-

旋风除尘器作为常用的工业除尘设备,具有结构简单、无运动部件、性能稳定等特点,被广泛应用于工业除尘、选粉等领域[1-3]。传统旋风除尘器对比重和粒径较大的固体颗粒分离效率较高,但对细小的颗粒分离效率较低,使其应用受到了很大程度的限制。因旋风除尘器的分离效率低,给后续设备的运行增加了负荷[4]。

针对上述问题,国内外很多专家进行了改进研究。孙国刚等[5]、董瑞倩等[6]提出了一种新型旋风除尘器,在PV型旋风除尘器的基础上对排气管、筒体等结构进行改进,对结构强度以及分离性能有所提高。IRFAN等[7]设计了一种分离空间由外圆柱体和涡旋板组成的除尘器,其分离性能优于常规性除尘器。陆元宝等[8]、吴晓明等[9]、杨景轩等[10]、孟文等[11]考察了排气管插入深度、直径和形状对除尘器除尘效率的影响。YUKI等[12]通过在旋风除尘器排气管上加装锥形环的方法,使得旋风除尘器更容易获得最大效率和最小压降。HSIAO等[13]采用实验的方法对旋风除尘器的几个结构进行了系统的研究,通过改变出口直径和入口形式,在一定程度上提高了其分离效率,但对于细颗粒的分离效率并不理想,对于旋风除尘器的分离效率仍需要进一步提高。

本研究针对传统旋风除尘器分离效率低的问题,提出了一种球柱形旋风除尘器;通过数值模拟和实验研究,分析了其流场特性和分离性能。

全文HTML

-

实验物料为石英砂颗粒,密度为2 650 kg·m−3,其粒度参考实验所用物料,见表1。其中,中位径为12.61 µm、体积平均径为19.07 µm、面积平均径为4.53 µm。

-

实验仪器:0~160 m3·h−1 转子流量计(江苏泰州俊海仪表有限公司)、U形压差计(衡水斯菲尔仪表有限公司)、球柱形旋风除尘器(直径100 mm,排气管直径30 mm,排气管插入深度30 mm,排尘口直径20 mm)、XK-RB型漩涡气泵(上海辛恪实业有限公司)、BT-9300S型激光粒度分析仪(丹东百特仪器有限公司)、电子天平(福州华志普力特斯科学仪器有限公司)、振动加料系统(郑州汇通矿山机械有限公司)。实验现场如图1所示。

-

实验原料由振动加料系统送入进风管道中,在管道内分散并与空气混合,再经进气管进入旋风除尘器内进行分离。其中,绝大部分颗粒通过排尘口进入集料箱被捕集,一小部分粒径小且轻的颗粒经排气管排出。用U形压差计测量旋风除尘器压降,由转子流量计检测进口风量,进口风量大小调节通过变频器控制气泵电机转速实现。用集料箱收集被分离出的颗粒进行称重,并用激光粒度仪进行粒度测试。

为了更好地研究柱段高度对颗粒运动轨迹的影响,单颗粒入射点选择在进气口截面中间位置,颗粒群射入位置选择在整个进气口截面垂直均匀射入;针对传统旋风除尘器对于5 µm以下粒径颗粒分离效率不理想的缺点,选择颗粒粒径为1 µm和5 µm。

-

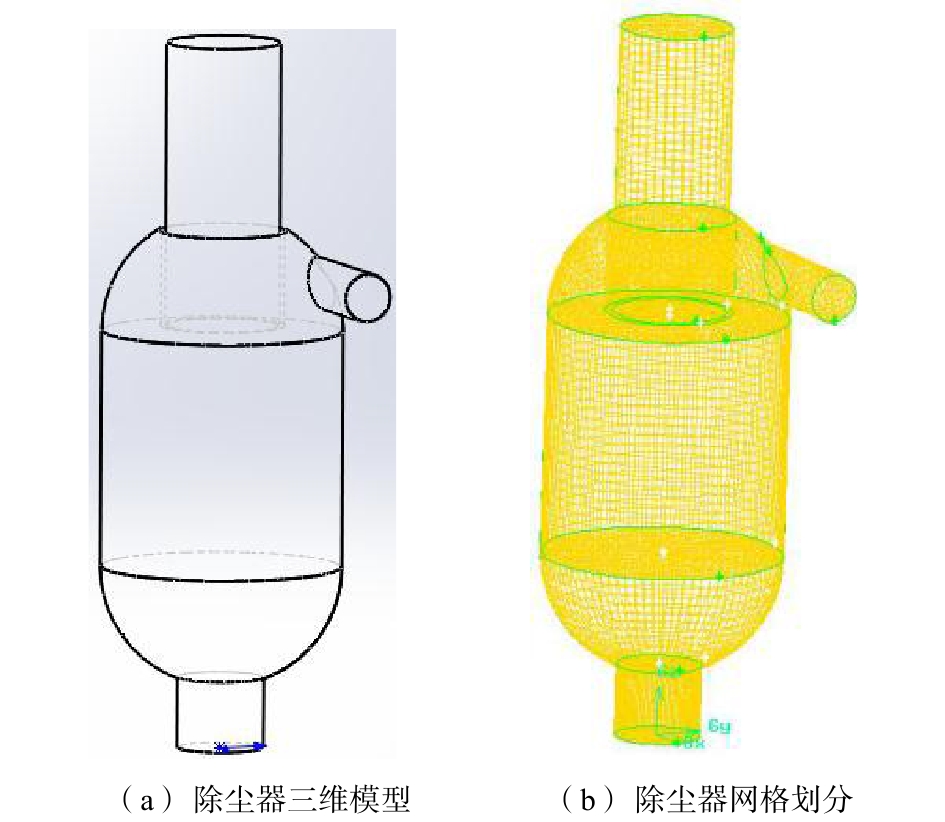

1)模型建立及网格划分。采用Solidworks软件对球柱形旋风除尘器建立三维数值模型,并利用Gambit软件进行网格划分,结果如图2所示。将旋风除尘器分为进料体、环柱段、柱段、下球体(锥体)、排尘管和排气管6部分。其中,进料体采用四面体网格,其余均采用六面体网格。经过对网格数量为238 845、258 630和278 213的球柱形旋风除尘器模型计算结果的关联性比较,最终确定网格数量为258 630,同时对旋风除尘器网格进行质量检查,以满足模拟要求。

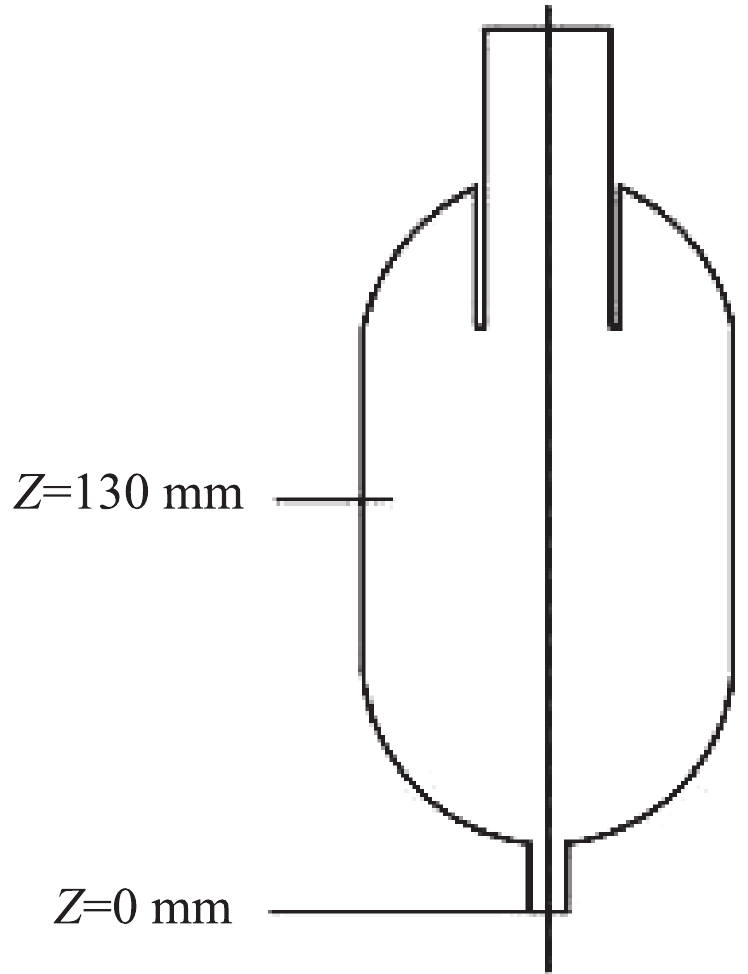

2)边界条件设置。采用Fluent14.5软件进行气-固两相模拟计算。多相流模型选用DPM模型,湍流模型选用雷诺应力模型,离散格式采为QUICK格式,压力插补格式为PRESTO格式,算法为SIMPLEC。入口边界条件采用速度入口,速度设置为20 m·s−1,气固两相,固相为石英砂颗粒。排气管出口设置为自由出口,流量权重为1;排尘口设置为无气体流出。壁面条件设置为无滑移边界,采用标准壁面函数,流体与壁面无相对速度。为了探究柱段高度对球柱形旋风除尘器内部流场的影响,选用不同的柱段高度,分别为0、100、150、200和300 mm,选取球柱形旋风除尘器的中间截面位置处(如图3所示),并且绘制静压力和速度分布曲线进行分析。

1.1. 实验原料

1.2. 实验装置

1.3. 实验方法

1.4. 数值模拟方法

-

球柱形旋风除尘器运行时,烟尘以一定的速度由进气管进入到球柱形旋风除尘器内部,由于上球体结构的作用,在上球体和排气管之间快速旋转并且向下流动,称之为外旋流。烟尘流经柱段之后带动排气管下面的圆形气柱旋转,当气流运动到下球体底端时,由于下球体的结构作用而发生折转,并跟随圆形气柱向上运动,称之为内旋流。整个过程中,烟尘颗粒在外旋流、重力以及离心力的作用下沿壁面旋转向下运动,通过排尘口排出,统一进行收集;而留下的气体则在内旋流的作用下通过排气管向上排出。

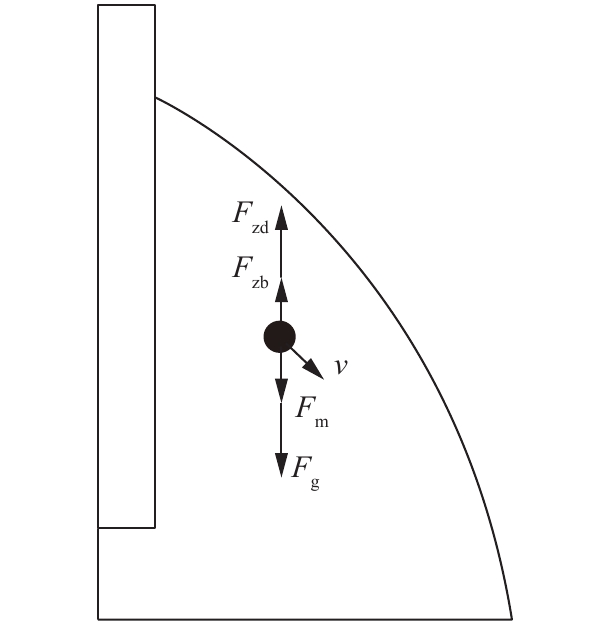

球柱形旋风除尘器的原理示意图如图4所示。不同于传统柱锥形旋风除尘器,球柱形旋风除尘器上端与下端均采用半球体结构,中间部分采用筒体结构与上下两端半球体连接。如图5所示,因上端半球体结构作用,与传统柱锥形旋风除尘器相比,烟尘颗粒在受离心力、阻力等力的基础上,还受到力Fn的轴向分量Fzn的作用,使得轴向方向的速度增大,从而减小了旋转圈数,缩短了运动到除尘器下球体的时间,进而有利于分离效率的提高。因下端半球体结构作用,增加了外旋流的空间,减小了因上升气流下部摆动造成的二次返混,从而有利于颗粒分离。

-

柱段高度对球柱形旋风除尘器内部流场及分离性能影响很大[6]。因此,首先探究柱段高度对球柱形旋风除尘器内部流场的影响。

-

由图6(a)中的静压力分布曲线可知,不同柱段高度下的静压力分布规律基本相同,沿内壁到中心轴线方向,静压力逐渐降低,并在中心轴线处达到最小。随着柱段高度的增加,静压力数值相应减小,并且减小的幅度不断降低。旋风除尘器是在重力和离心力共同作用下完成分离过程的,产生离心力的基本前提是切向速度,并且对分离效率有重要的影响。由图6(b)可以看出,柱段高度为100、150、200和300 mm时,切向速度均呈“M”型分布,并且基本具有一致的变化规律:在壁面处切向速度为零,沿半径方向由外而内,切向速度先增大后减小,在中心轴线处达到最小。随着柱段高度的增加,切向速度逐渐减小,在中间位置时差值最大,达到6 m·s−1。柱段高度为0 mm时,中间位置有一部分处被排气管壁占据,从而导致切向速度为零,但分布与其他柱段高度时大体一致,并且切向速度大于其他柱段高度切向速度,差值最大达到12 m·s−1。

轴向速度的大小可影响颗粒在内部分离与滞留时间,也是影响分离效率的一个重要因素。由图6(c)可以看出,当柱段高度为0 mm时,在进气口壁面处轴向速度随半径的减小先增大后减小,然后再反向增大最后又减小,与其他柱段高度相比具有不同的分布规律。这是由2个方面的原因造成的:其一是因为排气管插入长度过大而导致分离空间减少,气体因摩擦作用减小了速度;其二是此处还存在旋涡作用,由于排气管插入长度过大,使部分颗粒受到内旋流的影响,被卷入内旋流由排气管排出。柱段高度为100、150、200和300 mm时,轴向速度在壁面处分布一致,随着半径的减小,轴向速度绝对值先增大后减小;随着半径的继续减小,轴向速度绝对值都增大。在中心轴线附近会出现回流和滞流现象,这是由于气流强烈旋转使法向压力梯度变大,中心轴线附近压力较低,进而使得轴向速度变小,其数值有正有负。旋风除尘器内部径向速度是相比于切向速度和轴向速度中最小的一个,对内部流场的影响较小,但也存在一定的影响。由图6(d)可以看出, 不同柱段高度球柱形旋风分离器的径向速度均关于中心轴线对称,在近壁面处变化较小,在中心轴线变化稍大,并且随着高度的增加,会出现波动,这是由强湍流引起的。

-

图7为1 µm和5 µm 2种粒径的单颗粒和颗粒群在不同柱段高度下的运动轨迹。可以看出,随着柱段高度的增加,粒径1 µm颗粒运动轨迹变长,并且不规律,特别是在旋风除尘器下部位置;粒径5 µm颗粒螺旋向下的圈数增多,并且螺距逐渐增大,这说明颗粒下降速度增快,有利于分离效率的提高。除尘器内部,5 µm颗粒的螺距在除尘器上部较大,随着颗粒向下运动,螺距减小。这是由于随着柱段高度的增加,除尘器内的旋转气流未达到下半球段就终止了,导致外旋流并没有沿下半球的球形结构发生聚拢,而是向壁面发生偏移,出现摆尾现象,所以导致颗粒在除尘器上部螺距较大,在下部螺距较小。

由表2可以看出,5 µm颗粒在不同柱段高度下都被完全被捕集,分离效率到达100%;随着柱段高度的增加,1 µm颗粒被捕集数增加。

-

从图8中可以看出,柱段高度为0 mm时,压降为775.5 Pa;柱段高度增大至300 mm时,压降为588 Pa;随着柱段高度的增大,压降逐渐减小。其原因是,旋风除尘器的压降主要是由排气口处流体的黏性耗散决定的,而黏性耗散的数值基本上和速度的平方数值接近。因此,柱段高度增大后旋转强度增强意味着增加压力损失。然而,速度降低使得在排气管处的损失降低。这是因为,在上升流中速度相对较大,减小的幅度较大,占主要影响。因此,增大旋风除尘器柱段高度,压降会相应减小。

-

总分离效率是指在相同时间内被捕集的粉尘质量与进口处的粉尘总质量的比值,是评价旋风除尘器性能的一个极其重要指标。从图9(a)可以看出,当柱段高度由0 mm增大至150 mm时,总分离效率由84.42%增大为92.01%;柱段高度继续增大到300 mm时,总分离效率又减小为88.3%。随柱段高度的增大,总分离效率先增高后降低。前文数值模拟计算中选用的1 µm颗粒与5 µm颗粒是为了重点探究5 µm及以下颗粒分离效果,实验环境下由于条件限制与模拟条件略有不同,但数值模拟的结果与实验结果变化趋势一致。

因尘粒直径和分散程度不同,旋风除尘器效率也会不同,所以,要全面评定除尘器的性能还需要对比颗粒分离效率,即某一粒径或某一粒径范围内粉尘的分离效率。颗粒分离效率可以更加准确地反映除尘器对颗粒的捕集能力。从图9(b)可以看出:其一,不同柱段高度时,相同粒径颗粒的分离效率先增大后减小;其二,柱段高度为150 mm时,颗粒分离效率最高;其三,随颗粒粒径的增大,分离效率先减小后增大,这是由于小颗粒团聚作用较强,随着粒径的增大,团聚作用减弱,但离心力作用增强,所以随颗粒直径的增大,分离效率先减小后增大,既所谓“鱼钩”效应[14]。

与传统柱锥形旋风除尘器相比,球柱形旋风除尘器压降更小,而总分离效率更高,有很大的优越性。这是因为球柱形旋风除尘器的上球体作用,使颗粒加快向下运动,同时减少了上灰环和短路流等二次流,增大固相颗粒被捕集的概率,使总分离效率增大;另外,进气口处的球形结构减少了气体在除尘器内因摩擦而损耗的能量,降低了压力损失。

2.1. 球柱形旋风除尘器原理分析

2.2. 数值模拟结果分析

2.2.1. 柱段高度对球柱形旋风除尘器分离特性的影响

2.2.2. 柱段高度对颗粒运动轨迹的影响

2.3. 实验结果分析

2.3.1. 柱段高度对压降的影响

2.3.2. 柱段高度对分离效率的影响

-

1)数值模拟结果表明, 除尘器柱段高度不为零时,随着柱段高度的增加,内流体静压力逐渐变小,其切向速度均呈“M”型分布,内流体轴向速度在壁面处随着半径的减小,其绝对值先增大后减小,随着半径的继续减小,其绝对值又开始增大,内流体径向速度均关于中心轴线对称。

2)实验结果表明,除尘器柱段高度为0 mm时,内流体压降为775.5 Pa;除尘器柱段高度增大至300 mm时,内流体压降为588 Pa;随着柱段高度的增大,压降逐渐减小。

3)综合分析压降、颗粒分离效率和分离效率可得出:当除尘器柱段高度为150 mm时,总分离效率最高,达到92.01%。

DownLoad:

DownLoad: