-

近年来,生活垃圾产生量逐年上升,预计2030年我国将产生超3×108 t生活垃圾[1]。焚烧在实现生活垃圾减量的同时,其回收的能量可以缓解当今能源紧缺的问题[2],已成为生活垃圾的主要处理方式之一。2016年,欧盟27国焚烧处理生活垃圾占全部处理垃圾的28.6%[3];2018年美国焚烧的城市固体废物约占总量的13%[4];2020年中国生活垃圾焚烧量居世界首位,占垃圾处理总量的50.7%[5-6]。随着垃圾焚烧比例和数量的上升,产生了大量焚烧副产物飞灰,其中重金属 (如Cd、Pb、Cr、Zn、Ni等) 浸出质量浓度较高且环境风险较大,已被列入《国家危险废物名录》[7]。由于生活垃圾焚烧飞灰中Cd、Pb、Cr、Zn和Ni的浸出质量浓度较高[8],FAN等[9]使用粉煤灰和硅酸盐水泥分别固化飞灰,发现飞灰中的Zn、Pb和Cd离子均实现了有效固定。有研究[10]发现,采用电渗析修复预处理飞灰去除重金属,可有效降低Pb、Zn、Cr、Cu和Ni的浸出质量浓度。为消除飞灰对土壤和地下水的污染隐患,现有技术可分为分离、热处理和固化稳定化等。分离技术是采用化学试剂、生物试剂或电渗析法从飞灰中分离重金属,其处理效果较好但成本高且分离后污染物还需要二次处理[11]。热处理可分为烧结、熔融、玻璃化和热化学处理,高耗能与低安全性制约了热处理的推广[12-13]。固化稳定化后填埋是按照一定比例将飞灰与药剂混合,固化后形成高强度块体。通过物理包埋、吸附和化学沉淀等方法固定重金属,是当前飞灰主要处理处置技术。其中,飞灰固化剂主要有化学药剂和水泥2大类,化学药剂生产成本过高、缺乏原料资源、长期稳定性差等问题导致其应用范围局限[14]。水泥作为广泛应用的建筑材料具有价格低廉、耐用性好、环境适应性好、固化产物渗透率低、耐化学应力高等优势[15],使用水泥固化飞灰后填埋符合当前市场要求。

目前,飞灰拌合普通硅酸盐水泥形成硬度高、耐酸性强的固化块后送入垃圾填埋场的方法已有广泛应用[16]。水泥水化产生的C-S-H结构可包裹细度极低的飞灰[17],同时,水泥水化产物氢氧化钙与重金属形成氢氧化物沉淀[18] (如Zn(OH)2) ,硅酸根结合重金属离子形成硅酸盐沉淀 (如PbSiO3) ,可较好地固化飞灰中的重金属。固化块长期稳定性研究表明,普通硅酸盐水泥中的熟料相硅酸三钙、硅酸二钙、铝酸三钙和钙铝铁氧体与飞灰的固化过程中伴随着晶体的生长[19],晶体相较于非晶体的晶格能更强,抵抗填埋场渗滤液长时间腐蚀的效果更好。固化块孔隙结构可影响其抗渗性,飞灰提供的钙离子和氯离子促进了固化块累计空隙分布的均匀性,有利于水泥水化完全进行,增加水泥水化产物,使得固化结构之间的胶粘增强,形成更密实的网状。市面上现有325到625R型号的普通硅酸盐水泥共7种,随着其标号的上升,强度增加。因此,探究不同标号不同添加量的普通硅酸盐水泥固化飞灰中不同重金属的特性,分析固化块重金属浸出质量浓度、晶体结构和孔隙大小,有利于填埋场比选飞灰固化材料,实现经济效益最大化。

固化块强度受到水泥标号影响,选用325、425、525的普通硅酸盐水泥,28 d标准养护抗压强度依次可达到32.5、42.5、52.5 MPa,每吨价格分别为400、500、600 元。筛选水泥标号及添加量较普遍的水泥,以期在填埋场的长期运行中应对渗滤液和酸雨的侵蚀风险并兼顾经济价值[20]。分别对飞灰和固化块进行重金属浸出实验、重金属形态提取实验、X射线衍射表征、扫描电子显微镜下成像和全孔分析,对比原始飞灰与固化块差异。本研究以飞灰中的重金属为目标污染物,探讨不同标号不同用量的水泥在固化飞灰前后重金属的浸出质量浓度和形态变化,以期揭示其固化机理,为节约水泥资源、提升现代危险废物经济化填埋、降低填埋场污染风险提供应用参考。

-

本实验飞灰于2022年3月初从成都采集,采用炉排炉焚烧工艺,其烟气净化系统为“脱硝系统+半干法+干法+活性炭喷射+布袋除尘+脱硫系统”。本实验选用3种标号 (325、425和525) 的普通硅酸盐水泥购于重庆某水泥厂。使用去离子水对飞灰和水泥进行拌合及养护。

-

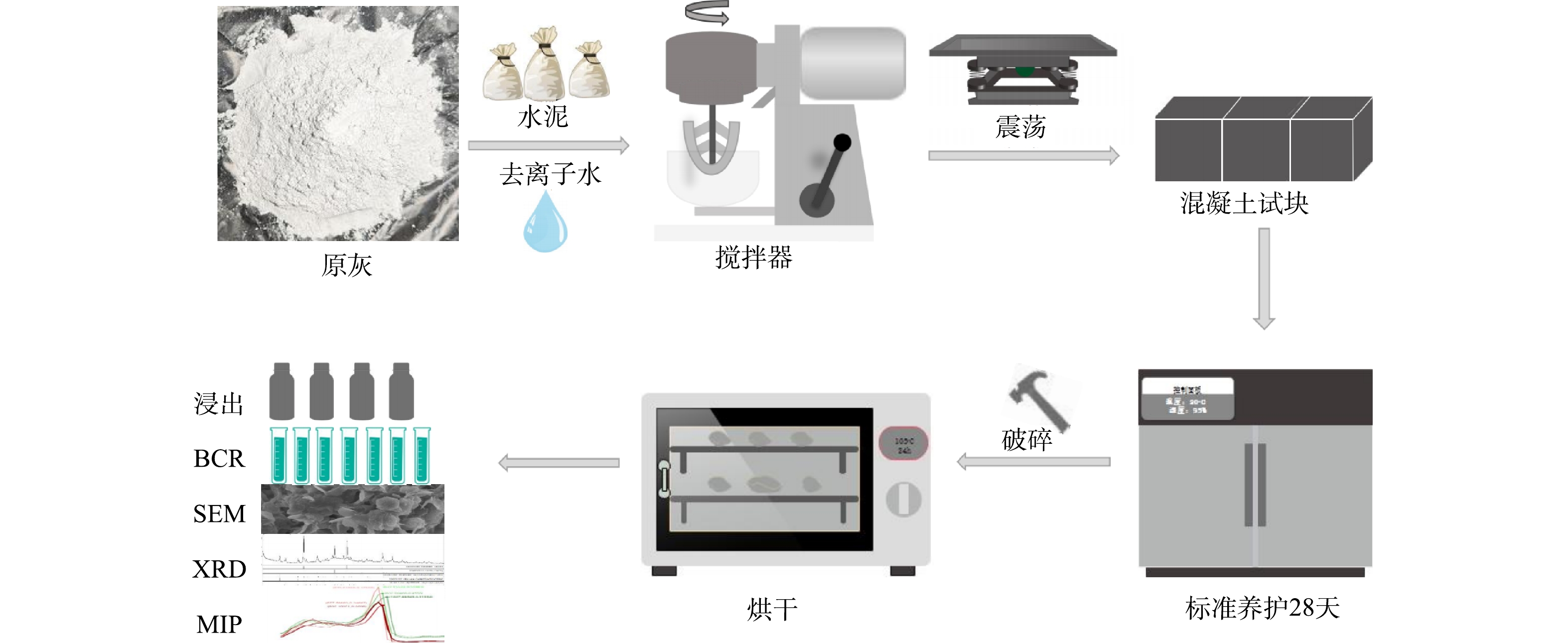

3种标号的水泥325、425、525添加量分别为30% (记为F2~F4) 和40% (记为F5~F7) 与原始飞灰 (记为F1) 混合,加入去离子水搅拌4分钟,得到的浆体浇筑到标准磨具 (70.1 mm×70.1 mm×70.1 mm) 中,通过振动排出浆液中的气泡。最后将样品置于标准养护箱 (温度20 ℃;湿度高于95%) 中养护28 d,达到龄期后取出放置于阴凉通风处对样品进行后续测试,固化块的制备如表1,养护流程如图1所示。

-

1) 醋酸法浸出。本实验参考《固体废物 浸出毒性浸出方法 醋酸缓冲溶液法》(HJ/T 300-2007)[21],测定飞灰和固化块中重金属的浸出质量浓度。步骤为:固化块过12目筛;称取样品 (100 g) ,按照固液比S∶L (g·mL−1) =1∶20与醋酸浸出液 (pH=2.65±0.05) 混合,在翻转震荡器以32 r·min−1的速度震荡18 h;最后,过滤浸出液并检测,每个样品进行3组平行1组空白。

2) BCR法形态提取。采用欧共体标准物质局提出的 BCR 连续提取法[22-23],测定固化块中重金属的化学形态。步骤为:药剂萃取样品,离心并过滤得到其上清液,重复以上步骤3次。最后消解残渣并定容至50 mL,测定每一步液体的质量浓度。

3) 实验仪器。水泥胶砂搅拌机 (ISO 0679,无锡市迈方仪器) ;混凝土振动台 (HZJ-A,献县宏达建筑仪器) ;电感耦合等离子体质谱仪 (NexlON 350X,美国PerkinElmer公司) ;X射线衍射仪 (D8 ADVANCE,德国布鲁克公司) ;扫描电子显微镜 (S4800,德国日立仪器公司) ;压泵仪器 (MicroActive AutoPoreV9600,美国麦克仪器公司) 。

-

根据预实验检测19种常见重金属中Cr、Zn、Cd、Pb、Ni的质量浓度较高、对环境危害大,作为本研究目标重金属,浸出结果见表2。从表2可以看出,F1的浸出液中Pb的质量浓度为587.670 μg·L−1超出《生活垃圾填埋场污染控制标准》(GB 16889-2008)[24] (以下简称“标准”) 1倍以上,Ni的浸出质量浓度为614.079 μg·L−1,超出标准 22.8%。高质量浓度的重金属可浸出到渗滤液中通过填埋场漏点污染土壤与地下水,危害人体健康。对比原样F1和固化后的F2~F7发现,添加水泥后,5种重金属的质量浓度均降低到标准以下,3种标号的水泥均可较好的固化飞灰中的重金属。对比相同标号不同添加量的固化块也可以发现, 30%添加量的水泥对重金属的固化效果已达到填埋场入场标准,与40%添加量的固化块浸出质量浓度差异较小。对比不同标号水泥,Cr和Cd的浸出质量浓度会随着水泥标号的上升而减小。ZHANG等[25]发现,飞灰中的Cr、Cd等阳离子的浸出质量浓度会随着pH的上升更稳定。根据水泥标号的上升,固化块中硅酸三钙和硅酸二钙质量分数上升,水化更完全,pH随之上升,Cr和Cd的固化效果更好。与之相反,Ni的重金属浸出质量浓度则随水泥标号的上升而增加。根据Ni的活性显示,水泥标号上升环境pH随之上升,激发了Ni的活性降低其在固化块中的Ni(OH)2和NiO沉淀[26]。30%添加量的固化块中Zn和Pb的浸出质量浓度因水泥标号的上升而下降,当添加量为40%时则相反。童立志等[27]研究发现,Zn和Pb以氯化物和氧化物的形式存在,具有较高的相关性,浸出结果也相似。

综上可看出,水泥可有效结合重金属降低飞灰浸出毒性,但是不同标号的水泥对重金属的固化效果有差异,水泥标号上升可有效提升Pb和Ni固化效果,对本地区飞灰使用标号为325、添加量为30%的水泥即可有效降低重金属浸出的质量浓度,达到填埋场入场标准。

-

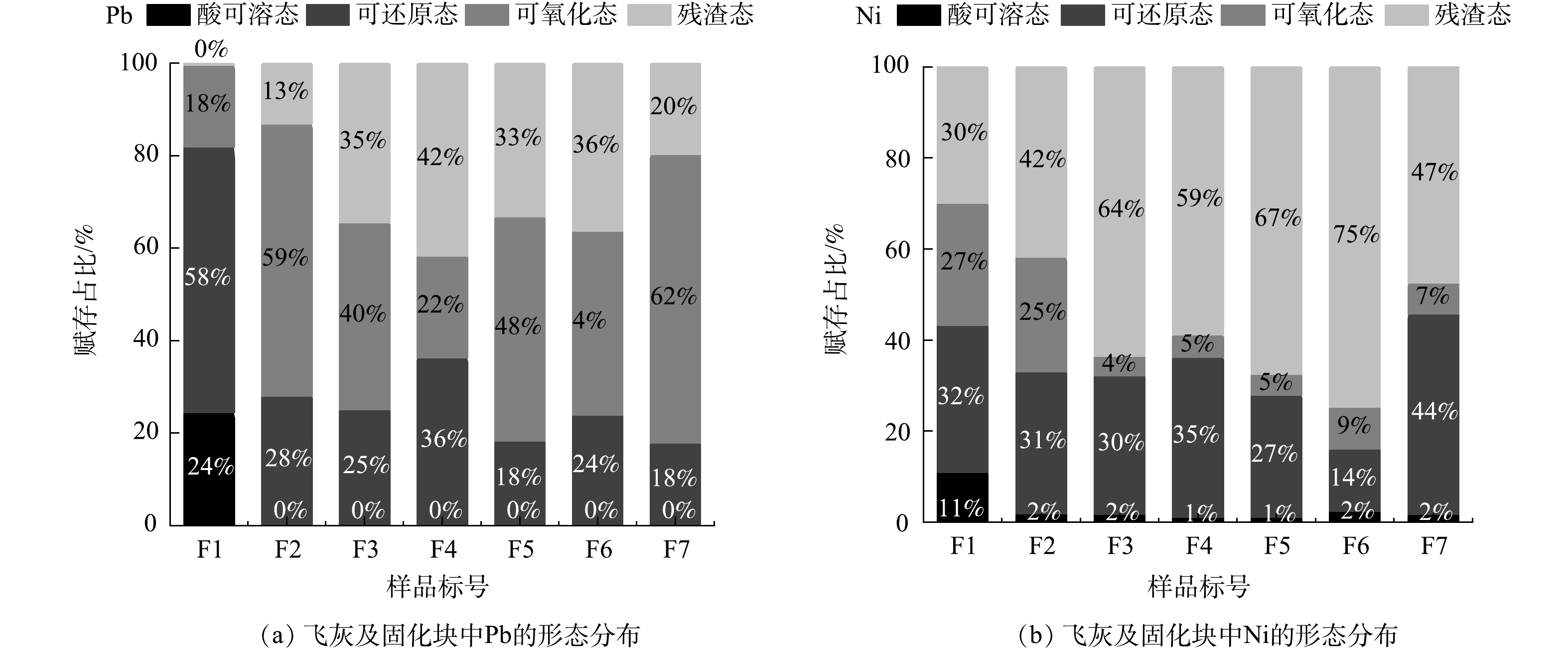

经检测,本实验飞灰主要组分CaO、Cl和CO2的总质量分数高达73.7%,次要组分Na2O、SO3和K2O的总质量分数为22%。在垃圾焚烧过程中挥发至气相中的重金属将同烟气进一步反应生成各种形态的化合物,不同形态的金属化合物毒性差异较大。因此,研究重金属的化学形态对探究重金属在环境中的迁移和毒性具有重要意义。利用BCR连续提取法分别将飞灰和固化块中的重金属划分为4种形态:酸可溶态 (易溶于水与碳酸盐结合) 、可还原态 (与铁锰氧化物结合) 、可氧化态 (与有机物结合部分) 和残渣态 (最为稳定) [28]。其中酸可溶态在填埋场渗滤液作用下容易浸出;可还原态为重金属在氧化电位下被浸提的部分;可氧化态主要为重金属与有机物和硫化物结合部分[29-30];残渣态是环境介质中最稳定的形态不易浸出。

由图2 F1~F7中Pb和Ni化学形态分布可知,水泥可较好地固化飞灰中的重金属,使其酸可溶态比例下降80%以上,残渣态比例上升。图2(a)中F2 的残渣态相较于F1大幅上升,主要原因是Pb的提取受到胶结过程的影响,水泥形成的凝胶状态可胶结Pb[31]。对比图2(a) 中F2~F4和F5~F7,在相同水泥添加量下随着标号上升固化块内部水化更完全,形成了更多C-S-H凝胶结构,残渣态比例上升,可更好的抵抗长期风化过程中CO2和其他酸性物质的侵蚀。因此,水泥标号上升可增加Pb的固化效果,有利于重金属在填埋场场景下的长期稳定性。随着水泥用量由30%上升到40%,F2相较于F5中Pb的残渣态上升20%。在水泥体系中大量的Pb不是固定在C-S-H的层状结构内,而是吸附在C-S-H表面[32],水泥用量上升后增加了Pb的吸附位点[33]。水泥标号和用量上升均可有效提高固化块中Pb的残渣态比例。325水泥在30%用量下已实现较好的固化效果,固化块中重金属浸出降低50%以上。随着水泥标号和用量上升水化产物过剩导致其残渣态比例上升较小。

研究发现[34],气态Ni的沸点为800 oC低于常见重金属,因此Ni主要存在于颗粒表面的固相或液相中,浸出质量浓度极易超过标准[24]。根据图2(b)可知,飞灰中Ni离子以可还原态为主 (32%),酸可溶态 (11%) 占比最小。对比F1和F2发现,掺入不同标号的水泥后样品残渣态比例上升,酸可溶态比例均下降到2%左右。结合重金属浸出质量浓度差异较小发现,使用不同标号的水泥对Ni的酸可溶态比例影响不大,但是水泥标号上升可增加固化块中Ni的残渣态比例,提高其长期稳定性[35]。根据Ni易被氧化为可溶于水的镍硫酸盐的特性,水化比例上升后水溶性组分降低残渣态上升。同时水泥水化结合可氧化态Ni离子凝结成不可浸出的固体氧化物,降低了Ni离子对氧化还原反应的敏感性[36]。325水泥即可有效降低Ni离子浸出质量浓度以达到进入填埋场标准,随着水泥标号的上升其残渣态质量分数上升,形成的氧化物集中在水泥间隙之间,可增加固化块致密性与长期稳定性。

水泥标号上升对Pb和Ni的固化效果更好但残渣态上升比例较低。325标号的水泥对Pb和Ni已达到较好的固化效果,达到填埋场适用标准[24]的同时325水泥较425水泥和525水泥成本更低,可降低焚烧厂的运营成本。

-

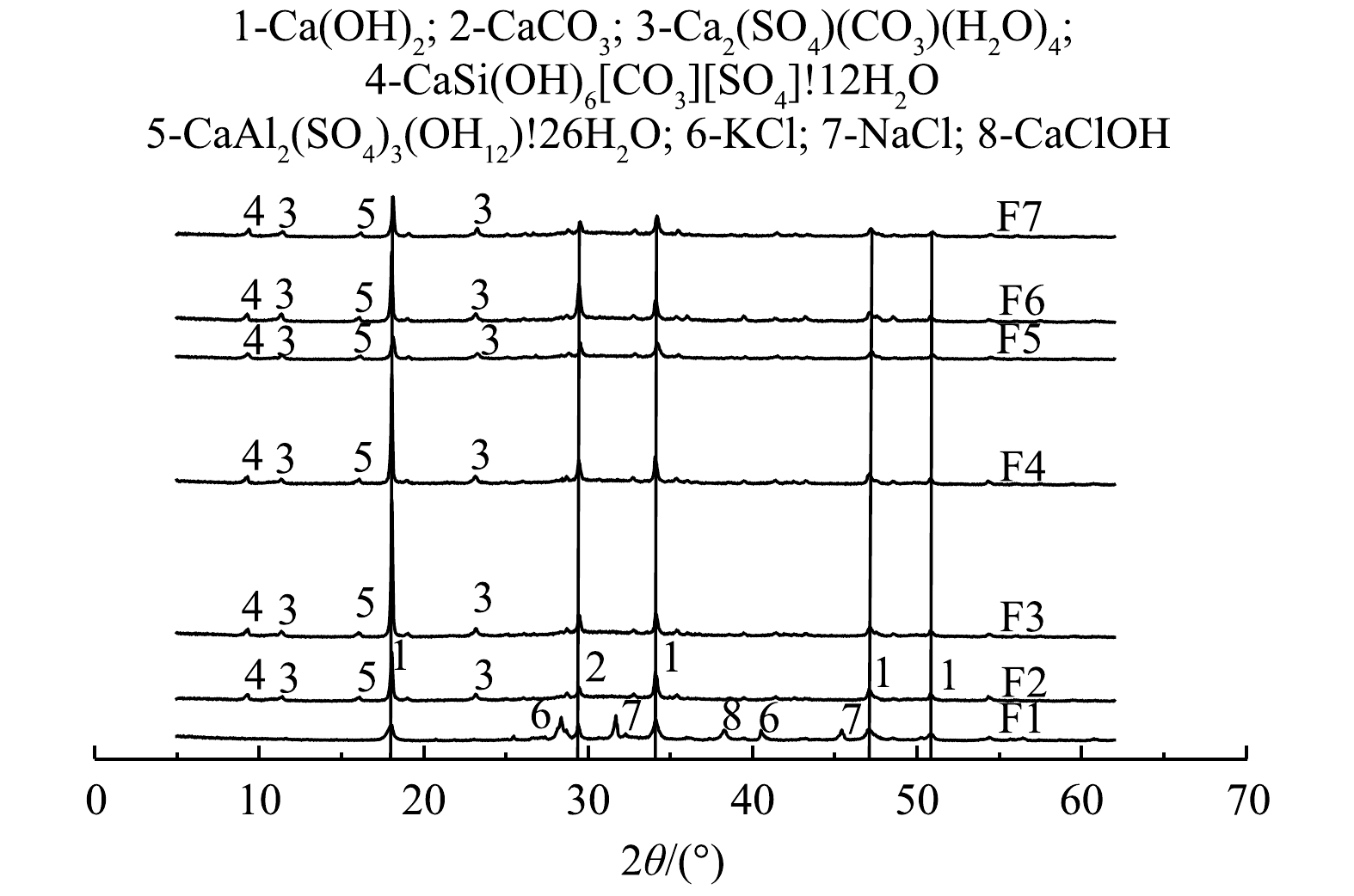

1) XRD图表征。如图3所示,成都生活垃圾焚烧飞灰主要由Ca(OH)2、CaCO3、KCl、NaCl和CaClOH组成。同时,生活垃圾中含有大量氯成分较高的厨余垃圾和塑料,导致F1中KCl、NaCl和CaClOH峰值较高。固化后的飞灰相较于固化前产生了新的晶体相。不同衍射峰的面积和高度也发生了较大变化,这2项参数通常可以代表同系列样品在相同实验条件下晶相的相对质量分数[37]。与F2~F7相比,F1中Ca(OH)2和CaCO3的衍射峰面积更小高度更低。水泥固化后F2~F7中含钙化合物衍射峰面积及高度大幅度上升,晶体 (硅灰石膏、钙矾石) 占比上升,提高了重金属及氯的固化率[38]。水泥水化后形成的多孔C-S-H、硅灰石膏和碳酸盐也可形成 “表皮”抵抗钙矾石形成的高pH环境的腐蚀[39],增加固化块耐久性。

不同标号的水泥含有的硅酸三钙和硅酸二钙不同,C-S-H凝胶占水泥水化产物的70%左右保障了水泥的耐久性。水化反应如式(1)~式(2)所示。

结合3种标号水泥相似的出峰数量与位置可知,水化产物与飞灰中的物质均发生了以上化学反应。随着水泥标号上升(F2~F4)含钙化合物的衍射峰面积逐渐增大与BCR形态提取结果一致,重金属固定在晶体中更加稳定。水泥添加量由30%上升到40%对比F2~F4和F5~F7,Ca(OH)2衍射峰面积和高度降低CaCO3升高。高强度的硅酸盐晶体形成并覆盖于固化块表面,增强了固化块的抗压强度,阻碍了固化块内部重金属释放提升了固化效果[40]。

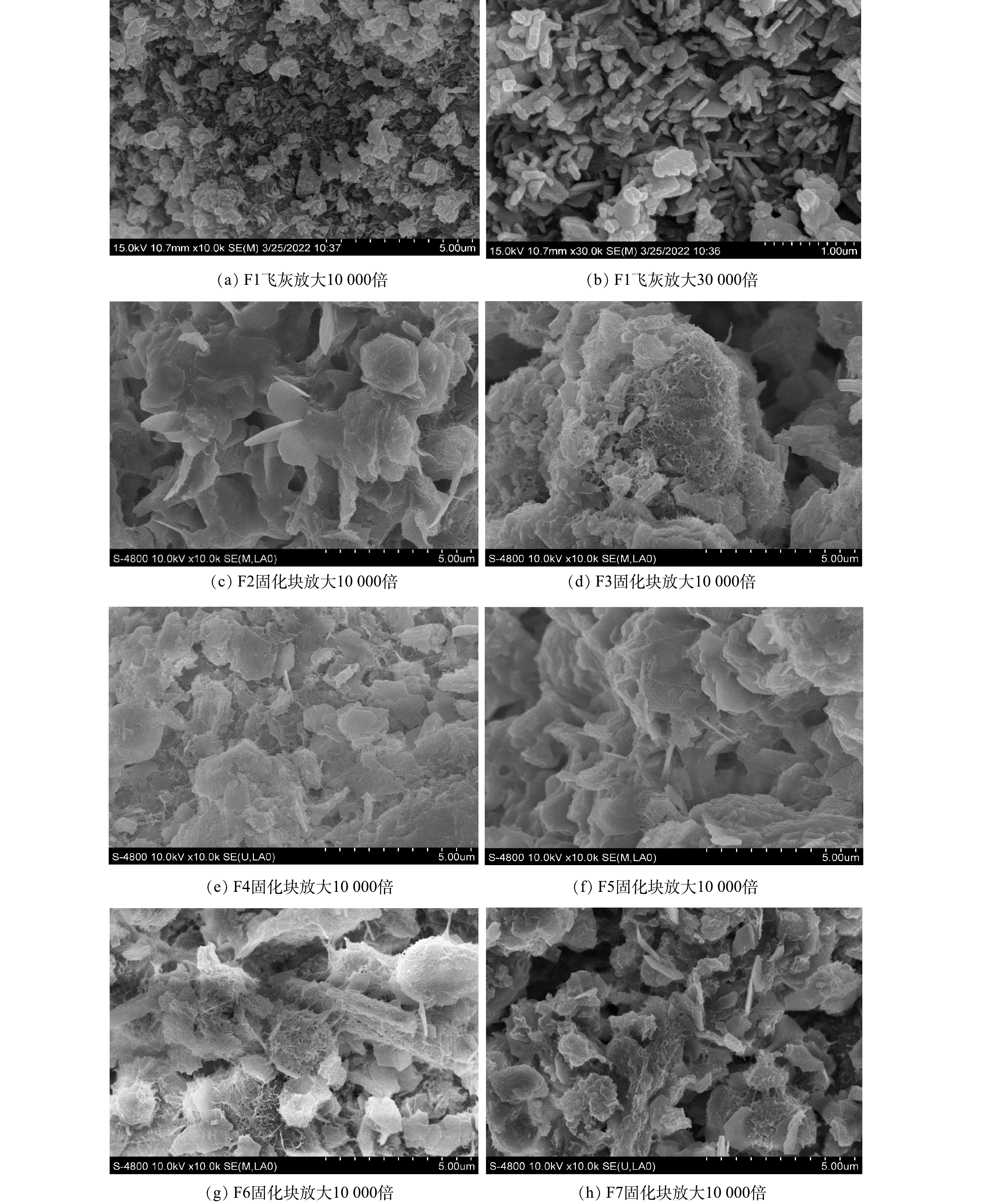

2) 表面形貌变化。原灰为灰白色粉状呈酥松、细腻、分散状态。SEM图像提供了飞灰微观形态信息,图4(a)为放大10 000后倍周围的颗粒堆积且形成流动的岩浆状。进一步放大到30 000倍,图4(b)其内部结构致密且相互聚集、排列不均、形态多样,主要为棒状、针状、片状。

固化块与原灰相比,电镜下的结构由疏松多孔变得致密有序。图4(c)~图4(e)中水泥的水化产物C-S-H 和Ca(OH)2形成丝状凝胶,可促进固化块中硅氧四面体的聚合度并增强固化块强度[41]。当水泥添加量增加到40%时,图4(f)~图4(h)的结构更紧密且矿物晶体边缘更模糊。由此可知水泥与重金属反应形成了沉淀且矿物晶体层表面结合更紧密[42]。对比图4(c)~图4(e),随着水泥标号上升固化块中片层结构更明显, C-S-H凝胶和石晶体中的细化结构增加了重金属的沉淀和固定[43],降低了浸出毒性。图4(e)结合XRD结果分析可知,525水泥中的氢氧钙石和方解石质量分数较为接近,形成的蜂窝状凝胶比层状方解石晶体固化重金属效果更好[44]。因此水泥标号上升可增加固化块的胶粘能力,可降低危险废物的浸出毒性与腐蚀性。

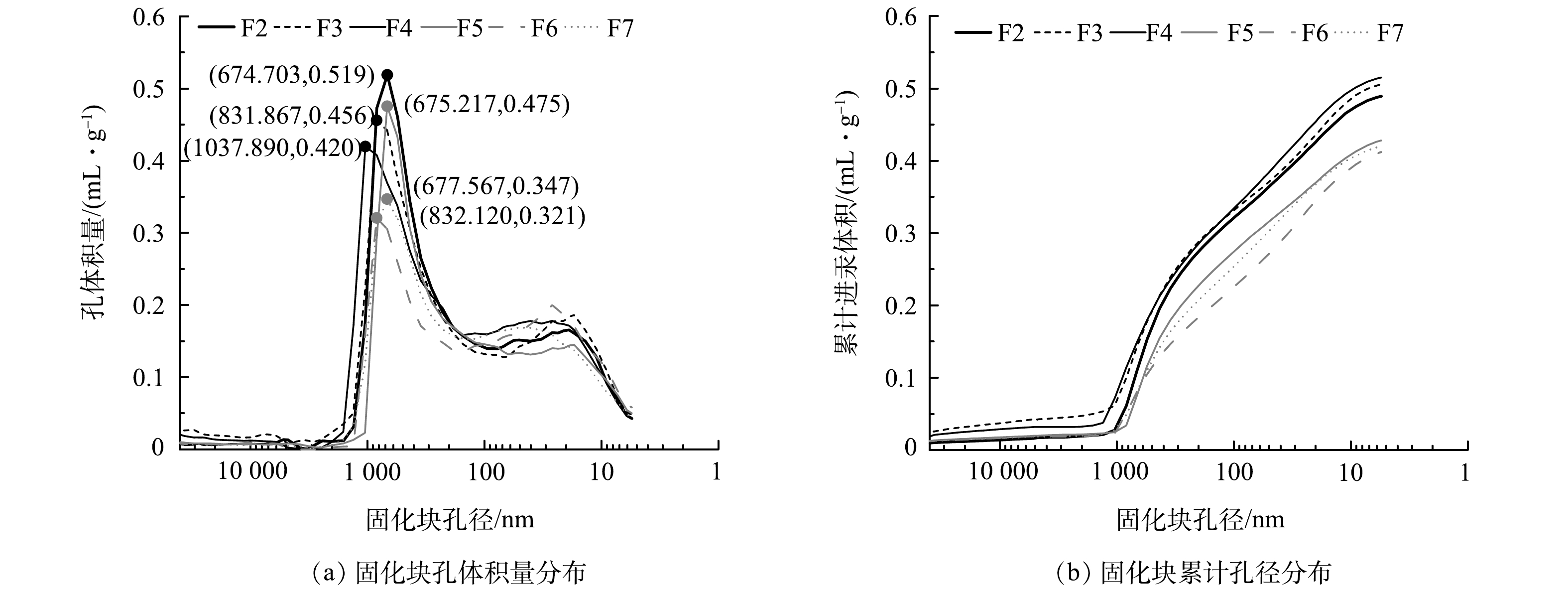

3) 孔径变化。通过分析固化块孔径变化可较好的分析样品的抗渗性、机械强度、毛细吸力[45]。6种固化块的孔体积量曲线如图5(a)所示,所有固化块呈单峰分布且孔径在1 nm以上。F2在675 nm位置孔体积量最高,F3和F4的孔累积量最高点对应的孔径逐渐增大。在此范围内的氢氧根和钠钾离子存在于粘合剂浆料中可产生碱-硅凝胶[46],随着孔径的增加水泥对重金属的吸附与固化效果更好。同时观察其累积进汞体积如图5(b)所示,随着水泥标号增加,累计进汞体积上升孔体积量也升高,水泥标高升高固化块孔径变大。F4孔累计量的最高点最低,图像的区域较为集中且峰值在30~100 nm范围的孔体积量总量较大,因此F4孔径较为均匀[47]。综上,随着水泥标号增加,水泥孔径更加均匀,固化块力学性能更好且包裹重金属能力变强。

当水泥添加量为40%时,孔体积量分布曲线的最高点较30%水泥添加量整体向右偏移,由此可知固化块中结构更致密,结合XRD分析固化块中形成了高密度CaCO3。同时,F6的孔体积量最高点和累计进汞体积均为最低,说明提高水泥标号和添加量均可有效增强固化块密实度,提高重金属固化效果[48]。综上所述,孔径分布较为均匀且总孔径体积较小的固化块能更有效的阻碍飞灰中的重金属的浸出,稳定性更好。

-

1) 3种标号(325、425、525)的普通硅酸盐水泥都能较好的固化飞灰中的重金属,使Cr、Zn、Cd、Pb、Ni的浸出质量浓度低于生活垃圾填埋场污染控制标准。

2)标准养护情况下,固化块中Pb、Ni的残渣态比例大幅度上升,酸可溶态比例下降到1%,3种标号 (325、425、525) 的水泥对飞灰中的重金属固化效果均较好。

3) 随着水泥标号上升,固化块中晶体比例增加,大部分重金属被固定在晶体中,降低了重金属浸出量。水泥标号上升,固化块晶体种类改变,内部结构更加密实水化更完全,孔径分布更均匀,能更好的应对填埋场渗滤液的侵蚀。

4) 飞灰进入填埋场前使用标号325,添加量30%的水泥对其进行固化,可提高填埋场长期运营的稳定性、应对环境风险、保证填埋场周围土壤与地下水的安全性且经济价值较高。

水泥标号对飞灰中重金属固化机理影响

Effect of cement grade on the mechanism of heavy metal solidification in fly ash

-

摘要: 一般可通过水泥固化生活垃圾焚烧飞灰中重金属,但不同标号水泥的固化效果与经济效益不同。研究了3种标号 (325、425、525) 的普通硅酸盐水泥在不同用量 (30%、40%) 下对飞灰中重金属的固化作用。结果表明,飞灰中5种特征重金属Cr 、Zn 、Cd 、Pb 、Ni中仅有Pb 和Ni的浸出质量浓度超过《生活垃圾填埋场污染控制标准》,水泥添加量为30%时,3种标号325、425、525的固化块中Pb的浸出质量浓度分别为46.266、61.122、67.423 μg·L−1,相较于40%添加量为80.315、31.791、25.392 μg·L−1,其浸出结果差异较小,Ni的浸出结果与Pb类似。分析重金属化学形态发现,随着水泥标号的上升,Pb和Ni的残渣态百分比呈上升趋势。对比固化块的XRD结果、电镜图像、孔隙结构和累计孔隙度发现,随着水泥标号上升固化块结构更密实,飞灰中的重金属固化效果更好,但3种标号的水泥对飞灰的固化效果差异较小。因此,掺加30%的325水泥即可较好地固化垃圾焚烧飞灰。本研究结果可为控制填埋场中飞灰固化块的浸出浓度提供参考。Abstract: Heavy metals in fly ash from municipal solid wastes incineration can generally be cured by cement, but the curing effects and economic benefits vary among different grades of cement. The curing effects of three grades (325, 425, 525) of ordinary silicate cement at different dosages (30%, 40%) on heavy metals in fly ash were studied. The results showed that among the five heavy metals Cr, Zn, Cd, Pb, and Ni, only Pb and Ni exceeded the original fly ash leaching mass concentration of the "Pollution Control Standard for Municipal Solid Landfill", and the leaching mass concentrations of Pb in the cured blocks of the three grades 325, 425, and 525 at 30% cement addition were 46.266, 61.122, and 67.423 μg·L−1, respectively, which were less different compared to the 40% additions of 80.315, 31.791, and 25.392 μg·L−1, and the leaching results of Ni were similar to those of Pb. Analysis of the chemical forms of heavy metals revealed that the percentage of residue states of Pb and Ni tended to increase with the increase of cement grade. Comparison of XRD results, electron microscope images, pore structure and cumulative porosity of the cured blocks revealed that the structure of the cured blocks was denser and the heavy metals in the fly ash were cured better as the cement grade rose, but the difference in the curing effect of the three grades of cement on the fly ash was small. Therefore, the addition of 30% of 325 cement can cure waste incineration fly ash better. The results of this study can provide a reference for controlling the leaching concentration of fly ash curing blocks in landfills and reducing the operating cost of landfills.

-

表 1 固化块制作基本参数汇总

Table 1. Summary of basic parameters for curing block production

样品编号 水泥质量/g 飞灰质量/g 纯水质量/g 水泥标号 F1 — 600 — — F2 180 600 468 325 F3 180 600 468 425 F4 180 600 468 525 F5 240 600 504 325 F6 240 600 504 425 F7 240 600 504 525 表 2 飞灰及固化块样品的重金属浸出质量浓度实验结果

Table 2. Experimental results of heavy metal leaching concentration of fly ash and curing block

样品编号 重金属离子质量浓度/ (μg·L−1) Cr Zn Cd Pb Ni F1 35.146 67.480 0.342 587.670 614.079 F2 95.198 5.283 0.673 46.266 261.101 F3 76.390 8.369 0.562 61.122 335.213 F4 42.737 8.497 0.446 67.423 379.813 F5 78.101 8.331 0.544 80.315 257.020 F6 65.454 4.675 0.502 31.791 332.221 F7 44.692 3.611 0.396 25.392 355.599 -

[1] LU J W, ZHANG S, HAI J, et al. Status and perspectives of municipal solid waste incineration in China: A comparison with developed regions[J]. Waste Management, 2017, 69: 170-186. doi: 10.1016/j.wasman.2017.04.014 [2] LI J S, XUE Q, WANG P, et al. Leaching characteristics of chlorine from municipal solid waste incineration fly ash by up-flow percolation column tests[J]. Environmental Earth Sciences, 2016, 75(1): 714. [3] CASTILLO-GIMENEZ J, MONTANES A, PICAZO-TADEO A J. Performance and convergence in municipal waste treatment in the European Union[J]. Waste Management, 2019, 85: 222-231. doi: 10.1016/j.wasman.2018.12.025 [4] LIU Y, CLAVIER K A, SPREADBURT C, et al. Limitations of the TCLP fluid determination step for hazardous waste characterization of US municipal waste incineration ash[J]. Waste Management, 2019, 87: 590-596. doi: 10.1016/j.wasman.2019.02.045 [5] CHEN D, CHRISTENSEN T H. Life-cycle assessment (EASEWASTE) of two municipal solid waste incineration technologies in China[J]. Waste Management & Research, 2010, 28(6): 508-519. [6] WEI J, LI H, LIU J. Curbing dioxin emissions from municipal solid waste incineration: China's action and global share[J]. Journal of Hazardous Materials, 2022, 5(5): 435. [7] 孙绍锋, 郝永利, 许涓, 等. 解析《国家危险废物名录》[J]. 中国环境管理, 2013, 5(2): 46-48. doi: 10.3969/j.issn.1674-6252.2013.02.011 [8] 董光辉, 左武, 赵润博, 等. 水泥窑协同处置生活垃圾焚烧飞灰过程中 Pb 和 Zn 的迁移转化特性[J]. 环境工程学报, 2023, 17(1): 250-258. doi: 10.12030/j.cjee.202210043 [9] FAN C C, WANG B, AI H M, et al. A comparative study on solidification/stabilization characteristics of coal fly ash-based geopolymer and Portland cement on heavy metals in MSWI fly ash[J]. Journal of Cleaner Production, 2021, 319: 128-790. [10] ZHAN X, KIRKELUND G M. Electrodialytic remediation of municipal solid waste incineration fly ash as pre-treatment before geopolymerisation with coal fly ash[J]. Journal of Hazardous Materials, 2021, 8(33): 125-220. [11] LI J, ZENG M, JI W. Characteristics of the cement-solidified municipal solid waste incineration fly ash[J]. Environmental Science and Pollution Research, 2018, 25(36): 36736-36744. doi: 10.1007/s11356-018-3600-z [12] VAITKUS A, GRAZULYTE J, SERNAS O, et al. An algorithm for the use of MSWI bottom ash as a building material in road pavement structural layers[J]. Construction and Building Materials, 2019, 212(10): 456-466. [13] KANHAR A H, CHEN S, WANG F. Incineration Fly Ash and Its Treatment to Possible Utilization: A Review[J]. Energies, 2020, 13(24): 66-81. [14] OKADA T, TOMIKAWA H. Effects of chemical composition of fly ash on efficiency of metal separation in ash-melting of municipal solid waste[J]. Waste Management, 2013, 33(3): 605-614. doi: 10.1016/j.wasman.2012.08.013 [15] MA W, CHEN D, PAN M, et al. Performance of chemical chelating agent stabilization and cement solidification on heavy metals in MSWI fly ash: A comparative study[J]. Journal of Environmental Management, 2019, 247(11): 169-177. [16] MAEKAWA K, ISHIDA T, KISI T. Multi-scale modeling of concrete performance integrated material and structural mechanics[J]. Journal of Advanced Concrete Technology, 2003, 1(2): 91-126. doi: 10.3151/jact.1.91 [17] TIAN X, RAO F, ESTRELLA R M, et al. Effects of aluminum dosage on gel formation and heavy metals immobilization in alkali-activated MSWI fly ash[J]. Energy & Fuels, 2020, 34(4): 4727-4733. [18] TLC A, YHC B, MYD A, et al. Stabilization-solidification-utilization of MSWI fly ash coupling CO2 mineralization using a high-gravity rotating packed bed[J]. Waste Management, 2021, 121: 412-421. doi: 10.1016/j.wasman.2020.12.031 [19] WELDEGHEBRIE M F, LOWENSTEIN T K, GARCIA-VEIGAS J, et al. Combined LA-ICP-MS and cryo-SEM-EDS: An improved technique for quantitative analysis of major, minor, and trace elements in fluid inclusions in halite[J]. Chemical Geology, 2020, 551: 19762-119762. [20] TSICILIS S, CHANIOTAKIS E, KAKALI G, et al. An analysis of the properties of Portland limestone cements and concrete[J]. Cement and Concrete Composites, 2002, 13(2): 371-378. [21] 国家环境保护总局. 固体废物 浸出毒性浸出方法 醋酸缓冲溶液法: HJ/T 300—2007[S]. 北京: 中国环境科学出版社, 2007. [22] WANG J M, JIANG J G, LI D, et al. Removal of Pb and Zn from contaminated soil by different washing methods: the influence of reagents and ultrasound[J]. Environmental Science & Pollution Research, 2015, 22(24): 20084-20091. [23] ÁLVAREZ M B, GARRIDO M, LISTA A G, et al. Three-way multivariate analysis of metal fractionation results from sediment samples obtained by different sequential extraction procedures and ICP-OES [J]. Analytica Chimica Acta, 2008, 620(1): 34-43. [24] 中国人民共和国环境保护部, 中华人民共和国国家质量监督检验检疫总局. 生活垃圾填埋场污染控制标准: GB 16889-2008[S]. 北京: 中国环境科学出版社, 2008. [25] ZHANG Y, CETIN B, LIKOS W J, et al. Impacts of pH on leaching potential of elements from MSW incineration fly ash[J]. Fuel, 2016, 184: 815-825. doi: 10.1016/j.fuel.2016.07.089 [26] SHEN Y, WANG H, KIM N S. Ammonia separation of Ni from spent fly ash leach liquor[J]. Minerals & Metallurgical Processing, 2020, 27(3): 154-157. [27] 童立志, 韦黎华, 王峰, 等. 焚烧飞灰重金属含量及浸出长期变化规律研究[J]. 中国环境科学, 2020, 40(5): 8. doi: 10.3969/j.issn.1000-6923.2020.05.033 [28] WALI A, COLINET G, KSIBI M. Speciation of heavy metals by modified BCR sequential extraction in soils contaminated by phosphogypsum in sfax, tunisia[J]. Environmental Research Engineering & Management, 2014, 70(4): 14-26. [29] ZHOU J Z, SIMIAO W, PAN Y, et al. Mercury in municipal solids waste incineration (MSWI) fly ash in China: Chemical speciation and risk assessment[J]. Fuel, 2015, 158: 619-624. doi: 10.1016/j.fuel.2015.05.071 [30] LI H L, FAHEEM M, YAN Y J, et al. Electrokinetic remediation of heavy metals from municipal solid waste incineration fly ash pretreated by nitric acid[J]. Royal Society open science, 2018, 5(8): 2054-5703. [31] WEIBEL G, EGGENBERGER U, Schlumberger S, et al. Chemical associations and mobilization of heavy metals in fly ash from municipal solid waste incineration[J]. Waste Management, 2016, 62: 147. [32] WANG X, ZHANG L, ZHU K, et al. Distribution and chemical species transition behavior of chlorides in municipal solid waste incineration fly ash during the pressure-assisted sintering treatment [J]. Chemical Engineering Journal, 2021, 415: 128873. [33] 蒋旭光, 段茵, 吕国钧, 等. 垃圾焚烧飞灰中重金属固化稳定机理及系统评价方法的研究进展[J]. 环境工程学报, 2022, 16(1): 10-19. doi: 10.12030/j.cjee.202105098 [34] XIONG Y, ZHU F, ZHAO L, et al. Heavy metal speciation in various types of fly ash from municipal solid waste incinerator[J]. Journal of Material Cycles & Waste Management, 2014, 16(4): 608-615. [35] FONT O, QUEROL X, HUGGINS F E, et al. Speciation of major and selected trace elements in IGCC fly ash[J]. Fuel, 2005, 84(11): 1364-1371. doi: 10.1016/j.fuel.2004.06.039 [36] DI B, LI J, FANG W, et al. Comparison of long-term stability under natural ageing between cement solidified and chelator-stabilised MSWI fly ash[J]. Environmental Pollution, 2019, 250(JUL.): 68-78. [37] QUINA M J, BORDADO J C, QUINTA-FERREIRA R M. Treatment and use of air pollution control residues from MSW incineration: An overview[J]. Waste Management, 2008, 28(11): 2097-2121. doi: 10.1016/j.wasman.2007.08.030 [38] WU S, XU Y, SUN J, et al. Inhibiting evaporation of heavy metal by controlling its chemical speciation in MSWI fly ash[J]. Fuel, 2015, 158: 764-769. doi: 10.1016/j.fuel.2015.06.003 [39] CAO H T, BUCEA L, RAY A, et al. The effect of cement composition and pH of environment on sulfate resistance of Portland cements and blended cements[J]. Cement & Concrete Composites, 1997, 19(2): 161-171. [40] DOMINIC B V, CHAN W P, PHUA Z H, et al. The use of fly ashes from waste-to-energy processes as mineral CO2 sequesters and supplementary cementitious materials[J]. Journal of Hazardous Materials, 2020, 398: 822-906. [41] SINGH, KANWAR M, KUMAR, et al. Physiochemical and leaching characteristics of fly and bottom ash[J]. Energy sources, 2016, 38(16): 2377-2382. doi: 10.1080/15567036.2015.1057657 [42] 张海军, 于颖, 倪余文. 等. 采用巯基捕收剂稳定化处理垃圾焚烧飞灰中的重金属[J]. 环境科学, 2007(8): 1899-1904. doi: 10.3321/j.issn:0250-3301.2007.08.044 [43] ARNON C, SUPITCHAYA T, PHAKIN C. Thermogravimetric analysis and phase characterizations of Portland fly ash limestone cements[J]. Journal of thermal analysis and calorimetry, 2020, 142(1): 83-90. [44] 牟陈亚, 何亮, 李清毅, 等. 固化飞灰形状及填埋方式对重金属浸出的影响[J]. 中国环境科学, 2020, 40(4): 8. doi: 10.3969/j.issn.1000-6923.2020.04.027 [45] WANG Y, XU H, CHEN C, et al. Enhanced solidification/stabilization of lead in MSWI fly ash treatment and disposal by gelatinized sticky rice[J]. Environmental Technology, 2019, 42(12): 1-41. [46] MASSAZZA F, OBERTI G. Durability of pozzolanic cements and Italian experience in mass concrete[J]. Aci Special Publication, 1991, 15(9): 43-55. [47] RAMOS V, FERNANDES I, SILAVA S, et al. Assessment of the potential reactivity of granitic rocks — Petrography and expansion tests[J]. Cement & Concrete Research, 2016, 86(3): 63-77. [48] SUN Y, XU C, YANG W, et al. Evaluation of a mixed chelator as heavy metal stabilizer for municipal solid-waste incineration fly ash: Behaviors and mechanisms[J]. Journal- Chinese Chemical Society Taipei, 2018, 34(5): 32-56. -

下载:

下载: