-

易腐垃圾是指易腐烂的、含有大量有机物质的生活垃圾和部分农业生产废弃物,主要包括餐厨垃圾、城乡居民日常生活产生的垃圾、农贸市场产生的生鲜废弃物等,具有营养丰富,但量大、处理难度高的特点,给环境带来巨大压力[1]. 生物质的热解炭化处理在绿色低碳处理废弃生物质、应对日益严峻的固废环境污染和资源耗竭问题具有突出的优势. 热解炭化生成生物质炭可作为土壤培肥改良和环境修复的功能性材料,具有很大的资源化利用价值[2-3]. 生物质炭是生物质在无氧或限氧条件下热裂解(主要<700 ℃)产生的固体富碳产物,具有高度芳香化、稳定性好、比表面积大、孔隙结构丰富、富含植物所需的营养元素等特点[4-6]. 作为土壤改良修复材料,生物质炭可以改善土壤理化性质、增加养分、影响土壤微生物活动、缓解干旱和盐胁迫、钝化吸附土壤中的重金属和有机污染物[7]. 生物质炭的理化特性与其功能密切相关,而炭化温度和炭化原料是生物质炭结构、酸碱度等理化特性和应用功效的最主要影响因子[8-9]. 前人研究表明,生物质炭多为碱性,原料中的灰分含量越多,其制备的生物质炭pH相对越高[10-11]. 纤维基生物质炭的C含量和比表面积通常大于非纤维基生物质炭[12-13]. 随着炭化温度的升高,生物质炭的pH及C含量上升,比表面积增大,吸附作用增强,官能团丰度降低[12,14-16]. 与纤维基生物质炭相比,高灰分的畜禽粪便炭具有更高的pH,可以有效改良酸性土壤和贫瘠土壤. 简敏菲等[17]研究发现,秸秆炭C含量随炭化温度的升高而上升,而王煌平等[18]研究畜禽粪便等高灰分生物质炭发现,炭化温度的升高,C含量不变甚至下降. 随着畜禽粪便、污泥、餐厨垃圾、易腐垃圾等有机固废消纳问题的日益严重,此类非木质纤维素原料的生物质炭化研究逐渐增多. 目前,生物质炭原料主要来源于植物基的农林废弃物[17],炭化温度与原材料对生物质炭性能的影响研究往往是针对单一原料或单一温度,且制备规模以少量实验室制备为主,工厂化制备的研究较少,对实际应用有一定距离,缺少系统性、定量化关系研究. 猪粪、污泥基非植物来源,甚至是更复杂的混合有机原料,如易腐垃圾,给生物质炭的制备、理化性质和应用功效相关性研究带来了更多的不确定因素. 植物基与易腐垃圾基有机固废原料的共性分析与比较研究较少,所以有必要比较不同类型原料和炭化温度条件下,生物质炭pH、可溶性盐浓度这些土壤施用相关的理化特性,进行较为系统的因子分析.

生物质炭其理化特性因原料差异和炭化温度发生变化,350 ℃以下时,主要是半纤维素热解阶段,400—500 ℃是木质素大量降解阶段,超过500 ℃,产率趋向稳定,炭的芳香化程度和炭稳定性增强[19-20]. 因此,本文选取山核桃蒲壳、玉米秸秆和易腐垃圾为原料,在350、500、650 ℃热解温度下制备生物质炭,分析原料种类和温度对生物质炭元素组成、表面结构、pH值、可溶性盐浓度(EC)等影响土壤应用的理化特性的影响. 在较大的原料异质性条件下,探讨热解温度与生物质炭特性之间的定量关系,以期为易腐垃圾炭制备,及其农业土壤环境下的规模化应用提供依据.

-

试验用生物质炭由浙江金锅锅炉有限公司提供. 以山核桃蒲壳、玉米秸秆和易腐垃圾为原料,山核桃蒲壳来自地方农林废弃物处理点、易腐垃圾采自地方易腐垃圾处理中心(该处理中心的易腐垃圾主要来源于农贸市场的生鲜垃圾约60%,餐厨垃圾40%,以植物性垃圾为主). 其中用于制炭的易腐垃圾含水率为20%以下,是由新鲜易腐垃圾经过混合、破碎、干化处理后得到的垃圾混合物. 所用易腐垃圾原料的EC值为(5.23±0.21) mS·cm−1,磷含量为0.70%±0.06%,钾含量为2.52%±0.161%. 本研究分别在350、500、650 ℃条件下,限氧热裂解(炭化炉体内部不与空气接触,热解炭化过程中,没有氧气参与热解过程,压力为常压)制备山核桃蒲壳炭(WSB)、玉米秸秆炭(MB)和易腐垃圾炭(PWB). 每种原料每个温度条件下热解炭化,重复3次,抽取每次部分样品用于理化特性分析.

-

采用元素分析仪(vario EL,德国)测定生物质炭的C、H、N元素含量. O含量通过灰分法[21]间接测定,并计算H/C、O/C、(O+N)/C、C/N的原子比. O含量的计算:

-

生物质炭样品与KBr以质量比1:100混合压片,采用傅里叶红外光谱仪(Nicolet iS50,美国)对生物质炭进行红外光谱分析,观察生物质炭的官能团情况.

-

采用电镜能谱一体机(Phenom Prox,荷兰)观测生物质炭表面形貌和形态以及测定生物质炭表面元素. 电镜选择×3000放大倍数,EDS能谱选择面扫,选择清晰完整的样品部位,拍照保存并分析.

-

生物质炭样品与去离子水按1:20(W:V)混合,180 r·min−1振荡1 h,采用多参数测试仪(S470-USP/EP Mettler,瑞士)测pH和EC值[21],滤液采用火焰光度计(Shewood,英国)测生物质炭水溶性Na+、K+浓度.

-

元素组成分析、pH值与EC值等理化特性数据均为3份重复制备的生物质炭样品的平均值,红外光谱数据采用OMNIC处理,数据采用SPSS26.0进行数据统计分析和显著性检验.

-

山核桃蒲壳炭(WSB)和玉米秸秆炭(MB)的元素含量大小为C>O>H>N,而易腐垃圾炭(PWB)的元素含量大小为C>O>N>H(表1). 热解过程中的炭化温度被认为是生物质炭稳定性的一个指标[4],随着炭化温度的升高,WSB和MB的C含量上升,H、O元素含量下降,这和前人研究结果一致[22]. 然而,不同炭化温度制备的PWB的元素含量变化不显著. 不同炭化温度下,PWB的C含量显著低于WSB和MB,平均值为后二者的65.4%和68.8%,N含量则以WSB最低,PWB的C/N比值最低,平均为19.54. 随着炭化温度的升高,WSB和MB的C含量分别从47.68%、46.81%提高到59.41%、53.01%,分别提高了24.6%、13.2%;不同炭化温度下,PWB的C含量在34.13%—35.17%范围间波动,差异性不显著. H/C、O/C和(O+N)/C原子比作为重要指标可以用来表征生物质炭芳香性、亲水性、极性以及生物质炭结构.WSB和MB的O/C、H/C、(O+N)/C的原子比随炭化温度的升高而降低,H/C比值分别下降了58.7%和34.7%,PWB的O/C、(O+N)/C出现了一定波动,未表现出显著性差异,仅H/C显著下降了18.0%. 三类生物质炭的H/C下降,说明生物质炭的芳香性增强,结构更稳定. WSB和MB的O/C、(O+N)/C随温度的升高而下降,说明高温使得生物质炭亲水性和极性减弱.

以往研究偏重于炭化温度和植物基原料对生物质炭理化特性的影响,而对高灰分或来自生活固废的混合原料的生物质炭的理化特性变化规律研究较少. 姚红宇等[23]研究棉秆生物质炭发现,随炭化温度的上升,pH和EC值上升,CEC、有机碳含量、N呈下降趋势. 朱启林等[9]研究禾本科植物生物质炭发现,随炭化温度的上升,pH、灰分和C含量升高,水稻秸秆炭C/N下降. 王煌平等[18]研究畜禽粪便生物质炭发现,随炭化温度的上升,灰分、C/N呈上升趋势,C、N呈下降趋势,P、K和养分呈上升趋势;由于易腐垃圾是由菜叶、骨头、果壳、米饭等多种类型的有机废弃物混合而成,不同材料类型对炭化温度的响应不一. 王琬丽等[24]对餐厨垃圾沼渣热解特性研究发现,灰分质量分数的高低对热解过程有明显的影响. 赵金凤等[25]研究表明,灰分含量高的生物质炭化学稳定性更强. 本研究结果也表明PWB灰分含量接近50%,其他元素占比较小,最终对温度的综合响应总体表现为不敏感,稳定性强.

-

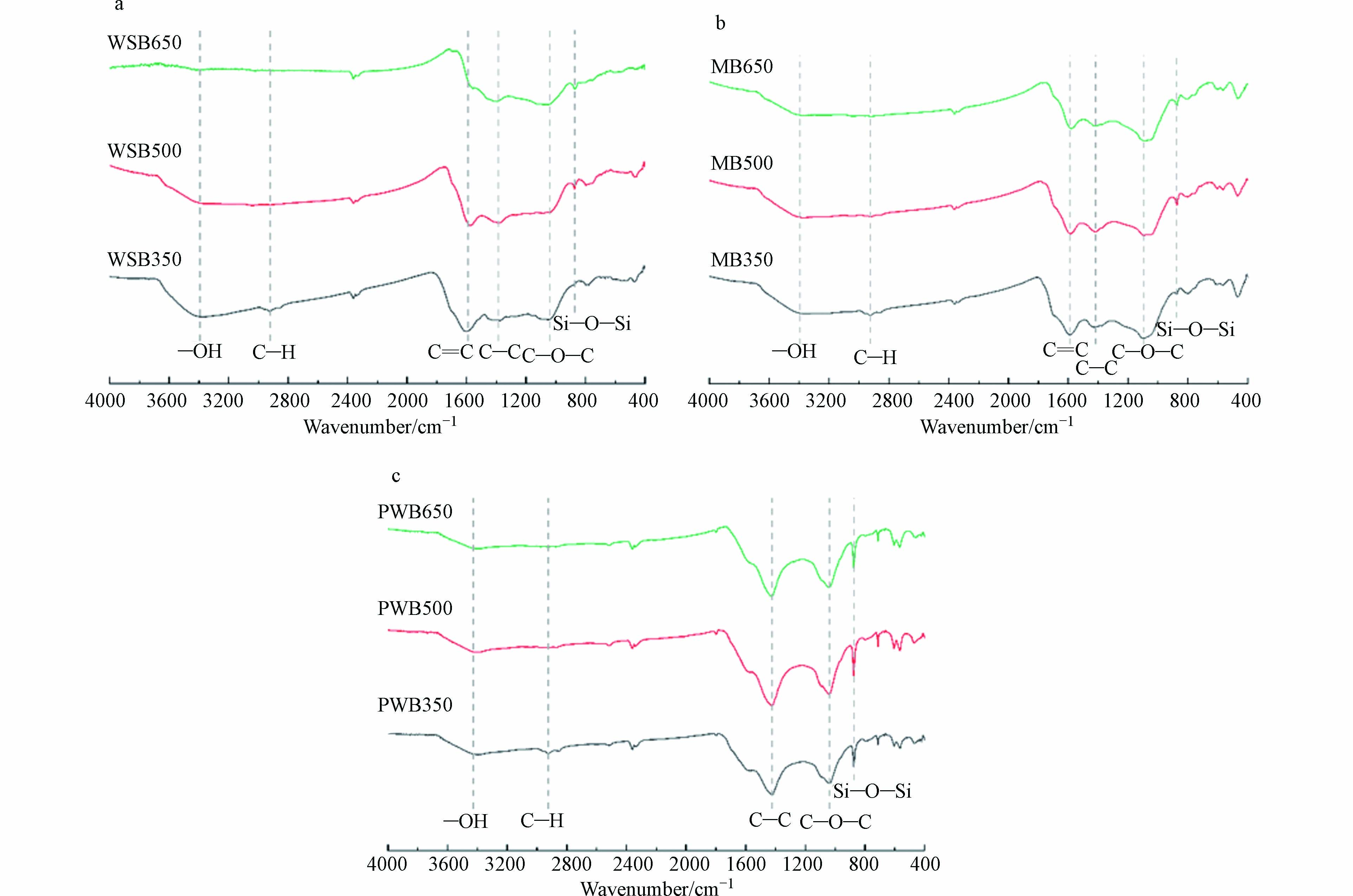

红外光谱分析结果表明,不同炭化温度和原料制备的生物质炭,其表面官能团因多种因素而存在差异(图1). 3种原料的生物质炭主要特征吸收峰出现在3393—3428 cm−1、2922—2926 cm−1、1388—1590 cm−1、1038—1096 cm−1、873 cm−1. 其中,3393—3428 cm−1为酚羟基和醇羟基拉伸振动峰[26],2922—2926 cm−1为脂肪族C—H的拉伸振动峰[27],1388—1590 cm−1出现苯环或芳香烃C=C、C—C伸缩振动峰[28],1038—1096 cm−1为纤维素中的C—O—C吸收峰[29],873 cm−1为Si—O—Si的拉伸振动峰[30]. 在3393—3428 cm−1处WSB和MB吸收峰强度随着炭化温度的升高而明显减弱,说明由氢键缔合的羟基逐渐断裂,酸性含氧官能团酚羟基减少,而PWB变化不明显,说明炭化温度的升高对PWB表面官能团的影响较小,这与元素含量变化得出的结论相吻合. 在2922—2926 cm−1处,生物质炭的伸缩振动强度均随炭化温度的升高而下降. 在350 ℃时,3种生物质炭振动强度已较弱,在500 ℃以上时,该伸缩振动峰消失,生物质炭的烷基基团丢失,说明炭化温度的升高,生物质炭的芳香化结构逐渐增强[31]. 在1388—1590 cm−1处,不同生物质炭峰值明显,表明生物质炭具有高度芳香化结构. 在1038—1096 cm−1处,WSB和MB随着炭化温度的升高,振动强度逐渐减小,说明炭化温度升高,纤维素和半纤维素损失,芳香族化合物相对保留下来,而PWB无明显变化. 在873 cm−1处,随炭化温度升高吸收峰增强,说明三类生物质炭Si-O-Si官能团富集,且PWB此处的峰更为明显.

-

扫描电镜和EDS能谱(图2)分析结果表明,WSB有较完整平滑的表面结构,K、Ca含量较高,Si、Na含量较少,随炭化温度的升高,表面崎岖程度增加,出现不平整的表面结构. MB有丰富的孔隙结构,Na、Si含量高于WSB,随炭化温度的升高,内部出现了一系列孔道,其孔道的形成与纤维素和木质素的分解有关. PWB原料成分复杂,具有最高的Si、Na含量,表面结构与表1元素组成随炭化温度变化较小,表明热稳定性较好. EDS分析结果表明,PWB有更多的Si含量,印证了其含有更多的Si—O—Si官能团.

-

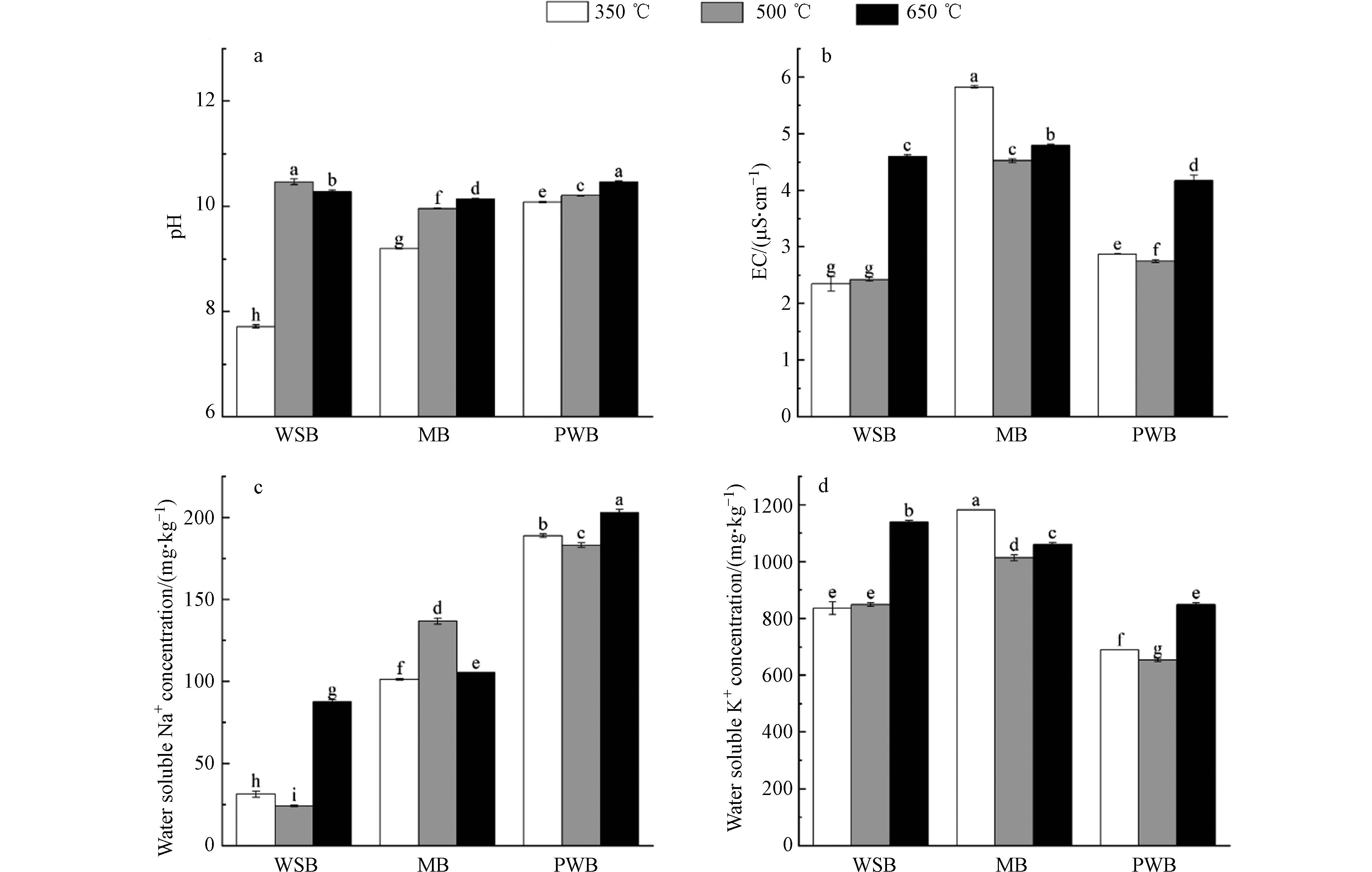

结果表明(图3a),本研究的生物质炭pH值均为碱性,500 ℃与650 ℃的生物质炭pH值显著高于350 ℃. 随着炭化温度的上升,三类生物质炭的pH呈上升趋势,这与以往研究结果一致[32]. 炭化温度是生物质炭理化特性和结构变化的重要影响因素,炭化温度的升高会导致生物质炭的一些酸性官能团在炭化过程中分离,pH上升,化学键重新排列并生产新的表面官能团等,从而改变生物质炭的性能[28]. 当炭化温度为350 ℃时,不同原料生物质炭间的pH值差异较大,依次为PWB>MB>WSB,其中WSB的pH值仅为7.72±0.03;不同原料生物质炭的H、O含量大小依次为WSB>MB>PWB. 当炭化温度由350 ℃升高到500 ℃时,pH值变化幅度大,WSB的pH值提升幅度最大,这与姚红宇[23]的研究结论一致. 随炭化温度的升高,生物质炭的H、O含量呈下降趋势. 500 ℃以上时,生物质炭pH值趋于稳定,都达10.0以上,其中WSB和PWB的pH最高能达到10.47,MB的pH最高达到10.14. 升温过程中,纤维素和木质素快速分解,支链和侧链断裂,O以H2O和CO2的形式排出[33],并且有机质和挥发性物质的逐渐减少,导致硅酸盐等不可挥发性物质的占比增大,进而使得灰分相对含量上升[34]. 灰分含量的快速上升,导致WSB的pH值快速上升.

EC值是表征生物质炭可溶性盐浓度的一个综合性指标[35],EC值取决于原料和炭化温度,与自身灰分中的碱金属盐和碱土金属阳离子相关[36]. 3种生物质原料中(图3b),MB的EC值最高,WSB与PWB相接近. 植物基生物质炭的EC值通常低于畜禽粪便炭[37]. 随着炭化温度的上升,WSB与PWB的EC值呈上升趋势. 而本试验的MB呈下降趋势,但在同炭化温度下,EC值的大小依次为MB>WSB>PWB. 其中,MB350的EC值最高,为5.82 mS·cm−1,WSB350的EC 值最低,为2.35 mS·cm−1.

3种原料生物质炭中(图3),PWB中的水溶性Na+浓度最高,波动范围为183.1—202.8 mg·kg−1,其次为MB、WSB. PWB水溶性K+浓度范围为653.7—848.5 mg·kg−1,低于MB和WSB.随着炭化温度的升高,WSB和PWB的水溶性K+、Na+浓度在500 ℃以上有大幅提高,而MB以500 ℃最高. 水溶性K+含量与EC值在不同原料和炭化温度间的变化趋势相近.

-

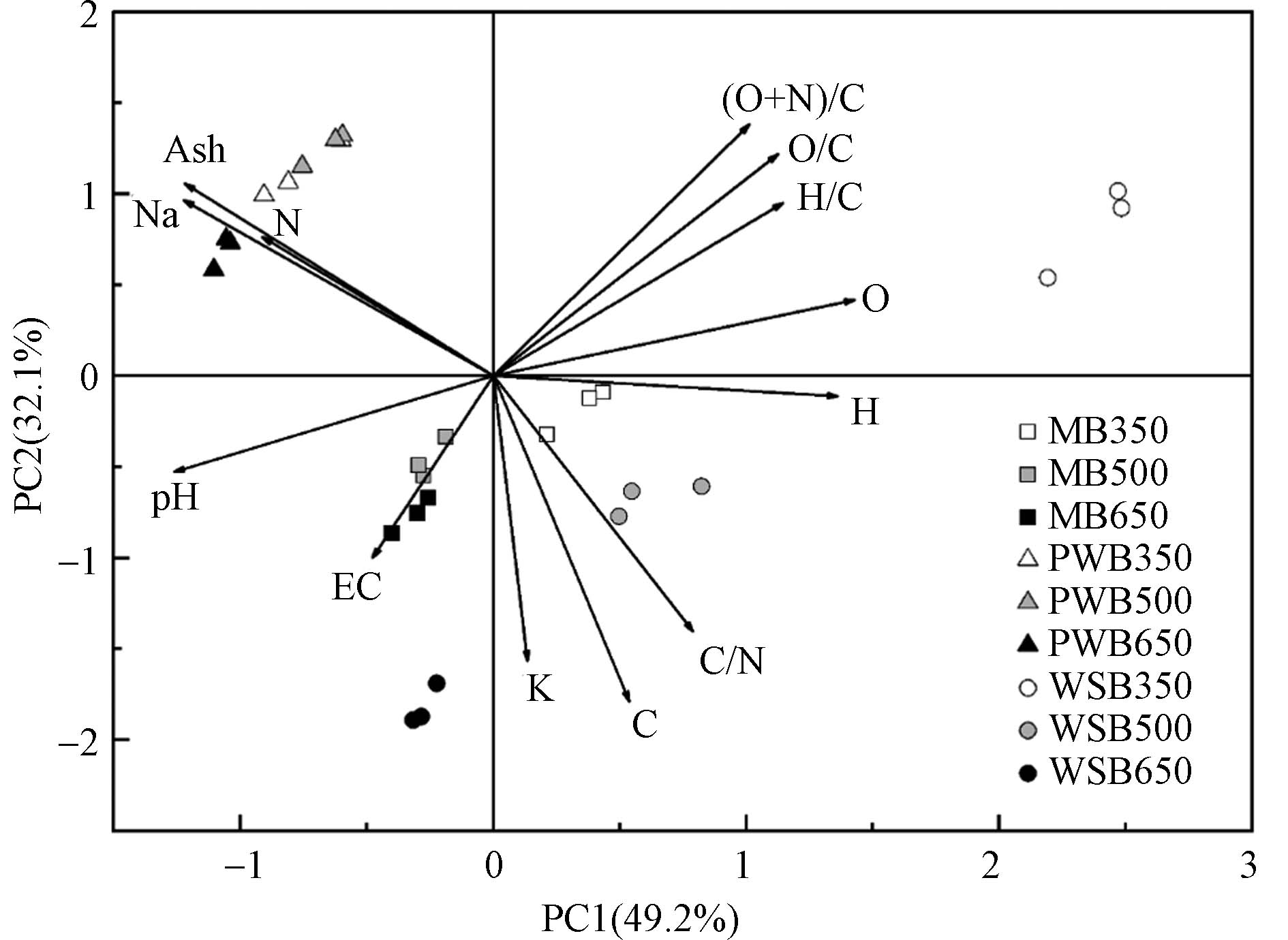

相关性分析表明(表2),灰分与C含量、C/N比值、水溶性K+含量呈极显著负相关,与N含量、水溶性Na+、pH值呈极显著正相关;pH与O含量、(O+N)/C、O/C、H/C呈极显著负相关;EC与(O+N)/C、O/C呈极显著负相关,与水溶性K+含量呈极显著正相关;主成分分析(PCA)结果表明(图4),灰分含量、水溶性Na+含量和C/N比值是区分3种原料来源生物质炭的重要因子,3种原料来源生物质炭的灰分含量依次为PWB>MB>WSB. 而(O+N)/C、O/C、H/C、EC值是区分不同炭化温度制备的生物质炭的重要因子,同时也发现WSB在不同炭化温度下差异最大,MB次之,PWB最小.

本研究结果表明,灰分是影响生物质炭理化特性的重要因子,也是影响其对炭化温度响应的关键因子. 灰分越高,生物质炭元素含量变化对温度的响应越不敏感. 在3种炭化温度下,PWB的C含量变化不显著,与其高灰分对生物质炭稳定性的保护作用有关. 从表1中可知,在较低温度时,灰分含量大的生物质炭H/C越小,说明在低温时,灰分含量高的生物质炭具有更强的稳定性. 在高温时,灰分越低的生物质炭有更低的H/C,低灰分生物质炭H/C的变化幅度高于高灰分生物质炭,说明高温可以使生物质炭更稳定,灰分对生物质炭其他元素有一定的保护作用[24-25,32]. Mcbeath等[38]研究表明,灰分富含矿物质,对有机组分提供了较强的保护作用,可提高生物质炭的芳香性,进而提高其热稳定性和化学稳定性. 不同于传统的纯植物基生物质炭,本研究中的易腐垃圾灰分含量高,并含有相当比例的硅氧化物和硅酸盐等矿物成分,可以为土壤提供更为丰富的矿质养分. 因此,灰分含量高是导致不同炭化温度下PWB的C含量相对稳定,且其pH值偏高.

近年来,易腐垃圾的有效减量化处理、资源化利用备受关注. 2020年实施新修订的《中华人民共和国固体废物污染环境防治法》,生活垃圾分类制度写进法律,从源头进行筛分处理,提高了易腐垃圾的资源化利用率. 易腐垃圾预处理技术和流程主要包括破袋、筛分、分选、破碎、生物干化或加热干化等,对于油脂丰富的餐厨垃圾,还需进行油水分离处理[39-40]. 经预处理后的易腐垃圾通常进行焚烧发电、填埋处理以及厌氧发酵但都存在二次污染或能耗大的问题[41]. 近期,地方提倡易腐垃圾通过厌氧或好氧发酵技术制备易腐垃圾有机肥,但还存在减量化慢、堆放占地、有一定盐分和有害微生物风险等问题,亟待更高效的处理技术和资源化利用方式. 易腐垃圾是有机易腐的生物质原料,可以热解炭化制备成生物质炭. 施庆文[42]的调查研究表明,7种易腐垃圾处理技术中,热解炭化的处理成本最低,同时,热解产生的热解气可燃烧利用,热解炭化产生的生物质炭可应用于农业、环保领域[43]. 本研究制备的易腐垃圾炭碳含量均大于30%,EC值甚至低于玉米秸秆炭,盐分未超标,适合于农业应用. 总之,易腐垃圾炭具有富碳多孔隙特性,与纯植物制备的生物质炭相比,其灰分和氮含量偏高,适用于改善土壤酸化和板结问题、绿化植物和农作物的栽培,尤其适合对土壤有机质有高要求的植物生长.

-

(1)因原料与炭化温度的不同,本研究的生物质炭理化特性存在较大差异,与纯植物基原料相比,易腐垃圾生产的生物质炭存在灰分、N含量高的特点. 矿质元素充分,性能相对稳定,比较适宜耕地施用.

(2)灰分是影响生物质理化特性的关键因子. 生物质炭的灰分大小为易腐垃圾炭>玉米秸秆炭>山核桃蒲壳炭,灰分越高,生物质炭pH与EC值越大,碳含量越低,受炭化温度的影响越小.

炭化温度对植物基生物质炭与易腐垃圾炭的理化特性影响比较

Effects of carbonization temperature on physicochemical properties of plant-based biochar and perishable waste biochar

-

摘要: 易腐垃圾具有产量大、有机易腐性高的特点,带来严重的环境压力和资源浪费. 炭化农用是其减量化处理和资源化利用的有效途径. 本研究以山核桃蒲壳、玉米秸秆和易腐垃圾为原料在350、500、650 ℃条件下热解炭化制备生物质炭,比较植物基生物质炭与易腐垃圾炭理化特性的差异及其影响因素. 结果表明,与山核桃蒲壳炭(WSB)和玉米秸秆炭(MB)相比,易腐垃圾炭(PWB)具有碳(C)含量低,氮(N)和灰分含量高的特点. 炭化温度对其元素组成影响较弱. 当炭化温度由350 ℃升到650 ℃时,WSB和MB的C含量分别提高了24.6%和13.2%,氢碳比值(H/C)分别下降了58.7%和34.7%;而PWB的C含量变化不显著,H/C比值仅下降了18.0%. 随着炭化温度升高,生物质炭的pH值、EC、水溶性K+和Na+含量呈上升趋势. 相关性分析结果表明,灰分与C/N、C含量、水溶性K+含量呈极显著负相关,与N含量、水溶性Na+含量、pH值呈极显著正相关. 因此,高灰分含量导致易腐垃圾炭对炭化温度响应弱于植物基生物质炭,同时使易腐垃圾炭能为土壤提供更多的矿质养分.Abstract: Perishable waste has the characteristics of large output and high organic perishability, which brings serious environmental pressure and waste of resources. Agricultural application of pyrolyzed perishable waste is an effective way for its reduction treatment and resource utilization. In this study, walnut shell, maize straw and perishable waste were pyrolyzed to produce biochars at 350 ℃, 500 ℃ and 650℃, respectively. The physicochemical properties between plant-based biochar and perishable waste biochar were studied. The results showed that the perishable waste biochar (PWB) had lower carbon (C), higher nitrogen (N) and higher ash contents, compared with the walnut shell biochar (WSB) and maize straw biochar (MB). The influence of carbonization temperature on element compositions of perishable waste was weaker than that of the others. With the increasing of carbonization temperature from 350℃ to 650℃, the C contents of WSB and MB increased by 24.6% and 13.2% respectively, and the H/C ratios decreased by 58.7% and 34.7% respectively. While, there was no significant influence of temperature on the C content of PWB, except for that H/C ratio decreased by 18.0%. The pH value, EC, water-soluble K+ and Na+ content of biochars increased with the increasing of carbonization temperature. The results of correlation analysis showed that ash content was negatively correlated to the C content, C/N ratio, and water-soluble K+ content, and positively correlated to N content, water-soluble Na+ content and pH value. It suggested that high ash content is the main contributor to the weak response of perishable waste biochar to carbonization temperature, and that the perishable waste biochar can provide rich mineral nutrients for soil.

-

Key words:

- pyrolysis carbonization /

- ash /

- feedstock /

- temperature /

- perishable waste /

- physicochemical properties.

-

表 1 不同炭化温度和原料制备的生物质炭元素组成

Table 1. Element composition of biochars with different carbonization temperature and raw feedstocks

生物质炭Biochar 炭化温度/ ℃Carbonization temperature 元素组成 Elemental composition 原子比 Atomic ratio C% H% O% N% 灰分Ash% O/C H/C (O+N)/C C/N WSB 350 47.68c 3.64a 34.08a 1.42d 13.18e 0.54a 0.92a 0.56a 39.21b 500 52.49b 2.28d 21.52b 1.28e 22.44d 0.31bc 0.52e 0.33c 47.96a 650 59.41a 1.88f 12.32d 1.40d 24.99cd 0.16e 0.38g 0.18e 49.43a MB 350 46.81c 2.80b 19.99b 2.12ab 28.28b 0.32bc 0.72b 0.36bc 25.76e 500 51.97b 2.40c 15.88c 2.12ab 27.63bc 0.23d 0.55d 0.26d 28.55d 650 53.01b 2.09e 15.84c 2.04bc 27.02bc 0.22d 0.47f 0.26d 30.32c PWB 350 35.16d 1.79f 12.86d 2.16a 48.02a 0.28cd 0.61c 0.33c 18.97f 500 34.13d 1.45g 15.79c 1.99c 46.64a 0.35b 0.51e 0.40b 19.99f 650 35.17d 1.45g 12.67d 2.09abc 48.61a 0.27cd 0.50ef 0.32c 19.66f 注:不同小写字母表示处理间差异显著(P<0.05). 下同. Notes: Different lowercase letters showed significant difference among treatments (P < 0.05). The same below. 表 2 生物质炭各指标的相关性分析

Table 2. Correlation analysis of physicochemical properties of biochars

指标 Index C N O (O+N)/C O/C H/C C/N Na+ K+ Ash pH EC Ash -0.819** 0.641** -0.693** -0.182 -0.287 -0.377 -0.783** 0.934** -0.522** 1 pH -0.077 0.214 -0.854** -0.757** -0.789** -0.924** -0.119 0.466* -0.063 0.565** 1 EC 0.332 0.442* -0.393* -0.534** -0.537** -0.251 -0.127 0.146 0.851** -0.038 0.145 1 注: *和**分别表示在P<0.05水平显著相关和P<0.01水平极显著相关. Notes: * and ** indicate significant correlation at P<0.05 and extremely significant correlation at P<0.01 respectively. -

[1] 安晓霞, 邵建越, 郑学娟, 等. 浅谈国内易腐垃圾生物处置现状、问题与对策 [J]. 中国资源综合利用, 2020, 38(2): 99-104,137. AN X X, SHAO J Y, ZHENG X J, et al. Discussion on status, problems and countermeasures of biological treatment of perishable waste in China [J]. China Resources Comprehensive Utilization, 2020, 38(2): 99-104,137(in Chinese).

[2] 潘根兴, 卞荣军, 程琨. 从废弃物处理到生物质制造业: 基于热裂解的生物质科技与工程 [J]. 科技导报, 2017, 35(23): 82-93. PAN G X, BIAN R J, CHENG K. From biowaste treatment to novel bio-material manufacturing: Biomaterial science and technology based on biomass pyrolysis [J]. Science & Technology Review, 2017, 35(23): 82-93(in Chinese).

[3] ELKHALIFA S, AL-ANSARI T, MACKEY H R, et al. Food waste to biochars through pyrolysis: A review [J]. Resources, Conservation and Recycling, 2019, 144: 310-320. doi: 10.1016/j.resconrec.2019.01.024 [4] 单胜道, 潘根兴, 施赟, 等. 生物质炭科技与工程[M]. 北京: 科学出版社, 2021. SHAN S D, PAN G X. SHI Y, et al.Biochar Technology and Engineering [M]. Beijing: Science Press, 2021(in Chinese).

[5] BEESLEY L, MORENO-JIMÉNEZ E, GOMEZ-EYLES J L, et al. A review of biochars'potential role in the remediation, revegetation and restoration of contaminated soils [J]. Environmental Pollution, 2011, 159(12): 3269-3282. doi: 10.1016/j.envpol.2011.07.023 [6] 孔丝纺, 姚兴成, 张江勇, 等. 生物质炭的特性及其应用的研究进展 [J]. 生态环境学报, 2015, 24(4): 716-723. KONG S F, YAO X C, ZHANG J Y, et al. Review of characteristics of biochar and research progress of its applications [J]. Ecology and Environmental Sciences, 2015, 24(4): 716-723(in Chinese).

[7] GUO X X, LIU H T, ZHANG J. The role of biochar in organic waste composting and soil improvement: A review [J]. Waste Management, 2020, 102: 884-899. doi: 10.1016/j.wasman.2019.12.003 [8] TOMCZYK A, SOKOŁOWSKA Z, BOGUTA P. Biochar physicochemical properties: pyrolysis temperature and feedstock kind effects [J]. Reviews in Environmental Science and Bio/Technology, 2020, 19(1): 191-215. doi: 10.1007/s11157-020-09523-3 [9] 朱启林, 曹明, 张雪彬, 等. 不同热解温度下禾本科植物生物炭理化特性分析 [J]. 生物质化学工程, 2021, 55(4): 21-28. doi: 10.3969/j.issn.1673-5854.2021.04.004 ZHU Q L, CAO M, ZHANG X B, et al. Physicochemical and infrared spectroscopic properties of Gramineae plants biochar at different pyrolysis temperatures [J]. Biomass Chemical Engineering, 2021, 55(4): 21-28(in Chinese). doi: 10.3969/j.issn.1673-5854.2021.04.004

[10] SINGH B, SINGH B P, COWIE A L. Characterisation and evaluation of biochars for their application as a soil amendment [J]. Australian Journal of Soil Research, 2010, 48(7): 516-525. doi: 10.1071/SR10058 [11] University of California. Davis. UC Davis Biochar Database[DB/OL]. [2022-01-03]. [12] 袁帅, 赵立欣, 孟海波, 等. 生物炭主要类型、理化性质及其研究展望 [J]. 植物营养与肥料学报, 2016, 22(5): 1402-1417. YUAN S, ZHAO L X, MENG H B, et al. The main types of biochar and their properties and expectative researches [J]. Journal of Plant Nutrition and Fertilizer, 2016, 22(5): 1402-1417(in Chinese).

[13] YAVARI S, MALAKAHMAD A, SAPARI N B. Biochar efficiency in pesticides sorption as a function of production variables-a review [J]. Environmental Science and Pollution Research International, 2015, 22(18): 13824-13841. doi: 10.1007/s11356-015-5114-2 [14] 张伟明, 修立群, 吴迪, 等. 生物炭的结构及其理化特性研究回顾与展望 [J]. 作物学报, 2021, 47(1): 1-18. doi: 10.3724/SP.J.1006.2021.02021 ZHANG W M, XIU L Q, WU D, et al. Review of biochar structure and physicochemical properties [J]. Acta Agronomica Sinica, 2021, 47(1): 1-18(in Chinese). doi: 10.3724/SP.J.1006.2021.02021

[15] KIM K H, KIM J Y, CHO T S, et al. Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida) [J]. Bioresource Technology, 2012, 118: 158-162. doi: 10.1016/j.biortech.2012.04.094 [16] LI H B, DONG X L, da SILVA E B, et al. Mechanisms of metal sorption by biochars: Biochar characteristics and modifications [J]. Chemosphere, 2017, 178: 466-478. doi: 10.1016/j.chemosphere.2017.03.072 [17] 简敏菲, 高凯芳, 余厚平. 不同裂解温度对水稻秸秆制备生物炭及其特性的影响 [J]. 环境科学学报, 2016, 36(5): 1757-1765. JIAN M F, GAO K F, YU H P. Effects of different pyrolysis temperatures on the preparation and characteristics of bio-char from rice straw [J]. Acta Scientiae Circumstantiae, 2016, 36(5): 1757-1765(in Chinese).

[18] 王煌平, 张青, 章赞德, 等. 不同热解温度限氧制备的畜禽粪便生物炭养分特征 [J]. 农业工程学报, 2018, 34(20): 233-239. WANG H P, ZHANG Q, ZHANG Z D, et al. Nutrient characteristics of biochar prepared from animal manures at different temperature with limited oxygen [J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(20): 233-239(in Chinese).

[19] 谭洪, 张磊, 韩玉阁. 不同种类生物质热解炭的特性实验研究 [J]. 生物质化学工程, 2009, 43(5): 31-34. TAN H, ZHANG L, HAN Y G. Experimental research on the characterization of char product from biomass pyrolysis [J]. Biomass Chemical Engineering, 2009, 43(5): 31-34(in Chinese).

[20] 彭云云, 武书彬. TG-FTIR联用研究半纤维素的热裂解特性 [J]. 化工进展, 2009, 28(8): 1478-1484. PENG Y Y, WU S B. Characteristics and kinetics of sugarcana bagasse hemicellulose pyrolysis by TG-FTIR [J]. Chemical Industry and Engineering Progress, 2009, 28(8): 1478-1484(in Chinese).

[21] JASSAL R S, JOHNSON M S, MOLODOVSKAYA M, et al. Nitrogen enrichment potential of biochar in relation to pyrolysis temperature and feedstock quality [J]. Journal of Environmental Management, 2015, 152: 140-144. [22] 赵越, 赵保卫, 刘辉, 等. 热解温度对生物炭理化性质和吸湿性的影响 [J]. 环境化学, 2020, 39(7): 2005-2012. doi: 10.7524/j.issn.0254-6108.2019050401 ZHAO Y, ZHAO B W, LIU H, et al. Effect of pyrolysis temperature on physicochemical properties and hygroscopicity of biochar [J]. Environmental Chemistry, 2020, 39(7): 2005-2012(in Chinese). doi: 10.7524/j.issn.0254-6108.2019050401

[23] 姚红宇, 唐光木, 葛春辉, 等. 炭化温度和时间与棉杆炭特性及元素组成的相关关系 [J]. 农业工程学报, 2013, 29(7): 199-206. YAO H Y, TANG G M, GE C H, et al. Characteristics and elementary composition of cotton stalk-char in different carbonization temperature and time [J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(7): 199-206(in Chinese).

[24] 王琬丽, 孙锴, 黄群星, 等. 无机灰分对餐厨沼渣中有机质热解特性的影响 [J]. 浙江大学学报(工学版), 2021, 55(9): 1652-1659. WANG W L, SUN K, HUANG Q X, et al. Effect of inorganic ash on pyrolysis characteristics of organic matter of biogas residue from food waste [J]. Journal of Zhejiang University (Engineering Science), 2021, 55(9): 1652-1659(in Chinese).

[25] 赵金凤, 陈静文, 张迪, 等. 玉米秸秆和小麦秸秆生物炭的热稳定性及化学稳定性 [J]. 农业环境科学学报, 2019, 38(2): 458-465. ZHAO J F, CHEN J W, ZHANG D, et al. Thermal stability and oxidation resistance of biochars derived from corn stalk and wheat stalk [J]. Journal of Agro-Environment Science, 2019, 38(2): 458-465(in Chinese).

[26] ZORNOZA R, MORENO-BARRIGA F, ACOSTA J A, et al. Stability, nutrient availability and hydrophobicity of biochars derived from manure, crop residues, and municipal solid waste for their use as soil amendments [J]. Chemosphere, 2016, 144: 122-130. doi: 10.1016/j.chemosphere.2015.08.046 [27] 陈昱, 梁媛, 郑章琪, 等. 浮萍生物炭的老化作用对其性质及对Cd(Ⅱ)吸附的影响 [J]. 环境工程, 2016, 34(10): 60-64. CHEN Y, LIANG Y, ZHENG Z Q, et al. Influnce of biochar ageing on its properties and Cd(Ⅱ) adsorption [J]. Environmental Engineering, 2016, 34(10): 60-64(in Chinese).

[28] 高凯芳, 简敏菲, 余厚平, 等. 裂解温度对稻秆与稻壳制备生物炭表面官能团的影响 [J]. 环境化学, 2016, 35(8): 1663-1669. doi: 10.7524/j.issn.0254-6108.2016.08.2016010607 GAO K F, JIAN M F, YU H P, et al. Effects of pyrolysis temperatures on the biochars and its surface functional groups made from rice straw and rice husk [J]. Environmental Chemistry, 2016, 35(8): 1663-1669(in Chinese). doi: 10.7524/j.issn.0254-6108.2016.08.2016010607

[29] FANG Q L, CHEN B L, LIN Y J, et al. Aromatic and hydrophobic surfaces of wood-derived biochar enhance perchlorate adsorption via hydrogen bonding to oxygen-containing organic groups [J]. Environmental Science & Technology, 2014, 48(1): 279-288. [30] 孙克静, 张海荣, 唐景春. 不同生物质原料水热生物炭特性的研究 [J]. 农业环境科学学报, 2014, 33(11): 2260-2265. doi: 10.11654/jaes.2014.11.027 SUN K J, ZHANG H R, TANG J C. Properties of hydrochars from different sources of biomass feedstock [J]. Journal of Agro-Environment Science, 2014, 33(11): 2260-2265(in Chinese). doi: 10.11654/jaes.2014.11.027

[31] 石林, 陈静文, 李浩, 等. 滇池沉积物生物炭的热稳定性及化学稳定性特征 [J]. 环境化学, 2018, 37(11): 2515-2521. doi: 10.7524/j.issn.0254-6108.2018062202 SHI L, CHEN J W, LI H, et al. Thermal and chemical stability of biochars derived from sediment in Dianchi Lake [J]. Environmental Chemistry, 2018, 37(11): 2515-2521(in Chinese). doi: 10.7524/j.issn.0254-6108.2018062202

[32] 闫代红, 马亚培, 宋凯悦, 等. 原料和热解温度对生物炭中可溶性有机质的影响 [J]. 环境科学, 2021, 42(10): 5030-5036. YAN D H, MA Y P, SONG K Y, et al. Effects of feedstock material and pyrolysis temperature on dissolved organic matter in biochars [J]. Environmental Science, 2021, 42(10): 5030-5036(in Chinese).

[33] IRFAN M, CHEN Q, YUE Y, et al. Co-production of biochar, bio-oil and syngas from halophyte grass (Achnatherum splendens L. ) under three different pyrolysis temperatures [J]. Bioresource Technology, 2016, 211: 457-463. doi: 10.1016/j.biortech.2016.03.077 [34] SONG W P, GUO M X. Quality variations of poultry litter biochar generated at different pyrolysis temperatures [J]. Journal of Analytical and Applied Pyrolysis, 2012, 94: 138-145. doi: 10.1016/j.jaap.2011.11.018 [35] KUMAR G, SHOBANA S, CHEN W H, et al. A review of thermochemical conversion of microalgal biomass for biofuels: Chemistry and processes [J]. Green Chemistry, 2017, 19(1): 44-67. doi: 10.1039/C6GC01937D [36] SMIDER B, SINGH B. Agronomic performance of a high ash biochar in two contrasting soils [J]. Agriculture, Ecosystems & Environment, 2014, 191: 99-107. [37] SINGH B, ARBESTAIN M C, LEHMANN J. Biochar: A Guide to Analytical Methods[M]. Clayton, Vic: CSIRO Publishing, 2017. [38] MCBEATH A V, SMERNIK R J, KRULL E S, et al. The influence of feedstock and production temperature on biochar carbon chemistry: A solid-state 13C NMR study [J]. Biomass and Bioenergy, 2014, 60: 121-129. doi: 10.1016/j.biombioe.2013.11.002 [39] 陈必鸣. 餐厨垃圾预处理技术综述 [J]. 环境卫生工程, 2015, 23(5): 10-12. CHEN B M. Food waste pretreatment technologies [J]. Environmental Sanitation Engineering, 2015, 23(5): 10-12(in Chinese).

[40] 焦敏娜, 任秀娜, 王权, 等. 垃圾分类背景下易腐有机垃圾资源化处理模式探讨 [J]. 环境卫生工程, 2022, 30(1): 28-35,40. JIAO M N, REN X N, WANG Q, et al. Discussion on the recycling treatment mode of perishable organic waste under the background of waste classification [J]. Environmental Sanitation Engineering, 2022, 30(1): 28-35,40(in Chinese).

[41] LIU M, OGUNMOROTI A, LIU W, et al. Assessment and projection of environmental impacts of food waste treatment in China from life cycle perspectives [J]. Science of the Total Environment, 2022, 807: 150751. doi: 10.1016/j.scitotenv.2021.150751 [42] 施庆文. 上海市湿垃圾处理运营补贴政策研究 [J]. 环境与可持续发展, 2021, 46(3): 195-197. SHI Q W. Research on the subsidy policy of wet waste treatment process operation in Shanghai [J]. Environment and Sustainable Development, 2021, 46(3): 195-197(in Chinese).

[43] 吕凡, 章骅, 郝丽萍, 等. 易腐垃圾就近就地处理技术浅析 [J]. 环境卫生工程, 2020, 28(5): 1-7. doi: 10.19841/j.cnki.hjwsgc.2020.05.001 LÜ F, ZHANG H, HAO L P, et al. Analysis on the treatment technology of organic fraction of municipal solid waste in the neighborhood or on-site [J]. Environmental Sanitation Engineering, 2020, 28(5): 1-7(in Chinese). doi: 10.19841/j.cnki.hjwsgc.2020.05.001

-

下载:

下载: