-

传统饮用水处理工艺不仅存在占地面积大、难以模块化、智能化等问题,对细菌、病毒等微生物的截留效果也较差,不利于水质安全。随着材料科学的发展,以超滤为核心的第3代饮用水净化工艺得以广泛应用,一些超滤饮用水厂规模甚至超过了106 m3·d−1[1-2]。较小的孔径使得超滤替代了传统工艺的过滤单元,出水浊度较低且稳定,并能有效去除细菌[3]。但是,运行过程中污染物不可避免地接触膜表面,甚至引起严重膜污染,进而造成膜法水处理工艺运行维护成本增加、膜使用寿命缩短等问题,从而一定程度上限制了超滤膜的推广应用[4-6]。

混凝作为饮用水处理工艺的核心环节已有百年之久的应用历程,该工艺中,水解形成的絮体在静电吸附、网捕卷扫等作用下能有效地去除污染物。基于此,为有效减缓膜污染,研究者逐渐研发了基于混凝预处理的膜法处理工艺:长流程常规膜滤工艺(混凝-沉淀-膜滤)、短流程膜滤工艺(混凝-膜滤)和一体式膜滤工艺(吸附剂直接注入膜池)。与短流程工艺和一体式工艺相比,尽管常规膜滤工艺去除污染物效果良好,但占地面积相对较大,且经过沉淀处理后,残留的小颗粒物质易形成致密滤饼层,加剧膜污染;而在短流程膜滤工艺中,原水经混凝单元后直接进入膜池,污染物去除效率得以保证,占地面积小,混凝出水的颗粒粒径较大,形成的滤饼层疏松,但膜池内大颗粒絮体极易沉淀,导致排泥量较大[7]。因此,将吸附剂直接注入膜池的一体式膜滤工艺逐渐受到关注。

以往关于一体式膜滤工艺的研究中,多以颗粒型的吸附剂为主,如活性炭、纳米铁、碳纳米管甚至砂砾石等[8-10]。然而长期运行过程中不仅存在刮伤膜表面的风险,且部分吸附剂价格昂贵。已有的研究工作表明通过使用松散且吸附效能强的混凝剂水解絮体,能有效解决上述问题[11-13],但多数研究仍处于小试阶段且污染负荷较小。为此,本研究中以江苏常州某河流的水样为原水,从药剂种类与投加量等因素初步考察了一体式絮体-超滤膜组合工艺的中试运行情况,以期为膜法水处理工艺提供参考。

全文HTML

-

实验中所用的聚合硫酸铁(polymerized ferrous sulfate,PFS,有效铁浓度21%)、硫酸铝(aluminum sulfate,AS,有效铝浓度53%,以Al2O3计)均为饮用水级,购于神美科技有限公司(河北沧州)。粉末活性炭(PAC)为饮用水级,目数为200目,购于郑州康净活性炭有限公司。烧碱(主要成分为NaOH)与次氯酸钠(活性氯浓度7%,游离碱浓度1%)为工业级,购于常州天林化学试剂有限公司。实验所用的浸没式中空纤维超滤膜购于天津膜天膜科技股份有限公司,材质为聚偏氟乙烯(PVDF)。超滤膜平均孔径为30 nm,膜丝内径为0.7 mm,外径为1.3 mm(厂商提供)。每个膜组件表面积为35 m2。原水取于常州某河流,水质如表1所示。

絮体配制过程为:首先取所需质量(分别以铝、铁计)的硫酸铝、聚合硫酸铁分别溶于水中,搅拌14 min。由于絮体的性质受pH的影响较大[11, 14],因此,用烧碱将pH统一调至7.5左右。静置沉降1 h,排去上清液,重复2~3次。已有研究[15-16]表明,中性条件下铁盐水解产物几乎全部为絮体,而铝盐水解产物约60%为絮体,因此,铁盐絮体几乎与投加量相同而铝盐絮体是其投加量的60%。

-

由于原水直接进入膜池,为防止泥沙等大颗粒污染物对膜丝造成损伤,实验所用河水经50 μm袋式过滤器预过滤后再进入原水箱,通过离心泵加入膜池,同时将配置好的絮体或粉末活性炭通过蠕动泵加入膜池中。实验中,保持恒流量运行,单膜池产水流量为1 m3·h−1,水力停留时间为1.17 h。膜组件每运行29 min后进行1 min的反洗(反洗流量1 m3·h−1),在反洗的同时进行曝气(曝气强度为5 m3·h−1)。为防止絮体或粉末活性炭下沉,产水过程中持续进行微量曝气(曝气强度为0.75 m3·h−1)。后期为进一步降低微生物对膜污染程度的影响,采用次氯酸钠进行预氧化。次氯酸钠通过隔膜泵加入原水箱,装置由液位计控制水位,自动运行(除加药外)。系统根据膜池液位和压力表示数每天自动记录跨膜压差(transmembrane pressure, TMP)。该膜组件跨膜压差的合理运行范围低于30 kPa(厂商建议)。实验装置如图1所示。

-

pH采用Thermo 310P-01台式pH计测定;原水浊度采用Hach2100Q浊度仪(美国Hach公司)测定;颗粒物粒径的测定采用MALVERN激光粒度分析仪(英国)测定;出水浊度采用Signet 4150在线浊度仪测定;细菌总数的测定采用平皿计数法;总有机碳(TOC)的测定采用燃烧氧化-非分散红外吸收法;氨氮测定采用水杨酸分光光度计法;总磷测定采用钼酸铵分光光度计法;铁离子浓度测定采用电感耦合等离子发射光谱法;化学需氧量(COD)采用Hach DR3900(美国Hach公司)可见分光光度计测定;超滤膜表面形貌采用扫描电子显微镜(SEM,日本JEOL公司)测定。

1.1. 实验材料

1.2. 实验装置及方法

1.3. 分析方法

-

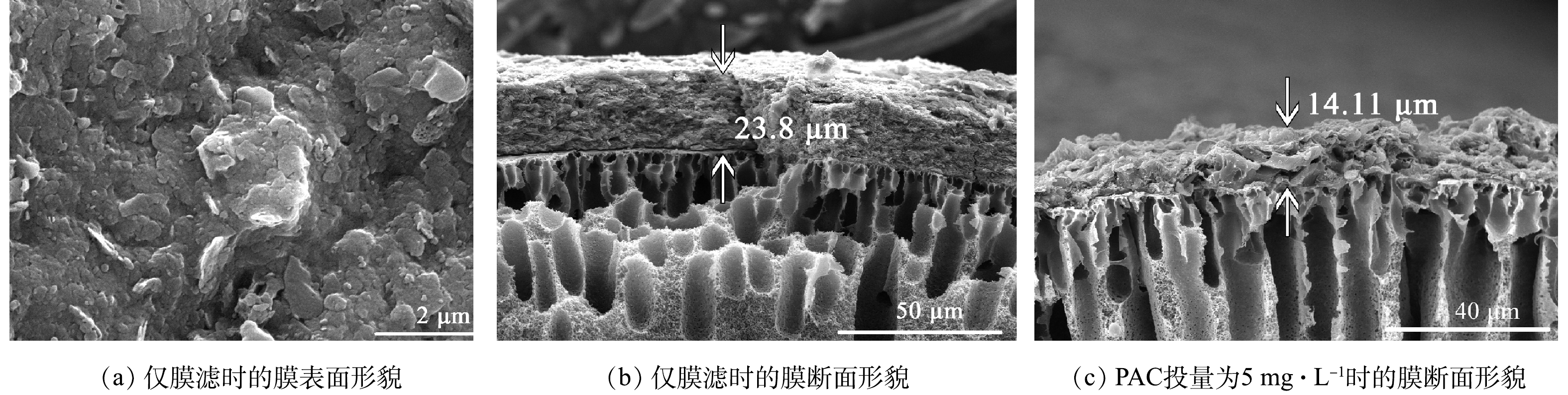

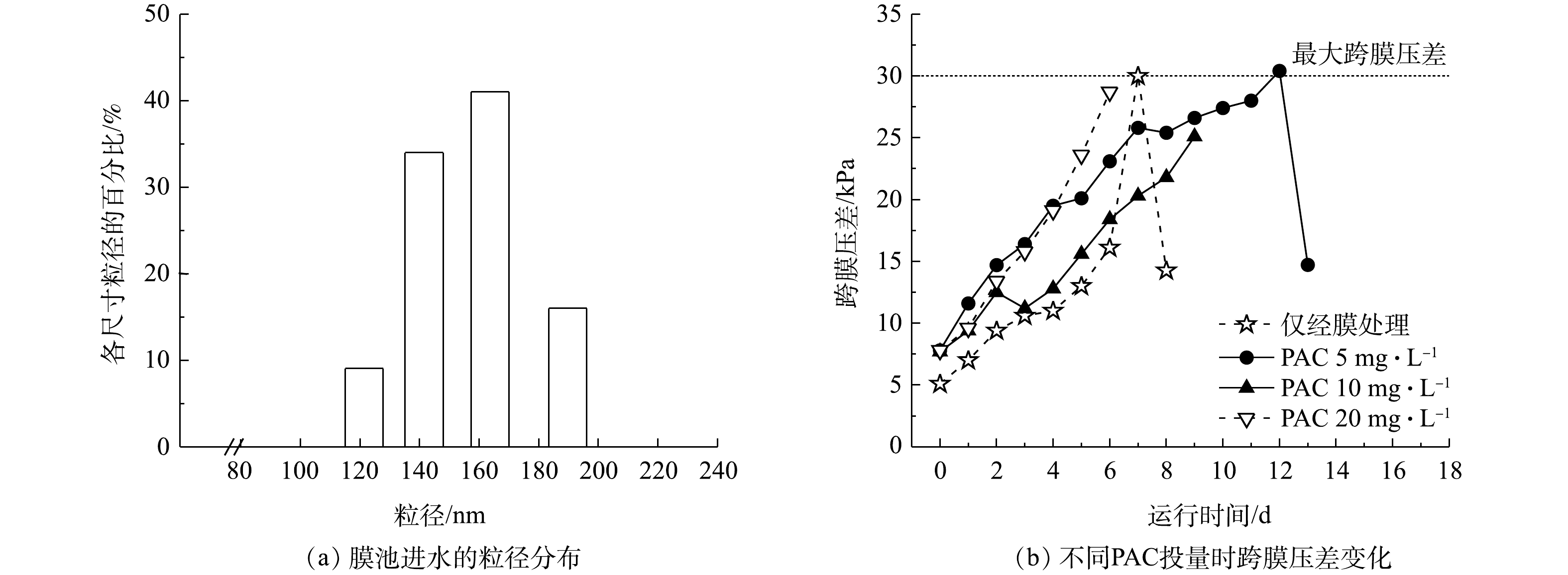

粉末活性炭在饮用水处理工艺中已得到广泛应用。本研究中,首先考察了一体式粉末活性炭-超滤工艺中膜污染的行为。SEM表征结果表明,滤饼层相对致密且较厚(图2(a)与图2(b)),因而当原水经预过滤后直接过膜时,仅运行7 d后TMP就急剧增至30 kPa(图3(b)),此时以空气和水同时冲洗膜表面,TMP由30 kPa急剧下降至14.26 kPa(8 d),且由图3(a)可见,膜池进水的颗粒物平均粒径为156.6 nm,大于实验中超滤膜平均孔径(30 nm),表明以滤饼层为主要形式的可逆污染是实验中引起超滤膜污染的主要机制。随着PAC投量的增加,污染物被吸附到PAC表面,减少了直接与膜表面接触的概率。当PAC的投加量为5 mg·L−1时,经过12 d的运行,TMP为30.4 kPa,运行结束后,以空气和水同时冲洗膜表面,TMP由30.4 kPa又急剧下降至14.72 kPa(13 d);当增加PAC投加量至10 mg·L−1时,经过9 d的运行,TMP达到25.1 kPa;继续增加PAC投加量至20 mg·L−1时,仅运行6 d后,TMP急剧增加至28.7 kPa。这是由于低剂量时污染物被PAC吸附,降低了其在超滤膜表面的附着,同时在膜池底部持续曝气的情况下,膜污染程度得以减缓(图2(c))。但随着PAC的持续投加,超滤膜表面PAC逐渐增多,污染负荷增大,因而导致膜污染程度加剧[17-18]。

-

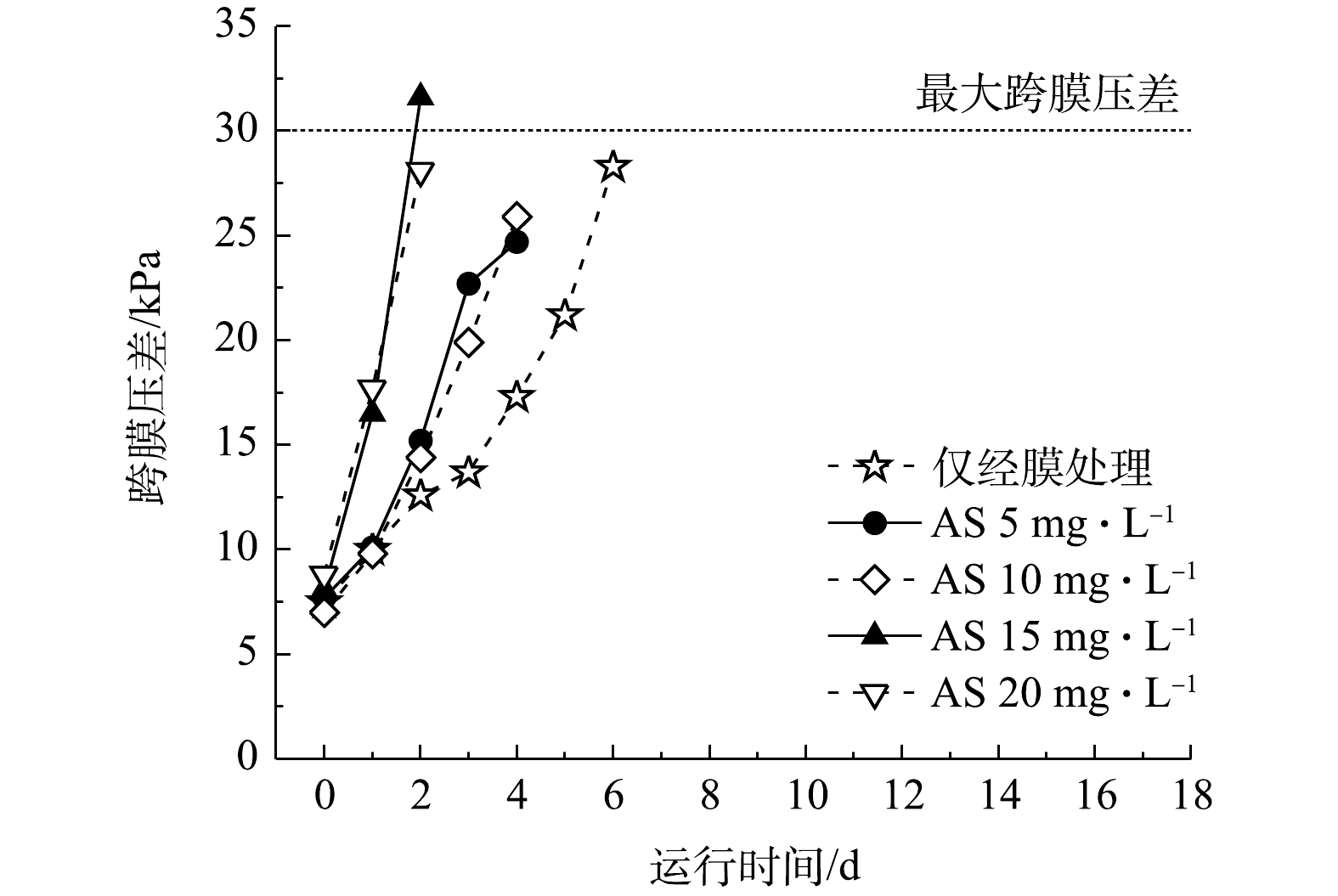

由于粉末活性炭多为颗粒型,长期运行过程中存在刮伤膜表面的风险,同时,铝盐、铁盐混凝剂在饮用水处理工艺中也广泛使用,因此,进一步考察了一体式铝盐絮体-超滤工艺的膜污染行为。由图4可知,当原水经预过滤直接过膜时,经过6 d的运行后TMP达到28.3 kPa。随着AS投加量的增加,膜污染程度逐渐加剧。当AS絮体的投加量为5 mg·L−1时,经过4 d的运行,TMP增至24.7 kPa;AS投加量提升至10 mg·L−1时,经过4 d的运行,TMP增至25.9 kPa;而当AS絮体的投加量继续增至15 mg·L−1和20 mg·L−1时,经过3 d的运行,TMP分别急剧增至31.6 kPa和28.1 kPa。这是因为:一方面,相对粒径较大的铝盐絮体使得滤饼层成为膜污染的主要原因;另一方面,虽然投加铝盐絮体能吸附/截留水中污染物,但铝盐絮体密度较小,不易沉淀,更多的絮体悬浮在膜池中,容易吸附在膜表面,从而增加膜表面的污染负荷,导致膜污染加剧[19-21],此时膜污染的程度甚至超过单独膜滤运行情况下的程度。

-

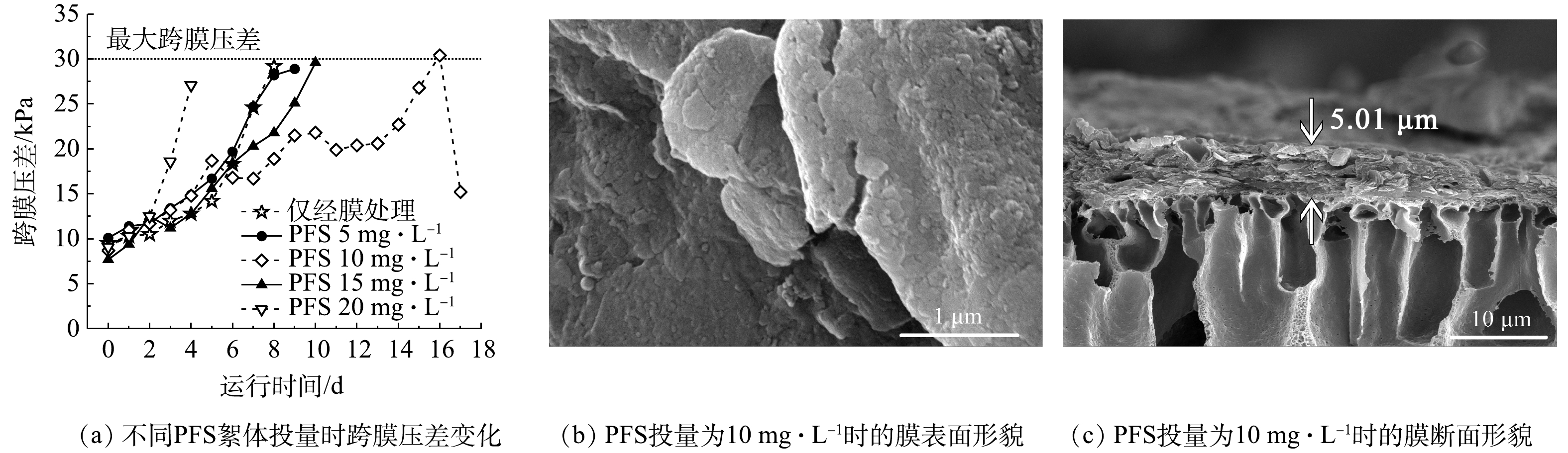

由于一体式铝盐絮体-超滤工艺无法有效减缓膜污染,因此,进一步考察了一体式铁盐絮体-超滤工艺膜污染的行为。由图5(a)可知,当原水经预过滤后直接过膜时,仅经过8 d的运行后TMP就达到29.2 kPa。随着铁盐絮体投加量的增加,膜污染程度呈现先减缓后加剧的趋势。当铁盐絮体的投加量为5 mg·L−1时,由于吸附剂投加量不足,使得絮体吸附的污染物较少,因此经过9 d的运行,TMP达到28.9 kPa,未明显减缓膜污染;将铁盐絮体的投加量增至10 mg·L−1时,经过16 d的运行,TMP达到30.4 kPa,此时以空气和水同时冲洗膜表面后跨膜压差急剧降至15.2 kPa(17 d);当铁盐絮体的增加至15 mg·L−1时,经过10 d的运行,TMP增至29.6 kPa;继续增加投加量到20 mg·L−1,仅经过4 d的运行,TMP就急剧增至27.1 kPa。这是由于随着膜池内絮体投加量的持续增加,其可有效吸附并拦截了污染物,从而阻碍了污染物直接接触超滤膜表面。同时,松散的絮体在膜池底部曝气的作用下破碎,所形成的滤饼层疏松且厚度进一步降低(图5(b)和图5(c)),因而膜污染程度降低。但是,进一步提高铁盐絮体的投加量,膜表面污染负荷会持续增大,致使膜污染程度加剧,进而导致膜通量降低。以往的一些研究[19, 22]也存在此类现象。

-

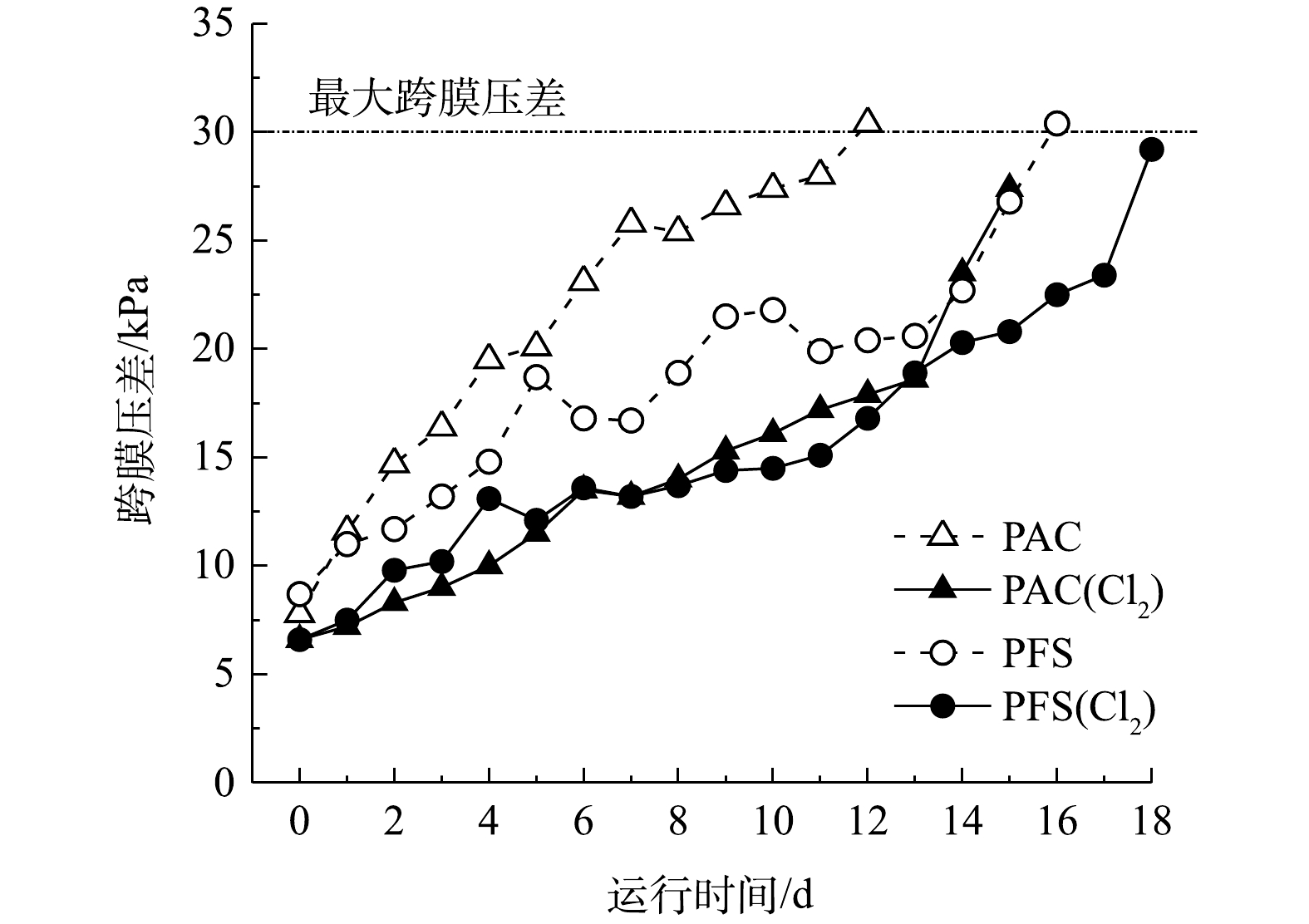

由表1可以看出,原水中不仅含有有机物,还含有氮、磷等,虽然实验用水经50 μm袋式过滤器预过滤后进入原水箱,但微生物检测结果仍表明,冬季低温时原水箱中菌落总数仍高达96 CFU·mL−1,说明原水中微生物相对丰富,极易引起膜污染。以往的研究表明,氧化预处理可以通过灭菌、氧化有机物等来减缓膜污染[11, 23]。以粉末活性炭与聚合硫酸铁水解絮体为吸附剂,将次氯酸钠(以有效氯计,原水箱中的浓度为1 mg·L−1)投加至原水箱中,考察了氧化预处理对一体式吸附-膜滤工艺的影响。由图6可知,加氯预处理可进一步减缓膜污染,从而延长超滤膜的运行时间。其中,单独投加PAC时,经过12 d的运行,TMP达到30.4 kPa;而加氯预处理后,经过15 d的运行,TMP达到27.4 kPa。单独投加铁盐絮体时,经过16 d的运行,TMP达到30.4 kPa;而加氯预处理后,经过18 d的运行,TMP达到29.2 kPa。虽然次氯酸钠能灭活膜池内微生物,并抑制其分泌的胞外聚合物含量[24-28],但一方面由于原水中污染组分复杂,污染负荷相对较大(表1),另一方面原水经滤袋过滤后微生物总量较少。因此,加氯预处理(以氯计,1 mg·L−1) 无法显著减轻膜污染。

-

出水水质是衡量膜法水处理工艺运行效果的重要指标,故进一步考察了一体式铁盐絮体-超滤工艺的出水水质(表2)。检测结果表明,中试运行期间一体式铁盐絮体-超滤工艺的平均出水浊度低于0.1 NTU。虽然膜池内持续注入铁盐絮体,但较大的絮体粒径极易被超滤膜拦截,因此,膜池出水的铁离子质量浓度始终低于0.01 mg·L−1,远低于国家生活饮用水水质标准(0.3 mg·L−1,GB 5749-2006)。在单独膜滤实验条件下,TOC的去除率为9.43%,耗氧有机物去除率(以COD计)的去除率为6.36%,总磷的去除率为45.45%,氨氮的去除率小于20%;在一体式铁盐絮体-超滤工艺中,由于絮体的吸附及其膜池内微生物的作用,上述指标的去除率均有一定程度的提高,其中TOC、耗氧有机物去除率(以COD计)、总磷、总氮去除率分别为21.7%~30.2%、20%~49.3%、77.8%~93.3%和<32.1%。

2.1. 一体式粉末活性炭-超滤工艺膜污染行为

2.2. 一体式铝盐絮体-超滤工艺膜污染行为

2.3. 一体式铁盐絮体-超滤工艺膜污染行为

2.4. 基于次氯酸钠预处理的一体式铁盐絮体-超滤工艺膜污染行为

2.5. 一体式铁盐絮体-超滤工艺的出水水质

-

1)一体式絮体-超滤工艺在原水水质波动幅度和污染负荷较大时仍可稳定运行,膜污染行为易受吸附剂种类及其投加量的影响。滤饼层是引起超滤膜污染的主要原因。与粉末活性炭和铝盐絮体相比,一体式铁盐絮体-超滤工艺的效果更优,但过量的铁盐絮体仍会加剧膜污染。

2)次氯酸钠氧化预处理对膜污染具有一定的减缓作用,但当原水水质污染负荷较大时,应优化次氯酸钠的投加量。

3)一体式铁盐絮体-超滤工艺出水水质稳定,且其中铁离子浓度较低,对TOC、耗氧有机物去除率(以COD计)、总磷和氨氮等污染物均有不同程度地去除。

下载:

下载:

百度学术

百度学术