-

土壤重金属污染亟需修复治理[1]。以多相态存在的重金属污染物具有不稳定性,不仅危及深层土体及地下水安全,而且易通过生物群落对人体健康造成不可逆伤害[2-4]。重金属污染物的迁移受多因素控制[5],厘清特定环境下重金属污染物的界面迁移规律及其影响因素,是污染控制及修复实施前应解决的关键问题。

土壤重金属污染问题大多表现为复合污染。河北省张家口市某电镀厂旧址场地受铜(Ⅱ)、铬(Ⅵ)和镍(Ⅱ)复合污染,点位超标率分别为2.8%、2.8%和12.3%[6];江西省贵溪市贵溪农田耕层土壤受铜(Ⅱ)和镉(Ⅱ)复合污染,其中铜(Ⅱ)质量分数高达864.77 mg·kg−1 [7];济源市平原区土壤中重金属镉(Ⅱ)、铅(Ⅱ)和砷(Ⅴ)的超标率均大于100%[8];广东省汕头市莲花山部分矿区土壤因重金属镉(Ⅱ)和砷(Ⅴ)严重超标,已影响下游稻田生长[9];常熟市严重复合重金属污染土壤已对大豆的生长发育产生了不利影响[10]。复合污染时重金属离子间存在相互作用[11-12],不仅影响彼此存在形态,甚至改变其毒性[13],需统筹考虑。

重金属污染物在土壤中的迁移与土质、污染浓度、土壤深度及粒径等因素有关。熊钡等[14]以砂土、砂壤土和黏土3种土壤为研究对象,外加电场下,镍(Ⅱ)在砂土和砂壤土的迁移速度明显比黏土快,最高迁移率分别为99.9%、68.3%和37.8%;LI等[15]指出土壤团聚体粒径<15 μm时有助于提高镉(Ⅱ)的迁移能力;VILLEN-GUZMAN等[16]选取西班牙某矿区砂壤土,证实土壤老化后铅(Ⅱ)的迁移速率降低;陈榕等[17]发现铅(Ⅱ)污染液浓度增加,迁移速率加快,穿透时间显著减小;吕达等[18]用砂箱试验装置模拟重金属在土壤系统中的迁移特征,表明重金属的垂向迁移能力铬(Ⅵ)>镍(Ⅱ)≈钴(Ⅱ)>铜(Ⅱ)。

基于电动原理的修复技术可实现介质中污染物的净化,是污染土治理领域热点[19-20]。重金属污染物随径流的迁移及在土壤中借助水头差、离子浓度差等作用下的迁移机制研究较为成熟[21-23]。因此,厘清以电动协同作用下界面迁移规律是推进电动修复技术应用的关键。

本研究以典型阴阳离子复合重金属 (铜(Ⅱ)-铬(Ⅵ)) 污染为对象,以砂土粒径、电压梯度、初始污染物浓度为影响因素,借助界面取样及多元重组构建重金属污染物的界面迁移规律,摸清影响因素的作用,明确污染物间的交互影响。以期丰富离子迁移理论,为复合重金属污染土的污染控制提供参考,并推动电动修复技术的工程应用。

-

采用CuCl2•2H2O和Na2Cr2O7•2H2O(分析纯)中的1种 (或2种,离子浓度以1:1等比例分别均匀混合) 制备单一/复合重金属污染液;实验所用砂土采用3种不同粒径,其相关参数见表1。使用去离子水反复清洗砂土,烘干并晾至室温,加入污染液并包裹保鲜膜均衡1 d设置质量分数分别为50 mg·kg−1、200 mg·kg−1、500 mg·kg−1和700 mg·kg−1 4个污染水平[21]的单一/复合重金属砂土,每组作3次平行实验。

-

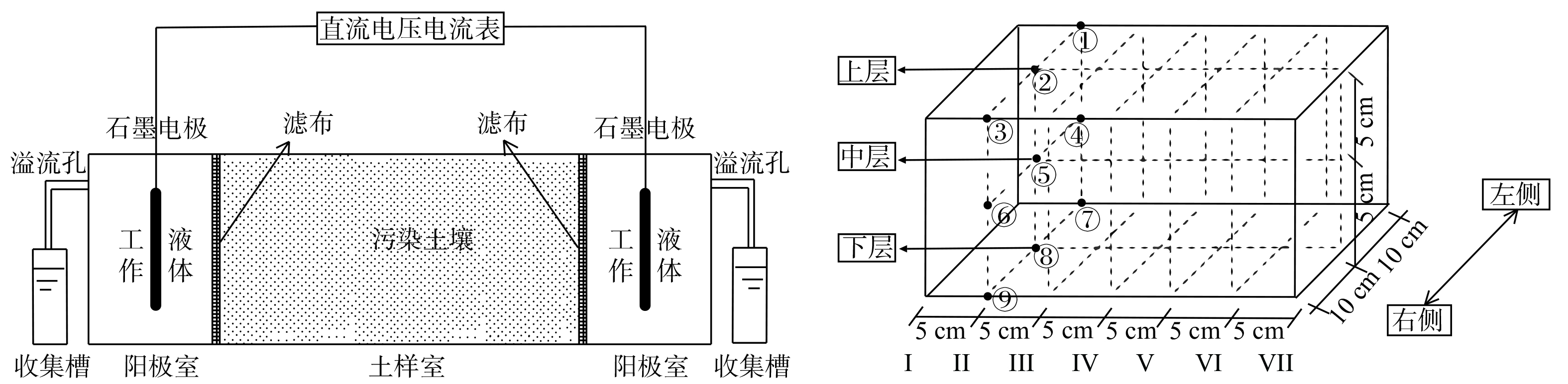

电动装置由土样室和电极室两部分组成 (图1) ,采用有机玻璃材料。土样室的尺寸为:长×宽×高=30 cm×20 cm×10 cm。两侧电极室的尺寸为:长×宽×高=10 cm×20 cm×10 cm。土样室和电极室连接部分多孔隔板内侧添加250目滤布,滤布与土体之间放入定制均匀多孔的有机玻璃隔板 (长×宽=20 cm×20 cm) ,防止实验砂土进入电极室;采用0.1 mol·L−1KCl溶液作为阳极和阴极工作液体加入阴、阳极室,与阴阳极室相连的是蠕动泵,用于保证电解液的体积恒定。电压梯度设置0.375 V·cm−1、0.750 V·cm−1、1.125 V·cm−1 [24]。

-

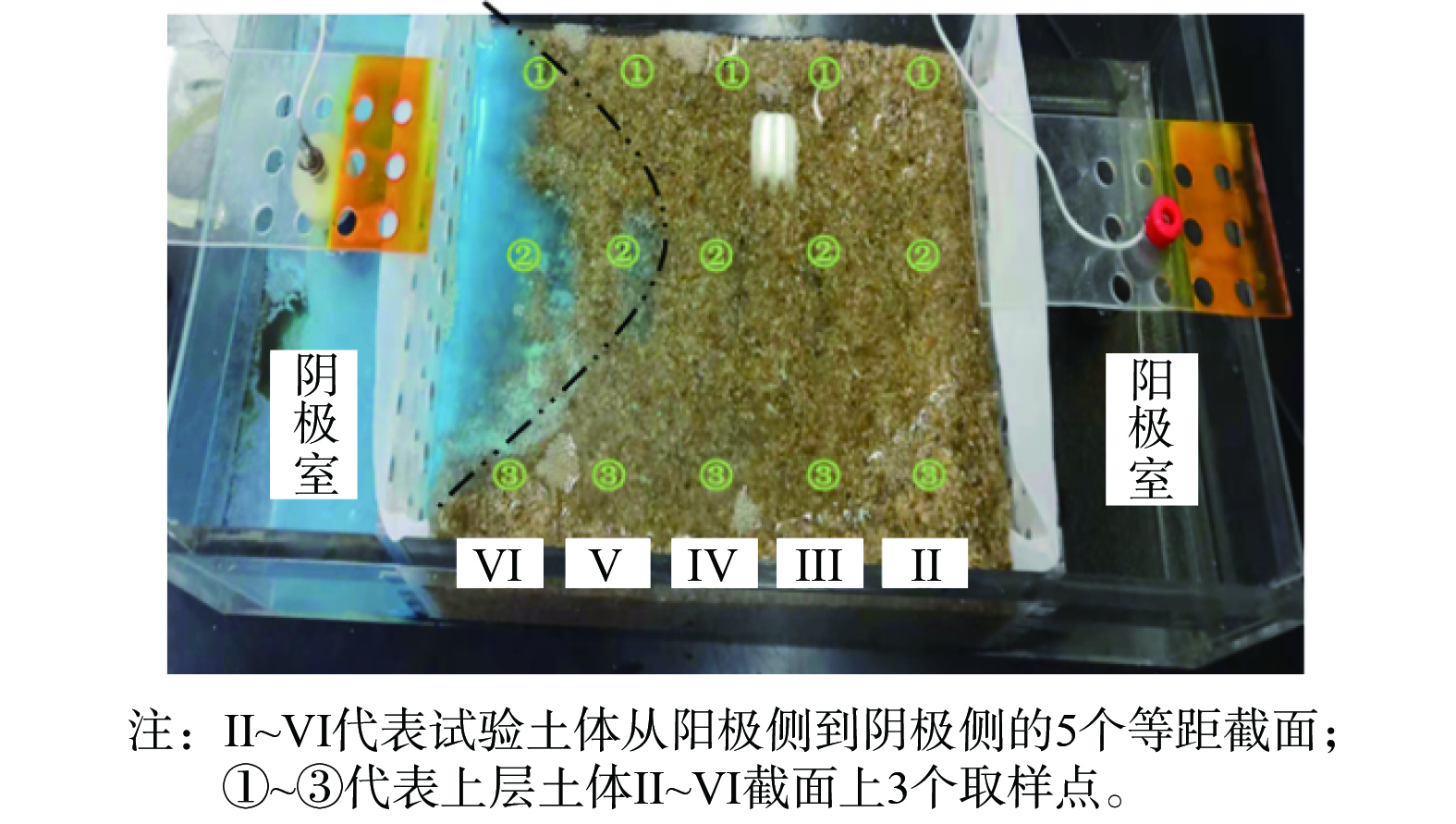

土样室区域由阳极到阴极平均分为7个截面,编号依次为I~VII。每个截面上设9个取样点 (图2) 。每次取样时从上至下挖至容器底部,以减小因扰动产生的误差。采用 Skyray手持式土壤重金属分析仪 (Expiorer 9000,江苏天瑞仪器股份有限公司) 对土体中的铜、铬重金属浓度进行测定,2种元素检出线分别为0.04 mg·kg−1和0.10 mg·kg−1 (以纯SiO2为测试基体)。

-

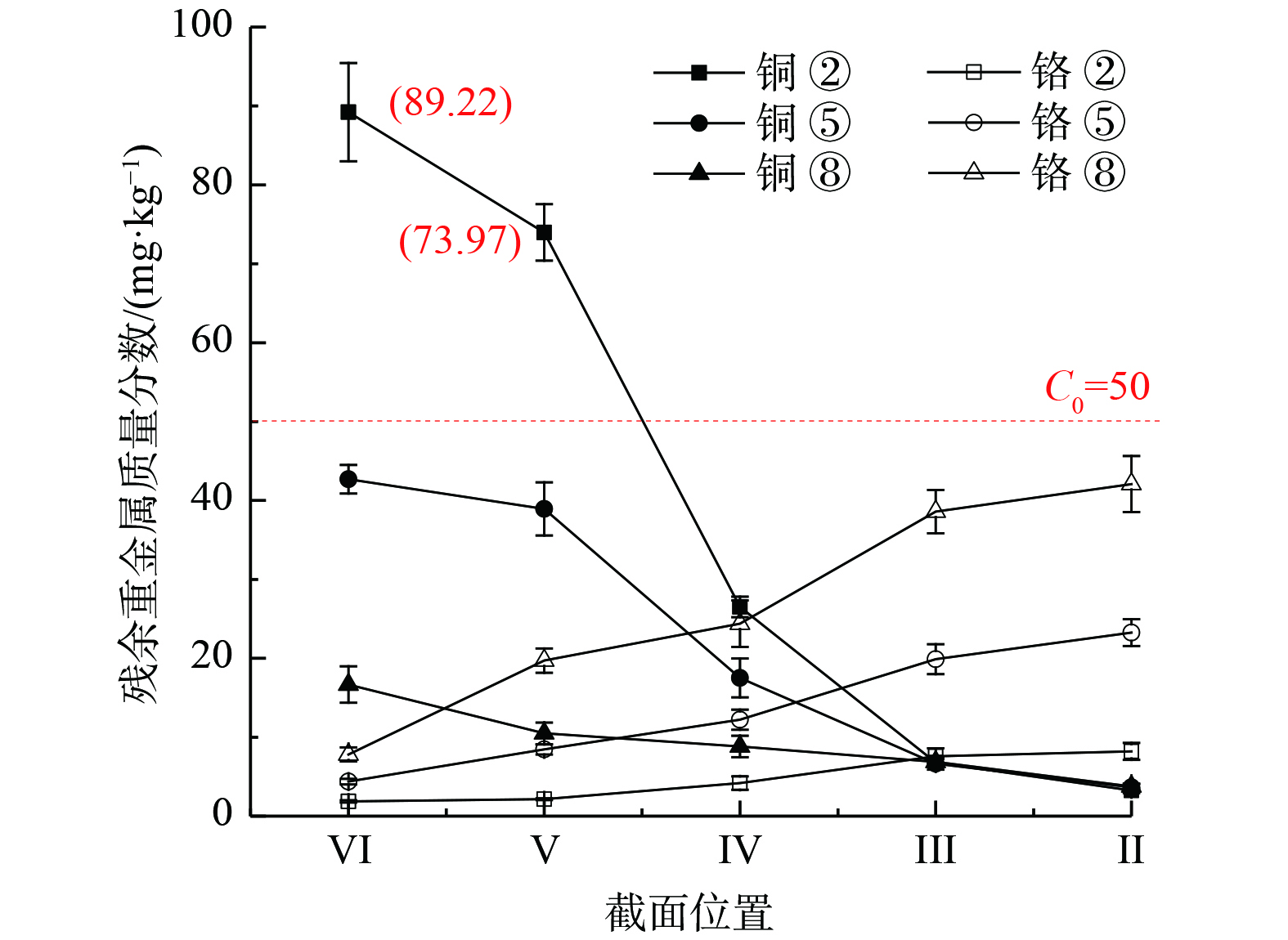

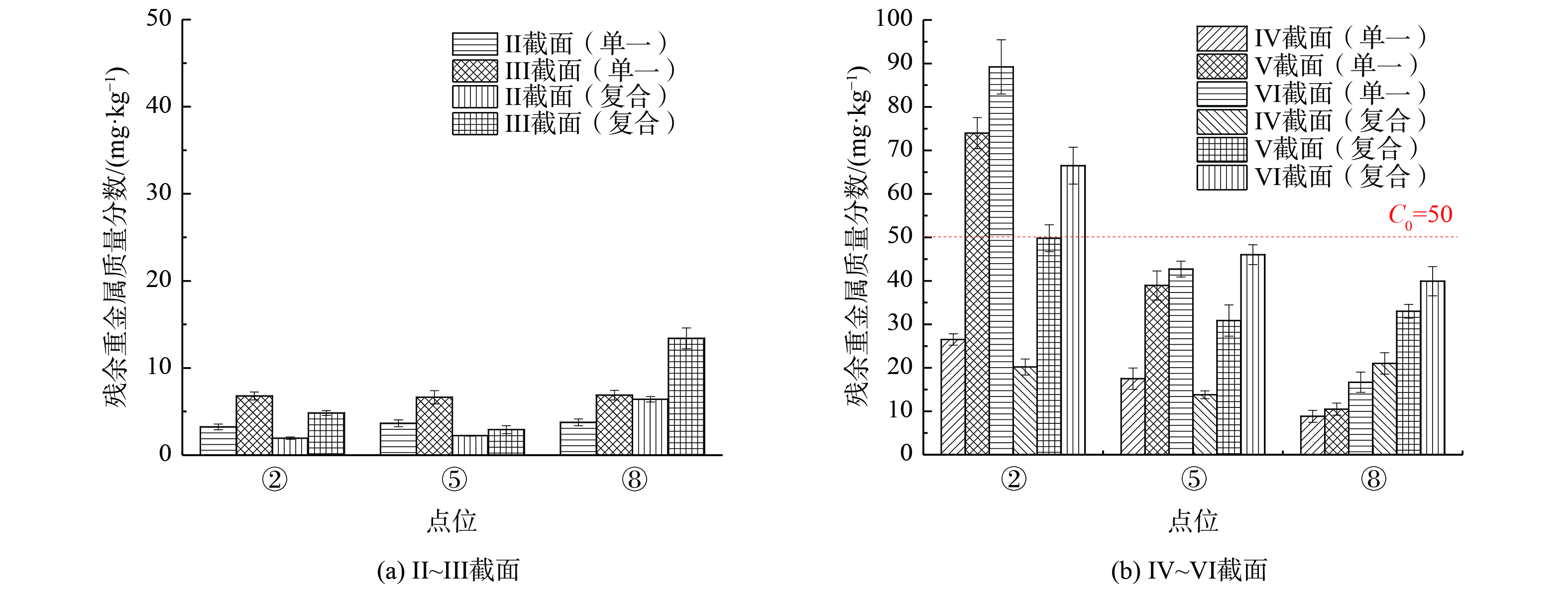

1) 中心点处重金属污染物的横向迁移规律。不同浓度条件下重金属污染物的横向迁移规律相似,以50 mg·kg−1质量分数为例进行说明。各中心点位残余铜在横向界面均呈向阴极递增趋势,且靠近阴极区域的V和VI截面各点位铜的残余质量分数远高于初始值,其②点的残余质量分数分别超出初始值的47.94%和78.44% (图2)。这是由于外加电场作用下,电解水过程产生的氢离子使铜解吸,转化为离子态,向阴极迁移富集[25]。而电解水产生的氢氧根离子电迁移率小于氢离子,阴极附近形成碱性带[26],铜溶解性降低,多以氢氧化铜絮状体形式赋存 (反应式 (1) ) ,出现聚焦效应[27]。

铬的整体残余质量分数低于初始值 (图2) ,其中②点位铬的残余质量分数为1.86~8.21 mg·kg−1,迁移较为完全;VI截面各中心点残余质量分数不超过8 mg·kg−1,满足建设用地土壤污染风险管控标准 ( GB36600—2018) 中第一类用地的管制值。在电动作用下,土体中的铬多以可溶态含氧阴离子形式存在,横向界面的迁移与铜相反,呈现向阳极递增趋势。这说明重金属离子的横向迁移方向取决于污染物赋存状态所带电荷类型。整体上铬表现出较强的迁移性,而铜的富集效应显著,迁移规律有明显差别,这与文献[18]的研究结果一致。

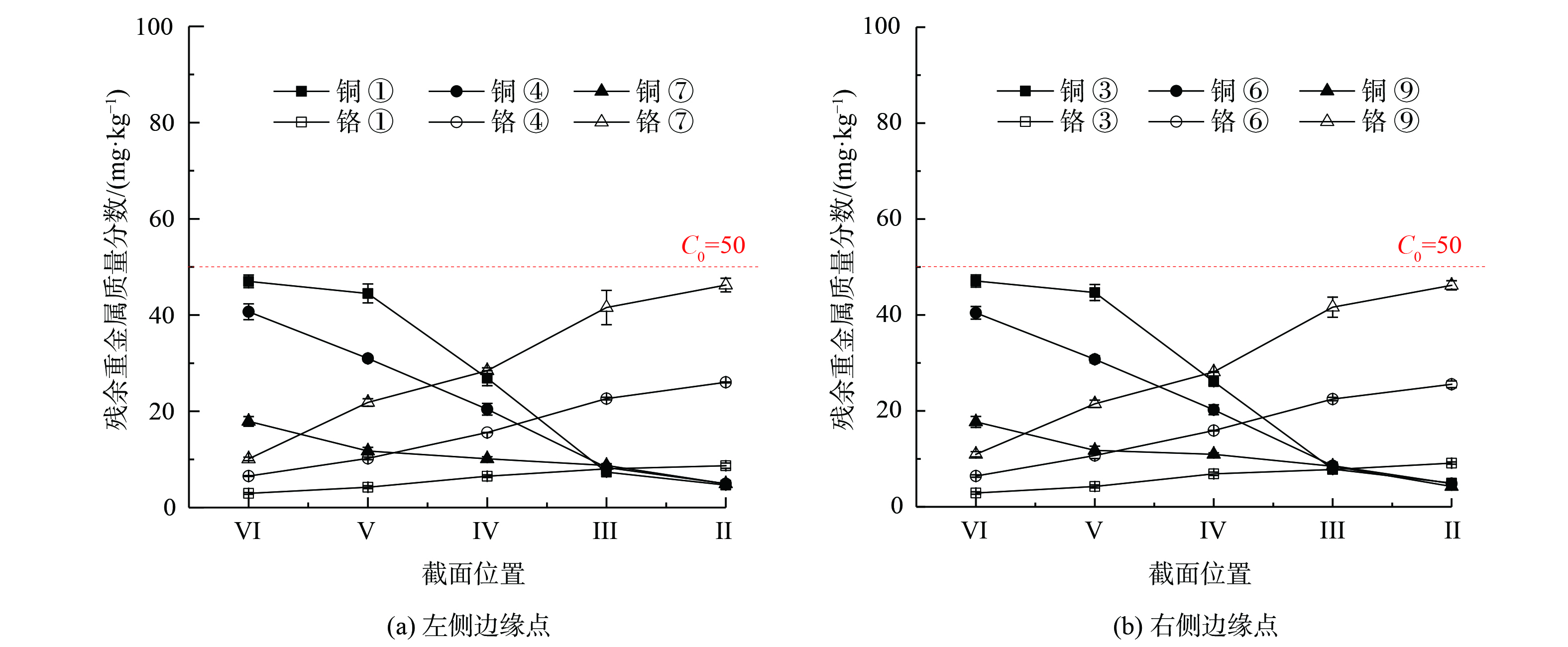

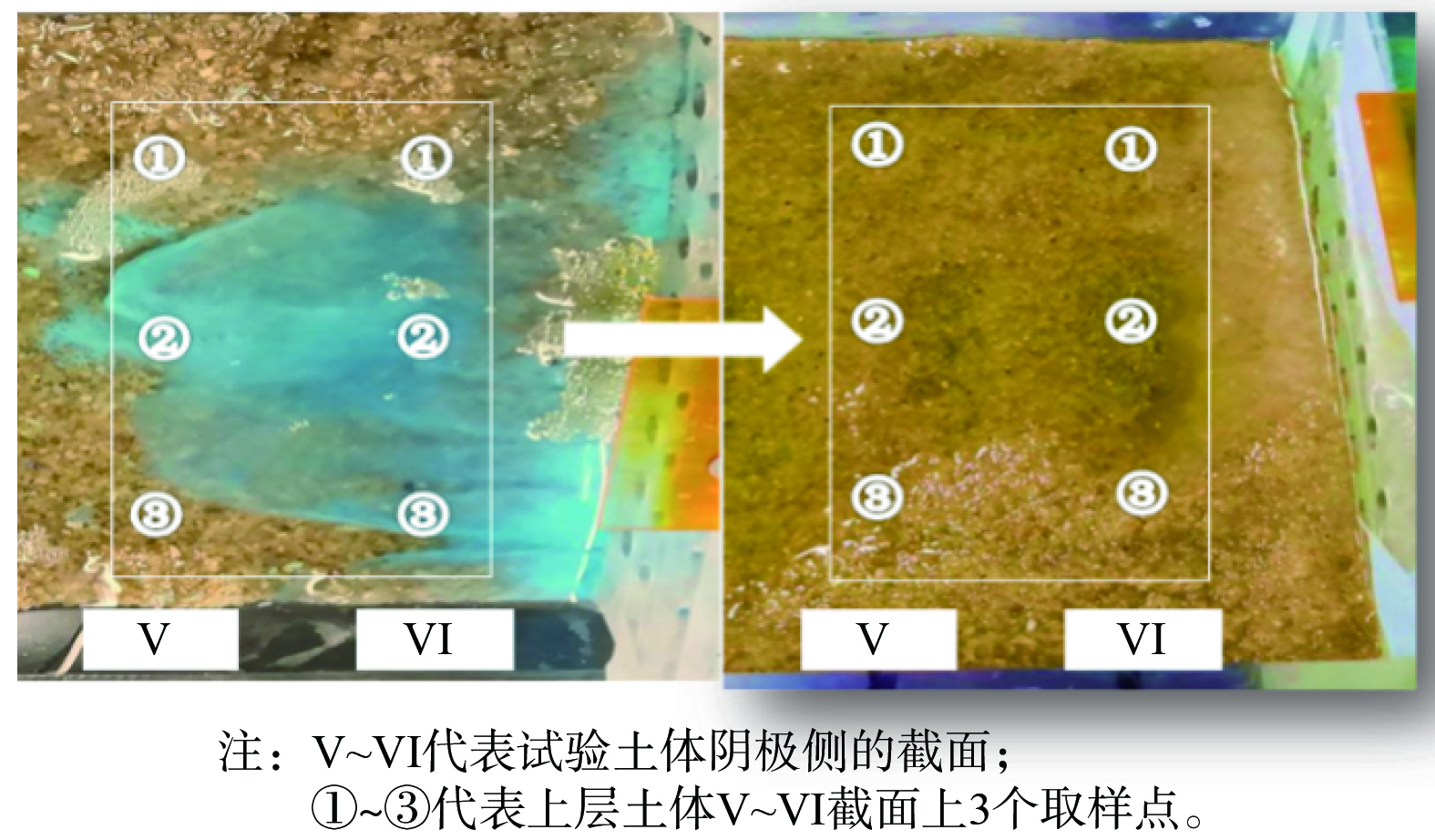

2) 两侧区域重金属污染物的横向迁移规律。围绕中心点左右两侧重金属的横向迁移因受力状态相同,呈现一致性,对应点残余浓度相近。对比中心及两侧区域的残余浓度分布 (图3和图4) 。在电动作用下,两侧区域重金属污染物的横向迁移与中心点处具有良好的同步性。整体上,两侧区域的残余质量分数均低于初始值 (图4) 。铜的残余质量分数低于中心点处,这是由于横截面不同土体位置酸碱度并不相同,铜的迁移受酸碱度影响较大。这一点与图3所展示的宏观实验现象一致,起因与所选棒状电极形态有关,证实靠近电极附近土体的酸碱度具有不均匀性。

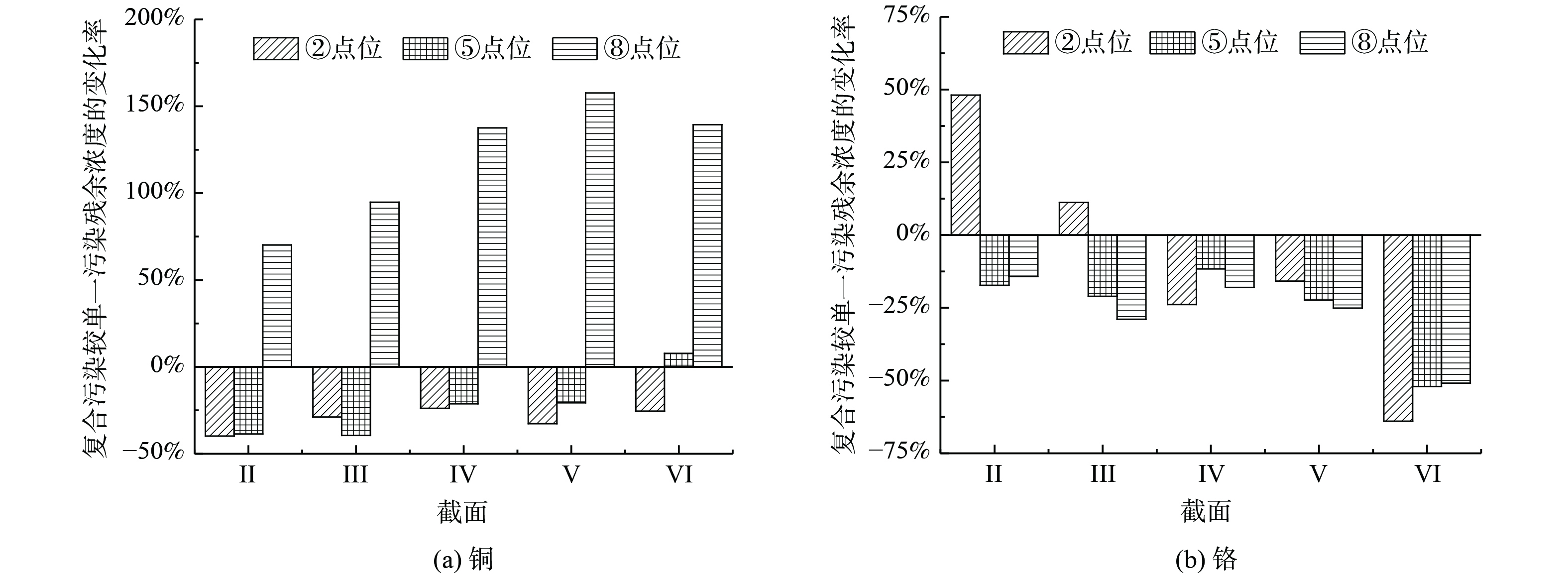

3) 复合污染条件下的横向迁移规律。对比分析不同点位铜、铬在复合污染条件和单一污染条件下的残余浓度变化率 (图5) 。在电动作用下,复合污染条件不改变重金属离子原始的迁移方向,并有助于增强各相的横向迁移,2种重金属在界面上的残余质量分数基本小于单一污染条件,主要表现为协同作用,与梁延鹏等[28]研究结果一致。但铜存在特殊层面, II~VI截面下层铜的变化率为70.21%~157.68%。这证实了复合污染深部土体中铜的横向迁移存在拮抗作用,即复合污染条件下铜的横向迁移受协同作用及拮抗作用双重影响,具有明显层面差异性。II、III截面上层铬的变化率分别为48.11%、11.20%,其余位置均小于0。其中,VI截面变化率低,变化率为−50.90%~−63.98%。对比铬沿横向界面变化率,可发现复合污染条件对铬的协同作用在阴极附近更为明显。

-

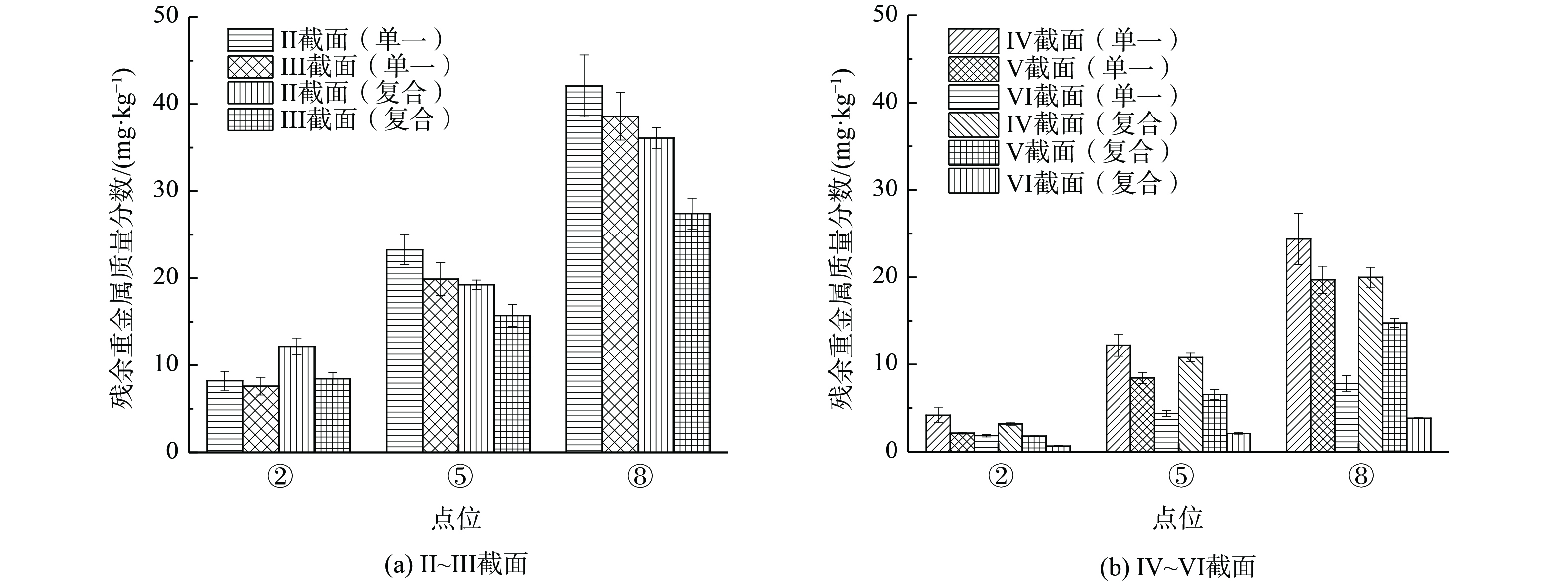

1) 铜的纵向迁移规律。单一污染下II和III截面中②、⑤、⑧点铜的残余质量分数很低且较为接近,分别维持在3.5 mg·kg−1和7 mg·kg−1 (图6 (a) ) 。IV~VI截面铜的残余质量分数分布均为②>⑤>⑧,在纵向呈现自下而上迁移 (图6 (b) ) ,且在②处质量分数高于初始值。这证实了存在明显的上浮力作用。这是由于在电动作用下,土体中的空气被分散成微小气泡,与铜胶体絮凝物包裹在一起,形成强粘着力絮凝物气囊,絮凝物体积膨胀,比重轻于水相,上浮到土体上层形成漂浮絮凝物[29-30]。这与图4对应的实验现象一致。

在复合污染条件下,II~III截面中上层及IV~VI截面上层铜残质量分数低于单一污染条件下的,而下层位置则出现明显增大。这说明铬的存在会引发上层土体中铜向下迁移。这是由于铬多以氧阴离子存在,提供了大量异号电荷,铜与铬间的相吸作用及其重力作用叠加有利于铜絮状物的聚沉。对比图7和图3,砂土表面蓝色絮状物的消失进一步证实了这一点。

2) 铬的纵向迁移规律。整个界面铬的纵向迁移规律一致,均呈现向下迁移 (图8) 。这说明重力作用是纵向迁移主导力。在单一污染条件下,重金属污染物铜和铬在纵向迁移方面呈现相反性。这说明污染物纵向分布不仅需要考虑其摩尔质量,而且需要考虑其赋存状态,浮力和重力作用共同决定着其最终纵向分布,该结果与李致春等[31]的研究结果一致。

-

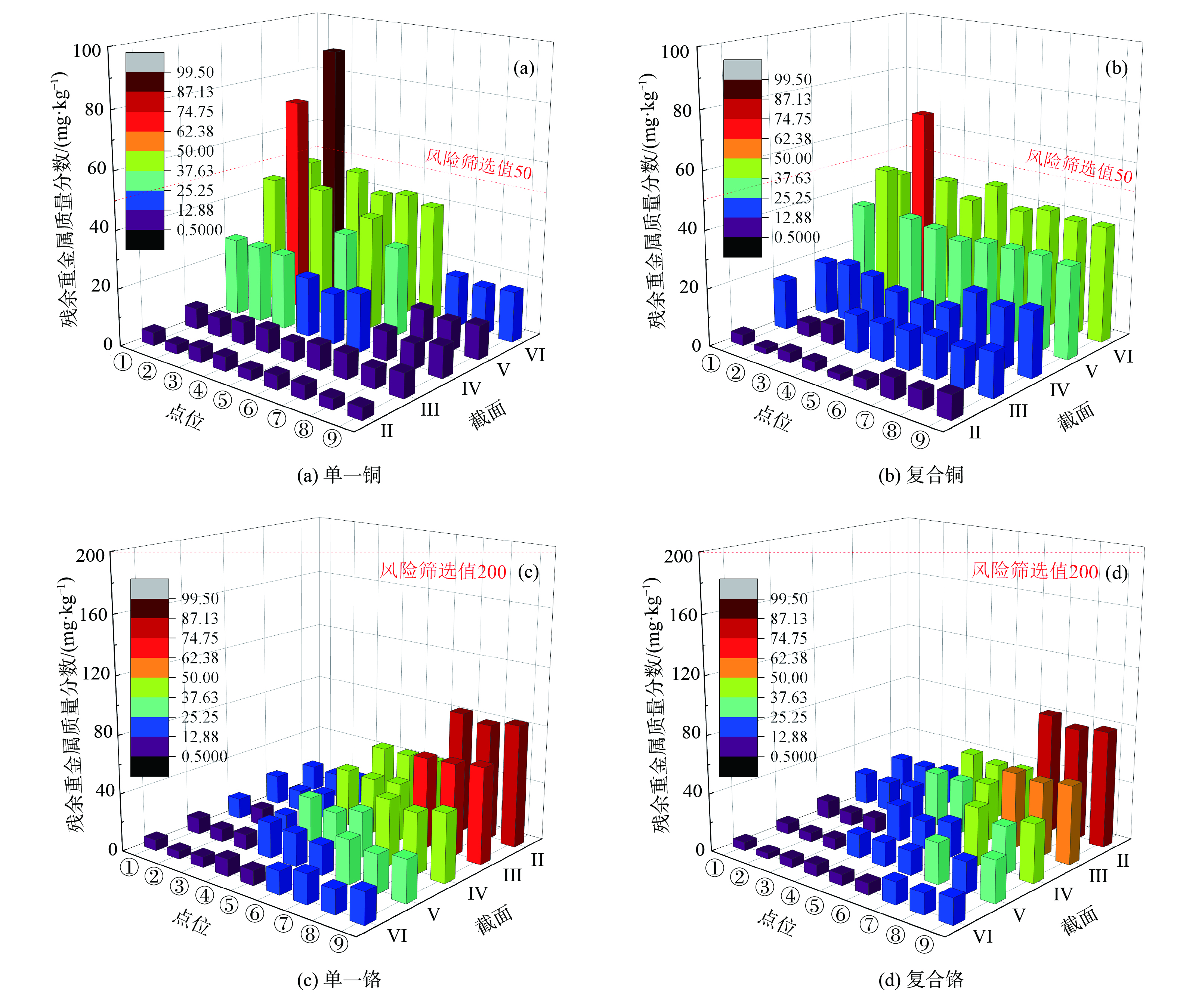

结合农用地土壤污染风险管控标准 (GB15618—2018) 中的风险筛选值,铜和铬的初始质量分数分别设置为50 mg·kg−1和200 mg·kg−1,构建重金属污染物三维分布图以对比分析单一及复合污染条件下的界面迁移过程 (图9) 。

单一污染下IV~V截面⑦~⑨点位及II~III截面①~⑨点位砂土中铜的残余质量分数为0.50~12.88 mg·kg−1,较初始值降低了80%,占总处理区域面积的1/3;V~VI截面②点位铜残余值高,分别超出初始值的47.94%和78.44%,阴极附近上中层土体为高浓度富集区域,需重点关注 (图9 (a) ) 。整体上铜的迁移性较差,无法顺畅迁出。

在单一污染下,铬整体上的残余质量分数均低于初始值,最大残余质量分数为初始值的42.35%,II~VI截面①~③点位及VI截面①~⑨点位砂土中铬残余质量分数为5.42~21.49 mg·kg−1。其中,VI截面①~③点位残余质量分数分别仅占初始值的2.71%、3.68%、3.80% (图9 (c) ) 。在总处理区域中, 污染面积的4/5可达到80%以上迁出率,相比于铜,铬在砂土中的迁移性更好。

对比复合污染和单一污染条件 (图9 (b) 和图9 (d) ) 可知,在复合污染时,虽然铜和铬之间的相互影响效果并不相同,但彼此在各点位的残余质量分数均呈现向中间值靠拢,低、高浓度所占面积比例减小,聚焦效应得到缓解,复合污染时的协同作用显著。

-

采取混合正交实验方法对影响因素的主次关系进行排序,根据正交实验分析理论计算极差,确定各因素对实验结果影响程度的大小。引入界面迁移率 (i值) 指标来考察各因素的敏感度。其中,C0和CT分别表示作用前、后II~VI截面取样点⑤中重金属污染物的质量分数(mg·kg−1)。i值越大表明污染物迁出率越高。

根据i值,铜和铬最大迁出所对应的组合条件分别为S3+0.750 V·cm−1+50 mg·kg−1和S3+1.125 V·cm−1+200 mg·kg−1。共性之处在于:均为粗砂,大粒径土体可提供顺畅的迁移通道,有利于重金属的迁出;适宜浓度均围绕在农用地土壤污染风险管控标准 (GB15618—2018) 中的风险筛选值。对比K值及极差R值,不同重金属迁移的影响因素略有差别,按照影响迁移效率程度,铜和铬的分别依次为:电压梯度>筛分粒径>初始浓度,电压梯度>初始浓度>筛分粒径 (表2和表3) 。S2+1.125 V·cm−1+50 mg·kg−1和S3+0.750 V·cm−1+50 mg·kg−1条件下铜的i值分别为275.28%和288.30%,铬的i值分别为303.72%和311.28%,电压梯度降低时增加砂土粒径,i值增大。此外,S2+0.750 V·cm−1+500 mg·kg−1和S2+1.125 V·cm−1+50 mg·kg−1条件下,在污染物质量分数降低,电压梯度升高时,2种污染物的i值存在变化小或降低现象。这些现象均证实电压梯度作为影响铜和铬迁移效率的主要外在因素,与污染物质量分数及土质参数相匹配能实现污染物的最佳迁出。

-

1) 电动作用下重金属污染物的横向界面迁移方向与其赋存状态及所带电荷有关。铜以离子态存在,向阴极迁移,且易于在阴极附近出现聚焦效应,浓度剧增。铬以酸根负离子状态存在,向阳极迁移。复合污染条件不改变污染物总体迁移方向,与异性电荷共存下,以协同作用下为主导力有助缓解聚焦问题,增强横向界面迁移。

2) 电动作用下重金属污染物的纵向界面迁移方向与污染物赋存状态及其摩尔质量有关,铜和铬两种污染物的纵向迁移规律相反。复合污染条件下异性电荷的相吸作用会引发共沉及减缓纵向迁移的现象。

3) 带有异性电荷复合污染时,污染物之间的相互影响程度不同,整体上各界面的残余浓度均呈现向中间值的靠拢趋势。电压梯度、土质参数及初始浓度均影响污染物的迁移性,铜和铬最佳迁出所对应的组合条件分别为: S3 (粗砂)+0.750 V·cm−1+50 mg·kg−1和S3 (粗砂)+1.125 V·cm−1+200 mg·kg−1,大粒径及风险筛选值对应质量分数条件下有利于重金属的迁出;电压梯度是作为影响铜、铬污染物迁移效率的主要外在因素,与污染物质量分数及土质参数相匹配可实现污染物的最佳迁出。

电动作用下铜(II)-铬(VI)复合污染砂土中重金属的界面迁移规律

Interfacial migration of heavy metals in copper (II) -Chromium (VI) contaminated soil under electrokinetic action

-

摘要: 厘清污染物的界面迁移是实现污染控制的前提。以铜(II)-铬(VI)复合污染砂土为研究对象,以电压梯度、砂土粒径及污染浓度为影响因素,研究电动驱动作用下复合重金属污染物的界面迁移规律。结果表明:重金属污染物的横向迁移方向取决于离子赋存状态所带电荷类型,纵向迁移方向取决于赋存形态及其摩尔质量双重作用;电动作用下带有相反电荷的物质复合污染时,各物质保持原始迁移方向,但各界面浓度趋于均匀化。横向迁移方面存在以协同作用为主导的局部拮抗现象,纵向迁移方面存在迁移减缓及物质共沉现象。铜和铬最佳迁出所对应的组合条件分别为:S3 (粗砂)+0.750 V·cm−1+50 mg·kg−1和S3 (粗砂)+1.125 V·cm−1+200 mg·kg−1。电压梯度是作为影响重金属迁移效率的主要外在因素,与大粒径及风险筛选值对应的浓度相匹配有利于重金属污染物在电动作用下的迁出。不同污染物的影响因素敏感度分布并不一致,建议复合污染土体的修复治理应针对污染物种类对主导因素进行细化。本研究结果可为电动修复技术的工程应用提供参考。Abstract: Clarifying the interface migration of contamination is the premise of control. Based on copper (II)-chromium (VI) composite contaminated sandy soil, the interface migration law of composite heavy metal contamination under electric drive was studied with some influencing factors, such as voltage gradient, soil particle diameter and contaminated concentration. The results show that the transverse migration direction of heavy metal contamination depends on the charge type in the occurrence state, while the longitudinal migration depends on the dual effect of contamination occurrence form and its molar mass. In the case of compound contamination with opposite charges, each substance retains its original migration direction under electric action, but the concentration tends to homogenize. Although there is local antagonism in the transverse migration, the dominant force is the synergistic function which can alleviate the aggregation problem and enhance the transverse migration of ions. In the aspect of longitudinal migration, there are a slower migration rate and co-sedimentation for compound contamination. The optimal combination conditions of Cu and Chromium are of S3 (coarse sand)+0.750 V·cm−1+50 mg·kg−1 and S3 (coarse sand)+1.125 V·cm−1+200 mg·kg−1, respectively Voltage gradient is a major external factor affecting the migrated efficiency of heavy metal , and it need match with the large particle diameter and the concentration corresponding to the risk screening value are conducive to the removal of heavy metal contaminants under electric action. The sensitivity distribution of the influencing factors of different pollutants is not consistent. It is suggested that the main factors should be refined according to the types of pollutants in the remediation of composite polluted soil.

-

表 1 砂土筛分粒径及物理化学性质

Table 1. Particle size distribution and physical-chemical properties of sand

编号 粒径/mm 饱和含水率 标准砂筛分 SiO2含量 可溶性盐含量 密度/ (g·cm−3) 比表面积/ (m2·kg−1) S0 0.08~2.0 17.6% 混合砂 >96% <0.2% 1.51~1.54 13.18 S1 0.08~0.5 20.0% 细砂 S2 0.5~1.0 19.4% 中砂 S3 1.0~2.0 12.3% 粗砂 表 2 正交实验设计L9 (3/4)

Table 2. Orthogonal test design L9 (3/4)

编号 筛分粒径 电压梯度/(V·cm−1) 初始质量分数/(mg·kg−1) i值/% 1 S1 0.375 50 (259.74,276.57) 2 S1 0.750 200 (273.16,314.64) 3 S1 1.125 500 (254.57,305.31) 4 S2 0.375 200 (263.62,297.41) 5 S2 0.750 500 (272.64,311.26) 6 S2 1.125 50 (275.28,303.72) 7 S3 0.375 500 (269.27,284.39) 8 S3 0.750 50 (288.30*,311.28) 9 S3 1.125 200 (265.29,336.16*) 表 3 正交实验结果L9 (3/4)

Table 3. Orthogonal test results L9 (3/4)

筛分粒径K1 电压梯度K2 初始质量分数K3 极差R (787.47,896.52) (811.54,912.39) (822.86*,931.83*) (35.39,35.31) (792.63,858.37) (834.10*,937.18) (795.14,945.19*) (41.47*,86.82*) (823,32*,891.57) (811.09,948.21*) (796.48,900.96) (26.84,56.64) 注:迁移效率、Ki及极差R中 (xxx,xxx) 形式,左右两侧数值分别代表铜、铬所对相应数值;*代表极大值。 -

[1] 王勤, 彭渤, 方小红, 等. 湘江长沙段沉积物重金属污染特征及其评价[J]. 环境化学, 2020, 39(4): 999-1011. doi: 10.7524/j.issn.0254-6108.2019101901 [2] 付淑清, 韦振权, 袁少雄, 等. 珠江口沉积物与土壤的重金属特征及潜在生态危害评价[J]. 安全与环境学报, 2019, 19(2): 600-606. [3] 王锐, 邓海, 贾中民, 等. 汞矿区周边土壤重金属空间分布特征、污染与生态风险评价[J]. 环境科学, 2021, 42(6): 3018-3027. [4] 陈家乐, 相满城, 唐林茜, 等. 运积型地质高背景稻田土壤重金属污染和人体健康风险评价[J]. 生态学杂志, 2021, 40(8): 2334-2340. [5] 韩丁, 黎睿, 汤显强, 等. 污染土壤/底泥电动修复研究进展[J]. 长江科学院院报, 2021, 38(1): 41-50. doi: 10.11988/ckyyb.20191038 [6] 赖冬麟, 张奇, 陈亭亭, 等. 张家口市某机械厂原址电镀污染场地土壤修复工程实践[J]. 环境工程, 2020, 38(6): 75-80. doi: 10.13205/j.hjgc.202006012 [7] 张志红, 李红艳, 陈家煜, 等. 混合重金属离子侵蚀饱和黏性土渗透特性试验研究[J]. 岩土力学, 2016, 37(9): 2467-2476. [8] WU J Z, HUANG D, LIU X M, et al. Remediation of As(III) and Cd(II) co-contamination and its mechanism in aqueous systems by a novel calcium-based magnetic biochar[J]. Journal of Cleaner Production, 2018, 34(8): 10-19. [9] 李英, 商建英, 黄益宗, 等. 镉砷复合污染土壤钝化材料研究进展[J]. 土壤学报, 2021, 58(4): 837-850. doi: 10.11766/trxb201912170575 [10] 李艳玲, 陈卫平, 杨阳, 等. 济源市平原区农田重金属污染特征及综合风险评估[J]. 环境科学学报, 2020, 40(6): 2229-2236. [11] 甘婷婷, 赵南京, 殷高方, 等. 长江三角洲地区农用地土壤重金属污染状况与防治建议[J]. 中国工程科学, 2021, 23(1): 174-184. [12] WANG Y F, ZHANG K, LU L, et al. Novel insights into effects of silicon-rich biochar (Sichar) amendment on cadmium uptake, translocation and accumulation in rice plants[J]. Environmental Pollution, 2020, 265: 1-10. [13] CAO Y R, ZHANG S R, ZHONG Q M, et al. Feasibility of nanoscale zero-valent iron to enhance the removal efficiencies of heavy metals from polluted soils by organic acids[J]. Environmental Pollution, 2018, 164(10): 464-473. [14] 熊钡, 邵友元, 易筱筠. 外加电场下镍污染土壤离子迁移过程及机理[J]. 环境科学与技术, 2015, 38(6): 33-38. [15] LI Y L, DONG S F, QIAO J C, et al. Impact of nanominerals on the migration and distribution of cadmium on soil aggregates[J]. Process Safety and Environmental Protection, 2020, 262: 1-9. [16] VILLEN-GUZMAN M, GARCIA-RUBIO A, PAZ-GARCIA J M. Aging effects on the mobility of Pb in soil: Influence on the energy requirements in electroremediation[J]. Chemosphere, 2018, 213: 351-357. doi: 10.1016/j.chemosphere.2018.09.039 [17] 陈榕, 周璐, 郝冬雪, 等. 重金属Pb~(2+)在砂土中的迁移及吸附特性[J]. 东北电力大学学报, 2019, 39(4): 54-60. doi: 10.19718/j.issn.1005-2992.2019-04-0054-07 [18] 吴众然, 刘桂建, 钱家忠, 等. Pb在饱水带-包气带的垂向迁移试验研究[J]. 环境科学与技术, 2019, 42(9): 36-41. doi: 10.19672/j.cnki.1003-6504.2019.09.006 [19] 王泓博, 苟文贤, 吴玉清, 等. 重金属污染土壤修复研究进展: 原理与技术[J]. 生态学杂志, 2021, 40(08): 2277-2288. [20] 储陆平, 周书葵, 荣丽杉, 等. 电动修复重金属污染土壤的研究进展[J]. 应用化工, 2020, 49(11): 2853-2858. doi: 10.3969/j.issn.1671-3206.2020.11.040 [21] 刘娟, 张乃明, 于泓, 等. 沘江两岸耕地土壤重金属径流迁移模拟研究[J]. 安全与环境学报, 2021, 21(4): 1823-1831. doi: 10.13637/j.issn.1009-6094.2020.0505 [22] 张炜华, 于瑞莲, 杨玉杰, 等. 厦门某旱地土壤垂直剖面中重金属迁移规律及来源解析[J]. 环境科学, 2019, 40(8): 3764-3773. doi: 10.13227/j.hjkx.201901227 [23] NANTHI B, ANITHA K, RAMYAA T, et al. Remediation of heavy metal(loid)s contaminated soils – To mobilize or to immobilize?[J]. Journal of Hazardous Materials, 2014, 266: 141-166. doi: 10.1016/j.jhazmat.2013.12.018 [24] 周建, 魏利闯, 詹芳蕾, 等. 生物表面活性剂及其与柠檬酸联合用于污泥重金属电动修复[J]. 湖南大学学报(自然科学版), 2019, 46(6): 109-119. doi: 10.16339/j.cnki.hdxbzkb.2019.06.016 [25] YEES N, BHASKAR S G, MOHD A H. Remediation of Pb/Cr co-contaminated soil using electrokinetic process and approaching electrode technique[J]. Environmental Science and Pollution Research, 2016, 23(1): 546-555. doi: 10.1007/s11356-015-5290-0 [26] SANA K, MUHAMMAD S, NABEEL K N, et al. A comparison of technologies for remediation of heavy metal contaminated soils[J]. Journal of Geochemical Exploration, 2017, 182: 247-268. doi: 10.1016/j.gexplo.2016.11.021 [27] BARBA S, VILLASENOR J, RODRIGO M A, et al. Effect of the polarity reversal frequency in the electrokinetic-biological remediation of oxyfluorfen polluted soil[J]. Chemosphere, 2017, 177: 120-127. doi: 10.1016/j.chemosphere.2017.03.002 [28] 梁延鹏, 李宗林, 张学洪, 等. 重金属单一与复合污染下水稻对铬的富集特征[J]. 生态环境学报, 2016, 25(9): 1540-1545. doi: 10.16258/j.cnki.1674-5906.2016.09.018 [29] 高腾跃, 刘奎仁, 韩庆, 等. 萃取-电沉积处理含铜氰化废水回收铜和氰化物[J]. 有色金属工程, 2018, 8(2): 87-90. [30] 刘慧, 仓龙, 郝秀珍, 等. 铜污染场地土壤的原位电动强化修复[J]. 环境工程学报, 2016, 10(7): 3877-3883. doi: 10.12030/j.cjee.201502112 [31] 李致春, 桂和荣, 孙林华, 等. 沱河芦岭矿塌陷区段沉积物重金属污染及迁移能力评价[J]. 环境科学与技术, 2013, 36(7): 13-17. doi: 10.3969/j.issn.1003-6504.2013.07.003 -

下载:

下载: