-

随着我国规模化畜禽养殖业的快速发展,畜禽粪便对环境的污染问题日益凸显。目前,畜禽粪便污染物总量已达近40×108 t[1-3],有效处理量不到50%,开展无害资源化处理与合理利用迫在眉睫[4-5]。同时,我国在农业生产过程中产生了大量的农业废弃物—作物秸秆,年产生总量在10.4×108 t,可收集资源量约9×108 t[6],秸秆综合利用率在一些区域较低,缺乏有效的资源化利用手段,导致随意丢弃或焚烧等问题较为严重[7]。

厌氧消化技术可以将粪便和秸秆等有机废弃物转化为沼气[8],沼气通过提纯净化后可进一步提质为生物天然气[9-11],而发酵残余物可以生产有机肥料[12]。因其具有解决污染、产生可再生能源和促进农业可持续发展等优点,越来越受到重视,已是解决农业面源污染的重要综合防治技术之一,也是农业部门实现“一控、二减、三基本”的重要手段。

传统大中型沼气工程在建设、运营、技术及管理水平上存在较多问题,国家和地方虽然投入大量扶持资金但还成效不明显[13-15]。为此,在2015—2017年连续3年中,国家有关部门着手大中型沼气工程的转型升级,鼓励发展日产10 000 m3以上规模化生物天然气(BNG)工程,共支持了64座中央预算内投资计划项目,本项目由此孕育而生。然而,64座项目进展非常不乐观,至2019年6月,运行及试运行仅22座(约1/3),严重打击了行业发展积极性。其原因主要为缺乏盈利模式,这已成为行业能否持续健康发展的核心推动因素。为此,本项目同时整合了其他相关互利项目,如畜禽污染整县推进战略-高台县畜禽粪污资源化利用项目和高台县现代农业示范园区绿色生态循环发展(沼液)项目,从全局角度治理县域内的畜禽粪便和秸秆等废弃物,探索治污费和“气-肥并举”联合盈利模式,示范效应明显。

项目基本方案的制定单位为北京化工大学,联合设计单位为北京金宇蓝天生态能源科技开发有限公司(工艺部分)和农业农村部规划设计研究院(土建部分)。2015年8月,此项目列为中央预算内投资计划项目,2015年底启动建设,2017年6月全部建成并开始联合试运行,历时约18个月。随着盈利模式日趋成熟,至2019年中期,项目正式进入良性运行循环轨道。

HTML

-

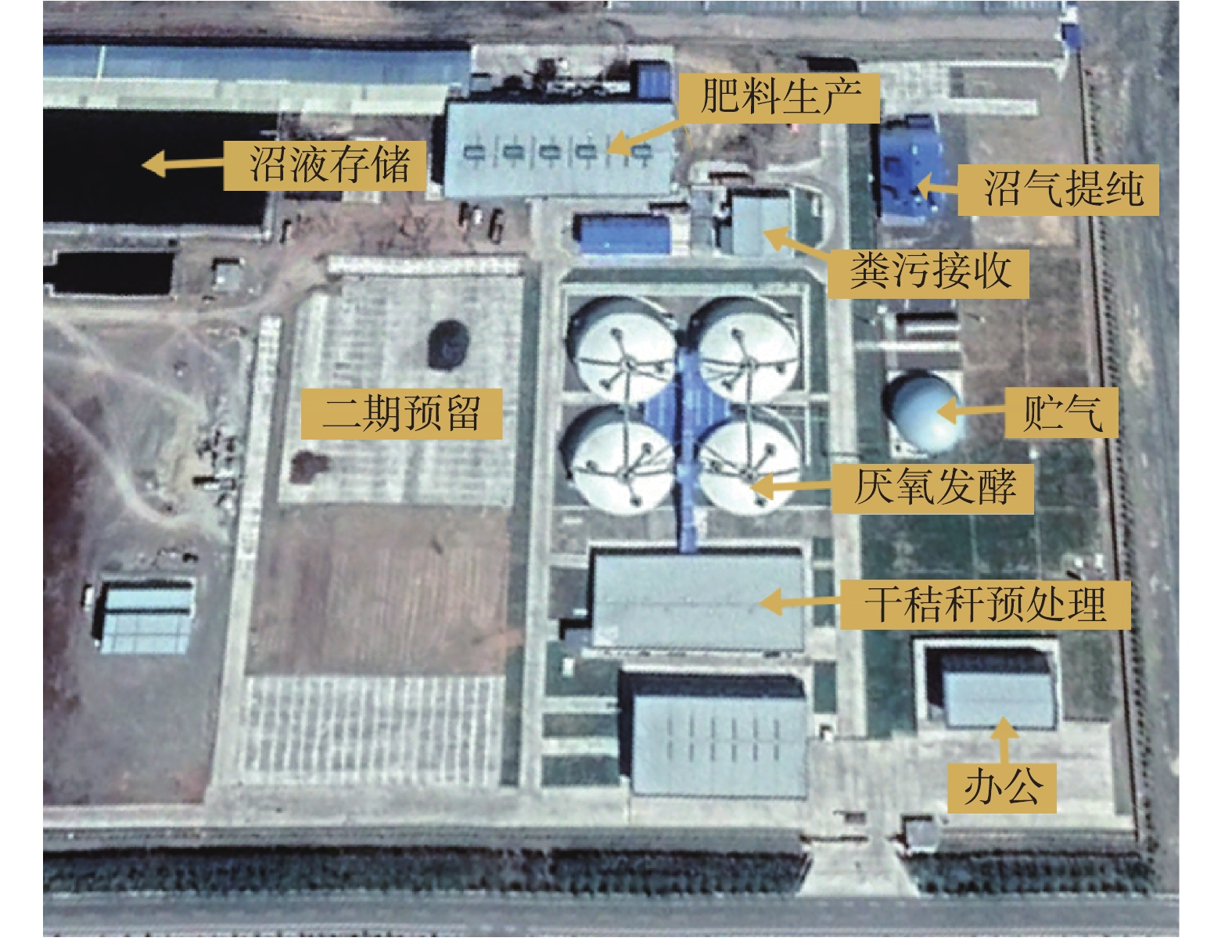

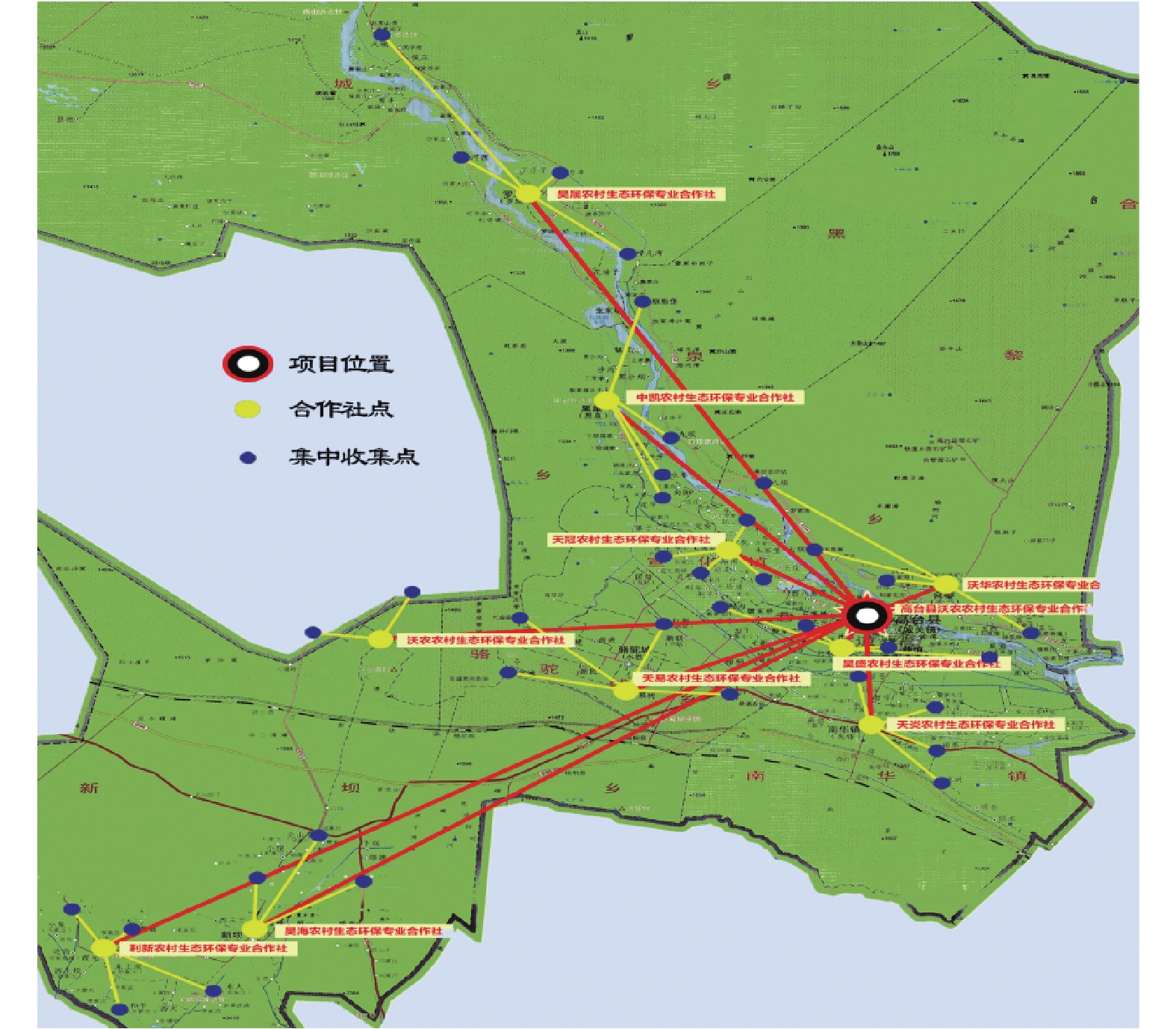

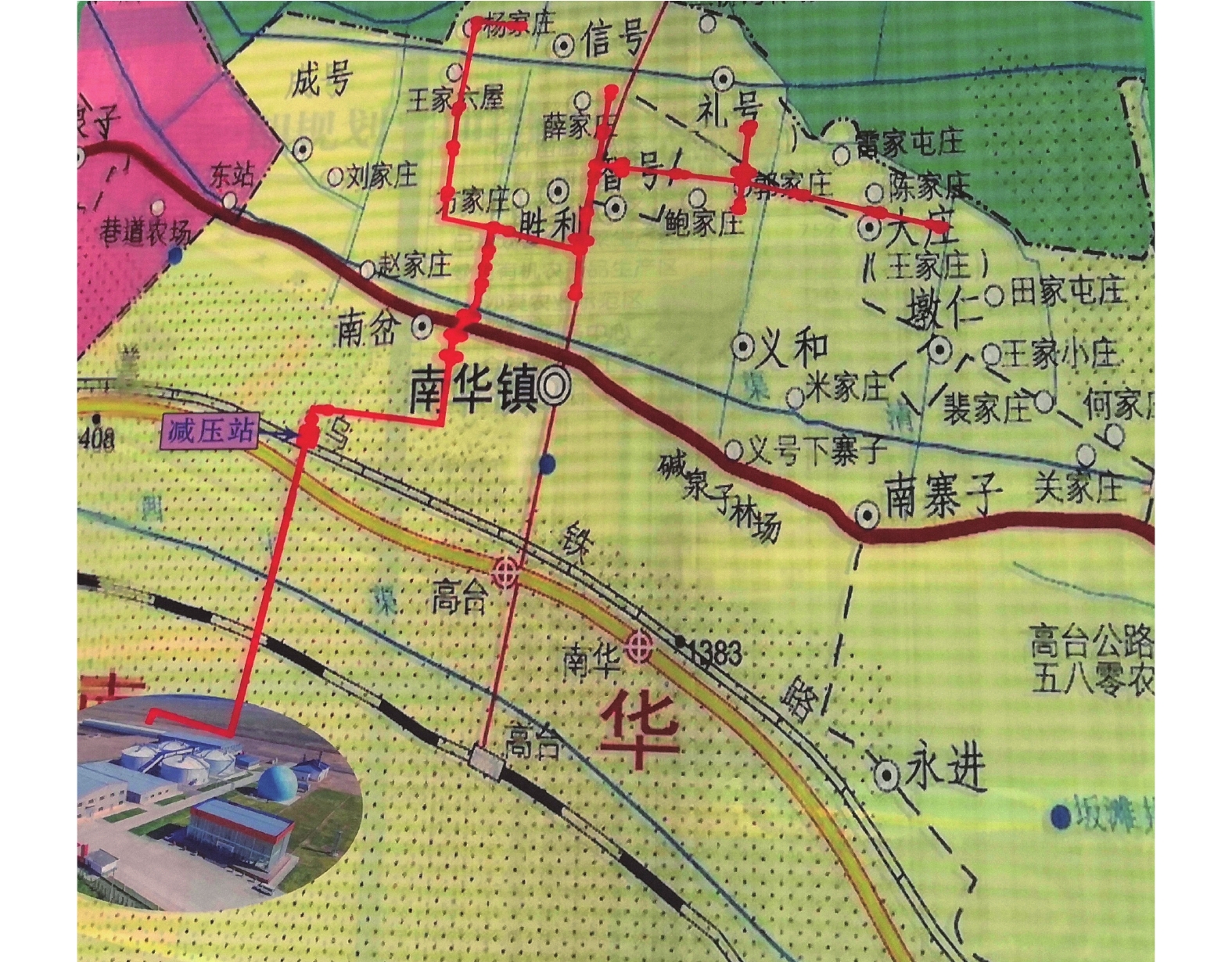

项目位于甘肃省张掖市高台县南华镇工业园,祁连山北麓,紧邻兰新高铁线高台站,项目卫星图见图1。工程设计规模:主厌氧发酵罐4座,单座容积7 500 m3,日产20 000 m3生物天然气,年产5×104 t有机肥,占地1×105m2(含二期预留区域),总投资1.2×108元。设计原料为畜禽粪污和干玉米秸秆的混合原料,原料基本情况(设计值)见表1,年可消纳处理干秸秆2.52×104 t、畜禽粪污1.4×105 t。收集半径控制在项目周边25 km范围内,覆盖南华镇、骆驼城镇、巷道镇、宣化镇等乡镇。畜禽粪污通过和当地规模化牛、猪、羊养殖场签署代消纳处理协议进行处理,干玉米秸秆采用农牧合作社代购与专业收割公司自行收集结合方式处理,合作社分布网络见图2,网络范围覆盖全县所有重点乡镇。

-

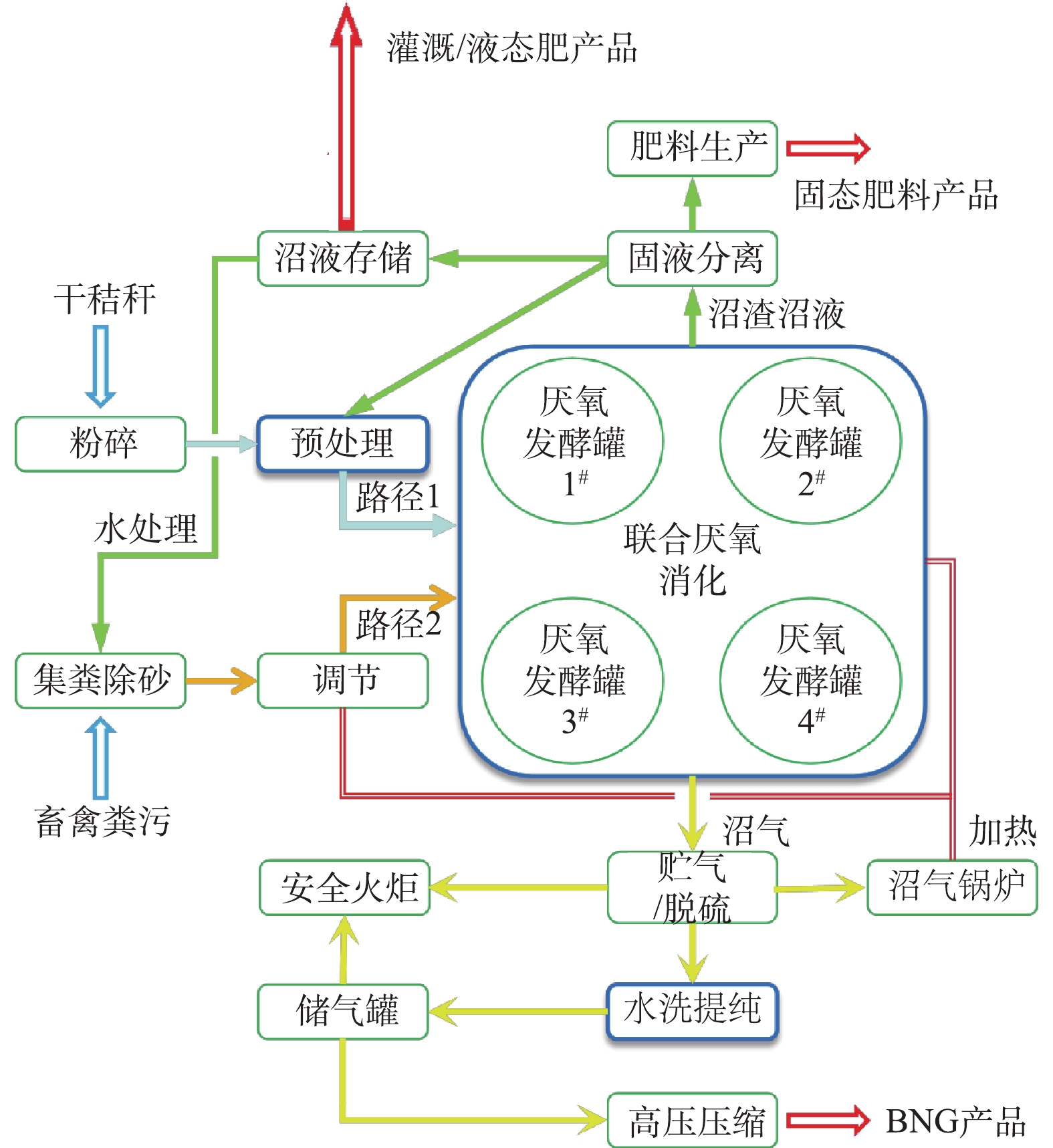

1)工艺流程简介。工艺流程如图3所示。根据2种原料的物性特点,采用了2条进料路径,其中干秸秆采用皮带+螺旋机械输送,畜禽粪污采用除砂后直接泵送。干秸秆原料因其由纤维素、半纤维素与木质素形成的复杂结构,需要经过一定尺寸程度的粉碎和合适的改性预处理才能改善其厌氧降解性能,同时秸秆混合液体泵送的方式能耗大且易造成设备损坏,因此,秸秆原料采用皮带+螺旋机械输送以区别于畜禽粪污的泵送。畜禽粪污厌氧前处理重点在于沉砂除杂,避免泵送过程中的设备损耗与发酵罐内的沉砂积累。

预处理后秸秆和除砂后的粪污在厌氧发酵罐内进行高浓度联合厌氧消化,此为项目工艺核心,根据物料特性调控发酵控制条件,实现高效降解有机质的目的。厌氧消化后,沼渣、沼液、固液分离后,沼渣进入肥料生产线生产有机肥料(NY 525-2012),分离后的沼液部分回流进入秸秆预处理环节,多余沼液管输至20 km外的现代农业示范园。少部分沼气锅炉燃烧后提供工艺自身所需热量,主要部分提纯为生物天然气BNG,采用的提纯技术为压力水洗工艺,设计提纯指标达到车用压缩天然气(GB 18047-2017)中规定的组分含量要求。

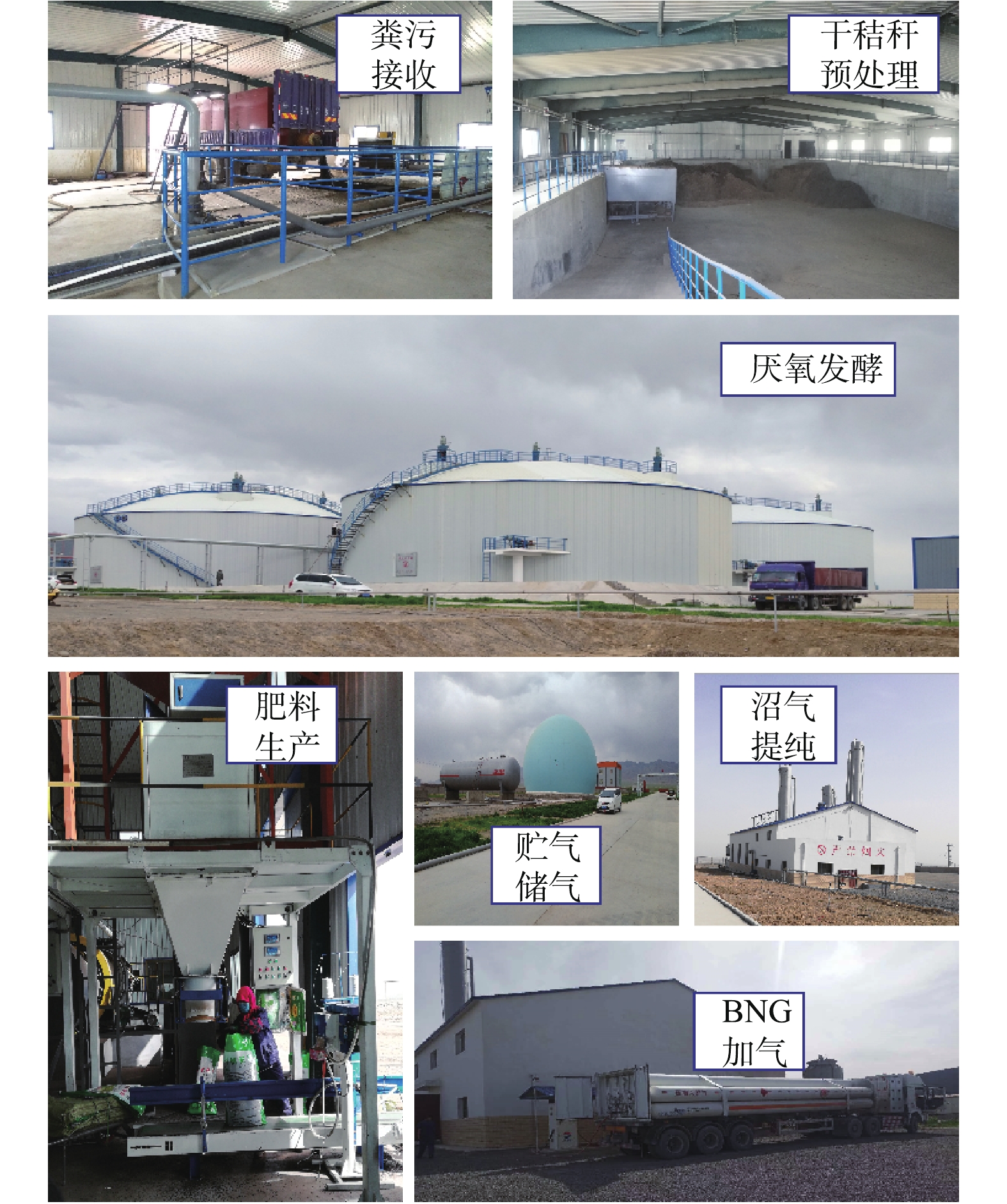

项目生产阶段现场图见图4,其中包括畜禽粪污接收、干秸秆预处理、厌氧发酵、肥料生产、沼气贮气/天然气储气、沼气提纯和BNG加气等关键工艺环节。工艺环节中涉及的关键设备和参数见表2。

2) 关键工艺技术-干秸秆预处理。秸秆主要由木质素、纤维素和半纤维素组成,三者以多种化学键连接在一起,以木质素-碳水化合物复合体(LCC)的形式存在,很难被厌氧分解,干秸秆尤为明显,因此,选择合适的预处理方式是厌氧发酵前的关键工艺。表3对比了几种预处理技术的优缺点,预处理目的在于改变木质纤维原料中细胞壁的结构,破坏木质素与纤维素、半纤维素之间的化学键联结,把纤维素和半纤维素从木质素的包裹中释放出来;同时,降低纤维素的晶体结构,增大内部反应的表面积,把复杂大分子成分预先降解成小分子等,从而显著提高木质纤维原料的生物降解性能和厌氧生物消化效率。根据项目干秸秆原料情况和对环保、节能的要求,采用了无化学药剂、可利用沼液余热的沼液预处理技术[16],其中的预处理设备通过计量、混合、参数控制实现精确的自动化预处理过程。同时,为了克服沼液预处理生物过程较缓慢的缺点,适当添加N、P、K类无机肥料来增强化学作用,无机肥料具有较强碱性,添加后起到了化学碱性预处理作用,如膨胀纤维结构、去除木质素和降解纤维素氢键等。这种做法可以降低预处理时间、减少预处理空间,添加N源又可克服纯秸秆原料C/N比过高的缺点,并可为后端肥料生产提供了部分养分元素,实现了多重作用的目的。

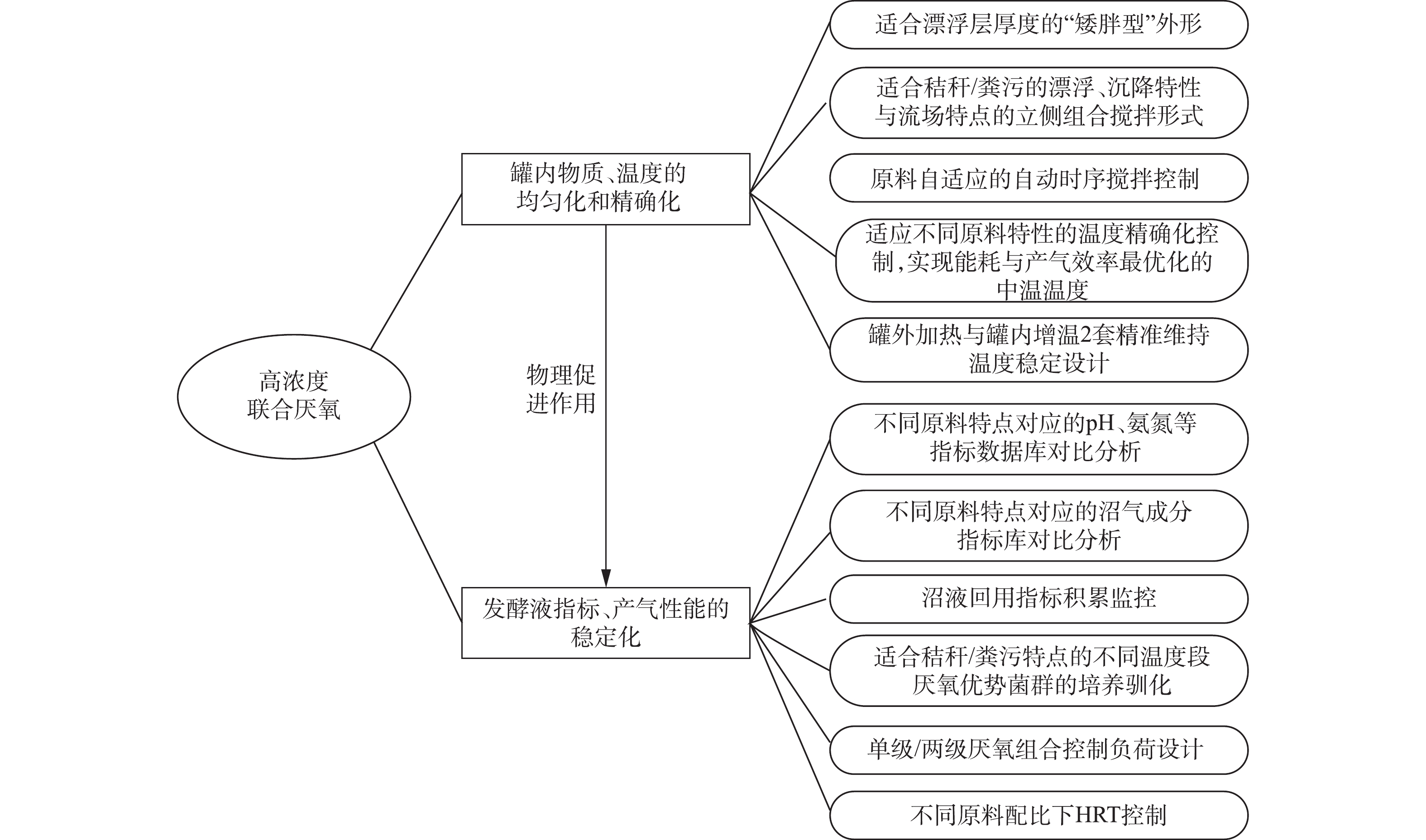

3) 关键工艺技术-高浓度联合厌氧发酵。厌氧发酵是沼气及生物天然气工程的核心,高浓度负荷、多原料适应性和优势菌群稳定性是高效发酵的重要表现[17],有利于提高单位原料干物质TS产气率、容积产气率、甲烷浓度以及降低水力停留时间HRT、减少发酵容积及缩减工程造价等。设计发酵温度36~42 ℃,设计进料浓度>12%,罐内发酵浓度8%~10%,属于中温、高浓度发酵。如图5所示,针对2种原料的物性特点,重点控制2方面的联合厌氧发酵因素:罐内物质、温度的均匀化和精确化以及发酵液指标、产气性能的稳定化。

4) 关键工艺技术-压力水洗沼气提纯。沼气提纯应用技术有多种,如压力水洗、化学吸收、膜分离、醇胺法等技术。本项目采用了压力水洗沼气提纯技术,主要基于该技术的以下性能优点[18-20]:吸收剂为水,而水可以循环使用,安全环保;采用传统塔器类设备,运行稳定可靠,分离指标高(CH4浓度达到99.7%)且指标稳定性好;对原料沼气中的H2S含量几乎无要求,并可同时去除H2S;低温有利于吸收,低温外界环境条件有利于降低能耗,特别适合高台县所处的高寒地区。

-

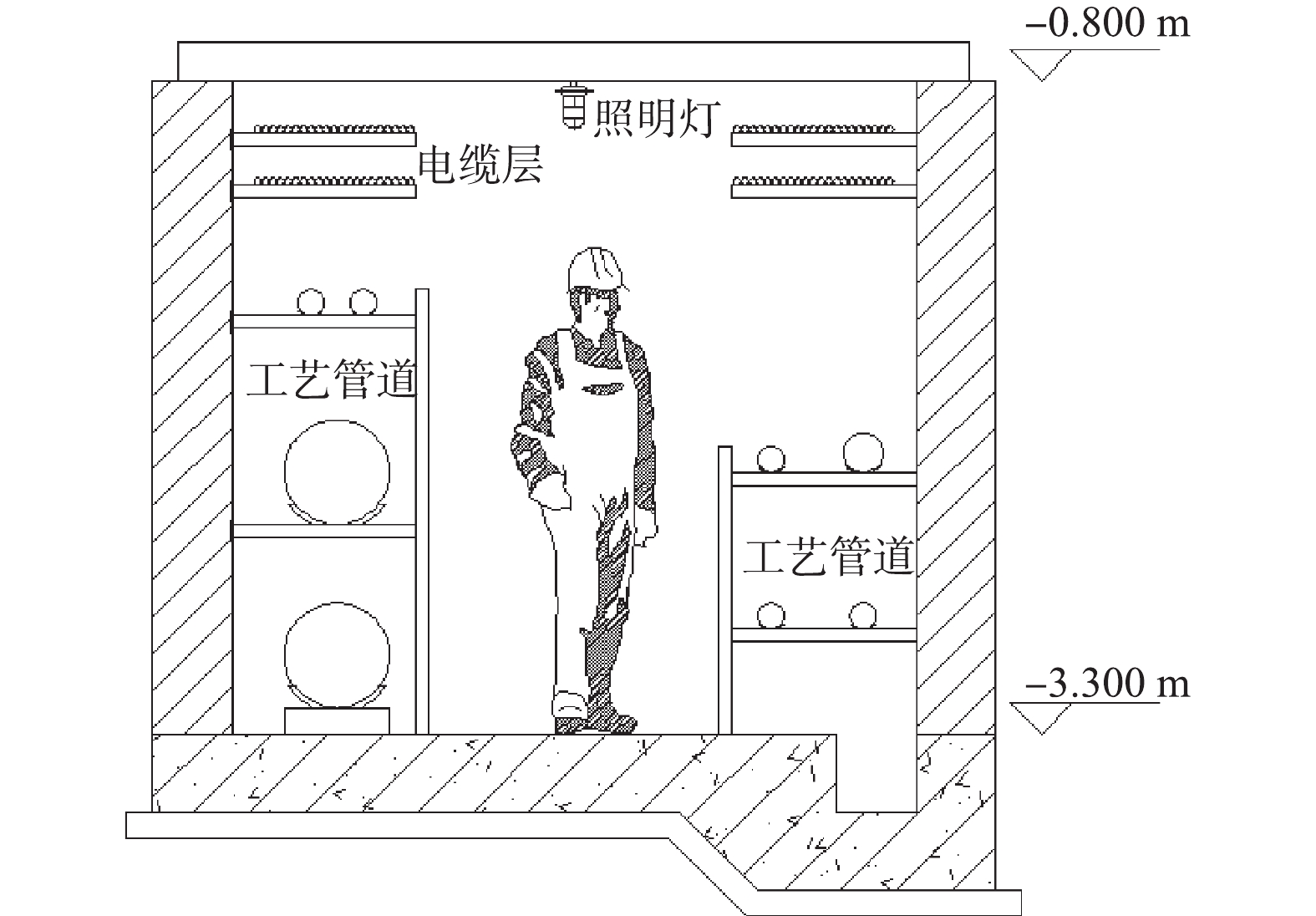

1) 布局特点。总体布局以实现工艺功能、便于运行维护为目的,围绕4座厌氧发酵罐(核心工艺功能,成组模块化)布置附属工艺区域,包括粉碎与预处理、集粪除砂、固液分离、肥料生产、气体贮存、沼气提纯、沼液存储、公用设施及生活办公等功能区划。布局总体符合《建筑设计防火规范》(GB 50016-2014)要求,危险性大的天然气区域同时执行《石油化工企业设计防火规范》(GB 50160-2008)相关防护要求。针对工艺管道种类复杂的特点,在管道集中区域设计地下综合管廊,将除可燃气体管外的所有工艺性管道及电缆按功能分层敷设于管廊内(图6),这种工艺设计给日常管路线路维修及日后功能升级改造带来了极大的便利。

2) 寒冷区域考虑。高台县位于西北河西走廊中部,低温期长,极端低温可达−30 ℃,低温特别容易发生发酵罐热损失大、产气效率下降、所产沼气大量自用等工艺问题,这给冬季沼气工程的运行带了巨大挑战。这也是我国很多北方寒冷地区,如东北西北内蒙,对大型沼气工程持否定态度的重要原因。为了克服这一关键工程技术问题,通过工艺运行和工程设计2种手段综合达到工艺节能的目的。

秸秆预处理采用固液分离后的沼液,沼液先储存在具有保温功能的池体内,利用了发酵液的余热和预处理过程中自行产生的热量;冬季原料以秸秆为主,避免进入大量粪污而导致的进罐低温源,秸秆水力停留时间HRT长,每日出料体积小、带出热量少。

采用特大型罐体(国内首座罐侧钢砼+罐顶钢结构特大型发酵罐体)降低比表面积,罐体底部增加抗压保温层;采用罐外加热与罐内增温2套温升系统精确保证罐内恒温,防止任一系统出现故障。

1.1. 工程概况

1.2. 工艺流程

1.3. 设计特点

-

自2017年6月试生产以来,工程未有大的设备更换或调整,关键设备如进料输送、搅拌、提纯和肥料等均一次性调试成功并稳定运行。夏秋季节以处理畜禽粪污为主,干秸秆为辅;冬春寒冷期则以干秸秆为主,畜禽粪污为辅。根据现场操作经验,最冷季节单罐每日温降最大不超过0.2 ℃(未进出料情况下),未出现因不能维持温度而导致的停产,表现出较好的工程设计和施工效果。根据产品后端市场需求的波动,投料量(直接影响BNG产品量)和肥料加工量需随之进行调整,加上季节性原料因素,厌氧发酵罐产气波动很大,单罐产量为3 000~8 000 m3·d−1。进料浓度最低TS负荷为4%(粪污),最高TS负荷为15%(干秸秆),发酵罐2年来未发生罐顶结壳、罐底积砂、pH异常等不利现象,表现出优异的系统稳定性。

-

缺乏盈利模式是影响规模化生物天然气行业健康发展的关键性因素。为此,本项目自2018年起积极探索符合区域特点的盈利模式,表4总结了粪污治理费+气(BNG)-肥并举的综合盈利模式,其中粪污治理费和BNG产品利润用来抵消运行成本以维持项目的基本运营,而项目的扩增盈利则主要通过肥料产品的销售利润来实现。结合建设单位近1年来到厂粪污治理费20元·t−1(按4%TS计)、车用BNG(自有加气站)3.5~4.0元·m−3和固态有机肥销售价1 000~1 500元·t−1的销售情况,年产值达到3.3×107元。考虑原料、电耗、人工和折旧等成本后,年运行综合平均成本为BNG 2.5~3.0元·m−3,固态有机肥为600~800元·t−1。目前,项目已正式步入盈利良性循环轨道,并且二期工程也正在筹划建设中。图7为将沼液管输至现代农业示范园(管输距离20 km,沼液接入点37处)的网络图。

2.1. 工程运行情况

2.2. 盈利模式

-

1)回流沼液+无机肥料对干秸秆进行预处理结合了生物和化学预处理的特点,能在快速高效预处理干秸秆的同时增加后续肥料生产所需的养分。高浓度联合厌氧发酵控制的关键因素在于罐内物质、温度的均匀化、精确化以及发酵液指标、产气性能的稳定化。

2)针对原料波动,根据秸秆/粪污物性特点,设计2路进料通道是非常有必要的。在寒冷区域实施工程时,工艺方案考虑季节性调节主/辅原料、多回流沼液利用余热、增加水力停留时间等节能性措施。工程设计角度,考虑加强罐底保温和设计罐内/罐外2套温升系统。

3)生物天然气工程作为沼气工程的规模化转型升级版本,建立符合地域特点的良性循环盈利模式是项目及行业成败的关键。实践证明,“粪污治理费+气-肥并举”的综合盈利模式是可参考的,生物天然气工程不应止步于早期设想和规划,应在工艺功能首先能正常运行的基础上,从污染处理环保角度和生态循环经济角度积极参与公益性社会竞争。

DownLoad:

DownLoad: