全文HTML

Fig. 1 Failure diagram of straight scraper

1 计算模型

1.1 离散相模型(DPM)及基本方程

dupdt=FD(u−up)+gx(ρp−ρ)/ρp+Fx

| (1) |

1.2 冲蚀磨损率计算模型

ε=K1[1+Ck(K12sin(90β0βp))]2V2pcos2βp(1−R2T)+K3(Vpsinβp)4

| (2) |

E0=N∑1mpεpAface

| (3) |

VdVa=1.0+0.416β1−0.499β12+0.292β13

| (4) |

VcVb=1.0−2.12β1+3.078β12−1.1β13

| (5) |

1.3 疲劳寿命

Nσm=C

| (6) |

lgN+mlgσ=lgC

| (7) |

2 刮刀冲蚀磨损数值模拟

2.1 刮刀模型建立

Table 1 Parameter of material characteristics

材料 | 弹性模量/GPa | 泊松比μ | 材料密度/(kg·m−3) | 转 速/(r·min−1) | 抗拉强度/MPa | 屈服极限/MPa |

45号钢 | 210 | 0.269 | 7 850 | 900 | ≥624 | ≥355 |

Table 2 Model parameters of Solidworks

直刮刀叶片锥角α /(°) | 转鼓高度H/mm | 转鼓大端直径D/mm | 刮刀与筛网间隙/mm | 弯刮刀螺旋角α/(°) | 刮刀叶片数量/个 | 刮刀叶片厚度/mm | 刮刀叶片径向长度/mm |

25 | 500 | 850 | 5 | 25 | 8 | 15 | 60 |

Fig. 2 Model of straight scraper rotor

Fig. 3 Model of bending scraper rotor

2.2 网格划分

Fig. 4 Relationship between the maximum erosion rate of the scraper and the number of model grids

Fig. 4 Relationship between the maximum erosion rate of the scraper and the number of model grids

Fig. 5 Mesh of straight scraper rotor

Fig. 6 Mesh of bending scraper rotor

2.3 边界条件设定

3 仿真计算结果与冲蚀磨损规律分析

3.1 仿真计算结果

3.1.1 冲蚀结果

Fig. 7 Erosion rate of straight scraper

Fig. 8 Erosion rate of bending scraper

3.1.2 轨迹分析

Fig. 9 Escape time of scraper particle

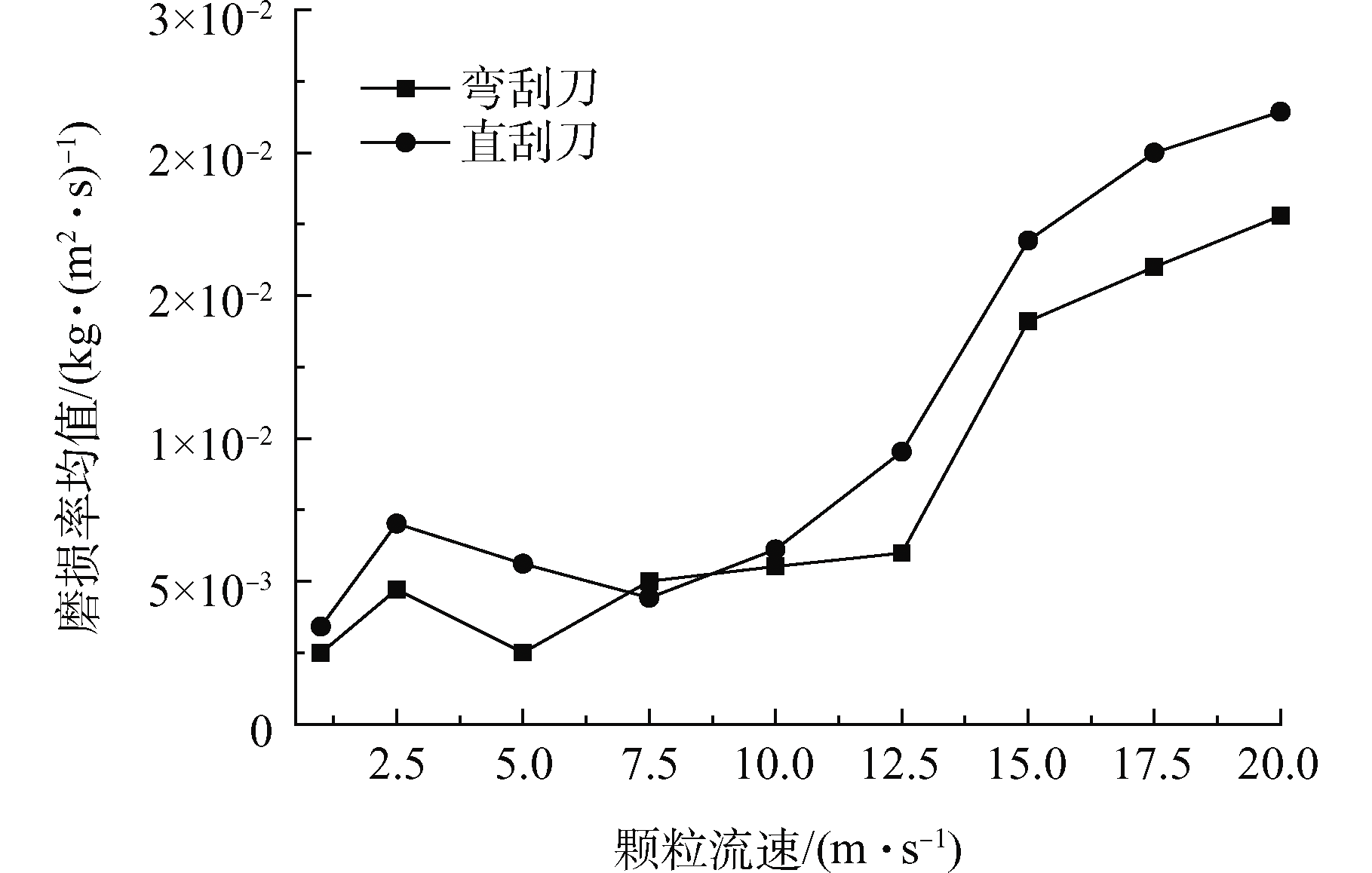

3.2 冲蚀磨损规律分析

Fig. 10 Particle size - average erosion rate

Fig. 11 Particle concentration - average erosion rate

Fig. 12 Entrance velocity-average erosion rate

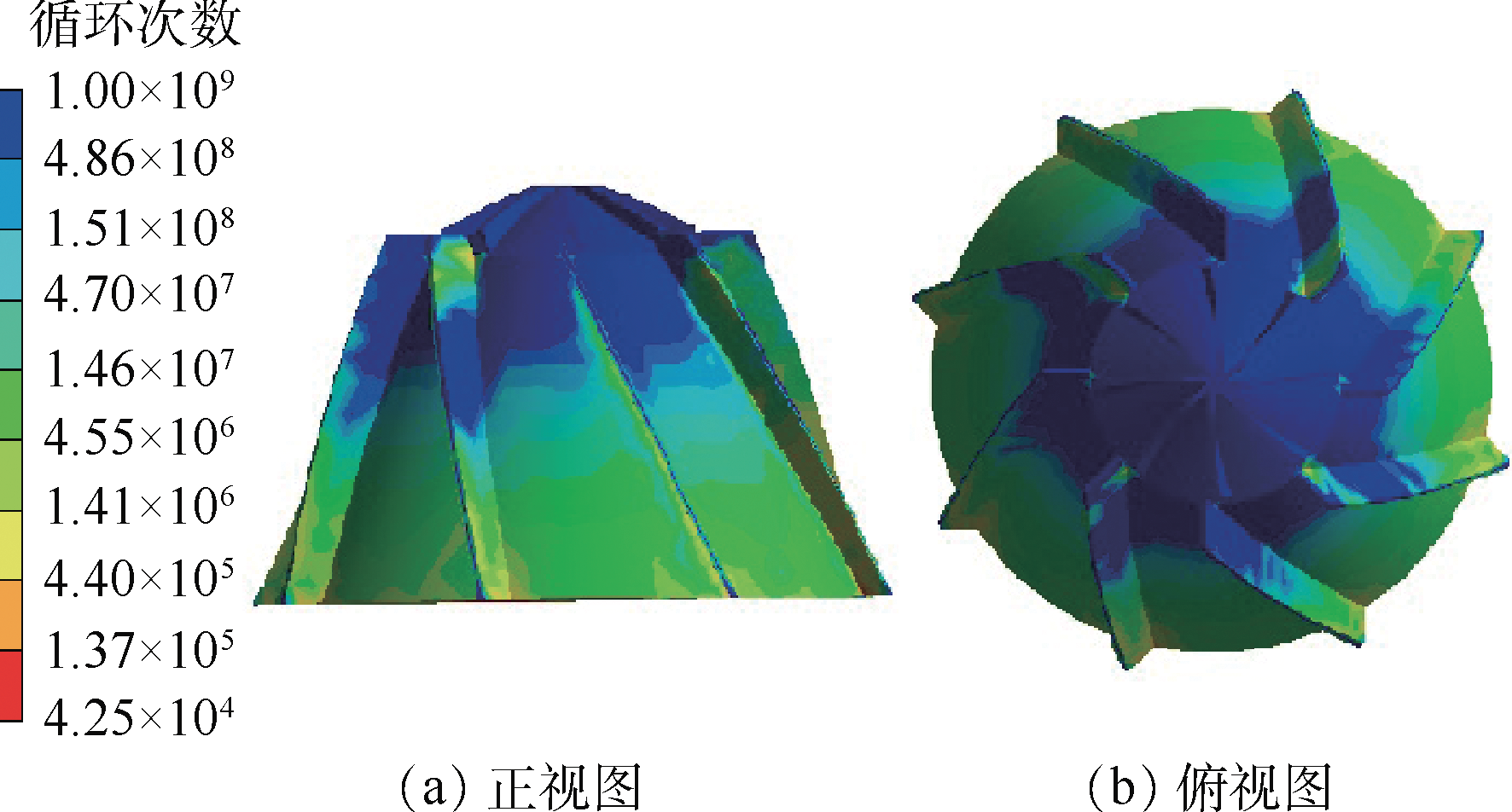

4 疲劳寿命分析

Fig. 13 Fatigue life of straight scraper rotor

Fig. 14 Fatigue life of bending scraper rotor

百度学术

百度学术

下载:

下载: