-

在装卸、堆取和露天存放过程中,铁矿粉在作业机械的剪切、抛洒以及自然风力作用下容易扬尘,可吸入颗粒物PM10浓度高达182.2 μg·m−3。铁矿粉的无组织排放不仅造成铁矿粉自身的损耗,也危害从业人员健康。钢铁生产企业因此导致的年损耗率高达0.66%[1],直接经济损失巨大。外逸的铁矿粉影响周边的环境空气质量,超标的铁离子及其伴生的镉离子导致水体和土地污染[2],金属含量超标的水源灌溉,植物种子的发芽率降低,影响正常成苗和植物生长。铁是人体的必需微量元素之一,但摄入过量则会引起金属中毒。我国饮用水源地的铁含量整体超标且呈不断上升趋势,超标倍数高达8.80倍,超标率高达86.1%[3]。因此,提高钢铁企业料场和矿区等污染源的控制效率,提高空气、水体和土地安全性的意义重大。

作为洒水抑尘的添加剂,抑尘剂通过润湿、保湿、聚集和固结等方式显著降低了煤炭[4]、渣土[5]和道路扬尘[6]的排放风险。但铁矿粉呈正电性[7],颗粒表面Fe-OH的极性大,这也决定了铁矿粉抑尘剂的特殊性。由于物理化学性质特殊,国内外对铁矿粉抑尘剂的技术研发进展缓慢,研究内容仍然停留在传统品种。表面活性剂可以润湿铁矿粉但无法提高内聚力,对PM10的控制效果不及水[8]。氯化钙和偏硅酸钠对PM10的控制效率达到85%,但这些无机盐腐蚀金属、严重影响植物生长,而且SiO2影响高炉冶炼[9]。制备安全、高效的抑尘剂,改善颗粒之间的相互作用,提高铁矿粉的稳定性和控制效率尤为必要。

铁矿粉是一种特殊的污染源,既影响空气质量、又影响水体和土地安全;铁矿粉扬尘既危害环境,又导致直接经济损失[1];其表面性质不同于常见的颗粒物[7],且矿粉品质容易受抑尘剂影响[9],因此抑尘剂技术研发进展缓慢。本研究从含水率、Zeta电位、表面形貌、化学组成与晶体结构等基本性质出发,探讨铁矿粉与水性聚合物的之间的相互作用,估算装卸过程和露天堆场的湿控制效率、现场测定露天堆场的规模化效果,提高铁矿粉扬尘的控制效率。

全文HTML

-

丙烯酸、甲基丙烯酸甲酯、丙烯酸丁酯和苯乙烯通过幂级加料方式合成水性聚合物抑尘剂[10],水溶胶状态,105 ℃固含量为39.7%,pH 为6.7。

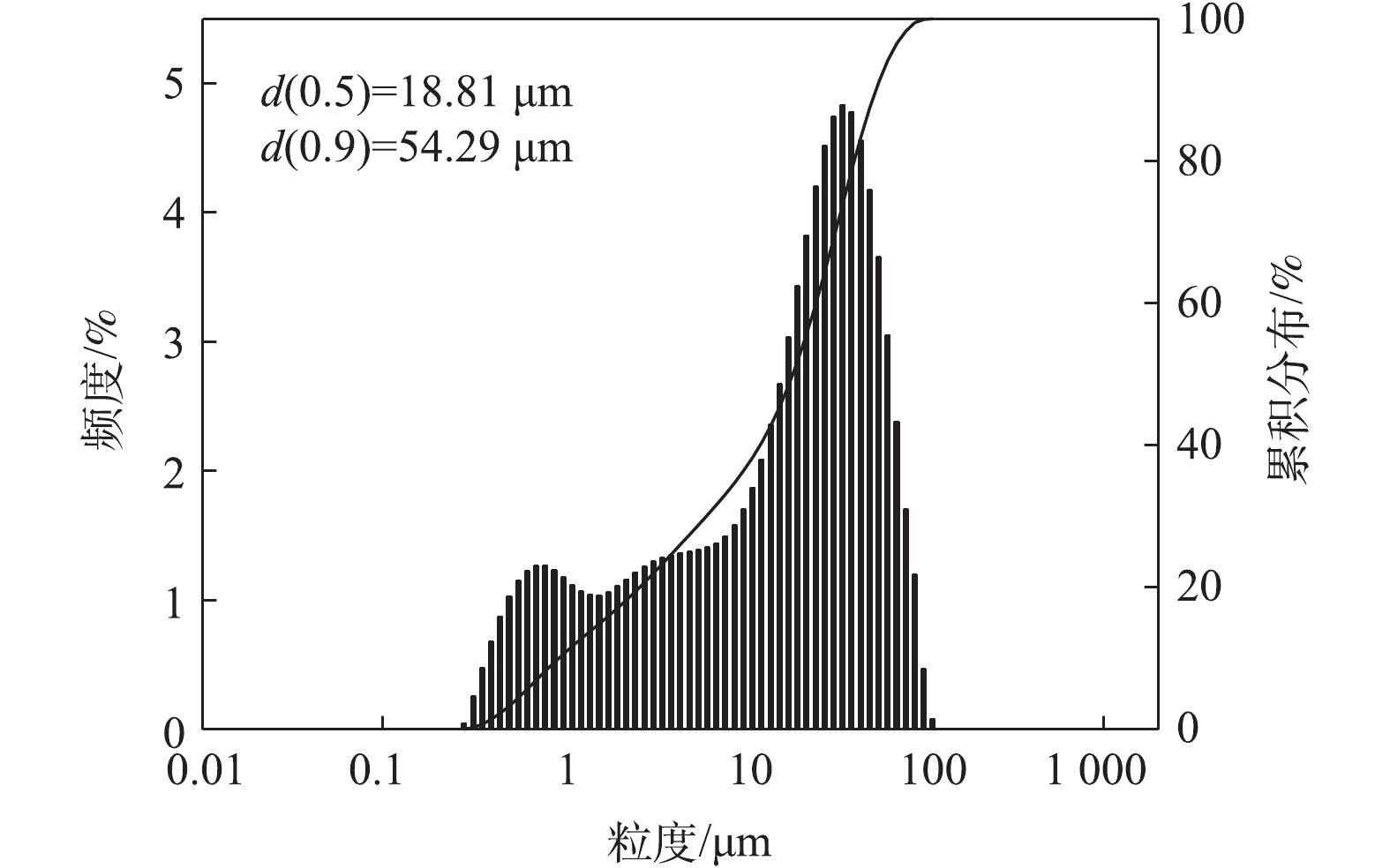

选择澳洲产铁矿粉,红褐色,某钢铁公司提供,自然干燥。过80目筛的粒级用于实验,其中,过200目筛的粒级占47.3%。由于扬尘主要来自75 μm以下的颗粒,参照AP-42方法[11],采用Mastersizer 2000激光粒度仪测定200目筛下粒级的粒度分布,如图1所示。可以看出,铁矿粉的中值粒径为18.81 μm,30 μm以下粒级的质量分数为66.93%。以ARL QUANT型X射线荧光光谱仪(XRF)测得其化学组成,结果见表1,Fe2O3含量为82.56%。

-

1)含水率。铁矿粉的真密度为5.2 kg·m−3,但堆密度只有1.5 kg·m−3左右[12]。洒水的主要作用是增加堆密度和内聚力,在一定时间内降低风力侵蚀性。春夏之交是高扬尘季节,以此作为测试条件。将初始质量W0为20.0 g的铁矿粉置于φ100 mm培养皿中,喷洒5.0 g浓度为2.0%的抑尘剂水溶液至充分湿润,纯粹聚合物的质量为铁矿粉的0.5%;作为对比,蒸馏水代替抑尘剂水溶液,重复以上操作。测定30 ℃、35%相对湿度下t时刻的样品质量Wt,其含水率如式(1)所示。

式中:P为含水率;Wt为t时刻的样品质量,g;W0为初始样品质量,g。

2) Zeta电位。根据式(2),在重力加速度g、空气密度ρ0、空气黏度γ和悬浮颗粒物密度ρ已确定时,其沉降速度ug取决于直径D[13]。直径增大,则降尘加快、空中滞留时间短、漂移范围小;粉体稳定性提高,风力扬尘量降低。

式中:g为重力加速度;ρ0为空气密度;γ为空气黏度;ρ为悬浮颗粒物密度;ug为沉降速度;D为直径。

铁矿粉呈正电性[7],聚集能力差,聚集体粒径低。借助Zeta电位,分析聚合物与铁矿粉颗粒之间的相互作用,藉以促进颗粒聚集。配制浓度为0.1%的铁矿粉悬浮液,以Nano-ZS90型电位分析仪测定Zeta电位。

3)表面形貌。聚集体进一步聚集,即可相互胶结成膜[14],以篷布覆盖的方式封闭粉体表面,从根本上避免了扬尘,摆脱了对含水率的依赖。喷洒之后的铁矿粉在室温下干燥,喷金制样,以Nova Nano SEM450型电镜观察表面状态特征。

4) X射线衍射分析。采用Bruker-D8 Focus型X-射线衍射仪(XRD)测定晶体结构,考察抑尘剂对铁矿粉结构和组成的影响[9]。扫描角度5°~80°,扫描速度12 (°)·min−1。

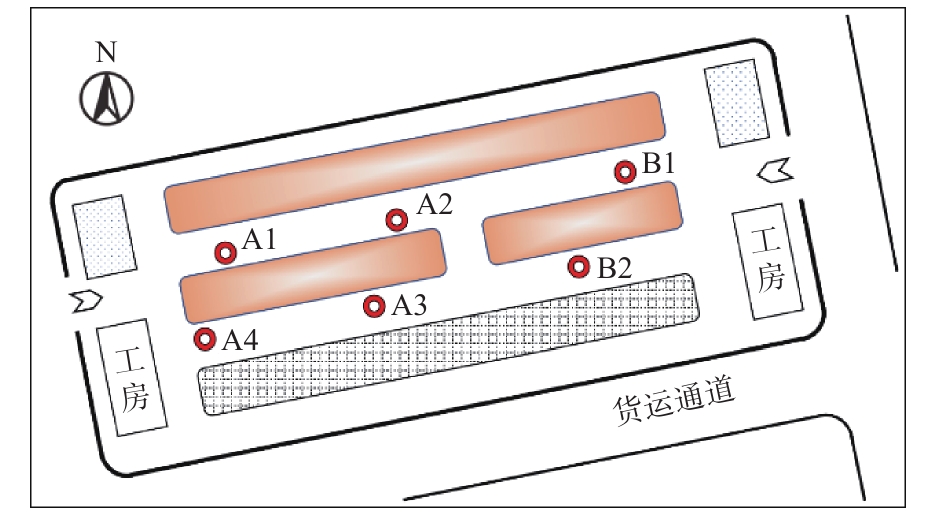

5)现场应用。在实验室评价的基础上,实施露天堆场的规模化抑尘。如图2所示,料场占地约60 hm2,南侧的料条以尼龙网苫盖,北侧料条正在堆取、装卸作业。中间料条为棱台状,地面长度740 m宽度40 m垂直高度7.5 m,东西两段相隔6 m。选择西段料条和料场地面为抑尘区域,东段料条作为对比区域。

距地面1.5 m处安置Trak 8530型气溶胶监测仪,跟踪监测PM2.5和PM10浓度。根据《环境空气质量监测点位布设技术规范(试行)》(HJ 664-2013)布设监测点位,A1、A2、A3和A4的浓度平均值作为抑尘区域的浓度,B1和B2的平均值作为对比区域的浓度。

2018年9月16日,架设扬尘在线物联网(IOT)系统,实时监测2.5 m高处的气象参数和颗粒物浓度(图3)。在上午10点30分,气温18 ℃相对湿度25%,晴,西北风,风速7.8 m·s−1,PM2.5和PM10浓度分别为46 μg·m−3和85 μg·m−3。

根据气象参数、颗粒物浓度和现场条件,采用多功能抑尘车喷洒地面,如图4所示。抑尘剂浓度为1.0%,喷洒量为1.0 kg·m−2,调整喷嘴的间隙和角度,后向喷洒、逆风行驶,车速不高于8 km·h−1;使用车载式高压喷枪喷洒西段料条,喷洒量约1.2 kg·m−2,自上而下蛇形操作。对比区域不做喷洒。

1.1. 实验材料

1.2. 实验方法

-

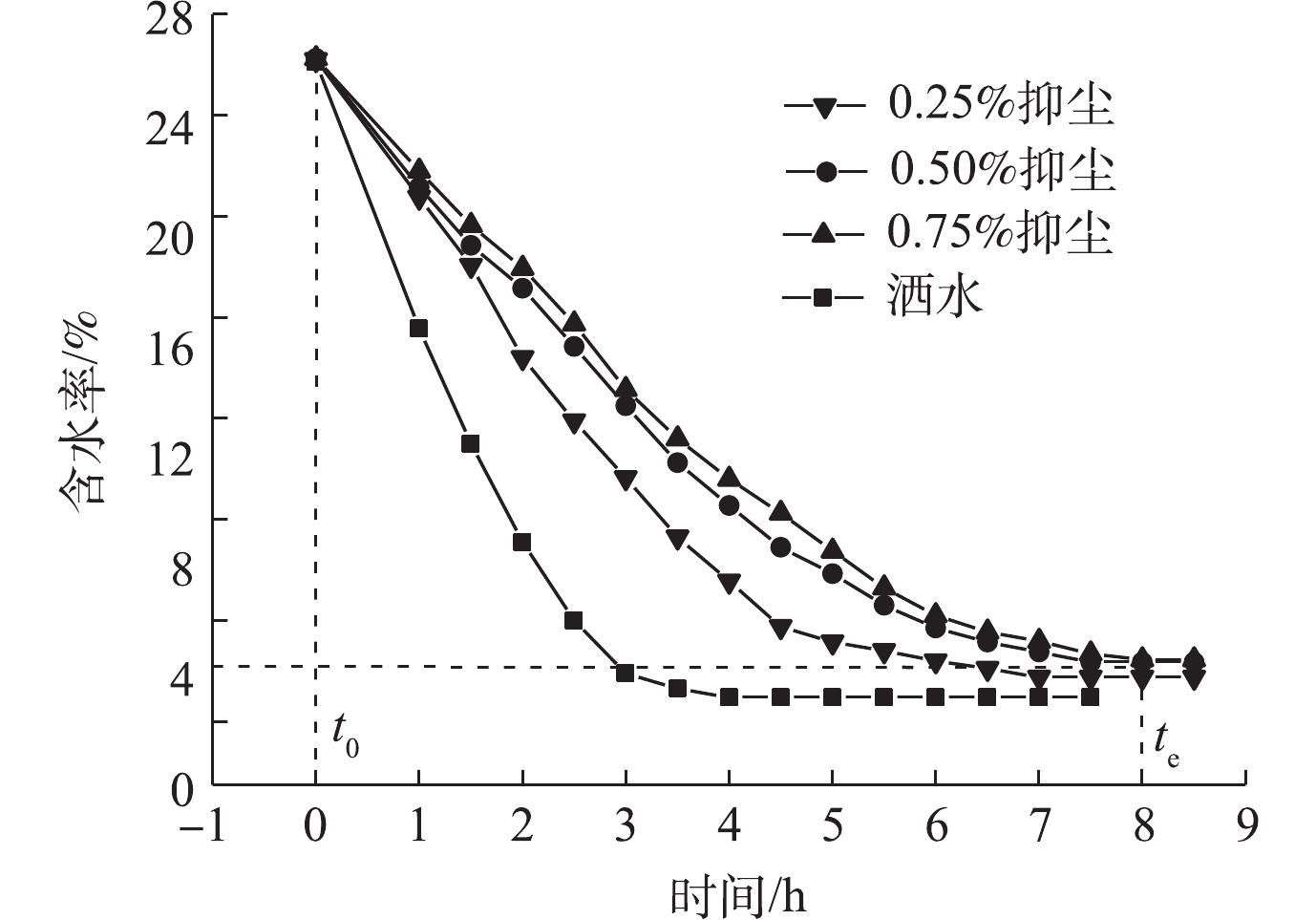

1)平均含水率。如图5所示,喷洒抑尘剂后,铁矿粉在30 ℃、35%相对湿度下失水缓慢。聚合物质量用量为0.25%、0.5%和0.75%时,含水率依次增大,但至完全干燥,即失水达到平衡时3者差别不大。因此,集中讨论0.5%用量的铁矿粉。其平衡时间(te)为8 h,平衡含水率为2.35%。洒水样品的含水率为0.95%,平衡时间为4 h。

含水率P随时间t的变化规律[6]如式(3)所示。

式中:P为含水率;A、B为常数。

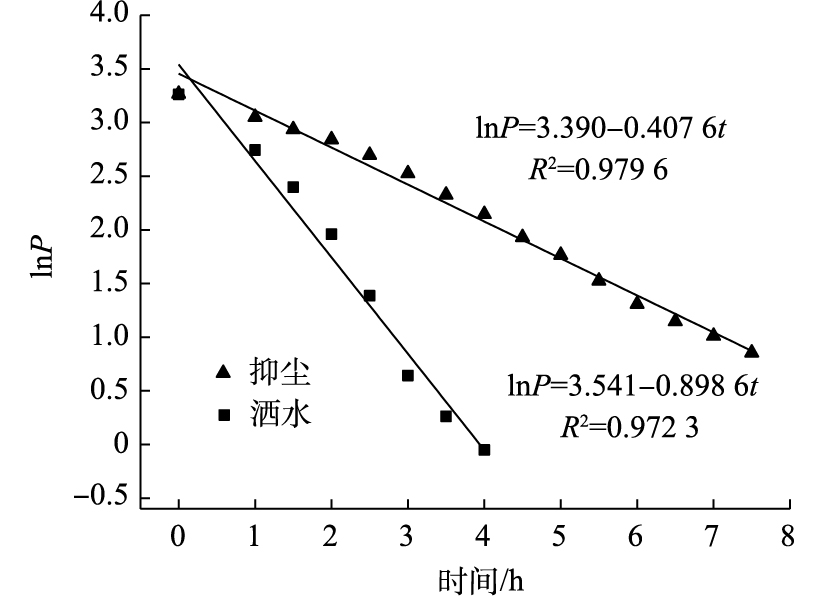

方程(3)取自然对数,回归结果见图6。根据式(4),抑尘铁矿粉从开始干燥的时刻t0到平衡时刻te,即干燥过程中抑尘铁矿粉的平均含水率为10.77%,洒水铁矿粉为4.8%。

式中:Pav为平均含水率;t0为开始干燥时间,h;te为平衡时间,h。

2)装卸过程扬尘的控制效率。根据式(5),可估算抑尘铁矿粉和洒水铁矿粉的排放系数Es和E0[15],结果见表2。根据式(6),可计算抑尘剂对装卸过程扬尘的控制效率η,结果为67.78%。

式中:E为堆场装卸扬尘的排放系数,g·t−1;ki为物料的粒度乘数,TSP、PM10和PM2.5分别为0.74、0.35和0.053;u为地面平均风速,以9.5 m·s−1计,属5级风力。

式中:η为控制效率;Es为抑尘铁矿粉的排放系数,g·t−1;E0为洒水铁矿粉的排放系数,g·t−1。

3)露天堆场扬尘的控制效率。式(7)是刘琴[16]建立的澳洲铁矿粉扬尘排放模型,据此计算9.5 m·s−1风速下洒水铁矿粉的扬尘量Q0,结果为33.68 g·(kg·h)−1,抑尘之后的扬尘量Qs为2.03 g·(kg·h)−1。参照式(6),抑尘剂对露天堆场铁矿粉扬尘的控制效率为93.96%。

式中:Q为扬尘量,g·(kg·h)−1;u为风速,m·s−1。

-

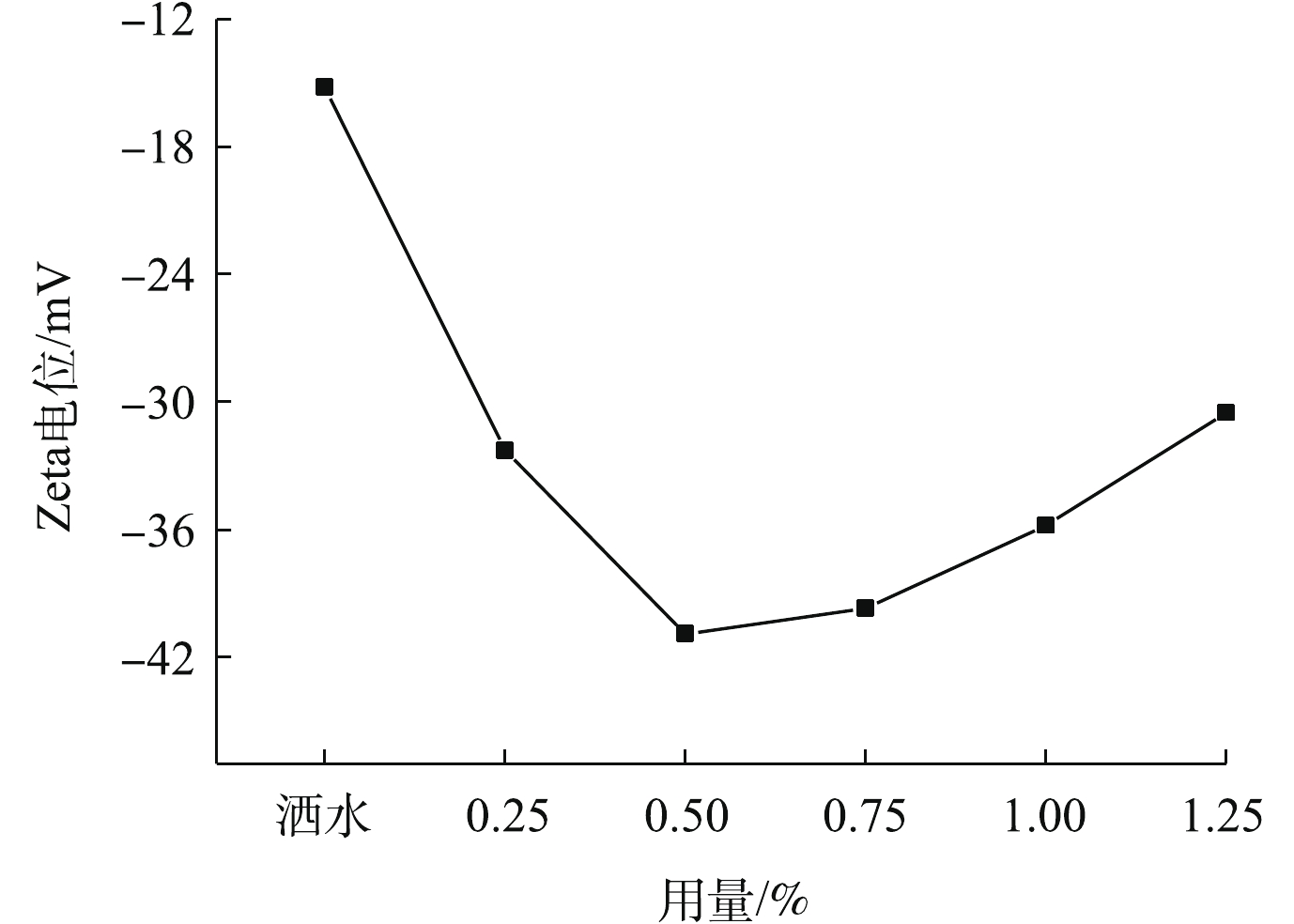

1) Zeta电位变化。铁矿粉在中性介质中以颗粒形式存在,表面呈正电性,Zeta电位仅为−14.6 mV。随聚合物用量的增加,图7的Zeta电位增强,说明铁矿粉与聚合物发生了化学吸附,吸附量增加,颗粒分散性提高;用量为0.5%时,极值电位达到−41.9 mV。用量持续增加,颗粒表面的负电荷则阻碍进一步吸附。

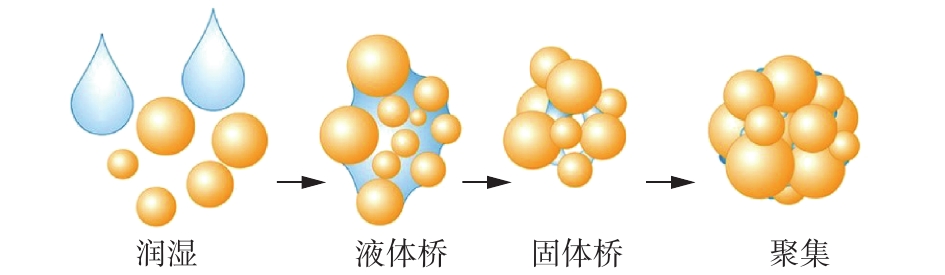

在干燥过程中,铁矿粉的含水率不断降低,由于聚合物羧基与Fe3+交联、Fe―OH氢键作用[14],铁矿粉的内聚力逐渐提高。如图8所示,颗粒密实堆砌,聚集体粒径增加,细颗粒相应减少,粉体稳定性提高,风力侵蚀性则降低[17]。

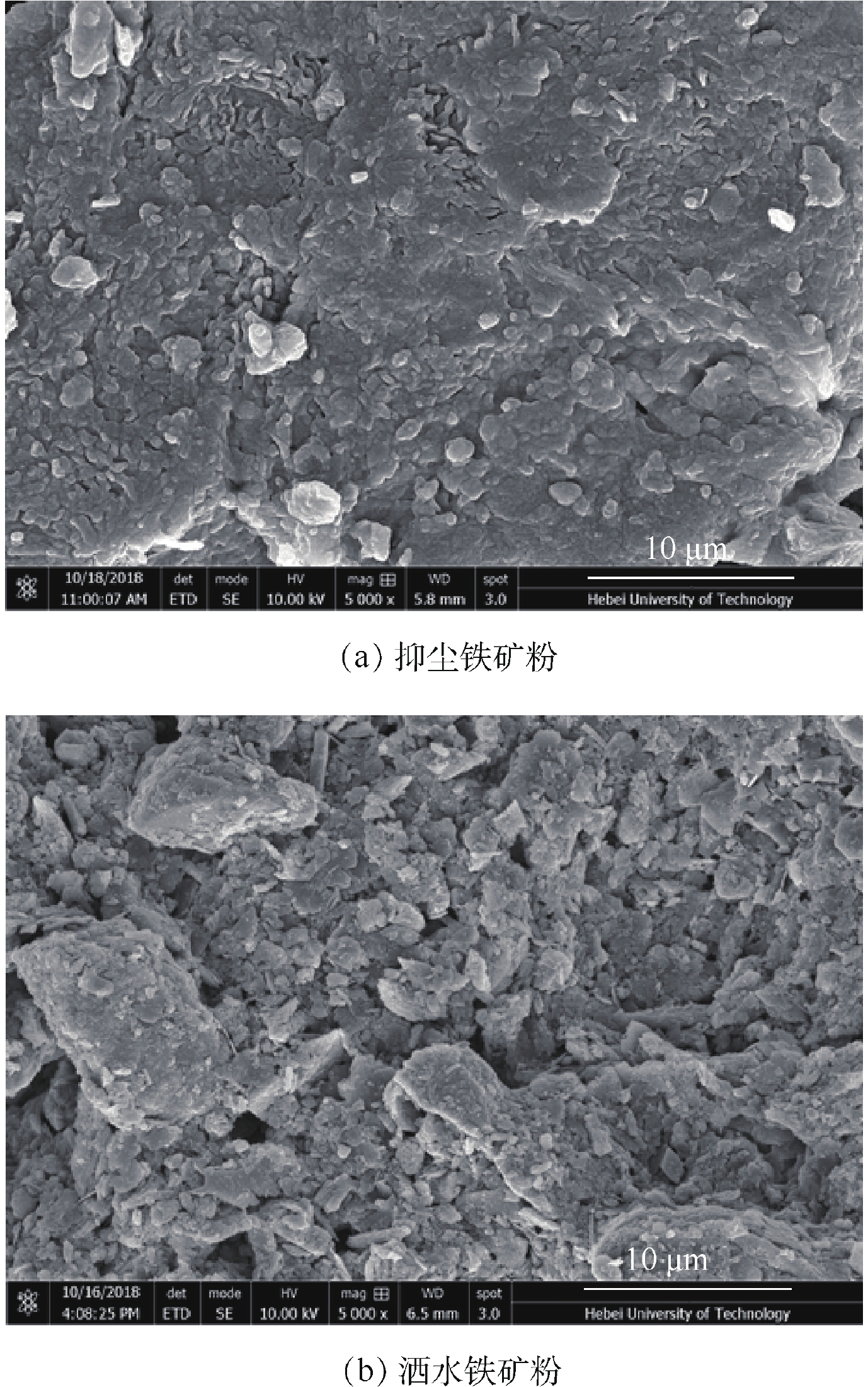

2)聚集体的表面形貌。水性聚合物的分散和交联作用可促进颗粒团聚,空隙降低,如图9(a)所示,有效阻塞水分传输,平均含水率因此提高了1.2倍。干燥之后,铁矿粉颗粒相互胶结成膜,形成致密的表面封闭层,风力侵蚀性显著下降。尽管澳洲铁矿粉的吸水性强、粒径小,但水的内聚能力低且有可逆性,洒水铁矿粉干燥之后的聚集状态较差,在图9(b)中表现为松散堆积,空隙可见。

此外,聚合物羧基与铁矿粉表面Si―OH、Al―OH的氢键作用可进一步增加内聚力[14]。而且,聚合物与颗粒之间的长程作用力具有加和性,其强度不亚于化学键。因此,铁矿粉的封闭层在干燥状态下有足够的强度抵御风力侵蚀,如果没有人为破坏和外来降尘,可以长期抑尘。

-

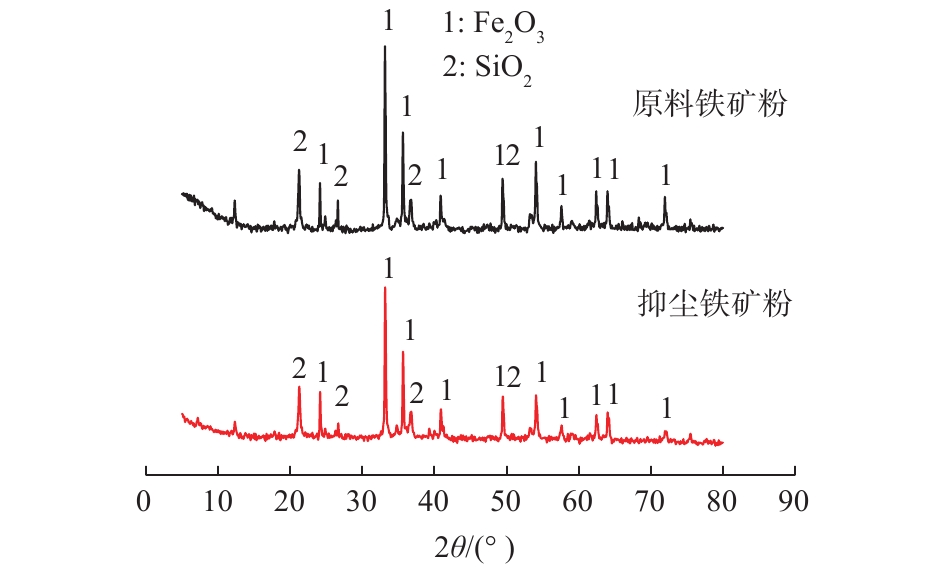

1)铁矿粉的晶体结构。图10为铁矿粉样品在喷洒抑尘剂前后的XRD图谱,Fe2O3和SiO2特征衍射峰的衍射角θ、晶面间距d和半峰宽度见表3。

聚合物抑尘剂不含VOC等低分子化合物,只与颗粒表面的官能团结合,不可能进入晶格。由表3看出,铁矿粉的结构和组成没有变化。

2)铁矿粉的化学组成。对比洒水铁矿粉和抑尘铁矿粉的化学组成(表4),有害元素S和P以及CaO、SiO2和Al2O3等杂质互有消长,但均在测试误差范围之内[18],故可以认为二者没有区别。结合XRD结果,足以说明抑尘剂没有影响铁矿粉的原料品质。

-

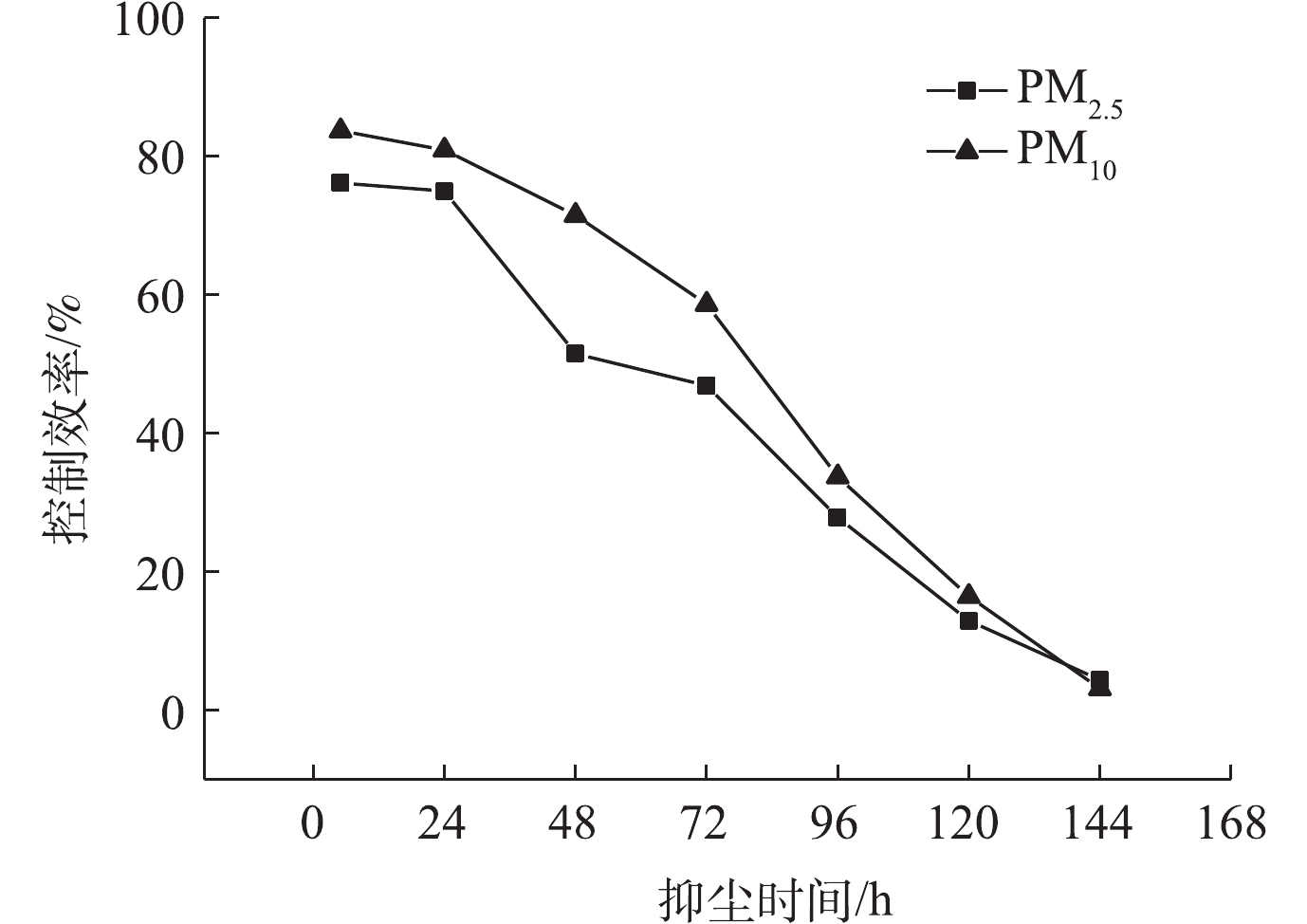

表5为现场监测的结果,0 h即抑尘剂喷洒施工之前,抑尘区的悬浮颗粒物浓度Cs和对比区浓度C0相当。喷洒之后Cs下降,根据式(8)计算控制效率,结果见图11。

式中:η为控制效率;Cs为抑尘区的悬浮颗粒物浓度,μg·m−3;C0为抑尘区的悬浮颗粒物浓度,μg·m−3。

在图11中,喷洒后5 h的PM2.5和PM10控制效率分别为76.19%和83.73%,24 h后分别为75.0%和80.95%,与估算结果非常接近,证实了以上评价方法的可行性。

因设备条件所限,北侧料条无法控制更新界面的扬尘,受风力和装卸作业的持续影响,48 h的PM2.5和PM10控制效率分别降至51.52%和71.51%,72 h后分别为46.88%和58.66%。尽管如此,在30 d的观察期间,抑尘的堆体和料场地面保持完好,封闭状态未受风力影响(图12)。

2.1. 聚合物的湿抑尘作用

2.2. 聚合物的湿抑尘作用

2.3. 聚合物对铁矿粉品质的影响

2.4. 现场应用

-

1)聚合物对铁矿粉的原料品质无不良影响,不会影响后期冶炼。该聚合物可通过离子交联和氢键作用,促进铁矿粉颗粒团聚、提高内聚力,使其平均含水率明显提高。装卸过程和露天堆场扬尘估算的控制效率分别为67.78%和93.96%。干燥状态下可形成封闭层,从而有效降低风力侵蚀,可实现半年以上的长期抑尘。

2)铁矿粉露天堆场PM2.5和PM10的24 h控制效率分别达到75.0%和80.95%,30 d内粉体的封闭状态稳定。现场与实验室结果接近,证实了实际应用和评价方法的可行性。今后应开展不同类型铁矿粉的应用研究,完善堆取作业面的扬尘控制设施。

DownLoad:

DownLoad:

百度学术

百度学术