-

近年来,我国炼化产业不断发展,油品周转量稳步提升,储罐的使用也更频繁。在储罐生产作业中,设备工艺技术的限制及人为的疏忽均会造成溢油事故[1]。溢出油品在挥发扩散后遇火源极易产生火灾,甚至爆炸[2-3]。2005年,英国第五大油库邦斯菲尔德(Buncefield)油库的912罐在接收汽油时溢流,油气迅速扩散并造成多次爆炸[4-5]。2009年,波多黎加勒比石油公司一座储量2×104 m3的储罐发生溢流,油气在扩散时遇到火源发生爆炸[6-7]。此外,油品汽化后会形成挥发性有机物(volatile organic compounds,VOCs)[8],而VOCs的控制与治理是环境污染防治与管理中的重要内容[9]。2020年,生态环境部与国家市场监督管理总局联合颁布的《储油库大气污染物排放标准GB 20950-2020》中规定企业边界排放限值应小于4 g·m−3(非甲烷总烃)[10]。2020年10月,生态环境部与国家发展和改革委员会提出,2021年VOCs的治理重心将继续以石油化工行业为主[11]。因此,有关罐区油气扩散规律的研究对储油区大气污染控制及相关企业的环保与安全管理具有重要意义。

计算流体动力学(computational fluid dynamics,CFD)是数值数学和计算机科学相结合的学科,已发展为重要的研究手段。相对于实验研究,该研究手段具有成本低和耗时短等优点[12-15]。WANG等[16]采用CFD方法评估了分隔距离对储罐场中气体扩散和蒸气云爆炸的影响。SUN等[17]借助大涡模拟(large eddy simulation,LES)模型模拟了强风天气下储罐密封圈的风压变化及气体扩散情况。刘瑞等[18]结合CFD方法和ANSYS Fluent仿真软件求解了覆土油罐泄漏后的油气扩散轨迹。然而,数值模拟的结果通常具有不确定性,必要时需开展可信度的验证[19]。风洞实验因具有优越的可控性与稳定性,被广泛应用于气体流动的研究[20-23]。ZHANG等[24]借助风洞平台搭建内浮顶罐缩比模型研究了正己烷蒸气的扩散规律。徐川等[25]和辛保泉等[26]建立风洞模型对天然气扩散特征进行了研究。目前,关于油气泄漏的研究主要可分为3个方面:1)油气泄漏扩散规律的研究;2)油气爆炸的数值模拟;3)城市VOCs溯源系统的研发。

在储罐油气泄漏扩散规律方面的研究主要集中在单罐或多罐[27-29]形式的扩散研究,而对于大型罐区的油气扩散规律的研究较少。基于此,拟通过风洞实验平台与CFD数值模拟相结合,以获得溢油事故后大型罐区内油气泄漏扩散规律,为罐区设计、油库运行管理及城市VOCs溯源系统的研发提供参考。

-

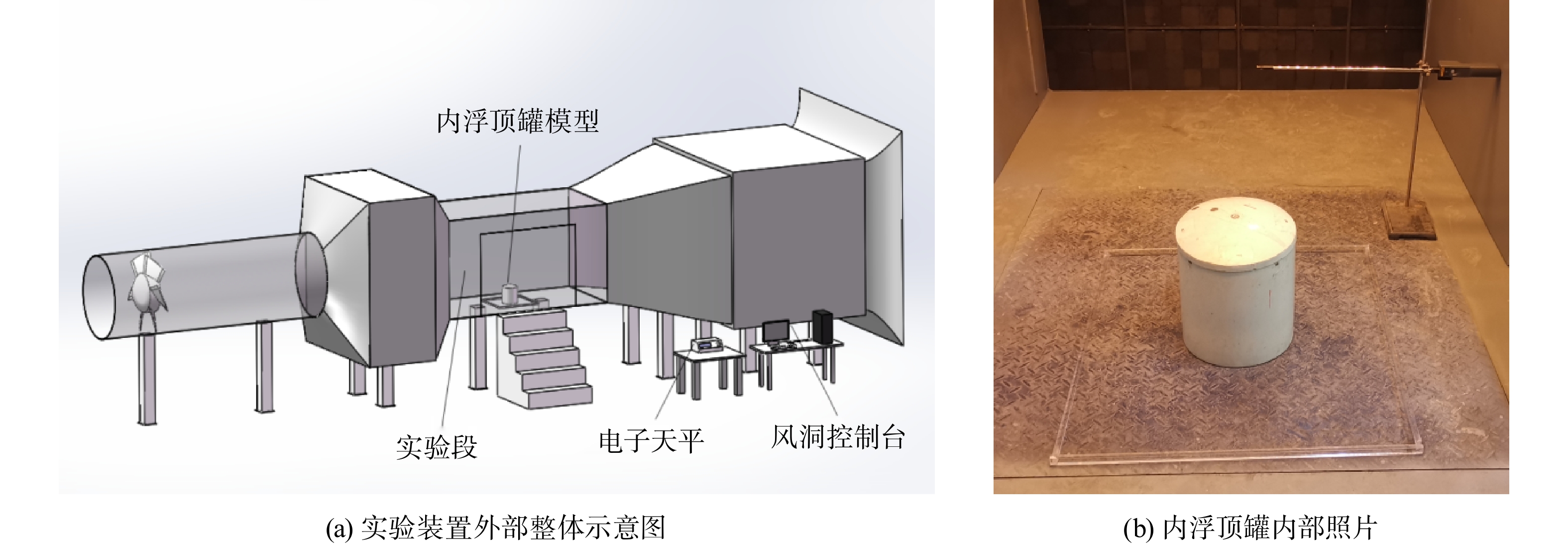

搭建的风洞实验平台主要设备为直流式风洞(型号:DFWT-10)。该风洞由集气段、稳定段、收缩段、实验段、第1扩散段、动力段及第2扩散段组成。实验段规格:长、宽、高分别为3.0、1.5、1.5 m,风速调节范围0.5~10(20) m·s−1,各风速点控制进度优于±0.3%FS;WT-30000-1B电子天平,量程0.000 0~30.000 0 kg,精度为0.000 1 kg;Fluke 923风速仪,风速量程为0.20~10(20) m·s−1。

数值模拟中需要设定物质蒸发扩散的速率。为保证数值模拟的准确性,需要测定油品的挥发速率。实验中主要测定风速对油品蒸发速率的影响,实验油品为92#汽油,风洞实验中温度保持恒定。由于汽油组分复杂,且在溢油过程中会不断有新油流入,所以会有轻组分不断挥发出来,取固定敞口容器装满油品,保证油品与空气充分接触,其中敞口容器直径尺寸为28 cm,高为17 cm,使用电子天平分别测量2 m·s−1与4 m·s−1风速下92#汽油在30 min内的质量变化。每隔5 min记录1次质量,共测5组,取其平均值。测得汽油的蒸发速率如下:风速2 m·s−1时,蒸发速率为0.004 1 kg·(m2·s)−1;风速4 m·s−1时,蒸发速率为0.005 5 kg·(m2·s)−1。由此结果可知,油品的蒸发损耗速率与风速有关,风速越大,蒸发损耗速度越快。

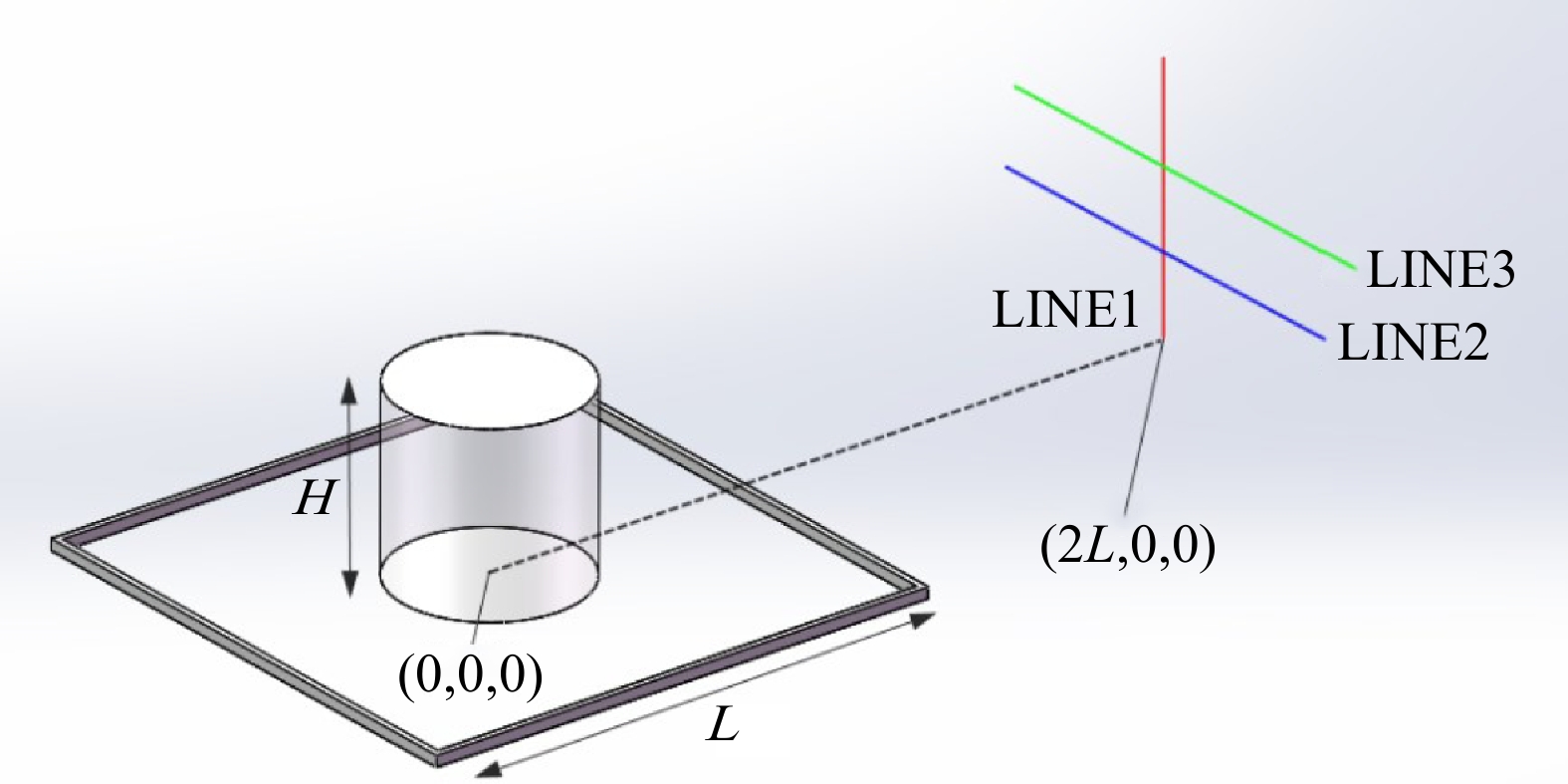

为保证风洞实验的准确性,根据设计规范HG 21502.2-1992《钢制立式圆筒形内浮顶储罐系列》、GB 50074-2014《石油库设计规范》,按照65∶1的比例建立3 000 m3内浮顶罐与防火堤模型(防火堤为正方形,尺寸:长、高、宽分别为47 、1.5、0.6 m)。其中,储罐内径D=0.260 m,罐壁高H=0.245 m,防火堤四边内长L =0.724 m,防火堤高h=0.023 m、宽d=0.010 m。风洞模型与原型应满足雷诺数(Re)相等,但将风速扩大65倍显然不太现实。为此,人们提出Re无关性原则,即当Re大于某个数值之后,流动结构不再发生变化,该数值称为临界Re[30]。风洞实验中的临界Re=22 000,储罐直径D为特征长度,流场入口最小Re=37 500,超过临界Re,可认为原型与模型相似。

图1为风洞实验图。将内浮顶罐与防火堤模型放置在风洞实验段中,使用风速仪在下风2L处设置3条长度为1.5H的直线检测模型后方流场变化,结果如图2所示。其中,LINE1垂直于地面,LINE2、LINE3平行于地面且离地面距离分别为0.75H和1.5H。使用风洞提供稳定风速,风速仪测量在LINE1、LINE2与LINE3这3条直线上不同点位的风速值。

-

计算流体力学的原理要求获得准确的数值模拟结果,需要选取正确的流动控制方程。流动基本控制方程通常包括质量守恒方程、动量守恒方程与能量守恒方程。实际情况下风速会随高度发生变化,因此还需要编译环境风UDF导入Fluent。

1)梯度风方程。实际情况下,近地面处的风速随高度变化且与地面粗糙度有很大关系,数值模拟时需将梯度风编译UDF导入Fluent当中,表达式见式(1)。

式中:W为z高度处的风速,m·s−1;W1为z1高度处的风速,m·s−1;n为风速稳定度参数,本研究的对象位于城市区域且罐区中储罐等建筑排列密集,n取值为0.25。

2)基本控制方程。油气蒸发扩散的过程需遵循质量守恒方程、动量方程与能量方程,控制方程的通用形式见式(2)。

式中:ρ为气体密度,kg·m−3;u为速度矢量;Φ为通用变量;Г为广义扩散系数;S为广义源项。

3)湍流方程。油气扩散受到风速影响较大,流场内流体一般处于湍流状态,可实现k-ε模型与标准k-ε模型都适用于湍流状态下的流动,但可实现k-ε模型能更好地表现流场内的气流扰动,更准确地展现流场内浓度分布,因此选用可实现k-ε模型,方程式为式(3)。

式中:ρ为气体的密度,kg·m−3;xj为j方向传输距离,m;uj为j方向速度,m·s−1;t为时间,s;K为湍流动能,m2·s−2;ε为耗散率,m2·s−3;μ为油气的动力黏度,Pa·s;μt为湍流黏度,Pa·s;ν为运动黏度,m2·s−1;Pk为由层流速度梯度而产生的湍流动能,m2·s−2,Gk是由平均速度梯度引起的湍流动能,m2·s−2;η为有效因子;Gb为由浮力而产生的湍流动能,m2·s−2;YM为在可压缩湍流中过渡扩散产生的波动,m2·s−2;C1、C1ε、C2、C3ε为经验常数;σk和σε为k方程和ε方程对应的普朗德数;S、Sij、Sk和Sε为用户定义的源项。

-

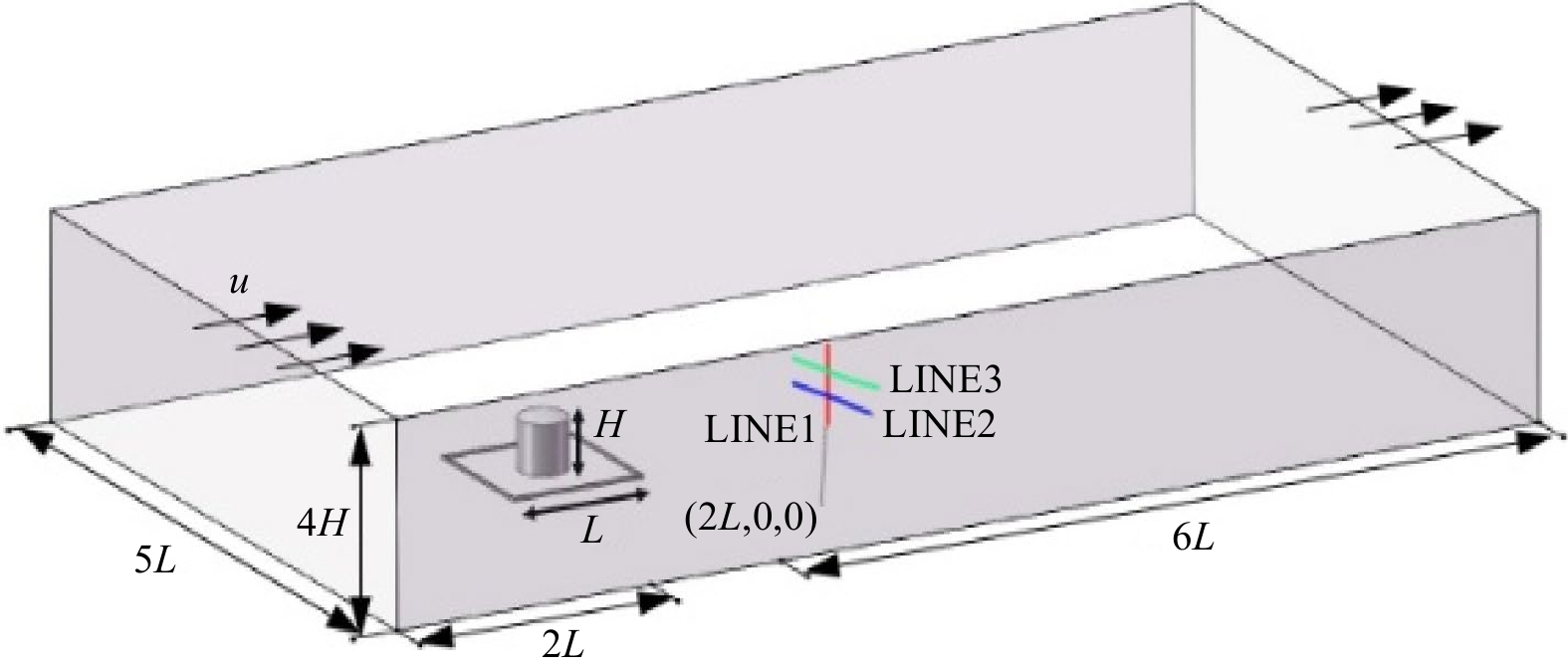

内浮顶罐发生溢油冒罐现象,大量油品会从罐中溢出流淌至地面,油气从地面油品液池不断蒸发扩散。油品从罐中下流过程视为气液的饱和平衡状态,即忽略下流过程的闪蒸。数值计算中,为了保证验证计算准确性,模型尺寸与风洞实验尺寸一致,三维计算域满足不大于7%的阻塞率。计算域如图3所示(长、宽、高分别为9L、5L、4H),LINE1、LINE2、LINE3为数据提取线。由于结构网格的质量较好且数据结构简单,非结构网格能适应各种复杂的模型,将两者结合采用ICEM CFD软件划分三维混合网格,网格如图4所示。网格节点对齐完整,ICEM CFD中Quality方式检查网格质量为0.31(一般0.3以上属于高质量网格),Fluent中设置求解器类型为“Pressure-Based”,使用非稳态求解,流场入口边界设置为速度入口边界条件,梯度风按式(1)编译UDF导入,风速沿x轴方向进入,流场出口边界设置为压力出口边界条件,网格交界面设置为内部边界,油气释放扩散源设置为质量流率边界条件,质量流率大小为实验测定,其他边界均设置为绝热固壁边界。

-

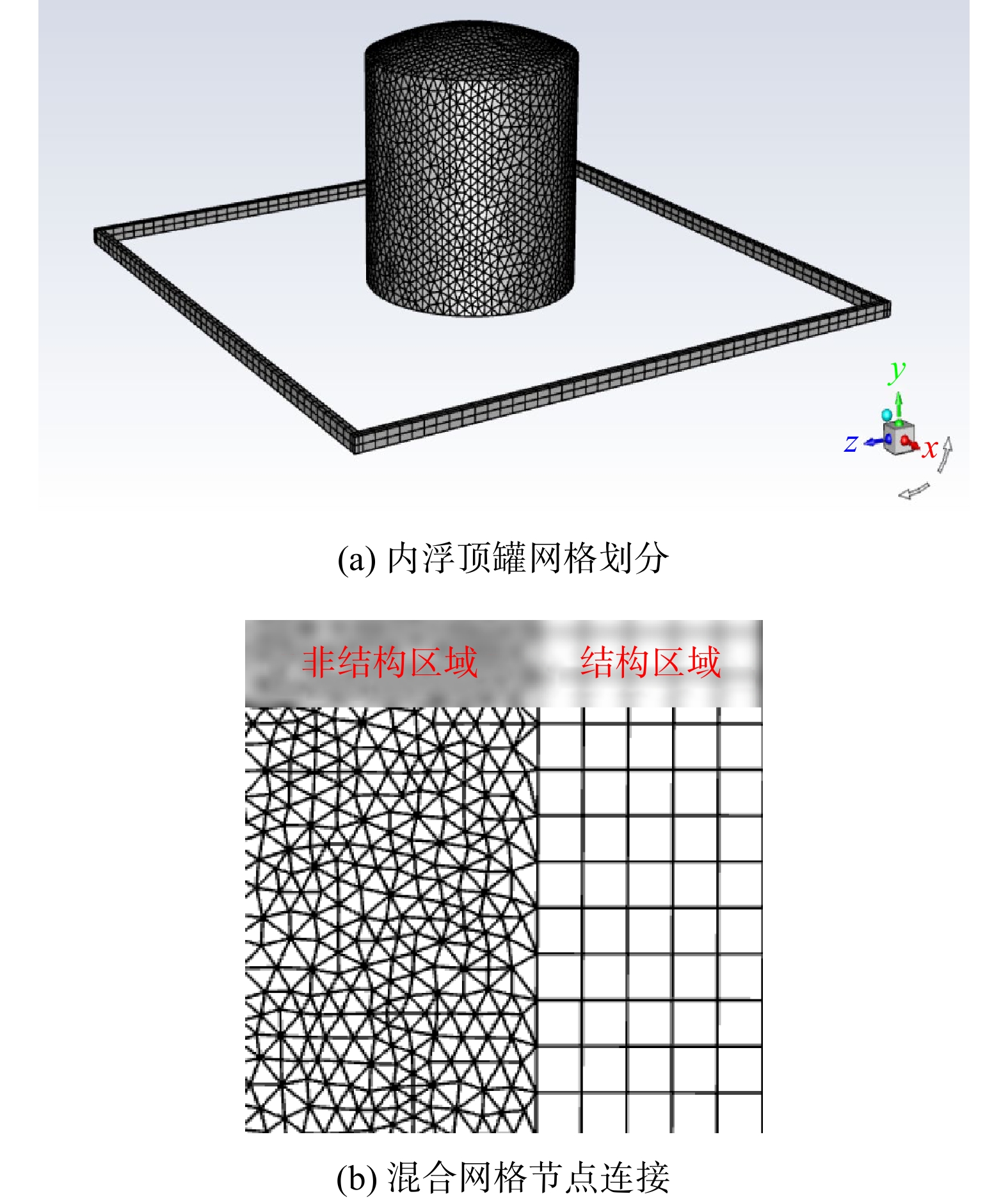

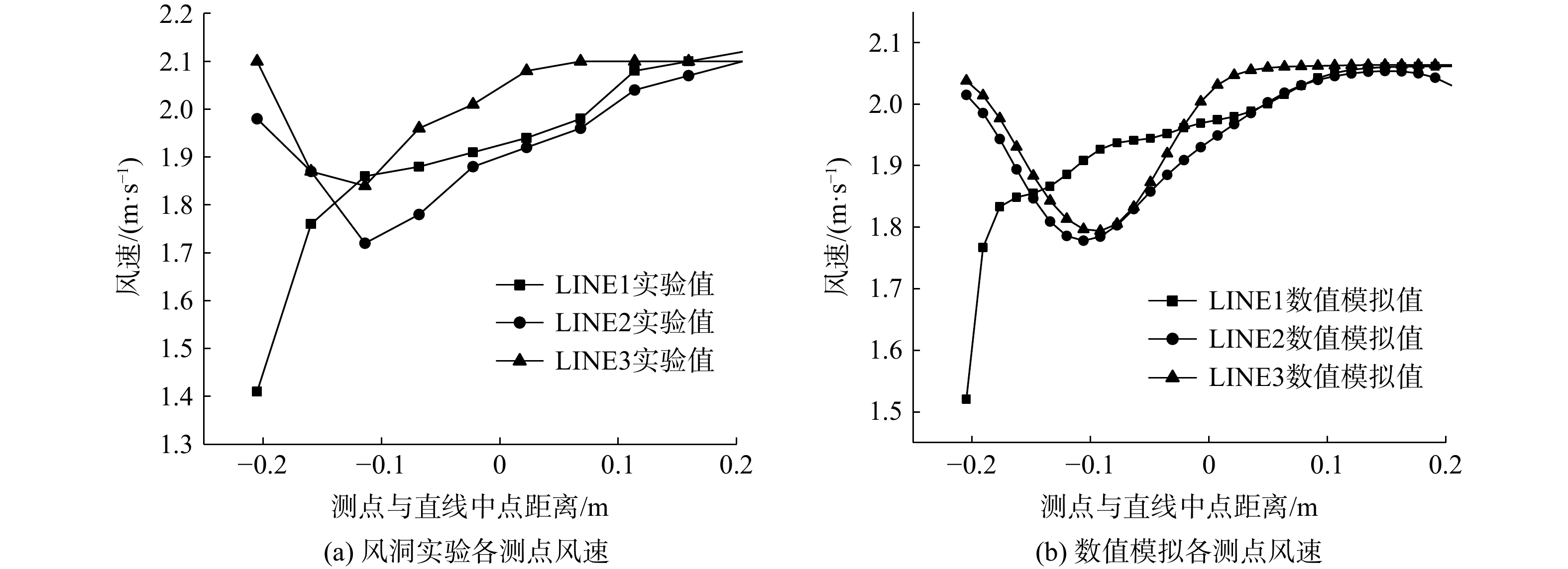

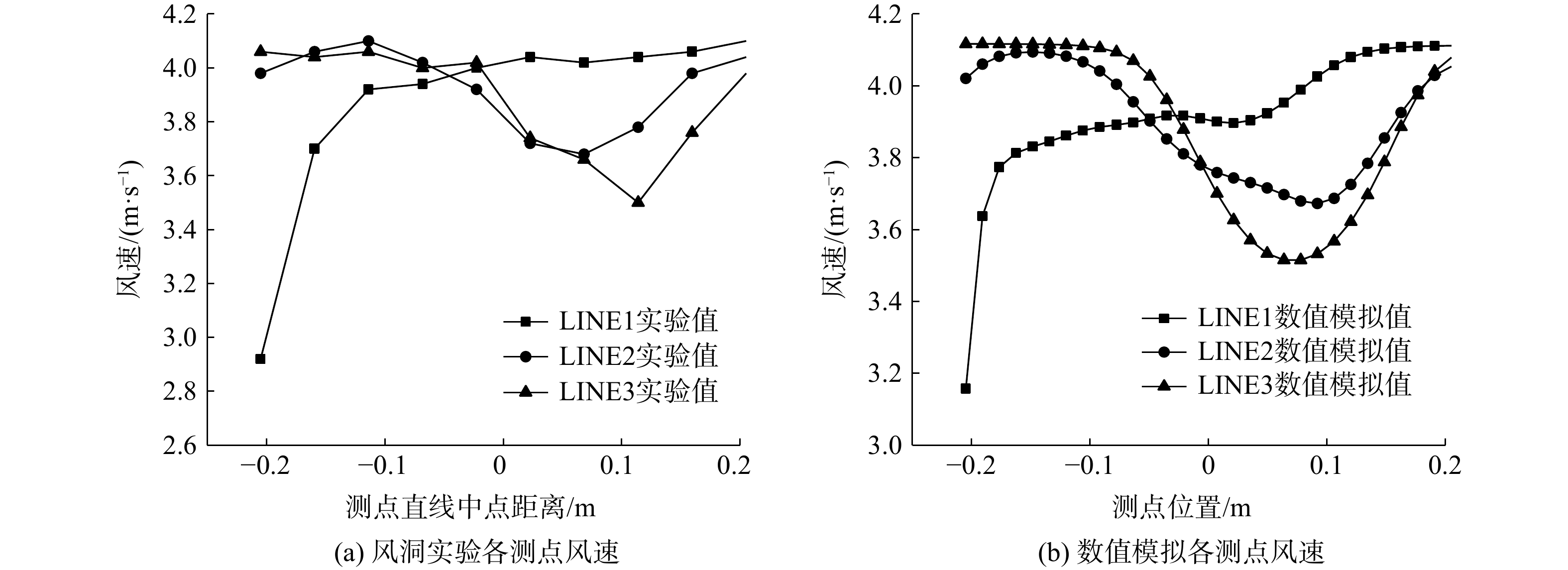

为确保后续研究中大型罐区油气扩散的准确性,对小罐的数值模拟结果进行实验验证,将不同风速条件下实验数据与数值模拟值进行比较。图5和图6分别为风速为2 m·s−1与4 m·s−1下的各测点风速的数值模拟值与实验值。由图5和图6可知,尽管由于实验仪器与实验条件的限制,实验值与数值模拟值有一些差距,但整体偏差率保持在7%以内,处于正常误差范围,且两者的变化趋势大体一致。这表明建立的数值模型是准确可行的。

-

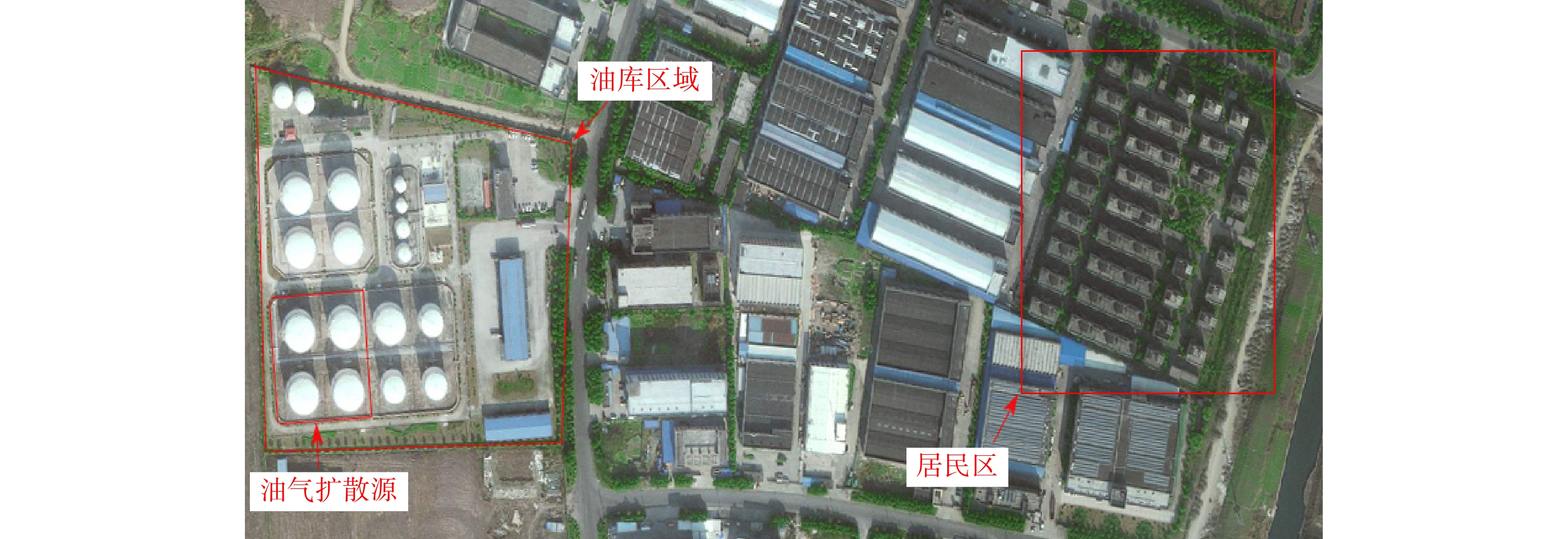

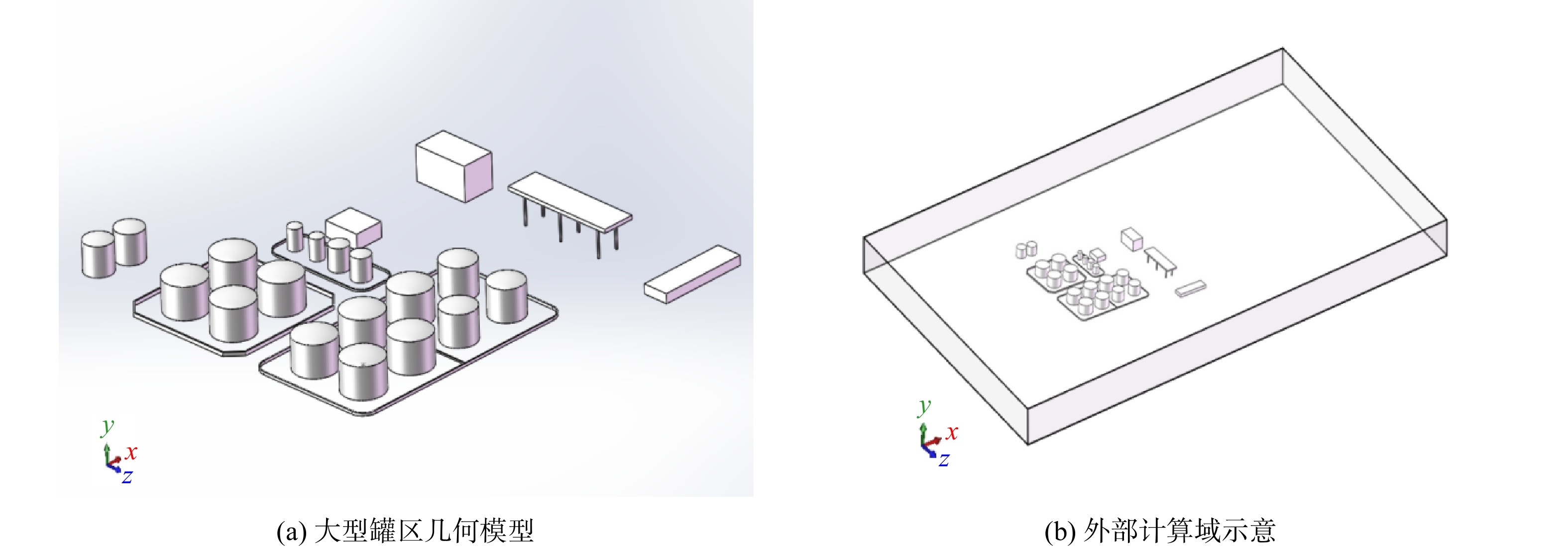

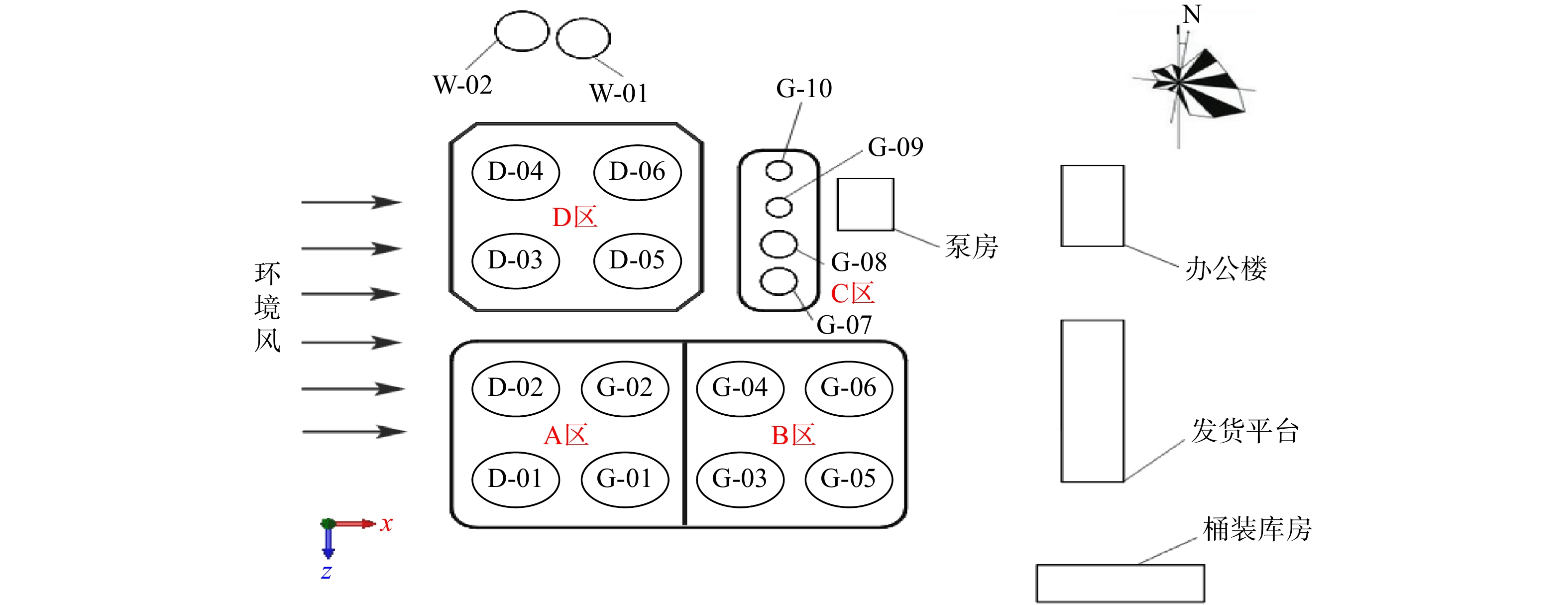

以江苏省境内一实体油库为研究对象,进行了实地考察。图7为实地油库周边地形图。因油库左侧为平坦道路开阔地形,对油气扩散行为影响较小,而油库储罐东南侧的建筑分布密集,因此本次模拟主要考虑西南风向。油库右侧为建筑密集区。本研究聚焦罐区内的油气扩散规律,为便于数值模拟的进行,则忽略油库区域外的建筑,建立与实地油库尺寸1∶1的大型罐区三维几何模型图(见图8(a))。图8(b)为大型罐区的外部计算域示意图,对罐区内的建筑进行编号,如图9所示。其中,D-01、D-02、D-03、D-04、D-05、D-06为8 000 m3柴油储罐;G-01、G-02、G-04为8 000 m3汽油储罐;G-03、G-05、G-06为5 000 m3汽油储罐;G-07、G-08为1 000 m3汽油储罐;G-09、G-10为500 m3汽油储罐;W-01、W-02为消防水罐。罐区内储罐皆为内浮顶罐,将罐油库分为A、B、C、D 4个罐区,罐区之间为消防通道。假设A区汽油储罐发生溢油泄漏事故,油品溢满A区,汽油溢出至地面过程发生的闪蒸忽略不计,油气持续从A区防火堤内蒸发扩散出来,环境风采用UDF导入,从左侧沿x轴方向进入。

-

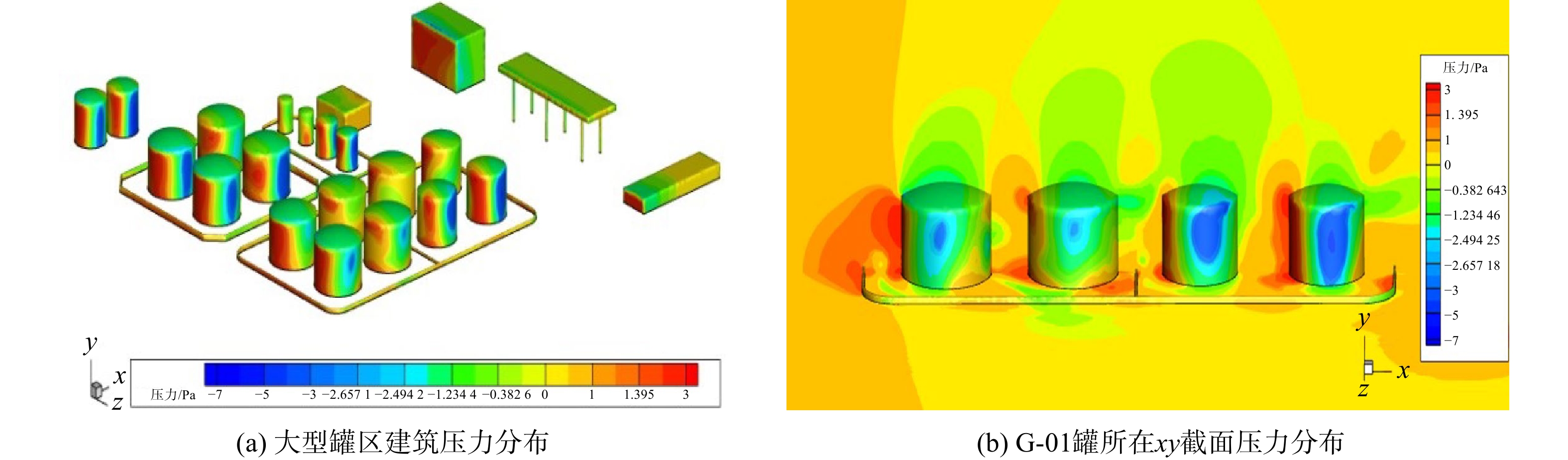

环境风对于罐区内气流流动影响很大,图10(a)为风速2 m·s−1时大型罐区建筑的压力云图。由图10(a)可知,环境风从左侧沿x轴正方向进入罐区,气流撞击前排储罐与防火堤,储罐以及防火堤的迎风侧压力会急剧上升,直接达到该风速下的最大压力,在罐壁形成大面积的红色区域;后排储罐由于前排储罐阻挡了部分气流,迎风侧的红色区域部分会比前排储罐小。由于储罐上方压强较小,在压差的牵引下,罐顶上方的气流速度会高于相同高度的其他区域,形成负压。部分气流在撞击储罐后,加速沿储罐两侧向后方流动,在储罐罐壁形成大面积的蓝色负压区。取G-01罐所在xy截面,得到该平面的压力云图(见图10(b))。由图10(b)可知,前排储罐背风侧与后排储罐迎风侧之间都存在明显的负压和高压区域,压强大的气流会流向压强小的区域,在储罐之间形成涡流,油气会在此处聚积,形成危险区域。

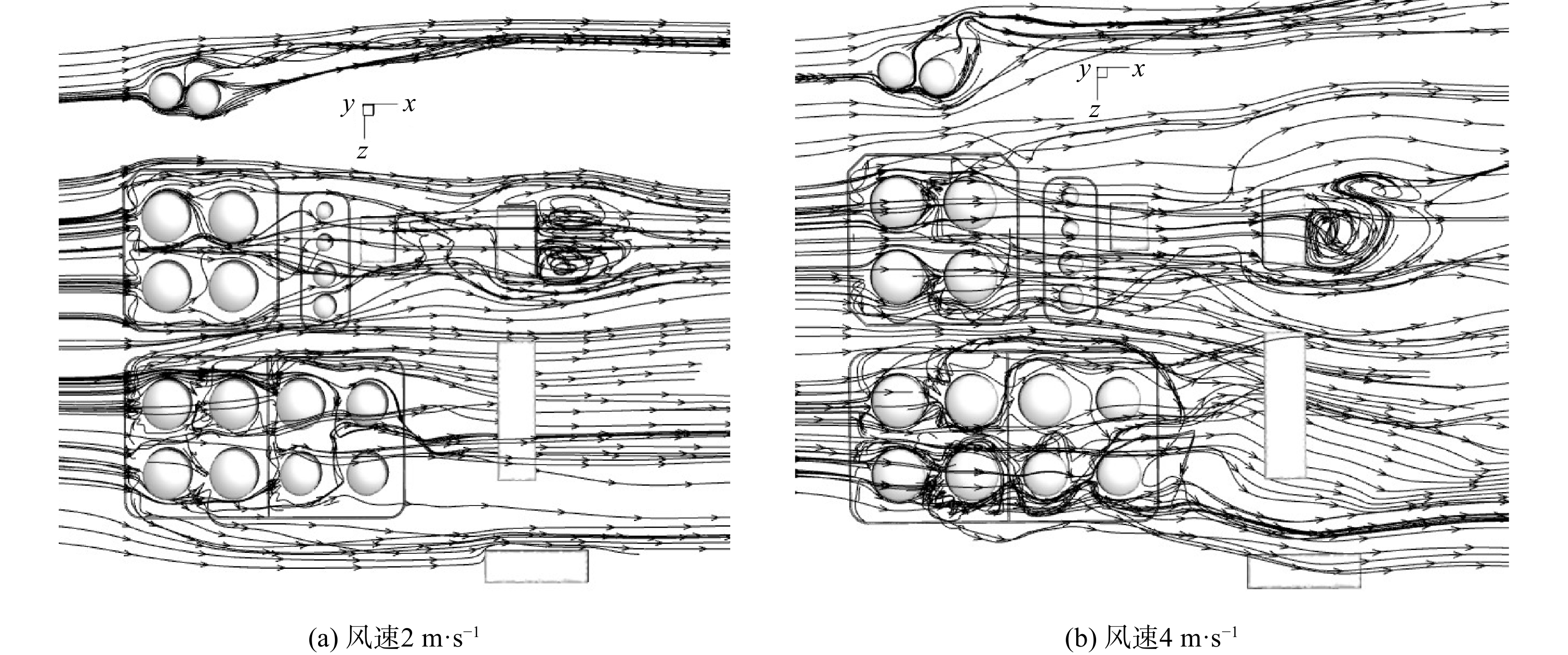

图11为不同风速下大型罐区内流线图。由于油气扩散源在A区,因此,主要分析从A区经过的气流轨迹。由图11(a)可知,当环境风从左侧进入罐区时,由于A区防火堤的阻碍作用,部分气流在防火堤背风侧形成沿防火堤分布的小漩涡,部分气流直接越过防火堤到达储罐群,在储罐后方形成大小不一的涡流。当风速为4 m·s−1时,由于风速变大,G-01罐前方漩涡明显变大,气流在经过漩涡后汇合形成一束强气流并流向后方储罐(见图11(b))。值得注意的是,经过A区的气流由于储罐的阻挡,一部分经过C区储罐流向办公楼,由于“卡门涡街”效应,风速2 m·s−1时办公楼背风侧形成了镜像分布的2个漩涡;当风速增大至4 m·s−1,2个漩涡汇合成1个,油气会在此处积聚,形成潜在危险区域。图12为不同风速下大型罐区xz截面的风速云图。由图12可知,在储罐、防火堤以及办公楼等建筑后方,都有速度较小的蓝色区域。这是建筑后方的涡流导致,风速云图整体符合上述风场规律。

-

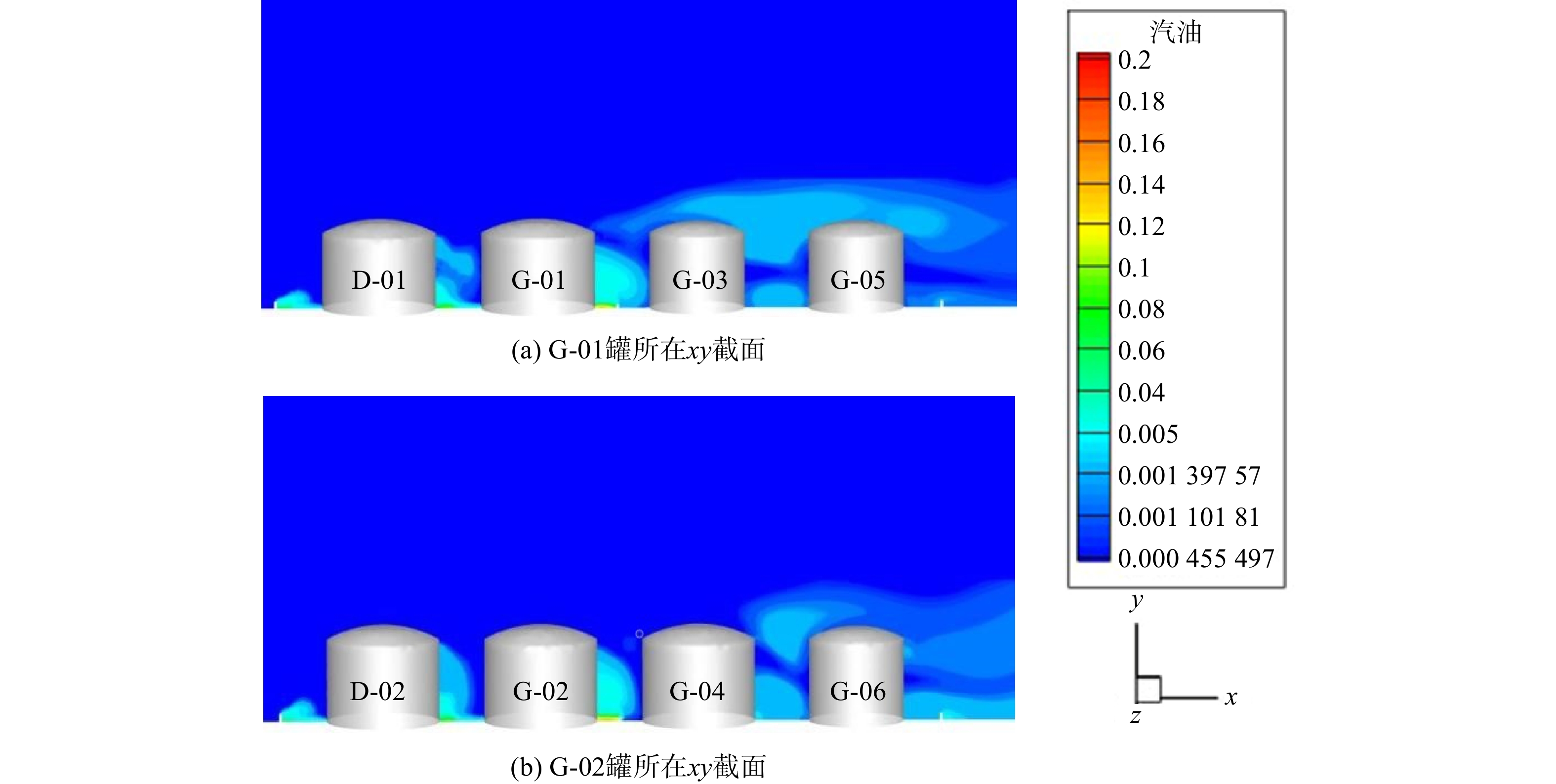

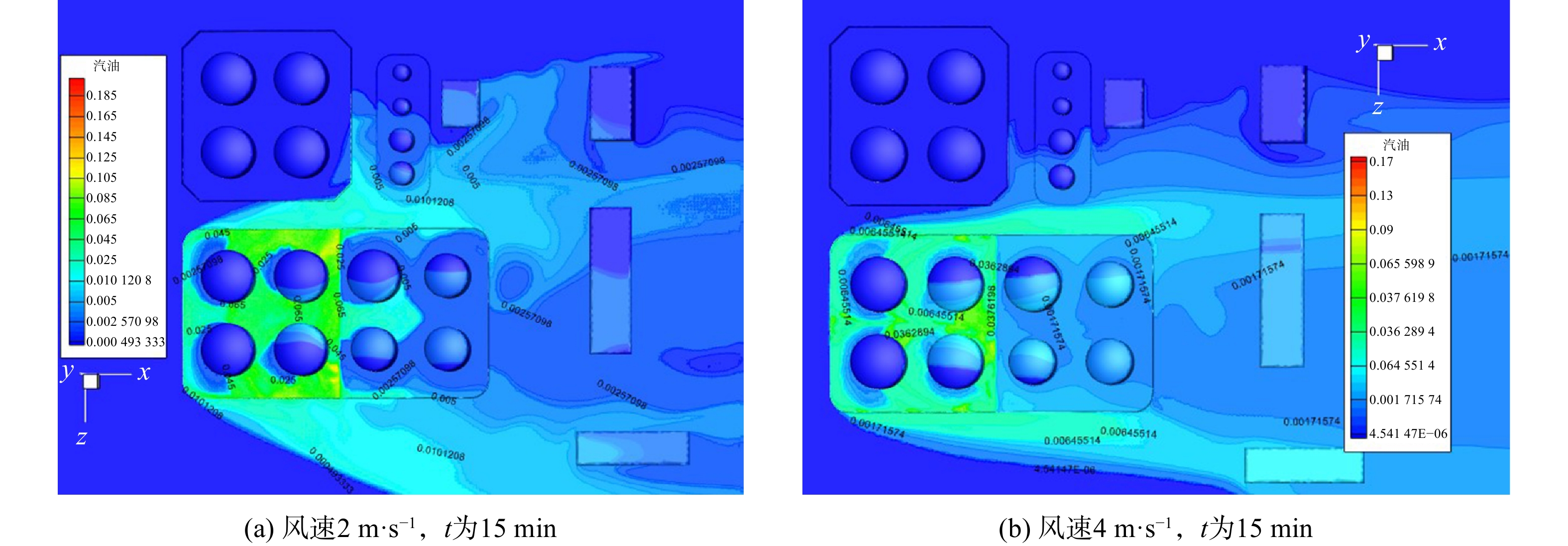

在实际情况中,大部分天气状况都不是无风状态,风速对于油气的蒸发扩散有一定的影响。分别取G-01与G-02罐的xy截面,得到该截面15 min的油气质量分数分布云图。由图13可知,由于重力和涡流的作用,罐间与防火堤背风侧都积聚了一定量油气。其中,G-01与G-03、G-02与G-04之间存在隔堤,油气在此处聚集量最大,油气质量分数为0.04~0.06。而汽油的爆炸极限体积分数为1.4%~7.6%,换算成质量分数为0.053~0.245,说明这几处油气质量分数达到汽油爆炸极限范围。G-03、G-05、G-06为5 000 m3内浮顶罐,G-01、G-04为8 000 m3内浮顶罐,后者罐高大于前者。气流在经过G-01罐顶时,会沿罐顶弧形结构向下运动,“挟卷”起G-01与G-03罐间聚积的油气,使G-03与G-05罐顶上方油气质量分数较高。同理,G-06上方的油气质量分数也高于同等高度的其他区域。

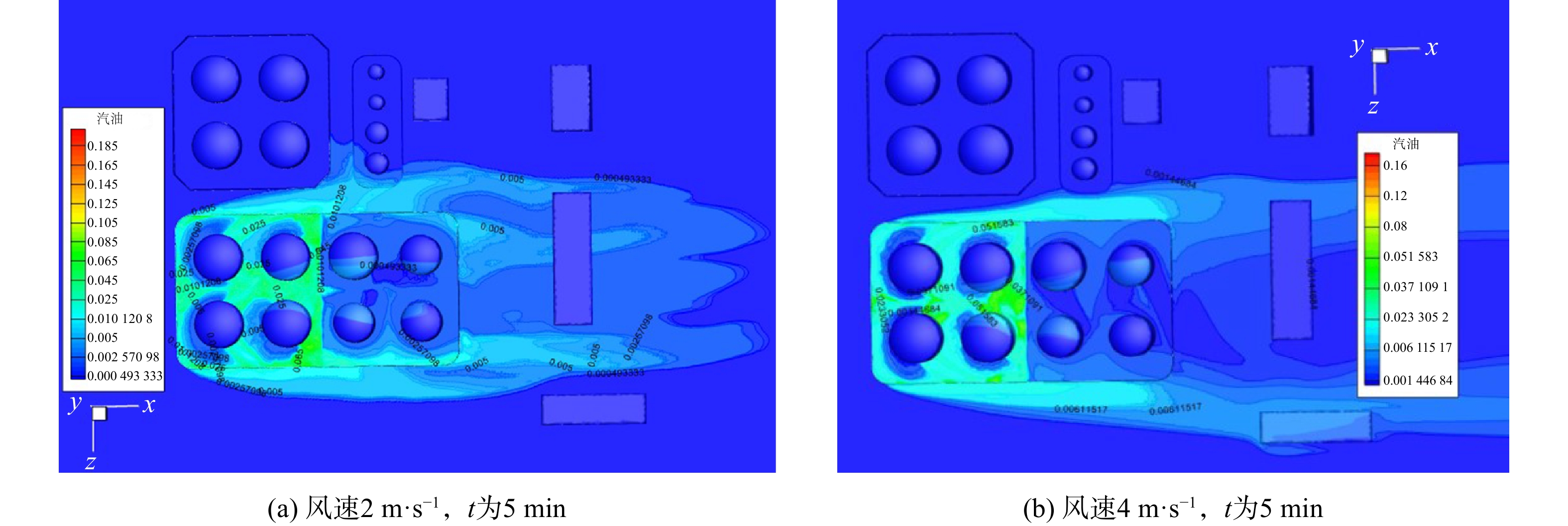

图14和图15为不同时间下大型罐区xz截面近地面1 m高度处油气质量分数分布云图。当罐区内发生溢油事故,油气从A区防火堤内不断蒸发扩散。由图14(a)可知,在5 min时,风速2 m·s−1时的油气最远已扩散至发货平台,在此区域工作的人员及车辆需要及时回避。由于储罐的阻滞作用,油气会向两侧发散,受两侧压强的牵引,向桶装库房以及C区储罐扩散。同时,由于C区一侧湍流强度较大,油气已经蔓延至C区内。当风速为4 m·s−1时,如图14(b)所示,C区内油气会被挟卷至远处,而库房一侧由于流速的增大和B区储罐的影响,会被油气迅速蔓延。当风速为2 m·s−1与4 m·s−1时,A区的油气质量分数最高分别达到了0.125和0.085,A区与D区之间的消防通道也被高浓度的油气覆盖,远超汽油的爆炸下限。因此,在事故后救援车辆应从溢油地点上风侧驶来,以避免汽车造成火星引发爆炸事故。

由图15可知,A区内油品不断蒸发,油气经过15 min的扩散,无论风速2 m·s−1还是4 m·s−1,C区与D区内都已充满油气,罐区外办公楼、发货平台以及桶装库房都被油气覆盖。但当风速4 m·s−1时,A区内油气质量分数为0.05~0.08,较风速2 m·s−1时有所下降。这是因为风会加速空气对油气的稀释,所以风速越小,罐区内油气质量分数越大,风速越大,油气扩散速度越快。

-

1)在风速的影响下,罐区内储罐迎风侧的压力大于背风侧的压力,在罐间存在大小不一的回流区域,在重力的影响下,整体趋势向下运动,造成罐间的油气聚集。因此,应在储罐间设置油气质量分数报警仪,预防罐区内的油气泄漏扩散等事故。

2)当储罐高度同等时,储罐间油气主要积聚在前排储罐背风侧下方,当前排储罐高于后排储罐时,气流会挟卷罐间油气至后排储罐罐顶,使其油气质量分数较高于同等高度区域。

3)罐区内一般会存在防火堤。若在防火堤上风处发生油气泄漏,防火堤对于油气的扩散有一定的阻滞作用,但此区域的油气质量分数也会相应增大,而防火堤的背风侧会形成沿防火堤分布的小涡流,造成油气的堆积。

4)不同风速下,风速小时油气扩散较慢;油气质量分数越高,风速越大油品的蒸发速率越大,油气扩散越快。在发生溢油事故后,在风速影响下油气会短时间内迅速扩散至附近消防通道,救援车辆应从事故地点上风侧驶入,以避免因车辆的火星造成爆炸事故。

基于风洞平台实验的大型罐区溢油事故后的油气扩散模拟

Numerical simulation of oil vapor diffusion after oil spill accident in large-scale tank farm based on wind tunnel platform

-

摘要: 通过研究江苏省境内某实体罐区发生溢油事故后油气蒸发的扩散规律,掌握罐区空气浓度的变化,以达到保障罐区环保与安全的目的。基于风洞平台实验,测定油气蒸发速率并通过实验风场数据验证数值模型的准确性,建立与实际油库1∶1的大型罐区模型,使用UDF编译环境风方程导入。通过CFD数值模拟,重点分析了罐区发生溢油事故后油气扩散规律、储罐间的油气积聚现象、风速对油气扩散及油气质量分数的影响。结果表明:在风速影响下,罐间会形成涡流,导致油气的积聚,形成危险区域;防火堤对油气扩散存在阻滞作用,而背风侧会使油气聚集;风速越小,油气扩散越慢,油气质量分数越高;风速越大,油品的蒸发速率越大,油气扩散越快,油气质量分数越小。本研究成果可为罐区设计、油库运行及安全环保管理提供参考。Abstract: Study on the law of oil vapor evaporation and diffusion after oil spill accident in tank farm is of great significance for ensuring the safety and environmental protection of tank farm. Based on the wind tunnel test platform, the evaporation rate of oil vapor was measured, and the accuracy of the numerical model was verified by the experimental wind field data. A large-scale tank farm model was established with a ratio of 1∶1 to the actual oil depot, and the environmental wind equation was compiled by UDF to import the numerical simulation. Through CFD numerical simulation, the pattern of oil vapor diffusion after the oil spill accident in tank farm, the oil vapor accumulation between tanks, and the influence of wind speed on the diffusion and concentration of oil vapor, were emphatically analyzed. The results showed that with the influence of wind speed, the vortex between tanks would lead to the accumulation of oil vapor, which was prone to form a dangerous area. The fire dike had a blocking effect on oil vapor diffusion, while the leeward side would cause oil vapor accumulation. The lower the wind speed, the slower the oil vapor diffusion and the higher the oil vapor concentration would be; the higher the wind speed, the greater the evaporation rate of oil and the faster the diffusion of oil vapor would be. The research results are of reference value for tank farm design, oil depot operation and safety and environmental protection management.

-

水是江南园林的重要组成部分,素有“无水不成景、无水不成园”的说法[1]。水体水质好坏会在很大程度上影响到园林景观,但大多数园林水体的流动性较差、水域面积较小、自净能力偏弱,容易受到降雨径流等外源污染的冲击[2-3]。为提高水体自净效果,一般需要采取人工曝气、旁路过滤和生态浮床等强化措施。但这些方法普遍存在施工量较大、运行维护要求较高和对周边景观影响较大等问题[4–6]。

固定化生物膜技术是一种将微生物固定在一定载体上,通过增加单位水体生物量的方式,提高功能菌对污染物的降解效能的技术。该技术已被广泛应用于河湖水体的水质净化工程。WEN等[7]以玉米芯、麦秆和花生壳等为代表的生物质碳源作为固定化载体,形成的生物膜能释放有机物和氮磷等基质,促进微生物在其表面附着生长,但生物质碳源中有机物的释放速率呈现先快后慢的特点,不利于水体水质的长效治理[8];NI等[9]在纤维生物滤池 (Fiber Biofilter) 中将聚合物填料作为微生物的固定化载体,并将形成的生物膜用于水产养殖中将有机物降解,以及将氨氮转化为硝酸盐;TABASSUM等[10]以粉末状活性炭和水性聚氨酯凝胶包裹的硝化细菌作为固定化载体 (Mass Bio System) ,形成生物膜被用于快速提升水体硝化活性。

近年来,有研究者提出了一种将具有很高的生物亲和性,能以相对恒定的速率向水体释放碳源的新型生物蜡作为微生物固定化载体的技术。该生物蜡可促进生物膜的形成,适合用于治理微污染水体[11]。目前,将生物蜡技术用于封闭园林水体水质改善与长效保持的研究仍鲜有报道,生物膜的主要功能尚不清楚。为此,本研究选取典型的江南园林水体,通过对比投放生物蜡模块前后主要水质指标的统计学变化,从工程应用的角度论证新型固定化生物膜技术对小型半封闭水体的水质净化效能,并采用高通量测序技术,对水体、沉积物和生物膜中的菌群结构功能进行分析,系统阐述利用生物蜡技术实现水质净化的关键反应机制,以期为江南园林水体的原位净化与长效保持提供参考。

1. 材料与方法

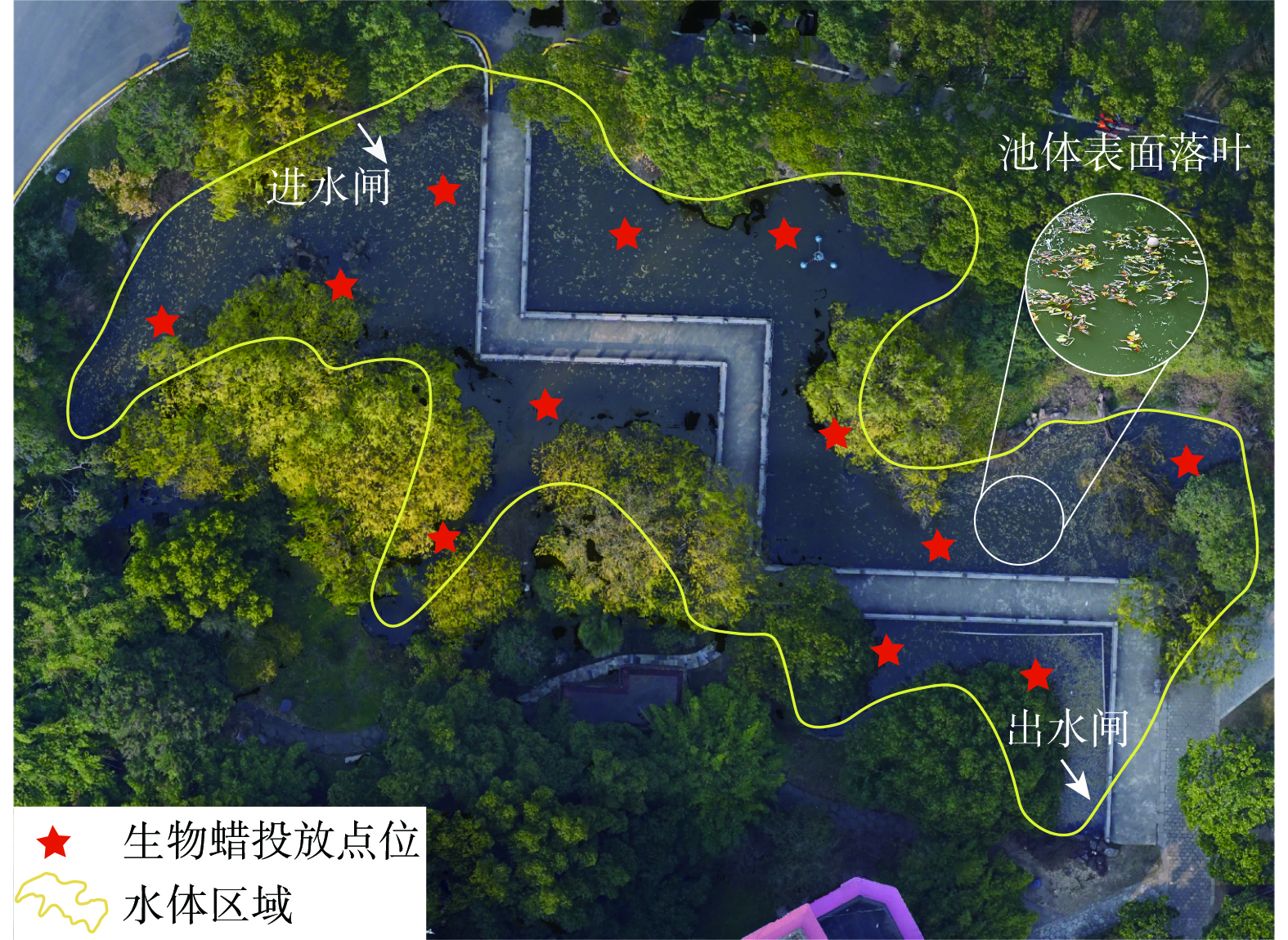

1.1 实验地点

实验地点选取典型的江南园林水体——苏州科技大学石湖校区九曲桥 (31°15′17.88″N,120°34′56.30″E),水域面积约为1 200 m2,平均水深0.6~0.7 m,池底无水生植物,周边有茂密的陆生植被,定期与外部河道进行换水操作,如图1所示。该水体在春夏季受河道进水、降雨径流和内源污染等影响,容易发生局部水华现象。

研究于2021年2月—6月开展,对水体本底值进行监测,并于当年10月份投放生物蜡模块。待生物蜡挂膜成功后,于次年2—6月开展水质常规监测,以评估水体水质变化,监测频次均为每周2次。据调查,2021年苏州市平均气温 18.3 ℃,降水量1 318.6 mm,2022年平均气温 18.1 ℃,降水量1 004.2 mm。2021年和2022年苏州春夏季降雨量、平均气温相差不大,降雨形成的地表径流和树木落叶是潜在的外源污染。水体换水周期为每季度3~4次,每次换水耗时约1~2 d,其余时间水体基本处于静止状态。

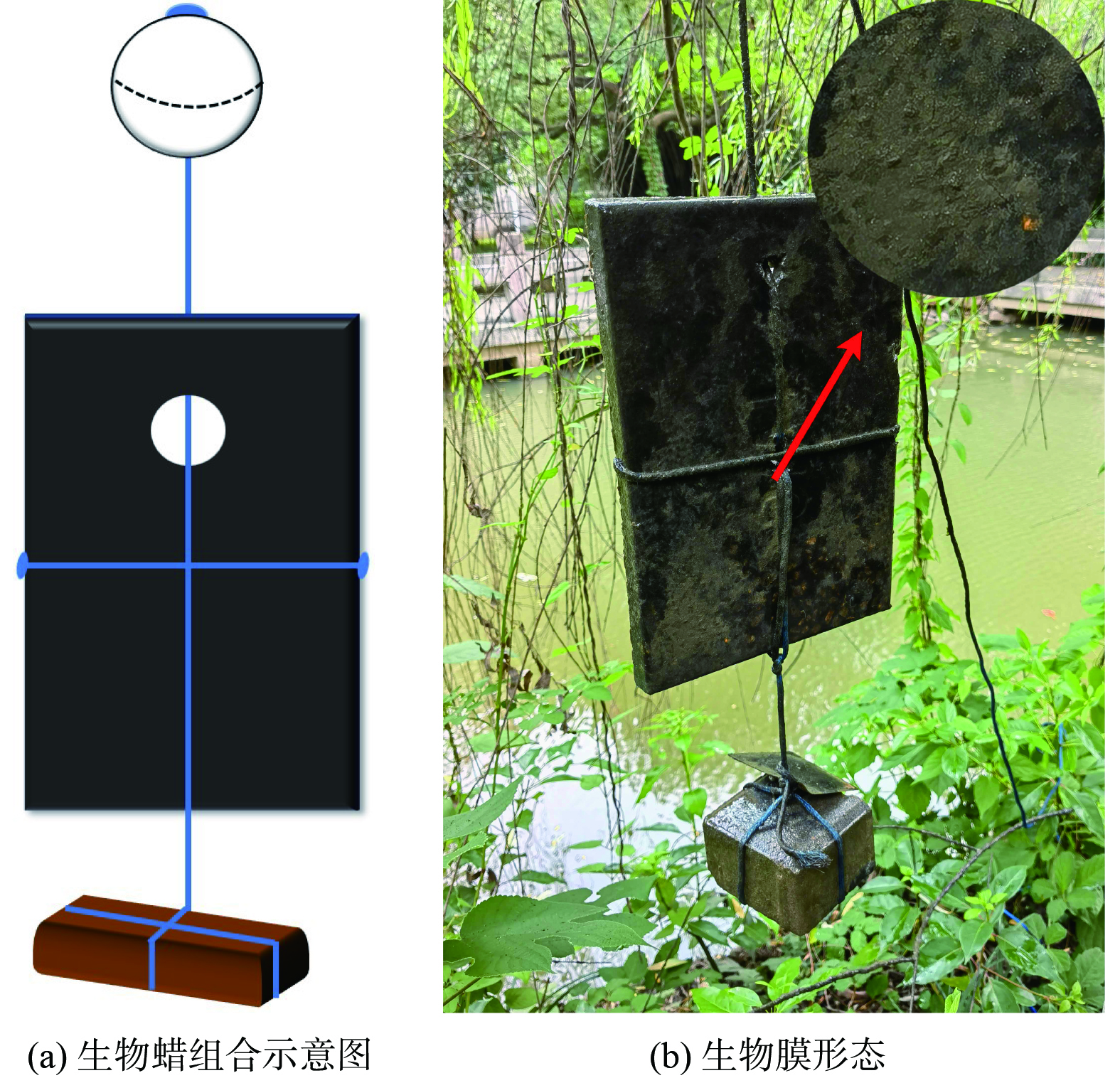

1.2 生物蜡投放

生物蜡是一种采用微晶蜡固定脂肪酸 (碳源0.5%,微量元素0.1%,其他为石蜡 (标号56#) ) 的块状基质,整体呈黑色[12-13]。在水体中设置有12个投放点,平均每100 m2水面投放1块0.317 m×0.220 m×0.025 m,重1.25 kg的生物蜡。利用浮漂和配重将生物蜡模块直立悬浮在水中,如图2 (a) 所示。在水流和微生物作用下,生物蜡缓慢释放营养物质,有效促进土著微生物在其表面生成稳定的生物膜结构,期间不投加任何菌种。生物蜡挂膜周期约3个月,成熟的生物膜形态如图2 (b) 所示。

1.3 水质指标分析

使用EXO水质分析仪 (YSI,USA) 现场测定了叶绿素a的浓度,使用赛氏盘现场测定了透明度。使用国标法测定水样的氨氮 ([NH4+-N]) 、总氮 (TN) 、总磷 (TP) ,使用重铬酸盐法测定水样COD。

1.4 微生物高通量测序

2022年7月,分别采集水体中水样 (Water) 、沉积物 (Sediment) 和生物蜡表面生物膜 (Biofilm) 样品。水样经0.22 μm孔径滤膜过滤后,与其他固态样品一同-80 ℃条件下保存。使用试剂盒 (Fast DNA Spin kit for soil,M.P。Company,U.S.) 对各组样品进行DNA提取,每组设置3个平行样。使用引物338F ( 5'-ACTCCTACGGGAGGCAGCA-3') 和806R ( 5'-GGACTACHVGGGTWTCTAAT-3') ,进行16S rRNAV3-V4区基因扩增。PCR扩增完成后,用AxyPrepTM DNA凝胶提取试剂盒 (Axygen Biosciences,Union City,U.S.) 对产物进行纯化。将处理完成后的样品送往Illumina MiSeq 测序平台进行高通量测序。

1.5 细菌群落多样性分析

使用Usearch (version 11) 以97 %的相似性对OTU代表序列进行分类学分析。基于抽平后的OTU数据集,使用Uparse (version 11) 计算了α多样性指数 (Chao1和Shannon指数) ,并进行 (PCoA) 主坐标分析。在门和属水平上,比较了不同介质菌群结构的差异性。采用Kruskal-Wallis 秩和检验方法检验对多组样本进行物种组间差异显著性检验。使用Gephi (version 0.10.1) 分析不同介质细菌在属水平上的共现性网络。使用Faprotax预测不同介质细菌的潜在代谢功能。

2. 结果与讨论

2.1 投放前后理化性质分析

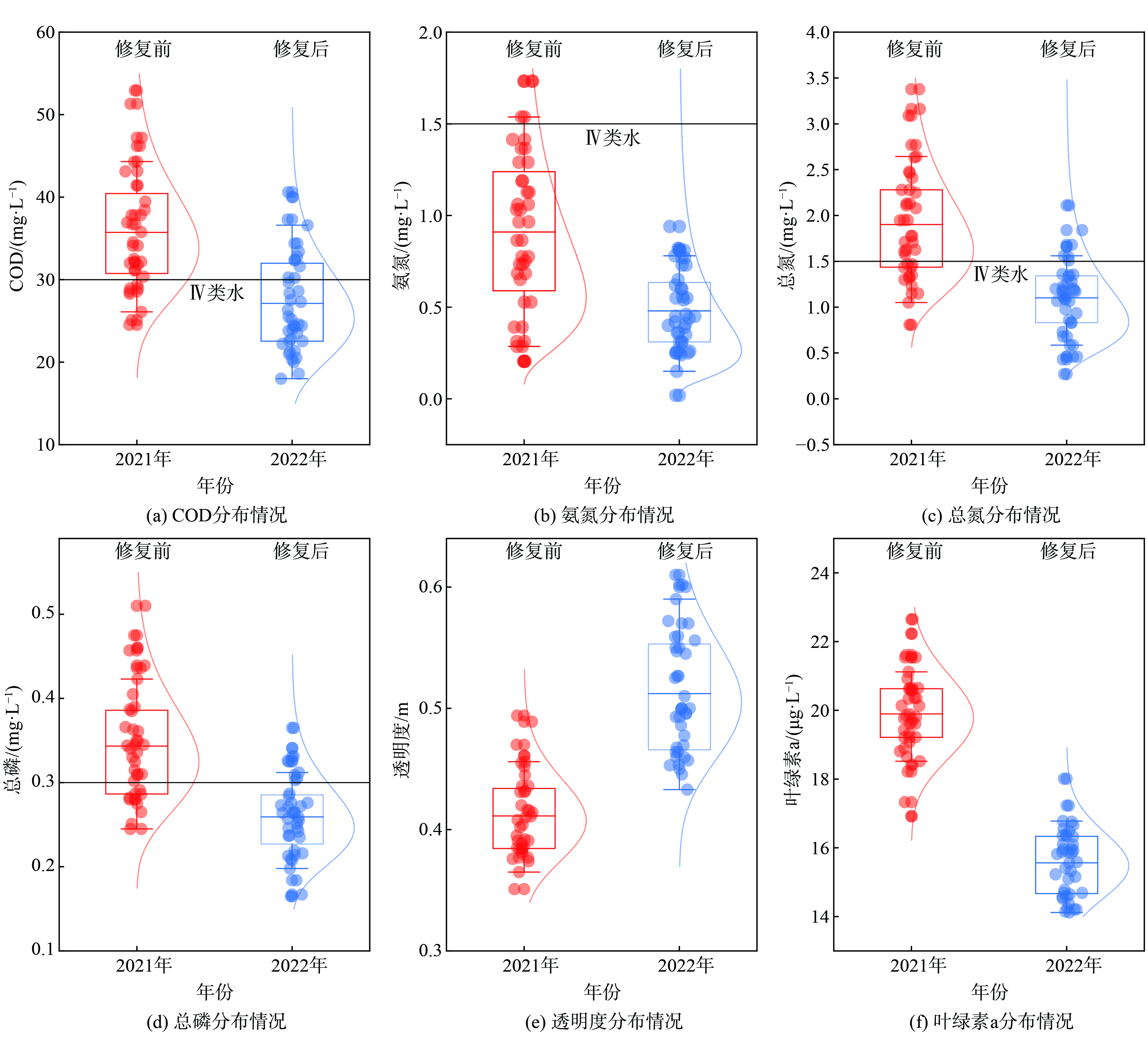

图3所示为投放生物蜡前后水体的各项监测数据,修复前为红色,修复后为蓝色。2021年2—6月:水体的COD、氨氮、总氮和总磷服从正态分布,均值分别为 (35.74±7.01) mg·L−1、 (0.91±0.43) mg·L−1、 (1.90±0.61) mg·L−1、和 (0.34±0.07) mg·L−1,离散系数分别为0.20、0.47、0.32和0.21;池体平均透明度为 (0.41±0.03) m,低于苏州水体均值0.51 m[14];叶绿素a的平均质量浓度为 (19.90±1.20) μg·L−1,高于苏州河道春夏季均值15.36 μg·L−1,这表明该水体属于轻度富营养化程度[15-16]。2022年2—6月:水体的COD、氨氮、总氮和总磷平均值分别为 (27.12±4.88) mg·L−1、 (0.48±0.21) mg·L−1、 (1.10±0.32) mg·L−1和 (0.26±0.05) mg·L−1,较2021年同期分别下降24.12 %、47.25 %、42.11 %和23.53 %,各项指标的离散系数降至0.18、0.44、0.29和0.19;水体透明度平均值升高至 (0.53±0.05) m;叶绿素a平均质量浓度降至 (15.96±0.96) μg·L−1,这表明该水体富营养化程度有所改善。与生物蜡的多种修复功能相比,传统的硅藻土和多孔黏土材料等生物膜载体仅能用于提高水体的生物量,改善部分指标[17-18]。

按照监测次数计算,2021年2—6月,COD、总氮、氨氮和总磷达到《地表水环境质量标准》 (GB3838-2002) Ⅳ 类标准的百分比分别为22.5 %、90.0 %、32.5 %和30.0 %。除受外河水质影响外,九曲桥周边分布有大量落叶乔木和灌木,落叶等凋落物是造成水体氮磷超标的重要源头之一[19]。2022年2—6月,水体COD、总氮、氨氮和总磷的Ⅳ类水达标率分别较2021年同期提高了3.0倍、1.1倍、2.1倍和2.3倍,九曲桥春夏季的水质得到明显改善 (图4) 。

2.2 功能菌群在不同介质中的分布

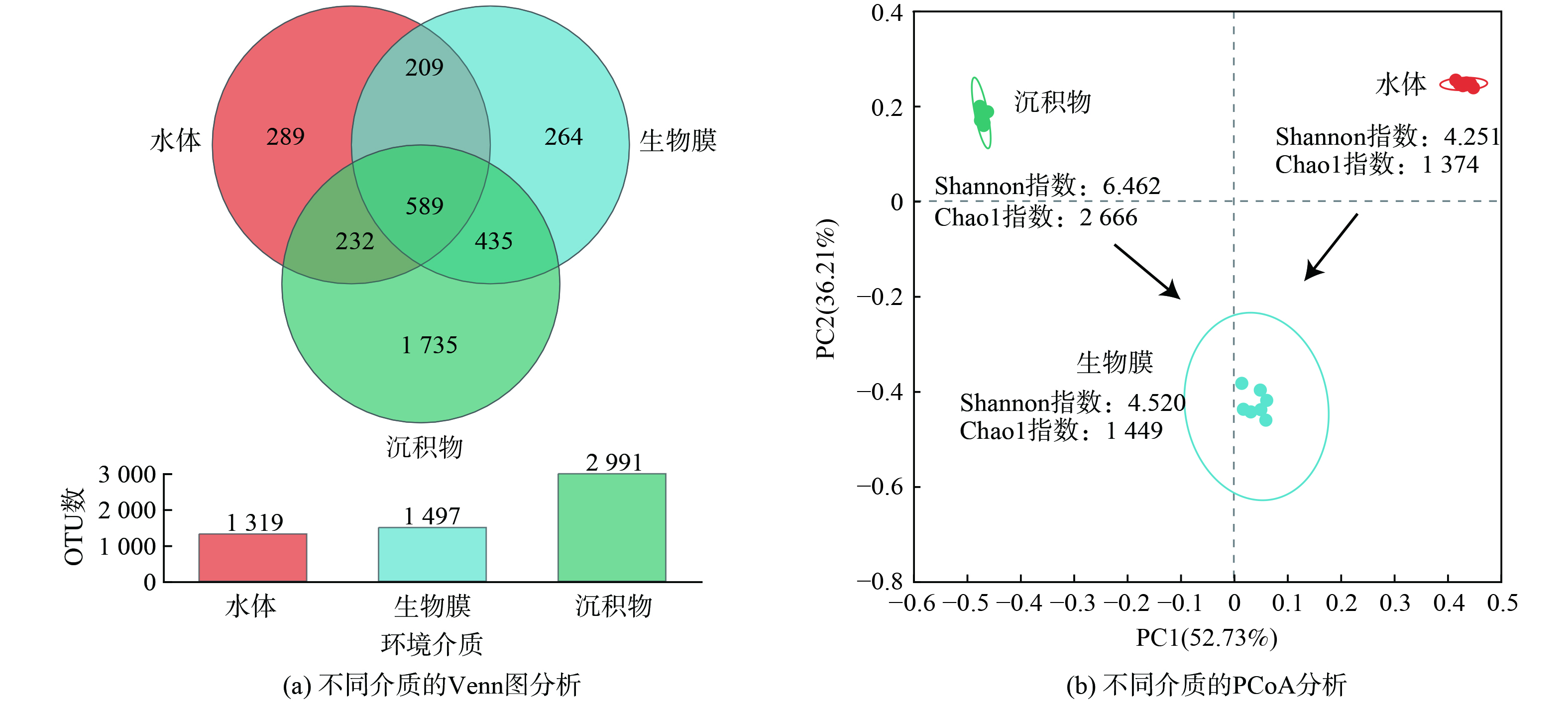

图5 (a) 表明,生物蜡表面生物膜的微生物丰度 (Chao1指数) 和多样性指数 (Shannon指数) 与水体接近,均明显低于沉积物的水平。这可能是由于在水流扰动作用下,沉积物-水体界面更容易形成基质梯度 (如溶解氧) ,进而形成显著的生态位分化,有利于不同功能菌群的协同生长[20-21]。

基于Bray-Curtis距离法的PCoA分析结果表明 (图5 (b) ) ,生物膜在PC1维度 (解释度52.73%) 上介于水体和沉积物之间,在PC2维度 (解释度36.21%) 上与水体和沉积物均存在很大差异。生物膜和水体、生物膜和沉积物共有的OTU数量分别为798个和1 024个,分别占生物膜OTU总数的53.3%和68.4%。相比之下,生物膜中特有的OTU数量为264个,仅占到总数的17.6%。这说明生物膜主要由水体的土著微生物构成,悬浮的生物蜡模块不仅提高了水体中的微生物总量,还改变了微生物的空间分布形态,为降解水中污染物创造了有利条件。

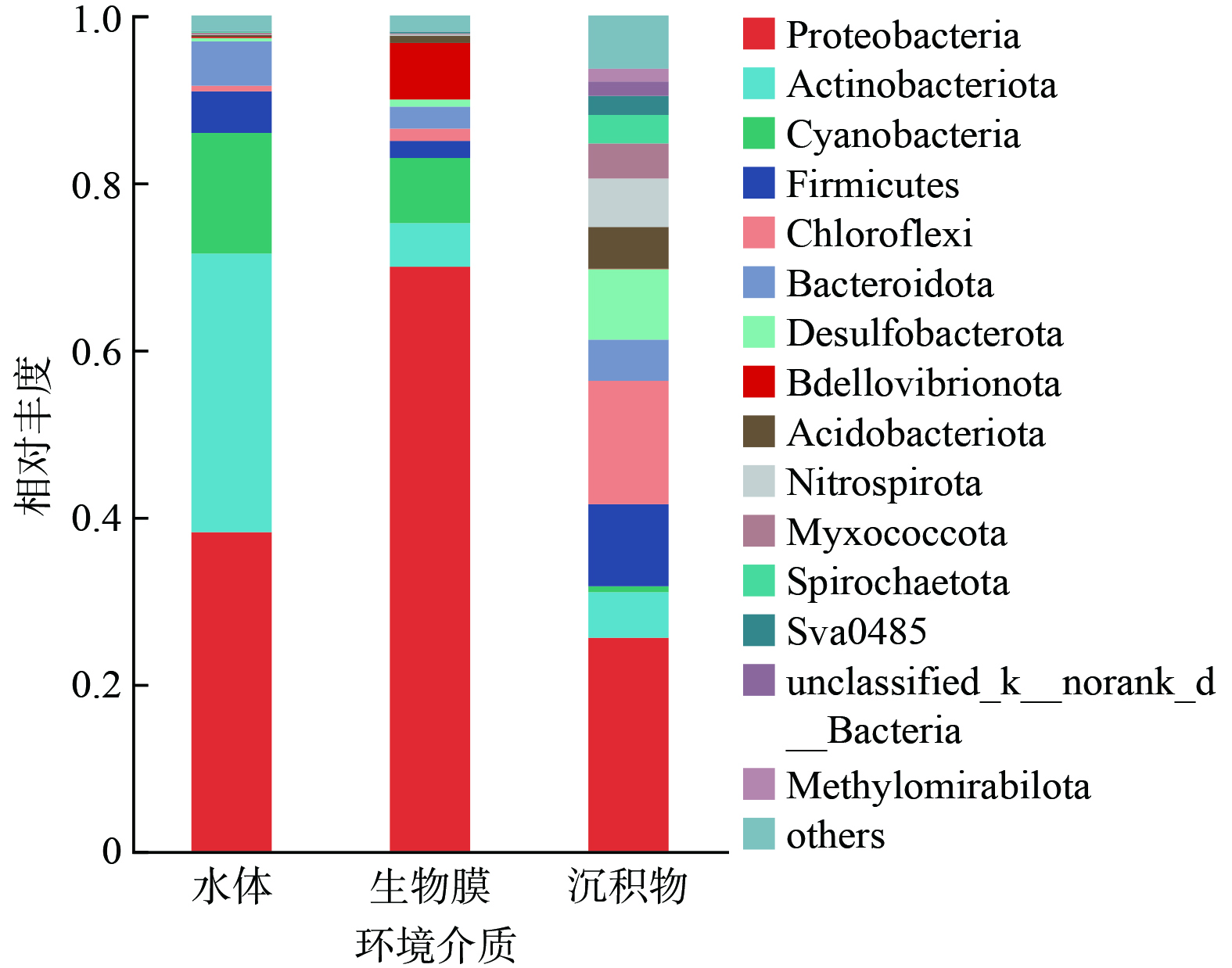

如图6所示,水体样品中的优势菌门分别为变形菌门 (Proteobacteria,相对丰度38.42 %) 、放线菌门 (Actinobacteriota,33.30 %) 、蓝藻门 (Cyanobacteria,14.44%) 、拟杆菌门 (Bacteroidota,5.32 %) 和厚壁菌门 (Firmicutes,4.97 %) 。变形菌门、拟杆菌门、放线菌门和蓝藻门在水体中的富集与其轻度富营养化状况是一致的[22-23]。在沉积物中,丰度前5的菌门包括变形菌门 (Proteobacteria,25.65 %),绿弯菌门 (Chloroflexi,14.78 %)、厚壁菌门 (Firmicutes,9.47 %) 、脱硫菌门 (Desulfobacterota,8.43 %) 和硝化螺旋杆菌门 (Nitrospirota,5.80 %) 。其中,绿弯菌门和厚壁菌门的富集与沉积物中典型的缺氧环境密切相关[24]。相比之下,生物膜中变形菌门的相对丰度最高,达到69.36 %,随后为蓝藻门 (Cyanobacteria,7.79%)、蛭弧菌门 (Bdellovibrionota,6.67%)、放线菌门 (Actinobacteriota,5.22 %) 和拟杆菌门 (Bacteroidota,2.64 %) 。通常认为,变形菌门具有较强的有机物和营养盐代谢潜力,同时,其能够分泌大量胞外聚合物 (EPS) ,为生物膜的形成提供了重要的结构性物质[25-26]。此外,蛭弧菌门在生物膜中的相对丰度分别为水和沉积物中的43.47 倍和159.38 倍。作为典型的掠食性细菌,蛭弧菌门的生长说明生物膜中形成了更长的食物链和更强的淘汰压,有利于形成特定功能化的菌群结构[27]。

如图7所示,通过在属水平上比较不同介质的细菌群落组合,可获得更详细的生态位信息。LEfSe (LDA Effect Size) 分析 (LDA>4) 表明水体中有Acinetobacter (变形菌门,3.63 %) 、 Aurantimicrobium (放线菌门,2.73 %) 、CL500-29_marine_group (放线菌门,3.40 %) 等12个属与其他介质存在显著差异,其中,Acinetobacter、Limnohabitans、CL500-29_marine_group和Polymucleobacter分别在硝化[28]、硝酸盐还原[29]、反硝化[30]和溶解性有机物降解[31]等碳氮循环的过程中发挥作用。具有溶磷能力的Exiguobacterium含量相对较少,这可能是水体磷元素去除率低的原因。沉积物中有norank_f_norank_o__SBR1031 (绿弯菌门,3.00 %) 、Sva0485 (Sva0485门,2.27 %) 、Anaeromyxobacter (黏球菌门,3.18 %) 等5个属与其他介质存在显著差异,其中norank_f_norank_o__SBR1031可利用多种有机物进行发酵生长,在清除微量有机物方面有积极作用[32]。生物膜中有Aquabacterium (变形菌门,16.25 %) 、Hydrogenophaga (变形菌门,7.23 %) 、Caulobacter (变形菌门,3.14 %) 等7个属与其他介质存在显著差异。同时生物蜡表面的生物膜上存在厌氧或厌氧兼性的反硝化细菌[33] (如Hydrogenophaga和Caulobacter) 和异养硝化-好氧反硝化细菌[34] (如Novosphingobium和Sulfuritalea) ,这些细菌为水体氨氮的高去除率和高达标率提供了前提条件。水环境中活性有机物降解菌和反硝化菌的明显增加,可有效减少耗氧污染物,提高水体的承载能力,有利于水质的改善。与玉米芯等生物质碳源作为固定化生物膜载体类似,投加生物蜡选择性地促进了具有固氮和反硝化能力的氮循环微生物的生长[35]。

2.3 不同介质中的菌群间功能预测

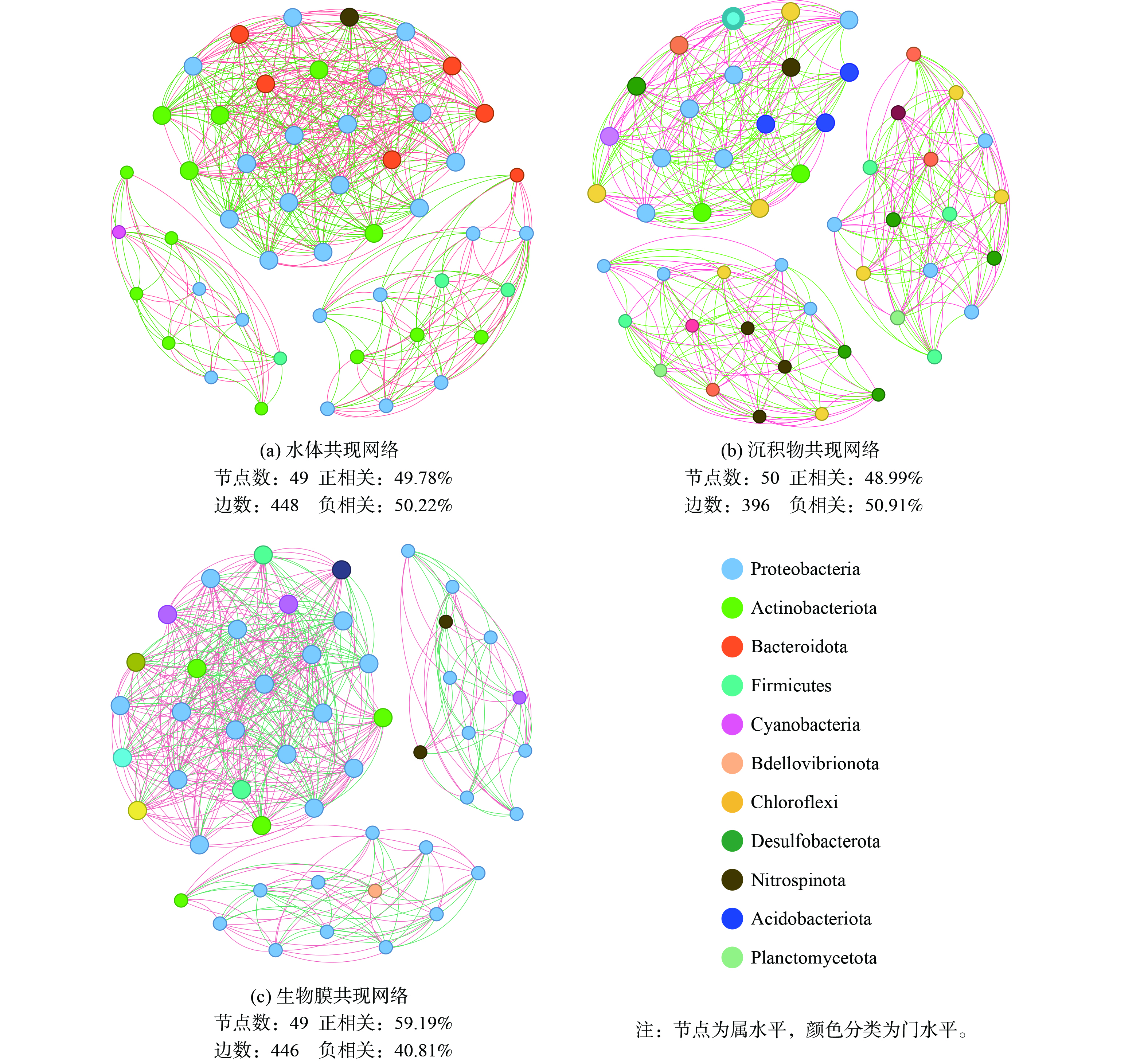

如图8所示,尽管沉积物中的微生物多样性远高于水和生物膜,但生物膜上形成了更为复杂的微生物关联关系。水体、沉积物和生物膜中丰度前50的菌属之间边数分别为448条边、396条边和446条边。从共现网络发现,水体和生物蜡表面微生物的相互作用主要以变形菌门、放线菌门和拟杆菌门为主,而沉积物中相互作用的微生物具有很高的均质性,以变形菌门、绿弯菌门和脱硫菌门为主。生物膜网络中的正相关性最高,而天然环境中的网络正负相似。这表明在生物膜上微生物之间发生了更紧密的共生关系,互利的共生关系可能涉及代谢物的交换、基因和电子的转移以及信号分子的传输[36], 生物蜡持续释放微生物生长基质有利于在生物膜中形成复杂的关联网络。目前,生物蜡对不同种土著微生物的选择性富集机理尚不清楚,有待后续探究。

共现网络的关键物种对潜在的微生物功能很重要,是细菌群落结构和生态系统稳定性的驱动力,与不同介质的代谢循环密切相关[37]。作为水体的关键物种,拟杆菌门的pseudarcicella利用藻类分解物中的多种物质 (碳水化合物,氨基酸,丙酮酸) 作为其碳源,且更适宜在贫营养低浊度环境下生存[38],hgc I_clade、Flavobacterium等具有溶藻能力的细菌[39],能与pseudarcicella形成“微循环”,增强水体的藻类分解和有机物去除能力。沉积物中脱硫菌门的Syntrophus 可能与硫酸盐还原有关,能在厌氧条件下以硫化物、元素硫、硫代硫酸盐和氢为电子供体,以硝酸盐为电子受体进行硫代谢[40]。生物膜上的关键物种是来自变形菌门的Limnohabitans,其在水体中含量更高,但在生物膜上与其他微生物具有更强的联系, Limnohabitans自身参与氮素营养盐还原[41],可为好氧反硝化细菌如Hydrogenophaga、Aquabacterium和Rhodobacter等提供电子受体[42],进一步稳定生物膜的菌间关系,强化水环境的氮循环能力。

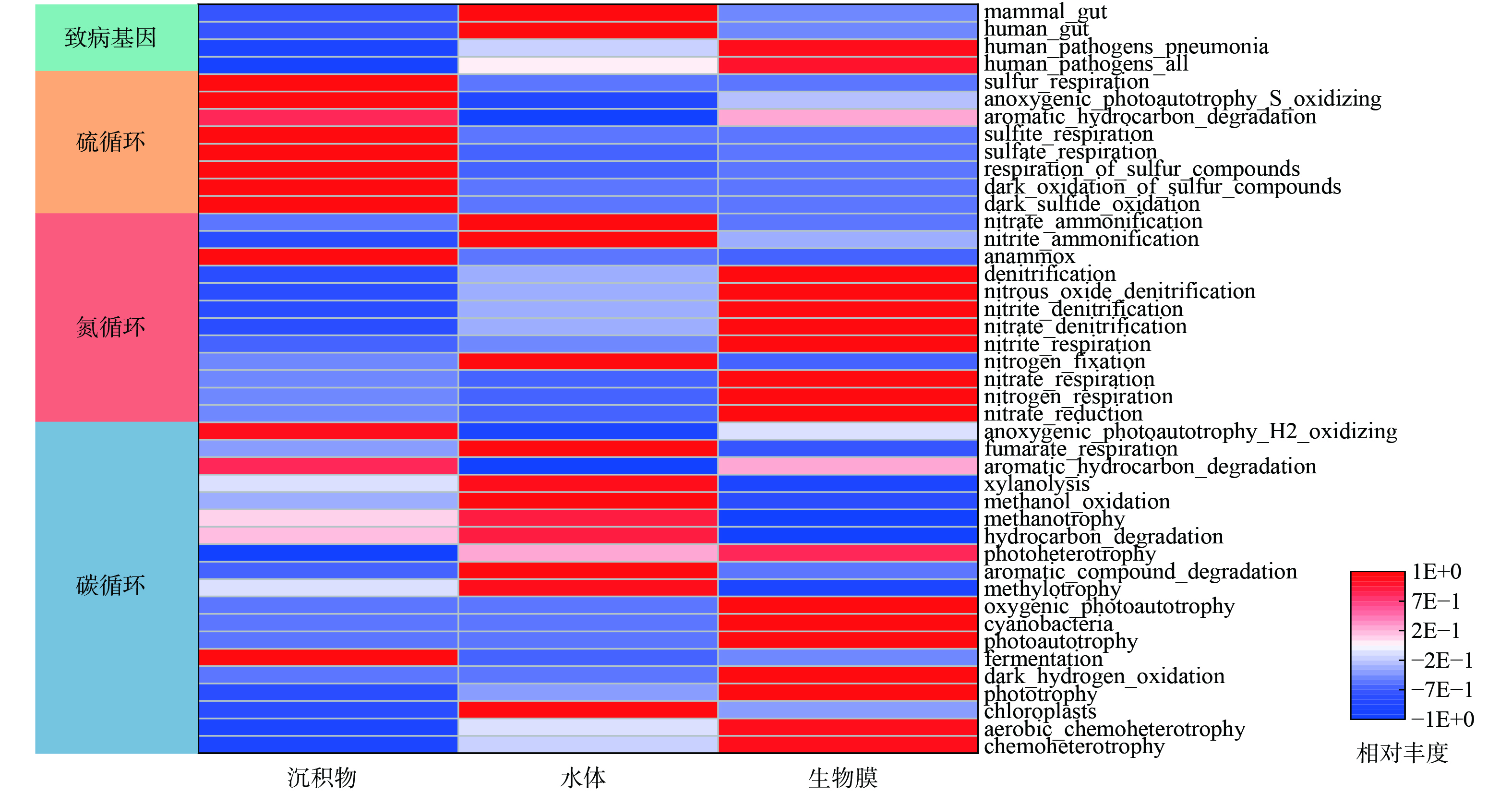

图9所示的Faprotax预测常用于描述菌群的代谢功能和生态位信息。水体中碳氮代谢的功能基因丰度较高,包括methanotrophy、methylotrophy、methanol_oxidation、nitrate_ammonification、nitrite_ammonification和nitrogen_fixation等,同时,也存在一定的致病风险 (如human_gut、manmal_gut) 。在沉积物中,sulfur_respiration、sulfite_respiration等硫循环功能基因占据主导。相比之下,生物膜中chemoheterotrophy、photoautotrophy和phototrophy等碳循环和nitrate_reduction、nitrogen_respiration、nitrate_respiration等氮循环功能基因丰度明显提高。尽管部分致病基因也得到了富集,但生物膜中未检出chloroplasts等藻类代谢基因,具有较高的功能化特征。

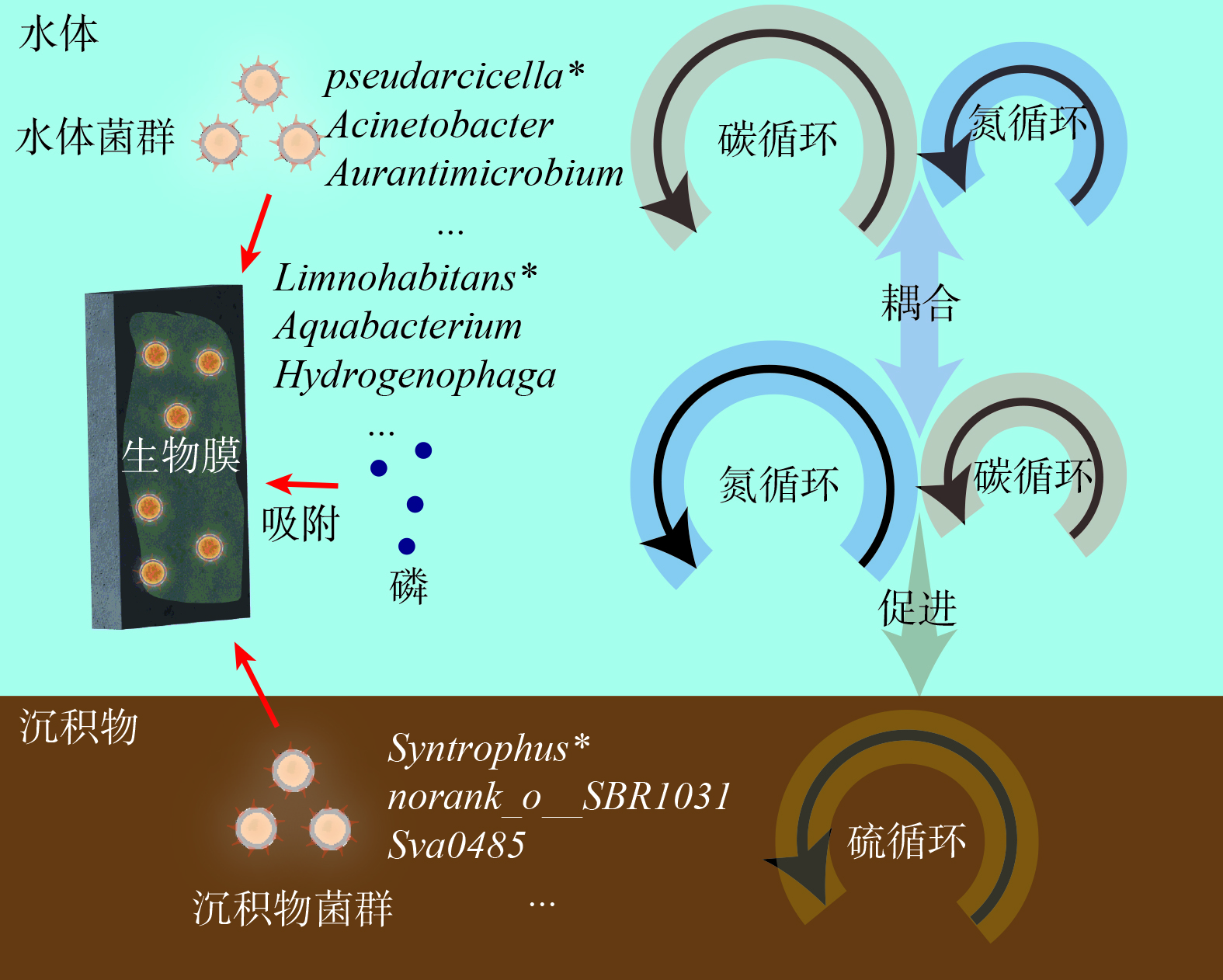

生物蜡技术的微生物反应机制如图10所示。生物蜡能富集水体和沉积物的土著菌种,与上述关键物种功能研究一致,各个介质的关键物种介导了各个介质的核心功能,且水体中主要存在的厌氧消化相关碳循环功能和生物膜上的硝态氮还原相关氮循环功能可进行耦合,进行碳和氮的同时去除[43]。沉积物中硫循环基因的主要代谢过程是将水环境中的硫元素转化为H2S,此过程更容易在厌氧或缺氧环境下进行[44],生物膜的关键物种 Limnohabitans可能会为此过程提供电子受体以促进沉积物硫代谢。功能预测结果表明,生物膜缺少典型的磷循环功能基因,考虑到修复后池体透明度得到改善,推测磷的去除途径主要是生物膜的吸附和含磷颗粒物的沉降,具体磷的去除路径需要在后续研究中进一步阐述。建议种植苦草等水生植物来协同磷元素的去除[45]。研究表明,在园林水体中不同环境介质上微生物功能存在显著的差异性,但水动力、季节更替等自然条件对生物膜功能的影响尚不明确,还需要后续进行研究。

3. 结论

投放生物蜡使水体的COD、氨氮、总氮和总磷分别降低了24.12 %、42.11 %、47.25 %和23.53 %,而且可长期保持在较低水平。同时发现:1) 生物蜡表面生物膜中82.4%的OTU都来源于水体和沉积物,以变形菌门为主,占69.36%,其中以Aquabacterium (变形菌门) 和Hydrogenophaga (变形菌门) 为主要的属。相关性分析筛选出水体的pseudarcicella属 (拟杆菌门) 、生物膜的Limnohabitans属 (变形菌门) 、沉积物的Syntrophus属 (脱硫菌门) 是各个介质的关键物种;2) 生物膜上的光能自养、化能异养和亚硝酸盐去除等核心功能呼吸加强了水环境中有机物的降解和氮化合物间的转化,实现了水体的碳氮耦合,能够增强沉积物的硫代谢能力,提高水环境的污染物降解能力。

生物蜡在促进微生物生长的同时可有效截留生物量,显著提高水体透明度和抑制藻类生长。与颗粒物对磷酸盐的吸附作用类似,生物吸附可能是导致水体总磷浓度降低的重要原因。在后续治理中,建议在池底分区种植能与生物蜡协同的苦草、狐尾藻和轮叶黑藻等水生植物,进一步提高水体除磷效能,同时,采取打捞池中落叶和池底淤泥等管理措施,有效削减内外源强,实现水质长效保持目标。

-

-

[1] CIRIMELLO P G, OTEGUI J L, RAMAJO D, et al. A major leak in a crude oil tank: Predictable and unexpected root causes[J]. Engineering Failure Analysis, 2019, 100: 456-469. doi: 10.1016/j.engfailanal.2019.02.005 [2] SHARMA R K. A violent, episodic vapour cloud explosion assessment: Deflagration-to-detonation transition[J]. Journal of Loss Prevention in the Process Industries, 2020, 65: 104086. doi: 10.1016/j.jlp.2020.104086 [3] ZHANG L, MA H, SHEN Z, et al. Influence of pressure and temperature on explosion characteristics of n-hexane/air mixtures[J]. Experimental Thermal and Fluid Science, 2019, 102: 52-60. doi: 10.1016/j.expthermflusci.2018.11.004 [4] ATKINSON G, COLDRICK S, GANT S, et al. Flammable vapor cloud generation from overfilling tanks: Learning the lessons from Buncefield[J]. Journal of Loss Prevention in the Process Industries, 2015, 35: 329-338. doi: 10.1016/j.jlp.2014.11.011 [5] ATKINSON G, COWPE E, HALLIDAY J, et al. A review of very large vapour cloud explosions: Cloud formation and explosion severity[J]. Journal of Loss Prevention in the Process Industries, 2017, 48: 367-375. doi: 10.1016/j.jlp.2017.03.021 [6] ORAN E S, CHAMBERLAIN G, PEKALSKI A. Mechanisms and occurrence of detonations in vapor cloud explosions[J]. Progress in Energy and Combustion Science, 2020, 77: 100804. doi: 10.1016/j.pecs.2019.100804 [7] CHAMBERLAIN G, ORAN E, PEKALSKI A. Detonations in industrial vapour cloud explosions[J]. Journal of Loss Prevention in the Process Industries, 2019, 62: 103918. doi: 10.1016/j.jlp.2019.103918 [8] 黄维秋. 油气回收基础理论及其应用[M]. 北京: 中国石化出版社, 2011. [9] 吴悦, 曾向东, 金海花, 等. 中国石油化工废气处理技术进展[J]. 石油学报(石油加工), 2000(6): 79-84. [10] 中华人民共和国生态环境部. 储油库大气污染物排放标准: GB 20950-2020[S]. 北京: 中国环境出版社, 2020. [11] 中华人民共和国生态环境部. 关于深入推进重点行业清洁生产审核工作的通知[EB/OL]. [2021-01-10]. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk05/202010/t20201020_803925.html, 2020-10-16. [12] SHEN R, JIAO Z, PARKER T, et al. Recent application of computational fluid dynamics (CFD) in process safety and loss prevention: A review[J]. Journal of Loss Prevention in the Process Industries, 2020, 67: 104252. doi: 10.1016/j.jlp.2020.104252 [13] 陈金金, 潘亚东, 郭翔宇. CFD软件在油气储运工程领域的应用研究[J]. 中国石油和化工标准与质量, 2019, 39(1): 144-145. doi: 10.3969/j.issn.1673-4076.2019.01.072 [14] 王福君. 计算流体动力学分析: CFD软件原理与应用[J]. 北京:清华大学出版社, 2004: 7-12. [15] 阎超, 屈峰, 赵雅甜, 等. 航空航天CFD物理模型和计算方法的述评与挑战[J]. 空气动力学学报, 2020, 38(5): 829-857. [16] WANG Q H, SUN Y L, SHU C M, et al. Effect of separation distance on gas dispersion and vapor cloud explosion in a storage tank farm determined using computational fluid dynamics[J]. Journal of Loss Prevention in the Process Industries, 2020, 68: 104282. doi: 10.1016/j.jlp.2020.104282 [17] SUN X, LI W X, HUANG Q Y, et al. Large eddy simulations of wind loads on an external floating-roof tank[J]. Engineering Applications of Computational Fluid Mechanics, 2020, 14(1): 422-435. doi: 10.1080/19942060.2020.1718757 [18] 刘瑞, 王冬, 张培理, 等. 覆土油罐油气泄漏扩散数值模拟[J]. 天然气与石油, 2020, 38(6): 136-142. doi: 10.3969/j.issn.1006-5539.2020.06.022 [19] 陈鑫, 王刚, 叶正寅, 等. CFD不确定度量化方法研究综述[J]. 空气动力学学报, 2021,39(4): 1-13. [20] HU T, YOSHIE R. Effect of atmospheric stability on air pollutant concentration and its generalization for real and idealized urban block models based on field observation data and wind tunnel experiments[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2020, 207: 104380. doi: 10.1016/j.jweia.2020.104380 [21] LIN C, OOKA R, KIKUMOTO H, et al. Wind tunnel experiment on high-buoyancy gas dispersion around isolated cubic building[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2020, 202: 104226. doi: 10.1016/j.jweia.2020.104226 [22] SUN D, SHI X, ZHANG Y, et al. Spatiotemporal distribution of traffic emission based on wind tunnel experiment and computational fluid dynamics (CFD) simulation[J]. Journal of Cleaner Production, 2021, 282: 124495. doi: 10.1016/j.jclepro.2020.124495 [23] 崔鹏义, 李卓, 陶文铨. 街道峡谷内污染物扩散的风洞试验与数值分析[J]. 工程热物理学报, 2014, 35(12): 2491-2495. [24] ZHANG G, HUANG F Y, HUANG W Q, et al. Analysis of influence of floating-deck height on oil-vapor migration and emission of internal floating-roof tank based on numerical simulation and wind-tunnel experiment[J]. Processes, 2020, 8(9): 1026. doi: 10.3390/pr8091026 [25] 徐川, 李万莉, 刘翠伟, 等. CFD模拟障碍物条件下甲烷扩散的有效性研究[J]. 油气田地面工程, 2019, 38(S1): 90-93. [26] 辛保泉, 喻健良, 党文义, 等. 复杂地形高含硫天然气风洞扩散实验及安全防护距离[J]. 天然气工业, 2020, 40(11): 149-158. doi: 10.3787/j.issn.1000-0976.2020.11.018 [27] HUANG W Q, HUANG F Y, FANG J, et al. A calculation method for the numerical simulation of oil products evaporation and vapor diffusion in an internal floating-roof tank under the unsteady operating state[J]. Journal of Petroleum Science and Engineering, 2020, 188: 106867. doi: 10.1016/j.petrol.2019.106867 [28] 黄维秋, 方洁, 吕成, 等. 内浮顶罐组油气泄漏扩散叠加效应的数值模拟与风洞实验研究[J]. 化工学报, 2019, 70(11): 4504-4516. [29] 刘国梁, 宣捷, 杜可, 等. 重烟羽扩散的风洞模拟实验研究[J]. 安全与环境学报, 2004,4(3): 27-32. doi: 10.3969/j.issn.1009-6094.2004.03.008 [30] 景海波, 黄维秋, 纪虹, 等. 基于数值模拟技术的油气扩散风洞实验相似准则数研究[J]. 常州大学学报(自然科学版), 2020, 32(4): 83-92. -

下载:

下载: