-

膜污染问题已成为限制膜分离效率的主要瓶颈[1],并显著提高了运行和维护成本[2]。通常,需要采用预处理技术来缓解膜污染。国内外常采用的预处理技术主要包括混凝[3]、吸附[4]、氧化预处理[5]、化学沉淀预处理[6]、生物预处理[7]以及多种技术的组合[8-9]。然而,这些预处理技术需要额外添加化学药剂且具有处理的选择性,这显著增加了膜分离工艺的维护成本[10]。电絮凝作为一种高效的水处理技术,具有操作简单、产泥量小、避免使用化学药品、易实现自动化和设备化控制等优点[11-12]。电絮凝(electrocoagulation, EC)组合膜分离技术,是一种不依赖于化学药剂的水处理方法[13-14]。该技术具有清除膜表面沉积污染物的能力,并且具备操作简便的特点[15-16]。电絮凝是有效减轻膜污染的处理工艺[17-18]。在EC中,通过优化电化学参数,可以调节原位生成的铝(Al)絮体的尺寸,从而减轻膜孔堵塞引起的膜污染问题[19-20],且电絮凝形成的氢氧根水解产物可以和污染物聚集形成较大絮凝体而无法对膜孔造成堵塞,对膜污染具有明显控制作用[21-22]。

电絮凝过程中存在的极板钝化问题,会导致电流效率下降以及运行成本不断升高。通过采用脉冲电源替代直流电源,利用脉冲电流进行电絮凝反应是缓解电极钝化的有效手段。已有研究表明,脉冲电絮凝工艺中极板的实际通电时间小于电絮凝处理的总反应时间有助于减少污染物在极板表面的沉积进一步缓解电极钝化,高效去除废水中的污染物[23-24]。在ECMCR(electrocoagulation-membrane cathode reactor, ECMCR)中,牺牲的Fe/Al阳极产生Fe/Al离子以凝固胶体和有机物,这可以通过改善滤饼层结构来增强膜分离效率并减轻膜污染[25]。在电场混凝和HA-Al絮凝极化的综合作用下,将电絮凝和超滤膜组件集成到一个单元中进一步改善了滤饼层结构[26]。如果采用脉冲电源,可以降低ECMCR中电极钝化,提高电流效率、降低能耗。脉冲电絮凝在污水治理中得到了广泛的应用,EYVAZ[27]等使用利用脉冲电絮凝法去除水中染料的影响进行了探究,脉冲电絮凝可以克服直流电絮凝的局限,通过使用脉冲电来消除阴极钝化,发现使用脉冲电絮凝可以节省能耗并提高染料的去除效率。张洁培[28]利用脉冲电絮凝去除聚乙烯醇(PVA),研究发现脉冲电絮凝对PVA去除效果更加明显,去除率可达90%以上,而直流电絮凝对PVA去除很难进一步提高,在相同的去除效率下,脉冲电絮凝的电极损耗比直流电絮凝降低了26.6%,脉冲电絮凝的能耗比直流电絮凝降低89.8%。刘方圆[29]针对传统电絮凝处理含Cr(VI)废水所产生的极板钝化、能耗以及污泥量等问题,提出引入脉冲电流来对传统电絮凝处理过程中所遇到的问题进行优化,实验发现,在达到相似去除率的前提下,与直流电絮凝相比,单脉冲电絮凝可以节省能耗89%,污泥量减少30%,双脉冲电絮凝比直流电絮凝节能80%,污泥量减少39%。从能耗考虑,单脉冲电絮凝是去除Cr(VI)的最佳选择;从污泥减量考虑,双脉冲电絮凝是去除Cr(VI)的最佳选择。罗皓鹏[30]研究APC-EC脉冲电絮凝工艺各工作参数对于实际处理效果的影响,分析比较确定其在饮用水方面的最佳工作参数,研究表明脉冲电絮凝在处理实际水体的成本上面却只有传统电絮凝工艺的44.22%,脉冲电絮凝去除阿特拉津和氟离子的效率相较于直流电絮凝分别提高了7%和13.94%。现有的研究主要集中在利用脉冲的方式提高电絮凝污染物去除效率,但脉冲电絮凝对于膜污染的控制效果尚不清楚,而解析电场对于滤饼层结构的调控作用是脉冲电絮凝与膜分离耦合的关键。

本研究通过建立了新型脉冲电絮凝-膜分离反应器(pulsed electrocoagulation-membrane membrane cathode reactor, PECMCR),将导电膜放置于极板中间,通过利用电气浮和极板之间存在的电场作用,减缓膜污染的同时,提高HA去除率。此外,还考察了反应器在相同产铝量和能耗下,PECMCR和ECMCR对HA去除效果、膜污染情况的差异,通过分析絮体尺寸和滤饼层结构来探究其原因并优化不同电流密度、初始pH、不同脉冲频率、不同占空比对PECMCR的影响,确定PECMCR最佳工作条件。本研究为PECMCR在实际工程中的应用奠定了基础并构建一种高效稳定的无药剂水处理技术。

-

腐殖酸储备液制备。将2 g腐殖酸(humic acid,HA,Sigma-Aldrich,U.S.A)溶于1 L超纯水中,用氢氧化钠调节其pH至12,再用0.45 μm的水系滤膜过滤,将得到的储备液置于4 ℃条件下避光备用。模拟水体的配置如下:利用氯化钠作为背景电解质,溶液中的电导率为1 000 μS·cm−1;利用0.5 mmol·L−1的碳酸氢钠作为模拟水体的缓冲物质;调节水体的HA浓度为5 mg·L−1。实验所用药品均为分析纯,EC出水通过注射器从ECMR中抽水之后过滤0.22 μm滤膜。

-

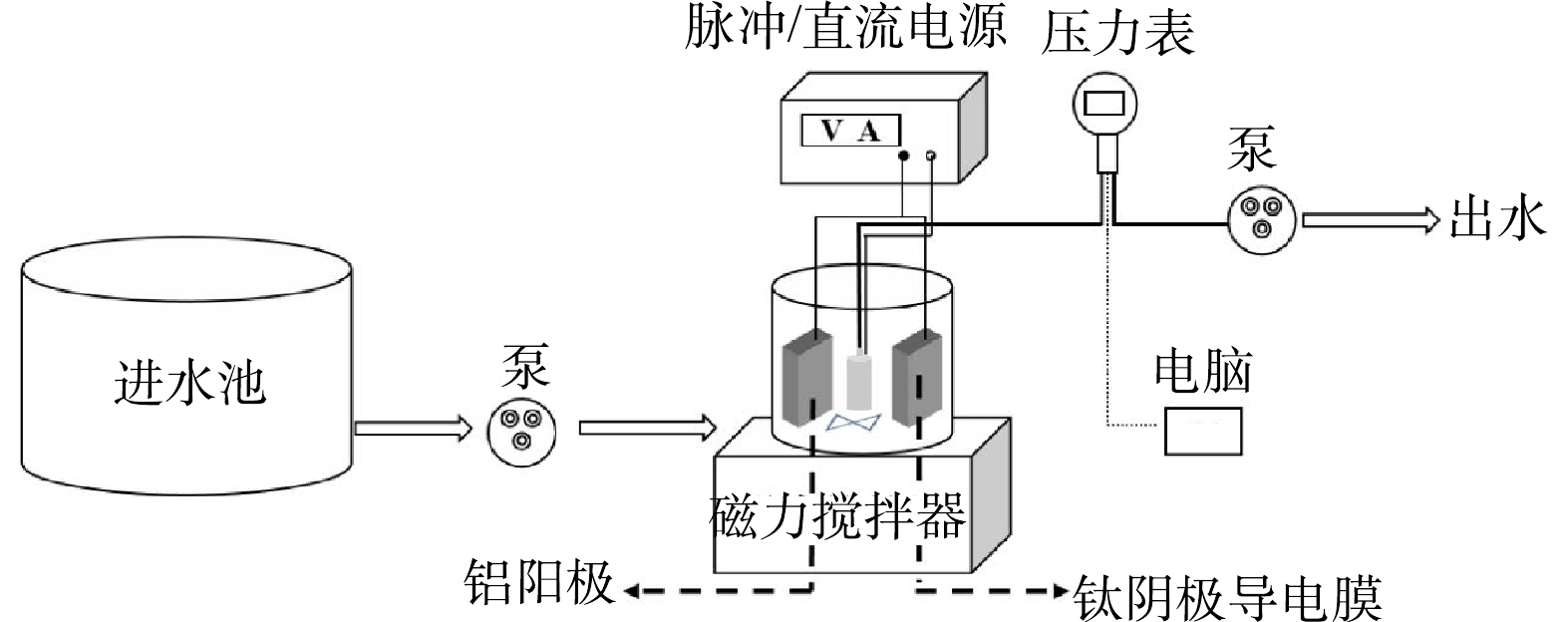

本实验采用烧杯(有效容积为1 000 mL)作为反应器,采用两块并联的铁或铝板作为阳极,极板尺寸为50 mm×60 mm×2 mm,极板间距10 mm。金属导电膜作为阴极由南京雄凯过滤设备有限公司提供。金属导电膜材质为钛金属,直径为150 mm,膜孔径为0.1 μm,膜有效过滤面积为21.86 cm2。调节泵速为11 r·min−1,流量控制在2 L·h−1,保证反应器中流量保持一致。实验中采用DH1765-1型程控直流稳压稳流电源(24 V,3 A)和SOYI-2410DM型脉冲电源(24 V,10 A);采用磁力搅拌器对溶液进行搅拌,以使电解液在反应器内分散均匀。实验模拟废水经泵进入电絮凝膜反应器,之后水经Ti导电膜分离流出。实验装置如图1所示。

-

采用厚度为2 mm的铝板或铁板,使用2000目SiC砂纸打磨表面氧化膜,浸泡在装有无水乙醇的烧杯中超声10 min以除去残留在表面的SiC颗粒和氧化膜粉末。

-

通过紫外-可见分光光度计(UV-3010,Hitachi,Japan)测量样品在254 nm处的紫外吸光度(UV254)来表示HA的浓度。水样通过0.45 μm水系滤膜过滤去除不溶性物质后用总有机碳分析仪(TOC-VCPH,Shimadzu,Japan)测定溶解性有机碳(DOC)。电导率的测定采用电导率仪(METTLERTOLEDO,S230),絮体粒径和性质的测定采用激光粒度分析仪(Mastersizer2000,Malvern,UK),膜表面情况采用场发射扫描电镜(SEM,JSM7401F,JEDL,Japan)表征,Zeta电位用Zetasizer 2000 (Malvern,UK)测定,滤饼层的粗糙度和孔隙率的测定采用原子力显微镜(AFM,Multimode8,USA,Bruker)和比表面积测试仪(BET,ASAP2020HD88,Micromeritics,USA),电化学阻抗谱测试使用电化学工作站(CHI760E,Chenhua,China),实验使用蠕动泵将水泵入反应器以确保液位恒定并保持在恒定通量,通过以跨膜压力差表征膜污染程度,即膜通量情况,用电脑连接压力表实时记录数据。

-

在电絮凝实验中,电极或者电极组件通常连接到外部直流电源。溶解或沉积的金属量取决于通过电解质溶液的电荷量。电流密度和溶解阳极的离子质量浓度可以由法拉第定律(式(1))进行计算。直流电絮凝法和脉冲电絮凝法的电能消耗根据式(2)进行计算。

式中:C为溶解阳极的离子质量浓度,mg·L−1;I为电流密度,A·cm−2;M为阳极的相对摩尔质量,g·mol−1;t为通电时间,s;n是氧化(还原)反应中的电子数;F为法拉第常数, 96 487 C·mol−1;V为反应器体积,L。

式中:E为能耗,kWh·m−3;U为电池电压,V;I为电流,A;t为通电的时间,h。

相同铝产量下根据法拉第效率公式计算,铝质量浓度为3 mg·L−1时,直流电源电流为0.018 A,脉冲电源电流为0.020 A,脉冲电絮凝能耗为0.007 78 kWh·m−3,实验全程采用稳流模式保证在反应30 min。相同能耗下根据式(2)计算,直流电絮凝能耗为0.006 3 kWh·m−3时,计算得出直流电源电流为0.018 A,脉冲电源电流为0.018 9 A,实验全程采用稳流模式保证在反应30 min。

-

为了考察相同能耗和相同理论产铝量下的PECMCR和ECMCR去除HA的效果,并比较了其膜污染情况,结果如图2所示。由图2中HA去除效果和跨膜压力差(TMP)的变化情况可以看出,相同产铝量和相同能耗下脉冲电絮凝在反应30 min时,对HA的去除率分别为94.23%和89.56%,而直流电絮凝在反应30 min时对HA的去除率为77.34%。可见脉冲电絮凝对HA的处理效果优于直流电絮凝,这主要是因为脉冲电源可以缓解极板钝化[31],絮凝生成尺寸更大[29]且高水通量的絮体[32]。有研究[33]表明,脉冲电絮凝可以通过电极引起的吸引/排斥力的瞬时破坏来引起质量传递,从而使离子(例如Al3+和OH−)或分子增加离子碰撞概率。从相同产铝量和相同能耗下对比跨膜压力差变化来看,脉冲电絮凝在反应30 min时TMP分别为38 kPa和48 kPa,均低于直流电絮凝60 kPa。从以上数据来看,相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝HA的去除率提高了5%,跨膜压力差降低了20%。因此,脉冲电絮凝跨膜压力差更低,可能是由于脉冲滤饼层结构更松散、孔径更大、孔隙率越高,具有更高的水通量,从而进一步缓解了膜污染。

-

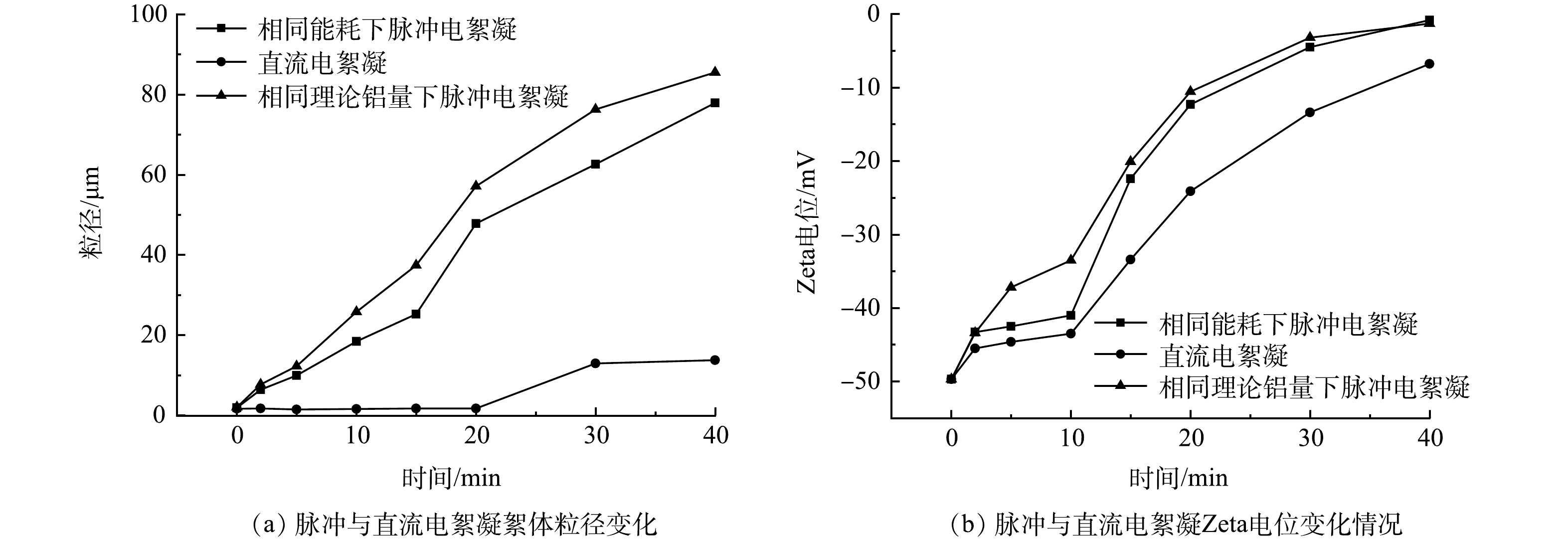

为了进一步探讨脉冲电絮凝处理效果优于直流电絮凝处理效果的原因,在相同产铝量和相同能耗下对比了脉冲电絮凝与直流电絮凝絮体的粒径和Zeta电位随时间的变化情况,结果如图3所示。可见,相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝絮体粒径提高了80%。根据图3(a)和图3(b)絮体粒径和Zeta电位随时间变化可以看出,絮凝开始5 min脉冲与直流电絮凝的絮体粒径无明显变化,Zeta电位处于稳定状态说明电絮凝电解释放的铝离子浓度小,絮体粒径小,体系较为稳定。在电絮凝反应10~40 min时间内脉冲电絮凝的絮体粒径大于直流电絮凝絮体粒径,而且在相同能耗和相同产铝量下脉冲电絮凝可以更快破坏体系的稳定性使其更快速絮凝。结合图2中HA去除率和TMP变化情况,发现脉冲电絮凝对HA具有更好的去除效果,而且可以生成更大尺寸的絮体沉积在膜孔表面,有助于缓解膜污染。这是因为在于脉冲电絮凝在未通电时间内可以有效缓解电极钝化和极板周围的浓度极化,使极板释放更多铝离子,促进絮体生长,导致絮体粒径更大。

-

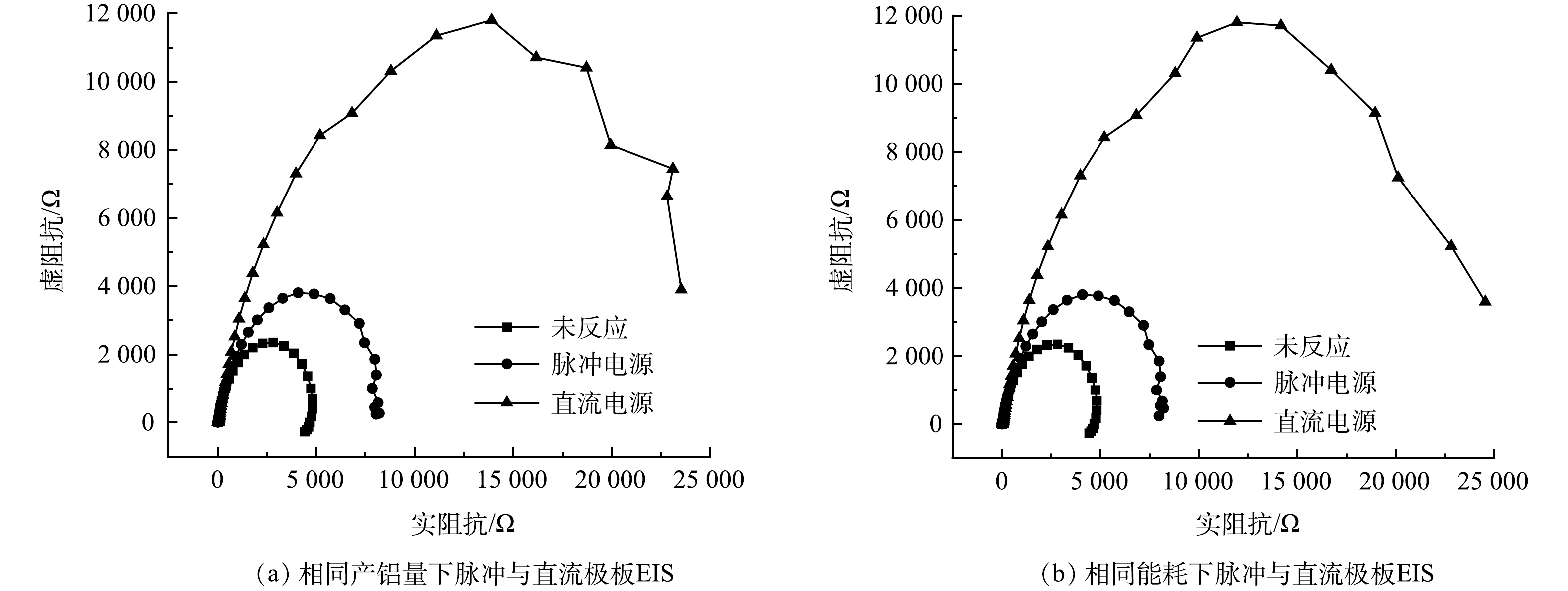

为了比较脉冲电絮凝和直流电絮凝的极板钝化情况,使用电化学交流阻抗量化钝化程度。实验选择在标准三电极体系下进行,工作电极由在相同能耗和相同产铝量下脉冲和直流电絮凝5 min后的铝阳极制成,铂片电极用作对电极,Ag/AgCl电极作为参比电极。使用聚酰亚胺绝缘胶带覆盖工作电极表面,保证测量面积恒定为1 cm2,所有电化学交流阻抗实验均在pH为11的30 g·L−1 硫酸钠溶液中进行,电压变化幅度为10 mV,测量频率为10−1~104 Hz,使用ZView软件对实验数据进行拟合。结果如图4所示。可见,相同产铝量下脉冲反应5 min后和直流反应5 min后,脉冲极板的Rct值从反应前41.27 Ω升高到123.5 Ω;直流极板的Rct值从反应前41.27 Ω升高到251.8 Ω。而在相同能耗下,脉冲反应5 min后和直流反应5 min后,脉冲极板的Rct值由反应前43.5 Ω升高到145.6 Ω,直流极板的Rct值从反应前43.5 Ω升高到289.65 Ω。由此可见,相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝极板等效电阻降低了50%。因此,脉冲反应电化学阻抗变小,直流电化学阻抗变大,说明脉冲可以缓解电极钝化提高反应器处理性能,在相同能耗和产铝量下,脉冲更有利于节省电能。

-

由于跨膜压力差的变化与滤饼层的表面结构有关,致密紧实的滤饼层相较于松散多孔的滤饼层的水通量更低,因此,需要进一步研究脉冲与直流电絮凝滤饼层表面形貌和结构的差异。结果如图5所示。由脉冲(图5(a))与直流电絮凝(图5(b))滤饼层SEM 表征结果可见,直流与脉冲电絮凝阴极膜表面滤饼层形状有差异,脉冲滤饼层表面多为片状且絮体尺寸较大。因此,脉冲电絮凝阴极膜表面的滤饼层具有更好的透水性,跨膜压差较低。由图5(b)可以看出,直流电絮凝阴极膜表面的滤饼层较为紧实且絮体尺寸较小。因此,直流电絮凝阴极膜表面的滤饼层水通量较差,跨膜压差较高。与实验中直流与脉冲电絮凝的跨膜压差的结果相一致。通过AFM测量相同能耗和产铝量下直流与脉冲电絮凝滤饼层的粗糙度,所有测试样品均呈现不均匀的岛形貌表面,相同能耗与产铝量下脉冲电絮凝滤饼层表面的平均粗糙度分别为150 nm和162 nm,直流电絮凝滤饼层表面的平均粗糙度为16.8 nm。脉冲电絮凝滤饼层较直流电絮凝滤饼层表面的峰谷间隙更大,表面直流电絮凝滤饼层表面更致密和平滑。

-

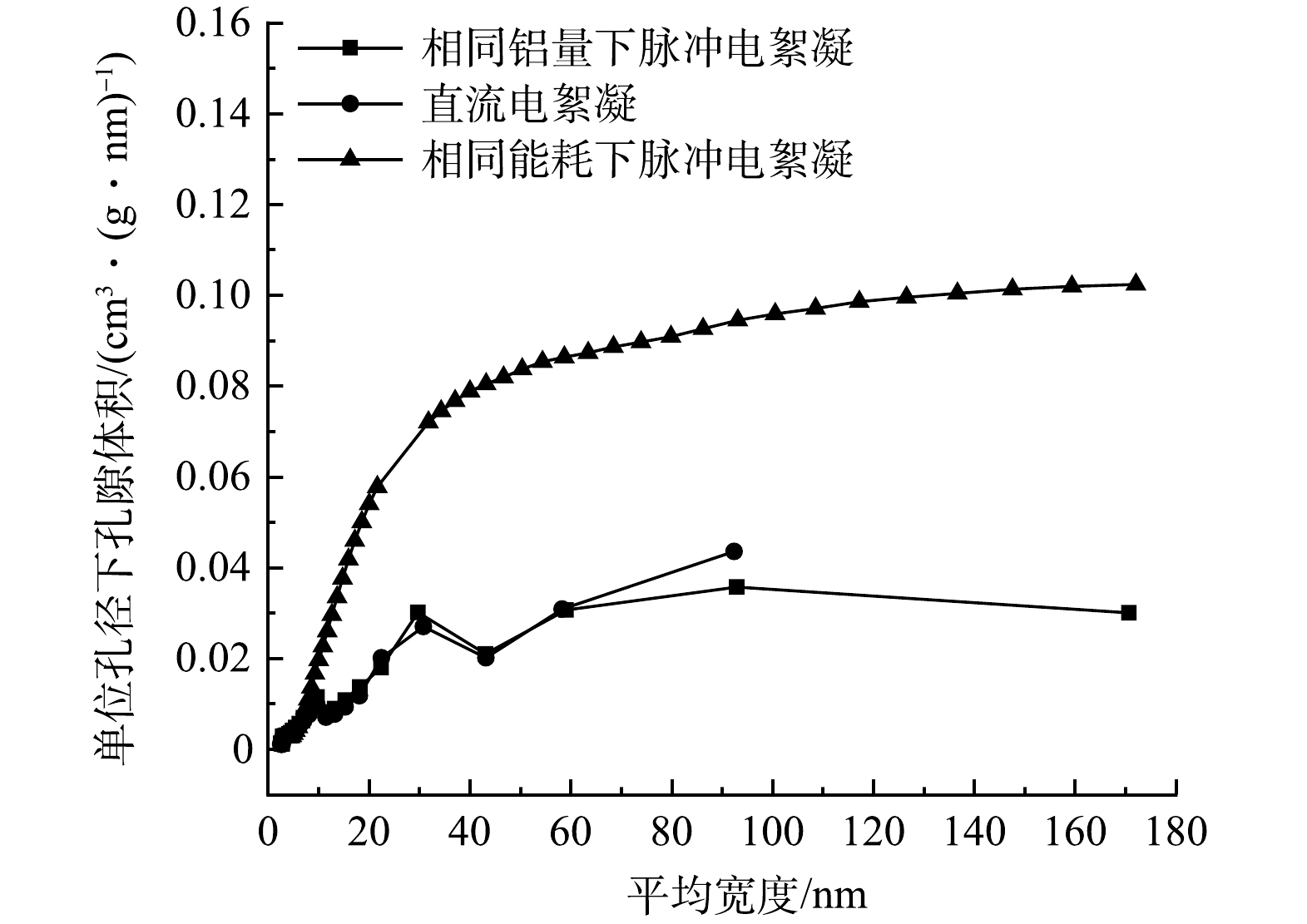

为了进一步比较直流与脉冲滤饼层结构的差异,实验选用比表面积分析仪分析了直流与脉冲滤饼层孔径和孔隙率的变化。由图6可见,直流与脉冲电絮凝滤饼层吸脱附曲线均为IV型吸附等温线,脉冲电絮凝滤饼层回滞环为H3型。H3型反映的孔包括平板狭缝结构、裂缝和楔形结构等。H3型迟滞回线由片状颗粒材料(粘土或由裂隙孔材料)构成,在较高相对压力区域没有表现出吸附饱和。直流电絮凝滤饼层回滞环为H4型,H4型出现在微孔和中孔混合的吸附剂上。由图7孔容分布结果可知,脉冲电絮凝絮体孔容分布范围更广,说明脉冲电絮凝絮体结构较直流电絮凝絮体结构更加疏松。从表1可以看出,脉冲电絮凝滤饼层与直流电絮凝滤饼层孔隙率分别为63%、60%和50%,比表面积分别为84.7715、86.3371和72.8180 cm3,孔隙平均宽度分别为170.7、173.8和92.4 nm,反应30 min后,相同产铝量和相同能耗下脉冲电絮凝滤饼层的孔容、密度和孔隙率均高于直流电絮凝滤饼层。因此,脉冲电絮凝滤饼层具有更高的水通量和膜污染缓解效果。

-

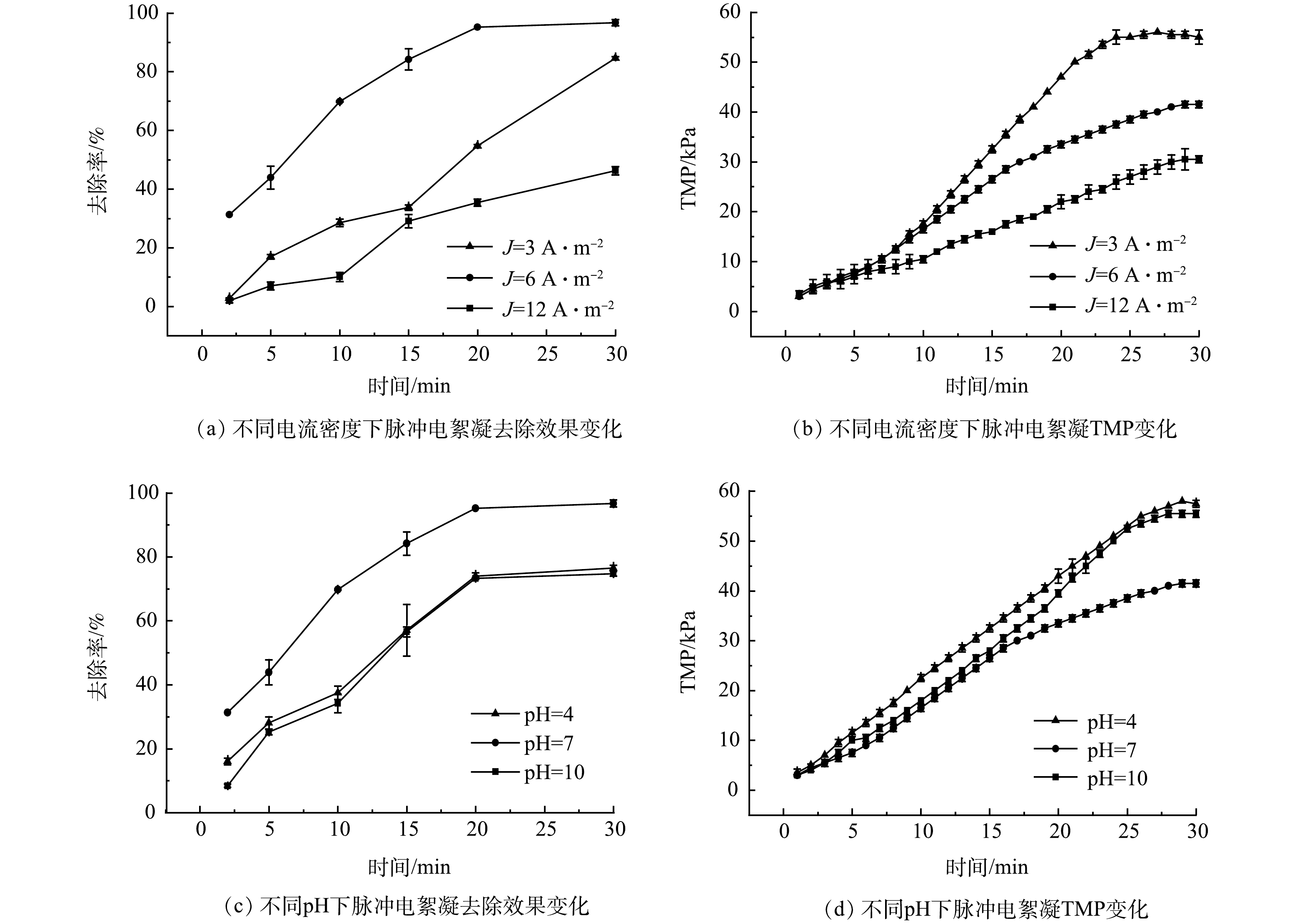

为了考察电流密度和初始pH对PECMCR的影响,分别选取电流密度为3、6、12 A·m−2以及选取初始pH为4、7、10。如图8所示,当电流密度为3 A·m−2时,由于电流密度低,电解生成铝离子浓度低,无法生成大尺寸絮体且有效去除污染物,跨膜压力差高,达到58 kPa。当电流密度为12 A·m−2时,较高的电流密度会产生较高电压,会使得极板发生钝化,无法有效生成絮体,污染物的去除效率低且无法在膜表面生成滤饼层。因此,选择6 A·m−2为最佳电流密度。另外在酸性条件下电极表面易钝化,铝极板表面生成的氧化物导致Al3+浓度下降,絮体尺寸较小;碱性条件下,絮体吸附能力下降,去除率下降;因此,选择pH=7为最佳pH。

-

为了考察脉冲频率和占空比对PECMCR的影响,分别选取脉冲频率为50、500、5 000 Hz以及选取占空比为100%、90%、70%、50%。由图9(a)和图9(b)可知,当周期一定时,占空比的高低决定着一个周期内通电时间的长短,也直接关系着从铝阳极溶解的铝离子的量,占空比高时,通电时间长,阳极板溶解的铝离子多;当占空比低时,通电时间短,阳极板溶解的铝离子少。直流电源腐殖酸的去除率在反应30 min内从9.95%上升至82.09%,脉冲电源腐殖酸的去除率在反应30 min内从12.61%上升至89.60%。结合图9(a)与图9(b)分析,在占空比为90%时脉冲电絮凝处理效果与膜污染控制情况最佳。增加占空比可以增加金属离子的产生和絮体的形成,提高污染物的去除效果。然而,由于在较高占空比下电极溶解增加,金属离子可能难以扩散到本体溶液中,从而导致浓度极化和电极钝化,降低处理效率。由图9(c)和图9(d)可知,当占空比为90%时,不同频率下,脉冲电源腐殖酸的去除率在反应30 min时由88.06%上升至88.3%。从腐殖酸的去除率来看,增加脉冲频率可以增加金属离子的产生和絮体的形成,提高污染物去除效果。从跨膜压差的变化来看,500 Hz对比50 Hz脉冲电源的跨膜压差从48 kPa上升至55 kPa,由于低频脉冲可以使电极表面钝化,而较高频率可以阻止浓度极化和钝化层形成,从而提高处理效率,因此,形成的絮体尺寸大且疏水性好。再加上阴极膜析氢冲刷膜表面的滤饼层,膜污染得到缓解。

-

本研究在相同产铝量和相同能耗下对比了2个反应器的膜分离性能和膜污染控制效果,对产生的絮体与滤饼层分别进行了表面形态的表征,并探究了脉冲电絮凝反应器的污染物去除和膜污染控制机理,主要结论如下。

1)相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝对HA的去除率提高了5%,跨膜压力差降低了20%,絮体粒径提高了80%,等效电阻降低了50%,且破坏体系稳定的时间较短。

2)对比脉冲电絮凝滤饼层与直流电絮凝滤饼层的形貌分析发现,滤饼层粗糙度提升90%,孔隙率提高10%,脉冲电絮凝滤饼层孔径分布范围更大。电流密度是6 A·m−2、初始pH=7、脉冲频率为500 Hz、占空比为90%时为反应器最佳运行工艺条件,此时去除率为94.23%,跨膜压差为38 kPa。

3)膜污染控制机理分析,脉冲电絮凝可以生成尺寸更大且吸附能力更强的HA-Al絮体,不仅防止膜孔阻塞,还有利于多孔饼层的形成,从而增强了PECMCR的水通量。而且脉冲电源可以缓解电极钝化,进一步降低处理能耗,具有更好的稳定性便于推广使用。

脉冲电絮凝-膜分离反应器的膜污染控制机制

Membrane contamination control mechanism in the pulsed electrocoagulation-membrane separation reactor

-

摘要: 为了改进直流电絮凝膜分离反应器(electrocoagulation-membrane cathode reactor, ECMCR)在实际应用中存在极板钝化、能耗高等不足,本研究开发了脉冲电絮凝膜分离反应器(pulsed electrocoagulation-membrane cathode reactor, PECMCR),并分析了其中的膜污染控制机制。研究发现ECMCR对腐殖酸(humic acid, HA)的去除率最高可达85.23%,相比之下相同产铝量和能耗下脉冲电絮凝膜分离反应器对HA的最佳去除效率可达到90%以上,且跨膜压差分别降低了36%和20%。PECMCR相较于ECMCR具有更好的HA去除效果和膜污染缓解效果,这可能是因为在脉冲电场的作用下,金属阳离子在溶液中加速扩散,减少或消除了金属阳极的钝化现象,从而有效提高HA的去除效率。而且HA与膜阴极之间的静电斥力降低了HA污染物在膜上的粘附,有助于进一步缓解膜污染。另外,脉冲电絮凝可以缓解电极钝化,有助于进一步节省能耗。此研究结果为PECMCR应用于水处理过程中膜污染控制提供了新的解决方案。Abstract: In order to improve the shortcomings of DC electrocoagulation-membrane cathode reactor (ECMCR) such as plate passivation and high energy consumption in practical applications, this study developed a pulsed electrocoagulation-membrane cathode reactor (PECMCR) and analyzed the membrane contamination control mechanism in it. It was found that ECMCR could remove humic acid (HA) up to 85.23%, by comparison, the optimal removal efficiency of HA of was higher than 90% by the pulsed electrocoagulation-membrane separation reactor with the same aluminum production and energy consumption, and their trans-membrane differential pressures decreased by 36% and 20%, respectively. PECMCR had better HA removal and membrane contamination mitigation effect compared with ECMCR, which may be attributed to the accelerated diffusion of metal cations in the solution under the action of pulsed electric field, which could reduce or eliminate the passivation phenomenon of the metal anode, and thus could effectively improve the removal efficiency of HA. Moreover, the electrostatic repulsion between HA and the membrane cathode could reduce the adhesion of HA pollutants on the membrane, which was conducive to further alleviating membrane contamination. In addition, pulsed electro-flocculation can alleviate electrode passivation, which was conducive to further saving energy consumption. The results of this study provide a new solution for the application of PECMCR to control membrane contamination in water treatment process.

-

Key words:

- humic acid /

- electrocoagulation /

- membrane separation /

- filter cake layer

-

膜污染问题已成为限制膜分离效率的主要瓶颈[1],并显著提高了运行和维护成本[2]。通常,需要采用预处理技术来缓解膜污染。国内外常采用的预处理技术主要包括混凝[3]、吸附[4]、氧化预处理[5]、化学沉淀预处理[6]、生物预处理[7]以及多种技术的组合[8-9]。然而,这些预处理技术需要额外添加化学药剂且具有处理的选择性,这显著增加了膜分离工艺的维护成本[10]。电絮凝作为一种高效的水处理技术,具有操作简单、产泥量小、避免使用化学药品、易实现自动化和设备化控制等优点[11-12]。电絮凝(electrocoagulation, EC)组合膜分离技术,是一种不依赖于化学药剂的水处理方法[13-14]。该技术具有清除膜表面沉积污染物的能力,并且具备操作简便的特点[15-16]。电絮凝是有效减轻膜污染的处理工艺[17-18]。在EC中,通过优化电化学参数,可以调节原位生成的铝(Al)絮体的尺寸,从而减轻膜孔堵塞引起的膜污染问题[19-20],且电絮凝形成的氢氧根水解产物可以和污染物聚集形成较大絮凝体而无法对膜孔造成堵塞,对膜污染具有明显控制作用[21-22]。

电絮凝过程中存在的极板钝化问题,会导致电流效率下降以及运行成本不断升高。通过采用脉冲电源替代直流电源,利用脉冲电流进行电絮凝反应是缓解电极钝化的有效手段。已有研究表明,脉冲电絮凝工艺中极板的实际通电时间小于电絮凝处理的总反应时间有助于减少污染物在极板表面的沉积进一步缓解电极钝化,高效去除废水中的污染物[23-24]。在ECMCR(electrocoagulation-membrane cathode reactor, ECMCR)中,牺牲的Fe/Al阳极产生Fe/Al离子以凝固胶体和有机物,这可以通过改善滤饼层结构来增强膜分离效率并减轻膜污染[25]。在电场混凝和HA-Al絮凝极化的综合作用下,将电絮凝和超滤膜组件集成到一个单元中进一步改善了滤饼层结构[26]。如果采用脉冲电源,可以降低ECMCR中电极钝化,提高电流效率、降低能耗。脉冲电絮凝在污水治理中得到了广泛的应用,EYVAZ[27]等使用利用脉冲电絮凝法去除水中染料的影响进行了探究,脉冲电絮凝可以克服直流电絮凝的局限,通过使用脉冲电来消除阴极钝化,发现使用脉冲电絮凝可以节省能耗并提高染料的去除效率。张洁培[28]利用脉冲电絮凝去除聚乙烯醇(PVA),研究发现脉冲电絮凝对PVA去除效果更加明显,去除率可达90%以上,而直流电絮凝对PVA去除很难进一步提高,在相同的去除效率下,脉冲电絮凝的电极损耗比直流电絮凝降低了26.6%,脉冲电絮凝的能耗比直流电絮凝降低89.8%。刘方圆[29]针对传统电絮凝处理含Cr(VI)废水所产生的极板钝化、能耗以及污泥量等问题,提出引入脉冲电流来对传统电絮凝处理过程中所遇到的问题进行优化,实验发现,在达到相似去除率的前提下,与直流电絮凝相比,单脉冲电絮凝可以节省能耗89%,污泥量减少30%,双脉冲电絮凝比直流电絮凝节能80%,污泥量减少39%。从能耗考虑,单脉冲电絮凝是去除Cr(VI)的最佳选择;从污泥减量考虑,双脉冲电絮凝是去除Cr(VI)的最佳选择。罗皓鹏[30]研究APC-EC脉冲电絮凝工艺各工作参数对于实际处理效果的影响,分析比较确定其在饮用水方面的最佳工作参数,研究表明脉冲电絮凝在处理实际水体的成本上面却只有传统电絮凝工艺的44.22%,脉冲电絮凝去除阿特拉津和氟离子的效率相较于直流电絮凝分别提高了7%和13.94%。现有的研究主要集中在利用脉冲的方式提高电絮凝污染物去除效率,但脉冲电絮凝对于膜污染的控制效果尚不清楚,而解析电场对于滤饼层结构的调控作用是脉冲电絮凝与膜分离耦合的关键。

本研究通过建立了新型脉冲电絮凝-膜分离反应器(pulsed electrocoagulation-membrane membrane cathode reactor, PECMCR),将导电膜放置于极板中间,通过利用电气浮和极板之间存在的电场作用,减缓膜污染的同时,提高HA去除率。此外,还考察了反应器在相同产铝量和能耗下,PECMCR和ECMCR对HA去除效果、膜污染情况的差异,通过分析絮体尺寸和滤饼层结构来探究其原因并优化不同电流密度、初始pH、不同脉冲频率、不同占空比对PECMCR的影响,确定PECMCR最佳工作条件。本研究为PECMCR在实际工程中的应用奠定了基础并构建一种高效稳定的无药剂水处理技术。

1. 材料与方法

1.1 实验材料

腐殖酸储备液制备。将2 g腐殖酸(humic acid,HA,Sigma-Aldrich,U.S.A)溶于1 L超纯水中,用氢氧化钠调节其pH至12,再用0.45 μm的水系滤膜过滤,将得到的储备液置于4 ℃条件下避光备用。模拟水体的配置如下:利用氯化钠作为背景电解质,溶液中的电导率为1 000 μS·cm−1;利用0.5 mmol·L−1的碳酸氢钠作为模拟水体的缓冲物质;调节水体的HA浓度为5 mg·L−1。实验所用药品均为分析纯,EC出水通过注射器从ECMR中抽水之后过滤0.22 μm滤膜。

1.2 实验装置

本实验采用烧杯(有效容积为1 000 mL)作为反应器,采用两块并联的铁或铝板作为阳极,极板尺寸为50 mm×60 mm×2 mm,极板间距10 mm。金属导电膜作为阴极由南京雄凯过滤设备有限公司提供。金属导电膜材质为钛金属,直径为150 mm,膜孔径为0.1 μm,膜有效过滤面积为21.86 cm2。调节泵速为11 r·min−1,流量控制在2 L·h−1,保证反应器中流量保持一致。实验中采用DH1765-1型程控直流稳压稳流电源(24 V,3 A)和SOYI-2410DM型脉冲电源(24 V,10 A);采用磁力搅拌器对溶液进行搅拌,以使电解液在反应器内分散均匀。实验模拟废水经泵进入电絮凝膜反应器,之后水经Ti导电膜分离流出。实验装置如图1所示。

1.3 铝电极的预处理

采用厚度为2 mm的铝板或铁板,使用2000目SiC砂纸打磨表面氧化膜,浸泡在装有无水乙醇的烧杯中超声10 min以除去残留在表面的SiC颗粒和氧化膜粉末。

1.4 分析方法

通过紫外-可见分光光度计(UV-3010,Hitachi,Japan)测量样品在254 nm处的紫外吸光度(UV254)来表示HA的浓度。水样通过0.45 μm水系滤膜过滤去除不溶性物质后用总有机碳分析仪(TOC-VCPH,Shimadzu,Japan)测定溶解性有机碳(DOC)。电导率的测定采用电导率仪(METTLERTOLEDO,S230),絮体粒径和性质的测定采用激光粒度分析仪(Mastersizer2000,Malvern,UK),膜表面情况采用场发射扫描电镜(SEM,JSM7401F,JEDL,Japan)表征,Zeta电位用Zetasizer 2000 (Malvern,UK)测定,滤饼层的粗糙度和孔隙率的测定采用原子力显微镜(AFM,Multimode8,USA,Bruker)和比表面积测试仪(BET,ASAP2020HD88,Micromeritics,USA),电化学阻抗谱测试使用电化学工作站(CHI760E,Chenhua,China),实验使用蠕动泵将水泵入反应器以确保液位恒定并保持在恒定通量,通过以跨膜压力差表征膜污染程度,即膜通量情况,用电脑连接压力表实时记录数据。

1.5 法拉第效率和能耗计算

在电絮凝实验中,电极或者电极组件通常连接到外部直流电源。溶解或沉积的金属量取决于通过电解质溶液的电荷量。电流密度和溶解阳极的离子质量浓度可以由法拉第定律(式(1))进行计算。直流电絮凝法和脉冲电絮凝法的电能消耗根据式(2)进行计算。

stringUtils.convertMath(!{formula.content}) (1) 式中:C为溶解阳极的离子质量浓度,mg·L−1;I为电流密度,A·cm−2;M为阳极的相对摩尔质量,g·mol−1;t为通电时间,s;n是氧化(还原)反应中的电子数;F为法拉第常数, 96 487 C·mol−1;V为反应器体积,L。

stringUtils.convertMath(!{formula.content}) (2) 式中:E为能耗,kWh·m−3;U为电池电压,V;I为电流,A;t为通电的时间,h。

相同铝产量下根据法拉第效率公式计算,铝质量浓度为3 mg·L−1时,直流电源电流为0.018 A,脉冲电源电流为0.020 A,脉冲电絮凝能耗为0.007 78 kWh·m−3,实验全程采用稳流模式保证在反应30 min。相同能耗下根据式(2)计算,直流电絮凝能耗为0.006 3 kWh·m−3时,计算得出直流电源电流为0.018 A,脉冲电源电流为0.018 9 A,实验全程采用稳流模式保证在反应30 min。

2. 结果与讨论

2.1 PECMCR和ECMCR工艺去除HA的效果对比

为了考察相同能耗和相同理论产铝量下的PECMCR和ECMCR去除HA的效果,并比较了其膜污染情况,结果如图2所示。由图2中HA去除效果和跨膜压力差(TMP)的变化情况可以看出,相同产铝量和相同能耗下脉冲电絮凝在反应30 min时,对HA的去除率分别为94.23%和89.56%,而直流电絮凝在反应30 min时对HA的去除率为77.34%。可见脉冲电絮凝对HA的处理效果优于直流电絮凝,这主要是因为脉冲电源可以缓解极板钝化[31],絮凝生成尺寸更大[29]且高水通量的絮体[32]。有研究[33]表明,脉冲电絮凝可以通过电极引起的吸引/排斥力的瞬时破坏来引起质量传递,从而使离子(例如Al3+和OH−)或分子增加离子碰撞概率。从相同产铝量和相同能耗下对比跨膜压力差变化来看,脉冲电絮凝在反应30 min时TMP分别为38 kPa和48 kPa,均低于直流电絮凝60 kPa。从以上数据来看,相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝HA的去除率提高了5%,跨膜压力差降低了20%。因此,脉冲电絮凝跨膜压力差更低,可能是由于脉冲滤饼层结构更松散、孔径更大、孔隙率越高,具有更高的水通量,从而进一步缓解了膜污染。

2.2 絮体粒径和Zeta电位分析

为了进一步探讨脉冲电絮凝处理效果优于直流电絮凝处理效果的原因,在相同产铝量和相同能耗下对比了脉冲电絮凝与直流电絮凝絮体的粒径和Zeta电位随时间的变化情况,结果如图3所示。可见,相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝絮体粒径提高了80%。根据图3(a)和图3(b)絮体粒径和Zeta电位随时间变化可以看出,絮凝开始5 min脉冲与直流电絮凝的絮体粒径无明显变化,Zeta电位处于稳定状态说明电絮凝电解释放的铝离子浓度小,絮体粒径小,体系较为稳定。在电絮凝反应10~40 min时间内脉冲电絮凝的絮体粒径大于直流电絮凝絮体粒径,而且在相同能耗和相同产铝量下脉冲电絮凝可以更快破坏体系的稳定性使其更快速絮凝。结合图2中HA去除率和TMP变化情况,发现脉冲电絮凝对HA具有更好的去除效果,而且可以生成更大尺寸的絮体沉积在膜孔表面,有助于缓解膜污染。这是因为在于脉冲电絮凝在未通电时间内可以有效缓解电极钝化和极板周围的浓度极化,使极板释放更多铝离子,促进絮体生长,导致絮体粒径更大。

2.3 EIS分析直流与脉冲电絮凝极板钝化情况

为了比较脉冲电絮凝和直流电絮凝的极板钝化情况,使用电化学交流阻抗量化钝化程度。实验选择在标准三电极体系下进行,工作电极由在相同能耗和相同产铝量下脉冲和直流电絮凝5 min后的铝阳极制成,铂片电极用作对电极,Ag/AgCl电极作为参比电极。使用聚酰亚胺绝缘胶带覆盖工作电极表面,保证测量面积恒定为1 cm2,所有电化学交流阻抗实验均在pH为11的30 g·L−1 硫酸钠溶液中进行,电压变化幅度为10 mV,测量频率为10−1~104 Hz,使用ZView软件对实验数据进行拟合。结果如图4所示。可见,相同产铝量下脉冲反应5 min后和直流反应5 min后,脉冲极板的Rct值从反应前41.27 Ω升高到123.5 Ω;直流极板的Rct值从反应前41.27 Ω升高到251.8 Ω。而在相同能耗下,脉冲反应5 min后和直流反应5 min后,脉冲极板的Rct值由反应前43.5 Ω升高到145.6 Ω,直流极板的Rct值从反应前43.5 Ω升高到289.65 Ω。由此可见,相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝极板等效电阻降低了50%。因此,脉冲反应电化学阻抗变小,直流电化学阻抗变大,说明脉冲可以缓解电极钝化提高反应器处理性能,在相同能耗和产铝量下,脉冲更有利于节省电能。

2.4 SEM和AFM分析直流与脉冲电絮凝滤饼层表面形貌和粗糙度

由于跨膜压力差的变化与滤饼层的表面结构有关,致密紧实的滤饼层相较于松散多孔的滤饼层的水通量更低,因此,需要进一步研究脉冲与直流电絮凝滤饼层表面形貌和结构的差异。结果如图5所示。由脉冲(图5(a))与直流电絮凝(图5(b))滤饼层SEM 表征结果可见,直流与脉冲电絮凝阴极膜表面滤饼层形状有差异,脉冲滤饼层表面多为片状且絮体尺寸较大。因此,脉冲电絮凝阴极膜表面的滤饼层具有更好的透水性,跨膜压差较低。由图5(b)可以看出,直流电絮凝阴极膜表面的滤饼层较为紧实且絮体尺寸较小。因此,直流电絮凝阴极膜表面的滤饼层水通量较差,跨膜压差较高。与实验中直流与脉冲电絮凝的跨膜压差的结果相一致。通过AFM测量相同能耗和产铝量下直流与脉冲电絮凝滤饼层的粗糙度,所有测试样品均呈现不均匀的岛形貌表面,相同能耗与产铝量下脉冲电絮凝滤饼层表面的平均粗糙度分别为150 nm和162 nm,直流电絮凝滤饼层表面的平均粗糙度为16.8 nm。脉冲电絮凝滤饼层较直流电絮凝滤饼层表面的峰谷间隙更大,表面直流电絮凝滤饼层表面更致密和平滑。

2.5 BET分析直流与脉冲滤饼层孔径分布变化和孔隙率

为了进一步比较直流与脉冲滤饼层结构的差异,实验选用比表面积分析仪分析了直流与脉冲滤饼层孔径和孔隙率的变化。由图6可见,直流与脉冲电絮凝滤饼层吸脱附曲线均为IV型吸附等温线,脉冲电絮凝滤饼层回滞环为H3型。H3型反映的孔包括平板狭缝结构、裂缝和楔形结构等。H3型迟滞回线由片状颗粒材料(粘土或由裂隙孔材料)构成,在较高相对压力区域没有表现出吸附饱和。直流电絮凝滤饼层回滞环为H4型,H4型出现在微孔和中孔混合的吸附剂上。由图7孔容分布结果可知,脉冲电絮凝絮体孔容分布范围更广,说明脉冲电絮凝絮体结构较直流电絮凝絮体结构更加疏松。从表1可以看出,脉冲电絮凝滤饼层与直流电絮凝滤饼层孔隙率分别为63%、60%和50%,比表面积分别为84.7715、86.3371和72.8180 cm3,孔隙平均宽度分别为170.7、173.8和92.4 nm,反应30 min后,相同产铝量和相同能耗下脉冲电絮凝滤饼层的孔容、密度和孔隙率均高于直流电絮凝滤饼层。因此,脉冲电絮凝滤饼层具有更高的水通量和膜污染缓解效果。

表 1 不同反应条件下脉冲与直流滤饼层比表面积、孔容、孔隙率和密度Table 1. Specific surface area, pore volume, porosity and density of pulsed and DC filter cake layers under different reaction conditions反应条件 密度/(g·cm−3) 质量/g 体积/cm3 孔容/(cm3·g−1) 比表面积/(m2·g−1) 孔隙率/% 直流电絮凝 2.249 0 0.306 9 0.123 7 0.247 5 72.818 0 50 相同铝量下脉冲电絮凝 2.307 7 0.390 0 0.169 0 0.268 2 84.771 5 63 相同能耗下脉冲电絮凝 2.255 05 0.350 0 0.155 2 0.258 7 86.338 1 60 2.6 不同电流密度和初始pH对PECMCR去除效果的影响

为了考察电流密度和初始pH对PECMCR的影响,分别选取电流密度为3、6、12 A·m−2以及选取初始pH为4、7、10。如图8所示,当电流密度为3 A·m−2时,由于电流密度低,电解生成铝离子浓度低,无法生成大尺寸絮体且有效去除污染物,跨膜压力差高,达到58 kPa。当电流密度为12 A·m−2时,较高的电流密度会产生较高电压,会使得极板发生钝化,无法有效生成絮体,污染物的去除效率低且无法在膜表面生成滤饼层。因此,选择6 A·m−2为最佳电流密度。另外在酸性条件下电极表面易钝化,铝极板表面生成的氧化物导致Al3+浓度下降,絮体尺寸较小;碱性条件下,絮体吸附能力下降,去除率下降;因此,选择pH=7为最佳pH。

2.7 不同占空比和脉冲频率对PECMCR效果的影响

为了考察脉冲频率和占空比对PECMCR的影响,分别选取脉冲频率为50、500、5 000 Hz以及选取占空比为100%、90%、70%、50%。由图9(a)和图9(b)可知,当周期一定时,占空比的高低决定着一个周期内通电时间的长短,也直接关系着从铝阳极溶解的铝离子的量,占空比高时,通电时间长,阳极板溶解的铝离子多;当占空比低时,通电时间短,阳极板溶解的铝离子少。直流电源腐殖酸的去除率在反应30 min内从9.95%上升至82.09%,脉冲电源腐殖酸的去除率在反应30 min内从12.61%上升至89.60%。结合图9(a)与图9(b)分析,在占空比为90%时脉冲电絮凝处理效果与膜污染控制情况最佳。增加占空比可以增加金属离子的产生和絮体的形成,提高污染物的去除效果。然而,由于在较高占空比下电极溶解增加,金属离子可能难以扩散到本体溶液中,从而导致浓度极化和电极钝化,降低处理效率。由图9(c)和图9(d)可知,当占空比为90%时,不同频率下,脉冲电源腐殖酸的去除率在反应30 min时由88.06%上升至88.3%。从腐殖酸的去除率来看,增加脉冲频率可以增加金属离子的产生和絮体的形成,提高污染物去除效果。从跨膜压差的变化来看,500 Hz对比50 Hz脉冲电源的跨膜压差从48 kPa上升至55 kPa,由于低频脉冲可以使电极表面钝化,而较高频率可以阻止浓度极化和钝化层形成,从而提高处理效率,因此,形成的絮体尺寸大且疏水性好。再加上阴极膜析氢冲刷膜表面的滤饼层,膜污染得到缓解。

3. 结论

本研究在相同产铝量和相同能耗下对比了2个反应器的膜分离性能和膜污染控制效果,对产生的絮体与滤饼层分别进行了表面形态的表征,并探究了脉冲电絮凝反应器的污染物去除和膜污染控制机理,主要结论如下。

1)相同产铝量与相同能耗下脉冲电絮凝相较于直流电絮凝对HA的去除率提高了5%,跨膜压力差降低了20%,絮体粒径提高了80%,等效电阻降低了50%,且破坏体系稳定的时间较短。

2)对比脉冲电絮凝滤饼层与直流电絮凝滤饼层的形貌分析发现,滤饼层粗糙度提升90%,孔隙率提高10%,脉冲电絮凝滤饼层孔径分布范围更大。电流密度是6 A·m−2、初始pH=7、脉冲频率为500 Hz、占空比为90%时为反应器最佳运行工艺条件,此时去除率为94.23%,跨膜压差为38 kPa。

3)膜污染控制机理分析,脉冲电絮凝可以生成尺寸更大且吸附能力更强的HA-Al絮体,不仅防止膜孔阻塞,还有利于多孔饼层的形成,从而增强了PECMCR的水通量。而且脉冲电源可以缓解电极钝化,进一步降低处理能耗,具有更好的稳定性便于推广使用。

-

表 1 不同反应条件下脉冲与直流滤饼层比表面积、孔容、孔隙率和密度

Table 1. Specific surface area, pore volume, porosity and density of pulsed and DC filter cake layers under different reaction conditions

反应条件 密度/(g·cm−3) 质量/g 体积/cm3 孔容/(cm3·g−1) 比表面积/(m2·g−1) 孔隙率/% 直流电絮凝 2.249 0 0.306 9 0.123 7 0.247 5 72.818 0 50 相同铝量下脉冲电絮凝 2.307 7 0.390 0 0.169 0 0.268 2 84.771 5 63 相同能耗下脉冲电絮凝 2.255 05 0.350 0 0.155 2 0.258 7 86.338 1 60 -

[1] ZHANG H, SUN M, SONG L, et al. Fate of NaClO and membrane foulants during in-situ cleaning of membrane bioreactors: Combined effect on thermodynamic properties of sludge[J]. Biochemical Engineering Journal, 2019, 147: 146-152. doi: 10.1016/j.bej.2019.04.016 [2] CHEN Y, TENG J, LIAO B Q, et al. Molecular insights into the impacts of iron(III) ions on membrane fouling by alginate[J]. Chemosphere, 2020, 242: 125232. doi: 10.1016/j.chemosphere.2019.125232 [3] YAO M, NAN J, CHEN T, et al. Influence of flocs breakage process on membrane fouling in coagulation/ultrafiltration process: Effect of additional coagulant of poly-aluminum chloride and polyacrylamide[J]. Journal of Membrane Science, 2015, 491: 63-72. doi: 10.1016/j.memsci.2015.05.018 [4] 郑武, 于萍. 吸附预处理减缓微滤膜污染试验研究[J]. 四川大学学报:自然科学版, 2018, 55: 1265. [5] 瞿芳术、杨枝盟、周鸿、荣宏伟、赫俊国、余华荣. 高锰酸钾预氧化对高藻水超滤过程中膜污染及锰沉积的影响[J]. 膜科学与技术, 2020, 40(6): 29-36. [6] 杜琦. 化学沉淀—离子交换法处理电镀含镍废水研究[D]. 兰州: 兰州大学, 2020. [7] WANG Y, JU L, XU F, et al. Effect of a nanofiltration combined process on the treatment of high-hardness and micropolluted water[J]. Environmental research, 2020, 182(Mar.): 109063.1-.9. [8] 张静, 吴慧芳, 陈佳琪, 等. 预处理技术对超滤膜污染控制的研究现状[J]. 能源环境保护, 2022, 36(1): 18-22. [9] 聂煜东, 李金, 张贤明. 水处理过程中膜污染问题及其预处理技术研究进展[J]. 化工进展, 2021, 40(4): 2278-2289. [10] 高倩, 张崇淼, 魏样, 等. 饮用水超滤处理中的膜污染及减缓技术研究进展[J]. 中国给水排水, 2020, 36(18): 13-18. [11] 高旭, 李鹏, 王学刚, 等. 絮凝与电絮凝对含铀废水的处理效果对比[J]. 环境工程学报, 2018, 12(2): 488-496. [12] 王思宁, 丁晶, 赵庆良, 等. 电絮凝技术处理高盐废水的研究进展[J]. 黑龙江大学自然科学学报, 2018, 35(1): 72-78. [13] 赵凯, 杨春风, 孙境求, 等. 调控絮体形态强化电絮凝减缓膜污染[J]. 环境科学, 2016, 37(11): 4255-4260. [14] 李梦琦, 杨春风, 赵凯, 等. 电絮凝-膜分离反应器还原-絮凝-超滤一体化处理六价铬废水[J]. 环境工程学报, 2018, 12(1): 79-85. [15] MAGNISALI E D, QUN Y, VAYENAS D V. Electrocoagulation as a revived waste water treatment method-Practical Approaches: A review[J]. Journal of Chemical Technology & Biotechnology, 2022, 97(1): 9-25. [16] SAHU O, MAZUMDAR B, CHAUDHARI P K. Treatment of wastewater by electrocoagulation: a review[J]. Environmental Science and Pollution Research, 2014, 21(4): 69-71. [17] SARDARI K, FYFE P, LINCICOME D, et al. Combined electrocoagulation and membrane distillation for treating high salinity produced waters[J]. Journal of Membrane Science, 2018, 564: 82-96. doi: 10.1016/j.memsci.2018.06.041 [18] HARIF T, HAI M, ADIN A. Electroflocculation as potential pretreatment in colloid ultrafiltration[J]. Water Supply, 2006, 6(1): 69-78. doi: 10.2166/ws.2006.008 [19] HARIF T, KHAI M, ADIN A. Electrocoagulation versus chemical coagulation: Coagulation/flocculation mechanisms and resulting floc characteristics[J]. Water Research, 2012, 46(10): 3177-3188. doi: 10.1016/j.watres.2012.03.034 [20] ROA-MORALES G, CAMPOS-MEDINA E, AGUILERA-COTERO J, et al. Aluminum electrocoagulation with peroxide applied to wastewater from pasta and cookie processing[J]. Separation and Purification Technology, 2007, 54(1): 124-129. doi: 10.1016/j.seppur.2006.08.025 [21] 乔波, 段谟华, 刘芬, 等. 在线反冲下电絮凝对可逆及不可逆膜污染的影响[J]. 水处理技术, 2019, 45(5): 76-81. [22] 周振, 姚吉伦, 庞治邦, 等. 电絮凝延缓陶瓷微滤膜污染[J]. 环境工程学报, 2016, 10(5): 2279-2283. [23] WANG J, YAO J, WANG L, et al. Multivariate optimization of the pulse electrochemical oxidation for treating recalcitrant dye wastewater[J]. Separation and Purification Technology, 2020, 230: 115851. doi: 10.1016/j.seppur.2019.115851 [24] KARAMATI-NIARAGH E, ALAVI MOGHADDAM M R, EMAMJOMEH M M, et al. Evaluation of direct and alternating current on nitrate removal using a continuous electrocoagulation process: Economical and environmental approaches through RSM[J]. Journal of Environmental Management, 2019, 230: 245-254. [25] SOEPRIJANTO, PERDANI A D, NURY D F, et al. Treatment of oily bilge water by electrocoagulation process using aluminum electrodes[J]. AIP Conference Proceedings, 2017, 1840(1): 110015. [26] YU B, SUN J, ZHAO K, et al. Mitigating membrane fouling by coupling coagulation and the electrokinetic effect in a novel electrocoagulation membrane cathode reactor[J]. Water Research, 2022, 217: 118378-. doi: 10.1016/j.watres.2022.118378 [27] EYVAZ M, KIRLAROGLU M, AKTAS T S, et al. The effects of alternating current electrocoagulation on dye removal from aqueous solutions[J]. Chemical Engineering Journal, 2009, 153(1): 16-22. [28] ZHANG J, LI J, MA C, et al. High-efficiency and energy-saving alternating pulse current electrocoagulation to remove polyvinyl alcohol in wastewater[J]. RSC Advances, 2021, 11(63): 40085-40099. doi: 10.1039/D1RA08093H [29] ZHOU R, LIU F, WEI N, et al. Comparison of Cr(VI) removal by direct and pulse current electrocoagulation: Implications for energy consumption optimization, sludge reduction and floc magnetism[J]. Journal of Water Process Engineering, 2020, 37: 101387. doi: 10.1016/j.jwpe.2020.101387 [30] 罗皓鹏. 脉冲电絮凝处理农村微污染饮用水的工艺优化[D]. 哈尔滨: 哈尔滨工业大学, 2021. [31] MüLLER S, BEHRENDS T, VAN GENUCHTEN C M. Sustaining efficient production of aqueous iron during repeated operation of Fe(0)-electrocoagulation[J]. Water Research, 2019, 155: 455-464. doi: 10.1016/j.watres.2018.11.060 [32] OLIVEIRA J T, DE SOUSA M C, MARTINS I A, et al. Electrocoagulation/oxidation/flotation by direct pulsed current applied to the removal of antibiotics from Brazilian WWTP effluents[J]. Electrochimica Acta, 2021, 388: 138499. doi: 10.1016/j.electacta.2021.138499 [33] CHEN Y M, ZHOU B X, LI L H, et al. Application of Pulse Electrocoagulation to Dye Wastewater Treatment[J]. Advanced Materials Research, 2011, 233-235: 444-451. doi: 10.4028/www.scientific.net/AMR.233-235.444 -

下载:

下载: