-

水资源短缺与能源危机推动了水处理技术的革新。在“双碳”背景下,传统的以能耗换水质的水处理技术已无法满足可持续发展的要求[1]。开发以能源再生-资源回收为目的的新技术,降低水处理过程中的碳排放,对于实现我国的“双碳”目标有着重要意义[2]。与传统的好氧生物处理技术相比,厌氧生物处理技术能够在废水处理过程中实现资源回收和能源再生,在水处理中具有广阔的应用前景[3-4]。近年来厌氧生物处理技术开始逐步应用于低浓度废水(如市政污水)的处理,但有机物含量低时厌氧微生物生长缓慢,且低产气量较难实现泥水混合液的充分搅拌,导致有机物的去除转化效果不理想,从而限制了厌氧技术在低浓度废水处理中的应用[5]。厌氧膜生物反应器(anaerobic membrane bioreactors, AnMBR)采用厌氧处理与膜分离相结合的方式,将水力停留时间(hydraulic retention time, HRT)和污泥龄(sludge retention time, SRT)分开[6],有效弥补了传统厌氧生物处理技术存在的弊端,具有生物量大、出水水质高以及能耗低等优点[7],是实现低浓度废水厌氧生物处理的理想技术。

已有很多研究报道了AnMBR用于处理低浓度废水时可以实现较好的有机物去除和产甲烷性能,但运行过程中存在着膜污染的问题,常需要通过沼气循环、混合液回流等方式增大体系混合程度来减轻膜污染。另一方面,AnMBR出水中含有较多的溶解性甲烷(dissolved methane, DCH4),甲烷是一种温室气体,DCH4解吸后[8](释放到大气)会造成能量流失和温室效应。现有研究[9-11]表明,AnMBR出水DCH4的质量浓度为8.8~19.1 mg·L–1,因此,而流失的甲烷占总甲烷产量的23%~88%。在较多研究中,测得DCH4的浓度经常高于亨利定律计算的理论值,即AnMBR出水的DCH4往往是过饱和的[12],其过饱和度即相比于理论DCH4的倍数为1.3~4.1倍[9,13]。已有部分研究通过外置气体分离器[14-17]对AnMBR出水DCH4进行回收并取得了较好的效果,但上述过程存在着能量消耗、占地增加和工艺流程长等问题。甲烷的液-气传质会显著改变甲烷的溶解程度,其传质系数[10,18]主要受反应器运行条件(如负荷、混合效率、温度)的影响,在不同工况下AnMBR出水DCH4的过饱和度具有较大的差异[19]。YEO等[10]在采用混合液循环的AnMBR中研究结果表明,随着负荷提升产气速率不断增大,有利于解除甲烷气-液传质的限制,从而降低了DCH4的过饱和度。研究不同工况对AnMBR中甲烷气-液分配特征的影响,有望通过反应器运行方式的调控,实现原位降低DCH4的浓度。为此,本研究针对AnMBR出水存在DCH4过饱和问题,基于AnMBR的低浓度废水处理过程,探究了不同负荷和混合方式对有机物去除和DCH4的影响。揭示上述过程甲烷气-液传质系数的变化规律并阐明AnMBR中甲烷的气-液分配特征,进一步用于指导反应系统运行,以期为降低AnMBR的碳排放量和能耗提供参考。

-

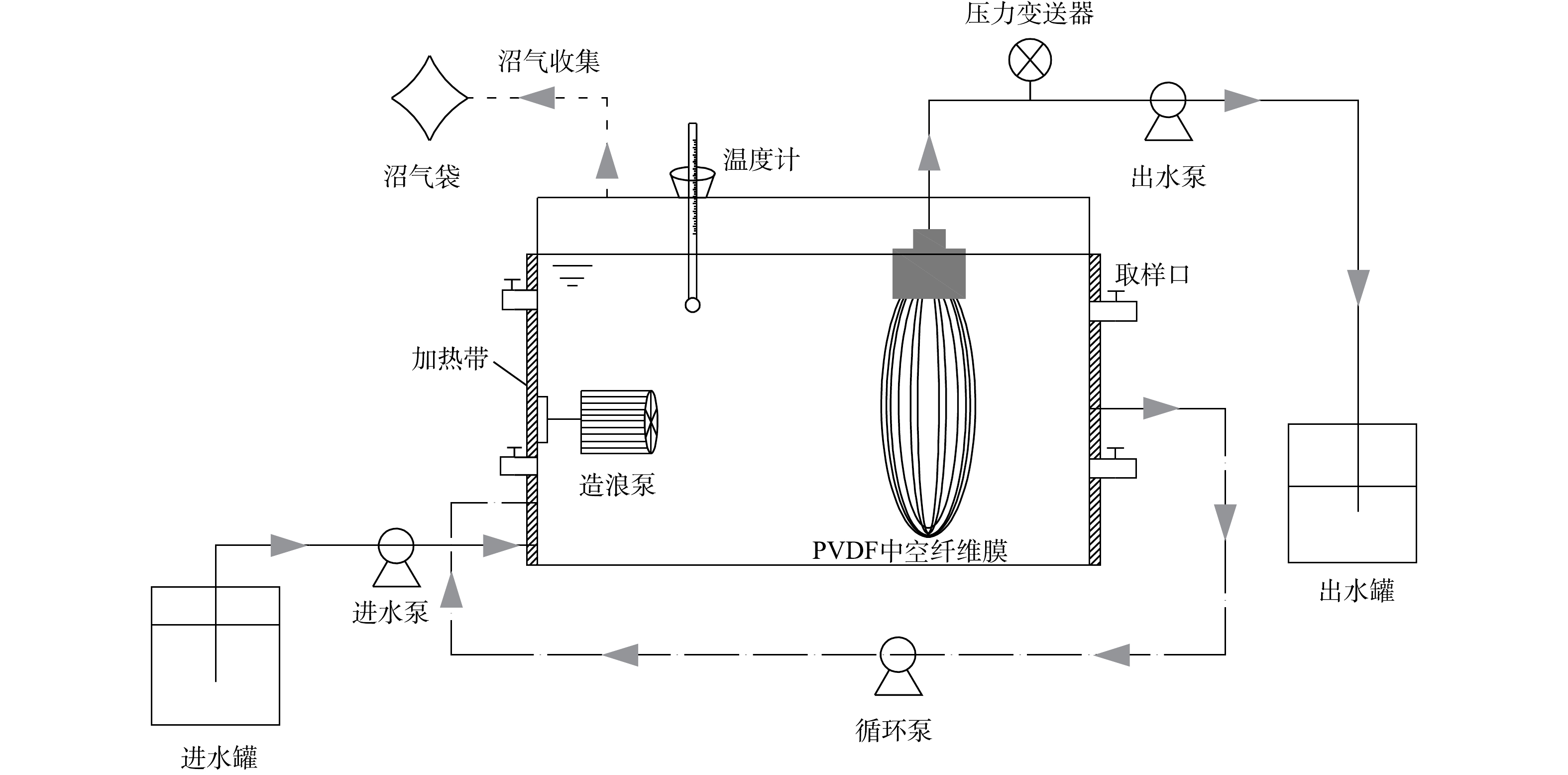

本实验所用AnMBR装置如图1所示,反应器主体为有机玻璃材质的长方体形容器(长×宽×高=30 cm×20 cm×25 cm),有效容积为11 L。反应器内设置聚偏氟乙烯(PVDF)材质的中空纤维膜(MBR-0.1F,海科滤膜),膜组件构型采用U型,膜丝数量共80根,单根膜丝的内、外径分别为0.8 mm和1.8 mm,膜孔径为0.1 μm,膜组件总有效面积0.19 m2。反应器进出水采用蠕动泵控制(BT100-2J,兰格恒流泵有限公司),出水泵与膜组件之间设有压力变送器(SIN-P300,中国杭州联测自动化技术有限公司),用于监测跨膜压差的变化。反应器外部覆盖有加热带(鸿泰电热配件),用于维持反应器内部的温度,内部温度由反应器顶部的温度计读取。反应器顶部设有阀门用于连接沼气袋和收集厌氧反应所产气体。反应器两侧均设有取样口用于采样分析。

AnMBR每个运行周期为10 min,其中出水8 min,松弛2 min。反应器设有2种不同的混合方式:从出水侧将泥水混合液泵回进水侧以进行循环混合;内部设置1个造浪泵(JVP-100AB)进行浪式脉冲混合。

-

反应器接种污泥为黑色厌氧颗粒污泥,取自升流式厌氧污泥床反应器。实验进水采用由葡萄糖、尿素、磷酸二氢钾等人工配制而成的模拟废水,具体水质成分如下:0.23 g·L–1 尿素、0.11 g·L–1 KH2PO4、1 g·L–1 K2HPO4、0.05 g·L–1 Na2SO4、0.1 g·L–1 MgCl2·6H2O、0.05 g·L–1 CaCl2·2H2O、10 mL·L–1 微量元素、10 mL·L–1 维生素(注:微量元素和维生素具体组成参考文献[20])。缓冲物质为质量浓度为1 g·L–1的碳酸氢钠。葡萄糖的用量根据实验进行调整。

-

控制AnMBR反应器温度为(35±1) oC,水力停留时间(HRT)为20 h,通过改变进水COD来改变反应器的负荷。反应器启动后共运行87 d,运行过程根据负荷和混合方式分为6个阶段,其中3个负荷水平(A、B、C)对应的进水COD分别为500、1 000、1 500 mg·L–1,每个负荷下混合方式分为循环混合与浪式脉冲混合,各运行工况条件见表1。

每天取进出水水样测定COD值(哈希(Hach)试剂盒,2125815-CN),取反应器内混合液样品用于DCH4的浓度测定(见1.4);沼气袋内收集气体的体积用注射器抽取测量,并用气相色谱(天美GC7900,中国)分析其组分及含量。各运行阶段结束时,取反应器内混合液用于生物量(MLSS和MLVSS)的测定(重量法)。

-

1)水中DCH4的测定。水中的DCH4采用顶空平衡法进行测定。在20 mL的密封小瓶中注入3.5 mol·L–1的盐酸1 mL,用于抑制产甲烷菌的生理活性,从反应器内采集9 mL混合液样品注入小瓶中。将小瓶在25 oC的振荡器中振荡5 min,并放置3 h使CH4达到气液平衡,平衡后取1 mL顶空气体注入气相色谱分析气体组成。反应器混合液中DCH4的浓度根据亨利定律计算(式(1))[21]所示。根据亨利定律推出式(2)。

式中:CL为液体中DCH4的质量浓度,mg·L–1;CG,eq是平衡后样品瓶顶空中CH4的质量浓度,mg·L–1;CL,eq是样品瓶液体中与顶空平衡的CH4质量浓度,mg·L–1;VG和VL分别为样品瓶中液体和气体的体积,L。

式中:PP,eq是CH4在顶空中与液相平衡时的分压,Pa;

{{M}}_{{\text{CH}}_{\text{4}}} 是CH4的相对分子质量,16 g·mol–1;Hcp为亨利常数,mol·(m3·Pa)–1,在25 ℃时为1.4×10–5 mol·(m3·Pa)–1。2) COD质量平衡计算。在各工况运行稳定后,根据式(3)[18]进行COD的物料衡算,以分析有机物分布去向。

式中:Cin和Ceff分别为进出水COD,mg·L–1;

{\text{C}}_{{\text{DCH}}_{\text{4}}} 为DCH4质量浓度(以COD计),mg·L–1;{\text{C}}_{{\text{GCH}}_{\text{4}}} 为以COD计气态CH4质量浓度,mg·L–1;Cother是其他所有包括生物质合成、微生物代谢产物(可溶性微生物产物(SMP)、胞外聚合物(EPS))生成和硫酸盐还原等用到的耗氧有机物(以COD计),mg·L–1。将产生的CH4转化为COD({\text{CH}}_{\text{4}}\text{+2}{\text{O}}_{\text{2}}\text{=}{\text{CO}}_{\text{2}}\text{+2}{\text{H}}_{\text{2}}\text{O} )。值的注意的是,CO2不会贡献COD,故不出现在COD质量平衡中[22]。3)CH4传质系数的计算。AnMBR中CH4由液相向气相的传质系数可由式(4)[10]进行计算。

式中:KLa为由液相向气相的传质系数,h–1;CL为液体中DCH4的质量浓度,mg·L–1;Qg为甲烷产气速率,L·h–1;V是反应器的有效体积,L;PCH4为AnMBR顶空中CH4的分压,Pa;R是理想气体常数,8.31×103 L·Pa·(mol·K)–1;T是温度,K;QV (Qg/V)为反应器的CH4产气量,L·(L·h)–1;Ceq是与气相中CH4分压处于热力学平衡的DCH4的质量浓度,mg·L–1;KH是CH4的亨利常数,35 oC时为1.18×10–7 mol·(L·Pa)–1。

4)能量计算。CH4的热值约为37.8 MJ·m–3,按电能转换效率为35%计算CH4转换成的电能(式(5))[23]。反应器运行过程中混合所用设备的能量需求通过设备的功率和运行时间得出(式(6))。反应器运行过程中的净能量(E)由设备能源消耗与回收甲烷所得能源的差值计算(式(7))。

式中:

{{W}}_{{\text{CH}}_{\text{4}}} 为CH4转化的电能,kWh;{{V}}_{{\text{CH}}_{\text{4}}} 为CH4的体积,m3式中:W消耗为设备消耗的能量,kWh;P为设备的功率,浪式脉冲设备功率为3 W,混合液循环设备功率为20 W;t为设备运行时间,h。

-

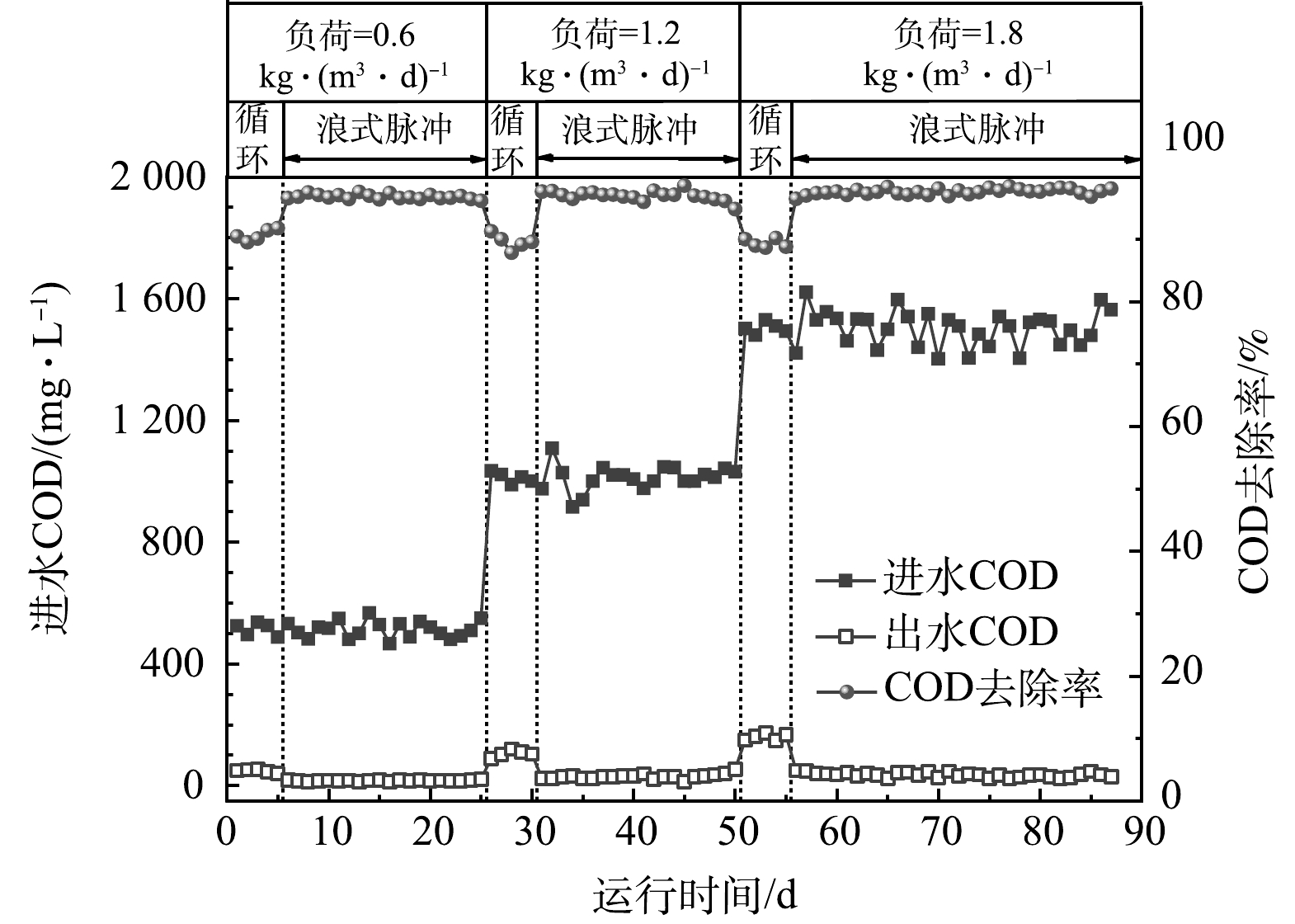

本研究中AnMBR共运行87 d,固定反应器的HRT为20 h,通过增加进水COD来提升负荷,在此期间研究了反应器不同混合形式对有机物去除性能的影响,各运行工况下进出水的COD值及去除率变化如图2所示。结果表明,AnMBR可实现对有机物的高效去除,COD平均去除率超过90%,提升进水负荷AnMBR对有机物仍可保持着良好的去除效果,具有一定的抗冲击负荷性。如图2所示,各负荷下AnMBR浪式脉冲混合时对有机物的去除效果均好于循环混合,在进水COD为500 mg·L–1,负荷为0.6 kg·(m3·d)–1时,循环混合模式下反应器出水的COD值为(48±4.9) mg·L–1,对应COD去除率为(90.7±0.8)%;改用浪式脉冲混合模式后,COD去除率提升至(96.8±0.4)%。这是因为浪式脉冲混合的系统扰动强度更高,促进了微生物与底物的接触与利用,从而提高了有机物的去除效果[24]。

-

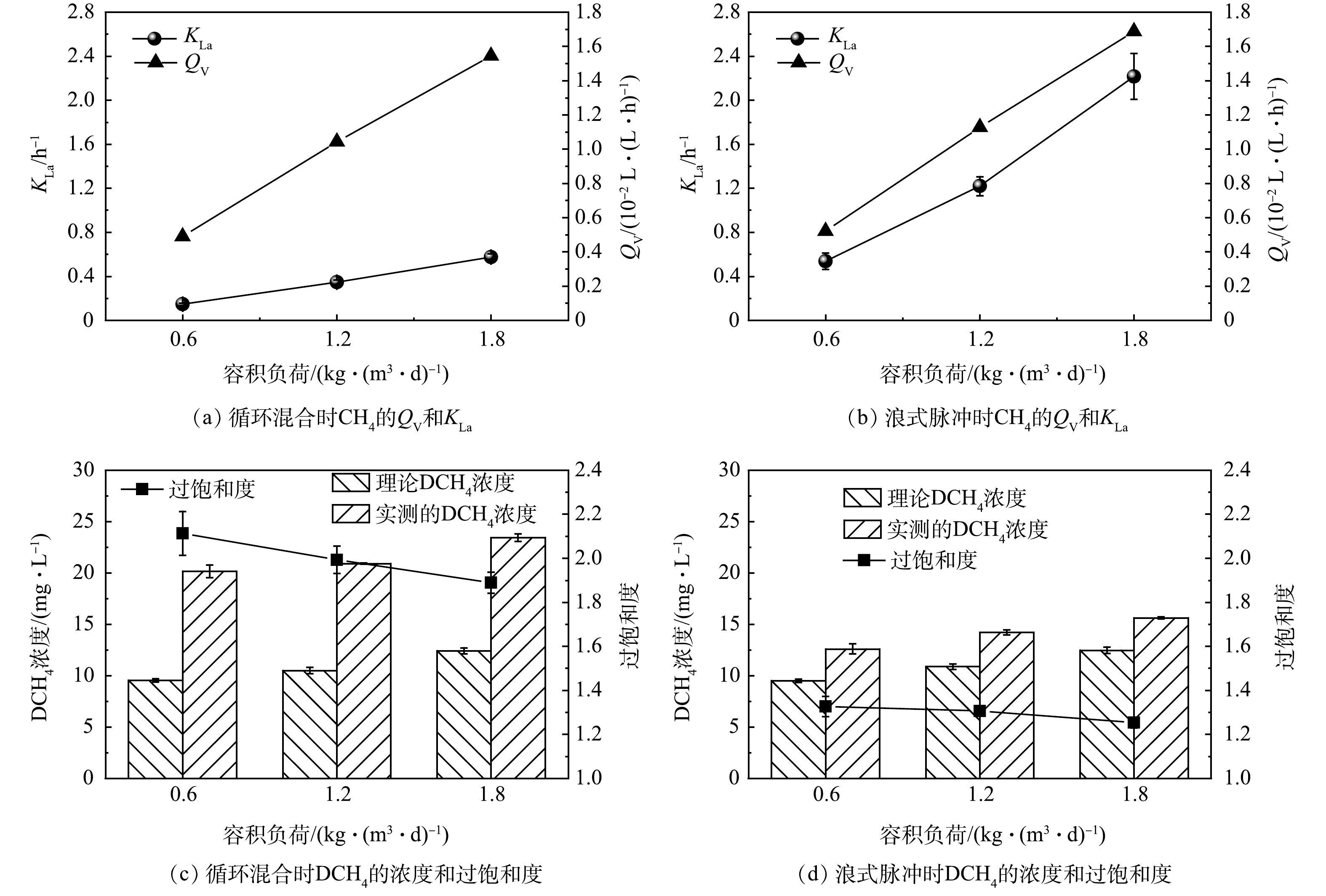

在AnMBR的运行过程中,测定各运行工况下的CH4产气量(QV)和DCH4,结合亨利定律和式(4)计算出理论DCH4和甲烷传质系数(KLa)。如图3所示,各阶段反应器液相中DCH4均处于过饱和状态,DCH4浓度为理论浓度的1.3~2.1倍,该水平位于已报道的AnMBR中DCH4过饱和度范围之内[25-26]。在相同负荷下,浪式脉冲混合时DCH4的浓度和过饱和度均低于循环混合时(图3(c)~(d))。在负荷为0.6 kg·(m3·d)–1下,循环混合时DCH4为20.2 mg·L–1,对应过饱和度为2.1;而浪式脉冲混合时DCH4为12.6 mg·L–1,对应过饱和度为1.3。上述结果是由于不同条件下CH4的KLa不同导致的,KLa较大时,CH4能更好地从液相扩散至气相,从而有利于降低DCH4浓度及过饱和度。KLa通常与甲烷生成速率、混合效率、流体黏度和温度等因素有关[10,27]。在本研究中,反应器内流体黏度与温度基本保持不变,而浪式脉冲混合时CH4的KLa更大,这主要由2方面原因造成:一方面,浪式脉冲混合时体系的混匀度更高;另一方面,由上文可知,浪式脉冲混合时有机物的去除效果更好,对应CH4的Qv更大。在相同负荷水平,YEO等采用沼气循环混合时DCH4的过饱和度为2.2~2.5[10],对应KLa为(0.018±0.003)~(0.088±0.017) h–1,由此可见,浪式脉冲混合在降低DCH4浓度及过饱和度方面比液体循环或气体循环混合具有更好的效果。

如图3所示,随着进水负荷的提升,2种混合方式的DCH4浓度均有升高。其中,循环混合时的DCH4由20.2 mg·L–1上升至23.4 mg·L–1(图3(c)),对应DCH4的过饱和度由2.1降至1.9;浪式脉冲混合时的DCH4由12.6 mg·L–1升至15.6 mg·L–1(图3(d)),对应DCH4的过饱和度由1.3降至1.2。可以看出,随着负荷的提升,DCH4的过饱和度逐渐降低。这一结果与YEO等[10]的研究结果一致。CH4的QV随负荷的提升而增加(图3(a)~(b)),Qv与负荷呈现较好的正相关关系(R2=0.998),WIJEKOON等[28]的研究中也得出了相似的结论。因为CH4的KLa正比于QV(式(4)),所以KLa随负荷提升也不断增大,且与负荷也呈现出较好的正相关关系(R2=0.997)。高负荷(1.8 kg·(m3·d)–1)时CH4的KLa ((0.57±0.03) h–1)约为低负荷(0.6 kg·(m3·d)–1)时KLa ((0.15±0.01) h–1)的3~4倍。综上所述,CH4的Qv和KLa均与负荷显著相关,随着负荷提升DCH4不断升高,但DCH4的变化程度(增加倍数)小于Qv,这是因为随负荷提升KLa也同时增大,导致更多的DCH4扩散至气相,从而使DCH4在过饱和度上呈现下降趋势。

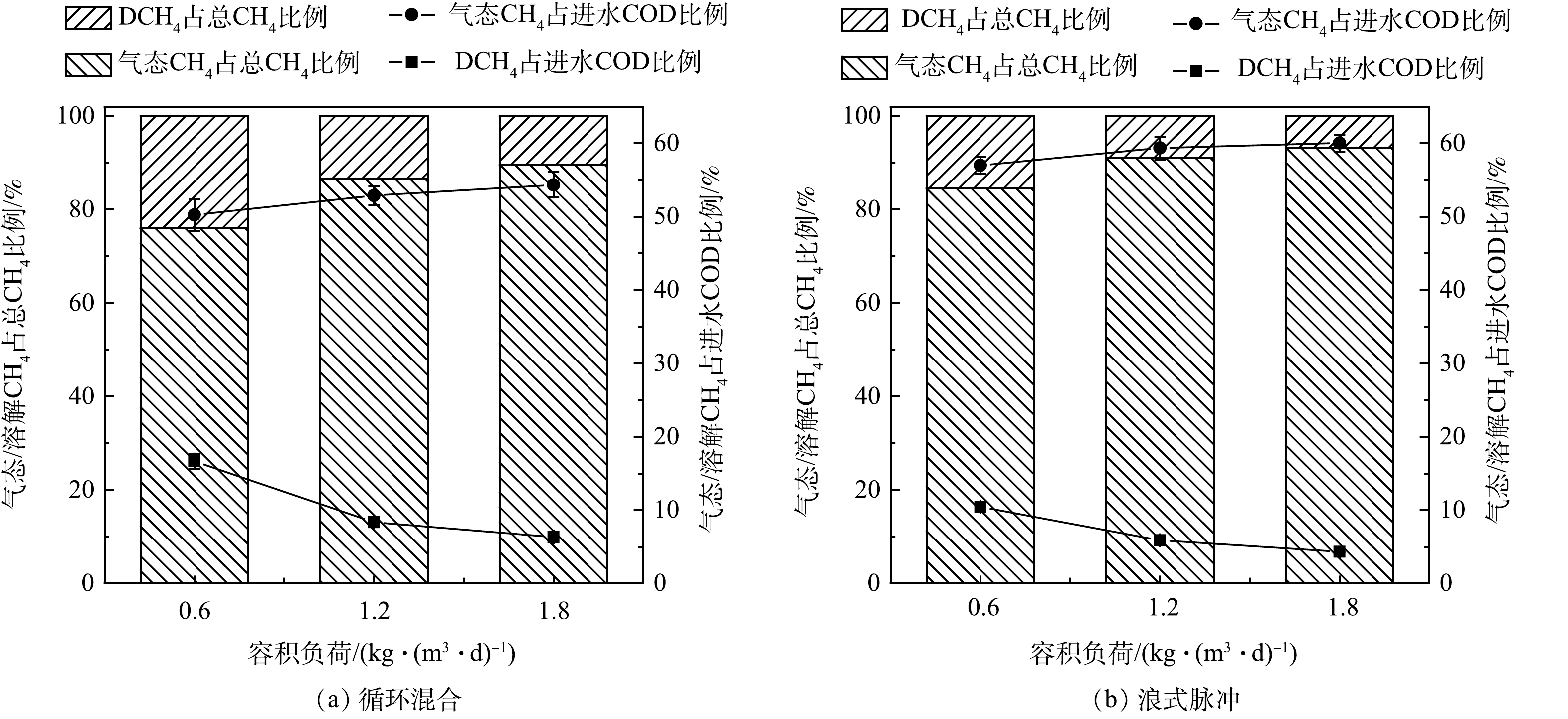

在AnMBR的运行过程中,计算不同运行工况下CH4在气/液相中的分布及在进水COD中的占比(见图4)。同负荷下,循环混合时气态CH4占总CH4及进水COD的比例均低于浪式脉冲混合时。如负荷为0.6 kg·(m3·d)–1,循环混合时气态CH4占总CH4及进水COD的比例分别为76.0%和50.2%;浪式脉冲混合时气态CH4占总CH4及进水COD的比例分别为84.5%和57.0%。这是因为浪式脉冲混合(KLa更大)可促进CH4从液相向气相的传质,这与上文的分析结果一致。

如图4所示,随着进水负荷的提升,DCH4占总CH4及进水COD的比例逐渐下降,而气态CH4占总CH4及进水COD的比例不断升高,表明AnMBR在高负荷下更容易对有机物中的能量进行回收。此外,AnMBR中可回收的气态CH4占进水COD的比例(50.2%~60.0%)低于通常文献报道的CH4含量70%~85%[29-31],这是由于本研究关注的处理对象为低浓度废水,所用的进水COD和负荷水平要低于上述报道,根据上文分析此时的KLa较低从而导致了较多的进水COD以DCH4形式存在。

-

进水COD在AnMBR中的转化形式可能为气相CH4、DCH4、生物量增长和出水残留等,为了进一步阐明进水底物的电子流向,对各运行工况下AnMBR进行了COD质量衡算,结果见图5。由图5可知,总CH4 (DCH4+气态CH4)占进水COD的主要部分,为61.0%~67.4%,DCH4占比为4.3%~16.1%。以COD计的气态CH4、DCH4和出水COD加和后与进水COD的差值表示为Cother,在3种不同的负荷下的占比为24.4%~30.6%,这部分COD主要用于生物量合成、微生物代谢产物(SMP、EPS)的产生和微量的硫酸盐还原等,在其他AnMBR中也观察到了类似的COD转化[17,32]。整个运行过程没有对AnMBR进行排泥,但反应器内生物量(MLVSS)变化较小,从6 020.4 mg·L–1增加到6 820.7 mg·L–1。生物量(MLVSS)与COD的换算关系[33]约为1 g=1.4 g,计算后可知,用于生物增长的COD只占了Cother的3.1%~3.5%,以上结果表明大部分Cother可能以微生物代谢产物(SMP、EPS)的形式存在。微生物代谢产物主要为大分子的多糖和蛋白质[34-35],出水膜可能对这些化合物有很强的截留作用,进而导致了膜污染。关于不同负荷与混合方式对微生物代谢产物及膜污染的特征影响需要后续进一步的研究。

-

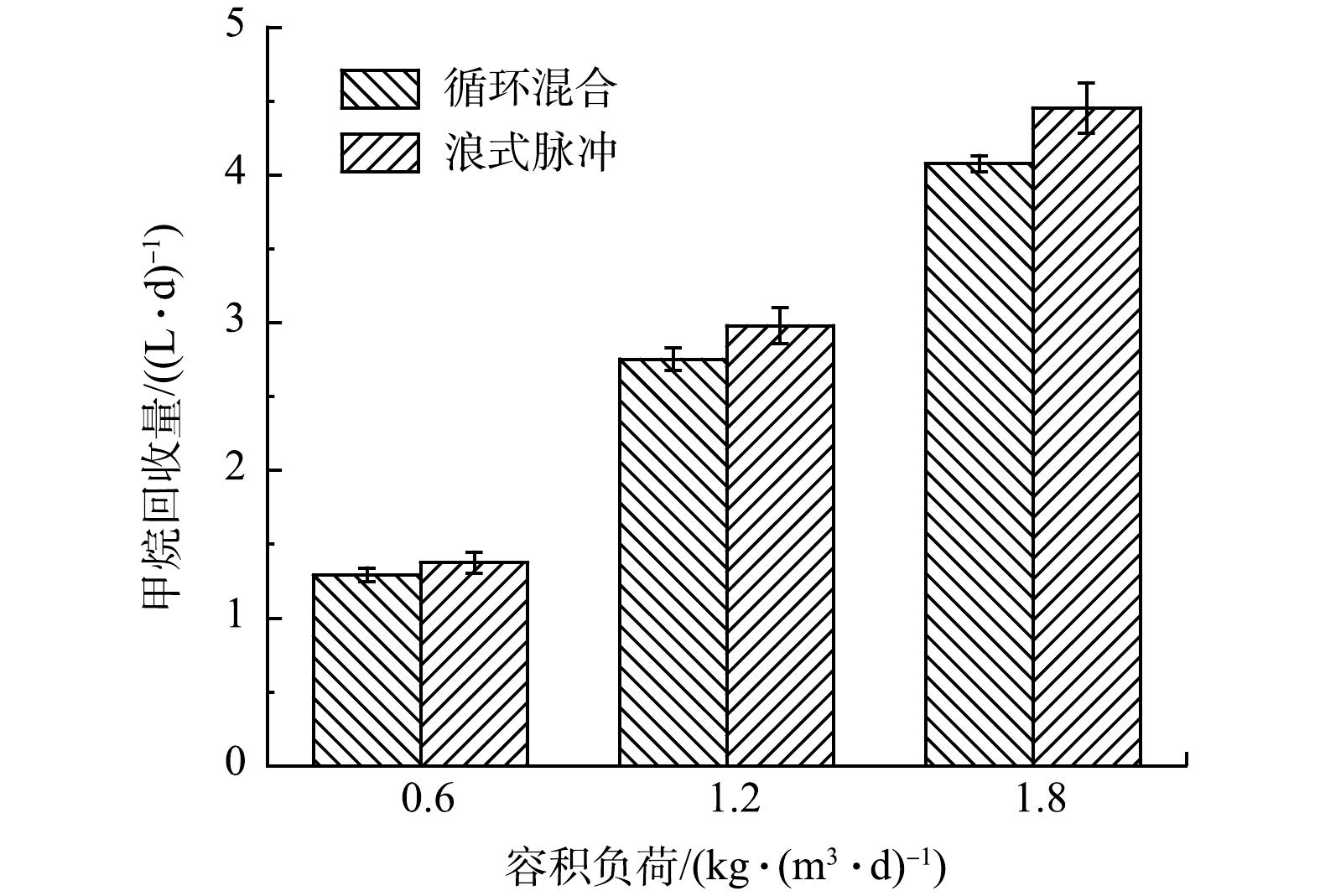

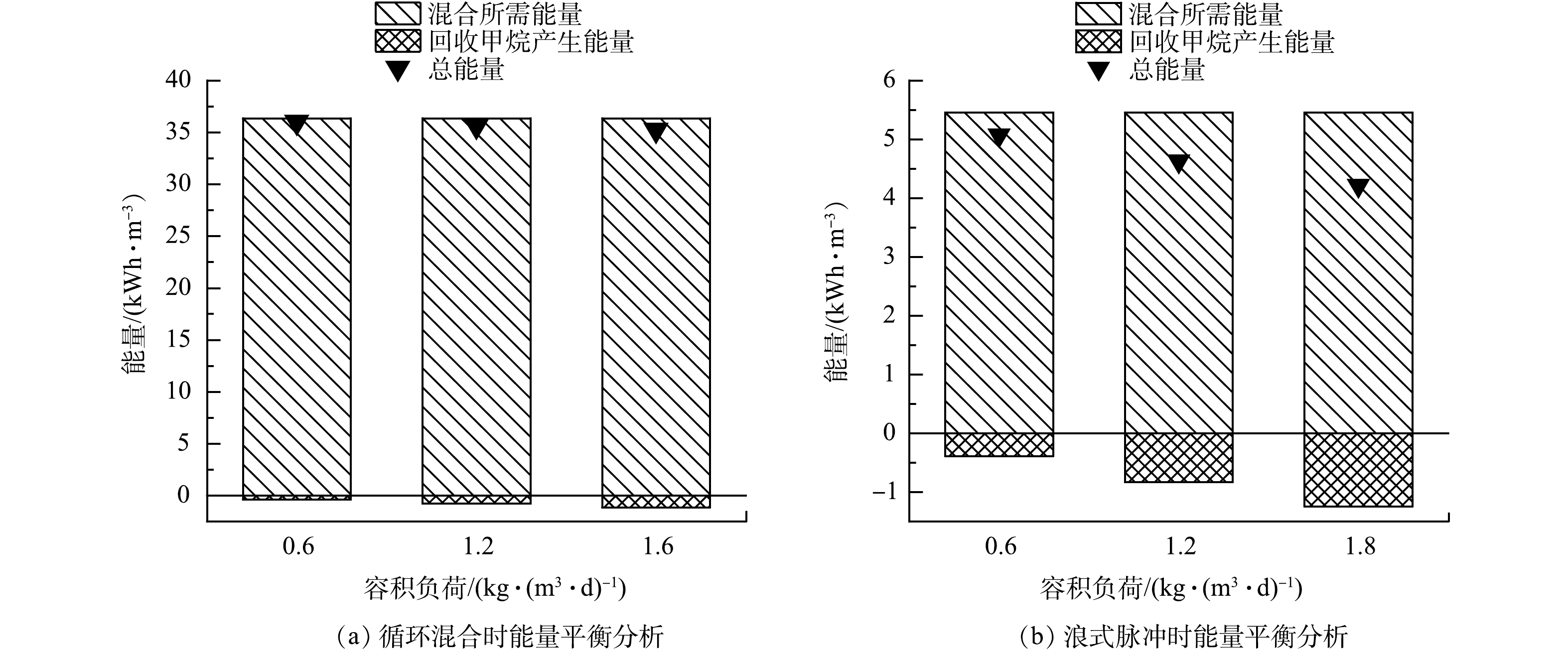

净能量平衡是评价系统应用时能量回收潜力的重要指标,通过能量需求与能量回收的差值来计算。本研究中,AnMBR运行过程保持HRT与温度恒定,各阶段的所需能量主要来自混合方式的电耗;各阶段的回收能量来自气相CH4。各运行条件下的CH4回收量和相关能量计算见图6和图7。

如图7所示,相比于循环混合,浪式脉冲混合时的CH4回收量更大且总能量消耗更低。浪式脉冲混合的CH4产量比循环混合条件下提高了6.5%~9.2%(图7)。由上文分析可知,这是由更多有机物转化和更高的气相CH4导致。另一方面,由图6和图7可知,浪式脉冲混合所需的能耗只有循环混合的15%,但甲烷回收率提升了6.5%~9.2%,因此,计算分析后,浪式脉冲混合时AnMBR总能量消耗比循环混合时降低了85.9%~88.0%。随着负荷的提升,AnMBR总能量消耗不断降低,高负荷(1.8 kg·(m3·d)–1)时总能耗比低负荷(0.6 kg·(m3·d)–1时下降了约16.9%。由此可知,通过调整运行参数如缩减HRT等进一步提升负荷有利于实现AnMBR处理废水过程的能量平衡甚至能量盈余。ASLAM等[36]在负荷为5.8 kg·(m3·d)–1的条件下,在流态化厌氧陶瓷膜生物反应器中实现了0.099 kWh·m–3的能量盈余,与本研究所得高负荷运行时AnMBR易实现能量平衡或盈余的结论一致。

-

1) HRT维持在20 h,进水负荷为0.6~1.8 kg·(m3·d)–1的运行条件下,AnMBR可实现高效稳定的有机物去除效果(COD去除率>90%),浪式脉冲混合时的有机物去除效果比循环混合时更好。

2) AnMBR在浪式脉冲混合时(KLa大),CH4能更好地从液相扩散到气相,其DCH4的浓度和过饱和度及占进水COD的比例均比循环混合时低,且随负荷提升,这些指标进一步降低。

3) AnMBR进水大部分COD (61.0%~67.4%)转化为了CH4,其中气相CH4占比为50.2%~60.0%,剩余进水COD主要转化为微生物代谢产物。

4) AnMBR浪式脉冲混合的总能耗比循环混合时低85.9%~88.0%,提高负荷有利于实现AnMBR处理污水过程的能量平衡甚至能量盈余。

负荷与混合方式对厌氧膜生物反应器中甲烷气-液分配特征的影响

Effects of load and mixing mode on methane gas-liquid distribution characteristics in anaerobic membrane bioreactors

-

摘要: 厌氧膜生物反应器(anaerobic membrane bioreactors, AnMBR)出水普遍存在过饱和的溶解性甲烷(dissolved methane, DCH4),易造成能量流失和温室效应,阐明AnMBR中甲烷气-液分配特征对提高甲烷回收率具有重要意义。为此,本文研究了负荷和混合方式对AnMBR中甲烷气-液分配特征的影响。结果表明,在35 oC,负荷为0.6~1.8 kg·(m3·d)–1的条件下,AnMBR实现了较好的有机物去除效果(COD去除率>90%),运行过程DCH4均处于过饱和状态(过饱和度为1.3~2.1),随着负荷的提升DCH4浓度升高,过饱和度有所下降;相比于循环混合,在浪式脉冲混合条件下的甲烷传质系数(KLa)更大,其中DCH4浓度、过饱和度及DCH4占进水COD的比例均较低。AnMBR大部分进水COD转化为甲烷,主要以气态形式存在 (50.2%~60.0%)。浪式脉冲混合时反应器总能耗比循环混合降低了85.9%~88.0%,提升负荷有利于实现AnMBR处理废水过程的能量平衡。

-

关键词:

- 厌氧膜生物反应器 (AnMBR) /

- 溶解性甲烷 /

- 负荷 /

- 混合方式 /

- 传质系数

Abstract: Dissolved methane (DCH4) is commonly found in the effluent of anaerobic membrane bioreactor (AnMBR), thus easily causing energy loss and greenhouse effect. Understanding the characteristics of methane gas-liquid distribution is crucial to improve the methane recovery in AnMBR. This study investigates the effects of load and mixing mode on the methane gas-liquid distribution in AnMBR. The results showed that the AnMBR achieved favorable organic removal (COD removal >90%) at 35 oC and 0.6~1.8 kg·(m3·d)–1 load, but DCH4 remained oversaturated (oversaturation ratio of 1.3~2.1) throughout operation. As the load was elevated, DCH4 concentrations also increased while the oversaturation ratios decreased. Wave-pulse mixing mode, with higher methane transfer coefficient (KLa), resulted in lower DCH4 concentration, oversaturation ratio and the proportion of DCH4 to influent COD compared with cyclic mixing mode. Most of the influent COD was converted to methane in gaseous form (50.2%~60.0%). The total energy consumption of reactor under wave-pulse mixing mode was 85.9%~88.0% lower than that of cyclic mixing mode. Elevating load is prone to achieve a net energy balance during AnMBR wastewater treatment.-

Key words:

- anaerobic membrane bioreactors (AnMBR) /

- dissolved methane /

- load /

- mixing mode /

- transfer coefficient

-

水资源短缺与能源危机推动了水处理技术的革新。在“双碳”背景下,传统的以能耗换水质的水处理技术已无法满足可持续发展的要求[1]。开发以能源再生-资源回收为目的的新技术,降低水处理过程中的碳排放,对于实现我国的“双碳”目标有着重要意义[2]。与传统的好氧生物处理技术相比,厌氧生物处理技术能够在废水处理过程中实现资源回收和能源再生,在水处理中具有广阔的应用前景[3-4]。近年来厌氧生物处理技术开始逐步应用于低浓度废水(如市政污水)的处理,但有机物含量低时厌氧微生物生长缓慢,且低产气量较难实现泥水混合液的充分搅拌,导致有机物的去除转化效果不理想,从而限制了厌氧技术在低浓度废水处理中的应用[5]。厌氧膜生物反应器(anaerobic membrane bioreactors, AnMBR)采用厌氧处理与膜分离相结合的方式,将水力停留时间(hydraulic retention time, HRT)和污泥龄(sludge retention time, SRT)分开[6],有效弥补了传统厌氧生物处理技术存在的弊端,具有生物量大、出水水质高以及能耗低等优点[7],是实现低浓度废水厌氧生物处理的理想技术。

已有很多研究报道了AnMBR用于处理低浓度废水时可以实现较好的有机物去除和产甲烷性能,但运行过程中存在着膜污染的问题,常需要通过沼气循环、混合液回流等方式增大体系混合程度来减轻膜污染。另一方面,AnMBR出水中含有较多的溶解性甲烷(dissolved methane, DCH4),甲烷是一种温室气体,DCH4解吸后[8](释放到大气)会造成能量流失和温室效应。现有研究[9-11]表明,AnMBR出水DCH4的质量浓度为8.8~19.1 mg·L–1,因此,而流失的甲烷占总甲烷产量的23%~88%。在较多研究中,测得DCH4的浓度经常高于亨利定律计算的理论值,即AnMBR出水的DCH4往往是过饱和的[12],其过饱和度即相比于理论DCH4的倍数为1.3~4.1倍[9,13]。已有部分研究通过外置气体分离器[14-17]对AnMBR出水DCH4进行回收并取得了较好的效果,但上述过程存在着能量消耗、占地增加和工艺流程长等问题。甲烷的液-气传质会显著改变甲烷的溶解程度,其传质系数[10,18]主要受反应器运行条件(如负荷、混合效率、温度)的影响,在不同工况下AnMBR出水DCH4的过饱和度具有较大的差异[19]。YEO等[10]在采用混合液循环的AnMBR中研究结果表明,随着负荷提升产气速率不断增大,有利于解除甲烷气-液传质的限制,从而降低了DCH4的过饱和度。研究不同工况对AnMBR中甲烷气-液分配特征的影响,有望通过反应器运行方式的调控,实现原位降低DCH4的浓度。为此,本研究针对AnMBR出水存在DCH4过饱和问题,基于AnMBR的低浓度废水处理过程,探究了不同负荷和混合方式对有机物去除和DCH4的影响。揭示上述过程甲烷气-液传质系数的变化规律并阐明AnMBR中甲烷的气-液分配特征,进一步用于指导反应系统运行,以期为降低AnMBR的碳排放量和能耗提供参考。

1. 材料与方法

1.1 实验装置

本实验所用AnMBR装置如图1所示,反应器主体为有机玻璃材质的长方体形容器(长×宽×高=30 cm×20 cm×25 cm),有效容积为11 L。反应器内设置聚偏氟乙烯(PVDF)材质的中空纤维膜(MBR-0.1F,海科滤膜),膜组件构型采用U型,膜丝数量共80根,单根膜丝的内、外径分别为0.8 mm和1.8 mm,膜孔径为0.1 μm,膜组件总有效面积0.19 m2。反应器进出水采用蠕动泵控制(BT100-2J,兰格恒流泵有限公司),出水泵与膜组件之间设有压力变送器(SIN-P300,中国杭州联测自动化技术有限公司),用于监测跨膜压差的变化。反应器外部覆盖有加热带(鸿泰电热配件),用于维持反应器内部的温度,内部温度由反应器顶部的温度计读取。反应器顶部设有阀门用于连接沼气袋和收集厌氧反应所产气体。反应器两侧均设有取样口用于采样分析。

AnMBR每个运行周期为10 min,其中出水8 min,松弛2 min。反应器设有2种不同的混合方式:从出水侧将泥水混合液泵回进水侧以进行循环混合;内部设置1个造浪泵(JVP-100AB)进行浪式脉冲混合。

1.2 接种污泥及实验用水

反应器接种污泥为黑色厌氧颗粒污泥,取自升流式厌氧污泥床反应器。实验进水采用由葡萄糖、尿素、磷酸二氢钾等人工配制而成的模拟废水,具体水质成分如下:0.23 g·L–1 尿素、0.11 g·L–1 KH2PO4、1 g·L–1 K2HPO4、0.05 g·L–1 Na2SO4、0.1 g·L–1 MgCl2·6H2O、0.05 g·L–1 CaCl2·2H2O、10 mL·L–1 微量元素、10 mL·L–1 维生素(注:微量元素和维生素具体组成参考文献[20])。缓冲物质为质量浓度为1 g·L–1的碳酸氢钠。葡萄糖的用量根据实验进行调整。

1.3 实验方法

控制AnMBR反应器温度为(35±1) oC,水力停留时间(HRT)为20 h,通过改变进水COD来改变反应器的负荷。反应器启动后共运行87 d,运行过程根据负荷和混合方式分为6个阶段,其中3个负荷水平(A、B、C)对应的进水COD分别为500、1 000、1 500 mg·L–1,每个负荷下混合方式分为循环混合与浪式脉冲混合,各运行工况条件见表1。

表 1 不同阶段的运行条件Table 1. Operation conditions of different phases阶段 负荷/(kg·(m3·d)–1) 进水COD/(mg·L–1) 混合方式 A1 0.6 500 循环 A2 0.6 500 浪式脉冲 B1 1.2 1 000 循环 B2 1.2 1 000 浪式脉冲 C1 1.8 1 500 循环 C2 1.8 1 500 浪式脉冲 每天取进出水水样测定COD值(哈希(Hach)试剂盒,2125815-CN),取反应器内混合液样品用于DCH4的浓度测定(见1.4);沼气袋内收集气体的体积用注射器抽取测量,并用气相色谱(天美GC7900,中国)分析其组分及含量。各运行阶段结束时,取反应器内混合液用于生物量(MLSS和MLVSS)的测定(重量法)。

1.4 分析及测试方法

1)水中DCH4的测定。水中的DCH4采用顶空平衡法进行测定。在20 mL的密封小瓶中注入3.5 mol·L–1的盐酸1 mL,用于抑制产甲烷菌的生理活性,从反应器内采集9 mL混合液样品注入小瓶中。将小瓶在25 oC的振荡器中振荡5 min,并放置3 h使CH4达到气液平衡,平衡后取1 mL顶空气体注入气相色谱分析气体组成。反应器混合液中DCH4的浓度根据亨利定律计算(式(1))[21]所示。根据亨利定律推出式(2)。

CL=CG,eqVG+CL,eqVLVL (1) 式中:CL为液体中DCH4的质量浓度,mg·L–1;CG,eq是平衡后样品瓶顶空中CH4的质量浓度,mg·L–1;CL,eq是样品瓶液体中与顶空平衡的CH4质量浓度,mg·L–1;VG和VL分别为样品瓶中液体和气体的体积,L。

Hcp=CL,eqPP,eq⋅MCH4 (2) 式中:PP,eq是CH4在顶空中与液相平衡时的分压,Pa;

MCH4 2) COD质量平衡计算。在各工况运行稳定后,根据式(3)[18]进行COD的物料衡算,以分析有机物分布去向。

Cin=Ceff+CDCH4+CGCH4+Cother (3) 式中:Cin和Ceff分别为进出水COD,mg·L–1;

CDCH4 CGCH4 CH4+2O2=CO2+2H2O 3)CH4传质系数的计算。AnMBR中CH4由液相向气相的传质系数可由式(4)[10]进行计算。

{{K}}_{\text{La}}=\left(\frac{{{Q}}_{\text{g}}{{P}}_{{\text{CH}}_{\text{4}}}}{{VRT}}\right)\left(\frac{\text{1}}{{{C}}_{\text{L}}–{{C}}_{\text{eq}}}\right)=\frac{{{Q}}_{\text{V}}}{{{K}}_{\text{H}}{RT}\left(\dfrac{{{C}}_{\text{L}}}{{{C}}_{\text{eq}}}–\text{1}\right)} (4) 式中:KLa为由液相向气相的传质系数,h–1;CL为液体中DCH4的质量浓度,mg·L–1;Qg为甲烷产气速率,L·h–1;V是反应器的有效体积,L;PCH4为AnMBR顶空中CH4的分压,Pa;R是理想气体常数,8.31×103 L·Pa·(mol·K)–1;T是温度,K;QV (Qg/V)为反应器的CH4产气量,L·(L·h)–1;Ceq是与气相中CH4分压处于热力学平衡的DCH4的质量浓度,mg·L–1;KH是CH4的亨利常数,35 oC时为1.18×10–7 mol·(L·Pa)–1。

4)能量计算。CH4的热值约为37.8 MJ·m–3,按电能转换效率为35%计算CH4转换成的电能(式(5))[23]。反应器运行过程中混合所用设备的能量需求通过设备的功率和运行时间得出(式(6))。反应器运行过程中的净能量(E)由设备能源消耗与回收甲烷所得能源的差值计算(式(7))。

{{W}}_{{\text{CH}}_{\text{4}}}=\frac{\text{37.8}{{V}}_{{\text{CH}}_{\text{4}}}\times{35\%}}{\text{3.6}} (5) 式中:

{{W}}_{{\text{CH}}_{\text{4}}} {{V}}_{{\text{CH}}_{\text{4}}} {{W}}_{\text{消耗}}=\frac{{Pt}}{\text{1}\text{}\text{000}} (6) 式中:W消耗为设备消耗的能量,kWh;P为设备的功率,浪式脉冲设备功率为3 W,混合液循环设备功率为20 W;t为设备运行时间,h。

{E}={{W}}_{\text{消耗}}-{{W}}_{{\text{CH}}_{\text{4}}} (7) 2. 结果与讨论

2.1 有机物去除性能

本研究中AnMBR共运行87 d,固定反应器的HRT为20 h,通过增加进水COD来提升负荷,在此期间研究了反应器不同混合形式对有机物去除性能的影响,各运行工况下进出水的COD值及去除率变化如图2所示。结果表明,AnMBR可实现对有机物的高效去除,COD平均去除率超过90%,提升进水负荷AnMBR对有机物仍可保持着良好的去除效果,具有一定的抗冲击负荷性。如图2所示,各负荷下AnMBR浪式脉冲混合时对有机物的去除效果均好于循环混合,在进水COD为500 mg·L–1,负荷为0.6 kg·(m3·d)–1时,循环混合模式下反应器出水的COD值为(48±4.9) mg·L–1,对应COD去除率为(90.7±0.8)%;改用浪式脉冲混合模式后,COD去除率提升至(96.8±0.4)%。这是因为浪式脉冲混合的系统扰动强度更高,促进了微生物与底物的接触与利用,从而提高了有机物的去除效果[24]。

2.2 甲烷气-液分配特征

在AnMBR的运行过程中,测定各运行工况下的CH4产气量(QV)和DCH4,结合亨利定律和式(4)计算出理论DCH4和甲烷传质系数(KLa)。如图3所示,各阶段反应器液相中DCH4均处于过饱和状态,DCH4浓度为理论浓度的1.3~2.1倍,该水平位于已报道的AnMBR中DCH4过饱和度范围之内[25-26]。在相同负荷下,浪式脉冲混合时DCH4的浓度和过饱和度均低于循环混合时(图3(c)~(d))。在负荷为0.6 kg·(m3·d)–1下,循环混合时DCH4为20.2 mg·L–1,对应过饱和度为2.1;而浪式脉冲混合时DCH4为12.6 mg·L–1,对应过饱和度为1.3。上述结果是由于不同条件下CH4的KLa不同导致的,KLa较大时,CH4能更好地从液相扩散至气相,从而有利于降低DCH4浓度及过饱和度。KLa通常与甲烷生成速率、混合效率、流体黏度和温度等因素有关[10,27]。在本研究中,反应器内流体黏度与温度基本保持不变,而浪式脉冲混合时CH4的KLa更大,这主要由2方面原因造成:一方面,浪式脉冲混合时体系的混匀度更高;另一方面,由上文可知,浪式脉冲混合时有机物的去除效果更好,对应CH4的Qv更大。在相同负荷水平,YEO等采用沼气循环混合时DCH4的过饱和度为2.2~2.5[10],对应KLa为(0.018±0.003)~(0.088±0.017) h–1,由此可见,浪式脉冲混合在降低DCH4浓度及过饱和度方面比液体循环或气体循环混合具有更好的效果。

如图3所示,随着进水负荷的提升,2种混合方式的DCH4浓度均有升高。其中,循环混合时的DCH4由20.2 mg·L–1上升至23.4 mg·L–1(图3(c)),对应DCH4的过饱和度由2.1降至1.9;浪式脉冲混合时的DCH4由12.6 mg·L–1升至15.6 mg·L–1(图3(d)),对应DCH4的过饱和度由1.3降至1.2。可以看出,随着负荷的提升,DCH4的过饱和度逐渐降低。这一结果与YEO等[10]的研究结果一致。CH4的QV随负荷的提升而增加(图3(a)~(b)),Qv与负荷呈现较好的正相关关系(R2=0.998),WIJEKOON等[28]的研究中也得出了相似的结论。因为CH4的KLa正比于QV(式(4)),所以KLa随负荷提升也不断增大,且与负荷也呈现出较好的正相关关系(R2=0.997)。高负荷(1.8 kg·(m3·d)–1)时CH4的KLa ((0.57±0.03) h–1)约为低负荷(0.6 kg·(m3·d)–1)时KLa ((0.15±0.01) h–1)的3~4倍。综上所述,CH4的Qv和KLa均与负荷显著相关,随着负荷提升DCH4不断升高,但DCH4的变化程度(增加倍数)小于Qv,这是因为随负荷提升KLa也同时增大,导致更多的DCH4扩散至气相,从而使DCH4在过饱和度上呈现下降趋势。

在AnMBR的运行过程中,计算不同运行工况下CH4在气/液相中的分布及在进水COD中的占比(见图4)。同负荷下,循环混合时气态CH4占总CH4及进水COD的比例均低于浪式脉冲混合时。如负荷为0.6 kg·(m3·d)–1,循环混合时气态CH4占总CH4及进水COD的比例分别为76.0%和50.2%;浪式脉冲混合时气态CH4占总CH4及进水COD的比例分别为84.5%和57.0%。这是因为浪式脉冲混合(KLa更大)可促进CH4从液相向气相的传质,这与上文的分析结果一致。

如图4所示,随着进水负荷的提升,DCH4占总CH4及进水COD的比例逐渐下降,而气态CH4占总CH4及进水COD的比例不断升高,表明AnMBR在高负荷下更容易对有机物中的能量进行回收。此外,AnMBR中可回收的气态CH4占进水COD的比例(50.2%~60.0%)低于通常文献报道的CH4含量70%~85%[29-31],这是由于本研究关注的处理对象为低浓度废水,所用的进水COD和负荷水平要低于上述报道,根据上文分析此时的KLa较低从而导致了较多的进水COD以DCH4形式存在。

2.3 有机物转化

进水COD在AnMBR中的转化形式可能为气相CH4、DCH4、生物量增长和出水残留等,为了进一步阐明进水底物的电子流向,对各运行工况下AnMBR进行了COD质量衡算,结果见图5。由图5可知,总CH4 (DCH4+气态CH4)占进水COD的主要部分,为61.0%~67.4%,DCH4占比为4.3%~16.1%。以COD计的气态CH4、DCH4和出水COD加和后与进水COD的差值表示为Cother,在3种不同的负荷下的占比为24.4%~30.6%,这部分COD主要用于生物量合成、微生物代谢产物(SMP、EPS)的产生和微量的硫酸盐还原等,在其他AnMBR中也观察到了类似的COD转化[17,32]。整个运行过程没有对AnMBR进行排泥,但反应器内生物量(MLVSS)变化较小,从6 020.4 mg·L–1增加到6 820.7 mg·L–1。生物量(MLVSS)与COD的换算关系[33]约为1 g=1.4 g,计算后可知,用于生物增长的COD只占了Cother的3.1%~3.5%,以上结果表明大部分Cother可能以微生物代谢产物(SMP、EPS)的形式存在。微生物代谢产物主要为大分子的多糖和蛋白质[34-35],出水膜可能对这些化合物有很强的截留作用,进而导致了膜污染。关于不同负荷与混合方式对微生物代谢产物及膜污染的特征影响需要后续进一步的研究。

2.4 能量分析

净能量平衡是评价系统应用时能量回收潜力的重要指标,通过能量需求与能量回收的差值来计算。本研究中,AnMBR运行过程保持HRT与温度恒定,各阶段的所需能量主要来自混合方式的电耗;各阶段的回收能量来自气相CH4。各运行条件下的CH4回收量和相关能量计算见图6和图7。

如图7所示,相比于循环混合,浪式脉冲混合时的CH4回收量更大且总能量消耗更低。浪式脉冲混合的CH4产量比循环混合条件下提高了6.5%~9.2%(图7)。由上文分析可知,这是由更多有机物转化和更高的气相CH4导致。另一方面,由图6和图7可知,浪式脉冲混合所需的能耗只有循环混合的15%,但甲烷回收率提升了6.5%~9.2%,因此,计算分析后,浪式脉冲混合时AnMBR总能量消耗比循环混合时降低了85.9%~88.0%。随着负荷的提升,AnMBR总能量消耗不断降低,高负荷(1.8 kg·(m3·d)–1)时总能耗比低负荷(0.6 kg·(m3·d)–1时下降了约16.9%。由此可知,通过调整运行参数如缩减HRT等进一步提升负荷有利于实现AnMBR处理废水过程的能量平衡甚至能量盈余。ASLAM等[36]在负荷为5.8 kg·(m3·d)–1的条件下,在流态化厌氧陶瓷膜生物反应器中实现了0.099 kWh·m–3的能量盈余,与本研究所得高负荷运行时AnMBR易实现能量平衡或盈余的结论一致。

3. 结论

1) HRT维持在20 h,进水负荷为0.6~1.8 kg·(m3·d)–1的运行条件下,AnMBR可实现高效稳定的有机物去除效果(COD去除率>90%),浪式脉冲混合时的有机物去除效果比循环混合时更好。

2) AnMBR在浪式脉冲混合时(KLa大),CH4能更好地从液相扩散到气相,其DCH4的浓度和过饱和度及占进水COD的比例均比循环混合时低,且随负荷提升,这些指标进一步降低。

3) AnMBR进水大部分COD (61.0%~67.4%)转化为了CH4,其中气相CH4占比为50.2%~60.0%,剩余进水COD主要转化为微生物代谢产物。

4) AnMBR浪式脉冲混合的总能耗比循环混合时低85.9%~88.0%,提高负荷有利于实现AnMBR处理污水过程的能量平衡甚至能量盈余。

-

表 1 不同阶段的运行条件

Table 1. Operation conditions of different phases

阶段 负荷/(kg·(m3·d)–1) 进水COD/(mg·L–1) 混合方式 A1 0.6 500 循环 A2 0.6 500 浪式脉冲 B1 1.2 1 000 循环 B2 1.2 1 000 浪式脉冲 C1 1.8 1 500 循环 C2 1.8 1 500 浪式脉冲 -

[1] 王旭, 刘玉, 罗雨莉, 等. 基于高附加值产品的废水资源化技术发展趋势与应用展望[J]. 环境工程学报, 2020, 14(8): 2011-2019. doi: 10.12030/j.cjee.202005128 [2] 刘佳乐, 雷振, 崔耀奎, 等. 厌氧膜生物反应器处理市政污水的产甲烷性能及微生物代谢特征[J]. 环境科学研究, 2022: 1-15. [3] PFLUGER A, VANZIN G, MUNAKATA-MARR J, et al. An anaerobic hybrid bioreactor for biologically enhanced primary treatment of domestic wastewater under low temperatures[J]. Environmental Science Water Research & Technology, 2018, 4(11): 1851-1866. [4] STAZI V, TOMEI M C. Enhancing anaerobic treatment of domestic wastewater: State of the art, innovative technologies and future perspectives[J]. Science of the Total Environment, 2018, 635: 78-91. doi: 10.1016/j.scitotenv.2018.04.071 [5] 田帅, 朱易春, 黄书昌, 等. 厌氧生物处理低浓度污水研究进展[J]. 化工进展, 2021, 40(4): 2338-2346. doi: 10.16085/j.issn.1000-6613.2020-1060 [6] CHEN R, NIE Y, JI J, et al. Submerged anaerobic membrane bioreactor (SAnMBR) performance on sewage treatment: removal efficiencies, biogas production and membrane fouling[J]. Water Science and Technology, 2017, 76(6): 1308-1317. doi: 10.2166/wst.2017.240 [7] 许颖, 夏俊林, 黄霞. 厌氧膜生物反应器污水处理技术的研究现状与发展前景[J]. 膜科学与技术, 2016, 36(4): 139-149. doi: 10.16159/j.cnki.issn1007-8924.2016.04.021 [8] HUETE A, de LOS COBOS-VASCONCELOS D, GÓMEZ-BORRAZ T, et al. Control of dissolved CH4 in a municipal UASB reactor effluent by means of a desorption – biofiltration arrangement[J]. Journal of Environmental Management, 2018, 216: 383-391. [9] COOKNEY J, MCLEOD A, MATHIOUDAKIS V, et al. Dissolved methane recovery from anaerobic effluents using hollow fibre membrane contactors[J]. Journal of Membrane Science, 2016, 502: 141-150. doi: 10.1016/j.memsci.2015.12.037 [10] YEO H, AN J, REID R, et al. Contribution of liquid/gas mass-transfer timitations to dissolved methane oversaturation in anaerobic treatment of dilute wastewater[J]. Environmental Science & Technology, 2015, 49(17): 10366-10372. [11] GOUVEIA J, PLAZA F, GARRALON G, et al. A novel configuration for an anaerobic submerged membrane bioreactor (AnSMBR). Long-term treatment of municipal wastewater under psychrophilic conditions[J]. Bioresource Technology, 2015, 198: 510-519. doi: 10.1016/j.biortech.2015.09.039 [12] HARTLEY K, LANT P. Eliminating non-renewable CO2 emissions from sewage treatment: An anaerobic migrating bed reactor pilot plant study[J]. Biotechnology and Bioengineering, 2006, 95(3): 384-398. doi: 10.1002/bit.20929 [13] SMITH A L, SKERLOS S J, RASKIN L. Anaerobic membrane bioreactor treatment of domestic wastewater at psychrophilic temperatures ranging from 15 °C to 3 °C[J]. Water Research & Technology, 2015, 1(1): 56-64. [14] SANCHIS-PERUCHO P, ROBLES Á, DURÁN F, et al. PDMS membranes for feasible recovery of dissolved methane from AnMBR effluents[J]. Journal of Membrane Science, 2020, 604: 118070. doi: 10.1016/j.memsci.2020.118070 [15] LEE E, ROUT P R, KYUN Y, et al. Process optimization and energy analysis of vacuum degasifier systems for the simultaneous removal of dissolved methane and hydrogen sulfide from anaerobically treated wastewater[J]. Water Research, 2020, 182: 115965. doi: 10.1016/j.watres.2020.115965 [16] LUO G, WANG W, ANGELIDAKI I. A new degassing membrane coupled upflow anaerobic sludge blanket (UASB) reactor to achieve in-situ biogas upgrading and recovery of dissolved CH4 from the anaerobic effluent[J]. Applied Energy, 2014, 132: 536-542. doi: 10.1016/j.apenergy.2014.07.059 [17] BANDARA W M K R, SATOH H, SASAKAWA M, et al. Removal of residual dissolved methane gas in an upflow anaerobic sludge blanket reactor treating low-strength wastewater at low temperature with degassing membrane[J]. Water Research, 2011, 45(11): 3533-3540. doi: 10.1016/j.watres.2011.04.030 [18] WU P, NG K K, HONG P A, et al. Treatment of low-strength wastewater at mesophilic and psychrophilic conditions using immobilized anaerobic biomass[J]. Chemical Engineering Journal, 2017, 311: 46-54. doi: 10.1016/j.cej.2016.11.077 [19] STAZI V, TOMEI M C. Dissolved methane in anaerobic effluents: A review on sustainable strategies for optimization of energy recovery or internal process reuse[J]. Journal of Cleaner Production, 2021, 317: 128359. doi: 10.1016/j.jclepro.2021.128359 [20] ZHAO Z, ZHANG Y, WOODARD T L, et al. Enhancing syntrophic metabolism in up-flow anaerobic sludge blanket reactors with conductive carbon materials[J]. Bioresource Technology, 2015, 191: 140-145. doi: 10.1016/j.biortech.2015.05.007 [21] JIMÉNEZ-ROBLES R, GABALDÓN C, MARTÍNEZ-SORIA V, et al. Simultaneous application of vacuum and sweep gas in a polypropylene membrane contactor for the recovery of dissolved methane from water[J]. Journal of Membrane Science, 2021, 604: 118070. [22] CHENG H, LI Y, HU Y, et al. Bioenergy recovery from methanogenic co-digestion of food waste and sewage sludge by a high-solid anaerobic membrane bioreactor (AnMBR): mass balance and energy potential[J]. Bioresource Technology, 2021, 326: 124754. doi: 10.1016/j.biortech.2021.124754 [23] ZHANG X, GU J, MENG S, et al. Dissolved methane in anaerobic effluent: Emission or recovery?[J]. Frontiers of Environmental Science & Engineering, 2022, 16(4): 161-163. [24] LINDMARK J, THORIN E, BEL FDHILA R, et al. Effects of mixing on the result of anaerobic digestion: Review[J]. Renewable and Sustainable Energy Reviews, 2014, 40: 1030-1047. doi: 10.1016/j.rser.2014.07.182 [25] YEO H, LEE H. The effect of solids retention time on dissolved methane concentration in anaerobic membrane bioreactors[J]. Environmental Technology, 2013, 34(13-14): 2105-2112. doi: 10.1080/09593330.2013.808675 [26] SMITH A L, SKERLOS S J, RASKIN L. Psychrophilic anaerobic membrane bioreactor treatment of domestic wastewater[J]. Water Research, 2013, 47(4): 1655-1665. doi: 10.1016/j.watres.2012.12.028 [27] YOO R, KIM J, MCCARTY P L, et al. Anaerobic treatment of municipal wastewater with a staged anaerobic fluidized membrane bioreactor (SAF-MBR) system[J]. Bioresource Technology, 2012, 120: 133-139. doi: 10.1016/j.biortech.2012.06.028 [28] PAUSS A, ANDRE G, PERRIER M, et al. Liquid-to-gas mass transfer in anaerobic processes: Inevitable transfer timitations of methane and hydrogen in the biomethanation process[J]. Applied and Environmental Microbiology, 1990, 56(6): 1636-1644. doi: 10.1128/aem.56.6.1636-1644.1990 [29] WIJEKOON K C, VISVANATHAN C, ABEYNAYAKA A. Effect of organic loading rate on VFA production, organic matter removal and microbial activity of a two-stage thermophilic anaerobic membrane bioreactor[J]. Bioresource Technology, 2011, 102(9): 5353-5360. doi: 10.1016/j.biortech.2010.12.081 [30] 肖诚斌, 童胜宝, 古创, 等. AnMBR处理垃圾渗滤液的运行效能及膜过滤特性分析[J]. 净水技术, 2022, 41(8): 95-100. [31] BASSET N, LÓPEZ-PALAU S, DOSTA J, et al. Comparison of aerobic granulation and anaerobic membrane bioreactor technologies for winery wastewater treatment[J]. Water Science and Technology, 2014, 69(2): 320-327. doi: 10.2166/wst.2013.713 [32] 孙凯, 陆晓峰, 周保昌, 等. 厌氧膜生物反应器(AnMBR)处理高浓度豆制品废水的研究[J]. 膜科学与技术, 2011, 31(4): 65-69. doi: 10.3969/j.issn.1007-8924.2011.04.013 [33] BERTOLA N C, GIANNUZZI L, ZARITZKY N E, et al. A modified method to determine biomass concentration as COD in pure cultures and in activated sludge systems[J]. Water SA, 2002, 28(4): 463-468. [34] LEI Z, WANG J, LENG L, et al. New insight into the membrane fouling of anaerobic membrane bioreactors treating sewage: Physicochemical and biological characterization of cake and gel layers[J]. Journal of Membrane Science, 2021, 632: 119383. doi: 10.1016/j.memsci.2021.119383 [35] 孙飞云, 李晓岩. 浸没式MBR中溶解性微生物产物聚集态演变影响膜污染机理研究[J]. 高校化学工程学报, 2013, 27(6): 1064-1071. doi: 10.3969/j.issn.1003-9015.2013.11.12.02 [36] ASLAM M, MCCARTY P L, SHIN C, et al. Low energy single-staged anaerobic fluidized bed ceramic membrane bioreactor (AFCMBR) for wastewater treatment[J]. Bioresource Technology, 2017, 240: 33-41. doi: 10.1016/j.biortech.2017.03.017 -

下载:

下载: