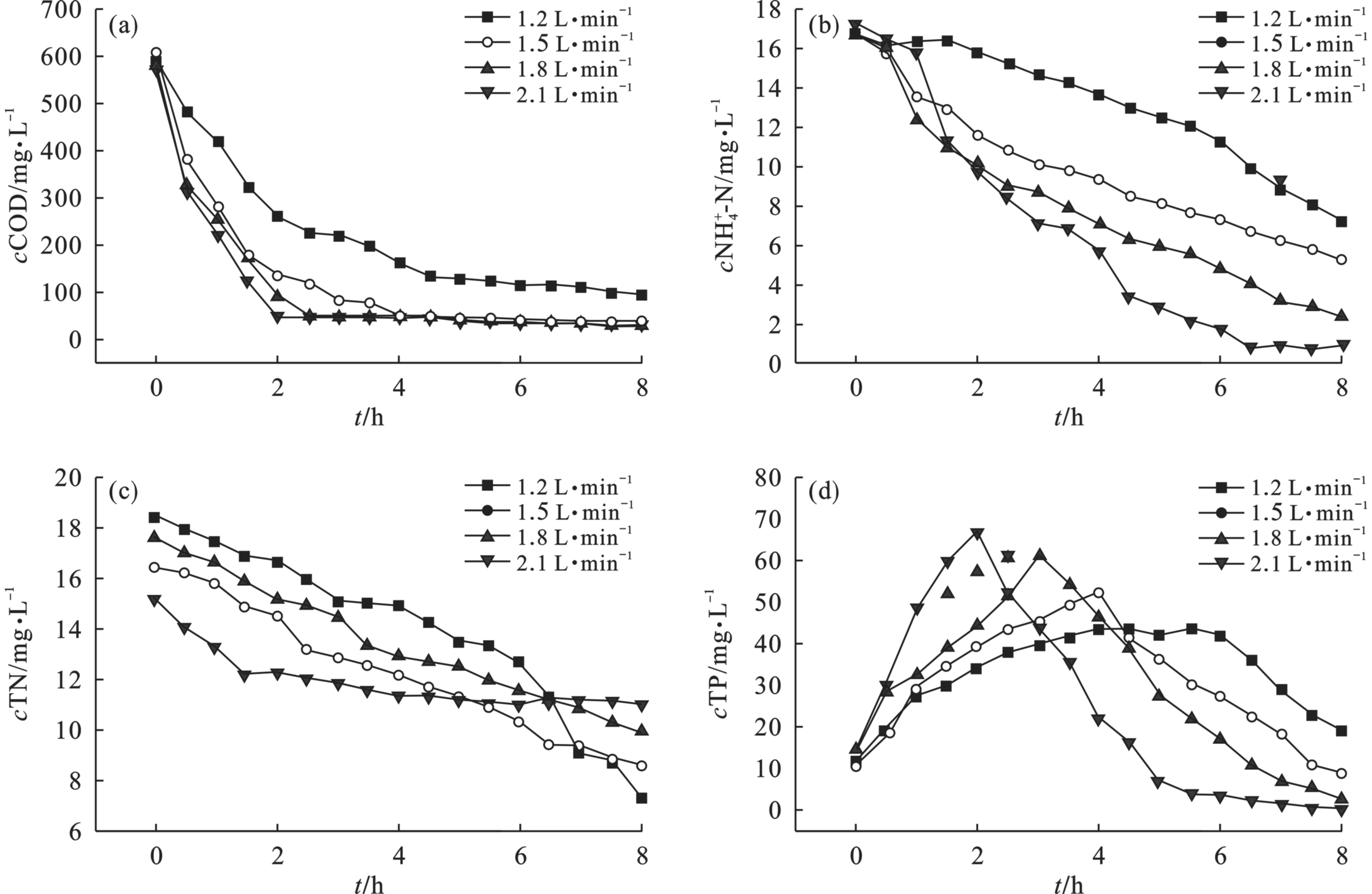

-

脉冲喷吹清灰除尘器通常被很多行业用于控制空气污染,如电力生产、煤矿挖掘[1]。灰尘通过烟气管道进入袋式除尘器而被滤袋收集,形成灰尘饼,由于灰尘的连续堆积,须定期对灰尘饼进行清洁[2]。脉冲喷吹清灰能周期性地进行定期清洁,所以这种清灰方式有着广泛的应用[3]。

在脉冲喷吹清灰时,脉冲阀释放一个短脉冲(50~150 ms),将干净的压缩空气分配到吹扫管的众多喷嘴中。每个喷嘴朝向滤袋开口端上方,压缩空气通过喷嘴的作用发生膨胀,形成脉冲射流,同时在脉冲射流周围的邻近区域,射流气体会夹带周围空气,与脉冲射流一同进入滤袋中,对滤袋进行清洁。关于脉冲喷吹清灰的研究有很多,多数都集中在高压清灰上,建立的CFD模型也仅仅是二维模型[4-6]。QIAN等[4]通过建立喷嘴与滤袋开口之间的最佳距离数值模型,研究了高压(0.6 MPa)清洁的清灰效果;万凯迪等[5]通过建立二维滤袋模型,研究了PPS针刺毡滤袋在高压(0.45 MPa)喷吹下的清灰效果;HAJEK[6]建立二维轴对称单滤袋模型,在不考虑射流偏移的情况下研究清灰效果。

近年来,人们对低压脉冲喷吹清灰的研究越来越感兴趣。低压清洁在0.2~0.3 MPa的罐压下运行,而传统的高压清洁可在更高的压力下运行,通常为0.4~0.7 MPa。本研究通过建立完整的三维CFD模型,考虑射流偏移,分析射流特性,并通过实际的实验测量验证了三维CFD模型的正确性;同时,使用三维CFD模型研究了低压(0.2 MPa)下不同喷嘴和文丘里管的设计对清灰效果的影响,为低压清灰系统的设计提供了参考。

全文HTML

-

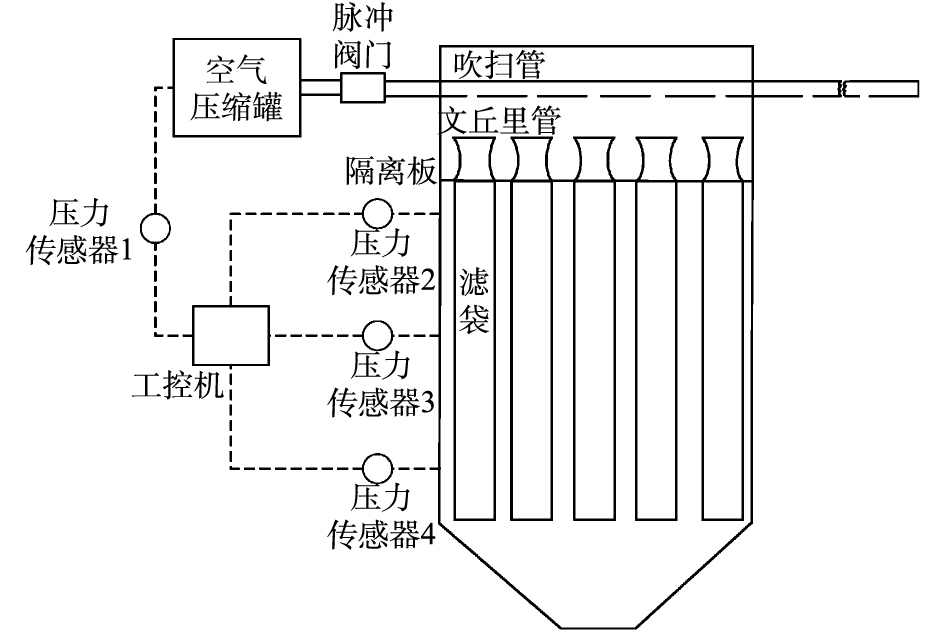

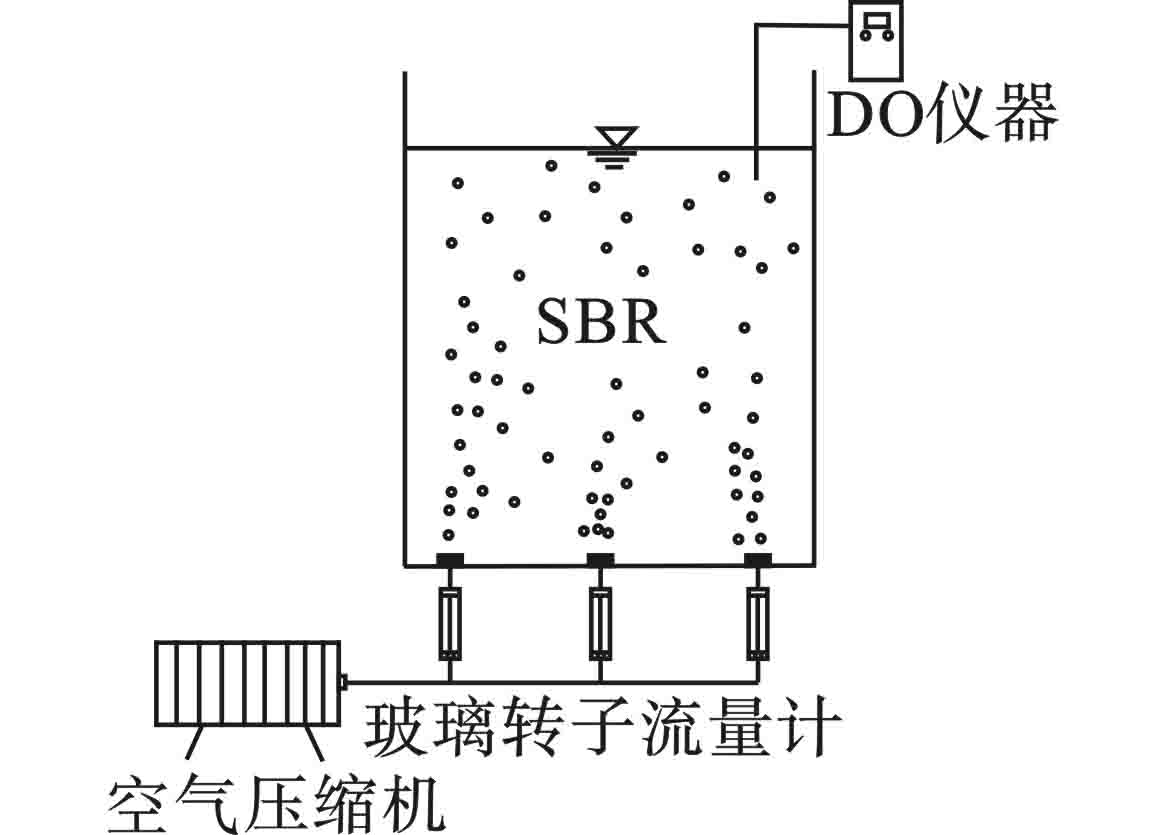

实验所用除尘器如图1所示。该装置包括1个带有3个脉冲阀的空气压缩罐(容积225 L),3个长度为2 m的吹扫管,每个吹扫管有11个等间距直孔。对于每个吹扫管,在除尘器腔体内放置5个孔和袋,构成测试部分。每个吹扫管中剩余的6个孔放在腔体外面。每个滤袋由内部袋笼保持固定,滤袋和内部钢笼之间的咬合紧密,清灰时,滤袋与内部钢笼之间的体积变化小于4%,滤袋长度为6 m,直径为160 mm。文丘里管(喉部直径65 mm)放置在每个袋子的开口处,通过隔离板,将灰尘区域与洁净区域分开。使用压力传感器对图1中的4个部位(空气压缩罐、滤袋的顶部、中部和底部)进行压力测量。测量所得的压力数据作为与数值模拟结果进行对比并验证数值模型合理性的实际数据。所有测试均在室温下进行,脉冲喷吹的初始罐压力为0.2 MPa,脉冲阀导通时间为100 ms。

-

脉冲喷射清洁期间的流动被表征为超音速和亚音速,由于湍流仅在某些区域中起作用,无须使用分离涡模拟(DES)和大涡模拟(LES)这类计算成本较高的方法,去解决湍流尺度的问题[7]。同时,黏性效应存在于脉冲喷射中,不能应用于超音速流的无黏性假设,因此,须采用雷诺平均纳维-斯托克斯公式。使用耦合流体的方法求解纳维-斯托克斯方程,耦合流体适用于冲击波和高度可压缩流动的研究。

-

控制方程是纳维-斯托克斯方程,包括质量(连续性)方程、动量(牛顿第二定律)方程和能量(热力学第一定律)方程。可压缩流体的质量守恒方程见式(1)。

式中:

ρ 为密度,kg·m−3;t 为时间,s;ui 为流体速度沿i方向的分量;xi 为i方向的坐标。动量守恒方程见式(2),计算时忽略引力。

式中:

τij 为黏性和湍流应力张量;p 为压力,Pa。能量守恒方程见式(3)。

式中:

h 为焓,kJ·mol−1;k 为导热系数,W·(m·K)−1;T 为热力学温度,K。可压缩流动密度遵循连续性方程,温度可以由式(3)得出。在已知密度和温度的情况下,压力可以应用理想气体定律的状态方程进行计算。

式中:

R 为气体常数,取值8.314 J·(mol·K)−1。 -

湍流模型使用可实现的k-ε模型[8],并通过双层壁功能处理近壁区域,考虑可压缩性,将可压缩耗散膨胀项[9]添加到湍流转换方程中。为了模拟在一个吹扫管中多个喷嘴的效果,并且完全捕获喷嘴和射流中的空间复杂流场,需要完整的3D模型。由于实验验证对数值模型的建立具有重要意义,因此,数值模型的几何形状必须与实验装置非常相似,三维CFD模型计算域如图2所示,不同的边界条件使用不同的颜色显示。

为清楚起见,图2为整个计算域对称的一半,其中浅黄色为出口、青色为阀门入口、绿色为滤袋、灰色为壁面。滤袋模拟为零厚度,多孔介质薄膜,允许流体通过,压力损失计算方法见式(5)。

式中:

Δp 为压降,Pa;ρ 为气体密度,kg·m−3;β 为多孔黏性阻力,m·s−1;vn 为边界法向速度,m·s−1。在脉冲清灰过程中,滤袋壁面峰值压力为2 000~6 000 Pa,有研究表明,滤袋阻力对滤袋内获得的峰值压力有很大影响[10-12],因此,可调整

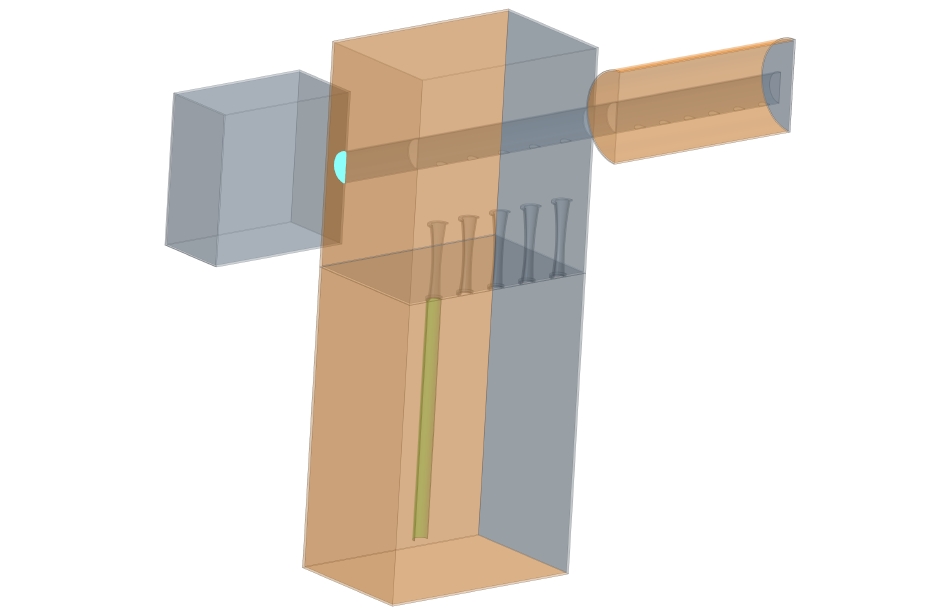

β 值,以与实验数据相匹配,本研究β 取值为30 000 m·s−1。滤袋的建模为刚性结构,即忽略滤袋偏转的潜在影响,虽然滤袋偏转会影响脉冲压力,但其在本研究所测试的除尘器中偏差非常小。脉冲阀门模型与滤袋类似,根据脉冲阀的实际特性,其多孔黏性阻力随时间的变化而变化。脉冲阀的工作过程可简化为3个阶段:1)阀门关闭,高阻力;2)阀门完全打开,非零低阻力;3)阀门关闭,高阻力。阀门阻力值通过反复实验确定,图3为本研究所用脉冲阀的多孔黏性阻力随时间的变化情况。打开时间总计为100 ms,阀门完全打开阶段为66 ms,当达到100 ms的模拟时间,多孔界面转变为阻碍任何质量交换的壁面。

-

边界条件:空气压缩罐的计算域设置为无滑动条件的绝热壁面。脉冲阀门计算域(图2青色区域)为多孔界面,其多孔黏性阻力设置如图3所示。滤袋计算域(图2绿色区域)为多孔界面,其多孔黏性阻力为30 000 m·s−1。将0 Pa(1个标准大气压下)的压力施加在计算域的出口(图2黄色区域),以模拟隔离板两侧无限大的体积。在脉冲喷射清灰期间,脉冲射流夹带上箱体的空气进入过滤室中,导致上箱体的压力降低,同时使得过滤室中压力增加。对于小规模的除尘器,这将极大地影响脉冲压力,但是对于中等或者较大规模的除尘器,包含吹扫管在内的整体有效体积很大,因此,本研究对计算域的近似是合理的。其余表面(图2灰色部分)设置为无滑动条件的绝热壁面。

初始条件:计算域向空气压缩罐施加0.2 MPa的压力,其余部分施加压力为0 Pa(1个标准大气压下);在整个计算域中施加300 K的温度;采用隐式方法进行迭代,时间步设置为

1×10−5 s,内迭代设置为20次,库朗数设置为50。 -

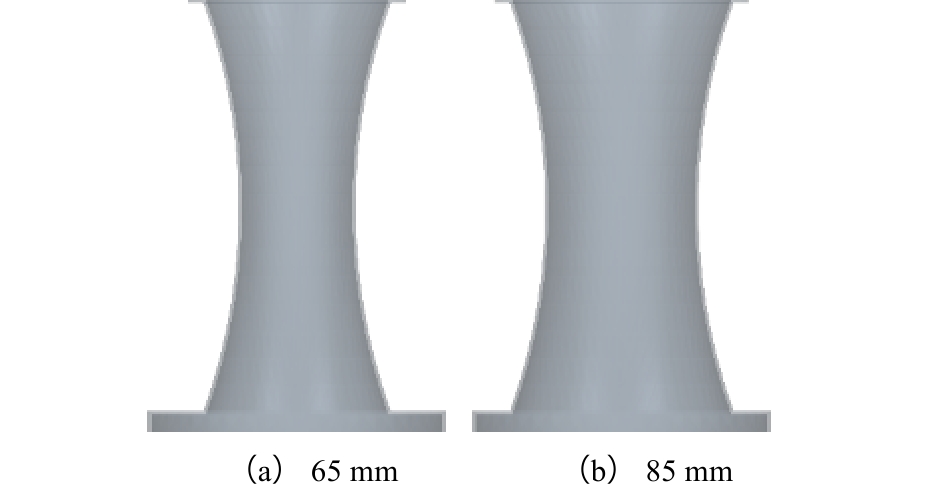

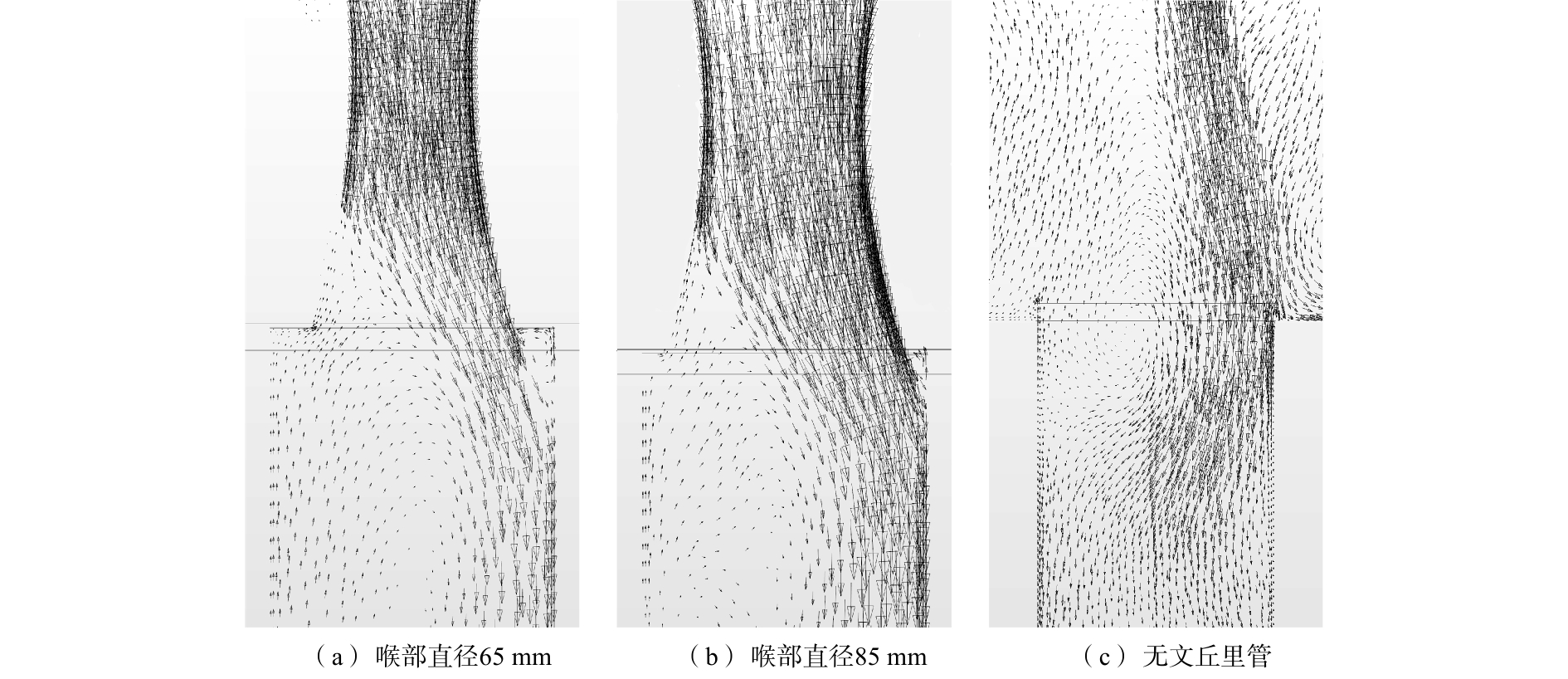

数值模型通过实验验证之后,修改数值模型,研究文丘里管和喷嘴对清灰效果的影响。建立3种数值模型,以研究文丘里管的流场与压力,包括无文丘里管、喉部直径为65 mm的文丘里管(其端口处的直径为108 mm,压缩段的长度为97.2 mm,喉管段的长度为43.2 mm,扩散段的长度为108 mm)和喉部直径为85 mm的文丘里管(其端口处的直径为129.6 mm,压缩段的长度为97.2 mm,喉管段的长度为54 mm,扩散段的长度为97.2 mm),文丘里管结构如图4所示。

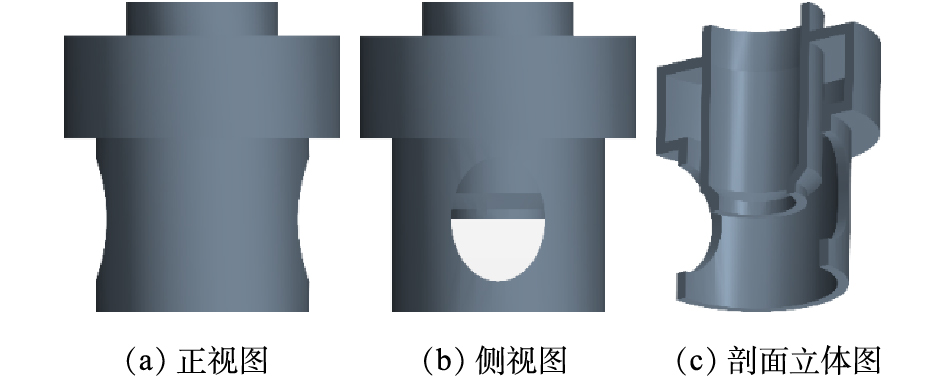

由于吹扫管自身具有一定的壁厚,同时又考虑到清灰气流在吹扫管中的流动情况,这些因素可能是导致经孔喷嘴流出的射流与文丘里管之间出现偏移的原因。因此,使用改进的喷嘴(图5)与孔喷嘴进行比较。

1.1. 实验方法

1.2. 数值计算方法

-

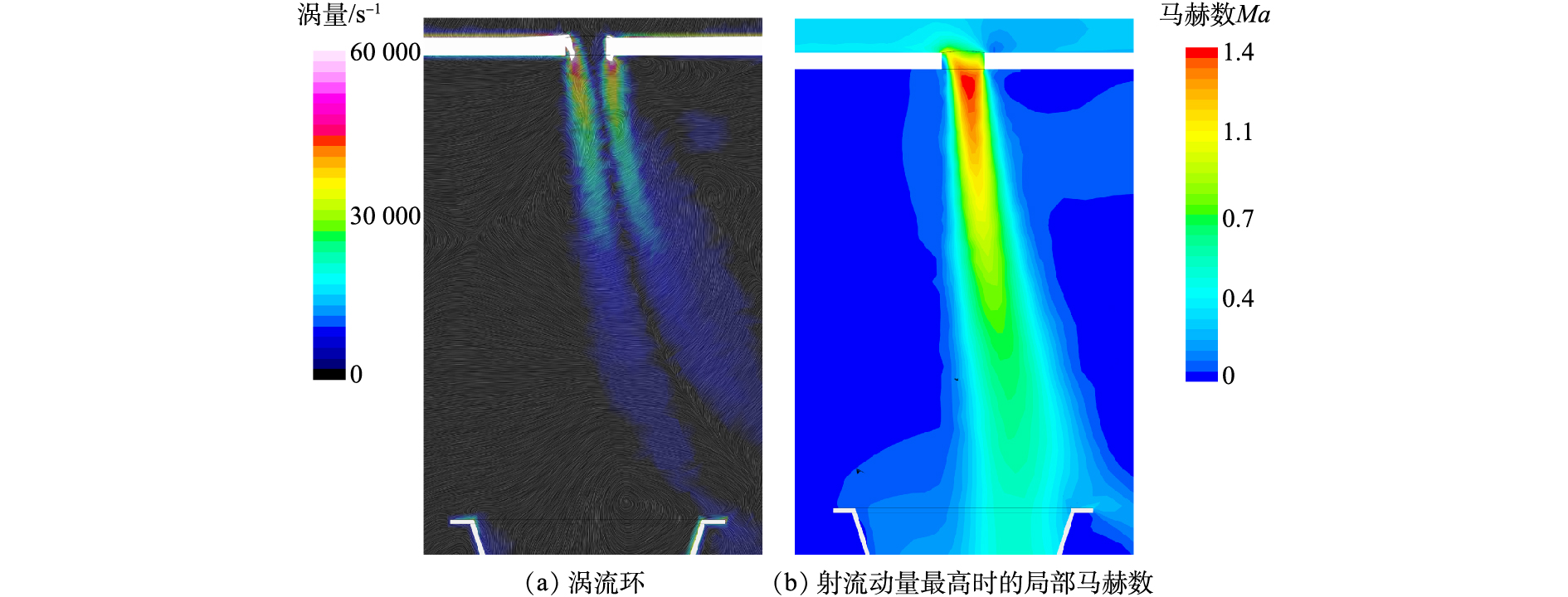

图6反映了处于不同动量时的脉冲射流特性。脉冲喷吹清灰系统中的流场不同于传统的喷射流场,使喷射清灰流场复杂化的因素包括流体的可压缩性和瞬态性、喷嘴的设计以及射流在吹扫管中的流动情况。当清灰射流动量相对较低时,射流受到类似开尔文-亥姆霍兹不稳定性的影响,出现动态波动[13],如图6(a)所示,射流和周围空气之间形成可压缩涡流环结构[14],但是由于射流快速通过,因此,这些涡流环并不明显。

图6(b)显示了射流动量处于最高时的局部马赫数。可以看出,射流的局部马赫数值超过了当地声速(Ma≥1,Ma为马赫数)。由于空间的离散化,射流出现了特征流动模式,这种现象也被称作冲击单元[15-16]。冲击单元的形成是由于射流过度膨胀和射流的内部冲击之间相互作用的结果。射流内部的相互作用导致射流核心出现了速度的强烈波动,当射流被压缩并最终达到环境压力时,射流核心的强度将沿着喷嘴方向进一步降低。

-

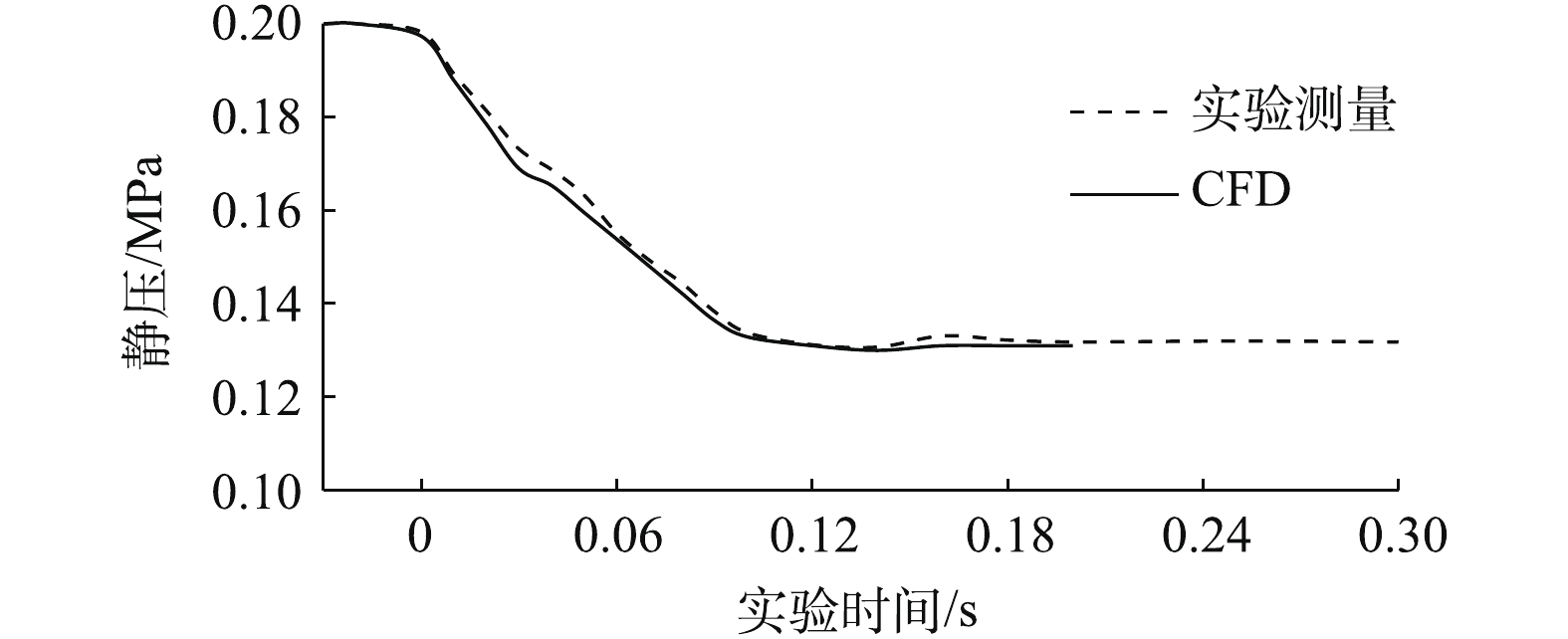

通过比较空气压缩罐和滤袋的数值模拟结果与实验压力数据来验证数值模型。对于空气压缩罐(如图7所示),数值模拟结果曲线与实验压力数据曲线之间具有良好的一致性。脉冲阀门在t=0 s时打开,空气压缩罐中压力迅速下降,直到t=0.03 s左右停止下降,这是因为清灰气流通过吹扫管传播,气流流经管壁时,经过多次反射,直到空气压缩罐中的压力和吹扫管中的压力相接近。从t=0.04 s开始,压缩空气罐以恒定的速率排压,排压速率受脉冲阀门和喷嘴两侧的压差限制。

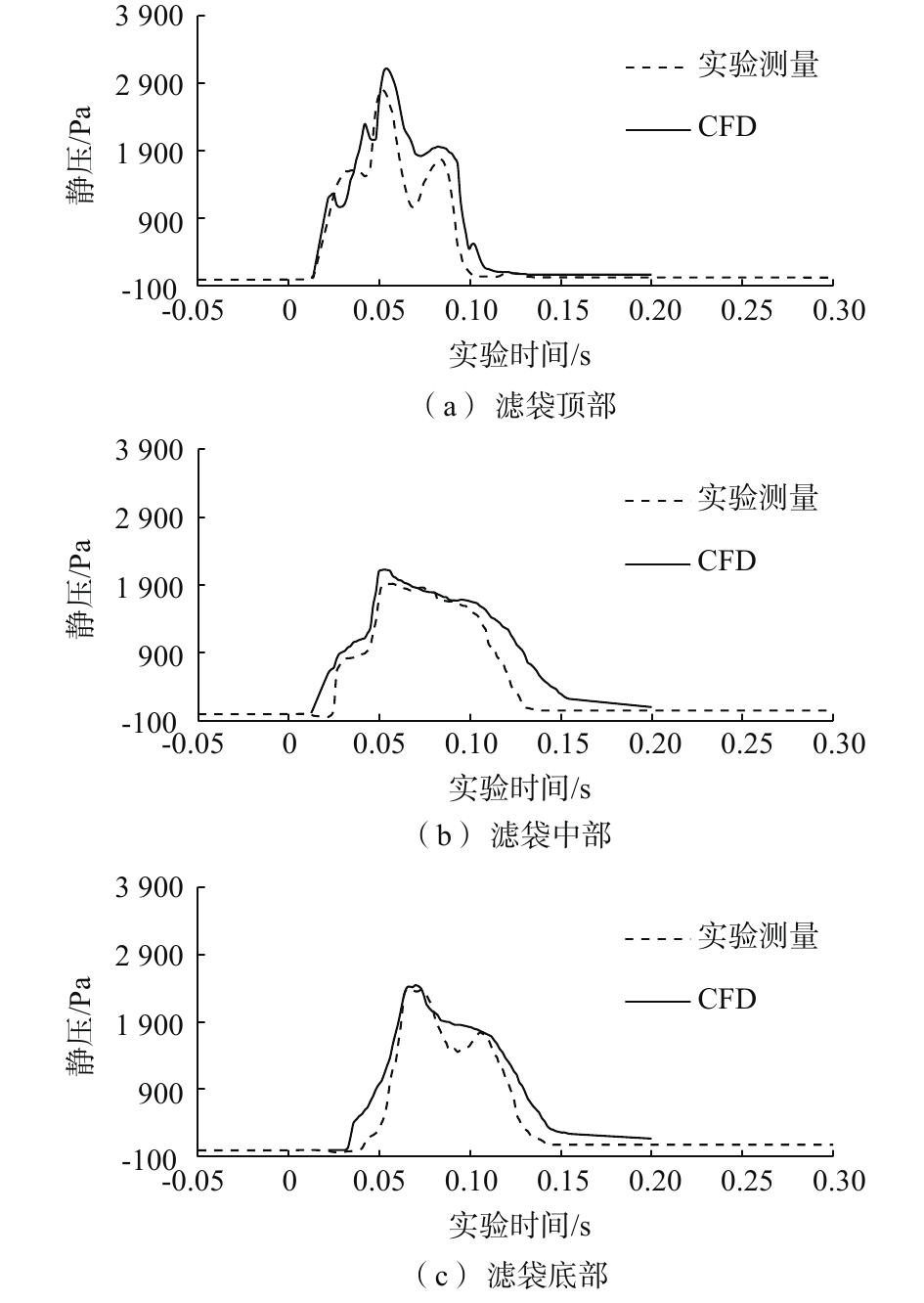

在滤袋中,数值结果与实验结果之间具有良好的一致性,如图8所示。在滤袋顶部位置脉冲压力短时间内上升到3 100 Pa(如图8(a)所示)。通过数值模拟研究发现,脉冲阀门的阻力控制方案(图3)与吹扫管内的压力波反射是导致滤袋顶部脉冲压力上升的主要因素,这与实验研究所得到的结论相吻合。

滤袋的顶部位置和底部位置都出现了明显的周期性振荡(见图8(a)和图8(c))。研究发现,脉冲射流的局部以接近音速的速度贯穿滤袋,在到达箱体底部时,由底部钢板反射,这是引起周期性振荡的主要原因。在滤袋顶部,振荡周期约为0.035 s,这与音速穿过滤袋并通过底部钢板反射的总行程(2×6.5 m)基本吻合。同时,由于吹扫管内存在压力波扰动和射流反射的客观现象,引起了脉冲射流速度的强烈波动。在滤袋中部位置(如图8(b)所示)未出现明显的周期性振荡,这是由于滤袋中存在多个频率的压力波,相互作用抵消造成的。

射流沿垂直方向贯穿滤袋时,部分射流穿过滤袋向外传播,滤袋峰值压力沿轴向下降。在滤袋中部位置,峰值压力为2 000~2 100 Pa,这足以实现对滤袋的清洁。根据SIEVERT等[17-18]的研究,需要400~500 Pa的峰值压力才能达到良好的清灰效果。

t=0.1 s后,滤袋3个部位的压力数值模型结果与实验结果相比,均出现了偏差。该偏差的出现是因为本研究将滤袋建模为刚性结构(即忽略了滤袋偏转),对滤袋模型设定了恒定的阻力系数而造成的。在实验装置中,滤袋由内部袋笼保持固定,滤袋与袋笼间存在很小的活动空间,在脉冲喷吹时,滤袋会出现一定程度的抖动,同时射流进入滤袋中,使得滤袋膨胀,滤袋内的纤维结构发生变形。LO等[19]研究发现,恒定的阻力系数是一个相对合理的假设,这与本研究的研究结果吻合。尽管存在一些偏差,但数值模型与实验结果之间的整体一致性良好,因此,本研究中的数值模型是有效的。

2.1. 射流分析

2.2. 数值模型验证

-

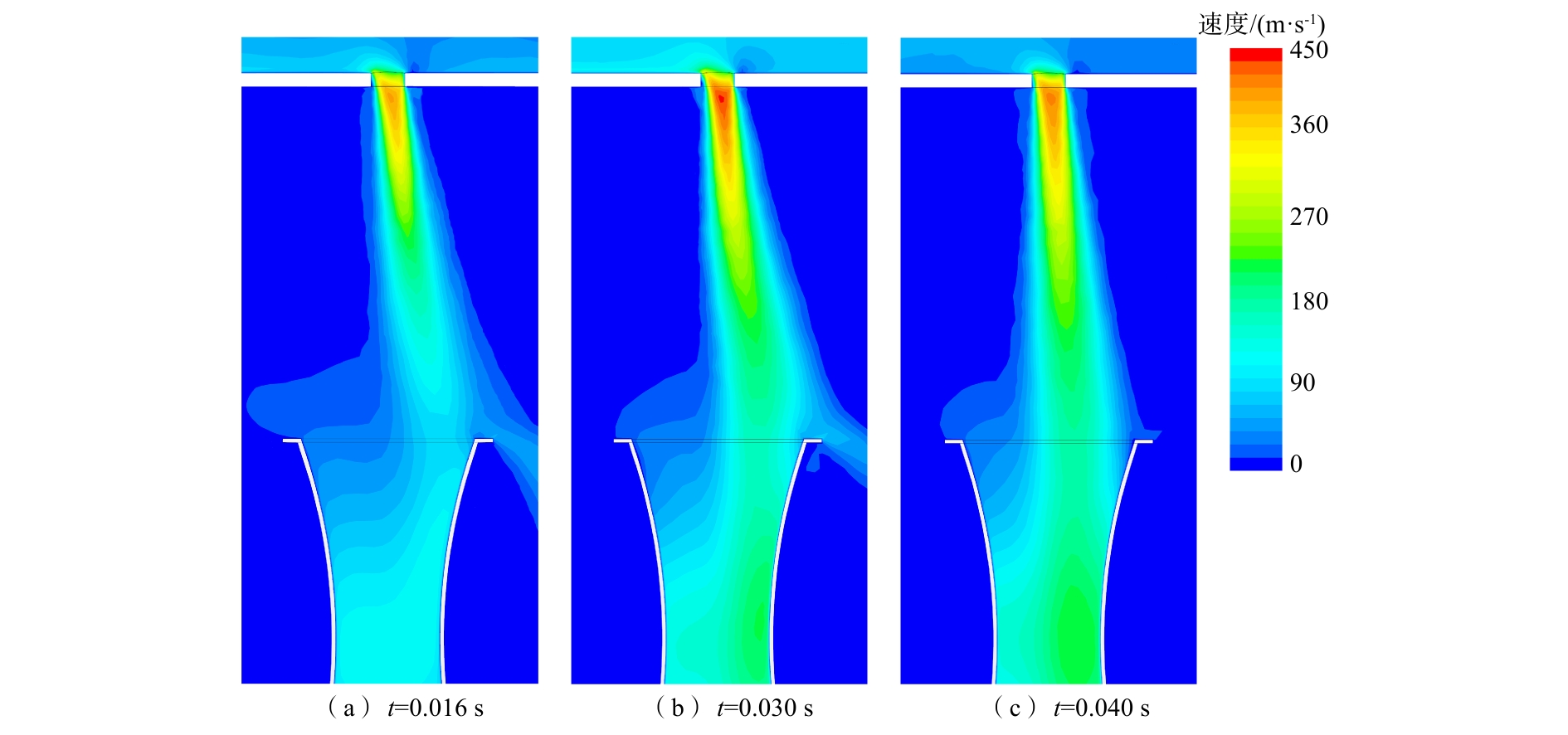

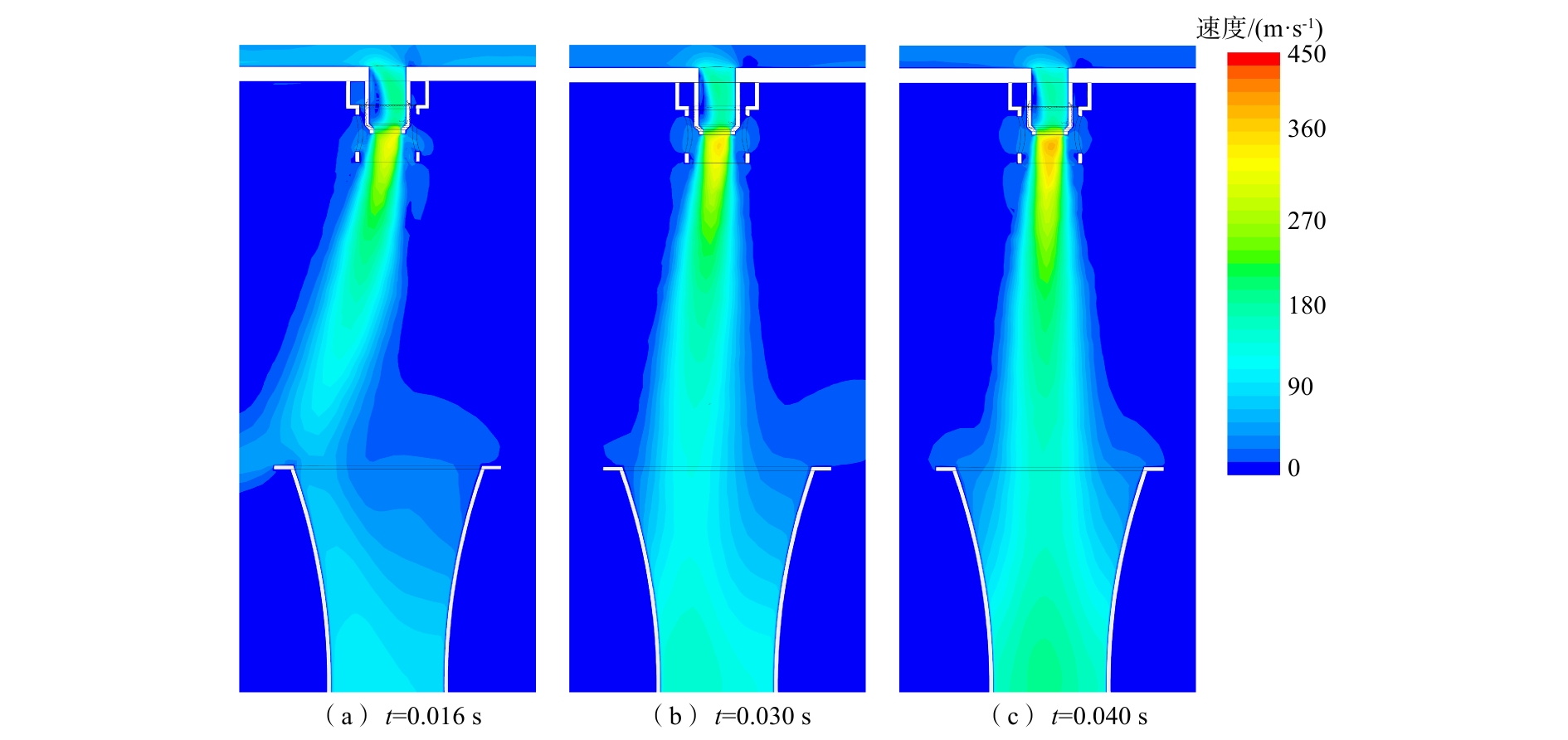

对2种类型的喷嘴进行数值模拟测试,结果以速度标量场的形式显示,结果如图9和图10所示。可以看到,射流明显未对准时,t=0.016 s;射流处于最大喷射速度时,t=0.030 s;射流处于最佳对准时,t=0.040 s。

对于孔喷嘴(图9),在明显未对准时(t=0.016 s),射流对文丘里管的入口边缘形成冲击并产生了分流;在t=0.030 s时,未对准情况减弱,射流主要集中在文丘里管喉部右侧1/2处;在t=0.040 s时,射流的未对准情况进一步改善,入口边缘的冲击分流现象消失,射流占据了文丘里管喉部2/3的位置。

对于改进的喷嘴(图10),在t=0.016 s时,射流的未对准现象与孔喷嘴相似,但方向朝相反侧。这是由改进喷嘴的内部几何形状导致的;在t=0.030 s时,与孔喷嘴相比,未对准现象略有改善;在t=0.040 s时,射流对准情况良好,射流近乎完全填充文丘里管的喉部。

为了量化改进效果,表1列出了在2种喷嘴中滤袋各部位峰值压力。改进喷嘴对滤袋各部位的峰值压力均有不同的提升,其中对滤袋底部的峰值压力提升最高,增长率为13.3%。研究发现,峰值压力是判断清灰效果是否良好的重要指标[20-23]。由于孔喷嘴存在射流未对准现象,改进喷嘴的峰值压力增加(5.1%~13.3%)会对滤袋清洁效果有所改进。此外,使用改进喷嘴导致峰值压力增加,使清灰系统在保持足够清洁强度的同时,降低罐压力,减少压缩空气消耗,达到节能的效果。

-

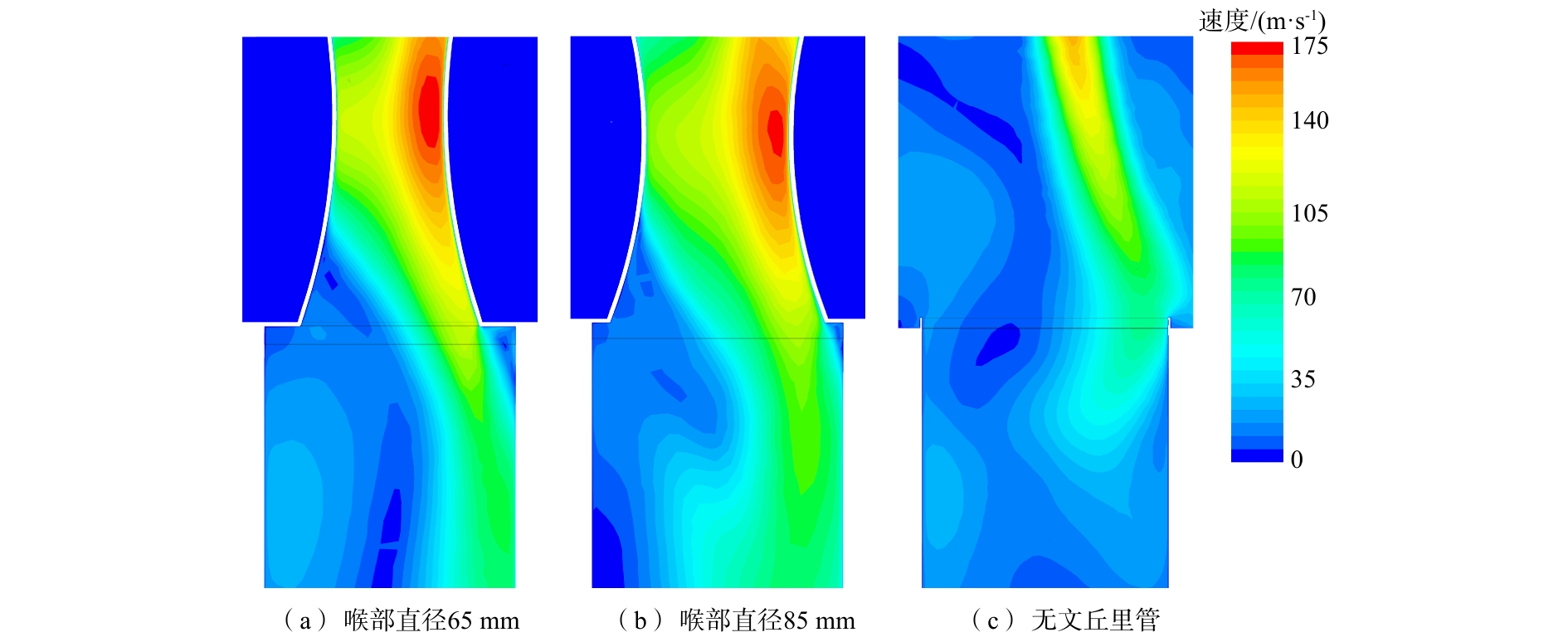

通过研究流经文丘里管的射流速度(图11、图12)以及滤袋中的峰值压力(表2),分析文丘里设计对清灰效果的影响。图11和图12表明,文丘里管以及文丘里管的喉部直径对进入滤袋的清灰射流有直接影响。对比喉部直径为65 mm和85 mm的文丘里管发现,减小喉部直径(65 mm)能适当减少回流,滤袋峰值压力增加了5.5%~7.6%。如图11(c)、图12(c)所示,从无文丘里管的设计中可以看到,在滤袋入口处,射流回流显著增加,与喉径为85 mm的文丘里管相比,其峰值压力降低了41.4%~46.3%。

文丘里管的工作原理是限制回流,回流会影响滤袋中的脉冲压力。文丘里管能使脉冲射流更容易进入滤袋中,同时限制射流逃逸,从而增加滤袋各部位的压力。喉部直径为65 mm和85 mm的文丘里管之间有较小的差异,说明可能存在一个最佳的喉部直径设计。

-

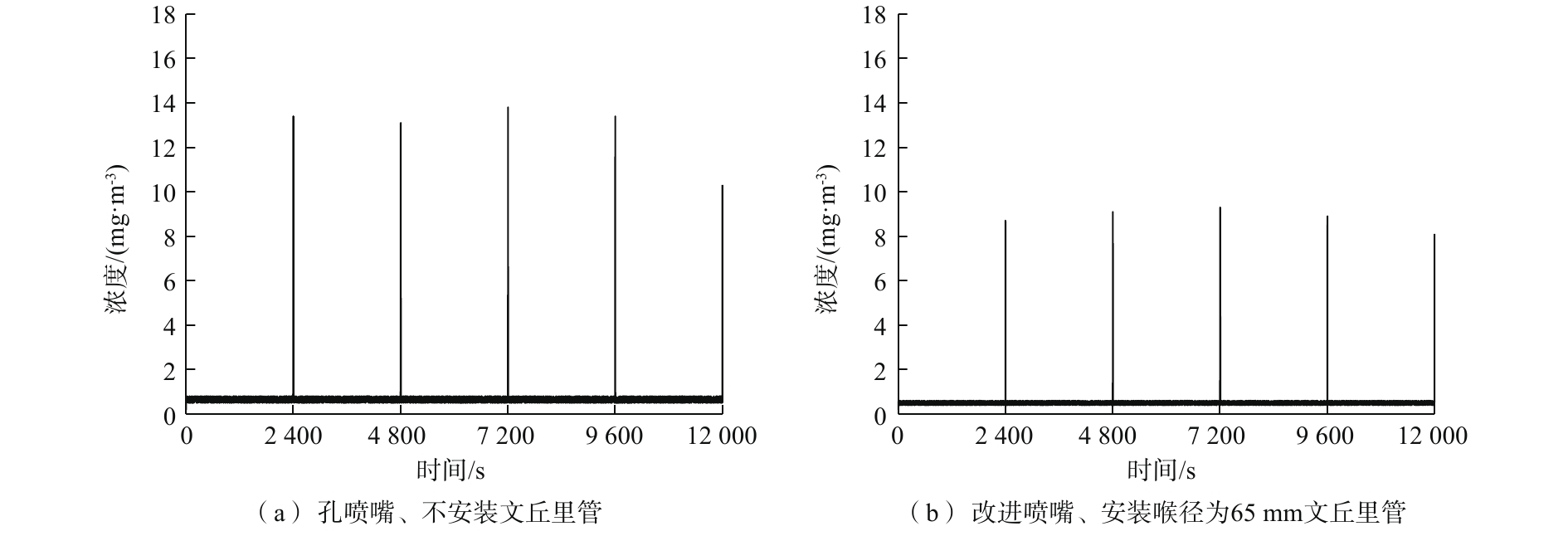

依托中材装备集团有限公司(天津水泥研究院)的袋式除尘器数字化综合工程设备,将改进的喷嘴与喉径为65 mm文丘里管进行实际应用,分析其对大气粉尘排放的影响。在过滤风速为1.5 m·min−1,入口粉尘浓度为102 g·m−3,连续过滤时间为40 min的工况下进行过滤;在罐压力为0.2 MPa、脉冲阀导通时间为100 ms下进行脉冲喷吹;总运行时间为200 min,在排放口进行粉尘浓度监测。

通过粉尘排放特性的研究(图13)发现,除尘器连续过滤时,粉尘排放浓度的变化较为平稳;脉冲喷吹时,粉尘排放浓度瞬间上升;脉冲喷吹结束后,粉尘排放浓度瞬间下降,之后再次进入连续过滤状态。使用改进喷嘴、喉径为65 mm文丘里管的除尘器,比使用孔喷嘴、不安装文丘里管的除尘器在脉冲喷吹时的粉尘排放浓度更低。从表3中可以看到,使用改进喷嘴、喉径为65 mm文丘里管除尘器的平均粉尘排放浓度为0.51 mg·m−3、平均峰值粉尘浓度为9.15 mg·m−3,明显低于使用孔喷嘴、不安装文丘里管除尘器的平均粉尘排放浓度0.66 mg·m−3、平均峰值粉尘浓度13.43 mg·m−3。由此可见,本研究对喷嘴和文丘里管的优化设计能够有效地降低粉尘排放,控制大气污染。

3.1. 改进喷嘴分析

3.2. 文丘里管分析

3.3. 大气粉尘的排放分析

-

1)脉冲阀门建模为阻力随时间变化的多孔界面,因此,在空气压缩罐中,实验测量数据与CFD模型之间具有良好的一致性。滤袋建模为恒定阻力系数的多孔界面,在滤袋中,CFD模型所得到的脉冲压力、峰值压力与实验测量结果吻合性良好,虽然出现了轻微偏差,但CFD模型与实验之间的总体一致性良好,所以该数值模型是有效的。

2)清灰射流表现出了瞬态行为以及可压缩效应,当射流动量较低时,射流与周围空气之间形成了可压缩涡流环,但由于射流快速通过,涡流效应并不明显。当射流速度超过当地声速时,由于射流过度膨胀,因此,出现了类似冲击单元的特征流动模式。

3)射流经过吹扫管从喷嘴流出,在孔喷嘴中出现了明显的射流错位现象,在改进喷嘴中,射流错位现象得到了改善。与原始的孔喷嘴相比,改进喷嘴对滤袋内脉冲压力提升了5.1%~13.3%

4)与喉部直径为85 mm的文丘里管相比,减小喉部直径(65 mm)的设计能够适当减少回流,使滤袋内峰值脉冲压力增加5.5%~7.6%;无文丘里管的设计使射流不易进入滤袋中,并且回流在袋口处显著增加,滤袋内峰值压力降低了41.4%~46.3%。

5)应用改进喷嘴与文丘里管(喉径65 mm)的袋式除尘器,在运行时能明显降低粉尘排放,其平均粉尘排放浓度为0.51 mg·m−3、平均峰值粉尘浓度为9.15 mg·m−3,低于使用孔喷嘴、不安装文丘里管除尘器的平均粉尘排放浓度(0.66 mg·m−3)和平均峰值粉尘浓度(13.43 mg·m−3)。

下载:

下载: