-

碳纤维增强聚合物基复合材料(CFRP)因其重量轻、强度高、耐腐蚀,被广泛应用于航空航天、风电叶片、交通工具、桥梁建筑等领域[1-3]。CFRP在日常生活中的普及应用造成废弃CFRP产生量也逐年增多。CFRP废料主要包括过期的预浸料、剩余边角材料和报废的CFRP产品。预计到2025年,全球每年产生废弃CFRP的数量将达到2×104 t左右[4]。废弃CFRP中含有大量难降解环氧树脂,填埋处理会占用大量土地,焚烧处理则会造成大气污染问题。此外,碳纤维制备成本高,能源消耗大,回收废弃CFRP可显著降低碳纤维生产成本,节约能源[5]。发展绿色高效的废弃CFRP回收技术将对我国环境保护和碳纤维产业可持续发展具有重要意义。

环氧树脂和不饱和聚酯树脂等固化树脂常作为CFRP结构的基体,为CFRP提供了优异的机械强度和化学稳定性[6]。但固化树脂具有不可逆三维网状结构,造成固化树脂无法二次熔化、重塑或再加工,增大了CFRP回收难度[7]。CFRP回收方法主要包括热解法、化学回收法和机械回收法[8-10]。热解法或化学降解法可去除CFRP中的热固性树脂,得到再利用价值较高的长丝束碳纤维。但是,热解法能耗较高,而化学法会产生大量废弃化学试剂;同时,CFRP中的固化树脂大多会被降解为小分子气相和油相产物[11]。油相降解产物中含有大量芳烃和酚类有毒物质,必须得到妥善处置,以避免环境污染。机械回收法主要通过粉碎、研磨等工艺将CFRP破碎成小块或粉末[12]。机械方法工艺简单、成本低,还可以避免废弃树脂降解所造成的环境污染问题。但是,CFRP具备较高的比强度和比模量,导致在机械回收过程中碳纤维的长度和强度损失较高,只能得到增强效果较差的碳纤维粉末或短纤维产物,极大限制了机械法的推广应用。因此,如何在机械回收过程中有效保留原始碳纤维长度和强度,提高机械回收产物的再利用价值,已成为机械回收法在推广应用过程中亟待解决的难题。

普通化学试剂很难在温和条件下高效降解固化环氧树脂(CEP),但是一些有机溶剂可以在一定程度上溶胀CEP。WANG等[13]研究发现,CEP在醋酸(180 °C,6 h)中的溶胀率约为56%,明显优于甲醇(18.79%)、乙醇(20.85%)、正丙醇(16.16%)、异丙醇(11.06%)和水(3.80%)。之后,选用醋酸作为溶胀剂,可配合AlCl3实现CEP高效催化降解。溶胀法不仅可以用于CEP选择催化断键降解,也可以用于复合材料分层解离回收。ZHU等[14]利用离子液体[EMIM+][BF4−](260 °C,20 min)成功实现废弃印刷线路板溶胀解离回收。WATH等[15]分别采用n-甲基-2-吡咯烷酮(100 ℃,90 min)和二甲基亚砜(90 ℃,90 min)成功实现废弃印刷线路板溶胀解离回收。当前溶胀法主要用于废弃印刷线路板解离回收,有关废弃CFRP的溶胀解离回收研究较少。因此,本研究尝试利用醋酸溶胀法实现废旧CFRP绿色回收,主要研究CEP在醋酸介质中的溶胀与降解特性;分析影响CEP溶胀和降解的主要因素和作用机制;并揭示CEP溶胀与降解作用对溶胀产物软化和分层现象的作用机制;同时,研究不同溶胀处理条件下制备CFRP的抗弯强度。

-

本研究所用碳纤维板均由碳纤维环氧树脂预浸料(WP3011)通过热压法制备。预浸料中碳纤维作为增强材料,树脂(6508型环氧树脂)质量分数为40%,固化剂为双氰胺。先将碳纤维预浸料布剪切成长方形(80 mm ×10 mm ×0.2 mm),之后将8层剪切预浸料通过热压法(成型压力为0.10 MPa)在120 ℃条件下固化180 min制备成80 mm ×10 mm ×2 mm 的碳纤维板。

将液态环氧树脂(与预浸料中所用树脂和固化剂种类和配比一致)放入硅胶模具中,在120 ℃下固化180 min,制备成边长为10 mm的正方体CEP。

-

1)醋酸溶胀CFRP。将1块CFRP(约2 g)和45 mL醋酸一起放入100 mL哈氏合金反应釜中密封加热。加热温度分别为100、120、140、160、180、200和 220 ℃,反应釜内部压力为0.07~1.03 MPa。待反应釜内部温度达到设定温度后,分别保持0.5、1、2和4 h。保温结束后,待反应釜冷却至室温,将溶胀产物从反应釜中取出。

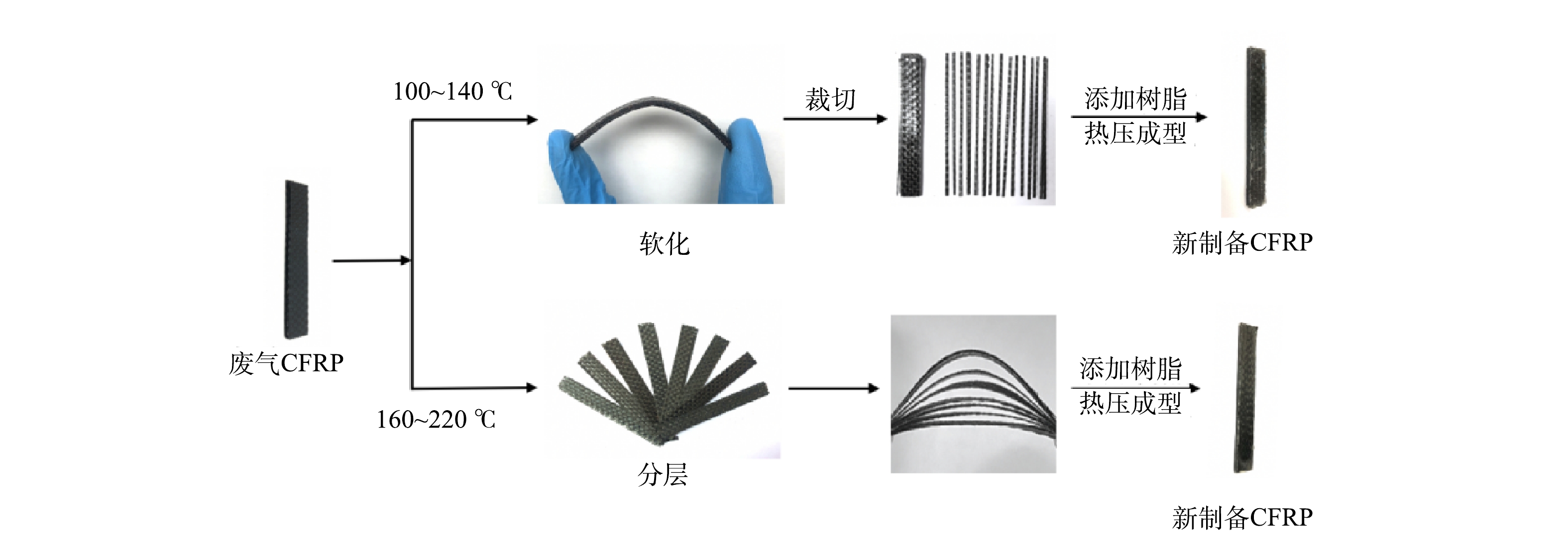

2)利用软化产物制备CFRP。将140 ℃条件下获得的软化产物切成细条状(80 mm× 2 mm× 2 mm),然后在105 °C烘干去除溶胀产物中的醋酸。之后在裁切产物中添加少量环氧树脂和固化剂(0.50 g左右),并通过热压法(在120 °C 下固化180 min,成型压力为0.10 MPa)制备出新的CFRP(80 mm× 10 mm× 2 mm)。

2)利用分层产物制备CFRP。将160~220 ℃下获得的分层产物在105℃烘干,之后在分层的碳纤维片上涂抹新的环氧树脂和固化剂(1.00 g左右),将8层分层产物通过热压法(在120 ℃下固化180 min,成型压力为0.10 MPa)制备新的CFRP(80 mm× 10 mm×2 mm)。在热压过程中时,部分多余环氧树脂可以从溶胀产物中挤压出来。

醋酸溶胀回收废弃CFRP过程如图1所示。

-

CEP在醋酸介质中的溶胀率(S)按式(1)计算,CEP降解率(D)按式(2)计算。

式中:m0是溶胀处理前块状CEP的初始质量,g;m1是醋酸溶胀处理后溶胀产物的质量(湿重,包含树脂内部吸附的醋酸质量以及从块状CEP表面碎裂脱落的颗粒状树脂质量),g;m2是溶胀产物烘干后的树脂质量,g。

抗弯强度(σ)通过3点弯曲测试计算,加载速度为 2 mm·min−1,按式(3)[16]计算。

式中:P是最大载荷,N;l是跨距,mm;b和h分别是CFRP的宽度和厚度,mm。

采用扫描电子显微镜(Supra 40,德国Zeiss公司)对溶胀产物的表面微观结构进行观察;采用傅里叶变化红外光谱(AIM-9000,日本Shimadzu公司)对树脂产品的主要化学结构进行表征分析。

-

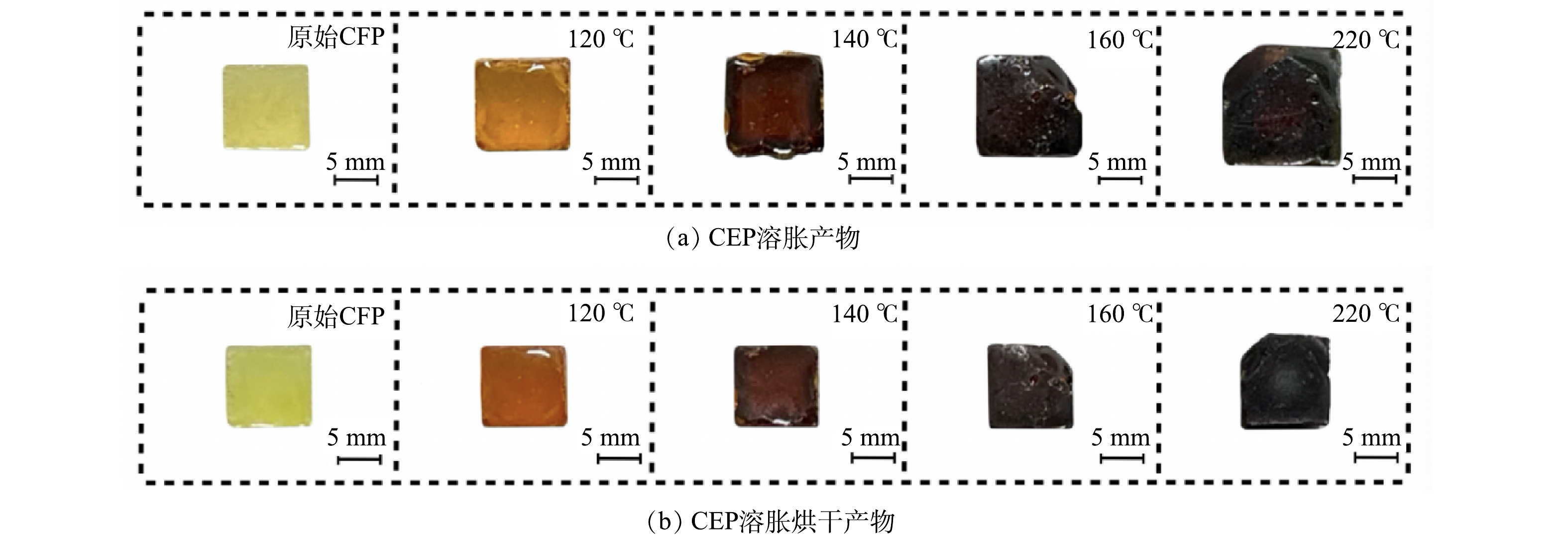

不同处理温度条件下CEP溶胀产物和对应烘干产物照片见图2(醋酸添加量和溶胀时间分别为45 mL和1 h)。从图2(a)可以看出,随着溶胀温度升高,CEP体积不断增大,CEP颜色也在逐渐加深。醋酸可以快速渗透进入CEP三维网络中,引发树脂基体的膨胀。但树脂的过度膨胀也会引发树脂碎裂现象的产生[17]。经120 ℃溶胀处理后,CEP发生轻微溶胀现象,其边长从10 mm增大到11 mm左右,CEP表面完整。当溶胀处理温度≥160 ℃后,CEP溶胀现象加剧,部分位于边角的树脂从CEP上脱落。CEP经220 ℃溶胀处理后,其边长增大至13 mm左右。不同处理温度条件下,CEP溶胀产物烘干照片见图2(b)。将溶胀产物在105 ℃烘干后,CEP内部所含醋酸被挥发去除,重新收缩恢复其原来的形状。当处理温度≤120 ℃,烘干产物表面仍然平整光亮;但是当处理温度超过140 ℃,烘干产物表面变得较为粗糙。

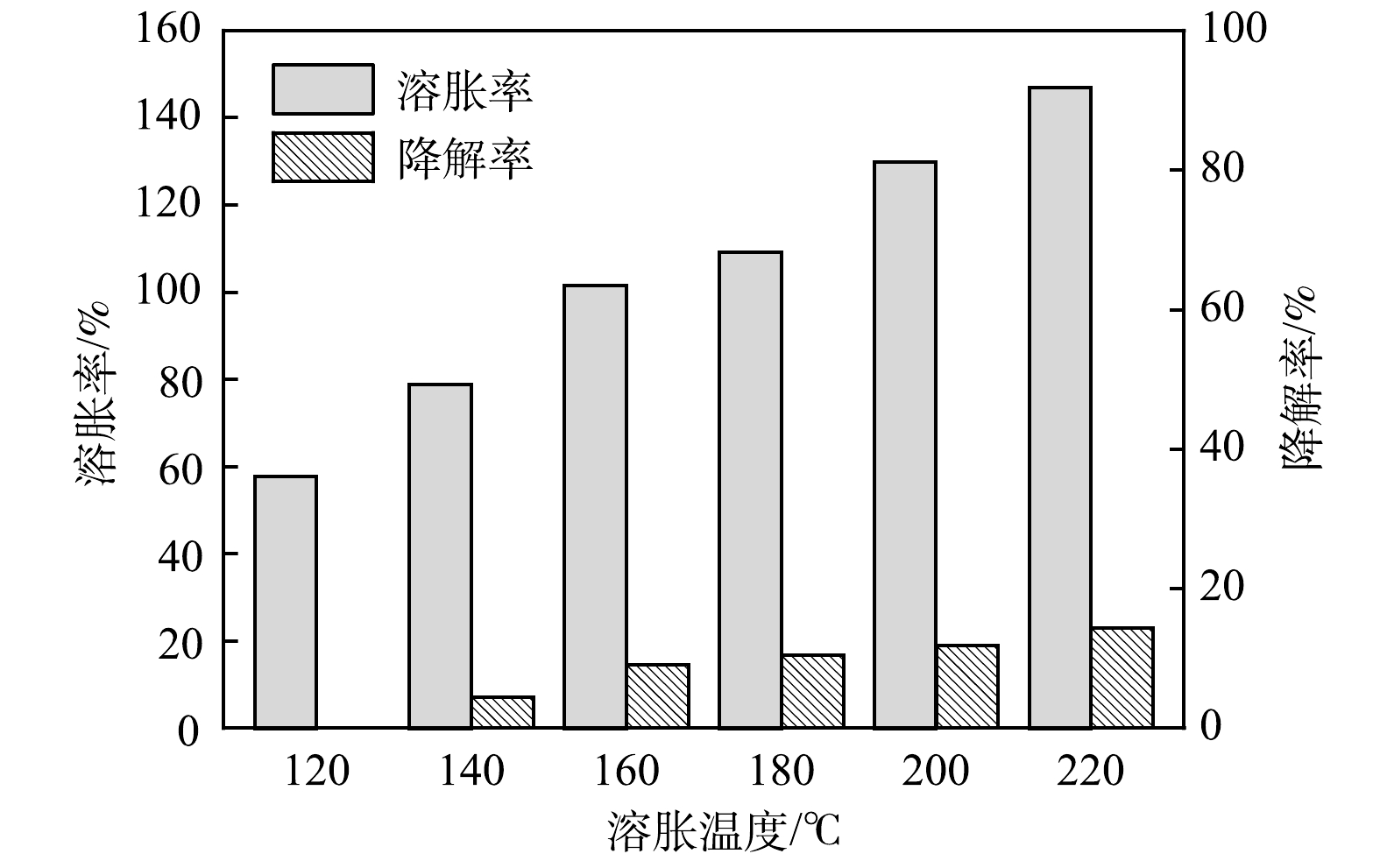

在不同溶胀温度条件下,醋酸对CEP的溶胀率和降解率见图3。从图3可以看出,CEP溶胀率和降解率均随着处理温度的升高不断增大。在120 ℃时,CEP仅发生轻微溶胀现象,溶胀率为57.81%,没有出现明显的降解现象。140 ℃时,溶胀率增加到78.88%,CEP 开始发生少量降解,降解率为4.49%。当温度升高到160 ℃,溶胀率迅速增加到101.55%,同时,降解率增加到9.08%。之后,随着温度进一步增加,溶胀率进一步增大。在220 ℃,溶胀率和降解率分别达到最高值147.00%和14.40%。

提升温度能够促进醋酸分子在CEP内的扩散速率,强化醋酸对CEP的溶胀效果和催化降解效果。而且,CEP中的三维网络结构主要由大量C-C、C-O-C和C-N键构成。随着温度的提升,醋酸溶胀体系提供的能量不断增大。当溶胀系统提供的能量超过CEP中化学键的键能,就能实现CEP的断键降解。但由于本溶胀工艺处理条件相对温和,溶胀系统提供能量不足以实现CEP大量断键降解,故当溶胀温度超过160 ℃后降解率增幅放缓。

-

溶剂分子可以通过聚合物-溶剂的相互作用来削弱和取代原来聚合物之间的相互作用,从而实现树脂溶胀。Hansen溶度参数(δ)常用于研究不同溶剂对树脂的溶胀效果,δ主要取决于溶剂分子的色散力、极性和氢键作用力。与聚合物具有相似溶度参数的溶剂,能够使聚合物的溶胀程度达到最大[18]。环氧树脂、醋酸、甲醇、乙醇、正丙醇和水的δ分别为19.85~20.46、21.40、29.60、26.50、24.35和47.80 MPa1/2[19]。其中醋酸的溶度参数(21.40 MPa1/2)最接近环氧树脂(19.85~20.46 MPa1/2),因此,在这些溶剂中醋酸对环氧树脂溶胀能力最强。

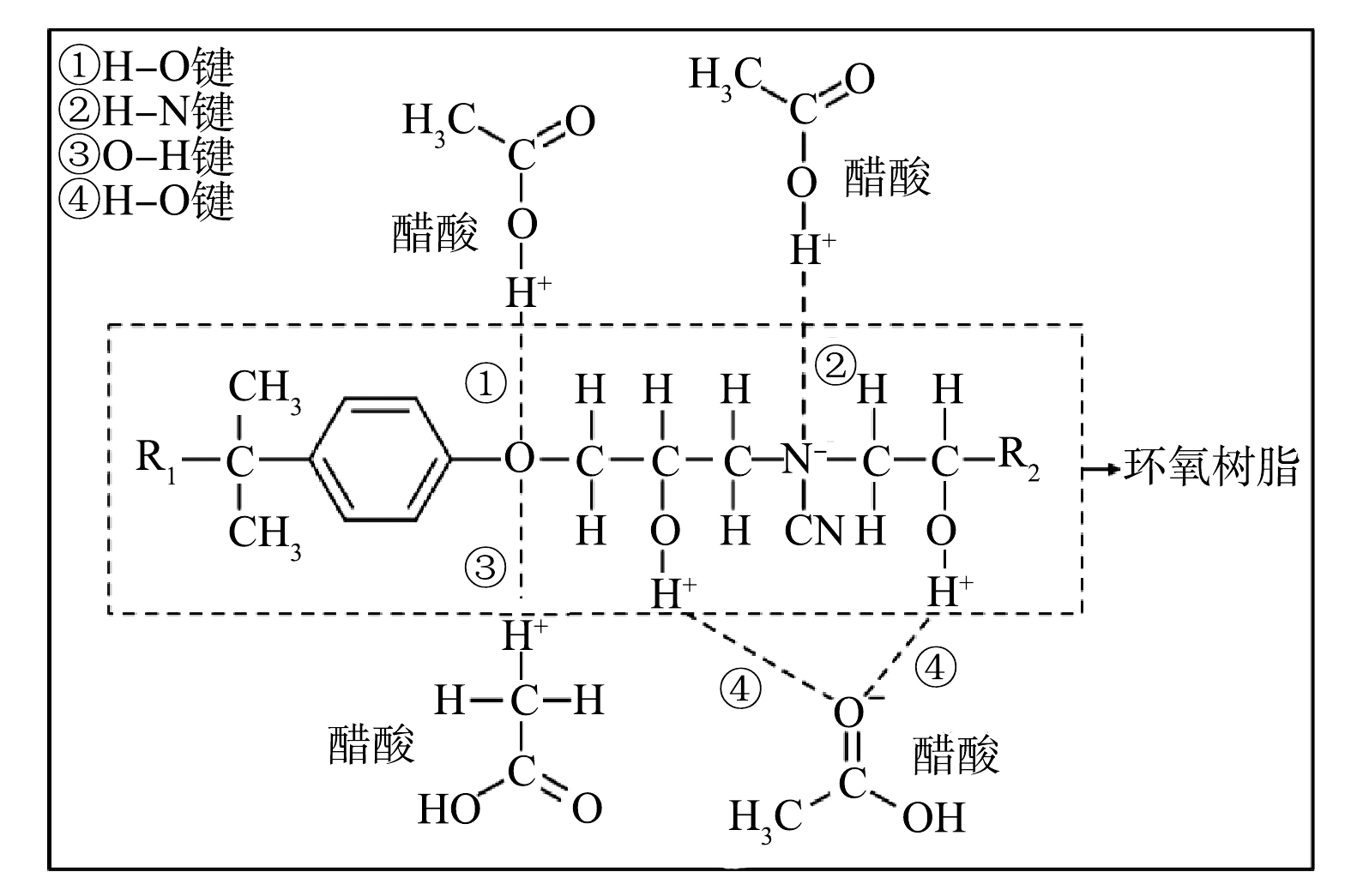

醋酸通过氢键作用溶胀CEP机理见图4。醋酸是一种极性溶剂,具有碳基(C=O)和羟基(C-OH)。而CEP是一种交联的聚合物,主要由C-O-C、C-C和C-N键组成。在溶胀过程中,CEP和醋酸之间会通过氢键相吸引。在溶胀过程中通过4种氢键吸引方式促使CEP在醋酸介质中快速充分溶胀[20]。

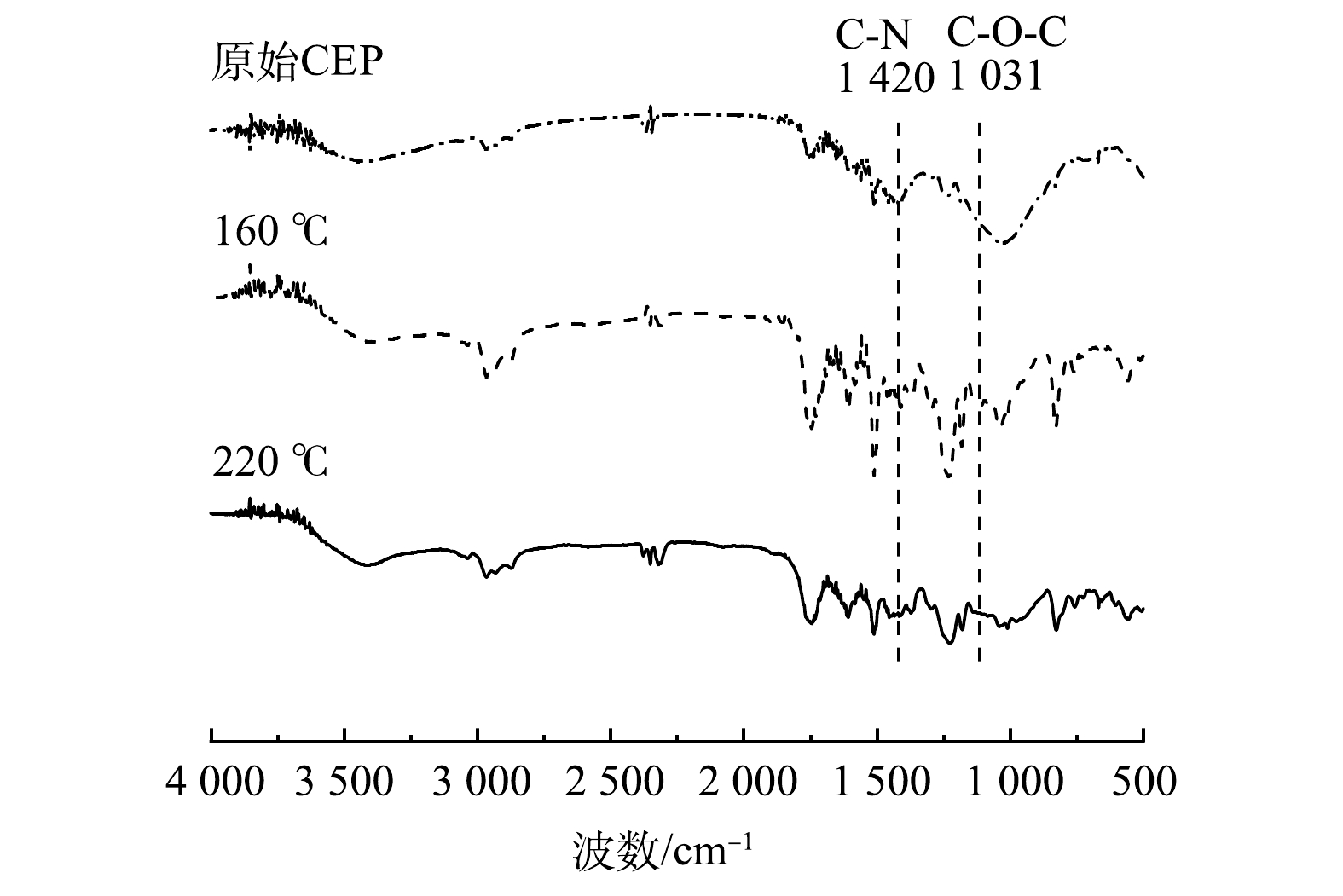

不同温度条件下所得CEP溶胀产物FTIR图见图5。CEP主要由C-O-C、C-C和C-N键构成。溶胀产物在1 420 cm−1处C–N键和1 031 cm−1处的C–O–C键的峰值强度随溶胀温度的升高逐渐降低。这表明,随着溶胀温度的升高,CEP中C–N键和C–O–C键发生断裂。C–N键(305 kJ·mol−1)和C–O–C键(326 kJ·mol−1)的键能低于C–C键(332 kJ·mol−1)、Ph–O键(358 kJ·mol−1)、Ph–CH2Ph键(378.2 kJ·mol−1)和Ph–CH(CH3)2键(413.8 kJ·mol−1)[21]。因此,C–N键和C–O–C键容易先于其他化学键断裂,会引发树脂轻微降解现象。此外,醋酸还可以提供大量具有催化作用的水合氢离子,以增强对CEP的酸碱催化降解效果[21-22]。

-

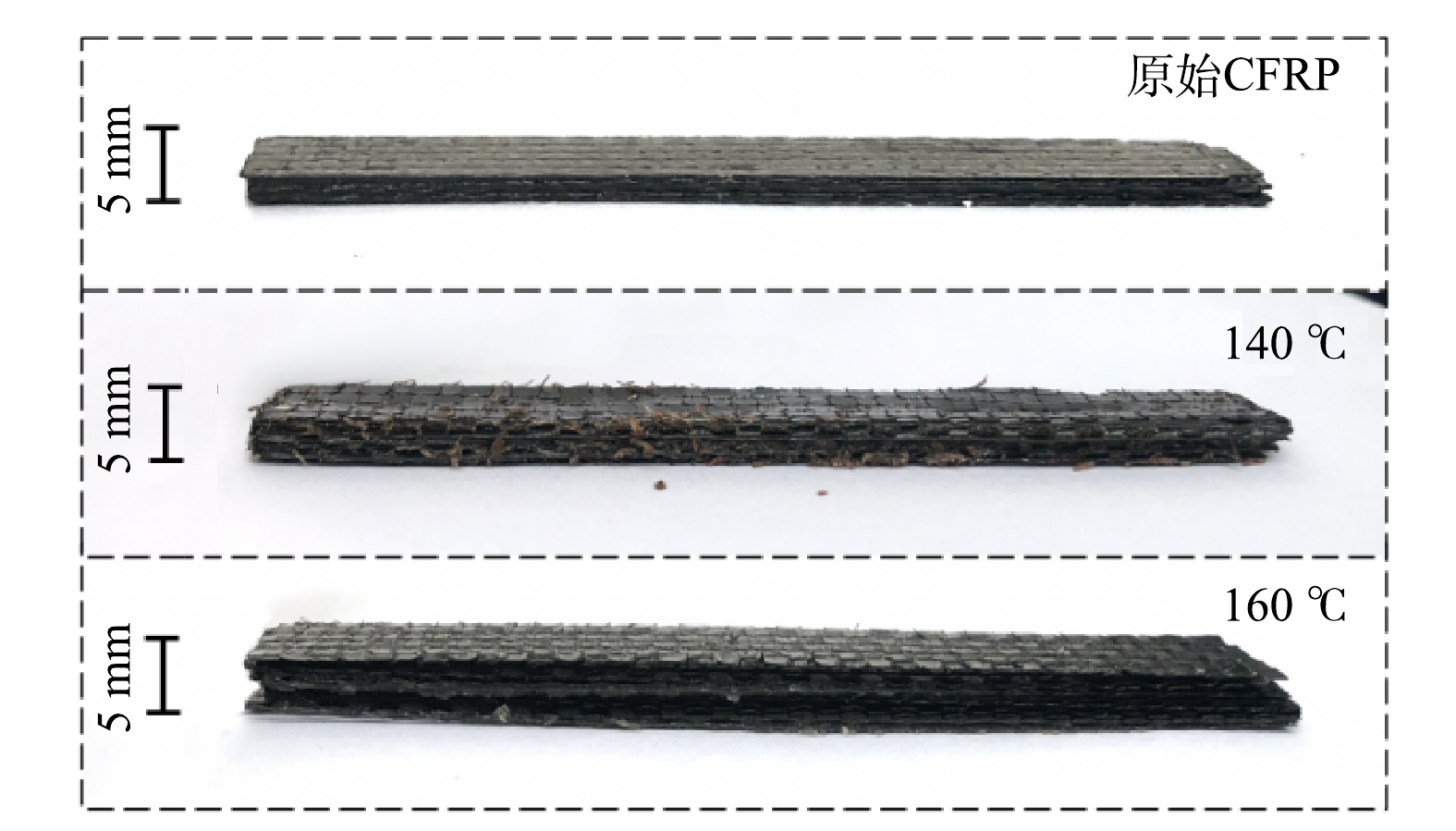

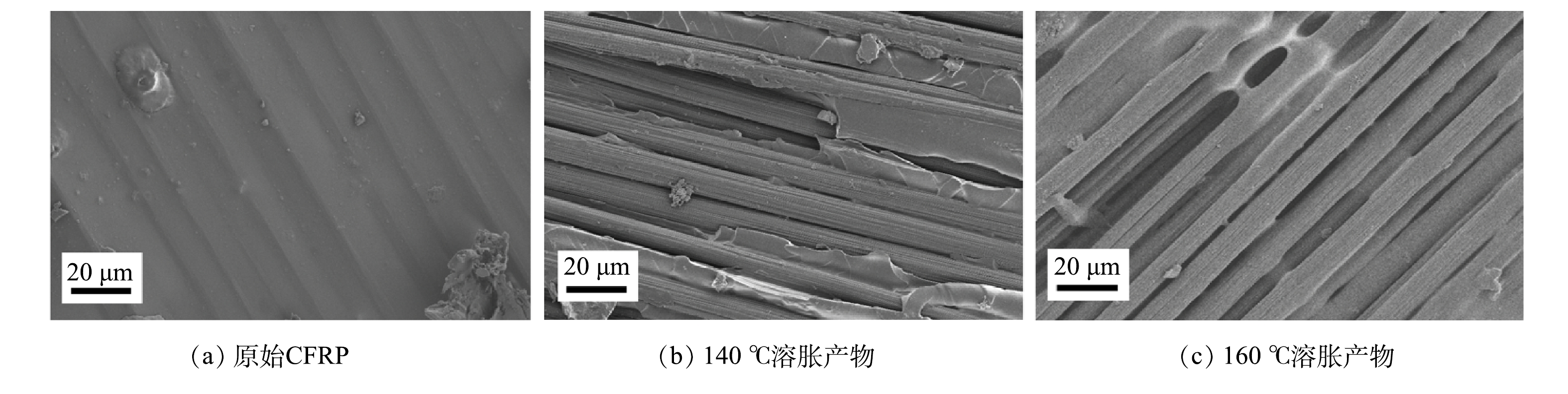

不同温度条件下溶胀产物厚度对比照片见图6。从图6中可以看出,随着溶胀温度的提升,导致溶胀产物厚度也随之增大。原始CFRP 板的厚度为0.20 cm左右。经140 ℃溶胀处理后,各碳纤维层之间的间隙逐渐变大,但各碳纤维层仍然粘连在一起,溶胀产物厚度增加到0.31 cm左右。经160 ℃溶胀处理后,各碳纤维层之间间隙进一步增大,各碳纤维层可以自动分离,溶胀产物的厚度增加到0.41 cm左右。

原始CFRP和不同温度下溶胀产物的SEM对比图见图7。从图7(a)可以看出,在原始CFRP表面光滑完整,CFRP中的碳纤维均被CEP紧密包裹。但是,当CFRP在140 ℃醋酸中溶胀处理1 h后,在图7(b)中可以观察到,部分长条状树脂从碳纤维之间的缝隙中断裂脱落。这可能是因为在溶胀过程中树脂体积剧烈膨胀,但是碳纤维热变形系数较低,故导致树脂和碳纤维之间的粘接力降低;同时,CEP的过度溶胀和轻微降解会导致树脂内部产生大量裂隙,甚至造成树脂碎裂。另外树脂降解现象可能会导致树脂间产生大量裂隙,从而加速醋酸在CEP内的扩散速度,最终实现CEP的快速溶胀。

-

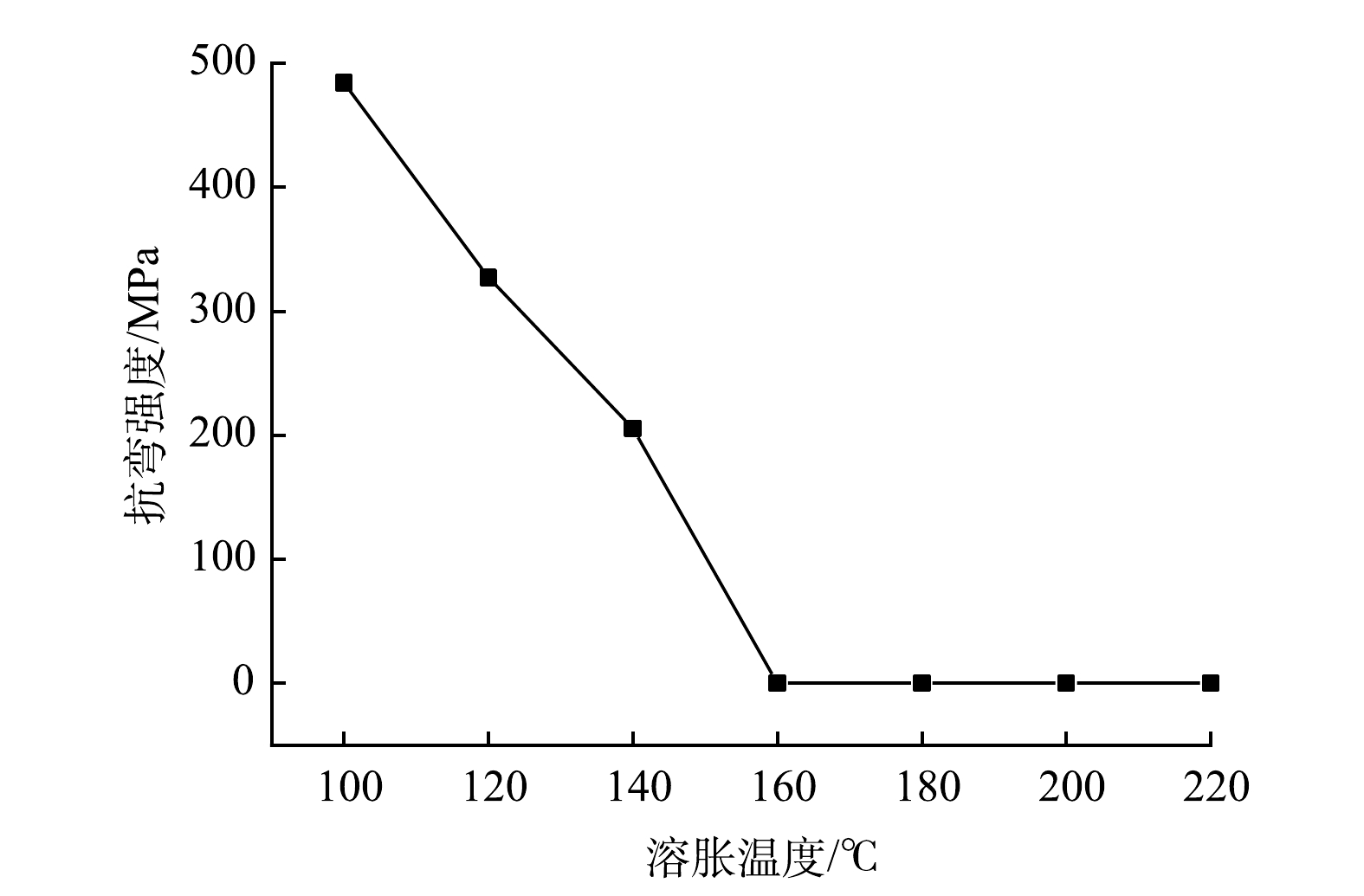

CFRP溶胀产物烘干后的抗弯强度见图8。溶胀产物在烘干过程中,醋酸会逐渐从溶胀树脂中挥发去除,CFRP溶胀产物会再次变硬。原始CFRP的抗弯强度为 604.61 MPa。当温度从100 ℃增加到140 ℃时,溶胀烘干产物抗弯强度从484.22 MPa降至205.57 MPa。WANG等[13]研究发现,醋酸溶胀体系(180 ℃,6 h)对再生碳纤维丝束的拉伸强度影响较小。造成CFRP产物抗弯强度下降的主要原因包括:1) CEP在溶胀和烘干过程中的过度膨胀和收缩导致CEP形成大量裂缝;2) CEP的过度膨胀和收缩致树脂和碳纤维之间的粘附力降低;3)在高温下,起基体作用的CEP发生部分降解。因此,烘干后的CFRP溶胀产物抗弯强度随着溶胀温度的增大不断降低。当溶胀温度≥160 ℃时,溶胀产物抗弯强度均低于设备检出限。

-

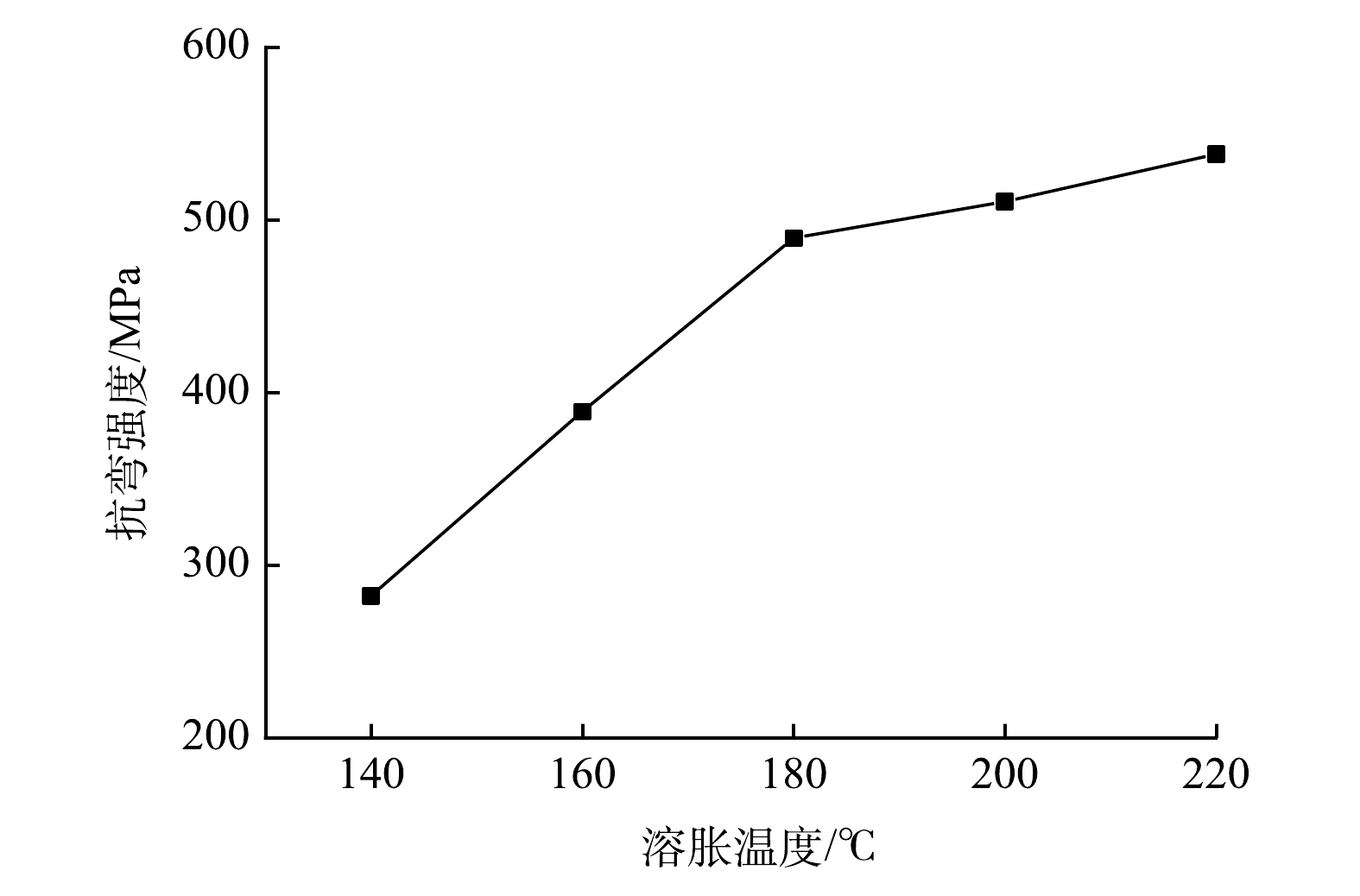

在100 ~120 ℃条件所得溶胀产物仍具备较高抗弯强度,难以通过机械裁切处理。故本研究主要利用在140 ~220 ℃,溶胀1 h条件下获得的溶胀产物制备新CFRP。剪切产物或分层产物可以重新添加环氧树脂经热压后固化在一起。经测试,分层产物的拉伸强度范围为734.67~745.07 MPa,为原始单层CFRP抗弯强度(759.05 MPa)的96.79%~98.16%。现阶段,所制备CFRP板材可用于一般承重需求,本研究主要对CFRP板材的抗弯强度进行分析。

利用不同温度条件下所得溶胀产物制备CFRP的抗弯强度见图9。利用140 ℃溶胀产物重新制备的CFRP抗弯强度仅为282.28 MPa,为原始CFRP抗弯强度的47%;160 ℃条件下溶胀产物重新制备的CFRP抗弯强度达到388.89 MPa,220 ℃条件下达到537.94 MPa,为原始CFRP的89%。在高温(160~220 ℃)条件下,CEP的溶胀率和降解率进一步增加,会导致CFRP中产生大量裂隙。新添加的液态环氧树脂可以通过这些裂缝渗透到分层产物内部,从而将剪切和分层产物有效粘接起来。但新添加的树脂会造成CFRP中碳纤维质量分数降低,碳纤维质量分数从原来60%降低到40.98%~48.08%。因此,新制备CFRP抗弯强度都较原始CFRP有一定程度的降低。

-

1)在温和醋酸溶胀体系中,CFRP中的固化环氧树脂会发生充分溶胀和轻微降解现象,从而导致原本坚硬脆性的CFRP发生软化和分层现象,易于机械裁切。

2)在140 ℃醋酸溶胀体系中溶胀处理1 h,废弃CFRP发生软化现象(溶胀率为78.88%,降解率为4.49%),在160~220 ℃下发生自动分层(溶胀率为101.54%~147.00%,降解率为9.08%~14.40%)。CEP的溶胀率和降解率随着温度的提升、溶胀时间的延长不断增大。

3) CEP的过度溶胀和轻微降解导致溶胀产物的抗弯强度随着温度的升高不断降低。新添加的环氧树脂能够渗透到溶胀产物的内部,弥补CEP的溶胀或降解所造成抗弯强度的损失。重新制备CFRP的抗弯强度能够达到原始CFRP的47%~89%。

醋酸溶胀回收废弃碳纤维增强聚合物基复合材料

Recycling of waste carbon fiber-reinforced polymer composite by acetic acid swelling method

-

摘要: 针对废弃碳纤维增强聚合物基复合材料(CFRP)在机械法回收过程中碳纤维长度和强度损失较高的难题,采用醋酸溶胀法改善CFRP机械加工性能,以降低碳纤维长度和强度损失,提高CFRP机械回收产物再利用价值。结果表明,CFRP中的固化环氧树脂(CEP)能够在醋酸介质中快速溶胀并发生轻微降解。CFRP在140 °C醋酸中浸泡1 h会发生软化现象(树脂溶胀率和降解率分别为78.88%和4.49%),当温度提升至160~220 °C后CFRP会发生分层现象(树脂溶胀率为101.54%~147.00%,降解率为9.08%~14.40%)。这些软化或分层产物易于被机械裁切成细条状、薄片状或其他各种形状。将烘干后的裁切产物或分层产物与适量未固化环氧树脂混合,采用热压法可重新制备CFRP。新制备的CFRP的抗弯强度可达到原始CFRP的47%~89%。本研究结果可为热固性环氧树脂复合材料绿色回收提供参考。Abstract: The losses of carbon fiber length and strength were high during the mechanical recycling process of the waste carbon fiber-reinforced polymer composite(CFRP). In response to this problem, acetic acid swelling method was used to improve the machinability of CFRP in order to reduce the losses of carbon fiber length and strength and improve the reuse value of CFRP mechanical recycled products. The results showed that cured epoxy resin (CEP) in CFRP could be fully swelled and slightly degraded in acetic acid medium. The stiff CFRP became soft in the acetic acid medium at 140 ℃ (swelling ratio and degradation ratio were 78.88% and 4.49%, respectively), and it delaminated into soft single CFRP layers at 160 ℃–220 ℃ within 1 h (swelling ratio and degradation ratio were 101.54%~147.00% and 9.08%~14.40%, respectively). Thus, the swollen CFRP can be easily cut into long strips, large thin slices, or other customized shapes while the length and strength of the carbon fibers were preserved well. The shear and delamination products (after drying) were mixed with uncured epoxy resin and prepared into new CFRP products through hot pressing method. The flexural strength of re-prepared CFRP boards can reach 47%~89% of the original CFRP board. This work can provide a green method for thermosetting composites recycling.

-

Key words:

- carbon fiber /

- cured epoxy resin /

- waste composites /

- resin swelling /

- resource utilization

-

-

[1] TANG S F, HU C L. Design, preparation and properties of carbon fiber reinforced ultra-high temperature ceramic composites for aerospace applications: a review[J]. Journal of Materials Science & Technology, 2017, 33(2): 117-130. [2] MACHADO J J M, GAMARRA P M R, MARQUES E A S, et al. Numerical study of the behaviour of composite mixed adhesive joints under impact strength for the automotive industry[J]. Composite Structures, 2018, 185: 373-380. doi: 10.1016/j.compstruct.2017.11.045 [3] ONWUDILI J A, MISKOLCZI N, NAGY T, et al. Recovery of glass fibre and carbon fibres from reinforced thermosets by batch pyrolysis and investigation of fibre re-using as reinforcement in LDPE matrix[J]. Composites Part B:Engineering, 2016, 91: 154-161. doi: 10.1016/j.compositesb.2016.01.055 [4] LONGANA M L, ONG N, YU H N, et al. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) method[J]. Composite Structures, 2016, 153: 271-277. doi: 10.1016/j.compstruct.2016.06.018 [5] 杜晓渊, 程小全, 王志勇, 等. 碳纤维复合材料回收与再利用技术进展[J]. 高分子材料科学与工程, 2020, 36(8): 182-190. [6] 马金焕. 胺类固化环氧树脂的解聚机理及CFRP回收技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2010. [7] ZHANG J, CHEVALI V S, WANG H, et al. Current status of carbon fibre and carbon fibre composites recycling[J]. Composites Part B:Engineering, 2020, 193: 108053. doi: 10.1016/j.compositesb.2020.108053 [8] MUSTATA F, TUDORACHI N. Curing kinetics and thermal characterization of epoxy resin cured with amidodicarboxylic acids[J]. Applied Thermal Engineering, 2017, 125: 285-296. doi: 10.1016/j.applthermaleng.2017.07.037 [9] KIM D H, LEE M, GOH M. Enhanced and eco-friendly recycling of carbon-fiber-reinforced plastics using water at ambient pressure[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(6): 2433-2440. [10] UHLMANN E, MEIER P. Carbon fibre recycling from milling dust for the application in short fibre reinforced thermoplastics[J]. Procedia CIRP, 2017, 66: 277-282. doi: 10.1016/j.procir.2017.03.277 [11] 金鑫, 隋刚, 杨小平. T700碳纤维/环氧树脂复合材料热降解实验研究[J]. 玻璃钢/复合材料, 2017(11): 56-61. [12] HOWARTH J, MAREDDY S S R, MATIVENGA P T. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite[J]. Journal of Cleaner Production, 2014, 81: 46-50. doi: 10.1016/j.jclepro.2014.06.023 [13] WANG Y Q, CUI X J, GE H, et al. Chemical recycling of carbon fiber reinforced epoxy resin composites via selective cleavage of the carbon–nitrogen bond[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(12): 3332-3337. [14] ZHU P, CHEN Y, WANG L Y, et al. A new technology for separation and recovery of materials from waste printed circuit boards by dissolving bromine epoxy resins using ionic liquid[J]. Journal of Hazardous Materials, 2012, 239-240: 270-278. doi: 10.1016/j.jhazmat.2012.08.071 [15] WATH S B, KATARIYA M N, SINGH S K, et al. Separation of WPCBs by dissolution of brominated epoxy resins using DMSO and NMP: a comparative study[J]. Chemical Engineering Journal, 2015, 280: 391-398. doi: 10.1016/j.cej.2015.06.007 [16] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449-2005[S]. 北京: 中国标准出版社, 2005. [17] VERMA H R, SINGH K K, MANKHAND T R. Dissolution and separation of brominated epoxy resin of waste printed circuit boards by using di-methyl formamide[J]. Journal of Cleaner Production, 2016, 139: 586-596. doi: 10.1016/j.jclepro.2016.08.084 [18] BATRA D, HAY D N T, FIRESTONE M A. Formation of a biomimetic, liquid-crystalline hydrogel by self-assembly and polymerization of an ionic liquid[J]. Chemistry of Materials, 2007, 19(18): 4423-4431. doi: 10.1021/cm062992z [19] HANSEN C M. Hansen solubility parameters: a user’s handbook[M]. Boca Raton, FL: CRC Press, 2007. [20] VERMA H R, SINGH K K, MANKHAND T R. Comparative study of printed circuit board recycling by cracking of internal layers using organic solvents-dimethylformamide and dimethylacetamide[J]. Journal of Cleaner Production, 2017, 142: 1721-1727. doi: 10.1016/j.jclepro.2016.11.118 [21] YIN J, LI G M, HE W Z, et al. Hydrothermal decomposition of brominated epoxy resin in waste printed circuit boards[J]. Journal of Analytical and Applied Pyrolysis, 2011, 92(1): 131-136. doi: 10.1016/j.jaap.2011.05.005 [22] XING M F, LI Y, ZHAO L, et al. Swelling-enhanced catalytic degradation of brominated epoxy resin in waste printed circuit boards by subcritical acetic acid under mild conditions[J]. Waste Management, 2020, 102: 464-473. doi: 10.1016/j.wasman.2019.11.011 -

下载:

下载: