-

水泥产业是典型的能源和资源消耗密集型产业,也是仅次于电力行业的第二大CO2、NOx排放源,减排形势严峻[1]。O2/CO2烟气循环煅烧水泥技术是将分离空气制得的高纯度O2与部分再循环烟气混合后通入回转窑和分解炉内助燃,使煤粉在O2/CO2氛围下燃烧,不仅能实现窑尾烟气中CO2的富集和回收,还能降低热力型NOx的排放[2],对水泥行业实现CO2和NOx减排具有重要意义。

许多学者针对煤粉颗粒在O2/CO2气氛下的燃烧特性展开了大量研究。楚化强等[3]利用数值模拟的方法研究了煤粉在空气和O2/CO2气氛下的燃烧情况,结果表明O2/CO2气氛下燃烧火焰温度较低。何先辉等[4]和SHEN等[5]研究表明,在O2/CO2气氛下,煤粉颗粒的完全燃尽时间延长了20%~25%左右。在流化床锅炉方面,有学者通过搭建中小型实验台[6-9]和数值模拟的方法[10-12]进行了O2/CO2燃烧技术的研究,目前O2/CO2燃烧技术已经逐渐应用在电站锅炉上的实际工程中。但是O2/CO2燃烧技术在水泥生产领域的研究还处于起步阶段,仅有少数研究者进行了初步的探索工作。DAVID等[13]通过建立回转窑氧燃料燃烧过程的三维数学模型发现,在同一氧气浓度下, 火焰长度比在空气条件下燃烧的火焰长度短30%~65%,辐射通量提高2~4.5倍,在相同的燃料消耗率下,可以提高熟料的生产率。FRANCISCO等[14]和MARIO等[15]分别以实验和数值模拟的方式验证了现代窑式燃烧器可在不作额外改造的情况下适用氧燃料燃烧。但三者都只单独进行了回转窑的研究,缺少炉、窑一体的研究,没有进一步研究分解炉中NOx的生成情况和煤粉燃烧特性的改变对生料分解产生的影响,无法支持该技术在水泥回转窑和分解炉上的应用。

本研究对某公司2 500 t·d−1回转窑和分解炉进行数值模拟,探讨了O2/CO2烟气循环煅烧水泥技术实现CO2和NOx减排的可行性,对比分析了21%O2/79%CO2助燃工况下与空气助燃工况下回转窑、分解炉的模拟结果,为水泥行业实现O2/CO2燃烧技术的应用提供参考。

全文HTML

-

考虑到分解炉、回转窑内均为复杂湍流,且有较强旋流和回流,因此,在解决工程问题时,回转窑、分解炉的气相湍流模型都采用了处理旋流和回流运动更准确的重整化群模型(即RNG κ-ε模型)。湍流动能 κ 方程见式(1);耗散率 ε 方程见式(2)。

式中:ui为xi、xj方向上的速度;Gκ为紊动能κ的生成项;μeff为有效黏性系数;C1ε、C2ε为模型常数;ακ、αε分别为κ和ε的逆有效普朗特数。

针对煤粉颗粒的轨迹模拟,选用DPM模型中随机轨道模型对颗粒进行追踪。针对分解炉内燃料燃烧与生料分解的耦合过程,选用组分输运模型结合涡耗散概念模型[16];不考虑回转窑内CaCO3分解反应,针对回转窑内湍流气相燃烧,采用预混燃烧下的涡耗散模型;针对煤粉燃烧过程和挥发分析出过程,选择单步竞争反应速率模型;针对剩余焦炭燃烧过程,选择动力/扩散控制反应速率模型;针对辐射换热过程,均选择P-1模型。在反应产生的NOx中,只计算NO;在分解炉中,只考虑燃料型NO;在回转窑中,只考虑热力型、燃料型NO。

-

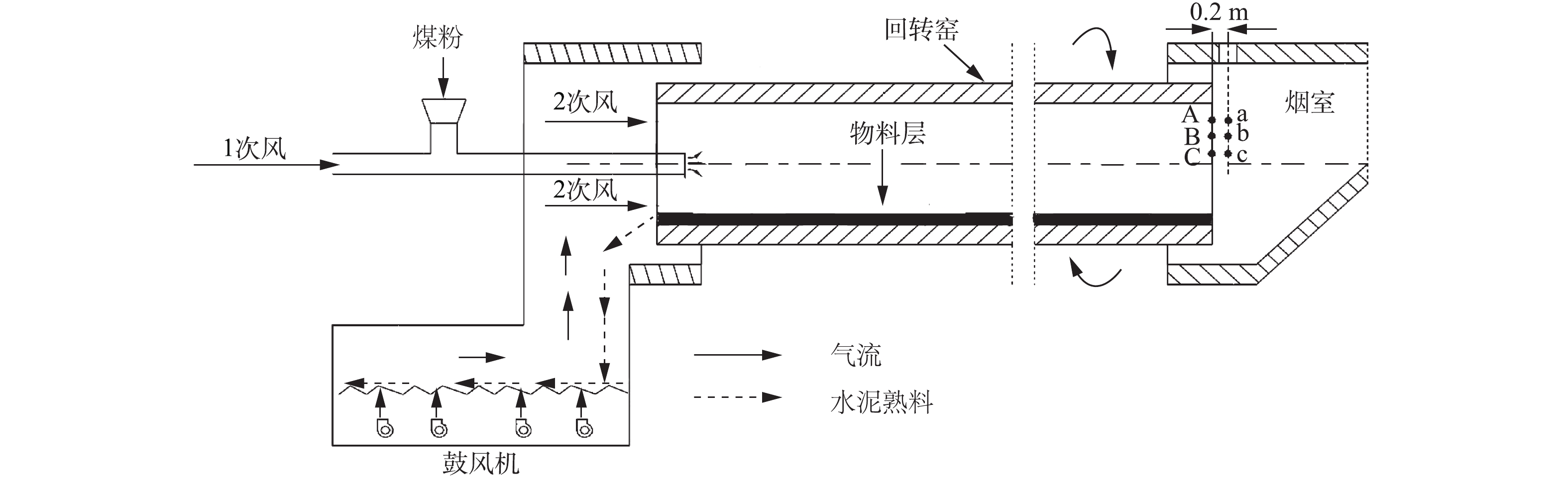

回转窑结构如图1所示。可以看出,1次风携带煤粉与2次风携带煤粉充分混合后燃烧,窑尾烟气通入烟室。考虑到回转窑的厚度,将模型的尺寸设定为60 m×3.6 m。回转窑内的物料区分别为冷却区、烧成区、反应区和分解区,在计算时,将物料区做壁面处理,并分别给定各个区域温度值。

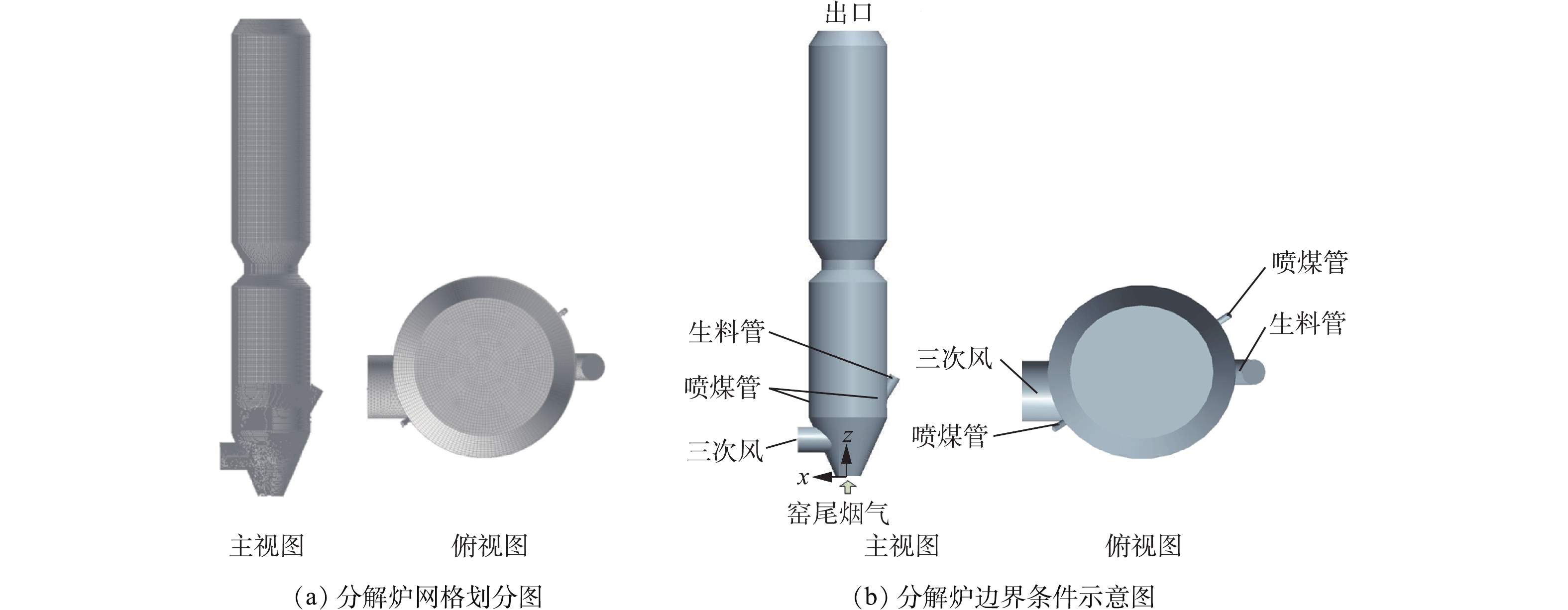

分解炉几何结构如图2所示。分解炉由上到下分别为上柱室、缩口、下柱室、底锥。在分解炉锥体底部插入1根3次风管,其偏心距离为0.6 m。生料管位于喷煤管的上方,与水平面成60°夹角,斜向下插入分解炉下柱室;在3次风管与生料管之间,斜向下对称插入2根喷煤管,与水平面成26°夹角,与下柱室壁面成35°夹角。

-

分解炉网格划分和边界条件如图3所示。回转窑内部使用的燃烧器为Duoflex DBC四通道燃烧器,燃烧器结构尺寸与回转窑整体尺寸相差较大,在进行局部加密处理后,网格总数为1.2×106 个,网格质量良好。分解炉网格划如图3(a)所示,用四面体网格对分解炉生料管以下位置进行划分并局部加密,用六面体网格划分其余部分,网格总数约为1.32×106个。

在回转窑内,物料上表面沿窑体自左向右分别给定温度为1 545、1 650、1 473和1 123 K,各区域长度之比为6∶42∶36∶16,除此之外的其余壁面温度均设为800 K,过量空气系数取α=1.20。通过查询资料获得所需回转窑燃烧器的结构参数,由热平衡测试获得数值模拟边界条件。表1为回转窑燃烧器运行参数。

分解炉的边界条件如图3(b)所示。基于分解炉的绝热设计,设定整个壁面温度为1 000 K,选择无滑移壁面标准函数进行描述,过量空气系数取α=1.15。在本研究中,分解炉进、出口边界条件为:3次风流量18.62 kg·s−1,温度1 300 K;生料流量35.45 kg·s−1,温度1 140 K,生料中烧失量质量分数35.40%、SiO2质量分数12.36%、Al2O3质量分数2.87%、Fe2O3质量分数1.98%、CaO质量分数44.31%、MgO质量分数3.08%;窑尾烟气流量30 kg·s−1,窑尾烟气温度1 250 K,窑尾烟气中CO2摩尔分数27.12%、O2摩尔分数3.9%、CO摩尔分数0.17%、N2摩尔分数68.81%;煤风速度45 m·s−1,温度321 K;出口压力−1 200 Pa。

本研究所使用的无烟煤A、烟煤B的工业分析与元素分析见表2。在基础运行工况下,回转窑使用的混煤为无烟煤A与烟煤B按质量比为4∶6混合得到的,煤粉质量流量为1.36 kg·s−1,平均粒径为80 μm;分解炉使用的是烟煤B,煤粉质量流量为2.58 kg·s−1,平均粒径为60 μm。

-

使用Ansys-Fluent软件进行数值模拟,采用有限体积法对连续相控制方程离散化,使用压力和速度耦合的SIMPLE算法,采用二阶迎风格式,使用TDMA法逐面迭代求解。连续相与颗粒相的相互耦合均采用先对连续相进行求解计算的方法,在达到初步收敛后,加入离散相进行耦合计算。

1.1. 数学模型

1.2. 物理模型

1.3. 计算模型和边界条件

1.4. 数值模拟方法

-

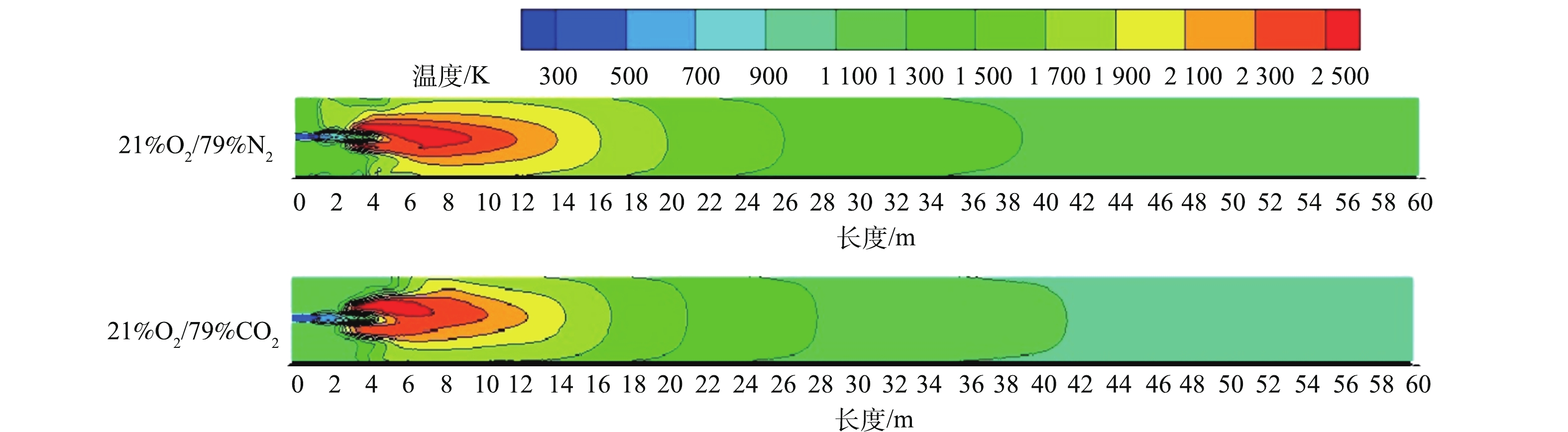

1)燃烧情况对比分析。在空气助燃氛围和21%O2/79%CO2助燃氛围下,回转窑Y=0截面温度云图如图4所示。回转窑内的火焰形状均呈现“棒槌”型,均匀地充满回转窑截面,但是后者的高温火焰长度较短,出口烟气温度较低,回转窑内平均温度较低,模拟计算得到煤粉燃尽率分别为95.47%和92.41%,O2/CO2工况下燃尽率下降了3.06%,说明煤粉的燃烧特性变差。单独观察21%O2/79%CO2工况,火焰填充度良好,沿回转窑方向温度梯度分明,燃烧稳定。火焰的高温区从回转窑3 m处开始,Duoflex DBC四通道燃烧器伸入回转窑的长度为1 m,说明该工况下燃烧器不会被烧坏,适应性良好,符合生产需求。

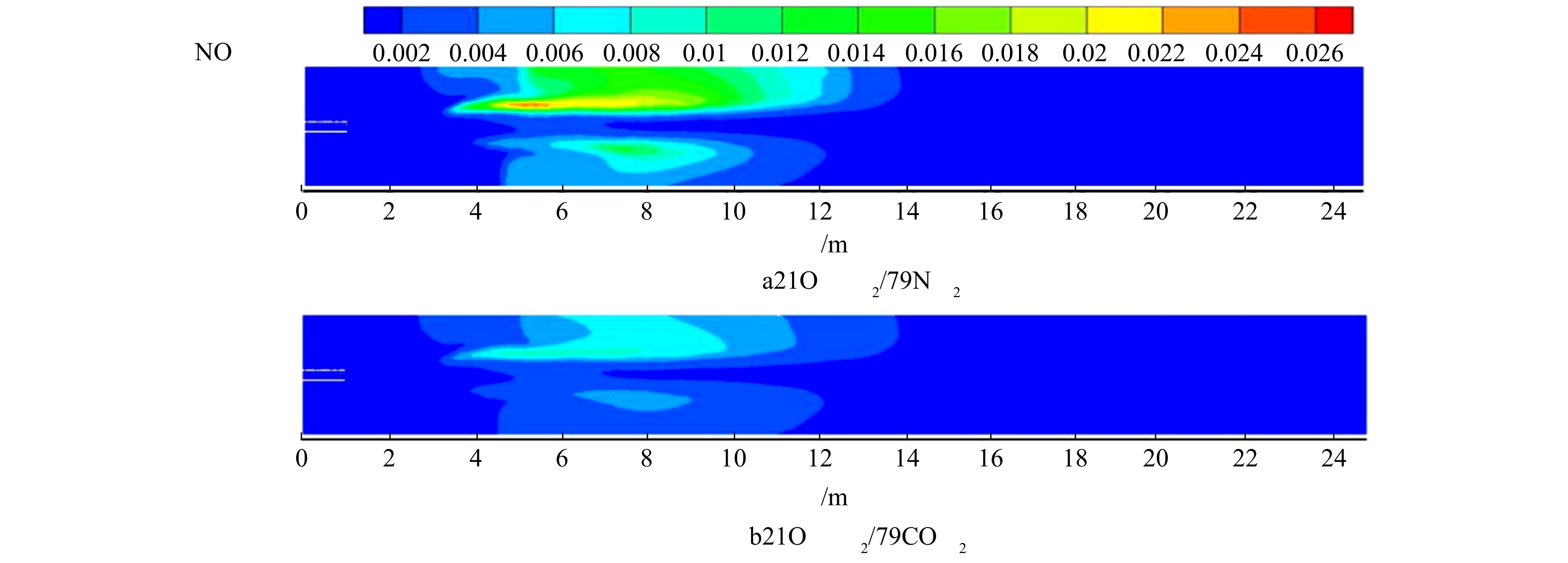

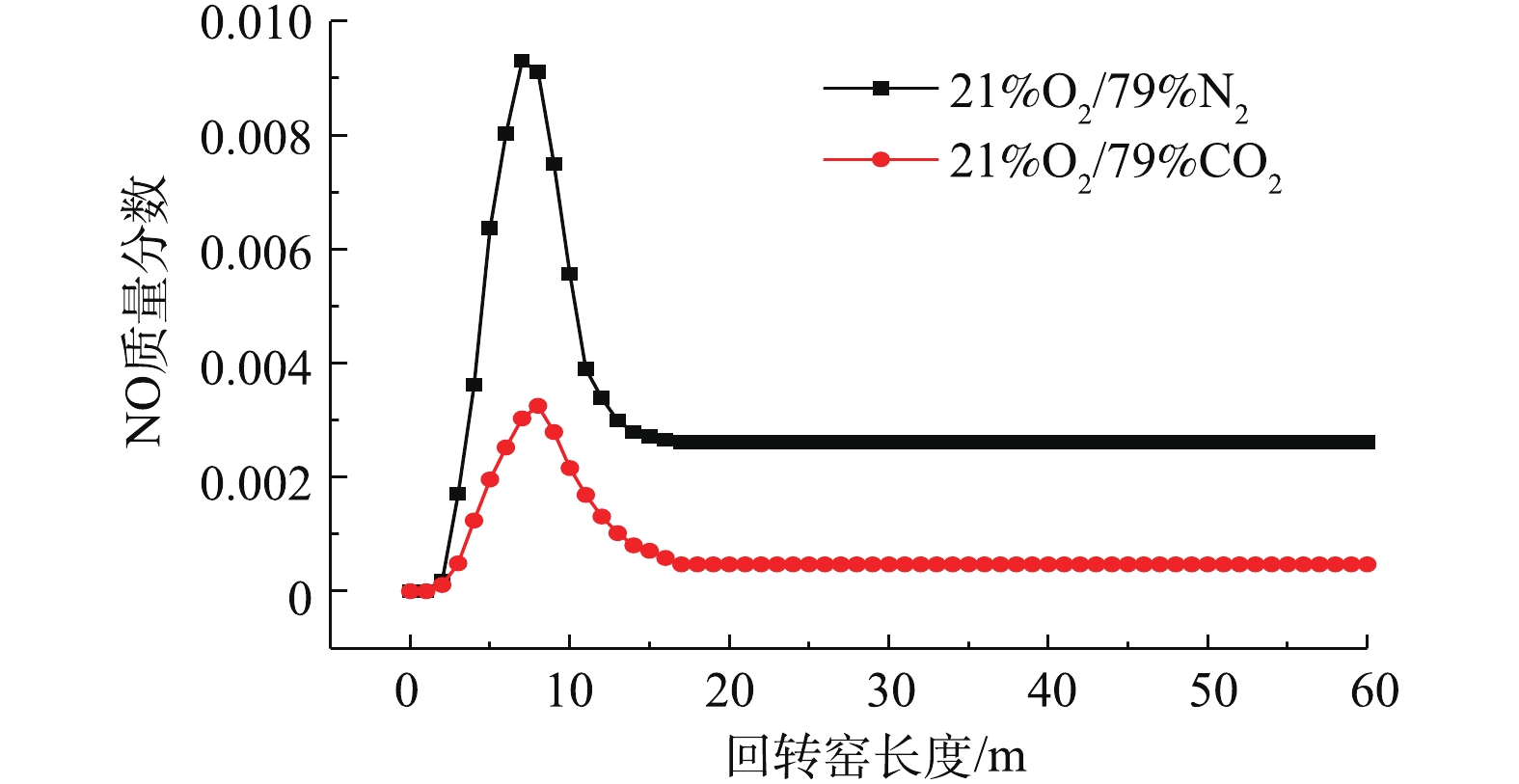

2) NO生成情况对比分析。21%O2/79%N2与21%O2/79%CO2 2种工况是在保证加入O2量、体积比不变的前提下,用同体积的CO2替换N2,因此,可以通过比较2种工况下NO的摩尔分数观察NO的生成情况。在空气助燃和21%O2/79%CO2助燃氛围下,回转窑Y=0截面NO摩尔分数分布云图如图5所示。可以看出,3~13 m区域为煤粉燃烧高温区域,温度高达2 100 K以上,此时回转窑内NO大量生成且热力型NO占据主导,浓度达到最高。高温区后,燃料中的含氮化合物生成少量的燃料型NO,NO浓度迅速下降。在回转窑NO生成过程中,热力型占据主导,因此,NO浓度分布基本遵循窑内温度分布,符合热力型NO生成机理。而21%O2/79%CO2助燃氛围下助燃气体中没有N2 ,根据热力型NO生成原理,可知此时没有热力型NO产生,因此,NO生成量有较大幅度的下降。

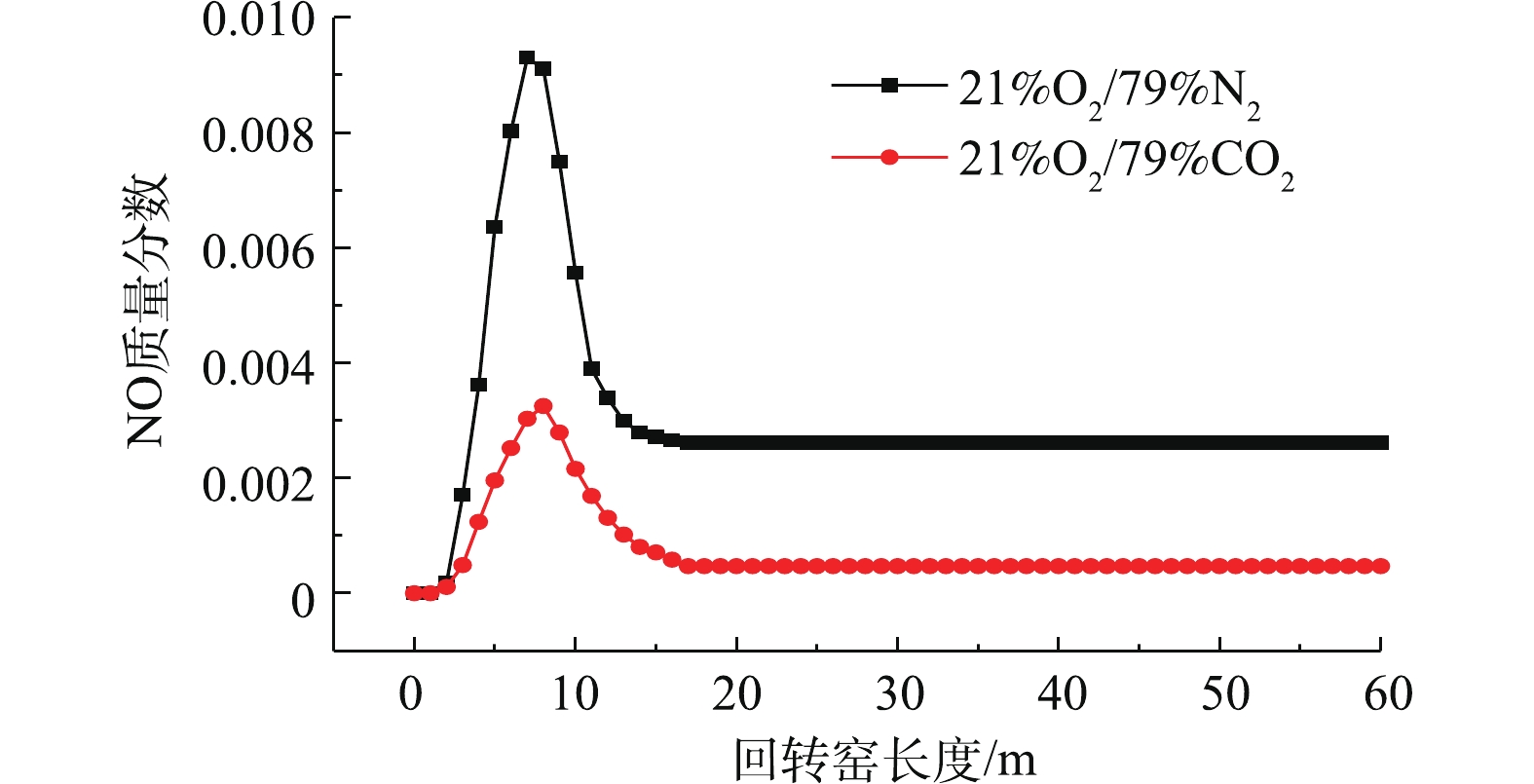

在空气助燃氛围和21%O2/79%CO2助燃氛围下,沿回转窑长度方向各横截面NO质量分数的变化如图6所示。2种工况下NO质量分数的变化趋势基本一致,均为先升高后回落,最终趋于稳定。O2/CO2工况下,NO浓度最高点比空气工况下延迟到达,且最高点的数值较小,这是因为21%O2/79%CO2助燃氛围下无热力型NO生成,且煤粉的燃烧特性变差导致了燃料型NO生成量减少。经换算,在空气工况下和O2/CO2工况下,回转窑出口烟气中NO质量流量分别为0.038 7 kg·s−1和0.009 84 kg·s−1,脱硝率为74.47%。

-

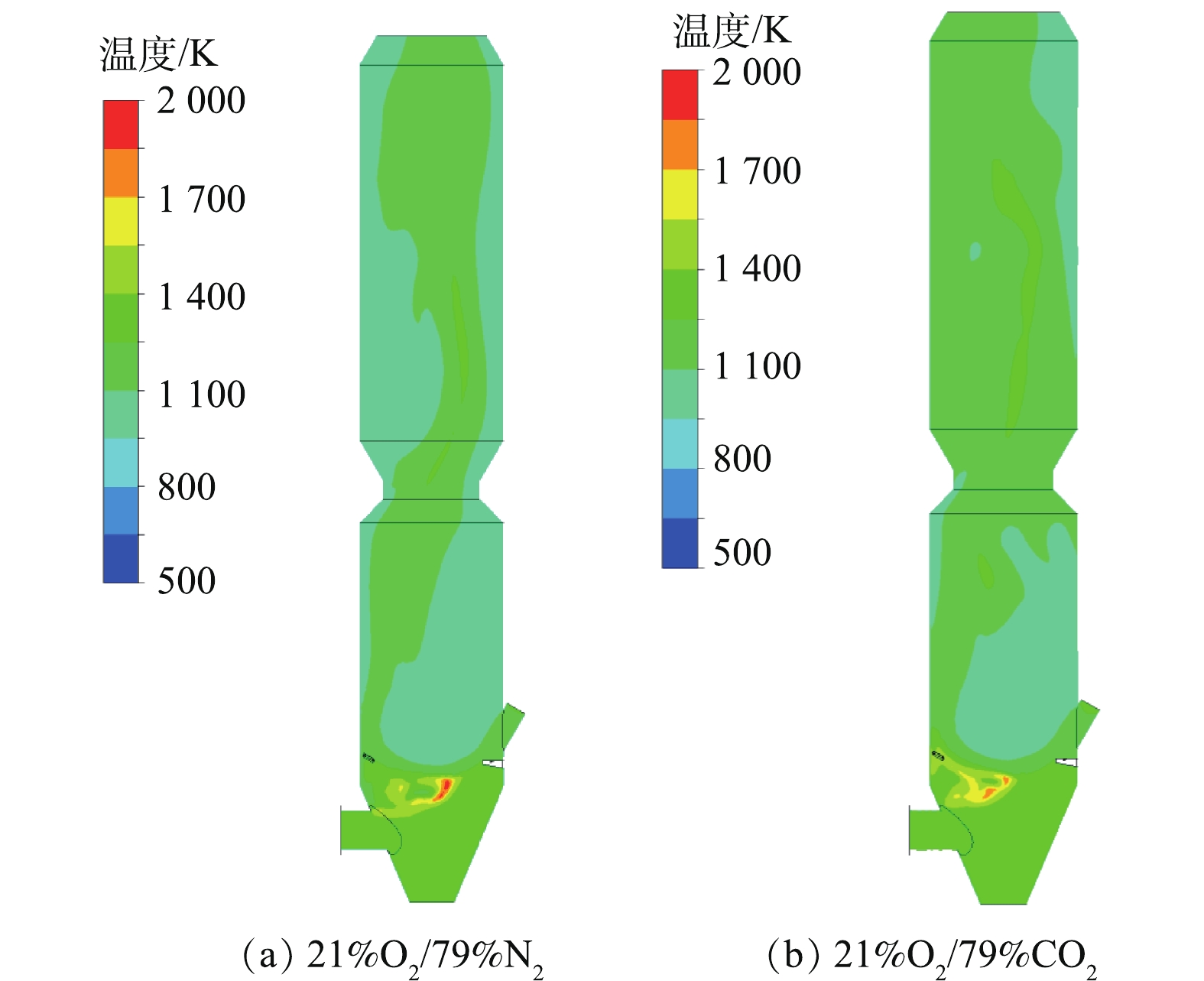

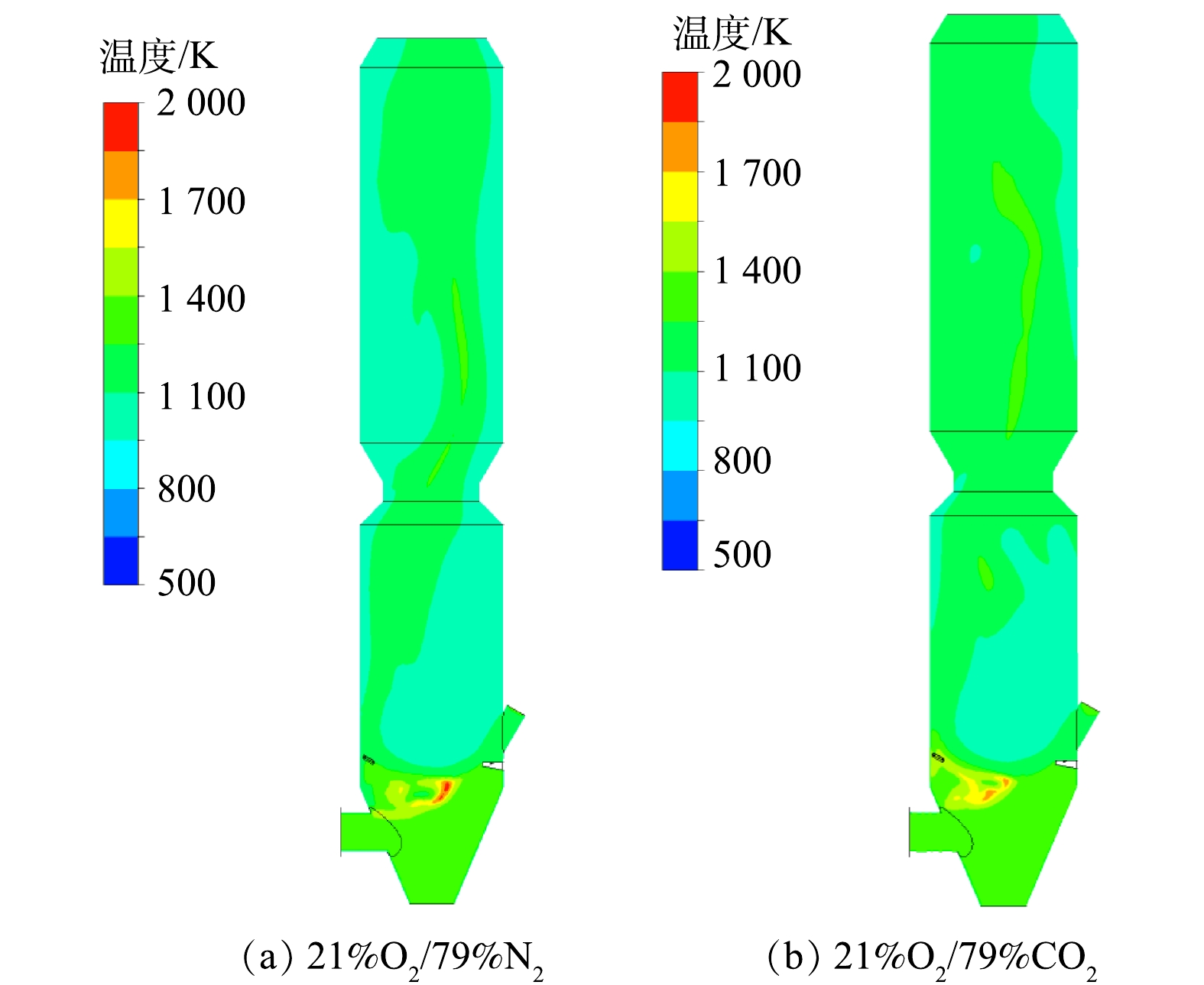

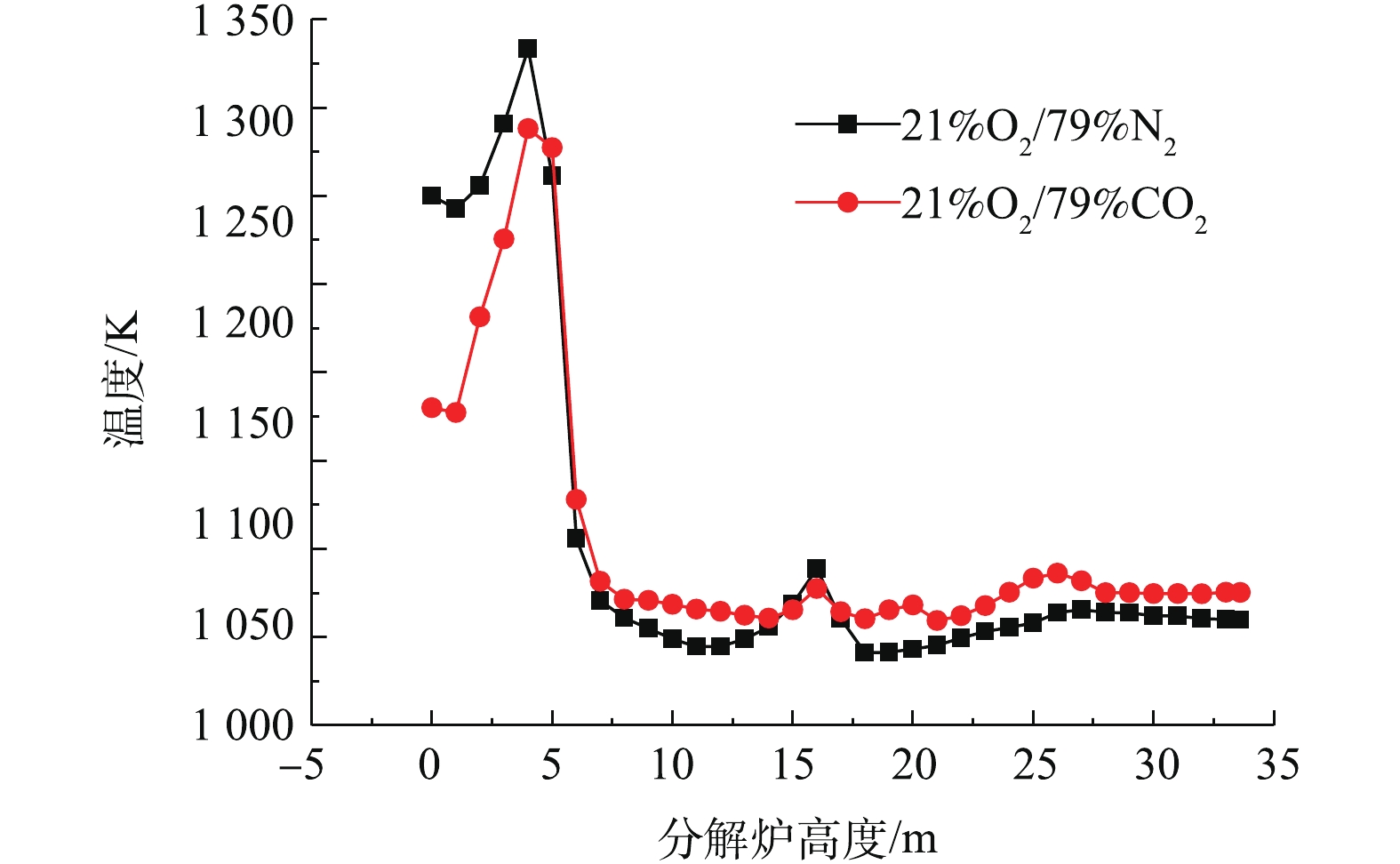

1)燃烧情况对比分析。在空气助燃和21%O2/79%CO2助燃下,分解炉X=0截面温度云图如图7所示。在分解炉下部的锥体处,3次风与煤粉发生剧烈的燃烧反应,放出大量热量,同时由于生料管入口下方设置的挡板对生料的阻挡作用,此处没有发生生料分解反应,因此,出现了局部高温区域。随后炉内煤粉燃烧放热速度减缓,生料分解大量吸热,炉内温度逐渐下降。2种工况下温度分布特征基本相同,其中O2/CO2工况下高温燃烧区域变小,这说明该处煤粉燃烧特性变差。在2种助燃条件下,沿分解炉高方向各横截面平均温度的变化如图8所示。可以看出,温度变化的基本趋势一致,均为先升高后降低,说明2种情况下流场稳定,燃烧稳定;2条曲线的起点温度不同,是由2种工况下回转窑燃烧状况不同和窑尾烟气温度不同导致的;在炉高2~5 m时,斜向下注入煤粉,与高温3次风充分混合,燃烧后释放出大量热量,使温度迅速达到峰值;在空气工况下,最高横截面平均温度为1 346 K,O2/CO2工况下最高横截面温度为1 271 K;高温区之后,从生料管喷入温度较低且分散性较好的生料,CaCO3迅速吸热发生分解反应,炉内温度降低。空气工况下煤粉燃烧情况良好,模拟计算得到的煤粉燃尽率为94.66%,比O2/CO2工况下燃尽率高3.51%,但此时O2/CO2工况下分解炉内高浓度的CO2在一定程度上抑制了CaCO3分解,生料分解总吸热量减少,导致分解炉内温度超过空气工况。

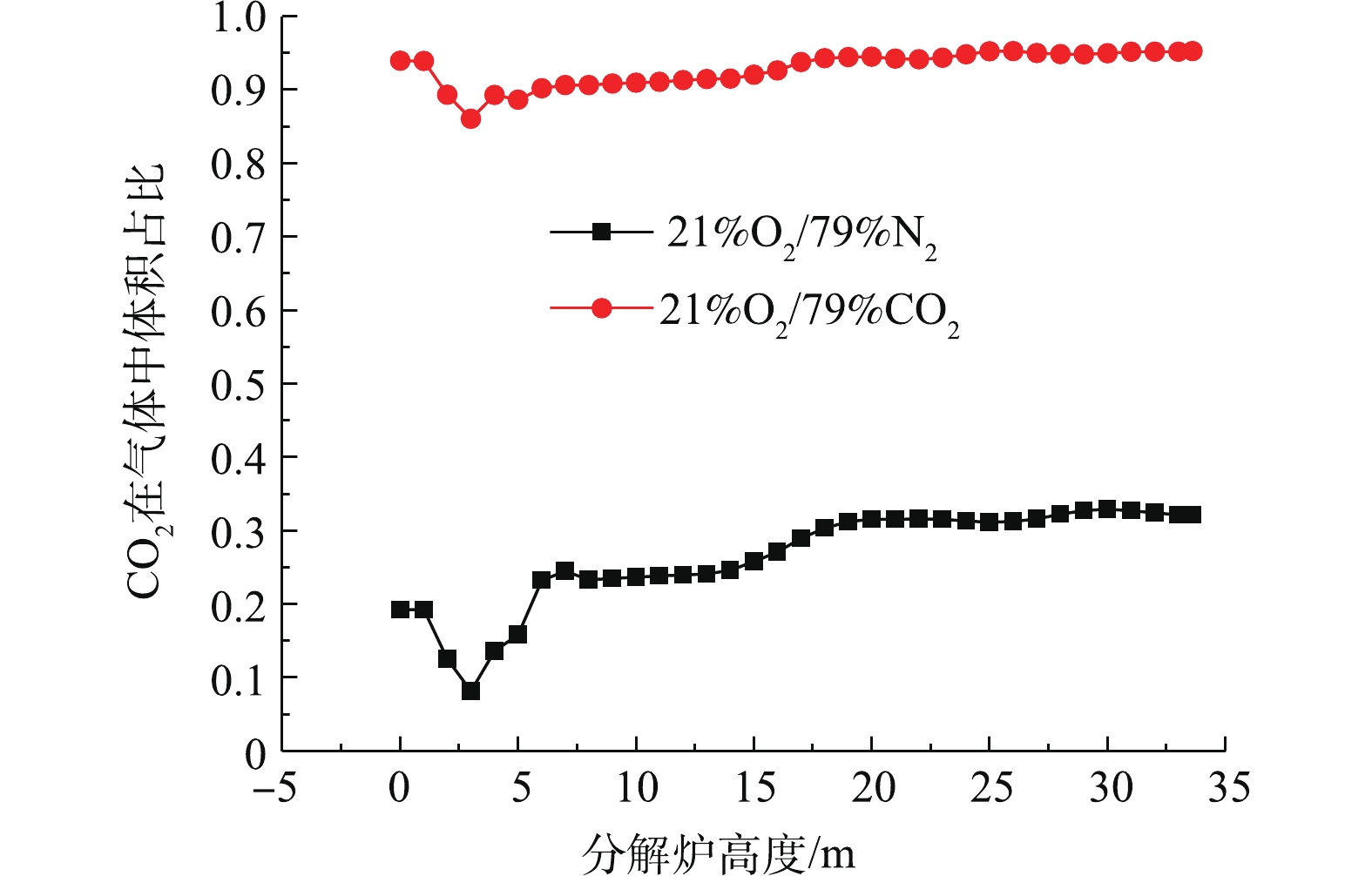

2)分解情况对比分析。通过对分解产物CaO和CO2的分析,可很好地说明生料分解状况。图9反映了21%O2/79%N2与21%O2/79%CO2燃烧氛围下分解炉炉高方向各截面CaO质量流量变化情况。2种工况下CaO质量流量变化趋势均为先保持不变,后迅速增长,最后增长减缓。在分解炉4 m处设置有挡板,因此,4 m以下没有生料分解反应发生,从生料管处加入CaCO3,生料吸收煤粉燃烧的热量并快速分解,CaO质量流量大幅度上升,随着分解炉高度的上升,炉内残余生料分解逐渐变缓。造成2种工况分解炉出口CaO质量流量有差异的主要原因是,O2/CO2氛围下炉内CO2浓度较高,抑制了CaCO3的分解反应。最终空气工况与O2/CO2工况出口CaO质量流量分别为18.47 kg·s−1和17.90 kg·s−1,对应的分解炉出口处生料分解率分别为93.44%和90.54%,后者较前者下降了2.90%。2种工况下分解炉炉高方向各横截面CO2在气体中平均体积占比变化情况如图10所示。分解炉内CO2最初体积占比的差异来自窑尾烟气中CO2浓度的差异。在分解炉3 m处,3次风汇入,CO2浓度下降,其中空气工况的下降幅较大。烟气中CO2浓度随着煤粉燃烧而上升,当燃烧趋于平稳时,CO2浓度趋于稳定,分解炉出口处空气工况与O2/CO2工况下CO2体积分数分别为32.23%和95.35%。

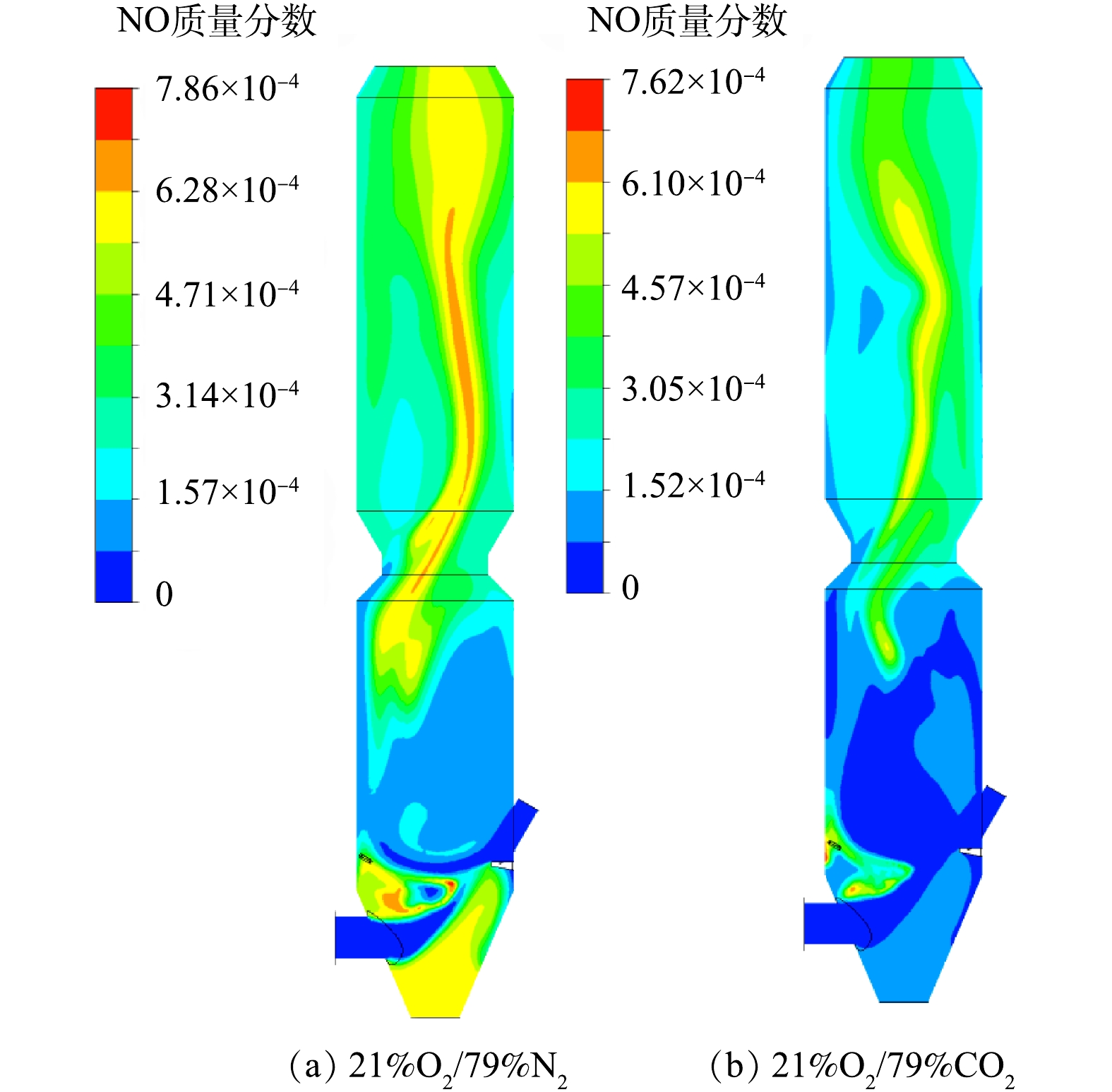

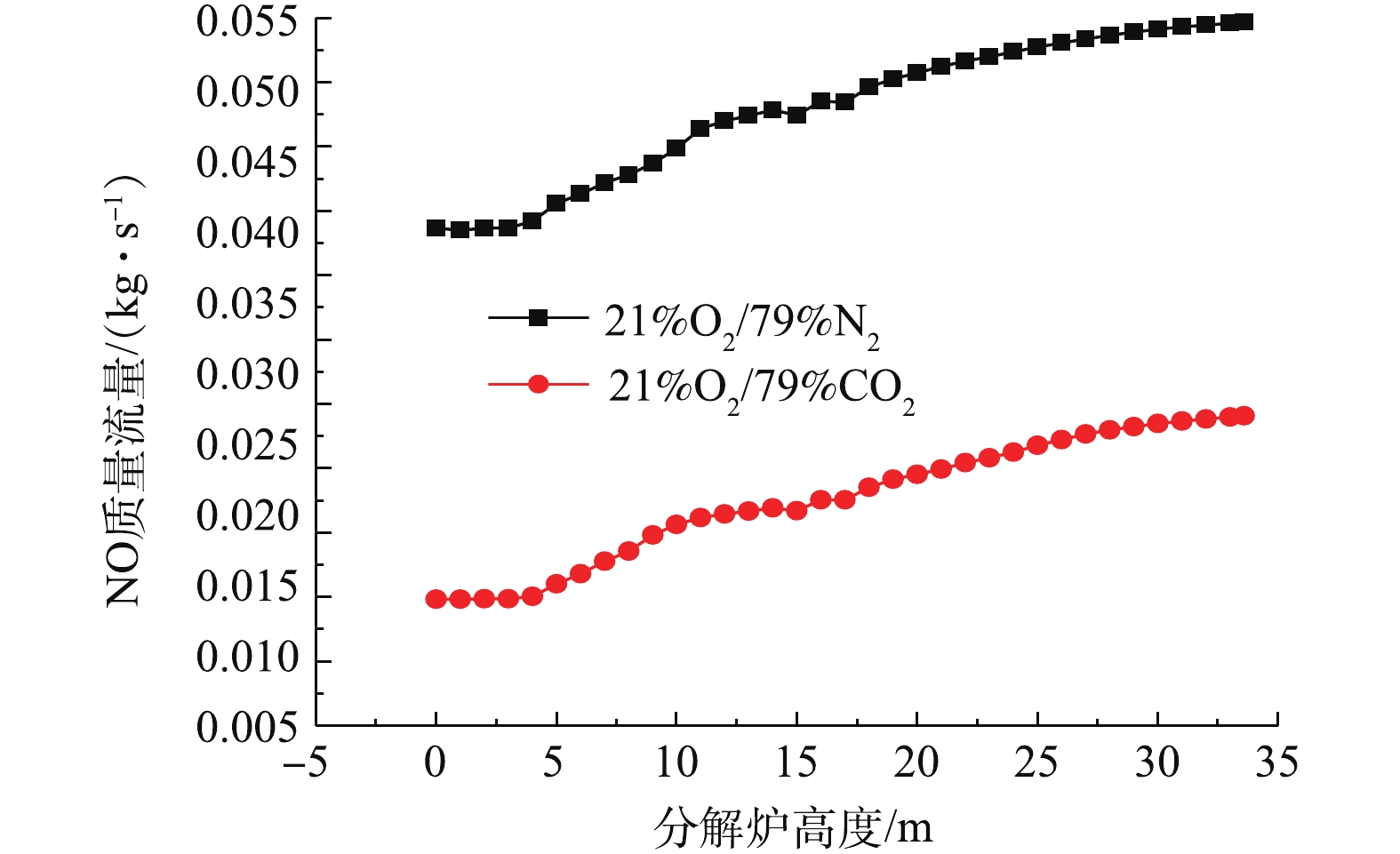

3) NO生成情况对比分析。在空气助燃氛围和21%O2/79%CO2助燃氛围下,分解炉X=0截面NO质量分数分布云图如图11所示。O2/CO2工况下来自窑尾的烟气中NO含量比空气工况下低,此时分解炉内产生的NO绝大部分为燃料型,所以2种工况下NO含量都有一定程度的增加。2种工况下分解炉炉高方向各截面NO平均质量流量如图12所示。开始的4 m几乎没有燃烧反应,大部分煤粉在4~8 m处被燃烧,对应的区域内NO快速生成,此时分解炉内的温度没有到达热力型NO的生成条件,几乎都是燃料型NO。8 m之后,剩余煤继续燃烧,NO缓慢增长,直至出口处。在空气工况下,NO质量流量从0.038 7 kg·s−1增长至0.054 7 kg·s−1,增幅为0.016 0 kg·s−1;在O2/CO2工况下,NO质量流量从0.009 84 kg·s−1增长至0.024 1 kg·s−1,增幅为0.014 2 kg·s−1,燃料型NO的生成主要与煤粉的燃烧情况有关,且O2/CO2工况下分解炉内有更多的还原性气体CO,因此,O2/CO2工况下分解炉内产生的NO较少,经计算,分解炉的脱销率为11.80%。

2.1. 回转窑内煅烧结果对比

2.2. 分解炉煅烧效果对比

-

在本研究中,通过将实测空气工况下的测量数据与模拟计算数据进行比较来判断模型的可靠性。如图1所示,为减少回转窑漏风、散热对测量结果的影响,在距离回转窑尾部出口截面中心0、0.5、1.0 m处的a、b和c 3个测点处进行测量,以测量结果代替窑尾出口实际数据。同理,在距离分解炉出口烟道截面中心0.6、1.2和1.8 m处,测量温度和烟气成分。回转窑、分解炉出口温度和烟气浓度实测平均值和模拟计算结果见表3和表4。

由表3可知,烟气温度的测量数据与计算数据之间的相对误差小于3%,组分浓度误差小于7%,在工程允许误差范围内,计算模型可靠。模拟数值与测量值产生误差的原因是窑尾漏风。

由表4可知:出口烟气温度的测量数据和计算数据相对误差值相对误差较小,可满足工程需要;烟气成分中O2浓度的测试数据和计算数据的最大相对误差为0.096,但绝对误差很小,基本能满足工程生产的需要。出口烟气中O2成分相对误差偏大的原因可能是炉体漏风和仪器误差共同作用的结果。

-

1) O2/CO2助燃氛围下回转窑内高温火焰长度比空气助燃氛围下要短,但是火焰填充度较好,温度分布沿窑长方向梯度分明,燃烧依然稳定;Duoflex DBC四通道燃烧器在该工况下适应性良好。

2) O2/CO2助燃工况下煤粉的燃烧特性变差,回转窑、分解炉中煤粉的燃尽率下降;烟气中CO2浓度较高,抑制CaCO3的分解反应,虽然分解炉出口处生料分解率降低,但仍可满足生产需求。

3)分解炉出口烟气中CO2摩尔分数从32.23%增加到95.35%,经过简单处理就能实现C捕捉;NO排放量明显下降,分解炉出口处NO浓度为274.5 mg·m−3,低于国家排放标准;O2/CO2烟气循环煅烧水泥技术可实现CO2和NOx的减排,具有良好的应用前景。

下载:

下载: