-

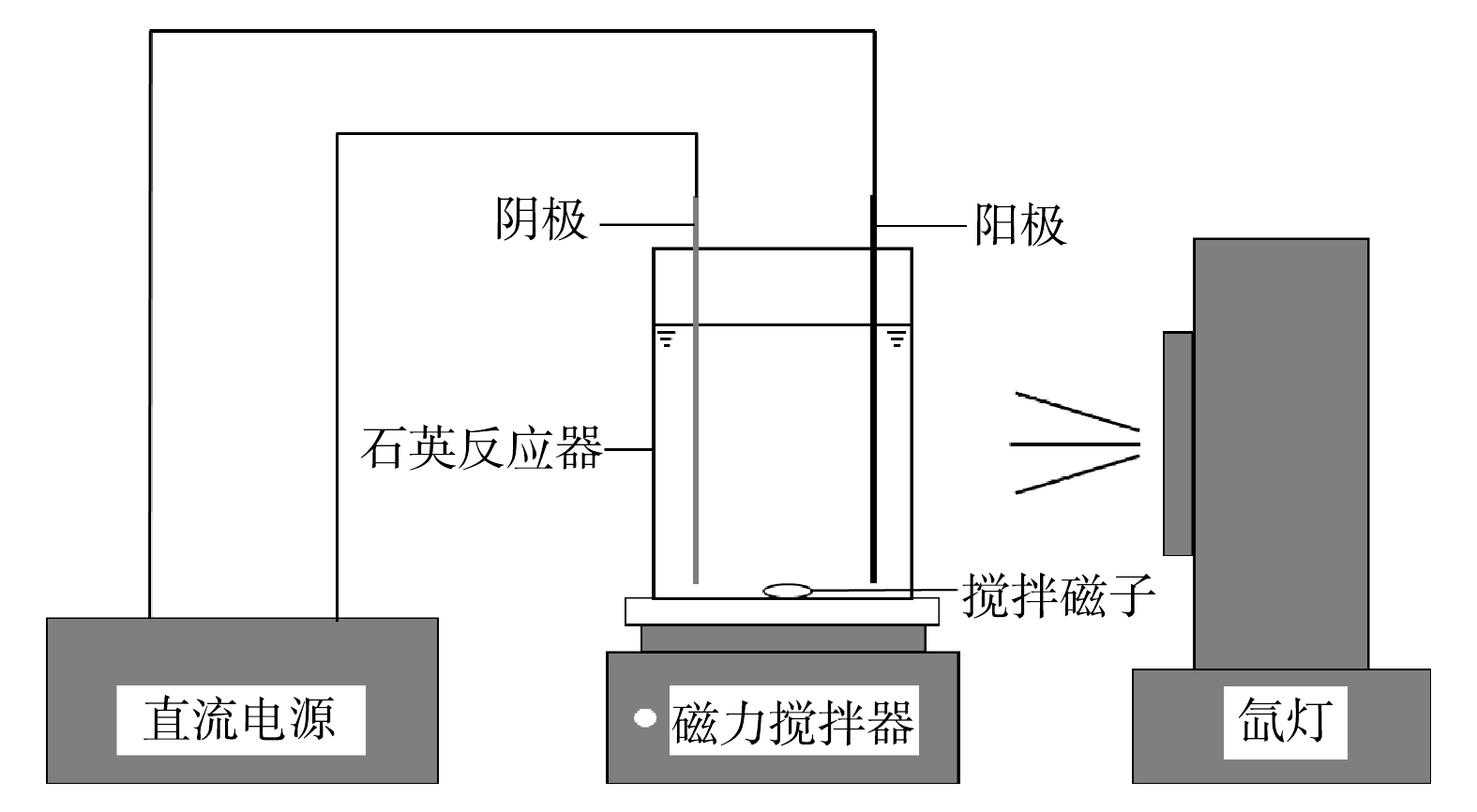

图 1 光电催化氧化实验装置示意图

Figure 1. Schematic diagram of the photoelectrocatalytic oxidation system

-

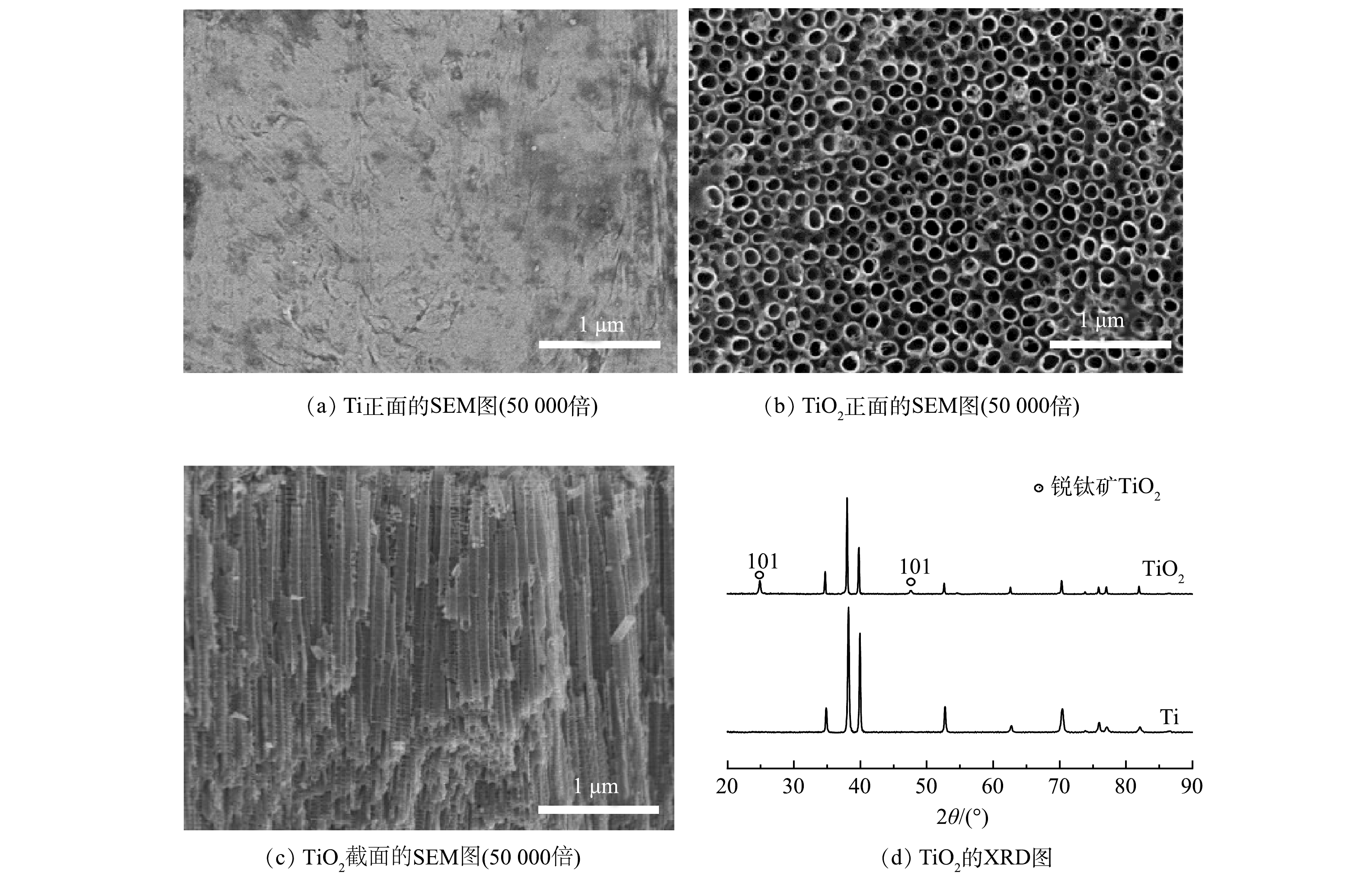

图 2 Ti基底和TiO2纳米管电极的SEM图像和XRD谱图

Figure 2. SEM images and XRD patterns of Ti substrate and TiO2 nanotube arrays electrode

-

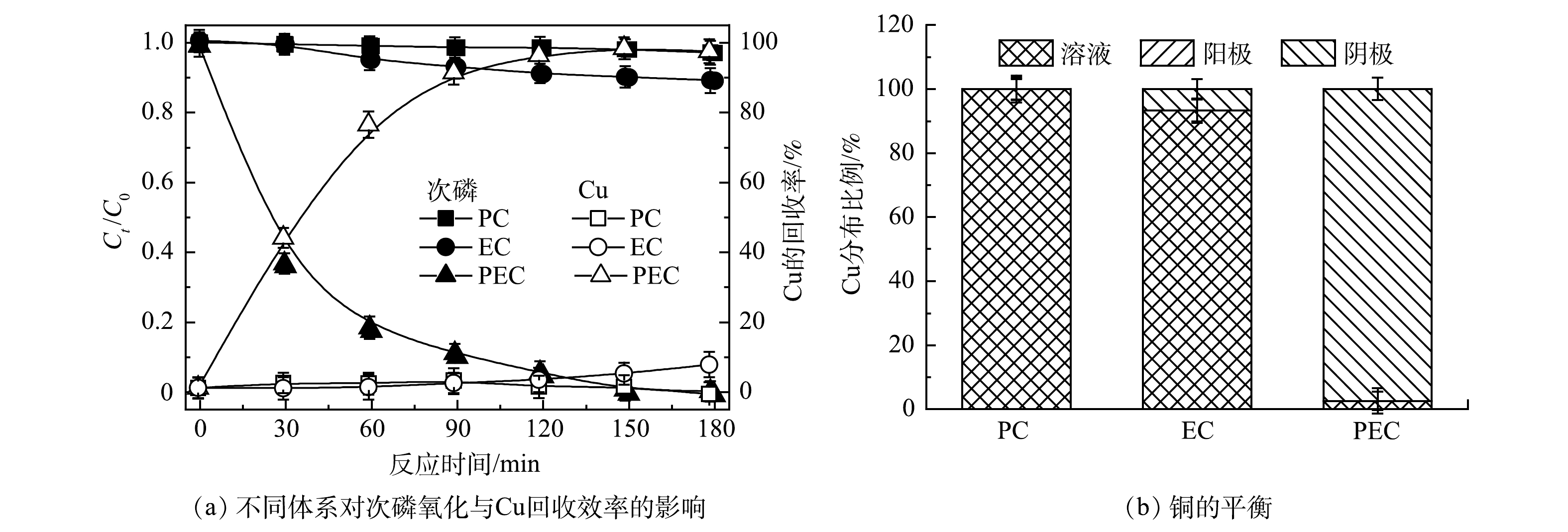

图 3 TiO2纳米管光阳极在光电催化(PEC)、电催化(EC)和光催化(PC)下对次磷氧化与Cu回收效果对比

Figure 3. Hypophosphite oxidation and Cu2+ ions recovery via photoelectrocatalytic (PEC), electrocatalytic (EC), and photocatalytic (PC) processes using TiO2 nanotube arrays photoanode

-

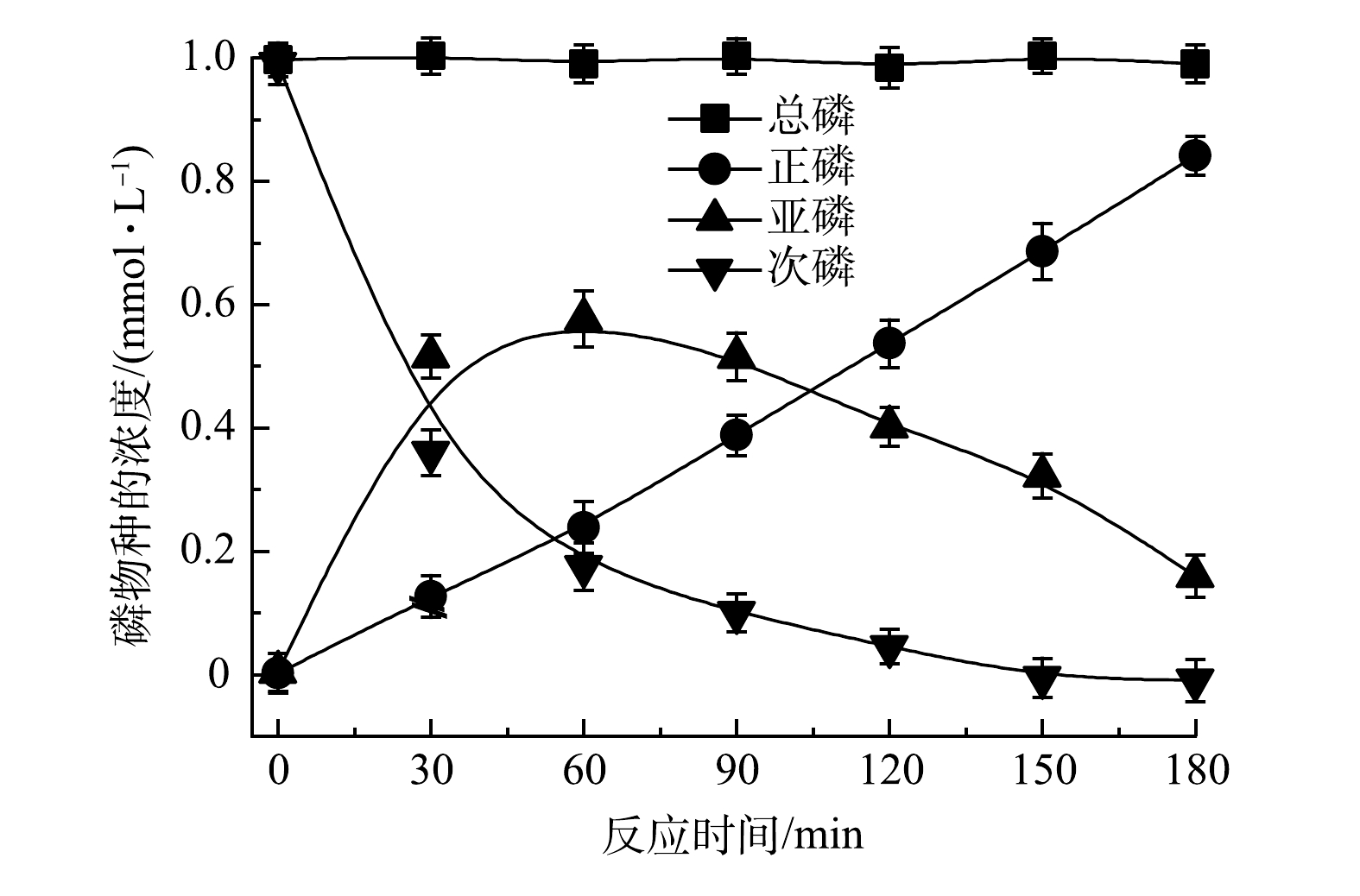

图 4 在电压为2.0 V条件下PEC体系次磷氧化过程中间产物的生成和P元素平衡

Figure 4. Generated intermediates and P mass balance in the PEC process for hypophosphite oxidation at 2.0 V bias potential

-

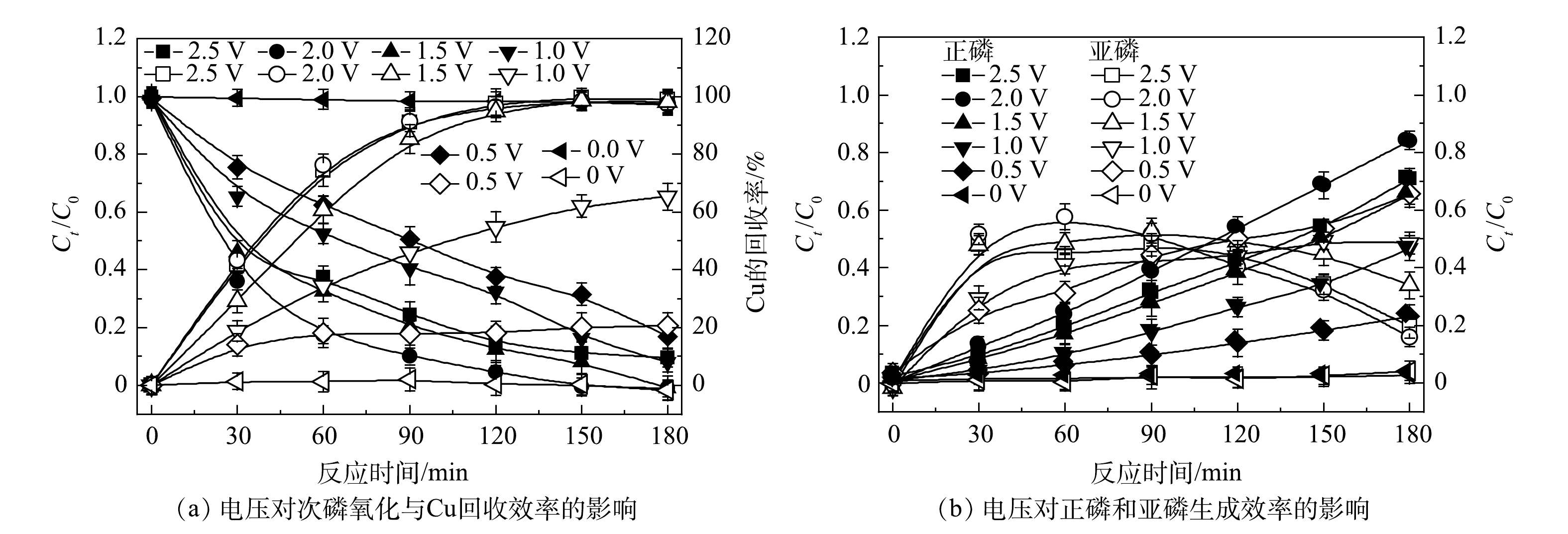

图 5 外加偏压对TiO2纳米管电极作为光阳极下PEC对次磷氧化与Cu回收效果的影响

Figure 5. Effect of applied voltages on hypophosphite oxidation and Cu2+ ions recovery via PEC process using TiO2 nanotube arrays photoanode

-

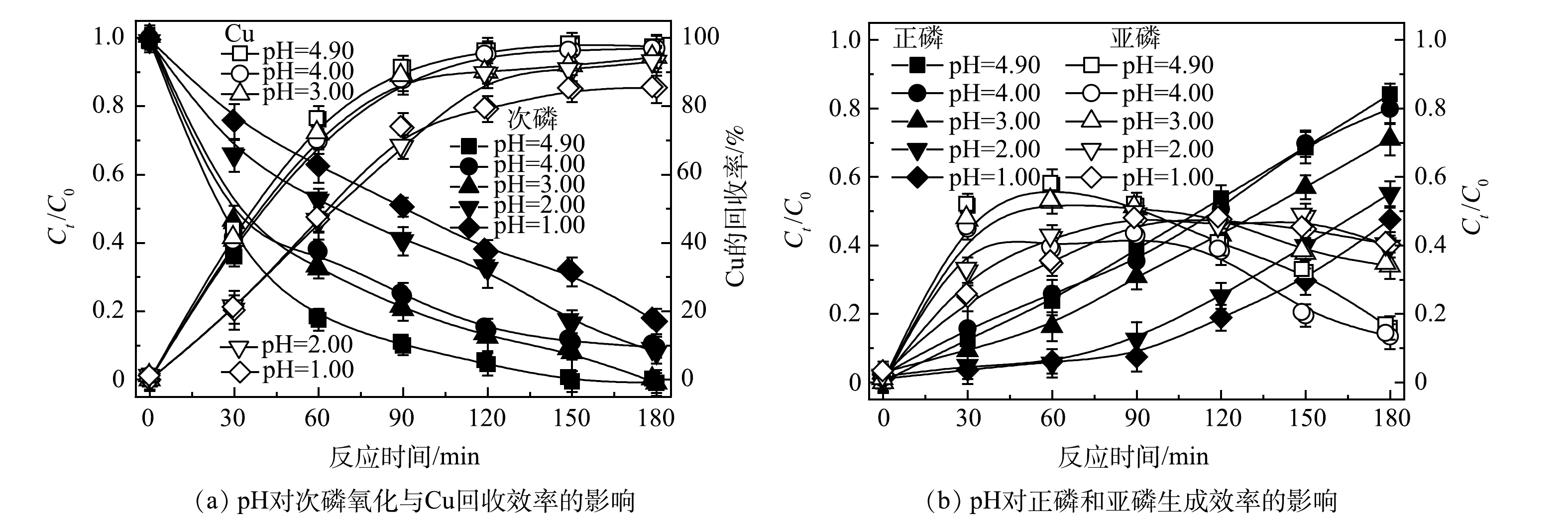

图 6 溶液初始pH对TiO2纳米管电极作为光阳极下PEC对次磷氧化与Cu回收效果的影响

Figure 6. Effect of initial pH on hypophosphite oxidation and Cu2+ ions recovery via PEC process using TiO2 nanotube arrays photoanode

-

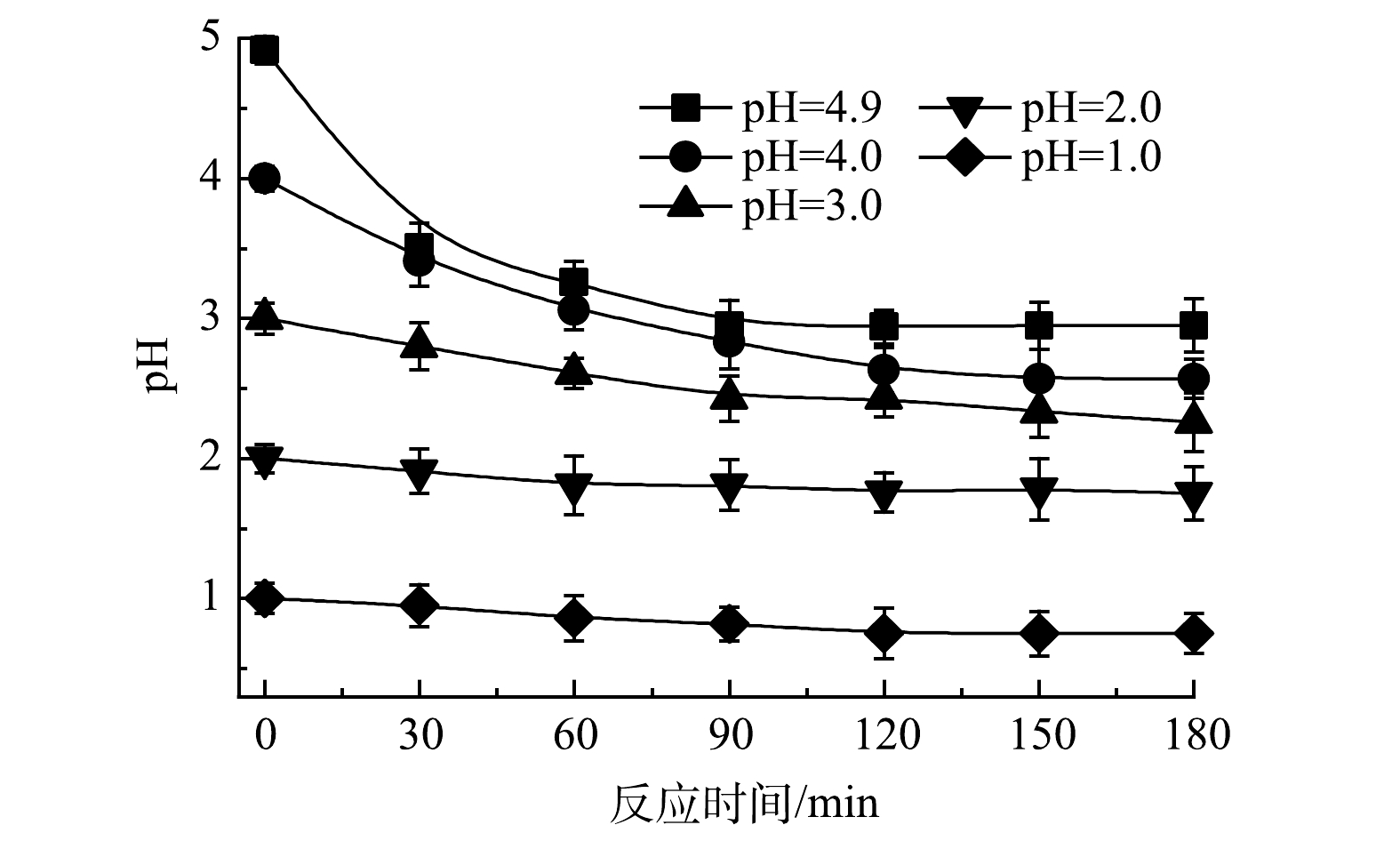

图 7 不同初始值时溶液pH的变化

Figure 7. Changes in the solution pH at different initial pH

-

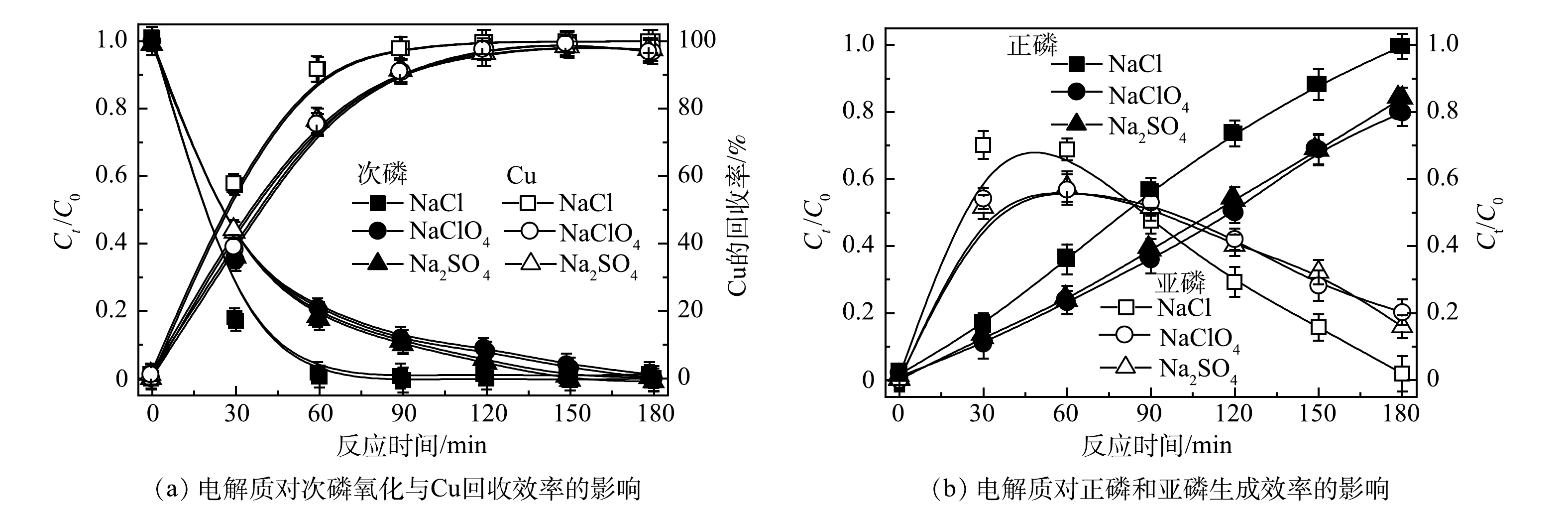

图 8 电解质种类对TiO2纳米管电极作为光阳极下PEC对次磷氧化与Cu回收效果的影响

Figure 8. Effect of electrolyte type on hypophosphite oxidation and Cu2+ ions recovery via PEC process using TiO2 nanotube arrays photoanode

-

图 9 不同浓度NaCl对TiO2纳米管电极作为光阳极下PEC对次磷氧化与Cu回收效果的影响

Figure 9. Effect of different NaCl concentrations on hypophosphite oxidation and Cu2+ ions recovery via PEC process using TiO2 nanotube arrays photoanode

-

图 10 不同浓度NaCl在反应过程中活性氯的产量

Figure 10. The amount of reactive chlorine produced in the PEC process with different concentrations of NaCl

-

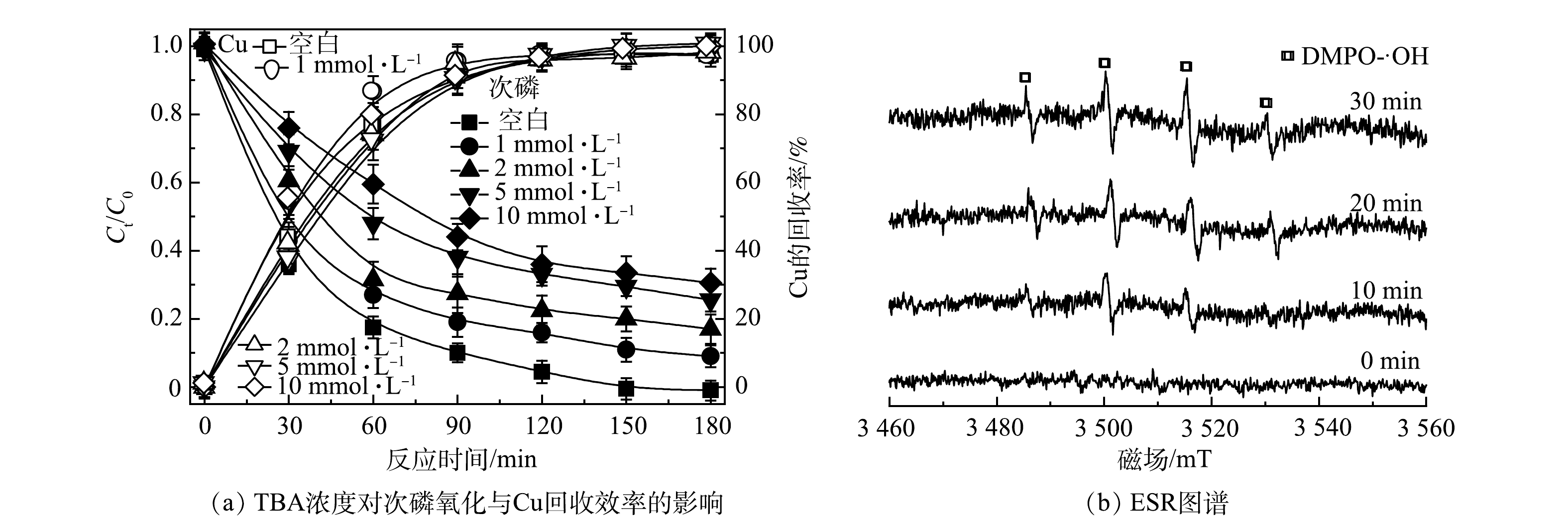

图 11 (a) 不同浓度TBA对TiO2纳米管电极作为光阳极下PEC对次磷氧化与Cu回收效果的影响以及反应过程中的DMPO−•OH的ESR图谱

Figure 11. Effect of different TBA concentrations on hypophosphite oxidation and Cu2+ ions recovery via PEC process using TiO2 nanotube arrays photoanode, and ESR signals of DMPO−•OH

-

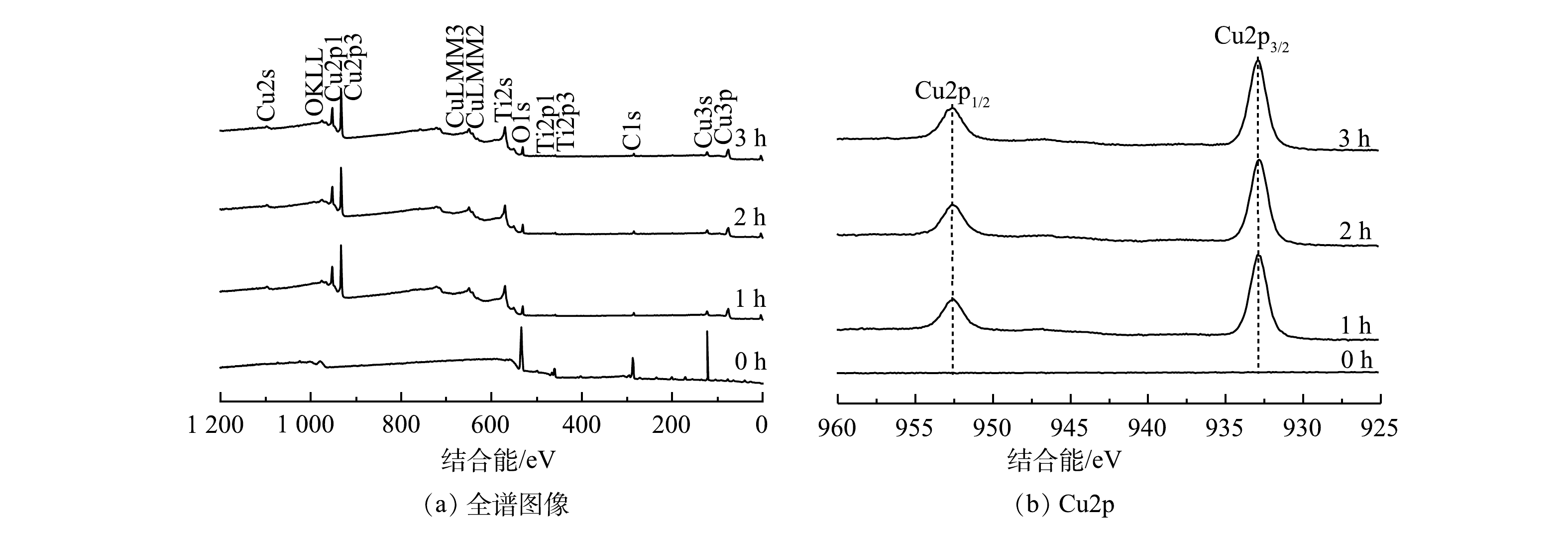

图 12 不同反应时间阴极沉积物的XPS图谱

Figure 12. XPS spectra of deposits on cathode films at different reaction time

Figure

12 ,Table

0 个