-

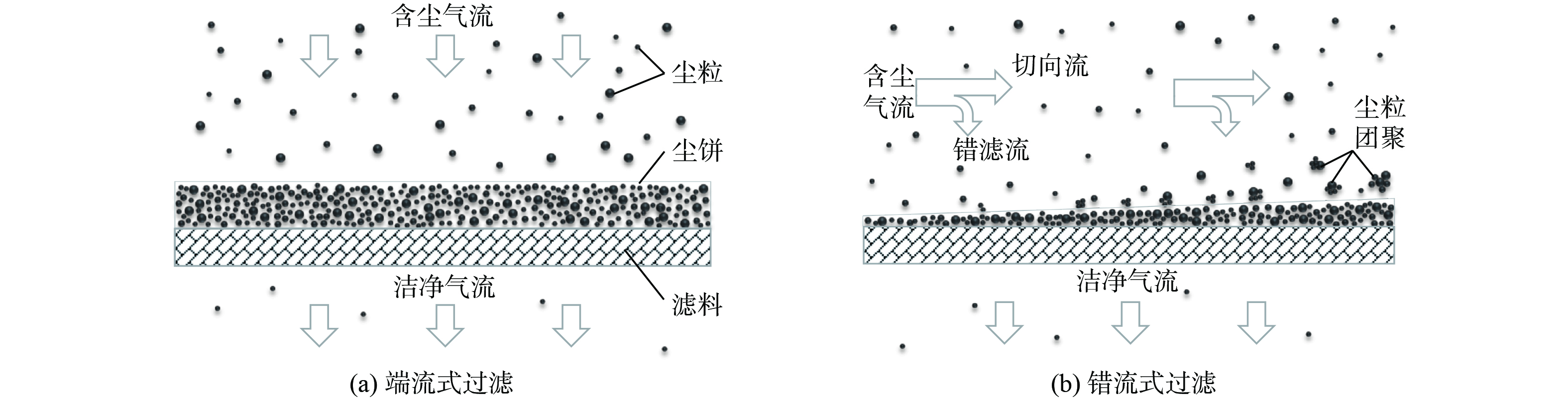

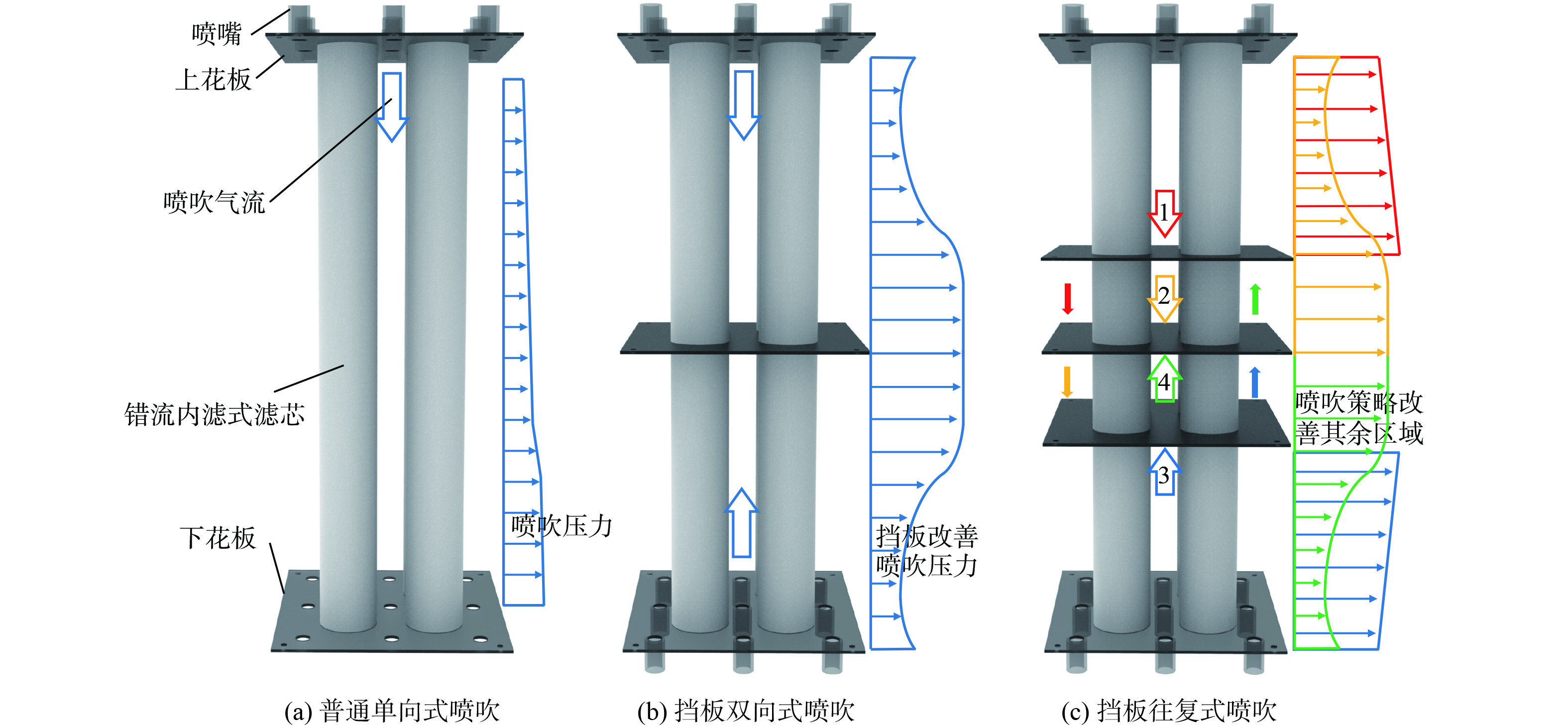

粉尘会诱发职业性尘肺病,危害人群健康[1];且粉尘还存在爆炸危险等安全风险[2]。因此,作业场所粉尘的控制具有重要的现实意义。传统的端流式过滤除尘技术 (图1 (a) ) ,具有净化效率高、工艺简单等优点而广泛运用于除尘领域[3]。但端流式过滤过滤阻力上升快、风机能耗大。错流式过滤除尘技术 (图1 (b) ) ,利用切向流的剪切力抑制尘饼生长变厚、阻滞过滤阻力上升[4],对于处理大风量高浓度粉尘具有优势。错流式过滤除尘一般采用内滤方式[5],对错滤面上的持续累积的粉尘可采用脉冲喷吹进行清灰。

目前,除尘滤芯的脉冲喷吹清灰已被广泛研究。林莉君等[6]研究了外滤式滤芯内部的脉冲喷吹清灰,在滤芯长度方向上,上部受到的压力最小、中部次之、底部最大;喷吹压力越大,滤芯内压力越大。LI等[7]提出在外滤式滤芯内部设置锥体,能提高脉喷气流的强度,显著提升了中部和顶部滤芯所受压力,改善滤芯压力分布提高脉喷清灰效果。艾子昂等[8]通过在外滤式滤芯内部增设半密闭式气流隔板,降低气流能量损耗,在[R,r]=[120,60]的情况下滤芯所受压力提升至2.11倍,清灰均匀性提升4.11倍,增强了滤芯内整体脉喷清灰性能。薛峰等[9]通过改进喷嘴,设计上部开口散射器和诱导喷嘴改善喷吹流场,提升外滤式滤芯的脉喷清灰性能,在定阻模式清灰条件下对比普通喷嘴清灰间隔分别延长220 s、95 s。QIU等[10]改进内部设置锥体为褶皱式锥体并考察锥体高度提升脉喷清灰的均匀性,在高度为760 mm时清灰效果最好。CHEN等[11]研究了褶式滤芯不同褶皱形状对滤芯脉喷清灰性能的影响,采用梯形褶式结构降低压力损失来提升外滤式滤芯脉喷清灰性能。CHEN等[12]提出了多脉冲喷吹技术改进喷吹策略提升外滤式滤芯清灰效果,喷吹压力提升6.5 %。然而,目前关于滤芯脉冲喷吹清灰的研究主要对象是外滤式滤芯,针对内滤式滤芯的脉喷清灰的研究不足。

本研究拟通过构建CFD数值模型,考察清灰装置的气流流场及错流内滤式滤芯压力变化,探究喷嘴入口压力的影响,考察错流滤芯所受压力随挡板位置移动的变化规律,并设计挡板往复式喷吹策略与其他喷吹策略进行对比,为内滤式滤芯的脉喷清灰设计提供参考。

-

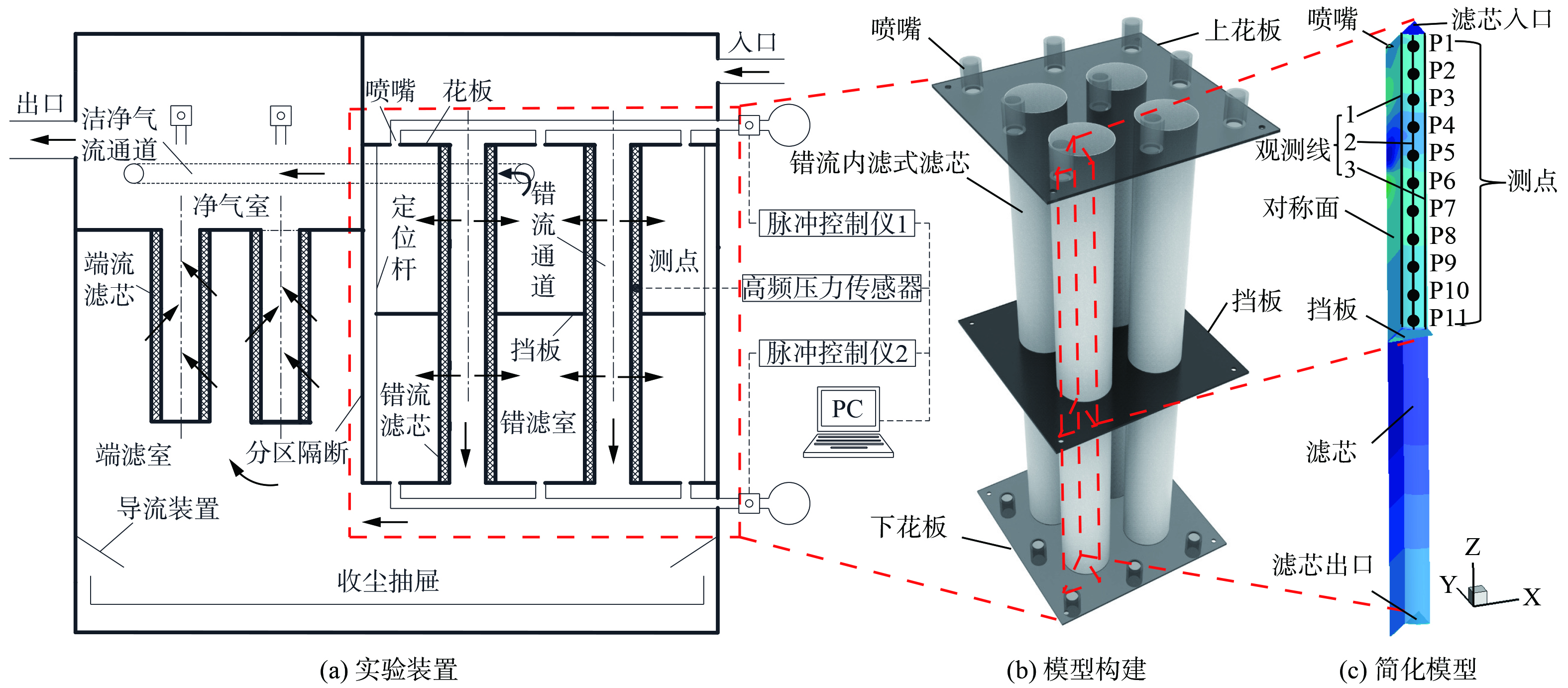

本模拟研究以错滤-端滤复合实验装置为基础,系统结构如图2 (a) 所示,其中除尘器主体长宽高尺寸为1 020 mm×500 mm×2 200 mm,箱体内有错滤和端滤区域,分别安装错流滤芯和端流滤芯。在错滤区域内,上下两块花板之间安装错流滤芯 (后文简称“滤芯”) ,滤芯长度1 000 mm,滤料厚度0.6 mm。滤芯周围设置多个喷嘴,每个喷嘴离滤芯中心轴线

75√2 mm,喷嘴直径25 mm,并且喷嘴入口与花板平齐。每个滤芯之间和每个喷嘴之间均相距150 mm,在花板之间设置一块挡板。脉冲喷吹时长设为150 ms,初始气包压力0.2 MPa,气包容积20 L。滤芯上安装有高频压力传感器,MYD-1530A型。本模拟研究错流过滤核心区域,将实验系统装置简化为如图2 (b) 所示模型。为节省计算量,根据对称性将此模型进一步简化为一个三棱柱区域如图2 (c) 所示。采用结构化网格划分,网格节点总数为148 260个,元素为159 541个,如图3 (a) 所示。

-

将滤芯入口和出口处设置为压力出口 (pressure outlet) ,花板以及挡板设置成标准固定墙体 (wall) ,喷嘴截面设置为压力入口 (pressure inlet) ,滤芯过滤层设置为多孔介质 (porous zone) ,多孔介质的厚度为0.6 mm,黏性损失系数 (1/α = 2.0×1011 m−2) 的计算可见先前报道[13]。在滤芯沿长度方向上设置3条平行的观测线,从左到右依次设置1~3号观测线 (图2 (c) ) ,因为滤芯是轴对称的,选取的3条观测线反应了滤芯内壁距离喷嘴最近、最远和中间的喷吹压力的分布。每条观测线上均有压力测点P1~P11,测点间距为50 mm,单次计算时长设置为0.000 5 s。计算域内流体假定为理想气体 (ideal gas) ,控制方程为质量守恒方程和Navier-Stokes 方程,流体在求解器中认为是等温可压缩、非稳态的湍流,选用Realizable k-ε湍流模型,采用压力-速度耦合算法。喷吹过程中忽略粉尘及粉尘对计算域的影响、不考虑碰撞挡板时的振动和滤芯形变。

喷嘴压力入口函数通过实验测试获取并拟合得到。实验中在喷嘴出口正前方1.0 cm处设置高频压力传感器,传感器测出喷嘴出口处脉喷气流的压力值,将其变化曲线进行分段拟合,得到式 (1) 。

式中:

Pn 为喷嘴的入口压力,Pa;t 为时间,s。将式 (1) 改编为用户自定义函数格式导入至喷嘴压力入口。 -

1) 在挡板位置 (挡板到滤芯顶部开口的距离) 500 mm条件下考察滤芯喷吹覆盖区 (上部花板和挡板之间的区域) 外侧脉喷气流喷吹压力的时空分布;2) 考察喷嘴入口压力分别为3 000、4 000、5 000、6 000、7 000、8 000、9 000、10 000 Pa时喷吹覆盖区中滤芯所受压力峰值情况,根据滤芯有效清灰压力确定最佳的喷嘴入口压力;3) 在最佳喷嘴入口压力条件下,考察挡板位置为250、300、350、400、450、500 mm对滤芯喷吹覆盖区中滤芯所受压力峰值情况,对比确定挡板往复位置,并设计挡板往复式喷吹策略。

-

为验证网格的独立性将滤芯内压力梯度变化较大的区域按如图3 (b) 所示加密,加密后网格节点总数为487 574个、元素512 893个。滤芯外壁中间测点计算出的模拟值如图4所示。对比喷吹压力值随时间变化趋势发现,网格加密前后计算出的压力值大致吻合,认为加密前的网格已满足网格独立性要求。

而实验与模拟的喷吹压力随时间的变化趋势大体一致,并与实验测定数值的均值匹配度较高,认为数值模拟与所得结果可反映实际情况。实验测定的数值相比模拟计算结果波动幅度较大。这可能是模拟未考虑滤芯侧壁区域的流固耦合,而实际脉喷气流作用时会引起挡板或滤芯振动,并使得传感器振动,从而引起测试数据的波动。

-

图5所示为脉冲喷吹过程中喷吹覆盖区的静压力云图与流线图。压缩空气从喷嘴喷出后形成一股高压气流,这股气流在喷嘴下方区域形成负压区,导致涡流的形成并卷吸周围气体进入喷吹气流中。喷吹气流挤压下方气体导致了滤芯外部空间整体形成一定的压力。撞击到挡板的喷吹气流在横向扩散的过程中与 (对称的) 其它喷嘴的横向气流发生二次撞击并形成空气墙,使得喷吹气流在挡板与滤芯外壁形成的区域内发生蓄积。

根据静压力云图可知,压力在喷吹覆盖区呈现底部最大、上部次之、中部最小的特点,其中底部的压力较高的规律与滤芯内部脉冲喷吹的压力分布规律一致[6,14-15];但值得注意的是本研究中滤芯上部压力大于中部压力,主要是顶部上方花板减缓了上升气流流速导致上部静压增大。从喷吹压力随时间的变化特征可知,开始滤芯受脉喷气流卷吸作用呈现负压,随后气流蓄积滤芯外壁所受静压迅速上升,到

t =0.020 s时达到稳定,t =0.080 s时达到最大值,并持续到t =0.160 s时后压力开始下降。喷吹压力在水平上分布如图6所示。沿滤芯水平方向比较发现,喷吹压力呈现两侧较中间高的规律,其中左侧偏大原因主要是离喷嘴距离近,所受气流影响大;右侧偏大原因主要是靠近空气二次对撞区域导致静压增大;由于考虑到滤芯的有效清灰,故后续数值模拟均取水平方向上最小压力 (2号观测线) 进行比较。

-

图7为不同入口压力情况下喷吹覆盖区滤芯的压力云图和流线图 (只考虑滤芯压力分布情况,故仅保留滤芯部分) 。

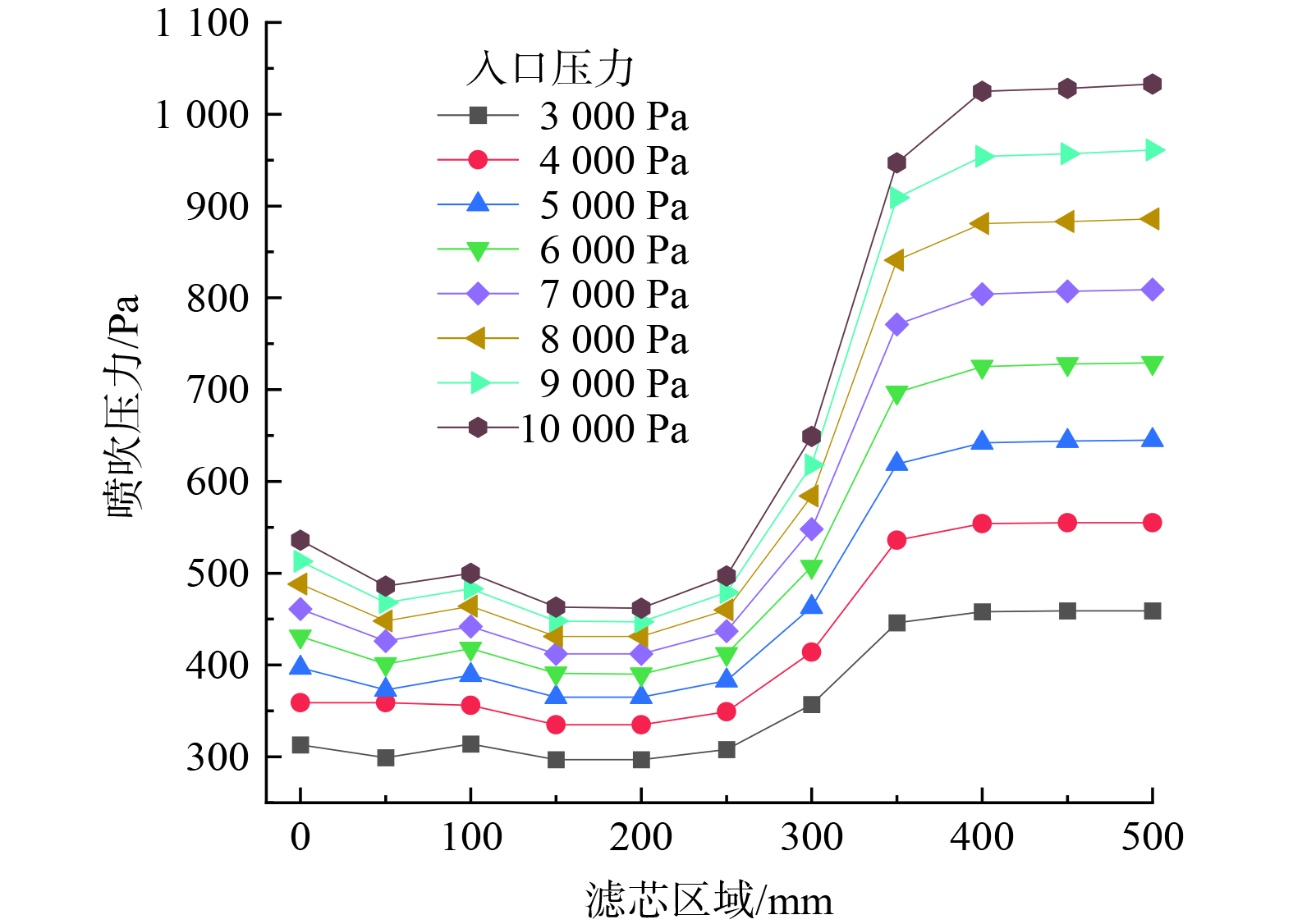

一般以喷吹压力>600 Pa能够进行有效清灰[16-20]。图8为不同喷嘴的入口压力下各测点的压力峰值,通过对比可发现,喷吹覆盖区滤芯整体压力随着入口压力的增大而升高;但值得注意的是滤芯350~500 mm区域 (挡板附近区域) 压力增长速率快于其它区域。喷嘴入口压力大于5 000 Pa时,有效清灰区域面积增长缓慢,浪费气包压力。喷嘴入口压力小于5 000 Pa时,无有效清灰区。

此次喷吹仅对滤芯350~500 mm区域进行有效清灰,但挡板位置可变化,故仅部分区域满足有效清灰即可,其他区域可通过挡板位置变化后再次进行脉冲喷吹实现清灰。最后确定了最佳喷嘴入口压力为5 000 Pa。

-

从之前的喷嘴的入口压力分析可知在挡板500 mm实现了滤芯350~500 mm区域有效清灰,通过挡板位置变化实现滤芯0~350mm区域的有效清灰。图9为挡板位置变化时滤芯各测点压力峰值,喷吹覆盖区压力随着挡板距离的减小而增大,再通过对比会发现挡板在350 mm处仅需进行一次喷吹实现了滤芯0~350 mm的有效清灰,若挡板距离减小如300 mm时会出现滤芯300~350 mm区域的清灰盲区,需再次更改挡板位置对此区域进行脉喷清灰,随着挡板位置减小喷吹覆盖区压力增加,同时清灰盲区面积扩大;若挡板距离增大如400 mm时喷吹覆盖区0~350 mm区域不能进行有效清灰。最后确定挡板位置在350 mm可实现滤芯0~350mm区域的有效清灰,在500 mm可实现滤芯350~500mm区域的有效清灰。

-

根据上述结论设计挡板往复式喷吹策略:1) 挡板开始在350 mm时上部喷吹,喷吹后位置移动至500 mm;2) 在500 mm处上部喷吹,喷吹后位置移动至650 mm;3) 在650 mm下部喷吹,喷吹后位置移动至500 mm;4) 在500 mm处下部喷吹,喷吹后位置移动到350 mm,完成一次挡板往复式喷吹。喷嘴入口压力为5 000 Pa条件下,对比3种喷吹策略对滤芯喷吹性能进行考察。

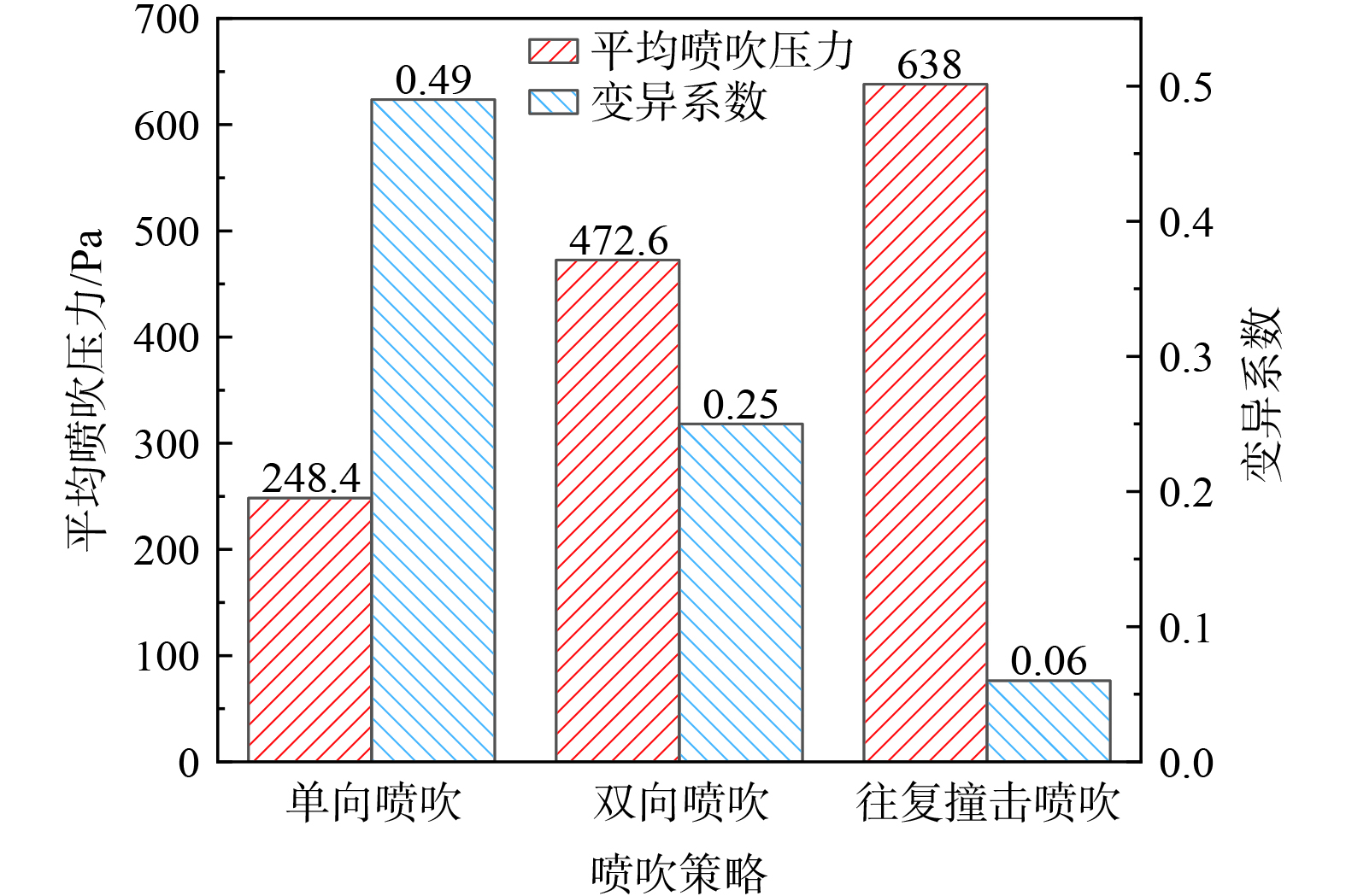

图10为3种不同喷吹策略示意图, (a) 为普通单向式喷吹、 (b) 为挡板双向式喷吹、 (c) 为挡板往复式喷吹。其脉冲喷吹的性能一般比较喷吹压力和喷吹均匀性[21-23],各测点正压力峰值的平均值

−p 越大说明喷吹压力越大,而峰值的变异系数C.V. 越小则意味着喷吹均匀性越好,变异系数以式 (2) 计算。式中:

pi 为各测点压力峰值,n 为测点总数。图11显示3种喷吹策略下的平均喷吹压力和喷吹均匀性的比较。普通单向式喷吹与挡板双向式喷吹比较后得出,后者相较于前者平均喷吹压力提升了224.2 Pa,为0.90倍,清灰均匀性提升了0.96倍 (变异系数降为原来的51.1 %) ,说明增设挡板蓄积气流提升滤芯整体压力,滤芯喷吹性能得到提升。挡板双向式喷吹与挡板往复式喷吹比较后得出,挡板位置的变化改进了对半固定式喷吹清灰不良区域的喷吹压力,平均喷吹压力进一步提升了0.35倍,均匀性提升了3.18倍,这说明改进喷吹策略,通过挡板位置变换来提高整体清灰均匀性,滤芯喷吹性能显著提升。逐级往复式喷吹可实现1000 mm滤芯有效清灰。综上所述,相比普通单向式喷吹,本研究设计的逐级往复式喷吹可实现滤芯外侧脉冲喷吹压力增大1.57倍,清灰均匀性提升7.17倍。

-

1) 挡板的设置迫使喷吹气流横向扩散并与相邻的喷吹气流发生二次撞击,由此蓄积局部较高静压从而对滤芯产生增强的清灰作用,滤芯所受气流压力呈现底部最大、上部次之、中部最小的特点;挡板附近滤芯的压力随喷嘴入口压力的增加而显著提高,最佳喷嘴入口压力为5 000 Pa。

2) 喷吹覆盖区滤芯外侧所受压力随着挡板距离的减小而增大,对于所研究的1 000 mm长的滤芯,挡板位置为500 mm和350 mm分别可实现350~500 mm和0~350 mm区域的有效清灰。

3) 设计了挡板往复式喷吹策略:挡板位置依次控制在350、500、650、500 mm处,对应的滤芯外侧平均喷吹压力为638 Pa、变异系数为0.06。相比普通单向式喷吹,平均喷吹压力提升了1.57倍、喷吹均匀性提高了7.17倍;相比挡板双向式喷吹,平均喷吹压力提升了0.35倍、均匀性提高了3.18倍。

错流内滤式滤芯脉喷清灰的数值模拟

Numerical simulation of cross-flow inside-out filter element pulse jet cleaning

-

摘要: 错流式过滤除尘技术利用切向风流抑制尘饼生长变厚,具有过滤阻力上升缓慢的优点,采用脉喷气流撞击设置在滤芯外的横向挡板并产生局部静压可实现内滤式滤芯的清灰。构建CFD数值模拟考察了喷吹气流的分布,分析了喷嘴入口处的喷吹压力和挡板位置对脉冲喷吹性能的影响,设计并考察了挡板往复式喷吹策略。结果表明:滤芯压力随喷嘴入口压力升高而增加,确定了最佳喷嘴入口压力为5 000 Pa;挡板位置的变化显著影响清灰的有效区,对于1 000 mm长的滤芯,挡板位置为500 mm和350 mm分别实现350~500 mm和0~350 mm区域的有效清灰;相比普通喷吹,设计的挡板往复式喷吹 (挡板位置依次为350、500、650、500 mm) 可实现滤芯喷吹压力增大1.57倍、均匀性提升7.17倍。该研究结果可为内滤式滤芯脉喷清灰提供参考。Abstract: Cross-flow filter dust removal technology uses tangential air flow to suppress the growth and thickening of dust cake and has the advantage of slow rise of filtration resistance. The inside-out filter element can be cleaned by using pulse jet flow to impact the transverse baffle set outside the filter element and generate local static pressure. In this paper, CFD numerical simulation was constructed to investigate the distribution of jet flow, analyze the influence of the injection pressure at the nozzle entrance and the position of baffle on the performance of pulse jet, and design and investigate the baffle reciprocating injection strategy. The results showed that the filter element pressure increased with the increase of nozzle inlet pressure, and the optimal nozzle inlet pressure was 5 000 Pa. The effective cleaning area was significantly affected by the change of baffle position. For the 1 000 mm long filter element, the effective cleaning area of 350~500 mm and 0~350 mm could be achieved with the baffle position of 500 mm and 350 mm, respectively. Compared with the ordinary injection, 1.57 times increase in filter element injection pressure and 7.17 times increase in uniformity were achieved by the designed baffle reciprocating injection (baffle position at 350, 500, 650, 500 mm in order) . The results of this study can provide a reference for pulse jet cleaning of inside-out filter element.

-

中国酒业协会的数据显示,2019年我国啤酒产量达3 765×104 t,每t啤酒需排放的废水量约为3 t[1],其COD约为780~3 610 mg·L−12]。目前常用的厌氧-好氧法处理啤酒废水效果较好,但会产生大量剩余污泥。光合细菌(PSB)可以高效降解啤酒废水中的污染物,同时利用其中C、N、P合成菌体;PSB菌体中富含蛋白质、多糖、类胡萝卜素、叶绿素、辅酶Q10等高价值物质,可广泛用于畜牧、农业、渔业等领域,也可作为食品与药物的原材料,因此,PSB技术是一项非常有潜力的新型污水资源化技术[3-4]。

PSB几乎不产生胞外聚合物(EPS),但沉降性能差,不易实现菌体回收。膜生物反应器(MBR)结合了传统的生物处理单元与膜分离单元[6],通过膜的高效截留作用使微生物被完全截留在反应器内,因而既有利于废水的一步达标[7],也有利于微生物的高效生长、繁殖和富集[8]。国内外学者将PSB、光生物反应器与膜组件结合起来,开发了光合细菌-膜生物反应器(PSB-MBR),在提高污水处理效果的同时可实现菌体的富集与回收[9]。该方法具有操作简便、处理效果好、生物资源回收率高[10]等优点,其菌体回收率可高达99.5%[11]。

膜污染是MBR应用中的关键问题[12],会对反应器的运行性能与效果产生负面影响。QIN等[13]、彭猛[14]研究了PSB-MBR处理啤酒废水的膜污染,发现膜污染较低,推测其原因是该系统的胞外聚合物(EPS)浓度较低。然而,现有PSB-MBR研究均采用较低的运行通量,如HÜLSEN等[15]设定的PSB-MBR恒定通量为2.1 L·(m2·h)−1,其它研究也在类似水平。然而,实际污水处理厂的MBR通量为20~30 L·(m2·h)−1,比现有PSB-MBR系统通量高10倍。如此大的差异,使得现有研究无法反映未来在工业运行中可能的PSB-MBR膜污染。要实现该技术的工业化应用,将其膜通量调整为工业运行通量,会更具有参考价值。

本研究模拟工业通量,设计了PSB-MBR处理啤酒废水的一系列实验,考察了在不同的运行通量、进水COD、温度和PSB浓度下的膜污染变化情况,以期为PSB-MBR的工业化应用提供参考。

1. 材料与方法

1.1 供试原料与反应器

1) PSB菌种。菌种为通用商业菌种,其中红假单胞菌(Rhodopseudomonas palustris)比例超过80%。

2)供试废水。前期实验结果表明,PSB-MBR工艺处理模拟啤酒废水与实际啤酒废水效果一致,为方便操作,本研究采用人工配制啤酒废水。分别对啤酒稀释10、20、30倍,获得模拟废水COD约为7 400、3 700、2 500 mg·L−1,对应高、中、低浓度废水;加入硫酸铵以补充氮源,控制C/N比约为20。

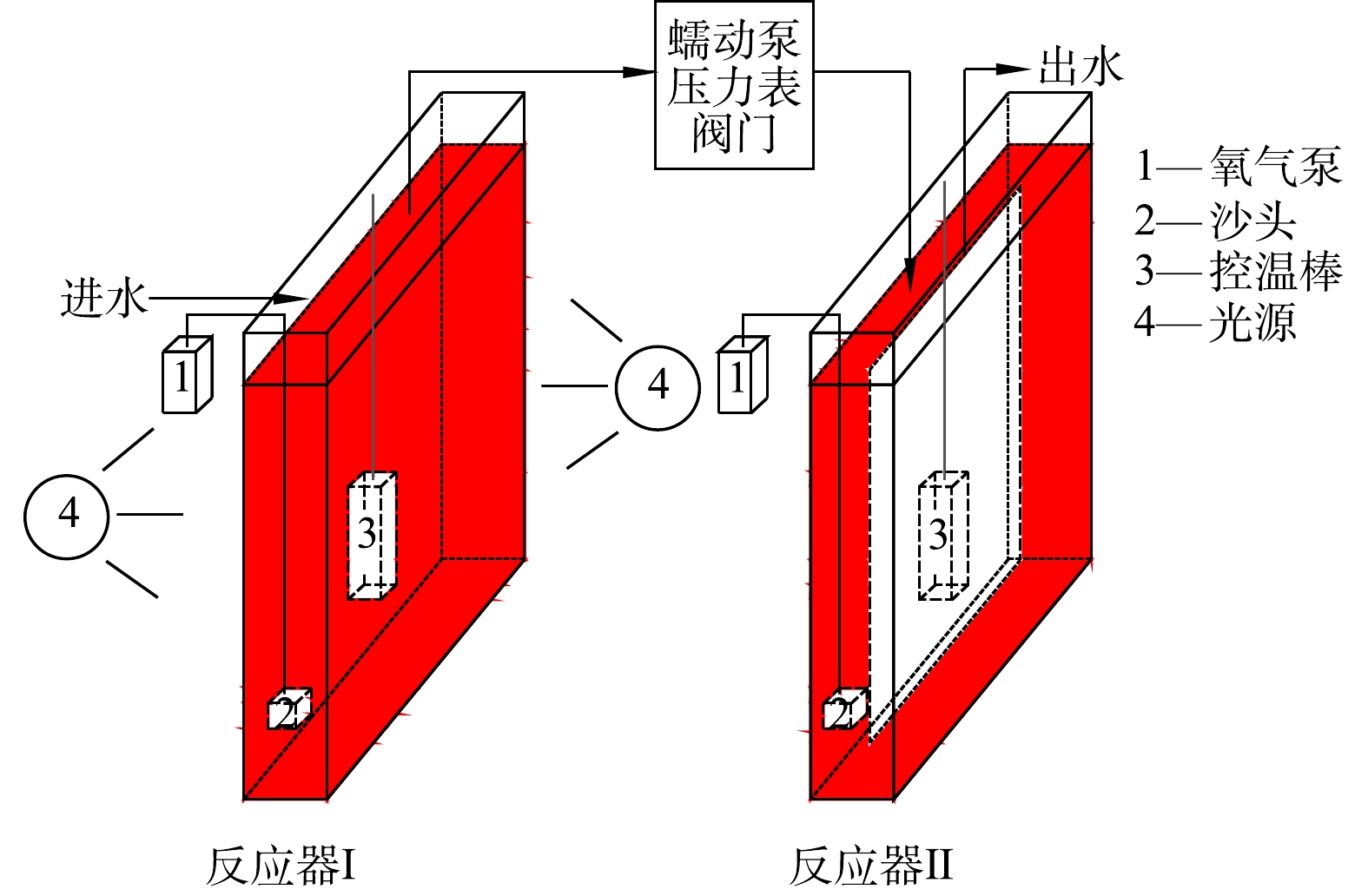

3) PSB-MBR反应器。反应器结构如图1所示,为长方体玻璃反应器,长

× × × × μ 1.2 实验方法及运行参数

生物反应器Ⅰ。PSB接种量为200~300 mg·L−1,废水利用氢氧化钠和盐酸溶液调节pH为7.2~7.6。通过氧气泵和DO仪控制溶解氧(DO)为0.2~0.5 mg·L−1,利用控温棒控制温度为约25 ℃,水力停留时间3 d。3种啤酒废水经过PSB处理后,COD分别为171、425、1 005 mg·L−1(均值),COD去除率为80%~93%。

膜分离反应器Ⅱ。该反应器运行参数取值尽量模拟可能的工业运行参数,因此取值范围较窄。生物处理后的废水输送到膜分离反应器Ⅱ中,分别考察不同进水通量、进水COD、运行温度和PSB浓度对运行过程中膜污染的影响。如无特殊说明,反应器Ⅱ的进水COD为170 mg·L−1、PSB浓度为1 000 mg·L−1、温度为25 ℃、运行通量为17.4 L·(m2·h)−1。

运行通量。设置2组反应器的运行通量为17.4、23.4 L·(m2·h)−1,这个范围是常见的污水处理膜通量,比通常的PSB-MBR实验研究高10倍[13-16]。

进水COD。根据生物反应器处理低、中、高废水的出水水质,膜分离反应器进水COD分别设置为170、425、1 000 mg·L−1。

运行温度。利用控温棒控制设定温度分别为常温(25 ℃)、低温(10 ℃),以考察低温下的膜污染。

PSB浓度。前期实验表明,PSB浓度低于1 000 mg·L−1时,污染物去除率低;高于1 500 mg·L−1时,PSB的增值率低;在1 000~1 500 mg·L−1范围内可以同时满足污染物去除与菌体合成以便后续回收利用。因此,控制进入反应器Ⅱ的PSB浓度分别为1 000、1 300、1 500 mg·L−1。

1.3 分析方法

1)水质分析。从反应器中取10 mL的菌-水混合物,在9 000 r·min−1下离心10 min后获得上清液用于水质检测。利用重铬酸钾法快速检测COD[17]。根据国标HJ 535-2009使用TU-1900分光光度计在420 nm的吸光度下分析氨氮[18]。PSB的生物量检测方法参考LU等[19]的方法。

2)膜污染阻力分析。根据达西定律(式1),测量平板膜在过滤过程中随时间变化的膜污染阻力,评估PSB-MBR系统中膜污染程度。

Rt=Rm+Rf=ΔPμ⋅J (1) 式中:Rt为膜的总过滤阻力,m−1;Rm为膜的固有阻力,m−1;Rf为膜丝污染阻力,m−1;ΔP为膜两侧的压力差,Pa;μ为透过液动力学粘度,Pa∙s;J为膜通量,m3·(m2·s)−1。

3)膜污染表征。用扫描电子显微镜(SEM,Hitachi S-4800型)对平板膜表面的微观结构进行观察,对膜表面的污染情况进行表征。将膜片浸泡在超纯水中24 h后,经0.45

μm 4)膜清洗。膜清洗有2种方式,其中物理清洗是用清水洗涤膜表面5 min;化学清洗是将膜片浸入0.75%NaClO溶液中浸泡2 h后,用清水冲洗膜表面5 min [14]。

2. 结果与讨论

2.1 操作参数对膜污染的影响

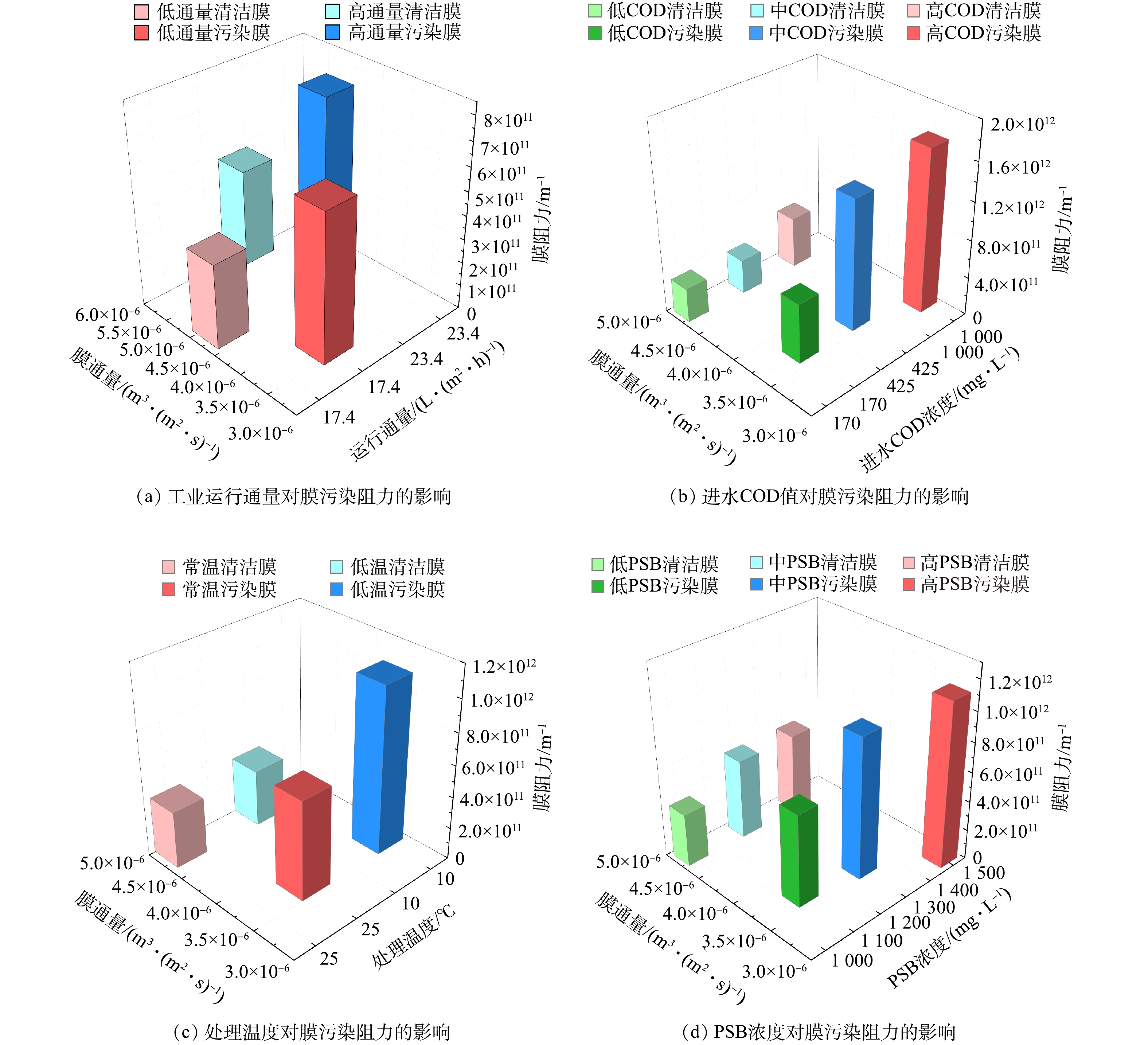

在传统MBR的运行过程中,高运行通量、高COD均会加剧污染物在膜表面的富集,从而加速膜污染的产生;一定的温度条件可能会引起微生物状态的变化,导致EPS浓度升高,进而加剧膜污染。因此,本研究分别考察了不同的运行通量、膜反应器Ⅱ进水COD与PSB浓度、运行温度等对膜的影响。当膜通量下降至初始值的80%时即判定膜受到污染。图2显示了不同操作参数对膜污染阻力的影响。

在膜设计通量范围内,膜通量随着运行通量的增加而增加(图2(a)),而膜阻力也明显随运行通量增加。以23.4 L·(m2·h)−1通量运行时,污染后膜阻力为7.44

× 膜分离反应器的进水浓度高,也导致了膜阻力增加,通量下降(图2(b))。当膜的进水COD为1 000 mg∙L−1时,膜通量达到3.42

× 运行温度对膜污染阻力影响较大(图2(c))。低温条件下的污染膜污染阻力为1.06

× 膜污染随着PSB浓度的上升逐渐加剧(图2(d)),当PSB浓度为1 500 mg·L−1时,污染后的膜通量为3.17

× 根据膜阻力变化情况,本研究中进水COD是影响膜污染最重要的因素,其次为PSB浓度、温度、运行通量(1.72×1012 m−1 > 1.12×1012 m−1 > 1.06×1012 m−1 > 7.44×1011 m−1)。而在对An MBR运行影响因素的相关研究中,温度是影响其运行特性最主要的因素,其次是污泥(或COD负荷)[21],这主要是由于温度会导致厌氧微生物通过分泌EPS等物质影响污泥的特性从而使得污泥絮体增大、膜污染加剧[25]。PSB几乎不产生EPS,主要可能是由废水中的有机负荷及菌体代谢造成膜污染。因此,进水COD成为了PSB-MBR模拟工业通量运行的主要影响因素,这也与彭猛[14]使用低通量研究时获得的结果一致。

2.2 PSB-MBR中膜污染分析

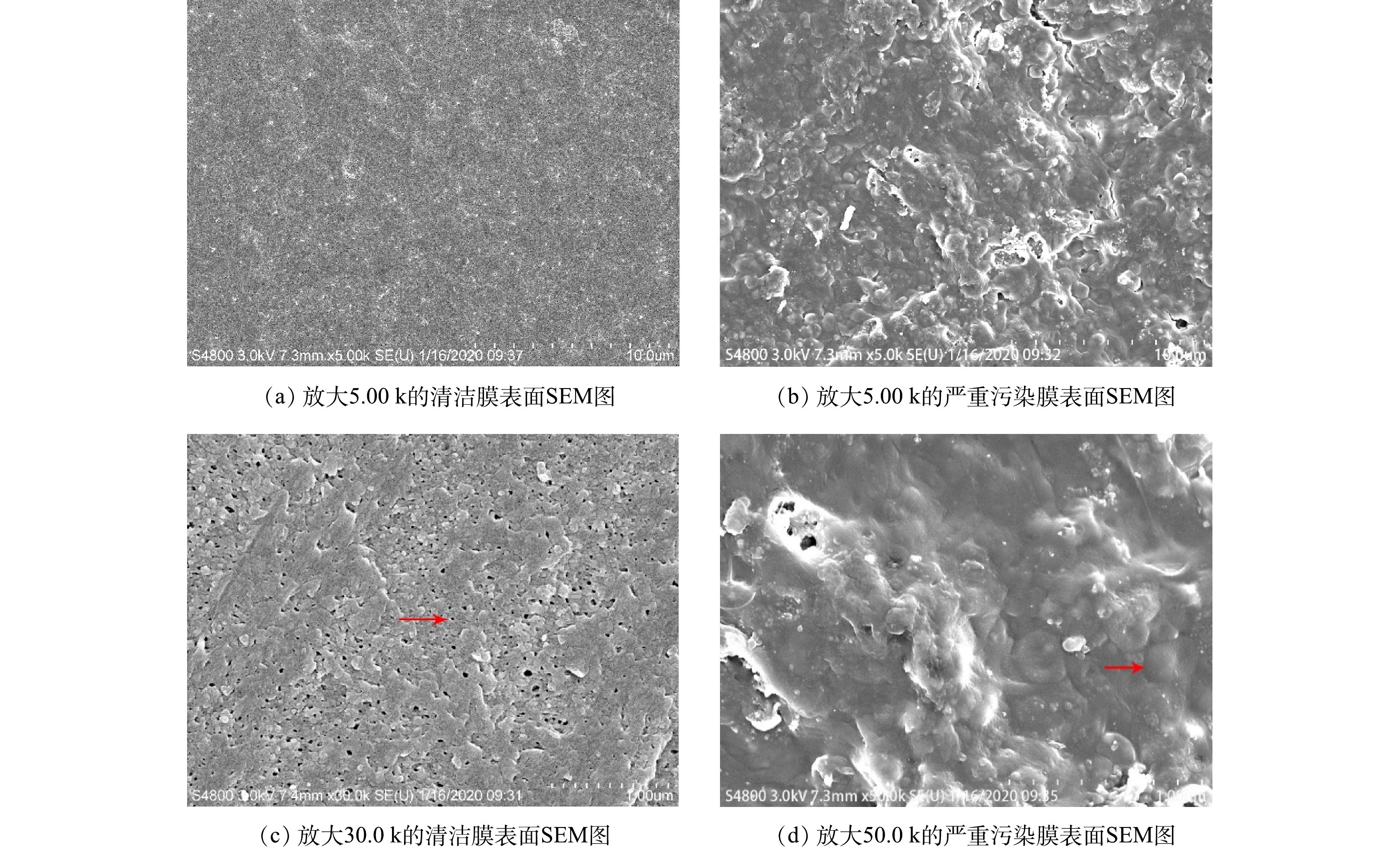

设定多次进行物理清洗后,膜通量无法恢复至初始通量的80%时为严重污染。根据2.1节中的结果,设置参数为,膜分离反应器Ⅱ进水COD 170 mg·L−1、PSB 1 000 mg·L−1、常温(25 ℃)、运行通量17.4 L·(m2·h)−1,在该条件下进行膜污染分析。利用SEM对运行后的PSB-MBR系统中膜的表面特性进行了物理分析。图3(a)显示,清洁膜片在放大倍数为5.00 k时表面平滑,无污染物质存在;在放大30.0 k时呈现明显多孔隙结构,可以判断照片中显示的孔隙即为膜片的过滤孔隙。图3(b)显示,严重污染膜在放大倍数为5.00 k的条件下,表面覆满污染物质;而图3(d)则显示污染物中有一些椭球形物体堆积,无法显示原有孔隙结构,这说明膜孔已被堵塞,大分子污染物堆积在膜表面。因此,在模拟工业通量运行时,PSB-MBR会产生较严重的膜污染,大量污染物会覆盖膜的原有结构,导致反应器的后续运行性能下降。而现有的PSB-MBR研究采用比工业通量低10倍的通量,并未发现这么明显的膜污染[15]。

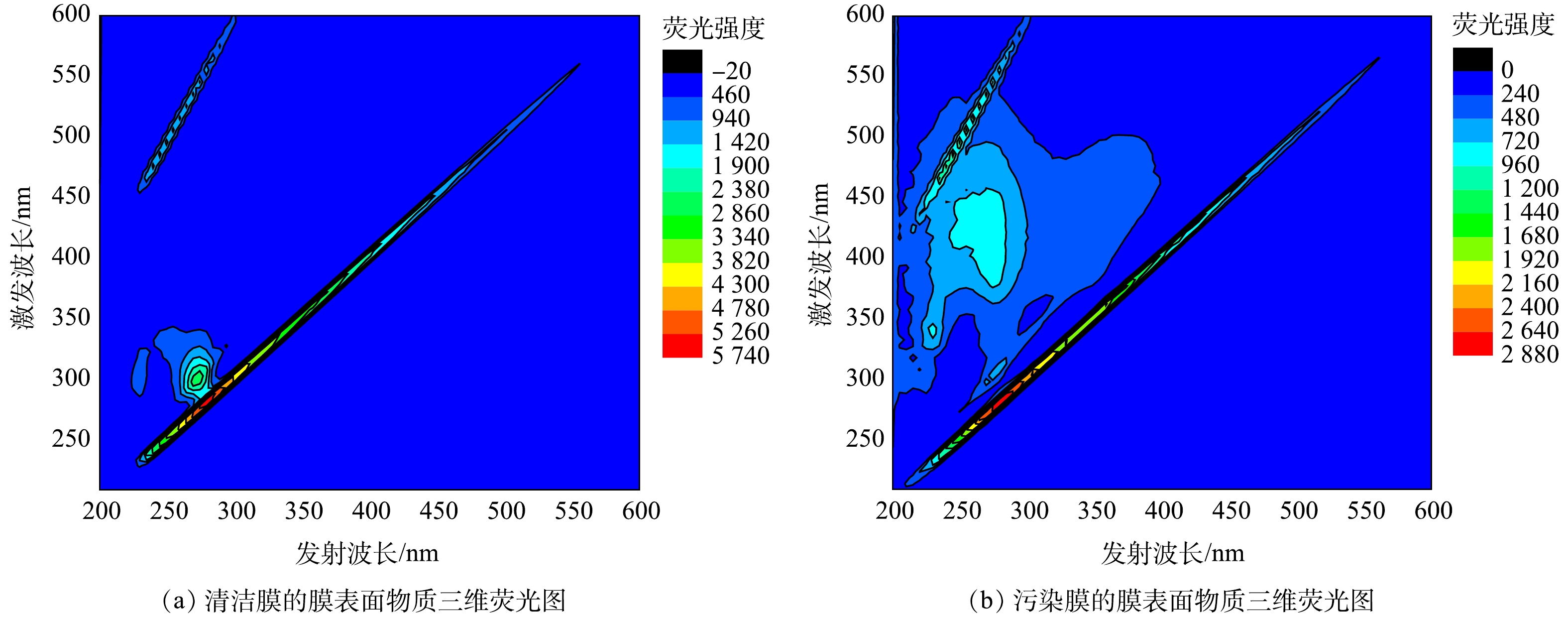

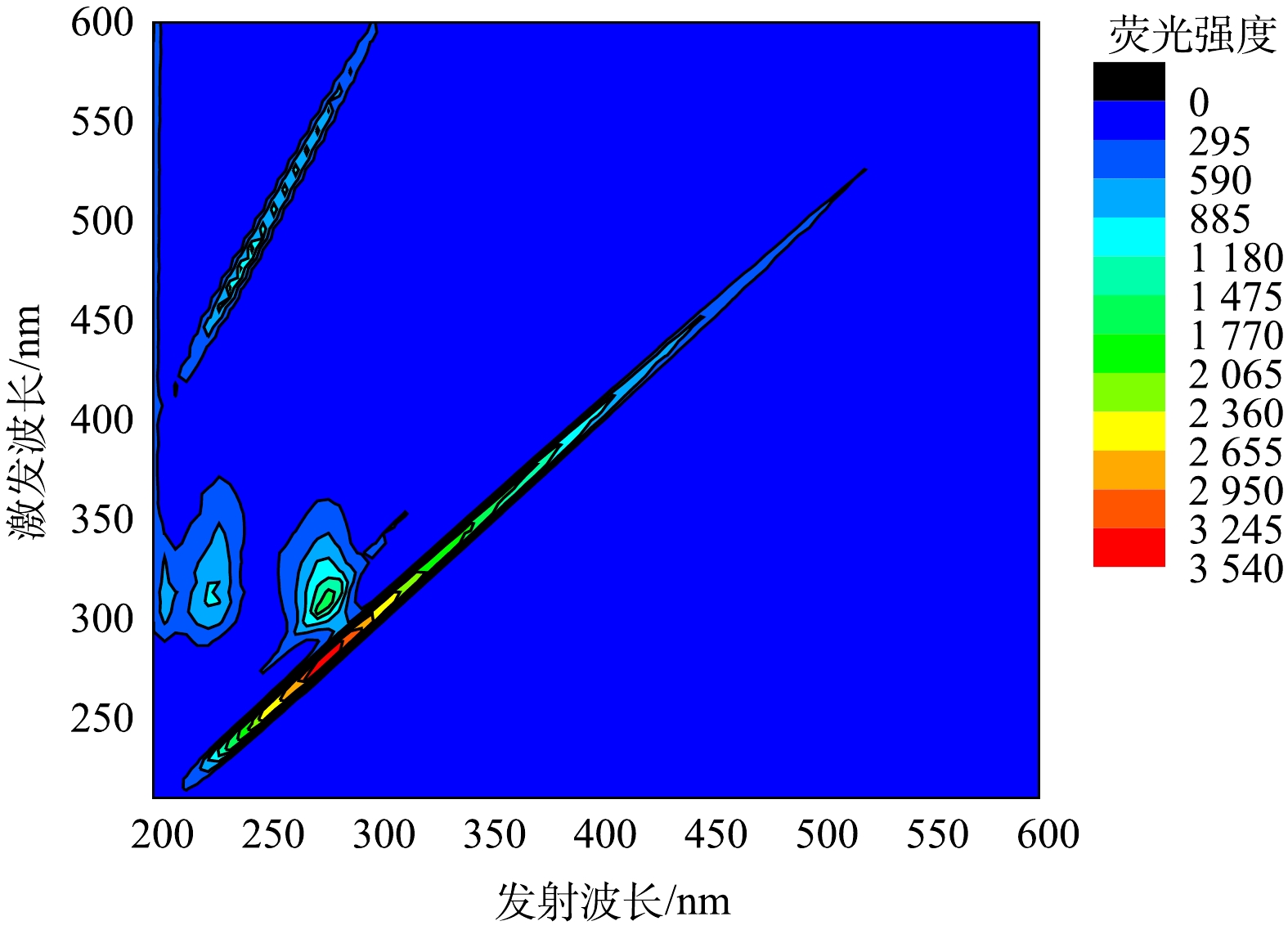

通过三维荧光光谱法对膜表面物质进行了分析,结果如图4所示。图4(a)显示,清洁膜表面主要为亲水性大分子蛋白类有机物,而图4(b)中则显示膜污染物质中含有亲水性大分子蛋白类有机物与有腐殖质。由于进水为模拟啤酒废水,不含大分子蛋白质与腐殖质[27],结合SEM分析结果(图3),可以推测,造成膜污染的主要是有机污染,来自PSB及其降解或分泌物质。

膜污染通常分为3个阶段,分别为初始污染阶段、缓慢污染阶段及跨膜压差(TMP)跃升阶段[28]。在初始污染阶段,膜表面与混合液发生相互作用,粒径小于膜孔径的污染物颗粒进入膜孔,其中一些被吸附于膜孔内,减小了膜孔的有效直径。因此,膜通量由4.83

× × μ μ × × 2.3 膜清洗

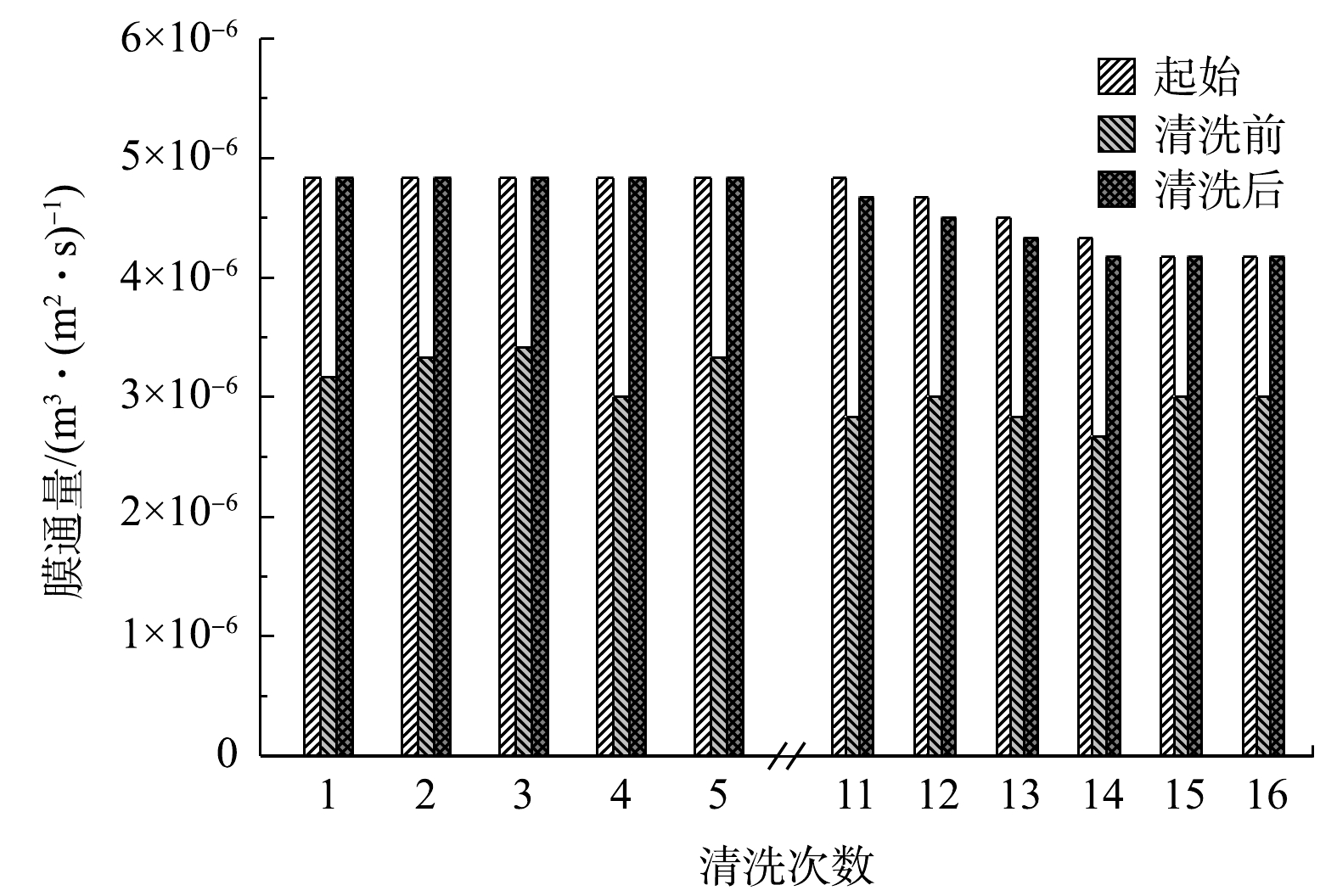

为使已经产生污染的膜恢复膜通量,需要对其进行清洗。膜清洗方法主要分为物理清洗和化学清洗。在反应器运行过程中,对平板膜进行周期性物理清洗(清水冲洗5 min)。由图5所示,初始阶段物理清洗效果很好,膜通量几乎完全恢复。第4次清洗前,膜通量下降到起始膜通量的62%,物理清洗后膜通量100%恢复;第11次物理清洗仍然可以使膜通量恢复至起始膜通量的97%。郭雅妮等的[30]研究表明,传统MBR中物理清洗后膜通量仅恢复至新膜的70%。因此,PSB-MBR系统中物理清洗效果远比传统MBR好,这有利于延长膜片的使用寿命。其原因是,由于PSB几乎不产生EPS,因此,传统MBR中污染最严重也较难清洗的EPS污染在PSB-MBR中几乎没有贡献,从而使得在PSB-MBR系统中物理清洗效果显著。然而,随着物理清洗次数的增加,膜通量恢复效果仍然在缓慢下降,这是因为有机污染逐渐积累,污染层结构逐渐致密化,导致物理清洗效果开始变差。在彭猛[14]的研究中,物理清洗40次,膜通量仍然可以100%恢复。这是因为,其采用的是低通量,其通量仅为本文研究的8%~15%。从图2(a)可知,通量越低,膜阻力越小,越容易恢复。这一结果也表明,在工业通量下,PSB-MBR系统的膜污染虽然比常规MBR低,但是比现有研究低通量PSB-MBR高。

当物理清洗无法使膜通量恢复至80%时,需要采用化学清洗以恢复膜通量。AHMAD等[31]研究了不同化学清洁剂对化学清洗后膜通量的恢复效果,发现用0.75% NaClO溶液的清洗效果最好,可以恢复约98%膜通量并且使膜孔基本恢复。康永和胡肖勇[32]发现,采用2.0%~5.0%的NaClO溶液清洗膜时,既可以去除污垢,又可以去除膜孔内附着的微生物和蛋白质等有机污染物。谢元华等[33]利用0.1%的NaClO溶液浸泡机械清洗后的膜2 h后,过膜阻力几乎完全恢复。根据以上研究,本研究使用NaClO溶液作为化学清洗药品,具体化学清洗方法为0.75% NaClO溶液浸泡2 h。清洗后膜通量100%恢复,4次清洗后仍然可达到这一效果。

此外,本研究采用三维荧光光谱法分析了化学清洗后的膜,结果见图6。化学清洗后的膜表面,主要污染物质是亲水性小分子蛋白类有机物,而由图4(b)可知,污染膜表面主要污染物是腐殖质和大分子蛋白类有机物,表明化学清洗将膜表面的大分子污染物转化成为小分子物质。其原因是NaClO的氧化性及其对微生物细胞的破坏作用。这一现象与常规MBR膜化学清洗相似[34],NaClO碱洗后膜通量几乎完全恢复,这说明有机污染是造成膜污染的主要原因。

3. 结论

1) PSB-MBR模拟工业级别运行通量(17.4 L·(m2·h)−1)时,PSB-MBR膜污染比现有研究中低通量下PSB-MBR膜污染高,但远低于常规MBR污染,其原因是PSB几乎不产生EPS。

2)高运行通量、高PSB浓度、高COD、低温会提高膜阻力,加剧膜污染。

3)造成PSB-MBR系统膜污染的主要来源是PSB菌体本身及其代谢产物。

4)物理清洗无法使膜通量恢复至80%时,化学清洗可以恢复膜通量,通过将原污染物中的腐殖质转变为亲水性小分子蛋白类有机物,解决膜孔堵塞问题。

-

-

[1] 国家卫生健康委员会规划发展与信息化司. 2021年我国卫生健康事业发展统计公报[J]. 中国病毒病杂志, 2022, 12(5): 321-330. doi: 10.16505/j.2095-0136.2022.0065 [2] 陈刚, 张晓蕾, 徐帅, 等. 我国2005-2020年粉尘爆炸事故统计分析[J]. 中国安全科学学报, 2022, 32(8): 76-83. [3] 杨燕霞, 张明星, 秦文茜, 等. 脉冲喷吹内置锥形滤筒的清灰性能[J]. 中国粉体技术, 2019, 25(1): 76-80. doi: 10.13732/j.issn.1008-5548.2019.01.013 [4] V. SIBANDA, R. W. GREENWOOD, J. P. K. SEVILLE, et al. Predicting particle segregation in cross-flow gas filtration[J]. Powder Technology, 2010, 203(3): 419-427. doi: 10.1016/j.powtec.2010.03.039 [5] 李建龙, 孙泽文, 杜雷恒, 等. 一种错端滤一体式复合滤筒除尘装置[P]. CN114432811A, 2022-05-06. [6] 林莉君, 陈海焱, 周喜, 等. 脉冲喷吹滤筒除尘器清灰性能的实验研究[J]. 暖通空调, 2009, 39(4): 148-151. doi: 10.3969/j.issn.1002-8501.2009.04.036 [7] LI J L, LI S H, ZHOU F B. Effect of cone installation in a pleated filter cartridge during pulse-jet cleaning[J]. Powder Technology, 2015, 284: 245-252. doi: 10.1016/j.powtec.2015.06.071 [8] 艾子昂, 吴泉泉, 孙燕, 等. 气流隔板改善滤筒脉喷清灰性能的数值模拟[J]. 南昌大学学报(工科版), 2021, 43(4): 384-391. doi: 10.13764/j.cnki.ncdg.2021.04.013 [9] 薛峰, 李朋, 黄琬岚, 等. 喷嘴型式对滤筒脉冲定阻清灰效果的影响[J]. 中国粉体技术, 2022, 28(5): 48-56. doi: 10.13732/j.issn.1008-5548.2022.05.007 [10] QIU J, WU D S, CHEN D R, et al. Reverse pulsed-flow cleaning of pleated filter cartridges having an inner pleated filter cone[J]. Process safety and Environmental Protection, 2021, 146: 481-489. doi: 10.1016/j.psep.2020.11.025 [11] CHEN S W, WANG Q, CHEN D R. Effect of pleat shape on reverse pulsed-jet cleaning of filter cartridges[J]. Powder Technology, 2017, 305: 1-11. doi: 10.1016/j.powtec.2016.09.013 [12] CHEN S W, CHEN D R. Numerical study of reverse multi-pulsing jet cleaning for pleated cartridge filters[J]. Aerosol and Air Quality Research, 2016, 16(8): 1991-2002. [13] 陈强, 林子捷, 李建龙, 等. 扩散喷嘴改善金锥滤筒脉喷清灰性能的数值模拟[J]. 环境工程学报, 2021, 15(5): 1634-1644. doi: 10.12030/j.cjee.202011010 [14] 李建龙, 王安琪, 范博, 等. 除尘器脉喷清灰影响阶段的粉尘分级排放特征[J]. 安全与环境学报, 2018, 18(1): 315-319. doi: 10.13637/j.issn.1009-6094.2018.01.059 [15] 袁彩云, 陈海焱, 李波. 脉冲喷吹滤筒除尘器喷吹清灰实验与数值模拟[J]. 暖通空调, 2012, 42(5): 104-107. doi: 10.3969/j.issn.1002-8501.2012.05.019 [16] HUMPHRIES W. , MADDEN J. Fabric filtration for coal-fired boilers: nature of fabric failures in pulse-jet filters[J]. Filtration & Separation, 1983, 20(1): 40-42. [17] SIEVERT J. , LOFFLER F. Dust cake release from non-woven fabrics[J]. Filtration & Separation, 1987,24(6): 424-427. [18] LU HSIN-CHUNG, TSAI CHUEN-JINN. A pilot-scale study of the design and operation parameters of a pulse-jet baghouse[J]. Aerosol Science and Technology, 1998, 29(6): 510-524. doi: 10.1080/02786829808965587 [19] LI J L, WANG P, WU D S, et al. Numerical study of opposing pulsed-jet cleaning for pleated filter cartridges[J]. Separation and Purification Technology, 2020, 234: 116086. doi: 10.1016/j.seppur.2019.116086 [20] 颜翠平, 张明星, 吕娟, 等. 脉冲喷吹大风量滤筒除尘器的清灰变化过程研究[J]. 环境工程学报, 2016, 10(2): 829-834. doi: 10.12030/j.cjee.20160250 [21] 李建龙, 陈源正, 林子捷, 等. 除尘滤筒脉喷清灰技术研究进展与展望[J]. 金属矿山, 2022, 557(11): 23-35. doi: 10.19614/j.cnki.jsks.202211003 [22] WU Q Q, LI J L, WU D S, et al. Effects of overall length and od on opposing pulse-jet cleaning for pleated filter cartridges[J]. Aerosol and Air Quality Research, 2020, 20: 432-443. [23] 李建龙, 赵艺, 孙泽文, 等. 环形缝隙喷嘴改进导流内锥式除尘滤筒脉冲喷吹性能的数值模拟[J]. 南昌大学学报(工科版), 2023, 45(1): 1-4. doi: 10.13764/j.cnki.ncdg.2023.01.001 -

下载:

下载: