-

我国生活垃圾的年产量逐渐增加。根据国家统计年鉴数据[1],我国生活垃圾的年产量从2015年的1.91×108 t增长到2020年的2.35×108 t。目前,生活垃圾的处理方式主要有填埋和焚烧2种。其中,焚烧法具有降低垃圾体积、消灭病原体、分解有害物质和回收能量等优势,是生活垃圾的重要处理方式[2]。但在垃圾焚烧过程中,垃圾中的重金属在炉膛中挥发,然后富集到飞灰中[3]。因此,垃圾焚烧飞灰被归类为危险废物,随着垃圾焚烧技术的推广应用,其处理处置已经引起了广泛关注。

目前,垃圾焚烧飞灰的处理方法主要有填埋[4]、水泥固化[5]、螯合剂稳定[2]、烧结[6]、熔融[7]等。其中,通过高温热处理法将垃圾焚烧飞灰转化成高附加值的微晶玻璃,既可以实现其无害化处理,又可制备高附加值产品,被认为是一种比较有潜力的方法。目前,利用垃圾焚烧飞灰制备微晶玻璃主要以纯化学试剂或自然资源作为辅料对垃圾焚烧飞灰进行成分调控,并引入一定量的晶核剂来促进结晶最后得到微晶玻璃产品。李保庆等[8]以垃圾焚烧飞灰和废玻璃为主要原料,以SiO2、Na2CO3、CaO、Al2O3、MgO为辅助原料制备了微晶玻璃。当烧结温度为1 030 °C时,微晶玻璃的机械性能最优,其密度为2.81 g∙cm−3、抗弯强度为83.78 MPa、显微硬度为7.40 GPa。PONSOT等[9]利用垃圾焚烧飞灰、粉煤灰、煤脱硫渣、硅溶胶、废玻璃和高岭土为原料制备微晶玻璃,混合原料在1 050 ℃下直接烧结后得到的微晶玻璃具有最优的物理机械性能,其密度为1.80 g∙cm−3,抗弯强度为(38.20±5.40)MPa。刘汉桥等[10]将垃圾焚烧飞灰和废玻璃以3∶1的比例混合并引入3%晶核剂TiO2,通过熔融烧结法制备了微晶玻璃,在850 ℃下烧结得到性能最优的微晶玻璃,其密度为2.62 g∙cm−3,抗弯强度为90.44 MPa,耐酸碱性分别为97.30%、99.10%。在上述的研究中,虽然制得的微晶玻璃具有优良的物理化学性能,但是纯化学试剂和晶核剂的使用提高了废物基微晶玻璃的成本。而利用具有成分互补特点的固体废弃物作为配料,实现全废物基飞灰微晶玻璃的研究少有报道。

在CaO-Al2O3-SiO2微晶玻璃系统中,SiO2是主要的玻璃网络形成氧化物,能增强玻璃网络的连接程度。CaO是主要的玻璃网络外体氧化物,可以提供游离氧,打破玻璃网络结构,促进玻璃的析晶,与SiO2的作用相反。吴春丽等[11]研究了CaO/SiO2比对不锈钢渣CaO-Al2O3-SiO2微晶玻璃性能的影响。结果表明,微晶玻璃的主晶相为硅灰石,性能在CaO/SiO2比为0.72时达到最优,其密度为3.11 g∙cm−3,显微硬度为6.49 GPa,吸水率为0.11%,耐酸性为96.51%,耐碱性为99.02%。汪振双等[12]研究了CaO/SiO2比对粉煤灰CaO-Al2O3-SiO2微晶玻璃性能的影响。微晶玻璃的主晶相为副硅灰石,次晶相为钙长石,当CaO/SiO2比为0.33时,微晶玻璃性能最优,其密度为2.87 g∙cm−3,抗压强度为105.28 MPa,抗弯强度为45.62 MPa。张雪峰等[13]研究了CaO/SiO2比对复合尾矿微晶玻璃性能的影响。结果表明,微晶玻璃的主晶相为普通辉石相,CaO/SiO2比的减小对样品力学性能和密度的影响不大,当CaO/SiO2比等于0.32时,微晶玻璃的性能最优,其抗折强度为169.20 MPa,密度为2.92 g∙cm−3,耐酸碱性分别为95.00%和98.00%。由此可见,碱度对不同固体废物基微晶玻璃性能的作用机制并不相同。因此,研究碱度对全废物基微晶玻璃性能的影响很有必要。

因此,本研究以垃圾焚烧飞灰为主原料,优势配伍具有成分互补特点的粉煤灰和废玻璃作为辅料,通过熔融烧结法制备了CaO-Al2O3-SiO2系统微晶玻璃。对不同碱度基础玻璃的析晶动力学和析晶机理进行了分析,并且研究了碱度和烧结温度对垃圾焚烧飞灰基微晶玻璃的晶相转变、机械物理性能、微观结构以及重金属浸出毒性的影响

-

垃圾焚烧飞灰(FA)、粉煤灰(CFA)和废玻璃(WG)分别取自天津某垃圾焚烧发电厂、火力发电厂和废玻璃回收站。采用X射线荧光分析仪(ZSX Primus 2型,日本理学公司)测定了原料的化学成分,如表1所示。

-

将垃圾焚烧飞灰、废玻璃和粉煤灰以3种比例混合(混合比例如表2所示),放入行星式球磨机中研磨20 min以保证混合均匀,得到3个比例的配料分别标记为GC1、GC2和GC3(化学成分如表2所示)。将不同原料放入刚玉坩埚,在高温马弗炉中以10 ℃∙min−1的升温速率加热至1 500 ℃并保温2 h,然后将其迅速取出,倒入循环冷水中得到基础玻璃。随后将基础玻璃破碎、研磨、过筛,得到基础玻璃粉末。在烧结阶段,每次取约3 g基础玻璃粉末,放入不锈钢模具中,在5 MPa压力下保持时间30 s,将其压制成直径为20 mm,厚度为5 mm的微晶玻璃,然后放入马弗炉中以5 ℃∙min−1的升温速率加热至850~1 050 ℃,温度梯度为50 ℃,待炉子自然冷却至室温得到全废物基微晶玻璃。

-

利用TG-DSC分析仪(SDT/Q600型,美国TA仪器)对基础玻璃的结晶行为和析晶动力学参数进行了测定;采用X射线衍射仪(Rigaku Smartlab 型,日本株式会社理学)测试了微晶玻璃粉末的X射线衍射图像;根据阿基米德法测得了微晶玻璃的密度;根据《陶瓷砖试验方法 第3部分:吸水率、显气孔率、表观相对密度和容重的测定》(GB/T 3810.3-2016)测得了微晶玻璃的吸水率;使用电子万能试验机(WDW-200型,长春科新试验仪器有限公司)测量微晶玻璃的抗压强度;使用显微硬度计(HMV-2T型,日本岛津公司)测得了微晶玻璃的显微硬度;采用电子扫描电镜(S4800型,日本日立公司)拍得微晶玻璃表面的SEM照片;根据毒性特征浸出程序(TCLP)制备了微晶玻璃的浸出液,利用电感耦合等离子体质谱仪(PerkinElmer NexION 300X型,美国赛默飞公司)测定了微晶玻璃的重金属浸出浓度。

-

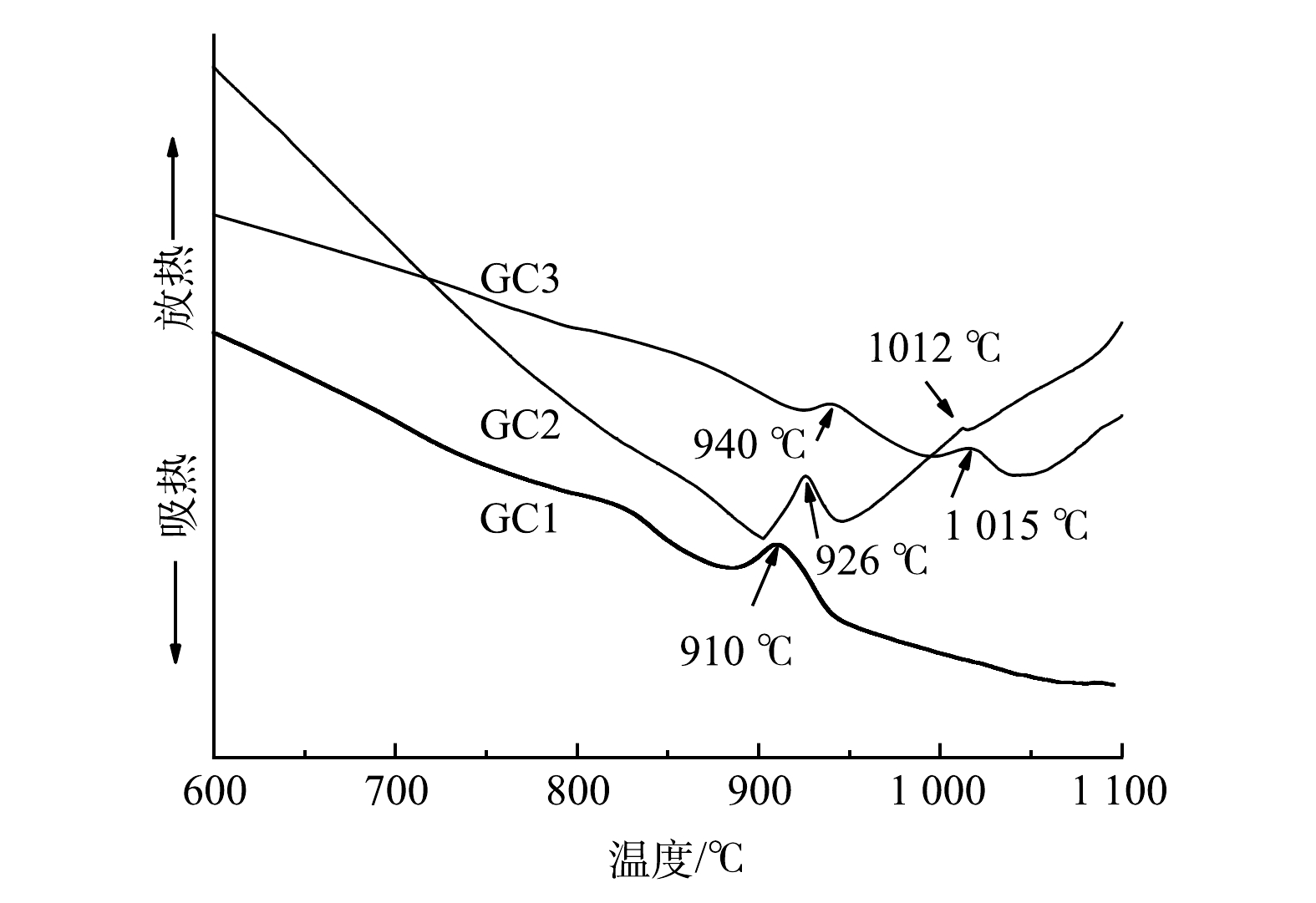

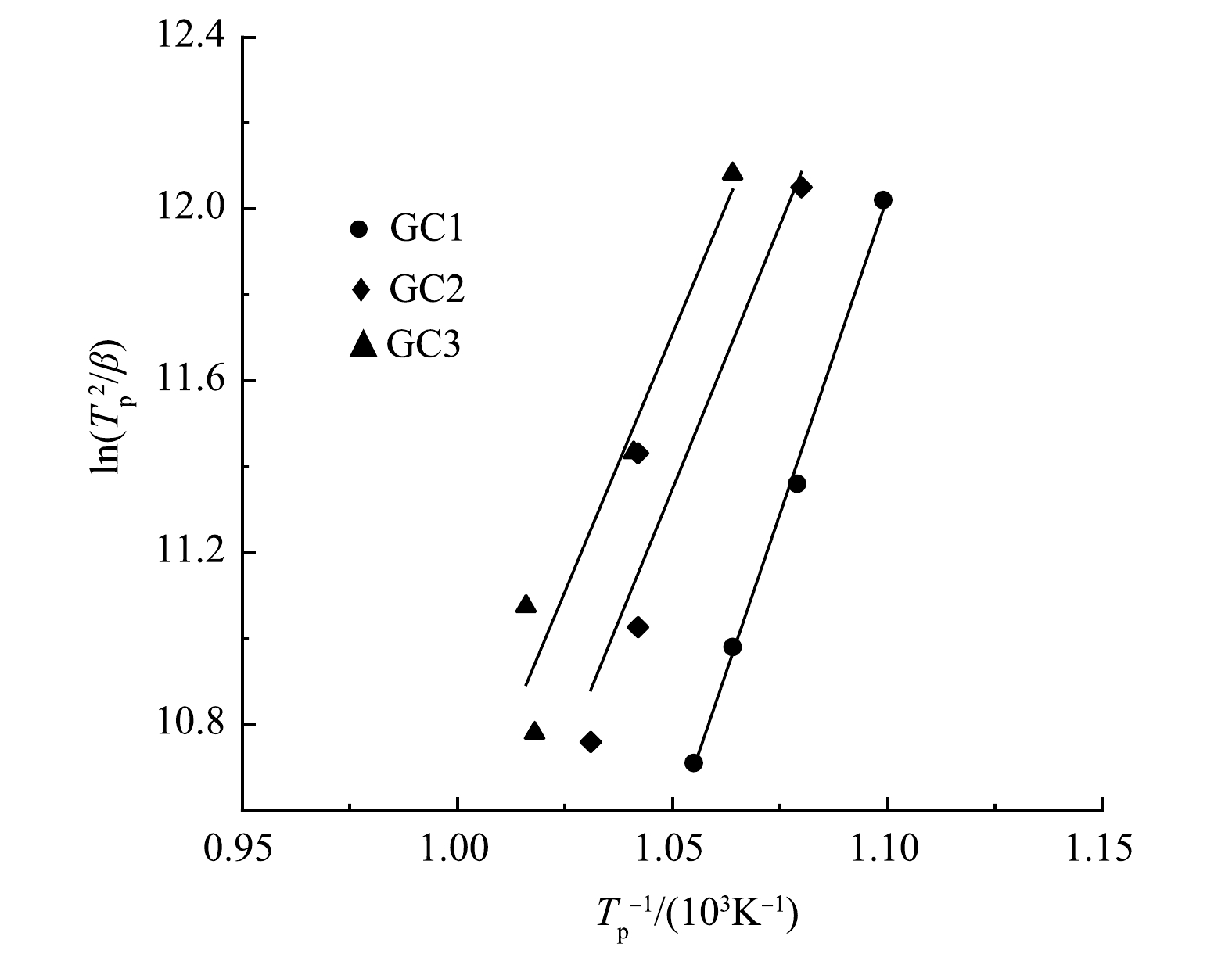

GC1-GC3基础玻璃的差热分析曲线如图1所示。GC1-GC3基础玻璃的结晶峰温度(Tp)分别为910、926、940 °C,随碱度的升高而逐渐升高。一般来说,CaO能够提供游离氧,破坏Si-O-Si玻璃网络结构,促进晶体的析出。但是过多的CaO会使基础玻璃在非析晶阶段析出细小晶粒,使基础玻璃的黏度增加从而抑制晶体析出[11]。与此同时,随着碱度的增加,GC2基础玻璃在第一个结晶峰后继续呈现出放热倾向,GC3基础玻璃在1 000~1 050 ℃之间出现了第2个结晶峰,说明了碱度的增加提高了基础玻璃在高温阶段的结晶倾向。不同碱度基础玻璃的ln(Tp2/β)和 Tp−1×103的线性拟合如图2所示。基础玻璃的活化能Ec和Avrami指数n分别根据Kissinger公式(1)和Augis–Bennett公式(2)计算得到,如表3所示。可以看出结晶活化能Ec在199.49~245.10 kJ∙mol−1之间且随着碱度的增加而降低,与DSC分析的结果一致。所有基础玻璃的Avrami指数n都大于3 且接近于 4,这说明结晶行为属于三维整体结晶[14]。

式中:β为升温速率,℃∙min−1;Tp为该升温速率下对应的结晶峰温度,℃; Ec为基础玻璃的结晶活化能,kJ∙mol−1;R为气体常数,其值为8.314 J∙(mol∙K)−1; ν为频率因子;n为Avrami指数;ΔT为结晶峰的半峰宽,℃。

-

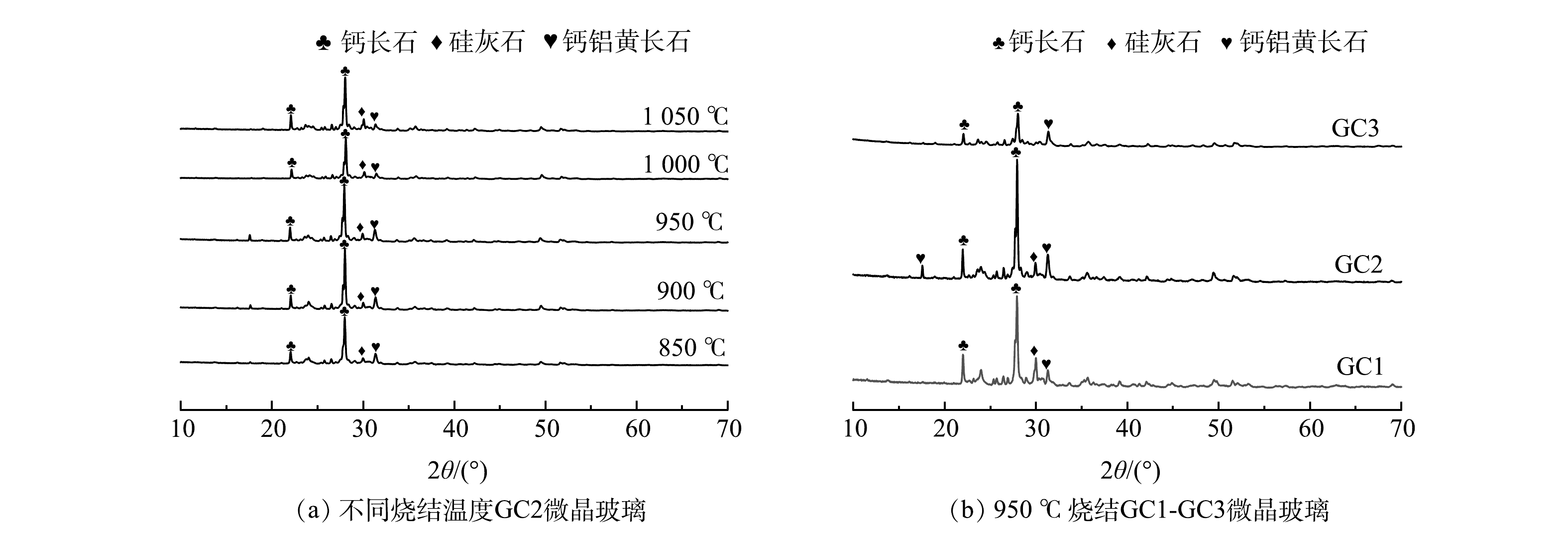

图3(a)为不同烧结温度下GC2微晶玻璃的XRD图谱。从图3(a)中可以看出,不同烧结温度下微晶玻璃的主晶相为钙长石(Anorthite, CaAl2Si2O8, PDF#041-1486),次晶相为硅灰石(Wollastonite, CaSiO3, PDF#043-1460)和钙铝黄长石(Gehlenite, Ca2Al2SiO7, PDF#035-0755)。随着烧结温度的升高,微晶玻璃中晶相的种类没有改变。钙长石的衍射强度随烧结温度的提高在总体上呈现出上升的趋势,但在1 000 ℃时略有下降。硅灰石的衍射强度随烧结温度逐渐升高,但钙铝黄长石的衍射强度却逐渐降低。这是由于主晶相钙长石中Al含量较高, 钙长石的析出使玻璃基体中Al含量降低,因此抑制了钙铝黄长石的析出而促进了不含Al的硅灰石的析出。

不同碱度微晶玻璃的XRD图谱如图3(b)所示。可以看出,GC1和GC2微晶玻璃中主晶相为钙长石,次晶相为硅灰石和钙铝黄长石。随着碱度的升高,钙长石和钙铝黄长石的衍射强度升高而硅灰石的衍射强度降低。根据表2中的结果,GC2微晶玻璃中的CaO和Al2O3含量高于GC1微晶玻璃,因此有利于钙长石和钙铝黄长石的析出。在GC3微晶玻璃中主晶相为钠长石,次晶相仅有钙铝黄长石,且各晶相的衍射强度明显降低,说明微晶玻璃中的晶体含量较低,与DSC结果一致。

-

在不同烧结温度下得到的GC2微晶玻璃的密度和吸水率如图4(a)所示。从图4(a)中可以看出,当烧结温度在850~950 ℃内时,密度随烧结温度的升高而增加,这是由于析晶是原子有序化排列的过程,晶体的析出使原子之间的排列更加紧密,因此晶体的析出有助于微晶玻璃的密度的提高。当烧结温度为1 000 ℃时,密度有所下降,这是由于晶体的生长挤压了周围的玻璃基体,从而产生细小裂缝,使微晶玻璃的密度下降。继续提高烧结温度,玻璃基体的黏度下降,与晶体之间的结合更加紧密,使密度再次增加[15]。不同碱度微晶玻璃的密度和吸水率如图4(b)所示。随着碱度的升高,密度先增加然后降低。这是由于CaO含量的提高促进了晶体的析出,导致了密度的升高。根据DSC和XRD结果可知,GC3微晶玻璃中的晶体含量较少,因此具有较低的密度。从图4(a)和(b)中可以看出,所有微晶玻璃样品都具有极低的吸水率,其值在0.05%~0.11%之间。

GC2微晶玻璃的抗压强度和显微维氏硬度随烧结温度的变化如图4(c)所示。抗压强度随着烧结温度的升高从195.75 MPa上升至501.09 MPa,在总体上呈现上升趋势。这是因为,晶体的析出有利于提高抗压强度,烧结温度的升高使基础玻璃的黏度下降,原子的迁移和重排加速,促进了晶体的析出,从而使抗压强度升高[16]。但值得注意的是,GC2微晶玻璃的抗压强度在1 000 ℃时急剧下降, 这是由于晶体的大量析出而玻璃基体的黏度较高使微晶玻璃内部产生了较高的应力,从而降低了抗压强度。从图4(c)中可以看出GC2微晶玻璃的显微维氏硬度随着烧结温度的提高逐渐降低。维氏显微硬度的影响因素主要有2个:晶体的类型和晶体粒径的大小。根据图3中XRD结果可知,烧结温度并未改变微晶玻璃中的晶体种类,而对晶体粒径的影响较大,因此晶体粒径的大小是影响微晶玻璃显微维氏硬度的主要因素。在微晶玻璃中,晶体与晶体和晶体与玻璃基体之间存在细小的裂缝,是微晶玻璃中力学性能最低的区域,晶体的生长会使裂缝变长,缩短了裂缝扩展的迂回长度,因此导致了显微维氏硬度的降低[17]。

在950 °C下烧结得到的具有不同碱度微晶玻璃的抗压强度如图4(d)所示。可以看出当碱度从0.48增加至0.56时,抗压强度从277.66 MPa增加至545.35 MPa。这是因为,CaO含量的升高促进了晶体析出导致了抗压强度的升高。但当碱度增加至0.70时,抗压强度降低至488.46 MPa。这是由于过高的CaO含量抑制了晶体的析出,导致GC3微晶玻璃的结晶度变低,因此造成了抗压强度的下降。随着碱度的上升,微晶玻璃的显微维氏硬度先下降然后增加,这是由于碱度的提高促进了晶体的析出,因此GC2微晶玻璃比GC1微晶玻璃具有更高的结晶度,导致了显微维氏硬度的降低[18]。而GC3微晶玻璃中只有少量的晶体析出,其中均匀致密的玻璃相较多,破裂所需要的迂回长度加长,而且并未检测到其中存在硅灰石,因此其显微硬度高于GC1微晶玻璃和GC2微晶玻璃。

-

不同烧结温度下GC2微晶玻璃的SEM照片如图5(a)~5(e)所示。在GC2微晶玻璃表面可以观察到颗粒状的晶体。当烧结温度为850 ℃时,少量的颗粒状晶体分布在玻璃基体上。随着烧结温度的升高,晶粒的粒径逐渐变大且数量逐渐增加。当烧结温度为1 000 ℃时,颗粒状晶体布满整个微晶玻璃表面并挤压在一起。当烧结温度为1 050 ℃时,微晶玻璃表面变得光滑致密,说明高温使玻璃相黏度的降低,增加了晶粒与玻璃相之间的结合,与抗压强度和显微维氏硬度的结果一致。

在950 ℃下烧结得到的GC1-GC3微晶玻璃的SEM照片分别如图5(f)、5(c)、5(g)所示。GC1-GC3微晶玻璃表面同样分布着颗粒状晶体。经过腐蚀后,GC1微晶玻璃表面仍存在一层玻璃相,随着碱度的升高,残余玻璃相的含量逐渐下降,这是由玻璃网络形成体SiO2含量降低导致的。而在GC3微晶玻璃表面主要是玻璃相,只有少量晶体存在。

-

由于垃圾焚烧飞灰中含有重金属,因此由其衍生的微晶玻璃产品的重金属浸出浓度是评价其安全性的重要指标。本研究选择TCLP浸出毒性测试方法,对Cr、Cd、Cu、Ni、Pb、Zn进行浸出毒性测试。所有微晶玻璃的重金属浸出浓度如表4 所示。可以看出,在所有的微晶玻璃样品中均未检测到Cr和Cu的浸出,Zn的浸出浓度在GC2-850 ℃微晶玻璃中检测出,仅为0.01 mg∙L−1。同时,Cd和Pb的浸出浓度分别在2.36~2.75 mg∙L−1和0.41~1.43 mg∙L−1,均远低于美国固体废物毒性特征浸出程序TCLP和中国国家标准《危险废物鉴别标准 浸出毒性鉴别》(GB 5085.3–2007)规定的重金属浸出浓度阈值。这表明了微晶玻璃具有较低的重金属浸出毒性。因此,通过熔融烧结法将垃圾焚烧飞灰转化为无毒无害的微晶玻璃产品是一个安全可行的方法。

-

1)碱度的增加虽然没有降低基础玻璃的结晶峰温度,但提高了基础玻璃在高温阶段的析晶倾向。所有基础玻璃的析晶方式为三维整体结晶。

2)抗压强度在总体上随烧结温度和碱度的升高而升高。但当烧结温度为1 000 ℃时,抗压强度急剧下降。显微维氏硬度随烧结温度的升高而降低但随碱度的升高而增加。

3)毒性浸出测试结果表明,所制得的微晶玻璃中典型6种重金属浓度远低于美国固体废物毒性特征浸出程序TCLP和中国国家标准《危险废物鉴别标准 浸出毒性鉴别》GB 5085.3–2007规定的重金属浸出浓度阈值,产品对环境无潜在风险。

利用生活垃圾焚烧飞灰制备全废物基微晶玻璃

Preparation of entirely waste-based glass-ceramics from municipal solid waste incineration fly ash

-

摘要: 生活垃圾焚烧飞灰被划定为危险废物,随着垃圾焚烧发电技术的推广应用,其处理处置引起了广泛关注。以垃圾焚烧飞灰为主原料,通过优势配伍粉煤灰和废玻璃,制备了全废物基CaO-Al2O3-SiO2系统微晶玻璃。重点研究了烧结温度与碱度(CaO/SiO2)对微晶玻璃的晶相演变、机械物理性能和微观结构的影响,以及不同微晶玻璃的析晶机理。结果表明,当碱度在0.48-0.70时,基础玻璃的结晶方式都为三维整体结晶,但碱度的升高可以降低基础玻璃的结晶活化能。所有微晶玻璃中的晶相为钠长石、硅灰石和钙铝黄长石,不受烧结温度和碱度变化的影响。当碱度为0.56(GC2)时,抗压强度随烧结温度的升高在总体上呈现增加的趋势,但显微维氏硬度却逐渐降低。随着碱度的增加,抗压强度先增加然后降低,当碱度为0.56时,最大值为553.77 MPa,显微维氏硬度逐渐升高,当碱度为0.70时,其最大值为5.89 GPa。此外,典型重金属的毒性浸出测试结果表明,微晶玻璃的重金属浸出浓度远低于规定的浸出阈值,对环境无潜在风险。该研究结果可为垃圾焚烧飞灰资源化利用提供参考。Abstract: Municipal solid waste incineration fly ash was categorized as hazardous waste and its management had drawn widespread attention with the promotion and application of waste-to-energy technology. An entirely waste-based glass-ceramic of CaO-Al2O3-SiO2 system was synthesized from municipal solid waste incineration fly ash, coal fly ash and waste glass. The effect of sintering temperature and basicity (CaO/SiO2) on the crystal phase transition, physical-mechanical performance and microstructure of the glass-ceramics and the crystallization kinetic of parent glasses were investigated. The results indicated that all the parent glass exhibited three-dimensional bulk crystallization when basicity was in range of 0.48-0.70, the increase of basicity decreased the crystallization activation energy of parent glass. The coexisting crystal phases in the glass-ceramics were anorthite, wollastonite and gehlenite and the type of crystal phases was not affected by sintering temperature and basicity. When basicity was 0.56 (GC2), the compressive strength increased in general with the increase of sintering temperature but the microhardness exhibited the opposite trend. With the increase of basicity, the compressive strength increased firstly and then decreased, its maximum value was 553.77 MPa when basicity was 0.56, the microhardness increased and its maximum value was 5.89 GPa when basicity was 0.70. In addition, the toxic leaching test results of typical heavy metals showed that the leaching concentrations of heavy metals in glass-ceramics were far below limitation and there was no potential risk to the environment. The results of this study can provide theoretical and data support for the resource utilization of municipal solid waste incineration fly ash.

-

我国生活垃圾的年产量逐渐增加。根据国家统计年鉴数据[1],我国生活垃圾的年产量从2015年的1.91×108 t增长到2020年的2.35×108 t。目前,生活垃圾的处理方式主要有填埋和焚烧2种。其中,焚烧法具有降低垃圾体积、消灭病原体、分解有害物质和回收能量等优势,是生活垃圾的重要处理方式[2]。但在垃圾焚烧过程中,垃圾中的重金属在炉膛中挥发,然后富集到飞灰中[3]。因此,垃圾焚烧飞灰被归类为危险废物,随着垃圾焚烧技术的推广应用,其处理处置已经引起了广泛关注。

目前,垃圾焚烧飞灰的处理方法主要有填埋[4]、水泥固化[5]、螯合剂稳定[2]、烧结[6]、熔融[7]等。其中,通过高温热处理法将垃圾焚烧飞灰转化成高附加值的微晶玻璃,既可以实现其无害化处理,又可制备高附加值产品,被认为是一种比较有潜力的方法。目前,利用垃圾焚烧飞灰制备微晶玻璃主要以纯化学试剂或自然资源作为辅料对垃圾焚烧飞灰进行成分调控,并引入一定量的晶核剂来促进结晶最后得到微晶玻璃产品。李保庆等[8]以垃圾焚烧飞灰和废玻璃为主要原料,以SiO2、Na2CO3、CaO、Al2O3、MgO为辅助原料制备了微晶玻璃。当烧结温度为1 030 °C时,微晶玻璃的机械性能最优,其密度为2.81 g∙cm−3、抗弯强度为83.78 MPa、显微硬度为7.40 GPa。PONSOT等[9]利用垃圾焚烧飞灰、粉煤灰、煤脱硫渣、硅溶胶、废玻璃和高岭土为原料制备微晶玻璃,混合原料在1 050 ℃下直接烧结后得到的微晶玻璃具有最优的物理机械性能,其密度为1.80 g∙cm−3,抗弯强度为(38.20±5.40)MPa。刘汉桥等[10]将垃圾焚烧飞灰和废玻璃以3∶1的比例混合并引入3%晶核剂TiO2,通过熔融烧结法制备了微晶玻璃,在850 ℃下烧结得到性能最优的微晶玻璃,其密度为2.62 g∙cm−3,抗弯强度为90.44 MPa,耐酸碱性分别为97.30%、99.10%。在上述的研究中,虽然制得的微晶玻璃具有优良的物理化学性能,但是纯化学试剂和晶核剂的使用提高了废物基微晶玻璃的成本。而利用具有成分互补特点的固体废弃物作为配料,实现全废物基飞灰微晶玻璃的研究少有报道。

在CaO-Al2O3-SiO2微晶玻璃系统中,SiO2是主要的玻璃网络形成氧化物,能增强玻璃网络的连接程度。CaO是主要的玻璃网络外体氧化物,可以提供游离氧,打破玻璃网络结构,促进玻璃的析晶,与SiO2的作用相反。吴春丽等[11]研究了CaO/SiO2比对不锈钢渣CaO-Al2O3-SiO2微晶玻璃性能的影响。结果表明,微晶玻璃的主晶相为硅灰石,性能在CaO/SiO2比为0.72时达到最优,其密度为3.11 g∙cm−3,显微硬度为6.49 GPa,吸水率为0.11%,耐酸性为96.51%,耐碱性为99.02%。汪振双等[12]研究了CaO/SiO2比对粉煤灰CaO-Al2O3-SiO2微晶玻璃性能的影响。微晶玻璃的主晶相为副硅灰石,次晶相为钙长石,当CaO/SiO2比为0.33时,微晶玻璃性能最优,其密度为2.87 g∙cm−3,抗压强度为105.28 MPa,抗弯强度为45.62 MPa。张雪峰等[13]研究了CaO/SiO2比对复合尾矿微晶玻璃性能的影响。结果表明,微晶玻璃的主晶相为普通辉石相,CaO/SiO2比的减小对样品力学性能和密度的影响不大,当CaO/SiO2比等于0.32时,微晶玻璃的性能最优,其抗折强度为169.20 MPa,密度为2.92 g∙cm−3,耐酸碱性分别为95.00%和98.00%。由此可见,碱度对不同固体废物基微晶玻璃性能的作用机制并不相同。因此,研究碱度对全废物基微晶玻璃性能的影响很有必要。

因此,本研究以垃圾焚烧飞灰为主原料,优势配伍具有成分互补特点的粉煤灰和废玻璃作为辅料,通过熔融烧结法制备了CaO-Al2O3-SiO2系统微晶玻璃。对不同碱度基础玻璃的析晶动力学和析晶机理进行了分析,并且研究了碱度和烧结温度对垃圾焚烧飞灰基微晶玻璃的晶相转变、机械物理性能、微观结构以及重金属浸出毒性的影响

1. 材料与方法

1.1 实验原料

垃圾焚烧飞灰(FA)、粉煤灰(CFA)和废玻璃(WG)分别取自天津某垃圾焚烧发电厂、火力发电厂和废玻璃回收站。采用X射线荧光分析仪(ZSX Primus 2型,日本理学公司)测定了原料的化学成分,如表1所示。

表 1 原材料的化学成分Table 1. Chemical compositions of raw materials% 供试样品 CaO SiO2 Al2O3 MgO Na2O Cl SO3 其他 垃圾焚烧飞灰 42.80 1.92 0.54 0.82 12.10 24.5 7.43 9.89 粉煤灰 2.45 51.10 37.30 0.67 0.21 0.06 0.68 7.53 废玻璃 10.4 69.20 1.44 3.79 12.90 0.08 0.35 1.84 1.2 微晶玻璃制备

将垃圾焚烧飞灰、废玻璃和粉煤灰以3种比例混合(混合比例如表2所示),放入行星式球磨机中研磨20 min以保证混合均匀,得到3个比例的配料分别标记为GC1、GC2和GC3(化学成分如表2所示)。将不同原料放入刚玉坩埚,在高温马弗炉中以10 ℃∙min−1的升温速率加热至1 500 ℃并保温2 h,然后将其迅速取出,倒入循环冷水中得到基础玻璃。随后将基础玻璃破碎、研磨、过筛,得到基础玻璃粉末。在烧结阶段,每次取约3 g基础玻璃粉末,放入不锈钢模具中,在5 MPa压力下保持时间30 s,将其压制成直径为20 mm,厚度为5 mm的微晶玻璃,然后放入马弗炉中以5 ℃∙min−1的升温速率加热至850~1 050 ℃,温度梯度为50 ℃,待炉子自然冷却至室温得到全废物基微晶玻璃。

表 2 不同混合比例原料的化学成分Table 2. Chemical compositions of raw materials under various mixing ratios% 样品编号 CaO SiO2 Al2O3 MgO Na2O GC1 18.96 39.32 13.68 1.66 8.18 GC2 20.18 35.05 15.42 1.35 7.50 GC3 21.40 30.78 17.17 1.05 6.83 1.3 微晶玻璃表征

利用TG-DSC分析仪(SDT/Q600型,美国TA仪器)对基础玻璃的结晶行为和析晶动力学参数进行了测定;采用X射线衍射仪(Rigaku Smartlab 型,日本株式会社理学)测试了微晶玻璃粉末的X射线衍射图像;根据阿基米德法测得了微晶玻璃的密度;根据《陶瓷砖试验方法 第3部分:吸水率、显气孔率、表观相对密度和容重的测定》(GB/T 3810.3-2016)测得了微晶玻璃的吸水率;使用电子万能试验机(WDW-200型,长春科新试验仪器有限公司)测量微晶玻璃的抗压强度;使用显微硬度计(HMV-2T型,日本岛津公司)测得了微晶玻璃的显微硬度;采用电子扫描电镜(S4800型,日本日立公司)拍得微晶玻璃表面的SEM照片;根据毒性特征浸出程序(TCLP)制备了微晶玻璃的浸出液,利用电感耦合等离子体质谱仪(PerkinElmer NexION 300X型,美国赛默飞公司)测定了微晶玻璃的重金属浸出浓度。

2. 结果与讨论

2.1 基础玻璃的DSC曲线和析晶动力学分析

GC1-GC3基础玻璃的差热分析曲线如图1所示。GC1-GC3基础玻璃的结晶峰温度(Tp)分别为910、926、940 °C,随碱度的升高而逐渐升高。一般来说,CaO能够提供游离氧,破坏Si-O-Si玻璃网络结构,促进晶体的析出。但是过多的CaO会使基础玻璃在非析晶阶段析出细小晶粒,使基础玻璃的黏度增加从而抑制晶体析出[11]。与此同时,随着碱度的增加,GC2基础玻璃在第一个结晶峰后继续呈现出放热倾向,GC3基础玻璃在1 000~1 050 ℃之间出现了第2个结晶峰,说明了碱度的增加提高了基础玻璃在高温阶段的结晶倾向。不同碱度基础玻璃的ln(Tp2/β)和 Tp−1×103的线性拟合如图2所示。基础玻璃的活化能Ec和Avrami指数n分别根据Kissinger公式(1)和Augis–Bennett公式(2)计算得到,如表3所示。可以看出结晶活化能Ec在199.49~245.10 kJ∙mol−1之间且随着碱度的增加而降低,与DSC分析的结果一致。所有基础玻璃的Avrami指数n都大于3 且接近于 4,这说明结晶行为属于三维整体结晶[14]。

表 3 不同碱度微晶玻璃的结晶峰温度(Tp/℃)和析晶动力学参数(Ec, n)Table 3. Crystallization temperatures (Tp/℃) and crystallization kinetic parameters (Ec, n) of glass-ceramics with various basicity样品编号 加热速率/(℃∙min−1) Ec /(kJ∙mol-1) n 5 10 15 20 GC1 910 927 940 948 245.10 3.90 GC2 926 960 960 970 204.44 4.59 GC3 940 961 984 982 199.49 7.08 ln(T2pβ)=EcRTp+ln(EcRv) (1) n=2.5RT2pΔTEc (2) 式中:β为升温速率,℃∙min−1;Tp为该升温速率下对应的结晶峰温度,℃; Ec为基础玻璃的结晶活化能,kJ∙mol−1;R为气体常数,其值为8.314 J∙(mol∙K)−1; ν为频率因子;n为Avrami指数;ΔT为结晶峰的半峰宽,℃。

2.2 晶相分析

图3(a)为不同烧结温度下GC2微晶玻璃的XRD图谱。从图3(a)中可以看出,不同烧结温度下微晶玻璃的主晶相为钙长石(Anorthite, CaAl2Si2O8, PDF#041-1486),次晶相为硅灰石(Wollastonite, CaSiO3, PDF#043-1460)和钙铝黄长石(Gehlenite, Ca2Al2SiO7, PDF#035-0755)。随着烧结温度的升高,微晶玻璃中晶相的种类没有改变。钙长石的衍射强度随烧结温度的提高在总体上呈现出上升的趋势,但在1 000 ℃时略有下降。硅灰石的衍射强度随烧结温度逐渐升高,但钙铝黄长石的衍射强度却逐渐降低。这是由于主晶相钙长石中Al含量较高, 钙长石的析出使玻璃基体中Al含量降低,因此抑制了钙铝黄长石的析出而促进了不含Al的硅灰石的析出。

不同碱度微晶玻璃的XRD图谱如图3(b)所示。可以看出,GC1和GC2微晶玻璃中主晶相为钙长石,次晶相为硅灰石和钙铝黄长石。随着碱度的升高,钙长石和钙铝黄长石的衍射强度升高而硅灰石的衍射强度降低。根据表2中的结果,GC2微晶玻璃中的CaO和Al2O3含量高于GC1微晶玻璃,因此有利于钙长石和钙铝黄长石的析出。在GC3微晶玻璃中主晶相为钠长石,次晶相仅有钙铝黄长石,且各晶相的衍射强度明显降低,说明微晶玻璃中的晶体含量较低,与DSC结果一致。

2.3 机械物理性能

在不同烧结温度下得到的GC2微晶玻璃的密度和吸水率如图4(a)所示。从图4(a)中可以看出,当烧结温度在850~950 ℃内时,密度随烧结温度的升高而增加,这是由于析晶是原子有序化排列的过程,晶体的析出使原子之间的排列更加紧密,因此晶体的析出有助于微晶玻璃的密度的提高。当烧结温度为1 000 ℃时,密度有所下降,这是由于晶体的生长挤压了周围的玻璃基体,从而产生细小裂缝,使微晶玻璃的密度下降。继续提高烧结温度,玻璃基体的黏度下降,与晶体之间的结合更加紧密,使密度再次增加[15]。不同碱度微晶玻璃的密度和吸水率如图4(b)所示。随着碱度的升高,密度先增加然后降低。这是由于CaO含量的提高促进了晶体的析出,导致了密度的升高。根据DSC和XRD结果可知,GC3微晶玻璃中的晶体含量较少,因此具有较低的密度。从图4(a)和(b)中可以看出,所有微晶玻璃样品都具有极低的吸水率,其值在0.05%~0.11%之间。

GC2微晶玻璃的抗压强度和显微维氏硬度随烧结温度的变化如图4(c)所示。抗压强度随着烧结温度的升高从195.75 MPa上升至501.09 MPa,在总体上呈现上升趋势。这是因为,晶体的析出有利于提高抗压强度,烧结温度的升高使基础玻璃的黏度下降,原子的迁移和重排加速,促进了晶体的析出,从而使抗压强度升高[16]。但值得注意的是,GC2微晶玻璃的抗压强度在1 000 ℃时急剧下降, 这是由于晶体的大量析出而玻璃基体的黏度较高使微晶玻璃内部产生了较高的应力,从而降低了抗压强度。从图4(c)中可以看出GC2微晶玻璃的显微维氏硬度随着烧结温度的提高逐渐降低。维氏显微硬度的影响因素主要有2个:晶体的类型和晶体粒径的大小。根据图3中XRD结果可知,烧结温度并未改变微晶玻璃中的晶体种类,而对晶体粒径的影响较大,因此晶体粒径的大小是影响微晶玻璃显微维氏硬度的主要因素。在微晶玻璃中,晶体与晶体和晶体与玻璃基体之间存在细小的裂缝,是微晶玻璃中力学性能最低的区域,晶体的生长会使裂缝变长,缩短了裂缝扩展的迂回长度,因此导致了显微维氏硬度的降低[17]。

在950 °C下烧结得到的具有不同碱度微晶玻璃的抗压强度如图4(d)所示。可以看出当碱度从0.48增加至0.56时,抗压强度从277.66 MPa增加至545.35 MPa。这是因为,CaO含量的升高促进了晶体析出导致了抗压强度的升高。但当碱度增加至0.70时,抗压强度降低至488.46 MPa。这是由于过高的CaO含量抑制了晶体的析出,导致GC3微晶玻璃的结晶度变低,因此造成了抗压强度的下降。随着碱度的上升,微晶玻璃的显微维氏硬度先下降然后增加,这是由于碱度的提高促进了晶体的析出,因此GC2微晶玻璃比GC1微晶玻璃具有更高的结晶度,导致了显微维氏硬度的降低[18]。而GC3微晶玻璃中只有少量的晶体析出,其中均匀致密的玻璃相较多,破裂所需要的迂回长度加长,而且并未检测到其中存在硅灰石,因此其显微硬度高于GC1微晶玻璃和GC2微晶玻璃。

2.4 微观结构分析

不同烧结温度下GC2微晶玻璃的SEM照片如图5(a)~5(e)所示。在GC2微晶玻璃表面可以观察到颗粒状的晶体。当烧结温度为850 ℃时,少量的颗粒状晶体分布在玻璃基体上。随着烧结温度的升高,晶粒的粒径逐渐变大且数量逐渐增加。当烧结温度为1 000 ℃时,颗粒状晶体布满整个微晶玻璃表面并挤压在一起。当烧结温度为1 050 ℃时,微晶玻璃表面变得光滑致密,说明高温使玻璃相黏度的降低,增加了晶粒与玻璃相之间的结合,与抗压强度和显微维氏硬度的结果一致。

在950 ℃下烧结得到的GC1-GC3微晶玻璃的SEM照片分别如图5(f)、5(c)、5(g)所示。GC1-GC3微晶玻璃表面同样分布着颗粒状晶体。经过腐蚀后,GC1微晶玻璃表面仍存在一层玻璃相,随着碱度的升高,残余玻璃相的含量逐渐下降,这是由玻璃网络形成体SiO2含量降低导致的。而在GC3微晶玻璃表面主要是玻璃相,只有少量晶体存在。

2.5 重金属浸出毒性分析

由于垃圾焚烧飞灰中含有重金属,因此由其衍生的微晶玻璃产品的重金属浸出浓度是评价其安全性的重要指标。本研究选择TCLP浸出毒性测试方法,对Cr、Cd、Cu、Ni、Pb、Zn进行浸出毒性测试。所有微晶玻璃的重金属浸出浓度如表4 所示。可以看出,在所有的微晶玻璃样品中均未检测到Cr和Cu的浸出,Zn的浸出浓度在GC2-850 ℃微晶玻璃中检测出,仅为0.01 mg∙L−1。同时,Cd和Pb的浸出浓度分别在2.36~2.75 mg∙L−1和0.41~1.43 mg∙L−1,均远低于美国固体废物毒性特征浸出程序TCLP和中国国家标准《危险废物鉴别标准 浸出毒性鉴别》(GB 5085.3–2007)规定的重金属浸出浓度阈值。这表明了微晶玻璃具有较低的重金属浸出毒性。因此,通过熔融烧结法将垃圾焚烧飞灰转化为无毒无害的微晶玻璃产品是一个安全可行的方法。

表 4 微晶玻璃的重金属浸出浓度Table 4. The heavy metal leaching concentrations of the resultant glass-ceramics样品 重金属浸出浓度 (mg∙L−1) Cd Cr Cu Ni Pb Zn GC2-850 ℃ 2.52 ND ND 0.97 1.96 0.01 GC2-900 ℃ 2.36 ND ND 1.43 3.13 ND GC2-950 ℃ 2.44 ND ND 1.30 1.30 ND GC2-1000 ℃ 2.54 ND ND 1.30 2.74 ND GC2-1050 ℃ 2.59 ND ND 1.23 2.59 ND GC1-950 ℃ 2.75 ND ND 0.41 0.75 ND GC3-950 ℃ 2.47 ND ND 1.23 2.56 ND 毒性阈值a 5.0 1.0 - - 5.0 - 毒性阈值b 5.0 1.0 100 10 5.0 100 注:ND表示未检测出;a US EPA TCLP 阈值;b中国国家标准《危险废物鉴别标准 浸出毒性鉴别》(GB 5085.3–2007)。 3. 结论

1)碱度的增加虽然没有降低基础玻璃的结晶峰温度,但提高了基础玻璃在高温阶段的析晶倾向。所有基础玻璃的析晶方式为三维整体结晶。

2)抗压强度在总体上随烧结温度和碱度的升高而升高。但当烧结温度为1 000 ℃时,抗压强度急剧下降。显微维氏硬度随烧结温度的升高而降低但随碱度的升高而增加。

3)毒性浸出测试结果表明,所制得的微晶玻璃中典型6种重金属浓度远低于美国固体废物毒性特征浸出程序TCLP和中国国家标准《危险废物鉴别标准 浸出毒性鉴别》GB 5085.3–2007规定的重金属浸出浓度阈值,产品对环境无潜在风险。

-

表 1 原材料的化学成分

Table 1. Chemical compositions of raw materials

% 供试样品 CaO SiO2 Al2O3 MgO Na2O Cl SO3 其他 垃圾焚烧飞灰 42.80 1.92 0.54 0.82 12.10 24.5 7.43 9.89 粉煤灰 2.45 51.10 37.30 0.67 0.21 0.06 0.68 7.53 废玻璃 10.4 69.20 1.44 3.79 12.90 0.08 0.35 1.84 表 2 不同混合比例原料的化学成分

Table 2. Chemical compositions of raw materials under various mixing ratios

% 样品编号 CaO SiO2 Al2O3 MgO Na2O GC1 18.96 39.32 13.68 1.66 8.18 GC2 20.18 35.05 15.42 1.35 7.50 GC3 21.40 30.78 17.17 1.05 6.83 表 3 不同碱度微晶玻璃的结晶峰温度(Tp/℃)和析晶动力学参数(Ec, n)

Table 3. Crystallization temperatures (Tp/℃) and crystallization kinetic parameters (Ec, n) of glass-ceramics with various basicity

样品编号 加热速率/(℃∙min−1) Ec /(kJ∙mol-1) n 5 10 15 20 GC1 910 927 940 948 245.10 3.90 GC2 926 960 960 970 204.44 4.59 GC3 940 961 984 982 199.49 7.08 表 4 微晶玻璃的重金属浸出浓度

Table 4. The heavy metal leaching concentrations of the resultant glass-ceramics

样品 重金属浸出浓度 (mg∙L−1) Cd Cr Cu Ni Pb Zn GC2-850 ℃ 2.52 ND ND 0.97 1.96 0.01 GC2-900 ℃ 2.36 ND ND 1.43 3.13 ND GC2-950 ℃ 2.44 ND ND 1.30 1.30 ND GC2-1000 ℃ 2.54 ND ND 1.30 2.74 ND GC2-1050 ℃ 2.59 ND ND 1.23 2.59 ND GC1-950 ℃ 2.75 ND ND 0.41 0.75 ND GC3-950 ℃ 2.47 ND ND 1.23 2.56 ND 毒性阈值a 5.0 1.0 - - 5.0 - 毒性阈值b 5.0 1.0 100 10 5.0 100 注:ND表示未检测出;a US EPA TCLP 阈值;b中国国家标准《危险废物鉴别标准 浸出毒性鉴别》(GB 5085.3–2007)。 -

[1] 中华人民共和国统计局. 中国统计年鉴[J]. 北京: 中国统计出版社, 2016-2021 [2] ZHU J M, HAO Q J, CHEN J J, et al. Distribution characteristics and comparison of chemical stabilization ways of heavy metals from MSW incineration fly ashes[J]. Waste Management, 2020, 113: 488-496. doi: 10.1016/j.wasman.2020.06.032 [3] YAO S C, ZHANG L F, ZHU Y M, et al. Evaluation of heavy metal element detection in municipal solid waste incineration fly ash based on LIBS sensor[J]. Waste Management, 2020, 102: 492-498. doi: 10.1016/j.wasman.2019.11.010 [4] LI W H, GU K, YU Q W, et al. Leaching behavior and environmental risk assessment of toxic metals in municipal solid waste incineration fly ash exposed to mature landfill leachate environment[J]. Waste Management, 2021, 120: 68-75. doi: 10.1016/j.wasman.2020.11.020 [5] CRISTELO N, SEGADES L, COELHO J, et al. Recycling municipal solid waste incineration slag and fly ash as precursors in low-range alkaline cements[J]. Waste Management, 2020, 104: 60-73. doi: 10.1016/j.wasman.2020.01.013 [6] WANG X X, JI G Z, ZHU K Y, et al. Integrated thermal behavior and compounds transition mechanism of municipal solid waste incineration fly ash during thermal treatment process[J]. Chemosphere, 2020: 128406. [7] LI Y, ZHANG J L, LIU Z J, et al. Harmless treatment of municipal solid waste incinerator fly ash through shaft furnace[J]. Waste Management, 2021, 124: 110-117. doi: 10.1016/j.wasman.2021.01.039 [8] 李保庆, 郭艳平, 方红生, 等. 晶化温度对飞灰/废屏玻璃协同制备CaO-Al2O3-MgO-SiO2系微晶玻璃析晶及性能的影响[J]. 陶瓷学报, 2018, 39(4): 443-448. [9] PONSOT I, BERNARDO E, BONTEMPI E, et al. Recycling of pre-stabilized municipal waste incinerator fly ash and soda-lime glass into sintered glass-ceramics[J]. Journal of Cleaner Production, 2015, 89: 224-230. doi: 10.1016/j.jclepro.2014.10.091 [10] 刘汉桥, 魏国侠, 梁茵, 等. 垃圾焚烧飞灰电弧炉熔渣微晶玻璃的晶化行为[J]. 土木建筑与环境工程, 2012, 34(2): 121-125. [11] 吴春丽, 张深根, 杨健, 等. CaO/SiO2质量比对不锈钢渣微晶玻璃析晶及性能的影响[J]. 材料导报B:研究篇, 2015, 29(9): 84-88. [12] 王振双, 苏昊林, 周梅. CaO-Al2O3-SiO2系粉煤灰微晶玻璃的制备及其性能[J]. 材料热处理学报, 2016, 31(1): 29-33. [13] 张雪峰, 张宁, 贾晓林, 等. CaO/SiO2对复合尾矿制备玻璃陶瓷性能的影响[J]. 中国陶瓷, 2014, 50(10): 60-63. [14] XIAO Y L, SHEN X M, WU X R, et al. Vitrification and Crystallization Behavior of CaO-SiO2-MgO-Al2O3-Fe2O3-Cr2O3 System[J]. Metallurgical and Materials Transactions B, 2020, 51: 827-835. doi: 10.1007/s11663-019-01743-5 [15] ZHENG F, LI M J, WANG J, et al. Effective utilization of extracted titanium tailing to prepare high performance glass-ceramic and their formation mechanism[J]. Ceramics International, 2021, 47: 17391-17399. doi: 10.1016/j.ceramint.2021.03.053 [16] ZHANG Z K, WANG J, LIU L N, et al. Preparation and characterization of glass-ceramics via co-sintering of coal fly ash and oil shale ash-derived amorphous slag[J]. Ceramics International, 2019, 45: 20058-20065. doi: 10.1016/j.ceramint.2019.06.269 [17] CHEN H, LI B W, ZHAO M, et al. Lanthanum modification of crystalline phases and residual glass in augite glass ceramics produced with industrial solid wastes[J]. Journal of Non-Crystalline Solids, 2019, 524: 119638. doi: 10.1016/j.jnoncrysol.2019.119638 [18] ZHANG Z K, WANG J, LIU L N, et al. Preparation of additive-free glass-ceramics from MSW incineration bottom ash and coal fly ash[J]. Construction and Building Materials, 2020, 254: 119345. doi: 10.1016/j.conbuildmat.2020.119345 -

DownLoad:

DownLoad: