-

随着我国城市污水处理能力的日益提升,污水处理厂的污泥量也急剧增加。目前,常用的污泥脱水技术包括机械脱水 (如离心脱水或带式压滤) 或热干化处理,多数企业采用添加絮凝药剂的方式以提升污泥脱水效果。也有研究采用高温水热处理[1]、超声波辅助[2]、聚季铵盐调理[3]、添加酸碱或强氧化性试剂[4-6]等技术以促进污泥絮体中胞外聚合物EPS水解,从而改变污泥中水分分布并减少污泥束缚水含量,以最终提高污泥过滤与脱水性能。受制于工艺运行成本、工程应用成熟度等因素影响,该类技术尚未在污泥脱水方面得以大规模推广应用。

生物干化技术最早应用于牛粪干燥处理,后来逐渐拓展到城市生活垃圾、餐厨垃圾等水分蒸发或有机质稳定化处理[7]。采用生物干化技术处理湿有机质废物时,微生物利用易降解有机物进行好氧代谢,释放的生物热维持堆体的自热高温状态,结合强制通风可实现水分的快速蒸发与去除,整个干化进程受到微生物好氧发酵和强制通风2类因素的共同影响[8]。湿污泥脱水处理时,生物干化、热干化、太阳能干化3种工艺技术的单位热耗量分别为178.12、2 800~3 800、90~108 kJ·kg−1水,生物干化的脱水能耗仅为热干化工艺的5%~6%,却是太阳能干化工艺的1.7~2.0倍。但太阳能干化处理效果受天气和季节性影响较大、占地面积大等因素约束,工程实践并不多见[9]。污泥生物干化具有无需外加热源、水分去除较快、运行成本低等特征,该技术在污泥脱水处理方面日益受到关注。研究表明,物料特性、通风速率、发酵温度等工艺条件明显影响污泥干化效果,采用预处理、干化产物接种等措施可强化生物干化进程[9-10]。污水厂污泥具有成分复杂、高粘高湿、富含亲水物质等典型特征,给生物干化进程带来了明显不利影响[6]。因此,亟待深入拓展污水处理厂污泥高效脱水的基础研究工作,优化污泥生物干化工艺技术参数,深化干化进程有机质代谢与水热平衡分析,探究水分去除作用机制并对生物干化进程予以调控。

本研究以中高海拨地区污水处理厂脱水污泥为对象进行生物干化处理,优化了干化进程的典型工艺条件,根据堆体含水率、温度变化、有机质转化及代谢等指标阐明了污泥干化进程的特性,并对污泥干化产物的后续利用进行了评价分析,研究成果可为污水厂污泥处理处置及资源化利用提供理论与技术支撑。

-

从昆明地区3个污水处理厂 (W1、W2、W3) 采集二沉池脱水污泥开展系列实验,其中W2污水处理厂在好氧池投加了化学药剂聚合氯化铝PAC以强化除磷效果。二沉池外排剩余污泥时定量添加聚丙烯酰胺PAM,之后采用带式压滤机进行脱水处理,脱水污泥含水率通常为80%左右,挥发性固体物质VS与总固体物质TS的比例通常为51.6%~55.2%,W1等3类污泥典型物化指标如表1所示。

-

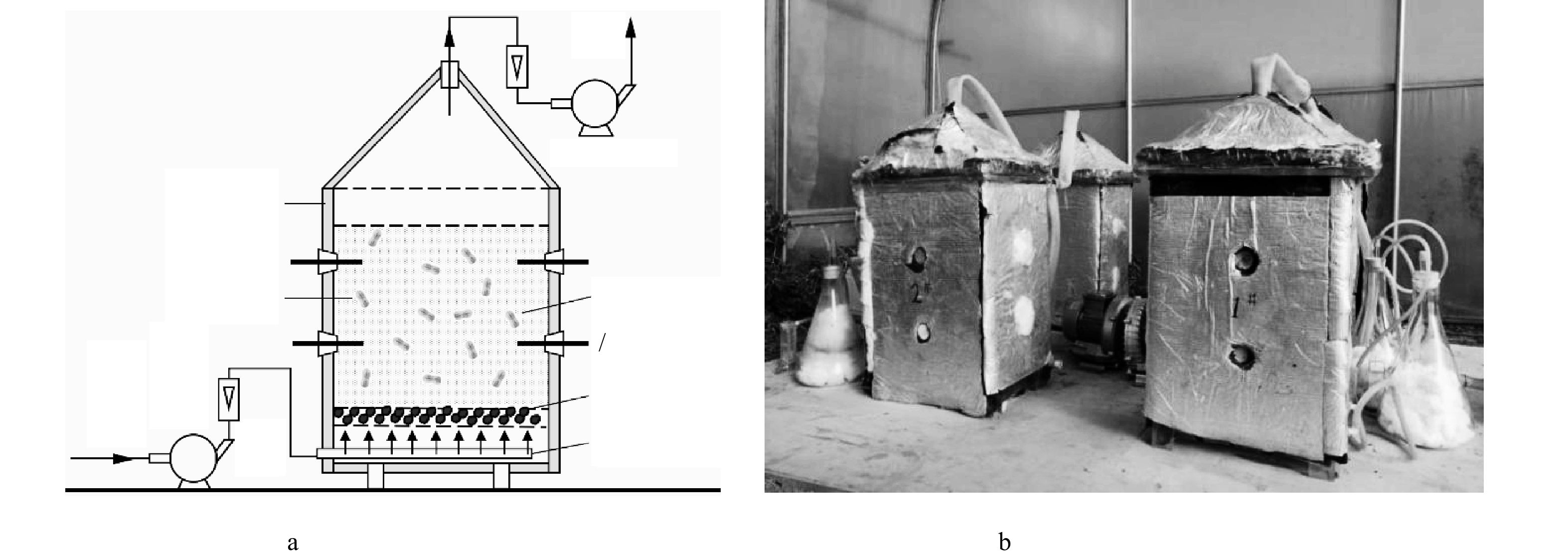

污泥生物干化装置如图1所示。仓式反应装置长35 cm、宽28 cm、高45 cm,厢体外壁包覆3 cm厚保温材料以减少热量散失,装置底部设置近1 cm高的陶粒作为承托层。承托层下部隔空层铺设有环形微孔曝气管,承托层上部即为待干化处理的污泥混合料,其装填质量为16~17 kg,置于温室大棚内开展对比实验。

-

1) 初始含水率与通风方式对污泥干化升温及水分去除影响。利用W1污水处理厂脱水污泥 (含水率81.1%) 与前期污泥干化后的晾晒产物 (含水率约12%) 均匀混合并将含水率分别调至70%、65%、60%和55%,再按混合料质量的8%加入花生壳作为填充剂,后将其装填至污泥干化装置中,启动曝气或抽风系统。通过脱水污泥与污泥干化后晾晒产物2者添加比例调配混合物料初始含水率,通风方式设置为底部间歇曝气+顶部间歇抽气。之后,在优化的初始含水率条件下,按照间歇或连续运行模式设置底部曝气、顶部抽气或2者组合的通风方式,考察污泥干化进程中水分去除、堆体温度变化等指标变化情况。间歇通风操作时,采取白天曝气/抽气12 h而晚上停止12 h的交替运行模式。结合垃圾堆肥强制通风[11]以及污泥干化前期预实验,采用底部曝气、顶部抽气或2者组合的通风方式,底部曝气强度为35 L·(h·kg)−1,顶部抽气强度为60 L·(h·kg)−1。

2) 污泥成分对干化升温及水分去除影响。取W1、W2污水厂的新鲜脱水污泥以及W3污水厂脱水污泥堆存120 d后的污泥样本开展对比实验,湿污泥与污泥干化后的晾晒产物按11∶3比例混合,之后添加混合料质量8%的花生壳填充剂,制备成初始含水率65%±3%的待处理物料,分别装填至R1~R3污泥干化装置中。同样,将W1污水厂新鲜脱水污泥与W3污水厂脱水污泥堆存120 d的厌氧发酵污泥按1∶1混合,再按本方案相同方法添加污泥干化晾晒产物及花生壳,制备的污泥混合料装填至R4生物干化装置中。R1~R4干化装置均采用底部曝气+顶部抽气相组合的运行方式,间歇通风操作,曝气/抽气的强度分别为35、60 L·(h·kg)−1。

-

干化处理进程中,每天早、中、晚3次测定反应装置内堆体温度及环境温度。每隔24 h采集不同位置污泥样本,混合均匀后测定物料水分、VS、TS、pH、短链挥发性脂肪酸 (SCFAs) 等指标。参照《生活垃圾化学特性通用检测方法》 (CJ/T 96-2013) [12]测定污泥样本中有机物质量分数。将污泥样本风干,并进行硝酸浸溶处理[13],之后采用ICP仪 (Iris-Advangtage1000,美国) 测定重金属质量浓度。参照《城镇污水处理厂污泥处置 园林绿化用泥质》 (GB/T 23486-2009) [14]测定污泥干化产物的种子发芽指数GI,其结果可由(1)所示。

式中:A1为堆肥浸提液中种子的发芽率;A2为堆肥浸提液培养的种子的平均根长,mm;B1为去离子水中种子的发芽率;B1为去离子水培养的种子的平均根长,mm。

按1∶10质量比将污泥样本添加至蒸馏水中,利用水浴摇床振荡并混合1 h,于12 000 g条件下离心处理5 min,所得上清液经0.45 µm滤膜过滤处理并收集滤液用于后续测试。按照《水与废水监测分析方法》[13]测定pH、可溶性磷酸盐等常规指标;采用TOC仪 (CD–800S,杭州启鲲科技公司) 及气相色谱仪 (GC 9790 Plus,浙江福立仪器公司) 分别检测溶解性有机碳 (DOC) 与SCFAs[15],测定的乙酸、丙酸等SCFAs组分相应折算为COD当量质量分数。

将0.8 g污泥样本置于2 mL离心管中,加入3 µL由SYTO 9荧光核酸染料和碘化丙啶组成的混合物,再加入磷酸盐缓冲液浸泡,于4 ℃条件下避光染色15 min。用包埋液包埋染色后的样品,将其置于冷冻切片机 (Cyrotome E,英国赛默飞公司) 进行-20 ℃冷冻处理,待样品完全冻硬,再以20 µm的厚度对包埋样品进行切片,将切片样品置于激光共聚焦显微镜 (TCSSP2,德国徕卡公司) 载玻片上,使用20倍物镜观察活菌和死菌的原位分布[16],使用Image-Pro Plus 6.0软件进行-像的形态学参数分析。

-

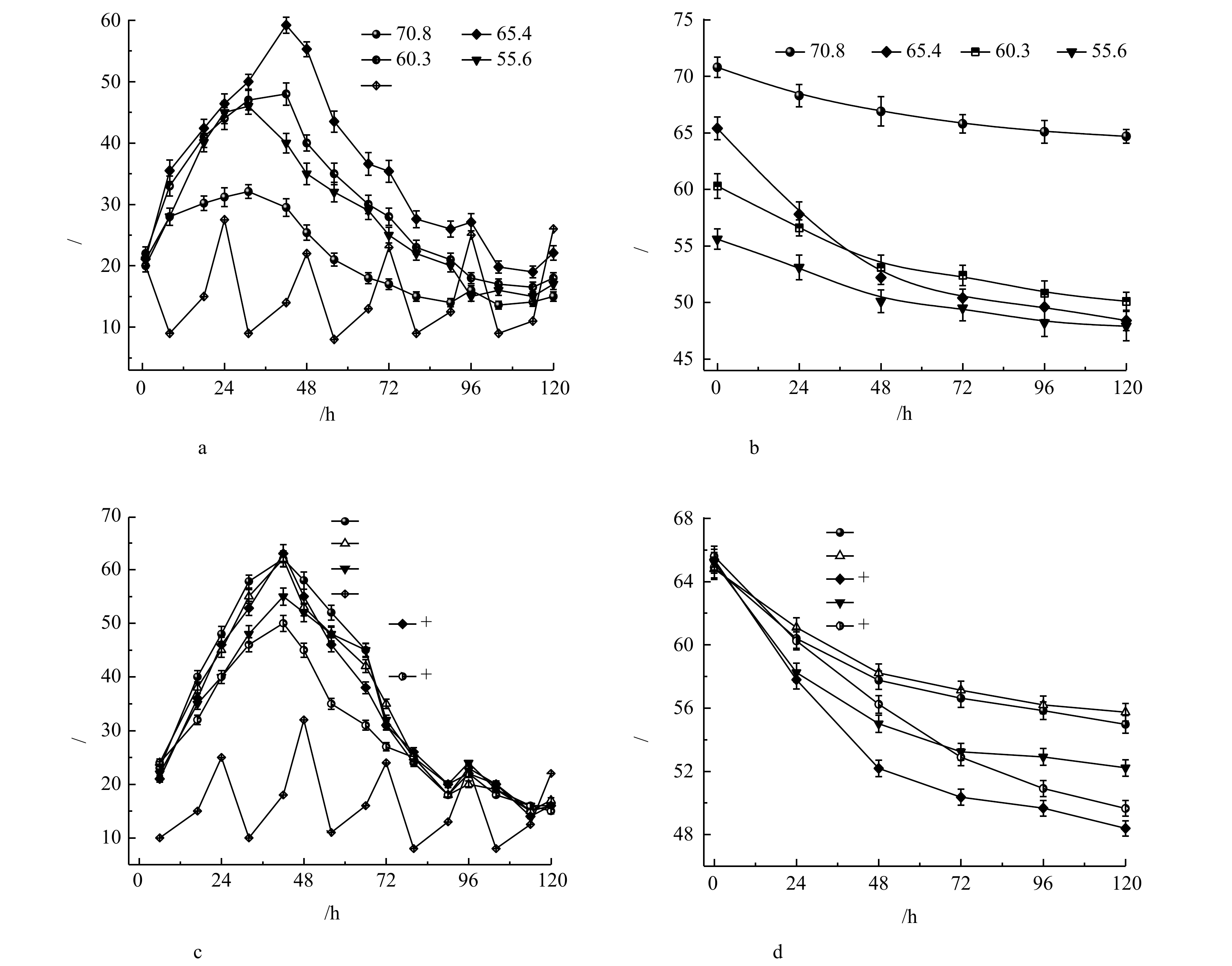

利用W1污水处理厂脱水污泥 (含水率81.1%) 与前期污泥干化后的晾晒产物 (含水率约12%) 均匀混合并将含水率分别调至70.8%、65.4%、60.3%、55.6%。由图2(a)可知,尽管环境温度波动较大且日平均气温差达到12~15 ℃,但堆体温度仍会在24~36 h时期自热升温至较高温度,之后因有机质质量分数下降而呈现温度回落。初始含水率为70.8%时,污泥混合料最高温度不超过32.1 ℃;干化处理120 h后,其含水率仍维持在64.7%较高水平。而初始含水率为65.4%时,体系自热升温达到59.2 ℃,其温度维持在45 ℃以上的高温期时间长达38 h;干化处理120 h后,堆体含水率下降至48.3% (图2(b)) ,含水率降低17.1%,水分去除效果明显优于其他干化体系。污泥生物干化处理时,含水率太高将导致堆体内部过于致密,影响氧气供给进而阻碍有氧代谢进程及自热升温;含水率太低时,微生物难以充分利用污泥中的溶解性有机质,有氧代谢进程受到抑制。综合分析堆体温度、水分变化,混合物料初始含水率65%左右时有利于污泥生物干化处理。

本研究进一步考察了底部曝气与顶部抽气、间歇曝气与连续曝气等不同通风方式对干化进程中升温与水分去除的影响。由图2(c)和图2(d)可知,连续曝气或抽风条件下堆体的温度通常相对较低,底部间歇曝气、顶部间歇抽风或将2者相结合时,堆体最高温度可达63.2 ℃,45 ℃以上的高温期持续时间均不低于32 h,最长可达45 h;从污泥物料含水率来看,底部间歇曝气+顶部间歇抽风是最适宜的通风方式,干化处理120 h后,含水率从最初的65.4%下降至48.4% (图2(d)) ,水分净去除量均高于其他通气方式。采用底部连续曝气+顶部连续抽风时,堆体中的水汽被及时带出干化装置[7],其含水率在120 h后也下降至49.7%;然而此条件下干化体系热量散失更快,堆体最高温度只能达到49.3 ℃,且45 ℃以上的高温期持续时间只有16 h,不利于污泥中病原微生物的有效杀灭。

-

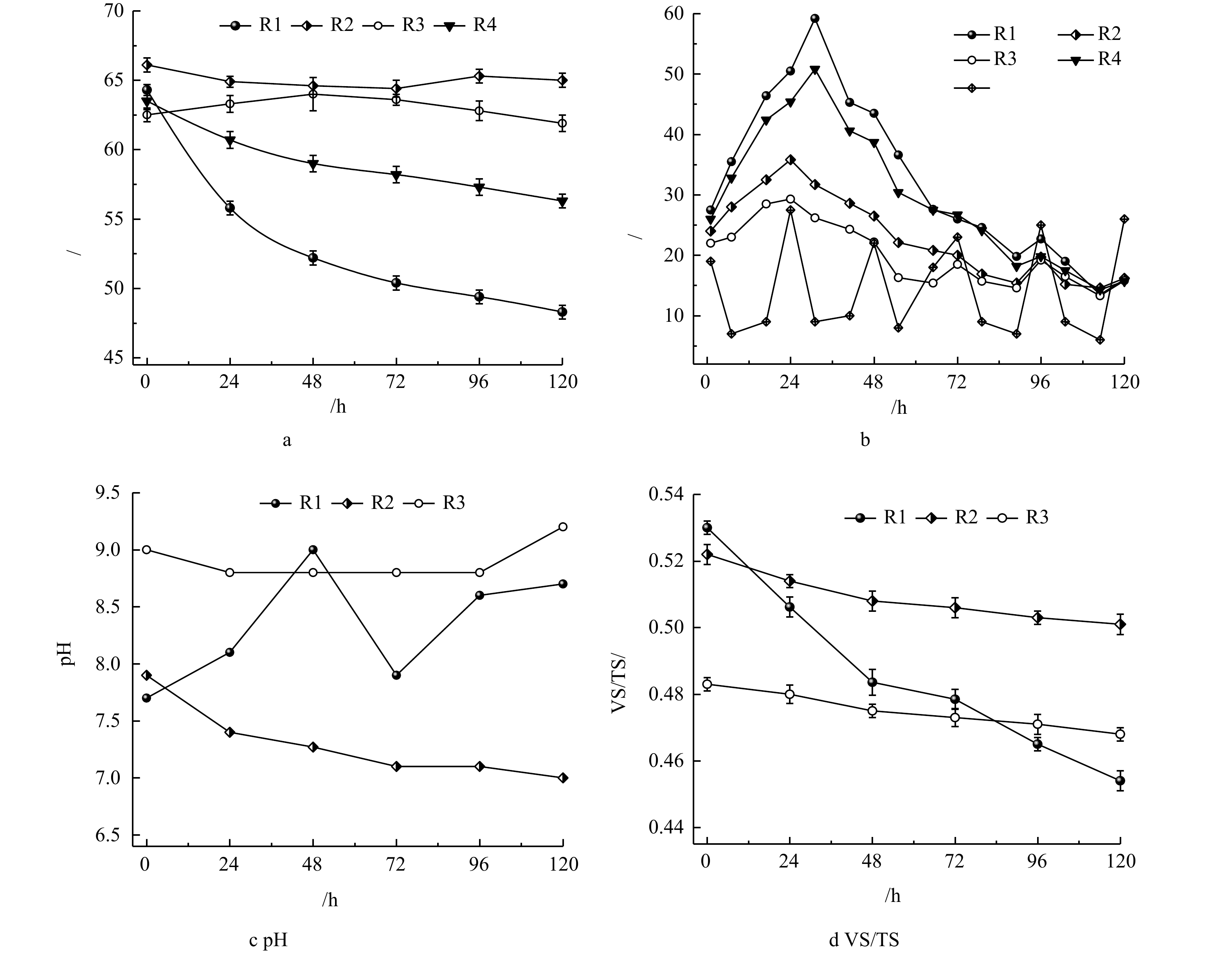

有机废物生物干化处理一般会经历升温、高温和降温3个典型阶段[17],物料含水率、堆体温度及高温持续时间是衡量湿有机质生物干化效果的重要指标。由图3(a)所示,混合物料生物干化处理120 h后,R1体系含水率从最初的64.3%下降至48.3%,含水率下降16.0%;尽管日均环境温度不高于14 ℃,且最低气温有时低至7 ℃,R1反应器仍可自热升温至59.2 ℃,堆体温度维持45 ℃以上的高温期时间达25 h(图3(b))。相比而言,R2与R3体系最高温度均低于36 ℃,其物料含水率在干化处理120 h后分别为65.1%、61.9%,净下降值分别为1.0%、0.6%。很明显,投加PAC实现强化除磷的脱水污泥 (W2污水厂) 以及脱水污泥 (W3污水厂) 较长时间堆存均不利于污泥生物干化处理。前者因混合物料中铝质量浓度已高达78.3 g·kg−1而抑制微生物活性[18],后者因待处理污泥料中易降解有机质质量分数流失严重而导致堆体无法自热升温,无法促使水分从物料内部随气流带出。R4体系启动时,W1污水厂脱水污泥与W3污水厂堆存120 d的湿污泥按1∶1混合,干化过程中其自热升温达到50.8 ℃,高温期持续时间为12.5 h;干化处理120 h后,该体系含水率下降至56.3%。可见,污泥生物干化处理时,维持较高的有机质甚为必要。而在干化后期,有机质有氧代谢产热效果不再明显,堆体温度受外界环境温度变化影响明显。

以R1~R3典型体系为对象,将不同时期的污泥样本与蒸馏水按1∶10比例混合并进行浸提处理。R1体系中,其初始pH为7.7,其在干化处理48 h时上升至9.0 (图3(c)) ,这与该时期堆体温度甚高而导致常温微生物快速衰亡并引起蛋白水解、氨气释放密切关联。干化末期,R1体系pH仍维持在8.7的碱性条件。R3混合物料的浸出液pH达到9.0,这一较高水平碱性环境对微生物的生理活动及底物代谢产生不利影响,加之污泥长期堆存导致易降解有机质质量分数偏低,其堆体温度难以实现自热升温,水分去除率也就不明显。另外,R2混合物料的浸出液pH从初始的7.9逐步降低至7.0,该体系含水率净降低值仅为0.6%,反映出混合物料铝质量浓度较高不利于污泥生物干化体系的水分去除。

本研究中,R3混合物料的VS/TS低至48.3%,反映出R3体系可利用的有机底物相对不足。干化处理120 h后,R1~R3体系中的VS/TS分别下降至45.4%、50.1%、46.8% (图3(d)) ,被利用的有机质总质量分别为1.29、0.33、0.25 kg。综合污泥干化过程中堆体温度、物料含水率以及VS/TS分析,当待干化处理物料中有机质更为丰富时,其有氧代谢释放热量的潜力更大,堆体升温更快、高温期维持时间更长,水分去除也就更为明显;但当干化体系受到不利因素干扰如混合料中铝质量浓度明显偏高时,微生物的有氧代谢受到抑制,堆体难以快速升温并维持高温状态,水分去除率明显偏低。

-

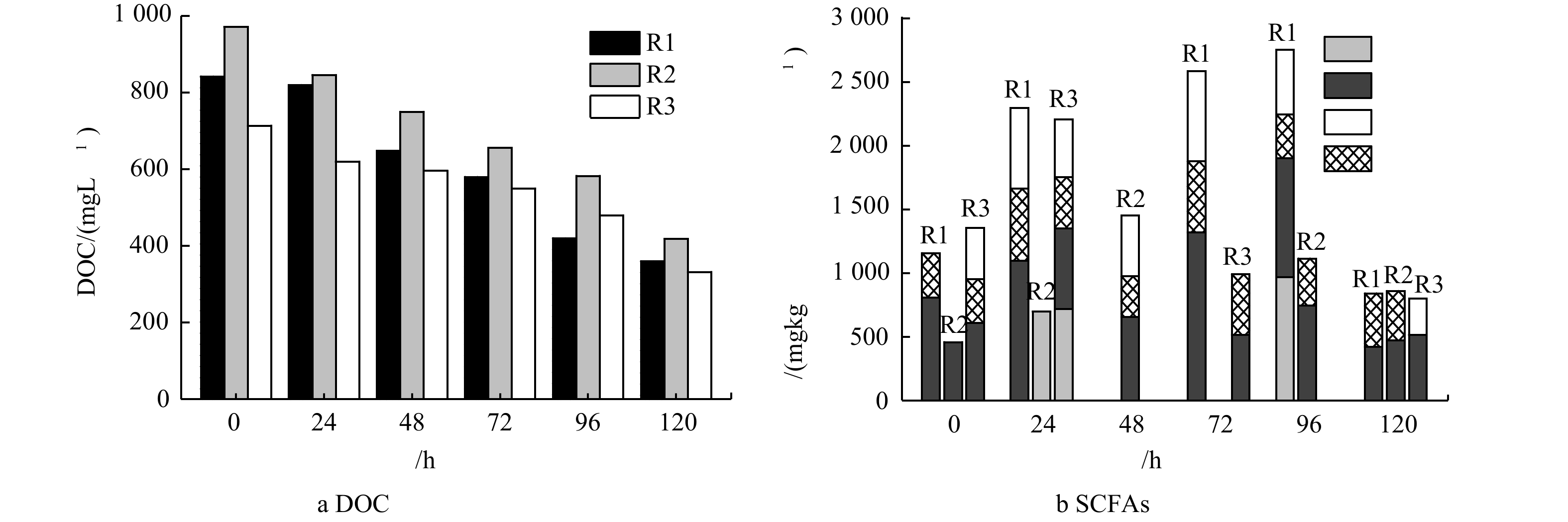

1) 含碳组分迁移转化。采用混合物料中浸出液溶解性有机碳DOC以及短链挥发性脂肪酸SCFAs来反映生物干化进程有机质的代谢及迁移转化。干化进程中,R1~R3混合物料的浸出液DOC质量浓度均呈逐步下降趋势,120 h后分别为360、418、332 mg·L−1,分别下降了57.2%、57.0%、53.5% (图4(a)) 。R3较R1体系相比,由于其污泥已堆存较长时间,初始污泥混合料中DOC相对较低,这与该体系堆体最高温度未超过30 ℃、水分净去除率低于1%这一实验结果直接相关。污泥干化处理时,一方面,堆体中有机质在胞外酶作用下发生水解而转化为水溶性有机质[8];另一方面,水溶性小分子有机质被微生物吸收利用并代谢产热,而水溶性大分子物质除降解生成水溶性小分子物质外,还会经过复杂的生化反应历程生成水溶性差的腐殖酸类物质。整体来看,生物干化进程DOC均呈降低趋势,这与湿有机质生物干化和堆肥处理的研究结论较为一致[16, 19]。

生物干化前期,污泥中底物的有氧代谢促使堆体温度上升,常温或中温微生物溶胞进程逐步增强[19],进而导致堆体中可溶性有机质质量分数升高,受既定供气速率以及高温代谢耗氧量大的影响,堆体中极易生成并累积SCFAs (图4(b)) 。R1体系污泥生物干化效果最为突出,在不同时期均会累积丙酸、异丁酸这类短链脂肪酸组分。R2体系混合物料初始VS/TS虽然也能达到52.2%,但120 h后有机物去除总量并不特别明显,该体系SCFAs累积量通常低于R1体系。对污泥生物干化处理体系而言,混合物料浸出液中是否累积SCFAs,不仅与其产生量相关,还受到生化代谢进程的明显影响。SCFAs组分及其质量浓度变化能很好反映湿物料干化进程中有机质降解情况,与堆体升温、水分去除具有内在密切联系。

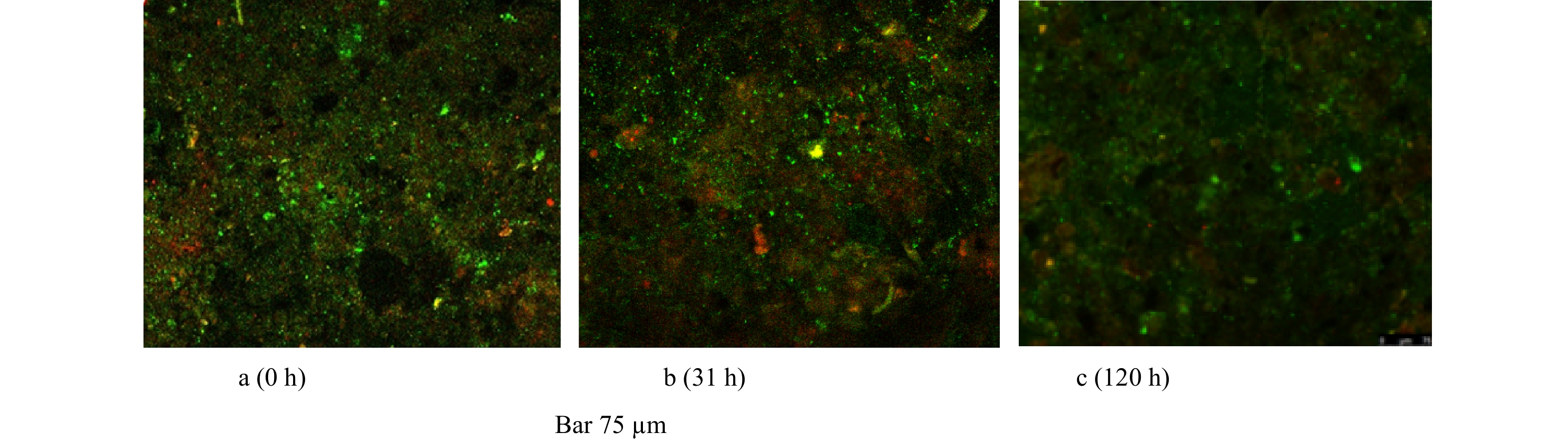

2) 微生物活性。以R1体系为典型代表,采用多重荧光标记结合CLSM观察污泥干化进程不同温度阶段活菌和死菌分布情况 (图5) 。污泥生物干化系统启动时,R1体系活菌和死菌的荧光强度分别为90.5、255(表2)。当R1体系在31 h自热升温至最高温59.2 ℃时,尽管Ureibacillus、Sphinggobacterium、Pseudoxanthomonas嗜热菌 (此处未列出微生物种群丰度测试数据) 快速发展成为优势种群,但常温与中温微生物开始衰亡、溶胞并释放胞内有机质,高温阶段活菌与死菌荧光强度均有所下降,嗜热活菌所占比例上升至52.5%。生物干化末期,温度回落至近室温,污泥干化产物中活菌的荧光强度又显著上升至54.2,是死菌荧光强度的1.54倍,这表明嗜温微生物开始再次繁殖。综上可知,污泥生物干化进程随着堆体温度的变化,常温、中温或嗜热微生物会发生明显更替,具有活性的微生物类型存在明显差异。

-

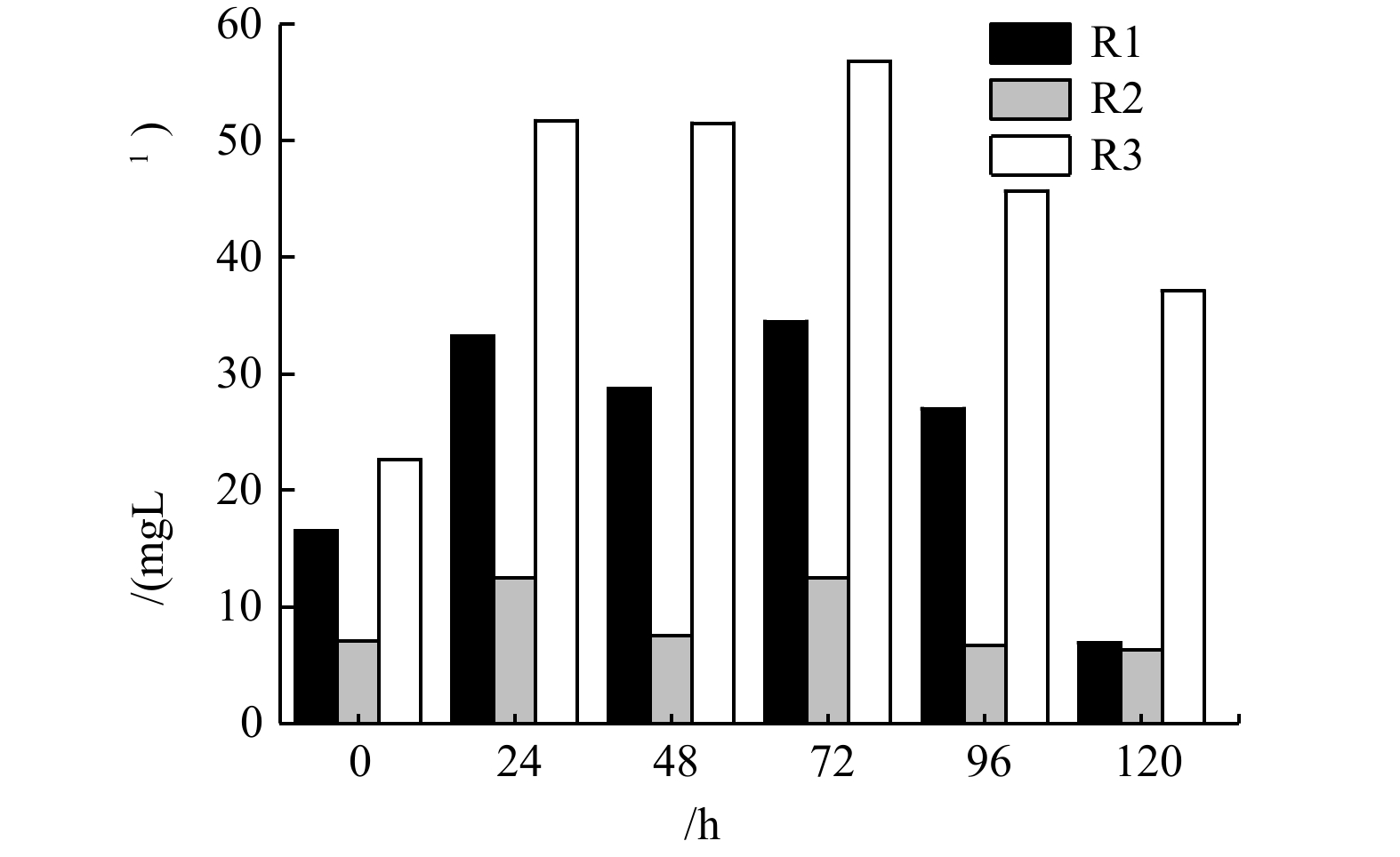

1) 可溶性磷酸盐及其他营养元素。本研究选取R1~R3典型体系,评价污泥生物干化产物后续土地利用潜力。R1~R3体系中,可溶性磷酸盐质量浓度均呈现前期波动中上升、后期回落的趋势 (图6) ,这一变化与堆体温度先升高后回落并趋于稳定密切相关。常温微生物随堆体温度升高而溶胞并释放胞内有机质,导致浸出液中磷酸盐质量浓度上升。干化后期,堆体温度已较为稳定,持续的间歇曝气使得微生物重新利用前期溶出的磷酸盐进行有氧代谢并将磷转移至生物体内,浸出液中磷酸盐因而有所下降。由于W2污水厂投加PAC以强化除磷,导致R2初始混合料及干化产物浸出液中磷酸盐明显低于R1体系。对R3体系而言,W3污水厂脱水污泥已经堆存120 d,厌氧发酵释放磷使其初始可溶性磷酸盐质量浓度相对较高。干化处理120 h后,R1体系水分下降至48.3%,浸出液中可溶性磷酸盐质量浓度为6.9 mg·L−1。与此同时,干化产物中氨态氮与硝态氮质量分数分别为325、10.6 mg·kg−1,钾质量分数达到2.7 g·kg−1。可见,R1体系生物干化产物营养元素较为丰富,具备不错的土地利用潜力。

2) 干化产物重金属。测定R1~R3典型体系中污泥干化产物As、Cr、Cd等重金属质量浓度,如表3所示。从R1体系来看,干化产物中Cr、Cu、Zn、Pb、Ni质量浓度分别为306、198、888、52.6、44.7 mg·m−3,均低于《农用污泥污染物控制标准》 (GB4284-2018) [20]A级标准限值;As、Cd、Hg质量浓度分别为61.7、14.6、3.7 mg·m−3,高于GB4284-2018 A级标准限值但低于B级标准限值。虽然R2与R3体系中重金属质量浓度均低于R1体系,但干化产物中As分别达到36.1、47.9 mg·m−3,仅能满足GB4284-2018 B级污泥要求,所以干化产物仅能在园地、牧草地、不种植食用农作物的耕地使用。

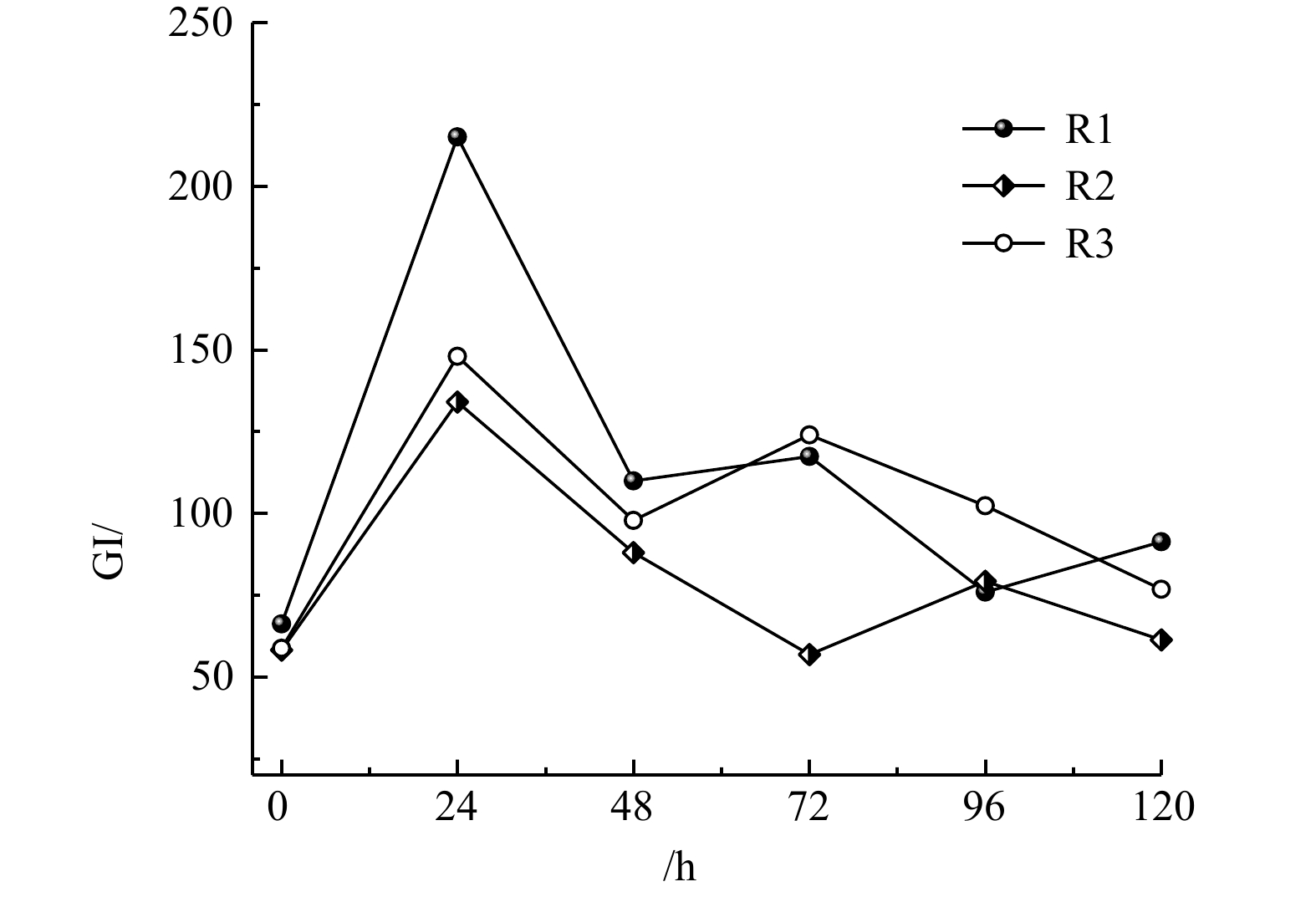

3) 种子发芽指数。种子发芽指数 (GI) 综合反映堆肥的植物毒性,被认为是最敏感、最可靠的堆肥腐熟度评价指标。由图7可知,R1~R3体系中初始混合物料GI分别为66.2%、58.2%、58.7%,干化产物的GI在24 h时分别快速上升至215%、134%、148%,此后GI有所下降并呈现适度波动的趋势,3个体系最终干化产物的GI分别为91.3%、61.3%、76.8%。在间歇通风条件下采用生物技术干化处理污泥时,混合物料中有机酸、多酚类物质随着堆体温度的升高而不断氧化分解或转化,从而减缓了该类物质对作物生长的抑制作用,GI因而明显较高;生物干化后期,堆体中容易利用的有机质质量分数逐步降低,温度明显回落,某些不利于作物生长的代谢产物重新累积并导致GI有所下降,但仍高于未经生物干化处理的初始混合物料。特别针对R1体系,污泥生物干化进程具有堆体温度高、高温期持续时间长、水分去除总量大等特征,且最终产物GI明显高于《城镇污水处理厂污泥处置 园林绿化用泥质》 (GB/T 23486-2009) [14]规定的污泥园林绿化利用时种子发芽指数应大于70%这一限值要求。综上分析,该类污泥干化产物在园林绿化、矿山修复以及荒漠化治理等方面具有良好的应用前景。

-

1) 采用污水厂新鲜脱水污泥进行生物干化处理时,堆体升温更快,高温期持续时间更长,混合物料中水分去除效果更明显。污泥堆存较长时间或者铝质量浓度偏高时,明显不利于生物干化进程。

2) 污泥生物干化处理以混合物料初始含水率65%左右较为适宜,采用底部间歇曝气+顶部间歇抽风的通风方式,混合物料含水率可降低至50%以下。

3) 污泥混合物料生物干化处理120 h后,干化产物中可溶性磷酸盐质量浓度为6.9 mg·L−1,钾质量分数达到2.7 g·kg−1,干化产物营养元素较为丰富。重金属Cd、As、Hg满足GB4284-2018 B级标准限值,Cr、Cu、Zn、Pb、Ni满足A级标准限值,种子发芽指数GI值高达90%,污泥干化产物在园林绿化、矿山修复以及沙漠化土壤改良等方面具有良好的应用前景。

剩余污泥生物干化处理及产物土地利用潜力

The treatment of biological drying for dewatered excess sludge and the potential of land utilization for the products

-

摘要: 以昆明地区污水处理厂脱水污泥为对象进行生物干化处理,考察了典型工况条件下污泥干化处理效果,探究了微生物活性及其有机质代谢,并对干化处理产物的土地利用潜力进行了评价分析。结果表明,采用污水厂脱水污泥进行处理时,混合物料初始含水率以65%左右较为适宜,采用底部间歇曝气+顶部间歇抽风的通风方式,堆体自热升温至60 ℃以上,高温期持续时间长达30 h;干化处理120 h时,含水率降低至50%以下,水分净去除率达到16%。干化进程中,混合料中DOC质量浓度呈降低趋势,但SCFAs组分及其浓度波动明显。伴随着堆体温度的变化,常温、中温或嗜热微生物发生更替,微生物活性及其生化代谢差异明显。干化产物中可溶性磷以及氮钾质量分数均较高,重金属Cd、As、Hg满足GB4284-2018 B级标准限值,Cr、Pb等其他重金属质量浓度满足A级标准限值,种子发芽指数GI值高达90%,污泥干化产物具备园林绿化、矿山修复等方面土地利用前景。本研究结果可为污水厂污泥处理处置及资源化利用提供参考。Abstract: Biological drying was employed to treat the dewatered excess sludge derived from sewage treatment plants in Kunming. The effects of sludge biodrying were investigated under typical parameters, the microbial activity and substrate metabolism were elucidated, and then the potential of land utilization for the drying products was analyzed. The results showed that when the dewatered sludge from sewage plant was used for treatment, the optimum moisture content of the mixed materials was about 65%, the mode of ventilation was intermittent bottom aeration combined with intermittent top suction, and the stack was self-heated to above 60 ℃, the period of thermophilic condition lasted for 30 h. After biodrying treatment for 120 h, the moisture content was reduced to less than 50%, and the water removal reached 16%. During the biodrying process, the content of DOC in the mixture presented downward trend, but the SCFAs and its concentration fluctuated significantly. As the temperature of the bioreactor changed, mesophilic or thermophilic microorganisms varied correspondingly, and the microbial activities and biochemical metabolism exhibited significantly different. For the drying products, the contents of soluble phosphorus and other nutrient elements such as nitrogen and potassium are abundant, the heavy metals Cd, As and Hg can meet the requirements stipulated by class B biosolids in GB4284-2018, and the other heavy metals such as Cr and Pb meet the standard of class A biosolids, and the seed germination index GI is up to 90%. The products after biodrying present the prospect of land utilization in garden landscaping, mine restoration and other aspects. The results can provide valuable supports for sludge disposal and land utilization.

-

Key words:

- dewatered excess sludge /

- biological drying /

- moisture removal /

- land utilization

-

截至2019年底,全国城镇累计建成污水处理厂超过1×104座,污泥的年产生量近6×107 t (以含水率80%计)。厌氧消化是国际上大力推行的污泥处置利用技术[1-2],然而,由于我国城镇污泥中有机质的含量偏低(40%~60%),厌氧消化产甲烷的效能低[3],导致目前配备厌氧消化设施的污水处理厂的比例不足30%。与此同时,随着餐饮业的快速发展,餐厨垃圾的产生急剧增多。据报道,我国目前餐厨垃圾的年产量已达6×107 t[4]。餐厨垃圾中易腐有机质含量高(>80%),厌氧消化过程中常出现挥发性脂肪酸积累、酸化抑制产甲烷的现象[5]。鉴于此,有研究者提出了将污泥与餐厨垃圾混合厌氧消化的技术思路[6-8]。从长沙、大连、襄阳等地的污泥-餐厨垃圾厌氧消化的工程运行实效来看,该方式可显著提升厌氧消化的稳定性和甲烷产率(500 t·d−1的处理条件下,标准状况下产气可达3×104 m3·d−1)。然而,混合厌氧消化后所产生的消化产物的含水率一般仍很高(>95%),从而给后续的转运、堆肥、焚烧以及土地利用等带来了很大的困难。如何促进污泥-餐厨垃圾厌氧消化物的高效脱水是一个亟需解决的技术难题。

近10年来,过硫酸盐高级氧化在促进城镇污泥脱水时具有快速、简便等特点,受到了众多研究者的广泛关注。其原理为:通过能量(光、热)或过渡金属(Fe0, Co2+等)活化,过一硫酸盐(PMS)或过二硫酸盐(PDS)产生高活性

SO−4 ∙(E0(

SO−4 ∙/

SO2−4 )=2.43 V,以NHE计),氧化裂解污泥细胞和降解胞外聚合物(EPS),促使大量结合态水的释放(转化为自由水),进而提升脱水性能。KIM等[9]发现,热活化PDS(投加量2 mmol∙g−1 VSS)可提高剩余活性污泥脱水,在80 ℃下、处理60 min,污泥CST可降低77%。宋秀兰等[10]发现,Fe2+活化PDS可使浓缩污泥的过滤比阻(SRF)下降96%。NI等[11]发现,通过Fe0活化PDS亦可明显改善好氧消化污泥的脱水性能,处理30 min后,CST从119.1 s降至21.9 s。然而,与剩余活性污泥和浓缩污泥相比,污泥-餐厨垃圾混合厌氧消化产物的碱度更高、絮体粒径尺寸更小[12],因此,相对而言更难脱水。

目前,关于过硫酸盐氧化促进污泥-餐厨垃圾厌氧消化物脱水的报道还相对较少,对于相关作用机理的认识也十分有限。为此,本研究以污泥-餐厨垃圾厌氧消化物为研究对象,探究了热活化过硫酸盐处理对其脱水性能的影响,并从处理体系中过硫酸盐分解、自由基的产生、胞外聚合物(EPS)含量和组成的变化以及消化物微观形貌等方面分析其可能的作用机制,旨在为污泥-餐厨垃圾厌氧消化物的高效脱水提供参考。

1. 材料与方法

1.1 供试样品

供试污泥取自南京某城镇污水处理厂的污泥浓缩池。该污水处理厂采用AO工艺,日处理水量达2×105 m3。污泥pH为7.3、含水率为97.5%、有机质含量为48.3%。餐厨垃圾取自南京农业大学校园餐厅,实验前去除纸巾、塑料等杂物并机械破碎至粒径5 mm左右。污泥-餐厨垃圾混合厌氧消化物来自于本实验室长期运行的中温湿式厌氧消化反应器,污泥与餐厨垃圾按1∶1(以挥发性固体含量VS计)序批式进料。消化周期为30 d、温度为(35±1) ℃。供试消化物的基本特性为:pH为8.4、含水率97.2%、有机质含量43.7%、多糖和蛋白质的含量分别为300.3和636.1 mg·L−1。

1.2 温度对热活化过硫酸盐氧化促进污泥-餐厨垃圾厌氧消化物脱水影响的实验设计

为探讨热活化温度的影响,根据KIM等[9]的报道和本研究前期预实验的结果,本研究设置了50、60、70、80 ℃ 4组处理,固定PDS(过硫酸钠Na2S2O8)的投加量为4 mmol·g−1 (以干物质计)。具体实验步骤为:将厌氧消化物置于500 r·min−1转速下搅拌并分别加热至上述温度,随后添加Na2S2O8。反应过程中分别在30、60、120、180、240 min取样,经冰浴淬灭3 min后,分别测定其pH、CST、Na2S2O8含量等指标。

1.3 分析方法

采用CST分析仪(304M型,Triton Electronics)测定消化物毛细吸水时间(capillary suction time, CST);采用NaHCO3/KI法[13]测定PDS浓度;采用电子自旋共振波谱仪(EPR) (EMX10/12,德国Bruker公司)测定自由基种类;采用扫描电子显微镜(SEM)(S-3400N,日本Hitachi公司)观察消化物处理前后的微观形貌。

EPS的提取参考SHENG等[14]的三层提取方法,分别为:溶解型EPS(SL-EPS)、松散型EPS(LB-EPS)和紧密型EPS(TB-EPS)。EPS化学组分中的蛋白质采用修正的Folin-Lowry法测定,多糖采用蒽酮比色法[15]测定。

2. 结果与讨论

2.1 热活化过PDS对污泥-餐厨垃圾厌氧消化物脱水性能的影响

在不同温度条件下的热活化PDS处理过程中,厌氧消化物CST的变化如图1(a)所示。由图可知,热活化PDS氧化可显著提高污泥-餐厨垃圾厌氧消化物的脱水性能,且随着温度的升高,脱水的改善效果愈显著。具体而言:随着反应的进行,4组不同温度下的处理体系的CST均呈现下降趋势,但下降的速率有较大的不同。在50、60、70、80 ℃条件下,处理240 min时,CST从初始1 064.9 s分别下降到657、296.6、39.4、39 s,降低了33%、72%、96%、96%。KIM等[9]利用热活化PDS调理剩余活性污泥的过程中发现,在80 ℃条件下反应60 min,污泥CST可降低77%。此外,从厌氧消化物沉淀后的上清液的浊度来看(图1(b)),80 ℃条件下反应60 min,上清液浊度为228 NTU;进一步延长反应时间至120 min,浊度可降至1.4 NTU,水质清澈。与此同时,在70 ℃下,处理240 min,厌氧消化物CST也可降至39 s,此时的上清液水质也较为清澈透明(浊度1.46 NTU)。另外,从最终压滤泥饼的含水率来看,70 ℃、处理240 min和80 ℃、处理120 min的样品含水率分别为60.1%和59.5%。因此,在脱水性能改善程度基本相近的条件下,综合考虑今后实际工程处理时控温所需的能耗成本,本研究推荐热活化PDS促进污泥-餐厨垃圾厌氧消化物脱水的最佳条件为70 ℃、240 min。

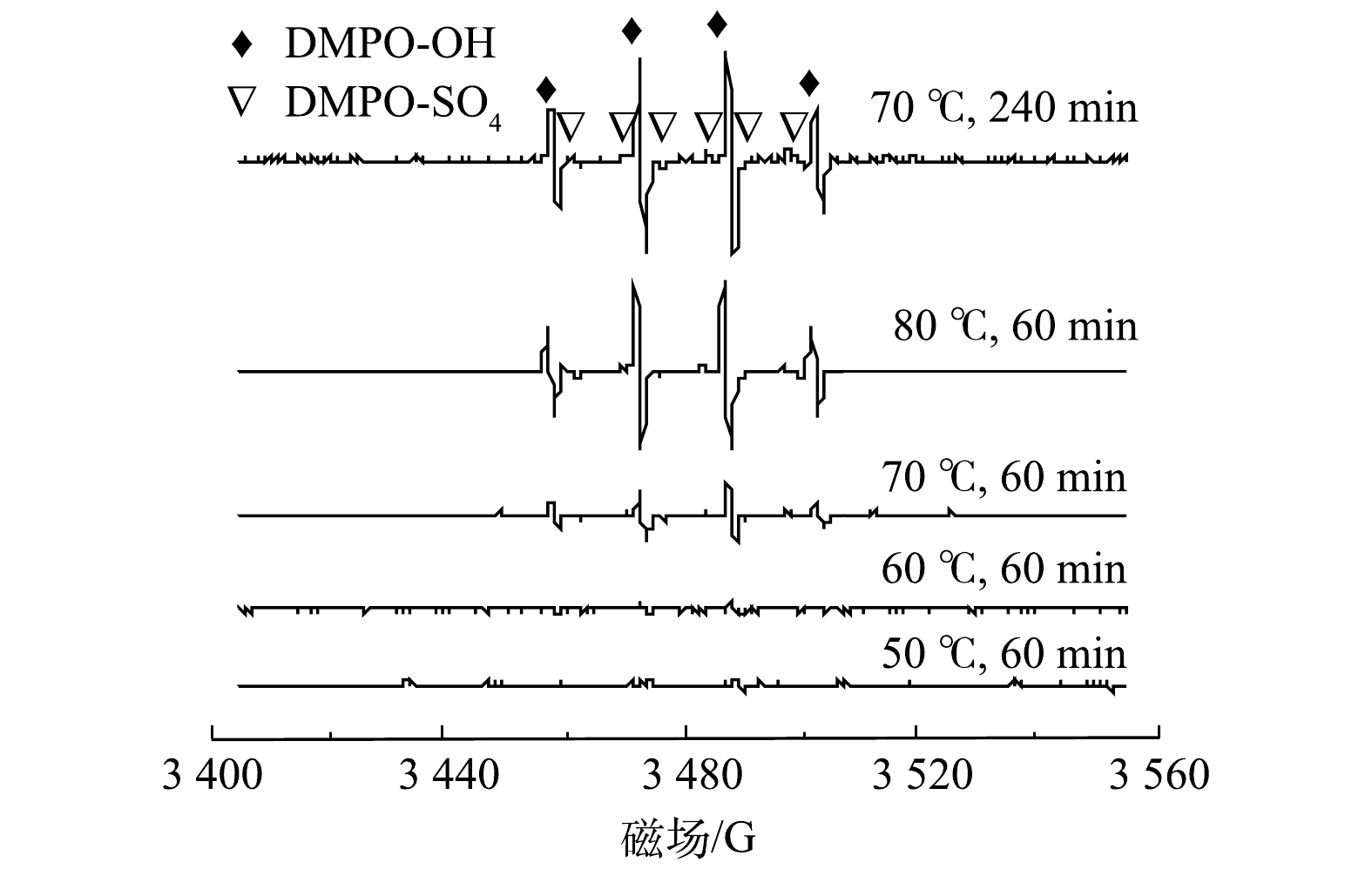

2.2 不同热活化温度条件下处理体系中PDS的分解及自由基的产生

已有报道[16]证实,热活化过硫酸盐氧化为吸热反应,当加热量大于140.2 kJ∙mol−1时,过硫酸盐中的O—O键可断裂,生成强氧化性的

SO−4 ∙。由图2可知,升高温度明显促进了反应体系中PDS的分解,这与前人的研究结果一致[16-17]。例如:50 ℃条件下反应240 min,PDS的浓度仅从4.00 mmol·g−1(以DS计)降到3.07 mmol·g−1,分解极为缓慢;而在相同时间,在80 ℃的反应条件下,PDS浓度则从4.00 mmol·g−1大幅降至0.05 mmol·g−1,减少了98.8%。EPR检测的自由基信号强度也证实了这一结果。如图3所示,热活化PDS体系在80 ℃条件下反应60 min检测出2种自由基特征峰,其中峰型为1∶2∶2∶1的特征峰是典型的DMPO捕获∙OH产生的超精细分裂图谱,同时还检测出较强的硫酸根自由基的特征峰[18];而50 ℃的反应条件下体系中并未检测到明显的自由基特征峰。此外,值得关注的是,在70 ℃条件下延长反应时间至240 min,体系中产生的

SO−4 ∙和∙OH自由基的峰强与80 ℃条件下反应60 min基本相当。这也解释了图1(a)中所观测到的70 ℃条件下反应240 min的脱水性能与80 ℃条件下反应60 min基本一致的原因。热活化过硫酸盐反应体系中自由基的产生的机理见式(1)~式(3)[16]。一些研究[18-19]表明,强氧化性的自由基

SO−4 ∙和∙OH攻击污泥絮体、降解高度亲水性的EPS,可促进絮体细胞中的结合水转变为自由水,进而提高厌氧消化物脱水性能。

S2O2−8+heat→2SO−4⋅ (1) SO−4⋅+H2O→SO2−4+⋅OH+H+ (2) SO−4⋅+OH−→SO2−4+⋅OH (3) 2.3 不同热活化温度条件下处理前后厌氧消化物EPS含量及组成

不同热活化温度下处理体系中EPS的组成如图4所示。从图4(a)中可以看出,原始消化物EPS中蛋白质含量主要集中在SL层和TB层中。在50和60 ℃条件下反应240 min,TB层蛋白质浓度分别从327.5 mg·L−1降至146.9和95.0 mg·L−1,SL层和LB层蛋白质浓度增多,EPS中的蛋白质浓度分别从636.1 mg·L−1增加到748.6和670.5 mg·L−1。这说明,加热使絮体细胞破解,释放EPS,一部分TB层蛋白质转移到SL层和LB层。在70 ℃下反应240 min和80 ℃下反应120 min的条件下,TB层蛋白质浓度分别从327.5 mg·L−1减少至76.7和77.4 mg·L−1;EPS中的蛋白质浓度从636.1 mg·L−1降至331.8和340.5 mg·L−1。此时污泥脱水速率提高可能的原因为:首先加热破解污泥细胞,释放EPS,并且一部分TB层蛋白质转至SL层,同时体系中产生的

SO−4 ∙和∙OH会破坏微生物细胞,氧化分解蛋白质,此时蛋白质分解消耗的速率远大于其释放的速度[20]。有研究指出,EPS中的蛋白质因含有大量的亲水基团,具有更强的持水能力,故EPS中蛋白质含量被广泛认为是影响污泥脱水性能的关键[9,11]。据此可以推测,TB-EPS中蛋白质的大幅削减可能是本研究中厌氧消化物脱水提高的重要原因之一。

EPS中的多糖含量在不同活化温度下变化趋势与蛋白质含量总体一致(图4(b))。在50、60、70、80 ℃条件下,EPS中总的多糖浓度由300.3 mg·L−1分别增加到853.2、818.4、656.4、507.3 mg·L−1。这表明,在热活化PDS处理过程中,微生物细胞破裂,胞内物质释放到胞外并被自由基的攻击、降解。EPS中多糖总量随着温度的升高,呈先上升后下降的趋势。但由于多糖的亲水性不如蛋白质,所以多糖含量的变化可能并不是影响污泥脱水性能提高的关键[21]。

2.4 热活化过PDS处理前后污泥-餐厨垃圾厌氧消化物的形貌特征

不同热活化温度处理条件下PDS氧化前后的厌氧消化物的微观结构特征如图5所示。由图可见,原始样品(图5(a))的絮体表面是光滑致密的,孔隙较少;而经过70 ℃条件下PDS反应240 min(图5(b))和80 ℃条件下反应120 min(图5(c)),厌氧消化物絮体变得较为松散,且其表面和内部都出现了大量的孔洞。这些大量增加的过滤通道对絮体内部的水分释放、排出十分有利,脱水性能进而得到较大的改善,这与许多研究学者的观测结果一致[19,22]。

3. 结论

1)热活化PDS氧化可大幅度提高污泥-餐厨垃圾厌氧消化物的脱水性能,且随着温度从50 ℃升至80 ℃,脱水的改善效果也相应提高。

2)在过硫酸钠的投加量4 mmol·g−1、温度70 ℃、处理时间240 min的条件下,厌氧消化物CST可从初始1 064.9 s降至39.4 s。

3)热活化PDS过程中产生

SO−4 ∙和∙OH自由基攻击厌氧消化物,促使其絮体结构破坏和物质释放并降解,这可能是脱水性能提高的主要原因。

-

表 1 实验所用3类污泥的物化指标

Table 1. Typical physico-chemical index of three types of sludge in the batch experiment

污泥种类 含水率/ % VS/% 干基碳/% pH 铝/(g·kg−1) 污泥状态 W1厂脱水污泥 81.1 10.4 21.6 7.5 69.8 新鲜污泥 W2厂脱水污泥 82.3 9.4 18.9 7.7 78.3 新鲜污泥 W3厂脱水污泥 83.1 8.8 15.3 8.7 68.3 陈旧污泥 (堆存120 d) 表 2 R1体系不同温度阶段活菌和死菌荧光强度及比例变化

Table 2. Fluorescence intensities and ratio of live and dead bacteria at different temperature stages for R1 system

温度阶段 细菌荧光强度 活死菌比例/% 活菌 死菌 活菌 死菌 初始阶段 (20.5 ℃,0 h) 90.5 255 26.2 73.8 最高温阶段 (59.2 ℃,31 h) 39.4 35.7 52.5 47.5 结束阶段 (16 ℃,120 h) 54.2 35.1 60.7 39.3 表 3 污泥干化产物重金属质量浓度

Table 3. Heavy metal content of sludge drying products

mg·m−3 产品或标准 组别或限值级别 As Cr Cu Cd Zn Pb Ni Hg 干化产物 (120 h) R1 61.7 306 198 14.6 888 52.6 44.7 3.7 R2 36.1 184 132 2.4 521 37.5 38.6 2.1 R3 47.9 247 142 2.3 555 22.5 33.4 3.1 GB4284-2018[20] A级 30 500 500 3 1 200 300 100 3 B级 75 1 000 1 500 15 3 000 1 000 200 15 -

[1] JOMAA S, SHANABLEH A, KHALIL W, et al. Hydrothermal decomposition and oxidation of the organic component of municipal and industrial waste products[J]. Advances in Environmental Research, 2003, 7(3): 647-653. doi: 10.1016/S1093-0191(02)00042-4 [2] 申晓娟, 邱珊, 李光明, 等. 超声波对污泥脱水的影响研究[J]. 中国给水排水, 2018, 34(3): 122-125. doi: 10.19853/j.zgjsps.1000-4602.2018.03.025 [3] 王子文, 曹蓉, 杨艳坤, 等. 聚季铵盐调理污泥深度脱水过程与中试效能[J]. 化工进展, 2019, 38(7): 3458-3464. [4] LIU C G, WU B, CHEN X E. Ultrasound enhanced zero-valent iron-activated peroxymonosulfate oxidation for improving dewaterability of aerobically digested sludge[J]. Chemical Engineering Journal, 2020, 392: 124850. doi: 10.1016/j.cej.2020.124850 [5] YU H X, GU L, ZHANG D F, et al. Enhancement of sludge dewaterability by three-dimensional electrolysis with sludge-based particle electrodes[J]. Separation and Purification Technology, 2022, 287: 120599. doi: 10.1016/j.seppur.2022.120599 [6] ZHANG W, CHENG H, PENG S, et al. Performance and mechanisms of wastewater sludge conditioning with slag-based hydrotalcite-like minerals (Ca/Mg/Al-LDH)[J]. Water Research, 2020, 169: 115265. doi: 10.1016/j.watres.2019.115265 [7] VELIS C A, LONGHURST P J, DREW G H, et al. Biodrying for mechanical–biological treatment of wastes: A review of process science and engineering[J]. Bioresource Technology, 2009, 100: 2747-2761. doi: 10.1016/j.biortech.2008.12.026 [8] 郭松林, 陈同斌, 高定, 等. 城市污泥生物干化的研究进展与展望[J]. 中国给水排水, 2010, 26(15): 102-105. doi: 10.19853/j.zgjsps.1000-4602.2010.15.029 [9] 呼永锋, 梁梅, 张永祥. 污泥生物干化工艺的工程实践与分析[J]. 环境卫生工程, 2022, 30(3): 19-25. doi: 10.19841/j.cnki.hjwsgc.2022.03.003 [10] YANG B Q, ZHANG L, JAHNG D. Importance of initial moisture content and bulking agent for biodrying sewage sludge[J]. Drying Technology, 2014, 32: 135-144. doi: 10.1080/07373937.2013.795586 [11] 褚莲清, 杨卫英, 陈全明, 等. 城市生活垃圾好氧堆肥工艺强制通风设计计算[J]. 环境卫生工程, 2001, 9(3): 120-122. [12] 中华人民共和国住房和城乡建设部. 生活垃圾化学特性通用检测方法: CJ/T 96-2013[S]. 北京: 中国标准出版社, 2013. [13] 国家环境保护总局. 水和废水监测分析方法[M]. 4 版. 北京: 中国环境科学出版社, 2002: 211-213 [14] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 城镇污水处理厂污泥处置 园林绿化用泥质: GB/T 23486-2009[S]. 北京: 中国标准出版社, 2009. [15] LIU S G, WANG Q C, GUAN Q Q, et al. Rapid release of internal carbon source from excess sludge with synergistic treatment via thermophilic microaerobic digestion and microcurrent[J]. Chemical Engineering Journal, 2019, 374: 637-647. doi: 10.1016/j.cej.2019.05.230 [16] LIU Y M, HU D, LIN Z Q, et al. Degradation of biochemical fractions in different temperature of food waste bioevaporation and their contribution to biogenerated heat[J]. Journal of Cleaner Production, 2019, 245: 118944-118955. [17] 席北斗, 赵越, 魏自民, 等. 三阶段温度控制堆肥接种法对有机氮变化规律的影响[J]. 环境科学, 2007, 28(1): 220-224. doi: 10.13227/j.hjkx.2007.01.040 [18] HE J, ZHANG Q, TAN B, et al. Understanding the effect of residual aluminum salt coagulant on activated sludge in sequencing batch reactor: Performance response, activity restoration and microbial community evolution[J]. Environmental Research, 2022, 212: 113449. doi: 10.1016/j.envres.2022.113449 [19] HUANG G F, WONG J, WU Q T, et al. Effect of C/N on composting of pig manure with sawdust[J]. Waste Management, 2004, 24(8): 805-813. doi: 10.1016/j.wasman.2004.03.011 [20] 国家市场监督管理总局, 中国国家标准化管理委员会. 农用污泥污染物控制标准: GB 4284-2018[S]. 北京: 中国标准出版社, 2018. -

下载:

下载: