-

臭氧已成为影响我国夏季空气质量的首要污染物[1]。挥发性有机物 (volatile organic compounds, VOCs) 是生成臭氧和细颗粒物的主要前体物[2-3]。人为源VOCs持续高强度排放是大气污染重要根源[4-5]。开展重点行业VOCs治理是改善城市空气质量的有效途径,并已成为研究热点[6-7]。石化企业是VOCs重点排放源,对区域大气影响显著[8-15]。设备组件与管线泄露、工艺废气、污水集输与处理、储罐和成品油装卸等是石化企业主要VOCs排放源,而不同污染源的VOCs排放特征及环境影响差异性较大[16-23]。现有研究多以石化行业整体为研究对象,而对具体污染源VOCs排放特征及影响尚不多[11-12,16-19,22]。

WEI 等[17]对北京地区炼化企业排放的VOCs进行了采样分析发现,催化裂化装置对周边环境影响最大。MO等[18]研究了我国长三角地区炼化装置的VOCs排放特征。CHEN等[19]指出,成品油装卸单元是重要的VOCs排放源。LV等[23]对我国地方炼化储罐、设备泄露和污水系统VOCs排放现状进行了研究。FENG等[24]通过厂区内强化采样方法,研究了华北地区炼化企业的VOCs组成特征,发现催化重整及污水处理过程中排放的烷烃占比最高,可达到48.0%和59.2%,而丙烯回收及催化裂化单元VOCs则以烯烃为主,另外,长链烷烃是延迟焦化重要组分。ZHANG等[25]在研究了我国珠三角地区炼化企业工艺装置及污水处理环节VOCs组成特征后发现,除化工装置外,其余装置及污水系统VOCs以烷烃为主,而C5~C6是首要组分。比较而言,成品油装卸过程,尤其是成品油装载过程中VOCs排放组分特征及对环境影响的研究相对较少[18]。

基于此,本研究以我国某石化企业的成品油公路罐车装载过程为对象,对汽油、航空煤油和柴油等成品油装载过程外排的VOCs和甲烷进行采样和全组分分析,以明确成品油装载过程中VOCs和甲烷等有机污染物的排放特征,并基于·OH反应速率和最大增量反应活性方法,开展光化学反应活性和臭氧生成潜势研究,进而定量评估成品油装载外排VOCs对周边环境的影响,以期为从源头开展成品油装载过程有机污染物的精准管控提供参考。

-

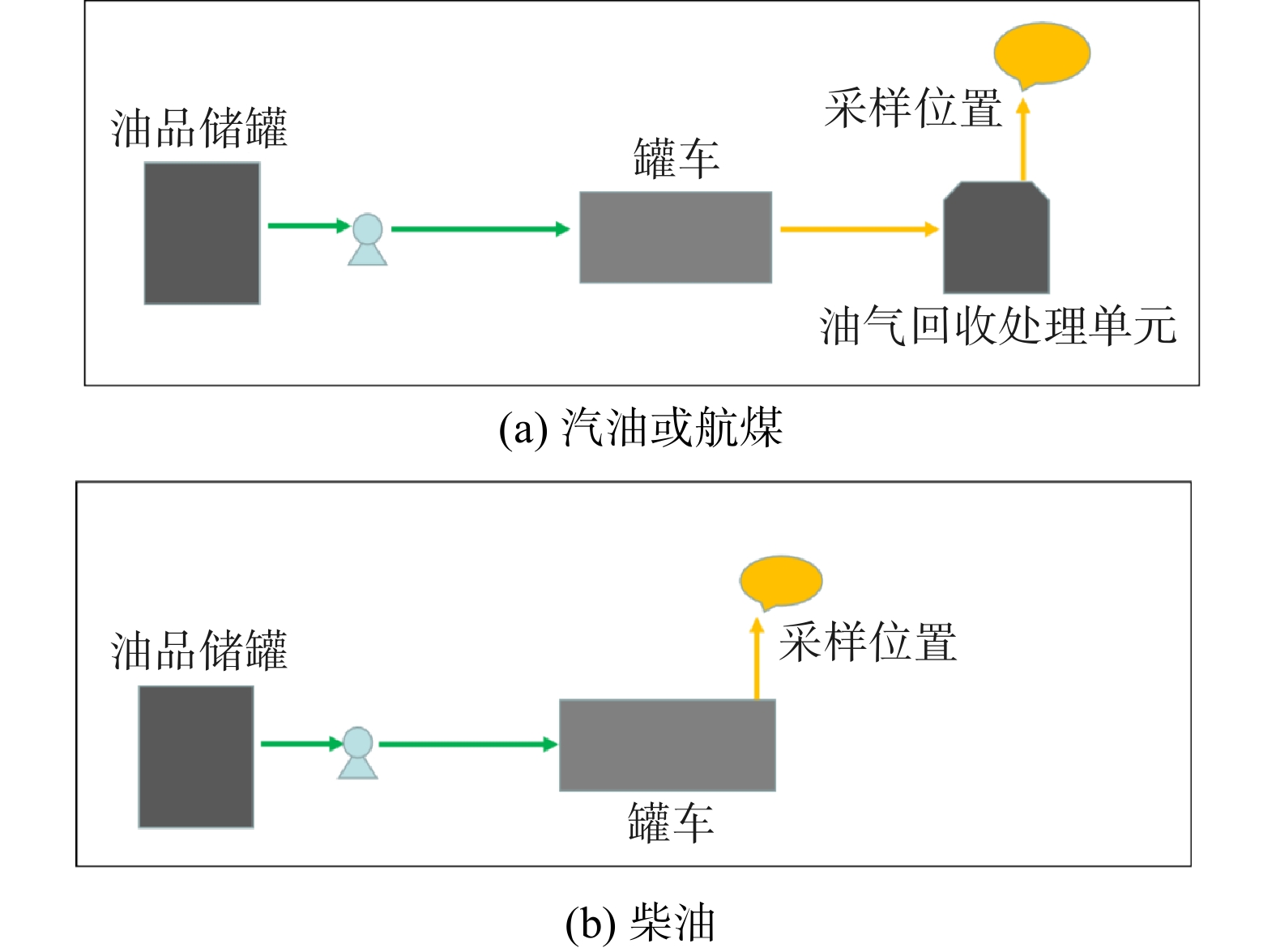

以我国西北某石化企业成品油公路罐车的装载过程为对象,对汽油、航煤和柴油装载过程外排的VOCs和甲烷进行了采样分析。装载过程可能的有机污染物排放过程包括在装载栈台的装油过程、运输过程及在储存单位的卸油过程。有机污染物种类包括甲烷和VOCs等。汽油装载栈台的年装载能力可达100万吨,柴油为30万吨,航煤为40万吨。汽油和航煤的装载过程均配备了油气收集处理装置,其VOCs废气处理能力达到300 m3·h−1。汽油和航煤装载过程的采样点均在油气回收处理装置外排废气采样口;柴油装载过程中尚无直接收集处理装置,为收集后直接排放。采样点为油罐车油气收集鹤管汇管采样口。

-

在不影响装置安全运行的前提下,采用SUMMA罐 (3.2 L, Entech., USA) 对成品油装载外排有机污染物进行采集,采样点如图1所示。汽油和航煤装载过程的采样点位于油气回收处理单元外排废气采样口,柴油装卸过程采样点位于鹤管油气汇管采样口。每个排放点采集2组,共采集6个样品。采样日期为2020年7月16日至2020年7月22日。采样日天气晴,气温为28~35 ℃,风速为0.1~1 m·s−1。

在采样前,通过自动清洗装置 (3100, ENTECH, USA) 对SUMMA罐进行了氮气置换清洗和抽真空等预处理。通过罐自抽气方式进行采样,采样时间为15 min。采样速率通过罐前置流量控制仪 (CS 1200E, Passive Sampler, ENTECH, USA) 来实现。采样步骤如下:在采样开始前,将SUMMA罐与前置流量控制仪连接 (流速为210 mL·min−1),将流量控制仪进气端管线末端与采样口通过硅胶管连接,随后打开罐顶采样阀进行采样。采取结束后关闭罐顶阀门,断开前置流量控制仪。

-

参照HJ 604-2017相关规范要求[26],通过气相色谱火焰离子检测仪 (GC-FID, 3420A, 北分瑞利, 中国) 对样品进行了甲烷与非甲烷总烃分析。分析条件为:色谱柱为甲烷柱 (4 mm×2 m) 和总烃柱 (0.53 mm×30 m);进样体积为1 mL;进样温度为100 ℃;柱箱温度为80 ℃;检测器温度为200 ℃;检测器为火焰离子检测器。

参考美国环境保护署 (EPA) 推荐的TO-15方法[27],对样品进行了VOCs组分分析。分析设备为气相色谱火焰离子检测与质谱分析联用仪 (GC-FID/MS, GC 7890B/MS 5977A, Agilent, USA)。气相色谱采用的分离柱为DB-1 (60 m×0.25 mm×1 μm) 和HP-PLOT/Q+PT (30 m×0.32 mm×20 μm)。质谱离子源温度为250 ℃,四级杆温度为250 ℃,扫描方式为SCAN。通过中心切割,轻质烃 (C2~C4) 进入FID检测器,其余组分进入质谱检测器。VOCs组分检出下限为0.1~1.6 μg·m−3 (进样量为400 mL),可满足分析要求。

通过PMAS标准气 (1 mg.m−3, SPECTRA GASES, USA) 配置了不同质量浓度的校准气体 (1、10、20、50和100 μg·m−3),并绘制了标准曲线。对各浓度校准曲线进行了相关性分析,其相关性在0.992 (R2) 以上。利用VOCs组分峰面积与对应质量浓度间的线性关系进行样品定量分析。样品中C2~C4组分的质量浓度通过外标法进行定量,其余VOCs组分通过内标法进行定量分析。内标物为溴氯甲烷和1,4-二氟苯。样品平行测试标准方差为0.17~0.36,结果为2组样品的平均值。

-

三类石化行业成品油在装载过程中外排甲烷及VOCs的质量浓度和强度如表1所示。不同成品油装载过程外排差异较大,排放的气态污染物中VOCs质量浓度远高于甲烷,汽油装载外排的VOCs质量浓度高于航煤和柴油。结合成品油密度,对装载过程的污染物排放强度进行估算后发现,汽油装载VOCs排放强度最高,每吨成品油的VOCs排放量达到36.4 g;柴油和航煤装载每吨成品油的VOCs排放强度较低,分别为5.9 g和2.2 g。除VOCs外,成品油装载过程也是重要的甲烷排放源。每吨成品油装载过程中甲烷排放强度达到0.004~0.14 g。汽油装载过程最高,航煤装载过程最低。

成品油物性及油气回收工艺的差异是导致装载过程中VOCs及甲烷排放特征不同的主要原因。考虑成品油挥发性,在成品油装载过程中产生VOCs质量浓度按降序排列依次为:汽油、航煤和柴油。在本研究中,在汽油装载过程中配有“贫油吸收+活性炭吸附”装置对VOCs进行回收处理,在航煤装载过程中配备VOCs处理工艺为“低温冷凝+膜分离+活性炭吸附”。经油气回收装置处理后,汽油及航煤装载环节排放的VOCs质量浓度大幅降低,而柴油装载过程未配置油气回收处理设施,这导致其直排废气中VOCs质量浓度与强度高于航煤。

由于汽油装载VOCs质量浓度极高,而活性炭吸附对低质量浓度VOCs处理效果较好,对高质量浓度VOCs处理效果相对有限,导致活性炭吸附后汽油装载中排放的VOCs仍较高。在现有工艺基础上配套深度处理单元是提高汽油装载有机污染物处理效果的有效途径。

对汽油和航煤装载过程有机污染物的处理效果进行分析。以处理前为基准,处理后汽油装载过程排放的VOCs质量浓度和强度分别降低了97.7% (运行初期) 和48% (平稳运行100 h后),而航煤装载过程VOCs削减了81.1%,每吨成品油装载VOCs减少量达到1 587.7g (汽油装载过程及运行初期) 和9.5 g(航煤装载过程)。我国《石油炼制工业污染物排放标准(31570-2015)》和《储油库大气污染物排放标准 (20950-2020) 》要求[28-29],汽油和航煤等成品油装载外排VOCs质量浓度不得超过25 g·m−3,处理效率不得低于95%。综上所述,该企业汽油装载过程中外排有机污染物质量浓度尚未达标,航煤处理装置效率亦有待提高。

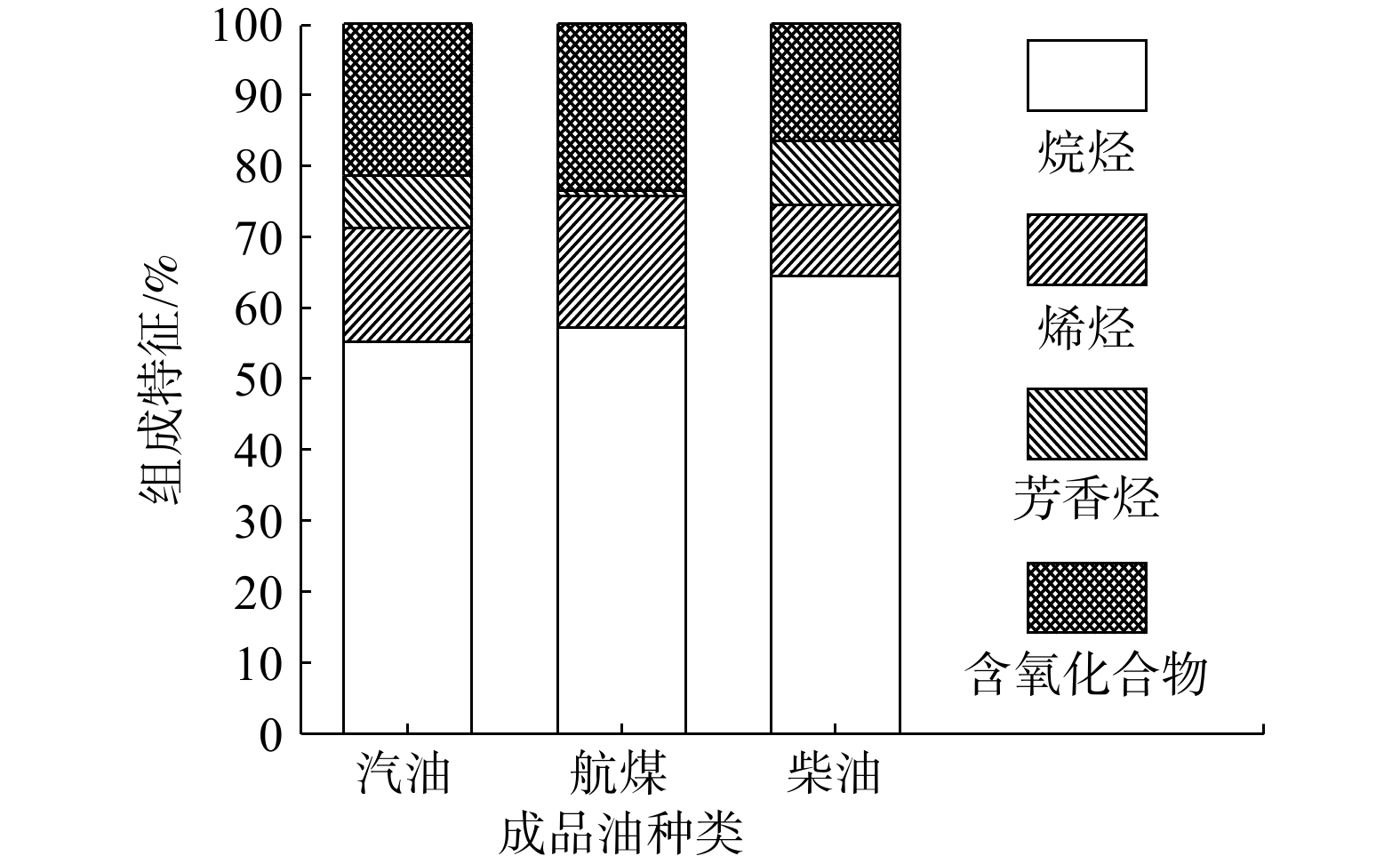

成品油装载过程中VOCs的组成如图2所示。外排VOCs含有烷烃、烯烃、芳香烃和含氧物质,组成的差异性较大。汽、柴、航煤等成品油装载过程中外排的VOCs以烷烃为主,其质量分数达到55.1%~64.5%。含氧类物质占比紧随其后,为16.5%~23.6%。烯烃是成品油装载外排VOCs的重要组成部分,其质量分数为16.1%~18.5%;芳香烃在成品油VOCs中占比较低,仅为0.7%~8.9%。

进一步分析发现,在汽油、航煤和柴油装载过程外排的VOCs中,C4~C5烷烃在饱和烃中的占比由77.2%逐渐降至41.1%,C6~C7烷烃占比则从4.4%不断升至43.4%;丁烯占烯烃比例从95.6%降至17.7%,戊烯和异戊二烯占比则由3.7%升至73.5%。这说明随成品油密度升高,烷烃类和烯烃类VOCs中长链高碳组分占比不断提升。甲苯、邻二甲苯和间/对二甲苯是成品油装载过程外排主要芳香化合物。丙酮是成品油装载过程中最主要的含氧类物质,占含氧类物质50%以上。

在成品油装载过程中,质量分数前5位的VOCs物质 (基于质量占比的优势物种)的分析结果如表2所示。成品油装载过程中外排的优势VOCs物种具有一定规律性和差异性。汽、柴、航煤装载外排VOCs中含量最高的组分为异戊烷,其次为丙酮。正丁烷、正戊烷和反-2-丁烯是汽油和航煤等装载过程的主要组分;柴油装载过程中高含量组分则以乙酸乙烯酯、正己烷和甲基环戊烷为主。因此,汽油和航煤等外排VOCs优势组分以C4~C5烷烃组分为主,柴油装载过程外排优势组分向C5~C6过渡。

综上所述,该石化企业成品油装载过程外排优势烷烃类VOCs物种为C4~C6,异戊烷占主导地位;优势烯烃组分为反-2-丁烯;优势含氧化合物为丙酮和乙酸乙烯酯;前5位VOCs组分占比超过45%。

-

·OH损失速率法 (LOH) 是判定VOCs组分光化学反应活性的重要方法[6,9]。VOCs组分与·OH之间的光化学反应十分复杂,反应过程如式(1)~(7)所示。以VOCs与·OH间的反应速率为基础,对成品油装载过程排放有机污染物的光化学反应活性进行了分析,计算方法如式 (8) 和 (9) 所示。

式中:LOH为废气·OH损失速率常数,s−1;LiOH为VOCs组分i的·OH损失速率常数(s−1);KiOH:组分i的·OH反应速率常数[30];Fi为组分i的浓度,mol·m−3。本研究检出VOCs组分的速率常数如表3所示。

在成品油装载过程中单位体积有机污染物的反应活性 (LOH) 达到1.5×105~1.8×106 s−1,其中航煤装载过程外排有机污染物的LOH值最低,汽油装载过程有机污染物的LOH值最高。进一步分析发现,外排有机污染物的中单位物质的量VOCs对应的反应活性为11.1~ 13.5 s−1,其中柴油装载过程最低,航煤装载过程最高。与烯烃和苯系物等VOCs组分反应活性进行了对比[28],装载过程外排有机污染物反应活性高于乙烯组分,与对二甲苯组分活性相当,其光化学反应活性很强。

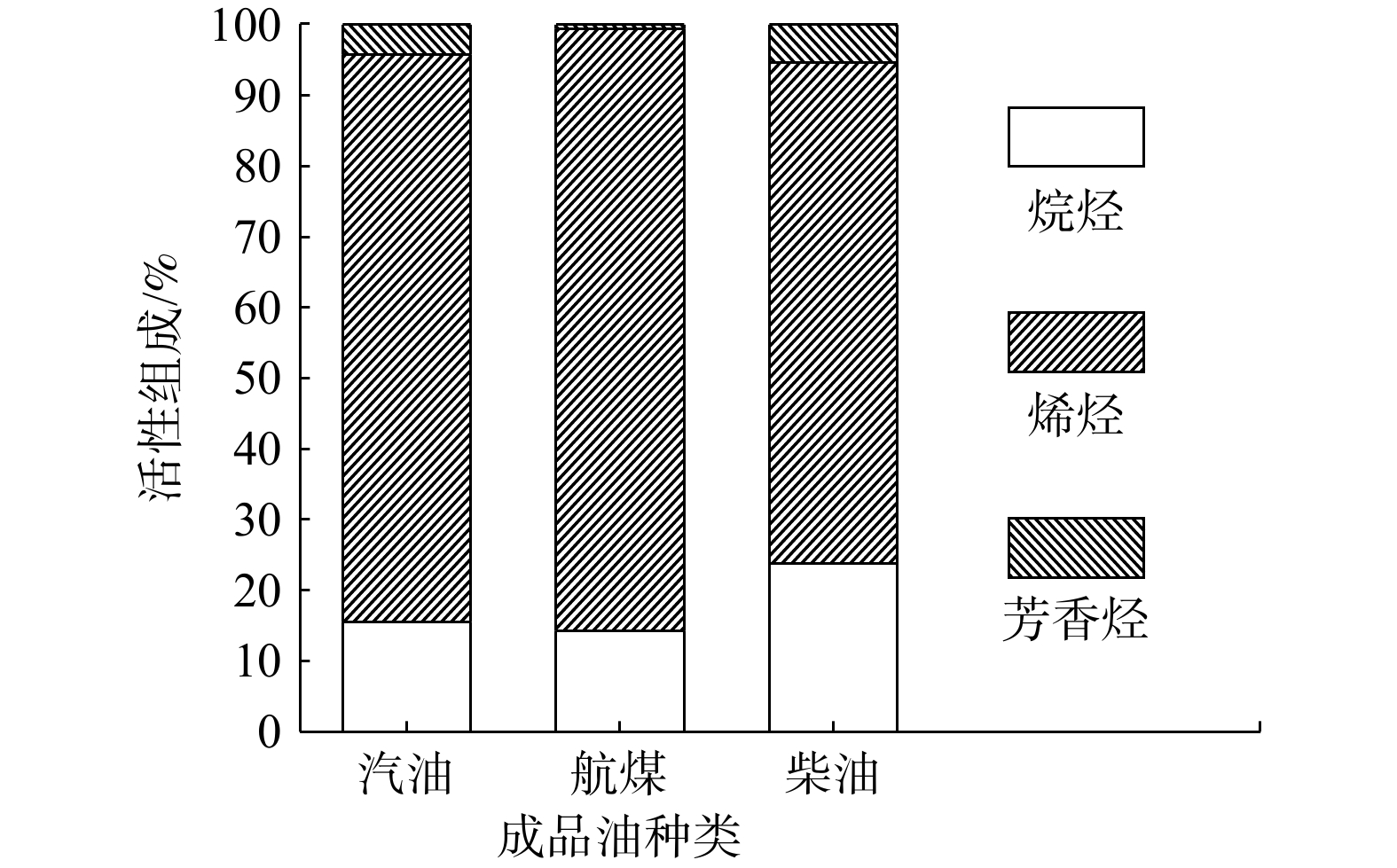

对外排有机污染物的LOH组成进行了分析,结果如图3所示。在成品油装载过程中反应活性主要来自于烯烃组分,贡献比例为70.8%~85.2%。其中,航煤装载过程中烯烃占比最高。对反应活性精细化的组分进行了分析,结果表明:反-2-丁烯和顺-2-丁烯对汽油装载反应活性发挥主导作用,占烯烃总活性的89.4%;反-2-丁烯、顺-2-丁烯和反-2-戊烯对航煤装载过程活性产生关键影响,占烯烃总活性比例接近83.8%;柴油装载过程主要活性组分为异戊二烯、反-2-戊烯和顺-2-戊烯,三者对烯烃总活性贡献比例总计为78.4%。

烷烃是成品油装载过程外排有机污染物反应活性的重要组成部分,占比为15.5%~23.8%。其中,异戊烷发挥主要作用,对烷烃反应活性的贡献范围为36.4%~58.3%。芳香烃对反应活性贡献比例较低,为0.6%~5.4%,其中比例最高的是柴油装载过程,最低的为航煤过程,而甲苯和间/对二甲苯为主要活性组分。

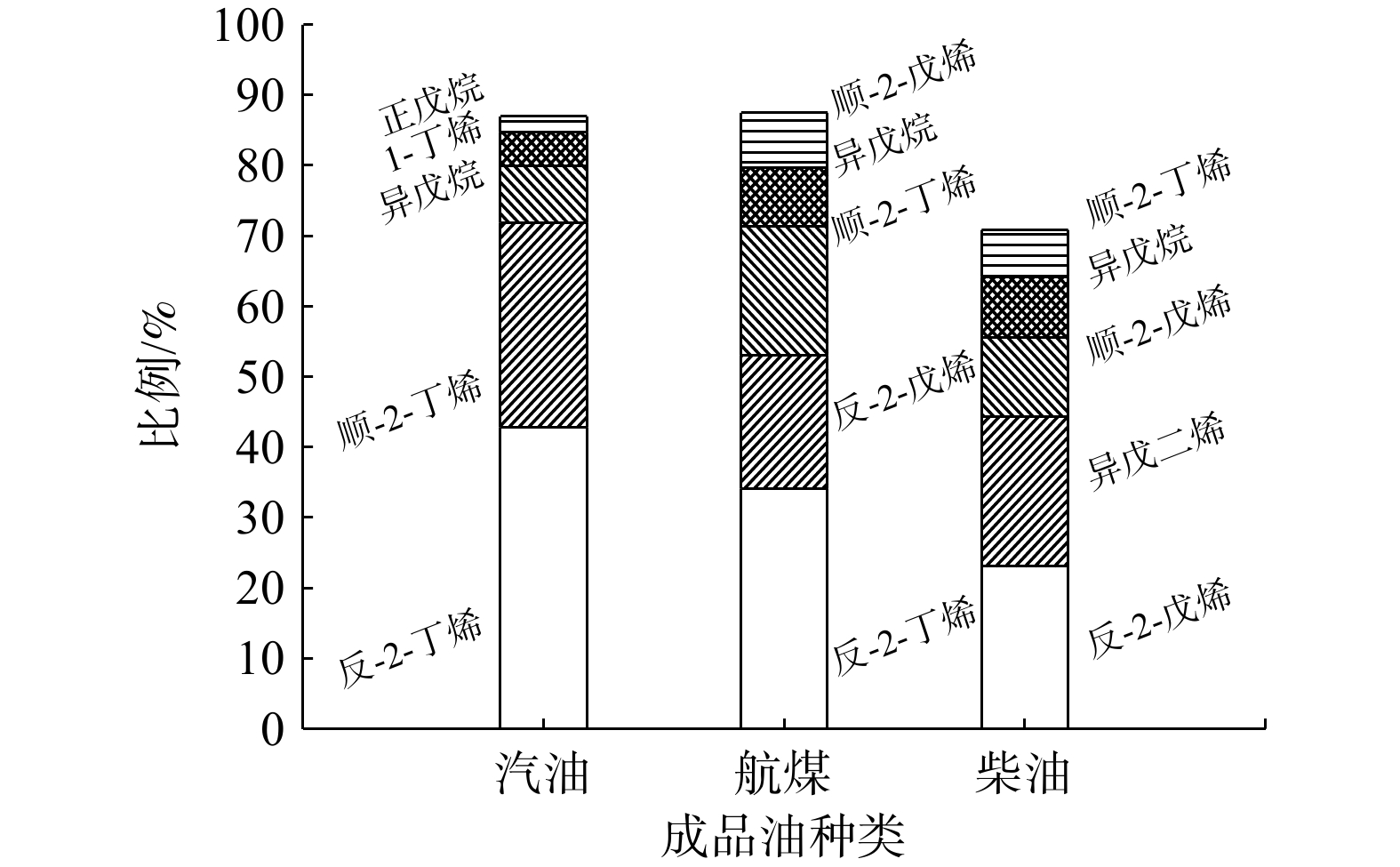

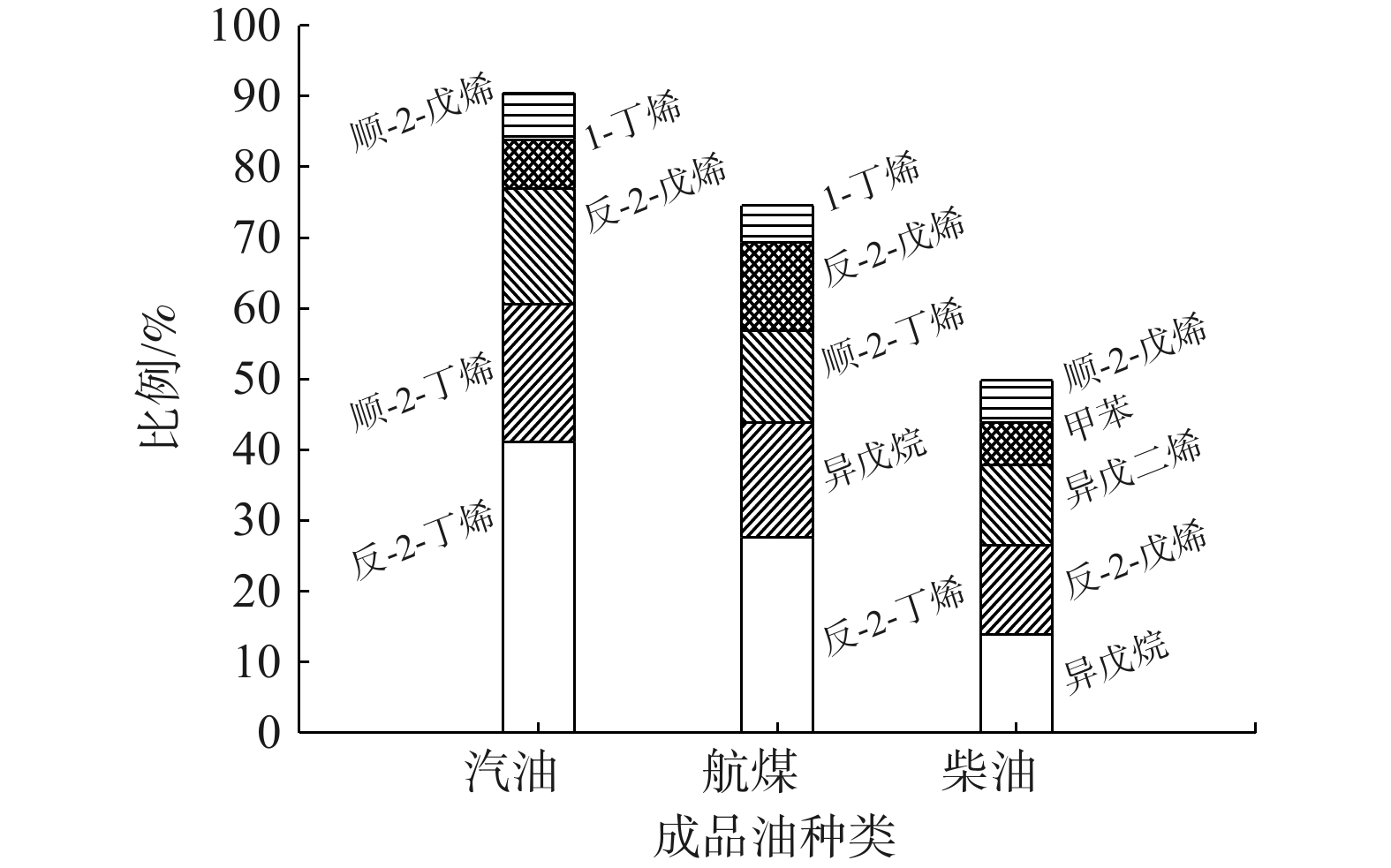

对LOH贡献占比前5位组分 (优势物种) 进行了分析,结果如图4所示。图中各组分按活性占比高低从左至右依次排列。不同成品油装载过程基于反应活性贡献的优势VOCs物种略有差异,但均以顺-2-丁烯、反-2-丁烯、异戊二烯、顺-2-戊烯、反-2-戊烯和异戊烷等C4~C6烷烃和烯烃组分为主。值得注意的是,随着成品油密度升高,外排废气中活性优势烯烃物种逐渐由C4烯烃向C5烯烃过渡。综上所述,成品油装载外排有机污染物的反应活性主要来源于优势物种,贡献比例前5位的物质对LOH合计贡献可达70.9%~87.5%,而丁烯、异戊二烯、戊烯和异戊烷等是最主要活性组分。

-

臭氧生成潜势 (ozone formation potential, OFP) 是研究VOCs组分大气臭氧生成能力的重要方法[18]。采用最大增量反应活性法 (maximum increment ractivity, MIR) 对成品油装载过程外排废气臭氧生成能力进行分析,废气的OFP计算方法如式 (10) 和 (11) 所示。

式中:OFP即废气臭氧生成潜势,mg·m−3;OFPi为组分i的臭氧生成潜势,mg·m−3;MIRi为组分i的MIR系数[31];Ci为组分i的质量浓度,mg·m−3。

成品油装载过程单位体积外排有机污染物的OFP可达1 865~ 1.25×104 mg·m−3,其中汽油装载过程数值最高,航煤装载过程最低。以单位质量VOCs对应OFP为依据,进一步分析发现,VOCs的臭氧生成潜力达到1.4~2.7 g·g−1,航煤装载外排有机污染物的数值最高,汽油装载过程最低。结合各组分臭氧生成潜势数据[29]发现:汽油装载外排有机污染物的臭氧生成能力与异戊烷基本相当;航煤装载外排有机污染物的臭氧生成能力与甲苯基本相当;柴油装载外排有机污染物臭氧生成能力介于异戊烷和甲苯之间,与正丙苯基本相当。

由于不同组分具有显著光化学反应活性差异,高活性组分对近污染源区域环境会产生显著影响,低活性组分主要对远距离环境臭氧产生影响。结合光化学反应活性分析结果,对成品油装载过程中周边地区臭氧影响进行分析(高活性组分臭氧潜势)后发现,汽油、航煤和柴油装载过程前5位优势活性组分臭氧生成潜势可达0.98、1.99和1.04 g·g−1,占总臭氧潜势47%以上。由此推断,成品油装载过程外排VOCs对近距离环境臭氧即可产生显著影响,应引起重视。

在不同成品油装载过程中,有机污染物中活性组分相对含量差异是导致OFP差异较大的主要原因。由于烯烃组分反应活性高,随VOCs中烯烃含量升高,对应的反应活性逐渐增加。如航煤装载外排有机污染物中烯烃含量达到18.5%,汽油装载有机污染物中烯烃含量为16.1%,而柴油装载过程烯烃相对含量仅为10.0%。因此,VOCs对应的臭氧生成能力与VOCs中烯烃含量呈正比。

MO等[18]对我国长三角地区炼化企业污染源废气反应活性进行分析后发现,各工艺装置单位质量VOCs臭氧生成潜势为1.0~10.5 g·g−1。FENG等[24]发现:我国华北地区典型炼化工艺装置排放VOCs的臭氧生成潜势为2.0~7.3 g·g−1;除丙烯回收装置,其余污染源OFP为2.0~4.0。对比分析表明,成品油装载过程外排有机污染物对应臭氧潜势与常减压和重整等典型炼化装置的反应活性大体相当。

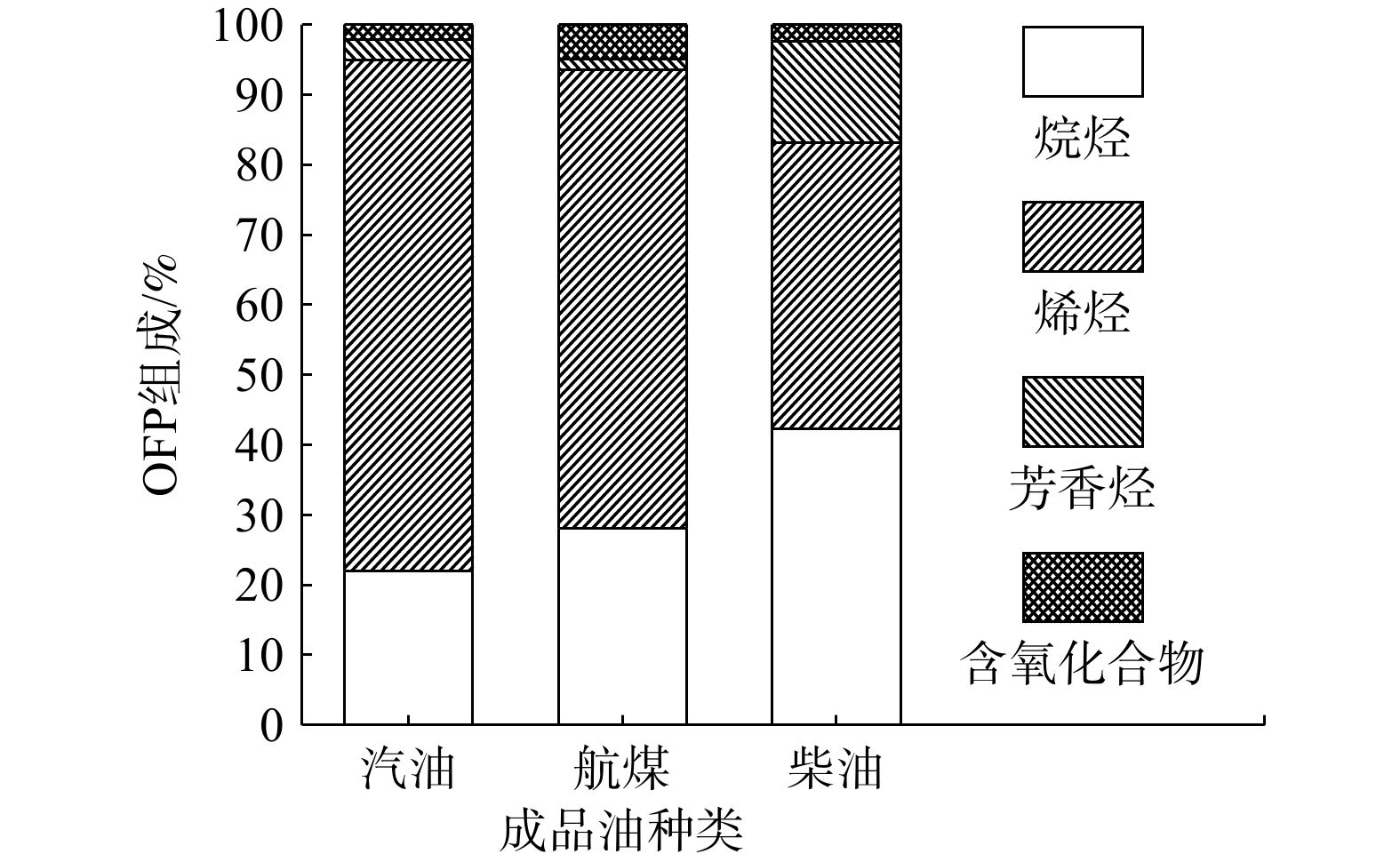

成品油装载过程排放有机污染物的OFP组成特征如图5所示。不同成品油OFP组成差异较大。汽油和航煤装载过程外排废气OFP主要来自于烯烃组分,贡献比例分别达到72.8%和65.3%,即丁烯、异戊二烯和戊烯等C4~C5组分发挥主导作用;烷烃和烯烃对柴油装载过程OFP贡献基本相当,分别为42.3%和40.8%,即异戊烷和戊烯等为关键组分。除烷烃和烯烃外,芳香烃和含氧物质也是成品油装载过程外排有机污染物OFP的重要组成部分。芳香烃对柴油装载过程OFP的贡献比例较大,可达到14.5%,对汽油和航煤装载过程贡献较低,占比为1.6%~2.9%,其中甲苯和间/对二甲苯是主要活性物种。含氧化合物对臭氧生成潜势贡献占比较低,仅为2.2%~4.9%,其中丙酮为主要组分。

成品油装载过程排放有机污染物的OFP贡献占比前5位组分 (优势物种) 的分析结果如图6所示,各污染源优势物种按贡献占比高低从左到右依次排列。不同污染源优势VOCs物种具有一定差异。汽油装载过程优势物种均为烯烃。其中,贡献比例最高为反-2-丁烯,其次为顺-2-丁烯、反-2-戊烯、1-丁烯和顺-2-戊烯。航煤装载过程中优势OFP组分包含烯烃和烷烃。各种物质依次为:反-2-丁烯,异戊烷、顺-2-丁烯、反-2-戊烯和1-丁烯。柴油装载过程排放的优势OFP物种包括烷烃、烯烃和芳香烃等。其中,烯烃以戊烯为主,烷烃为异戊烷,芳香烃为甲苯。因此,成品油装载过程外排有机污染物的臭氧生成潜势主要来源于优势物种,对有机污染物OFP贡献可达49.8%~90.5%。

-

我国对成品油装载外排有机污染物,特别是VOCs的管控提出了明确要求[28]。在当前阶段,吸附、吸收、膜分离和低温冷凝是工业VOCs的主流治理技术,在油气回收领域亦应用广泛[32-33]。虽然石化企业对汽油和航煤等成品油装载过程外排的VOCs均进行了回收和处理,但处理后的VOCs仍具有较高反应活性和臭氧生成能力。柴油装载油气普遍未进行VOCs治理,对本地区环境臭氧会产生直接影响。

1)升级现役的汽油和航煤装载过程油气回收装置,对采用活性炭吸附、溶剂油吸收等单一处理工艺进行提标改造,结合成品油装载量和实际VOCs排放负荷配套低温冷凝、膜分离等工艺单元,提高VOCs回收和处理效率。针对夏季高温造成的排放量大幅增加现象,通过优化工艺参数(降低冷凝温度、提高吸附剂装填量等)、提高运行负荷等措施实现VOCs高效脱除。

2)开展柴油装载废气处理装置的研发。结合柴油装卸过程排放特征,设计和建设油气回收处理设施,工艺技术以膜分离+吸附为主。当柴油与汽油、航煤在同一地点装载时,将柴油外排油气并入汽油和航煤油气,利用现有装置合并处理。

3)重点控制高臭氧潜势组分排放。异戊烷、丁烯(1-丁烯、顺-2-丁烯、反-2-丁烯)、异戊二烯、戊烯(顺-2-戊烯、反-2-戊烯)和甲苯等高臭氧潜势组分排放,通过选择性吸附和膜分离等技术,提高烯烃和芳香烃等活性组分去除效率,降低废气臭氧生成能力。

4)在油气回收处理装置配套安装在线监测系统,对外排烯烃和芳香烃等特征污染因子进行实时监测,以量化和明确成品油装卸过程污染排放及影响情况。

-

1)成品油装载过程是重要的污染物排放源,VOCs质量浓度可达1 716.8~27 096 mg·m−3。每吨成品油装载过程的VOCs排放强度达到2.2~36.4 g,甲烷排放强度达到0.004~0.14 g。成品油装载过程外排的VOCs以烷烃为主,占比可达55.1%~64.5%,丁烷、戊烷和己烷等C4~C6是主要组分。含氧类物质和烯烃是重要VOCs组分,丙酮是含量最高含氧物质,占总含氧物质的50%以上;丁烯、异戊二烯和戊烯是最主要的烯烃,占烯烃总量的70%以上。芳香烃在VOCs中占比较低。

2)在装载过程中外排VOCs反应活性较高,与二甲苯活性基本相当。烯烃是反应活性主要贡献源,占比高达70.8%~85.2%,其中C4~C5烯烃组分发挥主导作用。VOCs的臭氧生成潜势达到1.4~2.7 g·g−1,含氧化合物和芳香烃贡献占比较低,臭氧生成潜势主要源于C4~C5烷烃和烯烃,丁烯、戊烯和异戊二烯发挥主要作用。

3)石化企业成品油装卸过程外排油气回收处理装置和技术需进行优化和升级改造,以提升VOCs脱除效果。异戊烷、丁烯(2-丁烯、顺-2-丁烯、反-2-丁烯)、戊烯(顺-2-戊烯、反-2-戊烯)、异戊二烯和甲苯等是成品油装载过程需重点管控的优势活性物种。

某石化企业三类成品油装载环节的有机污染物排放特征、环境影响及控制措施

Emission characteristics, environmental implications and its control measures of organic pollutants from three typical petrochemical oil product loading process

-

摘要: 石化行业的成品油装载环节是有机污染物的重点排放源,包括挥发性有机物(VOCs)和甲烷等。对我国某石化企业的汽油、航煤和柴油三类成品油在装载过程中外排的尾气进行了监测,并采用·OH损失速率和最大增量反应活性法,重点分析了装载过程中VOCs和甲烷的排放特征、大气反应活性及环境影响,并提出相关控制措施。结果表明,成品油装载环节外排的VOCs以烷烃为主。每吨成品油在装载过程中排放的VOCs强度达到2.2~36.4 g,其中汽油排放强度最高。丁烷、戊烷和己烷等C4~C6烃是主要烷烃组分;丙酮是含量最高含氧物质;丁烯、异戊二烯和戊烯是最主要的烯烃组分。这类VOCs具有较高大气光化学反应活性和臭氧生成潜势(OFP),大气活性与二甲苯活性相当。VOCs的OFP(即每克VOCs可产生的O3质量)达到1.4~2.7 g·g−1。航煤装载环节外排VOCs的反应活性与臭氧潜势高于汽油和柴油。装载环节外排VOCs的反应活性及臭氧生成潜势主要源于烷烃和烯烃组分,异戊烷、C4~C5烯烃和甲苯等是需优先控制的高活性物质。本研究可为石化企业从源头开展VOCs等有机污染物的精准管控提供参考。Abstract: Petrochemical oil product loading process was key volatile organic compounds (VOCs) and methane emission source which vent valuable oil product into atmosphere and play vital roles in regional air pollution. The vents from loading process of petrol, jet-fuel, and diesel in a petrochemical facility were sampled and measured in this study. The ambient photochemical reactivity was developed based on the value of OH loss rate (LOH). By virtue of the maximum increment reactivity method, source influences in terms of ozone formation potential (OFP) were determined. The emission characteristics of VOCs were analyzed and control measures were developed. The results suggest that alkane was the largest fraction in VOCs of the oil product loading process. The VOCs emission strength of loading process ranges from 2.2 to 36.4 g per ton oil product loaded. The C4~C6 alkane including butane, pentane and hexane were founded to be primary species. Acetone was the main oxygen-containing compound while butene, isoprene and pentene dominate in alkene compounds. The oil product loading process vented VOCs features in relative high photochemical reactivity and OFP, with atmospheric reactivity equivalent to that of xylene and OFP ranging from 1.4~2.7 g·g−1. The atmospheric reactivity and OFP of jet-fuel related VOCs was higher than that of petrol and diesel. The alkane and alkene were found to contribute mostly to VOCs related photochemical reactivity and OFP during the loading process. The isopentane, C4~C5 alkene, and methyl-benzene were recommended to give preferred control priority.

-

Key words:

- oil product /

- loading process /

- volatile organic compounds /

- emission source /

- atmospheric reactivity

-

臭氧已成为影响我国夏季空气质量的首要污染物[1]。挥发性有机物 (volatile organic compounds, VOCs) 是生成臭氧和细颗粒物的主要前体物[2-3]。人为源VOCs持续高强度排放是大气污染重要根源[4-5]。开展重点行业VOCs治理是改善城市空气质量的有效途径,并已成为研究热点[6-7]。石化企业是VOCs重点排放源,对区域大气影响显著[8-15]。设备组件与管线泄露、工艺废气、污水集输与处理、储罐和成品油装卸等是石化企业主要VOCs排放源,而不同污染源的VOCs排放特征及环境影响差异性较大[16-23]。现有研究多以石化行业整体为研究对象,而对具体污染源VOCs排放特征及影响尚不多[11-12,16-19,22]。

WEI 等[17]对北京地区炼化企业排放的VOCs进行了采样分析发现,催化裂化装置对周边环境影响最大。MO等[18]研究了我国长三角地区炼化装置的VOCs排放特征。CHEN等[19]指出,成品油装卸单元是重要的VOCs排放源。LV等[23]对我国地方炼化储罐、设备泄露和污水系统VOCs排放现状进行了研究。FENG等[24]通过厂区内强化采样方法,研究了华北地区炼化企业的VOCs组成特征,发现催化重整及污水处理过程中排放的烷烃占比最高,可达到48.0%和59.2%,而丙烯回收及催化裂化单元VOCs则以烯烃为主,另外,长链烷烃是延迟焦化重要组分。ZHANG等[25]在研究了我国珠三角地区炼化企业工艺装置及污水处理环节VOCs组成特征后发现,除化工装置外,其余装置及污水系统VOCs以烷烃为主,而C5~C6是首要组分。比较而言,成品油装卸过程,尤其是成品油装载过程中VOCs排放组分特征及对环境影响的研究相对较少[18]。

基于此,本研究以我国某石化企业的成品油公路罐车装载过程为对象,对汽油、航空煤油和柴油等成品油装载过程外排的VOCs和甲烷进行采样和全组分分析,以明确成品油装载过程中VOCs和甲烷等有机污染物的排放特征,并基于·OH反应速率和最大增量反应活性方法,开展光化学反应活性和臭氧生成潜势研究,进而定量评估成品油装载外排VOCs对周边环境的影响,以期为从源头开展成品油装载过程有机污染物的精准管控提供参考。

1. 材料与方法

1.1 成品油装载过程

以我国西北某石化企业成品油公路罐车的装载过程为对象,对汽油、航煤和柴油装载过程外排的VOCs和甲烷进行了采样分析。装载过程可能的有机污染物排放过程包括在装载栈台的装油过程、运输过程及在储存单位的卸油过程。有机污染物种类包括甲烷和VOCs等。汽油装载栈台的年装载能力可达100万吨,柴油为30万吨,航煤为40万吨。汽油和航煤的装载过程均配备了油气收集处理装置,其VOCs废气处理能力达到300 m3·h−1。汽油和航煤装载过程的采样点均在油气回收处理装置外排废气采样口;柴油装载过程中尚无直接收集处理装置,为收集后直接排放。采样点为油罐车油气收集鹤管汇管采样口。

1.2 样品采集

在不影响装置安全运行的前提下,采用SUMMA罐 (3.2 L, Entech., USA) 对成品油装载外排有机污染物进行采集,采样点如图1所示。汽油和航煤装载过程的采样点位于油气回收处理单元外排废气采样口,柴油装卸过程采样点位于鹤管油气汇管采样口。每个排放点采集2组,共采集6个样品。采样日期为2020年7月16日至2020年7月22日。采样日天气晴,气温为28~35 ℃,风速为0.1~1 m·s−1。

在采样前,通过自动清洗装置 (3100, ENTECH, USA) 对SUMMA罐进行了氮气置换清洗和抽真空等预处理。通过罐自抽气方式进行采样,采样时间为15 min。采样速率通过罐前置流量控制仪 (CS 1200E, Passive Sampler, ENTECH, USA) 来实现。采样步骤如下:在采样开始前,将SUMMA罐与前置流量控制仪连接 (流速为210 mL·min−1),将流量控制仪进气端管线末端与采样口通过硅胶管连接,随后打开罐顶采样阀进行采样。采取结束后关闭罐顶阀门,断开前置流量控制仪。

1.3 仪器与分析

参照HJ 604-2017相关规范要求[26],通过气相色谱火焰离子检测仪 (GC-FID, 3420A, 北分瑞利, 中国) 对样品进行了甲烷与非甲烷总烃分析。分析条件为:色谱柱为甲烷柱 (4 mm×2 m) 和总烃柱 (0.53 mm×30 m);进样体积为1 mL;进样温度为100 ℃;柱箱温度为80 ℃;检测器温度为200 ℃;检测器为火焰离子检测器。

参考美国环境保护署 (EPA) 推荐的TO-15方法[27],对样品进行了VOCs组分分析。分析设备为气相色谱火焰离子检测与质谱分析联用仪 (GC-FID/MS, GC 7890B/MS 5977A, Agilent, USA)。气相色谱采用的分离柱为DB-1 (60 m×0.25 mm×1 μm) 和HP-PLOT/Q+PT (30 m×0.32 mm×20 μm)。质谱离子源温度为250 ℃,四级杆温度为250 ℃,扫描方式为SCAN。通过中心切割,轻质烃 (C2~C4) 进入FID检测器,其余组分进入质谱检测器。VOCs组分检出下限为0.1~1.6 μg·m−3 (进样量为400 mL),可满足分析要求。

通过PMAS标准气 (1 mg.m−3, SPECTRA GASES, USA) 配置了不同质量浓度的校准气体 (1、10、20、50和100 μg·m−3),并绘制了标准曲线。对各浓度校准曲线进行了相关性分析,其相关性在0.992 (R2) 以上。利用VOCs组分峰面积与对应质量浓度间的线性关系进行样品定量分析。样品中C2~C4组分的质量浓度通过外标法进行定量,其余VOCs组分通过内标法进行定量分析。内标物为溴氯甲烷和1,4-二氟苯。样品平行测试标准方差为0.17~0.36,结果为2组样品的平均值。

2. 结果与讨论

2.1 三类成品油装载过程中VOCs排放特征

三类石化行业成品油在装载过程中外排甲烷及VOCs的质量浓度和强度如表1所示。不同成品油装载过程外排差异较大,排放的气态污染物中VOCs质量浓度远高于甲烷,汽油装载外排的VOCs质量浓度高于航煤和柴油。结合成品油密度,对装载过程的污染物排放强度进行估算后发现,汽油装载VOCs排放强度最高,每吨成品油的VOCs排放量达到36.4 g;柴油和航煤装载每吨成品油的VOCs排放强度较低,分别为5.9 g和2.2 g。除VOCs外,成品油装载过程也是重要的甲烷排放源。每吨成品油装载过程中甲烷排放强度达到0.004~0.14 g。汽油装载过程最高,航煤装载过程最低。

表 1 成品油装载过程中有机污染物的质量浓度与排放强度Table 1. Concentration and emission strength of organic pollutants during oil product loading process成品油种类 CH4质量浓度/(mg·m−3) VOCs质量浓度/(mg·m−3) CH4排放强度/(g·t−1) VOCs排放强度/(g·t−1) 汽油 104.0 27 096.0 0.14 36.37 航煤 3.2 1 716.8 0.004 2.21 柴油 10.6 4 969.6 0.012 5.95 成品油物性及油气回收工艺的差异是导致装载过程中VOCs及甲烷排放特征不同的主要原因。考虑成品油挥发性,在成品油装载过程中产生VOCs质量浓度按降序排列依次为:汽油、航煤和柴油。在本研究中,在汽油装载过程中配有“贫油吸收+活性炭吸附”装置对VOCs进行回收处理,在航煤装载过程中配备VOCs处理工艺为“低温冷凝+膜分离+活性炭吸附”。经油气回收装置处理后,汽油及航煤装载环节排放的VOCs质量浓度大幅降低,而柴油装载过程未配置油气回收处理设施,这导致其直排废气中VOCs质量浓度与强度高于航煤。

由于汽油装载VOCs质量浓度极高,而活性炭吸附对低质量浓度VOCs处理效果较好,对高质量浓度VOCs处理效果相对有限,导致活性炭吸附后汽油装载中排放的VOCs仍较高。在现有工艺基础上配套深度处理单元是提高汽油装载有机污染物处理效果的有效途径。

对汽油和航煤装载过程有机污染物的处理效果进行分析。以处理前为基准,处理后汽油装载过程排放的VOCs质量浓度和强度分别降低了97.7% (运行初期) 和48% (平稳运行100 h后),而航煤装载过程VOCs削减了81.1%,每吨成品油装载VOCs减少量达到1 587.7g (汽油装载过程及运行初期) 和9.5 g(航煤装载过程)。我国《石油炼制工业污染物排放标准(31570-2015)》和《储油库大气污染物排放标准 (20950-2020) 》要求[28-29],汽油和航煤等成品油装载外排VOCs质量浓度不得超过25 g·m−3,处理效率不得低于95%。综上所述,该企业汽油装载过程中外排有机污染物质量浓度尚未达标,航煤处理装置效率亦有待提高。

成品油装载过程中VOCs的组成如图2所示。外排VOCs含有烷烃、烯烃、芳香烃和含氧物质,组成的差异性较大。汽、柴、航煤等成品油装载过程中外排的VOCs以烷烃为主,其质量分数达到55.1%~64.5%。含氧类物质占比紧随其后,为16.5%~23.6%。烯烃是成品油装载外排VOCs的重要组成部分,其质量分数为16.1%~18.5%;芳香烃在成品油VOCs中占比较低,仅为0.7%~8.9%。

进一步分析发现,在汽油、航煤和柴油装载过程外排的VOCs中,C4~C5烷烃在饱和烃中的占比由77.2%逐渐降至41.1%,C6~C7烷烃占比则从4.4%不断升至43.4%;丁烯占烯烃比例从95.6%降至17.7%,戊烯和异戊二烯占比则由3.7%升至73.5%。这说明随成品油密度升高,烷烃类和烯烃类VOCs中长链高碳组分占比不断提升。甲苯、邻二甲苯和间/对二甲苯是成品油装载过程外排主要芳香化合物。丙酮是成品油装载过程中最主要的含氧类物质,占含氧类物质50%以上。

在成品油装载过程中,质量分数前5位的VOCs物质 (基于质量占比的优势物种)的分析结果如表2所示。成品油装载过程中外排的优势VOCs物种具有一定规律性和差异性。汽、柴、航煤装载外排VOCs中含量最高的组分为异戊烷,其次为丙酮。正丁烷、正戊烷和反-2-丁烯是汽油和航煤等装载过程的主要组分;柴油装载过程中高含量组分则以乙酸乙烯酯、正己烷和甲基环戊烷为主。因此,汽油和航煤等外排VOCs优势组分以C4~C5烷烃组分为主,柴油装载过程外排优势组分向C5~C6过渡。

表 2 成品油装载过程中排放前5位的VOCs组分Table 2. Top five VOCs species for oil product loading process汽油 航煤 柴油 物质 占比/% 物质 占比/% 物质 占比% 异戊烷 27.8 异戊烷 31.1 异戊烷 21.9 丙酮 21.2 丙酮 23.5 丙酮 9.0 反-2-丁烯 8.6 正丁烷 7.4 乙酸乙烯酯 6.7 正丁烷 7.5 反-2-丁烯 7.3 正己烷 6.3 正戊烷 7.2 正戊烷 4.4 3-甲基戊烷 5.2 综上所述,该石化企业成品油装载过程外排优势烷烃类VOCs物种为C4~C6,异戊烷占主导地位;优势烯烃组分为反-2-丁烯;优势含氧化合物为丙酮和乙酸乙烯酯;前5位VOCs组分占比超过45%。

2.2 光化学反应活性分析

·OH损失速率法 (LOH) 是判定VOCs组分光化学反应活性的重要方法[6,9]。VOCs组分与·OH之间的光化学反应十分复杂,反应过程如式(1)~(7)所示。以VOCs与·OH间的反应速率为基础,对成品油装载过程排放有机污染物的光化学反应活性进行了分析,计算方法如式 (8) 和 (9) 所示。

stringUtils.convertMath(!{formula.content}) (1) stringUtils.convertMath(!{formula.content}) (2) stringUtils.convertMath(!{formula.content}) (3) stringUtils.convertMath(!{formula.content}) (4) stringUtils.convertMath(!{formula.content}) (5) stringUtils.convertMath(!{formula.content}) (6) stringUtils.convertMath(!{formula.content}) (7) stringUtils.convertMath(!{formula.content}) (8) stringUtils.convertMath(!{formula.content}) (9) 式中:LOH为废气·OH损失速率常数,s−1;LiOH为VOCs组分i的·OH损失速率常数(s−1);KiOH:组分i的·OH反应速率常数[30];Fi为组分i的浓度,mol·m−3。本研究检出VOCs组分的速率常数如表3所示。

表 3 检测出的VOCs组分·OH反应速率常数Table 3. Reaction rate with ·OH radical for identified VOCs species (s-1)烷烃种类 常数 烷烃种类 常数 烯烃种类 常数 芳香烃种类 常数 乙烷 0.248 2,3-二甲基丁烷 5.53 乙烯 8.52 苯 1.22 丙烷 1.09 2-甲基戊烷 5.2 丙烯 26.3 甲苯 5.63 异丁烷 2.36 3-甲基戊烷 5.2 反-2-丁烯 56.4 乙苯 7.0 正丁烷 2.36 2,4-二甲基戊烷 4.77 1-丁烯 31.4 间/对-二甲苯 13.6 异戊烷 3.6 甲基环戊烷 顺-2-丁烯 64 邻-二甲苯 23.1 正戊烷 3.8 2-甲基己烷 1,3-丁二烯 苯乙烯 58 正己烷 5.2 2,3-二甲基戊烷 4.77 1-戊烯 31.4 异丙苯 6.3 正庚烷 6.76 3-甲基己烷 反-2-戊烯 65 正丙苯 5.8 正辛烷 8.11 2,2,4-三甲基戊烷 3.34 异戊二烯 66.6 1,3,5-三甲基苯 56.7 正壬烷 9.7 甲基环己烷 9.64 顺-2-戊烯 66 1,2,4-三甲基苯 32.5 正葵烷 11 2,3,4-三甲基戊烷 6.6 1-己烯 37 1,2,3-三甲基苯 32.5 十一烷 12.3 2-甲基庚烷 1,4-二乙基苯 14.5 环戊烷 4.97 3-甲基庚烷 2-乙基甲苯 11.9 环己烷 6.97 十二烷, 13.2 3-乙基甲苯 18.6 2,2-二甲基丁烷 2.23 4-乙基甲苯 11.8 在成品油装载过程中单位体积有机污染物的反应活性 (LOH) 达到1.5×105~1.8×106 s−1,其中航煤装载过程外排有机污染物的LOH值最低,汽油装载过程有机污染物的LOH值最高。进一步分析发现,外排有机污染物的中单位物质的量VOCs对应的反应活性为11.1~ 13.5 s−1,其中柴油装载过程最低,航煤装载过程最高。与烯烃和苯系物等VOCs组分反应活性进行了对比[28],装载过程外排有机污染物反应活性高于乙烯组分,与对二甲苯组分活性相当,其光化学反应活性很强。

对外排有机污染物的LOH组成进行了分析,结果如图3所示。在成品油装载过程中反应活性主要来自于烯烃组分,贡献比例为70.8%~85.2%。其中,航煤装载过程中烯烃占比最高。对反应活性精细化的组分进行了分析,结果表明:反-2-丁烯和顺-2-丁烯对汽油装载反应活性发挥主导作用,占烯烃总活性的89.4%;反-2-丁烯、顺-2-丁烯和反-2-戊烯对航煤装载过程活性产生关键影响,占烯烃总活性比例接近83.8%;柴油装载过程主要活性组分为异戊二烯、反-2-戊烯和顺-2-戊烯,三者对烯烃总活性贡献比例总计为78.4%。

烷烃是成品油装载过程外排有机污染物反应活性的重要组成部分,占比为15.5%~23.8%。其中,异戊烷发挥主要作用,对烷烃反应活性的贡献范围为36.4%~58.3%。芳香烃对反应活性贡献比例较低,为0.6%~5.4%,其中比例最高的是柴油装载过程,最低的为航煤过程,而甲苯和间/对二甲苯为主要活性组分。

对LOH贡献占比前5位组分 (优势物种) 进行了分析,结果如图4所示。图中各组分按活性占比高低从左至右依次排列。不同成品油装载过程基于反应活性贡献的优势VOCs物种略有差异,但均以顺-2-丁烯、反-2-丁烯、异戊二烯、顺-2-戊烯、反-2-戊烯和异戊烷等C4~C6烷烃和烯烃组分为主。值得注意的是,随着成品油密度升高,外排废气中活性优势烯烃物种逐渐由C4烯烃向C5烯烃过渡。综上所述,成品油装载外排有机污染物的反应活性主要来源于优势物种,贡献比例前5位的物质对LOH合计贡献可达70.9%~87.5%,而丁烯、异戊二烯、戊烯和异戊烷等是最主要活性组分。

2.3 臭氧生成潜势分析

臭氧生成潜势 (ozone formation potential, OFP) 是研究VOCs组分大气臭氧生成能力的重要方法[18]。采用最大增量反应活性法 (maximum increment ractivity, MIR) 对成品油装载过程外排废气臭氧生成能力进行分析,废气的OFP计算方法如式 (10) 和 (11) 所示。

stringUtils.convertMath(!{formula.content}) (10) stringUtils.convertMath(!{formula.content}) (11) 式中:OFP即废气臭氧生成潜势,mg·m−3;OFPi为组分i的臭氧生成潜势,mg·m−3;MIRi为组分i的MIR系数[31];Ci为组分i的质量浓度,mg·m−3。

成品油装载过程单位体积外排有机污染物的OFP可达1 865~ 1.25×104 mg·m−3,其中汽油装载过程数值最高,航煤装载过程最低。以单位质量VOCs对应OFP为依据,进一步分析发现,VOCs的臭氧生成潜力达到1.4~2.7 g·g−1,航煤装载外排有机污染物的数值最高,汽油装载过程最低。结合各组分臭氧生成潜势数据[29]发现:汽油装载外排有机污染物的臭氧生成能力与异戊烷基本相当;航煤装载外排有机污染物的臭氧生成能力与甲苯基本相当;柴油装载外排有机污染物臭氧生成能力介于异戊烷和甲苯之间,与正丙苯基本相当。

由于不同组分具有显著光化学反应活性差异,高活性组分对近污染源区域环境会产生显著影响,低活性组分主要对远距离环境臭氧产生影响。结合光化学反应活性分析结果,对成品油装载过程中周边地区臭氧影响进行分析(高活性组分臭氧潜势)后发现,汽油、航煤和柴油装载过程前5位优势活性组分臭氧生成潜势可达0.98、1.99和1.04 g·g−1,占总臭氧潜势47%以上。由此推断,成品油装载过程外排VOCs对近距离环境臭氧即可产生显著影响,应引起重视。

在不同成品油装载过程中,有机污染物中活性组分相对含量差异是导致OFP差异较大的主要原因。由于烯烃组分反应活性高,随VOCs中烯烃含量升高,对应的反应活性逐渐增加。如航煤装载外排有机污染物中烯烃含量达到18.5%,汽油装载有机污染物中烯烃含量为16.1%,而柴油装载过程烯烃相对含量仅为10.0%。因此,VOCs对应的臭氧生成能力与VOCs中烯烃含量呈正比。

MO等[18]对我国长三角地区炼化企业污染源废气反应活性进行分析后发现,各工艺装置单位质量VOCs臭氧生成潜势为1.0~10.5 g·g−1。FENG等[24]发现:我国华北地区典型炼化工艺装置排放VOCs的臭氧生成潜势为2.0~7.3 g·g−1;除丙烯回收装置,其余污染源OFP为2.0~4.0。对比分析表明,成品油装载过程外排有机污染物对应臭氧潜势与常减压和重整等典型炼化装置的反应活性大体相当。

成品油装载过程排放有机污染物的OFP组成特征如图5所示。不同成品油OFP组成差异较大。汽油和航煤装载过程外排废气OFP主要来自于烯烃组分,贡献比例分别达到72.8%和65.3%,即丁烯、异戊二烯和戊烯等C4~C5组分发挥主导作用;烷烃和烯烃对柴油装载过程OFP贡献基本相当,分别为42.3%和40.8%,即异戊烷和戊烯等为关键组分。除烷烃和烯烃外,芳香烃和含氧物质也是成品油装载过程外排有机污染物OFP的重要组成部分。芳香烃对柴油装载过程OFP的贡献比例较大,可达到14.5%,对汽油和航煤装载过程贡献较低,占比为1.6%~2.9%,其中甲苯和间/对二甲苯是主要活性物种。含氧化合物对臭氧生成潜势贡献占比较低,仅为2.2%~4.9%,其中丙酮为主要组分。

成品油装载过程排放有机污染物的OFP贡献占比前5位组分 (优势物种) 的分析结果如图6所示,各污染源优势物种按贡献占比高低从左到右依次排列。不同污染源优势VOCs物种具有一定差异。汽油装载过程优势物种均为烯烃。其中,贡献比例最高为反-2-丁烯,其次为顺-2-丁烯、反-2-戊烯、1-丁烯和顺-2-戊烯。航煤装载过程中优势OFP组分包含烯烃和烷烃。各种物质依次为:反-2-丁烯,异戊烷、顺-2-丁烯、反-2-戊烯和1-丁烯。柴油装载过程排放的优势OFP物种包括烷烃、烯烃和芳香烃等。其中,烯烃以戊烯为主,烷烃为异戊烷,芳香烃为甲苯。因此,成品油装载过程外排有机污染物的臭氧生成潜势主要来源于优势物种,对有机污染物OFP贡献可达49.8%~90.5%。

2.4 管控策略

我国对成品油装载外排有机污染物,特别是VOCs的管控提出了明确要求[28]。在当前阶段,吸附、吸收、膜分离和低温冷凝是工业VOCs的主流治理技术,在油气回收领域亦应用广泛[32-33]。虽然石化企业对汽油和航煤等成品油装载过程外排的VOCs均进行了回收和处理,但处理后的VOCs仍具有较高反应活性和臭氧生成能力。柴油装载油气普遍未进行VOCs治理,对本地区环境臭氧会产生直接影响。

1)升级现役的汽油和航煤装载过程油气回收装置,对采用活性炭吸附、溶剂油吸收等单一处理工艺进行提标改造,结合成品油装载量和实际VOCs排放负荷配套低温冷凝、膜分离等工艺单元,提高VOCs回收和处理效率。针对夏季高温造成的排放量大幅增加现象,通过优化工艺参数(降低冷凝温度、提高吸附剂装填量等)、提高运行负荷等措施实现VOCs高效脱除。

2)开展柴油装载废气处理装置的研发。结合柴油装卸过程排放特征,设计和建设油气回收处理设施,工艺技术以膜分离+吸附为主。当柴油与汽油、航煤在同一地点装载时,将柴油外排油气并入汽油和航煤油气,利用现有装置合并处理。

3)重点控制高臭氧潜势组分排放。异戊烷、丁烯(1-丁烯、顺-2-丁烯、反-2-丁烯)、异戊二烯、戊烯(顺-2-戊烯、反-2-戊烯)和甲苯等高臭氧潜势组分排放,通过选择性吸附和膜分离等技术,提高烯烃和芳香烃等活性组分去除效率,降低废气臭氧生成能力。

4)在油气回收处理装置配套安装在线监测系统,对外排烯烃和芳香烃等特征污染因子进行实时监测,以量化和明确成品油装卸过程污染排放及影响情况。

3. 结论

1)成品油装载过程是重要的污染物排放源,VOCs质量浓度可达1 716.8~27 096 mg·m−3。每吨成品油装载过程的VOCs排放强度达到2.2~36.4 g,甲烷排放强度达到0.004~0.14 g。成品油装载过程外排的VOCs以烷烃为主,占比可达55.1%~64.5%,丁烷、戊烷和己烷等C4~C6是主要组分。含氧类物质和烯烃是重要VOCs组分,丙酮是含量最高含氧物质,占总含氧物质的50%以上;丁烯、异戊二烯和戊烯是最主要的烯烃,占烯烃总量的70%以上。芳香烃在VOCs中占比较低。

2)在装载过程中外排VOCs反应活性较高,与二甲苯活性基本相当。烯烃是反应活性主要贡献源,占比高达70.8%~85.2%,其中C4~C5烯烃组分发挥主导作用。VOCs的臭氧生成潜势达到1.4~2.7 g·g−1,含氧化合物和芳香烃贡献占比较低,臭氧生成潜势主要源于C4~C5烷烃和烯烃,丁烯、戊烯和异戊二烯发挥主要作用。

3)石化企业成品油装卸过程外排油气回收处理装置和技术需进行优化和升级改造,以提升VOCs脱除效果。异戊烷、丁烯(2-丁烯、顺-2-丁烯、反-2-丁烯)、戊烯(顺-2-戊烯、反-2-戊烯)、异戊二烯和甲苯等是成品油装载过程需重点管控的优势活性物种。

-

表 1 成品油装载过程中有机污染物的质量浓度与排放强度

Table 1. Concentration and emission strength of organic pollutants during oil product loading process

成品油种类 CH4质量浓度/(mg·m−3) VOCs质量浓度/(mg·m−3) CH4排放强度/(g·t−1) VOCs排放强度/(g·t−1) 汽油 104.0 27 096.0 0.14 36.37 航煤 3.2 1 716.8 0.004 2.21 柴油 10.6 4 969.6 0.012 5.95 表 2 成品油装载过程中排放前5位的VOCs组分

Table 2. Top five VOCs species for oil product loading process

汽油 航煤 柴油 物质 占比/% 物质 占比/% 物质 占比% 异戊烷 27.8 异戊烷 31.1 异戊烷 21.9 丙酮 21.2 丙酮 23.5 丙酮 9.0 反-2-丁烯 8.6 正丁烷 7.4 乙酸乙烯酯 6.7 正丁烷 7.5 反-2-丁烯 7.3 正己烷 6.3 正戊烷 7.2 正戊烷 4.4 3-甲基戊烷 5.2 表 3 检测出的VOCs组分·OH反应速率常数

Table 3. Reaction rate with ·OH radical for identified VOCs species (s-1)

烷烃种类 常数 烷烃种类 常数 烯烃种类 常数 芳香烃种类 常数 乙烷 0.248 2,3-二甲基丁烷 5.53 乙烯 8.52 苯 1.22 丙烷 1.09 2-甲基戊烷 5.2 丙烯 26.3 甲苯 5.63 异丁烷 2.36 3-甲基戊烷 5.2 反-2-丁烯 56.4 乙苯 7.0 正丁烷 2.36 2,4-二甲基戊烷 4.77 1-丁烯 31.4 间/对-二甲苯 13.6 异戊烷 3.6 甲基环戊烷 顺-2-丁烯 64 邻-二甲苯 23.1 正戊烷 3.8 2-甲基己烷 1,3-丁二烯 苯乙烯 58 正己烷 5.2 2,3-二甲基戊烷 4.77 1-戊烯 31.4 异丙苯 6.3 正庚烷 6.76 3-甲基己烷 反-2-戊烯 65 正丙苯 5.8 正辛烷 8.11 2,2,4-三甲基戊烷 3.34 异戊二烯 66.6 1,3,5-三甲基苯 56.7 正壬烷 9.7 甲基环己烷 9.64 顺-2-戊烯 66 1,2,4-三甲基苯 32.5 正葵烷 11 2,3,4-三甲基戊烷 6.6 1-己烯 37 1,2,3-三甲基苯 32.5 十一烷 12.3 2-甲基庚烷 1,4-二乙基苯 14.5 环戊烷 4.97 3-甲基庚烷 2-乙基甲苯 11.9 环己烷 6.97 十二烷, 13.2 3-乙基甲苯 18.6 2,2-二甲基丁烷 2.23 4-乙基甲苯 11.8 -

[1] 生态环境部. 2019中国生态环境状况公报[R/OL], 2020. https://www.mee.gov.cn/hjzl/sthjzk/zghjzkgb/202006/P020200602509464172096.pdf [2] ATKINSON R. Atmospheric chemistry of VOCs and NOx[J]. Atmospheric Environment, 2000, 34(12/13/14): 2063-2101. [3] ZIEMANN P J, ATKINSON R. Kinetics, products and mechanisms of secondary organic aerosol formation[J]. Chemical Society Reviews, 2012, 41(19): 6582-6605. doi: 10.1039/c2cs35122f [4] 余益军, 孟晓艳, 王振, 等. 京津冀地区城市臭氧污染趋势及原因探讨[J]. 环境科学, 2020, 41(1): 106-141. doi: 10.13227/j.hjkx.201905222 [5] WANG T, XUE L K, BRIMBLECOMBE P, et al. Ozone pollution in China: A review of concentrations, meteorological influences, chemical precursors, and effects[J]. Science of the Total Environment, 2017, 575: 1582-1596. doi: 10.1016/j.scitotenv.2016.10.081 [6] LI L Y, XIE S D, GENG L M, et al. Characteristics of volatile organic compounds and their role in ground-level ozone formation in the Beijing-Tianjin-Hebei region, China[J]. Atmospheric Environment, 2015, 113: 247-254. doi: 10.1016/j.atmosenv.2015.05.021 [7] 潘本锋, 程麟钧, 王建国, 等. 京津冀地区臭氧污染特征与来源分析[J]. 中国环境监测, 2016, 32(5): 17-23. doi: 10.19316/j.issn.1002-6002.2016.05.04 [8] CETIN E, ODABASI M, SEYFIOGLU R. Ambient volatile organic compound concentrations around a petrochemical complex and a petroleum refinery[J]. Science of the Total Environment, 2003, 312: 103-112. doi: 10.1016/S0048-9697(03)00197-9 [9] 吴亚君, 胡君, 张鹤丰, 等. 兰州市典型企业VOCs排放特征及反应活性分析[J]. 环境科学研究, 2019, 32(5): 802-812. doi: 10.13198/j.issn.1001-6929.2019.02.09 [10] 刘锦, 王秀艳, 杨文, 等. 天津临港石化企业VOCs排放特征及环境影响[J]. 环境科学研究, 2018, 31(2): 215-220. doi: 10.13198/j.issn.1001-6929.2017.03.66 [11] 程水源, 李文忠, 魏巍, 等. 炼油厂分季节VOCs组分及其臭氧生成潜势分析[J]. 北京工业大学学报, 2013, 39(3): 438-453. [12] WEI W, CHENG S Y, LI G, et al. Characteristics of ozone and ozone precursors (VOCs and NOx) around a petroleum refinery in Beijing, China[J]. Journal of Environmental Sciences, 2014, 26(2): 332-342. doi: 10.1016/S1001-0742(13)60412-X [13] SONG Y, DAI W, SHAO M, et al. Comparison of receptor models for source apportionment of volatile organic compounds in Beijing, China[J]. Environment Pollution, 2008, 156: 174-183. doi: 10.1016/j.envpol.2007.12.014 [14] HUANG C, CHEN C H, LI L, et al. Emission inventory of anthropogenic air pollutants and VOC species in the Yangtze River Delta region, China[J]. Atmospheric Chemistry and Physics, 2011, 11: 4105-4120. doi: 10.5194/acp-11-4105-2011 [15] WU R R, BO Y, LI J, et al. Method to establish the emission inventory of anthropogenic volatile organic compounds in China and its application in the period 2008-2012[J]. Atmospheric Environment, 2016, 127: 244-254. doi: 10.1016/j.atmosenv.2015.12.015 [16] 李凌波, 刘忠生, 方向晨. 炼油厂VOC排放控制策略-储运、废水处理、工艺废气、冷却塔及火炬[J]. 当代石油化工, 2013(13): 4-11. [17] WEI W, CHENG S Y, LI G H, et al. Characteristics of volatile organic compounds (VOCs) emitted from a petroleum refinery in Beijing, China[J]. Atmospheric Environment, 2014, 89: 358-366. doi: 10.1016/j.atmosenv.2014.01.038 [18] MO Z W, SHAO M, LU S H, et al. Process-specific emission characteristics of volatile organic compounds (VOCs) from petrochemical facilities in the Yangtze River Delta, China[J]. Science of the Total Environment, 2015, 533: 422-431. doi: 10.1016/j.scitotenv.2015.06.089 [19] CHEN C L, SHU C M, FANG H Y. Location and characterization of VOC emissions at a petrochemical plant in Taiwan[J]. Environmental Forensics, 2006, 7(2): 159-167. doi: 10.1080/15275920600667138 [20] 吴丽萍, 欧盛菊, 殷宝辉, 等. 新疆维吾尔自治区石化企业典型工艺无组织VOCs排放特征及光化学反应活性[J]. 环境科学研究, 2018, 31(12): 2103-2111. doi: 10.13198/j.issn.1001-6929.2018.09.10 [21] 李勤勤, 张志娟, 李杨, 等. 石油炼化无组织VOCs的排放特征及臭氧生成潜力分析[J]. 中国环境科学, 2016, 36(5): 1323-1331. doi: 10.3969/j.issn.1000-6923.2016.05.007 [22] LIU Y, SHAO M, FU L, et al. Source profile of volatile organic compounds (VOCs) measured in China: Part I.[J]. Atmospheric Environment, 2008, 42: 6247-6260. doi: 10.1016/j.atmosenv.2008.01.070 [23] LV D Q, LU S H, TAN X, et al. Source profiles, emission factors and associated contributions to secondary pollution of volatile organic compounds (VOCs) emitted from a local petroleum refinery in Shandong[J]. Environmental Pollution, 2021, 274: 116589. doi: 10.1016/j.envpol.2021.116589 [24] FENG Y X, XIAO A S, JIA R Z, et al. Emission characteristics and associated assessment of volatile organic compounds from process units in a refinery[J]. Environmental Pollution, 2020, 265: 115026. doi: 10.1016/j.envpol.2020.115026 [25] ZHANG Z J, YAN X Y, GAO F L, et al, 2018. Emission and health risk assessment of volatile organic compounds in various processes of a petroleum refinery in the Pearl River Delta, China[J]. Environmental Pollution, 2018, 238: 452-461. doi: 10.1016/j.envpol.2018.03.054 [26] 中华人民共和国生态环境部. 环境空气 总烃、甲烷和非甲烷总烃的测定 直接进样-气相色谱法[S]. 北京: 中国环境科学出版社, 2017. [27] US EPA. 1999. Compendium Method TO-15 Determination of Volatile Organic Compounds (VOCs) in Air Collected in Specially-prepared Canisters and Analyzed by GC/MS [R/OL]. http://www.epa.gov/ttnamti1/files/ambient/airtox/to-15r.pdf. [28] 中华人民共和国生态环境部. 石油炼制工业污染物排放标准[J]. 北京, 2015: 中国环境科学出版社. [29] 中华人民共和国生态环境部. 储油库大气污染物排放标准[J]. 北京, 2020: 中国环境科学出版社. [30] ATKINSON R, AREY J. Atmospheric degradation of volatile organic compounds[J]. Chemical Review, 2003, 103: 4605-4638. doi: 10.1021/cr0206420 [31] CARTER W. Development of ozone reactivity scales for volatile organic compounds[J]. Journal of the Air and Waste Management Association, 1994, 44: 881-899. [32] 席劲瑛, 武俊良, 胡洪营, 等. 工业 VOCs 气体处理技术应用状况调查分析[J]. 中国环境科学 2012, 32(11): 1955-1960. [33] 汪智伟, 陈明功, 王旭浩, 等. 挥发性有机物处理技术研究现状与进展[J]. 现代化工, 2018, 38(7): 79-83. doi: 10.16606/j.cnki.issn0253-4320.2018.07.018 -

下载:

下载: