-

近年来,我国城市污泥产量持续增加,预计至2021年,我国污泥的年产量将突破8 000×104 t,污泥处理处置形势十分严峻[1]。城市污泥含水率高且成分复杂,除了蛋白质、多糖和淀粉等主要组分,还含有大量的细菌、病原微生物和重金属等有毒有害物质,未经适当处理处置将对土壤环境和人群健康产生极大危害[2-3]。因此,亟需对城市污泥进行合理的处理处置。

污泥的水热处理是指,在密闭环境中加热水产生高温高压饱和蒸汽,使污泥的絮体结构解散和有机物分解,并消灭细菌和病原微生物的过程[4-5]。因其具有污泥适用性广、处理高效等优点而在污泥处理处置中得到广泛应用[6-7]。ZHUANG等[6]对污泥进行300 ℃水热处理,经240 min处理后污泥中近80%的氮被去除。张会文等[7]对市政污泥在500 ℃水热处理了10 min后,市政污泥减量率达到87.6%,有机质去除率可达62.7%。但这些过程处理温度较高、能耗较大。为了降低污泥处理的能耗并强化水热处理效果,在水热处理基础上加入氧化剂是一种较新的污泥水热处理方向[8-10]。宋宇佳等[11]利用H2O2强化水热处理含油污泥,发现H2O2的添加能够促进水热过程中污泥的溶胞脱水,显著降低了处理后污泥残渣的含水率。有学者认为,添加H2O2对水热处理过程中有机物的转化分解产生重要影响。KHALIL等[12]发现,水热处理过程中无论是否加入H2O2,污泥中的有机物的分解都能够很快进行,氧化剂的加入有利于将溶解的有机物转化为非有机的最终产物。同样,YOUSEFIFAR等[13]通过生物质进行水热处理和水热联合H2O2处理,发现未添加氧化剂的水热处理过程中分解的有机物不能进一步转化为乙酸、CO2和H2O等。这些研究表明,H2O2能够强化水热过程中污泥的脱水和有机物的分解。然而,在污泥水热处理过程中,添加不同质量分数的H2O2对产物理化特性影响的研究较少,有必要对此进行系统的研究。

本研究在水热温度200 ℃下,以城市污泥为原料,以质量分数为5%、10%和15%的H2O2强化水热处理,研究了添加不同质量分数H2O2对污泥水热产物分布、固相产物性质(含水率、重金属(Pb、Cd)质量浓度及其赋存形态)和液相产物性质(pH、挥发性脂肪酸(Volatile Fatty Acids, VFAs)、氨氮(NH3-N))的影响,以期为城市污泥的处理与处置提供参考。

全文HTML

-

城市污泥取自上海市宝山区某污水处理厂,初始含水率为80%。污泥的工业分析及其元素分析和重金属分析结果分别见表1和表2。

-

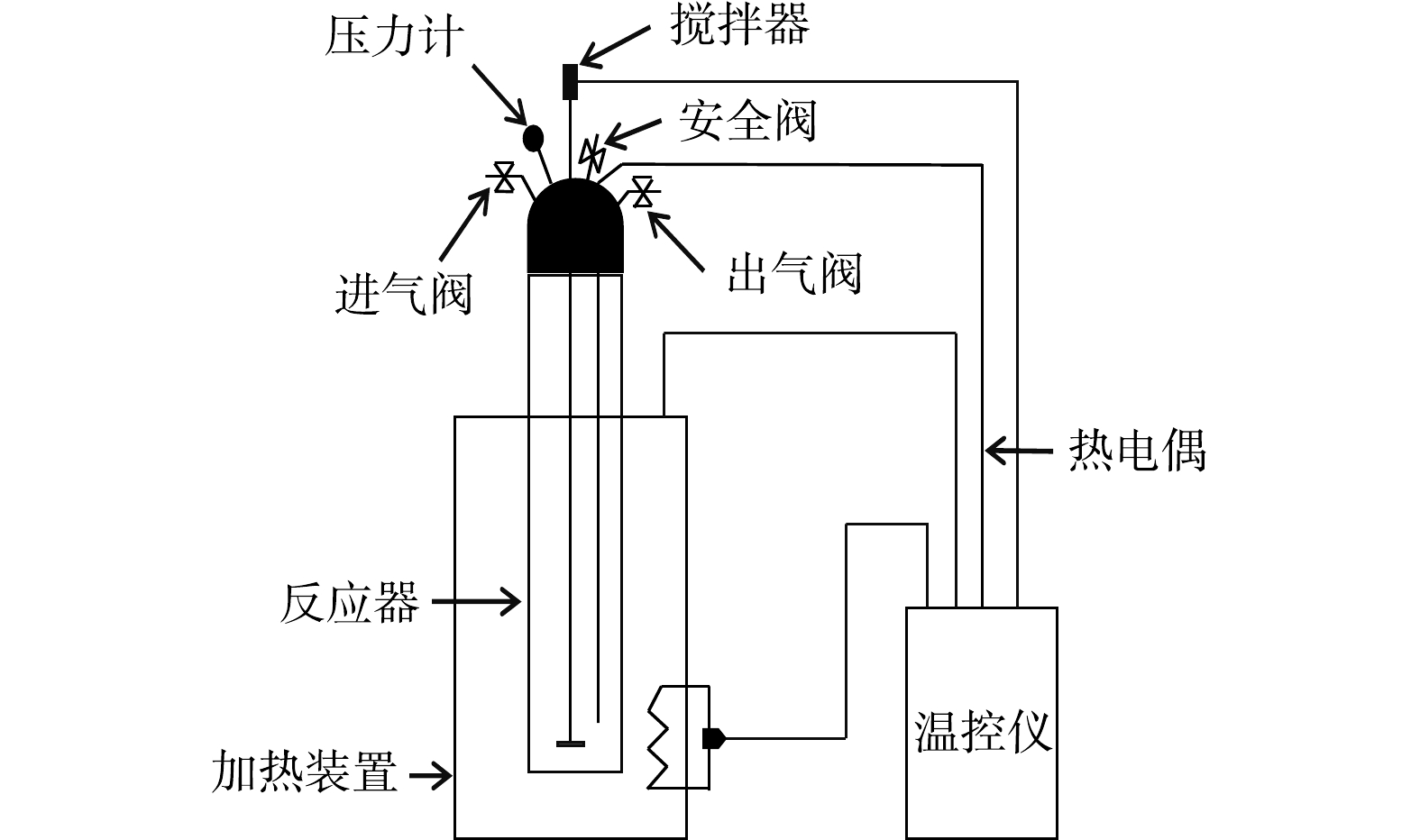

水热实验装置如图1所示,主要由反应器(上海恬恒FCF-1L,最大功率3 kW,最高温度400 ℃,内径25 cm)、加热装置、载气输送部分以及温控仪4部分组成。首先将10 g污泥、160 g去离子水和5 g不同质量分数的H2O2(5%、10%和15%)依次放入反应釜内,然后搅拌10 min充分混合。以10 ℃·min−1的速率升温到目标温度(200 ℃),在污泥水热处理期间通入100 mL·min−1的高纯氮气(99.999%)。水热实验完成后,向釜内冷却盘管通入冷却水冷却至室温,过滤斧内混合液得到固相产物和液相产物。固相产物经干燥、研磨和筛分(过100目筛)后放入密封袋中保存,按照添加H2O2的质量分数分别标记为SR-0、SR-5、SR-10和SR-15;液相产物移入棕色试剂瓶中低温保存并标记为LR-0、LR-5、LR-10和LR-15。

-

根据质量守恒定律,污泥经水热处理后气、液、固三相产物的质量等于反应前混合溶液的总质量。因此,固相产率MS和液相产率ML的计算参考式(1)、式(2),气相产率MG的计算根据差减法参考式(3)。固相产物含水率M的计算参考式(4)。

式中:Wms为污泥样品质量;WH2O为去离子水质量;WH2O2为H2O2溶液质量;W1和W11分别为盛装固相产物前后的烧杯质量;W2和W22分别为盛装液相产物前后的烧杯质量;W11′为装有固相产物烧杯干燥后的质量。以上变量单位均为g。

采用电感耦合等离子体质谱仪(7700,美国安捷伦科技有限公司)测定固相产物中重金属的质量浓度;重金属的赋存形态采用欧共体标准物质局(Community Bureau of Reference, BCR)提出的三步连续分级提取法进行分析(简称BCR法)[14],根据BCR法可将重金属的赋存形态按照生态毒性分级为直接毒性形态(F1+F2)、潜在毒性形态(F3)和无毒性形态(F4),具体步骤参考文献[15]。采用气相色谱-质谱联用仪(7890A-5975C,美国安捷伦科技有限公司)测定液相产物中挥发性脂肪酸质量浓度;基于纳氏试剂比色法,采用双光束紫外可见光分光光度计(UV-6300,上海美谱达仪器有限公司)测定液相产物中氨氮质量浓度;采用酸度计(PHS-3,上海佑科仪表有限公司)测定原污泥和液相产物的pH。

1.1. 供试原料

1.2. 水热实验

1.3. 分析方法

-

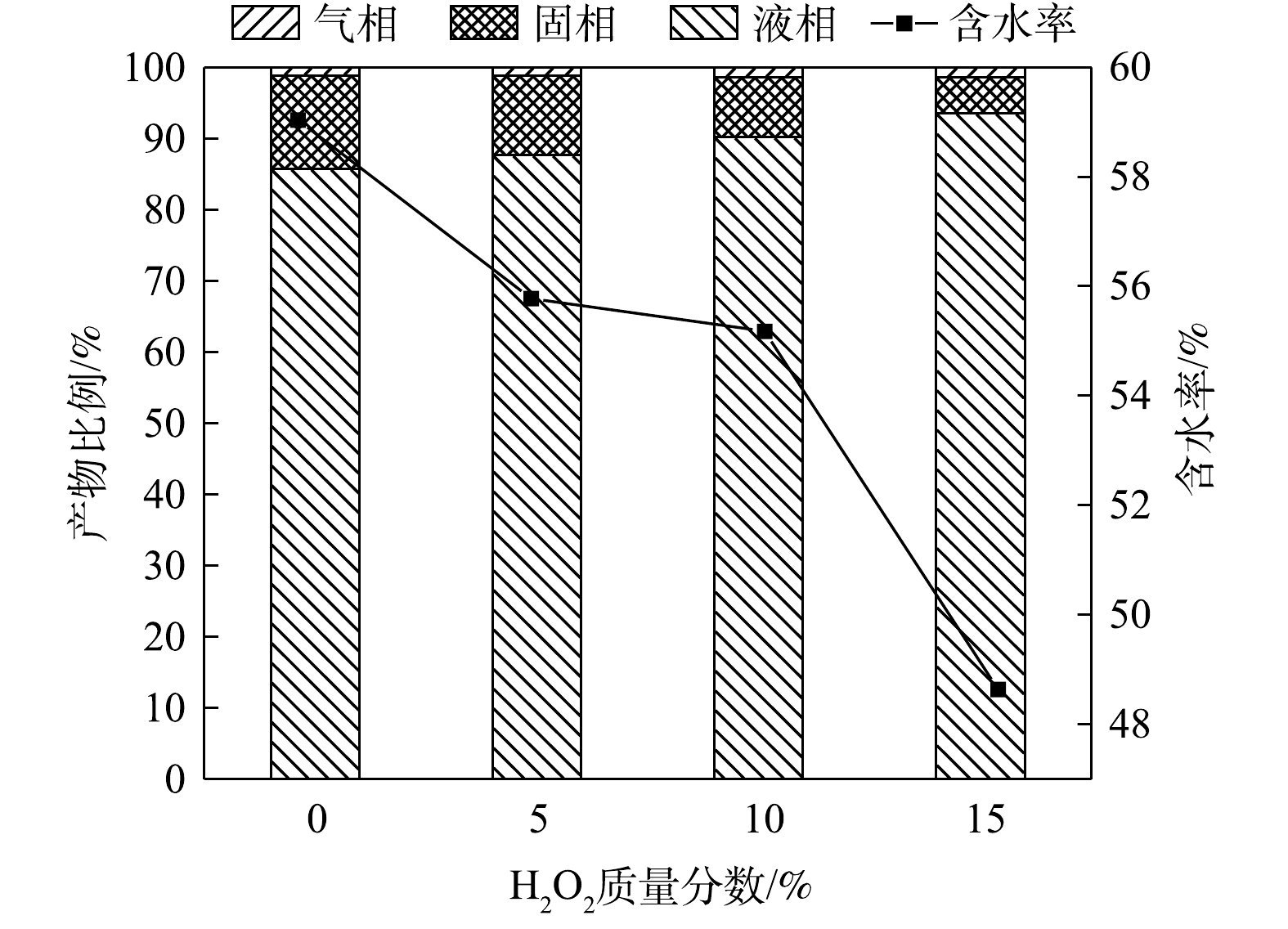

图2为添加不同质量分数的H2O2对水热处理污泥产物分布及固相产物含水率的影响。由图2可知,水热处理污泥的液相产物产率为85.72%,与之相比,H2O2强化水热处理污泥的液相产物产率随着H2O2质量分数的增大由85.72%升高至93.52%。相应地,固相产物产率由13.11%降低至5.04%,而气相产物产率变化不明显,仅由1.17%增加至1.44%。这表明,H2O2的添加能够促进水热处理污泥过程的进行。其原因是,H2O2具有氧化作用,能够促进先前在水热作用下污泥中初次分解破裂的有机大分子聚合物发生氧化还原反应,生成大量的小分子有机物和水等[5],导致固相产物产率减小,液相产物产率增大。

同时,由图2可知,不同质量分数的H2O2对应的固相产物含水率差别较大,随着H2O2质量分数的增大,固相产物含水率呈现快速下降的趋势,这表明H2O2的添加能够强化污泥水热处理的脱水作用。这主要受到2个方面的影响。一方面,水热作用破坏了污泥内部的絮体结构,导致污泥中絮体颗粒粒径和颗粒间空隙减小,使得絮体结构更加紧实,絮体空隙间的自由水得以释放进入液相,从而提高了污泥的脱水性能[16]。另一方面,添加的H2O2具有较强的氧化溶胞作用,不仅氧化分解了污泥中的蛋白质、多糖和淀粉等固体颗粒;而且,溶解了污泥中微生物的细胞壁,造成细胞内结合水释放析出为自由水,导致污泥水热固相产物的含水率进一步降低[17]。添加H2O2对污泥水热脱水效果较好,在添加H2O2的质量分数为15%时,固相产物含水率降低至48.64%。

-

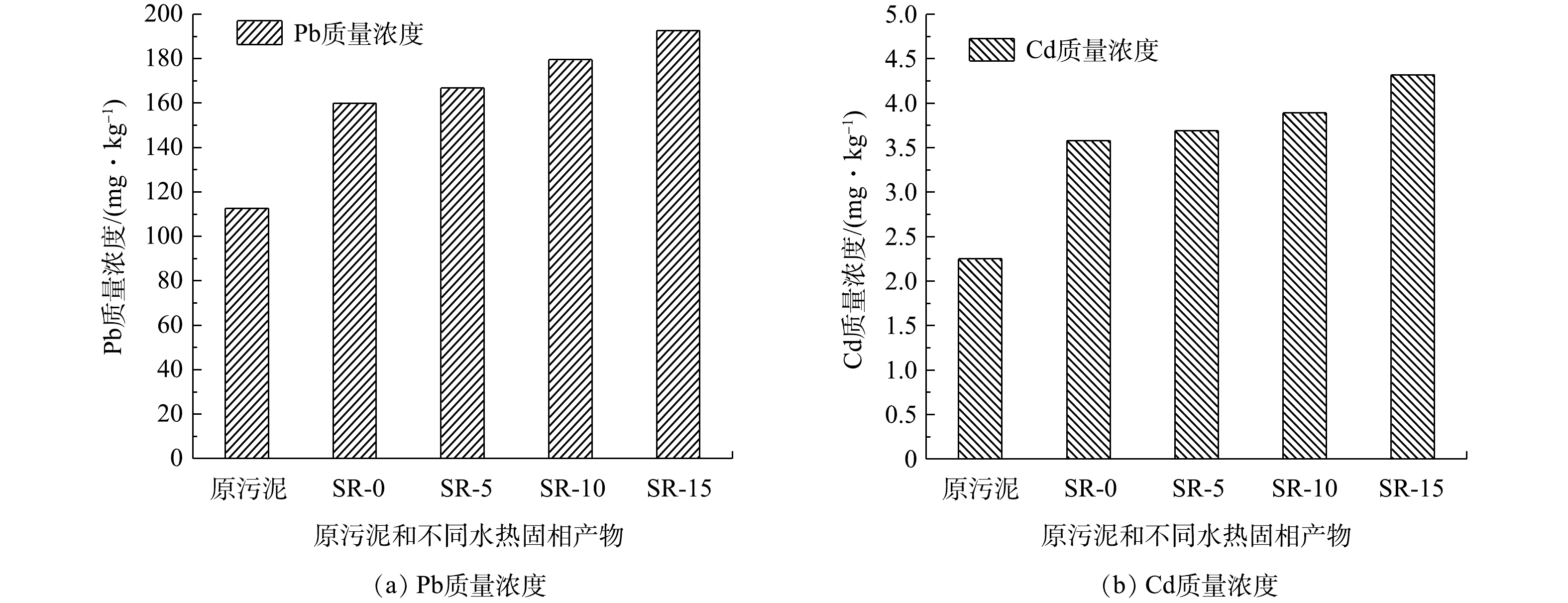

1)不同质量分数H2O2对重金属质量浓度的影响。由表2可知,污泥中含有Pb、Ni、Zn、Cd等重金属,其中Pb和Cd对人体和环境的潜在危害较大[18]。因此,本研究分析了固相产物中Pb和Cd的质量浓度及其赋存形态的变化。图3为添加不同质量分数H2O2对污泥水热固相产物中Pb和Cd质量浓度的影响。由图3(a)和3(b)可知,SR-0中Pb和Cd的质量浓度较原污泥增加,SR-5、SR-10和SR-15中Pb和Cd的质量浓度较SR-0进一步增加,且随着添加的H2O2质量分数的增大,SR-5、SR-10和SR-15中Pb和Cd的质量浓度呈现缓慢增加的趋势。这表明,水热处理有利于污泥中重金属在固相产物中富集,H2O2的添加能够进一步强化水热过程中重金属在固相产物中富集的效果。LIU等[19-20]的研究表明,水热产生的含氧官能团(Oxygen-containing Functional Groups, OFGs) 对金属阳离子有很强的吸附作用。JAIN[21]等的研究表明,在水热过程中添加H2O2能够促进OFGs的产生。因此,H2O2的添加进一步强化了水热固相产物对Pb和Cd的吸附能力。此外,根据2.1节所述,固相产物产率随着H2O2质量分数的增大而减小。因此,Pb和Cd的浓缩程度增大,两者质量浓度亦应有所增加。

2)不同质量分数H2O2对重金属赋存形态的影响。为了进一步研究不同质量分数的H2O2对重金属生态毒性的影响,测定了原污泥及其水热处理后固相产物中Pb和Cd的赋存形态,结果如表3所示。由表3可知,SR-0、SR-5、SR-10和SR-15中Pb和Cd的无毒性形态(F4)占比较原污泥更高,直接毒性形态(F1+F2)和潜在毒性形态(F3)占比较原污泥更低,表明水热处理和添加H2O2强化水热处理均利于Pb和Cd由直接毒性形态和潜在毒性形态向无毒性形态转化,这对污泥中重金属的钝化起积极作用。其原因为,水热作用导致了污泥中表面官能团的先分解后缩聚,而缩聚过程产生的较稳定和高浓缩的芳香化结构易吸附于水热固相产物,并能够络合固相产物表面和内部结构中的游离重金属,从而使Pb和Cd的毒性形态和潜在毒性形态更多的转换为相对稳定的无毒性形态[22]。同时,在添加的H2O2质量分数为5%时,Pb和Cd的无毒性形态占比进一步增大,此时,固相产物的重金属生态毒性较弱。这是因为,H2O2促进了污泥水热过程中大量OFGs的产生,导致缩聚反应更为剧烈,产生更多芳香化结构来络合游离的Pb和Cd[19]。

此外,对比SR-5、SR-10和SR-15中Pb和Cd无毒性形态与潜在毒性形态所占比例的变化,发现随着添加的H2O2质量分数的增大,Pb和Cd逐渐由无毒性形态迁移转化为潜在毒性形态,使固相产物的潜在生态毒性增强,但仍低于污泥原样的生态毒性。其原因可能是,在H2O2强化水热处理污泥过程中,水热作用和H2O2氧化作用产生协同效应,使污泥中的大分子有机物发生降解、分子有机物溶解,从而形成新的有机物和配位键。这些新产物能够诱导金属离子与其结合形成螯合物或复杂的沉淀物,使Pb和Cd的迁移性增强,从而有助于其由无毒性形态迁移转化为潜在毒性形态[23]。此外,由于污泥中Cd自身的可移动性较强,易吸附沉降于固相产物表面进而转化为潜在生态毒性部分,或与某些盐类结合形成无毒性部分[24]。因此,Cd的直接毒性形态占比为0。

-

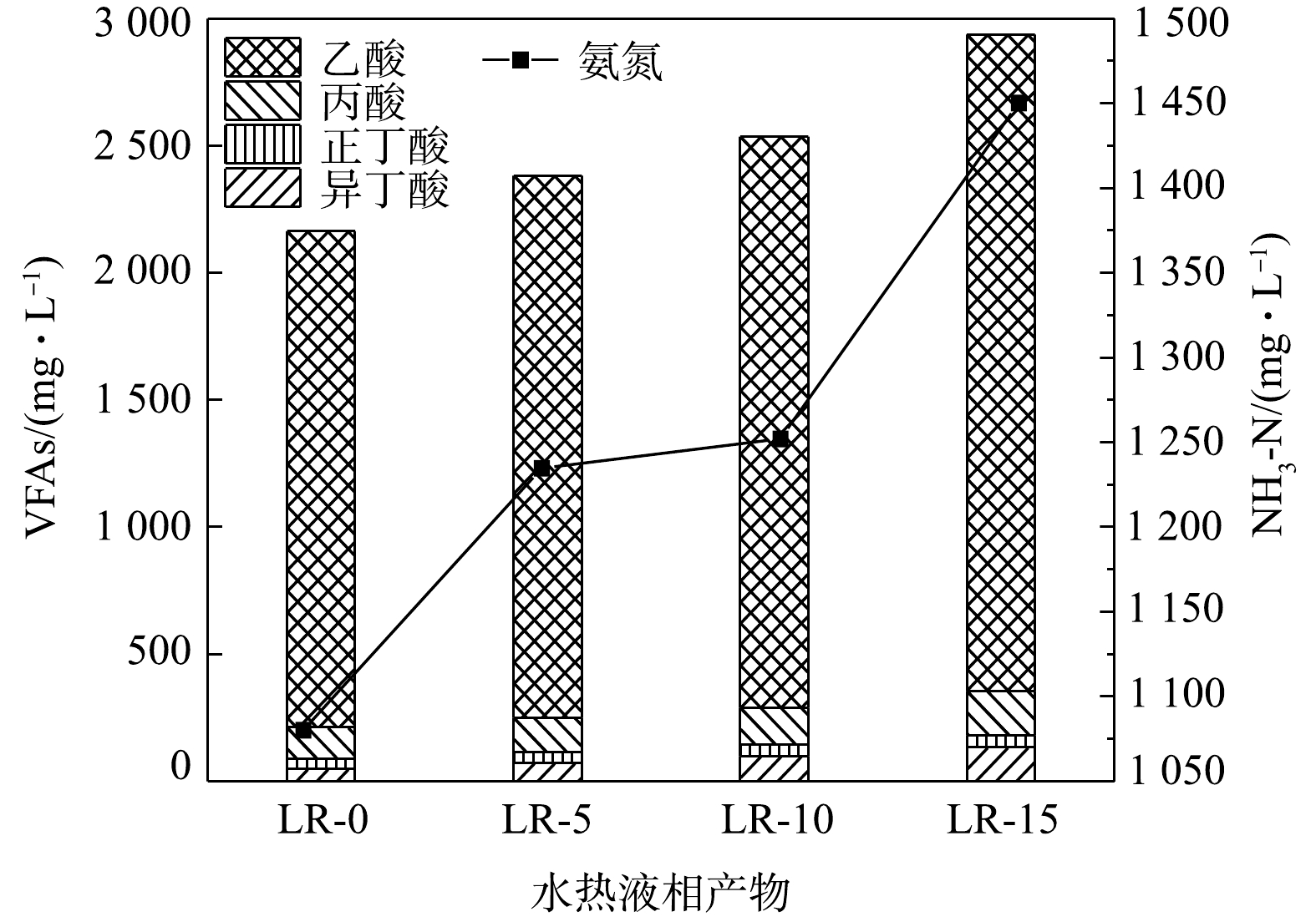

污泥中有机物的热水解产物主要为VFAs和NH3-N,因此,VFAs和NH3-N质量浓度能够在一定程度上反眏污泥中有机物的水解程度[25]。图4为添加不同质量分数H2O2对污泥水热液相产物中VFAs和NH3-N质量浓度的影响。由图4可知,水热液相产物LR-0中VFAs质量浓度为2 163.78 mg·L−1,与之相比,LR-5、LR-10和LR-15中VFAs质量浓度增加了10.11%~35.76%;LR-0中NH3-N质量浓度为1 080.24 mg·L−1,与之相比,LR-5、LR-10和LR-15中NH3-N质量浓度增加了14.31%~34.25%。这表明,H2O2能够强化污泥水热过程中有机物的水解,且添加的H2O2质量分数越大,有机物的水解程度越大。

由于污泥所含微生物细胞外的聚合有机物较细胞内的有机物更易分解[11],因此,在H2O2强化水热处理污泥的初始阶段,水热作用先分解了胞外聚合有机物中的易降解颗粒并转化生成部分VFAs。随着处理过程的进行,易降解颗粒有机物被水解完全,水热作用开始分解消耗胞外聚合有机物中的难降解颗粒物,使液相产物中VFAs质量浓度持续增加。与此同时,H2O2的强氧化溶胞作用破坏了污泥中微生物的细胞壁,使细胞内有机物释放析出,其中部分有机物以氨氮形式存在,部分有机物在水热作用下发生分解并产生大量的含氮类化合物,从而导致液相产物中NH3-N质量浓度增大[26]。但是,在H2O2质量分数由5%增大至10%阶段,NH3-N质量浓度增大趋势较缓。这可能是因为,有机物水解产生的羰基化合物和氨基化合物(氨基酸和蛋白质)发生Maillard反应生成复杂含氮杂环化合物,而不以氨氮形式存在[27]。

-

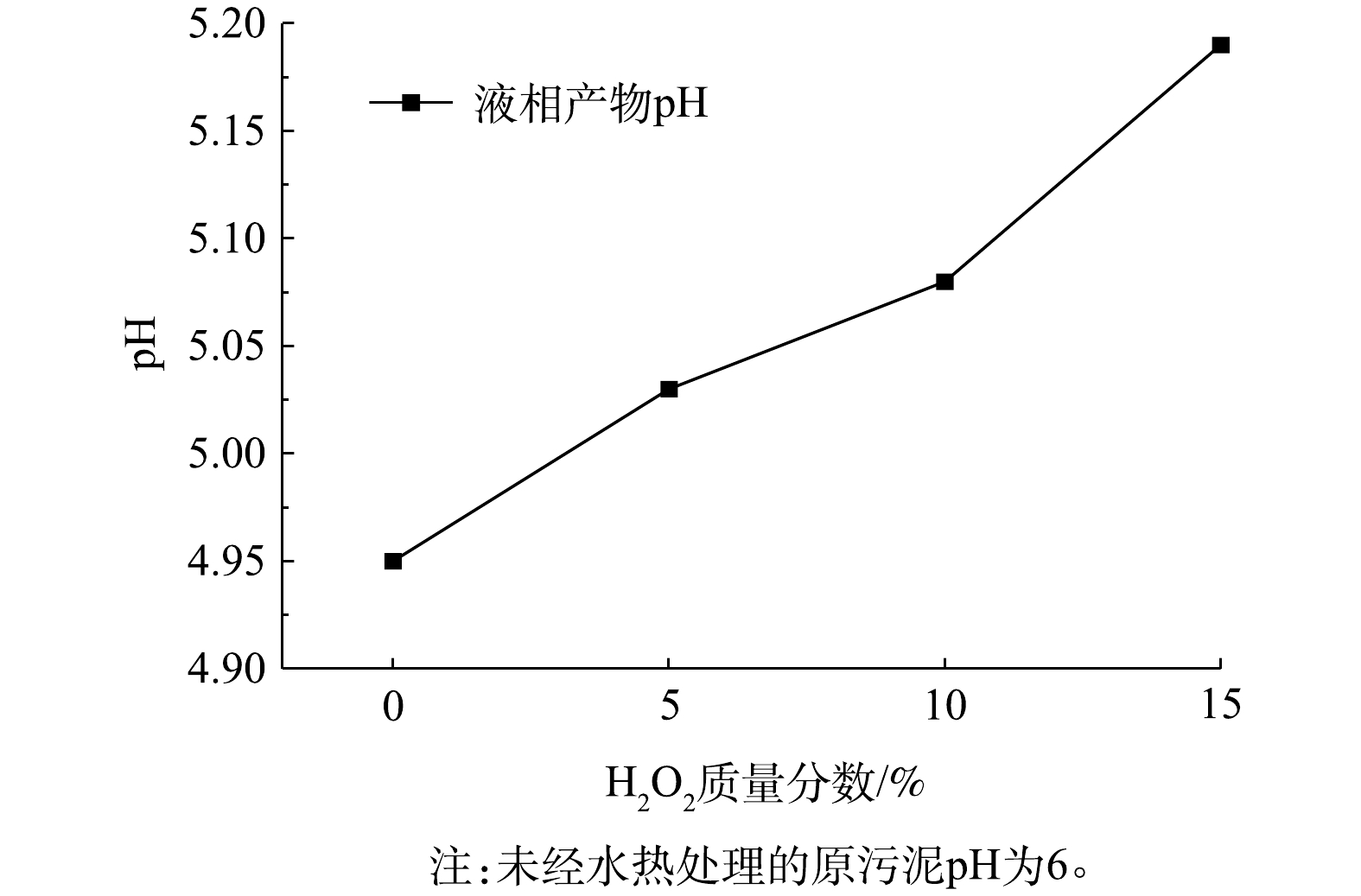

图5为添加不同质量分数H2O2对污泥水热液相产物pH的影响。由图5可知,原污泥的pH为6,呈弱酸性,经水热处理后液相产物pH为4.95,酸性增强;经不同质量分数H2O2强化水热处理后,液相产物pH由4.95升高至5.19,酸性相对减弱,这表明H2O2的添加有利于污泥水热液相产物酸性的减弱。结合图4分析,这主要由水热处理污泥生成的有机酸和氨氮互相作用决定[28]。一方面,水热作用促进了污泥中脂类有机物水解生成甘油和脂肪酸,蛋白质水解为肽类、简单有机酸、CO2和氨等[29]。其中,简单有机酸和CO2易溶于液相而增强液相产物的酸性,氨易溶于液相而增强液相产物的碱性,但简单有机酸和CO2产生更多。因此,其酸性作用强于氨氮的碱性作用,液相产物总体显酸性。另一方面,H2O2的添加强化了污泥水热处理过程中生成的简单有机酸部分氧化分解,导致氨氮溶于液相的碱性作用相对增强,液相产物酸性有所减弱,且添加的H2O2质量分数越大,简单有机酸氧化分解更多,液相产物的pH不断升高、酸性逐渐减弱。

2.1. 不同质量分数H2O2对水热产物分布和固相产物含水率的影响

2.2. 不同质量分数H2O2对固相产物中重金属质量浓度及其赋存形态的影响

2.3. 不同质量分数H2O2对液相产物中VFAs和NH3-N浓度的影响

2.4. 不同质量分数H2O2对液相产物pH的影响

-

1)对于水热处理污泥,添加H2O2能明显提高水热固相产物的脱水性能,固相产物含水率随添加H2O2质量分数的增大而降低。在水热温度为200 ℃、H2O2质量分数为15%时,固相产物含水率能降低至48.64%。

2)添加H2O2有利于水热处理污泥过程中Pb和Cd的富集和钝化。相比水热处理污泥,H2O2强化水热处理污泥的固相产物中Pb和Cd的质量浓度较大、生态毒性较小。

3)H2O2的添加强化了水热处理污泥过程中有机物的分解,水热液相产物中VFAs和NH3-N质量浓度较大,同时使液相产物的pH升高,酸性得到减弱。

下载:

下载: