-

随着人们环境保护意识的增强和国家环境保护政策的严格落实,城镇污水处理厂的数量逐年上升。现有城镇污水处理厂中,约90%采用活性污泥法,其中微生物对污水中氮磷的高效去除需有充足的有机物[1]。由于我国污水存在低C/N的特点,为保证出水氮磷达标排放,污水处理厂需投加大量外部碳源与除磷药剂,从而提高了污水处理厂的运行成本[2]。此外,日益严格的出水标准也进一步提高了污水处理厂的运行成本。因此,低运行成本的污水处理工艺成为研究热点。

生物絮凝系统内污泥微生物分泌的胞外蛋白,可有效将污水中悬浮态和颗粒态COD等难降解有机物絮凝,最终被截留的有机物和污泥可用于厌氧消化,转化为资源与能源物质[3-4]。张闻多等[5]研究发现,经热碱处理后的高有机质含量的剩余污泥厌氧发酵后,挥发性脂肪酸平均浓度为7.93 g·L−1。该挥发性脂肪酸可作为优质碳源,投加至厌氧池或缺氧池,从而降低污水处理厂的外部碳源消耗量,同时可保障污水处理工艺对氮磷污染物的高效去除。此外,生物絮凝系统可减小后续工艺因进水急剧变化而受到的影响,并为后续工艺提供稳定的低C/N进水。

低C/N的进水是反硝化除磷工艺的必要前提,其主要原因为:反硝化除磷工艺通过自养反硝化脱氮除磷,可节约50%的碳源消耗[6-8]。此外,反硝化除磷工艺可减少50%的污泥产量,并降低30%的曝气能耗[9],因此,反硝化除磷工艺的运行成本低于传统工艺。反硝化除磷工艺可分为单污泥工艺与双污泥工艺2类[10-11]。与双污泥工艺相比,单污泥工艺具有操作简便、应用范围广的特点,且与传统AAO工艺相比,AAAO工艺进水COD首先被用于缺氧反硝化过程,确保厌氧条件下释磷不受硝态氮(dissolved nitrates,

NO−3 -N)影响。此外,污泥厌氧消化后所产碳源可分点投加至该工艺厌氧池或缺氧池,从而强化脱氮除磷效能,降低污水处理过程外部碳源的使用量。因此,生物絮凝工艺与AAAO工艺相结合可降低污水处理过程中的能源消耗。本研究以城镇污水为对象,考察了中试规模下的生物絮凝-AAAO工艺对实际污水的去除效果。将模拟生物絮凝系统污泥厌氧发酵所产碳源投加至AAAO系统中,以期培养DPAO并强化该中试系统的污染物去除效能,进而为污水处理厂节能降耗与污泥资源化利用提供可借鉴的经验。

-

生物絮凝-AAAO系统所用污水为天津市某污水处理厂沉砂池出水,该厂采用特有除臭工艺将除臭污泥回流至进水泵房,使沉砂池出水SS(suspended solids)较高,沉砂池出水COD、TN、TP等指标随SS发生相似变化。此外,该污水处理厂上游有日处理量800 t的大型污泥处理厂,该厂所排废液含铝、铁等调理药剂污泥直接进入污水处理厂。中试系统进水水质及污泥发酵液成分具体参数见表1。

-

生物絮凝-AAAO工艺流程图如图1所示。中试装置主要构筑物包括生物絮凝池、一沉池、前缺氧池、厌氧池、缺氧池、好氧池和二沉池,有效容积分别为1、2.10、3.40、4.20和9.60 m3。生物絮凝池采用微曝气搅拌,其余均采用机械搅拌。中试系统所用电机、水泵、鼓风机均采用变频器控制。

生物絮凝-AAAO中试系统污水处理量50 m3·d−1。生物絮凝系统污泥回流比为100%,溶解氧(dissolved oxygen,DO)维持在0.30 mg·L−1左右。为控制该系统内污泥浓度,每日排泥量根据一沉池泥位确定,污泥龄(sludge retention time,SRT)为0.20~2 d。AAAO系统内回流比100%,外回流比80%,SRT为14 d,好氧池DO控制在3 mg·L−1左右。

-

化学需氧量(chemical oxygen demand,COD)、总氮(total nitrogen,TN)、氨氮(ammonia nitrogen,

NH+4 -N)、硝酸盐(nitrate,NO−3 -N)、总磷(total phosphorus,TP)与磷酸盐(dissolved phosphates,PO3−4 -P)采用标准方法[12]测定。反硝化过程碳氮消耗比测定方法。取8 L缺氧池活性污泥混合液,沉淀后撇去上清液,加入蒸馏水反复清洗3次,最终保留4 L泥水混合液。将4 L泥水混合液与4 L中试系统二沉池出水(COD低于20 mg·L−1,

NO−3 -N浓度约15 mg·L−1)混合。使用磁力搅拌器(DF-101T-10L,上海力辰仪器科技有限公司)对混合后的8 L水样搅拌,并用便携式溶氧仪(Multi3510,北京金洋万达科技有限公司)测定混合液DO,待混合液DO浓度降至0 mg·L−1后,将2 g乙酸钠(分析纯)加入混合液中,使混合液内COD升至145 mg·L−1以上。将乙酸钠加入混合液后,分别在0、5、10、20、30、45和60 min取20 mL混合液,使用0.45 μm玻璃纤维滤膜过滤水样,并测定滤后水样的COD和NO−3 -N浓度。反硝化吸磷过程氮磷消耗比测定方法。取8 L厌氧池活性污泥混合液,沉淀后撇去上清液,加入蒸馏水反复清洗3次,最终保留4 L泥水混合液,加入4 L中试系统二沉池出水(COD低于20 mg·L−1,

NO−3 -N浓度约15 mg·L−1),采用磁力搅拌器对混合后的8 L水样进行搅拌,使用便携式溶氧仪测定混合液DO,待混合液DO浓度降至0 mg·L−1后,分别在0、5、10、20、30、45和60 min取20 mL混合液,使用0.45 μm玻璃纤维滤膜过滤水样,并测定过滤后水样的PO3−4 -P、NO−3 -N浓度。碳源模拟污泥发酵液配置方法。污泥发酵液成分为:COD平均值40 002 mg·L−1、TN平均浓度459.50 mg·L−1、TP平均浓度13.1 mg·L−1。碳源模拟发酵液使用分析纯级的乙酸钠、磷酸二氢钾、氯化铵,按照COD∶TN∶TP为3 053.59∶35.08∶1配置。

缺氧池内TP、

PO3−4 -P、NO−3 -N浓度[13-15]按式(1)~式(4)计算。式中:C1为缺氧池内TP理论值,mg·L−1;C2为厌氧池内TP实际值,mg·L−1;C3为好氧池内TP实际值,mg·L−1;C4为缺氧池内TP实际值,mg·L−1;C5为前缺氧池内TP实际值,mg·L−1;R外为AAAO系统外回流比;R内为AAAO系统内回流比;η1为缺氧吸磷率;η2为好氧吸磷率;B为厌氧释磷率。

缺氧池内反硝化除磷氮磷消耗比按式(5)计算。

式中:F为缺氧池内反硝化除磷过程中的氮磷消耗比;D为实验过程中缺氧池内

NO−3 -N消耗量,mg·L−1;E为实验过程中缺氧池内TP消耗量,mg·L−1。AAAO系统释磷量与吸磷量之比按式(6)和式(7)计算。

式中:G为AAAO系统释磷量,mg·L−1;I为AAAO系统释磷量与吸磷量之比。

-

在图2中,生物絮凝系统进水COD、TP 、TN波动较大,进水

NH+4 -N波动较小,表明进水水质波动是由含COD、TP、TN的不可溶物质引起。生物絮凝系统出水较稳定,抗冲击能力较强。在图2(a)中,生物絮凝系统具有较好的有机物截留效果,其主要原因是微生物在低DO条件下具有大量吸收与贮存有机物的能力[16]。生物絮凝系统进水COD平均值为417.75 mg·L−1,出水COD平均值为117.45 mg·L−1,平均去除率67.23%。在图2(b)中,生物絮凝系统进水TN的平均浓度为44.17 mg·L−1,出水TN平均浓度为32.29 mg·L−1,TN平均去除效率为27%。由于生物絮凝系统DO浓度在0.30 mg·L−1以下,因此,该系统对NH+4 -N基本无去除效果,NH+4 -N平均去除率为2.91%。在图2(c)中,生物絮凝系统进水TP平均浓度为14.55 mg·L−1,出水TP平均浓度为4.52 mg·L−1,TP平均去除率为68.93%。生物絮凝系统除磷效果较好的原因是:生物絮凝系统进水含部分除磷药剂,除磷药剂通过网捕、吸附架桥等作用吸附进水非溶解性与溶解性磷并形成絮体[17]。生物絮凝系统通过微生物的物理吸附与化学药剂的絮凝作用,对COD、TN和TP均有较好的吸附截留效果,该系统出水C/N为3.64。低C/N污水结合适宜的污水处理工艺,可用于驯化DPAO[18]。

-

AAAO系统进水为生物絮凝系统出水,该系统进水COD、TP、TN与

NH+4 -N等指标变化较小,受到冲击负荷影响的风险较低。在AAAO系统DO、pH等参数均无异常条件下,COD、TN和TP等污染物由该系统内微生物去除。由图3可知,AAAO系统出水COD满足一级A出水标准,但出水TN和TP明显超出一级A出水标准。在图3(a)和图3(c)中,AAAO系统出水COD、TP平均浓度分别为27.35 mg·L−1与3.11 mg·L−1,平均去除率为75.82%与33.63%。图3(b)中,AAAO系统硝化效果较好,出水NH+4 -N平均浓度为0.10 mg·L−1,平均去除率为99.67%。但该系统反硝化效果较差,出水TN平均浓度为21.85 mg·L−1,平均去除率仅为31.63%。生物脱氮是通过微生物硝化与反硝化作用实现,其中反硝化作用需以碳源为电子供体将NO−3 -N还原为氮气。生物除磷则是是通过聚磷菌(phosphate accumulating organisms,PAOs)厌氧池内消耗COD后释磷,而后在曝气池内过量吸磷得以实现[19]。因此,AAAO系统生物脱氮除磷效率较低与进水COD较低有关。综上所述,在进水C/N较低的条件下,厌氧池与缺氧池内厌氧释磷、缺氧反硝化效率较低,AAAO系统自身生物脱氮除磷效果受到抑制。此外,较低厌氧释磷效率,也将提高DPAO的驯化难度。

-

虽然生物絮凝-AAAO中试系统进水水质波动较大,但生物絮凝系统出水水质波动较小,这为DPAO的培养提供了稳定的进水条件。DPAO的培养需保证厌氧池内微生物有较好的厌氧释磷效果,并且缺氧池内

NO−3 -N、DO和COD的浓度均应较低。由前述2.2节内容可知,AAAO系统进水C/N较低,无法为厌氧池内微生物厌氧释磷提供所需有机物,因此需以模拟生物絮凝污泥厌氧发酵后的有机酸为碳源,并将其适量投加至厌氧池以促进DPAO的驯化。 -

活性污泥系统反硝化去除1 mg的

NO−3 -N需消耗有机物量由各系统内微生物的异样产率系数决定,而活性污泥系统异样产率系数受外界环境影响较大,实际反硝化过程有机物消耗量稍有差异[20-21]。因此,AAAO系统的实际COD与NO−3 -N消耗之比需通过实验确定。如图4所示,在COD充足的条件下,AAAO系统内微生物反硝化过程中COD与NO−3 -N消耗比为4.5∶1。通过长期监测发现,前缺氧池中NO−3 -N的浓度在5~9 mg·L−1范围内波动,在碳源不足条件下,厌氧池中较高浓度的NO−3 -N影响厌氧释磷速率[22]。为保证厌氧池PAOs释磷效率,将50 mg·L−1模拟碳源投加至厌氧池进水口处。结合图3可知,投加模拟碳源后AAAO系统进水C/N、C/P分别升高至5.18与37.04。 -

图5为模拟碳源投加第0、10、20天3次全流程测试结果对比。由图5(a)可知,AAAO系统在投加模拟碳源后前缺氧池与厌氧池对COD去除效果有明显改善,二沉池出水COD值进一步降低。投加的模拟碳源分别参与厌氧池内PAOs释磷与反硝化细菌脱氮过程。在此过程中,厌氧池内COD并未明显升高,表明模拟碳源投加量并未超出厌氧池内微生物实际需求。如图5(b)所示,AAAO系统出水TN明显降低,该系统生物脱氮效率较投加模拟碳源前提升了37.67%,反硝化过程主要发生在前缺氧池与厌氧池。此外,第10天和第20天的二沉池出水TN浓度均低于15 mg·L−1,满足一级A出水标准。图5(c)中,AAAO系统在投加模拟碳源后厌氧池内聚磷菌释磷率最高可达167%,随着厌氧释磷效果改善,好氧池内PAOs出现过量吸磷现象。第10天和第20天好氧吸磷率平均为49.78%与66.4%,AAAO系统总磷去除率分别为83.93%与90.27%。

由图5(b)可知,第10天缺氧池内

NO−3 -N浓度低于3 mg·L−1,经核算发现缺氧池出现异养反硝化现象,为降低所投模拟碳源对缺氧池的影响;从第11天开始,将AAAO系统内回流比由100%升至200%,模拟碳源投加量降至40 mg·L−1。由第20天全流程测试结果可知,采取的调节措施效果明显,缺氧池内NO−3 -N由1.40 mg·L−1升至7.60 mg·L−1,缺氧池出现氮、磷同步下降现象;第20天缺氧池吸磷率为44.57%,缺氧池内氮磷消耗比为1∶0.56。综上所述,投加模拟碳源后AAAO系统运行效果明显改善,COD、TN和TP去除率最高可达76.15%、57.43%和90.27%,氨氮去除率基本可达100%,出水COD和TP可稳定达到一级A出水标准,TN存在超标风险。与之类似的现象还出现在A2N-SBR反硝化除磷系统中,在低C/N条件下,该系统TN去除率仅66%,而

PO3−4 -P去除率可维持在88%[23]。结合全流程测试结果可知,AAAO系统缺氧池内反硝化效率较低,若需进一步提高AAAO系统脱氮效率,可提高进水C/N或将部分模拟碳源投加至缺氧池。 -

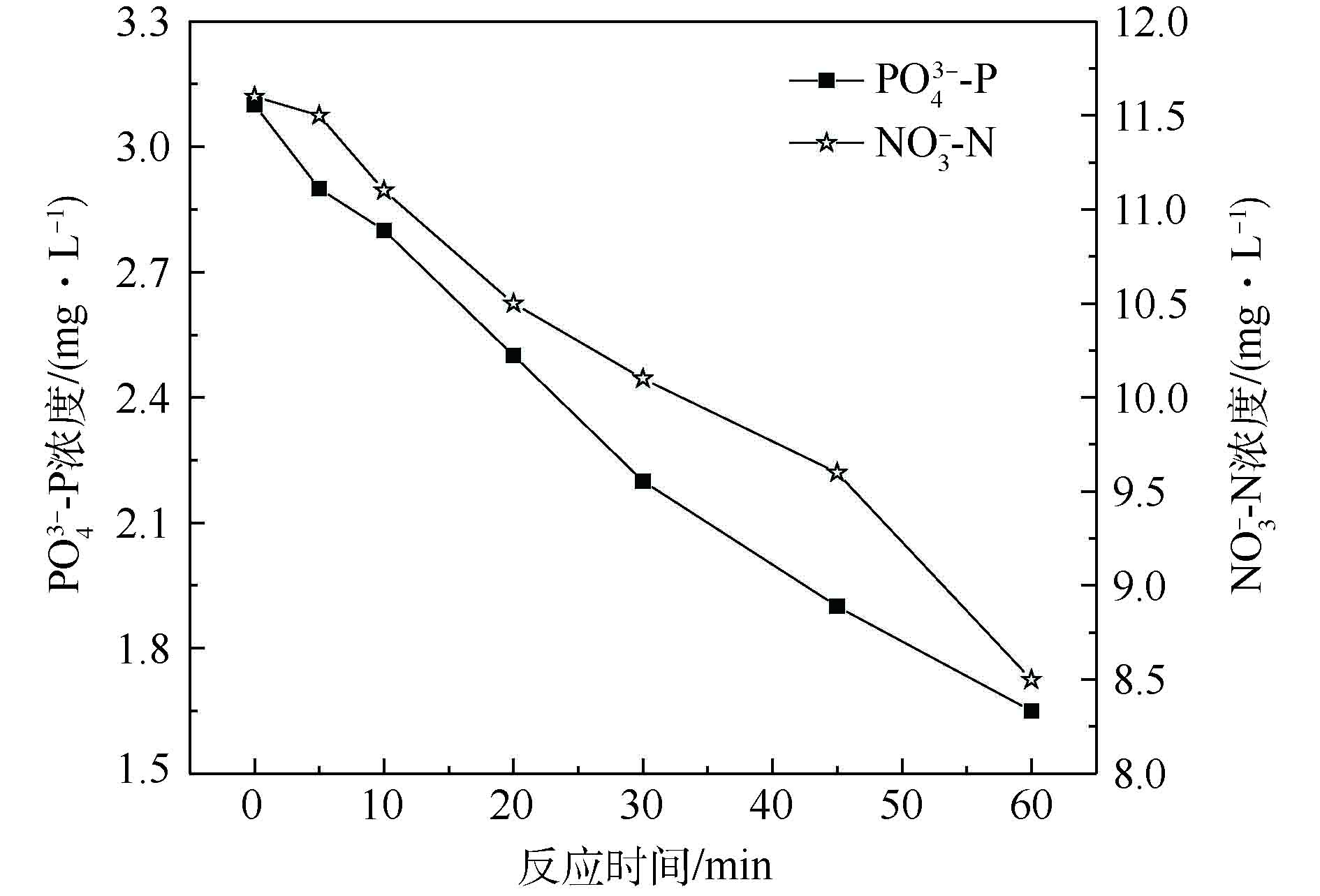

如图6所示,缺氧池内TP浓度下降是DPAO缺氧吸磷所致,

PO3−4 -P浓度和NO−3 -N浓度分别降低1.45 mg·L−1与3.10 mg·L−1。KERRN等[24]在研究固定生物膜反应器反硝化除磷系统时,发现缺氧池氮磷消耗比为1∶2,而AAAO系统缺氧池内氮磷消耗比为1∶0.47。缺氧池内反硝化除磷过程中氮磷消耗比分别由缺氧池内氮磷比例关系与系统内DPAO菌群数量决定。由于AAAO进水PO3−4 -P浓度较低,导致缺氧池内PO3−4 -P浓度较低,因此,缺氧池内DPAO氮磷消耗比与生物膜反应器中所测值存在一定差距。AAAO系统不同时间除磷效果及缺氧池和好氧池吸磷率如图7所示。随着AAAO系统运行时间的延长,厌氧池释磷率逐渐升高,反硝化吸磷率由34.86%升至62.97%并趋于稳定,好氧吸磷率稳定在34%,AAAO系统TP去除率可达96.97%。厌氧释磷水平的高低决定了系统的除磷能力。随着厌氧池内PAOs释磷率逐渐升高,出水TP浓度由初始0.4 mg·L−1降至0.18 mg·L−1。有研究发现,除磷过程中PAOs厌氧释磷量与好氧吸磷量之比为1∶2.96[25],AAAO系统释磷量与吸磷量之比平均值仅为1∶1.27。这是由于工艺系统和运行条件的不同,使污泥微生物菌群结构和代谢特性存在差异[26-27]。因此,不同系统实际厌氧释磷量与好氧吸磷量之比也存在一定差异。

-

1)生物絮凝系统出水COD、TN和TP的平均浓度分别为117.45、32.29和4.52 mg·L−1,平均去除率达67.23%、27%和68.93%。未补充模拟碳源前,AAAO系统在出水COD、TN和TP的平均浓度仅为27.35、21.85和3.11 mg·L−1,平均去除率达75.82%、31.63%和33.63%。

2)通过模拟生物絮凝污泥厌氧发酵后的有机酸为碳源,将其适量投加至厌氧池强化生物释磷后,可实现DPAO的培养培养工作。投加碳源后AAAO系统对进水COD、TN和TP的去除率分别提高31.53%、37.67%与26.37%,缺氧吸磷率达62.97%,好氧吸磷率达31.59%,最终出水TP可降至0.18 mg·L−1。

3)生物絮凝-AAAO中试系统所产高有机质剩余污泥资源化产生的优质碳源可辅助DPAO的培养并强化生物系统的脱氮除磷效果,从而降低污水处理过程资源与能源消耗量,为污水处理厂的碳中和与节能减排等研究奠定基础。

生物絮凝-AAAO中试系统污染物去除特性及反硝化除磷菌的培养

Contaminant removal characteristics of bioflocculation-AAAO pilot system and cultivation of denitrifying polyphosphate-accumulating organisms

-

摘要: 为降低污水处理成本并实现出水稳定达标,采用中试规模生物絮凝-AAAO工艺处理城镇生活污水,并模拟生物絮凝污泥厌氧消化所产生的碳源,用于强化反硝化除磷菌(DPAO)驯化效果。实验结果表明:生物絮凝系统抗冲击负荷能力较强,化学需氧量(COD)、总氮(TN)和总磷(TP)平均去除率可达67.23%、27%与68.93%。将模拟厌氧消化后产生的碳源投加至厌氧池促进DPAO的驯化后,AAAO系统对COD、TN和TP去除率分别提升31.53%、37.67%和26.37%,反硝化吸磷率最高可达62.97%,二沉池出水COD、TN均满足一级A出水标准,TP可低于0.30 mg·L−1。生物絮凝-AAAO工艺脱氮除磷效果较好,可为污水处理厂节能降耗运行奠定基础并有望得到广泛应用。Abstract: In order to reduce the operation cost and achieve good effluent, the pilot-scale bioflocculation-anoxic-anaerobic-anoxic-oxic(AAAO) process was established to cultivate denitrifying polyphosphate-accumulating organisms(DPAOs) and further enhance phosphorus removal by adding simulative carbon source from bioflocculation sludge through anaerobic digestion(AD) process. The experimental results showed that the bioflocculation process presented good resistance to shock loads, and the average removal rates of chemical oxygen demand(COD), total nitrogen(TN) and total phosphorus(TP) were 67.23%, 27% and 68.93%, respectively. After dosing carbon source produced from simulative anaerobic digestion to anaerobic tank, and DPAO acclimation was promoted, then the COD, TN and TP removal rates of AAAO system increased by 31.53%, 37.67% and 26.37%, respectively. In addition, the maximum phosphorus uptake rate during denitrification process was up to 62.97%, and the TN and COD in effluent of secondary tank could meet the Class A of National Effluent Standard, the effluent TP even decreased to below 0.30 mg·L−1. The pilot-scale bioflocculation-AAAO process demonstrated a good nitrogen and phosphorus removal capacity, which can lay a foundation for energy-saving and cost-reducing operation of wastewater treatment plants, and is expected to be widely promoted.

-

现代城市中由VOCs引发的污染问题已引起人们广泛关注,不仅会导致O3污染等问题,还对人体健康造成危害。目前,国内学者[1-3]针对O3污染来源、VOCs排放对O3的影响开展了大量研究,但不同城市大气中VOCs的排放来源差异较大,使得各种组分的浓度水平、化学反应活性差别非常大,因此找出城市的关键物种并归溯其来源,才能对症下药,精细化管控。为了解大连市VOCs浓度水平及各物种化学反应活性,找出导致我市夏季臭氧浓度高的活性组分,本研究对大连市区2019年5~8月份大气VOCs的组分及浓度进行了监测,并分析了VOCs月变化特征,对VOCs各物种的化学反应活性进行评估,最终利用PMF模型解析的方法推算出大连市夏季VOCs的污染排放来源及贡献率。

1. 监测与分析

1.1 采样时间和地点

大连市地处欧亚大陆东岸,辽东半岛最南端,位于东经120°58′~123°31'、北纬38°43′~40°10′之间,大连属三面环海,属海洋性季风气候,夏季以偏南风为主。夏季为大连市臭氧污染高发季节,近年自5月开始,臭氧持续升高并取代PM2.5成为夏季首要污染物。

本研究针对2019 a夏季臭氧浓度较高月份(5~8月),连续测定大气中VOCs的浓度,设置1个监测点位,位于辽宁省大连生态环境监测中心4层楼顶(东经121°33′49″,北纬38°53′04″),距地面高度大约为15 m,在这个高度上污染物基本混合均匀。该点位毗邻国控点位星海三站,离中山路主干路较近,车流量较密集,周边环境以学校、行政办公、医院和居住区为主,机动车流量等各方面都具有很好的代表性,监测数据可以反映大连市区综合环境质量状况。

1.2 样品采集

在本次监测过程中,采用Synspec GC955-611/811臭氧前驱体(VOCs)在线气相色谱仪持续观测环境空气中VOCs,GC955臭氧前驱体分析系统由低碳(C2-C5)分析仪和高碳(C6-C12C)分析仪两套仪器组成。根据VOCs在线监测相关质控规定,为保证数据的有效性,仪器采集率尽可能接近100%,有效性不低于80%,每周使用标准气体对系统校正,保证仪器稳定持续运行,工作人员每日对VOCs数据进行审核,保障数据完整可靠。

1.3 PMF源解析方法

由芬兰赫尔辛基大学Paatero教授和Tapper于1993年提出的正矩阵因子分解法,是一种被广泛的应用于大气环境中颗粒物及VOCs来源解析研究中[4-7]的多元统计分析方法。本研究应用PMF源解析,在监测出的37种物质中,剔除了无效数据和浓度长期低于检出限的物种,另外一些化学性质活泼的物质也不参与解析,以下为具体物种选择原则及因子数目设定原则,模型解析的不确定度参照文献[8]确定。

1.3.1 物种选取原则

①浓度较小的物种不纳入计算;②校准相对误差超过允许范围的组分不纳入计算;③大气光化学活性强、大气存留寿命较短的组分不纳入计算;④异常样本、零值多且浓度较低以或偏离平均值严重的VOCs组分均予以删除。

1.3.2 因子数目设定原则

PMF分析至少需要4个因子数;在该因子数目下,所有因子都具有实际物理意义,都对应大气中的某一排放源活化学过程。

参数设定及模拟结果如下:

使用EPA PMF5.0版本模型进行源解析,经过多次试验尝试,确定5个因子,物质22种(bad:2,4-二甲基戊烷,反-2-丁烯,正己烷,环己烷、2-甲基戊烷、3-甲基己烷、2,2,4-三甲基戊烷、2,3,4-三甲基戊烷;week:正戊烷)。

2. 结果分析

2.1 浓度水平分析

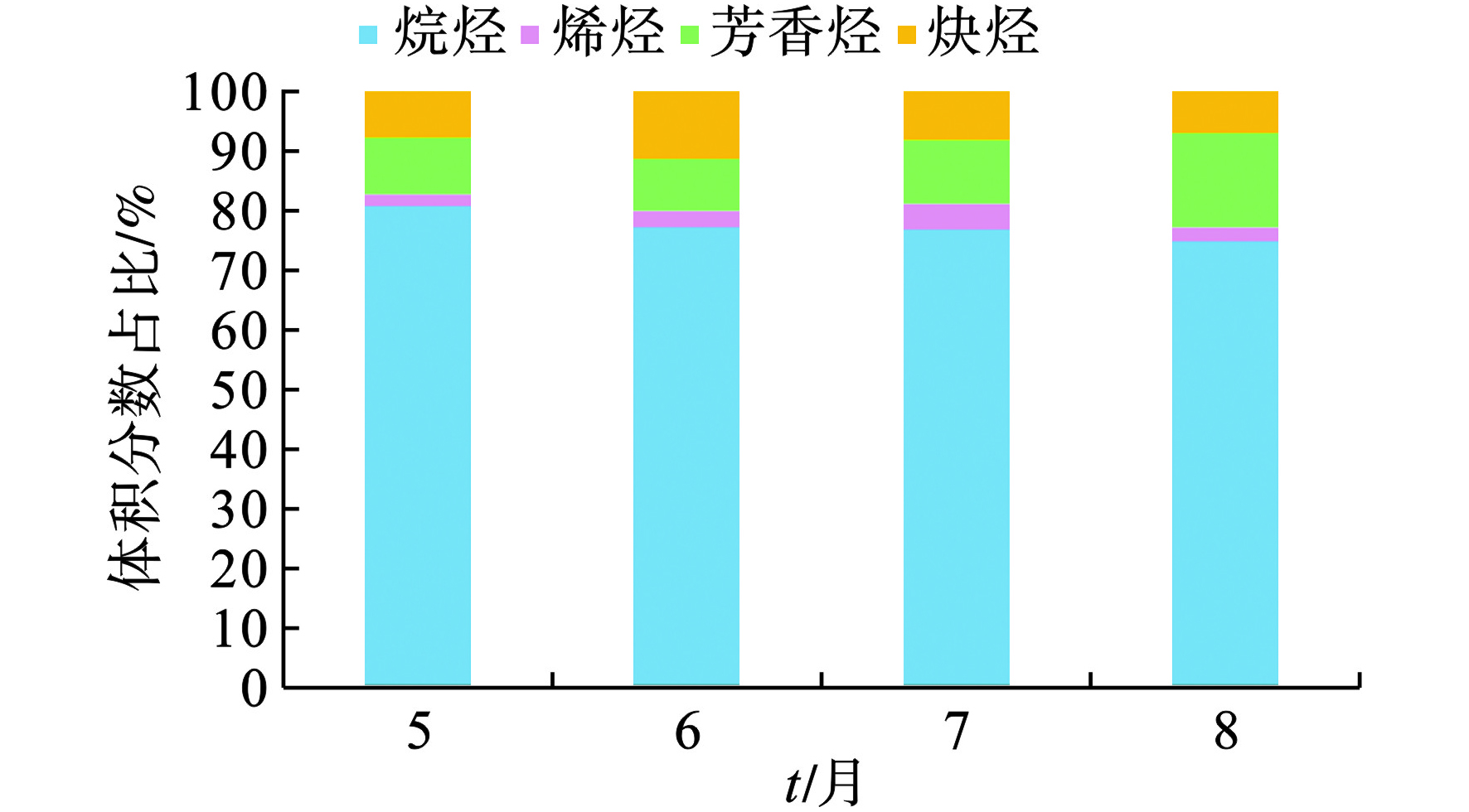

本研究共检出37种挥发性有机化合物,其中烷烃20种,烯烃8种,芳香烃8种,炔烃1种。大连市夏季VOCs平均体积分数为6.87×10−9,从VOCs组分体积分数来看,烷烃>芳香烃>炔烃>烯烃,分别占总量的77.0%、11.9%、8.4%和2.7%。

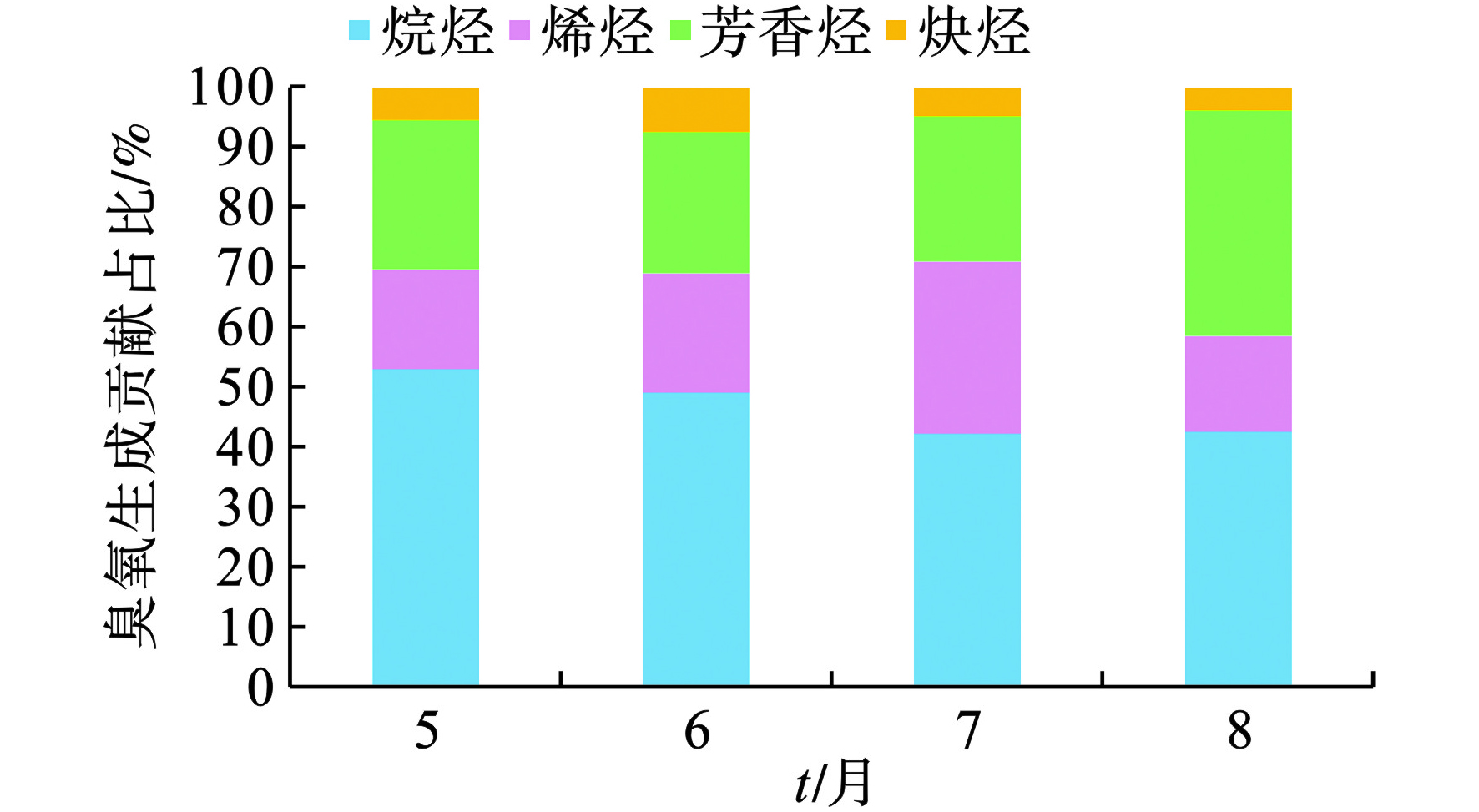

各月组分占比略有不同,其中烷烃占比最大(74.7%~80.6%),其次为芳香烃(8.8%~16.0%)、炔烃(6.9%~11.4%)和烯烃(2.0%~4.1%),见图1。

从夏季各月浓度变化情况来看,5月份VOCs平均体积分数最低,为5.59×10−9,主要成分依次为烷烃、芳香烃、炔烃和烯烃;6月、7月平均体积分数略微升高,分别为6.30×10−9和5.90×10−9,各组分体积分数变化较稳定,依然以烷烃为主,其他3种组分浮动变化较小。8月大连市平均气温较5~7月平均温度有所升高,VOCs在高温情况下其挥发性更为活跃,VOCs体积分数升高,为9.71×10−9,其中,烷烃和芳香烃有明显升高,炔烃和烯烃则变化较小。烷烃是大连市城区环境空气中含量最高的VOCs,这些物质主要来自机动车排放及燃料挥发等,与2018年同期相比,各月VOCs体积浓度下降显著,下降幅度分别为63.3%、68.3%、54.2%和65.9%,其中6月降幅最大。

2.2 活性水平分析

大气有机物化学反应活性是指某一有机物通过反应生成产物或者生成臭氧的潜势(OFP),OFP计算方法以CARTER[9]研究给出的最大增量反应活性(max incremental reactivities,MIR)的修正值计算臭氧生成潜势(OFP)。OFP为某VOCs化合物环境体积分数与该VOCs的MIR系数的乘积,计算见式(1)。

OFPi=MIRi×[VOCs]i (1) 式(1)中:

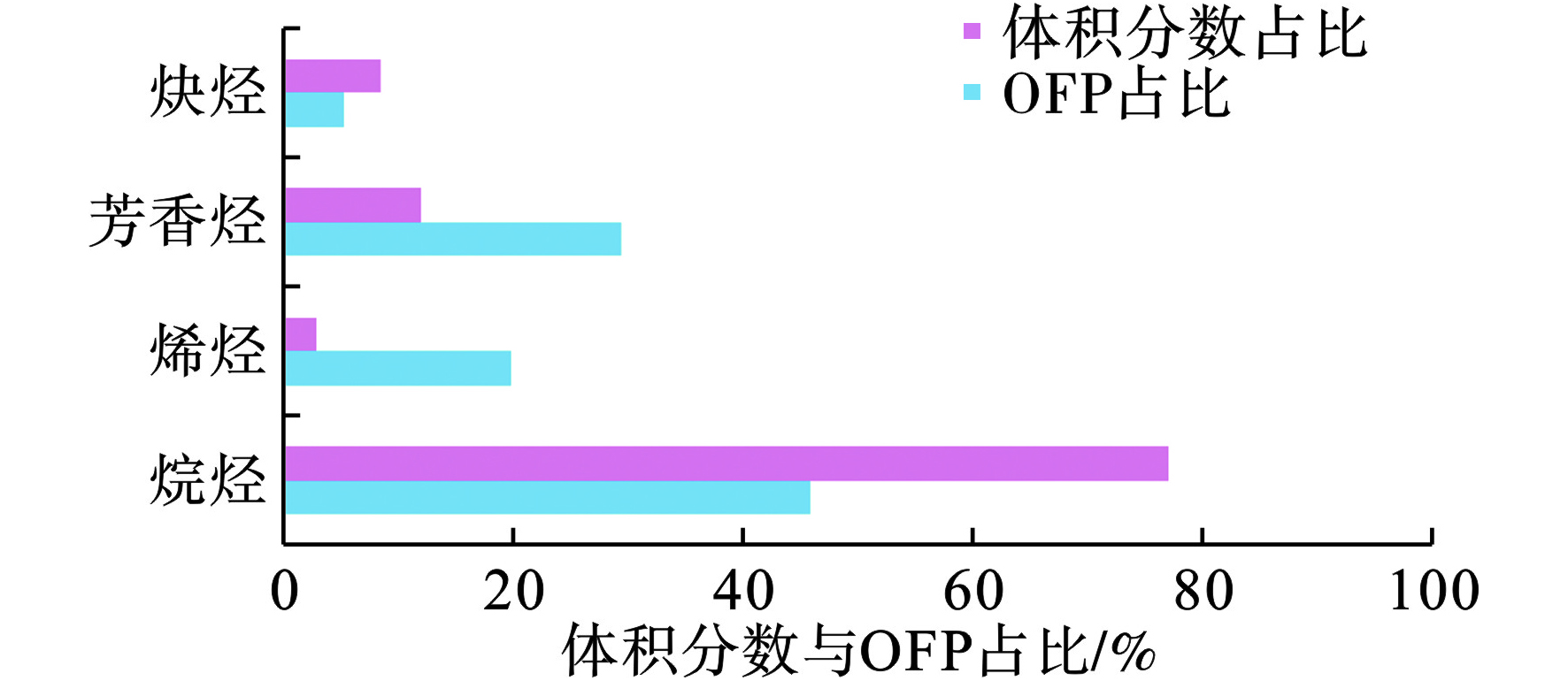

[VOCs]i 表示实际观测中的某VOCs大气环境浓度,单位为×10−9,MIRi 用Carter研究所得的MIR系数。根据OFP的计算结果可知,夏季大连市大气中VOCs平均化学反应活性浓度为10.64×10−9,5月最低,活性浓度为7.35×10−9,8月最高,活性浓度为16.42×10-9。从活性组分来看,烷烃占比最大且月变化较为稳定,其次为芳香烃和烯烃,炔烃占比最低,各类组分占比分别为45.8%、29.3%、19.8%和5.1%。7月份烯烃占比有所升高,8月份则芳香烃占比明显增加,见图2。

各组分体积分数和化学反应活性水平并不完全成正比,由于烯烃较为活泼,在浓度较低的情况下,其活性水平大于炔烃,见图3。

2.3 关键物种分析

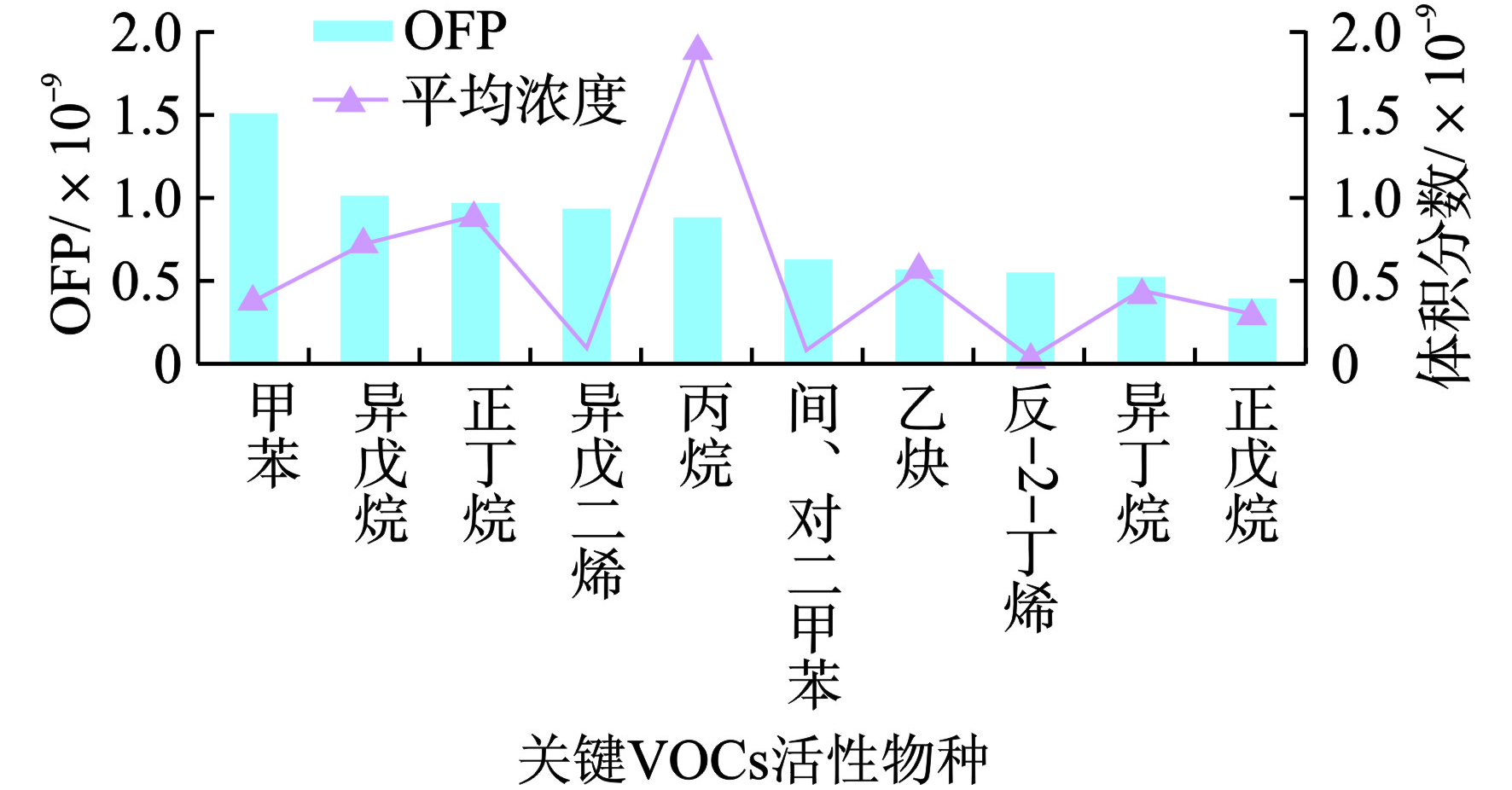

监测结果显示,大连市VOCs体积浓度最高的前10种物质占VOCs总体积分数的比例为丙烷>正丁烷>异戊烷>乙炔>异丁烷>甲苯>正戊烷>正己烷>癸烷>苯,累计占VOCs总浓度的86.3%,优势物种为烷烃、芳香烃和炔烃等。

根据OFP计算方法得出,大连市大气中活性浓度最高的前10种物质依次是甲苯>异戊烷>正丁烷>异戊二烯>丙烷>间、对二甲苯>乙炔>反-2-丁烯>异丁烷>正戊烷,累计占VOCs的79.1%。其中排在前三位的甲苯、异戊烷和正丁烷的体积浓度占TVOC的29.3%,各物质浓度与OFP并不完全成正比,关键VOCs活性物种浓度与OFP对比见图4。

2.4 污染来源分析

对筛选出的22种物质,利用PMF模型来进行源解析研究,经过反复尝试最终确定了5类因子。

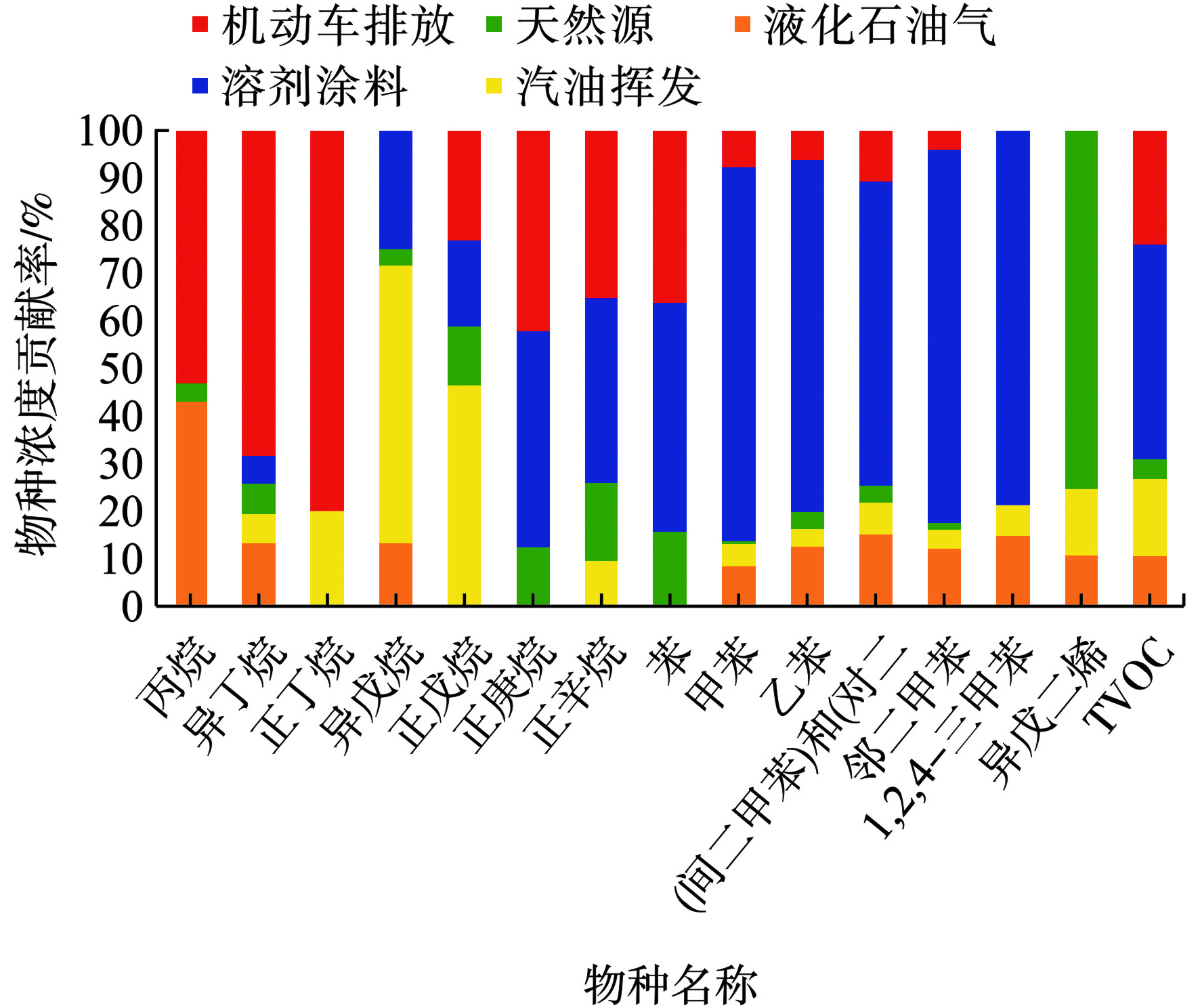

因子1富含正丁烷、异丁烷、苯等烷烃及芳香烃类,是机动车排放的表征物质,因此推断因子1为机动车排放源[10]。因子2中甲苯、邻二甲苯、1,2,4-三甲苯、乙苯的浓度占总浓度的80%以上,这些物质为重要的溶剂表征物质[11],因而判断因子2为溶剂涂料源。因子3中异戊二烯含量占比达到76%,考虑夏季异戊二烯主要来自植被排放,其排放强度受光照和温度影响较大,为天然植物源排放的重要特征物质,其他物种含量相对较低,故判断因子3为天然源。因子4中占比较高的有异戊烷、正戊烷、正丁烷、异丁烷等汽油蒸汽挥发的特征物种[12],因此判断因子4应为汽油挥发源。因子5中含有液化石油气表征物质丙烷、正丁烷和异丁烷[13]等,因此说明该因子很有可能是液化石油气排放源。

VOCs源解析显示,因子1为机动车排放源,因子2为溶剂涂料,因子3为天然源,因子4为油气挥发,因子5为液化石油气,PMF源解析结果见图5。

通过PMF模型结果得出,2019年5月−8月大连市VOCs主要来源来自涂料/溶剂使用(45.1%)、机动车排放(24.0%)、油气挥发(16.1%)、液化石油气(10.7%)、天然源(4.0%)。

通过对比各月VOCs污染来源贡献,大连市城区夏季VOCs溶剂涂料类贡献占比最大,贡献率范围在42.3%~44.5%;其次为机动车排放,贡献率范围在13.8%~23.2%;再次为燃料挥发类,贡献率在17.7%~23.4%;天然源贡献率占比在4.2%~7.1%。各月VOCs物种浓度和保留物种不完全一致,因此源解析的因子种类偶有差异,从总体来看,溶剂涂料和机动车排放是对大连市夏季VOCs贡献率最大的两个因子。

3. 结论

1)本研究共检出37种挥发性有机化合物,其中烷烃20种,烯烃8种,芳香烃8种,炔烃1种。各类组分体积浓度百分比从大到小排序为:烷烃>芳香烃>炔烃>烯烃,并且各组份含量有明显的差别;与2018 a同期相比,各月VOCs浓度下降显著,其中6月VOCs浓度下降幅度最大,为68.2%。

2)各类组分OFP百分比从大到小排序为:烷烃>芳香烃>烯烃>炔烃,其中烷烃臭氧生成潜势占比达45.8%,烯烃浓度最低,但由于化学性质较活泼,其臭氧生成贡献反而高于炔烃。

3)VOCs体积浓度排名前10的物种中烷烃浓度占比最高对臭氧生成贡献也最大;其次为芳香烃,其中甲苯臭氧生成贡献最大。

4)PMF模型源解析显示,2019年5月~8月大连市VOCs主要来源来自涂料/溶剂使用(45.1%)、机动车排放(24.0%)、油气挥发(16.1%)、液化石油气(10.7%)、天然源(4.0%)。

-

表 1 中试系统进水水质及污泥发酵液成分

Table 1. Pilot system influent water quality details and composition of sludge fermentation broth

统计值 COD TN NH4+-N TP SS Al Fe 进水浓度范围 245~852 34.46~54.99 26.95~41.31 6~32 400~2 400 2~10 2~8 进水平均浓度 417.50±177.89 44.17±6.20 33.48±4.03 14.04±6.96 1 362.50±740.54 5±0.12 3±0.15 -

[1] 戴晓虎. 我国城镇污泥处理处置现状及思考[J]. 给水排水, 2012, 38(2): 1-5. doi: 10.3969/j.issn.1000-4602.2012.02.001 [2] LEE W S, CHUA A S M, YEOH H K, et al. A review of the production and applications of waste-derived volatile fatty acids[J]. Chemical Engineering Journal, 2014, 235(1): 83-99. [3] 郝晓地, 李季, 曹达啟. 污水处理碳中和运行需要污泥增量[J]. 中国给水排水, 2016, 32(12): 1-6. [4] 潘宁, 石淑倩, 柯崇宜, 等. 吸附生物降解法(AB工艺)A段反应机理分析[J]. 环境工程, 2000, 18(4): 21-23. doi: 10.3969/j.issn.1000-8942.2000.04.006 [5] 张闻多, 余雷, 刘和, 等. 工程规模下碱类型对污泥预处理效果及发酵产酸的影响[J]. 环境工程学报, 2018, 12(5): 1517-1527. [6] KUBA T, LOOSDRECHT M C M V, HEIJNEN J J. Biological dephosphatation by activated sludge under denitrifying conditions pH influence and occurrence of denitrifying dephosphatation in a full-scale wastewater treatment plant[J]. Water Science & Technology, 1997, 36(12): 75-82. [7] ZENG W, WANG X, LI B, et al. Nitritation and denitrifying phosphorus removal via nitrite pathway from domestic wastewater in a continuous MUCT process[J]. Bioresource Technology, 2013, 143: 187-195. doi: 10.1016/j.biortech.2013.06.002 [8] ZHANG Y, LI M, ZHANG Q, et al. Start-up performance of anaerobic/aerobic/anoxic-sequencing batch reactor (SBR) augmented with denitrifying polyphosphate-accumulating organism (DPAO) and their gene analysis[J]. Water Science Technology, 2018, 78(3/4): 523-533. [9] ZHANG M, YANG Q, ZHANG J, et al. Enhancement of denitrifying phosphorus removal and microbial community of long-term operation in an anaerobic anoxic oxic-biological contact oxidation system[J]. Journal of Bioscience and Bioengineering, 2016, 122(4): 456-466. doi: 10.1016/j.jbiosc.2016.03.019 [10] 张淼, 彭永臻, 张建华, 等. 进水C/N对A2/O-BCO工艺反硝化除磷特性的影响[J]. 中国环境科学, 2016, 36(5): 1366-1375. doi: 10.3969/j.issn.1000-6923.2016.05.014 [11] LIU H, CHEN P, CHEN Z. Role of influent split ratio in a two-line BNR process performing denitrifying phosphorus removal[J]. Chemical Engineering Journal, 2015, 267: 266-273. doi: 10.1016/j.cej.2015.01.036 [12] 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境科学出版社, 2002. [13] SUN L, ZHAO X, ZHANG H, et al. Biological characteristics of a denitrifying phosphorus-accumulating bacterium[J]. Ecological Engineering, 2015, 81(1): 82-88. [14] LU Q, QIAN W, LIU W, et al. A fluorescence in situ hybridization method for the measurement of denitrifying phosphorus-accumulation organisms and study on the metabolisms of activated sludge[J]. Journal of Cleaner Production, 2017, 152(1): 28-37. [15] 黄剑明, 赵智超, 郑隆举, 等. 低温下A2/O-BAF反硝化除磷脱氮特性[J]. 环境科学, 2018, 39(10): 4621-4627. [16] CECH J S, HARTMAN P. Competition between polyphosphate and polysaccharide accumulating bacteria in enhanced biological phosphate removal system[J]. Water Research, 1993, 27(7): 1219-1225. doi: 10.1016/0043-1354(93)90014-9 [17] 宋志伟. 水污染控制工程[M]. 北京: 中国矿业大学出版社, 2013. [18] LV X, LI J, SUN F, et al. Denitrifying phosphorus removal for simultaneous nitrogen and phosphorus removal from wastewater with low C/N ratios and microbial community structure analysis[J]. Desalination and Water Treatment, 2014, 57(4): 1890-1899. [19] ONG Y H, CHUA A S M, HUANG Y T, et al. The microbial community in a high-temperature enhanced biological phosphorus removal (EBPR) process[J]. Sustainable Environment Research, 2016, 26(1): 14-19. doi: 10.1016/j.serj.2016.04.001 [20] KIM M G, NAKHLA G. Comparative performance of A2/O and a novel membrane-bioreactor-based process for biological nitrogen and phosphorus removal[J]. Water Environment Research, 2010, 82(1): 69-76. doi: 10.2175/106143009X447966 [21] VANDEKERCKHOVE T G L, DE MULDER C, BOON N, et al. Temperature impact on sludge yield, settleability and kinetics of three heterotrophic conversions corroborates the prospect of thermophilic biological nitrogen removal[J]. Bioresource Technology, 2018, 269(1): 104-112. [22] 田文德. BBSNP工艺性能及反硝化聚磷菌除磷特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2013. [23] WANG Y, PENG Y, STEPHENSON T. Effect of influent nutrient ratios and hydraulic retention time (HRT) on simultaneous phosphorus and nitrogen removal in a two-sludge sequencing batch reactor process[J]. Bioresource Technology, 2009, 99(14): 3506-3512. [24] KERRN J, JENS P, HENZE M. Biological phosphorus uptake under anoxic and aerobic conditions[J]. Water Research, 1993, 27(4): 617-624. doi: 10.1016/0043-1354(93)90171-D [25] 罗富金. 螺旋升流式反应器脱氮除磷效果及污泥特性的试验研究[D]. 重庆: 重庆大学, 2004. [26] 曾薇, 李博晓, 王向东, 等. MUCT短程硝化和反硝化除磷系统中Candidatus Accumulibacter的代谢活性和菌群结构[J]. 中国环境科学, 2013, 33(7): 1298-1308. [27] 戴娴, 王晓霞, 彭永臻, 等. 进水C/N对富集聚磷菌的SNDPR系统脱氮除磷的影响[J]. 中国环境科学, 2015, 35(9): 2636-2643. doi: 10.3969/j.issn.1000-6923.2015.09.011 -

下载:

下载: