-

随着世界人口增长与工业化进程加快,水资源短缺与污染问题严重影响人类生活. 印染行业的发展给我们带来了五颜六色的染料和布料,与此同时,也产生了几十万吨的废水[1]. 据统计,印染废水占全球排放废水的20%. 印染废水成分复杂含有大量的染料和无机盐,大量有害染料排放到水体对生态环境造成严重危害,且丰富的无机盐排放也造成了资源浪费[2 − 3]. 因此,高效处理印染废水并实现染料和无机盐有效分离具有重要的现实意义.

目前,常用的印染废水处理工艺有吸附法、化学氧化、电化学沉淀等,这些方法能够有效处理印染废水,但无法实现染料和无机盐混合物选择性分离,且常规工艺易产生二次污染[4]. 与其他技术相比,膜分离技术表现出能耗低、无二次污染等优点,其中纳滤技术被广泛用于处理印染废水中[5]. 然而,商业纳滤膜具有致密的分离层,可以有效去除染料分子并对无机盐有较高的去除率,却很难实现染料分子和无机盐的选择性分离[6]. 最近,较大孔径的疏松复合膜得到越来越多的关注[7].

近年来,界面聚合(IP)法是制备疏松纳滤膜最常用的方法,通过添加多孔和官能团的材料来制备染料和盐选择性分离的疏松纳滤膜[8],例如,在分离层中加入二维材料、两性离子、金属有机框架(MOFs)等功能性材料,来改善膜的性能[9 − 11]. MOFs材料由于其高比表面积和可调节孔径等性质,已广泛用于制备疏松纳滤膜[12]. 例如,Zhou等通过真空过滤辅助和化学交联制备了CuTz-1/GO复合膜,该膜具有高渗透通量40.2 L·m−2·h−1·bar−1,刚果红的去除率高达99.4%,以及低脱盐率(NaCl为0.3%),并且在可见光照下,膜表面附着的染料被有效光催化去除,膜的性能几乎恢复到原来的分离效果[13]. 另外,单宁酸(TA)是一种廉价的天然多酚化合物,具有丰富的酚羟基,可以与金属离子发生螯合反应生成非晶体化的金属/多酚网络,这在膜分离领域引起了关注[14]. Liu等通过配位组装将TA和PEI接枝到聚醚砜/Fe超滤膜上,优化后的疏松复合膜具有较高纯水通量(124.6 L·m−2·h−1·bar−1),高染料去除率(刚果红为99.8%)和低脱盐率(NaCl为5.3%)[15].

本研究以单宁酸为改性剂,通过溶剂热合成了具有亲水性和光催化特性的MIL-53(Fe) 纳米颗粒 (TA@MIL-53(Fe)). 由于TA含有大量的酚羟基,利用其亲水性包覆复合材料,此外,利用TA与金属离子发生螯合反应,使得TA与MOF中的Fe3+配位生成金属/多酚网络. 利用TA的弱酸性蚀刻MOF,蚀刻过程不会改变材料的框架结构. 因此,TA@MIL-53(Fe) 可以作为良好的材料用于制备疏松复合膜. 对合成的缺陷型TA@MIL-53(Fe) 纳米颗粒的结构和性能进行了系统的研究,以哌嗪(PIP)为水相单体,均苯三甲酰氯(TMC)为油相单体,通过IP法将TA@MIL-53(Fe) 纳米颗粒包埋在PA层中制备疏松复合膜. 详细分析了TA@MIL-53(Fe) 负载对复合膜形貌、化学结构及分离性能的影响. 另外,对最优疏松纳滤膜进行了染料脱盐、长期稳定性、抗污性能及光催化自清洁测试. 结果表明,所制备的疏松复合膜具有高渗透通量,优异的染料截留率和较低的脱盐率,且具有优异的光催化自清洁性能.

-

商用聚醚砜(PES, Mw =

5800 )购自巴斯夫有限公司(德国). 无水哌嗪(PIP)、正己烷、N, N- 二甲基乙酰胺(DMAc)、二甘醇(DEG)、聚乙二醇(PEG)(Mw: 600、1000 、2000、4000 和6000 ),甲基蓝(MB)、乙醇、硫酸钠(Na2SO4,> 99%)和氯化钠(NaCl,> 99%)由国药化学试剂有限公司供应. 单宁酸(TA)、N, N-二甲基甲酰胺(DMF)、甲基橙(MO)、甲苯胺蓝(TB)购自阿拉丁(中国上海). 六水氯化铁(FeCl3·6H2O)和对苯二甲酸(PTA)购自上海麦克林生物化工有限公司. 亚甲基蓝(MBA)由美亚有限公司提供. -

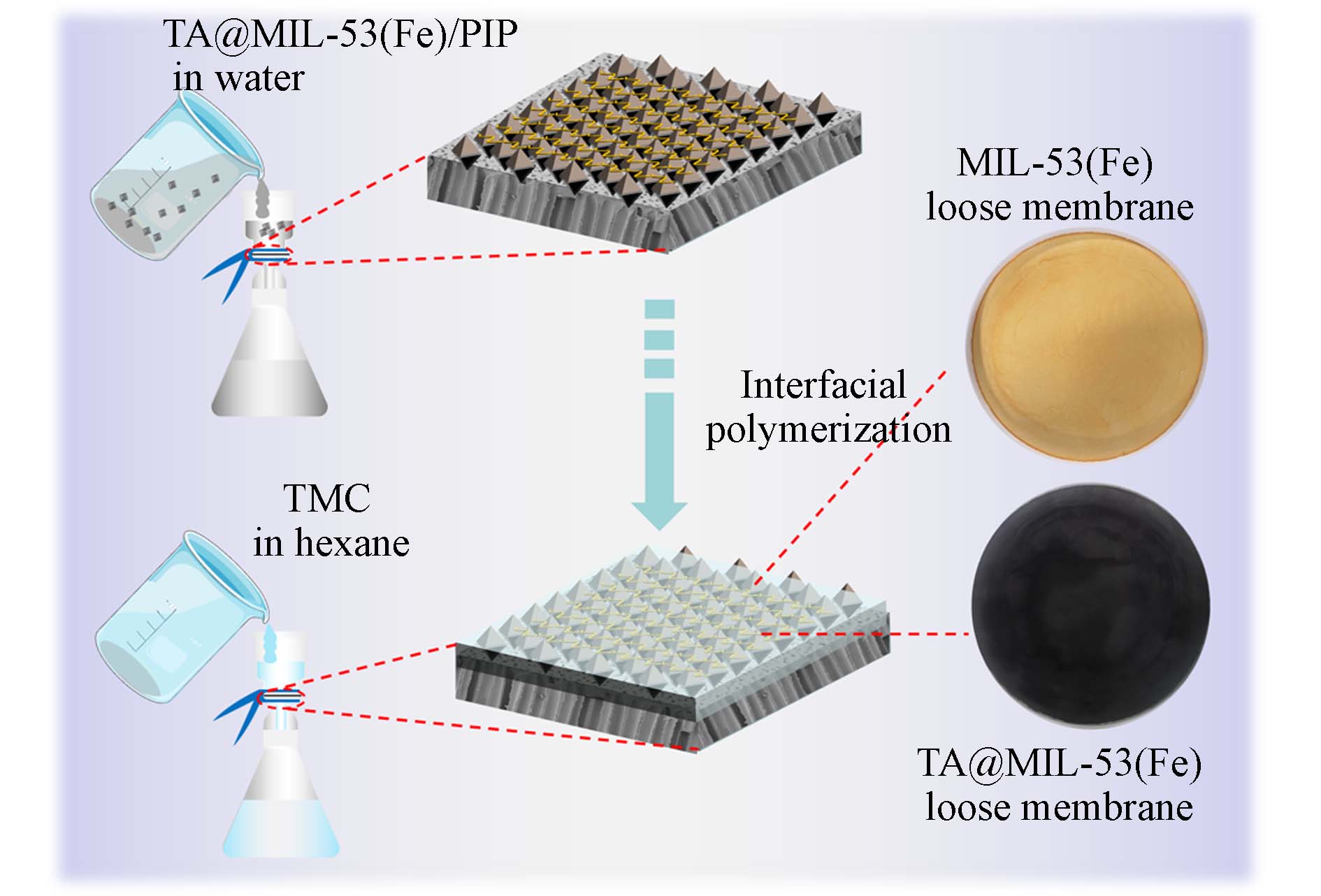

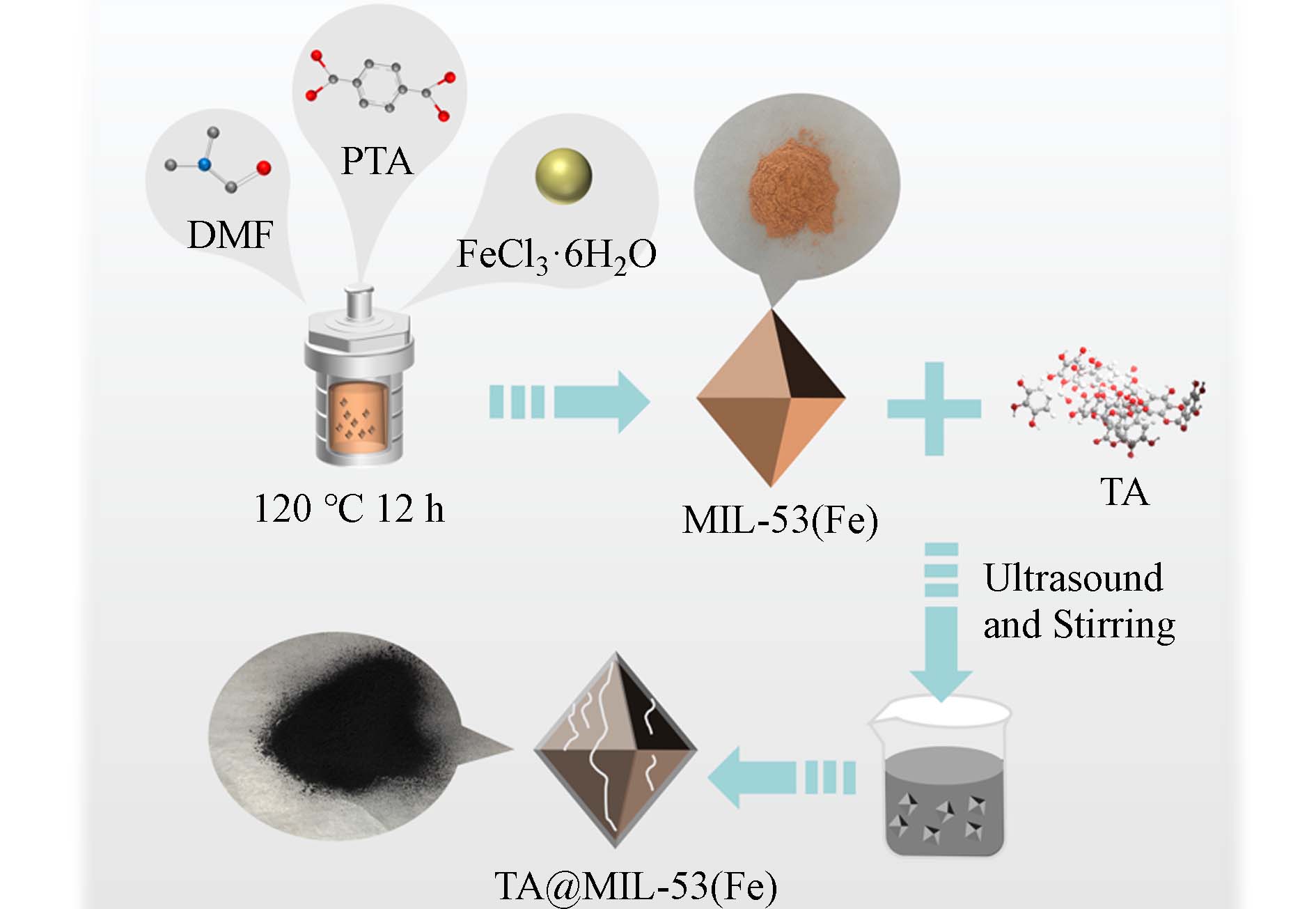

根据前人的文献报道[16],采用溶剂热法合成了MIL-53(Fe). 合成步骤如图1所示,先称量

0.6757 g FeCl3·6H2O 并溶于50 mL DMF 中,然后将0.4153 g PTA 溶于50 mL DMF 中,将两种溶液充分混合搅拌20 min,直至混合物变为透明. 最后,将混合物转移到100 mL聚四氟乙烯高压釜中,加热至120 ℃,持续10 h. 反应器自然冷却至室温后,以5000 r·min−1 离心5 min,用 DMF和乙醇连续洗涤3次,并重复进行3次离心洗涤操作. 将制备的材料在80 ℃ 下干燥12 h, MIL-53(Fe)块状颗粒研磨,筛分并放入干燥箱,备用. 0.4 g TA 溶于50 mL 去离子水中,加入0.1 g MIL-53(Fe)粉末充分混合,在50 ℃下连续搅拌30 min. 然后,通过离心、洗涤和干燥得到 TA@MIL-53(Fe)粉末. -

首先称取1.5 g PIP 溶解到100 mL 去离子水中,向PIP溶液里加入0.02 g TA@MIL-53(Fe)粉末并持续搅拌30 min直至TA@MIL-53(Fe)均匀分散在PIP溶液里. 然后,称取0.1 g TMC加入到75 mL 正己烷中,在室温下搅拌10 min直至溶液变透明. 按照图2所示,制备TA@MIL-53(Fe)/TA疏松纳滤膜. 首先将PES超滤膜固定在真空抽滤装置上,将TA@MIL-53(Fe)/PIP混合溶液倒到膜上,在空气中静置3 min,利用真空抽滤将材料抽到膜表面. 然后将TMC正己烷溶液倒入到膜上,反应1 min后立即用正己烷和去离子水交替冲洗膜表面数次. 将制备的TA@MIL-53(Fe) 复合膜浸泡在去离子水中,命名为MTPA-X (X表示TA@MIL-53的添加量).

-

使用扫描电子显微镜(SEM,Hitachi SU5000,Japan)对MIL-53(Fe)和TA@MIL-53(Fe)的表面形貌进行了表征. 使用IS10光谱仪(赛默飞世尔科学公司)测定材料和复合膜的化学键. 利用X射线衍射(XRD; Bruker, D8 Advanced)分析了所制备的纳米粒子的晶体结构. 用热重分析表征了纳米粒子的热稳定性. 在150 mL·min−1的N2气氛中,纳米粒子的温度以10 ℃·min−1 的速率由25 ℃ 升高到

1000 ℃. 使用能量色散X射线光谱(EDX-Mapping; X Flash6110 ,BRUKER)和 X射线光电子能谱(XPS; Escalab 250XI,Thermo Fisher Scientific)来检测膜表面化学元素的分布. -

膜的分离性能包括渗透性和选择性,是膜性能测试的重要指标. 在本实验中复合膜的渗透通量和截留率采用自制的错流实验装置进行测定. 首先,将复合膜剪成直径为7 cm的圆片,固定在装置支架上,随后使用去离子水在0.2 MPa(2 bar)操作压力下预压30 min,待通量稳定后,收集5 min的渗透液并用量筒读取渗透体积,通过下式(1)计算复合膜的渗透通量:

式中,PWF(L·m−2·h−1·bar−1)为纯水通量;Q(L)为渗透体积;A(m2)为膜的有效面积;t(h)为操作时间;∆P(bar)为操作压力.

用无机盐(NaCl和Na2SO4)、染料(MB、MO、MBA、TB)和重金属离子(Cr6+)来分析膜的截留率和渗透性,截留率公式(2)如下:

式中R(%)为截留率;Cp为流出料液的浓度(mg·L−1);Cf为进料液的浓度(mg·L−1).

采用台式电导率仪(S 230-B)测定截留前后无机盐溶液的电导率值. 使用哈希的紫外分光光度计(DR

6000 )测定截留前后染料溶液的吸光度. -

MWCO是评价膜分离性能的重要参数,本实验选取不同分子量的PEG(Mw=400、600、800、

1000 、2000、4000 Da)作为实验溶液评估膜的截留尺度. 在操作压力为2 bar,进料液浓度为100 mg·L−1条件下,预压30 min后,收集渗透液. PEG进料液和渗透液浓度使用岛津的TOC-L型TOC仪测定,PEG的截留率按式2计算. 根据公式3计算PEG的斯托克斯直径. -

长期稳定性测试是评估膜分离性能的另一重要参数,本实验制备的复合膜的长期稳定性使用自制的错流过滤装置进行. 以MB(100 mg·L−1)或TB(100 mg·L−1)和NaCl(1 g·L−1)染料盐混合液作为进料液,在操作压力为2 bar下进行20 h膜的稳定性实验.

-

膜的抗污性能是判断膜使用寿命及分离性能的另一重要参数,本实验以MB和TB作为污染源,对制备的复合膜进行了抗污性能测试. 在操作压力为2 bar,进料溶液浓度为100 mg·L−1下进行. 首先,将制备的复合膜在2 bar压力下预压30 min,使复合膜渗透通量保持稳定,然后连续通纯水120 min,每30 min记录一次纯水通量记为Jw. 之后,换上浓度为100 mg·L−1的MB溶液运行240 min,每隔30 min记录一次通量记为Jp. 用去离子水清洗30 min以去除表面污染物,随后使用去离子水运行120 min,每30 min记录一次通量记为Jw2,重复上述操作3次. 之后分别以TB和Cr6+溶液进行抗污染循环实验,操作同上述一致. 最后通过引入通量恢复率(FRR)、总污垢率(Rt)、可逆污垢率(Rr)和不可逆污垢率(Rir)等4个指标来评估膜的抗污性能,公式如下:

-

通过SEM、XRD和FT-IR分析仪器对MIL-53(Fe)和TA@MIL-53(Fe) 进行表征[17]. 如图3(a)所示,用SEM观察MIL-53(Fe)的形貌,呈现八面体结构的锥形体,平均直径为200—500 nm,这与文献报道的相一致[18]. 如图3(b)所示,经过TA改性后,MIL-53(Fe)表面更加光滑且结构均匀,结果表明TA蚀刻后的MIL-53(Fe) 结构不会坍塌,保持原有八面体结构.

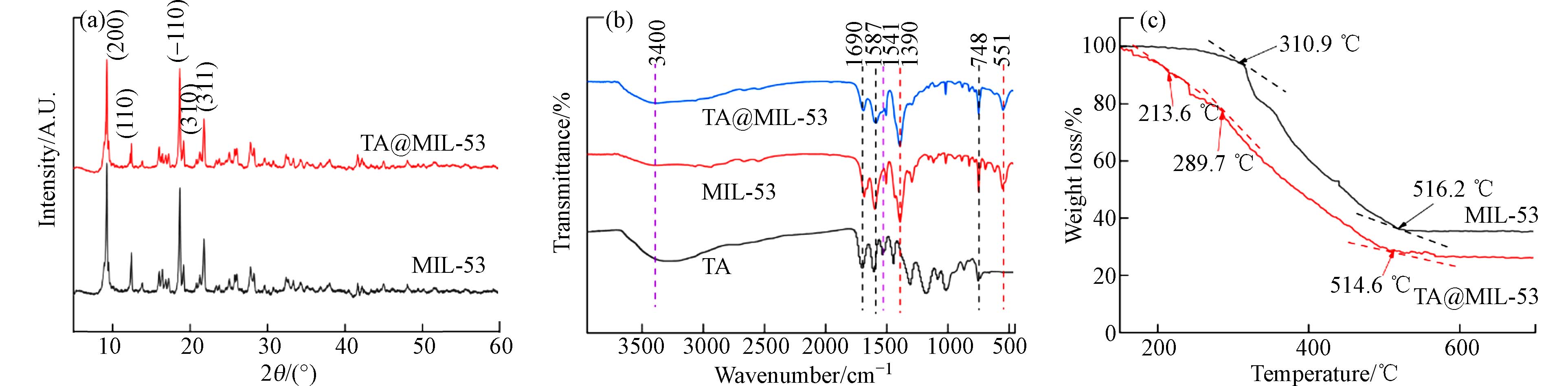

如图4(a)所示,用XRD分析MIL-53(Fe) 和TA@MIL-53(Fe) 的晶体结构. 从图4可以观察到,9.3°、12.5°、18.7°、19.2°和21.8°的5个特征峰,这5个特征峰分别对应着(200)、(110)、(-110)、(310)和(311)的晶面,和其他文献中报道的相一致[17 − 18]. 在XRD图里有一些多余的杂峰,与SEM图比较分析,可能是缺陷的MOF坍塌分解和微量有机溶剂造成. 另外,衍射峰的形状相对尖锐,表明本工作合成的粉末具有良好的结晶度. 图4(b)显示的是粉末的红外测试图. 在MIL-53光谱中,

1300 —1600 cm−1范围内显示着PTA里—COOH的典型振动峰,1390 cm−1和1587 cm−1处的吸收峰分别对应羧基的不对称振动和对称振动,而1690 cm−1处的特征峰代表着羰基拉伸振动[19]. 748 cm−1处的峰是由于PTA中苯环的C—H弯曲振动引起. 551 cm−1处的特征峰是由Fe—O拉伸运动引起,这也表明PTA的羧基和Fe3+之间存在金属-氧键. 在TA的FT-IR谱图中,1610 、1541 、748 cm−1处的吸收峰分别对应着C—H、C—O和C=C拉伸振动.3400 cm−1和1690 cm−1分别对应着O—H伸缩振动和酯基的C=O伸缩振动. 在TA@MIL-53的FT-IR光谱中,出现了上述TA和MIL-53(Fe) 的特征峰,由此表明TA成功改性MIL-53(Fe),与文献中报道的一致[17 − 20].材料的热稳定性和比表面积大小是限制其在膜领域内应用的重要参数[19]. 通过TGA分析粉末的热稳定性,分析结果如图4(c)所示,采用TGA进一步分析MIL-53和TA@MIL-53的化学组成和热稳定性,与MIL-53相比,多出的一段分解温度是由于TA分解造成的,这与TA的分解温度一致. 另外,TA@MIL-53在25 ℃到213.6 ℃范围内出现了8.7%的重量损失,这是由于粉末中残留的水分子和有机溶剂被去除. 另外,根据先前文献报道和PTA的分解温度推测,在289.7 ℃出现陡坡式的重量损失是由MIL-53粉末分解造成的,最后在514.6 ℃分解完全.

-

通过SEM和AFM的手段表征TA@MIL-53(Fe) 负载量对复合膜形貌及粗糙度的影响. 如图5(a)一列是复合膜的表面形貌图,纯IP膜表面有一些褶皱疏松的地方,这可能是由于复合膜制备过程中,未将膜冷却到室温直接加入到去离子水中,温差过大造成聚酰胺层交联度降低. 当TA@MIL-53(Fe) 粉末从0.02% wt增加到0.04% wt时,明显的能看到颗粒团聚现象. 另外,随着TA@MIL-53(Fe) 材料在膜上负载量的增加,膜表面PA层还出现了分裂,这可能是纳米颗粒增加使得PA层交联度降低,这也从宏观角度说明了复合膜渗透性降低的原因. 由截面图结果可以看出,MPTA-0和MPTA-0.01的交联层厚度从120 nm增加到550 nm,这是因为添加了TA@MIL-53(Fe) 纳米颗粒造成的. 随着粉末添加量的增加,从膜截面可以看出,PA层的厚度也随之增加,而PA层的膜厚是影响复合膜渗透性-选择性的重要因素. 所以,添加合适尺寸的纳米颗粒可以控制复合膜PA层的厚度,从而优化膜的渗透选择性,有效协调复合膜的trade-off效应[21].

如图5(c)所示,TA@MIL-53添加量对复合膜粗糙度的影响. MPTA-0纯IP膜与MPTA-0.01复合膜相比,膜的Ra值从17.4 nm增加到了39 nm,这一结果是与TA@MIL-53加入到PA层有关的,在界面聚合过程中,亲水性的TA@MIL-53(Fe)均匀分散在膜表面,但TA@MIL-53(Fe)材料的锥形框架结构使得膜表面高低不平,从而增加了复合膜的粗糙度,这与其他文献中复合膜的结果相一致.

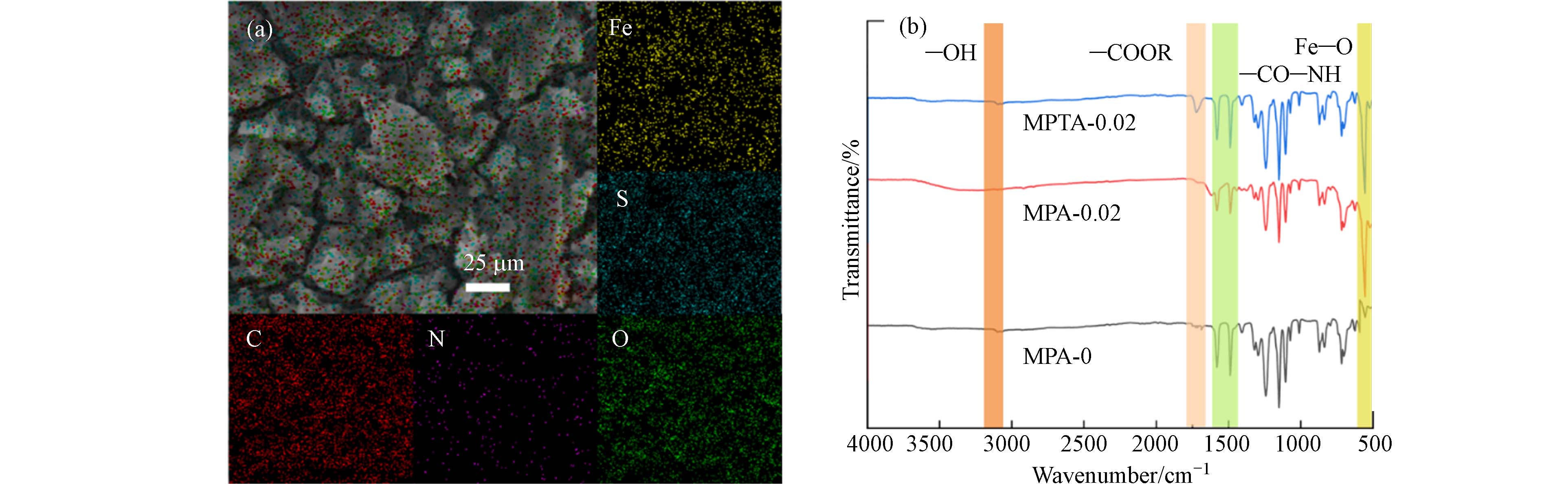

为了进一步探究TA@MIL-53(Fe) 在复合膜表面中的分散情况,对MPTA-0.02复合膜测了EDS-mapping图谱,从图6(a)中看出,Fe元素均匀分散在复合膜表面,结果表明TA@MIL-53(Fe) 纳米颗粒均匀分散在膜表面. 另外,N元素均匀分散在膜表面,这也从侧面表明PIP和TMC成功反应生成PA层[22].

为了表征TA@MIL-53(Fe) 复合膜表面化学结构,采用FT-IR对复合膜表面化学官能团进行了测试. 如图6(b)所示,在

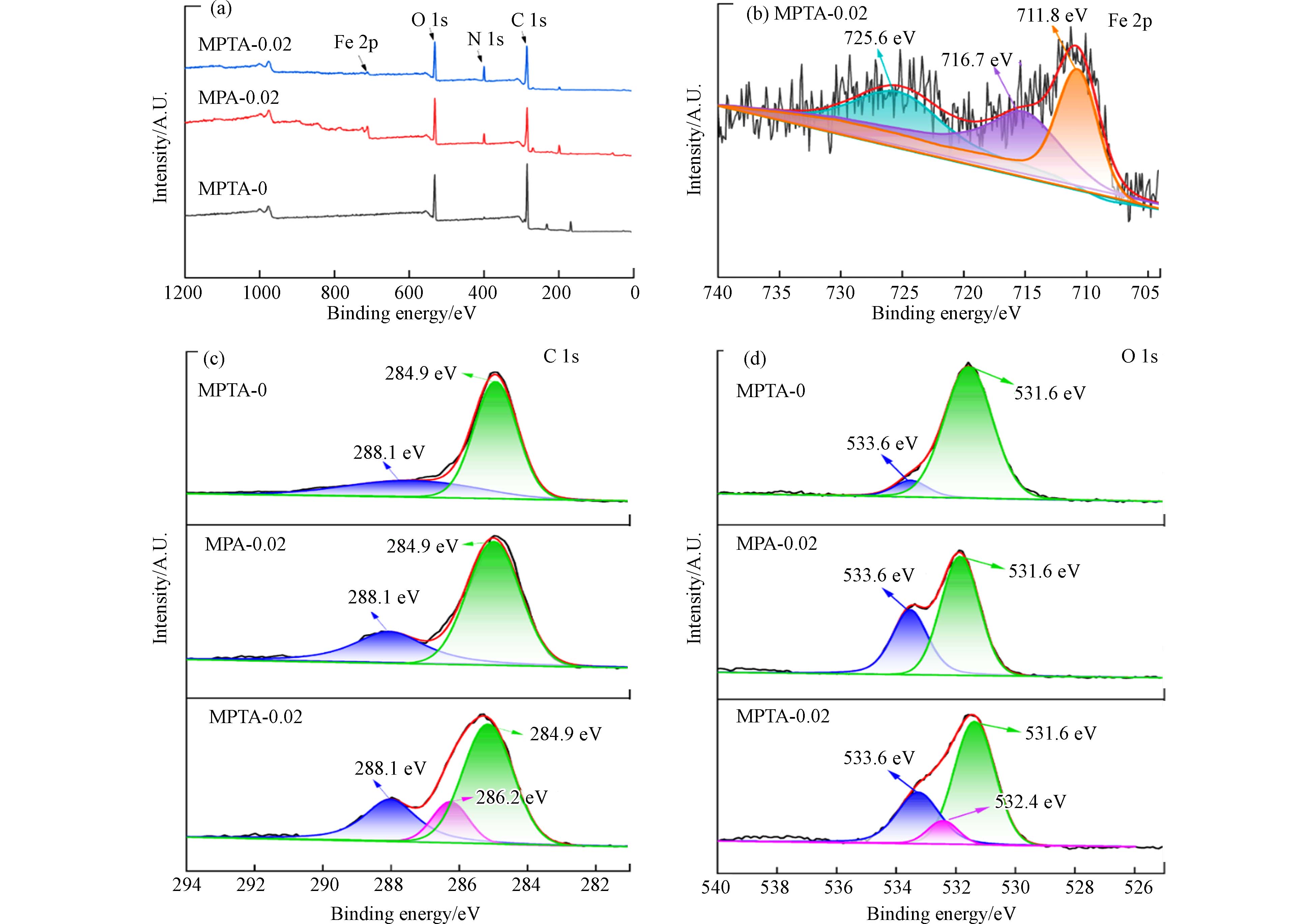

1582 cm−1和1489 cm−1处的特征峰分别对应着酰胺基团中的C=O和N—H,这是由基团的拉伸振动引起,这证明了PIP和TMC成功反应生成了PA层. 在1731 cm−1处的特征峰是由羧基的振动引起的,相对于另外两个复合膜,MPTA-0.02复合膜在1731 cm−1处峰面积增加,这可能是由过多的酰氯基团水解产生. 与MPA-0.02膜相比,MPTA-0.02复合膜在3110 cm−1处存在的吸收峰是由TA的—OH伸缩振动引起的,这也表明亲水基团—OH成功引入复合膜[23 − 24]. 与MPTA-0膜相比,MPTA-0.02在768 cm−1处出现的特征峰是由PTA中C—H基团弯曲振动引起,另外,在558 cm−1处出现的新的吸收峰是由于Fe3+和PTA里的—COO−基团相互作用引起的Fe—O拉伸,该结果说明了TA@MIL-53(Fe) 成功引入了复合膜的PA层.为了进一步探究添加TA@MIL-53(Fe) 纳米颗粒对PA层的影响,并解释MIL-53(Fe) 复合膜和TA@MIL-53(Fe) 复合膜之间的差异,采用XPS谱分析复合膜表面元素组成和元素价态. 在图7(a)的XPS总谱中,检测到Fe、O、C、N和S元素,这与EDS-mapping测试结果相吻合. 图7(b)显示的是MPTA-0.02复合膜的Fe 2p的光谱,725.6 eV和711.8 eV处的两个特征峰分别代表着Fe 2p1/2和Fe 2p3/2. 这两个峰的差值为13.8 eV,说明Fe-oxo团簇中存在Fe3+. 在716.7 eV处观测到的谷峰可归因于卫星峰,这是Fe3+的典型特征. 图7(c)是复合膜的C 1s谱,MPTA-0的C 1s谱在284.9 eV和288.1 eV处有两个特征峰,这是TMC中的C=C/C—C和酰胺基团的C=O. 另外,MPA-0.02的C 1s谱在284.9 eV和288.1 eV处的两个峰对应着PTA里的C=C和C=O. 与MPA-0.02相比,MPTA-0.02复合膜的C 1s谱观察到3个峰,286.2 eV处的峰对应着TA的苯甲酸环[17 − 25],这也证明了TA成功改性MIL-53,亲水性的TA@MIL-53(Fe) 复合膜有助于提高膜的渗透性和抗污性能. 如图7(d)所示,MPA-0.02复合膜在531.6 eV和533.6 eV处的两个峰分别对应着PTA中的O=C(O—Fe) 和O—C. 与MPA-0.02复合膜相比,MPTA-0.02复合膜在532.4 eV处多出的峰对应着TA上未参与反应的羟基[26]. 综上所述,成功利用TA制备出亲水性有缺陷的MIL-53(Fe),并进一步证实将TA@MIL-53(Fe) 纳米颗粒引入PA层.

-

膜表面亲水性是评价膜渗透性能和抗污性能的重要指标. 如图8所示,添加MIL-53(Fe) 和TA@MIL-53(Fe) 纳米颗粒对复合膜接触角的影响. MPTA-0复合膜的水接触角为70.5°,加入TA@MIL-53(Fe) 纳米颗粒后,复合膜水接触角开始下降. 随着TA@MIL-53(Fe) 添加量从0%增加到0.04%,复合膜的水接触角从70.5°降低到34.75°,这是由于有缺陷的TA@MIL-53(Fe) 为水分子提供了更多的通道. 另外,与MPTA-0.02复合膜相比,添加了疏水性的MIL-53(Fe) 纳米颗粒对改善膜的亲水性帮助甚微,这也从另一方面证明了TA成功改性MIL-53(Fe)纳米颗粒,使得TA中的亲水基团(—OH)与MIL-53(Fe)结合,从而提高膜的亲水性[27]. 因此,添加TA@MIL-53(Fe)纳米颗粒降低膜的水接触角,从而达到提高膜的亲水性效果,这与文献报道的结果相一致[28 − 29].

-

为了进一步分析膜孔变化,通过不同分子量PEG来测试复合膜的MWCO. 如图9所示,MPTA-0复合膜的MWCO约为2000 Da,当加入TA@MIL-53纳米颗粒后,复合膜的截留性能提高,MPTA-0.02复合膜有效的MWCO约为

1665 Da. 根据Stokes半径公式(2-3)计算得到MPTA-0.02复合膜的孔径约为1.02 nm[30 − 31]. 另外,随着TA@MIL-53(Fe) 纳米颗粒的增加,复合膜的截留尺度降低. 因此,为了进一步对复合膜性能做出评估,后续选择MPTA-0.02复合膜做分离性能、稳定性和抗污性能测试. -

采用不同分子量和不同电荷的4种染料作为实验溶液,对MIL-53(Fe)和TA@MIL-53(Fe)复合膜进行分离性能测试(操作条件:0.02 MPa,染料浓度:100 mg·L−1). 如图10所示,MPTA-0复合膜渗透通量为29.3 L·m−2·h−1·bar−1,对阴离子染料MB的截留率为96.3%. 相比于MPTA-0复合膜,当TA@MIL-53(Fe) 负载量从0增加到0.02% wt时,膜渗透通量增加1.8倍,提高到53.6 L·m−2·h−1·bar−1,同时对MB的去除率也有所提高,提高到了99.1%. 这主要是因为亲水性TA@MIL-53(Fe) 纳米颗粒加入PA层有助于在交联层表面形成亲水分子层,提高对水分子的吸引力. 另外,TA@MIL-53(Fe) 的加入会使致密的PA层变得疏松,从而提高膜的渗透通量,TA@MIL-53(Fe) 具有合适的窗口尺寸,可以选择性地截留染料分子[19 − 32]. 随着TA@MIL-53(Fe) 负载量的增加,复合膜截留性能开始下降,这主要是由以下原因造成的,一方面由于过多的TA@MIL-53(Fe) 会在膜表面发生团聚,从而使得PA层性能下降,另一方面是过多的负载量会使得复合膜的交联度降低,使得PA层出现断裂,从而导致复合膜截留性能下降. 对于不同电荷、分子量相近的染料,复合膜表现出对阴离子染料更高的截留率,这可能是由于复合膜带负电荷,对阴离子染料具有强排斥作用[33]. 另外,对于相同电荷的染料,随着染料分子量的提高,截留率也在提高,这主要是由复合膜的孔径筛分决定,此结果与其他文献报道的结果一致[34 − 36].

除以染料溶液为进料液外,还使用4种无机盐溶液来测试复合膜的盐渗透性能. 如图10(b)所示,随着TA@MIL-53(Fe)添加量的增加,复合膜对无机盐的截留率降低,这主要是由于过多的NPs抑制了缩聚反应,从而破坏了PA层,降低了复合膜的截留性能. 另外,MPTA-0.02复合膜对盐的截留率为NaCl(4.3%)<MgCl2(7.1%)<Na2SO4(11.5%)<MgSO4(15.3%),复合膜表现出较低的盐截留率. 为了进一步探究复合膜染料脱盐性能,选用性能最佳的MPTA-0.02复合膜来测试膜的染盐分离性能. 使用0.1 g·L−1的MB或TB和1 g·L−1的NaCl或Na2SO4混合溶液来进行过滤实验,如图10(c)所示,以染料盐混合液为进料液,MPTA-0.02复合膜的渗透通量在58.9—64.2 L·m−2·h−1·bar−1之间. 与单一染料的分离实验相比,MPTA-0.02复合膜对MB的截留率略微较低,从99.1%降到了96.3%和97.8%. 这主要是由于高浓度的盐与染料分子结合,从而提高了染料分子的水溶性,从而导致复合膜的染料截留率降低. 另外,与单一染料的分离实验相比,MPTA-0.02复合膜对TB的截留率降低较少,这主要是由于复合膜表面带负电荷,阳离子染料吸附到膜表面堵塞膜孔,从而提高复合膜的染料截留率,另一方面,盐溶液提高了染料分子的水溶性,从而降低复合膜的染料截留率,一增一减之下,使得复合膜对TB染料具有较高的去除率(97.9%和96.4%). 总的来说,MPTA-0.02复合膜对染料分子的截留率高达95%以上,并且具有优异的盐渗透性能(高于85%). 图10(d)比较了本研究与其它疏松复合膜的渗透通量和染料截留率[1 − 2, 6, 9, 11, 14 − 15, 34]. 结果表明,与其他文献中的疏松复合膜相比,本研究所制备的复合膜具有较高的渗透通量和良好的染料截留率.

-

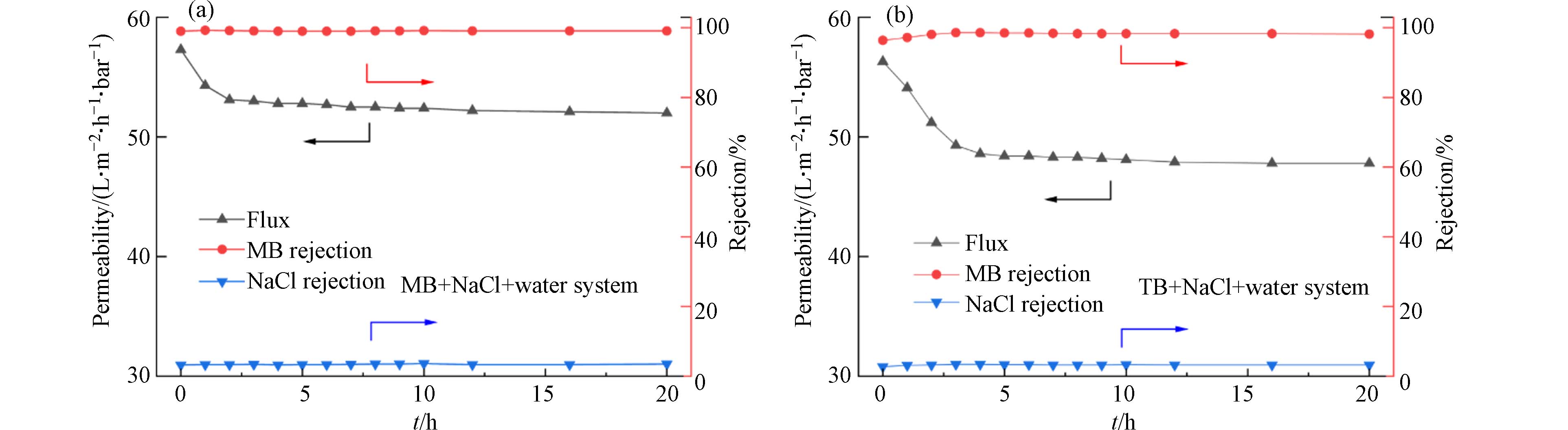

膜的稳定性测试是评估膜性能及推广应用的重要参数. 为了探究MPTA-0.02复合膜在高浓度含盐染料废水中的稳定性,配置100 mg·L−1染料(MB和TB)和1 g·L−1 NaCl混合溶液来模拟染料废水,复合膜在0.2 MPa的操作压力下运行20 h. 如图11所示,运行前3 h,复合膜的渗透通量下降,这是由于混合液中盐离子使得染料分子在水中分散的更加均匀,小的染料分子因为静电效应被吸附到PA层. 另外,图11(b)可看出,与用阴离子染料MB作为模拟废水相比,在阳离子染料TB模拟废水中,复合膜的渗透通量下降的更多,这是由于复合膜表面携带负电荷,对阳离子染料分子具有更强的吸附性,从而使得染料分子堵塞膜孔,导致膜通量下降. 此外,MB和TB染料具有良好的水溶性,在水溶液中可以建立起动态平衡,使过滤过程保持稳定,在过滤过程中,由于浓差极化和膜污染的形成,在复合膜表面渐渐形成了一层薄薄的凝胶层,这也导致复合膜对MB和TB的截留率略有提高,对MB和TB的截留率分别为99.1%和98.4%. 这表明改复合膜对染料具有很好的去除性能. 另外,在长期的运行中保持对NaCl的高渗透性. 总的来说,MPTA-0.02复合膜具有良好的稳定性,可进一步开发用于含盐染料废水的实际应用中.

-

膜的抗污染测试是评估膜性的另一个重要参数. 为了进一步探究MPTA-0.02复合膜在染料废水中的应用,采用阴离子染料MB和阳离子染料TB作为污染源,进行复合膜的抗污性能测试. 如图12(a)所示,在处理染料废水时,由于浓差极化作用,在循环的初始阶段通量下降,随着运行的进行,染料分子在膜表面形成凝胶层,进一步造成通量降低并趋于稳定. 为了进一步探究膜的抗污性能和膜污染类型,引入膜通量恢复率(FRR)、总污垢率(Rt)、不可逆污垢率(Rir)和可逆污垢率(Rr). 如图12(b)所示,MB染料所造成的污染主要以可逆污染(Rr=7.7%)为主,这是由于浓差极化作用造成的. 另外,TB染料对复合膜造成的污染主要以不可逆污染(Rir=8.6%)为主,这可能是由于复合膜表面带负电荷,对阳离子染料具有强吸引力,造成的膜污染无法通过水力清洗恢复[37 − 38]. 如图12(c)所示,复合膜的通量恢复率都很高,循环3次MB染料下复合膜的FRR分别为93.6%、93.5%和93.7%,根据之前分析,这主要是由于复合膜对阴离子染料的排斥作用,从而降低了污染结垢形成可能性,该结果表明该复合膜对阴离子染料具有良好的抗污性能. 另外,循环3次TB染料下复合膜的FRR分别为91.3%、95%和93.9%. 相较于其他两次循环,由于静电作用和膜表面缺陷,使得更多的TB分子沉积在膜表面,导致膜通量降低,膜通量恢复率略低. 总的来说,亲水性MPTA-0.02复合膜具有良好的抗污性能,有望进一步开发用于染料废水的实际应用.

-

在印染废水的实际应用中,当膜进料压力过大或膜污染严重时,需要使用水力反冲洗和化学清洗剂来恢复膜的性能,这不仅会损害膜的机体结构,还会降低膜的性能,从而增加膜组件消耗成本. 因此,光催化自清洁膜的开发利用可以有效避免这一问题. 本研究使用UV-VIS光谱进一步研究复合膜的光吸收特性,以反映用MIL-53(Fe) 和TA@MIL-53(Fe) NPs制备的复合膜的自清洁性能. 如图13(a)所示,MPA-0.02和MPTA-0.02复合膜的吸收边缘的波长分别为434 nm和478 nm,这说明了TA改性后的MIL-53(Fe) 吸收边缘发生了红移. 另外,也反映了MIL-53(Fe) 和TA@MIL-53(Fe) 复合膜在可见光范围内的响应能力. 如图13(b)所示,MPA-0.02复合膜的禁带约为2.93 eV,而MPTA-0.02复合膜的禁带宽度为2.75 eV,这表明TA的改性可以增强光的吸收,缩小MIL-53(Fe) 的带隙宽度. 根据相关文献报道,MIL-53(Fe) 在可见光范围内具有光催化特性,但单独的MIL-53(Fe) 的光催化自清洁的性能并不高,Xin等将MIL-53(Fe) 引入纺丝纤维滤膜中,单独使用MIL-53(Fe) 对罗丹明的降解效果只有50%,当引入PS电子受体后,对罗丹明的降解效果达到了60%[39]. 另外,常用的电子受体还有H2O2、TA、过硫酸盐等.

图13(c)显示了3种膜在100 mg·L−1 的MB溶液中进行3循环测试时的通量变化. 预压30 min后,每张膜用纯水过滤60 min,然后以MB溶液为进料液运行60 min. 在第一和第二循环之间,使用纯水对膜进行过滤清洗30 min,在第二和第三循环之间,将膜放在H2O2溶液中并使用可见光照射膜表面30 min. 在通入MB溶液后,由于浓差极化和尺寸效应的共同作用,3张膜的渗透通量大幅度下降,并随之形成凝胶层. 经过水力反冲洗后,3张膜表现出相似的低通量恢复趋势,这表明单纯的水力冲洗,无法有效去除吸附MB所引起的不可逆污染. 如图13(d)所示,在水力冲洗下,MPTA-0、MPA-0.02、MPTA-0.02复合膜的FRR1分别为85.4%、86.3%和85.7%. 然而,在可见光照射下,与MPTA-0复合膜相比,MPA-0.02和MPTA-0.02复合膜的FRR2分别为94.6%和96.5%,这比水力冲洗获得的FRR1多了20%. 这也说明了亲水性和光催化材料组合有望制备出优异自清洁性能的疏松复合膜.

图14说明了TA@MIL-53(Fe) 疏松复合膜的自清洁机理. 在可见光照条件下,嵌入PA层的TA@MIL-53(Fe)吸收可见光,将电子从价带(VB)激发到导带(CB),在激发过程中形成活性氧(ROS),例如·O2-、·OH、和h+. 其中电子-空穴对(h+)是由TA@MIL-53(Fe) 受可见光照射产生的;·O2-是光生电子与吸附在膜表面的O2进一步反应生成的,另一部分光生电子与H2O2反应生成·OH. 一般来说,光催化剂产生的ROS可以用来降解膜表面的污染物[40],对于染料这类小分子污染物直接与ROS发生氧化还原反应被降解成H2O和CO2,而对于一些大分子污染物会被断裂分子结构转化为小分子物质[41]. 断裂的有机污染物在经过水力冲洗后很容易从膜上去除,从而有效恢复膜通量. 同时实验结果表明经过光催化自清洁后复合膜的渗透通量恢复到了初始膜通量的96.5%.

在可见光照射条件下,MPTA-0.02复合膜的光催化自清洁的作用机理如下:

-

本研究采用单宁酸蚀刻法制备了有缺陷的TA@MIL-53(Fe)纳米颗粒. 随后,采用真空抽滤辅助IP反应制备了TA@MIL-53(Fe)复合膜. 在PA选择层中添加TA@MIL-53(Fe)可以提高复合膜的亲水性,为水分子提供一个特殊的通道,使水通量从29.3 L·m−2·h−1·bar−1增加到53.6 L·m−2·h−1·bar−1. 然而,过多的纳米粒子负载可能会降低PA的交联程度,从而导致保留率的急剧下降. 在最佳条件下制备的复合膜MPTA-0.02具有良好的性能,在染料和无机盐混合溶液中的渗透通量在58.9—64.2 L·m−2·h−1·bar−1之间,对MB和TB的截留率分别为97.8%和96.4% ,对盐的渗透性能高于85%. 此外,MPTA-0.02复合膜长期运行20 h后,水通量和截留率较好,对染料/盐混合溶液的截留率较高. 同时,由于MIL-53(Fe)的光催化活性,制备的复合膜具有良好的自清洁能力,与水力冲洗后膜的通量恢复率相比,膜的通量恢复率高达96.5%. 因此,该复合膜能够实现印染废水中盐和染料的分离,并具有优异的自清洗性能,对印染废水的回用具有重要意义.

基于单宁酸改性MIL-53(Fe)制备光催化自清洁复合膜用于高效染料/盐分离

Preparation of photocatalytic self-cleaning composite membrane high-efficiency dyes/salt separation based on tannin modified MIL-53(Fe)

-

摘要: 膜分离技术已广泛应用于印染废水处理中,用于染料/盐混合物的选择性分离. 然而,目前商业膜通量低和不可避免的污染问题大大降低了处理效率. 本文利用单宁酸(TA)的表面官能化和刻蚀作用制备了具有亲水性和光催化活性的TA@MIL-53(Fe)粉末,并通过真空抽滤辅助技术将光催化活性材料引入聚酰胺(PA)选择层,制备了一种新型高通量自清洁复合膜. 使用SEM、AFM、FTIR以及UV-vis等表征探究材料对复合膜的影响以及光催化自清洁机理. 结果表明,当TA@MIL-53(Fe)添加量为0.02% wt时,复合膜性能最优,通量高达64.2 L·m−2·h−1·bar−1,对MB和TB的染料截留率均保持在95%以上. 同时,所制备的膜对盐的去除率较低. 此外,与水力冲洗后的膜通量回收率(FRR)相比,MPTA-0.02复合膜经光催化自清洗后的FRR高达96.5%. 与此同时,MPTA-0.02复合膜具有良好的自清洗性能和长期稳定性. 这为开发具有优良防污性能的染料/盐分离膜提供了新的思路.

-

关键词:

- 单宁酸 /

- MIL-53(Fe) /

- 高通量 /

- 光催化自清洁 /

- 染料/盐.

Abstract: Membrane separation has been widely employed in printing and dyeing wastewater treatment (PDW) for selective separation of dyes/salt mixtures. However, the current low membrane flux and inevitable fouling issues greatly reduce treatment efficiency. In this paper, TA@MIL-53(Fe) powder with hydrophilic and photocatalytic activity was prepared by surface functionalization and etching of tannins (TA). Subsequently, a novel high-throughput self-cleaning composite membrane was developed by incorporating photocatalytic active materials into the polyamide (PA) selection layer using vacuum filtration assisted technology. SEM, AFM, FTIR and UV-vis were used to explore the influence of materials on composite membranes and the photocatalytic self-cleaning mechanism. The results revealed that the composite membrane exhibited optimal performance when the amount of TA@MIL-53(Fe) added was 0.02% wt. At this composition, the membrane demonstrated a flux of 64.2 L·m−2·h−1·bar−1, with the dye retention rate for MB and TB remaining above 95%. At the same time, the prepared membrane had a low salt removal rate. Furthermore, compared to the membrane flux recovery (FRR) achieved through hydraulic flushing, the FRR of the MPTA-0.02 composite membrane after photocatalytic self-cleaning reached 96.5%. At the same time, MPTA-0.02 composite film had good self-cleaning performance and long-term stability. This provides a new approach for the development of dyes/salt separation membranes with excellent antifouling properties.-

Key words:

- tannic acid /

- MIL-53(Fe) /

- high throughput /

- photocatalytic self-cleaning /

- dyes/salts.

-

随着世界人口增长与工业化进程加快,水资源短缺与污染问题严重影响人类生活. 印染行业的发展给我们带来了五颜六色的染料和布料,与此同时,也产生了几十万吨的废水[1]. 据统计,印染废水占全球排放废水的20%. 印染废水成分复杂含有大量的染料和无机盐,大量有害染料排放到水体对生态环境造成严重危害,且丰富的无机盐排放也造成了资源浪费[2 − 3]. 因此,高效处理印染废水并实现染料和无机盐有效分离具有重要的现实意义.

目前,常用的印染废水处理工艺有吸附法、化学氧化、电化学沉淀等,这些方法能够有效处理印染废水,但无法实现染料和无机盐混合物选择性分离,且常规工艺易产生二次污染[4]. 与其他技术相比,膜分离技术表现出能耗低、无二次污染等优点,其中纳滤技术被广泛用于处理印染废水中[5]. 然而,商业纳滤膜具有致密的分离层,可以有效去除染料分子并对无机盐有较高的去除率,却很难实现染料分子和无机盐的选择性分离[6]. 最近,较大孔径的疏松复合膜得到越来越多的关注[7].

近年来,界面聚合(IP)法是制备疏松纳滤膜最常用的方法,通过添加多孔和官能团的材料来制备染料和盐选择性分离的疏松纳滤膜[8],例如,在分离层中加入二维材料、两性离子、金属有机框架(MOFs)等功能性材料,来改善膜的性能[9 − 11]. MOFs材料由于其高比表面积和可调节孔径等性质,已广泛用于制备疏松纳滤膜[12]. 例如,Zhou等通过真空过滤辅助和化学交联制备了CuTz-1/GO复合膜,该膜具有高渗透通量40.2 L·m−2·h−1·bar−1,刚果红的去除率高达99.4%,以及低脱盐率(NaCl为0.3%),并且在可见光照下,膜表面附着的染料被有效光催化去除,膜的性能几乎恢复到原来的分离效果[13]. 另外,单宁酸(TA)是一种廉价的天然多酚化合物,具有丰富的酚羟基,可以与金属离子发生螯合反应生成非晶体化的金属/多酚网络,这在膜分离领域引起了关注[14]. Liu等通过配位组装将TA和PEI接枝到聚醚砜/Fe超滤膜上,优化后的疏松复合膜具有较高纯水通量(124.6 L·m−2·h−1·bar−1),高染料去除率(刚果红为99.8%)和低脱盐率(NaCl为5.3%)[15].

本研究以单宁酸为改性剂,通过溶剂热合成了具有亲水性和光催化特性的MIL-53(Fe) 纳米颗粒 (TA@MIL-53(Fe)). 由于TA含有大量的酚羟基,利用其亲水性包覆复合材料,此外,利用TA与金属离子发生螯合反应,使得TA与MOF中的Fe3+配位生成金属/多酚网络. 利用TA的弱酸性蚀刻MOF,蚀刻过程不会改变材料的框架结构. 因此,TA@MIL-53(Fe) 可以作为良好的材料用于制备疏松复合膜. 对合成的缺陷型TA@MIL-53(Fe) 纳米颗粒的结构和性能进行了系统的研究,以哌嗪(PIP)为水相单体,均苯三甲酰氯(TMC)为油相单体,通过IP法将TA@MIL-53(Fe) 纳米颗粒包埋在PA层中制备疏松复合膜. 详细分析了TA@MIL-53(Fe) 负载对复合膜形貌、化学结构及分离性能的影响. 另外,对最优疏松纳滤膜进行了染料脱盐、长期稳定性、抗污性能及光催化自清洁测试. 结果表明,所制备的疏松复合膜具有高渗透通量,优异的染料截留率和较低的脱盐率,且具有优异的光催化自清洁性能.

1. 材料与方法(Materials and methods)

1.1 主要试剂

商用聚醚砜(PES, Mw =

5800 )购自巴斯夫有限公司(德国). 无水哌嗪(PIP)、正己烷、N, N- 二甲基乙酰胺(DMAc)、二甘醇(DEG)、聚乙二醇(PEG)(Mw: 600、1000 、2000、4000 和6000 ),甲基蓝(MB)、乙醇、硫酸钠(Na2SO4,> 99%)和氯化钠(NaCl,> 99%)由国药化学试剂有限公司供应. 单宁酸(TA)、N, N-二甲基甲酰胺(DMF)、甲基橙(MO)、甲苯胺蓝(TB)购自阿拉丁(中国上海). 六水氯化铁(FeCl3·6H2O)和对苯二甲酸(PTA)购自上海麦克林生物化工有限公司. 亚甲基蓝(MBA)由美亚有限公司提供.1.2 金属-有机框架MIL-53(Fe)和TA@MIL-53(Fe)的制备

根据前人的文献报道[16],采用溶剂热法合成了MIL-53(Fe). 合成步骤如图1所示,先称量

0.6757 g FeCl3·6H2O 并溶于50 mL DMF 中,然后将0.4153 g PTA 溶于50 mL DMF 中,将两种溶液充分混合搅拌20 min,直至混合物变为透明. 最后,将混合物转移到100 mL聚四氟乙烯高压釜中,加热至120 ℃,持续10 h. 反应器自然冷却至室温后,以5000 r·min−1 离心5 min,用 DMF和乙醇连续洗涤3次,并重复进行3次离心洗涤操作. 将制备的材料在80 ℃ 下干燥12 h, MIL-53(Fe)块状颗粒研磨,筛分并放入干燥箱,备用. 0.4 g TA 溶于50 mL 去离子水中,加入0.1 g MIL-53(Fe)粉末充分混合,在50 ℃下连续搅拌30 min. 然后,通过离心、洗涤和干燥得到 TA@MIL-53(Fe)粉末.1.3 TA@MIL-53(Fe)疏松复合膜的制备

首先称取1.5 g PIP 溶解到100 mL 去离子水中,向PIP溶液里加入0.02 g TA@MIL-53(Fe)粉末并持续搅拌30 min直至TA@MIL-53(Fe)均匀分散在PIP溶液里. 然后,称取0.1 g TMC加入到75 mL 正己烷中,在室温下搅拌10 min直至溶液变透明. 按照图2所示,制备TA@MIL-53(Fe)/TA疏松纳滤膜. 首先将PES超滤膜固定在真空抽滤装置上,将TA@MIL-53(Fe)/PIP混合溶液倒到膜上,在空气中静置3 min,利用真空抽滤将材料抽到膜表面. 然后将TMC正己烷溶液倒入到膜上,反应1 min后立即用正己烷和去离子水交替冲洗膜表面数次. 将制备的TA@MIL-53(Fe) 复合膜浸泡在去离子水中,命名为MTPA-X (X表示TA@MIL-53的添加量).

1.4 复合膜的表征

使用扫描电子显微镜(SEM,Hitachi SU5000,Japan)对MIL-53(Fe)和TA@MIL-53(Fe)的表面形貌进行了表征. 使用IS10光谱仪(赛默飞世尔科学公司)测定材料和复合膜的化学键. 利用X射线衍射(XRD; Bruker, D8 Advanced)分析了所制备的纳米粒子的晶体结构. 用热重分析表征了纳米粒子的热稳定性. 在150 mL·min−1的N2气氛中,纳米粒子的温度以10 ℃·min−1 的速率由25 ℃ 升高到

1000 ℃. 使用能量色散X射线光谱(EDX-Mapping; X Flash6110 ,BRUKER)和 X射线光电子能谱(XPS; Escalab 250XI,Thermo Fisher Scientific)来检测膜表面化学元素的分布.1.5 复合膜的性能测试实验

膜的分离性能包括渗透性和选择性,是膜性能测试的重要指标. 在本实验中复合膜的渗透通量和截留率采用自制的错流实验装置进行测定. 首先,将复合膜剪成直径为7 cm的圆片,固定在装置支架上,随后使用去离子水在0.2 MPa(2 bar)操作压力下预压30 min,待通量稳定后,收集5 min的渗透液并用量筒读取渗透体积,通过下式(1)计算复合膜的渗透通量:

stringUtils.convertMath(!{formula.content}) (1) 式中,PWF(L·m−2·h−1·bar−1)为纯水通量;Q(L)为渗透体积;A(m2)为膜的有效面积;t(h)为操作时间;∆P(bar)为操作压力.

用无机盐(NaCl和Na2SO4)、染料(MB、MO、MBA、TB)和重金属离子(Cr6+)来分析膜的截留率和渗透性,截留率公式(2)如下:

stringUtils.convertMath(!{formula.content}) (2) 式中R(%)为截留率;Cp为流出料液的浓度(mg·L−1);Cf为进料液的浓度(mg·L−1).

采用台式电导率仪(S 230-B)测定截留前后无机盐溶液的电导率值. 使用哈希的紫外分光光度计(DR

6000 )测定截留前后染料溶液的吸光度.1.6 截留分子量(MWCO)测试实验

MWCO是评价膜分离性能的重要参数,本实验选取不同分子量的PEG(Mw=400、600、800、

1000 、2000、4000 Da)作为实验溶液评估膜的截留尺度. 在操作压力为2 bar,进料液浓度为100 mg·L−1条件下,预压30 min后,收集渗透液. PEG进料液和渗透液浓度使用岛津的TOC-L型TOC仪测定,PEG的截留率按式2计算. 根据公式3计算PEG的斯托克斯直径.stringUtils.convertMath(!{formula.content}) (3) 1.7 长期稳定性测试实验

长期稳定性测试是评估膜分离性能的另一重要参数,本实验制备的复合膜的长期稳定性使用自制的错流过滤装置进行. 以MB(100 mg·L−1)或TB(100 mg·L−1)和NaCl(1 g·L−1)染料盐混合液作为进料液,在操作压力为2 bar下进行20 h膜的稳定性实验.

1.8 抗污性能测试实验

膜的抗污性能是判断膜使用寿命及分离性能的另一重要参数,本实验以MB和TB作为污染源,对制备的复合膜进行了抗污性能测试. 在操作压力为2 bar,进料溶液浓度为100 mg·L−1下进行. 首先,将制备的复合膜在2 bar压力下预压30 min,使复合膜渗透通量保持稳定,然后连续通纯水120 min,每30 min记录一次纯水通量记为Jw. 之后,换上浓度为100 mg·L−1的MB溶液运行240 min,每隔30 min记录一次通量记为Jp. 用去离子水清洗30 min以去除表面污染物,随后使用去离子水运行120 min,每30 min记录一次通量记为Jw2,重复上述操作3次. 之后分别以TB和Cr6+溶液进行抗污染循环实验,操作同上述一致. 最后通过引入通量恢复率(FRR)、总污垢率(Rt)、可逆污垢率(Rr)和不可逆污垢率(Rir)等4个指标来评估膜的抗污性能,公式如下:

stringUtils.convertMath(!{formula.content}) (4) stringUtils.convertMath(!{formula.content}) (5) stringUtils.convertMath(!{formula.content}) (6) stringUtils.convertMath(!{formula.content}) (7) 2. 结果与讨论(Results and discussion)

2.1 MIL-53(Fe)和TA@MIL-53(Fe) 的表征

通过SEM、XRD和FT-IR分析仪器对MIL-53(Fe)和TA@MIL-53(Fe) 进行表征[17]. 如图3(a)所示,用SEM观察MIL-53(Fe)的形貌,呈现八面体结构的锥形体,平均直径为200—500 nm,这与文献报道的相一致[18]. 如图3(b)所示,经过TA改性后,MIL-53(Fe)表面更加光滑且结构均匀,结果表明TA蚀刻后的MIL-53(Fe) 结构不会坍塌,保持原有八面体结构.

如图4(a)所示,用XRD分析MIL-53(Fe) 和TA@MIL-53(Fe) 的晶体结构. 从图4可以观察到,9.3°、12.5°、18.7°、19.2°和21.8°的5个特征峰,这5个特征峰分别对应着(200)、(110)、(-110)、(310)和(311)的晶面,和其他文献中报道的相一致[17 − 18]. 在XRD图里有一些多余的杂峰,与SEM图比较分析,可能是缺陷的MOF坍塌分解和微量有机溶剂造成. 另外,衍射峰的形状相对尖锐,表明本工作合成的粉末具有良好的结晶度. 图4(b)显示的是粉末的红外测试图. 在MIL-53光谱中,

1300 —1600 cm−1范围内显示着PTA里—COOH的典型振动峰,1390 cm−1和1587 cm−1处的吸收峰分别对应羧基的不对称振动和对称振动,而1690 cm−1处的特征峰代表着羰基拉伸振动[19]. 748 cm−1处的峰是由于PTA中苯环的C—H弯曲振动引起. 551 cm−1处的特征峰是由Fe—O拉伸运动引起,这也表明PTA的羧基和Fe3+之间存在金属-氧键. 在TA的FT-IR谱图中,1610 、1541 、748 cm−1处的吸收峰分别对应着C—H、C—O和C=C拉伸振动.3400 cm−1和1690 cm−1分别对应着O—H伸缩振动和酯基的C=O伸缩振动. 在TA@MIL-53的FT-IR光谱中,出现了上述TA和MIL-53(Fe) 的特征峰,由此表明TA成功改性MIL-53(Fe),与文献中报道的一致[17 − 20].材料的热稳定性和比表面积大小是限制其在膜领域内应用的重要参数[19]. 通过TGA分析粉末的热稳定性,分析结果如图4(c)所示,采用TGA进一步分析MIL-53和TA@MIL-53的化学组成和热稳定性,与MIL-53相比,多出的一段分解温度是由于TA分解造成的,这与TA的分解温度一致. 另外,TA@MIL-53在25 ℃到213.6 ℃范围内出现了8.7%的重量损失,这是由于粉末中残留的水分子和有机溶剂被去除. 另外,根据先前文献报道和PTA的分解温度推测,在289.7 ℃出现陡坡式的重量损失是由MIL-53粉末分解造成的,最后在514.6 ℃分解完全.

2.2 TA@MIL-53(Fe) 疏松复合膜的表征

通过SEM和AFM的手段表征TA@MIL-53(Fe) 负载量对复合膜形貌及粗糙度的影响. 如图5(a)一列是复合膜的表面形貌图,纯IP膜表面有一些褶皱疏松的地方,这可能是由于复合膜制备过程中,未将膜冷却到室温直接加入到去离子水中,温差过大造成聚酰胺层交联度降低. 当TA@MIL-53(Fe) 粉末从0.02% wt增加到0.04% wt时,明显的能看到颗粒团聚现象. 另外,随着TA@MIL-53(Fe) 材料在膜上负载量的增加,膜表面PA层还出现了分裂,这可能是纳米颗粒增加使得PA层交联度降低,这也从宏观角度说明了复合膜渗透性降低的原因. 由截面图结果可以看出,MPTA-0和MPTA-0.01的交联层厚度从120 nm增加到550 nm,这是因为添加了TA@MIL-53(Fe) 纳米颗粒造成的. 随着粉末添加量的增加,从膜截面可以看出,PA层的厚度也随之增加,而PA层的膜厚是影响复合膜渗透性-选择性的重要因素. 所以,添加合适尺寸的纳米颗粒可以控制复合膜PA层的厚度,从而优化膜的渗透选择性,有效协调复合膜的trade-off效应[21].

如图5(c)所示,TA@MIL-53添加量对复合膜粗糙度的影响. MPTA-0纯IP膜与MPTA-0.01复合膜相比,膜的Ra值从17.4 nm增加到了39 nm,这一结果是与TA@MIL-53加入到PA层有关的,在界面聚合过程中,亲水性的TA@MIL-53(Fe)均匀分散在膜表面,但TA@MIL-53(Fe)材料的锥形框架结构使得膜表面高低不平,从而增加了复合膜的粗糙度,这与其他文献中复合膜的结果相一致.

为了进一步探究TA@MIL-53(Fe) 在复合膜表面中的分散情况,对MPTA-0.02复合膜测了EDS-mapping图谱,从图6(a)中看出,Fe元素均匀分散在复合膜表面,结果表明TA@MIL-53(Fe) 纳米颗粒均匀分散在膜表面. 另外,N元素均匀分散在膜表面,这也从侧面表明PIP和TMC成功反应生成PA层[22].

为了表征TA@MIL-53(Fe) 复合膜表面化学结构,采用FT-IR对复合膜表面化学官能团进行了测试. 如图6(b)所示,在

1582 cm−1和1489 cm−1处的特征峰分别对应着酰胺基团中的C=O和N—H,这是由基团的拉伸振动引起,这证明了PIP和TMC成功反应生成了PA层. 在1731 cm−1处的特征峰是由羧基的振动引起的,相对于另外两个复合膜,MPTA-0.02复合膜在1731 cm−1处峰面积增加,这可能是由过多的酰氯基团水解产生. 与MPA-0.02膜相比,MPTA-0.02复合膜在3110 cm−1处存在的吸收峰是由TA的—OH伸缩振动引起的,这也表明亲水基团—OH成功引入复合膜[23 − 24]. 与MPTA-0膜相比,MPTA-0.02在768 cm−1处出现的特征峰是由PTA中C—H基团弯曲振动引起,另外,在558 cm−1处出现的新的吸收峰是由于Fe3+和PTA里的—COO−基团相互作用引起的Fe—O拉伸,该结果说明了TA@MIL-53(Fe) 成功引入了复合膜的PA层.为了进一步探究添加TA@MIL-53(Fe) 纳米颗粒对PA层的影响,并解释MIL-53(Fe) 复合膜和TA@MIL-53(Fe) 复合膜之间的差异,采用XPS谱分析复合膜表面元素组成和元素价态. 在图7(a)的XPS总谱中,检测到Fe、O、C、N和S元素,这与EDS-mapping测试结果相吻合. 图7(b)显示的是MPTA-0.02复合膜的Fe 2p的光谱,725.6 eV和711.8 eV处的两个特征峰分别代表着Fe 2p1/2和Fe 2p3/2. 这两个峰的差值为13.8 eV,说明Fe-oxo团簇中存在Fe3+. 在716.7 eV处观测到的谷峰可归因于卫星峰,这是Fe3+的典型特征. 图7(c)是复合膜的C 1s谱,MPTA-0的C 1s谱在284.9 eV和288.1 eV处有两个特征峰,这是TMC中的C=C/C—C和酰胺基团的C=O. 另外,MPA-0.02的C 1s谱在284.9 eV和288.1 eV处的两个峰对应着PTA里的C=C和C=O. 与MPA-0.02相比,MPTA-0.02复合膜的C 1s谱观察到3个峰,286.2 eV处的峰对应着TA的苯甲酸环[17 − 25],这也证明了TA成功改性MIL-53,亲水性的TA@MIL-53(Fe) 复合膜有助于提高膜的渗透性和抗污性能. 如图7(d)所示,MPA-0.02复合膜在531.6 eV和533.6 eV处的两个峰分别对应着PTA中的O=C(O—Fe) 和O—C. 与MPA-0.02复合膜相比,MPTA-0.02复合膜在532.4 eV处多出的峰对应着TA上未参与反应的羟基[26]. 综上所述,成功利用TA制备出亲水性有缺陷的MIL-53(Fe),并进一步证实将TA@MIL-53(Fe) 纳米颗粒引入PA层.

2.3 TA@MIL-53(Fe) 疏松复合膜水接触角

膜表面亲水性是评价膜渗透性能和抗污性能的重要指标. 如图8所示,添加MIL-53(Fe) 和TA@MIL-53(Fe) 纳米颗粒对复合膜接触角的影响. MPTA-0复合膜的水接触角为70.5°,加入TA@MIL-53(Fe) 纳米颗粒后,复合膜水接触角开始下降. 随着TA@MIL-53(Fe) 添加量从0%增加到0.04%,复合膜的水接触角从70.5°降低到34.75°,这是由于有缺陷的TA@MIL-53(Fe) 为水分子提供了更多的通道. 另外,与MPTA-0.02复合膜相比,添加了疏水性的MIL-53(Fe) 纳米颗粒对改善膜的亲水性帮助甚微,这也从另一方面证明了TA成功改性MIL-53(Fe)纳米颗粒,使得TA中的亲水基团(—OH)与MIL-53(Fe)结合,从而提高膜的亲水性[27]. 因此,添加TA@MIL-53(Fe)纳米颗粒降低膜的水接触角,从而达到提高膜的亲水性效果,这与文献报道的结果相一致[28 − 29].

2.4 TA@MIL-53(Fe) 疏松复合膜截留分子量

为了进一步分析膜孔变化,通过不同分子量PEG来测试复合膜的MWCO. 如图9所示,MPTA-0复合膜的MWCO约为2000 Da,当加入TA@MIL-53纳米颗粒后,复合膜的截留性能提高,MPTA-0.02复合膜有效的MWCO约为

1665 Da. 根据Stokes半径公式(2-3)计算得到MPTA-0.02复合膜的孔径约为1.02 nm[30 − 31]. 另外,随着TA@MIL-53(Fe) 纳米颗粒的增加,复合膜的截留尺度降低. 因此,为了进一步对复合膜性能做出评估,后续选择MPTA-0.02复合膜做分离性能、稳定性和抗污性能测试.2.5 TA@MIL-53(Fe) 疏松复合膜的分离性能

采用不同分子量和不同电荷的4种染料作为实验溶液,对MIL-53(Fe)和TA@MIL-53(Fe)复合膜进行分离性能测试(操作条件:0.02 MPa,染料浓度:100 mg·L−1). 如图10所示,MPTA-0复合膜渗透通量为29.3 L·m−2·h−1·bar−1,对阴离子染料MB的截留率为96.3%. 相比于MPTA-0复合膜,当TA@MIL-53(Fe) 负载量从0增加到0.02% wt时,膜渗透通量增加1.8倍,提高到53.6 L·m−2·h−1·bar−1,同时对MB的去除率也有所提高,提高到了99.1%. 这主要是因为亲水性TA@MIL-53(Fe) 纳米颗粒加入PA层有助于在交联层表面形成亲水分子层,提高对水分子的吸引力. 另外,TA@MIL-53(Fe) 的加入会使致密的PA层变得疏松,从而提高膜的渗透通量,TA@MIL-53(Fe) 具有合适的窗口尺寸,可以选择性地截留染料分子[19 − 32]. 随着TA@MIL-53(Fe) 负载量的增加,复合膜截留性能开始下降,这主要是由以下原因造成的,一方面由于过多的TA@MIL-53(Fe) 会在膜表面发生团聚,从而使得PA层性能下降,另一方面是过多的负载量会使得复合膜的交联度降低,使得PA层出现断裂,从而导致复合膜截留性能下降. 对于不同电荷、分子量相近的染料,复合膜表现出对阴离子染料更高的截留率,这可能是由于复合膜带负电荷,对阴离子染料具有强排斥作用[33]. 另外,对于相同电荷的染料,随着染料分子量的提高,截留率也在提高,这主要是由复合膜的孔径筛分决定,此结果与其他文献报道的结果一致[34 − 36].

除以染料溶液为进料液外,还使用4种无机盐溶液来测试复合膜的盐渗透性能. 如图10(b)所示,随着TA@MIL-53(Fe)添加量的增加,复合膜对无机盐的截留率降低,这主要是由于过多的NPs抑制了缩聚反应,从而破坏了PA层,降低了复合膜的截留性能. 另外,MPTA-0.02复合膜对盐的截留率为NaCl(4.3%)<MgCl2(7.1%)<Na2SO4(11.5%)<MgSO4(15.3%),复合膜表现出较低的盐截留率. 为了进一步探究复合膜染料脱盐性能,选用性能最佳的MPTA-0.02复合膜来测试膜的染盐分离性能. 使用0.1 g·L−1的MB或TB和1 g·L−1的NaCl或Na2SO4混合溶液来进行过滤实验,如图10(c)所示,以染料盐混合液为进料液,MPTA-0.02复合膜的渗透通量在58.9—64.2 L·m−2·h−1·bar−1之间. 与单一染料的分离实验相比,MPTA-0.02复合膜对MB的截留率略微较低,从99.1%降到了96.3%和97.8%. 这主要是由于高浓度的盐与染料分子结合,从而提高了染料分子的水溶性,从而导致复合膜的染料截留率降低. 另外,与单一染料的分离实验相比,MPTA-0.02复合膜对TB的截留率降低较少,这主要是由于复合膜表面带负电荷,阳离子染料吸附到膜表面堵塞膜孔,从而提高复合膜的染料截留率,另一方面,盐溶液提高了染料分子的水溶性,从而降低复合膜的染料截留率,一增一减之下,使得复合膜对TB染料具有较高的去除率(97.9%和96.4%). 总的来说,MPTA-0.02复合膜对染料分子的截留率高达95%以上,并且具有优异的盐渗透性能(高于85%). 图10(d)比较了本研究与其它疏松复合膜的渗透通量和染料截留率[1 − 2, 6, 9, 11, 14 − 15, 34]. 结果表明,与其他文献中的疏松复合膜相比,本研究所制备的复合膜具有较高的渗透通量和良好的染料截留率.

2.6 TA@MIL-53(Fe) 疏松复合膜的长期稳定性

膜的稳定性测试是评估膜性能及推广应用的重要参数. 为了探究MPTA-0.02复合膜在高浓度含盐染料废水中的稳定性,配置100 mg·L−1染料(MB和TB)和1 g·L−1 NaCl混合溶液来模拟染料废水,复合膜在0.2 MPa的操作压力下运行20 h. 如图11所示,运行前3 h,复合膜的渗透通量下降,这是由于混合液中盐离子使得染料分子在水中分散的更加均匀,小的染料分子因为静电效应被吸附到PA层. 另外,图11(b)可看出,与用阴离子染料MB作为模拟废水相比,在阳离子染料TB模拟废水中,复合膜的渗透通量下降的更多,这是由于复合膜表面携带负电荷,对阳离子染料分子具有更强的吸附性,从而使得染料分子堵塞膜孔,导致膜通量下降. 此外,MB和TB染料具有良好的水溶性,在水溶液中可以建立起动态平衡,使过滤过程保持稳定,在过滤过程中,由于浓差极化和膜污染的形成,在复合膜表面渐渐形成了一层薄薄的凝胶层,这也导致复合膜对MB和TB的截留率略有提高,对MB和TB的截留率分别为99.1%和98.4%. 这表明改复合膜对染料具有很好的去除性能. 另外,在长期的运行中保持对NaCl的高渗透性. 总的来说,MPTA-0.02复合膜具有良好的稳定性,可进一步开发用于含盐染料废水的实际应用中.

2.7 TA@MIL-53(Fe) 疏松复合膜抗污性能

膜的抗污染测试是评估膜性的另一个重要参数. 为了进一步探究MPTA-0.02复合膜在染料废水中的应用,采用阴离子染料MB和阳离子染料TB作为污染源,进行复合膜的抗污性能测试. 如图12(a)所示,在处理染料废水时,由于浓差极化作用,在循环的初始阶段通量下降,随着运行的进行,染料分子在膜表面形成凝胶层,进一步造成通量降低并趋于稳定. 为了进一步探究膜的抗污性能和膜污染类型,引入膜通量恢复率(FRR)、总污垢率(Rt)、不可逆污垢率(Rir)和可逆污垢率(Rr). 如图12(b)所示,MB染料所造成的污染主要以可逆污染(Rr=7.7%)为主,这是由于浓差极化作用造成的. 另外,TB染料对复合膜造成的污染主要以不可逆污染(Rir=8.6%)为主,这可能是由于复合膜表面带负电荷,对阳离子染料具有强吸引力,造成的膜污染无法通过水力清洗恢复[37 − 38]. 如图12(c)所示,复合膜的通量恢复率都很高,循环3次MB染料下复合膜的FRR分别为93.6%、93.5%和93.7%,根据之前分析,这主要是由于复合膜对阴离子染料的排斥作用,从而降低了污染结垢形成可能性,该结果表明该复合膜对阴离子染料具有良好的抗污性能. 另外,循环3次TB染料下复合膜的FRR分别为91.3%、95%和93.9%. 相较于其他两次循环,由于静电作用和膜表面缺陷,使得更多的TB分子沉积在膜表面,导致膜通量降低,膜通量恢复率略低. 总的来说,亲水性MPTA-0.02复合膜具有良好的抗污性能,有望进一步开发用于染料废水的实际应用.

图 12 MPTA-0.02复合膜抗污性能测试: (a) 复合膜在不同染料溶液中循环过滤测试, (b) 复合膜污染情况, (c) 膜的通量恢复率(FRR)Figure 12. MPTA-0.02 composite membrane anti-fouling performance test: (a) cyclic filtration test of the composite membrane in different dye solutions, (b) contamination of the composite membrane, (c) flux recovery rate (FRR) of the membrane

图 12 MPTA-0.02复合膜抗污性能测试: (a) 复合膜在不同染料溶液中循环过滤测试, (b) 复合膜污染情况, (c) 膜的通量恢复率(FRR)Figure 12. MPTA-0.02 composite membrane anti-fouling performance test: (a) cyclic filtration test of the composite membrane in different dye solutions, (b) contamination of the composite membrane, (c) flux recovery rate (FRR) of the membrane2.8 TA@MIL-53(Fe) 疏松复合膜光催化自清洁及机理分析

在印染废水的实际应用中,当膜进料压力过大或膜污染严重时,需要使用水力反冲洗和化学清洗剂来恢复膜的性能,这不仅会损害膜的机体结构,还会降低膜的性能,从而增加膜组件消耗成本. 因此,光催化自清洁膜的开发利用可以有效避免这一问题. 本研究使用UV-VIS光谱进一步研究复合膜的光吸收特性,以反映用MIL-53(Fe) 和TA@MIL-53(Fe) NPs制备的复合膜的自清洁性能. 如图13(a)所示,MPA-0.02和MPTA-0.02复合膜的吸收边缘的波长分别为434 nm和478 nm,这说明了TA改性后的MIL-53(Fe) 吸收边缘发生了红移. 另外,也反映了MIL-53(Fe) 和TA@MIL-53(Fe) 复合膜在可见光范围内的响应能力. 如图13(b)所示,MPA-0.02复合膜的禁带约为2.93 eV,而MPTA-0.02复合膜的禁带宽度为2.75 eV,这表明TA的改性可以增强光的吸收,缩小MIL-53(Fe) 的带隙宽度. 根据相关文献报道,MIL-53(Fe) 在可见光范围内具有光催化特性,但单独的MIL-53(Fe) 的光催化自清洁的性能并不高,Xin等将MIL-53(Fe) 引入纺丝纤维滤膜中,单独使用MIL-53(Fe) 对罗丹明的降解效果只有50%,当引入PS电子受体后,对罗丹明的降解效果达到了60%[39]. 另外,常用的电子受体还有H2O2、TA、过硫酸盐等.

图13(c)显示了3种膜在100 mg·L−1 的MB溶液中进行3循环测试时的通量变化. 预压30 min后,每张膜用纯水过滤60 min,然后以MB溶液为进料液运行60 min. 在第一和第二循环之间,使用纯水对膜进行过滤清洗30 min,在第二和第三循环之间,将膜放在H2O2溶液中并使用可见光照射膜表面30 min. 在通入MB溶液后,由于浓差极化和尺寸效应的共同作用,3张膜的渗透通量大幅度下降,并随之形成凝胶层. 经过水力反冲洗后,3张膜表现出相似的低通量恢复趋势,这表明单纯的水力冲洗,无法有效去除吸附MB所引起的不可逆污染. 如图13(d)所示,在水力冲洗下,MPTA-0、MPA-0.02、MPTA-0.02复合膜的FRR1分别为85.4%、86.3%和85.7%. 然而,在可见光照射下,与MPTA-0复合膜相比,MPA-0.02和MPTA-0.02复合膜的FRR2分别为94.6%和96.5%,这比水力冲洗获得的FRR1多了20%. 这也说明了亲水性和光催化材料组合有望制备出优异自清洁性能的疏松复合膜.

图14说明了TA@MIL-53(Fe) 疏松复合膜的自清洁机理. 在可见光照条件下,嵌入PA层的TA@MIL-53(Fe)吸收可见光,将电子从价带(VB)激发到导带(CB),在激发过程中形成活性氧(ROS),例如·O2-、·OH、和h+. 其中电子-空穴对(h+)是由TA@MIL-53(Fe) 受可见光照射产生的;·O2-是光生电子与吸附在膜表面的O2进一步反应生成的,另一部分光生电子与H2O2反应生成·OH. 一般来说,光催化剂产生的ROS可以用来降解膜表面的污染物[40],对于染料这类小分子污染物直接与ROS发生氧化还原反应被降解成H2O和CO2,而对于一些大分子污染物会被断裂分子结构转化为小分子物质[41]. 断裂的有机污染物在经过水力冲洗后很容易从膜上去除,从而有效恢复膜通量. 同时实验结果表明经过光催化自清洁后复合膜的渗透通量恢复到了初始膜通量的96.5%.

在可见光照射条件下,MPTA-0.02复合膜的光催化自清洁的作用机理如下:

stringUtils.convertMath(!{formula.content}) stringUtils.convertMath(!{formula.content}) stringUtils.convertMath(!{formula.content}) stringUtils.convertMath(!{formula.content}) stringUtils.convertMath(!{formula.content}) stringUtils.convertMath(!{formula.content}) stringUtils.convertMath(!{formula.content}) 3. 结论(Conclusion)

本研究采用单宁酸蚀刻法制备了有缺陷的TA@MIL-53(Fe)纳米颗粒. 随后,采用真空抽滤辅助IP反应制备了TA@MIL-53(Fe)复合膜. 在PA选择层中添加TA@MIL-53(Fe)可以提高复合膜的亲水性,为水分子提供一个特殊的通道,使水通量从29.3 L·m−2·h−1·bar−1增加到53.6 L·m−2·h−1·bar−1. 然而,过多的纳米粒子负载可能会降低PA的交联程度,从而导致保留率的急剧下降. 在最佳条件下制备的复合膜MPTA-0.02具有良好的性能,在染料和无机盐混合溶液中的渗透通量在58.9—64.2 L·m−2·h−1·bar−1之间,对MB和TB的截留率分别为97.8%和96.4% ,对盐的渗透性能高于85%. 此外,MPTA-0.02复合膜长期运行20 h后,水通量和截留率较好,对染料/盐混合溶液的截留率较高. 同时,由于MIL-53(Fe)的光催化活性,制备的复合膜具有良好的自清洁能力,与水力冲洗后膜的通量恢复率相比,膜的通量恢复率高达96.5%. 因此,该复合膜能够实现印染废水中盐和染料的分离,并具有优异的自清洗性能,对印染废水的回用具有重要意义.

-

图 12 MPTA-0.02复合膜抗污性能测试: (a) 复合膜在不同染料溶液中循环过滤测试, (b) 复合膜污染情况, (c) 膜的通量恢复率(FRR)

Figure 12. MPTA-0.02 composite membrane anti-fouling performance test: (a) cyclic filtration test of the composite membrane in different dye solutions, (b) contamination of the composite membrane, (c) flux recovery rate (FRR) of the membrane

-

[1] SUN Z Y, ZHU X W, TAN F X, et al. Poly(vinyl alcohol)-based highly permeable TFC nanofiltration membranes for selective dye/salt separation[J]. Desalination, 2023, 553: 116479. doi: 10.1016/j.desal.2023.116479 [2] JOSHI U S, JEWRAJKA S K. Tight ultrafiltration and loose nanofiltration membranes by concentration polarization-driven fast layer-by-layer self-assembly for fractionation of dye/salt[J]. Journal of Membrane Science, 2023, 669: 121286. doi: 10.1016/j.memsci.2022.121286 [3] SONG Y F, SUN Y K, ZHANG N, et al. Custom-tailoring loose nanocomposite membrane incorporated bipiperidine/graphene quantum dots for high-efficient dye/salt fractionation in hairwork dyeing effluent[J]. Separation and Purification Technology, 2021, 271: 118870. doi: 10.1016/j.seppur.2021.118870 [4] EWUZIE U, SALIU O D, DULTA K, et al. A review on treatment technologies for printing and dyeing wastewater (PDW)[J]. Journal of Water Process Engineering, 2022, 50: 103273. doi: 10.1016/j.jwpe.2022.103273 [5] ZHAO D L, FENG F, SHEN L G, et al. Engineering metal-organic frameworks (MOFs) based thin-film nanocomposite (TFN) membranes for molecular separation[J]. Chemical Engineering Journal, 2023, 454: 140447. doi: 10.1016/j.cej.2022.140447 [6] FENG X Q, LIU D C, YE H, et al. High-flux polyamide membrane with improved chlorine resistance for efficient dye/salt separation based on a new N-rich amine monomer[J]. Separation and Purification Technology, 2021, 278: 119533. doi: 10.1016/j.seppur.2021.119533 [7] ZHANG P F, RAJABZADEH S, SONG Q Q, et al. Development of loose nanofiltration PVDF hollow fiber membrane for dye/salt separation[J]. Desalination, 2023, 549: 116315. doi: 10.1016/j.desal.2022.116315 [8] SAMSAMI S, MOHAMADIZANIANI M, SARRAFZADEH M H, et al. Recent advances in the treatment of dye-containing wastewater from textile industries: Overview and perspectives[J]. Process Safety and Environmental Protection, 2020, 143: 138-163. doi: 10.1016/j.psep.2020.05.034 [9] ZHAO A N, ZHANG M, BAO Y M, et al. Loose nanofiltration membrane constructed via interfacial polymerization using porous organic cage RCC3 for dye/salt separation[J]. Journal of Membrane Science, 2022, 664: 121081. doi: 10.1016/j.memsci.2022.121081 [10] MARADDI A, HALAKARNI M, MANOHARA HALANUR M, et al. Fe-MOF induced biopolymer-based sustainable self-cleaning membranes for effective selective separation and wastewater treatment[J]. Sustainable Materials and Technologies, 2023, 35: e00537. doi: 10.1016/j.susmat.2022.e00537 [11] HE J S, WANG Y, NI F, et al. Ultra-Highly permeable loose nanofiltration membrane containing PG/PEI/Fe3+ ternary coating for efficient dye/salt separation[J]. Separation and Purification Technology, 2022, 292: 121020. doi: 10.1016/j.seppur.2022.121020 [12] TONG Y H, WU Y Z, XU Z L, et al. Photocatalytic self-cleaning EVAL membrane by incorporating bio-inspired functionalized MIL-101(Fe) for dye/salt separation[J]. Chemical Engineering Journal, 2022, 444: 136507. doi: 10.1016/j.cej.2022.136507 [13] ZHOU S Y, FENG X Q, ZHU J Y, et al. Self-cleaning loose nanofiltration membranes enabled by photocatalytic Cu-triazolate MOFs for dye/salt separation[J]. Journal of Membrane Science, 2021, 623: 119058. doi: 10.1016/j.memsci.2021.119058 [14] LIU Y F, BAI Z X, LIN G, et al. Covalent cross-linking mediated TA-APTES NPs to construct a high-efficiency GO composite membrane for dye/salt separation[J]. Applied Surface Science, 2022, 584: 152595. doi: 10.1016/j.apsusc.2022.152595 [15] LIU Y F, BAI Z X, LIN G, et al. Tannic acid-mediated interfacial layer-by-layer self-assembly of nanofiltration membranes for high-efficient dye separation[J]. Applied Surface Science, 2022, 602: 154264. doi: 10.1016/j.apsusc.2022.154264 [16] JIANG Y, YANG Q M, XU Q J, et al. Metal organic framework MIL-53(Fe) as an efficient artificial oxidase for colorimetric detection of cellular biothiols[J]. Analytical Biochemistry, 2019, 577: 82-88. doi: 10.1016/j.ab.2019.04.020 [17] YANG J X, WANG D, WANG J H, et al. Corrosion resistance and near-infrared light induced self-healing behavior of polycaprolactone coating with[email protected]on magnesium alloy[J]. Applied Surface Science, 2022, 585: 152729. doi: 10.1016/j.apsusc.2022.152729 [18] JIA Y, LIU P X, LIU Y B, et al. In-situ interfacial crosslinking of NH2-MIL-53 and polyimide in MOF-incorporated mixed matrix membranes for efficient H2 purification[J]. Fuel, 2023, 339: 126938. doi: 10.1016/j.fuel.2022.126938 [19] KACHHADIYA D D, MURTHY Z V P. Highly efficient chitosan-based bio-polymeric membranes embedded with green solvent encapsulated MIL-53(Fe) for methanol/MTBE separation by pervaporation[J]. Journal of Environmental Chemical Engineering, 2023, 11(2): 109307. doi: 10.1016/j.jece.2023.109307 [20] WU C J, VALERIE MAGGAY I, CHIANG C H, et al. Removal of tetracycline by a photocatalytic membrane reactor with MIL-53(Fe)/PVDF mixed-matrix membrane[J]. Chemical Engineering Journal, 2023, 451: 138990. doi: 10.1016/j.cej.2022.138990 [21] GHANBARI R, NAZARZADEH ZARE E, PAIVA-SANTOS A C, et al. Ti3C2Tx MXene@MOF decorated polyvinylidene fluoride membrane for the remediation of heavy metals ions and desalination[J]. Chemosphere, 2022, 311(Pt 2): 137191. [22] QIN Y, LIU H L, LIU Y M, et al. Design of a novel interfacial enhanced GO-PA/APVC nanofiltration membrane with stripe-like structure[J]. Journal of Membrane Science, 2020, 604: 118064. doi: 10.1016/j.memsci.2020.118064 [23] XIE H L, SHEN L G, XU Y C, et al. Tannic acid (Ta)-based coating modified membrane enhanced by successive inkjet printing of Fe3+ and sodium periodate (sp) for efficient oil-water separation[J]. SSRN Electronic Journal, 2022: 120873. [24] LIU S, TONG X, LIU S H, et al. Multi-functional tannic acid (TA)-Ferric complex coating for forward osmosis membrane with enhanced micropollutant removal and antifouling property[J]. Journal of Membrane Science, 2021, 626: 119171. doi: 10.1016/j.memsci.2021.119171 [25] XIE H L, CHEN B H, LIN H J, et al. Efficient oil-water emulsion treatment via novel composite membranes fabricated by CaCO3-based biomineralization and TA-Ti(IV) coating strategy[J]. The Science of the Total Environment, 2023, 857(Pt 2): 159183. [26] JI K, YUE Y L, YANG P. Interface effect in MIL-53(Fe)/metal-phenolic network (Ni, Co, and Mn) nanoarchitectures for efficient oxygen evolution reaction[J]. Applied Surface Science, 2023, 608: 155184. doi: 10.1016/j.apsusc.2022.155184 [27] GAO C M, CHEN H Y, LIU S H, et al. Bimetallic polyphenol networks structure modified polyethersulfone membrane with hydrophilic and anti-fouling properties based on reverse thermally induced phase separation method[J]. Chemosphere, 2022, 288: 132537. doi: 10.1016/j.chemosphere.2021.132537 [28] XUE J J, XU M J, GAO J M, et al. Multifunctional porphyrinic Zr-MOF composite membrane for high-performance oil-in-water separation and organic dye adsorption/photocatalysis[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2021, 628: 127288. doi: 10.1016/j.colsurfa.2021.127288 [29] CHEN Y Z, BAI Y T, MENG L J, et al. Engineering nanocomposite metal-phenolic network membranes with hollow MOFs via in-situ etching for High-efficiency organic solvent nanofiltration[J]. Chemical Engineering Journal, 2022, 437: 135289. doi: 10.1016/j.cej.2022.135289 [30] SINGH S, KHULBE K C, MATSUURA T, et al. Membrane characterization by solute transport and atomic force microscopy[J]. Journal of Membrane Science, 1998, 142(1): 111-127. doi: 10.1016/S0376-7388(97)00329-3 [31] JIA T Z, LU J P, CHENG X Y, et al. Surface enriched sulfonated polyarylene ether benzonitrile (SPEB) that enhances heavy metal removal from polyacrylonitrile (PAN) thin-film composite nanofiltration membranes[J]. Journal of Membrane Science, 2019, 580: 214-223. doi: 10.1016/j.memsci.2019.03.015 [32] BURTS K, PLISKO T, DMITRENKO M, et al. Novel thin film nanocomposite membranes based on chitosan succinate modified with Fe-BTC for enhanced pervaporation dehydration of isopropanol[J]. Membranes, 2022, 12(7): 653. doi: 10.3390/membranes12070653 [33] GU Y H, YAN X, CHEN Y, et al. Exquisite manipulation of two-dimensional laminar graphene oxide (GO) membranes via layer-by-layer self-assembly method with cationic dyes as cross-linkers[J]. Journal of Membrane Science, 2022, 658: 120738. doi: 10.1016/j.memsci.2022.120738 [34] SUN W G, ZHANG N, LI Q, et al. Bioinspired lignin-based loose nanofiltration membrane with excellent acid, fouling, and chlorine resistances toward dye/salt separation[J]. Journal of Membrane Science, 2023, 670: 121372. doi: 10.1016/j.memsci.2023.121372 [35] SHI Q H, ZHANG N, WANG D, et al. Polyethylenimine-mica nanosheets/cellulose nanofibers stacked loose nanofiltration membrane for effective dye/salt separation[J]. Desalination, 2023, 551: 116410. doi: 10.1016/j.desal.2023.116410 [36] LI S L, GUAN Y X, QIN Y W, et al. An antifouling loose nanofiltration membrane prepared by cross-linking HPAN ultrafiltration membrane with zwitterionic polymer PEI-CA for efficient dye desalination[J]. Desalination, 2023, 549: 116354. doi: 10.1016/j.desal.2022.116354 [37] WANG Y, BAO C Y, LI D, et al. Antifouling and chlorine-resistant cyclodextrin loose nanofiltration membrane for high-efficiency fractionation of dyes and salts[J]. Journal of Membrane Science, 2022, 661: 120925. doi: 10.1016/j.memsci.2022.120925 [38] WANG X L, DONG S Q, QIN W, et al. Fabrication of highly permeable CS/NaAlg loose nanofiltration membrane by ionic crosslinking assisted layer-by-layer self-assembly for dye desalination[J]. Separation and Purification Technology, 2022, 284: 120202. doi: 10.1016/j.seppur.2021.120202 [39] XIANG X, CHEN D Y, LI N J, et al. Mil-53(Fe)-loaded polyacrylonitrile membrane with superamphiphilicity and double hydrophobicity for effective emulsion separation and photocatalytic dye degradation[J]. Separation and Purification Technology, 2022, 282: 119910. doi: 10.1016/j.seppur.2021.119910 [40] KUSWORO T D, YULFARIDA M, KUMORO A C, et al. A highly durable and hydrophilic PVDF- MoS2/WO3-PVA membrane with visible light driven self-cleaning performance for pollutant-burdened natural rubber wastewater treatment[J]. Journal of Environmental Chemical Engineering, 2023, 11(2): 109583. doi: 10.1016/j.jece.2023.109583 [41] CHEN J C, GAO C M, ZHAO S Q, et al. Construction of PES membranes using NH2-MIL-125 and Pluronic F127 via RTIPS method toward elevated ultrafiltration, antifouling and self-cleaning performance[J]. Journal of Environmental Chemical Engineering, 2022, 10(2): 107162. doi: 10.1016/j.jece.2022.107162 -

下载:

下载: