融对土壤矿物化学性能改变不大,但对其粒径粉化效果显著,但冻融循环受环境制约难以大规模推广。张素等[8]认为干湿/冷热扰动有利于基质微粒含量的快速提升。通过瓦斯烟气余热利用对煤矸石进行强化风化处理,增强环境扰动的强度和频率,有望实现煤矸石的快速粉化及矿物转化,均衡其土壤学要素,达到综合性能的提升,开辟煤矸石原位风化成土的新途径。所以将煤矸石与瓦斯烟气余热进行协同处理处置,实现资源与能源的高效利用,是煤炭企业绿色可持续发展的重要课题。

针对煤矸石粒径粗大、持水能力薄弱的问题,本研究利用瓦斯烟气余热,强化煤矸石干湿/冷热的交替循环,加速煤矸石结构风化粉化,促进煤矸石的矿物分解与重构,提升风化产物的透气保墒性能,并通过植物生长考核其风化产物的生态化应用效果,以实现煤矸石与瓦斯烟气余热的资源能源的高效利用。

1. 材料与方法

1.1 实验原料

实验所用煤矸石来自云南恩洪煤矿,岩性以页岩、砂岩、泥岩为主,矿物成分主要为钙长石、伊利石、方解石等,以及少量黄铁矿。实验设置3组样品,初始持水率为6.3%±0.5%,每组样品重量为1 kg,样品粒径分布如表1所示。

表 1 煤矸石样品初始粒径分布Table 1. The initial particle size distribution of coal gangue samples5~10 mm 2~5 mm 1~2 mm 0~1 mm 68%±5% 6%±2% 12%±2% 14%±2% 1.2 实验方法

1) 干湿交替实验。对煤矸石进行高频干湿/冷热交替的扰动模拟,将煤矸石用滤布包裹后放入直径15 cm的PVC反应器,向容器中注入1 000 mL超纯水对煤矸石浸泡30 min并记录容器总重;提起滤布取出样品,沥干30 min,然后在45~50 ℃下烘干8 h,此为1个循环。样品分别经历10、20、30次循环,样品命名为CG1、CG2、CG3,干湿交替过程中堆浸液循环使用,每次浸泡时补充超纯水至初始记录总重,堆浸液命名为R1、R2、R3。反应完成后底部煤矸石微粒采用真空抽滤进行分离。

2) 紫花苜蓿生长试验。处理后的样品各取80 g,混匀后放入种植盆,每盆播种20颗紫花苜蓿种子,观察紫花苜蓿发芽及生长状况。每组样品设计3组平行样。

1.3 分析方法

1) 堆浸液。堆浸液静置沉淀30 min,样品过0.45 μm滤膜,使用电导率仪 (上海雷磁,DDS-11A) 检测其电导率,为减小实验误差,相邻2次电导率取平均值作图。样品分别循环处理完成后,30次循环的堆浸液上清液过0.45 μm滤膜烘干得到堆浸液盐分结晶,测定浸出液盐分的元素种类。样品粒径检测采用干筛法,筛分时间t (

m样品50g×20 2) 风化产物。利用XRD (日本 Rigaku Ultima IV) 检测颗粒矿物种类;将干湿交替循环结束的样品经105 ℃干燥,利用体式显微镜 (江西凤凰 XTL-165-VB) 表征循环处理风化产物表面形貌,用XRF (美国 Thermo Scientific™ Niton™ XL3t 600) 表征结晶盐元素含量,使用SEM-EDS (捷克 TESCAN MIRA LMS) 表征20次循环颗粒表面结晶盐形貌及元素种类;紫花苜蓿发芽后记录发芽时间,待其继续生长7 d后测定其发芽率、用直尺测量茎长。

2. 结果与讨论

2.1 煤矸石干湿/冷热交替盐分溶出规律

如图1所示,干湿/冷热交替过程中,R1、R2、R3堆浸液电导率呈现上升、下降、再次上升的趋势,将0~6次循环划分为干湿交替初期。将7~22次循环划分为干湿交替中期,将22次以后的循环划分为后期。溶液电导率与其离子质量浓度呈正比,说明干湿交替初期煤矸石盐分快速溶出,造成堆浸液电导率上升,中期时堆浸液内盐分下降,而后煤矸石颗粒再次发生溶出。

干湿/冷热交替初期盐分大量溶出,电导率持续上升说明除颗粒表面游离盐分外,煤矸石可溶性组分也不断溶解。干湿交替过程提高了水分的迁移速率,增加了与可溶性组分的接触面积,对其进行溶解,而后在干燥的条件下水分受热蒸发,向颗粒表面移动,盐分随着水流一起向外转移,并进入溶液。这与SHEILA[9]、ZHANG等[10]研究结果相符,干湿交替促进水分不断侵入新区域,还萌生、连接了微裂隙,提高了岩石颗粒孔隙度。可溶组分的持续溶解和溶出通道的形成加速了干湿交替初期煤矸石所含盐分向溶液转移的过程,导致盐分质量浓度的显著上升。

干湿/冷热交替中期堆浸液电导率下降可能的原因是煤矸石颗粒经历了初期的快速溶出,颗粒表面活性组分含量下降,盐分溶出作用受限。而溶液中盐分在干燥作用下发生重结晶,不但堵塞盐分溶出通道还粘附在容器上,从溶液中脱除;除重结晶作用,盐分还被煤矸石中微粒吸附、固定,当盐分脱除速度高于盐分的溶出速度时,溶液盐分质量浓度下降。ZHAO等[11]对砂岩的研究结果表明,随着干湿交替进行,颗粒中低溶性组分相对含量增加,盐分溶出速率下降。HAYNES等[12]、曹勇等[13]认为非晶铝硅酸盐、页硅酸盐以及采矿伴生的黏土对溶液离子有较强吸附作用。本试验初期的盐分溶出使矿物向非晶格形式或次生黏土矿物转变,溶液中离子的吸附固定作用增强,总体而言,溶液盐分含量变化受溶出作用与多方面的固定作用影响,盐分的固定作用强于溶出作用时,溶液盐分质量浓度下降。

干湿/冷热交替后期溶液电导率上升说明颗粒表面可溶组分再次增加,其可能的原因是煤矸石颗粒形成了大量的活性界面,水的溶出作用会降低表面活性,所以这部分活性界面的形成应来源于干湿交替过程中颗粒的物理性损伤。ZHU等[14]研究煤矸石粉改良膨润土裂隙发育的机理,结果表明干湿交替过程中颗粒内部会形成不与外界相连的裂隙,随着循环次数的增加,裂隙不断发育、连接,最终形成宏观裂隙或断面,与外界联系。HUANG等[15]的研究结果也表示风化导致煤矸石中粗孔、大裂隙发育明显,提升了煤矸石元素的溶出速率。MA等[16]研究了干湿交替对固废再生絮凝膏体的破坏作用,发现样品宏观裂隙是逐渐发育的过程,颗粒受到周期性损伤,在中途的4~5个循环时变质程度显著加大。随着干湿/冷热交替的不断进行,煤矸石内微裂隙逐渐发育,形成宏观断面,暴露出新鲜界面,使后期溶液盐分质量浓度再次上升。

2.2 干湿/冷热交替作用下煤矸石矿物溶出与重构过程分析

如图2所示,煤矸石颗粒表面出现盐分重结晶,能谱表征显示其为硫酸盐,结果表明干湿/冷热交替过程中煤矸石发生了涉硫组分的溶出与重构。煤矸石中涉硫组分以黄铁矿为主,占总硫组分90%以上,所以认为颗粒表面硫酸盐的来源是黄铁矿氧化溶解。硫酸盐随水分向颗粒表面转移,而后水分蒸发,盐分再结晶并附在颗粒表面。黄铁矿氧化过程如式(1)所示。黄铁矿在氧气和水分作用下氧化,干湿交替增大了煤矸石的孔隙度,从而加速氧气与水分的扩散,提高了黄铁矿的氧化速度。

stringUtils.convertMath(!{formula.content}) (1) 干湿/冷热交替处理30次的风化产物进行XRD表征,其结果与原煤矸石结果对比如图3所示。处理后煤矸石所含黄铁矿、钙长石、方解石等衍射强度显著降低,黄铁矿峰趋于消失。但煤矸石为复杂矿物混合物,杂峰较多,且本试验未外加溶蚀药剂对矸石浸出,所以图3显示的前后样品结果变化幅度较小,难以直接说明煤矸石矿物溶出重构过程。CHETTY[17]认为矿渣脉石矿物所含长石、伊利石在表面溶蚀作用下向高岭石转变,YUAN等[18]认为中性条件下,长石向高岭石转变并生成正硅酸。基于图3显示的煤矸石黄铁矿、钙长石、方解石发生溶出,在H+存在及中性条件下的条件下,对含钾含钙矿物进行热力学分析,反应如式(2)~(7)所示。

stringUtils.convertMath(!{formula.content}) (2) stringUtils.convertMath(!{formula.content}) (3) stringUtils.convertMath(!{formula.content}) (4) stringUtils.convertMath(!{formula.content}) (5) stringUtils.convertMath(!{formula.content}) (6) stringUtils.convertMath(!{formula.content}) (7) 公式(2)~(7)说明钙长石、伊利石等含钾含钙矿物在H+存在时具有自发反应趋势,而在无H+时反应难度较大。煤矸石中含有的黄铁矿在干湿/冷热交替下氧化溶解速率提升,H+产率上升,从而加快长石等硅酸盐矿物溶解速率。NORDSTROM等[19]研究认为硅酸盐矿物、碳酸盐矿物在高浓度酸性矿山废水中起到显著的中和作用,说明黄铁矿的大量氧化形成的H+可与伴生矿物快速反应并导致钾、钙组分的溶出。

样品处理完成后,将30次处理的浸出液烘干得到盐结晶,进行XRD表征,结果如图4所示。堆浸液结晶盐主要成分为硫酸钙、硫酸钠、硫酸钾,说明溶出的盐分中SO42−、K+、Ca2+、Na+含量最高。其中SO42−、K+、Ca2+来源于矿物的溶出,Na+在原煤矸石XRD表征中没有对应的晶型含钠矿物,所以认为钠元素为煤矸石自身所含的可溶性组分,在处理过程中直接溶解在水中,在水分蒸发后与溶液中硫酸根结合,形成硫酸钠。

使用XRF测定堆浸液烘干后的盐结晶,结果如表2所示。除硅酸盐矿物组分外,Fe含量也较高,根据前文结果,认为这部分Fe来自黄铁矿的氧化溶出。干湿/冷热交替过程导致岩石矿物碎裂,进而生成大量高反应活性界面,热力学不平衡也会导致矿物化学键的减弱,所以也存在含钾含钙矿物直接与表面水膜发生物质交换的可能。

表 2 堆浸液结晶盐XRF检测结果Table 2. XRF detection results of heap leach liquid crystallization saltmg·kg−1 样品编号 K Ca S Fe R1 2 371 9 557 160.4×103 1 734 R2 4 203 7 396 142.3×103 1 458 R3 820 18.1·103 96.5×103 1 487 2.3 煤矸石粉化过程分析

如图5所示,干湿/冷热交替处理完成后观察20次处理的颗粒表面形貌,图(a)、(b)、(c)、(d)表明10~30次处理后产物颗粒都出现盐分重结晶现象。所以煤矸石颗粒的粉化除2.2所述可溶矿物的溶解外,还受盐分结晶的挤压作用。高润东等[20]研究认为干湿交替使含硫混凝土盐分溶出,随着蒸发进行,盐分发生重结晶,而结晶作用可对颗粒产生挤压应力,促使裂隙的进一步发育。CELIK和SERT[21]对安山岩进行冻融、热冲击和盐结晶处理,试验表明空隙的重结晶作用有助于裂隙和孔洞的扩大。AN等[22]对长石砂岩进行干湿交替处理,试验发现盐的结晶作用对砂岩的劣化效果最为显著。干湿/冷热交替加速颗粒组分的结晶频率,从而促使颗粒裂隙发育,侵蚀离子、水分子进入颗粒内部,与新鲜活化界面反应、溶出,使煤矸石粉化反应不断进行。

如图6所示,图(a)、(b)、(c)、(d)表明10~30次处理后煤矸石颗粒都受到损伤,出现裂隙,根据煤矸石颗粒岩性,认为这部分裂隙除盐结晶作用外,还可能是黏土矿物不均匀性膨胀、收缩造成的。煤矸石中伊利石、长石等具有不同的膨胀性能,梁冰等[23]对弱崩解泥岩开展干湿循环试验,结果表明含伊利石、高岭石较多的泥岩在干湿交替过程中,界面结合处发生力学破坏能,加速促进裂隙、微裂隙的扩展。YANG等 [24]对泥岩进行干湿交替处理,发现水的侵入导致黏土矿物膨胀,并产生拉伸应力,失水导致的收缩使裂隙不断发展,进而有利于下一次水分的侵入,展示了混合矿物颗粒裂隙发育原理。因此,煤矸石在干湿交替过程中会发生物理性损伤而粉化。

煤矸石颗粒在干湿/冷热交替过程中发生盐分溶解作用、盐结晶挤压作用、黏土矿物崩解作用,3类作用促使煤矸石颗粒不断粉化,形成微粒,过程如图7所示。

2.4 煤矸石风化产物土壤性能

干湿/冷热交替处理后检测煤矸石粉化效果,测定各粒径范围内煤矸石颗粒的含量变化,结果如表3、图8所示。干湿交替对煤矸石颗粒粉化具有显著效果,3组样品中,5~10 mm颗粒显著下降,1 mm以下微粒显著上升,20和30次循环后1 mm以下细砂含量上升30%以上,可达35.4%,较低扰动强度 (10次循环) 对1 mm以下微粒提升也有较好的效果。ZHANG等[25]实验表明干湿交替处理过程中,10次循环时,岩石颗粒微观结构已发生较大变化,20~30个循环后,颗粒劣化速度趋于稳定。1~5 mm颗粒含量略微上升,说明在此粒径范围内集中的主要是结构较为稳定的矿物或岩石颗粒,粉化作用较5~10 mm颗粒弱。

表 3 干湿/冷热交替处理前后煤矸石样品粉化粒径分布Table 3. Pulverized particle size distribution of coal gangue samples before and after dry-wet/cold-heat alternate treatment粒径分布/mm CG3 CG2 CG1 处理前/% 处理后/% 处理前/% 处理后/% 处理前/% 处理后/% 5~10 71.5 28 66.1 24.5 63.1 34.2 2~5 4.8 7.2 9.5 15 7.1 9.3 1~2 12.2 18 12.2 15.6 15 18.5 0~1 11.5 46.9 12.4 44.9 15.2 38 煤矸石经历干湿/冷热交替后,其粒度显著下降,风化产物的持水率与孔隙度上升,与循环次数呈正比,如图9所示。持水率和空隙度是土壤物理性质的重要指标,两者的提高有利于风化基质的生态化利用。风化产物持水率在30次循环后最大,达到12.82%,该指标满足砂土持水标准。毛管空隙度上升可提高风化产物透气性能,未经处理的煤矸石粒径粗大,颗粒间缝隙大,因此宏观上较为透气,但颗粒本身致密,无法满足土壤基质缓冲、透气的要求。本试验中煤矸石毛管孔隙度随循环次数增加而不断上升,与DEHESTANI等[26]研究结果一致,即岩石颗粒的有效孔隙度与干湿循环次数呈正比。

20与30次循环后,煤矸石1 mm以下微粒增长量相似,但30次循环后风化基质毛管孔隙度提升较多,说明30次循环后样品含有较多的微裂隙或小孔,此结果与前文所述煤矸石电导率变化情况相符合,证明煤矸石颗粒的崩解存在一个缓慢发育的周期,由微裂隙/微孔逐渐扩大,最终形成断面,微粒含量提高。

紫花苜蓿是常见的牧草,是牧业种植的重要经济作物。风化产物进行紫花苜蓿种植,其考核结果如表4所示,经过干湿交替处理的煤矸石基质发芽率、同生长时间茎长等均优于未处理的对照组,图10为3组样品经干湿交替后种植效果展示。

表 4 紫花苜蓿生长指标Table 4. Growth index of alfalfa样品 发芽率/% 茎长/cm 发芽时间/d 原煤矸石 20 0.97 20 10次循环产物 40 1.76 20 20次循环产物 60 2.21 21 30次处理产物 85 2.64 18 3. 结论

1) 干湿/冷热交替可显著降低煤矸石的结构强度,加速煤矸石的风化粉化,风化产物中0~1 mm微粒含量上升30%以上,风化产物粒度级配得到优化,显著提升了煤矸石风化产物的透气保墒性能。

2) 干湿/冷热交替促进煤矸石发生矿物分解与重构,加速盐分的溶出与重结晶,产生挤压应力加速煤矸石碎裂及矿物稳定化;硫化矿物发生氧化溶出,并轰击硅酸盐矿物,导致K、Ca、S、Si等元素的溶出,提升煤矸石风化产物的肥力性能。

3) 紫花苜蓿种植结果表明,基于余热利用的干湿循环可显著加速煤矸石风化成土过程,显著提升风化产物的土壤学性能,有效促进苜蓿等绿肥植物的生长,进而为煤矸石的大规模生态化利用提供可靠路径。

-

表 1 煤矸石样品初始粒径分布

Table 1. The initial particle size distribution of coal gangue samples

5~10 mm 2~5 mm 1~2 mm 0~1 mm 68%±5% 6%±2% 12%±2% 14%±2% 表 2 堆浸液结晶盐XRF检测结果

Table 2. XRF detection results of heap leach liquid crystallization salt

mg·kg−1 样品编号 K Ca S Fe R1 2 371 9 557 160.4×103 1 734 R2 4 203 7 396 142.3×103 1 458 R3 820 18.1·103 96.5×103 1 487 表 3 干湿/冷热交替处理前后煤矸石样品粉化粒径分布

Table 3. Pulverized particle size distribution of coal gangue samples before and after dry-wet/cold-heat alternate treatment

粒径分布/mm CG3 CG2 CG1 处理前/% 处理后/% 处理前/% 处理后/% 处理前/% 处理后/% 5~10 71.5 28 66.1 24.5 63.1 34.2 2~5 4.8 7.2 9.5 15 7.1 9.3 1~2 12.2 18 12.2 15.6 15 18.5 0~1 11.5 46.9 12.4 44.9 15.2 38 表 4 紫花苜蓿生长指标

Table 4. Growth index of alfalfa

样品 发芽率/% 茎长/cm 发芽时间/d 原煤矸石 20 0.97 20 10次循环产物 40 1.76 20 20次循环产物 60 2.21 21 30次处理产物 85 2.64 18 -

[1] 魏忠义, 王秋兵. 大型煤矸石山植被重建的土壤限制性因子分析[J]. 水土保持研究, 2009, 16(1): 179-182. [2] 胡振琪, 肖武, 赵艳玲. 再论煤矿区生态环境“边采边复”[J]. 煤炭学报, 2020, 45(1): 351-359. doi: 10.13225/j.cnki.jccs.YG19.1694 [3] 蔡毅, 严家平, 陈孝杨, 等. 表生作用下煤矸石风化特征研究——以淮南矿区为例[J]. 中国矿业大学学报, 2015, 44(5): 937-943+958. doi: 10.13247/j.cnki.jcumt.000398 [4] 张清峰, 王东权, 于广云, 等. 煤矸石风化对其物理力学性能影响的研究[J]. 中国矿业大学学报, 2019, 48(4): 768-774. doi: 10.13247/j.cnki.jcumt.001032 [5] 孔涛, 黄舒漫, 梁冰, 等. 木霉菌对煤矸石分解和绿化效果的影响[J]. 煤炭学报, 2018, 43(11): 3204-3211. doi: 10.13225/j.cnki.jccs.2018.0187 [6] 郭海桥, 程伟, 尚志, 等. 水分和冻融循环对酷寒矿区煤矸石风化崩解速率影响的定量研究[J]. 煤炭学报, 2019, 44(12): 3859-3864. doi: 10.13225/j.cnki.jccs.SH19.0797 [7] ZHANG Z, ZHAI J B, Melnikov Andrey, et al. Cryogenic soil—product of mineral weathering processes[J]. Minerals. 2022, 12: 805. [8] 张素, 郑学用, 熊东红, 等. 干湿交替对干热河谷冲沟发育区不同土壤崩解性的影响[J]. 水土保持学报, 2016, 30(2): 111-115+121. doi: 10.13870/j.cnki.stbcxb.2016.02.020 [9] SHEILA D. Application of particle size distribution analysis in evaluating the weathering in coal mine rejects and tailings[J]. Fuel Processing Technology. 2007, 88(3): 295-301. doi: 10.1016/j.fuproc.2006.10.013 [10] ZHANG C Y, Dai Z W, Tan W J, et al. Multiscale study of the deterioration of Sandstone in the three gorges reservoir area subjected to cyclic wetting-cooling and drying-heating[J]. Rock Mechanics and Rock Engineering. 2022, 55(9): 5619-37. doi: 10.1007/s00603-022-02929-1 [11] ZHOU W, CHENG J L, ZHANG G K, et al. Effects of wetting–drying cycles on the Breakage characteristics of slate rock grains[J]. Rock Mechanics and Rock Engineering. 2021, 54(12): 6323-6337. doi: 10.1007/s00603-021-02618-5 [12] HAYNES R, ZHOU Y F, WENG X T. Formulation and use of manufactured soils: A major use for organic and inorganic wastes[J]. Critical Reviews in Environmental Science and Technology. 2021, 52: 1-21. [13] 曹勇, 毕银丽, 宋子恒, 等. 物理改良对采矿伴生黏土水分和养分保持能力的影响[J]. 矿业研究与开发, 2021, 41(1): 116-121. doi: 10.13827/j.cnki.kyyk.2021.01.021 [14] ZHU H X, ZHANG Y, LI Z H, et al. Study on crack development and micro-pore mechanism of expansive soil improved by coal gangue under drying-wetting cycles[J]. Materials. 2021, 14(21): 6546. doi: 10.3390/ma14216546 [15] HUANG Y L, LI J M, SONG T Q, et al. Microstructure of coal gangue and precipitation of heavy metal elements[J]. Journal of Spectroscopy, 2017: 3128549. [16] MA D , KONG S B , LI Z H , et al. Effect of wetting-drying cycle on hydraulic and mechanical properties of cemented paste backfill of the recycled solid wastes[J]. Chemosphere, 2021, 282: 131163. [17] CHETTY D. Acid-Gangue interactions in heap leach operations: A Review of the role of mineralogy for predicting ore behaviour[J]. Minerals. 2018, 8(2): 47. doi: 10.3390/min8020047 [18] YUAN W, LIU X R, FU Y. Chemical thermodynamics and chemical kinetics analysis of sandstone dissolution under the action of dry-wet cycles in acid and alkaline environments[J]. Bulletin of Engineering Geology and the Environment. 2019, 78(2): 793-801. doi: 10.1007/s10064-017-1162-9 [19] NORDSTROM D K, BLOWES D W, PTACEK C J. Hydrogeochemistry and microbiology of mine drainage: An update[J]. Applied Geochemistry. 2015, 57: 3-16. doi: 10.1016/j.apgeochem.2015.02.008 [20] 高润东, 赵顺波, 李庆斌, 等. 干湿循环作用下混凝土硫酸盐侵蚀劣化机理试验研究[J]. 土木工程学报, 2010, 43(2): 48-54. doi: 10.15951/j.tmgcxb.2010.02.018 [21] CELIK M Y, SERT M. Accelerated aging laboratory tests for the evaluation of the durability of hydrophobic treated and untreated andesite with respect to salt crystallization, freezing-thawing, and thermal shock[J]. Bulletin of Engineering Geology and the Environment. 2021, 79(7): 3751-3770. [22] AN W B, WANG L G, CHEN H. Mechanical Properties of Weathered Feldspar Sandstone afterExperiencing Dry-Wet Cycles[J]. Advances in Materials Science and Engineering, 2020: 6268945. [23] 梁冰, 曹强, 王俊光, 等. 弱崩解性软岩干-湿循环条件下崩解特性试验研究[J]. 中国安全科学学报, 2017, 27(8): 91-96. doi: 10.16265/j.cnki.issn1003-3033.2017.08.016 [24] YANG Y L, ZHANG T, LIU S Y, et al. Mechanical Properties and Deterioration Mechanism of Remolded Carbonaceous Mudstone Exposed to Wetting–Drying Cycles[J]. Rock Mechanics and Rock Engineering. 2022, 55(6): 3769-3780. doi: 10.1007/s00603-022-02833-8 [25] ZHANG Z Z, NIU Y X, SHANG X J, et al. Deterioration of Physical and Mechanical Properties of Rocks by Cyclic Drying and Wetting[J]. Geofluids, 2021: 6661107. [26] DEHESTANI A, HOSSEINI M, BEYDOKTI A T. Effect of wetting–drying cycles on mode I and mode II fracture toughness of sandstone in natural (pH=7) and acidic (pH=3) environments[J]. Theoretical and Applied Fracture Mechanics. 2020, 106: 102448. doi: 10.1016/j.tafmec.2019.102448 -

DownLoad:

DownLoad: