-

2018年,我国铁尾矿产生量为4.76×108 t,约占全国尾矿产生量的40%。相比较其他种类尾矿,铁尾矿占比最大[1]。而目前铁尾矿的综合利用率却不足30%,远低于发达国家[2]。在我国,铁尾矿主要储存方式为露天堆放,这样不仅有溃坝的风险[3],而且还可能会对周边水体造成污染[4-5]。因此,铁尾矿堆放处理对环境造成的污染问题不容小觑,亟需解决。

铁尾矿对环境造成危害的同时也是一种“放错地方的资源”。铁尾矿中含有大量的SiO2、Al2O3、Fe2O3,这与黏土的成分十分相似,可以代替黏土用作烧结砖的原料。已有大量研究[6-10]证实了铁尾矿制备烧结砖的可行性。严捍东等[8]分别利用铁尾矿、粉煤灰和海泥制备出多孔烧结砖;其结果表明,与粉煤灰相比,铁尾矿更利于减缓烧结砖的泛霜程度。LUO等[9]利用铁尾矿、煤矸石等作为主要原料,并用污泥和页岩作为黏结剂制备烧结砖;结果表明,在烧结温度1 100 ℃、烧结时间3 h的最佳条件下,烧结砖的抗压强度为14.24 MPa、吸水率为17.47%。有研究结果[11-12]表明,将废玻璃加入到烧结砖中会极大地提高黏土烧结砖的力学强度。VORRADA等[11]发现,向黏土砖中添加废弃玻璃,在一定范围内会提高烧结砖的力学强度;在温度为1 100 ℃、玻璃添加量为15%的条件下,会提高2~3倍的力学强度,吸水率可降低至2%~3%。这些研究多数关注在烧结砖力学性能的研究上,而忽略了烧结砖中重金属释放到环境中的潜在风险,特别是对于含有较高重金属的铁尾矿。重金属在烧结砖中的形态分布和浸出特性的问题值得关注。

本研究中,利用铁尾矿、废玻璃和粉煤灰制备烧结砖,以探究其可行性。研究不同温度和配比条件对烧结砖性能的影响和重金属的浸出风险;并研究了在烧结过程中的重金属形态分布、孔径分析、XRD和SEM,以揭示烧结砖的固化机理。本研究结果可为铁尾矿的资源化利用提供数据参考。

全文HTML

-

供试铁尾矿来自广东省大宝山槽对坑尾矿库,铁尾矿样品置于烘箱中105 ℃烘干,利用行星式球磨机(QM-3SP2,南京南大仪器有限公司)进行球磨,过200目标准筛后储存于密封袋中,置于干燥器中储存。供试废玻璃为高硼硅玻璃,利用球磨机进行球磨,过200目标准筛后储存于密封袋中,置于干燥器中储存。供试粉煤灰来自广东省某燃煤发电厂,粉煤灰样品在烘箱中105 ℃烘干至恒重后,置于干燥器中储存。

-

将铁尾矿、粉煤灰和废玻璃按照表1的比例进行充分混合,加入去离子水使得胚料含水率为10%。将胚料放在钢模具内,利用压片机使胚料成型,成型压力为15 MPa。成型后的砖胚置于105 ℃烘箱中,干燥24 h;然后将砖胚置于马弗炉中,设定升温速率为5 ℃·min−1,升温至特定温度(900、1 000、1 100、1 200 ℃),保温时间为2 h。

-

将烧结砖样品浸泡在超纯水中,浸泡24 h后取出,用滤纸擦干样品表面,称量样品吸水后的质量,烧结砖样品的吸水率按照式(1)计算。

式中:w是烧结砖的吸水率;m1是烧结砖未浸泡前的质量,g;m2是烧结砖浸泡后取出并擦干的质量,g。

-

1)采用X射线荧光光谱(XRF)(EDX-7000,日本岛津公司)测定原料中的主要化学成分。

2)原料重金属含量的测定。取0.1 g样品于消解罐中,加入40%氢氟酸2 mL、35%浓盐酸2 mL和65%硝酸6 mL,于微波消解仪中进行消解;消解完成后赶酸,用超纯水稀释至25 mL,利用火焰原子吸收分光光度计(TAS-990F,北京普析通用仪器有限公司)测定总的重金属含量。

3)物相结构分析。采用X射线衍射仪(XRD)(Bruker D8,德国布鲁克公司)进行物相结构分析;扫描角度为10°~80°、步长为0.02°、计数时间为0.03 s。

4)抗压强度。采用万能材料试验机(Instron 5697,美国Instron)测试样品的抗压强度,以式(2)计算烧结砖的抗压强度。

式中:p是烧结砖的抗压强度,MPa;F是测量受力面所承受最大的压力,N;A是受力面的面积,mm2。

5)重金属形态分析。烧结砖中的重金属形态分析采用欧共体标准物质局的BCR顺序提取法[13],分为4个形态:弱酸提取态、可还原态、可氧化态、残渣态。

6)孔径分析。采用全自动比表面及孔隙度分析仪(TriStar II 3flex,美国麦克仪器公司)进行孔径分析;以N2作为吸附气体,脱气温度为150 ℃、脱气时间为2 h,采用BJH分析模型处理数据。

7)扫描电镜分析。采用电子扫描电镜(Sigma 300,德国蔡司仪器公司)观察样品微观形貌;利用X射线能谱仪(XFlash6,德国布鲁克公司)做EDS分析。

8)重金属浸出浓度测定。烧结砖重金属浸出浓度通过《固体废物浸出毒性浸出方法-醋酸缓冲溶液法》(HJ/T 300-2007)[14]进行;在样品管中加入1 g样品和20 mL醋酸缓冲溶液,放入翻转式振荡器中以30 r·min−1的转速翻转18 h;翻转完成后,再通过0.45 μm滤膜过滤,用火焰原子吸收分光光度计测定样品浸出液中重金属(Cu、Pb、Zn)的浓度。

1.1. 实验原料

1.2. 烧结砖的制备

1.3. 吸水率实验

1.4. 测定方法

-

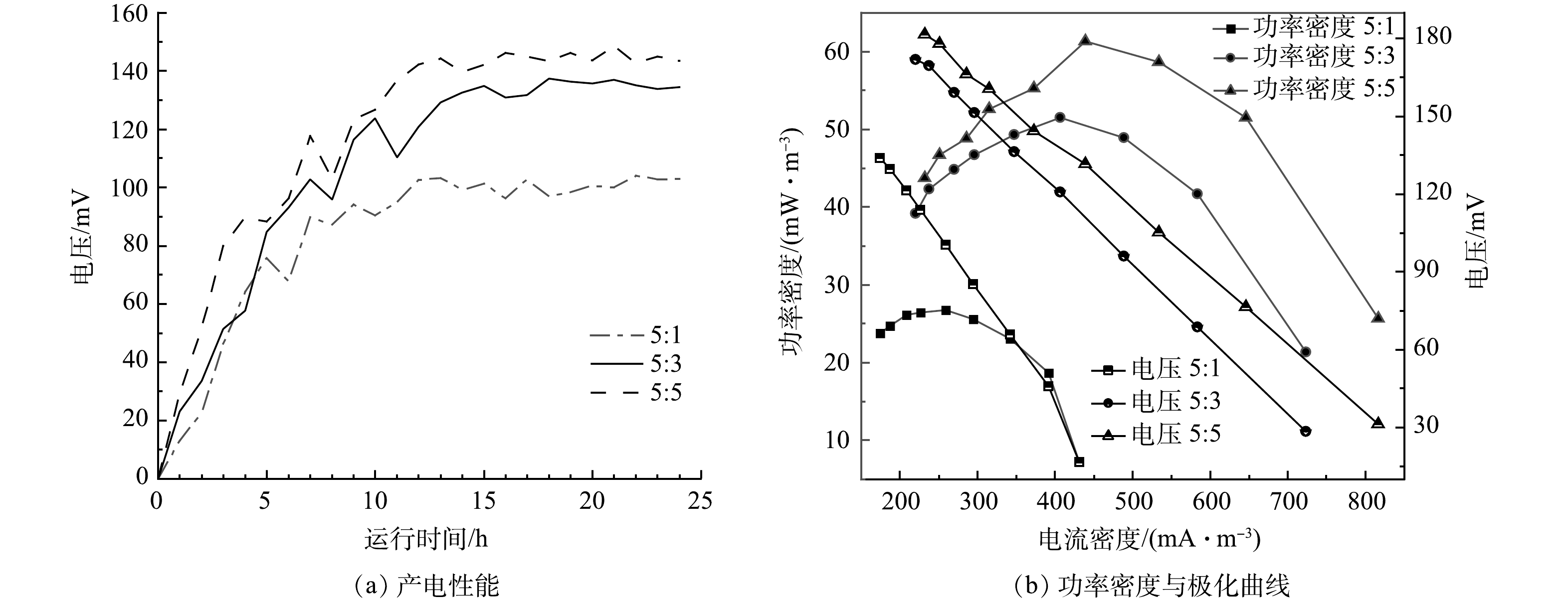

供试铁尾矿外观呈红色的颗粒状,平均粒径为189.24 μm,粒径较小。表2为铁尾矿、粉煤灰、废玻璃的化学组成。通过表2可知,铁尾矿主要化学成分有Fe2O3、SiO2、Al2O3,这些成分的含量与国内外其地区铁尾矿的成分相似[15]。CHEN等[16]指出,铁尾矿中的Fe2O3成分在制备烧结砖的过程中有促进烧结的作用,可以降低烧结砖的烧成温度。粉煤灰中含有大量的SiO2、Al2O3硅铝氧化物,可弥补铁尾矿低硅、低铝的缺点;粉煤灰还含有少部分K2O、Na2O等碱性金属氧化物,因而有助熔的作用。废玻璃的主要成分为SiO2和Na2O,在体系中可以起到黏结作用。另外,从铁尾矿的XRD分析图谱(图1)可以看出,铁尾矿中的主要矿物组成为石英、赤铁矿和高岭石。

从表3可以看出,铁尾矿中重金属种类较多,含量差异较大,是典型的多金属伴生尾矿。其中,Cu、Zn、Pb的含量较高,长期露天堆放会对环境造成隐患。

通过对3种制砖原料理化性质的分析可初步判断,铁尾矿结合粉煤灰、废玻璃制备烧结砖是具有可行性的。

-

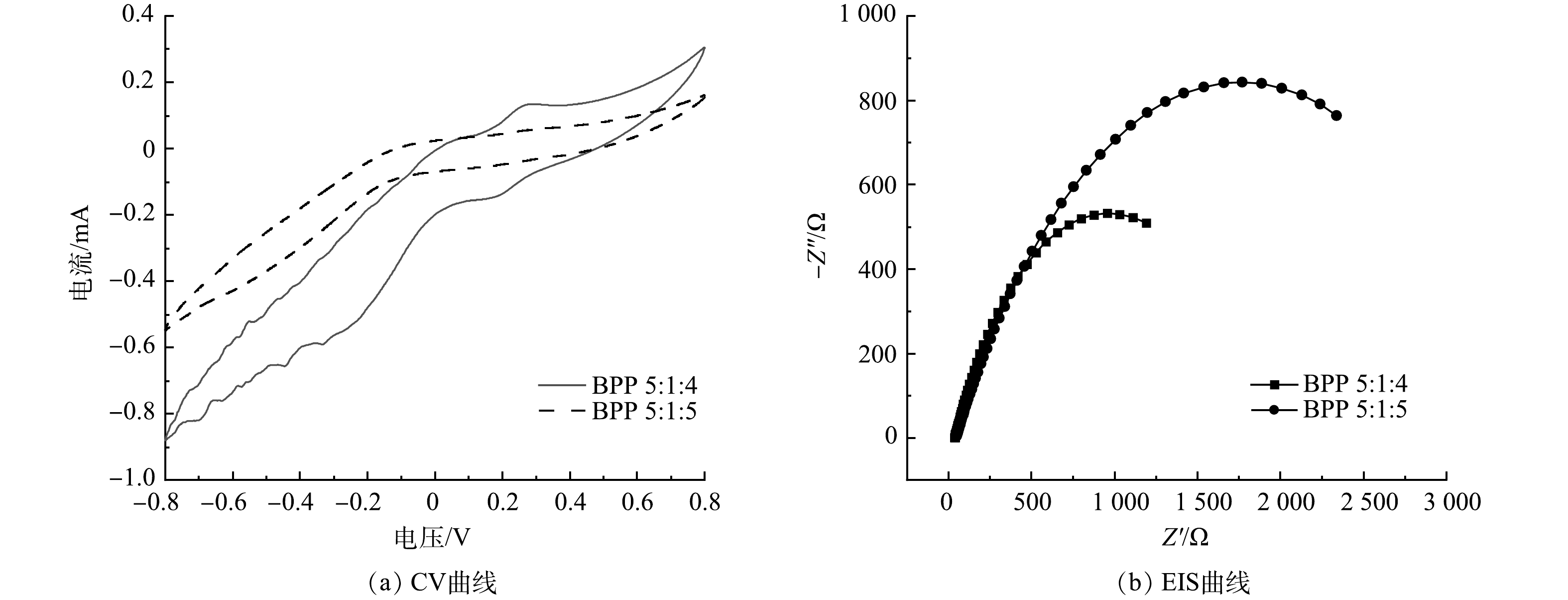

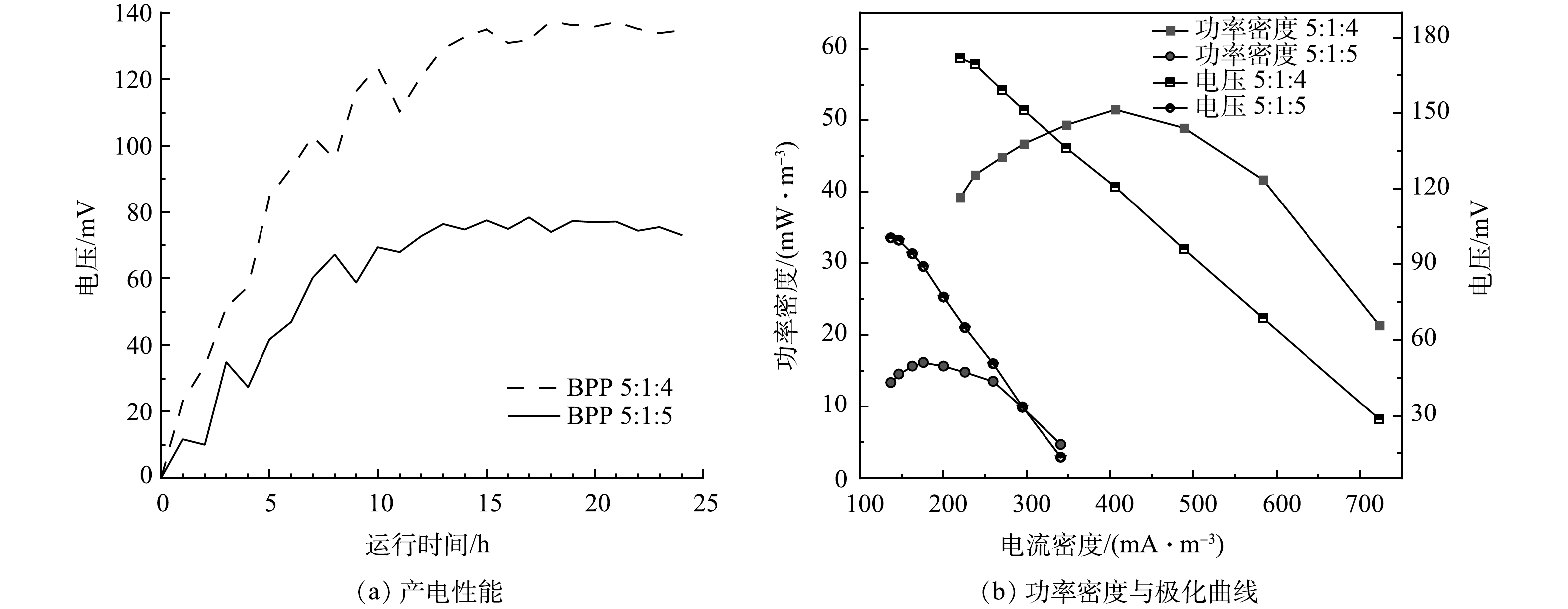

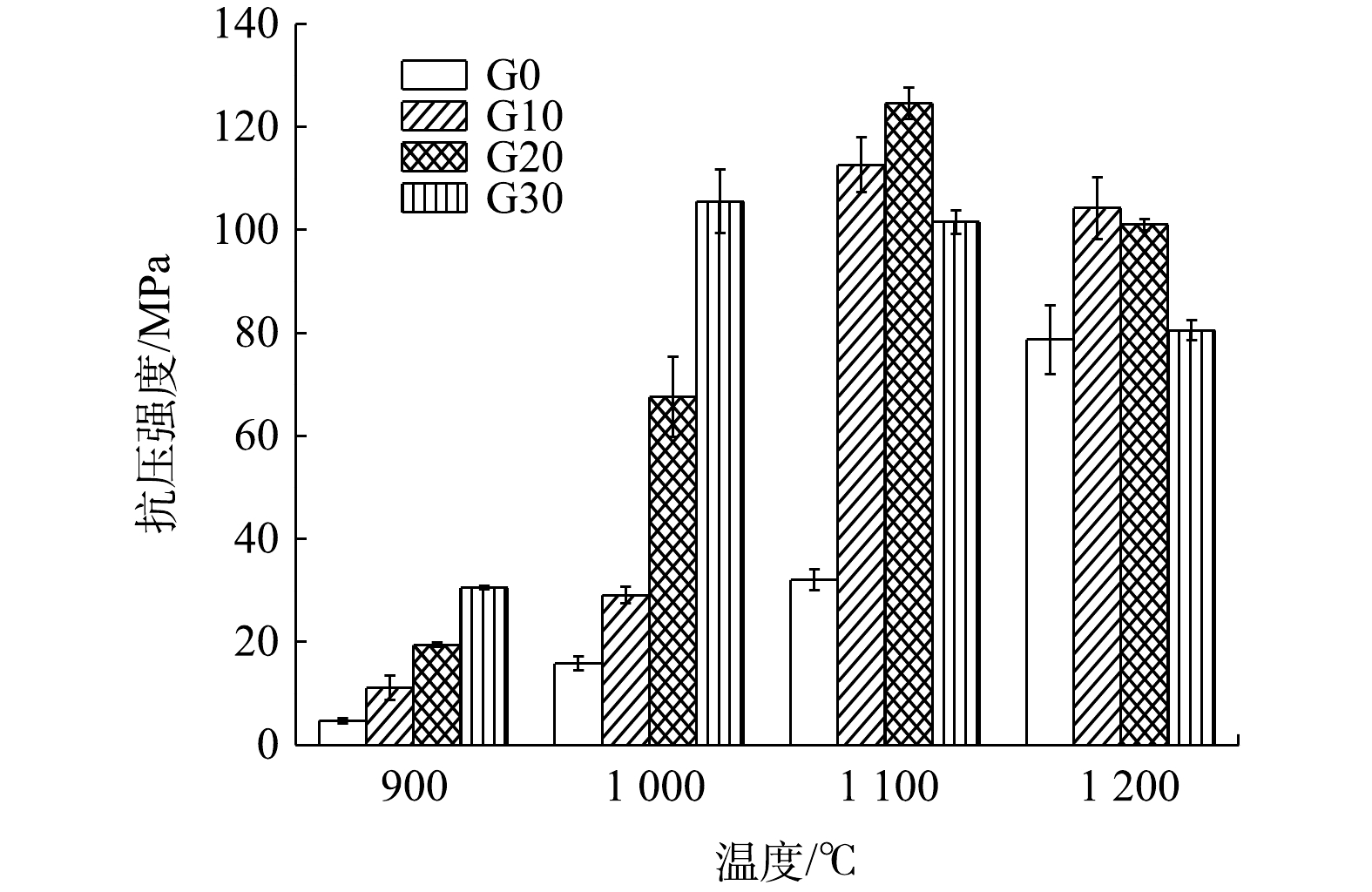

1)烧结砖的抗压强度。抗压强度测试是重要的力学强度指标,可以反映烧结砖承受压缩载荷的能力。图2结果表明,在900~1 100 ℃的条件下,各配比烧结砖的抗压强度均随着烧结温度的上升而增加。在900和1 000 ℃条件下,废玻璃含量对烧结砖抗压强度的影响较为明显。其原因在于,在温度低于1 000 ℃时,铁尾矿与粉煤灰间未发生反应,矿物骨架未形成,导致砖体结构松散[17]。但在此条件下,废玻璃已经达到软化温度,以流动相的形式存在于胚料中,冷却后将铁尾矿和粉煤灰胶结在一起。因此,温度低于1 000 ℃条件下烧结砖主要的力学强度都由玻璃提供[18]。随着烧结温度继续上升至1 000~1 100 ℃,铁尾矿和粉煤灰开始发生反应,烧结砖中的骨架结构形成;废玻璃进一步填充了骨架结构中的孔隙,并进一步提高了烧结砖的力学强度。此条件下所制备烧结砖的力学强度由矿物骨架和废玻璃共同提供。而在1 200 ℃的条件下,烧结砖出现过烧现象[19],呈现较深的红色。此时,砖胚出现膨胀、变形现象,抗压强度出现下降趋势。这是因为,过高的温度破坏了烧结砖的结构。在烧结温度过高或保温时间过长的条件下,烧结砖会形成大量的熔融体,烧结砖中的骨架结构被破坏,导致冷却后出现膨胀、变形的情况,从而降低了砖体的抗压强度。

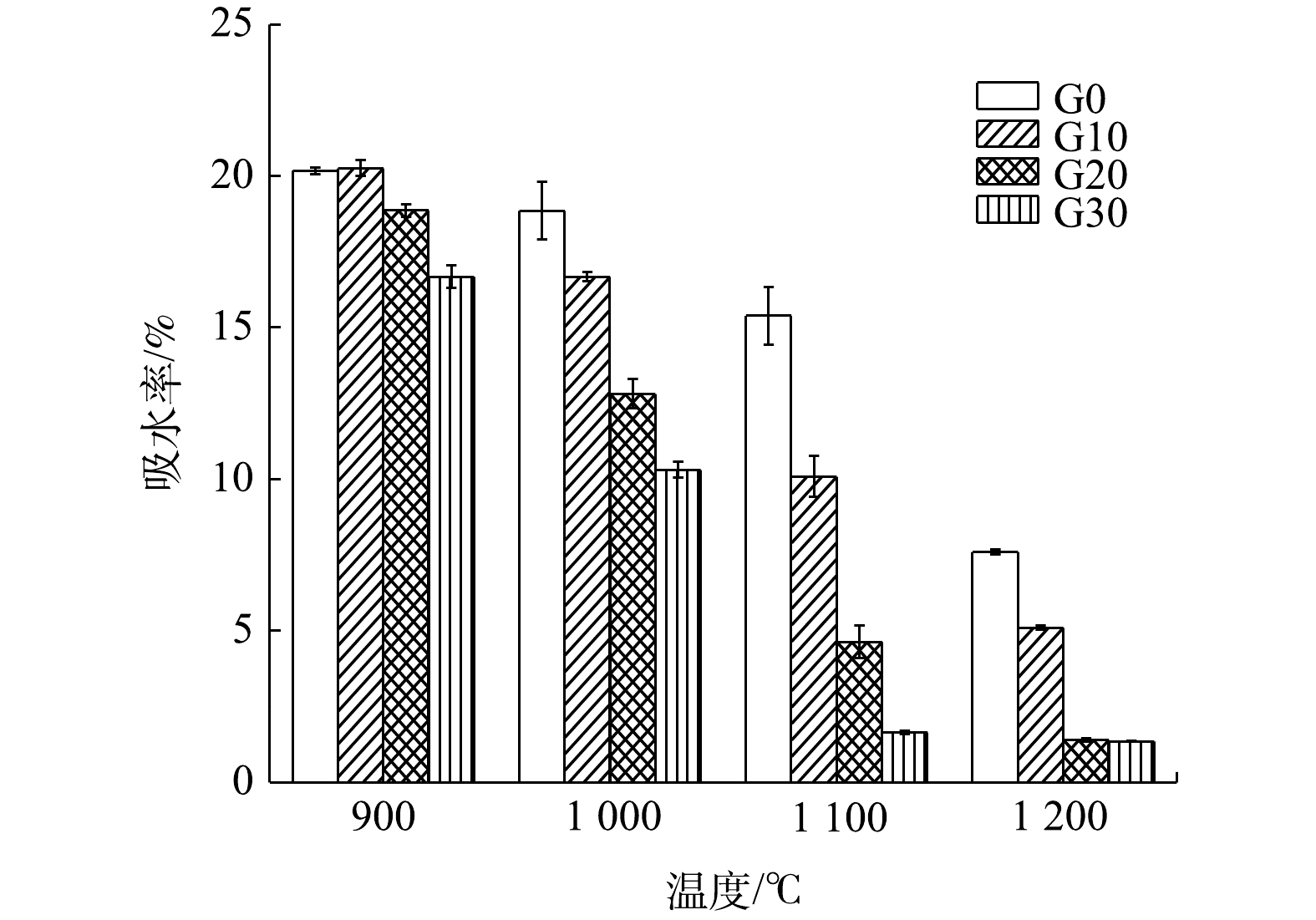

2)烧结砖的吸水率。吸水率可反映烧结砖的内部结构情况。从图3可以看出,在相同配比情况下,烧结砖的吸水率随着烧结温度上升而降低。在900 ℃下,各配比烧结砖的吸水率均在15%以上;而随着烧结温度上升至1 200 ℃,吸水率最低为1.3%。这说明,升高温度有助于烧结砖内部的致密化。在烧结过程中,烧结砖内部的气孔逐渐缩小,内部结构趋于致密化。在相同的烧结温度条件下,吸水率会随着废玻璃含量的增加而降低。

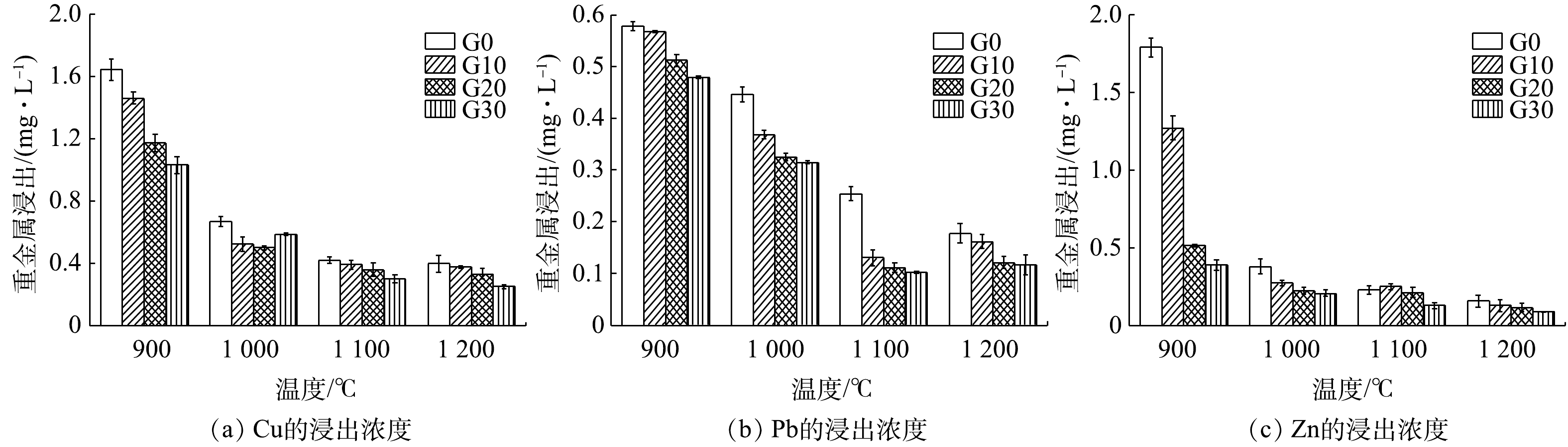

3)烧结砖的重金属浸出毒性。从图4中可以看出,烧结温度在900~1 000 ℃时,烧结砖中Cu、Pb、Zn的浸出浓度会随着废玻璃含量的增加而明显下降。MAO等[20]发现,玻璃在高温条件下的成型过程中会把重金属离子有效地包裹起来,形成玻璃体。当温度到达1 100~1 200 ℃,玻璃含量对重金属浸出的影响极小。这是因为,此时重金属间发生反应主要以稳定的结晶相形式存在,只有较少的重金属以不稳定的形式存在。

Cu、Pb、Zn的浸出浓度均随着烧结温度的上升而减小,最终在1 100 ℃趋于稳定。从图4(a)和(c)中可以看出,Cu和Zn在浸出特征上出现相似的规律;在温度为900 ℃时,重金属浸出浓度都较高,最高可达1.5 mg·L−1。在温度为900~1 000 ℃,3种重金属的浸出浓度下降均超过50%。有研究者[21]发现,Zn和Fe2O3在热反应过程中,可能会形成尖晶石结构ZnFe2O4,从而增加Zn的稳定性,不易被浸出。从图4(b)可以看出,Pb的浸出浓度随着温度的上升而下降。当温度为900时,Pb浸出浓度不足0.6 mg·L−1,远低于Cu和Zn的浸出浓度。这说明,当温度低于900 ℃的条件下,Pb比Cu和Zn更早地发生了固化反应。PbO在700 ℃的条件下,会与Al2O3发生化学反应,生成抗酸蚀能力强的PbAl2O4,从而抵制外界的酸性环境[22]。烧结砖中Cu、Pb、Zn的浸出浓度随烧结温度的升高均呈现降低的趋势。这说明,烧结过程对重金属的固化起到了积极作用,降低了重金属的释放风险。本研究制得的烧结砖中,重金属浸出浓度均低于《危险废物鉴别标准 浸出毒性鉴别》(GB 5085.3-2007)[23]的限值,符合安全标准。

综合分析抗压强度、吸水率、重金属浸出3个方面,采取G20作为最佳配比进行后续实验,以研究烧结过程中烧结砖的重金属形态分布变化、孔隙结构变化、物相结构的转化和微观形貌的变化。

-

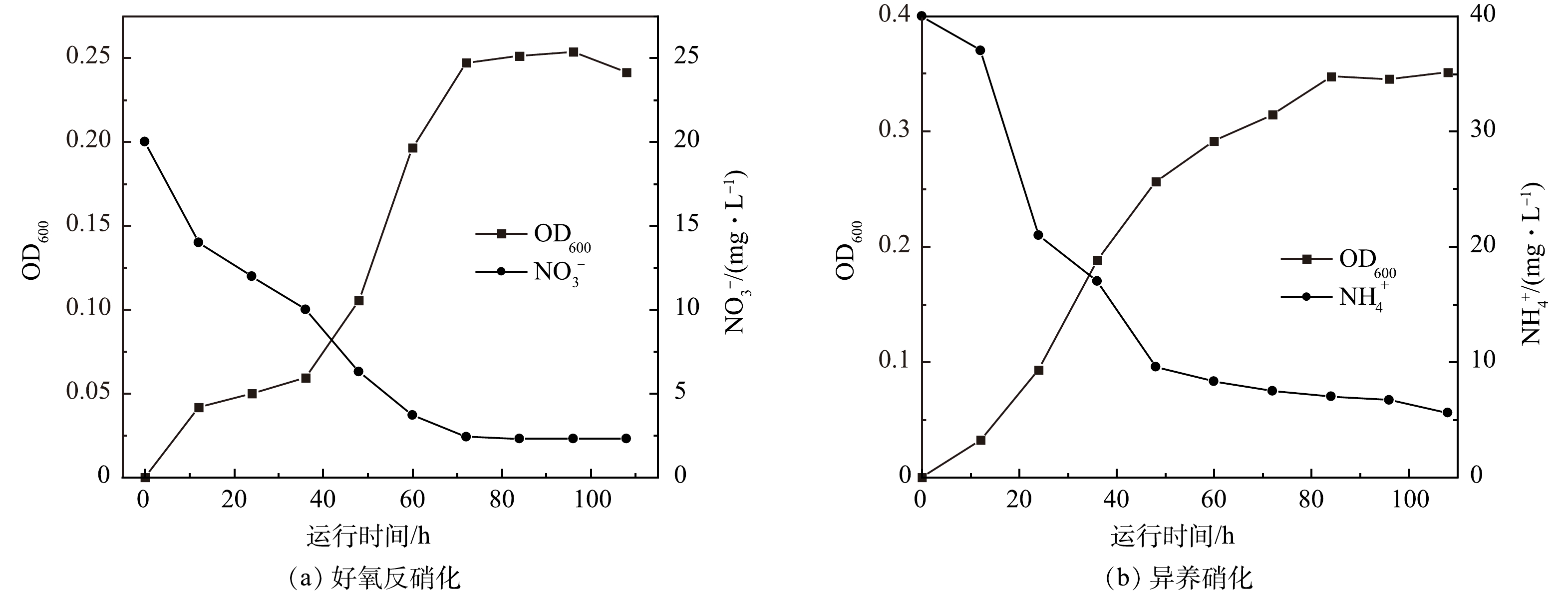

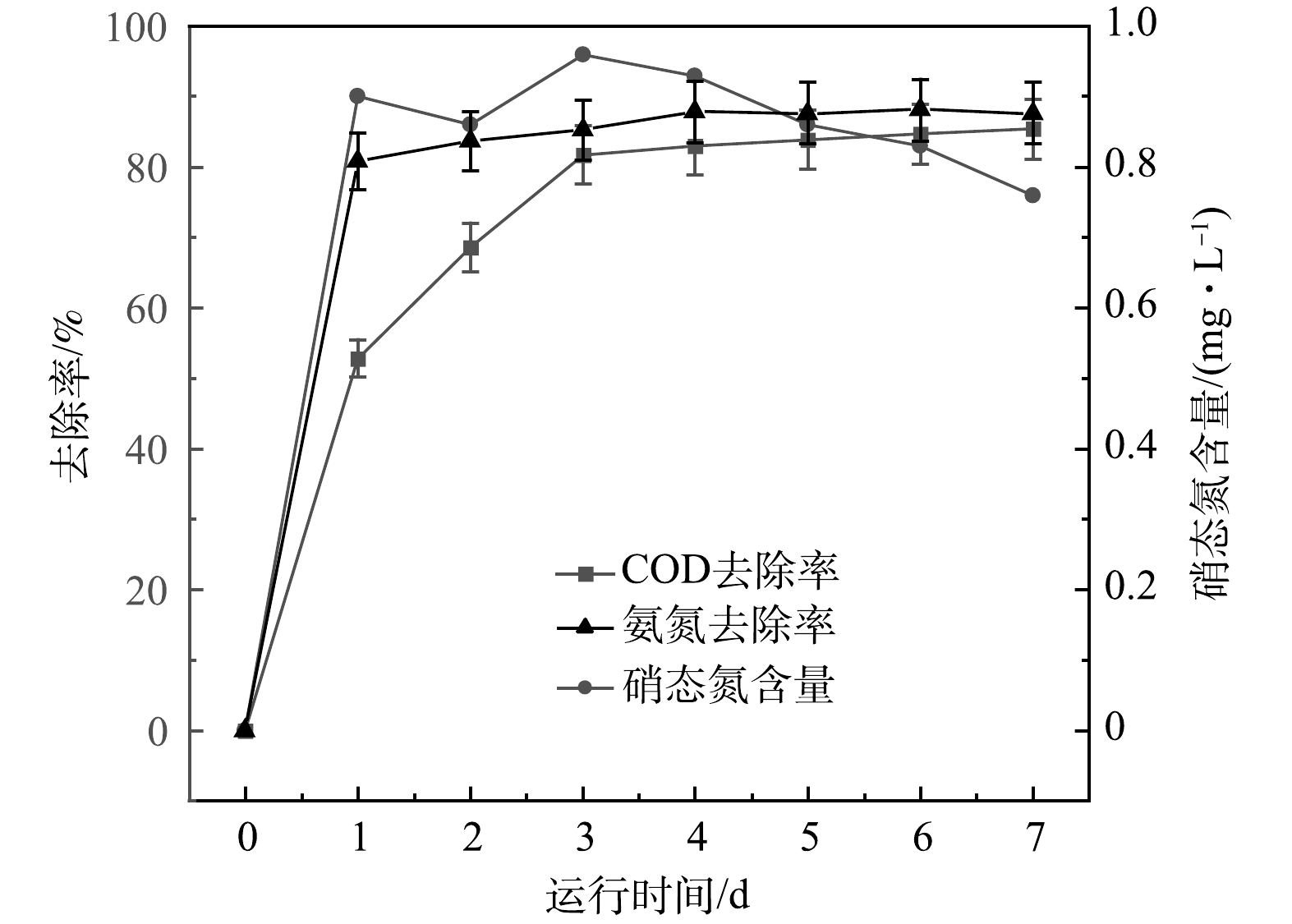

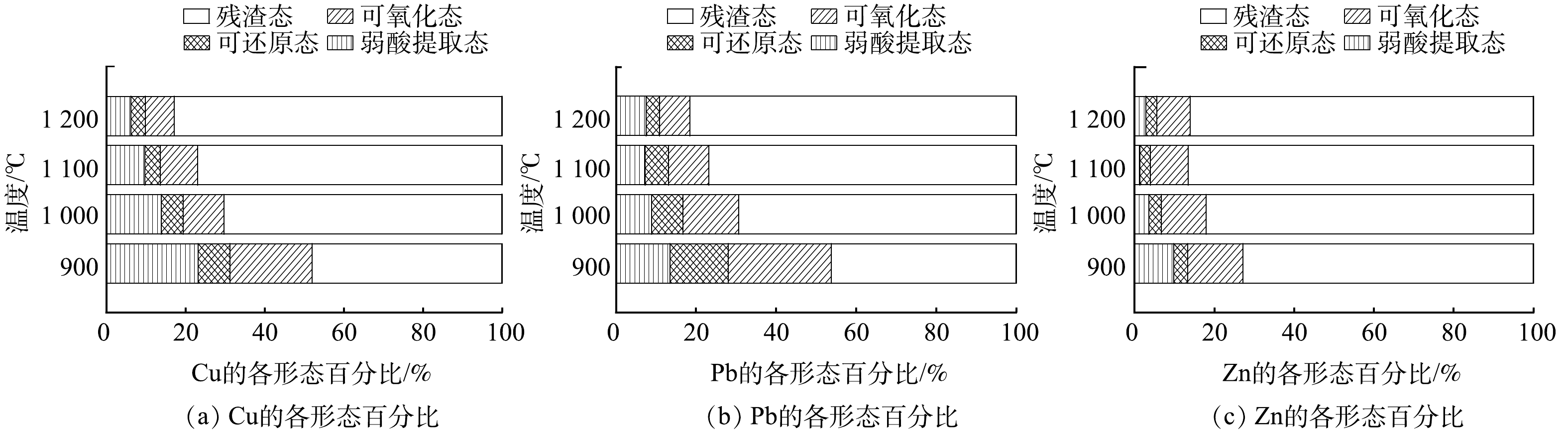

1)烧结砖的重金属形态分布。重金属的形态分布影响着烧结砖的浸出毒性与安全性;同时,也是影响重金属迁移转化能力强弱的重要因素。BCR法把重金属形态分为4种形态:弱酸提取态,是最容易提取的状态,与生物的毒性作用呈正相关;可还原态,是离子键结合的形态;可氧化态,只有在强氧化的条件下才会被释放的状态;残渣态,存在于矿物结晶相中,十分稳定,对生物的毒性作用最小。

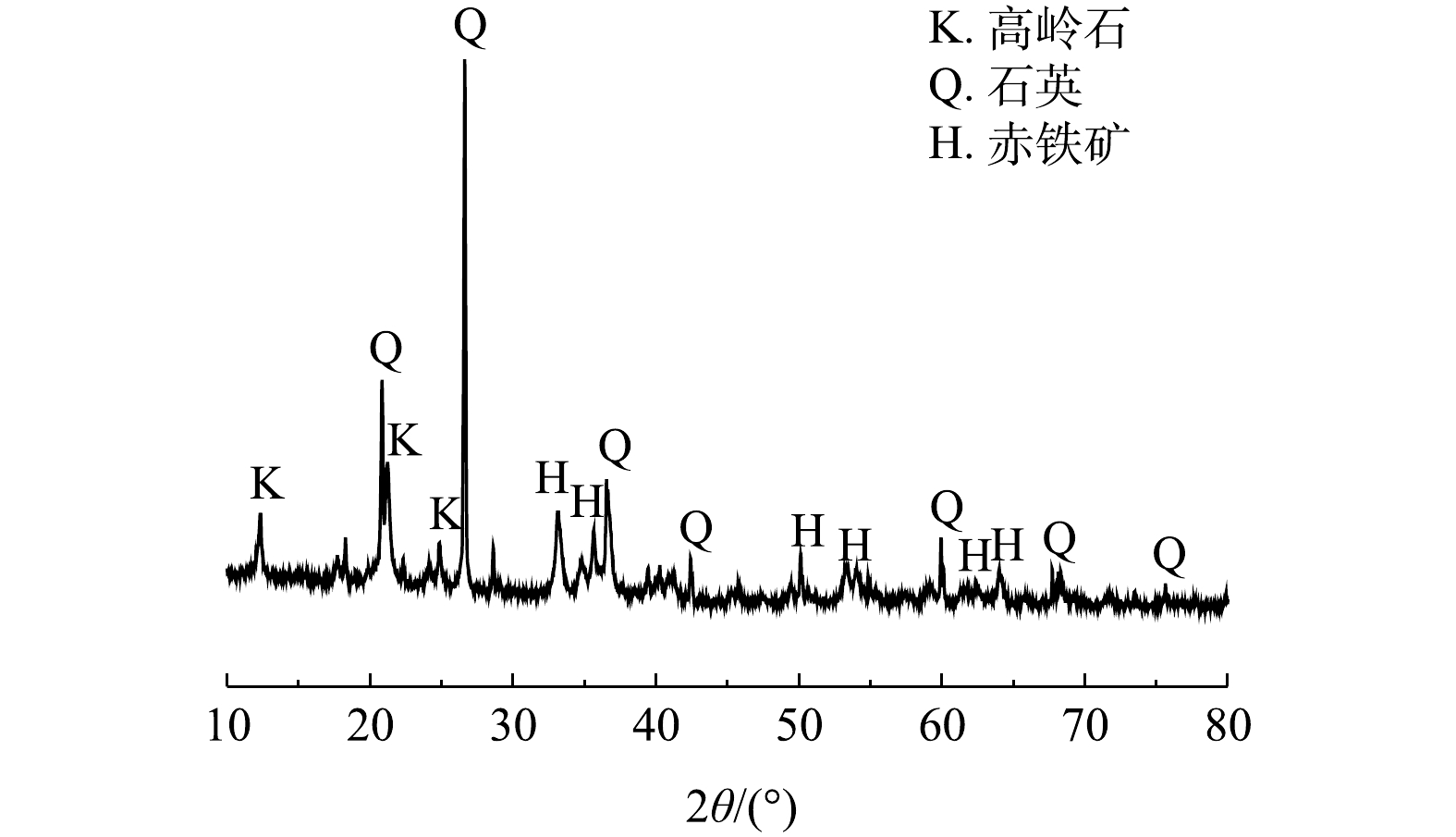

图5为G20配比在烧结过程中的重金属各形态分布变化。在温度为900 ℃的条件下,Pb和Cu的稳定性较差,Pb的形态分布为弱酸提取态13.56%、可还原态14.49%、可氧化态25.79%、残渣态46.16%。Cu形态分布为弱酸提取态23.26%、可还原态7.97%、可氧化态20.79%、残渣态47.98%。Pb和Cu的形态特征非常类似,残渣态均不足50%。随着烧结温度的上升,Pb和Cu的残渣态占比上升至81.55%和82.80%。与Pb和Cu相比,Zn的稳定性较好,在900 ℃下,主要形态为残渣态(72.82%)。这说明,Zn主要以结晶相的形式存在,稳定性较好。随着烧结温度上升,Zn的形态转化没有Pb和Cu明显,迁移性较差,因而更稳定。结合图4和图5进行综合分析可知,残渣态占比的上升往往伴随着重金属浸出浓度的下降。这说明重金属在烧结固化过程中,以结晶相的形式而稳定下来。

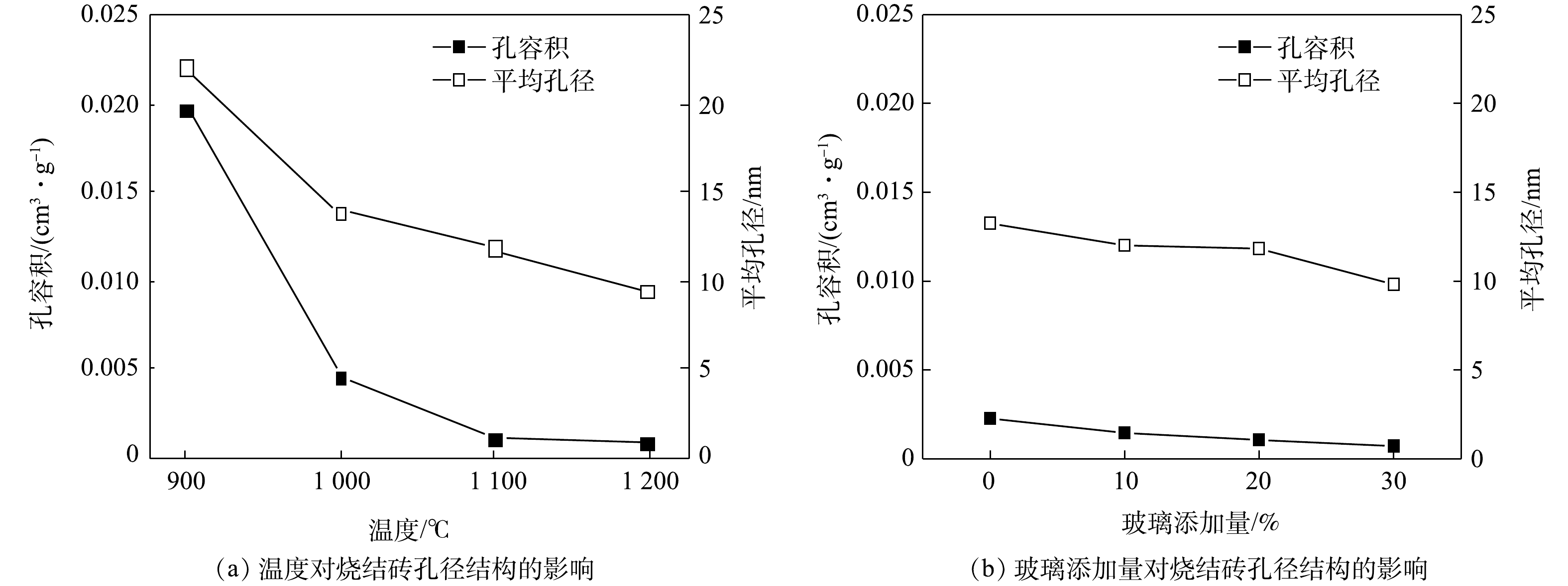

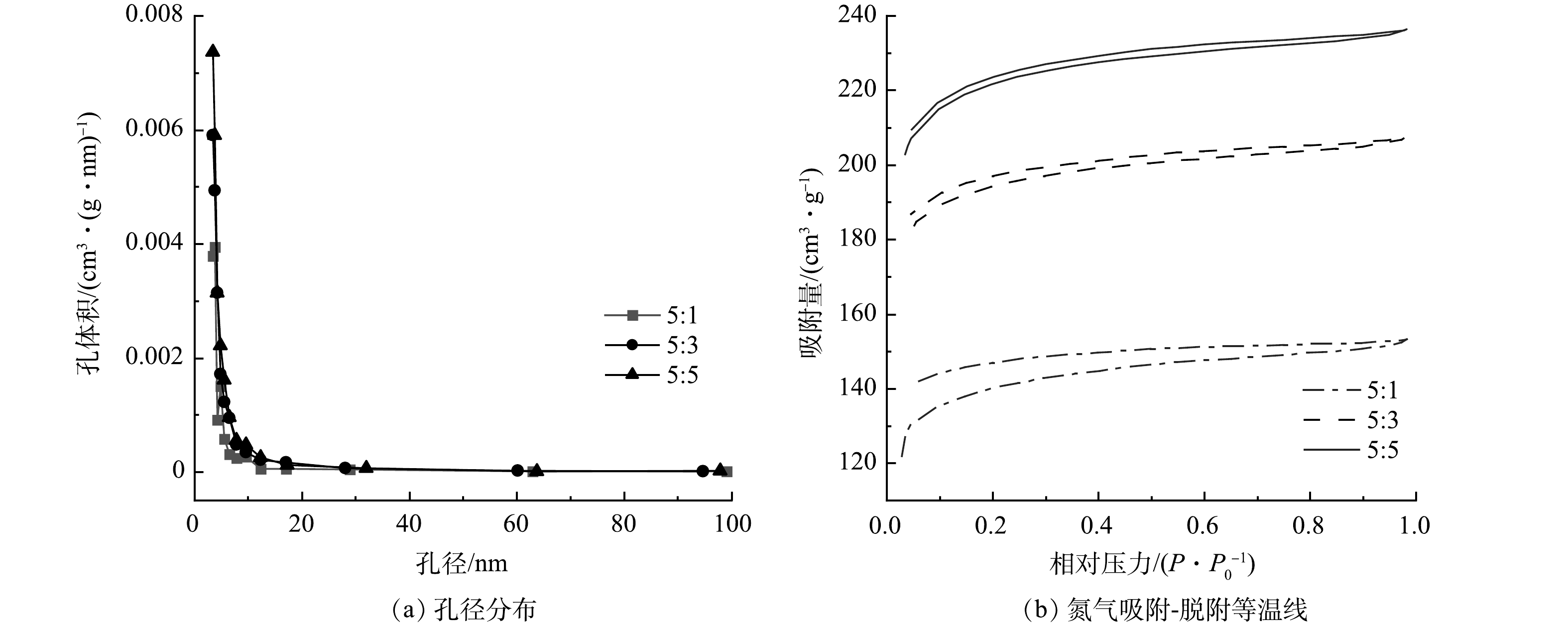

2)烧结砖的孔隙结构变化。孔容积和孔径大小可以反映烧结砖内部的孔隙结构。图6(a)为G20配比烧结砖在烧结过程中孔容积和孔径大小的变化情况。烧结温度对孔容积的影响较为明显。在温度为900 ℃的条件下,孔容积最大,达到了0.019 cm3·g−1;而当温度上升至1 000 ℃时,孔容积迅速下降至0.004 5 cm3·g−1。随着温度继续升高到1 100 ℃,孔容积进一步下降到0.001 1 cm3·g−1;当温度到达1 200 ℃时,孔容积下降到0.001 cm3·g−1。这说明,当烧结温度为900 ℃时,烧结砖内部存在大量的孔隙结构;而随着温度的升高,孔隙结构逐渐减少,趋于致密化。

孔径大小随着温度的升高而降低,当烧结温度为900 ℃时,孔径大小为22.1 nm;而随着温度上升至1 200 ℃,孔径最终降低至9.3 nm。从图6(b)可以看到,废玻璃含量的增加也会降低孔径大小和孔容积。相比较于图6(a),图6(b)中孔容积和孔径大小的变化并不显著。综合分析可知,温度对孔径大小的影响大于废玻璃含量对孔径大小的影响。孔容积和孔径大小的变化趋势与吸水率的变化趋势一致。这说明,孔隙结构可能是影响吸水率大小的内部因素。孔径结构也会影响重金属浸出的反应过程。这是因为,较小的孔径会阻碍浸出液与重金属离子间的接触,而松散的结构则有利于重金属的释放。

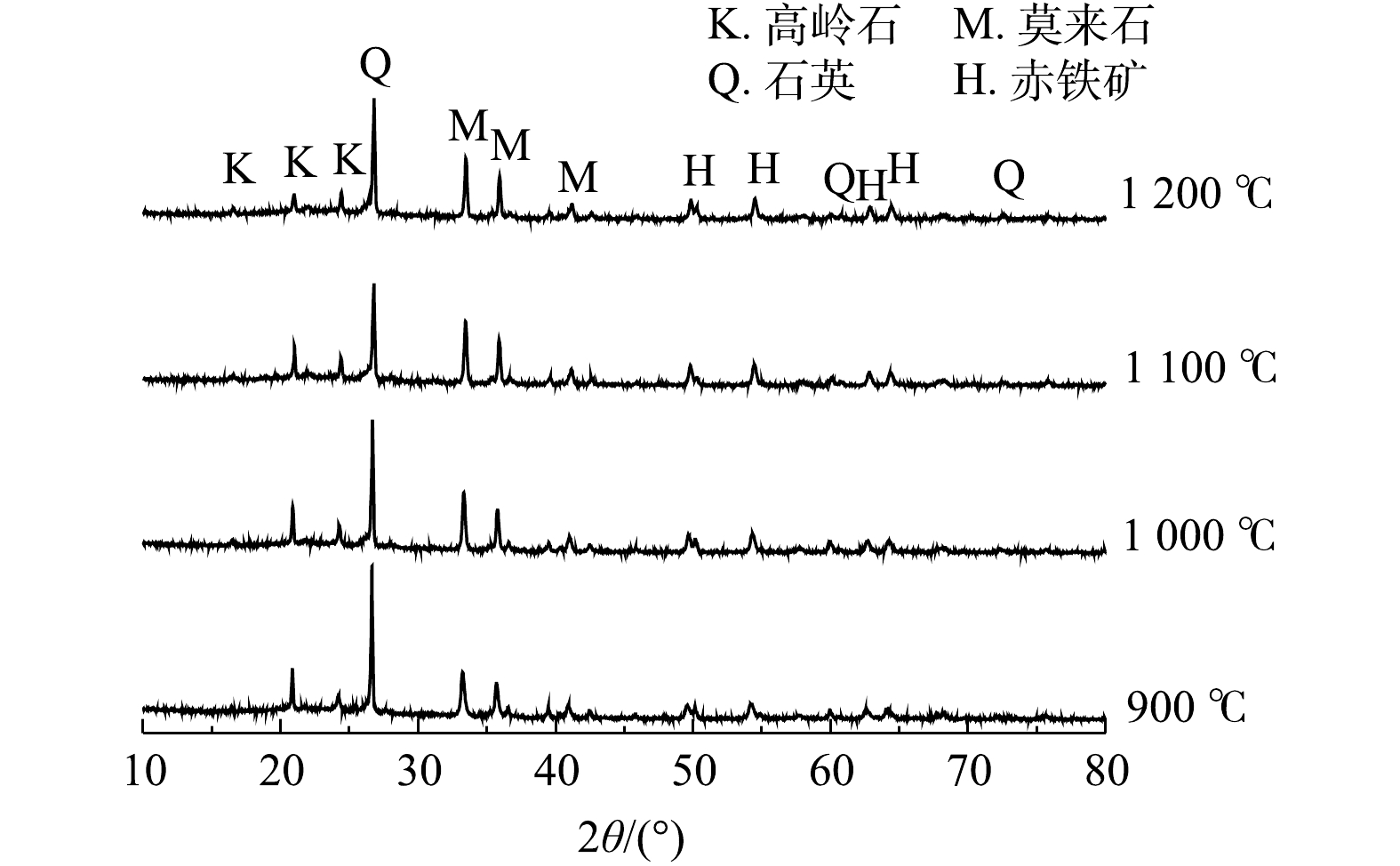

3)烧结砖的物相结构变化。图7为G20配比烧结砖在烧结过程中物相结构的变化。从图7中可以看出,烧结砖主要矿物相为高岭石、石英、莫来石和赤铁矿。烧结砖中的赤铁矿相在烧结过程中并未发生明显变化。高岭石和石英的特征峰随着烧结温度上升而降低,莫来石相的特征峰随着烧结温度的上升而升高。有研究者发现[24-25],烧结砖的结构主要是在烧结条件下形成了莫来石晶相结构。因此可推测,在本研究中的烧结过程中,石英相与高岭石相反应生成了莫来石相。莫来石相是一种常见的硅铝酸盐结构,硬度、强度等力学性能较优异,可以有效地增加烧结砖的抗压强度。

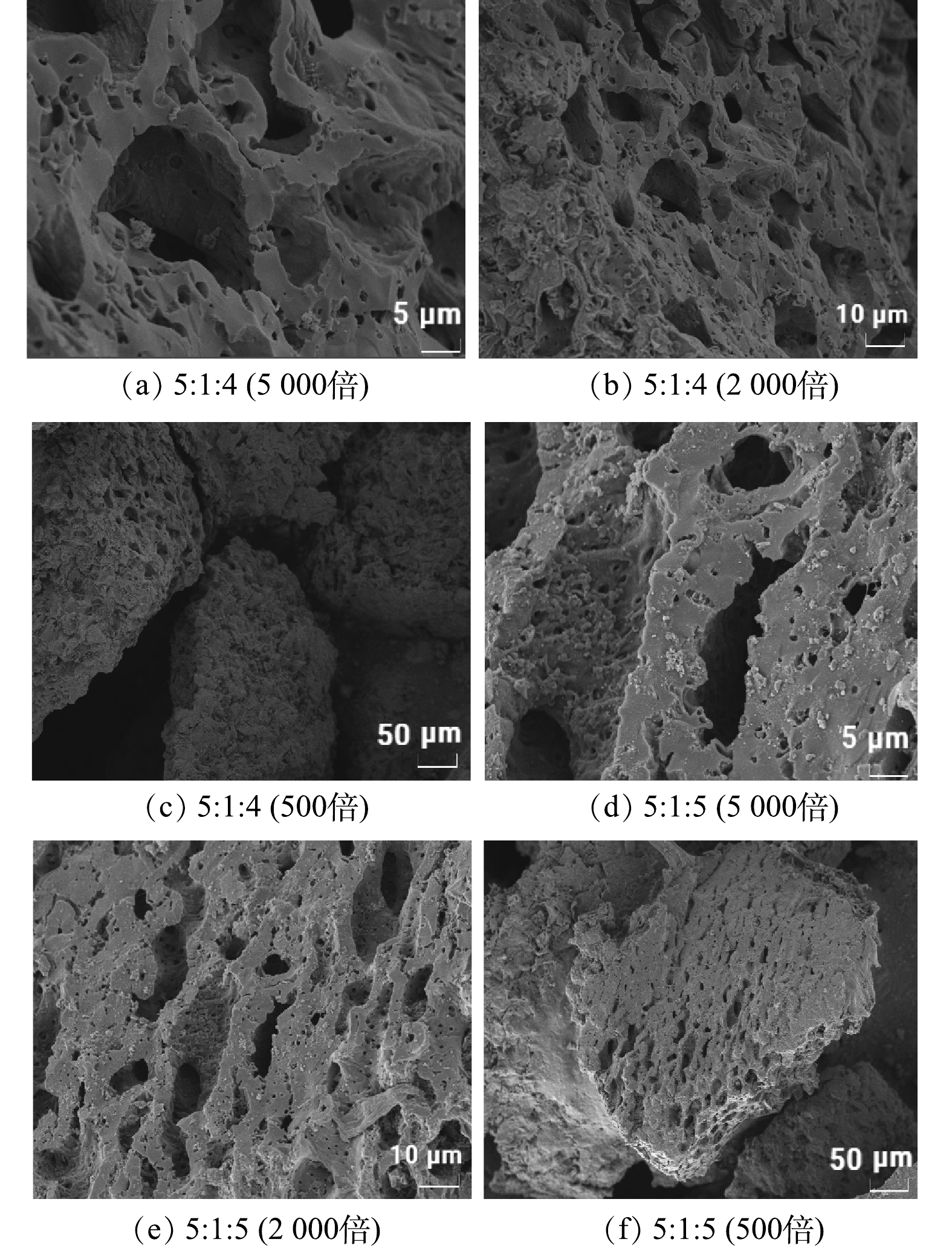

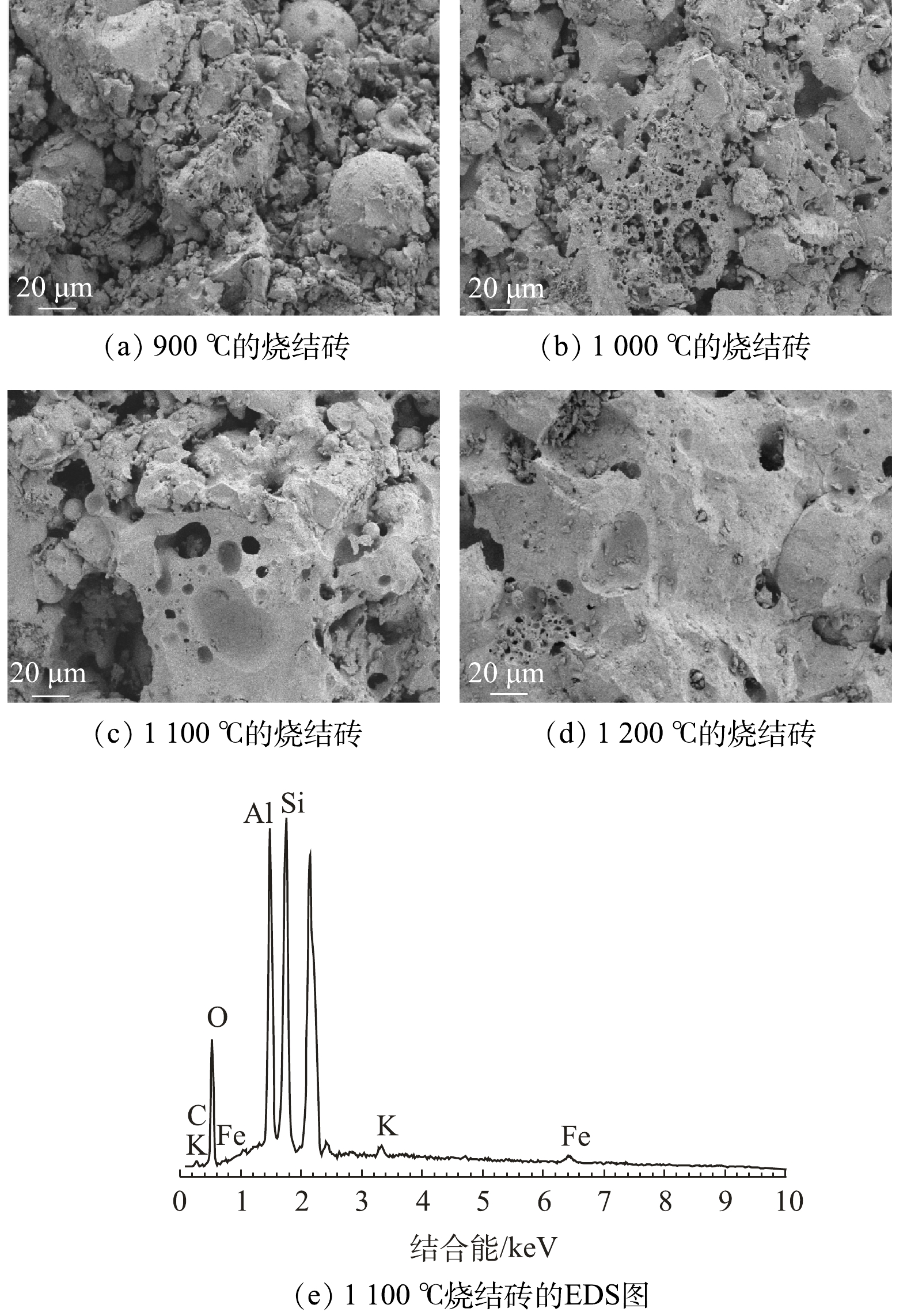

4)烧结砖的微观形貌变化。图8展现了烧结砖在烧结过程中的微观形貌变化。图8(a)显示了900 ℃下烧结砖的微观形态,可以看出,其表面粗糙,有许多大小不一的球形颗粒离散地分布在烧结砖表面。这说明,此时物料间还未开始发生反应,颗粒间的空隙较大。由图8(b)~图8(d)可以看出,随着烧结温度从1 000 ℃升高到1 200 ℃,离散的颗粒不断减少,颗粒间的空隙变小,孔径不断变小。由此可知,烧结过程是一个内部结构致密化的过程,烧结温度的上升会降低孔径大小。经过图8(e)EDS表征,可确定烧结砖结构主要由Si、Al、O元素组成。这说明,烧结砖中矿物骨架结构主要为硅铝酸盐结构。综合XRD结果(图7)可知,烧结砖的物相结构中,只有莫来石相是硅铝酸盐结构。因此推测,图8烧结砖中的硅铝酸盐结构有可能是莫来石结构。

2.1. 供试原料制砖可行性

2.2. 烧结砖的基本性能

2.3. 烧结砖制备的固化机理

-

1)在烧结温度为1 100 ℃、玻璃含量为20%的最优条件下,烧结砖的抗压强度可达124 MPa、吸水率为4.63%;其重金属浸出浓度远低于《危险废物鉴别标准 浸出毒性鉴别》(GB 5085.3-2007)的限值。

2)烧结砖的固化机理可能是,在烧结过程中,烧结砖内形成以莫来石相为主的硅铝酸盐结构,以导致烧结砖的孔径和孔容积不断减小,使得烧结砖孔隙结构致密化,提高了烧结砖的强度。

下载:

下载: