-

微生物燃料电池(microbial fuel cells ,MFCs)是一种利用产电微生物分解废水中有机物, 将有机物中的化学能转变成电能的新型装置[1-2]。然而,由于微生物燃料电池输出功率密度较低、使用寿命短,极大地限制了其发展及大规模使用。阳极作为微生物载体,决定了微生物的负载量、微生物燃料电池的运行稳定性,以及电极/微生物间的电子传递速率,对MFCs的产电性能及使用寿命有重要影响。因此,开发高性能的阳极材料是解决以上问题的有效途径之一。

碳布、碳纸、碳毡等传统碳基材料的价格便宜、导电性优良,已被广泛用于微生物燃料电池中[3]。虽然这些阳极具有较高的电导率,但其活性表面积低,在表面形成的生物膜有限,使得MFCs的电压输出较低[4]。因此,碳材料的表面改性成为提高MFCs产电性能的关键。MFCs阳极的修饰方法主要包括阳极表面处理、导电聚合物修饰和金属及其氧化物修饰等[5-6]。如用金、钯等贵金属纳米颗粒修饰碳材料来增加电极表面的亲水性,进而提高MFCs的输出电压。然而,贵金属产量稀少、价格昂贵,不利于MFCs的应用[7]。ZHU等[8]将易被腐蚀的铜作为微生物燃料电池的阳极,发现MFCs的输出电流仅稳定在0.30×10−2 mA,输出最大功率密度仅为2 mW·m−2。尽管腐蚀的铜电极增大了电极表面积,但由于其毒性,铜并不适宜作为微生物燃料电池的阳极。过渡金属氧化物多变和可控的微观形貌有助于形成比表面积大的多孔结构[9],有利于微生物附着,并为微生物生物膜的生长提供足够的三维空间[10]。近年来,通过各种结构工程制备的三维过渡金属化合物修饰电极已成为MFCs阳极的热门材料。DUAN等[11]采用简易电泳沉积法将纳米SnO2修饰在碳纳米管上制备出三维CNTs-SnO2复合阳极,产生的最大电流密度为2.21 mA·m−2,显著提高了MFCs产电效率。JIA等[12]以TiO2纳米线修饰的碳布作为阳极,使得MFCs的最大功率密度为392 mW·m−2,远高于未修饰碳布作阳极的功率密度。这是由于TiO2纳米线在碳布表面形成了三维互通结构,这为外膜c-型细胞素提供了巨大的接触面积,从而增加了生物电的产生。LV等[13]将RuO2纳米层涂覆在碳毡上作为微生物燃料电池的阳极,产生的最大功率密度为3 080 mW·m−2,高出无涂层阳极数倍。以上研究虽通过形成三维结构来增大电极的比表面积,促进细菌附着,但自身缺少可有效调控的多孔结构,适当大小的孔径是促进微生物在电极表面附着的关键[14],因此阻碍了此类材料对MFCs性能的提升。

本课题组采用一步液相合成法在碳布表面生长ZIF-67纳米片前驱体,以高温热解前驱体的方式合成碳布负载的四氧化三钴多孔纳米片阵列电极(Co3O4/CC)[15]。Co3O4是典型的p型半导体,金属空位形成能级提供空穴,且价格相对廉价,化学稳定性好,具有特殊的光电特性等,使其在太阳能转换、传感、光催化、锂离子电池等领域应用广泛[16]。Co3O4在常见过渡金属氧化物中表现出优异的电化学性能,这归因于其可调的纳米孔结构,包括可稳定形成的大比表面积、良好的可逆氧化还原性能和长期耐腐蚀稳定性[17]。本研究利用Co3O4比表面积高、金属活性位点多及孔隙率高的优点来提高MFCs的产电性能,采用SEM、XRD、FTIR及XPS等方法对Co3O4/CC进行表征,考察Co3O4/CC电极对MFCs产电性能的影响,并探讨其促进产电作用的机制,为多孔过渡金属氧化物修饰阳极在微生物燃料电池中的应用提供参考。

-

Co(NO3)2·6H2O(分析纯)购自国药集团化学试剂有限公司。2-甲基咪唑(分析纯)购自阿拉丁化学试剂有限公司。实验所用水均为去离子水。

-

将碳布(碳能科技股份有限公司WOS 1009)剪成1 cm×1 cm的正方形,依次在丙酮、无水乙醇和去离子水中超声清洗30 min,最后在50°C干燥箱中烘干备用。

金属离子与有机配体的浓度比例为1∶8,即将0.05 mol六水合硝酸钴和0.40 mol2-甲基咪唑分别溶于20 mL去离子水中,在室温下超声30 min进行混匀。将2-甲基咪唑水溶液迅速倒入恒定搅拌时的Co(NO3)2·6H2O溶液中,并立即将清洗后的碳布置于混合溶液中浸泡24 h。碳布表面负载一层紫色物质ZIF-67,用去离子水洗涤3次,并在干燥箱中50°C干燥过夜,得到前驱体ZIF-67/CC(图1)。将ZIF-67/CC在管式炉中,以2°C·min−1的升温速度分别加热至350°C和450°C,并保持180 min,得到生长在碳布上的多孔Co3O4纳米片,分别记为CO3O4-350、CO3O4-450。

-

研究采用典型双室结构(各腔室体积均为50 mL,图2为双室MFCs实物图)的MFCs。其中,Co3O4-350和Co3O4-450电极为阳极,碳刷电极为阴极,通过阳离子交换膜(Nafion 117,美国杜邦公司)将阴阳两极腔室隔开。对照组采用相应碳布作为MFCs阳极,其余实验条件不变。向阳极室加入10 mL从污水处理厂污泥中提取并驯化的微生物菌悬液,并加入40 mL培养液(包含乙酸钠2 g·L−1,PBS 50 mmol·L−1,维生素 50 mL·L−1,微量元素12.5 mL·L−1)。阴极液为50 mmol·L−1铁氰化钾溶液。阳极和阴极间连接1 000 Ω的电阻,将MFCs反应器置于(37 ± 0.50)℃恒温箱中。采用KEITHLEY 2700数据采集器(美国)监测并记录输出电压,采集频率为10 min−1。当输出电压低于0.10 V时,更换阴极液和阳极液。当电池连续4个周期最大输出电压恒定在固定数值范围内,视为电池启动完成。

-

采用热重分析法(thermogravimetric analysis,TGA)优化煅烧条件,将材料置于一定温度范围的空气中热解,以2℃·min−1加热至350℃,保持180 min,然后以5℃·min−1的升温速率升至500℃,同时跟踪材料质量保持率的变化[18]。扫描电子显微镜(scanning electron microscope,SEM)表征材料的形貌,将材料用导电胶固定铜板表面、真空下对样品表面喷金,工作电压为15 kV。采用能谱仪(energy dispersive spectrometer,EDS)配合扫描电子显微镜来分析材料微区成分的元素种类与含量。X射线粉末衍射(X-ray diffraction,XRD)通过对材料进行X射线衍射测试,分析其衍射图谱,获得材料的成分、材料内部原子或分子的结构或形态等信息。使用铜Kα辐射(λ=1.55 Å)记录复合材料在2θ(5°~70°)的谱图,从而确定复合材料的物相及结构信息。表面官能团属性采用傅里叶红外光谱(Fourier Transform infrared spectroscopy,FTIR)方法分析。本研究用到的红外光谱仪为美国PerkinElmer,测量范围是400~4 000 cm−1,扫描次数20次,分辨率是4 cm−1。采用Thermo ESCALAB 250Xi X射线光电子能谱仪(X-ray photoelectron spectroscopy,XPS)测试并分析材料的元素构成和价态。材料的比表面积、孔径分布则通过ASAP 2460型全自动氮气吸附比表面仪测试。样品在100℃下脱气8 h,用(Brunauere Emmette Teller,BET)方法计算比表面积。

-

使用电化学工作站(CHI660E上海辰华)对负载产电菌前后的Co3O4-350和Co3O4-450进行循环伏安扫描(cyclic voltammetry,CV),检测在新鲜阳极液中进行。电化学阻抗测试(electrochemical impedance spectroscopy,EIS)得到的抗谱曲线通过等效电路图拟合,可得出电极材料的溶液电阻Rs和电荷传递内阻Rct。

电化学测试在三电极体系中开展。其中,Co3O4-350和Co3O4-450为工作电极,铂丝电极为对电极,饱和Ag/AgCl电极为参比电极。在进行CV测试时,扫描区间为-0.80~0.20 V,扫速为5 mV·s−1。在进行EIS测试时,扫描频率为0.01~100 kHz。

在MFCs稳定运行后,使用电阻箱调节外接电阻(2 000~100 Ω),对其进行功率密度测试。在该过程中,电池电压和电极电位均由数据采集器进行记录。功率密度计算式为式(1),以阳极的有效面积(2 cm2)作为计算基准。

式中:U为电池的输出电压,V;R为达到输出电压时的外接电阻,Ω;A为电极材料的有效面积,m2。

-

1)固定。将运行结束的负载生物膜的阳极用2.50%的戊二醛固定(4°C过夜),然后用磷酸缓冲液(pH为7.20)冲洗3次,每次冲洗20 min。2)脱水。将上一步预处理后样品分别在质量分数为30%、50%、70%、85%、95%的乙醇溶液中各处理20 min,再用100%的乙醇溶液处理2次,每次20 min。3)置换。将上一步中的样品在乙酸异戊酯溶液中浸泡(4°C)过夜。4)干燥。将上一步处理后的样品在临界干燥仪中二氧化碳临界点干燥。5)将干燥后的样品用导电胶带贴到样品盘上喷金,最后在SEM下观察阳极表面微生物的生长情况。

-

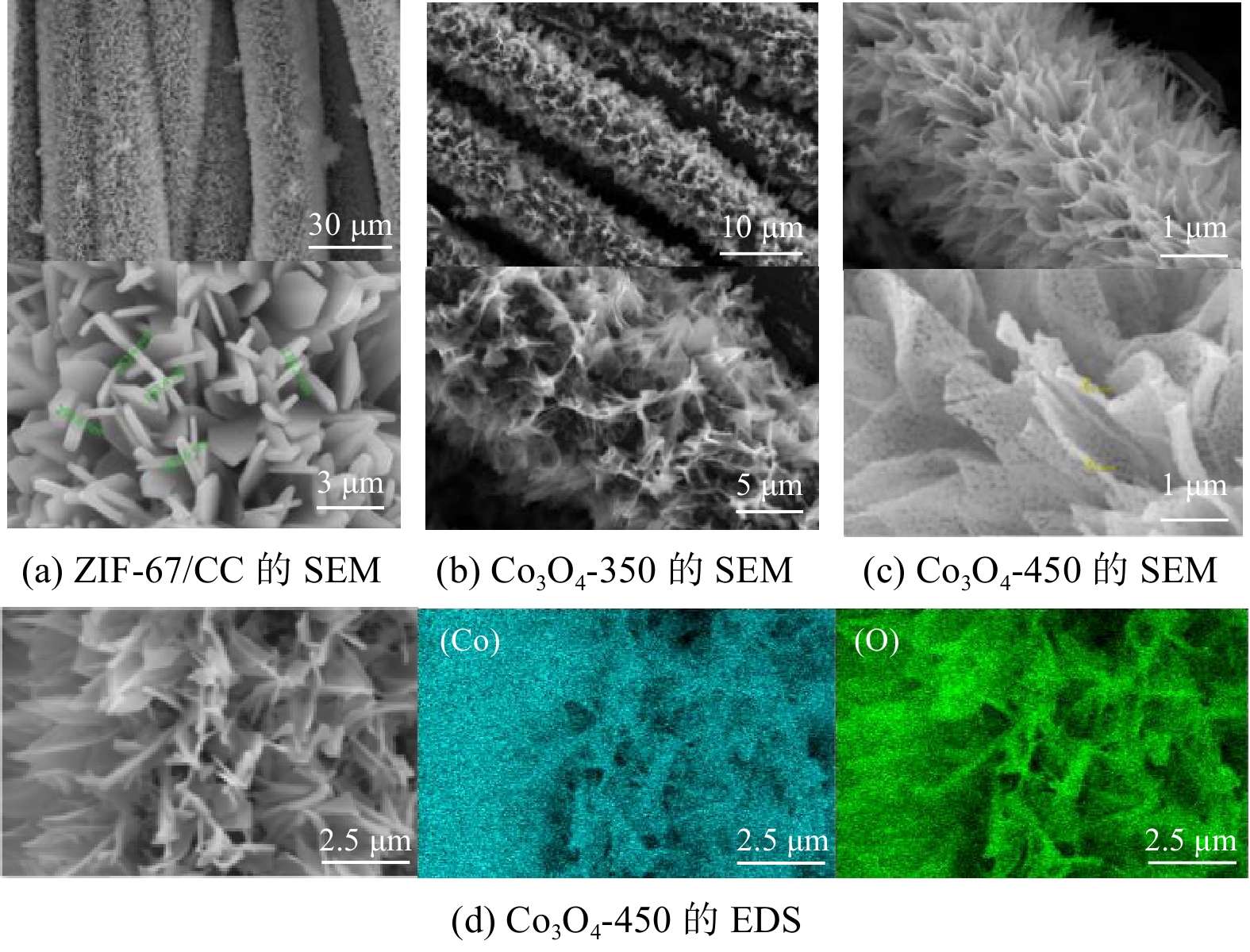

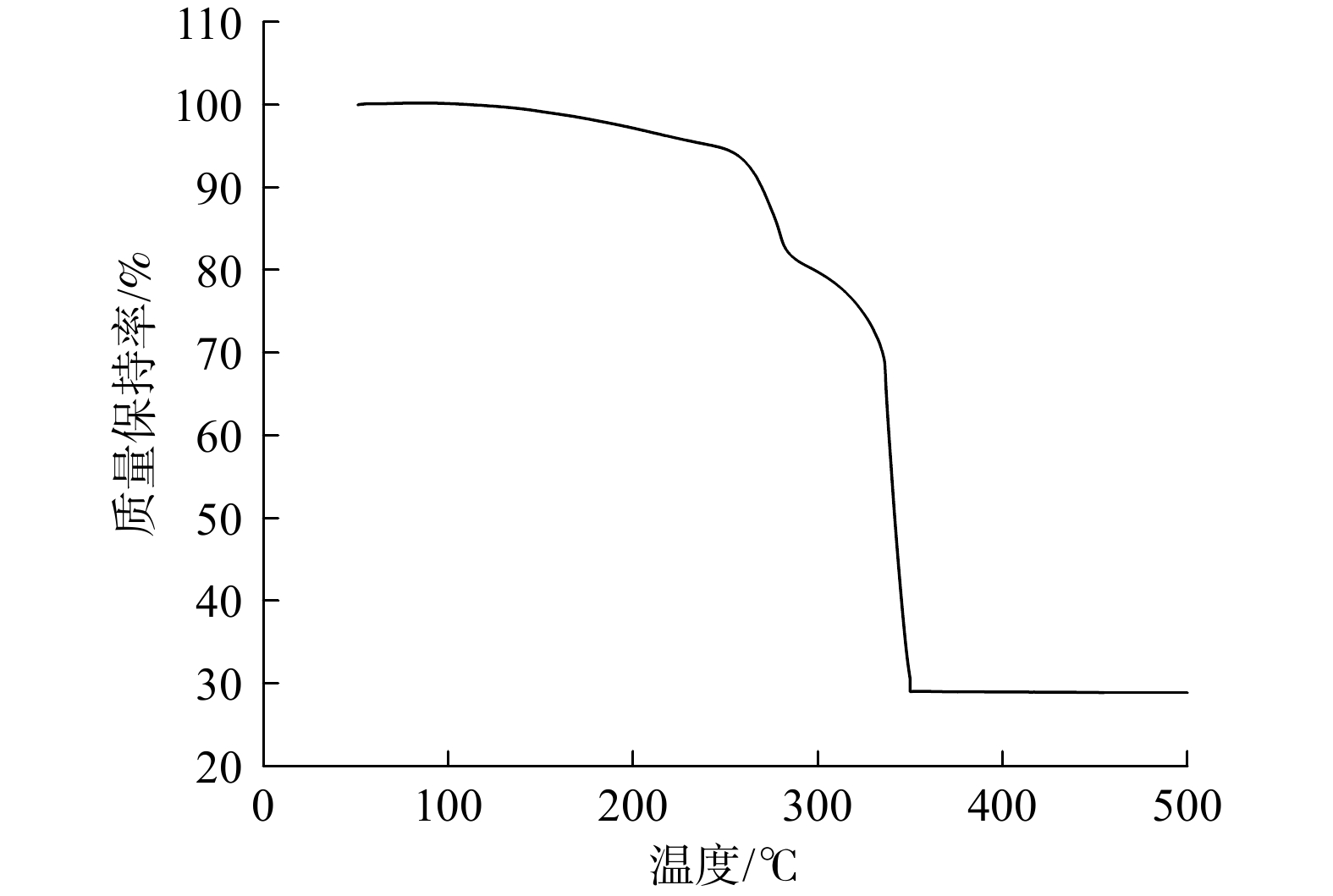

将制备的ZIF-67/CC前驱体和Co3O4材料进行SEM测试。由图3(a)~(b)可见,碳布纤维表面均匀包覆了一层垂直生长的纳米片,即ZIF-67。在未经高温热解前,ZIF-67纳米片的厚度约为200 nm。在2种不同温度下热解后ZIF-67纳米片转化为Co3O4-350和Co3O4-450。图3(c)~(d)为Co3O4-350不同倍数下的SEM。碳布纤维表面的二维片层结构较热解前并未坍塌,依旧垂直包覆在碳纤维表面,片层厚度约为70 nm。图3(e)~(f)为Co3O4-450不同倍数下的SEM,其形貌和Co3O4-350一致,但片层厚度约为40 nm。可见纳米片层表面出现了疏松的孔结构。这表明随着温度升高,ZIF-67纳米片发生了剧烈氧化,金属有机框架中的有机配体发生热解,导致结构坍塌,转化为由团簇多孔且紧密连接的纳米颗粒组成的Co3O4[19]。纳米片层中的纳米颗粒和孔隙结构对体系电化学性能至关重要[20],不仅提供所需的比表面积,促进电极与电解质接触,有助于存储更多电荷,减少离子扩散长度,还可以在电化学反应中缓冲体积变化[21],最终提高电极材料储存电荷的性能。由于在空气中热解消除了氮和碳等元素,金属元素的相对强度变强。采用SEM-EDS面扫Co3O4-450表面(图3(g))得到元素组成图。其中,Co元素见图3(h),O元素见图3(i),元素分布总谱图为图3(j)。Co和O元素的含量较高。Co元素的含量高达68.30%,O元素的含量为22%。纳米片中的Co元素为活性中心,具有较好电催化活性[22]。而材料中含量较高的O元素可提高材料的亲水性,更有利于产电微生物的附着[23]。为确认活性材料中有机框架是否被去除,除EDS元素映射外,对ZIF-67进行了额外热重量分析(TGA),结果见图4。热解温度达到350℃前,质量保持率持续下降;在350℃保持180 min后,质量无明显变化。这表明大多数ZIF-67前驱体在350℃条件下可稳定存在,借助XRD测试可确定其热解产物的物相和结构信息。

-

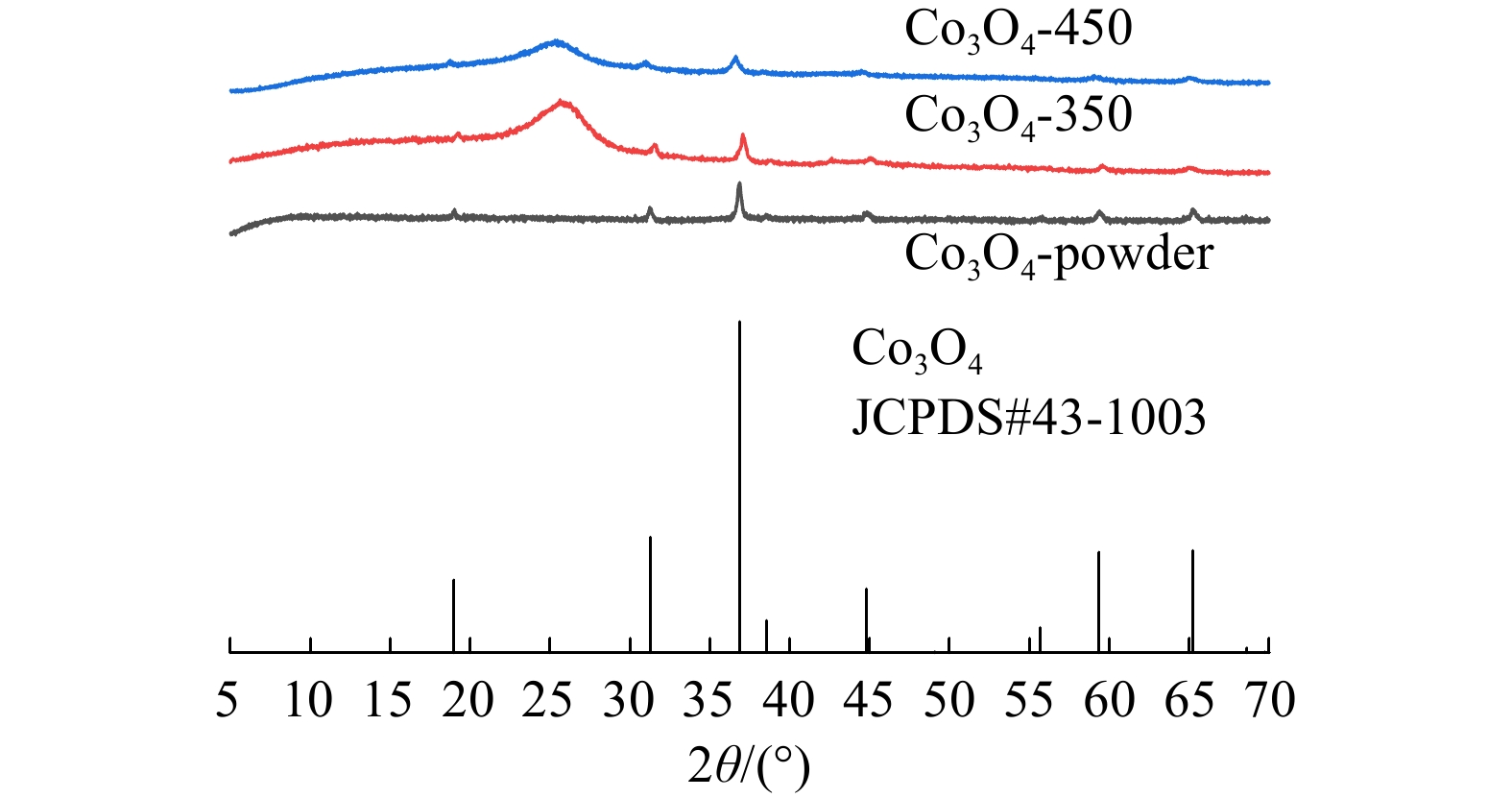

将煅烧产物进行XRD分析以确定所制备材料的物相。图5为空气条件下高温热解制得的Co3O4-350和Co3O4-450和Co3O4粉末样品的XRD谱图。Co3O4-350和Co3O4-450均显示位于25°和43°处的2个弱峰,分别为石墨(002)和(001)碳的衍射面[24],2θ在19.10°、31.40°、37.10°、44.70°、59.60°和65.60°的衍射峰归属于Co3O4尖晶石的(111)、(220)、(311)、(400)、(511)和(440)衍射峰[25]。这表明ZIF-67空气氧化后形成的物质为Co3O4。同时制备的Co3O4-350和Co3O4-450与Co3O4粉末的衍射峰一致。以上结果表明,ZIF-67/CC在空气中高温热解后,以Co2+为中心的ZIF-67纳米片发生坍塌,有机配体高温分解,形成Co的氧化物Co3O4。并且,2种温度下得到Co3O4的所有衍射峰都非常尖锐和强,表明制备的Co3O4具有良好晶型。

-

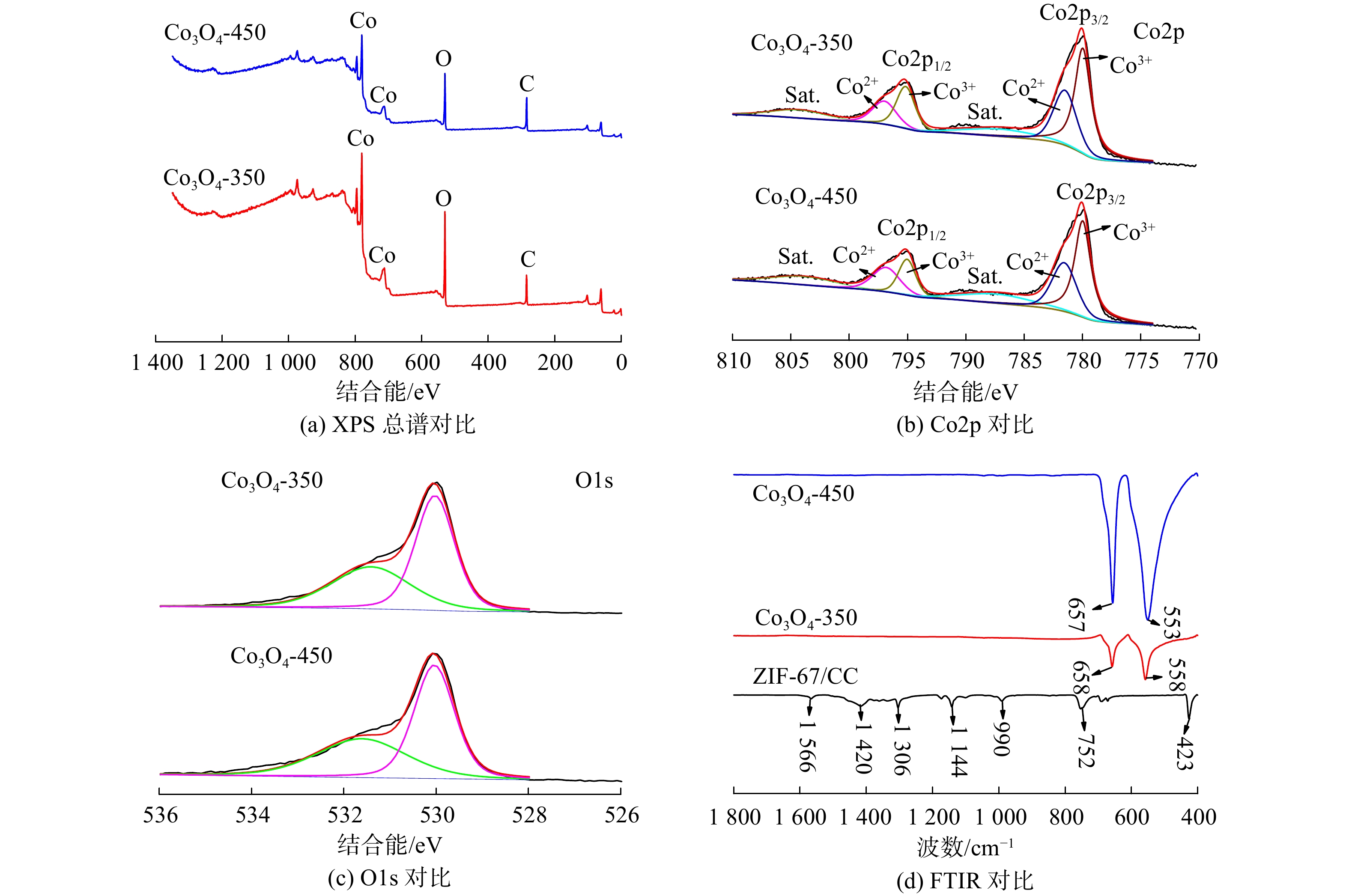

XPS总光谱可反映Co3O4样品中元素的价态及相对含量。结果表明,在这2个样品中都存在Co和O元素(图6(a))。Co3O4-350和Co3O4-450的Co2p谱图(图6(b))表明,在795.40和780.40 eV处有一对峰,分别归属于Co的2p3/2和2p1/2,自旋轨道分裂为15 eV。此外,Co2p谱的反褶积给出了2个自旋轨道拟合峰。结合能为796.90和781.60 eV的拟合峰归因于Co2+,另外2个位于795.30和780.20 eV的拟合峰归属于Co3+。789.60和804.5 eV处的2个卫星峰,均由Co2+造成[26-27]。对于O1s,图6(c)中观察到2个峰,其结合能量分别为530.20和531.60 eV,分别归属于Co—O键和O—H键[28-29]。对比Co3O4-350和Co3O4-450的Co2p1/2和Co2p3/2,发现Co3O4-350的Co2+/Co3+峰强度比约为0.63,略低于Co3O4-450的Co2+/Co3+峰强度比,约为0.73。这主要是由于随着温度的升高,材料继续氧化,Co3O4纳米片上形成了氧空位,导致电子在氧空位附近离域,最初占据了O1s轨道,Co3+的电荷密度和配位发生了变化,部分Co3+被还原为Co2+。Co2+被认为是OER过程中Co3O4电催化剂的主要活性中心[30],故推断Co3O4-450具有较高的电催化性能。

采用FTIR分析碳布上片状ZIF-67、Co3O4-350和Co3O4-450的官能团类别(图6(d))。黑色曲线为ZIF-67/CC的FTIR。744 cm−1处特征吸收峰为咪唑环的面外弯曲,而在994、1 417和1 565 cm−1处吸收峰分别与C—N拉伸、C—C拉伸和C=N拉伸有关[31]。1 145和1 303 cm−1处的峰值归因于C—H振动。以上结果与文献[32-34]报道一致,证实了ZIF-67/CC复合材料中存在2-甲基咪唑配体。经过高温热处理后,ZIF-67/CC的所有峰(如423 cm−1 的Co—N拉伸、1 144和1 306 cm−1处的C—H振动、1 420 cm−1的C—C拉伸、1 566 cm−1的C=N拉伸)均消失。而Co3O4在550和660 cm−1处的2个峰分别共享给OB3(B表示八面体孔中的Co3+)的振动和尖晶石晶格中的ABO3(A表示四面体孔中的Co2+)[35]。对比材料热解前后的特征峰,证实ZIF-67/CC中的有机配体高温热解,ZIF-67/CC前驱体完全转化为Co3O4。

-

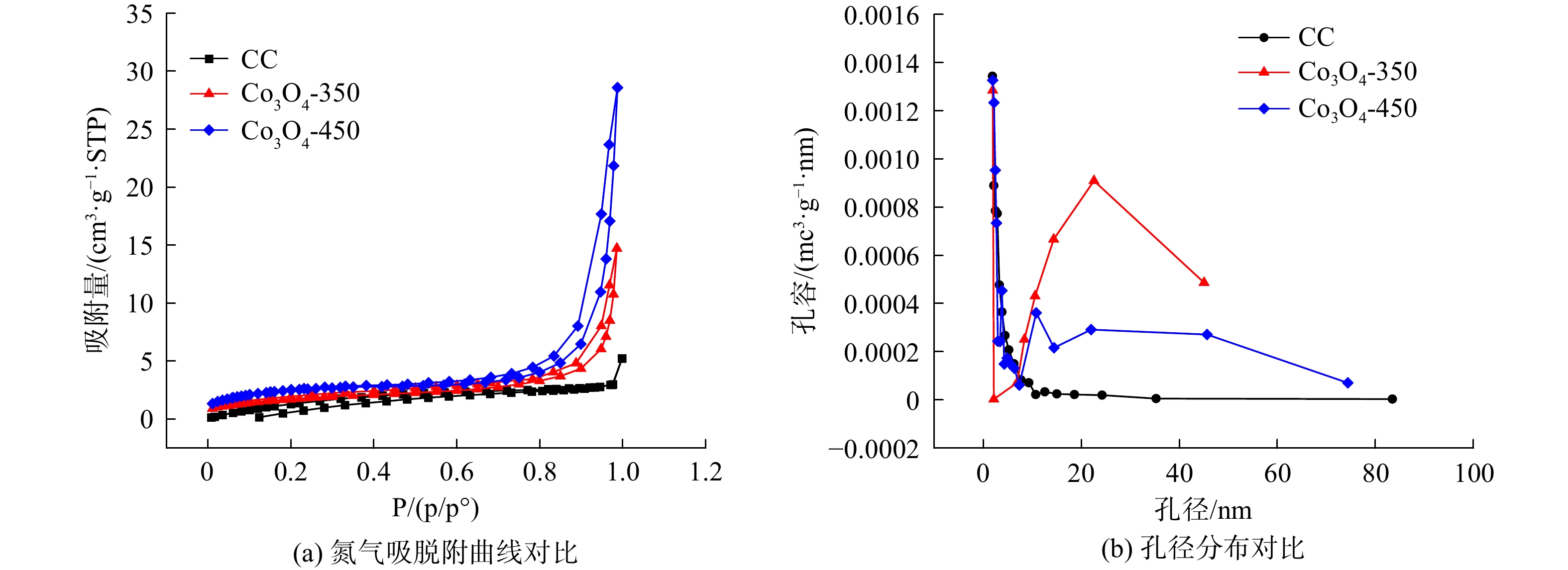

高比表面积和大孔隙率的阳极是提高MFCs功率密度的前提之一。本研究采用ASAP 2460型全自动氮气吸附比表面仪对合成材料的比表面积和孔结构进行分析,得出Co3O4-450的比表面积为8 m2·g−1,高于Co3O4-350的5 m2·g−1。由氮气脱吸附曲线(图7(a))可见,相对CC,Co3O4-350和Co3O4-450曲线尾部均出现明显的回滞环,说明纳米片表面存在介孔结构。与图7(b)中孔结构信息相吻合,二者均具有10~20 nm的介孔。然而,Co3O4-450具有较高孔容,高比表面积更有助于产电微生物的附着,介孔结构有利于电解液在材料表面的扩散,以及产电菌和材料表面间的电子传递。

-

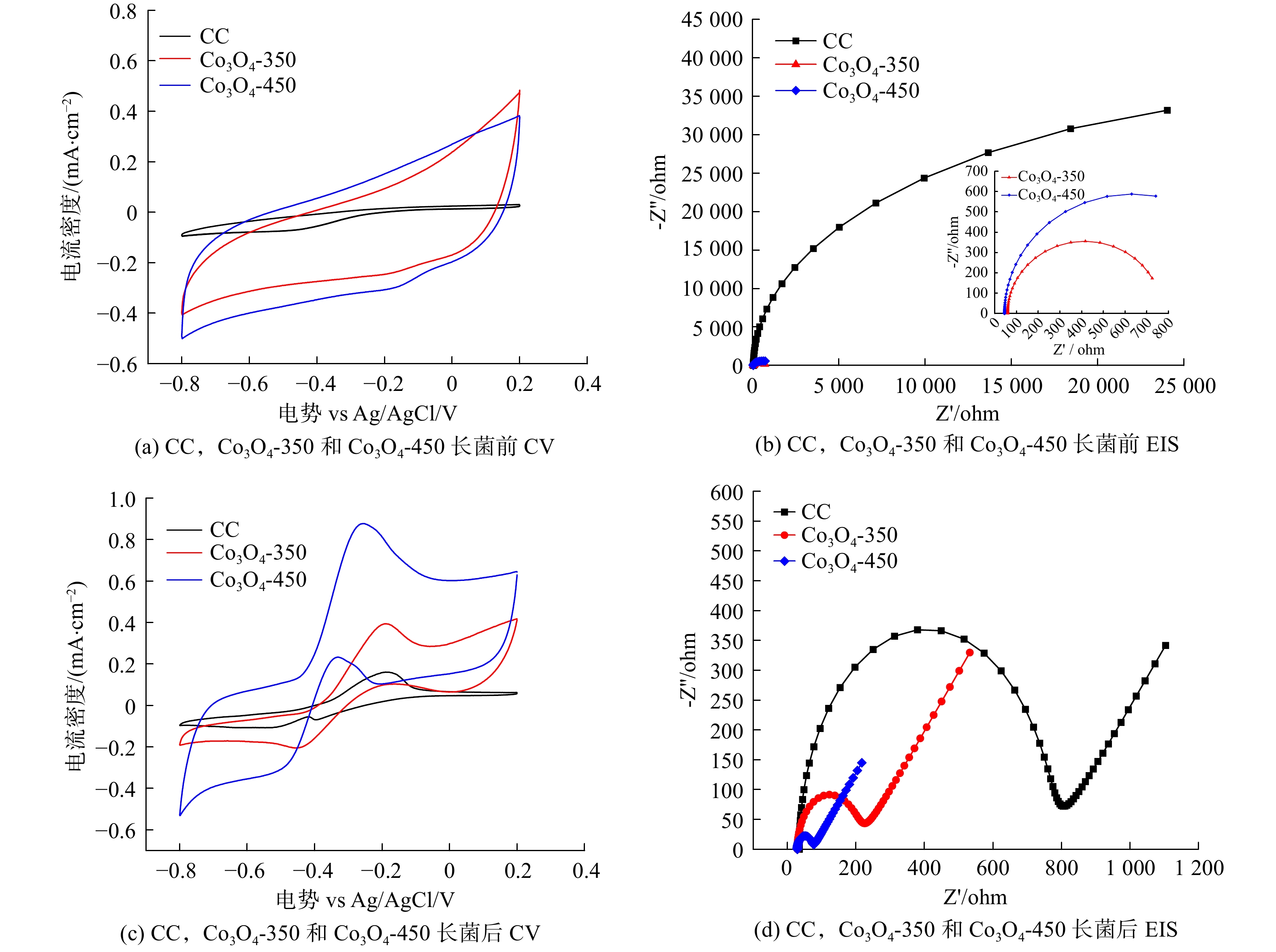

在磷酸盐缓冲液(PBS)中添加维生素和微量元素的乙酸钠2 g·L−1,制得新鲜阳极电解液。在生物膜形成前,在阳极液中比较CC、Co3O4-350和Co3O4-450的CV结果(扫速为5 mV·s−1)。由图8(a)可见,CC、Co3O4-350和Co3O4-450的CV曲线未出现氧化还原峰(典型的S型曲线),这表明在材料表面未形成生物膜时,材料没有催化氧化乙酸钠的功能。但与Co3O4-350相比,Co3O4-450的CV曲线呈矩形,表明其具有较高比电容。Co3O4-450表面的孔隙结构使得溶液中的离子更易进入阳极而达到电中性。图8(b)为CC、Co3O4-350和Co3O4-450在阳极液中的EIS(0.01~100 kHz)对比。相比CC的Rct(6.50×107 Ω),Co3O4-350 (651.50 Ω)和Co3O4-450(1 411 Ω)具有较低Rct值。Rct代表电荷传递阻抗,其值越低,材料和电解液间的电荷传质阻力越小。Co3O4-350的Rct值较CC和Co3O4-450相差不大,说明二者在阳极液中具有较好的扩散和传质效率。图8(c)为在生物膜形成后,于含乙酸钠的阳极电解液中观察到的CC、Co3O4-350和Co3O4-450阳极出现S形状的CV曲线(扫速为5 mV·s−1),表现为2个主要的氧化还原峰,分别位于−0.2 V和−0.4 V(vs Ag/AgCl)附近。这表明阳极材料负载产电菌后具有催化氧化乙酸钠的功能,与先前报道的结果相似[36]。Co3O4-450的CV曲线氧化还原峰高于Co3O4-350和CC,且单位面积的电荷强度最高。由于较高的氧化还原峰值电流强度及单位面积较大的电荷意味着在生物膜中有更多氧化还原活性物种[37]。不同阳极的CV曲线也证实了上述结果。用EIS技术进一步鉴定了包覆生物膜和电解质的阳极的界面性能。在阳极液中进行EIS测试,其结果用等效电路图拟合后的奈奎斯特图显示Co3O4-350和Co3O4-450阳极的Rct在生物膜形成后分别为174.80和43.40 Ω,远低于CC(729.20 Ω)(见图8(d)和表1)。结合CV表征的结果,修饰层中Co3O4的存在增大了阳极比电容,有利于降低阳极的Rct。Co3O4-450具有最低Rct值,较低电荷传质阻力允许产电菌和电极表面间快速进行电子转移。表1中Rs代表溶液电阻(Solution resistance,Rs),其大小与电解质溶液浓度有关。电化学工作站测得阳极材料在阳极液中的电化学阻抗谱(EIS),采用Zsimpwin软件选择图8(d)中的等效电路图拟合数据,得到电荷传递电阻Rct和溶液电阻Rs。

-

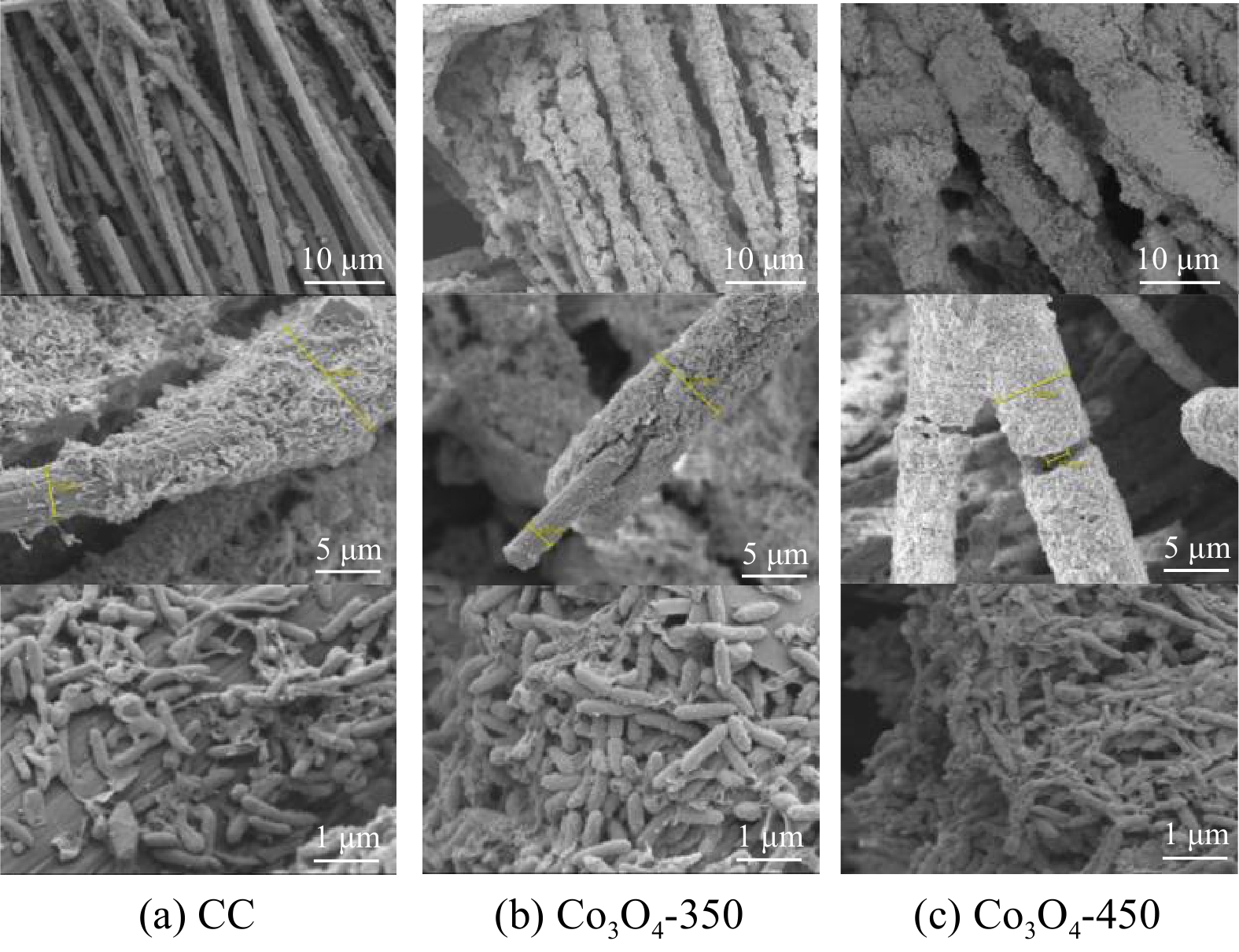

微生物在电极表面的附着状况可直观反映出电极性能优劣,并侧面反映电极内部的物质传输状况。图9为不同电极表面的SEM图。CC、Co3O4-350和Co3O4-450电极表面均附着了较厚的生物膜。然而,三者表面的生物膜附着情况存在较大差异。由于CC电极的比表面积和孔隙度较小,其外表面的的生物量明显分布稀疏,不能形成致密生物膜(图9(g))。单根纤维包裹的生物膜直径为18.80 μm(图9(d))。Co3O4-350电极表面的生物量较CC有所提升(图9(b))。相应的,单根纤维包裹生物膜的直径(图9(e))为22 μm,较CC增加了15%。生物膜密集且呈堆叠状(图9(h))。Co3O4-450电极表面生物量(图9(c))三者中最高,基底碳纤维表面包裹生物膜直径为58 μm。生物膜分布均匀且致密,堆叠厚度(图9(i))高于Co3O4-350电极。由SEM结果发现,CC电极因比表面积较小,不利于物质向电极表面传输,从而限制了微生物在电极表面的附着。而高比表面积和孔隙度的Co3O4-450表面物质传输状况良好,有利于微生物向电极表面的生长。因此,可通过对电极结构进行优化设计,在保证电极具有较大比表面积的条件下提升电极表面物质传输,从而提升电极的性能。

-

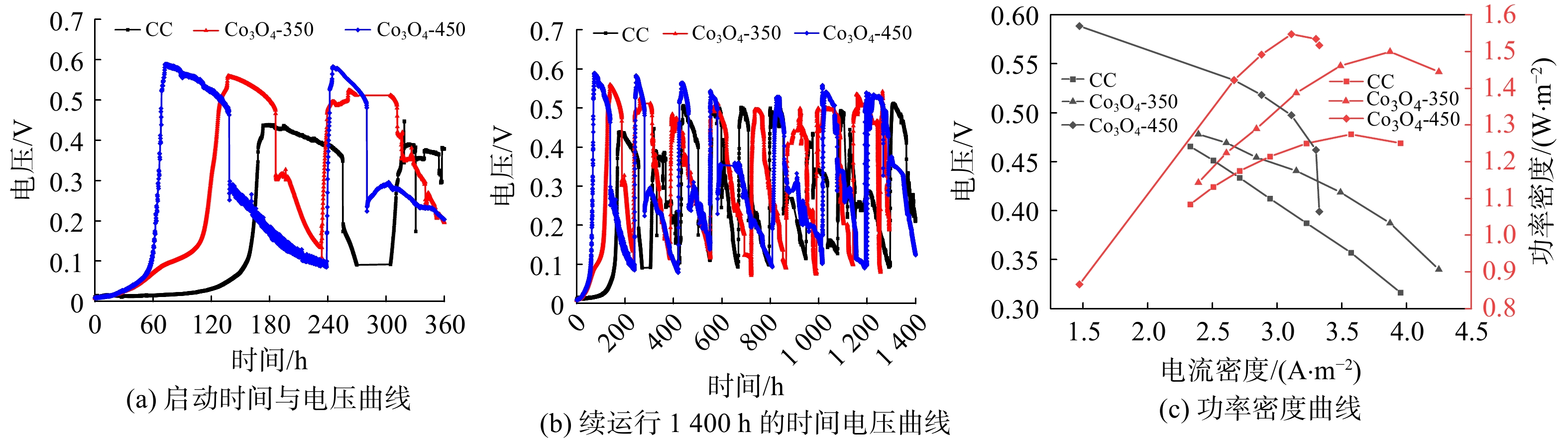

在经典的双室微生物燃料电池体系中,对Co3O4-350和Co3O4-450阳极的电池性能进行了评价。图10(a)为Co3O4-350、Co3O4-450和CC阳极在含有2 g·L−1乙酸钠的阳极培养液和从污泥中驯化的混合厌氧菌中的初始启动电压和时间曲线。在外接1 000 Ω外阻下,系统运行130 h后,Co3O4-350阳极的启动电压为0.55 V,Co3O4-450经过60 h达到电压0.58 V,CC阳极在启动170 h达到电压0.43 V。与CC相比,Co3O4-350和Co3O4-450阳极达到启动电压的时间分别缩短了23%和64.70%。图10(b)为电池体系连续运行1 400 h的时间电压曲线。3种阳极材料均可在体系中稳定存在且保持稳定输出电压。这是由于阳极生物膜在生长的同时不断产生电子,直到阳极表面形成完整生物膜体系,产电性能亦趋于稳定[38]。细菌内细胞色素类物质具有储存电子的能力,可在阳极生物膜中充当超级电容器的作用,使得阳极生物膜具有电化学活性[39]。如在细胞色素c分子结构中,血红素基团的中心Fe能通过在还原态Fe2+和氧化态Fe3+间的可逆变化,实现电子存储及其向阳极表面的传递。Co通常也存在Co2+和Co3+两种价态,因此,Co3O4同样可通过氧化还原过程存储和将电子传递到阳极表面。此外,修饰层中Co3+的存在可加快电子由产电微生物向阳极表面的传递,从而降低阳极的Rct,有利于体系输出电压的提高。经过4次循环稳定后,测量了Co3O4-350、Co3O4-450和CC阳极的极化和功率密度曲线。如图10(c)所示,Co3O4-350阳极产生的最大功率密度为1 500 mW·m−2,比CC(1 275 mW·m−2)提高15%。Co3O4-450最高可达1 547 mW·m−2,较裸碳布提高17.60%。综上所述,Co3O4-450中Co2+和Co3+的含量高于Co3O4-350,可促进产电菌和材料表面的电子传递,这表明Co3O4-450表面更适合产电菌的附着,进而提高电池体系的产电效率。

-

1)随着ZIF-67热解温度的升高,Co3O4-450纳米片的厚度和孔结构数量优于Co3O4-350,并且输出电压与热解温度成正比。MFCs运行稳定后,Co3O4-450的电荷转移电阻Rct为43.48 Ω,远低于Co3O4-350的174.80 Ω和CC的729.20 Ω,证明了Co3O4-450与电解液间的电子传递速度最高。Co3O4-450的输出电压为0.55 V,较CC的0.49 V提高11%,最大功率密度由1 275 mV·m−2增至1 547 mV·m−2,MFCs的产电效率提高17.60%。

2)由于Co3O4-450大的表面积和介孔结构促进了微生物富集,单根材料表面微生物的富集量由裸碳布的18.80 μm增至Co3O4-450的58 μm。由于Co3O4-450电极制作方式简单可控,可通过对Co3O4-450纳米片的厚度和孔结构,促进电极表面微生物生长及电解液扩散,从而进一步提升电极性能。

碳布负载的Co3O4纳米片阵列阳极对微生物燃料电池产电性能的影响

Effect of carbon cloth-loaded Co3O4 nanosheet array anode on the power generation performance of microbial fuel cell

-

摘要: 微生物燃料电池(MFCs)是一种在处理废水的同时产生电能的新型装置,阳极作为产电微生物富集、电子产生和传递的区域对提高MFCs的性能具有至关重要的作用。以碳布负载的四氧化三钴多孔纳米片阵列(Co3O4/CC)作为阳极,探究了可调控的纳米片孔缺陷对MFCs产电性能的影响。结果表明:Co3O4/CC阳极的产电性能显著优于碳布,且正比于Co3O4纳米片的孔隙率;液固界面处的电荷传递电阻(Rct)由729.20 Ω降至43.48 Ω,所获得的最大功率密度由1275 mW·m−2增加至1547 mW·m−2。本研究开发了一种孔结构可控的金属氧化物负载碳布策略,所制备的高性能阳极材料可为MFCs的性能提升提供参考。Abstract: Microbial Fuel cells (MFCs) are new devices that can generate electric energy while treating wastewater. The anode is the area where microbial enrichment, electron generation and transmission happen, which plays a crucial role in improving the performance of MFCs. In this paper, the effects of controllable pore defects on the electrical performance of MFCs were investigated by using carbon cloth loaded porous cobalt tetroxide nanosheet array (Co3O4/CC) as the anode. The results showed that the electrical performance of Co3O4/CC anode was significantly better than that of carbon cloth, and it was proportional to the porosity of Co3O4 nanosheets. The charge transfer resistance (Rct) at the liquid-solid interface decreased from 729.20 Ω to 43.48 Ω, and the maximum power density obtained increased from 1 275 mW•m-2 to 1 547 mW•m-2. In this work, a strategy of metal oxide loaded carbon cloth with controllable pore structure was developed, and the prepared high performance anode material provided a new idea for the development of MFCs.

-

表 1 运行后阳极材料EIS阻抗拟合值

Table 1. Impedance fitting values of EIS anode materials after operation

样品 Rs(Ω) Rct(Ω) CC 30.30 729.20 Co3O4-350 29.97 174.80 Co3O4-450 29.80 43.48 -

[1] LOGAN B E, REGAN J M. Electricity-producing bacterial communities in microbial fuel cells[J]. Trends in Microbiology, 2006, 14(12): 512-518. doi: 10.1016/j.tim.2006.10.003 [2] RABAEY K, ROZENDAL R A. Microbial electrosynthesis - Revisiting the electrical route for microbial production[J]. Nature Reviews Microbiology, 2010, 8(10): 706-716. doi: 10.1038/nrmicro2422 [3] LOGAN B E. Microbial fuel cells: methodology and technology.[J]. Environmental Science & Technology, 2006, 40(17): 5181-5192. [4] LOGAN B E, REGAN J M. Microbial fuel cells-challenges and applications.[J]. Environmental Science & Technology, 2006, 40(17): 5172-80. [5] 周俊, 王秀军. 微生物燃料电池阳极改性修饰最新研究进展[J]. 化学工业与工程技术, 2014, 35(1): 56-60. [6] SCOTT K, RIMBU G A, KATURI K P, et al. Application of Modified Carbon Anodes in Microbial Fuel Cells[J]. Process Safety & Environmental Protection, 2007, 85(5): 481-488. [7] 钟登杰, 刘雅琦, 廖新荣, 等. 金属及其化合物修饰微生物燃料电池阳极的研究进展[J]. 环境化学, 2017, 36(7): 208-219. [8] ZHU X, LOGAN B E, et al. Copper anode corrosion affects power generation in microbial fuel cells[J]. Journal of Chemical Technology & Biotechnology, 2014, 89(3): 471-474. [9] PENG L, PAN X, LU M, et al. Holey two-dimensional transition metal oxide nanosheets for efficient energy storage[J]. Nature Communications, 2017, 8: 15139. doi: 10.1038/ncomms15139 [10] 杨杰男, 付乾, 李俊, 张亮, 等. 3D打印微生物燃料电池阳极及其性能特性[J]. 化工进展, 2020, 39(10): 3987-3994. [11] DUAN T G, CHEN Y, WEN Q, et al. Three-dimensional macroporous CNT-SnO2 composite monolith for electricity generation and energy storage in microbial fuel cells[J]. RSC Advances, 2016, 64(6): 59610-59618. [12] JIA X Q, HE Z H, ZHANG X J, et al. Carbon paper electrode modified with TiO2 nanowires enhancement bioelectricity generation in microbial fuel cell[J]. Synthetic Metals, 2016, 215: 170-175. doi: 10.1016/j.synthmet.2016.02.015 [13] LV Z, XIE D, YUE X, et al. Ruthenium oxide-coated carbon felt electrode: A highly active anode for microbial fuel cell applications[J]. Journal of Power Sources, 2012, 210(Jul.15): 26-31. [14] ANITHA V C, LEE J H, LEE J, et al. Biofilm formation on a TiO2 nanotube with controlled pore diameter and surface wettability[J]. Nanotechnology, 2015, 26(6): 065102-065102. doi: 10.1088/0957-4484/26/6/065102 [15] YUAN L, BD A, YI C, et al. Nanostructured Co3O4 for achieving high-performance supercapacitor[J]. Materials Letters, 2020: 285. [16] 张一江, 倪洁, 张利芳, 等. 多孔过渡金属氧化物材料在能源环境中的应用进展[J]. 中国陶瓷, 2017(2): 1-12. [17] DONDERS M E, KNOOPS H, KESSELS W, et al. Co3O4 as anode material for thin film micro-batteries prepared by remote plasma atomic layer deposition[J]. Journal of Power Sources, 2012, 203(Apr.1): 72-77. [18] LIM G, LIU X, GUAN C, et al. Co/Zn bimetallic oxides derived from metal organic frameworks for high performance electrochemical energy storage[J]. Electrochemical Acta, 2018, 291: 177-187. doi: 10.1016/j.electacta.2018.08.105 [19] SINGH D, KUNDU V S, MAAN A S, et al. Structural, morphological and gas sensing study of palladium doped tin oxide nanoparticles synthesized via hydrothermal technique[J]. Journal of Molecular Structure, 2015, 1100: 562-569. doi: 10.1016/j.molstruc.2015.08.009 [20] XU X, CAO R, JEONG S, et al. Spindle-like Mesoporous α-Fe2O3 Anode Material Prepared from MOF Template for High-Rate Lithium Batteries[J]. Nano Letters, 2012, 12(9): 4988-4991. doi: 10.1021/nl302618s [21] REDDY A, GOWDA S R, SHAIJUMON M M, et al. Hybrid nanostructures for energy storage applications.[J]. Advanced Materials, 2012, 24(37): 5045-5064. doi: 10.1002/adma.201104502 [22] ARTERO V, CHAVAROT-KERLIDOU M, FONTECAVE M. ChemInform Abstract: Splitting Water with Cobalt[J]. ChemInform, 2011, 42(51). [23] 彭新红, 于宏兵, 王鑫, 等. 碳纤维毡表面改性对微生物燃料电池性能的影响[J]. 环境工程学报, 2013, 7(10): 4139-4143. [24] YANG Z, ZHOU X, NIE H, et al. Facile construction of manganese oxide doped carbon nanotube catalysts with high activity for oxygen reduction reaction and investigations into the origin of their activity enhancement.[J]. Acs Applied Material & Interfaces, 2011, 3(7): 2601-2606. [25] LI B J, HUA Q, et al. Co3O4@graphene Composites as Anode Materials for High-Performance Lithium-Ion Batteries[J]. Inorganic Chemistry, 2011, 50(5): 1628-1632. doi: 10.1021/ic1023086 [26] XU L, JIANG Q, XIAO Z, LI X, HUO J, WANG S, et al. Plasma Engraved Co3O4 nanosheets with oxygen vacancies and high surface area for the oxygen evolution reaction[J]. Angewandte Chemie-International Edition, 2016, 55(17): 5277-5281. doi: 10.1002/anie.201600687 [27] WANG Y, ZHOU T, JIANG K, DA P, PENG Z, TANG J, Et al. Reduced mesoporous Co3O4 nanowires as efficient water oxidation electrocatalysts and supercapacitor electrodes[J]. Advanced Energy Materials, 2014, 4(16): 1400696. doi: 10.1002/aenm.201400696 [28] TAO H, CHEN D, JIAO X, ET al. Solubility-controlled synthesis of high-quality Co3O4 nanocrystals[J]. Chemistry of Materials, 2005, 17(15): 4023-4030. doi: 10.1021/cm050727s [29] XU R, ZENG H C, ET al. Self-generation of tiered surfactant superstructures for one-pot synthesis of Co3O4 nano cubes and their close- and non-close-packed organizations[J]. Langmuir, 2004, 20(22): 9780-9790. doi: 10.1021/la049164+ [30] ZHANG S, WEI N, YAO Z, et al. Oxygen vacancy-based ultrathin Co3O4 nanosheets as a high-efficiency electrocatalyst for oxygen evolution reaction[J]. International Journal of Hydrogen Energy, 2020, 46(7): 5286-5295. [31] GROSS A F, SHERMAN E, VAJO J J, et al. Aqueous room temperature synthesis of cobalt and zinc sodalite zeolitic imidazolate frameworks[J]. Dalton Transactions, 2012, 41(18): 5458-5460. doi: 10.1039/c2dt30174a [32] FANG G, ZHOU J, LIANG C, et al. MOFs nanosheets derived porous metal oxide-coated three-dimensional substrates for lithium-ion battery applications[J]. Nano Energy, 2016, 26: 57-65. doi: 10.1016/j.nanoen.2016.05.009 [33] XUE H, KAI T, DING W, et al. Design of a porous cobalt sulfide nanosheet array on Ni foam from zeolitic imidazolate frameworks as an advanced electrode for supercapacitors[J]. Nanoscale, 2018, 10(6): 2735-2741. doi: 10.1039/C7NR07931A [34] WANG D C, HUANG N B, SUN Y, et al. GO clad Co3O4 (Co3O4@GO) as ORR catalyst of anion exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2017, 42(31): 20216-20223. doi: 10.1016/j.ijhydene.2017.05.236 [35] SURAJA P V, YAAKOB Z, BINITHA N N, et al. Photocatalytic degradation of dye pollutant over Ti and Co doped SBA-15: Comparison of activities under visible light[J]. Chemical Engineering Journal, 2011, 176: 265-271. [36] YUAN Y, ZHOU S, YI L, et al. Nanostructured Macroporous Bioanode Based on Polyaniline-Modified Natural Loofah Sponge for High-Performance Microbial Fuel Cells[J]. Environmental Science & Technology, 2013, 47(24): 14525-14532. [37] LIU C, LI J, ZHU X, et al. Effects of brush lengths and fiber loadings on the performance of microbial fuel cells using graphite fiber brush anodes[J]. International Journal of Hydrogen Energy, 2013, 38(35): 15646-15652. doi: 10.1016/j.ijhydene.2013.03.144 [38] BARANITHARAN E, KHAN M R, PRASAD D, et al. Effect of biofilm formation on the performance of microbial fuel cell for the treatment of palm oil mill effluent[J]. Bioprocess & Biosystems Engineering, 2015, 38(1): 15-24. [39] BONANNI P S, SCHROTT G D, ROBUSCHI L, et al. Charge accumulation and electron transfer kinetics in Geobacter sulfurreducens biofilms[J]. Energy & Environmental Science, 2012, 5(3): 6188-6195. -

下载:

下载: