-

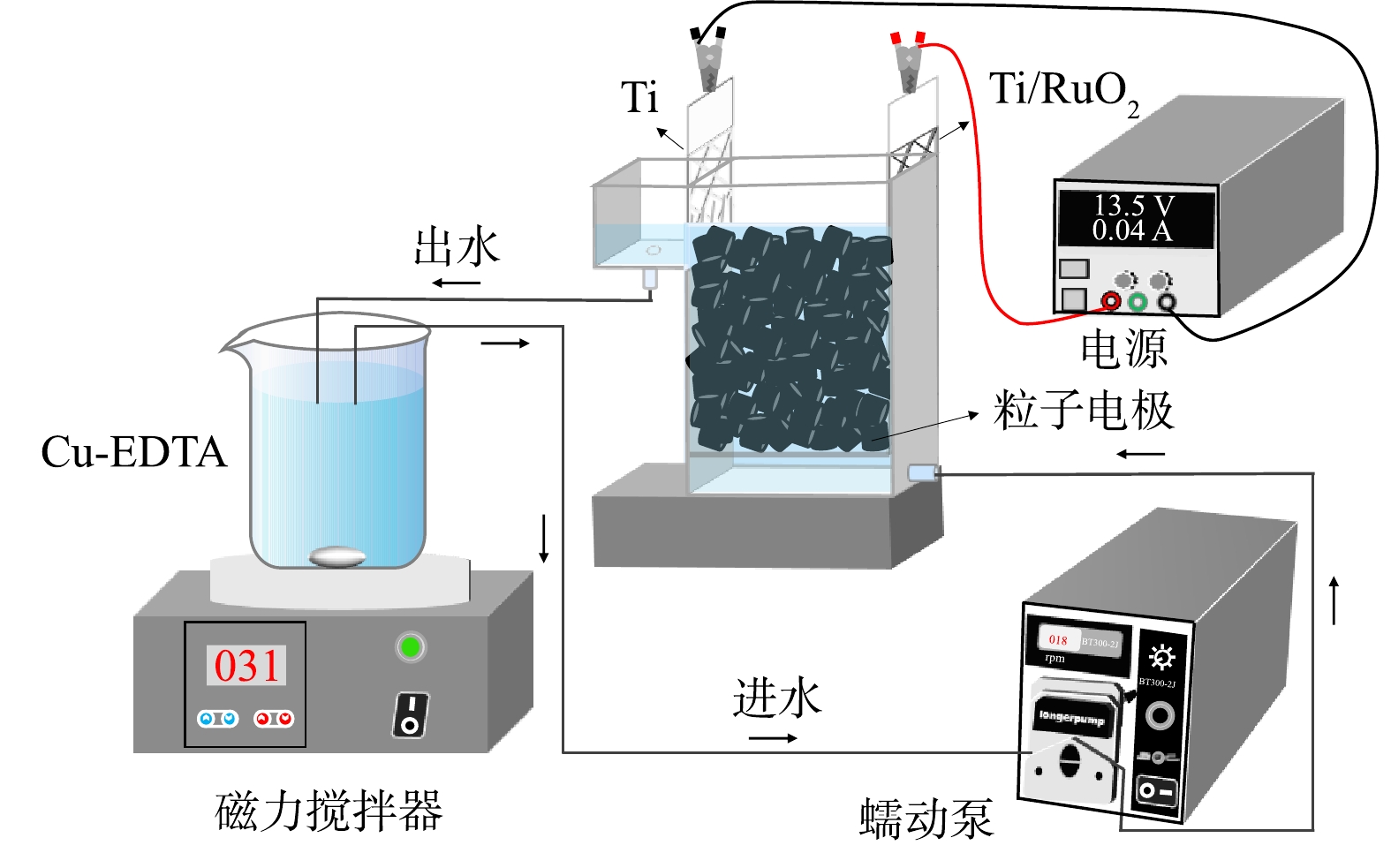

图 1 电催化Cu-EDTA解络反应装置图

Figure 1. Schematic diagram for electrocatalytic decomplexation of Cu-EDTA

-

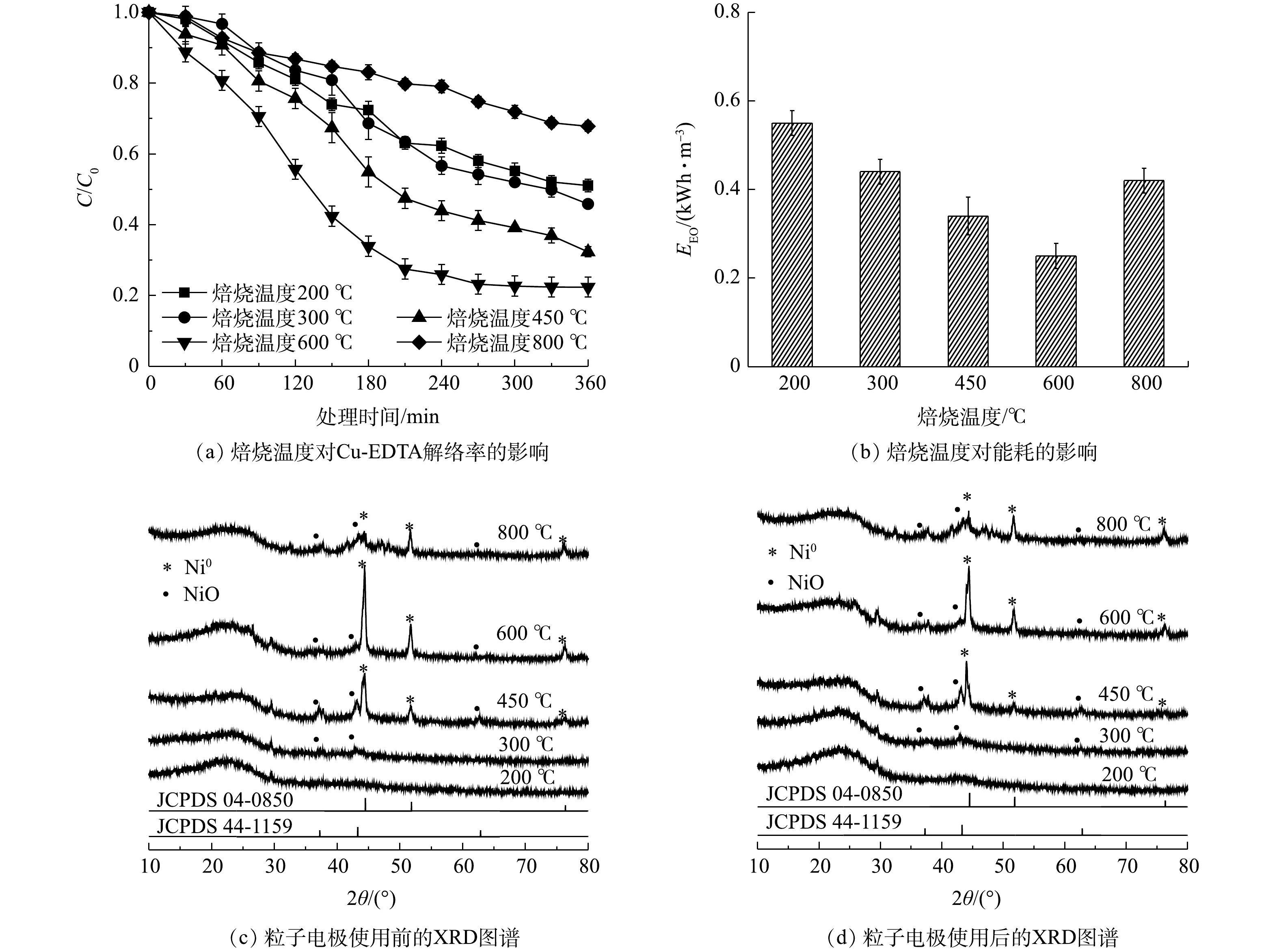

图 2 焙烧温度对Cu-EDTA解络率、能耗和粒子电极使用前后晶体结构的影响

Figure 2. Effect of calcination temperature on Cu-EDTA decomplexation efficiency, energy consumption, crystal structure of particle electrode before and after use

-

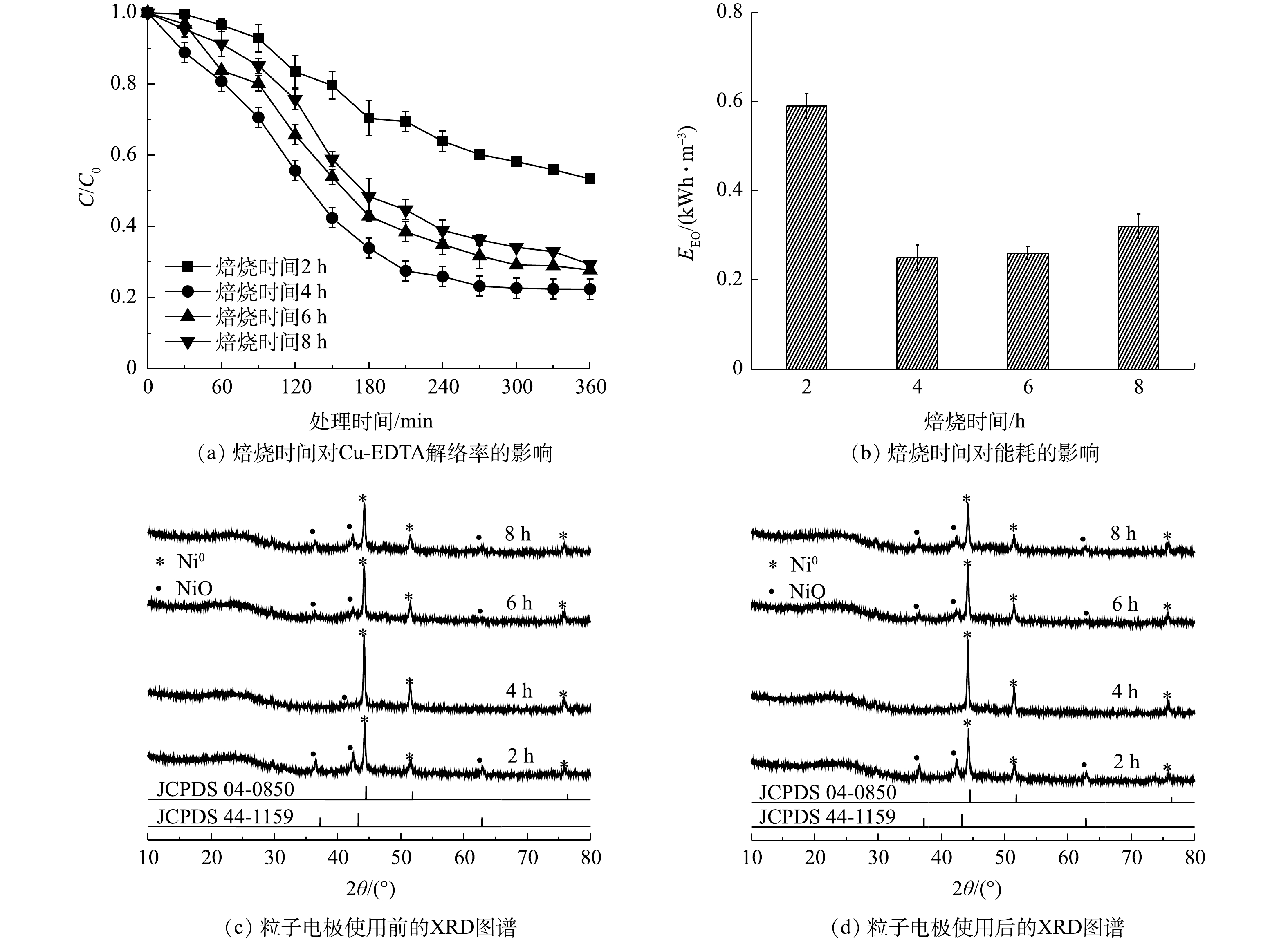

图 3 焙烧时间对Cu-EDTA解络率、能耗和粒子电极使用前后晶体结构的影响

Figure 3. Effect of calcination time on Cu-EDTA decomplexation efficiency, energy consumption, crystal structure of particle electrode before and after use

-

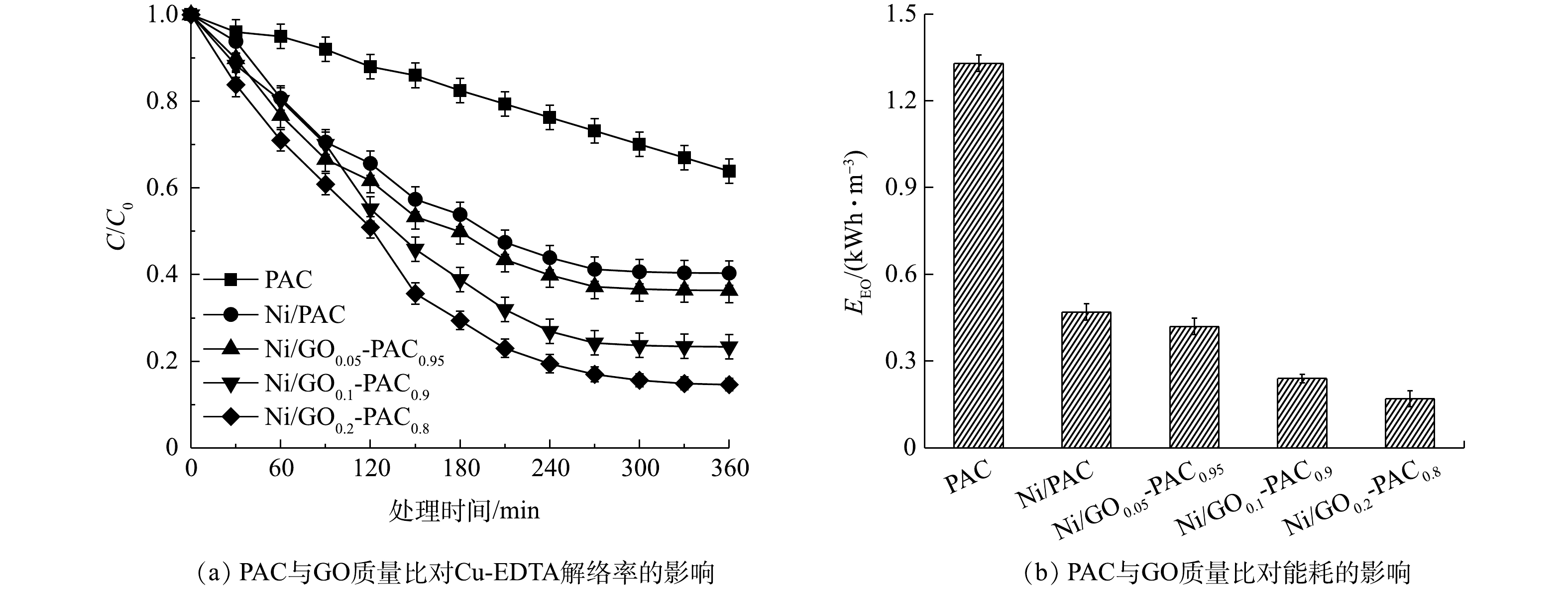

图 4 PAC与GO质量比对Cu-EDTA解络率和能耗的影响

Figure 4. Effect of mass ratio of PAC to GO on Cu-EDTA decomplexation efficiency and energy consumption

-

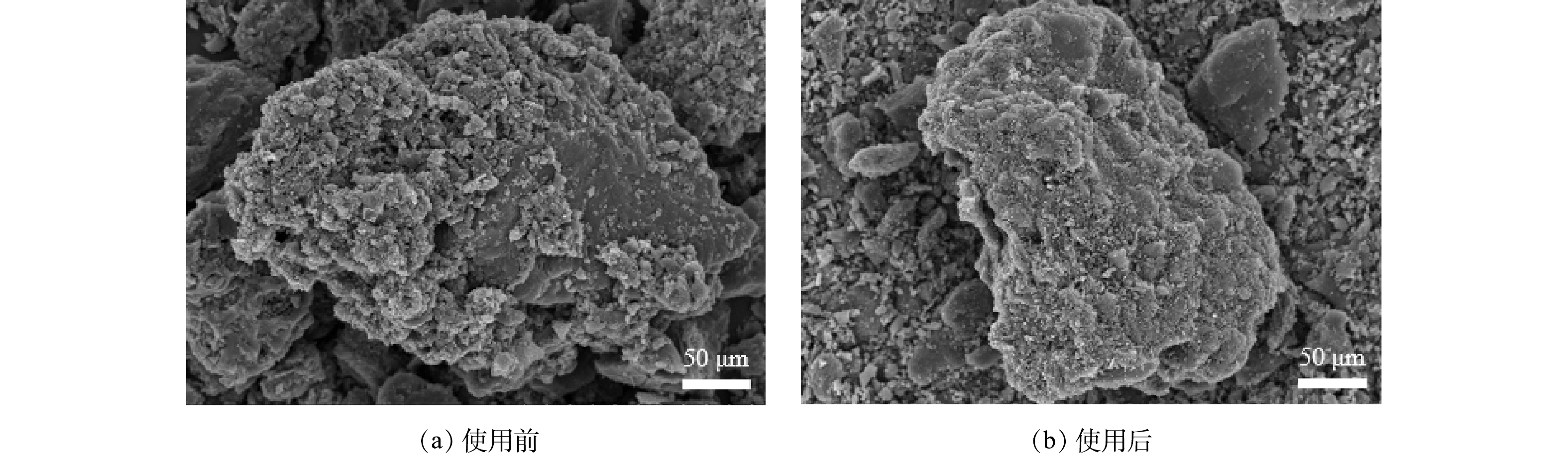

图 5 Ni/GO0.2-PAC0.8使用前后的SEM图

Figure 5. SEM images of Ni/GO0.2-PAC0.8 before and after use

-

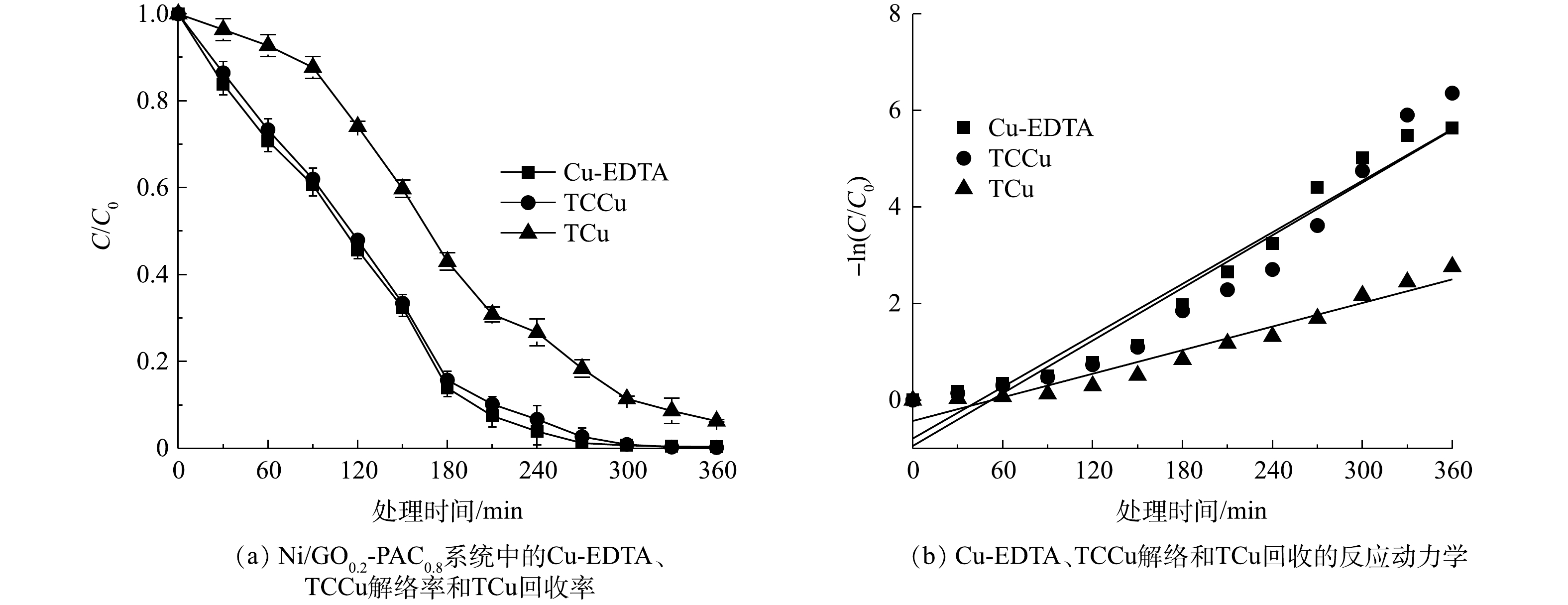

图 6 Ni/GO0.2-PAC0.8 系统中的Cu-EDTA、TCCu解络率和TCu回收率以及相应的反应动力学

Figure 6. Decomplexation efficiency of Cu-EDTA, TCCu and recovery efficiency of TCu, and corresponding reaction kinetics in Ni/GO0.2-PAC0.8 system

-

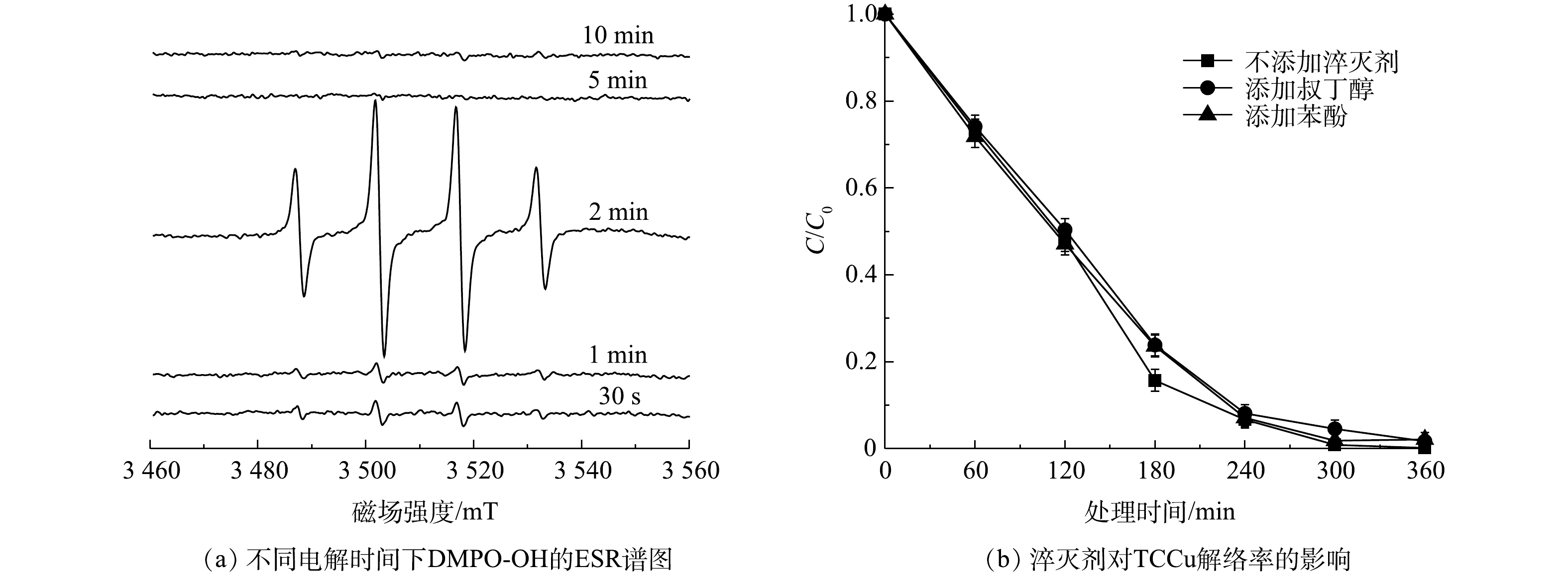

图 7 Ni/GO0.2-PAC0.8系统中DMPO-OH的ESR谱图和淬灭剂对TCCu解络率的影响

Figure 7. ESR spectra of DMPO-OH and effect of quencher on the decomplexation efficiency of TCCu in Ni/GO0.2-PAC0.8 system

-

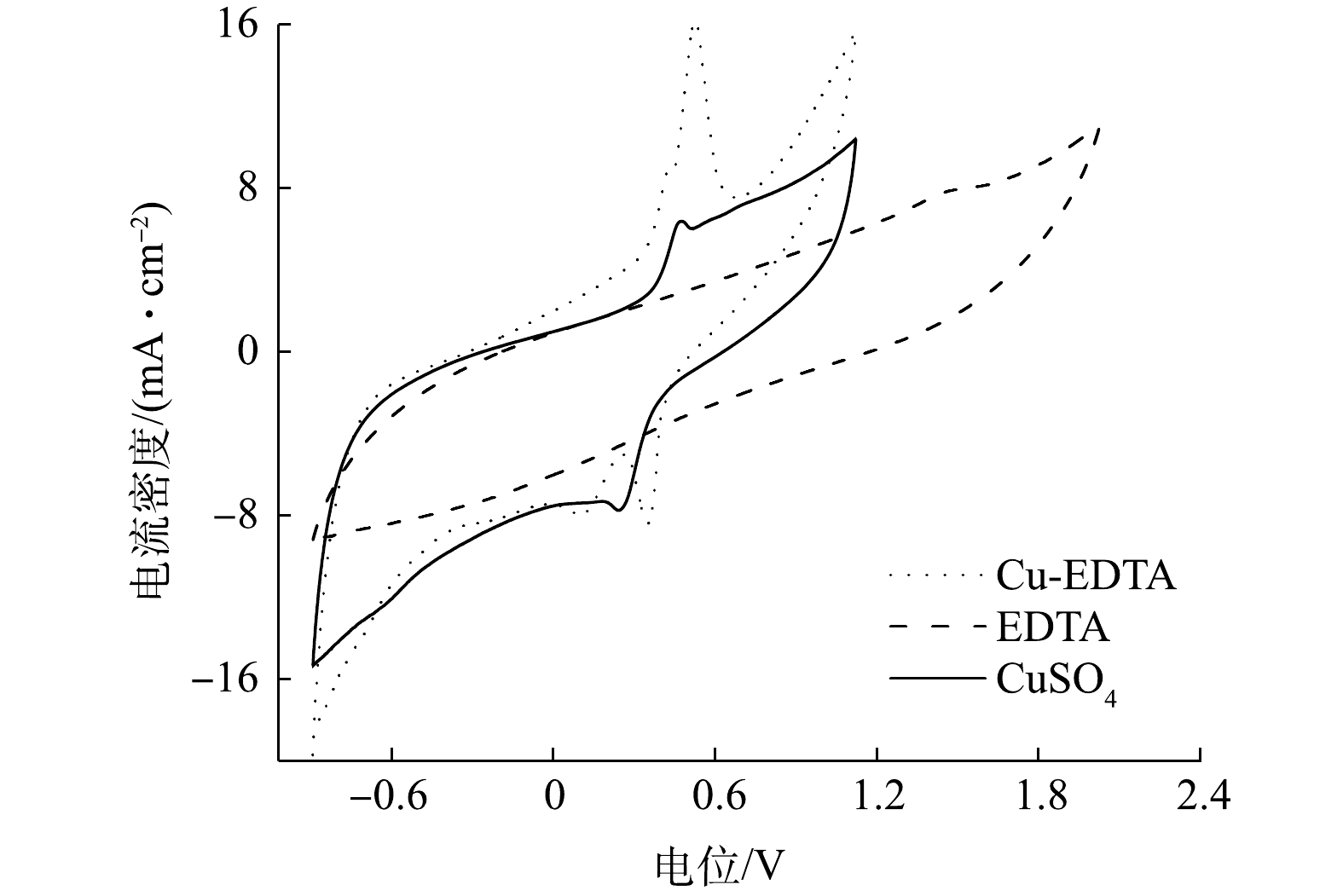

图 8 Ni/GO0.2-PAC0.8在Cu-EDTA、EDTA和CuSO4溶液中的循环伏安曲线

Figure 8. Cyclic voltammetry curves of Ni/GO0.2-PAC0.8 in Cu-EDTA, EDTA and CuSO4 solutions

Figure

8 ,Table

2 个