-

目前,我国每年大约产生3.0×107 t城市污泥[1],且随着中国污水处理厂的升级和扩建,城市污泥产量每年以13%的速率递增[2]。大量城市污泥的处理与处置是我国目前亟待解决的环境问题。食品处理厂剩余污泥中有机物含量高,营养丰富,大多为蛋白质、多糖、脂肪等[3],不含有毒有害物质。目前,我国食品污泥处理的方法主要有厌氧消化、好氧发酵、焚烧、卫生填埋、土地利用等。同时,我国农作物秸秆近20种,年产量约7.0×108 t,约占世界秸秆总量的25%。随着社会经济迅速发展和人口的增加,农作物秸秆总量将以每年5%~10%的速度递增[4]。然而,目前农村地区的秸秆利用率还很低,存在秸秆焚烧、随意丢弃等现象[5]。好氧堆肥方法成本低、无害化程度高、处理量大、处理后的产品可作为有机肥,在农业生产上具有广阔的应用前景。利用食品厂污水处理剩余污泥与农作物秸秆进行混合好氧堆肥,既解决了剩余污泥与农作物秸秆问题,又可得到生物有机肥[6],适用于农业大田生产、果树种植及园林绿化,对减轻长期施用化肥造成的农田环境污染、增加土壤肥力[7-8]、提高农产品品质及增加农业收入,具有良好的经济、环境和社会效益。

在堆肥初期,由于堆体中土著微生物数量较少,微生物活性较低,存在着发酵周期长、堆肥效率慢等缺点。复合微生物菌剂因微生物间的协同作用,可有效调节堆肥原料中的菌群结构,加快堆肥速率,缩短堆肥周期,促进堆体腐熟[9]。目前,我国已在堆肥微生物菌剂的研究方面取得了一定进展。ZHAO等[10]从堆肥中筛出4株嗜热放线菌,制成一种微生物菌剂,能够提高堆体腐熟程度,缩短了堆肥周期。XI等[11]在堆肥过程中投加了一种复合微生物菌剂,增加堆肥过程中优势菌的多样性,提高堆肥效率。ZHOU等[12]在堆肥过程中接种了一种由放线菌、哈茨木霉、米曲霉等组成的复合微生物菌剂,缩短了堆肥周期,提高了木质纤维的降解效率。

与液态微生物菌剂相比,固态菌剂中的微生物更易存活,保存时间长,保存成本低,运输方便,更适用于大规模的生产与应用。针对食品厂剩余污泥与秸秆的组成,本研究筛选出5株优势芽孢杆菌,研制出一种固态微生物菌剂。本研究首先以活菌数和芽孢率为评价依据,优化固态微生物菌剂制备过程中的关键影响因素,在此基础上,通过正交实验获得最佳固态微生物菌剂的制备方法,通过比较不同保存时间固态微生物菌剂的实际堆肥效果,研究固态微生物菌剂的稳定性,为其工业化生产提供参考。

全文HTML

-

实验用脱水污泥为某食品厂污水处理剩余污泥,玉米秸秆购自河南郑州。营养肉汤培养基购自青岛海博生物技术有限公司。

堆肥反应器为聚丙烯塑料箱(560 mm×360 mm×325 mm),总容积为65 L,曝气泵底部间歇供氧,每12 h曝气1次,曝气1 h,曝气量为0.3 L·(L·min)−1,并通过距离箱底高约10 cm的多孔筛板实现均匀供氧。当堆体温度高于55 ℃时,每天翻堆1次。

-

1)菌株来源。本研究用于制备固态微生物菌剂的菌株为实验室已有5株芽孢杆菌,编号分别为ZX5、ZX6、GX2、GX5和GX9,其获得方法如下:以食品厂污水处理剩余污泥为堆肥原料、市售玉米秸秆为辅料,二者的添加比例分别为60%和40%,再加入5%江苏省无锡市某区含落叶的表层土壤;所得混合物料共计30 kg,混合物的含水率为60%±5%,碳氮比(C/N比)为25±5,混合均匀后,装入堆肥反应器中,持续曝气,定期翻堆,进行好氧堆肥;当堆体温度维持35 ℃和55 ℃达7 d左右时,分别从堆体中心和四周取5个等量堆肥样品,混匀后,依次进行微生物的初筛、复筛及分离纯化,进而获得上述菌株。将5株芽孢杆菌分别接种至高温灭菌后的营养肉汤培养基中,接种量为1.0×107 CFU·mL−1。ZX5和ZX6的培养温度为35 ℃,培养1~2 d;GX2、GX5和GX9的培养温度为50 ℃,培养1~2 d。将获得的不同菌株的发酵液按1∶7∶617∶295∶443的比例混合,制成复合微生物菌液,备用。

2)固态微生物菌剂的影响因素研究。①载体筛选。分别选择秸秆、炭化秸秆、腐熟物料、褐煤作为载体,将其研磨,过30目筛网,121 ℃灭菌30 min,然后放在105 ℃烘箱中烘干备用。将复合微生物菌液与载体按照5∶1的比例混匀,放在35 ℃烘箱中烘干。将制备好的微生物菌剂室温下密封干燥保藏30 d后,测定菌剂中活菌数及芽孢率。②海藻糖浓度。以腐熟物料作为载体,将其研磨,过30目筛网,121 ℃灭菌30 min,然后放在105 ℃烘箱中烘干备用。在复合微生物菌液中投加0%、4%、8%、12%、16%和20%的海藻糖,混匀后,再与载体按照5∶1的比例混匀,放在35 ℃烘箱中烘干。将制备好的微生物菌剂室温下密封干燥保藏30 d后,测定菌剂中活菌数及芽孢率。③含水率。以腐熟物料作为载体,将其研磨,过30目筛网,121 ℃灭菌30 min,然后放在105 ℃烘箱中烘干备用。将复合微生物菌液与载体按照5∶1的比例混匀,放在35 ℃烘箱中烘至含水率为15%、20%、25%、30%、35%和40%。将制备好的微生物菌剂室温下密封干燥保藏30 d后,测定菌剂中活菌数及芽孢率。

3)固态微生物菌剂影响因素的正交实验。根据单因素实验的结果,进行3因素3水平正交实验(见表1),将制备好的微生物菌剂室温下密封干燥保藏30 d后,测定菌剂中活菌数及芽孢率。研究载体种类、海藻糖浓度及含水率对菌剂保存效果的影响,进而获得最佳菌剂制备条件。

4)所得固态微生物菌剂的堆肥效果。以食品厂污水处理剩余污泥为堆肥原料,市售玉米秸秆为辅料(二者质量之比为6∶4),获得用于好氧堆肥的混合物料,其组成如下:有机质含量为87.29%、凯氏氮含量为19.24 mg·g−1、C/N比为26.32、pH为6.35、含水率为67.24%、粪大肠菌群数为2.0×103 MPN·g−1、蛔虫死亡率为45.14%、种子发芽指数44.79%、半纤维素、纤维素和木质素含量分别为238.1、318.2和59.4 mg·g−1。将15 kg物料装入堆肥箱中进行好氧堆肥,具体操作同菌株来源,共4个堆肥箱,其中,对照实验不添加任何菌剂,记为CK,添加新鲜固态复合微生物菌剂的实验记为ZJ,添加室温下保存30 d菌剂的实验记为ZJ-30,添加室温下保存60 d菌剂的实验记为ZJ-60,研究所得固态微生物菌剂保存时间对堆肥效果的影响。微生物菌剂直接添加在堆肥原料中,菌剂添加量均为堆体湿重的0.3%,整个堆肥过程持续10 d。

-

菌剂中有效活菌数采用平板计数法[13]测定。芽孢率的测定:将菌液在70 ºC下加热10 min,再利用平板计数法检测菌剂中的芽孢数,其芽孢率[14]计算见式(1)。

式中:w为芽孢率;m0为灭菌前菌落数,CFU·g−1;m1为加热后菌落数,CFU·g−1。

粪大肠菌群数和蛔虫死亡率均按照生物有机肥标准(NY 884-2012)中的方法测定。种子发芽指数(GI)测定方法:堆肥样品按水∶物料=10∶1浸提,160 r·min−1振荡1 h后过滤,吸取5 mL滤液于铺有滤纸的培养皿中,滤纸上放置10颗籽粒饱满、均匀一致的种子,25 ºC下培养72 h后,测定种子的根长,同时用去离子水做空白对照,种子发芽指数计算方法[15]见式(2)。

式中:RGI为种子发芽指数;q0为去离子水处理的种子发芽率;q1为堆肥浸提液处理的种子发芽率;l0为去离子水处理的种子根长,cm;l1为堆肥浸提液处理的种子根长,cm。

有机质含量采用重铬酸钾氧化法(NY 525-2012)测定。有机碳含量=有机质含量/1.724(氧化系数)[16]。凯氏氮(TKN)采用凯氏定氮法[17]测定。C/N比为有机碳含量/凯氏氮含量[18]。pH的测定是将样品与水按1∶10的比例混合,浸提1 h后,采用pH计法[19]测定。含水率采用烘箱干燥法[20]测定。

半纤维素、纤维素、木质素的测定:采用ANKOM A2000i型全自动纤维分析仪测定堆体中半纤维素、纤维素和木质素的含量[21]。

堆体温度每隔12 h测定1次,在堆体的中央和四周均匀测温5次,取平均值[17]。

1.1. 实验材料

1.2. 实验方法

1.3. 分析测试项目与方法

-

活菌数是衡量菌剂质量的有效指标[22]。芽孢杆菌是一种革兰氏阳性菌,在其生长的一定阶段内,会在营养细胞内形成一个圆形、卵圆形或圆柱形的休眠体,即为芽孢[23]。芽孢能适应不良环境,对高温、紫外线、干燥、电离辐射和很多有毒的化学物质都有很强的抵抗性[24],而在条件适宜时又可转变为营养细胞,从事正常的代谢活动,因此,在测定活菌数的同时,可观察芽孢率的变化情况[25]。

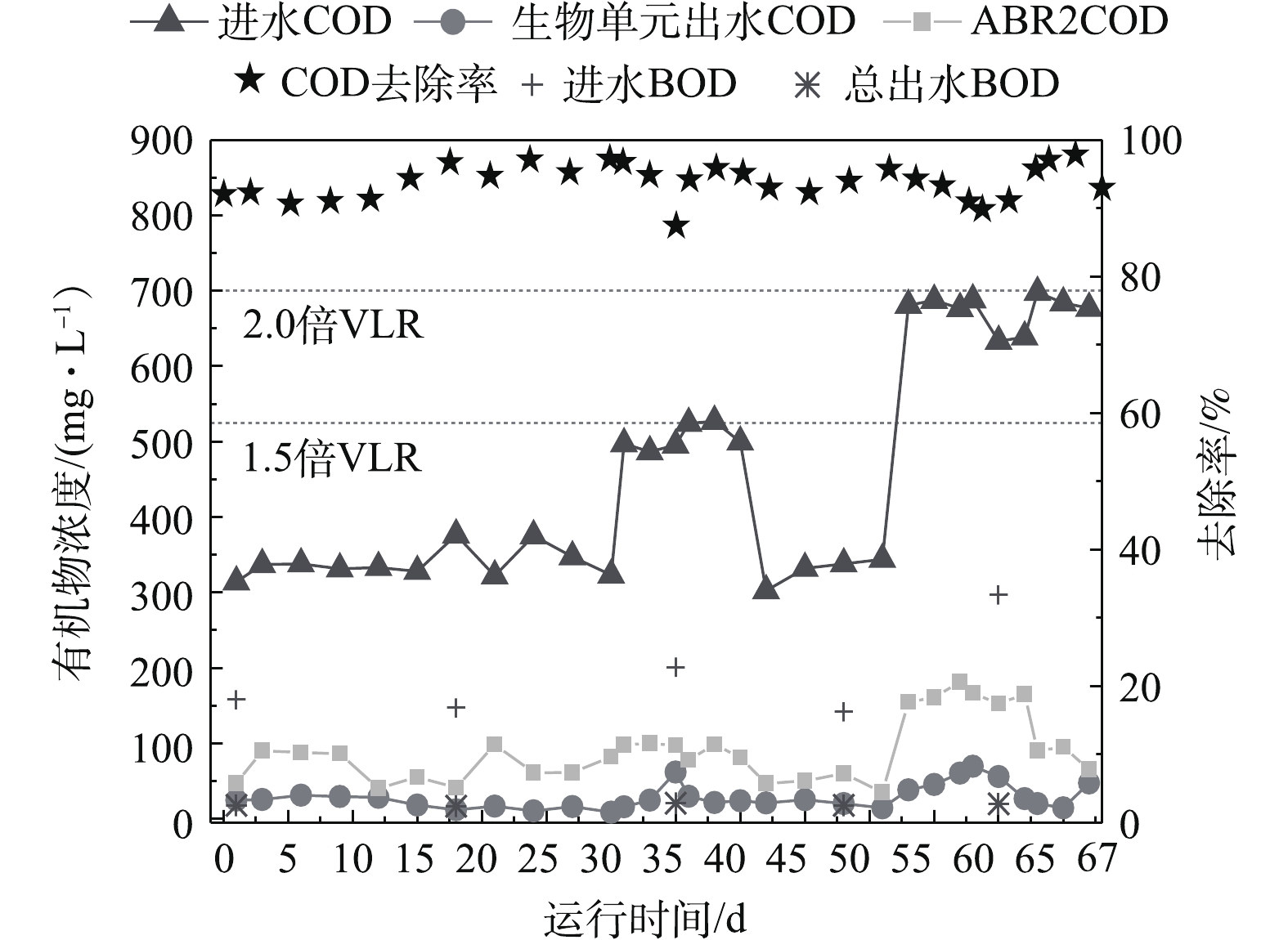

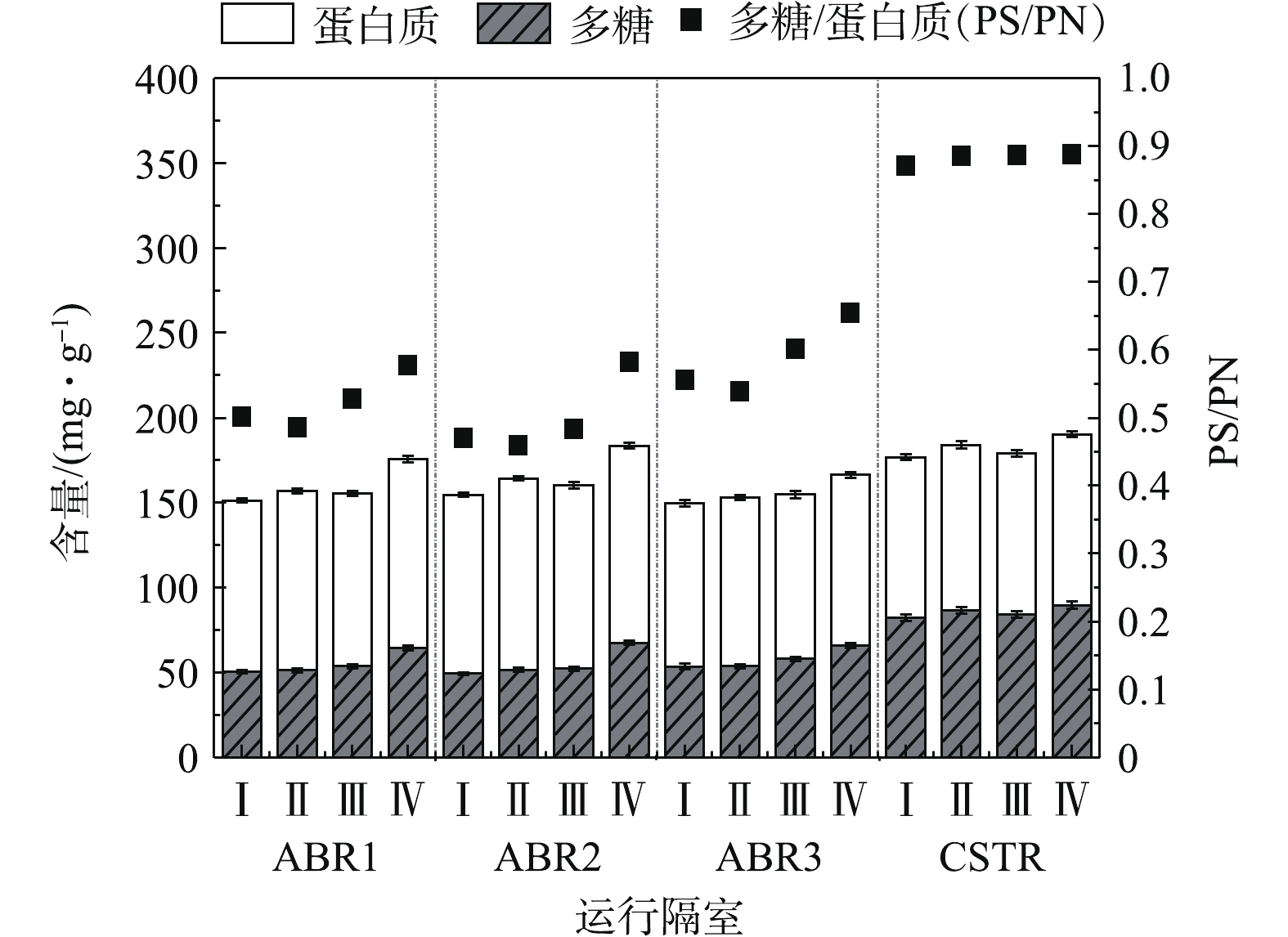

1)载体类型对活菌数及芽胞率的影响。由图1可知,4种载体对菌剂活菌数及芽孢率的影响顺序依次为腐熟物料>秸秆>炭化秸秆>褐煤,其中,以腐熟物料作为载体的菌剂活菌数和芽孢率最高,以秸秆为载体的菌剂次之。以腐熟物料、秸秆和炭化秸秆为载体的菌剂保藏30 d后,活菌数均较高,均为5.0×109 CFU·g−1以上,芽孢率则分别为87.3%、76.4%和72.1%。以褐煤为载体的菌剂保藏30 d后,活菌数仅为1.0×109 CFU·g−1,芽孢率仅为37.5%,不利于长期保藏。因此,选择腐熟物料、秸秆和炭化秸秆作为正交实验时的3个水平。由于腐熟物料更易得,以下研究均以腐熟物料为固态微生物菌剂的载体。

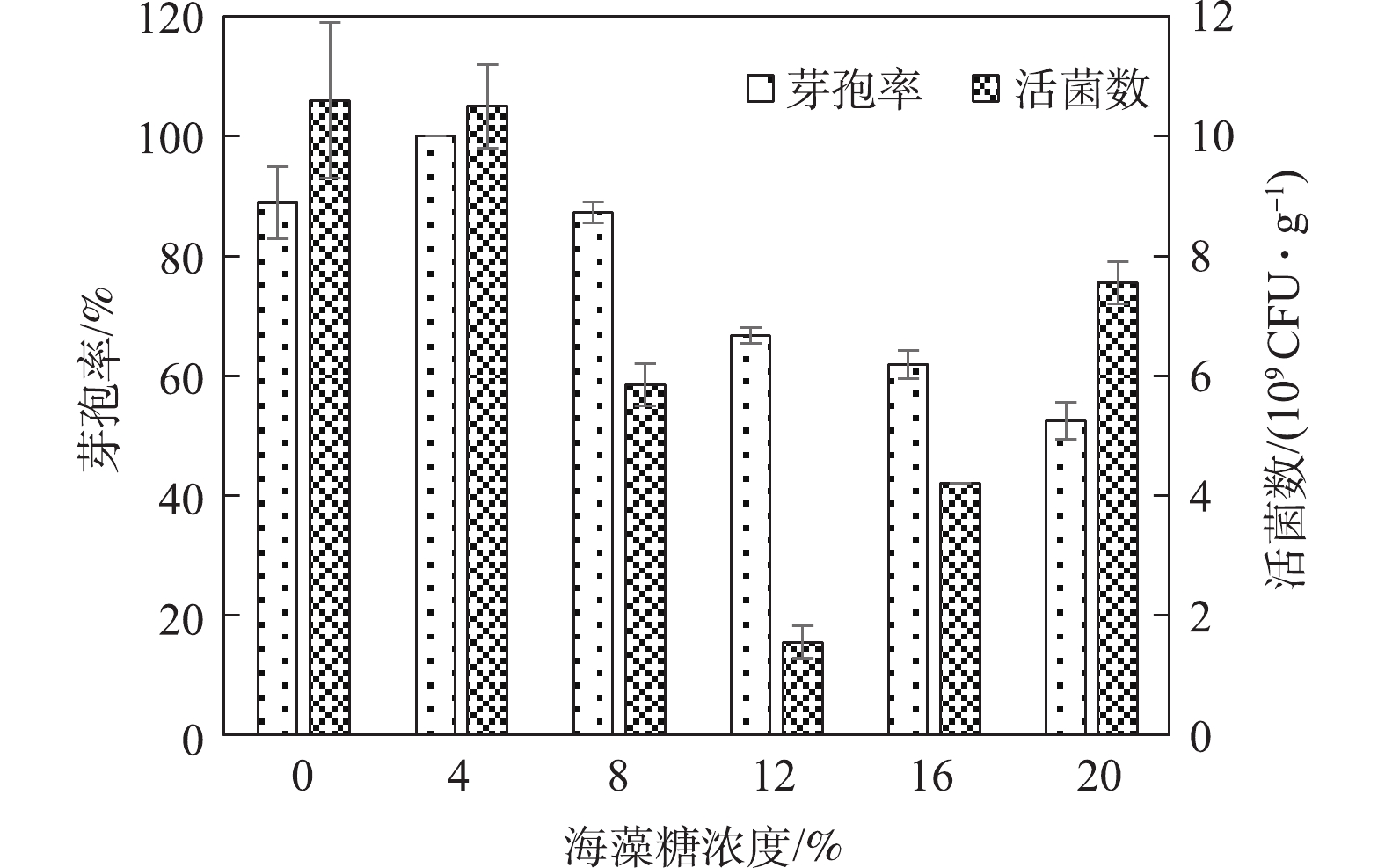

2)海藻糖浓度对活菌数及芽胞率的影响。研究表明,在高温、冷冻、干燥等恶劣条件下,海藻糖能够在细胞表面形成独特的保护膜,有效保护生物分子不被破坏,提高微生物菌剂的存活率,延长微生物菌剂的储存期[26]。由图2可知,随着海藻糖浓度的提高,菌剂中芽孢率呈现先上升后下降的趋势,而活菌数含量却呈现先下降后上升的趋势。海藻糖也是生物体储备的碳源[27],可以被微生物所利用。海藻糖浓度过高时,微生物可利用的碳源增多,芽孢就会萌发,转化为营养细胞而过早失活,降低菌剂的使用效果。因此,当海藻糖投加量为12%~20%时,菌剂中芽孢率较低。当海藻糖投加量为0%~8%时,菌剂中芽孢率较高,且此时菌剂中活菌数也较高,均为5.0×109 CFU·g−1以上。故选用0%、4%、8%作为正交实验中3个水平。

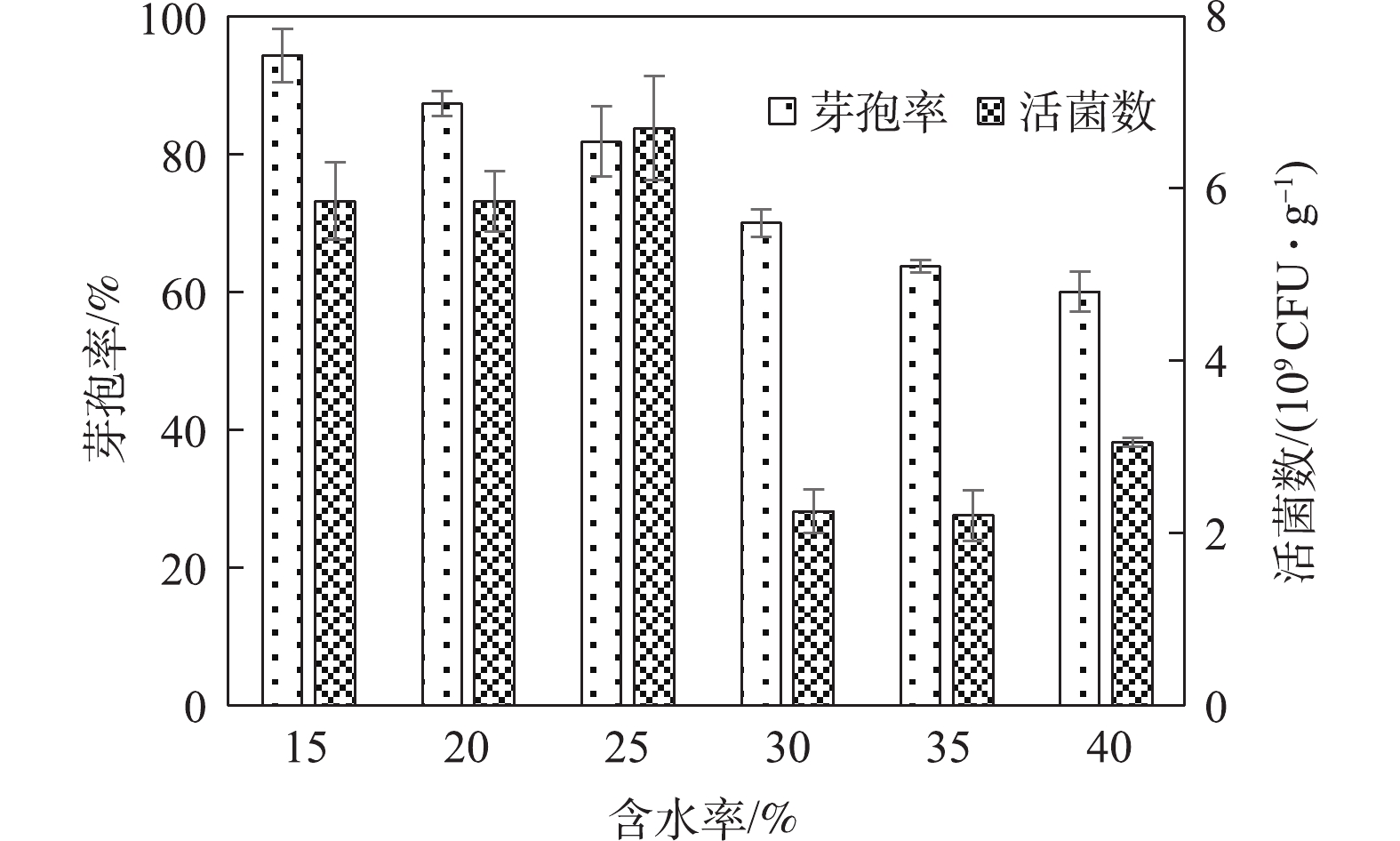

3)含水率对活菌数及芽胞率的影响。固态菌剂的含水率会显著影响菌剂的保存效果,含水率越高,越不利于菌剂的长期保藏[28]。菌剂中含水率越高,越促进芽孢的萌发,使其转化为营养细胞,不利于长期保存。此外,菌剂中含水率越高,越易在保存过程中发霉,滋生出大量杂菌[29]。由图3可知,随着固态菌剂最终含水率的提高,菌剂中芽孢率在不断降低。含水率为15%~25%时,菌剂中芽孢率较高,高于80%;活菌数高于5.0×109 CFU·g−1。当菌剂的含水率为30%~40%时,菌剂中芽孢率较低,均在70%以下,活菌数也较低,不利于菌剂的长期保存。这可能是由于菌剂中水分适宜,会促进芽孢萌发,使其转换为营养细胞,降低了菌剂中的芽孢率;在长期保存过程中,营养细胞失活,降低了菌剂中活菌数。减少含水率,更有利于菌剂的长期保存[30]。故选用15%、20%、25%作为正交实验中的3个水平。

4)正交实验。在上述单因素实验的基础上,进行影响因素的正交实验(见表2)。对正交实验结果进行分析,结果如表3所示。从活菌数来看,载体、海藻糖浓度和含水率对其影响程度分别为海藻糖浓度(B)>含水率(C)>载体(A),菌剂最佳配方为B2C1A3。从芽孢率来看,载体、海藻糖浓度和含水率对其影响程度分别为含水率(C)>载体(A)>海藻糖浓度(B),菌剂最佳配方为C1A3B2。综合考虑活菌数和芽孢率的变化情况,最佳菌剂配方为:以腐熟物料作为载体,投加4%的海藻糖,含水率为15%。

对上述正交实验结果进行了方差分析,结果如表4所示。在置信区间ɑ=0.05范围内,载体、海藻糖浓度和含水率对活菌数影响显著。在置信区间ɑ=0.05范围内,含水率对芽孢率影响显著,而载体和海藻糖浓度对芽孢率影响不显著。因此,确定腐熟物料作为载体,投加4%的海藻糖,含水率为15%作为最佳菌剂配方。

-

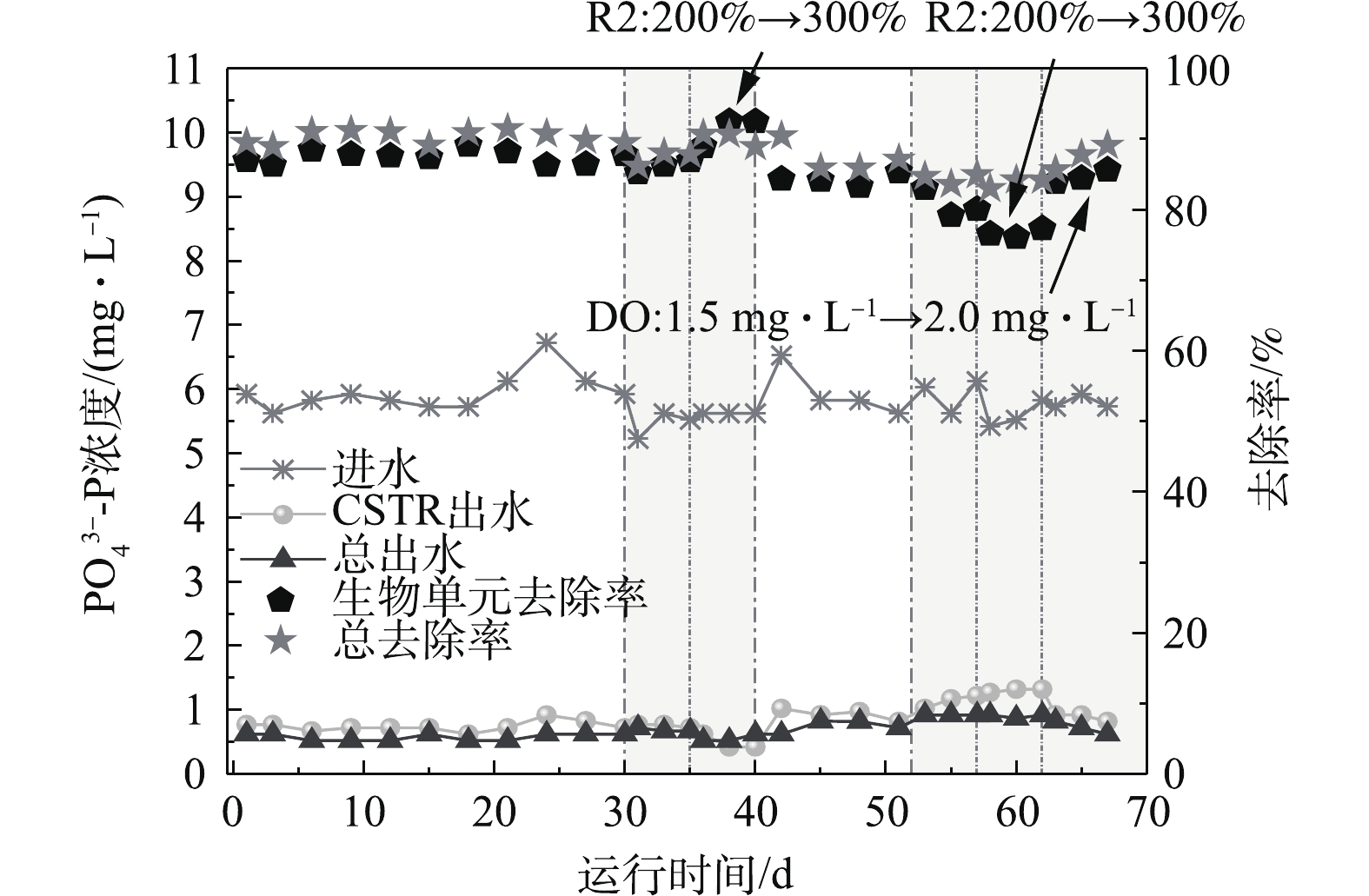

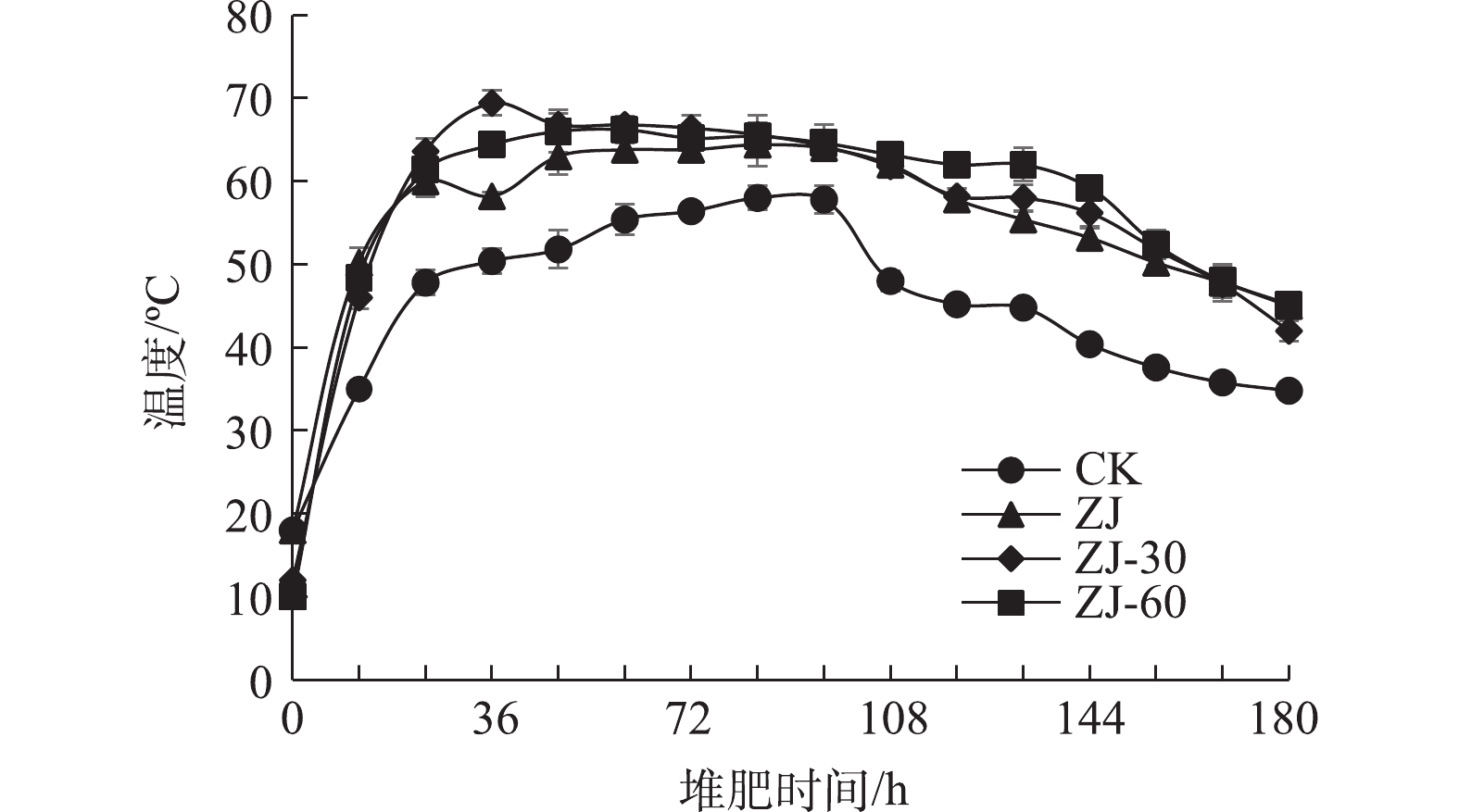

1)堆体温度的变化。以空白为对照,分别将新鲜固态微生物菌剂、保藏30 d的菌剂以及保藏60 d的菌剂用于好氧堆肥,研究菌剂保存时间对堆肥效果的影响。随着保存时间的延长,4个堆体中温度变化如图4所示。

结果表明,堆体CK在60 h左右进入55 ℃以上的高温期,在84 h左右出现堆体最高温度,为58 ℃,55 ℃以上的高温持续时间为40 h,50 ℃以上的持续时间为70 h。堆体ZJ在18 h左右进入55 ℃以上的高温期,在60 h左右出现堆体最高温度,为64 ℃,55 ℃以上的高温持续时间为114 h,50 ℃以上的持续时间为144 h。堆体ZJ-30在18 h左右进入55 ℃以上的高温期,在36 h左右出现堆体最高温度,为69 ℃,55 ℃以上的高温持续时间为129 h,50 ℃以上的持续时间为147 h。堆体ZJ-60在19 h左右进入55 ℃以上的高温期,在48 h左右出现堆体最高温度,为66 ℃,55 ℃以上的高温持续时间为132 h,50 ℃以上的持续时间为148 h。相比于堆体CK,堆体ZJ、堆体ZJ-30、堆体ZJ-60分别提前了42、42和41 h进入高温阶段,高温持续时间分别延长了74、89和92 h,50 ℃以上的持续时间分别延长了74、77和78 h。比复合微生物菌剂PTCMA,自制复合微生物菌剂能够提前7 d进入高温期,且最高温度可提高2~7 ℃[31];比复合菌剂F12,能够延长高温持续时间,其50 ℃以上的持续时间可延长2 d[32]。

可见,尽管固态菌剂的保存时间不同,但均能在18~19 h左右促使堆体进入高温期,随着菌剂保存时间的延长,堆体的高温持续时间略有增加,而50 ℃以上的持续时间变化不大。该固态菌剂的性能稳定,保存一段时间后依旧能使堆体快速进入高温阶段,且持续时间长,可使堆体达到无害化要求。

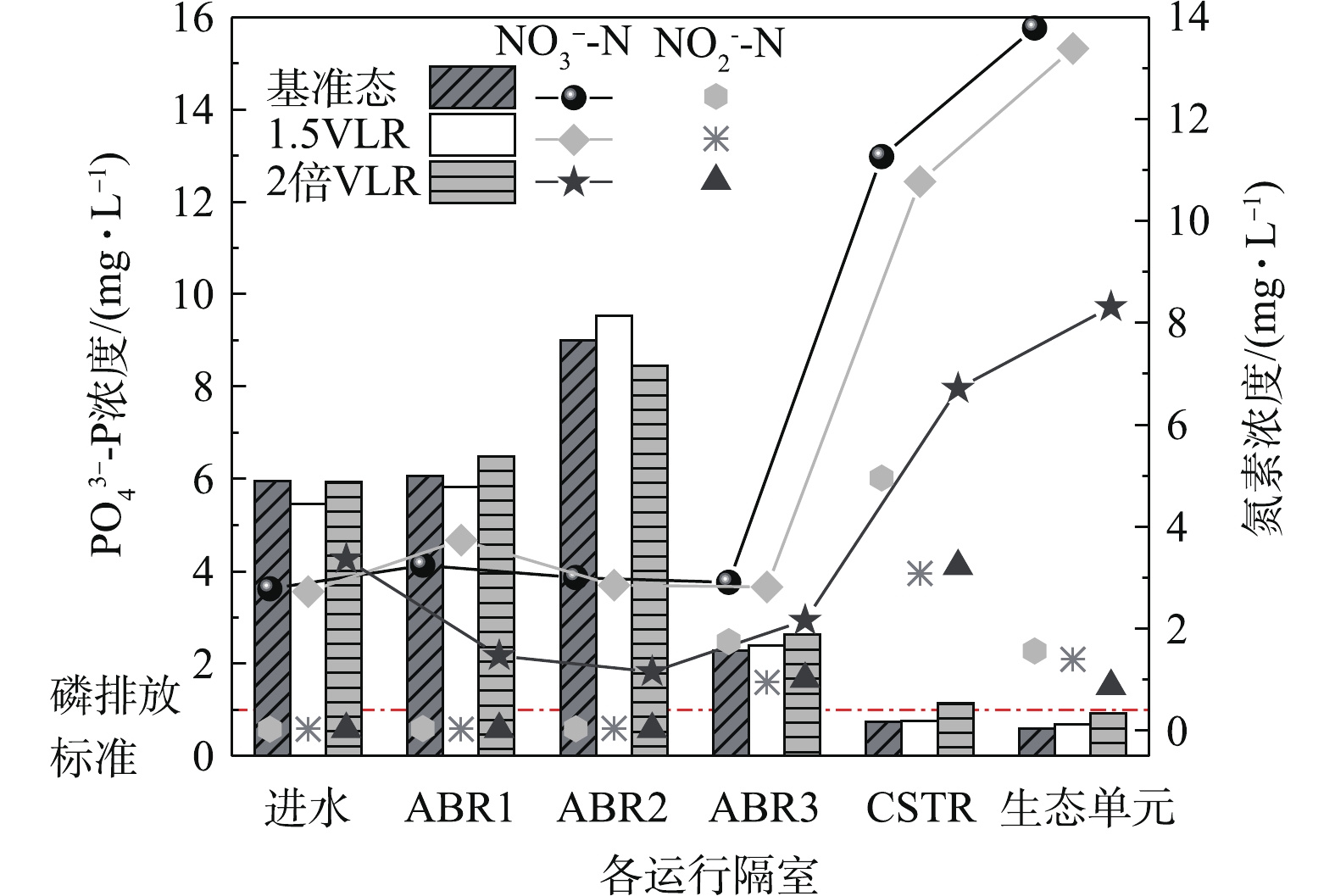

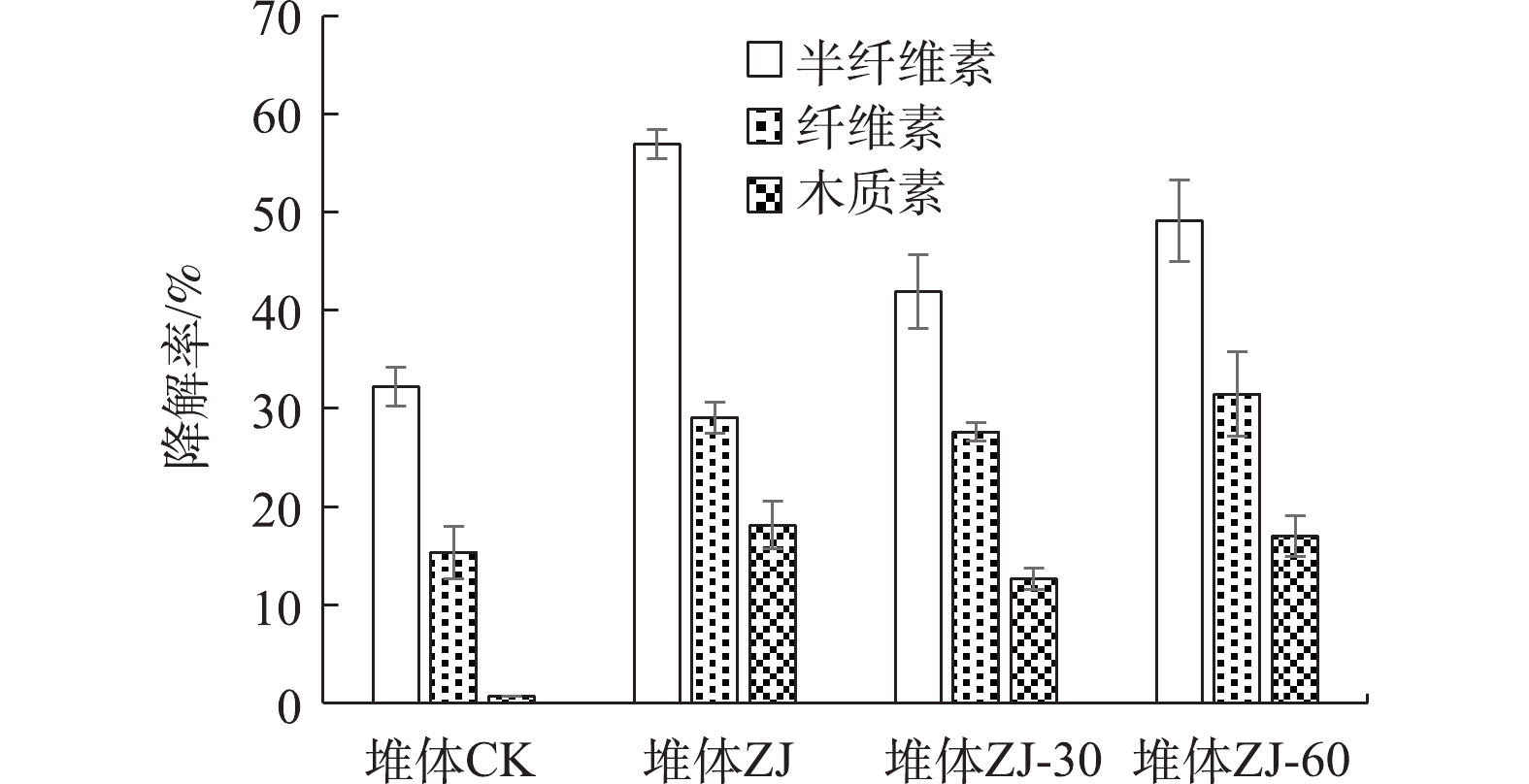

2)半纤维素、纤维素和木质素的降解率。如图5所示,堆肥结束后,堆体中半纤维素、纤维素和木质素含量均有所降低。半纤维素最易降解,而木质素是一种高分子有机化合物,结构非常复杂[31],较难降解,因此,堆体中半纤维素降解率最高,木质素降解率最低。

由于添加自制复合微生物菌剂中含有芽孢杆菌,在堆肥高温阶段具有良好的活性,可有效促进木质素和纤维素的降解;优化堆体的微生物生态,可激活并促进木质纤维素降解菌的生长繁殖;且投加菌剂的堆体中高温持续时间更长,有助于促进堆体中半纤维素、纤维素和木质素的降解[33-34]。因此,与空白相比,不同保藏时间的菌剂依旧能够有效促进堆体中半纤维素、纤维素和木质素的降解。随着菌剂保存时间的延长,堆体中半纤维素降解率分别为56.93%、41.91%、49.10%;纤维素降解率分别为29.03%、27.58%、31.45%;木质素降解率分别为18.12%、12.64%、17.02%;堆体中半纤维素、纤维素和木质素的降解率呈现先下降后上升的变化规律。

与复合微生物菌剂DN-1堆肥12 d后相比,自制复合微生物菌剂提高了半纤维素和木质素的降解率,半纤维素降解率分别提高了58.27%、16.51%、36.50%;木质素降解率分别提高了87.97%、31.12%、76.56%[35]。与复合微生物菌剂HJ相比,自制复合微生物菌剂提高了堆体中半纤维素和纤维素降解率,半纤维素降解率分别提高了244.61%、153.69%、197.22%,纤维素降解率分别提高了28.51%、22.09%、39.22%[36]。自制固态微生物菌剂具有较好的降解木质纤维素的能力。

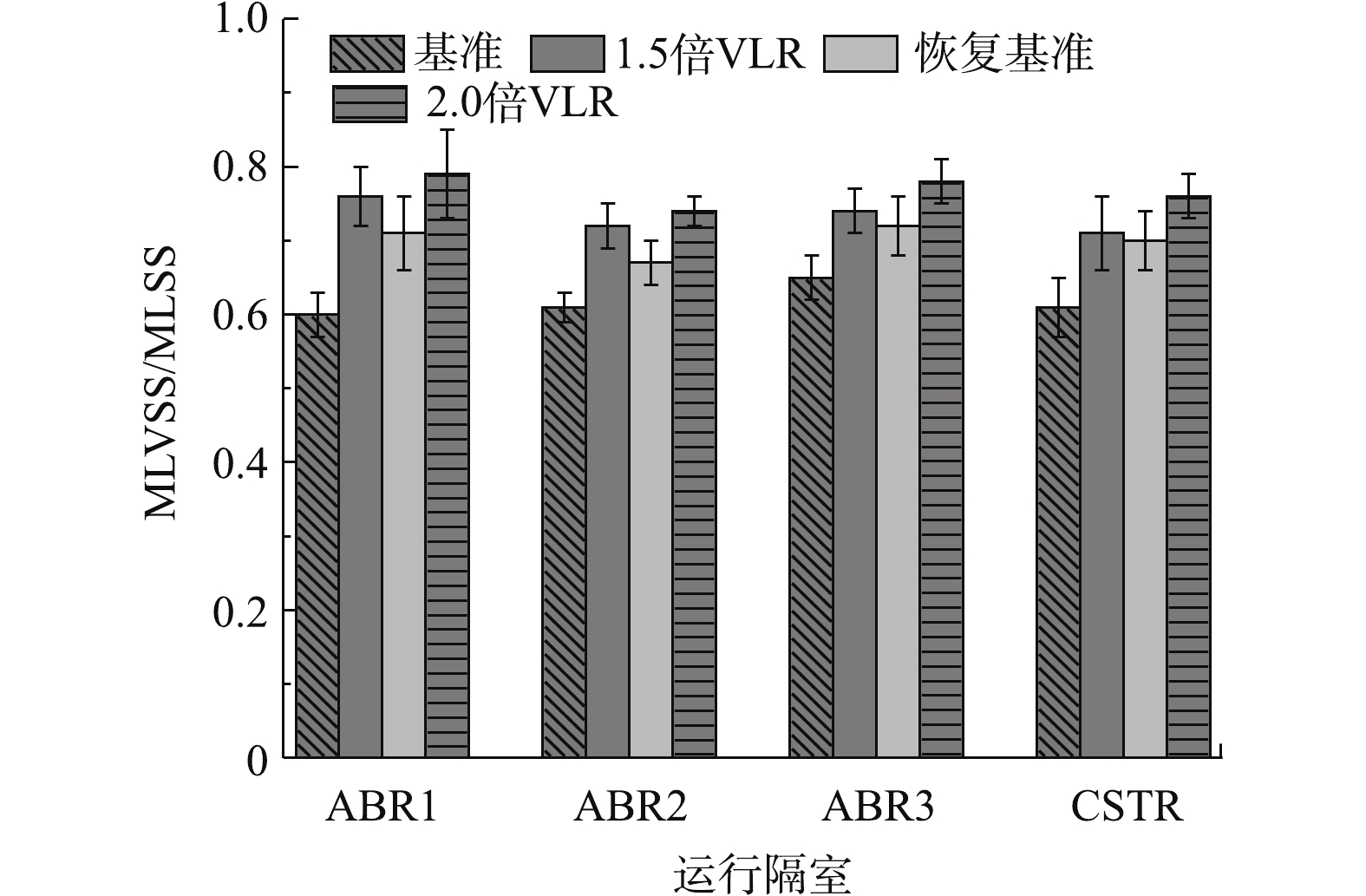

3)堆肥产品的品质。堆肥结束后,测定了各堆体中有机质含量、TKN、C/N、pH、含水率、蛔虫死亡率、粪大肠菌群数和GI,其结果如表5所示。

堆肥结束后,堆体CK、堆体ZJ、堆体ZJ-30、堆体ZJ-60中有机质含量分别为66.30%、58.67%、58.19%、57.56%,其降解率分别为24.05%、32.79%、33.34%、34.06%。投加菌剂的堆体中有机质降解率更高,这是由于其高温持续时间更长,嗜热菌活动剧烈,使得更多有机物被降解。与放线菌菌剂[33]相比,自制复合微生物菌剂提高了有机质降解率,降解率分别提高了20.55%、22.57%、25.22%。与堆肥初期(表2)相比,4个堆体中TKN即全氮含量均呈现上升趋势,添加自制复合微生物菌剂的3个堆体中全氮含量上升幅度更大。与勾云龙[37]制备的复合微生物菌剂相比,自制复合微生物菌剂中氮素含量分别提高了153.03%、255.93%、231.33%。表明自制复合微生物菌剂能够有效促进对氮素的吸收与利用,有利于堆肥产品保氮,提高堆肥产品的养分含量[12]。

采用不同保存时间的固态微生物菌剂进行好氧堆肥,所得堆肥产品的理化性质包括有机质及TKN的含量等均相差不大;蛔虫死亡率均大于95%,粪大肠菌群数均低于100 MPN·g−1,满足我国生物有机肥标准(NY 884-2012)中的生物学指标要求。同时,C/N比低于20,种子发芽指数均高于85%,完全腐熟。与常温微生物菌剂(36 d时C/N比低于20,30 d时GI高于50%)[19]相比,自制复合微生物菌剂能够缩短堆肥周期,提高堆体腐熟度。然而,由于高温持续时间不足,对照堆肥产品的卫生状况未能达到上述标准,且种子发芽指数较低。

2.1. 固态微生物菌剂的制备技术

2.2. 固态微生物菌剂的堆肥效果

-

1)固态微生物菌剂的最佳制备条件为以腐熟物料作为载体,投加4%的海藻糖,含水率为15%。

2)随保存时间的延长,固态微生物菌剂的性能稳定,均能在18~19 h左右促使堆体进入高温期,并有效促进堆体中半纤维素、纤维素和木质素的降解,所得堆肥产品的理化性质相差也不大,各项指标均符合我国生物有机肥标准(NY 884-2012)中的相关要求,且种子发芽指数均高于85%,完全腐熟。

3)所得固态微生物菌剂的制备方法有助于菌剂的大规模生产与应用,具有较为重要的实践价值。

下载:

下载: