-

静电除尘器(ESP)是一种能够有效去除颗粒物的装置,是集除尘效率高、运行阻力小和较强的适用性等多种优点于一身的处理装置,并在发电、水泥、冶金等行业生产过程中的颗粒物处理阶段得到广泛应用[1-5],其总体除尘效率可达99%[6-8]。但是,传统静电除尘器对荷电量低、受离子风流场影响强烈的微细颗粒物的收集效果远不如大粒径颗粒物,而且尺寸较小的颗粒更倾向于与烟气一起运动而被排放到空气中,这些细微颗粒物极可能被人体吸入肺部而引发各种呼吸道疾病[9-11]。

目前,已有大量研究以对传统静电除尘器的电极设计改造为出发点[12-14],设计了网电极板、孔电极板、C型板、S型板、H型板等异型收尘极板以及芒刺线、星型线、十字针刺线等新型高压电极[15-19],使微细颗粒物去除效率有所提高,排放浓度得以降低。但是,许多成果[20-27]均须重新设计收尘极板或者高压电极,存在改造工程量大,投入成本高等不足之处。

针对上述问题,本研究在传统线-板除尘装置的基础上,结合课题组所研制的新型除尘结构(发明专利:ZL201510238547.X)并利用本课题组发明的流体模拟手段(发明专利:ZL201310263782.3),重新设计极板排布方式——错位板排布,以求用最小的改造成本,获得更大的应用价值,达到令人满意的除尘效果;利用FLUENT软件探究了错位板结构下,电晕放电空间产生的离子风流场对微细颗粒物在放电空间运动的影响,从而更好地体现错位板的改造优势;主要针对低浓度、超微细粉尘在电流体场中的运动规律,通过对空间电场分布、流速以及主流风速与离子风流场之间的相互作用的分析,证明了极板错位排布的可行性,为除尘器的进一步改造提供参考。

-

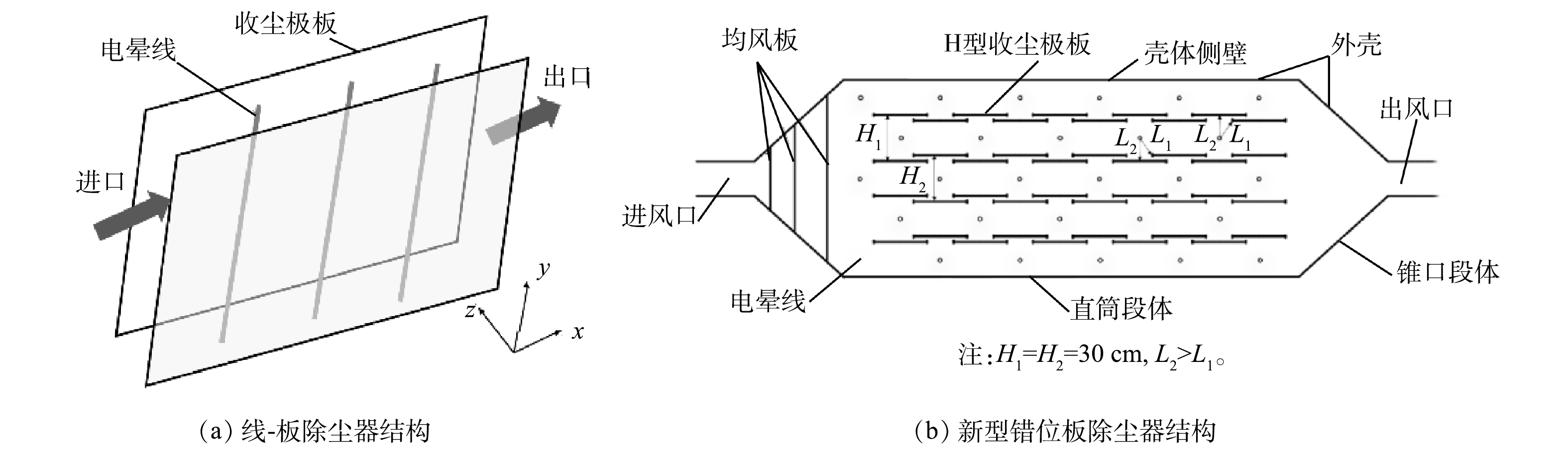

现有的大型静电除尘器90%以上为线-板结构,其结构形式见图1(a)。本文在此结构基础上,对收尘极板进行错位排布,结构见图1(b)。

如图1(b)所示,进风口与出风口相对,除尘器外壳由直筒段体、壳体侧壁和锥口段体构成。除尘器内部,除尘部分由电晕线和H型收尘极板组成,均风部分由临近进风口的锥口段体中设的多层多孔均风板组成。

收尘极板成行设置在除尘器中,各行收尘极板的板面相互平行,并与进、出风口之间的中心线相平行。在除尘器中,每行收尘极板交错排布,在两列极板中同列相邻的2个收尘极板之间保留有间距小于单个收尘极板幅宽的极板空当,且每列极板上的极板空当被同行另一列极板中紧邻该极板空当的一个收尘极板所遮挡,电晕线直立成行,分布在极板空当的中垂线上。根据所设计除尘器结构特征,选取部分区域作为研究对象,按照1∶1的比例建立如图2所示的计算域模型,并进行二维数值模拟。

相关参数如下:极线直径1.2 mm,极板长46 cm,H型凸起高1 cm,极板纵向间隔5 cm,极板横向间隔23 cm,电极距15 cm,流场通道长184 cm。

放电过程中,在放电结构一定的情况下,放电电压的高低决定了电晕强度。图3为负高压20、30、40和50 kV时放电极电晕区发光强度图,因此,在研究电流体时,首先需要确定离子风射流源的尺度。

通过MATLAB模拟线板电晕放电,图4为外加电压40 kV时的电场强度变化情况。可以看出,在离开电晕线很短的距离内,场强出现陡降,约下降一个数量级(由107量级变为106量级)。

陡降区的变化距离为0~5 mm,因此,将电晕线外缘至外边缘5 mm的范围内定义为射流源范围,即离电晕线中心距离为0.75~5.75 mm,确定半径2.1 mm区域为40 kV时电晕放电边缘,也就是离子风射流源的边缘。

-

本课题组的前期研究结果[28-29]表明,在高压除尘电场中,较大粒径的粉尘颗粒受到的电场力和离子风力几乎处于同一数量级;但较小粒径的粉尘颗粒受到的离子风力远远大于其所受电场力,大致为所受电场力的10~100倍,即微细颗粒物在除尘器中的运动状态受离子风影响较电场力大得多。而本模拟也主要是针对末级电场中粒径微小、形状不规则、荷电量低、受电场力极小、受离子风力大的微细颗粒物,故在本研究中不考虑微细颗粒物所受到的电场力作用,仅考虑引风流与离子风流对其的影响,电场控制方程只用于对错位板空间电场分布分析。同时,鉴于末级电场中颗粒物粒径微小、占空比低的特点,故将含尘气流假定为单相气流,忽略颗粒相。

根据电晕线附近的离子风速与电晕极电压满足的关系式[28],可得电晕放电射流源初始风速,计算方法见式(1)。

式中:v为离子风速,m·s−1;U为电晕电压,V。

当外加电压为40 kV时,各边界条件设置如下:电晕线处离子风速度设置15.61 m·s−1;出口边界为自由出口;流体域上下边界为对称面;其他默认流体域边界面为墙壁面,且为光滑、无滑移的墙壁。

-

电晕线外加电压20、30、40、50 kV时,错位板放电空间的电势分布如图5所示。随着外加电压的升高,空间电势不断提高。观察2 000 V电势等值线位置可以发现,随着外加电压的升高,此等值线离收尘极板的距离越来越近。

整体而言,各外加电压下电势等值线分布并无太大差异,电晕线表面电势等值线密度很大,且电晕线较近范围内的分布近似呈圆形。随着向通道边缘的扩散,电势逐渐减小,电势等值线密度变小。由于边缘放电效应在2个极板间隙处形成凸起,整体状态等值线分布呈不规则椭圆形,电势由电晕电极中心位置向极板方向衰减速度大于横向通道方向。

-

在外加电压为40 kV时,以各电晕区为射流源,研究了主流风速分别为0、0.3、0.5、0.8、1.2和1.5 m·s−1时,其对离子风流场的影响以及整个流场的变化。仿真模拟得出的速度云图见图6,速度矢量图见图7。

电晕极附近风速较收尘极背部区域高,由于主流风速与离子风速相互作用,因此,在放电极附近形成湍流区,这一区域的形成不仅可以增加颗粒物在电场中的停留时间,更可大大增加粉尘颗粒的荷电率,从而有利于收尘。

当主流风速为0 m·s−1时,离子风流场呈现典型的双螺旋结构,从入射源入射到达收尘极板形成回旋,形成2个方向相反的螺旋结构。为便于说明情况,在上部电极线从左到右分别记作A、B、C,下部电极线从左到右分别记作D、E,可以发现E电极处的离子风出现明显偏转,这是由B电极处的离子风通过错位板空当流入E电极处造成的。随着主流风速的从0 m·s−1增加到0.3 m·s−1,离子风流场也随之发生了变化。以A处电极为例,可以观察到,当主流风速为0.3 m·s−1 时,离子风流场受主流风速水平方向力影响,原本呈双螺旋结构的离子风,在主流风速的影响下发生偏转,部分主流风速及离子风流入板背区域,在2种流场的作用下,颗粒物便到达湍流强度和风速较低的极板背部区域,从而被捕集到。另外,采用H型收尘极板,观察到H形凸起可以有效阻挡主流风速以及偏转离子风对收尘极板的冲刷作用,减小了二次扬尘发生的概率。当主流风速增加到0.5 m·s−1,可以观察到离子风受主流风速影响增大,从而使偏转度加大。离子风流进入电极板背部的量很小,离子风主流可到达较近极板位置,并被H形凸起阻挡,从而避免对收尘极板的冲刷。随着主流风速的继续增加,离子风流的偏转角度增大,当主流风速达到0.8 m·s−1时,上半区的离子风流受主流风速影响偏转量很大,已经不足以流入错位板空当;当主流风速达到1.2 m·s−1时,离子风流受到主流风速的极大影响,只有部分离子风流可以到达极板;当主流风速达到1.5 m·s−1时,已无法到达收尘极板,此时主流风速已成为影响除尘效率的首要因素,颗粒物将随主流风速一同进入大气环境中。

-

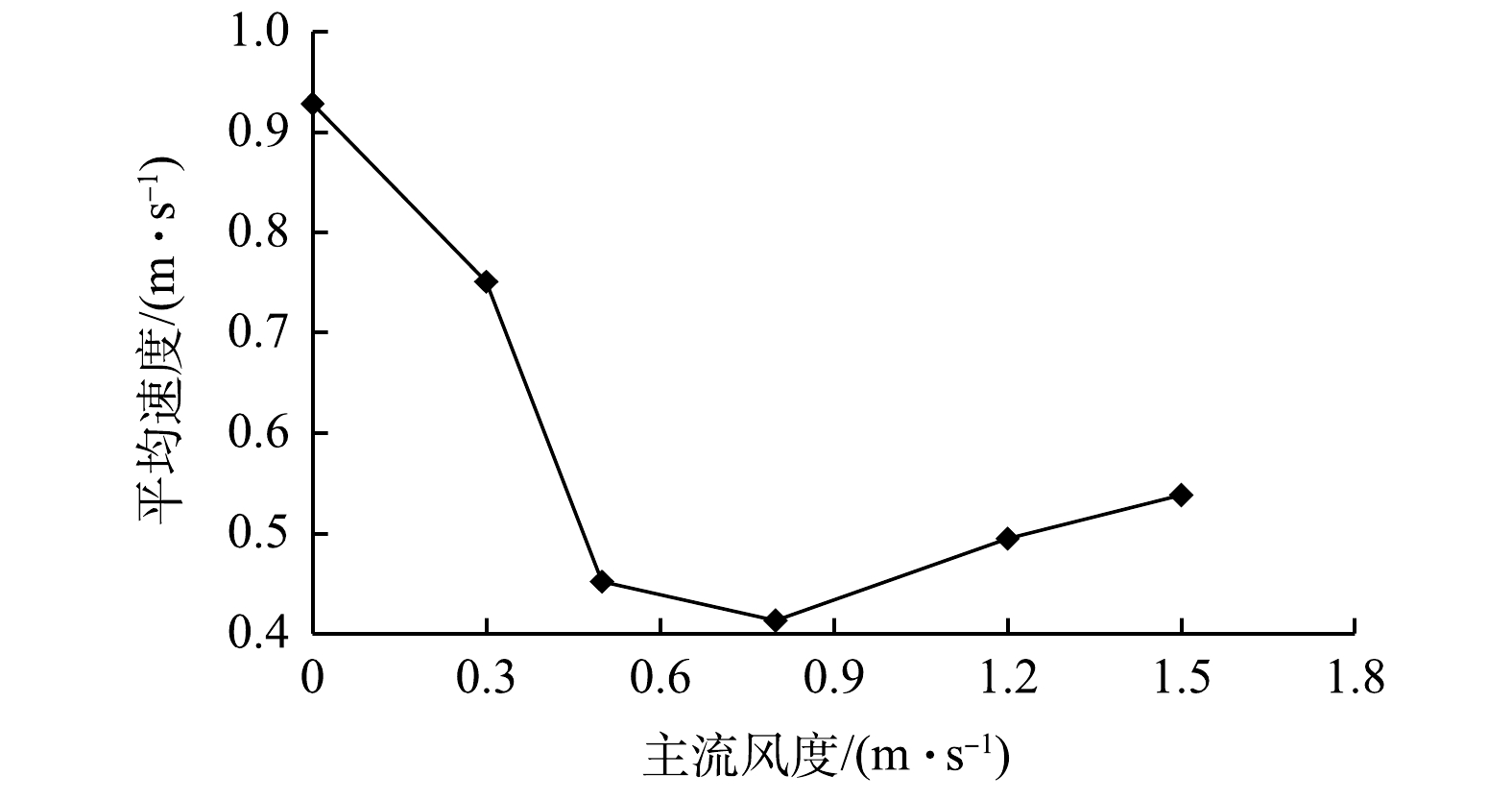

每行收尘极板上形成交替分布的容纳仓和低风速区,并使得原来对微细粉尘的捕集起干扰和阻碍作用的离子风变成对微细粉尘的捕集起主导和促进作用的“动力源”。这就使得静电除尘器中高压放电产生的离子风变害为利,使静电除尘器对低比电阻颗粒的有效去除成为可能,本设计的关键也在于此。当提取主流风速0~1.5 m·s−1时,错位板空当中心线y=0.125 m上的速度分布如图8所示。

由图8可知,在此平面不同区域速度变化相对复杂,但整体而言,变化基数却很小,基本在0.5~1.25 m·s−1,变化值限于0.75 m·s−1。极板错位形成的背部交叉区域较主流道窄小,内部气流流速较小,该区域不仅可以减少气流对微细粉尘的扰动,还可提高带电粉尘的碰撞概率,提高流入此处的超微细颗粒的荷电凝并概率,继而达到较高的凝并效果,以保证对超微细粉尘的捕集效率。

由图6和图7可知,当主流风速较高时,离子风流受主流风速的影响较大,发生了大角度的偏转,流入错位板间隙离子风流减少,此时极板间隙速度减小,吹入基板背部的颗粒物也会减少。但是,不论主流风速是大是小,都可以发现极板背部的各容纳仓均存在部分低风速区,这也使流入此区域的颗粒物可以较大限度地被收集。

错位板空当中心线上的平均速度如图9所示,随着主流风速的增大,呈先降后升的趋势。下降的原因是,随着主流风速的增大,对离子风流的吹动作用增大,离子风团会像烛焰随气流偏转。可以看出,当主流风速为0.5~0.8 m·s−1时,平均速度变化不足0.05 m·s−1,此时主流风速与离子风处于相互制衡阶段,主流风刚好使得离子风不能流入错位板间隙,但反过来离子风的阻挡作用却会使主流风携带颗粒物流入错位板空当从而被捕集。上升的原因是,虽然离子风气流发生大角度偏转已不足以进入错位板间隙,但离子风团会对主流风产生一定的阻流作用,从而使部分主流风气流流入错位板空当。此时在总气流的影响下,仍然会使颗粒物进入错位板空当,从而达到收尘效果。

总之,无论主流风速是大是小,离子风团都可以通过影响主流风流向,使气流流入错位板空当,并在该区域进行粉尘捕集。

-

1)电极结构、极配方式、放电强度是影响离子风气流分布的主要因素。

2)当主流风速小于0.5 m·s−1时,离子风影响较为明显地增加了对流场的扰动;当主流风速达到0.8 m·s−1以上时,主流风成为影响空间流场分布的主要因素,离子风的影响被削弱,但此时的离子风团仍然会促进气流流入错位极板背部,从而达到收集目的。

3)新型错位板电极排布形式,不仅可以削弱离子风,还可以利用离子风流作为“动力源”进行除尘,并且可对原有线-板除尘器直接进行改造,因而可大大节约经济成本。

4)从气流分布的角度分析,新型错位板电极排布形式可有效提高对微细粉尘、低比电阻粉尘的收集效率,并可以实现超低排放。

新型错位板对静电除尘器流场影响的数值模拟

Numerical simulation of the influence of a new type of dislocation plate on the flow field of the electrostatic precipitator

-

摘要: 为降低现有除尘器的改造成本,提高微细粉尘的收集效率,在现有除尘器的基础上,对阳极板排布方式进行调整,设计错位排布方式,最大化地利用原有除尘器的资源,以最小的改造成本,达到较满意的除尘效果。利用目前应用广泛的FLUENT仿真软件进行数值模拟,观察分析了其电势分布和气流分布。数值模拟结果表明:当主流风速小于0.5 m·s−1时,离子风对流场的影响较大;当主流风速达到0.8 m·s−1以上,主流风成为影响空间流场分布的主要因素,离子风的影响被削弱,但此时的离子风团仍会促进气流流入错位极板背部达到收集目的。错位板间隙设计可以削弱离子风对阳极板的冲刷作用,证明了错位板排布有利于改善离子风对粉尘收集的负面影响,有效提高对微细粉尘的收集效率。数值模拟的结果对静电除尘器的设计与改进有一定的参考意义。Abstract: In order to reduce the upgrading cost of the existing precipitator and improve its collection efficiency of fine dust, on the basis of the existing precipitator, the arrangement of the anode plates was adjusted. The dislocation arrangement was designed to maximize the use of the original precipitator resources, minimize upgrading cost, and achieve a satisfactory dust removal effect. The widely used FLUENT simulation software at present was used to perform numerical simulation, and the electric potential distribution and airflow distribution were observed and analyzed. Numerical simulation results showed that when the mainstream wind speed was lower than 0.5 m·s−1, the ion wind had a greater impact on the flow field; when the mainstream wind speed was over 0.8 m·s−1, the mainstream wind became the main factor affecting the spatial flow field distribution. The impact of ion wind was weakened, but the ion wind group at this time still promoted the airflow to flow into the back of the misplaced plate and completed the collection. The gap design of the dislocation plate could weaken the scouring effect of the ion wind on the anode plate, which proved that the arrangement of the dislocation plate was beneficial to conteract the negative influence of the ion wind on the dust collection and effectively improved the collection efficiency of fine dust. The result of numerical simulation has a certain reference significance for the design and improvement of electrostatic precipitator.

-

Key words:

- ionic wind /

- flow field /

- primary air flow /

- dislocation plate gap /

- fine dust

-

镉 (Cd) 是人体非必需的有剧毒的重金属元素[1-2],极易在小麦等农作物中富集,并通过食物链对人体健康产生威胁[3-5]。近年来河南[6]、甘肃[7]和陕西[8]等地均相继出现不同程度的小麦Cd含量超标现象。SONG等[9]指出小麦对我国北方人群Cd摄入量的贡献高达29.8%。土壤-小麦系统Cd污染风险识别与评估是小麦Cd污染防治策略制定的前提和重要参考。

近年来国内外研究人员对土壤-小麦污染风险进行了大量研究,多集中于应用不同评价指标对Cd污染土壤和小麦进行污染等级划分与定性评估[5,10-11]。其中,MULLER开发的地积累指数法被广泛用于土壤及河道沉积物Cd污染风险研究[12]。HAKANSON提出的潜在生态风险指数综合考虑了Cd毒性效应和相对贡献度等参数,在农田土壤Cd累积研究中应用较多[13]。ZHUANG等[14]应用地积累指数法对我国主要小麦产区土壤Cd生态风险进行了量化评估。李艳玲等[15]应用潜在生态指数对济源市平原区小麦田Cd污染特征进行了评估分析。美国环保署开发的健康风险评估模型建立了Cd暴露途径与人体Cd摄入量的定量关系,被广泛用于评估污染小麦摄入风险评估的研究中[8,16]。然而土壤Cd累积周期长,影响因素繁杂,不同区域农田土壤Cd空间异质性显著[1,11,17-18]。贵州土壤Cd背景值 (0.66 mg·kg−1) 约为内蒙古土壤Cd背景值 (0.05 mg·kg−1) 的13.2倍[17]。上述评价模型多使用固定评价因子和参考标准,难以对区域农田Cd污染风险进行量化分析[19-20]。同时,我国幅员辽阔,不同地区农田土壤理化性质、社会经济水平和人群生活习惯与国外研究差别较大,固定参数的直接应用使评价结果存在较大偏差[21-22],难以充分反映区域土壤-小麦系统Cd污染风险变化趋势。

基于以上问题,本研究以河南省某地为研究对象,基于部分区域大面积调查和不确定性理论,将Monte-Carlo随机模拟方法引入到区域农田Cd污染风险综合评估中,获取该地区土壤和小麦Cd污染风险概率分布情况,探讨有效可行的污染防控目标,以期为区域小麦Cd污染风险管理提供理论指导。

1. 材料与方法

1.1 研究区概况和样点采集

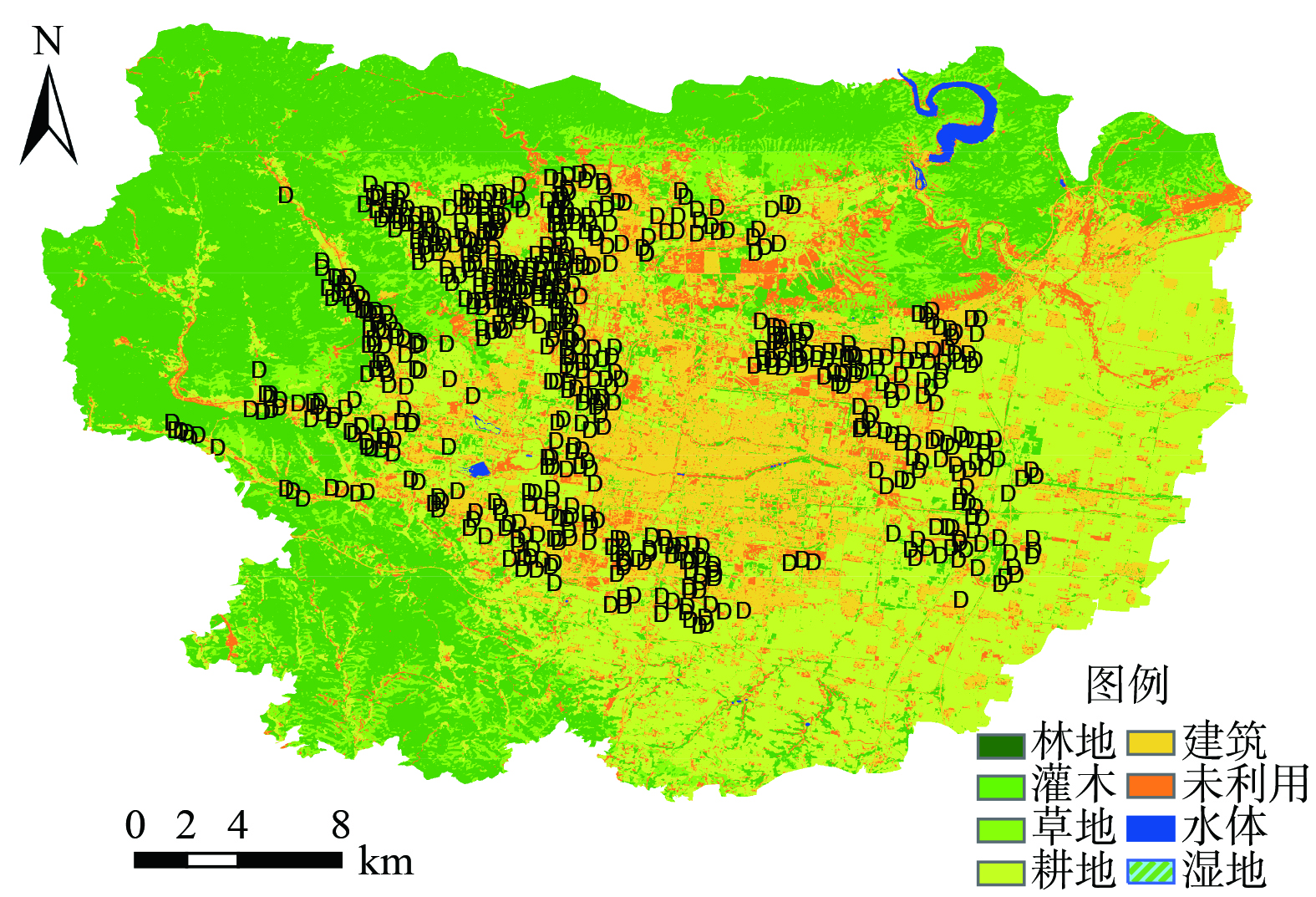

研究区位于河南省某地,年平均温度为15.5 ℃,年平均降水量为546.6~686.2 mm[2],研究区概况如图1所示。区域调查共布设635个采样点位,样点具体分布见图1。另外,10个土壤背景样品采集自研究区远离工矿企业和人类活动干扰的山区[6]。每个采样点应用五点混合采样法采集耕作层土壤 (0~20 cm) 样品1.0 kg左右,同时采集5~10株对应小麦样品,样品标记后带回实验室进行处理分析。

1.2 实验室分析

土壤样品经风干、研磨和过筛后置于自封袋密封备用。小麦样品经去泥、洗净分出籽粒后再用去离子水冲洗2~3遍,晾干后置于烘干箱中105 ℃杀青30 min,60 ℃烘干至恒重,脱壳后研磨粉碎,置于自封袋密封备用。土壤pH使用电极法测定,土水比为1∶2.5。土壤有机质 (SOM,乙二胺四乙酸—乙酸铵溶液浸提法) 和阳离子交换量 (CEC,盐酸浸提法) 具体测定方法方法参见文献[23]。应用四酸法HCl-HNO3-HF-HCIO4消解土壤样品,应用HNO3-HClO4消解小麦样品[6,24]。使用ICP-MS (7500A,Agilent,USA) 测定样品Cd含量,测定过程中应用国家标准物质 (GBW 07427华北平原土壤;GBW 10046河南小麦) 进行质量控制,回收率在91.8%~108.7%之间。

1.3 数据处理

小麦Cd富集系数 (BCF) 常被用来分析土壤-小麦系统Cd富集特征,并可在一定程度上消除区域环境因子影响差异[13,21]。其计算公式见式(1)。

BCF=WCd/SCd (1) 式中:BCF表示小麦籽粒Cd富集因子;WCd表示小麦籽粒Cd含量,mg·kg−1;SCd表示土壤Cd含量,mg·kg−1。

Moran’s I指数多用于空间自相关分析,可有效衡量同一区域内观测值间的依存效应[25],具体计算公式见式(2)~式(3)。

Moran’sI=∑ni∑nj≠iwij(xi−ˉx)(xj−ˉx)/∑ni∑nj≠iwij(xi−ˉx)(xj−ˉx)(S2×∑ni∑nj≠iwij)(S2×∑ni∑nj≠iwij) (2) S2=(1/n)×∑ni(xi−ˉx)2 (3) 式中:n表示空间对象数量;wij表示空间对象i和空间对象j的空间权重矩阵,如果i和j是相邻的,则权重为1,否则为0;xi和xj代表在空间对象i和空间对象j的属性值 (i,j=1,2,3……n) ;

ˉx 地积累指数 (Igeo) 考虑了自然地质条件下土壤Cd背景值的影响,是区分和快速判断人类活动影响程度的重要参数[12,14],具体计算公式见式(4)。

Igeo=log2[SCd/(1.5×Bn)] (4) 式中:SCd表示土壤Cd含量 (mg·kg−1) ,Bn表示土壤Cd背景值,本研究采用研究区土壤Cd背景值 ((0.324±0.105) mg·kg−1) [6]。地积累指数评价结果划分为7个等级,具体等级见表1。

表 1 土壤风险指数分级Table 1. Grade of of soil risk index分级 0 1 2 3 4 5 6 Igeo值 <0 0~1 1~2 2~3 3~4 4~5 >5 污染程度 无 轻度 轻~中 中度 中~重 重度 极严重 Er值 — <40 40~80 80~160 160~320 >320 — 生态风险 — 低 中等 中~高 高 极高 — 潜在生态风险指数 (Er) 考虑了土壤Cd毒理效应和环境生态效应对生态环境造成的影响[13,15],其具体计算公式见式(5)。

Er=Tr×SCd/Bn (5) 式中:Tr表示Cd生物毒性系数 (Tr-Cd=30) ,SCd表示土壤Cd含量 (mg·kg−1) ,Bn表示土壤Cd背景值,本研究采用研究区土壤Cd背景值 (0.324±0.105 mg·kg−1) [6]。潜在生态风险指数评价结果分为5个等级,具体分级情况见表1。

健康风险评估模型建立了暴露途径与人体健康风险的定量关系[6,16],计算公式见式(6)。

ADD−WCd=(WCd×IR×f)/BW (6) 式中:ADD-WCd为区域成人经摄食小麦摄入的Cd日均暴露剂量,mg·kg−1·d−1;WCd为小麦Cd含量,mg·kg−1;IR为研究区成人日均小麦食用量,g·d−1;f为河南省居民食用自产小麦的比例,%;BW为研究区成人平均体重,kg。

耦合公式(1)和(6),人体健康评估模型可进一步用来表征土壤-小麦系统Cd富集量与人体健康风险的量化关系,其计算公式见式(7)。

ADD−SCd=(SCd×BCF×IR×f)/BW (7) 暴露参数对健康风险评价的结果具有关键性影响[9,21]。本研究中,成人日均小麦食用量 (IR) 和平均体重 (BW) 来自于区域人群健康调查,分别设定为 (307.6±98.8) g·d−1的对数正态分布变量和 (58.6±5.6) kg的正态分布变量[6]。河南省居民食用自产小麦的比例 (f) 参考中国人群暴露参数手册河南部分设定为80.2%[26]。蒙特卡洛 (Monte-Carlo) 模拟是一种基于概率抽样的数理统计方法[19],通过对观测样本已知分布内的随机抽样,获取目标变量的概率分布[20,22]。本研究应用monte carlo模拟方法来降低土壤-小麦系统Cd污染综合风险评估结果的不确定性。

1.4 数据分析

应用SPSS 25.0进行农田Cd富集特征统计分析,应用ArcGIS 10.8和Origin 2021进行空间分析和制图,应用Matlab R2021a进行Monte-Carlo随机模拟,设定随机模拟的迭代次数为10000次。

2. 结果与讨论

2.1 土壤-小麦系统Cd富集特征分析

研究区土壤-小麦系统Cd富集特征统计结果如表2所示。区域土壤pH在5.44~8.60之间,平均值为8.05,其中94.7%土壤采样点pH均为碱性。耕作层土壤Cd平均含量为1.45 mg·kg−1,为农用地土壤风险筛选值 (0.6 mg·kg−1,《土壤环境质量农用地土壤污染风险管控标准 (试行) 》GB 15618-2018) [27]的2.42倍,约92.8%的土壤样点超过农用地土壤风险筛选值。土壤Cd变幅高达3.78 mg·kg−1,属强变异水平。以上结果说明区域土壤Cd污染形势严峻且受人为活动影响较为剧烈。

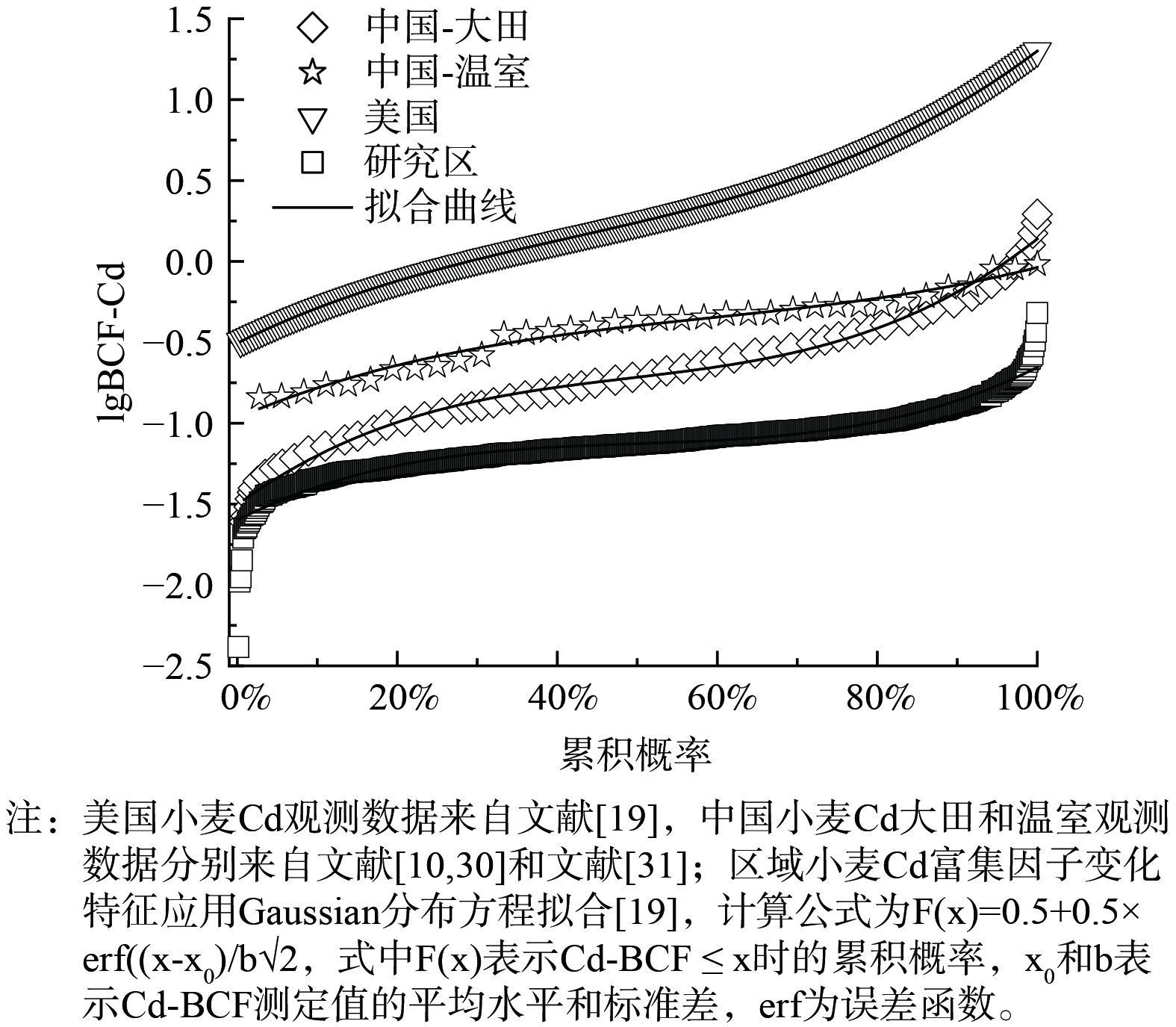

表 2 区域土壤基本性质及土壤-小麦Cd含量特征Table 2. Descriptive statistics of soil properties and Cd concentration in the soil-wheat system being investigated检测参数 最小值 最大值 平均值 中值 标准差 土壤pH 5.44 8.60 8.05 8.23 0.56 土壤有机质/(g·kg−1) 10.90 72.90 23.80 21.80 8.82 黏粒/% 16.50 47.30 28.50 28.00 5.54 阳离子交换量 10.60 27.50 18.20 17.8 3.35 土壤Cd/(mg·kg−1) 0.11 3.89 1.45 1.40 0.63 小麦Cd/(mg·kg−1) 0.04 0.51 0.18 0.17 0.09 小麦Cd-BCF 0.022 3.24 0.16 0.12 0.18 研究区小麦籽粒Cd平均含量为0.18 mg·kg−1,为《食品安全国家标准食品中污染物限量》GB 2762-2022 (0.1 mg·kg−1) 1.84倍[28],显著高于我国河北 (0.05 mg·kg−1) [29]和陕西 (0.02 mg·kg−1) 等[8]小麦产区的小麦籽粒Cd含量,略低于甘肃地区 (0.23 mg·kg−1) [7]小麦籽粒Cd含量。区域小麦籽粒样品超标率高达84.0%,可见区域小麦富Cd现象广泛存在且较为严重。小麦Cd富集系数 (BCF) 可以量化Cd在土壤-小麦的转移过程,表征小麦吸收积累Cd的能力[24,29]。研究区BCF范围为0.02~3.24,平均值为0.16。Gaussian分布方程[19]拟合结果显示区域小麦BCF服从对数正态分布 (图2) ,拟合结果显著 (p<0.001) 。进一步对中国和美国小麦Cd-BCF拟合发现研究区小麦Cd-BCF显著低于美国小麦Cd-BCF (美国小麦Cd-BCF平均值为3.98±5.29,中值为1.96,图2) [19]。另外,中国小麦Cd-BCF大田观测结果 (小麦Cd-BCF平均值为0.28±0.35,中值为0.19) [10,29]和温室观测结果 (小麦Cd-BCF平均值为0.43±0.22,中值为0.44) [30]与区域小麦Cd-BCF累积分布较为相似,可见研究区小麦Cd富集特征具备一定的典型性。

2.2 空间异质特征分析

研究区土壤-小麦Cd含量空间自相关分析结果如图3所示。区域土壤-小麦Cd含量Moran’s I指数在0~20 km内均为正值,p值均<0.05,Z值均>2,超过20 km后p值>0.05,说明在该范围内 (0~20 km) 区域土壤-小麦Cd含量存在显著空间自相关关系[25]。土壤Cd含量Moran’s I指数在0~10 km范围内变化较大,整体上呈现先显著下降,再轻微上升,再持续下降的趋势。小麦Cd含量Moran's I指数在0~10 km内下降幅度较大,之后趋于平缓。由此可知区域土壤-小麦系统Cd分布特征存在较强的空间聚集性,这种现象可能是由于当地的工矿企业作业和交通运输活动的干扰所致[6]。整体来看,区域土壤-小麦系统Cd含量Moran’s I指数在0~20 km内均表现出随距离增加而逐渐降低的趋势,这表明可以进一步进行空间插值分析。

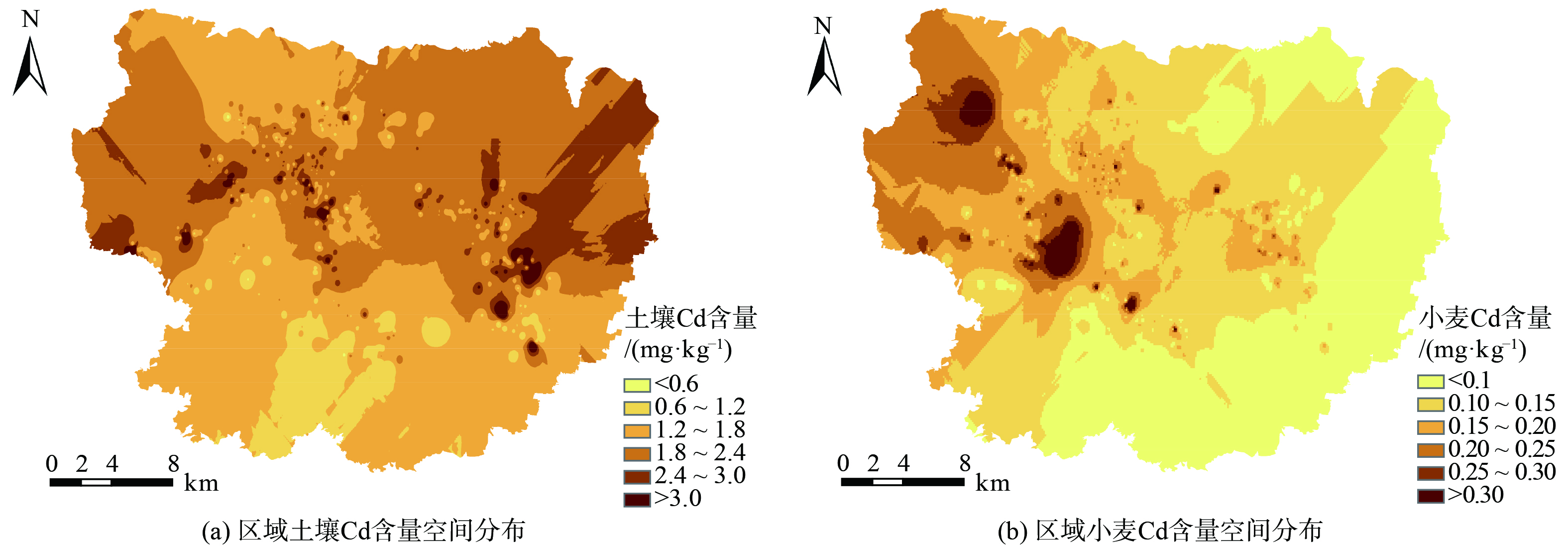

采用反距离加权法对研究区土壤-小麦Cd含量进行空间插值,空间分布如图4所示。由图4(a)可知,土壤Cd含量整体由西北向东南逐渐降低。土壤Cd高值区 (土壤Cd>1.8 mg·kg−1) 主要分布在研究区西北部和中东部区域。LI等[6]对研究区麦田土壤Cd污染进行溯源分析,指出区域西北部靠近铅锌冶炼厂区,中东部靠近人口密集区,频繁的人类活动容易造成土壤Cd累积。同时,区域土壤Cd含量高值区靠近当地主要河流上游,存在通过河流进行Cd迁移的风险。由图4(b)可知,研究区西北部和中部出现小麦Cd富集现象。空间尺度上,区域土壤和小麦Cd含量在研究区西北部表现出一定的相关性,均出现了较高水平的Cd富集现象。但研究区中东部区域存在一定空间差异,出现土壤Cd含量较高而小麦Cd含量较低现象。由以上结果可知区域工矿企业活动对于小麦Cd富集趋势影响显著,针对该地区的污染风险评估是确保研究区耕地安全利用的关键。

2.3 综合风险评估

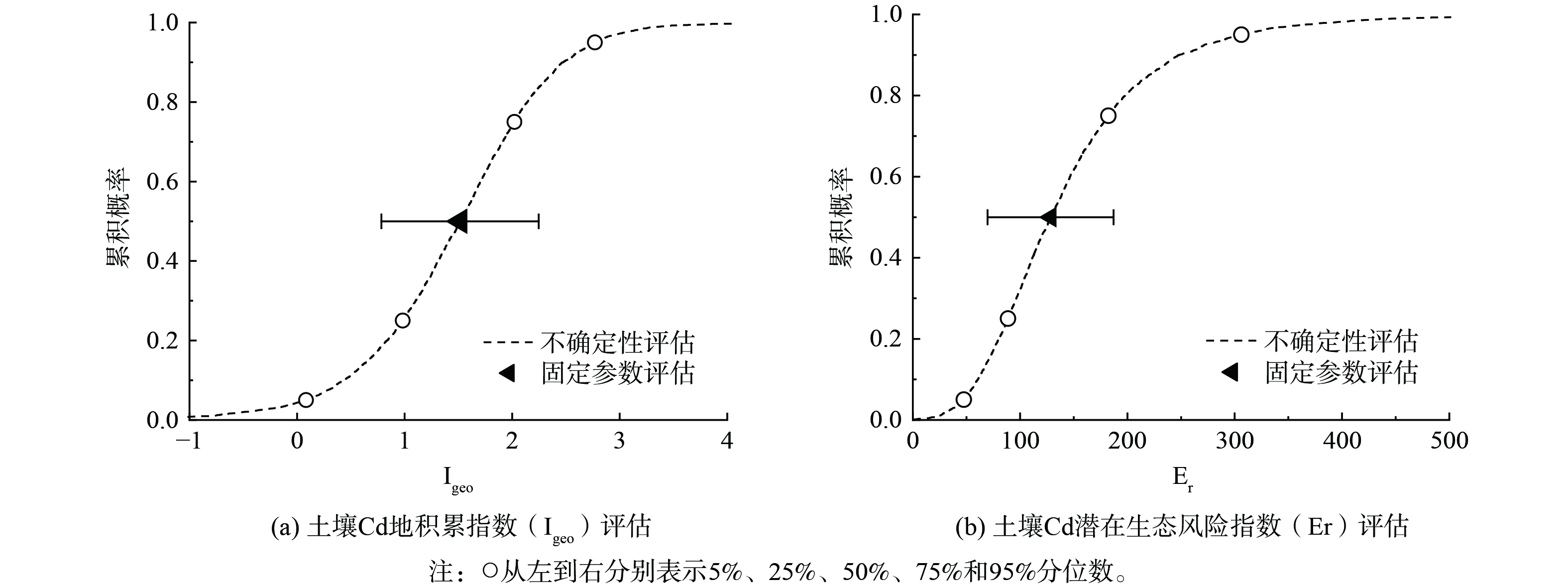

应用地积累指数 (Igeo) 和潜在生态风险指数 (Er) 开展基于固定参数的区域土壤Cd污染风险评估,评价结果见图5。由图5(a)可知,区域土壤Cd地积累指数平均值为1.42±0.73,隶属于轻中度污染等级 (表1) 。由图5(b)可知,区域土壤Cd潜在生态风险指数平均值为134±58.7,属中高等污染水平 (表1) 。考虑到区域土壤Cd含量的强空间异质性水平,进一步开展基于不确定性理论的区域土壤Cd污染风险评估 (图5) 。由图5(a)可知,区域土壤Cd地积累指数主要集中在1.01~1.89之间 (25%~75%分布) ,所调查样点隶属于无污染、轻度、轻中度、中度、中重度污染等级的比例分别为4.4%、21.5%、48.1%、23.2%和2.5%。由图5(b)可知,区域土壤Cd潜在生态风险指数主要集中在90.9~167之间 (25%~75%分布) ,所调查样点隶属于低污染、中等、中高等、高等和极高等污染等级的比例分别为3.2%、1.7%、4.7%、29.2%和4.3%。可见区域土壤Cd生态风险普遍处在高位,需对耕地上风向和河流上游的工矿企业排污进行治理 (图4) ,并避免出现新的污染源以加重区域土壤Cd累积趋势。

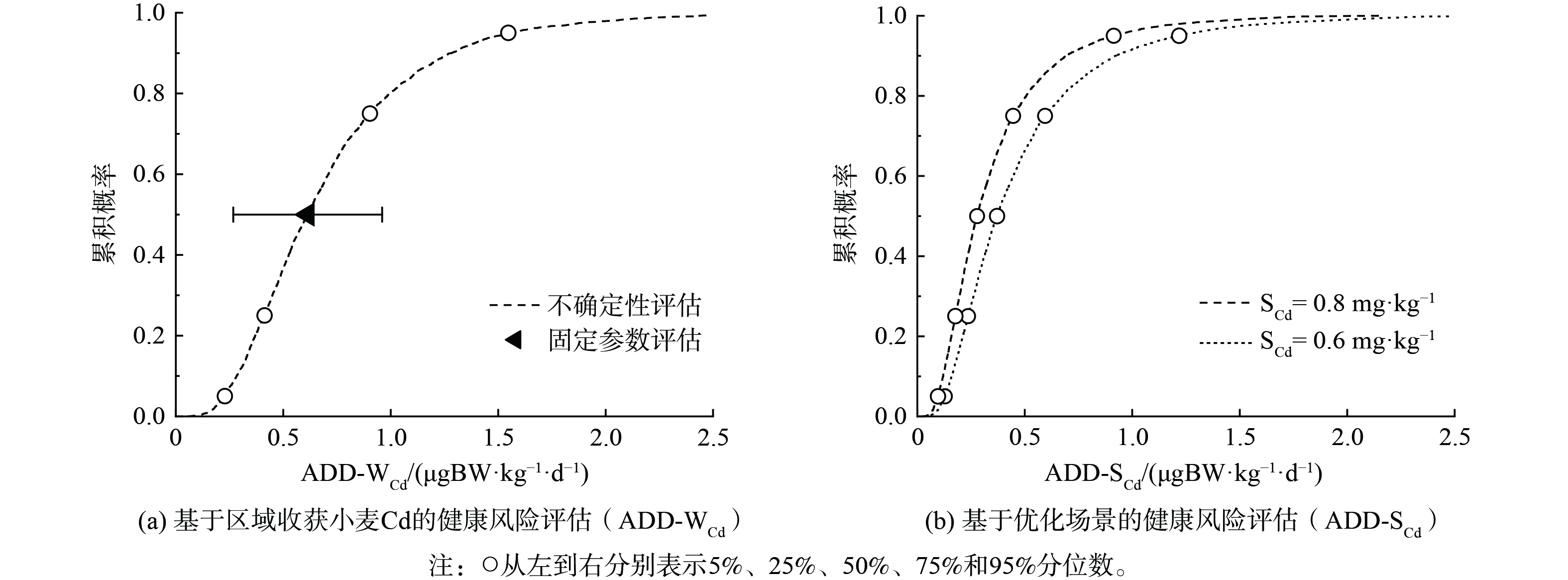

基于固定参数的小麦籽粒Cd人体健康风险评估结果如图6所示。结果显示,研究区成人Cd日均摄入量 (ADD) 为0.71±0.35μg BW·kg−1 d−1,略低于世界卫生组织 (WHO) 推荐的成人Cd摄入量安全值 (0.83 μg BW·kg−1·d−1) [31]。SONG等[9]对我国成人Cd摄入量的研究指出饮食结构的不同、小麦Cd含量差异等因素会促进健康风险评估结果的变异。简单的标准对比难以充分反映区域人群Cd摄入风险变化趋势。进一步开展基于不确定性理论的区域人群Cd摄入风险评估 (图6) 。由图6(a)可知区域人群经食用小麦Cd平均摄入量 (ADD) 主要集中在0.41~0.90 μg BW·kg−1·d−1之间 (25%~75%分布) ,近31.6%的区域人群Cd摄入量超过WHO推荐的安全值 (0.83 μg BW·kg−1·d−1) 。在小麦Cd含量较高的研究区西北部,该风险概率显著上升至79.3%,该区域ADD均值为1.12 μg BW·kg−1·d−1,为研究区人群经食用小麦摄入Cd量的1.58倍。考虑到研究区部分乡镇食用自产小麦比例接近100%,因此造成的危害也较大,在风险管理时应给予足够重视。

2.4 不同场景评估

国务院于2016年印发了《土壤污染防治行动计划》 (简称“土十条”) ,提出我国受污染耕地安全利用率到2030年要达到95%左右[4]。近年来,当地政府积极落实“土十条”各项指标,采取了诸如关闭重污染企业、优化产业格局、减少秸秆还田等手段以降低区域土壤Cd累积趋势,但是不同措施应用下区域人群Cd摄入风险仍不明确。基于不确定性理论应用所构建的人体健康风险评估模型 (公式7) 开展多场景评估,评价结果如图6(b)所示。由图6(b)可知,当区域小麦土壤Cd含量下降到0.80 mg·kg−1 (区域土壤Cd含量25%分布) 时,区域人群Cd摄入量由0.71 μg BW·kg−1·d−1显著下降至0.37 μg BW·kg−1·d−1,超过WHO推荐安全值 (0.83 μg BW·kg−1·d−1) [31]的风险概率由31.6%显著下降至14.1%。ÅKESSON和CHANEY[3]指出人体经饮食摄入Cd含量造成的危害随着Zn摄入量的增加而减小。增加牛奶、鸡蛋等高Zn食物在区域人群日常饮食中的比例[3,9]可进一步降低区域人群Cd摄入风险。

土壤酸化是影响Cd在土壤-小麦系统中富集的主要因子[5-6]。在本研究中,有9.61%的土壤pH<7.5,最小值 (pH=5.44,表2) 低于酸化土壤阈值 (pH=5.5,GB 15618-2018) [27]。为保证区域95%农田的安全利用,研究区土壤Cd含量应控制在0.6 mg·kg−1以下 (《土壤环境质量农用地土壤污染风险管控标准 (试行) 》GB 15618-2018) [27]。该场景下区域人群Cd摄入量为0.28 μg BW·kg−1·d−1,超标风险概率可进一步下降至7.3%。在这些土壤酸化区域增施石灰、生物炭等土壤调理剂可有效控制小麦Cd富集[24,32-33],提升小麦质量水平并降低人群Cd摄入风险。众多研究指出土壤-小麦系统Cd累积量还受到距工业区、矿区和城镇区的距离,不同种类肥料的投入及气候条件等多种因素影响[5,34-35]。充分考虑这些因素的影响,基于不确定性分析原理评估区域Cd污染风险水平及相应概率,使评价过程更加稳健可靠,该方法与空间分析的联合使用更有助于风险决策的科学性和合理性。

3. 结论

将Monte-Carlo随机模拟方法引入到地积累指数、潜在风险因子指数和健康风险评价研究中,综合评估区域土壤-小麦系统Cd污染风险。案例分析说明研究区土壤-小麦系统Cd含量空间异质性强,污染风险较高,以区域西北部Cd富集现象最为显著。研究区成人通过食用当地小麦存在一定的健康风险,需引起当地政府足够重视,并根据不同地区概况采取适当防范措施以减少Cd污染危害,保障区域小麦的安全和高质生产。基于不确定性理论开展模拟分析,结果可同步展示不同场景下区域土壤Cd生态风险和小麦Cd健康风险的风险水平及其相应概率,为当地Cd污染防治提供决策支撑,对其他用地类型的重金属污染防治也有一定借鉴作用。

-

[1] 张文. 中国大范围雾霾期间空气污染空间分布特征研究[D]. 兰州: 西北师范大学, 2015. [2] 沈欣军. 电除尘器内细颗粒物的运动规律及其除尘效率研究[D]. 杭州: 浙江大学, 2015. [3] 段璐. 电袋除尘器颗粒物脱除理论和实验研究进展[J]. 粉煤灰综合利用, 2019(4): 97-101. doi: 10.3969/j.issn.1005-8249.2019.04.025 [4] 孙振龙, 顾珊, 刘茂省, 等. 针刺电晕线在线-管式静电除尘器中的放电特性应用研究[J]. 电力学报, 2018, 33(4): 353-358. [5] KOHEI A, RYOTA T, AKINORI Z, et al. Simulation and measurement of charged particle trajectory with ionic flow in a wire-to-plate type electrostatic precipitator-ScienceDirect[J]. Journal of Electrostatics, 2020, 107: 103488-103497. doi: 10.1016/j.elstat.2020.103488 [6] OHENOJA K, WIGREN V, VALTER W, et al. Fly ash classification efficiency of electrostatic precipitators in fluidized bed combustion of peat, wood, and forest residues[J]. Journal of Environmental Management, 2018, 206: 607-614. [7] 张建平, 高鹏飞, 徐达成, 等. 不同烟气流速下线板式电除尘器中磁场效应验证[J]. 环境工程学报, 2020, 14(11): 3121-3127. doi: 10.12030/j.cjee.201906006 [8] 方梦祥, 柳佳佳, 岑建孟, 等. 高温静电除尘技术研究进展及应用前景[J]. 高电压技术, 2019, 45(4): 1108-1117. [9] 陈熙勐, 张皓旻, 顾万清, 等. 我国PM25主要成分及对人体健康危害研究进展[J]. 中华保健医学杂志, 2019, 21(1): 83-85. doi: 10.3969/.issn.1674-3245.2019.01.026 [10] 郝毅仁, 孟超, 刘坤坤. 工业大气污染治理技术发展分析[J]. 中国资源综合利用, 2020, 38(6): 132-134. doi: 10.3969/j.issn.1008-9500.2020.06.041 [11] 柴发合. 我国大气污染治理历程回顾与展望[J]. 环境与可持续发展, 2020, 45(3): 5-15. [12] 冯启琨, 黄磊, 刘荻帆, 等. 针-板与棒-板电极结构在不同温度下的负电晕放电特性[J]. 高电压技术, 2021, 47(5): 1847-1856. [13] 李庆, 刘晓娃, 剧晓晨, 等. 针-板电极负电晕放电下离子分布状态的影响因素[J]. 高电压技术, 2017, 43(5): 1700-1706. [14] ZHU J B, ZHAO Q X, YAO Y P, et al. Effects of high-voltage power sources on fine particle collection efficiency with an industrial electrostatic precipitator[J]. Journal of Electrostatics, 2012, 70(3): 285-291. doi: 10.1016/j.elstat.2012.03.009 [15] ANATOL J, ANDRZEJ K, TADEUSZ C. Modern electrostatic devices and methods for exhaust gas cleaning: A brief review[J]. Journal of Electrostatics, 2006, 65(3): 133-155. [16] 邓云峰, 刘功智, 张国权. 宽间距长芒刺静电除尘技术的应用[J]. 中国安全科学学报, 2003, 13(10): 45-48. doi: 10.3969/j.issn.1003-3033.2003.10.013 [17] 常玉锋, 李梦玲, 叶罗威, 等. 线-管式双极预荷电器的极间电场分布模型[J]. 江汉大学学报(自然科学版), 2019, 47(6): 507-513. [18] 王翔, 常景彩, 徐纯燕, 等. 线-板式静电除尘器芒刺电晕线放电特性[J]. 高电压技术, 2017, 43(2): 533-540. [19] WANG X, CHANG J C, XU C Y, et al. Discharge characteristic of barbed electrodes in wire-plate electrostatic precipitator[J]. High Voltage Engineering, 2017, 43(2): 533-540. [20] 吴华, 杨春振, 董力, 等. 空气环境下线板电除尘器RS芒刺的放电特性[J]. 能源科技, 2020, 18(3): 42-48. [21] 曾宇翾, 沈欣军, 章旭明, 等. 电除尘器中离子风的实验研究[J]. 浙江大学学报(工学版), 2013, 47(12): 2208-2211. [22] 龙正伟, 冯壮波, 姚强. 静电除尘器数值模拟[J]. 化工学报, 2012, 63(11): 3393-3401. doi: 10.3969/j.issn.0438-1157.2012.11.003 [23] 李海英, 多鹏, 王茹. 离子风对ESP气流分布和除尘效率影响的数值模拟[J]. 环境科学与技术, 2017, 40(9): 136-142. [24] 胡建华, 潘洋洋. 电除尘器中离子风对除尘效果的影响[J]. 装备环境工程, 2018, 15(3): 76-80. [25] PODLINSKI J, NIEWULIS A. Electrohydrodynamic flow and particle collection efficiency of a spike-plate type electrostatic precipitator[J]. Journal of Electrostatics, 2009, 67(2/3): 99-104. [26] DEKOWSKI J, KOCIK M. Measurement of the flow velocity field in multi-field wire-plate electrostatic precipitator[J]. Czechoslovak Journal of Physics, 2004, 54: 922-930. doi: 10.1007/BF03166509 [27] YAMAMOTO T, VELKOFF H R. Electrohydrodynamics in an electrostatic precipitator[J]. Journal of Fluid Mechanics, 1981, 108: 1-18. doi: 10.1017/S002211208100195X [28] 李庆, 王利, 杨青, 等. 板-袋收尘极板对微细粉尘收集效果的影响分析[J]. 高电压技术, 2016, 42(2): 361-367. [29] 李庆, 李海凤, 孙晓荣, 等. 电晕放电电流体状态实验研究与数值模拟[J]. 高电压技术, 2010, 36(11): 2739-2744. -

下载:

下载: