-

煤、石油等燃料的燃烧产生的气体中富含SO2和NOx,它们不仅有毒,还是形成酸雨和光化学烟雾的主要原因[1]。物理、化学工艺净化SO2和NOx方法有湿法脱硫、选择性催化还原法等,虽然这些技术已经发展成熟且应用广泛,但存在运行费用高、容易产生二次污染等缺点[2-3]。随着20世纪80年代生物科学技术的迅猛发展,以环境友好、高效和低成本著称的环境生物技术成为了行业关注热点。有研究[4-5]表明,生物工艺在净化低质量浓度SO2和NOx废气时,可以表现出不错的去除能力,但传统的生物工艺存在长期运行时导致填料堵塞的问题,直到生物转鼓工艺(RDB)的出现,才得以较好地解决。CHEN等[6]的研究表明,RDB在厌氧条件下同步净化SO2和NO,可以达到较好的去除效果,但由于NO气液扩散效果差,需要额外添加络合剂Fe(II)(EDTA)。此外,WANG等[7]在生物滴滤塔同步净化SO2和NOx的研究中发现,将O2体积分数从4%提高到20%时,NOx的去除效果可以从49.28%提高至80.85%,这归功于O2对NO的氧化。此外,即使在好养环境下,填料内部由于外部微生物包裹易形成厌氧环境,也能为部分厌氧反应提供基础条件[7]。这为好氧条件下RDB同步脱硫脱硝提供了理论基础。其中,SO2最终的代谢产物为S,NOx则最终净化为N2,具体反应过程[8-12]如式(1)和式(2)所示。

然而,对RDB好氧同步脱硫脱硝的工艺条件和净化效果仍缺乏研究,因此,本实验探讨了好氧条件下RDB同步脱硫脱硝效果受SO2质量浓度、NOx质量浓度、营养液体积和EBRT变化的影响情况,并借助动力学模型分析和验证实验结果,以期为今后的研究提供参考。

-

本实验中的SO2和NOx气体均通过化学反应制备而得,SO2气体制备的化学反应见式(3),NOx气体制备的化学反应见式(4)。其中,H2SO4、Na2SO3、NaNO2溶液浓度均为1 mol·L−1,SO2和NOx气体的质量浓度通过调整Na2SO3溶液和NaNO2溶液的滴定速度来控制,同时用空气泵将反应瓶中的气体吹出,从而得到了人工制备的含SO2和NOx的废气,废气中氧气的体积分数约为20%。

实验所用的活性污泥取自宁波市污水处理厂二沉池,营养液中各营养物质的质量浓度为C6H12O6 3 500 mg·L−1、NaCl 500 mg·L−1、K2HPO4 2 000 mg·L−1、MgSO4·7H2O 600 mg·L−1、NaHCO3 500 mg·L−1、CaCl2 55.4 mg·L−1、CaSO4·5H2O 15.7 mg·L−1、CoCl2·6H2O 16.1 mg·L−1、MnCl2·4H2O 50.6 mg·L−1、ZnSO4·7H2O 220 mg·L−1、FeSO4·7H2O 49.9 mg·L−1。

NOx质量浓度采用盐酸萘乙二胺分光光度法(HJ 479-2009)测定,SO2质量浓度采用甲醛吸收-副玫瑰苯胺分光光度法(HJ 482-2009)测定,吸光度采用UV-1800型紫外可见分光光度计测定,液相中NO3−和SO42–的质量浓度采用ICS-600离子色谱仪测定。目前,SO2和NOx的排放标准如表1所示。可以看出,对排放废气中SO2和NOx最高质量浓度要求均在100~200 mg·m−3,故为符合排放标准,实验要求RDB净化结果应满足SO2和NOx的出气质量浓度低于100 mg·m−3。

-

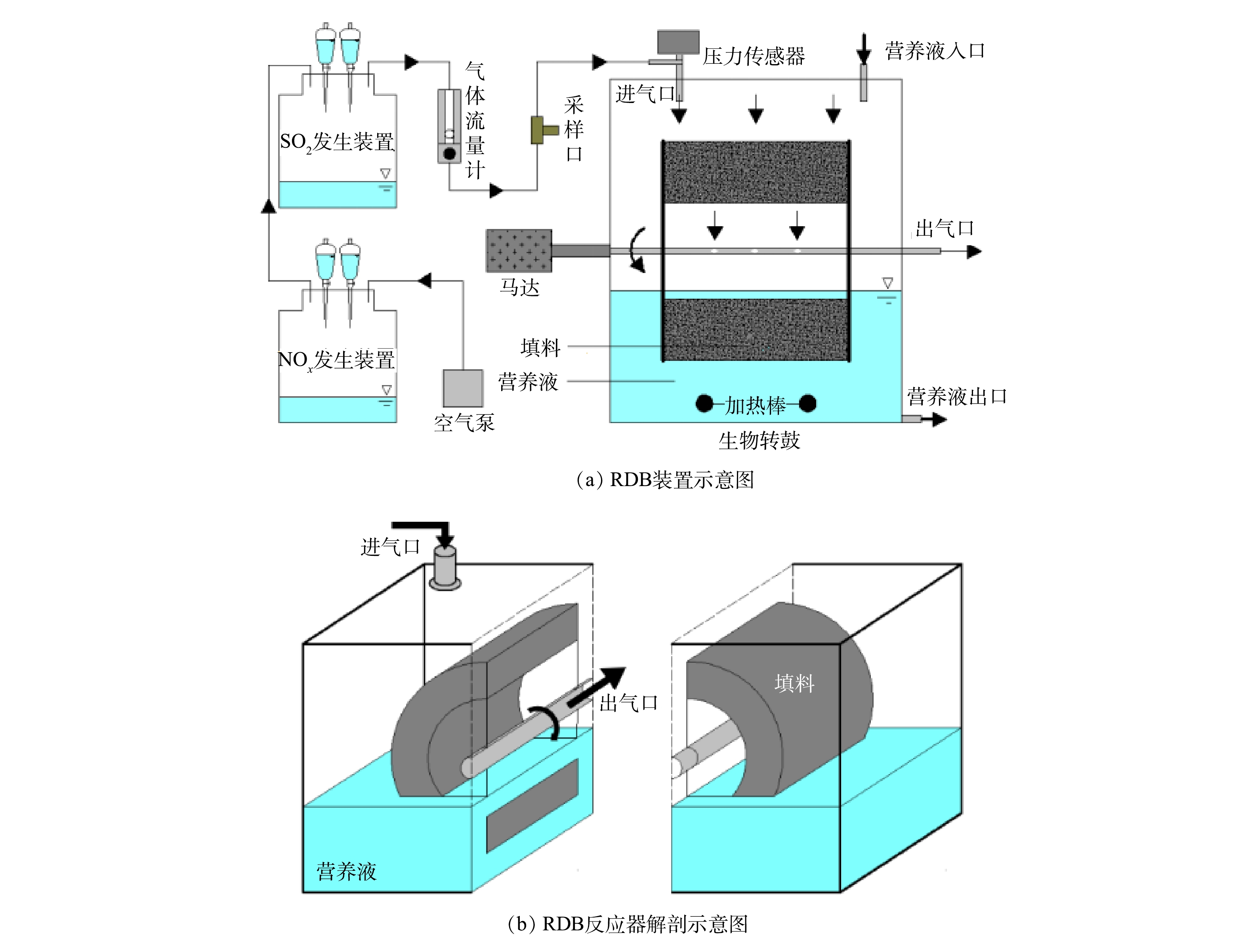

RDB实验装置如图1所示。实验装置主体部分采用有机玻璃材料、全密闭设计,外部采用不锈钢材料作为框架支撑,并配有温度控制和气压监测等功能。反应器总容积为51 L;填料为环状改性聚氨酯海绵(孔径约1 mm),外径220 mm,内径80 mm,体积为5 L。废气由转鼓顶部进入,净化后通过中心转轴向外排出,填料通过转轴带动间歇接触营养液,为微生物提供营养物质和水分。

-

将10 L沉降后的污泥与10 L营养液混合均匀加入到RDB内,以NaNO3和Na2SO4作为氮源和硫源,对污泥中的DNB和SRB富集培养,驯化挂膜。其中,NaNO3的质量浓度按梯度从100 mg·L−1逐步递增至1 200 mg·L−1,Na2SO4的质量浓度按梯度从200 mg·L−1逐步递增至1 600 mg·L−1。每隔24 h,检测1次营养液中NO3−和SO42−的质量浓度变化。当营养液中NO3−和SO42–去除负荷维持相对稳定后,开始通入SO2和NOx废气代替硫源和氮源,待SO2和NOx去除率稳定后视为启动完成。整个启动阶段耗时70 d。RDB启动完成后,开始考察SO2质量浓度、NOx质量浓度、营养液体积、EBRT对RDB脱硫脱硝性能的影响。实验期间,温度为30 ℃,pH为7,转速为3 r·min−1,气体流速为0.24 m3·h−1,每隔12 h更换营养液1 L,并测量pH值,pH偏差大于0.5时,用1 mol·L−1的HCl或NaOH溶液调节。

-

SO2和NOx在RDB内的净化过程主要分为3个部分:由气相向营养液和填料的扩散,营养液吸收积累、生物降解及与填料间的传递,在填料生物膜中的扩散、富集与降解。陈浚等[13-14]假设:①RDB去除NO为一稳态过程,温度、pH 等不随时间变化;②填料匀速转动,且径向同一半径截面任一位置转动一圈经历的状态一致;③生物膜只存在填料表面,均匀稳定且厚度已知,液膜厚度也均匀;④气相和液相沿填料径向分布均匀,气流沿径向运动,忽略轴向方向上的质量扩散,且气流在填料孔隙间的流动假设为层流;⑤液相对污染物的吸收遵循亨利定律;⑥NO在营养液中与在水中的物理属性一致,反应在无氧条件下发生,NO完全降解为N2,无中间产物。并由此根据质量守恒定律和Monod动力学方程联立了RDB在气相(式(5))、液相(式(6))、生物相(式(7))中NO净化过程的质量组分方程。

式中:CG为污染物出气质量浓度,mg·m−3;C0为污染物进气质量浓度,mg·m−3;DL为污染物在液相中的扩散系数[7,15],SO2为1.91×10−5 cm2·s−1,NO为2.32×10−5 cm2·s−1;α为填料比表面积[14],6 cm2·cm−3;V为填料的体积,cm3;R0为径向外径,cm;r为径向半径,cm;ε为填料真实孔径率,0.94%;δ为微生物膜厚度[14],0.1 cm;VG为污染物流动速率,cm·s−1;μmax为微生物最大比生长速率[13,16],SRB为3.44×10−5 s−1,DNB为2.78×10−5s−1;ρb为液相生物密度[14],0.05 g·cm−3;KS为半饱和系数[17-18],SO42–为1.5×10−3 g·cm−3,NO3−为1.2×10−3 g·cm−3;kL为液相中的转移系数,cm·s−1;kL为液相中的转移系数,cm·s−1;k1为生物膜中的转移速率,s−1;W为填料的持液量,mL。

微分解得算式模型见式(8),其中参数计算见式(9)和式(10)。

由于NO的溶解度很低,微生物对NO的降解速率远大于NO在营养液中的物理传质速率[14],即

δk1≫kL ,因此式(8)可简化为式(11)。根据液膜传质系数方程[19](kL=DLαV/W),陈浚等[13]最终得到了的动力学模型(式(12))。该模型建立在生物传质控制反应的基础上,能较好描述RDB对低质量浓度(小于600 mg·m−3)NO的去除过程。

由于本实验的污染废气源为SO2和NOx的混合废气,其中SO2易溶于水,NOx中的NO在空气环境下亦会被完全氧化成NO2,NO2能与水发生反应。对式(10)的假设做出一些调整:①RDB处在稳态,温度、pH保持不变;②填料径向截面各处反应速率一致;③填料各处生物膜、液膜均稳定且厚度一致;④气相和液相沿填料径向分布均匀,污染物仅做径向运动,流动方式为层流;⑤2种污染物之间不发生反应;⑥SRB和DNB两类细菌在填料中均匀分布,且互不相影响;⑦SO2完全降解为S,NOx完全降解为N2,无中间产物。且在本实验中,SO2和NOx的液相传质速率远大于生物降解速率,即δk1<<kL。根据以上推论,将式(12)的动力学模型进行了优化和调整后,得到模型(式(13))(该模型建立在液相传质控制反应的基础上)。

-

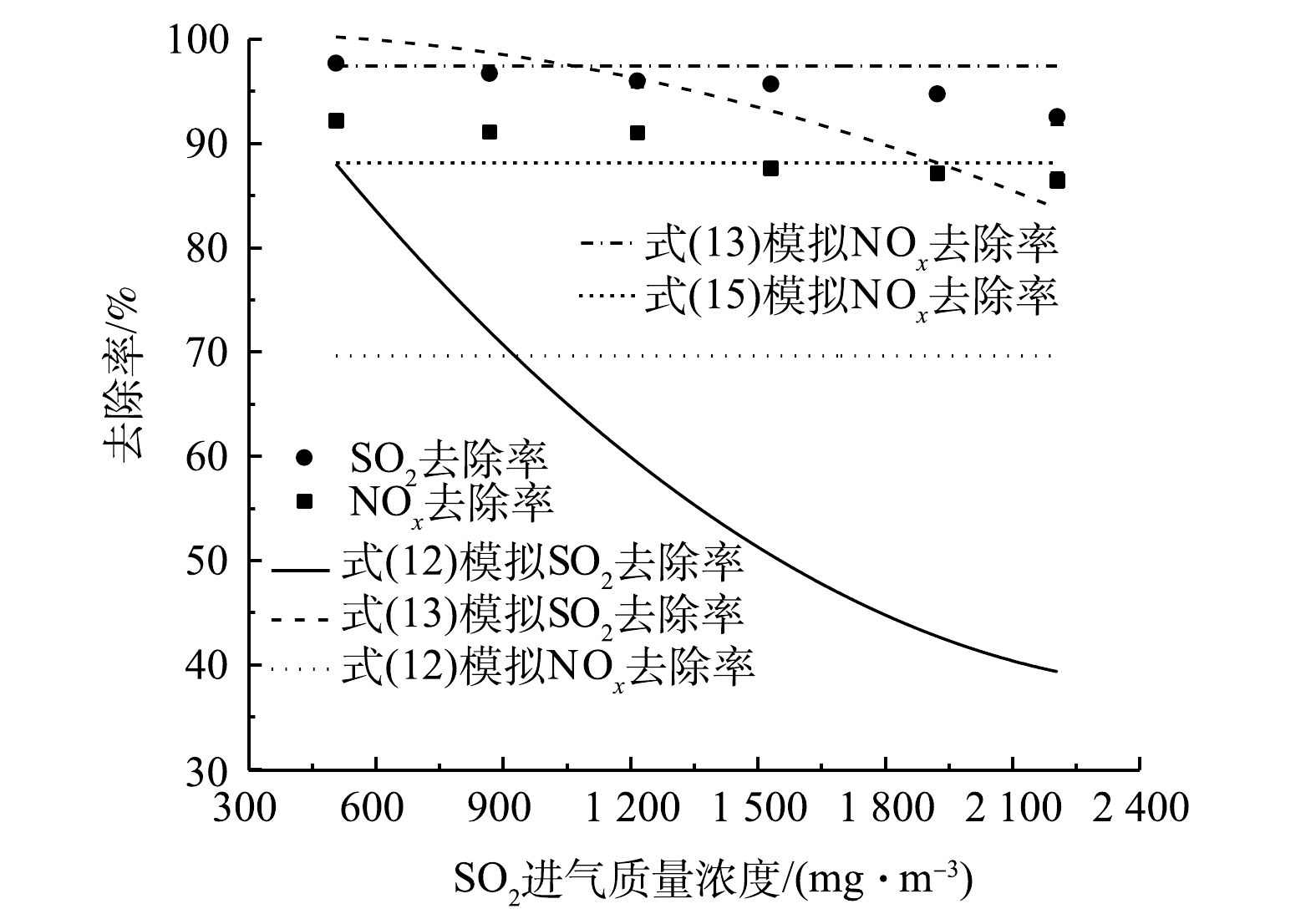

在NOx进气质量浓度为800 mg·m−3、温度为30 ℃、气体流量为4 L·min−1、pH为7、转速为3 r·min−1、营养液体积为19.5 L时,不同SO2进气质量浓度下,RDB对SO2和NOx去除率的实验数据和模拟数据比较如图2所示。实验中SO2进气质量浓度从505.93 mg·m−3上升至2 205.52 mg·m−3,去除率从97.69%逐渐降低至92.55%;当SO2进气质量浓度大于1 530.80 mg·m−3时,SO2出气质量浓度高于100 mg·m−3。且随着SO2进气质量浓度的增加,NOx去除率从92.16%降至86.34%。可见,高SO2质量浓度会对NOx去除产生一定影响。这是由于SO2易溶于水,进气SO2质量浓度增加致使液相中SO42-浓度增加,SRB竞争力得以强化[20],且中间产物S2-的增加易产生H2S,从而抑制DNB活性[21-22]。因此,在反应中SO2质量浓度应维持适宜水平,既能最大程度净化SO2,又不会对NOx去除产生严重影响。当SO2质量浓度从1 216.23 mg·m−3增加到1 530.80 mg·m−3时,NOx去除率出现了明显下降,可见SO2最适质量浓度应为1 200 mg·m−3。

对比式(12)和式(13)模拟数据与SO2和NOx实验数据之间的拟合情况,优化后的式(13)与SO2实验数据的拟合情况优于式(12)。但由于液膜厚度和微生物活性等参数的实际情况与假设仍有误差,导致式(11)的模拟数据与实验数据仍有0.60%~11.60%的绝对误差。式(12)和式(13)与NOx实验数据的平均绝对误差分别为19.62%和8.19%,由于模型假设RDB生物相为稳态,因此,通过式(12)和式(13)预测的去除率均保持不变,而实际DNB受限导致NOx去除率下降。

-

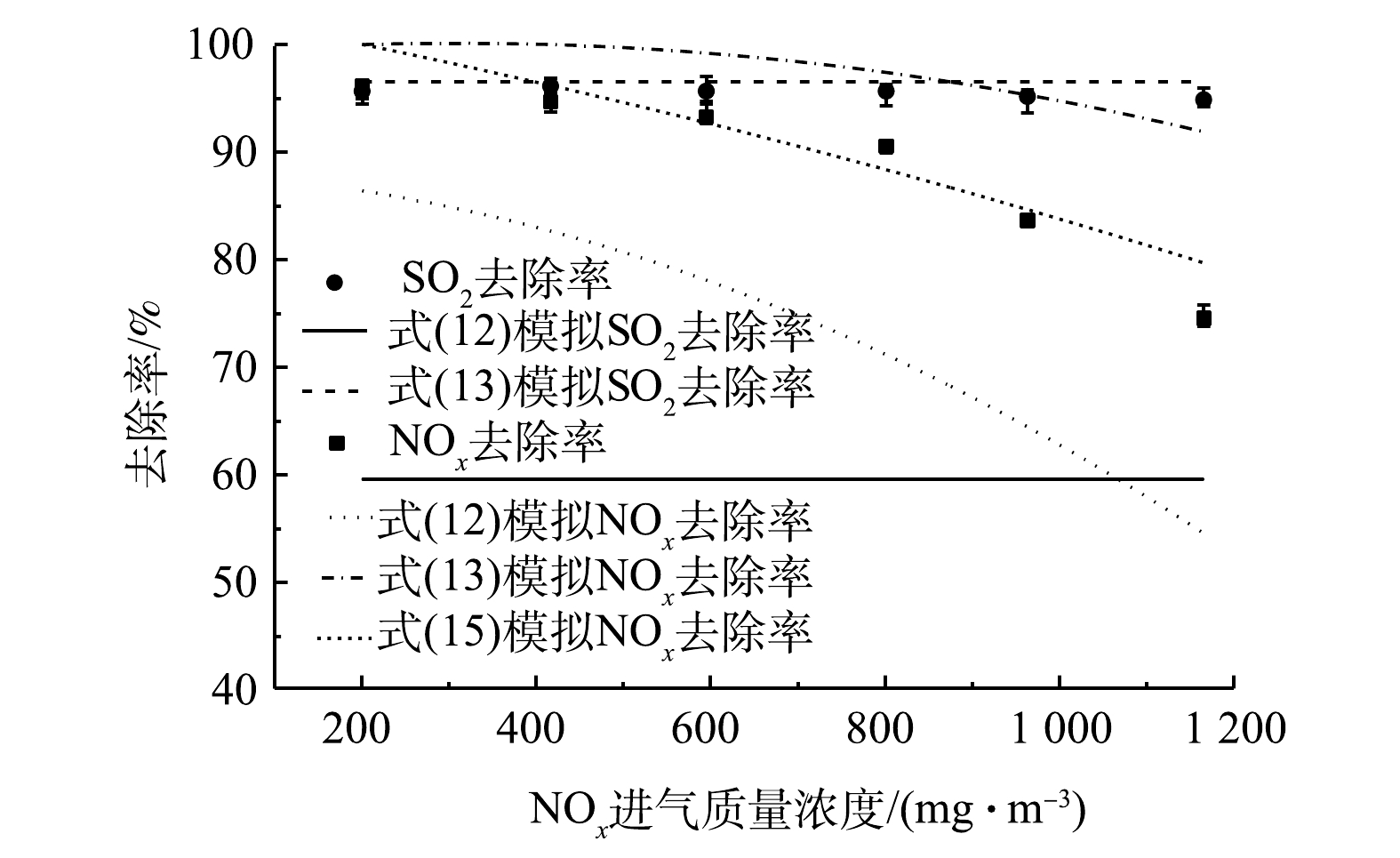

在SO2进气质量浓度为1 200 mg·m−3、温度为30 ℃、气体流量为4 L·min−1、pH为7、转速为3 r·min−1、营养液体积为19.5 L时,不同NOx进气质量浓度下,RDB对SO2和NOx去除率的实验数据和模拟数据比较如图3所示。实验中SO2的去除率维持在95%左右,实验结果与式(13)模拟数据的平均绝对误差为1.05%,且SO2的去除率未随着NOx进气质量浓度的增加而发生改变,这是由于SO2反应受气液传质控制,NOx浓度对此过程的干扰可忽略不计。

NOx进气质量浓度从200.62 mg·m−3上升至1 165.65 mg·m−3,RDB对NOx的去除率从96.11%下降至74.55%,当NOx质量浓度高于801.51 mg·m−3后,RDB对NOx去除负荷几近饱和,NOx去除率出现明显下降,且NOx出气质量浓度高于100 mg·m−3。因此,最适NOx质量浓度应该为800 mg·m−3。相较于NOx去除率的实验数据,式(12)的模拟数据偏低16.80%~22.54%,式(13)的模拟数据偏高5.27%~11.00%。

-

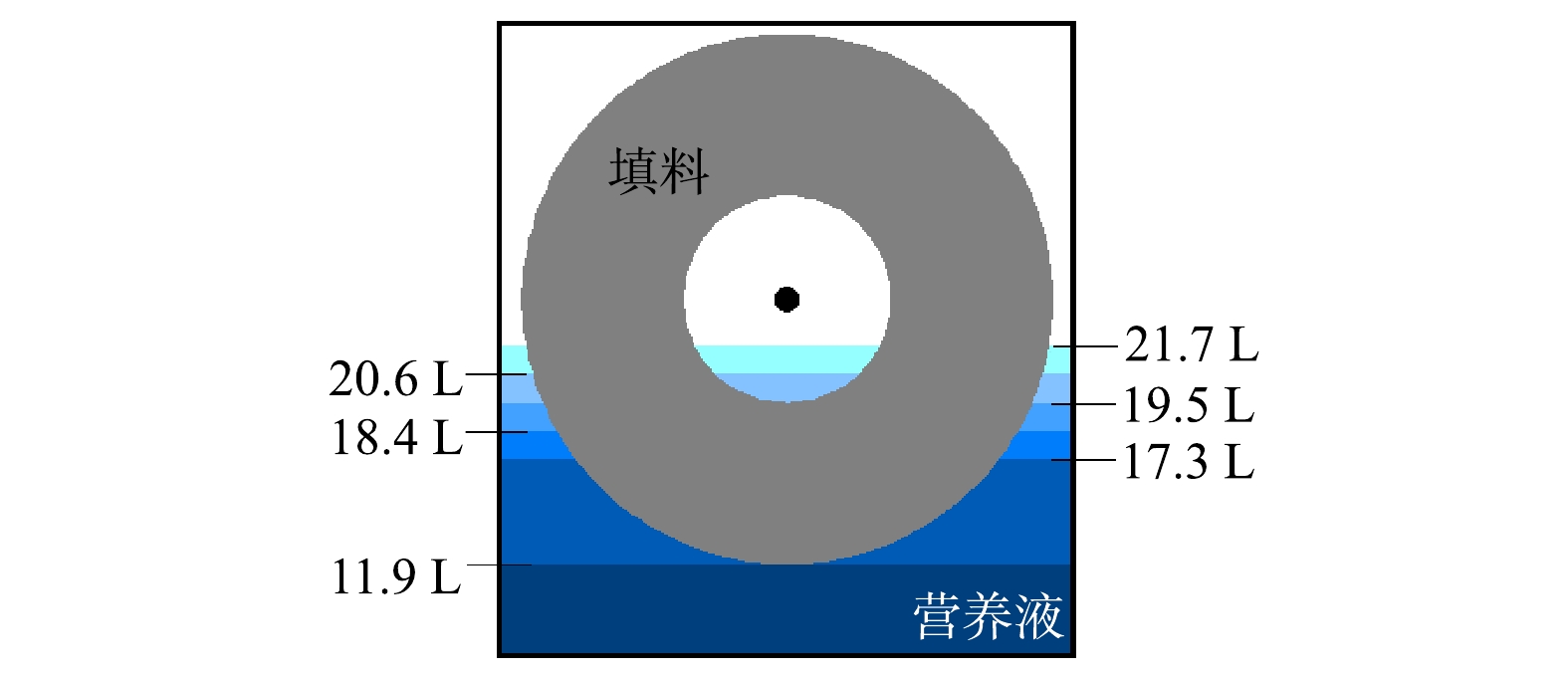

在SO2进气质量浓度为1 200 mg·m−3、NOx进气质量浓度为800 mg·m−3、温度为30 ℃、气体流量为4 L·min−1、pH为7、转速为3 r·min−1时,不同营养液体积下填料持液量的变化及SO2和NOx去除率的实验数据和模拟数据比较结果如图4所示。可以看出,随着营养液体积从17.3 L增至21.7 L,填料持液量有明显上升,因此,液膜面积增加,有助于SO2的气-液传质过程,SO2去除率从90.61%上升至97.73%,能与式(13)模拟数据较好拟合,平均绝对误差为1.78%。

NOx去除率的实验数据与式(13)的拟合数据平均绝对偏差为7.89%,优于式(12)。填料持液量上升,液膜面积增加有助于NO2传质,因此,式(13)的拟合数据呈现上升趋势。而实验中NOx去除率在营养液体积为20.6 L时达到最大,为90.83%;当营养液体积大于20.6 L后,NOx去除率出现了下降的趋势。有分析认为,液膜面积增加虽有利于NO2的气-液传质过程,但会抑制NO(NO2与水反应生成)气-生物传质过程[14]。当营养液体积小于20.6 L时,对NO2传质的促进大于对NO传质的抑制,因此,表现出NOx去除率增加;而当营养液体积大于20.6 L时,对NO传质的抑制大于对NO2传质的促进,NOx去除率下降。但依据生物传质控制的模型(12),没有表现出相同趋势,这是因为模型假设RDB中液膜均匀分布且填料体积不变,仅以液膜厚度表示填料持液量。而实验中,持液量上升不仅会改变液膜厚度,还会增大液膜面积。如图5所示,随着营养液体积增加,液面上升,填料浸没体积增加,有效体积减小,这些均不利于NO生物传质过程[23-24]。最后,考虑到SO2和NOx都能保持理想的去除效果,本实验的最佳营养液体积应为20.6 L。

-

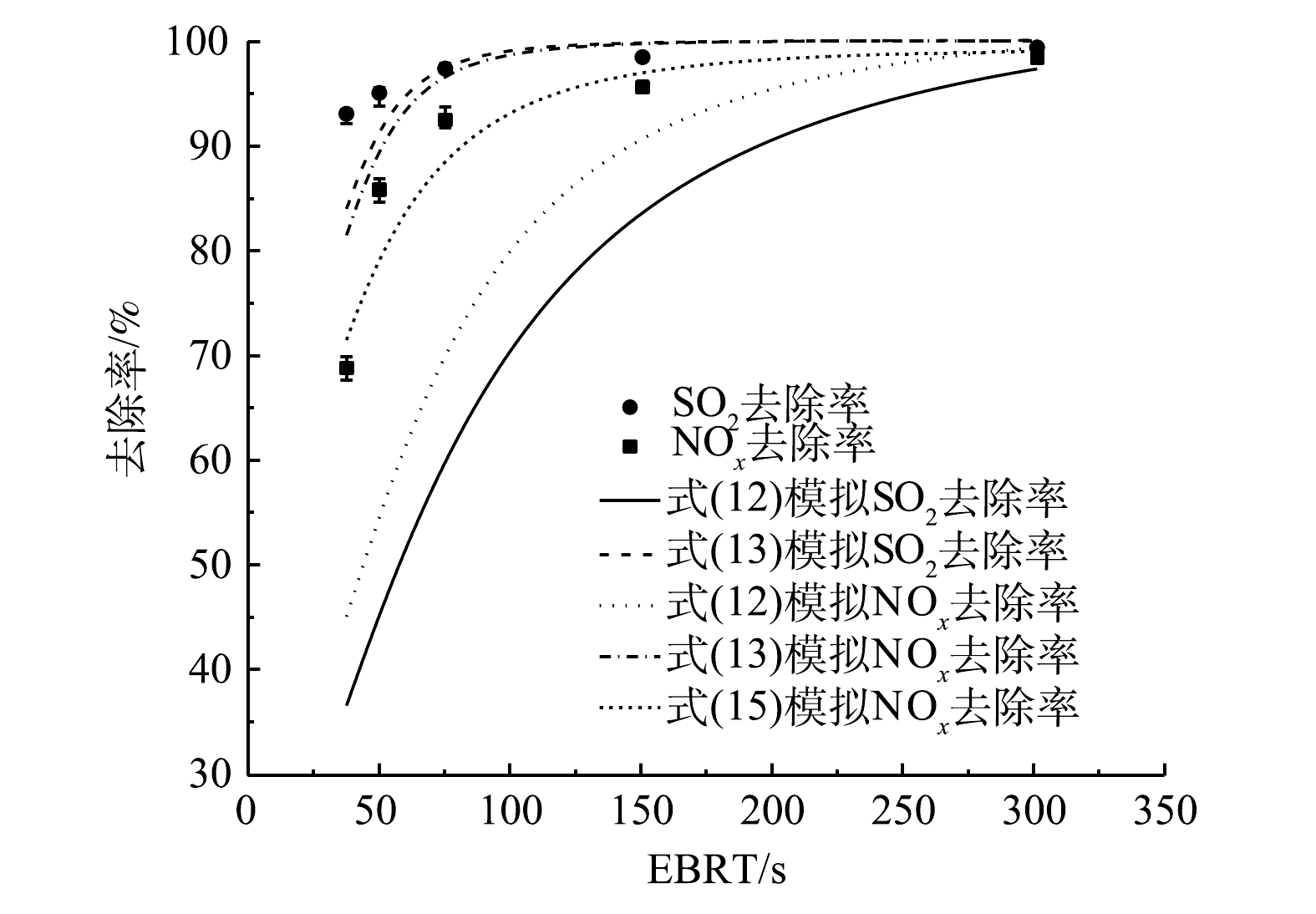

增加EBRT是通过延长污染物与液相和生物相的接触和反应时间来提高SO2和NOx的去除率。在SO2进气质量浓度为1 200 mg·m−3、NOx进气质量浓度为800 mg·m−3、温度为30 ℃、气体流量为4 L·min−1、pH为7、转速为3 r·min−1、营养液体积为19.5 L时,不同EBRT下SO2和NOx的去除率如图6所示。当EBRT从37.68s增加至75.36 s时,SO2去除率从93.06%提高到97.38%,NO去除率从68.81%提高到90%。随着EBRT从75.36 s进一步增加到301.44 s,SO2和NOx的去除率开始放缓,最终分别提高到99.40%和98.41%。从理论上来说,EBRT越长,RDB对SO2和NOx的去除效果越好。但从工程应用的角度上来说,过长的EBRT意味资源浪费和成本增加。因此,选一个相对较短且能保证SO2和NOx去除效果的EBRT是必要的。根据实验结果,本实验中EBRT应为75.36 s。

从式(12)和式(13)拟合情况来看,式(13)与SO2去除率的实验数据更接近,平均绝对误差为4.01%。而在实验中,污染物的运动轨迹会受液相和生物相等分布不均的影响,无法保持理想的层流运动,使实际的EBRT大于理论值,且EBRT低,污染物流速快,与理想的层流运动差距更大,因此,在EBRT为37.86 s时,式(13)的模拟数据低于实际数据11.60%。NOx去除率的实验数据仍位于式(12)和式(13)之间,平均绝对误差分别为16.68%和6.30%。

-

由上文可知,SO2和NOx去除率的实验数据与式(12)的模拟数据存在较大偏差,平均绝对误差分别为33.07%和17.59%。

优化后的式(13)对SO2去除率的模拟数据与实验数据能拟合情况较好,平均绝对误差为2.68%,但式(13)对NOx去除率的模拟数据与实验数据偏差依然较大,平均绝对误差为7.72%。

由于式(12)是依据生物反应控制来建立的,式(13)是依据液相反应控制来建立的,从图2、图3、图4和图6中可以看出,NOx的实验数据始终介于式(12)与式(13)的模拟数据之间。此外,虽然NOx在空气中会被完全氧化成NO2,但NO2和水发生化学反应仍会产生NO(式(14))。

由此可以推测,好氧条件下NOx在RDB内的净化可能为NO2和NO的综合反应,即通过生物相和液相的协同完成。根据反应式进一步分析,具体的反应过程应为:2/3的NO2形成NO3−进入液相,再通过DNB反硝化途径净化;其余1/3生成NO,直接被DNB吸收净化。因此,可将RDB好氧条件下NOx的降解方程进行修正,结果见式(15)。

经修正后的式(15)与实验数据的拟合对比情况可以在图2、图3、图4和图6中看到,SO2和NOx实验数据与各动力学模型模拟数据的绝对误差见表2,式(13)与本实验SO2去除率的实验数据能较好拟合,平均绝对误差为2.68%,修正后式(15)与NOx去除率实验数据更加契合,平均绝对误差为3.18%。

-

通过以上实验确定了RDB运行的最佳工艺参数,即SO2进气质量浓度为1 200 mg·m−3、NOx进气质量浓度为800 mg·m−3、温度为30 ℃、气体流量为4 L·min−1、pH为7、转速为3 r·min−1、营养液体积为19.5 L、EBRT为75.36 s。在此条件下,式(13)预测得出的SO2去除率为96.56%,式(15)预测得出的NOx去除率为88.17%。

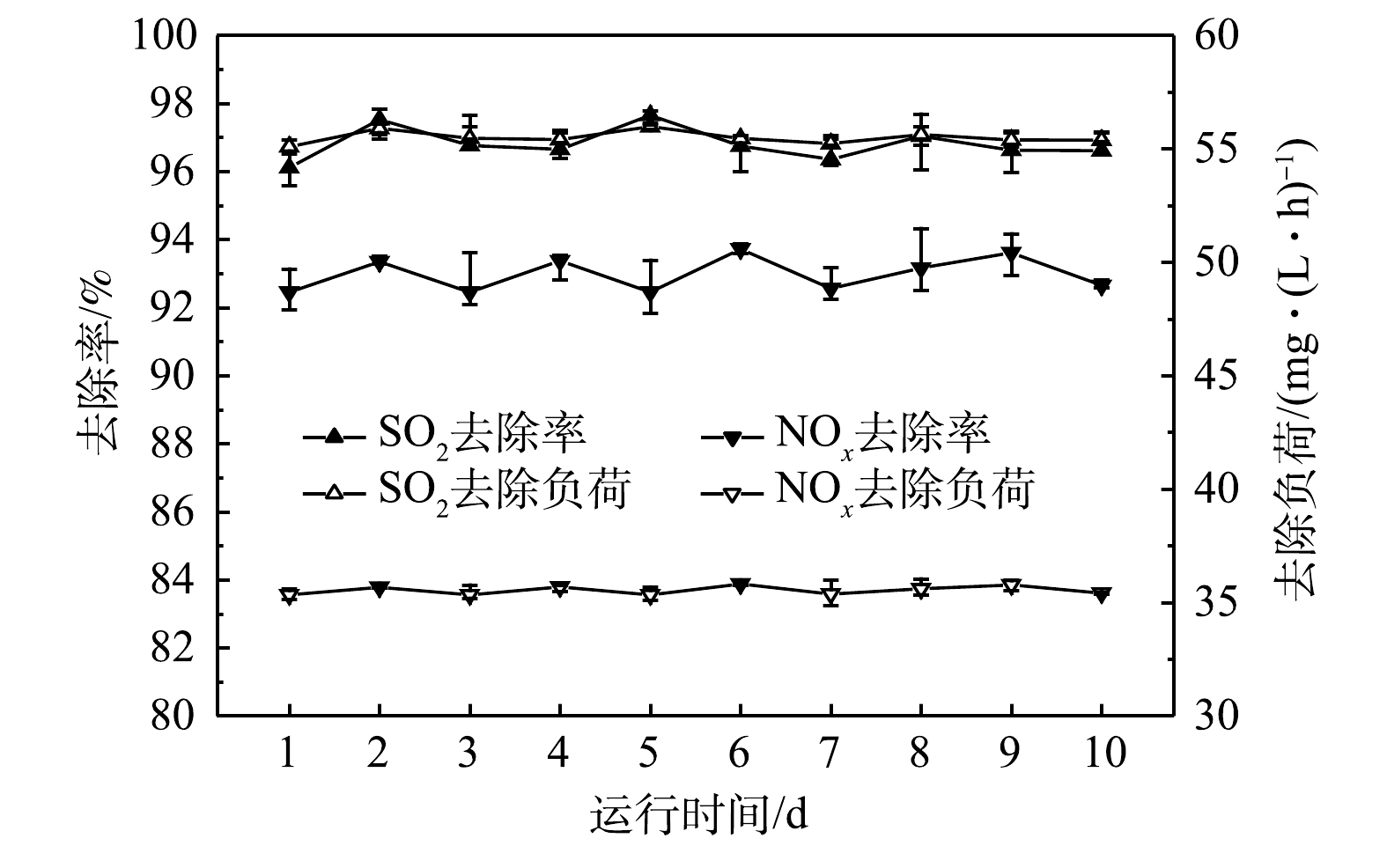

最后,连续运行10 d,考察RDB在最佳工艺条件下的脱硫脱硝效果,期间RDB对SO2和NOx的去除效果如图7所示。SO2的平均去除率为96.81%,与式(13)模拟数据相差0.25%;NOx的平均去除率为92.98%,与式(15)模拟数据相差4.81%,SO2和NOx去除负荷分别为55.50 mg·(L·h)−1和35.53 mg·(L·h)−1。此外,SO2和NOx的出气质量浓度均低于100 mg·m−3,能满足最初实验设计。

-

1) SO2质量浓度增加,SRB竞争力增强,且中间产物H2S会抑制DNB活性,影响NO的生物传质过程,导致降低NOx去除率降低;本实验最适SO2质量浓度应该为1 200 mg·m−3。由于SO2的传质有液相控制,NOx质量浓度增加对SO2的去除基本没有影响,但由于受负荷限制,最适NOx质量浓度为800 mg·m−3。

2)营养液体积增加导致填料中持液量上升,总体液膜面积增大,从而有利于SO2 和NO2的传质,但不利于NO的生物传质过程;在营养液体积为20.6 L时,NOx的去除率达到最大。EBRT增加,可提高SO2和NOx净化效果;但EBRT过大,就会降低去除负荷,实验中最佳的EBRT为75.36 s。

3)好氧条件下,SO2的净化主要受液相传质过程控制,实验数据与式(13)的拟合情况较好,平均绝对误差为2.68%;NOx的传质过程由生物相和液相协同完成,实验数据与修正后的式(15)的模拟数据能较好吻合,平均绝对误差为3.18%。

4)在最佳工艺参数下,SO2和NOx的平均去除率分别为96.81%和92.98%,平均去除负荷分别为55.50 mg·(L·h)−1和35.53 mg·(L·h)−1,且出气质量浓度均低于100 mg·m−3。

好氧条件下生物转鼓同步脱硫脱硝性能及相应动力学模型的优化

Performance and kinetic model optimization of simultaneous desulfurization and denitrification for rotating drum biofilter under aerobic conditions

-

摘要: 为探究高效同步脱硫脱硝的生物工艺,以生物转鼓反应器为实验对象,研究了好氧条件下SO2质量浓度、NOx质量浓度、营养液体积和气体停留时间(EBRT)的变化对生物转鼓同步脱硫脱硝效果的影响,并用动力学模型拟合值与实验数据进行了对比。实验结果表明:生物转鼓同步脱硫脱硝最适条件为SO2质量浓度1 200 mg·m−3,NOx质量浓度800 mg·m−3,营养液体积20.6 L,气体停留时间(EBRT) 75.36 s;SO2过程净化主要受液相传质控制,NOx传质过程由生物相和液相协同完成;修正求得了能较好描述好氧条件下生物转鼓脱硫脱硝效果的动力学模型,因存在生物相、液膜、污染物流动等变量与假设的差异,SO2和NOx模拟数据与实验数据分别有2.68%和3.18%的平均绝对误差;在最佳条件下,SO2和NOx的平均去除率分别为96.81%和92.98%,平均去除负荷分别为55.50 mg·(L·h)−1和35.53 mg·(L·h)−1,且出气质量浓度均低于100 mg·m−3。可见,生物转鼓是一种可行的高效同步脱硫脱硝生物工艺。Abstract: In order to explore a biological process that can efficiently and simultaneous desulfurization and denitrification, the rotating drum biofilter was taken as the experimental object, the effects of SO2 mass concentration, NOx mass concentration, nutrient solution volume and gas empty bed residence time in rotating drum biofilter on simultaneous desulfurization and denitrification under aerobic conditions were studied, and the fitted values of the kinetic model were compared with the experimental data. The results showed that the optimum conditions of simultaneous desulfurization and denitrification for rotating drum biofilter were SO2 mass concentration of 1 200 mg·m−3, NOx mass concentration of 800 mg·m−3, nutrient solution volume of 20.6 L and gas empty bed residence time of 75.36 s. The SO2 purification process was mainly controlled by liquid phase mass transfer, and the NOx mass transfer process was completed by the cooperation of biological phase and liquid phase. In addition, the kinetic model which can better describe the desulfurization and denitrification effect of rotating drum biofilter under aerobic condition was modified. Due to the differences of biological phase, liquid film, pollutant flow and other variables and assumptions, the average absolute errors of SO2 and NOx simulation data and experimental data were 2.68% and 3.18%, respectively. Under the optimum conditions, the average removal rates of SO2 and NOx were 96.81% and 92.98%, respectively, the average removal loads of SO2 was 55.50 mg·(L·h)−1 and NOx was 35.53 mg·(L·h)−1, respectively, and the outlet gas mass concentrations of SO2 and NOx were lower than 100 mg·m−3. It can be seen that the rotating drum biofilter is a feasible and efficient biological process for simultaneous desulfurization and denitrification.

-

表 1 SO2和NOx的排放标准

Table 1. Effluent discharge standard of SO2 and NOx

标准 设备类型 SO2/(mg·m–3) NOx/ (mg·m–3) 石油化学工业污染物排放标准(GB 31571-2015) 工艺加热炉 100 150 锅炉大气污染物排放标准(DB44/ 765-2019) 燃煤锅炉(新建) 200 200 燃油锅炉(新建) 100 200 火电厂大气污染物排放标准(GB 13223-2011) 燃煤锅炉(新建) 100 100 以油为燃料的锅炉或燃气轮机组(新建) 100 100 表 2 各模型SO2和NOx模拟数据与实验数据的比较

Table 2. Comparisons of SO2 and NOx removal efficiencies between model results and experiment data

污染物 工艺条件 各模型模拟数据与实验数据间的绝对误差/% 式(12) 式(13) 式(15) 最大 最小 平均 最大 最小 平均 最大 最小 平均 SO2 SO2浓度 53.62 9.34 33.79 8.54 0.42 3.89 NOx浓度 36.52 35.23 35.90 1.72 0.43 1.05 营养液体积 43.92 8.31 30.42 3.61 0.21 1.78 EBRT 56.61 2.06 32.18 11.60 0.60 4.01 NOx SO2浓度 16.80 22.53 19.62 11.00 5.27 8.19 4.00 0.55 2.18 NOx浓度 21.00 10.72 15.91 17.35 3.88 8.49 5.33 0.46 2.43 营养液体积 27.15 6.56 17.59 11.65 5.87 7.89 9.95 2.12 4.97 EBRT 31.00 0.91 16.68 15.17 1.58 6.30 6.67 1.29 3.16 -

[1] 李菲, 谭浩波, 邓雪娇, 等. 2006-2010年珠三角地区SO2特征分析[J]. 环境科学, 2015, 36(5): 1530-1537. [2] XIAO Z, LI D, ZHU Q, et al. Simultaneous removal of NO and SO2 through a new wet recycling oxidation-reduction process utilizing micro-nano bubble gas-liquid dispersion system based on Na2SO3[J]. Fuel, 2020, 263: 116682. doi: 10.1016/j.fuel.2019.116682 [3] ZHANG D, MA Z, WANG B, et al. VxMn(4-x)Mo3Ce3/Ti catalysts for selective catalytic reduction of NO by NH3[J]. Journal of Environmental Sciences, 2020, 88: 145-154. doi: 10.1016/j.jes.2019.07.010 [4] 郑超群, 张艮林, 孙珮石, 等. 化学强化法烟气同时脱硫脱氮的动力学研究[J]. 环境工程, 2018, 36(5): 110-114. [5] SUN C C, YUAN J Q, XU H, et al. Simultaneous removal of nitric oxide and sulfur dioxide in a biofilter under micro-oxygen thermophilic conditions: Removal performance, competitive relationship and bacterial community structure[J]. Bioresource Technology, 2019, 290: 1-8. [6] CHEN J, GU S Y, ZHENG J, et al. Simultaneous removal of SO2 and NO in a rotating drum biofilter coupled with complexing absorption by Fe(II)(EDTA)[J]. Biochemical Engineering Journal, 2016, 114: 87-93. doi: 10.1016/j.bej.2016.06.027 [7] WANG X C, XIAO Y B, PEI S S, et al. Effects of oxygen content on the simultaneous microbial removal of SO2 and NOx in biotrickling towers[J]. Biotechnology and Bioprocess Engineering, 2015, 20: 924-930. [8] 闫亮, 赵辉. 硫酸盐还原菌酶学性质及应用的研究进展[J]. 中国农学通报, 2020, 36(31): 13-19. doi: 10.11924/j.issn.1000-6850.casb20191100879 [9] RINK R, KLOK J B M, HEERINGEN G J, et al. Increasing the selectivity for sulfur formation in biological gas desulfurization[J]. Environmental Science & Technology, 2019, 53(8): 4519-4527. [10] MUYZER G, SOROLIN D Y, MAVROMATIS K, et al. Complete genome sequence of “Thioalkalivibrio sulfidophilus” HL-EbGr7[J]. Standards in Genomic Sciences, 2011, 4(1): 23-35. doi: 10.4056/sigs.1483693 [11] JIN R, LIU T, LIU G, et al. Simultaneous heterotrophic nitrification and aerobic denitrification by the marine origin bacterium pseudomonas sp. ADN-42[J]. Applied Biochemistry & Biotechnology, 2015, 175(4): 2000-2011. [12] JI B, YANG K, ZHU L, et al. Aerobic denitrification: A review of important advances of the last 30 years[J]. Biotechnology and Bioprocess Engineering, 2015, 20(4): 643-651. doi: 10.1007/s12257-015-0009-0 [13] 陈浚, 蒋轶锋, 沙昊雷, 等. 生物转鼓过滤器反硝化去除NO的模型研究和实验验证[J]. 高校化学工程学报, 2008, 22(2): 344-350. doi: 10.3321/j.issn:1003-9015.2008.02.029 [14] CHEN J, JIANG Y, CHEN J, et al. Dynamic model for nitric oxide removal by a rotating drum biofilter[J]. Journal of Hazardous Materials, 2009, 168(2/3): 1047-1052. [15] 邬成贤, 郑成航, 张军, 等. 脱硫浆液中组分扩散及SO2溶解的分子动力学研究[J]. 环境科学学报, 2014, 34(11): 2904-2910. [16] HAN Y Q, ZHANG W J. Simultaneous removal of NOx and SO2 in exhausted gas through landfill leachate[J]. Indian Journal of Experimental Biology, 2010, 48(12): 1237-1242. [17] CALABROP S, MANNINA G, VIVIANI G. In sewer processes: Mathematical model development and sensitivity analysis[J]. Water Science & Technology, 2009, 60(1): 107-115. [18] 胡安辉, 郑平, 胡宝兰. 3种硝化污泥性能的比较研究[J]. 四川大学学报(工程科学版), 2009, 41(6): 89-96. [19] 柯斯乐E L. 扩散-流体系统中的传质[M]. 2版. 北京: 化学工业出版社, 2002: 144. [20] 金鹏康, 杨珍瑞, 李蓉, 等. 反硝化抑制硫酸盐还原的工艺特性[J]. 环境科学, 2017, 38(5): 1982-1990. [21] OH S E, KIM K S, CHOI H C, et al. Kinetics and physiological characteristics of autotrophic denitrifying sulphur bacteria[J]. Water Science & Technology, 2000, 42(3): 959-968. [22] CHEN J, LI B, ZHENG J, et al. Control of H2S generation in simultaneous removal of NO and SO2 by rotating drum biofilter coupled with Fe(II)(EDTA)[J]. Environmental Technology, 2018, 40(1): 1-35. [23] 黎宝仁, 陈洲洋, 王剑斌, 等. 复合催化膜生物反应器处理一氧化氮废气研究[J]. 环境科学, 2016, 37(3): 847-853. [24] TOMOYA H, YUSHI M, SHINGO N, et al. Structural basis of biological N2O generation by bacterial nitric oxide reductase[J]. Science, 2010, 330(6011): 1666-1670. doi: 10.1126/science.1195591 -

下载:

下载: